Page 1

96M11027

Read this manual before using the system in order to

achieve maximum performance.

Keep this manual in a safe place for future reference.

RS-485 Master Unit

User's Manual

N-410

Page 2

Introduction

Thank you for purchasing the N-410 RS-485 master unit.

The N-410 can be used as a master unit on a multi-drop link network of KEYENCE BL Series

barcode readers, SR Series code readers, and RF Series RFID system.

This manual explains the connections, communications and additional functions for using the

N-410 on a multi-drop link network with BL/SR/RF Series devices.

Please read this manual carefully.

The devices that can be connected to the N-410 are the BL-700 Series, the BL-600 Series, the BL180 Series, the BL-210 Series, the RF-500 Series, the SR-500 Series, the BL-1300 Series, and the SR600 Series.

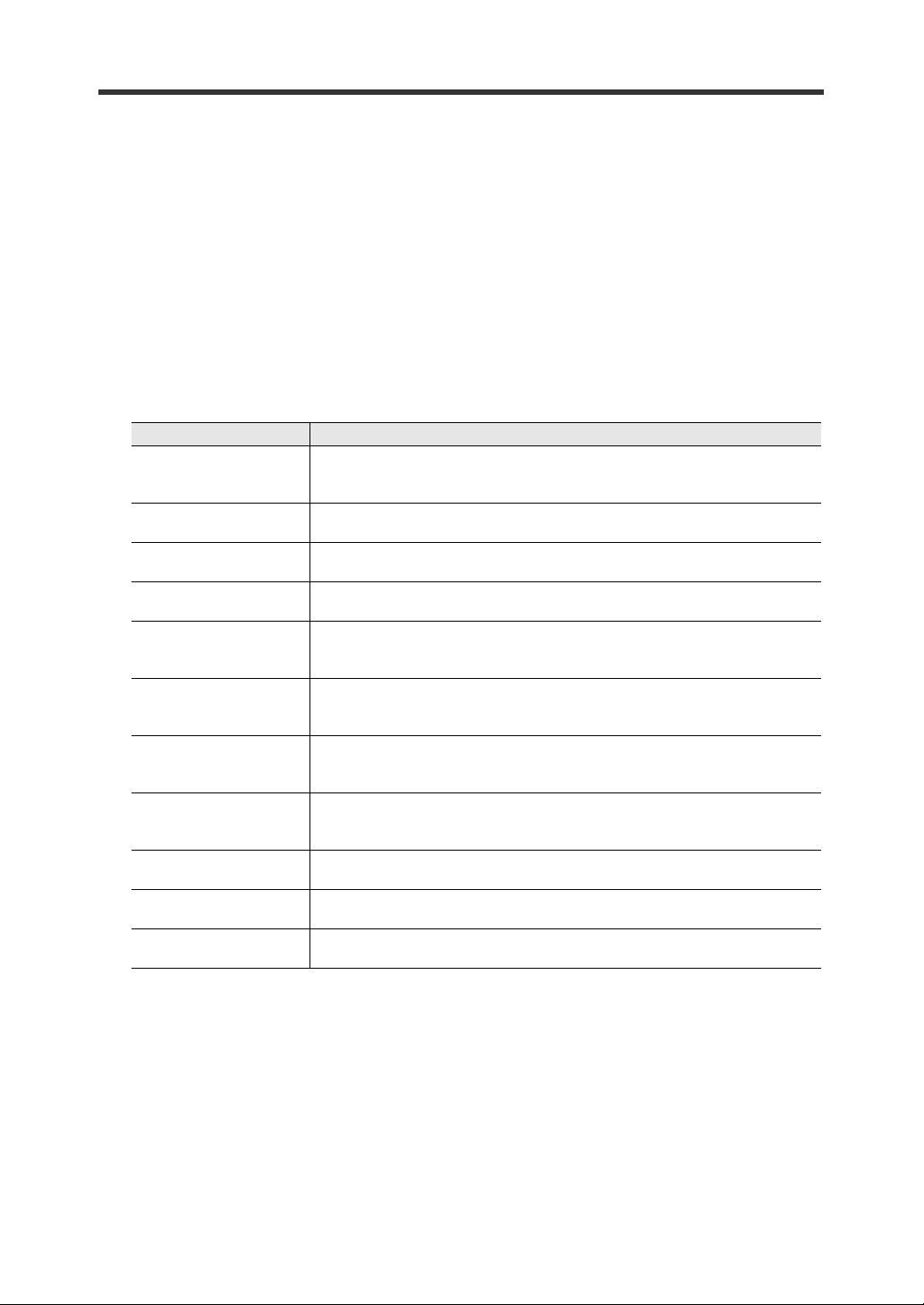

Manuals related to the N-410

Be sure to read the following manuals when using the N-410.

Manual Contents

BL-700 Series

BL-U1, BL-U2, N-42

User’s Manual

BL-600 Series

User’s Manual

BL-180 Series

User’s Manual

BL-210 Series

User’s Manual

RF-500

Installation and

Connection Manual

RF-500

Operation Manual

AutoID Navigator

User’s Manual

(PDF only)

N-410

User’s Manual

SR-500 Series

User’s Manual

BL-1300 Series

User’s Manual

SR-600 Series

User’s Manual

This explains the connections, wiring, installation, settings and notes for the BL700 Series long-range laser barcode reader and the BL-U1, BL-U2 and N-42

communication units.

This explains the connections, wiring, installation, settings and notes for the BL600 Series ultra-short range laser barcode reader.

This explains the connections, wiring, installation, settings and notes for the BL180 Series ultra-short range CCD barcode reader.

This explains the connections, wiring, installation, settings and notes for the BL210 Series handy laser barcode reader.

This manual explains the connections, installation and operation of the RF-500

Series and related devices.

This section explains the operation of the devices that make up the system, the

settings for operation

the communication commands for those devices.

and

This explains the indicates operation and settings for the AutoID Navigator

general AutoID system setting software.

This manual.

This explains the settings and procedures required for installation, connection

and operation of the N-410 RF-485 master unit.

This explains the connections, wiring, installation, settings and notes for the SR500 Series fixed 2D code reader.

This explains the connections, wiring, installation, settings and notes for the BL1300 Series laser barcode reader.

This explains the connections, wiring, installation, settings and notes for the SR600 Series fixed 2D code reader.

Page 3

Safety Precautions

Important

Note

Reference

This manual explains the usage, procedure and cautions of the N-410.

To get the most out of your N-410, make sure that you have read and understood this manual.

Always keep this manual in a safe place for future reference whenever needed.

Ensure that the manual is passed to the end user in case of transfer of the unit.

Symbols

The following warning symbols are used to ensure safety and to prevent injury and/or damage to

property when using the N-410.

Danger

Warning

Caution

Indicates that the operator is at risk of death or serious physical injury if the

system is improperly operated or this precaution is not followed.

Indicates that the operator is at risk of physical injury if the system is

improperly operated or this precaution is not followed.

Indicates that property damage (including product malfunction) may occur if

the system is improperly operated or if this precaution is not followed.

Indicates cautions and controls that must be observed while using this device.

Indicates an important operating procedure that could be easily overlooked.

Indicates further information that may be useful to know.

Indicates a page in this manual or another manual to refer to.

96M11027

1

Page 4

General Cautions

• Before starting work or before starting the system, confirm that all the functions of the system are

working properly.

• If any product of our company fails, take full safety measures to prevent damage before using the

system again.

• If the system is used beyond published specifications or if the system is modified, the functions

and performance cannot be guaranteed.

• Please note that when the N-410 is used in combination with other instruments, its functions and

performance may be degraded,

• Do not use the N-410 for protecting the human body.

Be Sure to Use this Product Correctly

Caution

• Refer to "2-8 Installation" (Page 2-32) before installing and make sure to install the device in an

appropriate place.

• Use the recommended cables for RS-485 connections and make sure those connections are made as

specified in this manual.

• If the wiring is not handled as specified, communication errors may occur.

"Wiring an RS-485" (Page 2-24)

"Wiring an RS-485" (Page 2-30)

• Be sure to use only 24 V DC power for the N-410, N-R4, N-48, NX-50RS.

Use of any other power source may result in damage

• This is a precision instrument. It may be damaged if dropped. Take care

when carrying or installing this device.

2

Page 5

UL/CE Certification

Notes regarding the international certifications of the N-410

Europe

Notes regarding EMC directives (2004/108/EC)

Keyence Corporation has confirmed that this product complies with the essential

requirements of the applicable EU Directives, based on the following specifications.

Be sure to consider the following specifications when using this product in the

Member States of European Union.

• General certification (EMI) EN61326-1 Class A

• General certification (EMS) EN61326-1

• I/O cables and power cables should be shorter than 30 m.

These specifications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to EMC Directive.

America

Notes regarding the FCC

The N-410 is regulated by the FCC.

• General certification FCC Part 15 Subpart B - Unintentional Radiator,

Class A digital device

Notes regarding UL certification

The N-410 is regulated by the UL/CSA and bears UL/C-UL certification.

• Certifications UL508

CAN/CSA C22.2 No. 14-M95

• UL File No. E207185

• UL categories NRAQ, NRAQ7

• Be sure to use an NFPA70 (NEC: National Electrical Code) certified Class 2 electrical output.

• Place this on the control board.

Canada

Notes regarding Canada IC (Industry Canada) regulation

The N-410 is regulated by Canadian Electromagnetic Wave Regulations.

