Page 1

User's Manual

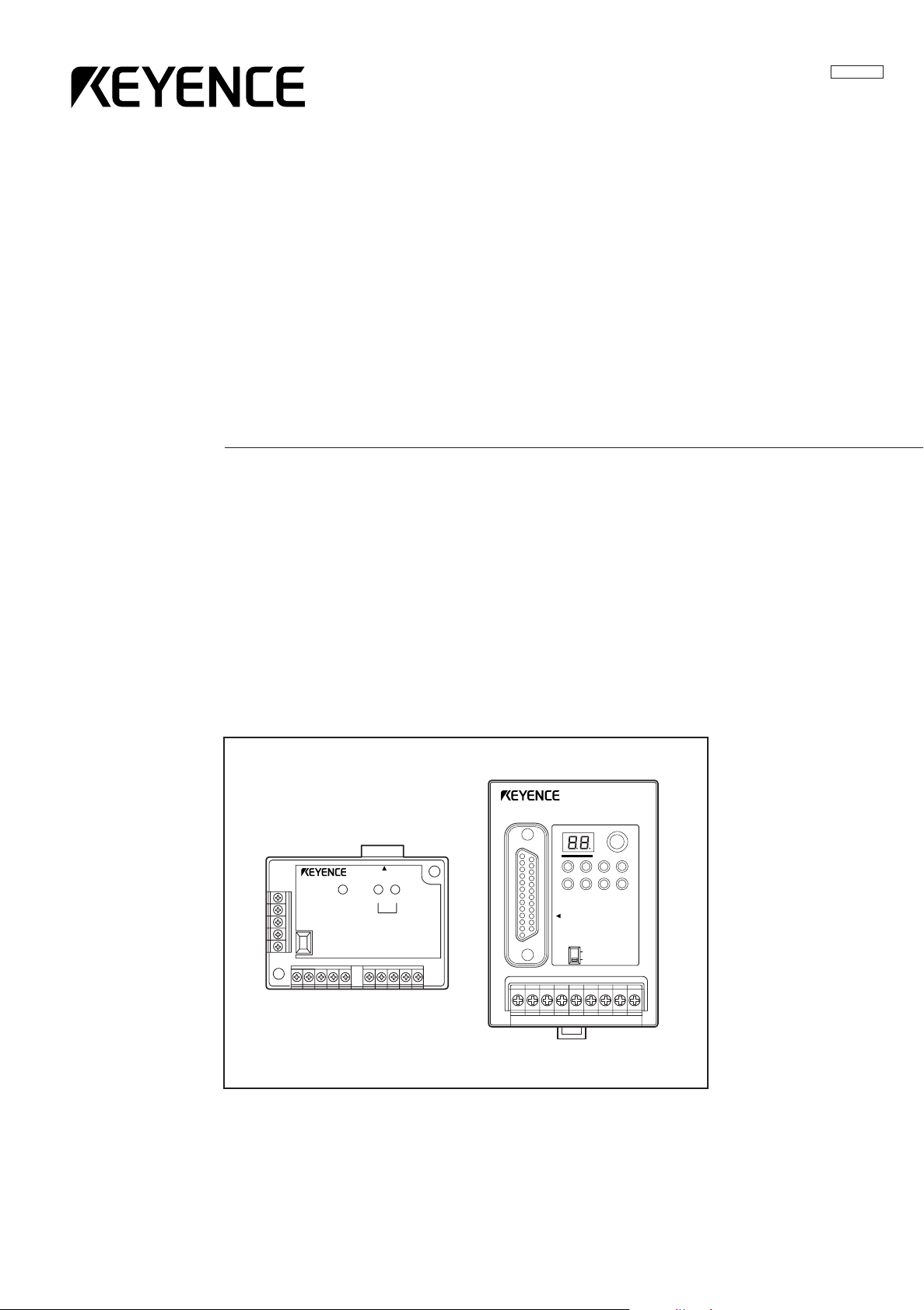

Multi-Drop Controller for BL Series

96M0353

N-400

READER

POWER SD RD

TERMINATOR

ON

OFF

SD RD

POWER TIMING

RS-232C

TERMINATOR

ON

OFF

N-400

TEST

RS-232C

CS RS

SD

RS-455

RD

Page 2

Software License Agreement

Please read this license agreement carefully and be sure you accept its terms

before you use the software. By using the software you signify that you consent to

be bound by the terms and conditions of this agreement.

Keyence grants to you, and you accept a license to use the programs and the

related materials delivered with this agreement.

The manual and the software are copyrighted with all rights reserved. Your rights of

ownership are subject to the limitations and restrictions imposed by copyright laws.

Under the copyright laws, you may not copy the manual or software, in whole or in

part, without the written consent of Keyence, except in the normal use of the

software or to make a backup copy.

It is illegal to copy, reproduce, or transmit any part of the manual or the software in

any form or by any means (including translation to another language, computer

language, or format)except as permitted by the Copyright law. You are permitted to

write the contents of the software into the machine memory of your computer so

that the software can be executed. The software may be associated with one

computer and may be used by more than one person on that computer, or may be

associated with one person and used by that person on more than one computer.

However, in no event shall two or more persons use the software at the same time.

You may not rent or lease the software, but you transfer the software and accompanying written materials on a permanent basis provided you retain no copies and

the recipient agrees to the terms of this agreement. You may not reverse engineer,

decompile, or disassemble the software.

Keyence warrants that if you discover physical defects in the media on which this

software is distributed, or in the manual distributed with the software, Keyence will

replace the media or manual at no charge to you, provided you return the defective

items, postage prepaid and with proof of purchase, within ninety days of the date of

purchase. Keyence reserves the right to revise this software and manual without

obligation to notify any person of such revision. In no event will Keyence be liable

for loss of profits or goodwill or other indirect, special, incidental, or consequential

damages resulting from any defect in the software, media, or manual. Keyence’s

liability for damages to you or others will in no event exceed the total amount paid

by you for the software. In particular, Keyence shall have no liability for any data

stored in or used with Keyence’s products, including the costs of recovering such

data.

MS Windows, Windows 95 are registered trademarks of Microsoft Corporation. All

other company, product names in this publication are registered trademarks of their

respective owners.

i

Page 3

Safety Precautions

This instruction manual describes the operation and function of the N-400. Read

this manual carefully to ensure safe use and maximum performance from your N-

400.

The N-400 can be connected to the BL-700, BL-180 and BL-500 series.

Symbols

The following symbols alert you to important messages. Be sure to read these

messages carefully.

General Precautions

WARNING

CAUTION

Note:

• At startup and during operation, be sure to monitor the functions and performance of the N-400.

•We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the N-400 or use it in any way other than described in

the specifications.

•When the N-400 is used in combination with other instruments, functions and

performance may be degraded, depending on operating conditions and the

surrounding environment.

Failure to follow instruction may lead to injury. (electric

shock, burn, etc.)

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

• Do not use the N-400 for the purpose of protecting the human body.

Warnings and Cautions Specific to the N-400

CAUTION

• To operate the N-400/N-48, use a 24 VDC power supply.

Using a different type of power supply may damage the unit.

• This unit is a precision instrument and may be damaged if dropped. Be

careful when carrying and mounting the unit.

• To install this unit, read “Chapter 2, 2.6 Mounting Procedure” in this manual

thoroughly for instructions on proper mounting conditions.

• For the RS-485 connections, use the recommended cable and follow the

instructions given in this manual. (

or “Chapter 2, 2.4.5 Connecting RS-485”.

following these instructions may cause a communication error.

➮

See “Chapter 2, 2.3.3 Connecting RS-485”

) Connecting the RS-485 cable without

ii

Page 4

List of Package Contents

The N-400 includes the following equipment and accessories. Before using the

unit, ensure that all of these items are included with your N-400.

■ N-400 package contents

• N-400 (x 1)

• User’s Manual (x 1)

• N-400 setup software (x 1)

■ N-48 package contents

• N-48 (x 1)

• Instruction manual (x 1)

■ BL-U1 1. package contents

• BL-U1 (x 1)

■ BL-U2 package contents

• BL-U2 (x 1)

1. BL-U1 is not available in Europe. Use BL-U2 instead.

iii

Page 5

Contents

Chapter 1 Overview of the N-400

Chapter 2 Installation Procedure

1.1 Functions of the N-400 ..........................................................................2

1.2 System Configuration ............................................................................4

1.3 Part Names .............................................................................................5

2.1 Installing the N-400 ..............................................................................10

2.2 Connecting N-400 and Wiring .............................................................12

2.2.1 Terminals of I/O terminal block and wiring..............................................12

2.2.2 Connecting RS-232C..............................................................................13

2.3 Connecting N-48 and Wiring ...............................................................16

2.3.1 Connecting the BL series........................................................................16

2.3.2 Terminals of I/O terminal block and connection......................................16

2.3.3 Connecting RS-485.................................................................................19

2.4 Connecting BL-U1 and Wiring ............................................................21

2.4.1 Connecting power supply........................................................................21

2.4.2 Connecting BL series..............................................................................21

2.4.3 Setting BL-U1 DIP switches....................................................................22

2.4.4 Terminals of I/O terminal block and wiring..............................................23

2.4.5 Connecting RS-485.................................................................................25

2.5 Using Connection Test Mode .............................................................26

2.6 Mounting Procedure ............................................................................27

2.6.1 Precautions for mounting environment ...................................................27

2.6.2 Mounting N-400 ......................................................................................28

2.6.3 Mounting N-48 ........................................................................................28

2.6.4 Mounting BL-U1......................................................................................29

Chapter 3 N-400 Setup Procedure

3.1 Installing Setup Software ....................................................................32

3.2 Setup Software Operating Procedure ................................................34

3.2.1 Operating procedure...............................................................................34

3.2.2 Description on each setup screen...........................................................35

3.2.3 Outline of operation.................................................................................36

3.3 Details of Operating Procedure .........................................................38

3.3.1 Setting procedure....................................................................................38

3.3.2 Reading/Saving/Printing File...................................................................44

3.4 Sending/Receiving Settings ................................................................48

3.5 Using Terminal .....................................................................................52

3.6 List of Error Messages ........................................................................55

iv

Page 6

Chapter 4 Multi-Drop Link Mode Control Procedure

4.1 Multi-Drop Link Mode ..........................................................................58

4.1.1 Controlling multi-drop link mode .............................................................58

4.1.2 Setup procedure .....................................................................................60

4.2 Data Communication in Multi-Drop Link Mode .................................61

4.2.1 Auto polling .............................................................................................61

4.2.2 Manual polling.........................................................................................62

4.2.3 Capacity of Transmission Buffer.............................................................63

4.2.4 Handshaking protocol .............................................................................65

4.3 Command Transmission To BL Series ..............................................66

4.4 N-400 Direct Control Commands ........................................................69

4.4.1 Communication procedure......................................................................69

4.4.2 Description of commands .......................................................................70

4.5 N-400 Setup Command ........................................................................75

4.6 Communication Time Consideration ..................................................83

Chapter 5 Multi-Head Mode Control Procedure

5.1 Multi-head Mode ...................................................................................88

5.1.1 Controlling multi-head mode...................................................................88

5.1.2 Setup procedure .....................................................................................89

5.2 Reading Operation in Multi-Head Mode .............................................91

5.2.1 Difference in operation depending on reading mode..............................91

5.2.2 Trigger input signal type..........................................................................93

5.2.3 Data transmission timing.........................................................................94

5.3 Data Communication in Multi-Head Mode .........................................95

5.3.1 Communication format............................................................................95

5.3.2 Handshaking protocol .............................................................................95

5.3.3 Read error code......................................................................................95

5.4 Command Communication in Multi-Head Mode ...............................96

5.4.1 Sending a command to BL series...........................................................96

5.4.2 N-400 direct control/setup commands ....................................................96

5.5 Interference Suppression Function ...................................................97

5.6 Communication Time ..........................................................................98

v

Page 7

Chapter 6 PLC Link

6.1 PLC Link .............................................................................................102

6.1.1 List of PLCs used for PLC link ..............................................................102

6.1.2 Devices used for PLC link.....................................................................103

6.2 Setup Procedure ................................................................................104

6.2.1 Setting the BL Series ............................................................................104

6.2.2 Setting the N-400..................................................................................105

6.2.3 Setting the PLC.....................................................................................106

6.3 Device Assignment ............................................................................108

6.3.1 Device assignment in multi-drop link mode ..........................................108

6.3.2 Device assignment in multi-head scan mode .......................................113

6.4 PLC Link Error ....................................................................................116

Appendices

Appendix A Specifications .....................................................................120

Appendix B Dimensions .........................................................................122

Appendix C Sample Programs ...............................................................124

Appendix D Troubleshooting .................................................................131

Appendix E Indications on the N-400 ....................................................133

Appendix F ASCII Code Table ................................................................134

Appendix G Checksum Calculation Method .........................................135

Appendix H Setup Parameter List ..........................................................137

Appendix I Default Setting List .............................................................139

Appendix J Sample Printout of Setting List .........................................140

Sample programs for multi-drop link......................................124

Sample program for PLC link ................................................126

WARRANTIES

WARRANTIES AND DISCLAIMERS ............................................................141

vi

Page 8

vii

Page 9

Chapter 1

Overview of the N-400

1.1 Functions of the N-400 .........................................................2

1.2 System Configuration ..........................................................4

1.3 Part Names ............................................................................5

Page 10

Chapter 1 Overview of The N-400

1.1 Functions of the N-400

The N-400 multi-drop controller allows the following functions to be added to the BL

series.

1

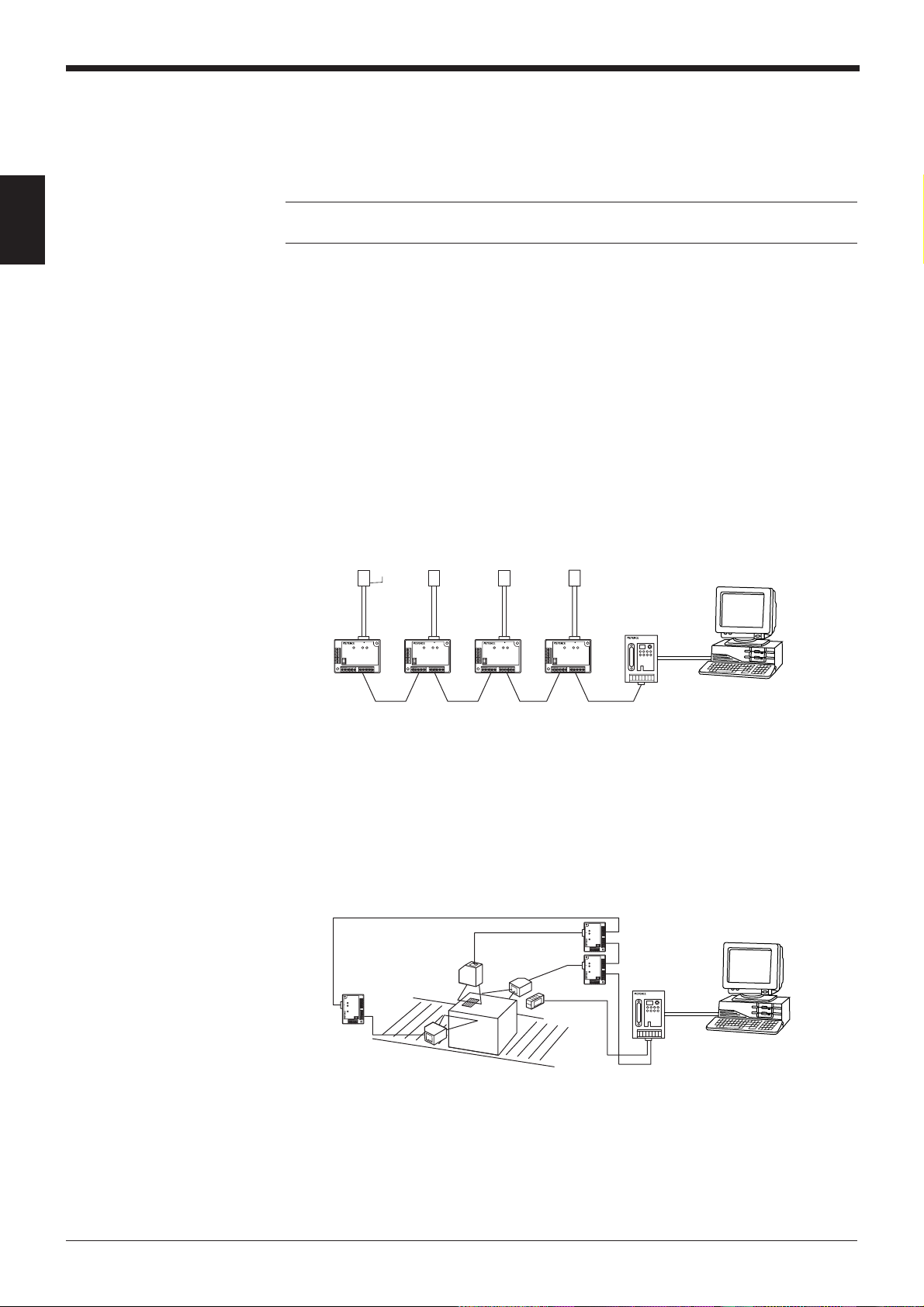

Multi-drop link function (mode)

Note: The BL-U1 and N-48 can be used as an RS-232C to RS-485 converter.

However, the BL-U1 is not available in Europe.

The N-400 can control up to thirty-one BL series units using a host computer,

enabling the multi-drop link configuration.

The communication path is an RS-485 cable, which provides high noise-resistance

and enables data transmission over a long distance (up to 1.2 km). Since a twisted

pair cable (two cables) is used for the connections, the multi-drop link configuration

can be realized with simple wiring.

The N-400 controls the complicated communication (RS-485 communication)

between each BL series and the N-400. Since the host computer works only for

communication with the N-400, it can be operated with a simple program. (The ID

number assigned to the head of the transmitted data allows you to identify the BL

series unit that sends the data.) Therefore, the host computer’s job is reduced with

this system configuration.

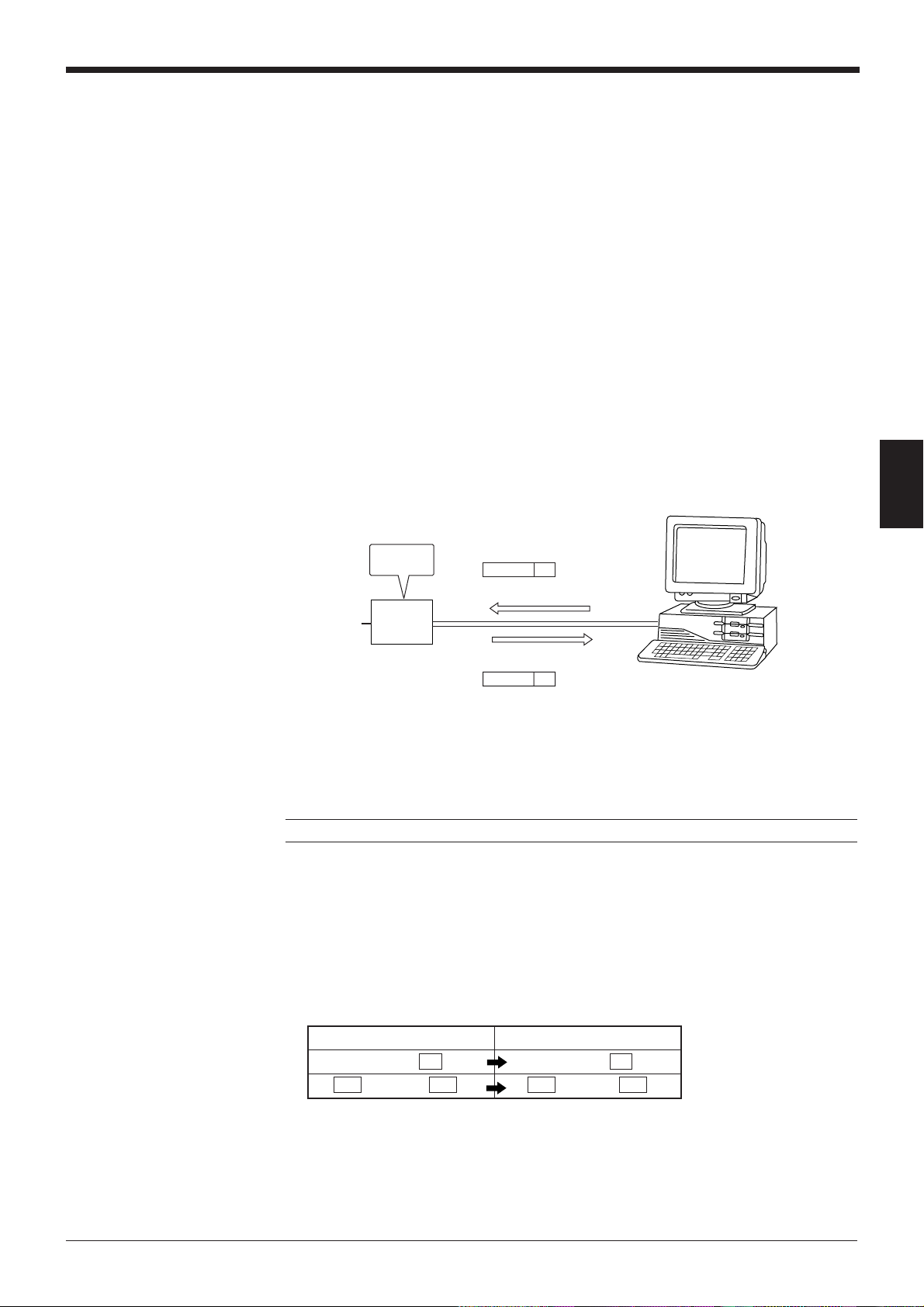

BL series

N-400

RS-232C

Multi-head scan function (mode)

If the position of bar codes is unknown in a product, or bar codes are printed in

several positions, the bar codes cannot be read with a single bar code reader. In

such cases, several bar code readers need to be mounted in various positions or at

various angles.

When the N-400 controller is used in multi-head scan mode, a host computer can

control several BL series units as if they were a single unit.

N-48

or

BL-U1

N-48

or

BL-U1

*

BL series

Sensor for

trigger input

RS-485

N-400

RS-485

*

RS-232C

Host

Host

2

Page 11

Chapter 1 Overview of The N-400

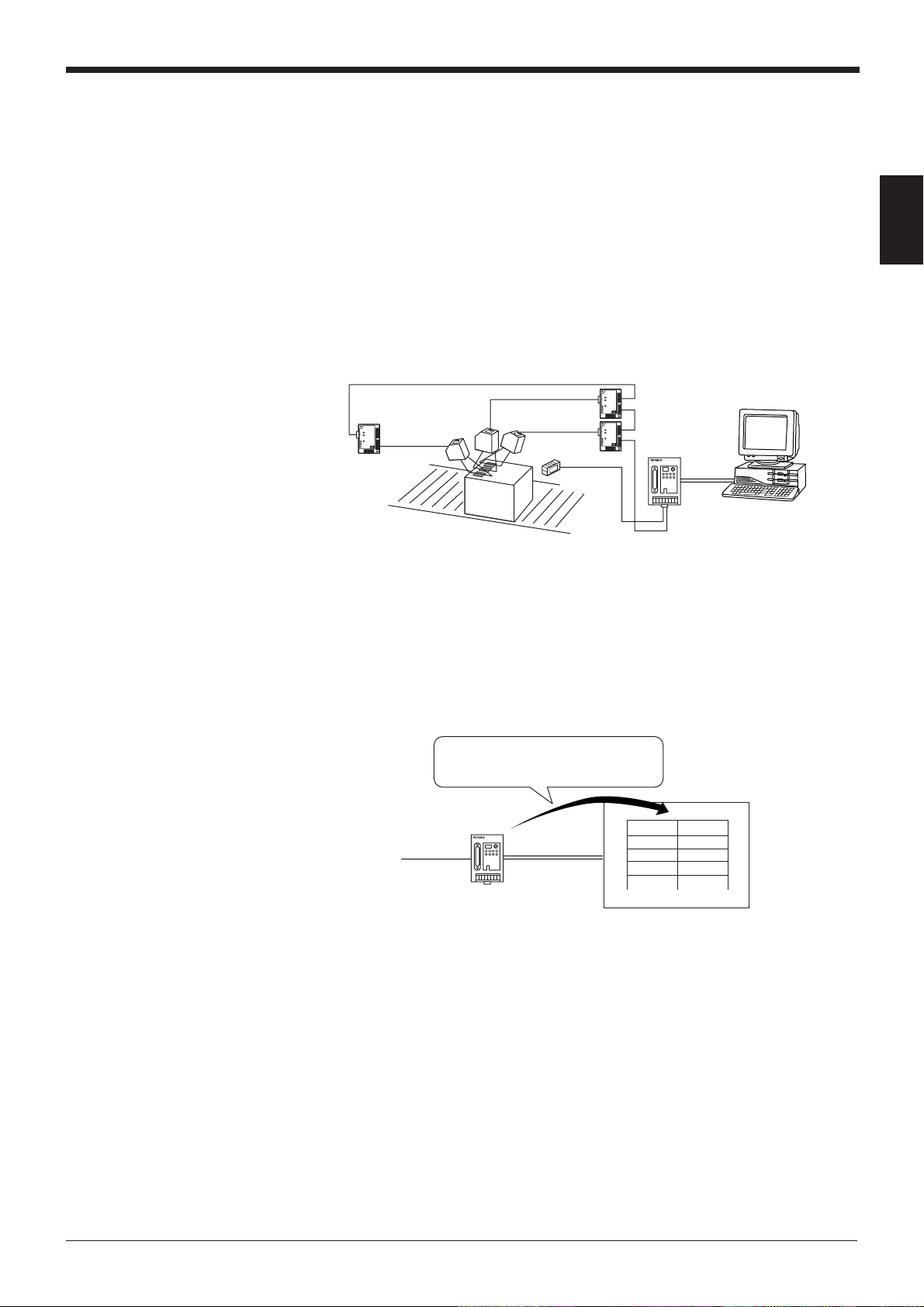

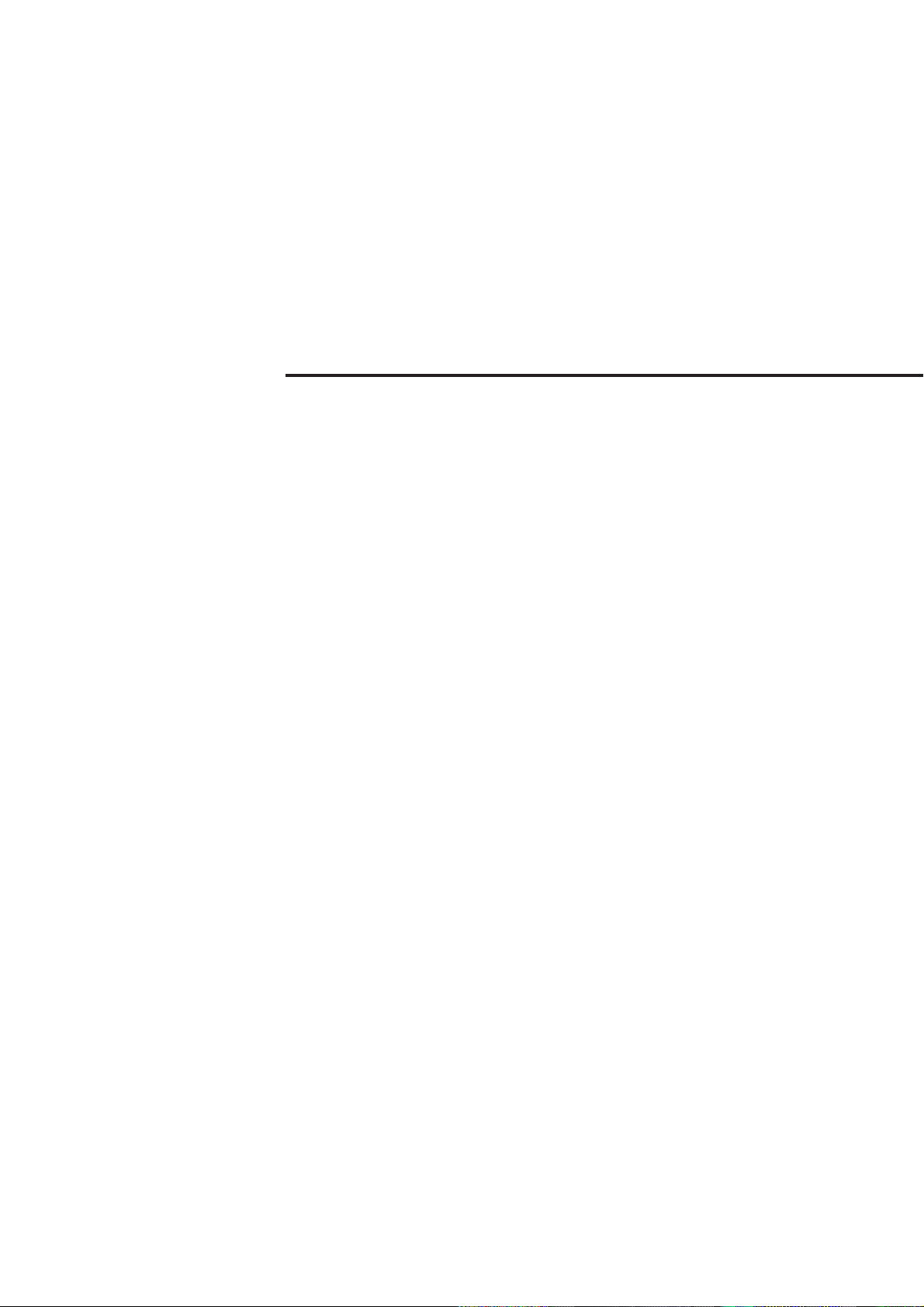

■ Mutual-interference suppression function (in multi-head scan mode)

When several bar code readers are mounted close to each other, for example when

reading multi-stage labels as shown below, the units’ light sources (laser beams)

interfere with each other, affecting the reading stability.

The mutual-interference suppression function allows the BL series’ laser beams to

turn ON sequentially, thus suppressing the mutual interference to ensure stable

readings.

Since the laser beams turn ON sequentially, the duration of laser OFF time (when

each unit is not reading a bar code) becomes longer as the number of connected

units is increased. Therefore, the bar code readers may fail to read bar codes if the

line speed is set too fast.