• General regulation ICES-003 - Digital Apparatus, Class A

3

Page 6

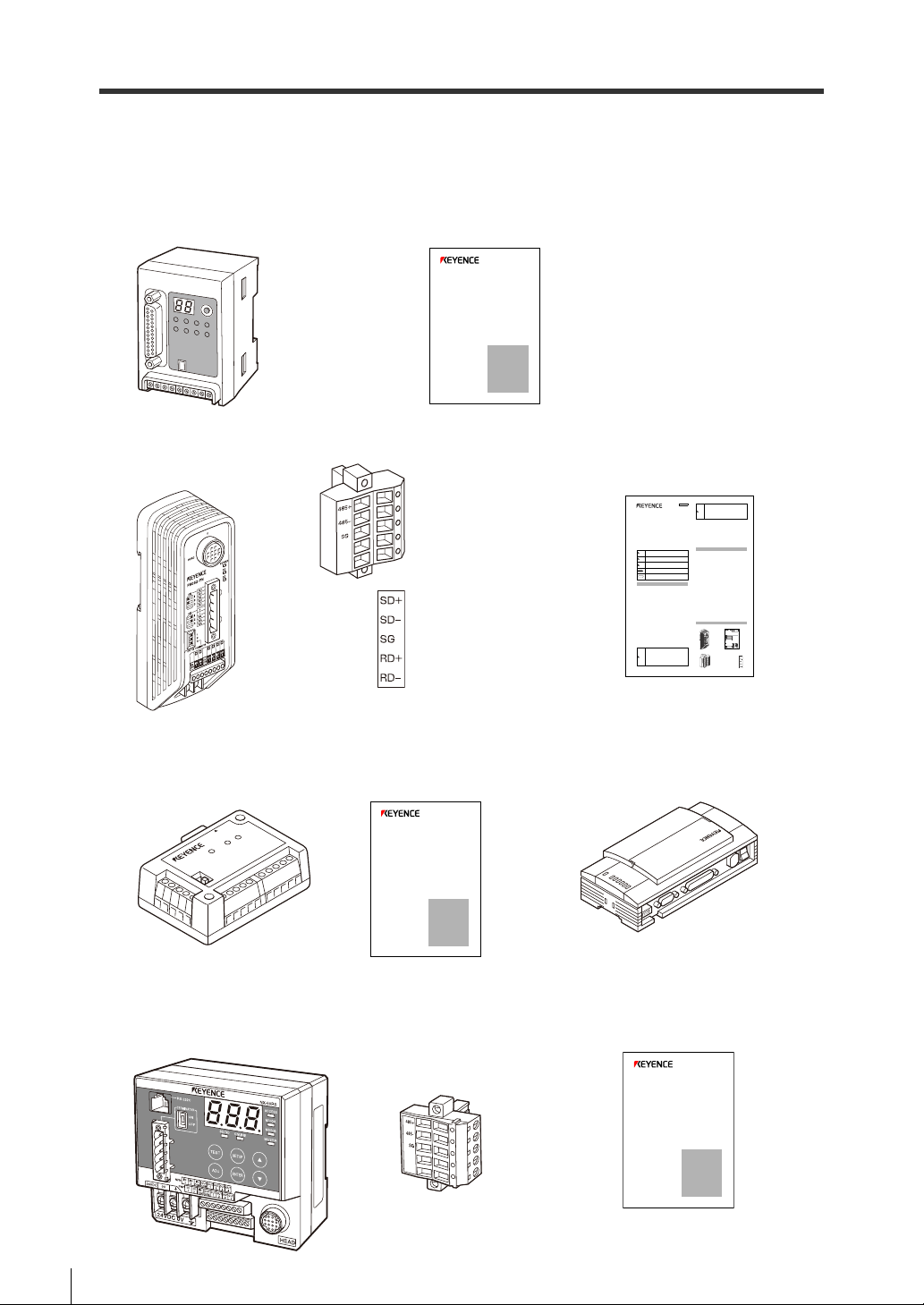

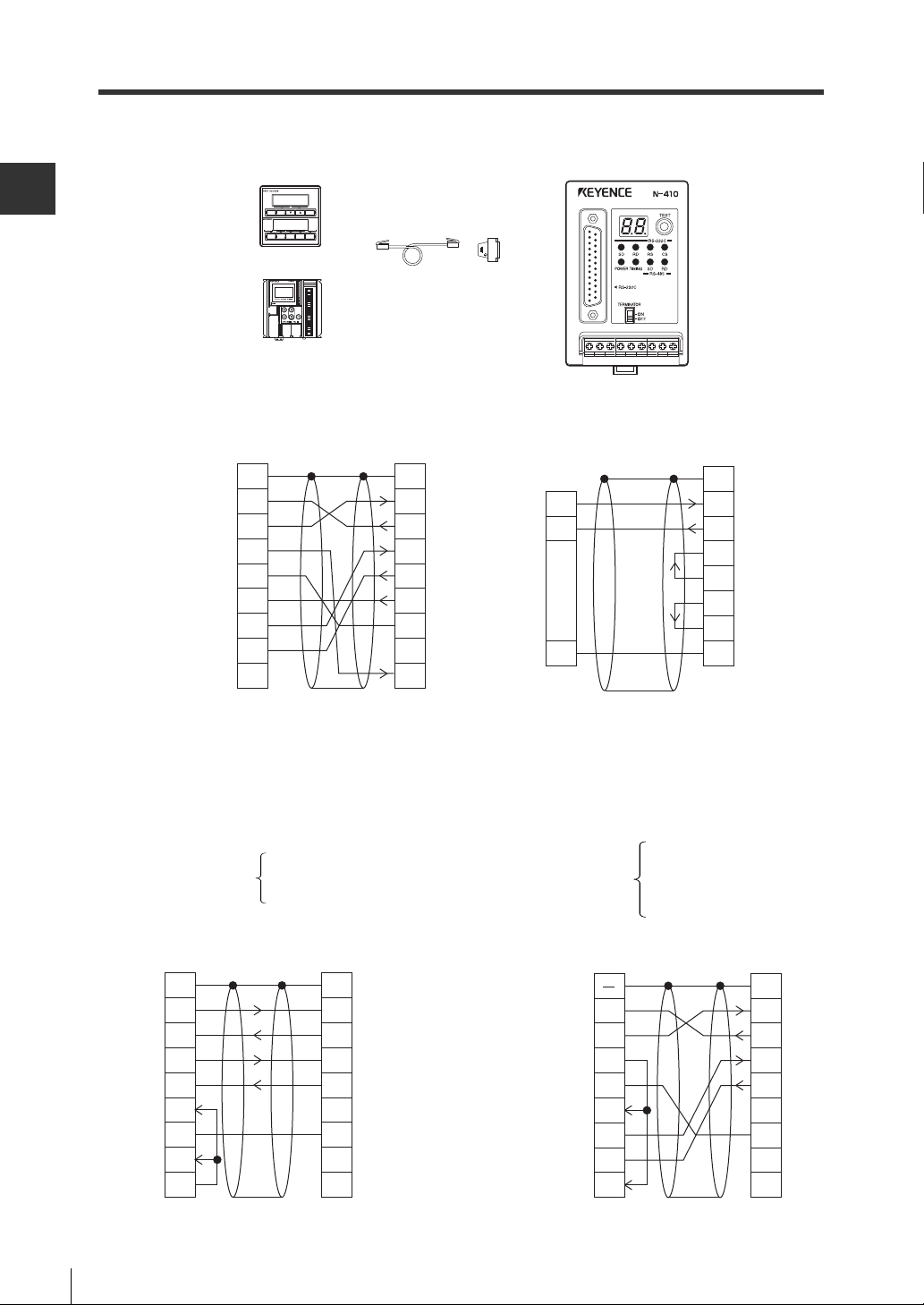

Package Contents

N-410...1

User's manual...1

User's Manual

1

E N-R4-IM

Dedicated Communication Unit

RS-422A/485 Output Type

N-R4

Instruction Manual

■General precautions

• At startup and during operation, be sure to check that the

functions and performance of the N-R4 is operating properly.

• We recommend that you take substantial safety measures to

avoid any damage in the event a problem occurs.

• If the N-R4 is modified or used in any way other than described in

the specifications, its function and performance cannot be

guaranteed.

• When the N-R4 is used in combination with other instruments, the

function and performance may be effected by operating conditions

and the surrounding environment.

• Do not use the N-R4 for the purpose of protecting the human

body.

• The information contained in this manual is subject to change

without notice.

■Notice

When this product is used under the circumstances and operating

environments described below, adhere to the limitations of the ratings,

take adequate measures to ensure safety such as fail-safe installations

and consult a KEYENCE sales representative.

• For use under circumstances or environments which are not

described in the manual

• For use with nuclear power control, railway, aircraft, vehicles,

incinerators, medical equipment, entertainment equipment, safety

devices etc.

• For use in applications where death or serious property damage is

possible and extensive safety precautions are required.

■For properly using the product

Do not install the N-R4 in the following locations:

• Locations subject to direct sunlight

• Locations where the surrounding air temperature is outside the

range of 0 to +50C or locations subject to condensation as the

result of severe changes in temperature

• Locations where the ambient humidity is outside the range of 35

to 85%RH.

• Locations subject to corrosive or flammable gases

• Locations subject to dust, salts, iron dust, or oil smoke

• Locations subject to shock or vibration

• Locations subject to exposure of water, oil, or chemicals

• Locations where strong magnetic or electric fields are generated

■UL certification

The N-R4 complies with the following UL/CSA standards and has

obtained the UL/C-UL certification.

• Applicable standards UL508, UL60950-1

• UL File No. E207185, E167973

• UL category NRAQ/NRAQ7, NWGQ2/NWGQ8

Be sure to observe the following installation and environment conditions.

• Pollution degree 2

• Overvoltage category I

Caution - Do not connect directly to the branch circuit. This product must

be supplied power by a suitable, approved isolated transformer or power

supply not exceeding 200 VA max.

■FCC regulations

The N-R4 complies with the following FCC EMI regulations.

• FCC Part 15 Subpart B, Class B digital device

■Canada IC (Industry Canada) regulations

The N-R4 complies with the following IC EMI regulations.

• ICES-003, Class B digital apparatus

■CE marking

The N-R4 complies with the following essential requirements of the EU

Directive.

• EMC Directive (2004/108/EC)

The following harmonized standards are applied to this product in order

to confirm the compliance.

• Applicable standards (EMI) EN55011, Class A

EN55022, Class B

• Applicable standards (EMS) EN61000-6-2

EN61000-6-1

*The length of the communication and power cables should be less than 30 m.

DANGER

Failure to follow these instructions may lead to death or

serious injury.

WARNING

Failure to follow these instructions may lead to injury.

CAUTION

Failure to follow these instructions may lead to product

damage (product malfunction, etc.).

Note

Provides additional information on proper operation.

TIPS

Indicates useful information or information that aids

understanding of text descriptions.

For Safely Using the Product

CAUTION

•

Do not use the N-R4 in an environment subject to

flammable, explosive, or corrosive gases.

•Be sure that all screws are tightened securely.

•Use crimp contacts of the specified size for wiring.

•The N-R4 uses a 24 VDC power supply. Using a power

supply outside this range or an AC power supply may

cause product failure.

•

Do not disassemble or modify the N-R4. This may cause

product failure.

96M00269

CAUTION

•Locate the cables as far as possible from high-voltage

lines and power lines. Otherwise, generated noise may

cause product failure or malfunctions.

•The N-R4 is a precision instrument. If the unit is

dropped or shock is applied, it may be damaged. Use

caution when unpacking, carrying, and mounting.

•Be sure to observe all warnings, cautions, and

precautions specified in the manual.

Foreign Regulations and Standards

Package Contents List

1

E N-R4-IM

Dedicated Communication Unit

RS-422A/485 Output Type

N-R4

Instruction Manual

General precautions

•At startup and during operation, be sure to check that the

functions and performance of the N-R4 is operating properly.

•We recommend that you take substantial safety measures to

avoid any damage in the event a problem occurs.

•If the N-R4 is used in any way other than described in the

specifications or if modified, its functions and performance cannot

be guaranteed.

•When the N-R4 is used in combination with other instruments,

functions and performance may be degraded, depending on the

operating conditions and the surrounding environment.

•Do not use the N-R4 for the purpose of protecting the human

body.

•The information contained in this manual is subject to change

without notice.

Notice

When the product is used under the circumstances or environment

below, adhere to the limitations of the ratings and functions, take

countermeasures for safety precautions such as fail-safe installations

and consult a KEYENCE sales representative.

•For use under circumstances or environments which are not

described in the manual

•For use with nuclear power control, railway, aircraft, vehicles,

incinerators, medical equipment, entertainment equipment, safety

devices etc.

•For use for applications where death or serious property damage

is possible and extensive safety precautions are required

For properly using the product

Do not install the N-R4 in the following locations:

•Locations subject to direct sunlight

•Locations where the ambient temperature is outside the range of

0to +50°C or locations subject to condensation as the result of

severe changes in temperature

•Locations where the ambient humidity is outside the range of 35

to 85%RH.

•Locations subject to corrosive or flammable gases

•Locations subject to dust, salts, iron dust, or oil smoke

•Locations subject to shock or vibration

•Locations subject to exposure of water, oil, or chemicals

•Locations where strong magnetic or electric fields are generated

UL approval

The N-R4 conforms to the following UL/CSA standards and has obtained

the UL/C-UL approval.

•Conforming standardsUL508, UL60950-1

•UL File No. E207185, E167973

•UL category NRAQ/NRAQ7, NWGQ2/NWGQ8

When using the N-R4 as a UL approved product, be sure to observe the

following installation and environment conditions.

•Pollution degree 2

•Overvoltage category I

FCC regulations

The N-R4 conforms to the following FCC EMI regulations.

•Conforming regulationsFCC Part 15 Subpart B, Class B

digital equipment

Canada IC (Industry Canada regulations)

The N-R4 conforms to the following IC EMI regulations.

•Conforming regulationsICES-003, Class B Digital equipment

CE marking

The N-R4 conforms to the following essential requirements of the EU

directive.

•EMC directive (2004/108/EC)

By checking the conformity to the following EN standards, the conformity

to the essential requirements of the EMC directive is checked and the CE

marking is indicated.

•Conforming standards (EMI)EN55011, Class A

EN55022, Class B

•Conforming standards (EMS)EN61000-6-2

EN61000-6-1

*The length of the communication and power cables should be less than 30 m.

DANGER

Failure to follow these instructions may lead to death or

serious injury.

WARNING

Failure to follow these instructions may lead to injury.

CAUTION

Failure to follow these instructions may lead to product

damage (product malfunction, etc.).

Note

Provides additional information on proper operation.

TIPS

Indicates useful information or information that aids

understanding of text descriptions.

For Safely Using the Product

CAUTION

•

Do not use the N-R4 in an environment subject to

flammable, explosive, or corrosive gases.

•Be sure that all screws are tightened securely.

•Use crimp contacts of the specified size for wiring.

•The N-R4 uses a 24 VDC power supply. Using a power

supply outside this range or an AC power supply may

cause product failure.

•

Do not disassemble or modify the N-R4. This may cause

product failure.

96M00275

CAUTION

•Locate the cables as far as possible from high-voltage

lines and power lines. Otherwise, generated noise may

cause product failure or malfunctions.

•The N-R4 is a precision instrument. If the unit is

dropped or shock is applied, it may be damaged. Use

caution when unpacking, carrying, and mounting.

•Be sure to observe all warnings, cautions, and

precautions specified in the manual.

Foreign Regulations and Standards

Package Contents List

Main unit Instruction manual

Connector for the RS-422A/485Seal for the connectors

(used when wiring RS-422A)

For 422 connector

1

E N-R4-IM

Dedicated Communication Unit

RS-422A/485 Output Type

N-R4

Instruction Manual

General precautions

•At startup and during operation, be sure to check that the

functions and performance of the N-R4 is operating properly.

•We recommend that you take substantial safety measures to

avoid any damage in the event a problem occurs.

•If the N-R4 is used in any way other than described in the

specifications or if modified, its functions and performance cannot

be guaranteed.

•When the N-R4 is used in combination with other instruments,

functions and performance may be degraded, depending on the

operating conditions and the surrounding environment.

•Do not use the N-R4 for the purpose of protecting the human

body.

•The information contained in this manual is subject to change

without notice.

Notice

When the product is used under the circumstances or environment

below, adhere to the limitations of the ratings and functions, take

countermeasures for safety precautions such as fail-safe installations

and consult a KEYENCE sales representative.

•For use under circumstances or environments which are not

described in the manual

•For use with nuclear power control, railway, aircraft, vehicles,

incinerators, medical equipment, entertainment equipment, safety

devices etc.

•For use for applications where death or serious property damage

is possible and extensive safety precautions are required

For properly using the product

Do not install the N-R4 in the following locations:

•Locations subject to direct sunlight

•Locations where the ambient temperature is outside the range of

0to +50°C or locations subject to condensation as the result of

severe changes in temperature

•Locations where the ambient humidity is outside the range of 35

to 85%RH.

•Locations subject to corrosive or flammable gases

•Locations subject to dust, salts, iron dust, or oil smoke

•Locations subject to shock or vibration

•Locations subject to exposure of water, oil, or chemicals

•Locations where strong magnetic or electric fields are generated

UL approval

The N-R4 conforms to the following UL/CSA standards and has obtained

the UL/C-UL approval.

•Conforming standardsUL508, UL60950-1

•UL File No.E207185, E167973

•UL categoryNRAQ/NRAQ7, NWGQ2/NWGQ8

When using the N-R4 as a UL approved product, be sure to observe the

following installation and environment conditions.

•Pollution degree 2

•Overvoltage category I

FCC regulations

The N-R4 conforms to the following FCC EMI regulations.

•Conforming regulationsFCC Part 15 Subpart B, Class B

digital equipment

Canada IC (Industry Canada regulations)

The N-R4 conforms to the following IC EMI regulations.

•Conforming regulationsICES-003, Class B Digital equipment

CE marking

The N-R4 conforms to the following essential requirements of the EU

directive.

•EMC directive (2004/108/EC)

By checking the conformity to the following EN standards, the conformity

to the essential requirements of the EMC directive is checked and the CE

marking is indicated.

•Conforming standards (EMI)EN55011, Class A

EN55022, Class B

•Conforming standards (EMS)EN61000-6-2

EN61000-6-1

*The length of the communication and power cables should be less than 30 m.

DANGER

Failure to follow these instructions may lead to death or

serious injury.

WARNING

Failure to follow these instructions may lead to injury.

CAUTION

Failure to follow these instructions may lead to product

damage (product malfunction, etc.).