BL series

N-400

N-48

or

BL-U1

Sensor for

trigger input

RS-232C

Host

1

RS-485

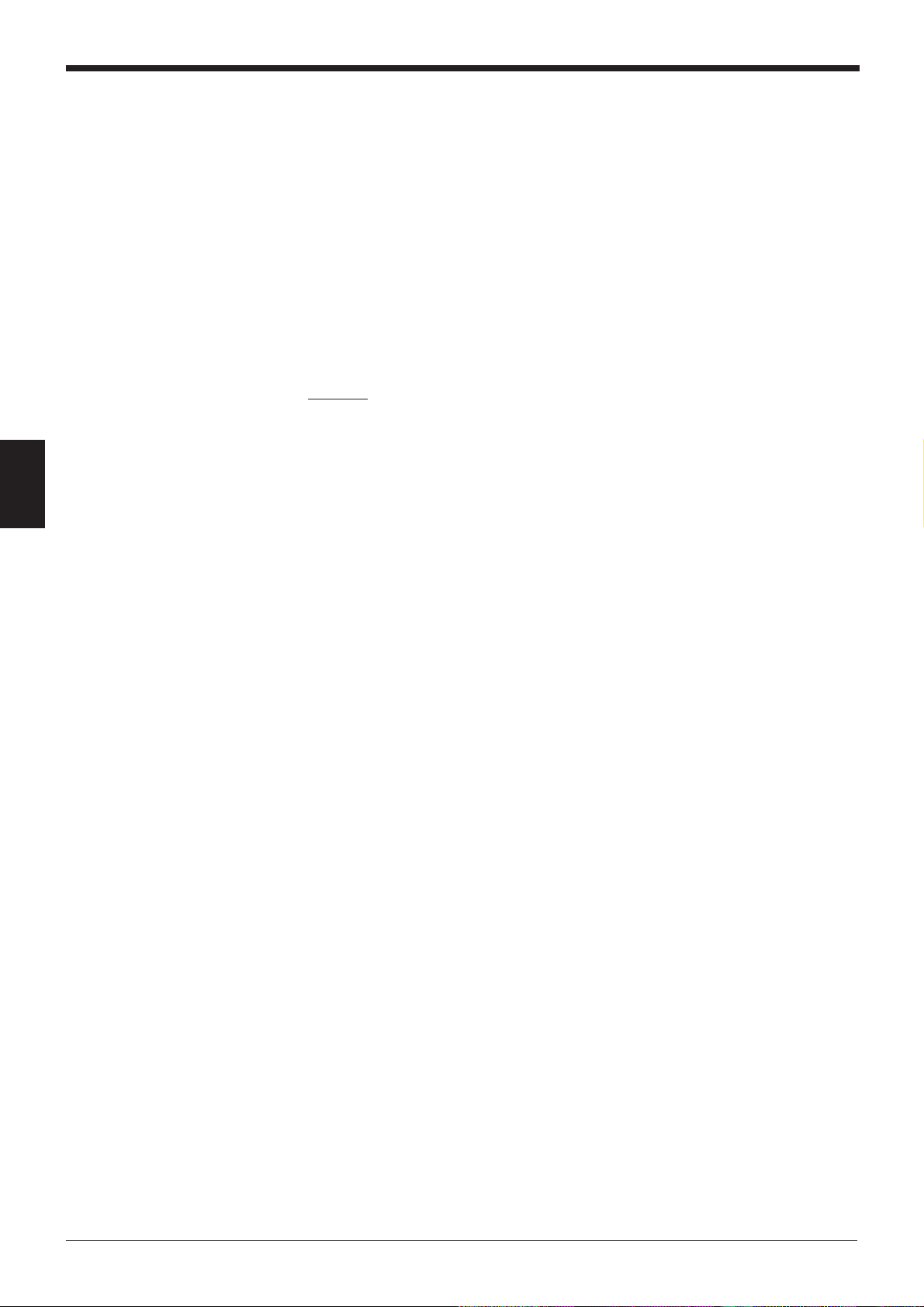

■ PLC link function

In the multi-drop link mode or multi-head scan mode, the PLC link function enables

the BL series’ data to be sent to a PLC without a communication program. Using

this function, you can reduce the number of steps for a PLC program.

No communication program is necessary,

because the N-400 stores the data read by

the BL series directly into the PLCs memory.

N-400

To BL

DM103

DM104

DM105

DM106

•

•

•

4

&30

&31

&32

•

•

•

3

Page 12

Chapter 1 Overview of The N-400

N-400

RS-232C

RS-485

Host

Sensor for

trigger input

BL series

*

*

N-48

or

BL-U1

N-400 setup

software

for Windows

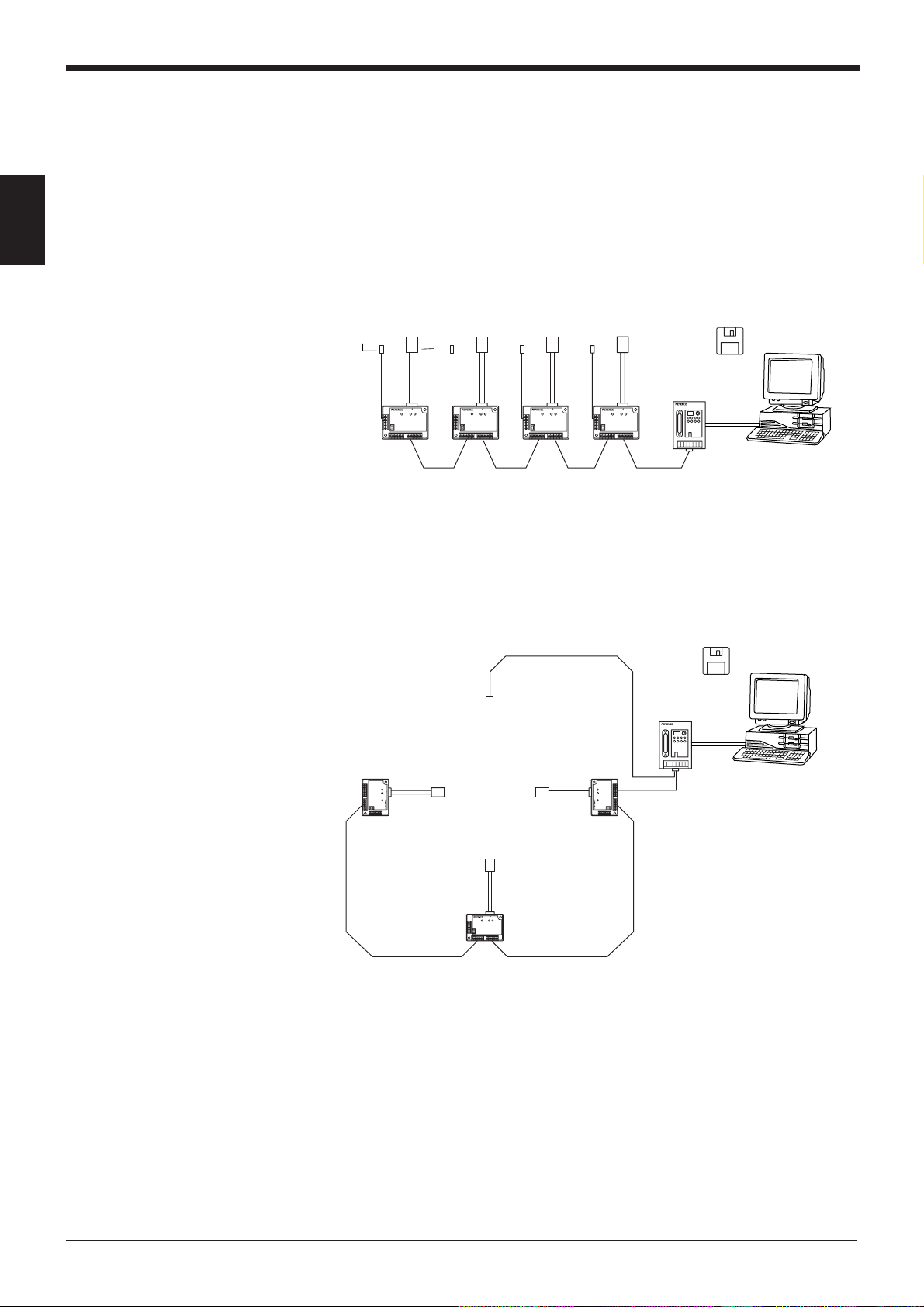

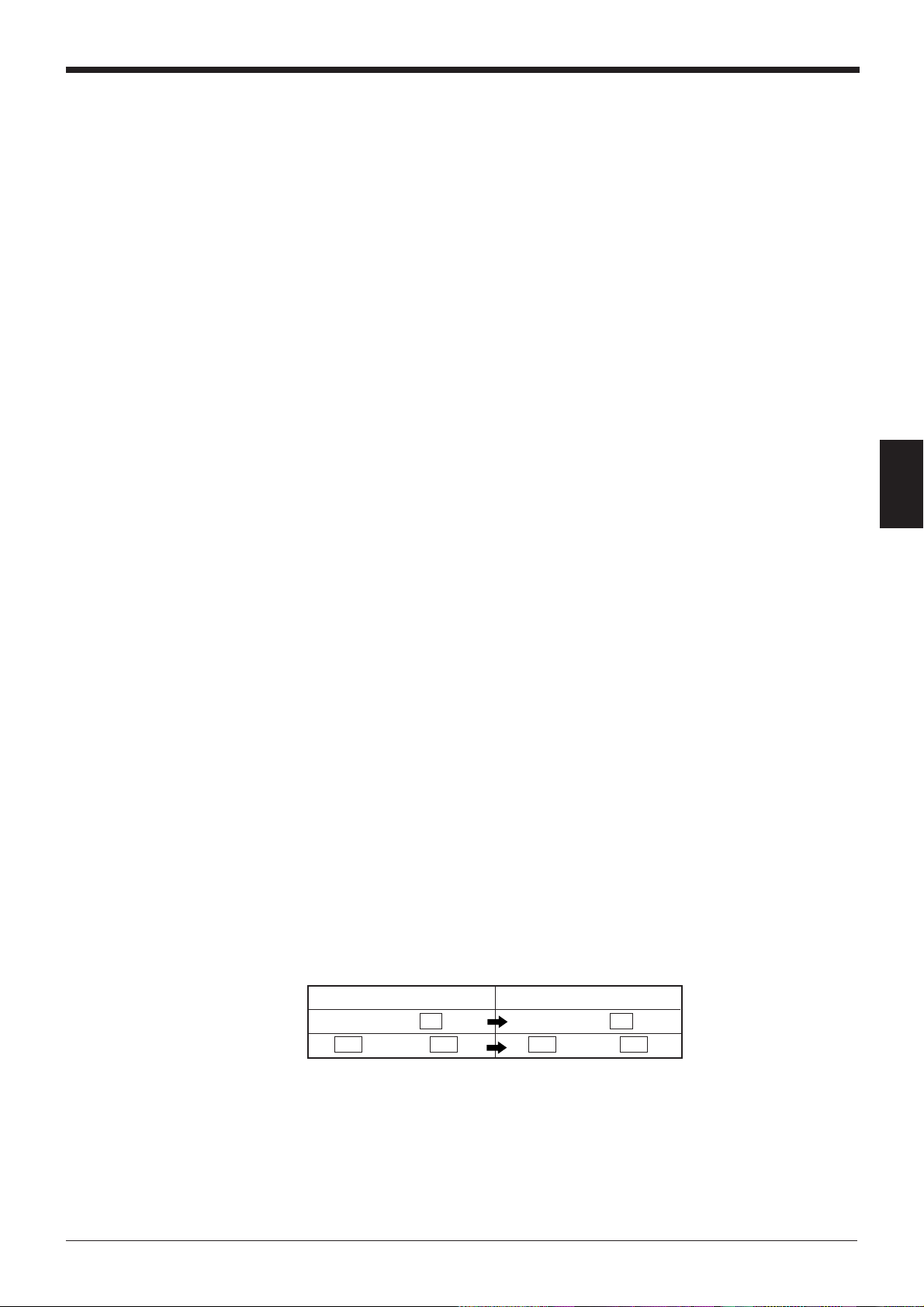

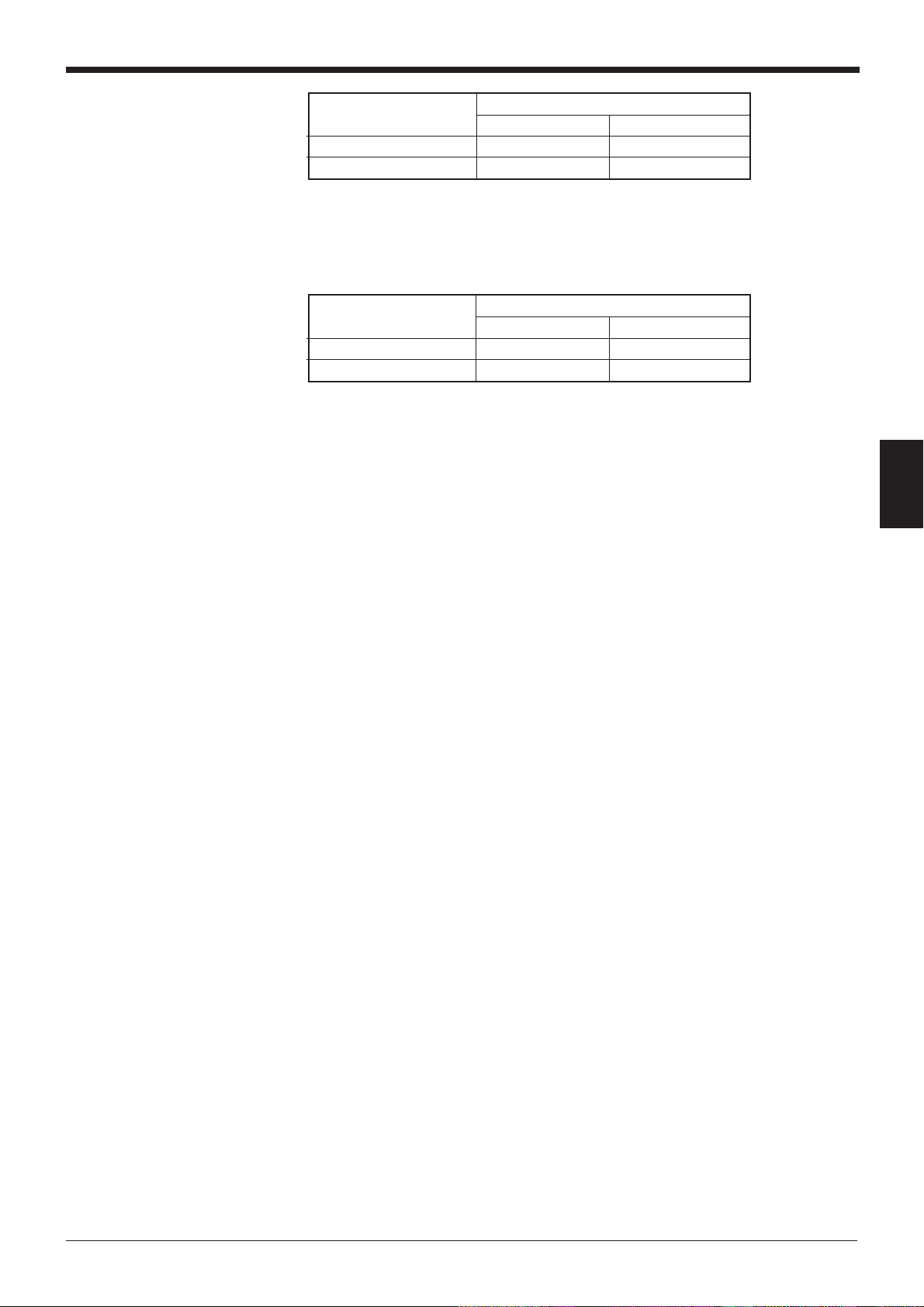

1.2 System Configuration

The system configurations using the N-400 controller are as follows:

This section describes multi-drop link mode and multi-head scan mode individually.

1

Multi-drop link mode

• Maximum number of connectable units: 31

• Maximum extension distance: 1.2 km

* The N-400 can be connected to the BL-700/BL-500/BL-180 series bar code

* Additional 24 VDC power supply is required for the N-400 and N-48.

readers.

Multi-head scan mode (with the interference suppression function)

• Maximum number of connectable units: 31

• Maximum extension distance: 1.2 km

Sensor for

trigger input

N-48

or

BL-U1

* Connect the sensor for trigger input to the N-400.

* The N-400 can be connected to the BL-700/BL-500/BL-180 series bar code

readers.

* Additional 24 VDC power supply is required for the N-400 and N-48.

N-400

RS-485

RS-232C

*

N-400 setup

software

for Windows

Host

4

Page 13

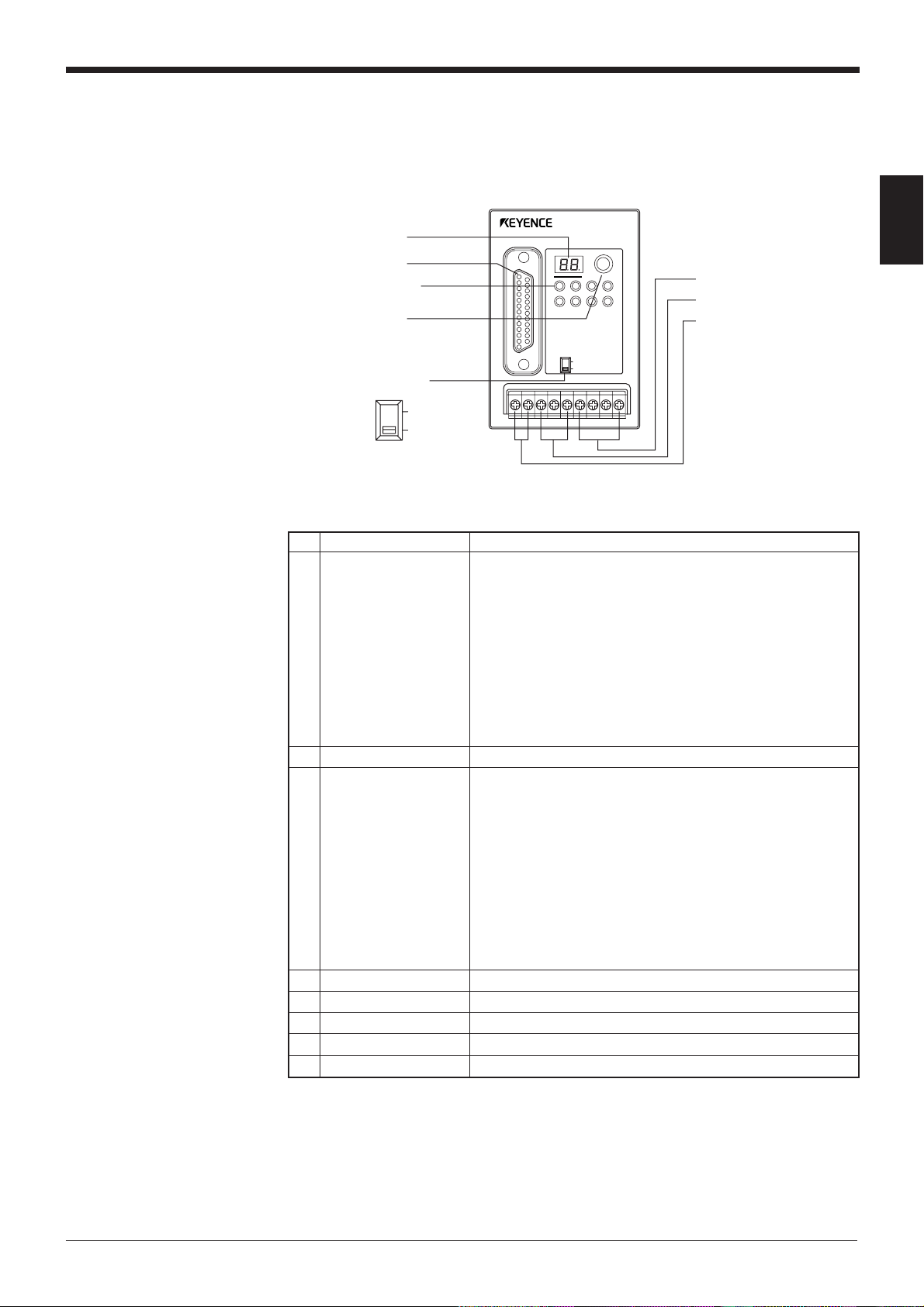

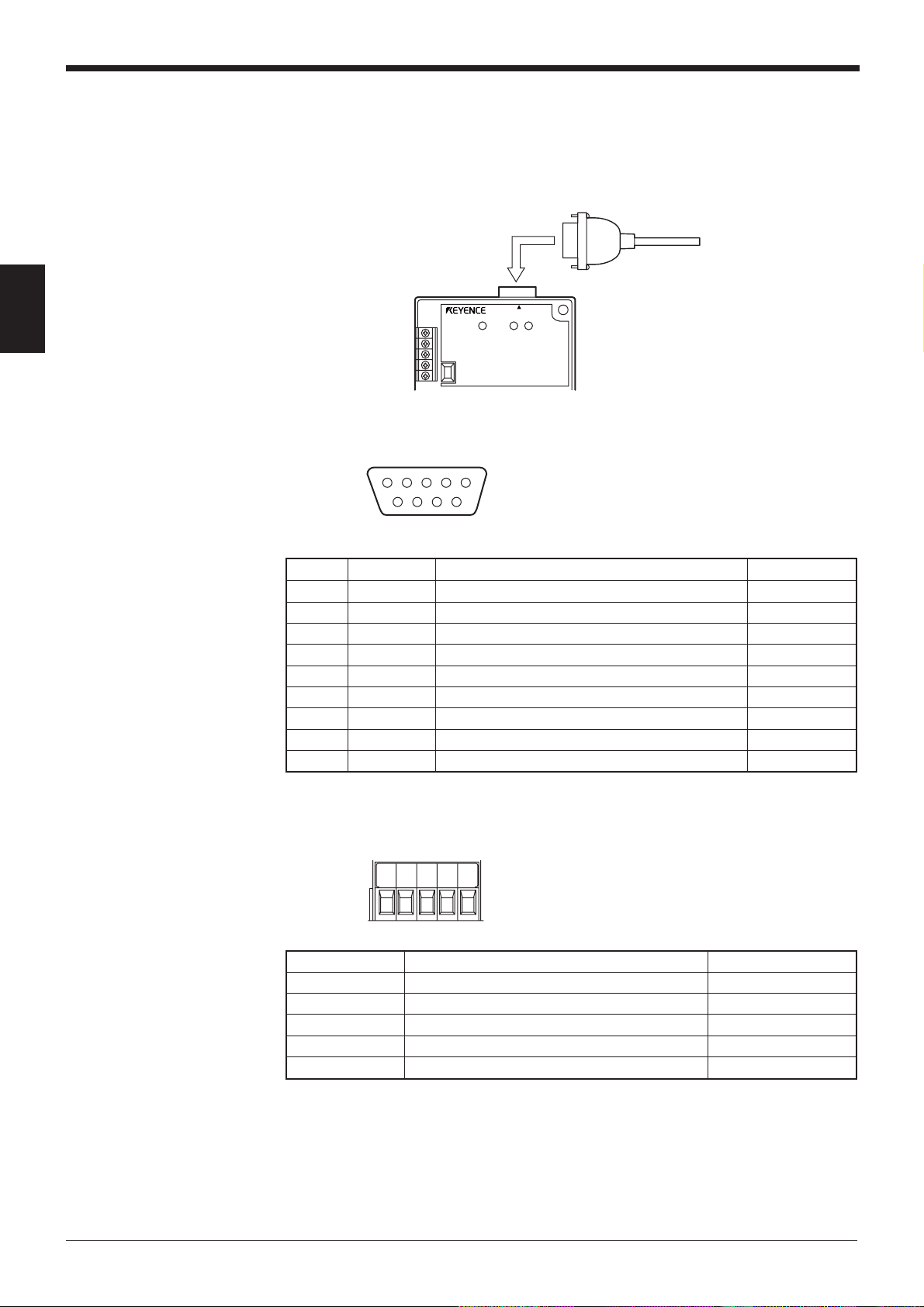

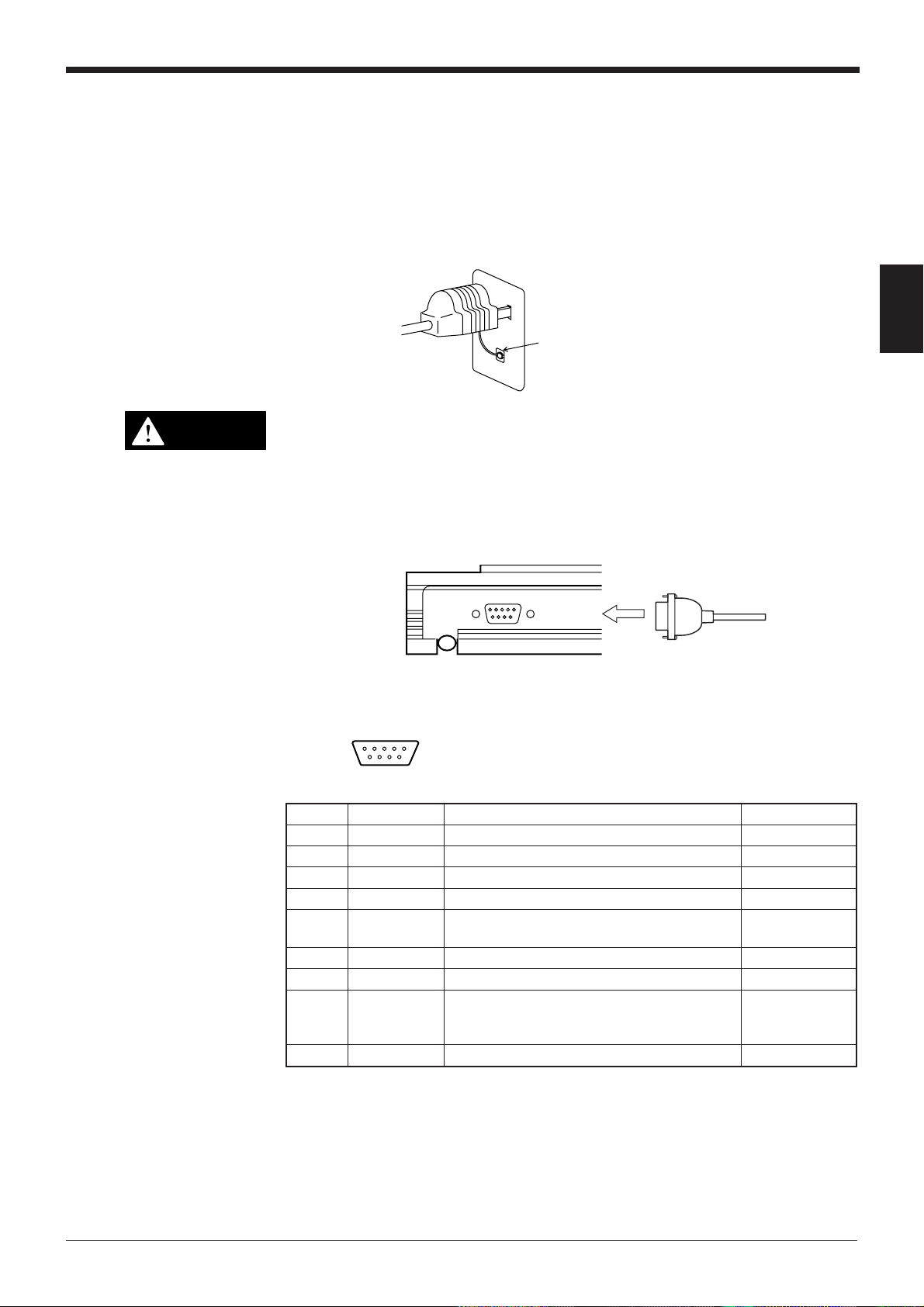

1.3 Part Names

N-400

Chapter 1 Overview of The N-400

SD RD

POWER TIMING

TERMINATOR

ON

OFF

N-400

TEST

RS-232C

CS RS

SD

RS-455

6 Power supply terminal

RD

7 RS-485 terminal

8 Trigger input terminal

1 Display LEDs

2 RS-232C port

3 Communication

status indicator LEDs

4 Test switch

5 Terminator switch

ON

OFF

No. Name Function

1 Display LEDs • Normally displays “00” (ID number of the N400).

• Displays the ID number of the device being tested.

(➮ See p. 26.)

• Displays “S1 (51)” to indicate setup mode.

(➮ See p. 75.)

• Displays “S0 (50)” to indicate initial communication status

after a setting change.

• Displays the N-400’s error condition.

(➮ See p. 48.)

(➮ See 131.)

• Displays the ID number of the device currently connected

when sending a hotline command.

(➮ See p. 73.)

2 RS-232C port • Connect a host computer or PLC to this connector.

3 • POWER: Lit when power is ON.

Communication

status indicator LEDs

• TIMING: Lit when the trigger input connected to the N-400

is ON.

(For the RS-232C connections)

Lit when the SD, RD, RS and CS signals are ON.

(For the RS-485 connections)

SD: Lit when the N-400 is sending data.

RD: Lit when the N-400 is receiving data.

* Both the SD and RD indicators are lit when the N-400 is

receiving data.