Note

Provides additional information on proper operation.

TIPS

Indicates useful information or information that aids

understanding of text descriptions.

For Safely Using the Product

CAUTION

•

Do not use the N-R4 in an environment subject to

flammable, explosive, or corrosive gases.

•Be sure that all screws are tightened securely.

•Use crimp contacts of the specified size for wiring.

•The N-R4 uses a 24 VDC power supply. Using a power

supply outside this range or an AC power supply may

cause product failure.

•

Do not disassemble or modify the N-R4. This may cause

product failure.

96M00275

CAUTION

•Locate the cables as far as possible from high-voltage

lines and power lines. Otherwise, generated noise may

cause product failure or malfunctions.

•The N-R4 is a precision instrument. If the unit is

dropped or shock is applied, it may be damaged. Use

caution when unpacking, carrying, and mounting.

•Be sure to observe all warnings, cautions, and

precautions specified in the manual.

Foreign Regulations and Standards

Package Contents List

Main unitInstruction manual

1

EN-R2-IM

Dedicated Communication Unit

RS-232C Output Type

N-R2

Instruction Manual

General precautions

•At startup and during operation, be sure to check that the

functions and performance of the N-L1 is operating properly.

•We recommend that you take substantial safety measures to

avoid any damage in the event a problem occurs.

•If the N-L1 is used in any way other than described in the

specifications or if modified, its functions and performance cannot

be guaranteed.

•When the N-L1 is used in combination with other instruments,

functions and performance may be degraded, depending on the

operating conditions and the surrounding environment.

•Do not use the N-L1 for the purpose of protecting the human body.

•The information contained in this manual is subject to change

without notice.

Notice

When the product is used under the circumstances or environment

below, adhere to the limitations of the ratings and functions, take

countermeasures for safety precautions such as fail-safe installations

and consult a KEYENCE sales representative.

•For useunder circumstances or environmentswhich are not

described in the manual

•For usewith nuclear power control, railway, aircraft, vehicles,

incinerators, medical equipment, entertainment equipment, safety

devices etc.

•For use for applications where death or serious property damage

is possible and extensive safety precautions are required

For properly using the product

Do not install the N-R2 in the following locations:

•Locations subject to direct sunlight

•Locations where the ambient temperature is outside the range of

0to +50°C or locations subject to condensation as the result of

severe changes in temperature

•Locations where the ambient humidity is outside the range of 35

to85%RH.

•Locations subject to corrosive or flammable gases

•Locations subject to dust, salts, iron dust, or oil smoke

•Locations subject to shock or vibration

•Locations subject to exposure of water, oil, or chemicals

•Locations where strong magnetic or electric fields are generated

UL approval

The N-R2 conforms to the following UL/CSA standards and has obtained

the UL/C-UL approval.

•Conforming standardsUL508, UL60950-1

•UL File No.E207185, E167973

•UL categoryNRAQ/NRAQ7, NWGQ2/NWGQ8

When using the N-R2 as a UL approved product,be sure to observe the

following installation and environment conditions.

•Pollution degree 2

•Overvoltage category I

FCC regulations

The N-R2 conforms to the following FCC EMI regulations.

•Conforming regulationsFCC Part 15 Subpart B, Class B

digital equipment

Canada IC (Industry Canada regulations)

TheN-R2 conforms to the following IC EMI regulations.

•Conforming regulationsICES-003, Class B Digital equipment

CE marking

The N-R2 conforms to the following essential requirements of the EU

directive.

•EMC directive (2004/108/EC)

By checking the conformity to the following EN standards, the conformity

to the essential requirements of the EMC directive is checked and the CE

marking is indicated.

•Conforming standards (EMI)EN55011, Class A

EN55022, Class B

•Conforming standards (EMS)EN61000-6-2

EN61000-6-1

*The length of the communication and power cables should be less than 30 m.

DANGER

Failure to follow these instructions may lead to death or

serious injury.

WARNING

Failure to follow these instructions may lead to injury.

CAUTION

Failure to follow these instructions may lead to product

damage (product malfunction, etc.).

Note

Provides additional information on proper operation.

TIPS

Indicates useful information or information that aids

understanding of text descriptions.

For Safely Using the Product

CAUTION

•Do not use the N-L1 in an environment subject to

flammable, explosive, or corrosive gases.

•Be sure that all screws are tightened securely.

•Use crimp contacts of the specified size for wiring.

•The N-L1 uses a 24 VDC power supply. Using a power

supply outside this range or an AC power supply may

cause product failure.

•Do not disassemble or modify the N-L1. This may cause

product failure.

96M00266

CAUTION

•Locate the cables as far as possible from high-voltage

lines and power lines. Otherwise, generated noise may

cause product failure or malfunctions.

•The N-R2 is a precision instrument. If the unit is

dropped or shock is applied, it may be damaged. Use

caution when unpacking, carrying, and mounting.

•Be sure to observe all warnings, cautions, and

precautions specified in the manual.

Foreign Regulations and Standards

Package Contents List

Main unitInstruction manual

1

EN-R2-IM

Dedicated Communication Unit

RS-232C Output Type

N-R2

Instruction Manual

General precautions

•At startup and during operation, be sure to check that the

functions and performance of the N-L1 is operating properly.

•We recommend that you take substantial safety measures to

avoid any damage in the event a problem occurs.

•If the N-L1 is used in any way other than described in the

specifications or if modified, its functions and performance cannot

be guaranteed.

•When the N-L1 is used in combinationwith other instruments,

functions and performance may be degraded, depending on the

operating conditions and the surrounding environment.

•Do not use the N-L1 for the purpose of protecting the human body.

•The information contained in this manual is subject to change

without notice.

Notice

When the product is usedunder the circumstances or environment

below, adhere to the limitations of the ratings and functions, take

countermeasures for safety precautions such as fail-safe installations

and consult a KEYENCE sales representative.

•For useunder circumstances or environments which are not

described in the manual

•For usewith nuclear power control, railway, aircraft, vehicles,

incinerators, medical equipment, entertainment equipment, safety

devices etc.

•For use for applications where death or serious property damage

is possible and extensive safety precautions are required

For properly using the product

Do not install the N-R2 in the following locations:

•Locations subject to direct sunlight

•Locations where the ambient temperature is outside the range of

0to +50°C or locations subject to condensation as the result of

severe changes in temperature

•Locations where the ambient humidity is outside the range of 35

to85%RH.

•Locations subject to corrosive or flammable gases

•Locations subject to dust, salts, iron dust, or oil smoke

•Locations subject to shock or vibration

•Locations subject to exposure of water, oil, or chemicals

•Locations where strong magnetic or electric fields are generated

UL approval

TheN-R2 conforms to the following UL/CSA standards and has obtained

the UL/C-UL approval.

•Conforming standardsUL508, UL60950-1

•UL File No.E207185, E167973

•UL categoryNRAQ/NRAQ7, NWGQ2/NWGQ8

Whenusing the N-R2 as a UL approved product,be sure to observe the

following installation and environment conditions.

•Pollution degree 2

•

Overvoltage category I

FCC regulations

TheN-R2 conforms to the following FCC EMI regulations.

•Conforming regulationsFCC Part 15 Subpart B, Class B

digital equipment

Canada IC (Industry Canada regulations)

TheN-R2 conforms to the following IC EMI regulations.

•Conforming regulationsICES-003, Class B Digital equipment

CE marking

TheN-R2 conforms to the following essential requirements of the EU

directive.

•EMC directive (2004/108/EC)

By checking the conformity to the following EN standards, the conformity

to the essential requirements of the EMC directive is checked and the CE

marking is indicated.

•Conforming standards (EMI)EN55011, Class A

EN55022, Class B

•Conforming standards (EMS)EN61000-6-2

EN61000-6-1

*The length of the communication and power cables should be less than 30 m.

DANGERFailure to follow these instructions may lead to death or

serious injury.

WARNINGFailure to follow these instructions may lead to injury.

CAUTION

Failure to follow these instructions may lead to product

damage (product malfunction, etc.).

Note

Provides additional information on proper operation.

TIPS

Indicates useful information or information that aids

understanding of text descriptions.

For Safely Using the Product

CAUTION

•Do not use the N-L1 in an environment subject to

flammable, explosive, or corrosive gases.

•Be sure that all screws are tightened securely.

•Use crimp contacts of the specified size for wiring.

•The N-L1 uses a 24 VDC power supply. Using a power

supply outside this range or an AC power supply may

cause product failure.

•Do not disassemble or modify the N-L1. This may cause

product failure.

96M00266

CAUTION

•Locate the cables as far as possible from high-voltage

lines and power lines. Otherwise, generated noise may

cause product failure or malfunctions.

•The N-R2 is a precision instrument. If the unit is

dropped or shock is applied, it may be damaged. Use

caution when unpacking, carrying, and mounting.

•Be sure to observe all warnings, cautions, and

precautions specified in the manual.

Foreign Regulations and Standards

Package Contents List

MainunitInstruction manual

Connector for the RS-422A/485Seal for the connectors

(used when wiring RS-422A)

For 422 connector

Main unit Instruction manual

Connector for the RS-422A/485 Label for the connectors

(used when wiring RS-422A)

For 422 connector

N-R4...1 Instruction manual...1Connector for

RS-422A/485...1

RS-422A

Terminal layout label...1

BL-U1...1N-48...1 Instruction manual...1

NX-50RS...1 RS-485

connector...1

Instruction manual...1

The following parts and devices can be found in this package. Confirm that all parts are present and

accounted for before using the device.

N-410 package contents

N-R4 package contents

N-48 package contents BL-U1 package contents

NX-50RS package contents

4

Instruction Maual

Instruction Maual

Page 7

Organization of this Manual

1234567

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Chapter

6

N-410 Overview

Installation

N-410 Settings

Controlling Multi-

drop Link Mode

Controlling Multi-

head Mode

Serial

Communication

This chapter outlines the features and functions of the N-410, as well as

the part names and the required system architecture.

This chapter describes how to connect the N-410 and confirm the

connection.

The AutoID Navigator is used to make settings for the N-410. This

chapter describes how to make the settings for the N-410.

This chapter describes how to control multi-drop link mode for the N-410.

This chapter describes how to control multi-head mode for the N-410.

This chapter describes the serial commands and configuration

commands for the N-410 Series

Chapter

7

PLC Link

Appendices

This chapter describes how to set and control the N-410 PLC link.

The chapter describes the exterior dimensions of the N-410, factory

default settings, error codes and other specifications.

5

Page 8

Table of Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Be Sure to Use this Product Correctly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

UL/CE Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Organization of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

How to Read this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Page Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1 N-410 Overview

1-1 What You Can Do with the N-410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Installation

2-1 Making Settings and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 N-410 Connections and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Installing and Wiring the Input and Output Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

RS-232C Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2-3 Connecting and Wiring to the N-R4 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Connecting to BL-1300 Series/SR Series/RF Series Devices . . . . . . . . . . . . . . . . . . . . . .2-10

Connecting the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

I/O Terminal Layout and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-4 NX-50RS Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-5 N-48 Connections and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Connecting to a BL/SR/RF Series Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Installing and Wiring the Input and Output Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Wiring an RS-485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2-6 BL-U1 Connections and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

Connecting to a BL/SR/RF Series Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

BL-U1 Dipswitch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Installing and Wiring the Input and Output Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Wiring an RS-485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

2-7 How to Use the Connection Confirmation Test. . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2-8 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Installing an N-410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

Installing an NX-50RS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Installing an N-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Installing a BL-U1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Installing the N-R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

6

Page 9

Chapter 3 N-410 Settings

3-1 Making Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Sending and Receiving Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-3 Using Terminal and Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Chapter 4 Controlling Multi-drop Link Mode

4-1 Multi-drop Link Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Controlling Multi-drop Link Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4-2 Multi-drop Link Mode Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Auto-polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Manual Polling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Setting Auto-polling/Manual polling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Send Buffer Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Chapter 5 Controlling Multi-head Mode

5-1 Multi-head Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Controlling Multi-head Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5-2 Operating in Multi-head Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Trigger Notification Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Read Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Data Transmission Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Trigger Input Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

5-3 Sending Data in Multi-head Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Error Code Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

5-4 Sending Commands in Multi-head Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Sending Commands to BL/SR/RF Series Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

N-410 Direct Control Commands and Setting Commands . . . . . . . . . . . . . . . . . . . . . . . .5-11

Chapter 6 Serial Communication

6-1 Serial Communication Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Type of Serial Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Serial Communication Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6-2 Details of Data Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Communication Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Send Buffer Capacity of the N-410 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

6-3 Command Communication with BL/SR/RF Series Devices . . . . . . . . . . . . . . . . 6-6

Command Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

7

Page 10

6-4 Direct Control Command of the N-410 Series. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Procedure for Command Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Command Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Details of Direct Control Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6-5 Setting Commands for the N-410 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Setting Command Communication Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

Command communication format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Setting Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Chapter 7 PLC Link

7-1 PLC Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Compatible PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Usable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7-2 Device Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Device Assignments for Multi-drop Link Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Device Assignments in Multi-head Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

7-3 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

BL Series and SR Series Settings (When Using an NR-4/N-48/BL-U1) . . . . . . . . . . . . . .7-13

BL Series and SR Series Settings (When Using an NX-50RS) . . . . . . . . . . . . . . . . . . . . .7-13

N-410 Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

KV Series Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Mitsubishi MELSEC Series Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Omron SYSMAC Series Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