4 Test switch Starts the connection test mode.

5 Terminator switch Switches the terminator’s ON/OFF status.

6 Power supply terminal Connect a 24 VDC power supply.

7 RS-485 terminal Used for the multi-drop link connection.

8 Trigger input terminal Used for trigger input in multi-head scan mode.

1

5

Page 14

Chapter 1 Overview of The N-400

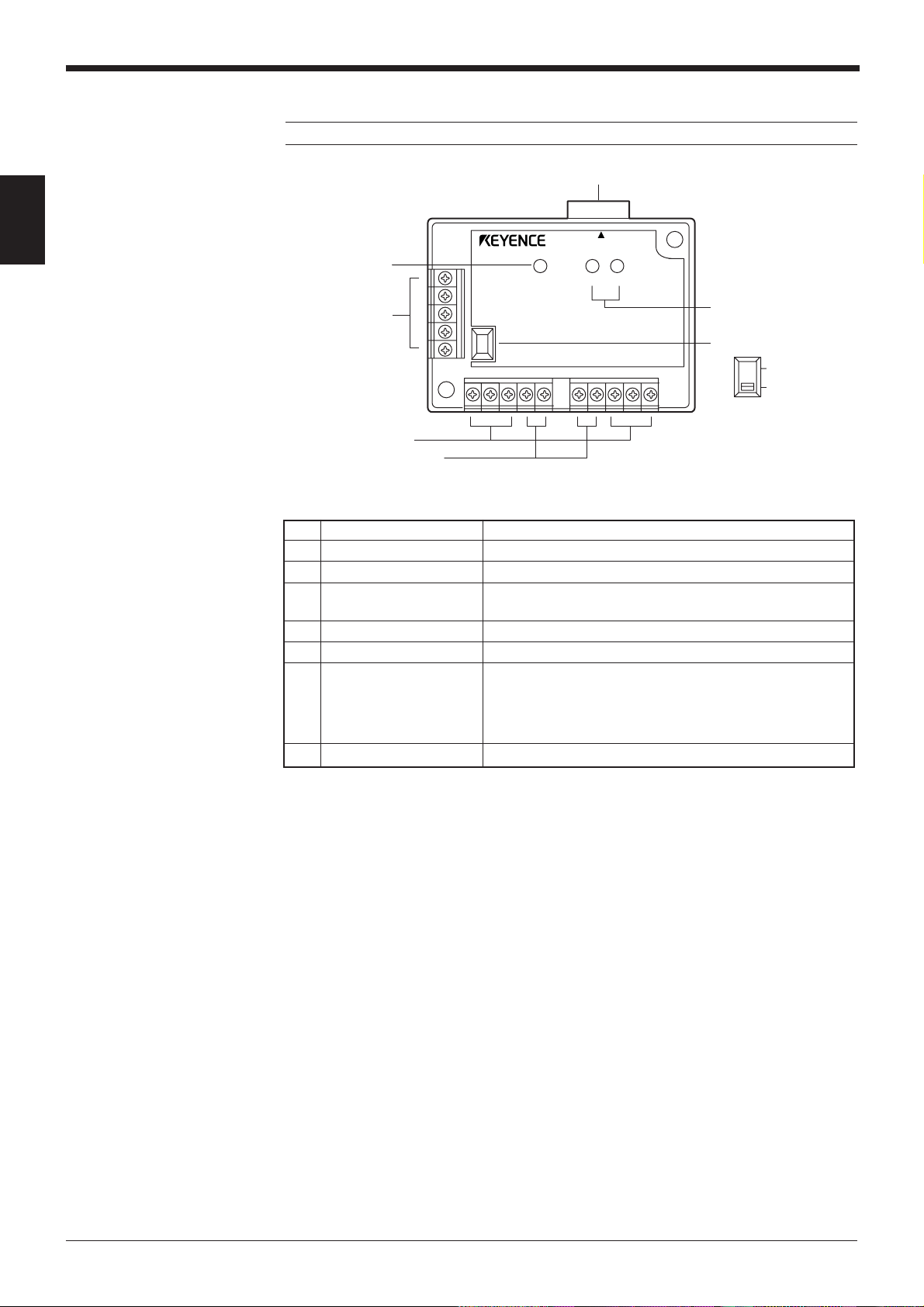

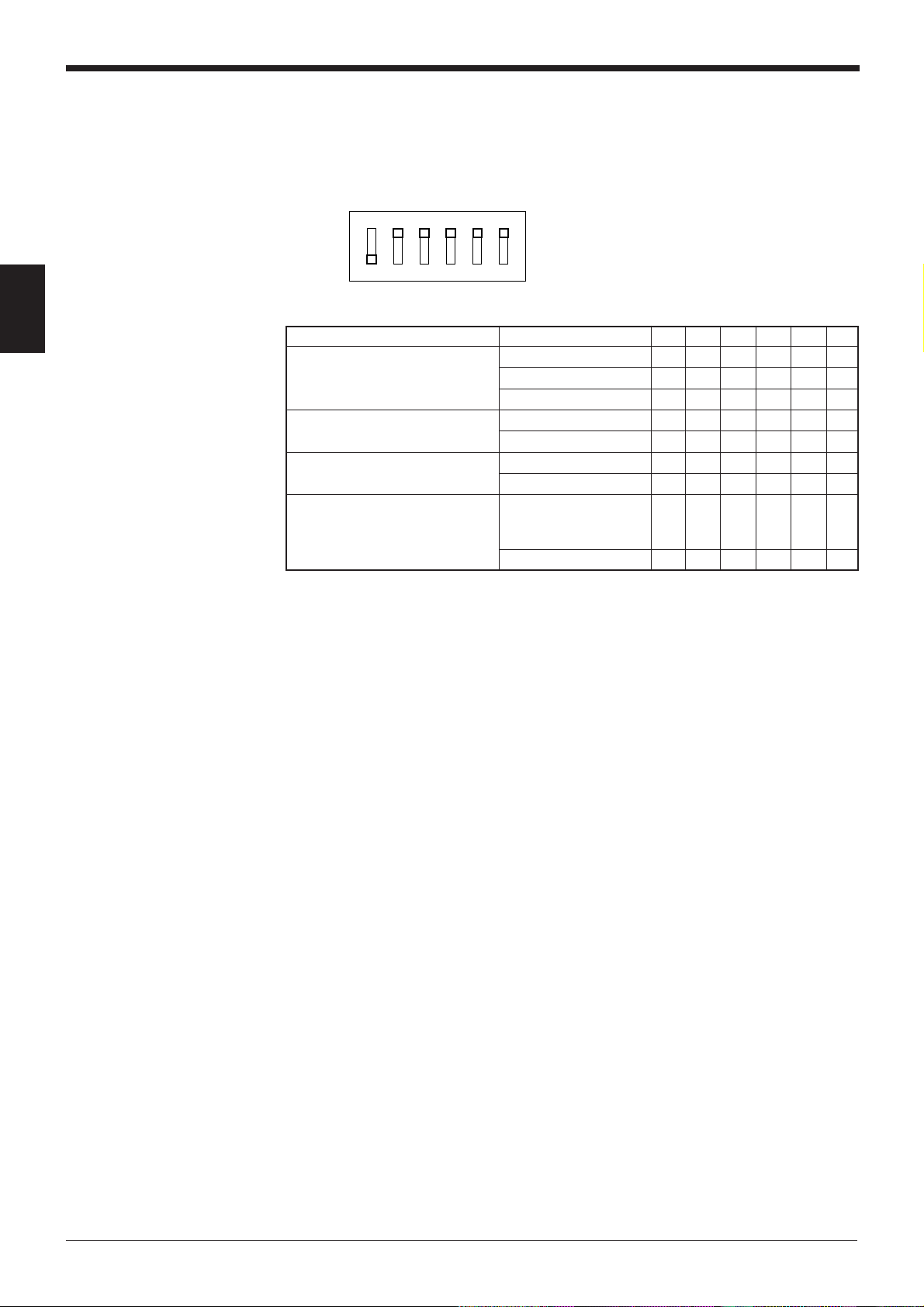

N-48

1

Note: BL-U1 is not available in the Europe area.

1 READER port

READER

2 POWER LED

POWER SD RD

3 I/O terminals

4 RS-485 terminals

5 Power supply terminals

6 Communication

status indicator

LEDs

7 Terminator switch

ON

OFF

No. Name Function

1 READER port Connect the BL series to this port.

2 POWER LED Lit when power is ON.

3 I/O terminals Includes the trigger input terminal and OK/NG output

terminals.

4 RS-485 terminals Used for multi-drop link mode.

Power supply terminals

5 Connect a 24 VDC power supply to these terminals.

6 Allows you to monitor the communication status of the

Communication status

indicator LEDs

7 Terminator switch Turns the terminator ON/OFF.

READER port.

SD: Lit when the BL series is sending data.

RD: Lit when the BL series is receiving a command.

6

Page 15

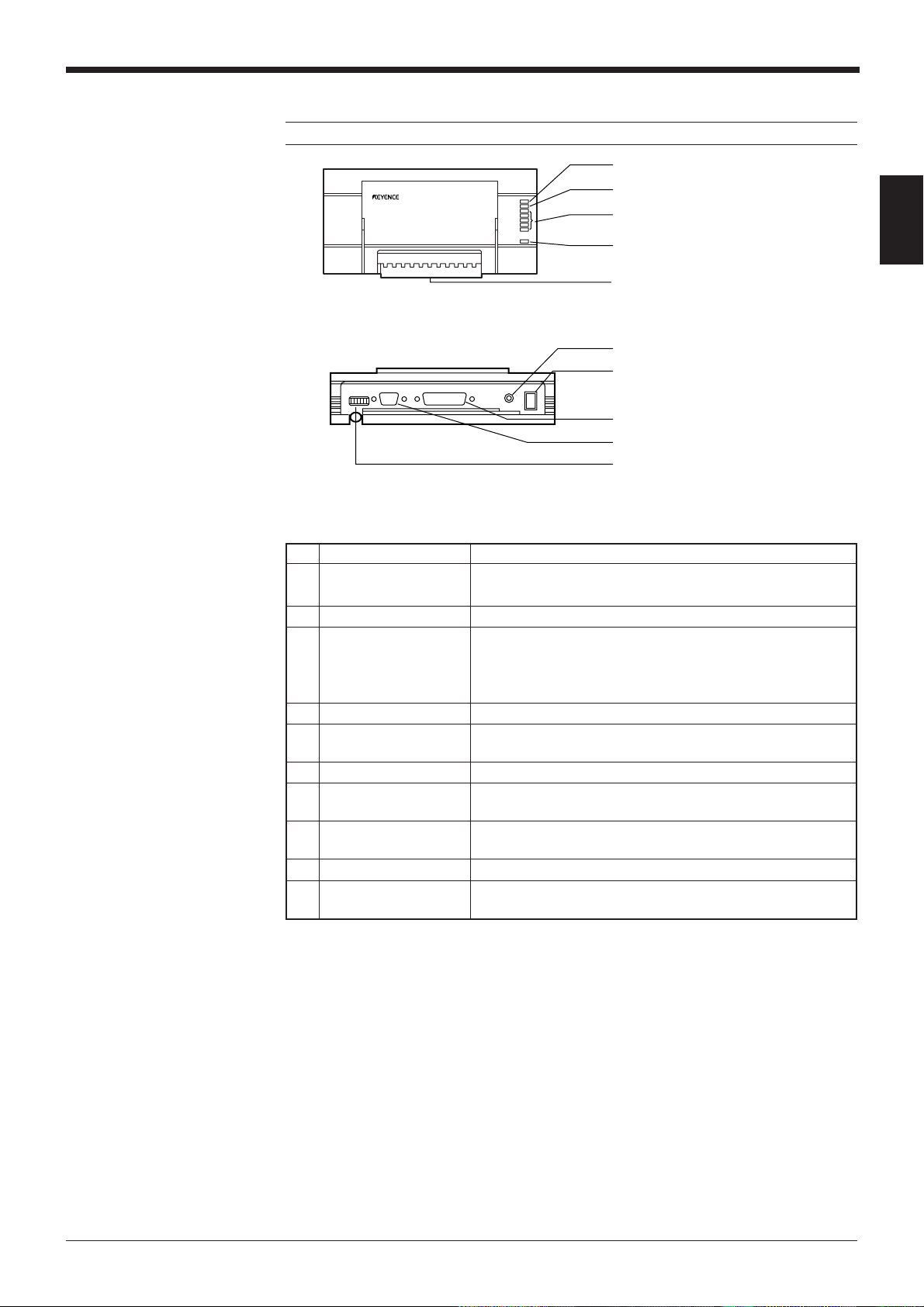

BL-U1

Note: The BL-U1 is not available in Europe

Chapter 1 Overview of The N-400

1 OK/NG LED

2 TIMING LED

3 Communication status indicator

LEDs

4 POWER LED

5 I/O terminal block

6 Power switch

7 Power supply cable (2 m)

8 RS-232C port

9 READER port

0 DIP switches

1

No. Name Function

1 OK/NG LED • When OK output is ON: The green LED lights.

• When NG output is ON: The red LED lights.

2 TIMING LED Lit when trigger input is ON.

3 • Allows you to monitor the communication status of the RS-

Communication status

indicator LEDs

4 POWER LED Lit when power is ON.

5 I/O terminal block Includes the trigger input terminal, OK/NG output terminals,

6 Power switch Turns the power ON/OFF.

Power supply cable

7 Use a 100 to 240 VAC (50/60 Hz) power supply.

(2 m)

8 RS-232C port Connect a personal computer to this port. This port is

9 READER port Connect the BL series to this port.

0 DIP switche Switches the communication port, and turns the terminator

232C port.

• The SD, RD, RS and CS indicators are provided in this

order from the top.

RS-422A terminal and RS-485 terminal.

unused in multi-drop link mode.

ON/OFF.

7

Page 16

Chapter 1 Overview of The N-400

1

8

Page 17

Chapter 2

Installation Procedure

2.1 Installing the N-400 .............................................................10

2.2 Connecting N-400 and Wiring ............................................12

2.2.1 Terminals of I/O terminal block and wiring.............................12

2.2.2 Connecting RS-232C.............................................................13

2.3 Connecting N-48 and Wiring ..............................................16

2.3.1 Connecting the BL series.......................................................16

2.3.2 Terminals of I/O terminal block and connection.....................16

2.3.3 Connecting RS-485 ...............................................................19

2.4 Connecting BL-U1 and Wiring ...........................................21

2.4.1 Connecting power supply ......................................................21

2.4.2 Connecting BL series.............................................................21

2.4.3 Setting BL-U1 DIP switches...................................................22

2.4.4 Terminals of I/O terminal block and wiring.............................23

2.4.5 Connecting RS-485 ...............................................................25

2.5 Using Connection Test Mode ............................................26

2.6 Mounting Procedure ...........................................................27

2.6.1 Precautions for mounting environment ..................................27

2.6.2 Mounting N-400 .....................................................................28

2.6.3 Mounting N-48 .......................................................................28

2.6.4 Mounting BL-U1.....................................................................29

Page 18

Chapter 2 Installation Procedure

2.1 Installing the N-400

2

■ Equipment used

• N-400 multi-drop controller

• BL series bar code readers

The N-400 can be connected to the BL-700, BL-500 and BL-180 series bar

code readers.

• N-48 (or BL-U1) power supply unit for BL series (RS-485 mode)

Each bar code reader requires one N-48 (or BL-U1) power supply.

• BL-U2 (or BL-U1) power supply unit for BL series (RS-232C mode)

To change the BL series’ settings, one BL-U2 or BL-U1 power supply unit is

required.

To use the N-48 for multi-drop link, an additional BL-U2 24 VDC power supply

unit is required. (The N-48 does not provide an RS-232C port.)

(The BL-U1 can be used as an RS-232C or RS-485 power supply.)

• RS-232C cable for the N-400

This cable is used to connect the N-400 and the host computer.

Use a cable appropriate for the personal computer and the PLC’s pin assignment. OP-98769 cable and OP-25057 connector are available.

• RS-232C cable for BL series setup

This cable is used to connect the BL-U2 (or BL-U1) and the host computer to

change the BL series’ settings. Since the wiring of this cable is different from

that of the RS-232C cable for the N-400, both cables must be prepared.

For wiring the BL-U2 and BL-U1, see the “BL-U2 Instruction Manual” and “BL

series User’s Manual”, respectively.

OP-27937 cable is available for BL-U2. (OP-22149 cable and OP-25057 are

available for BL-U1.)

• Twisted pair cable for the RS-485

Prepare the recommended cable.

• Host computer

Use a personal computer with an RS-232C port.

When large quantities of data are sent from several BL series, they may exceed

the host computer’s data processing capacity.

If this occurs, reduce the number of the connected BL series units, or enhance

the data processing capacity (including the programming language) of the host

computer.

■ Setup and connection

1) Setting the BL series bar code readers

Prepare the BL series unit, the BL-U2 (or BL-U1) RS-232C power supply unit,

the RS-232C cable used for setup, and a personal computer. Set up the BL

series using the BL series setup software.

For connection and setup procedures, see the “BL series User’s Manual”.

For the pin assignment of the connection cable between the BL-U2 and the host

computer, see the “BL-U2 Instruction Manual”.

(➮ See pp. 19, 20 and 25.)

10

The setting contents vary slightly depending on the mode being used. Refer to

the following pages for more information.

• Multi-drop link mode: p. 60

• Multi-head scan mode: p. 87

Page 19

Chapter 2 Installation Procedure

2) Setting the N-400

Prepare the N-400, the RS-232C cable for the N-400, and a personal computer.

Set up the N-400 using the N-400 setup software.

For the setup software operating procedure, see pp. 32 and following.

The setting contents vary slightly depending on the mode being used.

•Multi-drop link mode: p. 60

•Multi-head scan mode: p. 88

• PLC link: p. 102

3) Setting a host computer/PLC

For the RS-232C communication, set the baud rate, data length, parity and stop

bit length according to the settings of the N-400.

To use a PLC link, set up the PLC according to pp. 104 and 105.

4) Connection between the BL series and N-400 (See pp. 19, 20 and 25.)

Connect the N-48 (or BL-U1) power supply unit to the BL series. Then connect

the specified cable (twisted pair cable) between the power supply and the N-

400. Turn ON the equipment terminator at both ends of the connection.

When using the BL-U1, set the DIP switch to “RS-485”. (See p. 22.)

5) Connection between the N-400 and host computer/PLC (See pp. 13 to 15.)

To connect the N-400 to the host computer or PLC, use the RS-232C cable

whose pin assignment conforms to that of the host computer and PLC.

6) Checking the RS-485 connection between the N-400 and the BL series

The N-400 provides a connection test mode that checks whether the RS-485

connection is correct or not. Using this function, check whether the RS-485

communication can be correctly performed.

For the procedure for using this function, see p. 26.

7) Connecting a sensor for trigger input

Connect a sensor for trigger input to each N-48 or BL-U1 unit. (This sensor is

not required when controlling the BL series’ reading operation using the read

start/end commands.)

2

To use the BL series in multi-head scan mode, connect a sensor for trigger input

to the N-400. (This sensor is not required when controlling the BL series’ reading operation using the read start/end commands.)

If the sensor for trigger input is directly connected to each BL series, the BL

series cannot operate normally.

8) Checking operation

Using the terminal software included in the N-400 setup software, check

whether the RS-232C communication between the N-400 and host computer

can be performed correctly. (See p. 52.)

To use a PLC link, check whether data is stored in the PLC’s memory.

11

Page 20

Chapter 2 Installation Procedure

2.2 Connecting N-400 and Wiring

This section describes the procedure for connecting the N-400 to external equipment.

TIM

COM

2

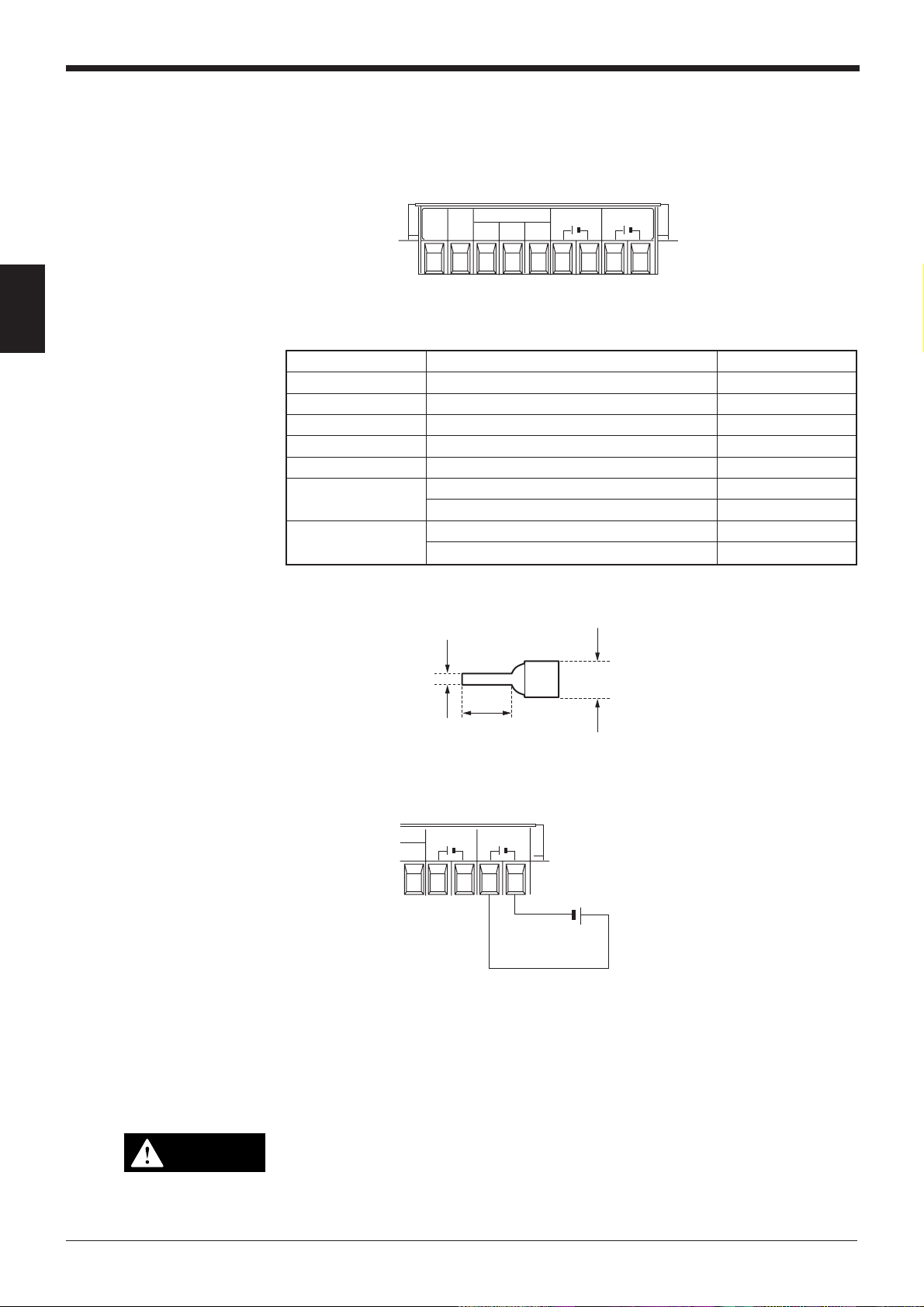

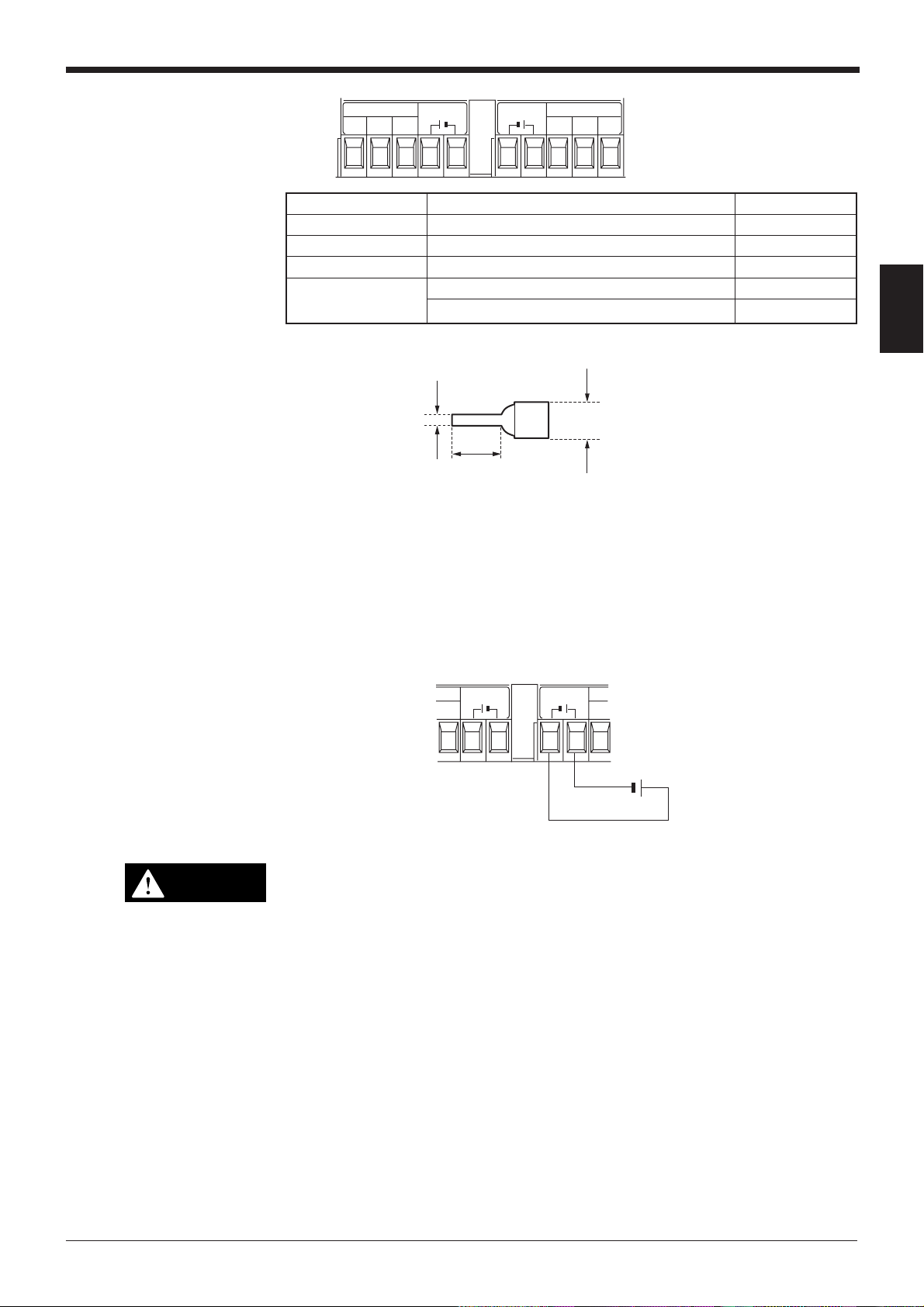

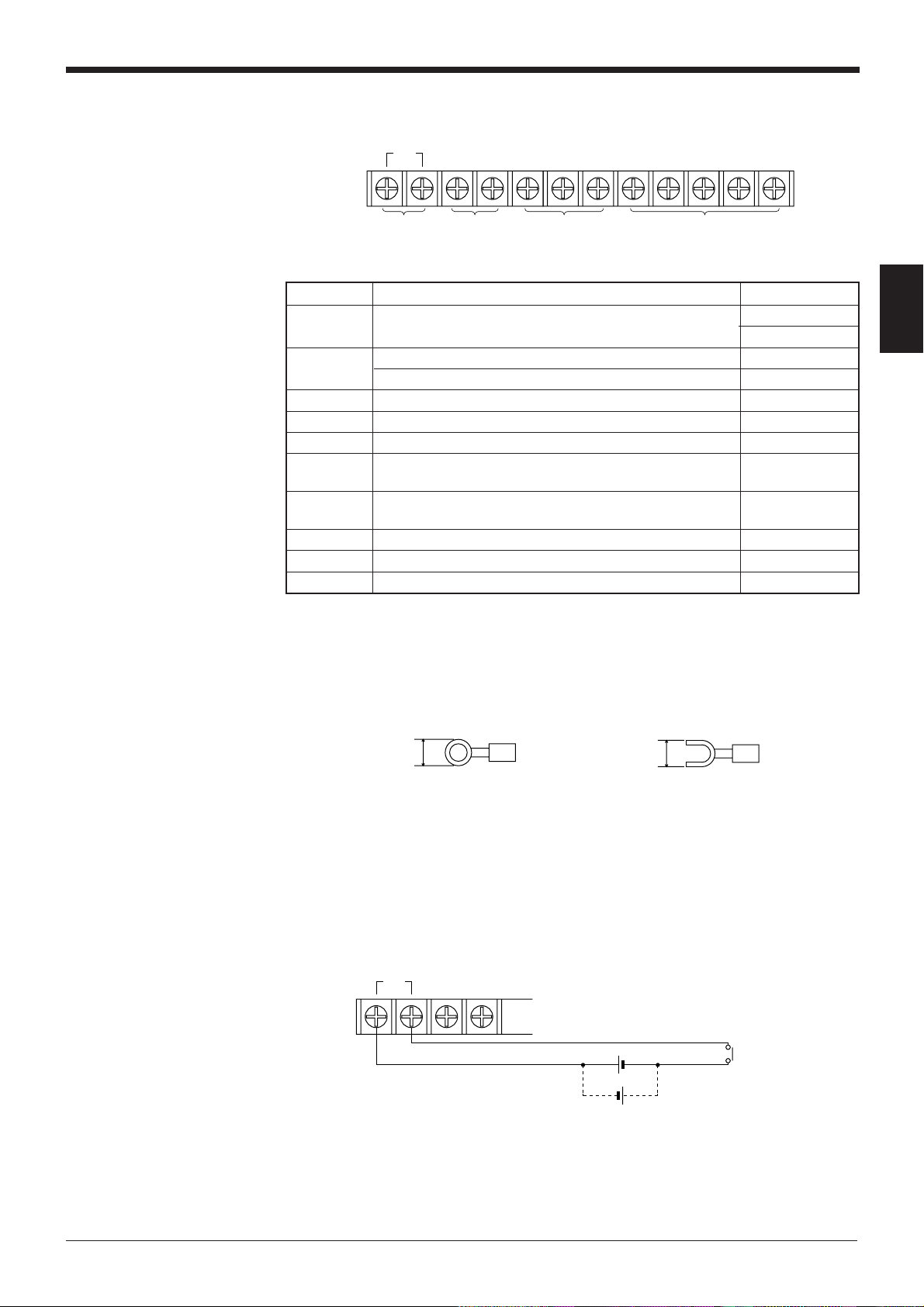

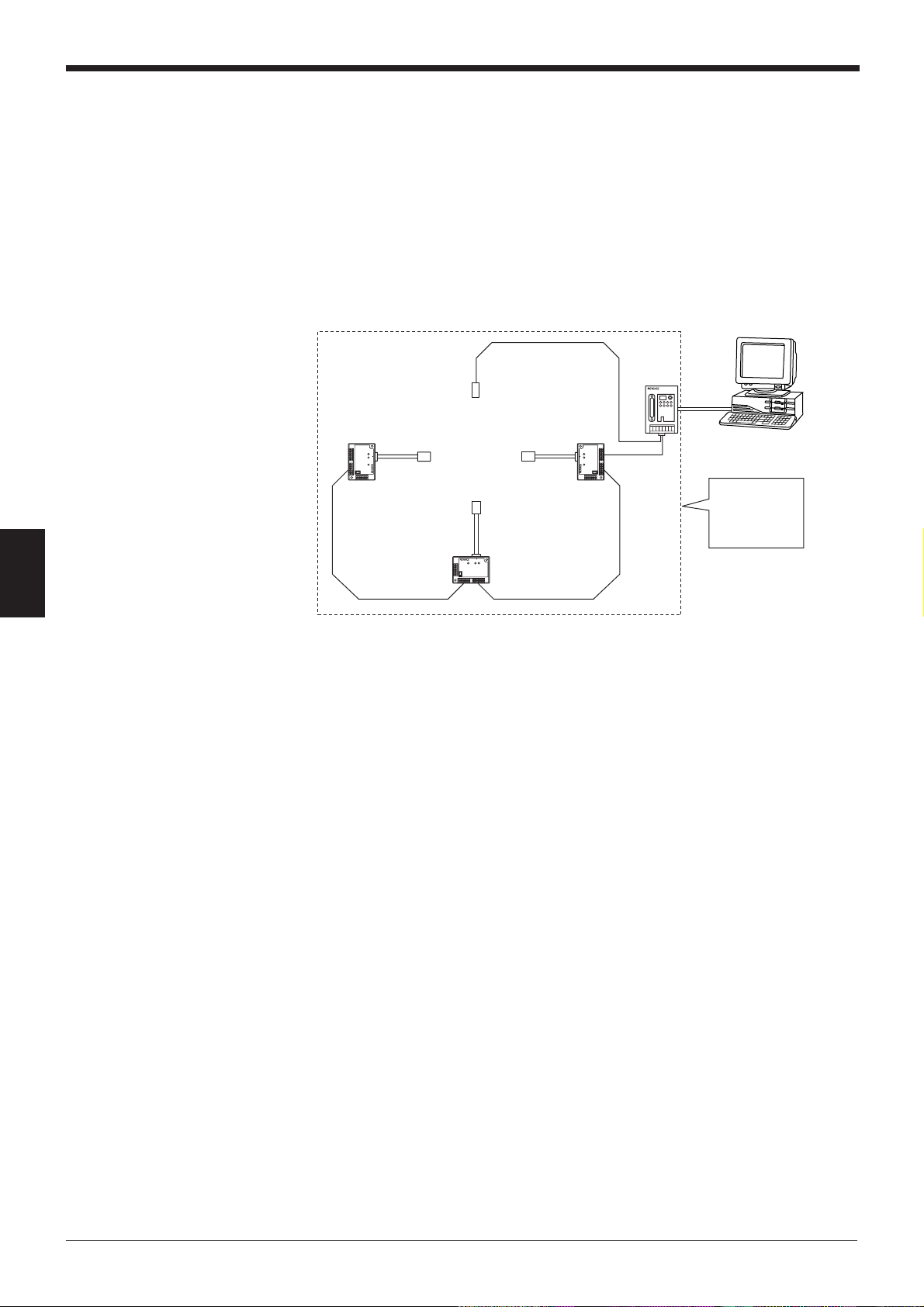

2.2.1 Terminals of I/O terminal block and wiring

Symbol Description Signal direction

TIM Trigger input Input

COM Common terminal for trigger input Input

RS-485 SG RS-485 signal ground –––

RS-485 + RS-485 + terminal Input/Output

RS-485 - RS-485 - terminal Input/Output

24 VDC OUT 24 VDC power output + terminal Output

24 VDC power output - terminal Output

24 VDC IN 24 VDC power input + terminal Input

24 VDC power input - terminal Input

* Viewed from the left of the terminal block.

• The following I-type clips can be used for the connections.

SG

RS-485

+-

24V DC IN

+–

24V DC IN

+–

Connecting power supply

2.0 mm

max.

6 mm min

5 mm max.

The N-400 operates with a 24 VDC power supply.

24V DC IN

+–

–

24V DC IN

+–

24 VDC

+

When a 24 VDC power supply is connected to the power supply “IN” terminal, the

“OUT” terminal can be used as the 24 VDC power supply output terminal. (Note:

The power supply connected to the “IN” terminal must have a capacity high enough

to supply power to the equipment connected to the “OUT” terminal.)

Using this function, the “OUT” terminal can be used as a 24 VDC power supply for

each BL series connected in the multi-drop link configuration. (For a connection

example, see p. 19.)

12

CAUTION

To operate the N-400, be sure to use a 24 VDC power supply. Using a power

supply exceeding 24 VDC or using an AC power supply may damage the unit.

If your system must comply with UL regulations, be sure to use the power

supply with NEC class 2 output.