7-4 PLC Link Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Appendices

1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

2 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

4 Main Device Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-12

5 ASCII Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-13

6 Calculating Checksums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

7 Setting Item List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-16

8 Factory Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-18

9 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-19

8

Page 11

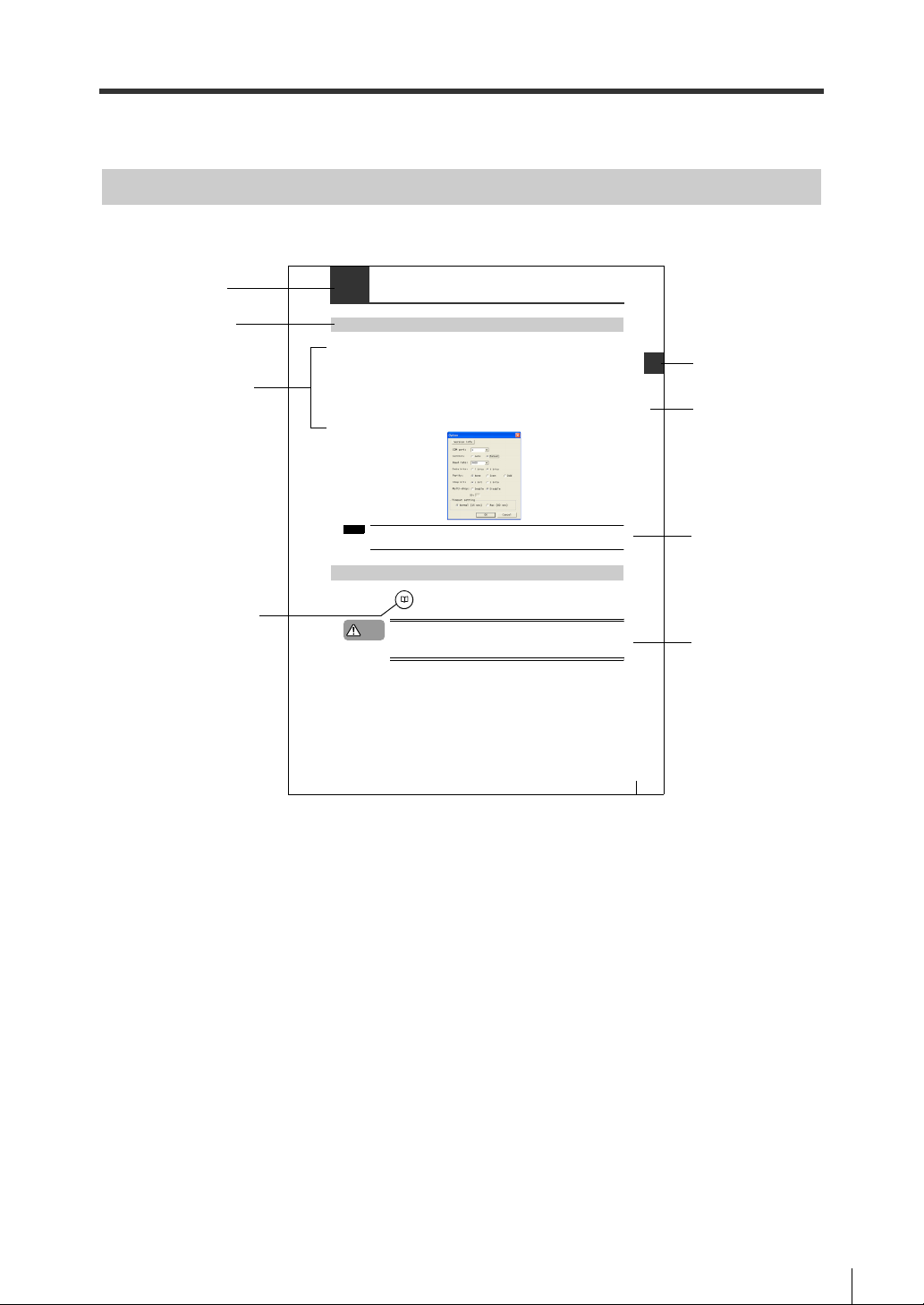

How to Read this Manual

N-410 Settings

3

3-9

3-2

Sending and Receiving Settings

Sending settings to the N-410

The changed settings are forwarded to the N-410. Perform the following steps.

1

Press and hold the N-410 dipswitch for 8 seconds.

When the N-410 display shows "SO (50)", the communications state is as follows.

·

Baud rate: 115200 bit/s · Stop bit: 1 bit

·

Data bits: 8 bit

·

PLC link: None

·

Parity: Even

2

Click the [Option] button on the AutoID Navigator, then make the settings for "COM port."

Make sure that the communication settings for the computer are compatible with those made in step

1. Click the [OK] button when settings are finished.

If "Multi-head mode" is selected, create the network using BL series devices

exclusively or using RF series devices exclusively.

Controlling Multi-head Mode

Sending commands to the N-410 and to BL/SR/RF series devices is the same as in multi-drop

link mode. Refer to "4-1 Multi-drop Link Mode" (pag e 4-2) for more information.

Use normal (sequential) notification if you have both N-48/BL-U1 and NX-

50RS power supplies on the network.

Note

Caution

This is a note.

These notes indicate

operations or

procedure where

errors are common.

Make sure to read

these carefully.

This is a large

headline.

This is the chapter

title.

This is a reference to

a different page or

manual. Related

information can be

found in the location

indicated.

This is a medium

headline.

These are operating

instructions.

* This page was created for the purposes of this explanation and is thus

different from any actual page in this manual.

This is an index.

There is one for each

chapter.

This is a caution.

There is a risk of

damage or breakage

if the information in

these sections is not

heeded.

This section explains the layout of each page and the symbols and words used in the manual.

Page Layout

9

Page 12

Terms

The explanations in this manual use the following terms frequently.

Ter m Meaning

N-410 This indicated the N-410 RS-485 master unit.

BL Series This indicates a BL Series barcode reader.

RF Series This indicates an RF-500 Series RFID system.

N-48 This indicates an N-48 24 V DC communication unit (RS-485 output).

BL-U1 This indicates a BL-U1 100 V AC communication unit.

NX-50RS This indicates an NX-50RS network controller.

AutoID Navigator This indicates the AutoID Navigator general AutoID system setting software.

SR-500 Series This indicates an SR-500 Series 2D code reader.

N-R4 This indicates an N-R4 24 V DC communication unit.

Symbols

The explanations in this manual indicate menus and buttons with the following symbols.

Symbol Meaning

[ ] This indicates a tab or menu in the setting software, or a button name in a dialog box.

" "

This indicates setting items, titles of sections within this manual, the name of a different

manual with relevant information, or words that have been emphasized.

10

Page 13

1

N-410 Overview

This chapter outlines the features and functions of the N-410, as well as the

part names and the required system architecture.

1-1 What You Can Do with the N-410 . . . . . . . . . . . . . . 1-2

1-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-1

Page 14

1

1-1 What You Can Do with the N-410

N-410

RS-485

BL/SR/RF Series

RS-232C

Host computer

Trigger sensor

N-R4

N-48

BL-U1

or

NX-50RS

Note

The N-410 allows you to add the following functions to any BL/SR/RF Series device.

N-410 Overview

Multi-drop Link mode

The N-410 allows you to control up to 31 BL/SR/RF Series devices for each host computer. This is

called "multi-drop link".

Communications are over RS-485, making longer distances (up to 1.2 km) possible with high

noise resistance. The connection is through a twist-pair cable (two lines), meaning that minimal

wire is used.

To allow the N-410 to control communication with each BL/SR/RF Series device, the host

computer should be set up to communicate only with the N-410. This uses a very simple program

(The BL/SR/RF Series device that sent each packet of data is identified by an ID number

appended to the head of the packet). The system can thus be constructed so that load on the

host computer is extremely low.

Multi-head mode

If the location of the code or IC tag on a product is unknown or there are multiple codes or IC

tags on a product, more than one unit will be needed to read the information. In these cases,

multiple devices will be needed to scan for barcodes or IC chips in multiple locations or from

multiple angles.

The N-410 can be used in multi-head mode in these cases to allow the host computer to control

multiple BL/SR/RF Series device as one unit.

The number of units that can be connected and the distance over which they can be connected

are the same as for multi-drop link mode, up to 31 units over 1.2 km.

N-R4

N-48

BL-U1

or

NX-50RS

BL/SR/RF

Series

N-410

RS-232C

RS-485

Host computer

1-2

• BL Series, SR Series, and RF Series devices cannot be connected at the same time in

multi-head mode.

• An NX-50RS Series device cannot be connected to an SR-600 Series device.

Page 15

1-1 What You Can Do with the N-410

1

Note

N-410

PLC

DM103

DM104

DM105

DM106

BL Series

SR Series

...

4

$30

$31

$32

...

The N-410 forwards the data read with a

code reader directly to the

PLC memory, so no communication

program is required.

Note

Interference suppression function

(when using a network in multi-drop mode with only BL/SR Series devices)

If the code readers must be positioned very close to each other, such as when reading a

multistage label, as shown below, their light sources may interfere with one another and have a

negative effect on the reading.

The interference suppression function activates the code reader lasers (LEDs) one after another,

thus preventing interference and stabilizing the reading.

Because the lasers are activated in an ordered fashion, the amount of time each laser (LED)

spends deactivated increases as the number of lasers connected increases. If the line speed is

too fast, the laser array may nor be able to make readings.

N-410 Overview

N-410

RS-232C

Host computer

RS-485

N-R4

N-48

BL-U1

or

NX-50RS

BL Series

SR Series

Trigger sensor

• This cannot be connected to RF Series devices.

• An NX-50RS Series device cannot be connected to an SR-600 Series device.

PLC link function (when using a network with only BL/SR Series devices)

The PLC link function allows data from a code reader in multi-drop link mode or multi-head mode to be

forwarded directly to a PLC without a program.

This helps reduce the number of man hours devoted to PLC programming.

• This cannot be connected to RF Series devices.

• An NX-50RS Series device cannot be connected to an SR-600 Series device.

1-3

Page 16

1

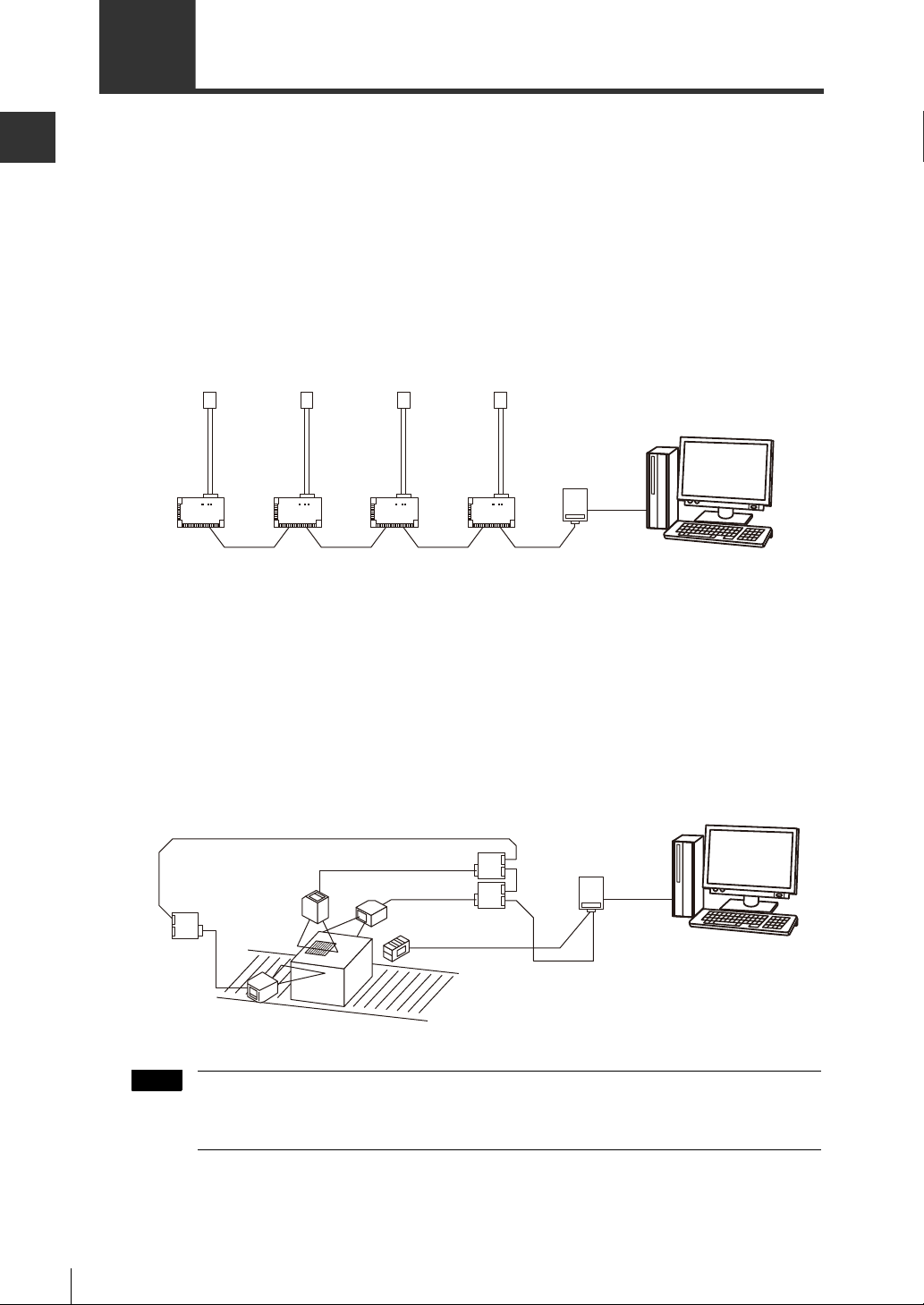

1-2 System Configuration

N-410

RS-485

RS-232C

Trigger sensor

N-R4

N-48

BL-U1

or

NX-50RS

AutoID

Navigator

The system configuration for using the N-410 is as follows. The configurations for multi-drop

link mode and multi-head mode will be explained separately.

N-410 Overview

For multi-drop link mode

• Maximum devices connected: 31

• Maximum connection distance: 1.2 km

Trigger

sensor

N-R4

N-48

BL-U1

or

NX-50RS

N-410

RS-232C

RS-485

AutoID

Navigator

* The settings for the N-410 are made with the AutoID Navigator.

* The devices that can be connected are the BL-1300/700/600/500/180/210 Series, the SR-500/

600 Series, and the RF-500 Series.

* The N-410, N-R4, N-48 and NX-50RS all requires a 24 V DC power source.