Page 21

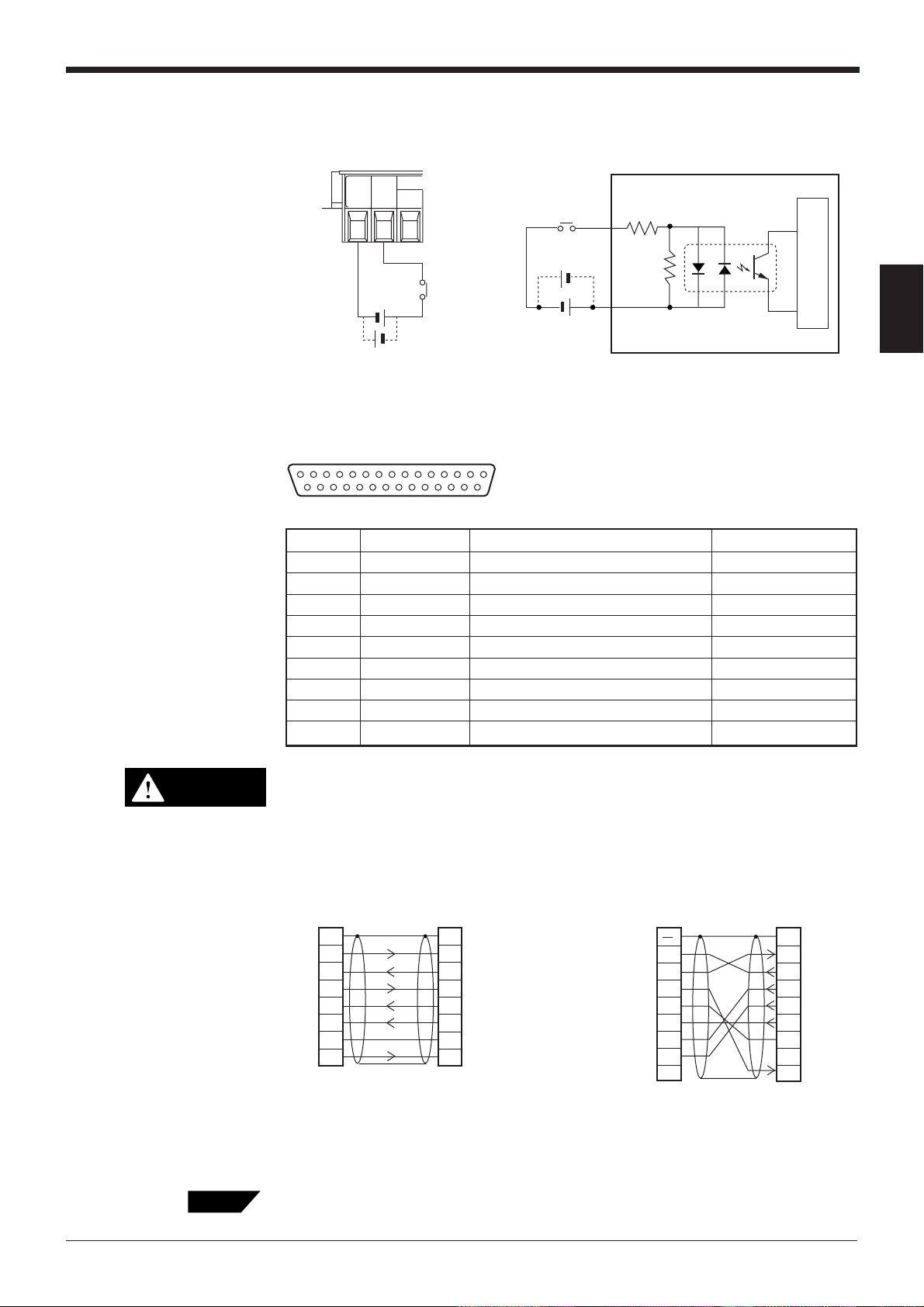

Connecting trigger input

To use multi-head scan mode, connect the trigger input to the N-400 only, instead

of to each BL series unit.

2.2.2 Connecting RS-232C

TIMSGCOM

+

+

15 to 26 VDC

Contact

or solid state

Chapter 2 Installation Procedure

TIM

+

Internal circuit

+

COM

2

Pin assignment

CAUTION

RS-232C cable connections

Tips

13 1

D-sub 25-pin (male)

DCE specification (defined as terminal)

25 14

M2.6 screw

Pin No. Symbol Function Signal direction

1FG Frame ground —

2 SD (TXD) Sends data. Input

3 RD (RXD) Receives data. Output

4 RS (RTS) Ready to send data. Input

5 CS (CTS) Request to send data. Output

6 DR (DSR) Connected to pin No. 20 inside. Output

7SG Signal ground —

20 ER (DTR) Connected to pin No. 6 inside. Input

25 +5 V 5 V power supply output (100 mA) Output

Pin No. 25 is used for a 5 V power supply output. Do not connect this terminal to the ground terminal or any other terminal when it is unused. Doing this

may damage the N-400 or the external device connected to this terminal.

■ Connecting personal computer

• Connecting the computer with 25-pin • Connecting IBM PC

Computer

2

SD

3

RD

4

RS

CS

5

6

DR

SG

7

ER

20

D-sub 25-pin (male)

M2.6 screw

* The OP-98769 cable (1.5 m: manufactured

by KEYENCE) can be used.

N-400

FGFG

11

2

SD

3

RD

4

SG

RS

5

6

CS

DR

7

ER

20

D-sub 25-pin (male)

M2.6 screw

Connector case

RD

SD

ER

SG

DR

RS

CS

CD

D-sub 9-pin (female)

#4-40 screw

* The OP-98769 cable (1.5 m: manu

PC

2

3

4

5

6

7

8

N-400

1

FG

SD

2

RD

3

4

RS

5

CS

6

DR

7

SG

8

201

ER

D-sub 25-pin (male)

M2.6 screw

factured by KEYENCE) and the

OP25057 conversion connector can

be used.

A commercially-available straight cable (D-sub 25 pin - 25 pin, or D-sub 25 pin - 9

pin) can be used.

13

Page 22

Chapter 2 Installation Procedure

2

■ Connecting KV series/Handheld programmer port

Use the optional cable manufactured by KEYENCE.

KV-10, 16, 24

KV-40, 80

or

OP-24025 (5 m)

OP-96369OP-24045 (1 m)

POWER TIMING

TERMINATOR

N-400

TEST

RS-232C

CS RS

SD RD

RD

SD

RS-455

ON

OFF

1.

KV-300

■ Connecting KV-L2

1.

1. KV-300 and KV-L2 are not available in Europe.

Port 1 Terminal block

KV-L2

2

SD

3

RD

4

RS

CS

5

6

DR

SG

7

ER

20

D-sub 25-pin (male)

M2.6 screw

* The OP-98769 cable (1.5 m: manufactured

by KEYENCE) or a commercially-available

straight cable can be used.

N-400

FGFG

11

2

SD

3

RD

4

SG

RS

5

6

CS

DR

7

ER

20

D-sub 25-pin (male)

M2.6 screw

KV-L2

5

RD

SG

Terminal block

1. KV-300 and KV-L2 are not available in Europe.

■ Connecting MELSEC-A series

N-400

FGSD

13

2

SD

3

RD

4

RS

CS

5

6

DS

ER

20

SG

71

D-sub 25-pin (male)

M2.6 screw

14

Connection with AJ71C24, AL71C24-S*,

A0J2-C214S1, AJ71UC24

N-400Link unit

FGFG

11

2SD

3

RD

4

RS

CS

5

6

DR

SG

7

CD

8

ER

D-sub 25-pin (male)

M2.6 screw

2

SD

3

RD

4

RS

CS

5

DR

6

SG

7

8

ER

2020

D-sub 25-pin (male)

M2.6 screw

Connection with A1SJ71C24-R2/PRF,

A2CCPUC24, A2CCPUC24-PRF,

A1SJ71UC24-R2/PRF

Connector case

RD

SD

ER

SG

DR

RS

CS

CD

D-sub 25-pin (male)

M2.6 screw

Link unit

2

3

4

5

6

7

8

N-400

1

FG

SD

2

RD

3

4

RS

5

CS

6

DR

7

SG

8

201

ER

D-sub 25-pin (male)

M2.6 screw

Page 23

■ SYSMAC-C series

Connection with C-200H-LK201(-V1),

C-500-LK203, C-500-LK201-V1, C120LK201-V1

Chapter 2 Installation Procedure

Connection with C-20H, C-28H,

C-40H, C-60H, C-80H

Link unit

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

N-400

FGFG

11

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

* The OP-98769 cable (1.5 m: manufactured by

KEYENCE) or a commercially-available

straight cable can be used.

Connection with C-200HS(CPU21/23/31/

33), CQM1(CPU21/41/42/43/44), C200HE(CPU42), C200HG(CPU43/63),

C200HX(CPU44/64), C200HWCOM02/

COM04/COM05/COM06

SD

RD

RS

CS

SG

PLC

2

3

4

5

9

N-400

11

2

3

4

5

7

FGFG

SD

RD

RS

CS

SG

PLC

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

N-400

FGFG

11

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

2

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

■ SYSMAC-CV series

Connection with CV500-LK201(Port 1) Connection with CV500-

LK201(Port 2), CV500, CV1000,

CVM1

Link unit

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

N-400

FGFG

11

2

SD

3

RD

4

RS

CS

5

SG

7

D-sub 25-pin (male)

M2.6 screw

* The OP-98769 cable (1.5 m: manufactured by

KEYENCE) or a commercially-available straight

cable can be used.

PLC

2

SD

3

RD

4

RS

CS

5

SG

9

D-sub 25-pin (male)

M2.6 screw

D-sub 25-pin (male)

M2.6 screw

N-400

11

2

3

4

5

7

FGFG

SD

RD

RS

CS

SG

15

Page 24

Chapter 2 Installation Procedure

2.3 Connecting N-48 and Wiring

2.3.1 Connecting the BL series

Connect the BL series to the READER port of the N-48.

2

Pin assignment

N-48

READER

POWER SD RD

12345

D-sub 9-pin (male)

DCE specification (defined as terminal)

#4-40 screw

6789

Pin No. Symbol Function Signal direction

1 TIM Trigger input Output

2 RD (RXD) Receives data. Output

3 SD (TXD) Sends data. Input

4OKOK Input

5 GND (SG) Ground (Common ground for respective signal) —

6NGNG Input

7 RS (RTS) Ready to send data. Input

8 CS (CTS) Request to send data. Output

9 +5 V 5 V power supply output (600mA) Output

BL series

2.3.2 Terminals of I/O terminal block and connections

TIM

COM

OK NG

COM

* Viewed from the left of the unit

Symbol Description Signal direction

TIM Trigger input Input

COM Common terminal for trigger input Input

OK OK output Output

NG NG output Output

COM Common terminal for output Output

16

Page 25

Chapter 2 Installation Procedure

Connecting power supply

RS-485 RS-485

SG SG

Symbol Description Signal direction

RS-485 SG RS-485 signal ground –––

RS-485 + RS-485 + terminal Input/Output

RS-485 - RS-485 - terminal Input/Output

24 VDC IN (OUT) 24 VDC power supply input (output) + terminal Input(Output)

24V DC OUT

++--

24 VDC power supply input (output) - terminal Input(Output)

24V DC IN

+–

* Viewed from the bottom of the unit

• The following I-type clips can be used for connections.

2.0 mm

max.

6 mm min

5 mm max.

2

CAUTION

Connect a 24 VDC power supply to the “IN” terminal.

When a 24 VDC power supply is connected to the “IN” terminal, the “OUT” terminal

can be used as a 24 VDC power supply output terminal. In this case, the “OUT”

terminal can be used as a power supply for other N-48 unit connected in the multidrop link configuration. (➮

For a connection example, see p. 19.

24V DC OUT

--

24V DC IN

+–

24 VDC

+

)

• Do not connect a power supply other than 24 VDC or the unit may be

damaged.

• Connecting a power supply to the RS-485 terminal may damage the N-48.

• Do not connect different types of power supplies to the IN and OUT terminals or the unit may not start normally due to the potential difference

between the power supplies.

17

Page 26

Chapter 2 Installation Procedure

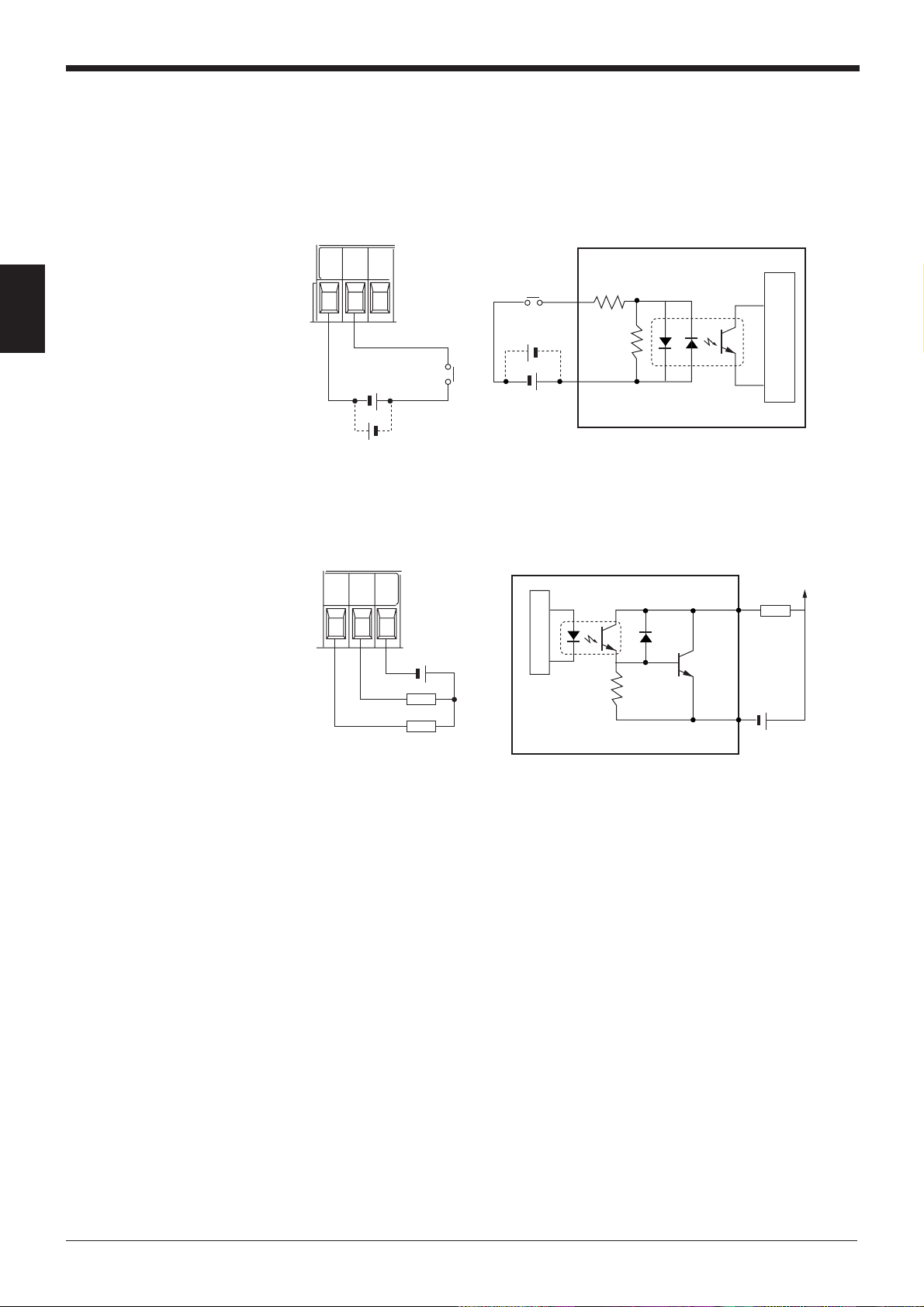

Connecting trigger input

2

Connecting OK/NG output

The trigger input allows the BL series to start reading bar codes (turn on the laser

beam).