For multi-head mode (including using interference suppression)

• Maximum devices connected: 31

• Maximum connection distance: 1.2 km

* Connect a trigger sensor to the N-410.

* The devices that can be conned are the BL-1300/700/600/500/180/210 Series, the SR-500/600

Series, and the RF-500 Series.

* The N-410, N-R4, N-48 and NX-50RS all requires a 24 V DC power source.

1-4

Page 17

1

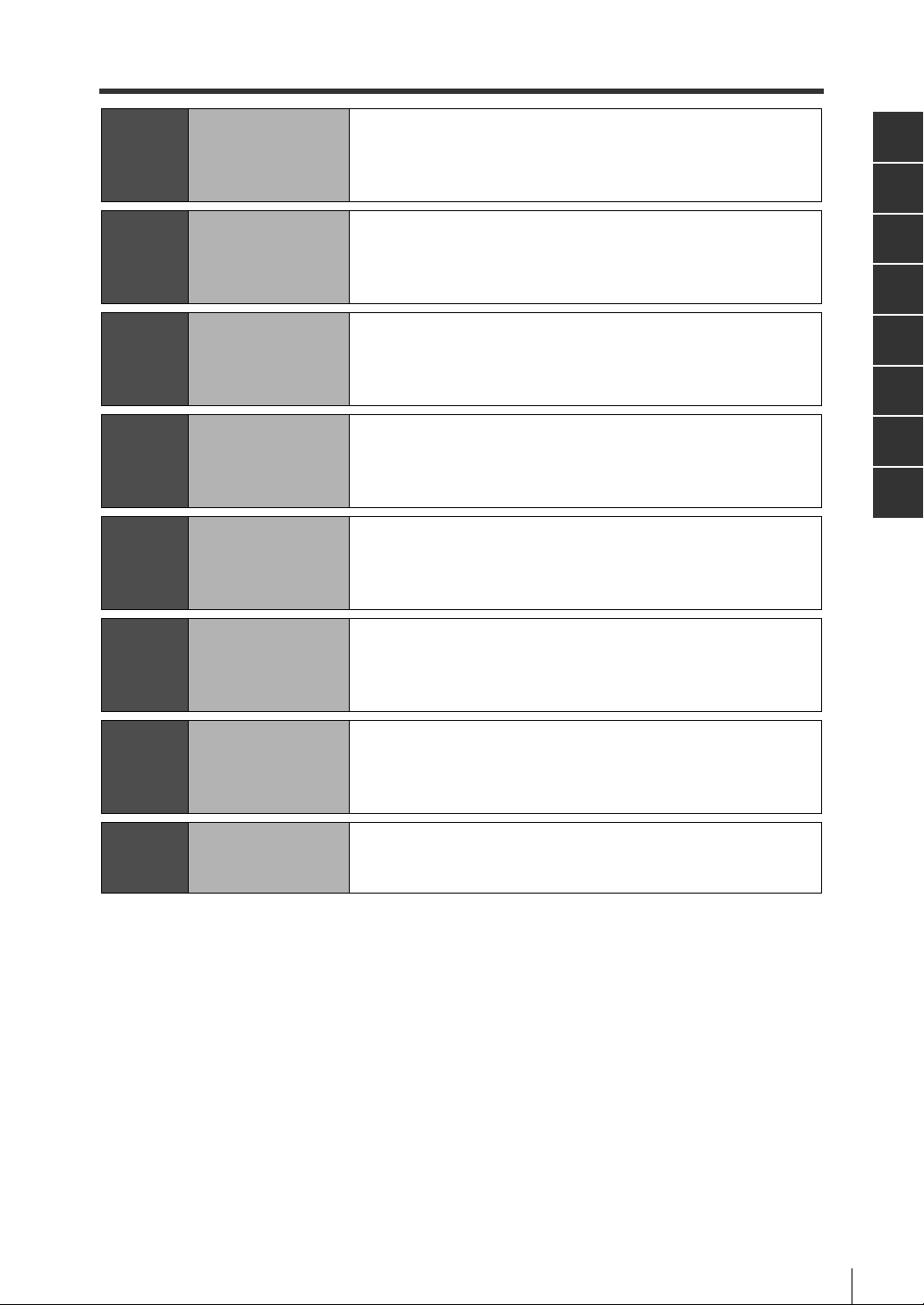

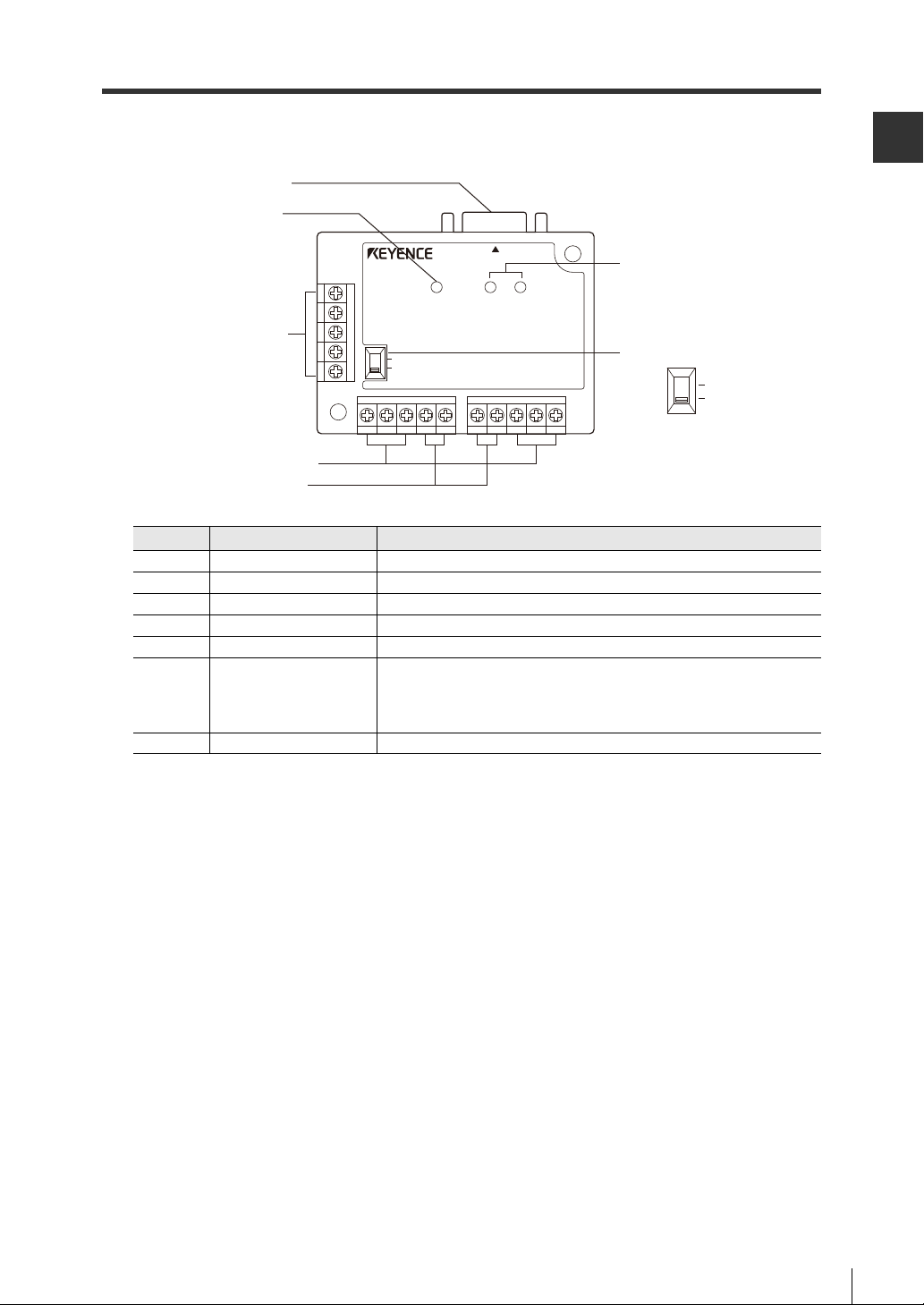

1-3 Part Names

1. Display LED

6. Power terminal

7. RS-485 terminal

8. Trigger input terminal

2. RS-232C

3. Communication state

display LEDs

4. Test switch

5. Terminator switch

N-410

Number Name Function

• Normally displays the ID number of the N-410, which is 00.

• Displays the ID number of any device undergoing a connection

.

test

"2-7 How to Use the Connection Confirmation Test" (Page 2-31)

• Displays "55" during setting mode.

1 Display LED

2 RS-232C Connects the host computer to the PLC.

Communication state

3

display LEDs

4 Test switch Activates test switch mode.

5 Terminator switch Toggles the terminator.

6 Power terminal Connects a 24 V DC power source.

7 RS-485 terminal Connects for multi-drop.

8 Trigger input jack Used for trigger input in multi-head mode.

"4-5 N-410 Setting Commands" (Page 4-22)

• Displays "50" while initiating communications to change settings.

"3-2 Sending and Receiving Settings" (Page 3-9)

• Displays the error state of the N-410.

"Appendix 4 Main device display" (Page A-12)

• Displays the ID number of the currently communicating device

when sending hotline commands.

"Specifying the ID number to send commands to" (Page 4-20)

• Power: Illuminates when power is on.

• Timing:Illuminates when the N-410 is receiving timing signals.

Illuminates when connected to a normal open point and is on.

Illuminates when connected to normal close point and is off.

(RS-232C)

SD, RD, RS, CS: Illuminates when there is communication over the

RS-232C port.

(RS-485)

SD: Illuminates when sending data

RD: Illuminates when receiving data

* When sending and receiving data, both SD and RD illuminate.

N-410 Overview

1-5

Page 18

1

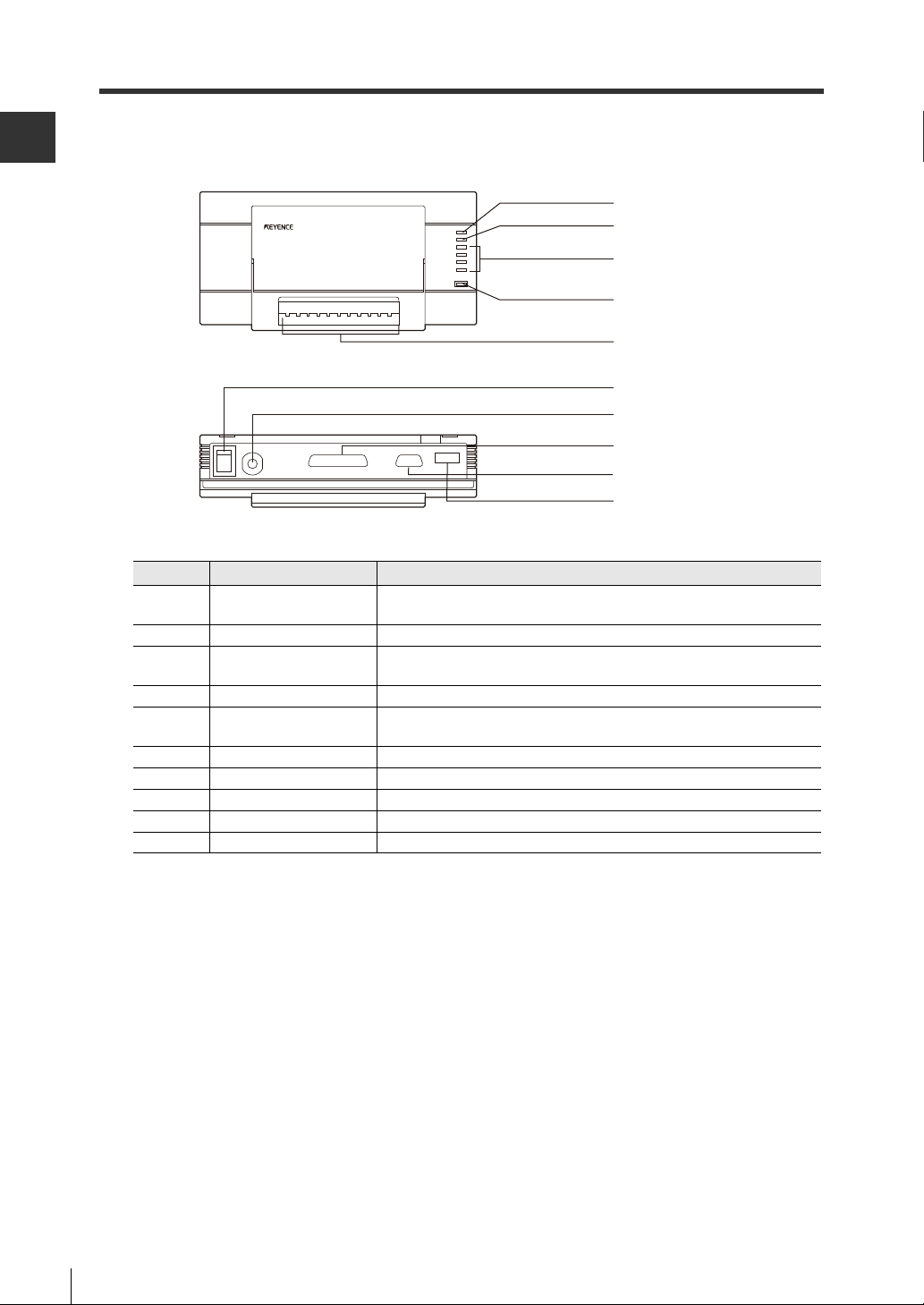

1-3 Part Names

1. Head port

2. Power LED

4. RS-422A/485 connector

5. I/O status LED

6. I/O terminals

7. Power terminal

8. DIN rail mounting tab

9. RS-422A/485

changeover switch

3. Communication status LED

10.Terminating

resistance switch

N-R4

N-410 Overview

States of RS-422A/485 changeover switch and terminating resistance switch

Number Name Function

1 Head port Used to connect the head.

2 Power LED Lights when the power is ON.

Communication status

3

LED

4 RS-422A/485 connector Used to connect to the host (personal computer, PLC).

5 I/O status LED Monitors the ON/OFF status of the I/O terminals.

6 I/O terminals Used to connect I/O signal lines of control units.

7 Power terminal Terminal for 24 V DC power supply input.

8 DIN rail mounting tab Used to secure the N-R4 to a DIN rail.

RS-422A/485

9

changeover switch

Terminating resistance

10

switch

Number

1 Left Right 2 Left Right 3- - Right

RS-422A

communication mode

Monitors the status of communication with the head.

Used to switch between RS-422A and 485 communications.

Used to switch between ON and OFF for terminating resistance.

RS-485

communication mode

Terminating

resistance ON

* Factory settings are by default RS-485 communication and the terminating resistance set to the

OFF position.

1-6

Page 19

1

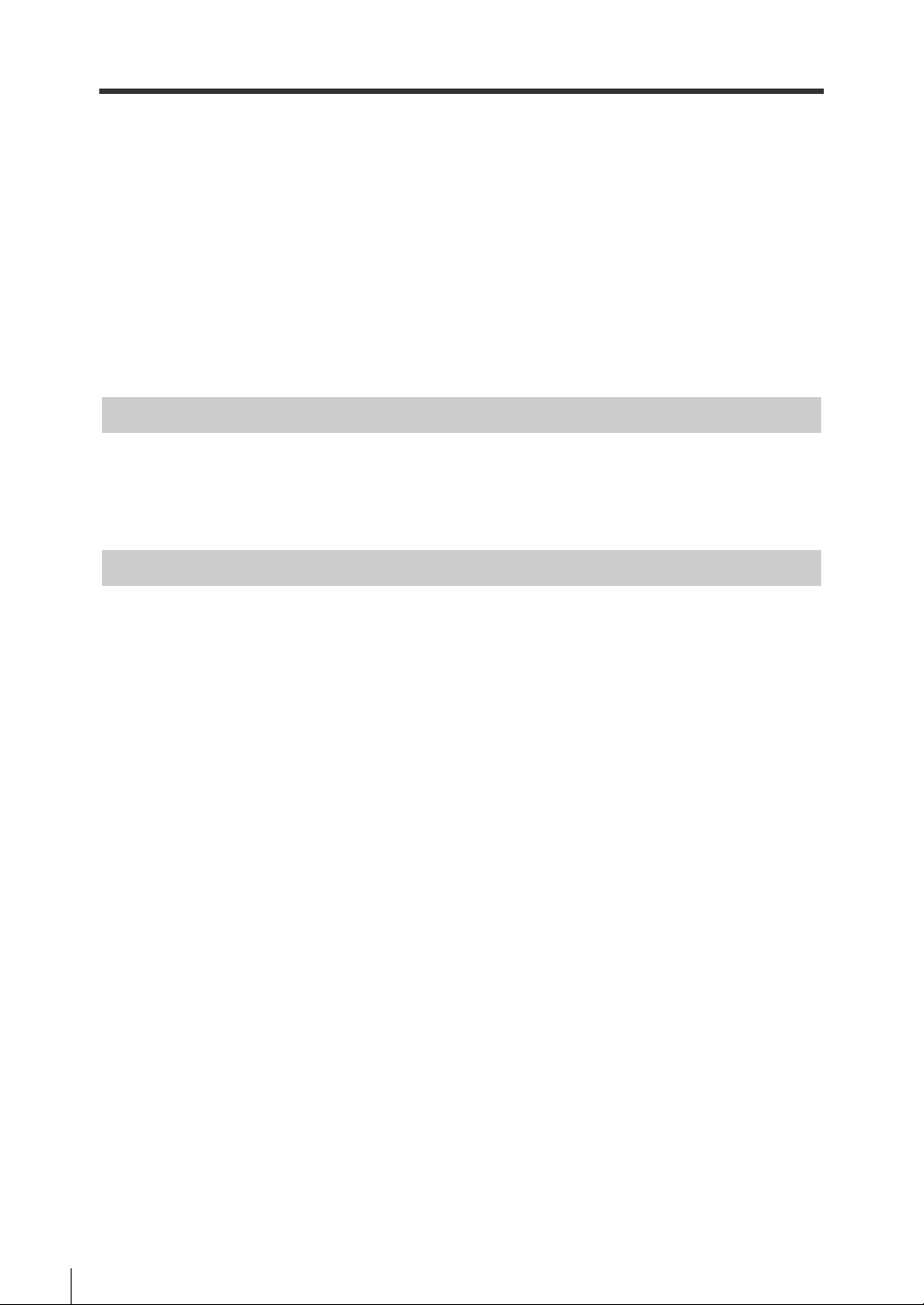

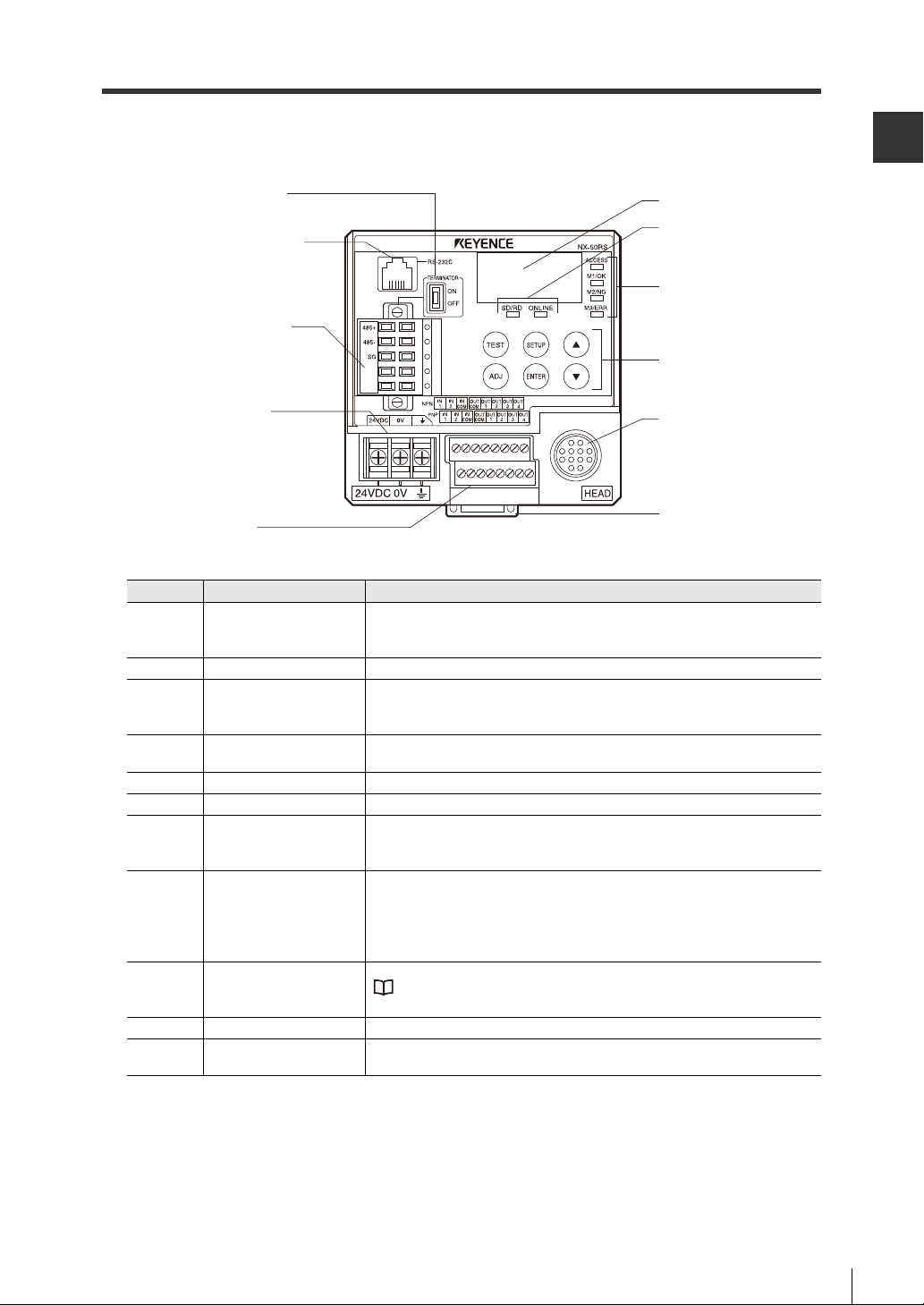

N-48

1-3 Part Names

1. Reader port

2. Power LED

READER

SD RD

N-48

3. Input/output

terminal

TERMINATOR

ON

OFF

POWER

4. RS-485 terminal

5. Power terminal

Number Name Function

1 Reader port Connects to BL/SR/RF Series devices.

2 Power LED Illuminates when power is on.

3 Input/output terminal There are terminals for input and OK/NG output.

4 RS-485 terminal Used for multi-drop connections.

5 Power terminal Connects a 24 V DC power source.

Monitors the state of communications at the reader port.

Communication state

6

display LEDs

7 Terminator switch Toggles the terminator.

SD: Illuminates when a BL/SR/RF Series device sends data.

RD: Illuminates when a BL/SR/RF Series device receives a

command.

6. Communication

state display LEDs

7. Terminator switch

ON

OFF

N-410 Overview

1-7

Page 20

1

1-3 Part Names

BL-U1

N-410 Overview

1. OK/NG LED

2. Timing LED

3. Communication

state display LEDs

4. Power LED

5. Input/output terminal

6. Power switch

7. Power cable(2m)

8. RS-232C port

9. Reader port

10. Dipswitch

Number Name Function

1OK/NG LED

2 Timing LED Illuminates when trigger input is on.

Communication state

3

display LEDs

4 Power LED Illuminates when power is on.

5 Input/output terminal

6 Power switch Turns the power on or off.

7 Power cable (2m) Use 100 to 240 V AC(50 / 60 Hz).

8 RS-232C port Connects to the computer. Not used for multi-drop connections.

9 Reader port Connects to BL/SR/RF Series devices.

10 Dipswitch Changes communication ports, toggles the terminator.

•Illuminates green when output is OK.

•Illuminates red when output is NG.

Monitors the state of communications at the RS-232C port.

From top to bottom: SD, RD, RS, CS

There are terminals for trigger input, OK/NG output, RS-422A and

RS-485.

1-8

Page 21

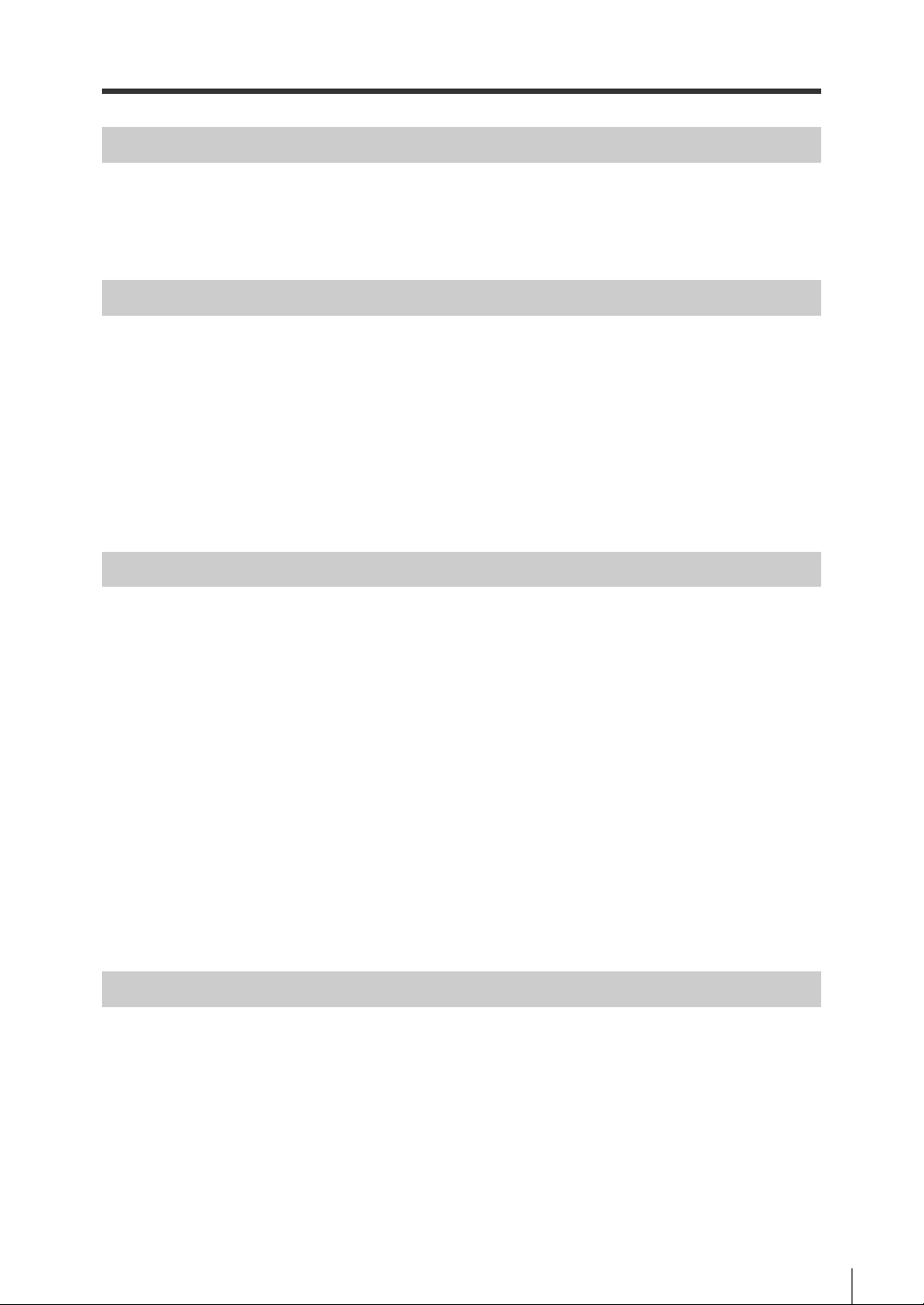

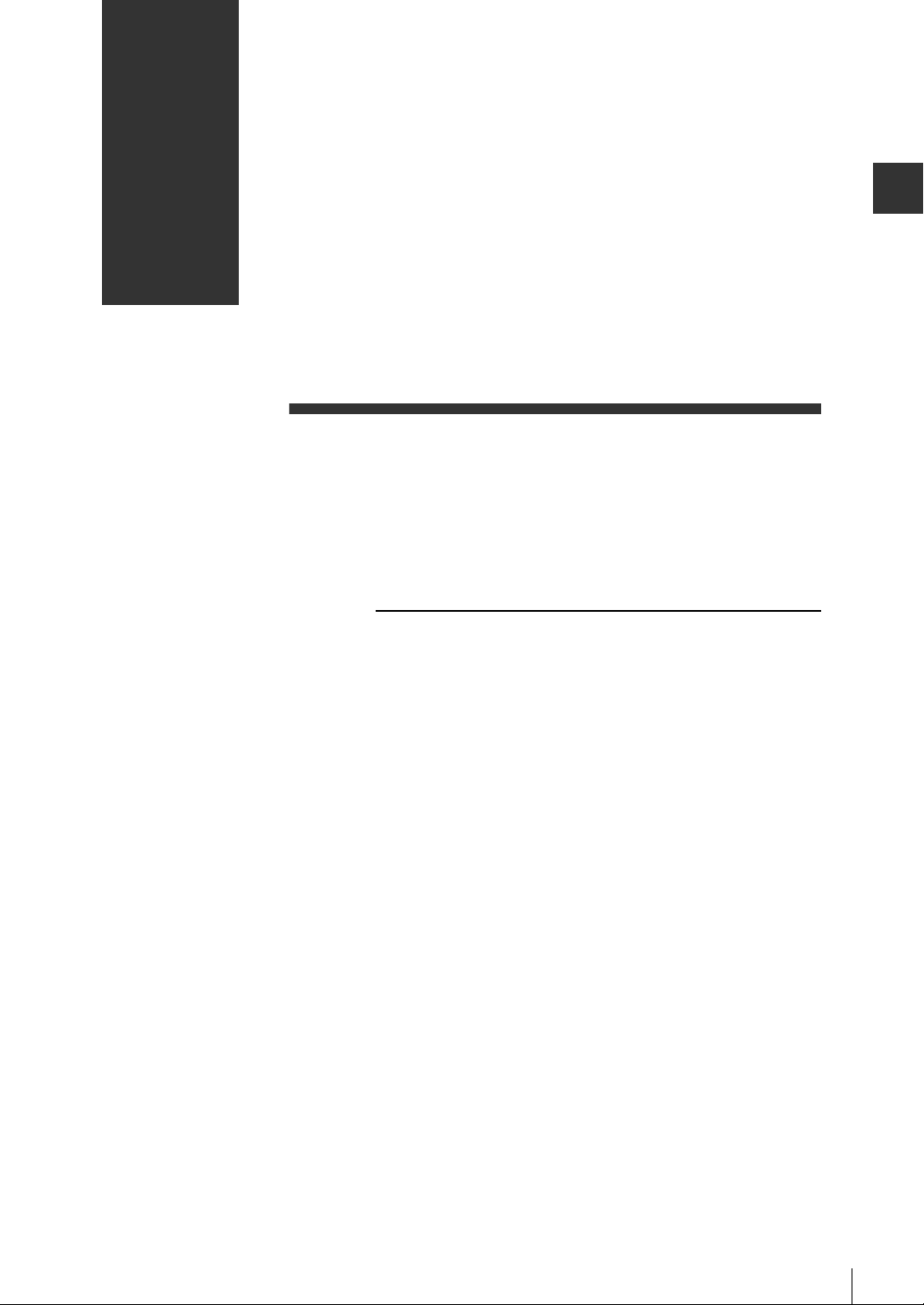

1

NX-50RS

1. Terminator switch

2. RS-232C connector

3. RS-485 connector

4. Power terminal

5. Input/output

terminal

6. Display

7. Network

communication

state LED

8. Head

communication

state LED

10. Head connector

11. DIN rail

mounting bracket

9. Control switch

Front panel

1-3 Part Names

N-410 Overview

Number Name Function

Toggles the terminator.

Terminator switch

1

RS-232C connector Used to connect to a computer.

2

RS-485 connector

3

Power terminal

4

Input/output terminal Connects input devices such as PLC via NPN/PNP.

5

Display Displays the status of the network controller.

6

Network communication

7

status LED

Head communication

8

state LED

Control switch

9

Head connector Connects to the head or the code reader.

10

DIN rail mounting

11

bracket

Turns on when the network controller is at the end of the main line. Turns off

at all other times.

Used to connect to a field network.

Used when connecting a device such as a network controller to a

multi-drop connection.

Used to connect to a 24 V DC power supply. Use a D type ground for

the FG pin.

Displays the communication status of the network.

SD/RD: Displays whether data is being sent or received.

Online: Displays whether the device is online.

Displays the communication status of the head via LED.

Access: Illuminates when the head is communicating.

M1/OK: Illuminates when the head is outputting an OK signal.

M2/NG: Illuminates when the head is outputting an NG signal.

M3/ERR: Illuminates when the head is outputting an error signal.

Used to control the network.

"RF-500 Series Setup and Connection Manual" "4-1 Network Controller

Functions"

Mounting bracket for DIN rails.

1-9

Page 22

1

1-3 Part Names

N-410 Overview

MEMO

1-10

Page 23

2

Installation

This chapter describes how to connect the N-410 and confirm the

connection.

2-1 Making Settings and Connections . . . . . . . . . . . . . 2-2

2-2 N-410 Connections and Wiring. . . . . . . . . . . . . . . . 2-5

2-3 Connecting and Wiring to the N-R4 Series. . . . . . 2-10

2-4 NX-50RS Connections and Wiring . . . . . . . . . . . . 2-16

2-5 N-48 Connections and Wiring. . . . . . . . . . . . . . . . 2-20

2-6 BL-U1 Connections and Wiring . . . . . . . . . . . . . . 2-26

2-7 How to Use the Connection Confirmation Test . . . 2-31

2-8 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2-1

Page 24

2

2-1 Making Settings and Connections

Use the following steps for installation.

<Required items>

• RS-485 master unit N-410

Installation

• BL Series barcode reader, SR Series 2D code reader, RF Series RFID system

The following units are compatible with the N-410.

BL Series- BL700/600/500/180/210 Series

SR Series- SR-500, SR-510

RF Series- RF-500, RF-550

• RS-485 power source for multi-drop (N-48, BL-U1, NX-50RS)

Each BL/SR/RF Series device requires its own communication unit.

• RS-232C type communication unit (BL-U2)

When using an N-48 to power a multi-drop network, a separate communication unit will be

required to change settings on any of the BL/SR/RF Series devices because the N-48 does

not include an RS-232C.

This is not required when using a BL-U1 or an NX-50RS to power a multi-drop network.

• RS-232C cable for N-410

This cable connects the N-410 to the host computer.

Be sure to use a cable with the proper pin settings for the computer or PLC that you are using.

• RS-232C cable for BL/SR/RF Series settings

This is the cable used to connect the computer, BL-U1, BL-U2 or NX-50RS to the computer

when changing settings on a BL/SR/RF Series device. This cable is different than the RS-232C

cable for the N-410 and must be prepared separately.

Refer to the user’s manual for each device for more information about wiring.

• Twist pair cable for RS-485

Use this for the settings cable.

"Wiring an RS-485" (Page 2-24)

"Wiring an RS-485" (Page 2-30)

•Host computer

Use a computer with an RS-232C.

It is possible to exceed the data handling capacity of the host computer when large amounts

of data are being sent from multiple BL/SR/RF Series devices.

In such cases, reduce the number of BL/SR/RF Series devices connected or use a host

computer with a higher data handling capacity.

2-2

Page 25

2-1 Making Settings and Connections

2

<Making Settings and Connections>

1. Set BL Series , SR Series, and RL Series devices

Use the BL/BL 210 Series AutoID Navigator software to change the settings on BL/SR/RF

Series devices. This requires preparing the BL/SR/RF Series devices, the communication unit

for an RS-232C (N-R2, BL-U1, BL-U2 or NX-50S), an RS-232C cable for changing BL/SR/RF

settings and a computer.

Refer to the user’s manual for each device for more information making settings and

connections.

The necessary settings vary greatly depending on the mode being used. Refer to the following

pages.

• Multi-drop Link mode "Settings" (Page 4-3)

• Multi-head mode "Settings" (Page 5-3)

2. Set the N-410

Use AutoID Navigator and the N-410, RS-232C cable for the N-410 and the computer to make

the settings. For more information on using AutoID Navigator, refer to the "AutoID

Navigator User's Manual".

The necessary settings vary depending on the mode being used. Refer to the following pages.

• Multi-drop Link mode "N-410 Settings" (Page 4-4)

• Multi-head mode "N-410 Settings" (Page 5-4)

• PLC link "7-1 PLC Link" (Page 7-2)

Installation

3. Set the host computer and PLC control

Change the settings for baud rate, data bits and stop bit length to match the RS-232C side of

the N-410 settings.

When using a PLC link, refer to "7-3 Settings" (Page 7-13) , then make the settings.

4. Connect BL/SR/RF Series devices to the N-410

First, connect a the BL/SR/RF Series device to a dedicated communication unit (N-R4, N-48,

BL-U1 or NX-50RS).

Then connect the communication unit to the N-410 with the specified cable, (RS-485, twist

pair). Set the terminator settings on both devices to on.

When using a BL-U1, be sure to set the dipswitch to "RS-485".

5. Connect the N-410 to the host computer or the PLC

Be sure that the RS-232C cable you are using has a pin layout compatible with your PLC or

host computer.

6. Confirm that the N-410 and BL/SR/RF Series devices are correctly connected by RS-485

The connection test mode will confirm if the N-410 and RS-485 are connected correctly and if

the AutoID Navigator is set correctly. Use it to confirm that the RS-485 connection is set up

correctly. Refer to "2-7 How to Use the Connection Confirmation Test" (Page 2-31) for more

information.

7. Connect the trigger sensor

Connect one trigger sensor for each power source.

(This is not necessary if reading operation is controlled by reading start and stop commands)

When used in multi-head mode, one trigger device is required for the N-410.

(This is not necessary if reading operation is controlled by reading start and stop commands)

Multi-head mode will not operate properly if a trigger sensor is connected to anything other than the

N-410.

2-3

Page 26

2

2-1 Making Settings and Connections

8. Confirm operation

Test the RS-232C connection between the N-410 and the host computer with the terminal

software in AutoID Navigator.

When using a PLC link, make sure that data is being input to PLC memory.

Installation

2-4

Page 27

2

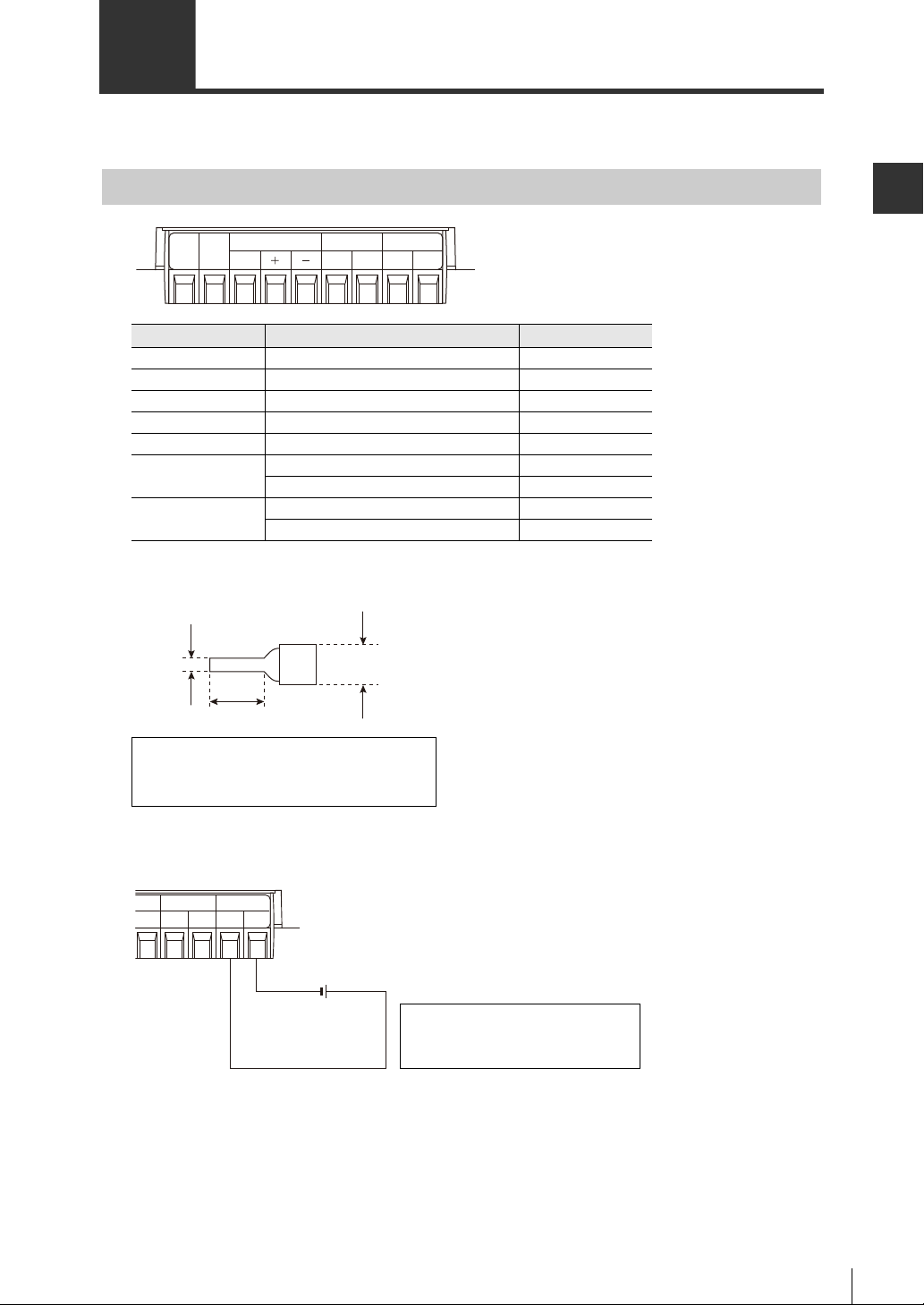

2-2 N-410 Connections and Wiring

5 mm max.

6 mm min.

2.0 mm

max.

Recommended manufacturer:

Maker: JST Manufacturing Company, Ltd.

Model: VTUB-1.25

–

DC OUT DC IN

24V DC

+

24V 0V 24V 0V

Use an NEC class 2 output

power source for UL

certification.

This section explains how to connect the N-410 to other devices.

Installing and Wiring the Input and Output Jacks

TIM COM

RS-485

SG 24V 0V 24V 0V

Symbol Explanation Signal direction

TIM Trigger input Input

COM Trigger input common Input

RS-485 SG RS-485 ground signal RS-485 + RS-485 + side Input/output

RS-485 - RS-485 - side Input/output

DC OUT

DC IN

24 V DC power source output + side Output

24 V DC power source output - side Output

24 V DC power source input + side Input

24 V DC power source input - side Input

* These appear in this order from left to right on the terminal.

DC OUT DC IN

Installation

Electrical wiring

• A bar terminal (I terminal) like that shown in the figure can be used.

Connect the N-410 to a 24 V DC power supply.

Connect the 24 V DC power source to the "IN" side of the power terminal to use the "OUT" side of

the terminal as a 24 V DC power supply (However, be certain that the power supply coming into

the "IN" side is will have enough power to power the device connected to the "OUT side").

2-5

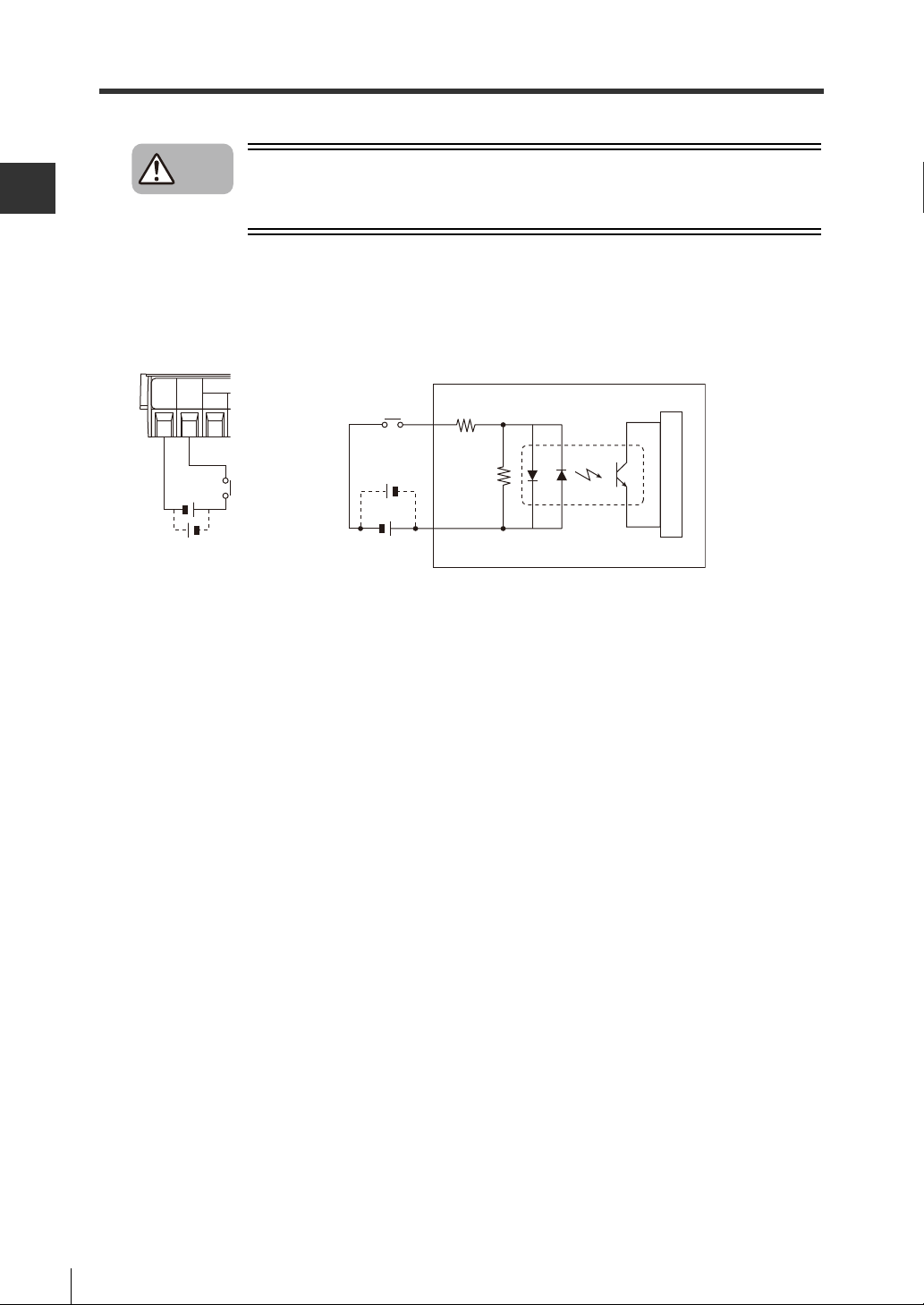

Page 28

2

2-2 N-410 Connections and Wiring

TIM COM

SG

+

+

Contact

or

non-contact

15 to 26V DC

+

+

Circuit diagram

Internal circuit

TIM

COM

Caution

Be sure to use only 24 V DC power for this device. Usage of any other power

supply, including AC power, may damage this device.

Installation

Wiring the trigger input

When used in multi-head mode, the timing device should be connected to the N-410, not the BL/

SR/RF Series devices.

2-6

Page 29

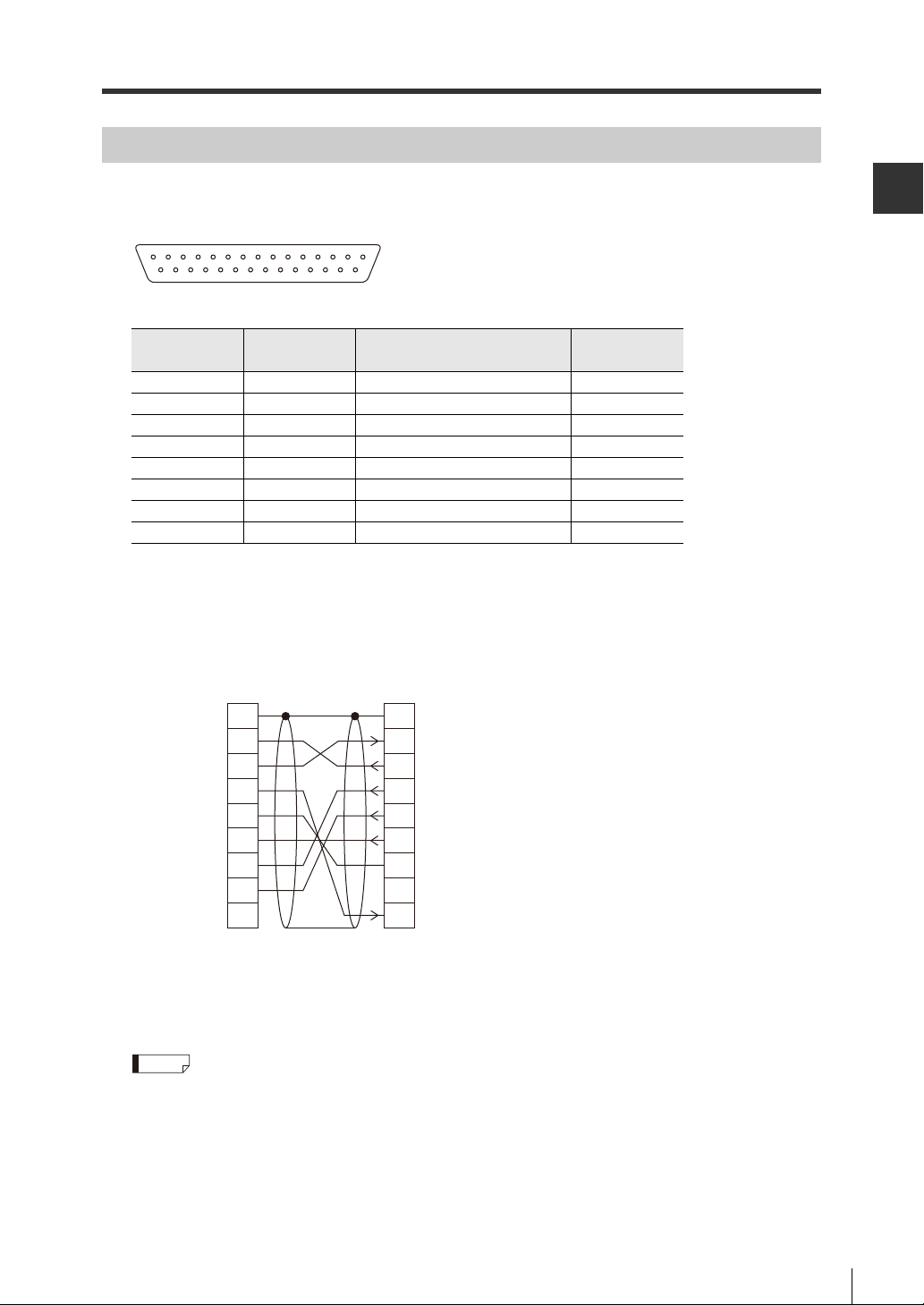

2

RS-232C Connections

13

25 14

1

D-sub 25 pin (female)

DCE specification

(modem definition)

M2.6 screws

Connecting to a DOS/V computer

FG

SD

RD

RS

CS

DR

SG

N-410

-

Connector case

2RD

3SD

4ER

5SG

6DR

7RS

8CS

DOS/V

CD 1

1

2

3

4

5

6

7

8

ER20

D-sub 9 pin (female)

#4-40 screws

D-sub 25 pin (male)

M2.6 screws

* A KEYENCE OP-29860 option cable

(1.5m) can be used.

Reference

<Pin Layout>

2-2 N-410 Connections and Wiring

Installation

Pin number Symbol Function

1 FG Frame ground 2 SD (TXD) Receive data Input

3 RD (RXD) Send data Output

4 RS (RTS) Send capability Input

5 CS (CTS) Request send Output

6 DR (DSR) Connects internally with pin #20 Output

7 SG Signal ground -

20 ER (DTR) Connects internally with pin #6 Input

<RS-232-C cable wiring>

Connecting to a computer

Signal

direction

Standard straight cables (D-sub 25 pin or D-sub 25 pin - 9 pin) can be used.

2-7

Page 30

2

2-2 N-410 Connections and Wiring

-

2

3SD

4ER

5SG

6DR

7RS

8

1

2

3

4

5

6

7

8

CS

FG

SD

RD

RS

CS

DR

SG

9 20-ER

KV-L20V N-410

D-sub 9 pin (female)

#4-40 screws

D-sub 25 pin (male)

M2.6 screws

Connector case

RD

3SD

5RD

1

1

2

3

4

5

6

20

7

SG

FG

SD

RD

RS

CS

DR

ER

SG

KV-L20V

N-410

Jack

D-sub 25 pin (male)

M2.6 screws

Port 1 Port 2

* A KEYENCE OP-29860 option cable

(1.5m) can be used.

Connecting to a

AJ71UC24

AJ71QC24N/-R2

Connector case

2RD

3SD

4ER

5SG

6DR

7RS

8

1

2

3

4

5

6

7

8

CS

FG

SD

RD

RS

CS

DR

SG

1 20CD ER

MELSEC N-410

D-sub 9 pin (male)

M2.6 screws

D-sub 25 pin (male)

M2.6 screws

A1SJ71UC24-R2/PRF

Connecting to a AJ71QC24N/-R2

QJ71C24N/-R2

Connecting to a KV Series programmable controller port

Use a KEYENCE option cable.

RESET ENTER

Installation

NEXT

F1 F2 F3 F4 F5

KV-10/16/24/40

KV-P

KV-3000/1000/700

OP-24045 (1m)

or

OP-24025 (5m)

OP-26485

Connecting to a KV-L20V

Connecting to a MELSEC Series device

2-8

MELSEC N-410

1FG

2SD

3RD

4RS

5CS

6DR

7SG

8

CD

20 20ER ER

D-sub 25 pin (male)

M2.6 screws

1

2

3

4

5

6

7

8

D-sub 25 pin (male)

M2.6 screws

FG

SD

RD

RS

CS

DR

SG

Page 31

2

SYSMAC Series

CV Series, CS1 Series, (CPU mounted board)

Connecting to a

CS1W-SCB21 (-V1)/41 (-V1)

CS1W-SCU21 (-V1)

CJ1W-SCU21 (-V1)/41 (-V1)

1FG

2SD

3RD

4RS

5CS

9SG

1

2

3

4

5

7

FG

SD

RD

RS

CS

SG

PLC N-410

D-sub 9 pin (male)

M2.6 screws

D-sub 25 pin (male)

M2.6 screws

2-2 N-410 Connections and Wiring

Installation

2-9

Page 32

2

2-3 C

37485

12

9

1112

6

10

Round 12-pin jack

onnecting and Wiring to the N-R4 Series

Connecting to BL-1300 Series/SR Series/RF Series Devices

Use the N-R4 when connecting an N-410 Series device to a BL-1300 Series/SR Series/RF Series

Installation

device. Connect it in the following way.