To connect the BL series in multi-head mode, send the trigger input to the N-400

instead of the N-48.

TIM

COM

OK

TIM

+

Internal circuit

+

+

15 to 26 VDC

+

COM

The OK/NG output indicates the result of the comparison with preset data, or

indicates whether reading is successful or not.

OK NG

*Rated load: 30 V max. (100mA)

COM

Load

Load

Load

+

Internal circuit

+

18

Page 27

2.3.3 Connecting RS-485

For the RS-485 connections, use the “RS-485 +” and “RS-485 -” terminals provided

on the terminal block.

Chapter 2 Installation Procedure

RS-485 SG

RS-485 +

RS-485 –

24V DC IN +

24V DC IN –

24V DC OUT –

24V DC OUT +

RS-485 +

RS-485 –

RS-485 SG

RS-485 SG

RS-485 +

RS-485 –

24V DC IN +

24V DC IN –

N-48

Shield cable

Twisted pair cable

*

+

24 VDC

TIM

COM

RS-485 SG

RS-485 +

RS-485 –

24V DC OUT +

24V DC OUT –

24V DC IN +

24V DC IN –

N-400

2

24V DC OUT –

24V DC OUT +

RS-485 +

RS-485 –

RS-485 SG

RS-485 SG

RS-485 +

RS-485 –

24V DC IN +

24V DC IN –

24V DC OUT –

24V DC OUT +

RS-485 +

RS-485 –

RS-485 SG

N-48

*

N-48

19

Page 28

Chapter 2 Installation Procedure

• The diagram on the previous page shows the connections to supply 24 VDC

power to the N-48 from the power supply connected to the N-400. In this case,

the 24 VDC power supply connected to the N-400 must have a capacity of at

least “140 mA (N-400 current consumption) + 260 mA (N-48 current consumption) x n (Number of N48 units connected)”.

Example

When five N-48 units are connected:

140 mA + 260 mA x 5 = 1.44 A

Use a power supply with at least 1.44 A capacity.

2

Note: The RS-485 cable can be extended up to 1.2 km. With the power supply

cable, however, the 1.2 km extension is not guaranteed.

To extend the power supply cable as shown in the connection diagram on the

previous page, ensure that the power voltage supplied to all the N-48 units is within

the range of 24 VDC -20% to +10%.

• To connect a 24 VDC power supply to each N-48 unit, remove the 24 VDC

wiring shown in the previous page. To connect the power supply, use the following cable.

Recommended RS-485 cable

• 0.75 mm2 x 2 cores, sheilded

• Up to thirty-one N-48 (BL series) units can be connected in multi-drop link mode.

• The total extension length of the RS-485 cable must be within 1.2 km.

• Turn ON the equipment terminator (termination resistance: 100 Ω) at both ends

of the RS-485 connection (marked with * in the figure above).

• Turn ON/OFF the N-48 terminator using the terminator switch. (

• Turn ON/OFF the N-400 terminator using the terminator switch. (

➮

See p. 7.

➮

See p. 6.

)

)

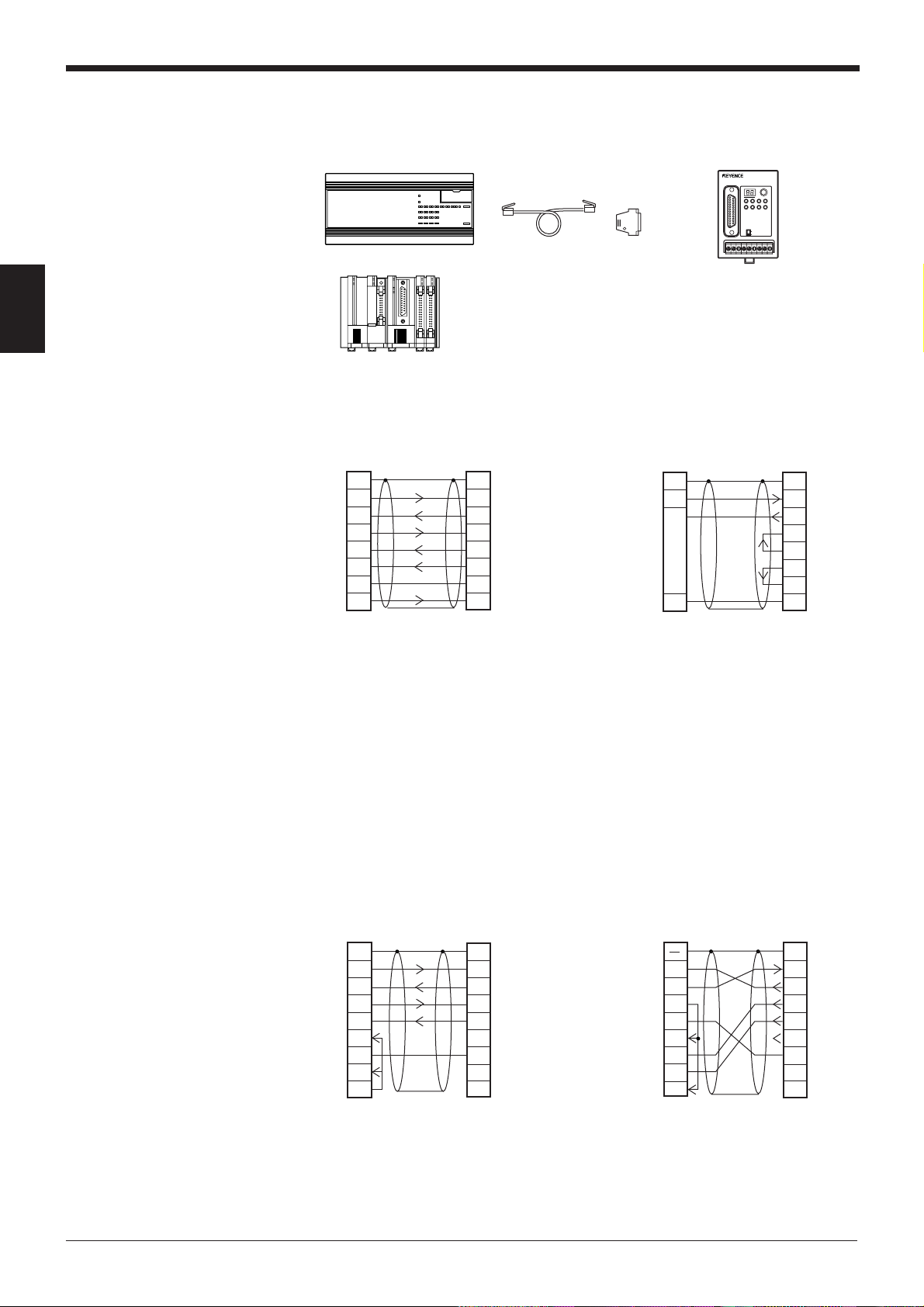

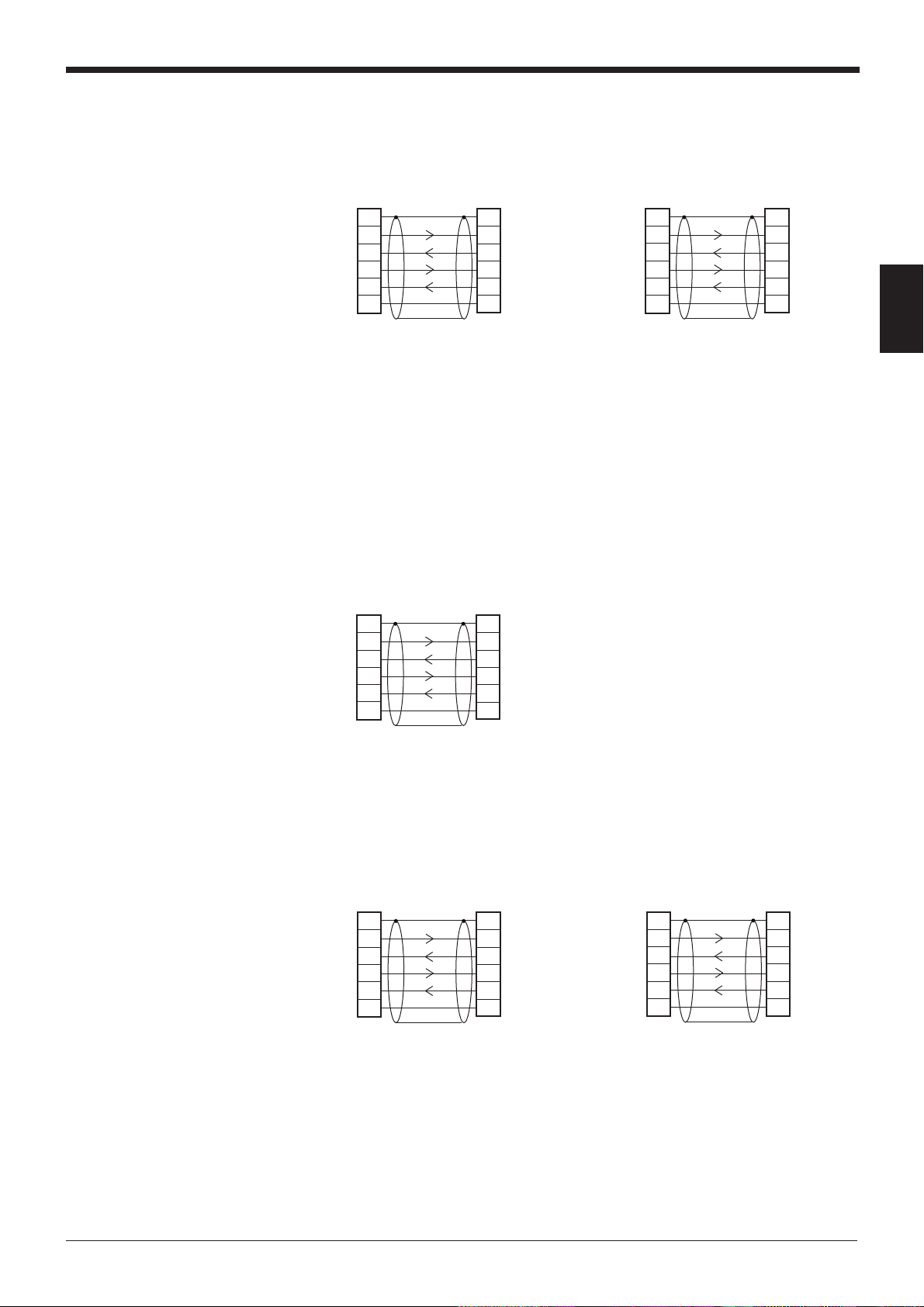

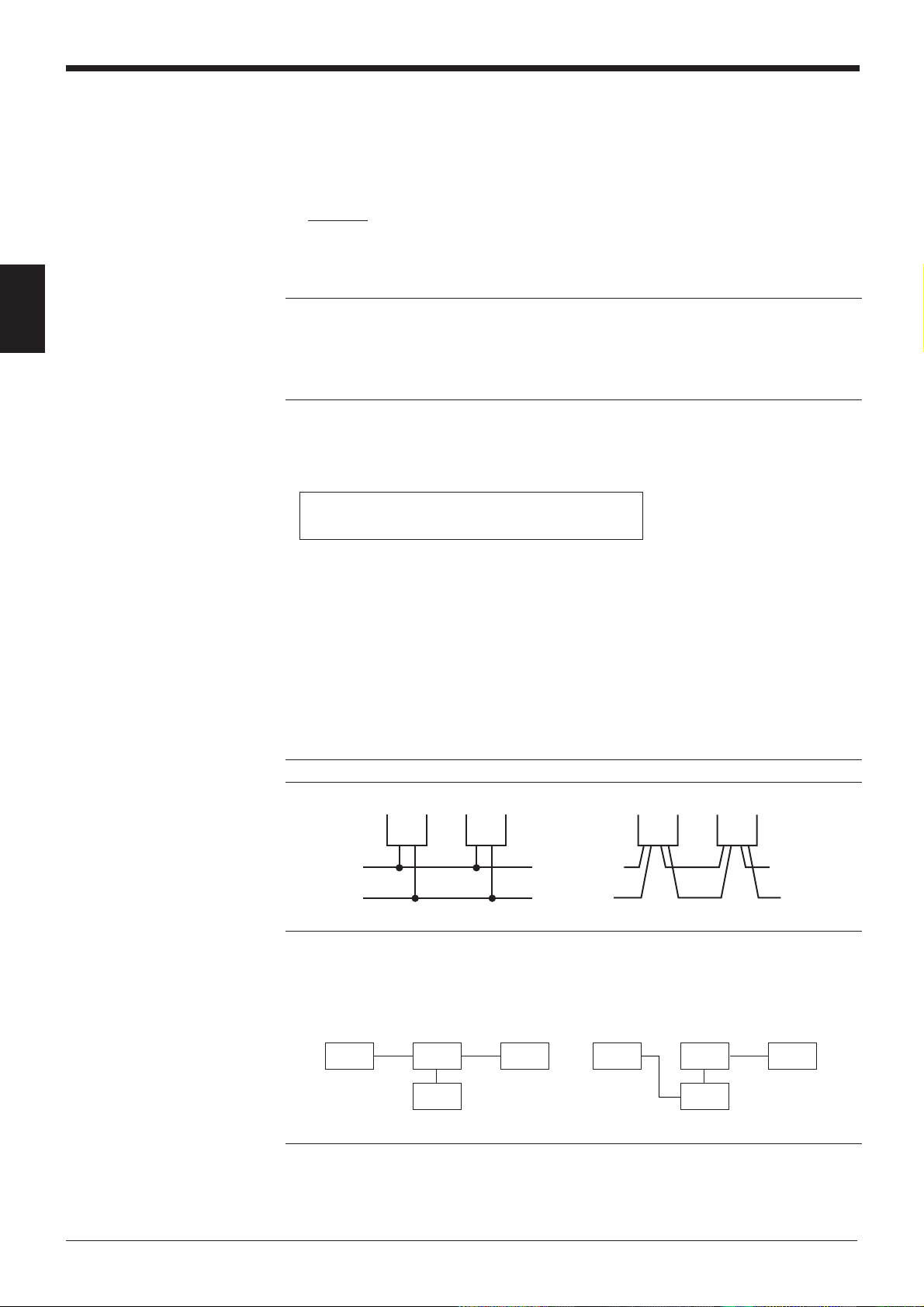

Note: Be sure not to connect the RS-485 cable using the terminal block.

Incorrect

Note 1: Do not place the RS-485 cable in the same conduit as a power cable.

Note 2: Do not branch the RS-485 connection as shown below.

Incorrect

(Connection with branch)

N-48 N-48

N-48

N-400 N-48 N-48

C orrect

(Connection without branch)

*

Correct

N-48

N-400

*

Terminator ON

*

20

Page 29

2.4 Connecting BL-U1 and Wiring

To use the BL-U1 AC power supply, connect it as described below.

2.4.1 Connecting power supply

Plug the BL-U1 power cable into an outlet.

Chapter 2 Installation Procedure

2

FG line

CAUTION

Use a power supply of 100 to 240 VAC ±10% (50/60 Hz).

2.4.2 Connecting BL series

Connect the BL series to the READER port of the BL-U1.

BL-U1 READER port pin assignment

Pin No. Symbol Function Signal direction

1 TIM Trigger input Output

2 RD (RXD) Receives RS-232C data. Output

3 SD (TXD) Sends RS-232C data. Input

4OKOK Input

5 GND (SG) Ground (Common ground for respective —

6NGNG Input

7 RS (RTS) Ready to send RS-232C data. Input

8 CS (CTS) Request to send RS-232Cdata. Output

9 +5 V +5 V power supply (1.5 A) Output

1234

6789

5

D-sub 9-pin (male)

DCE specification (defined as terminal)

#4-40 screw (female)

signal)

(Control method can be selected with the DIP

switches. See p. 22.)

21

Page 30

Chapter 2 Installation Procedure

2.4.3 Setting BL-U1 DIP switches

Switch the interface setting to “RS-485 multi-drop” using the BL-U1 DIP switches.

Switch the RS-485 terminator according to p. 25.

OFF

2

ON

123456

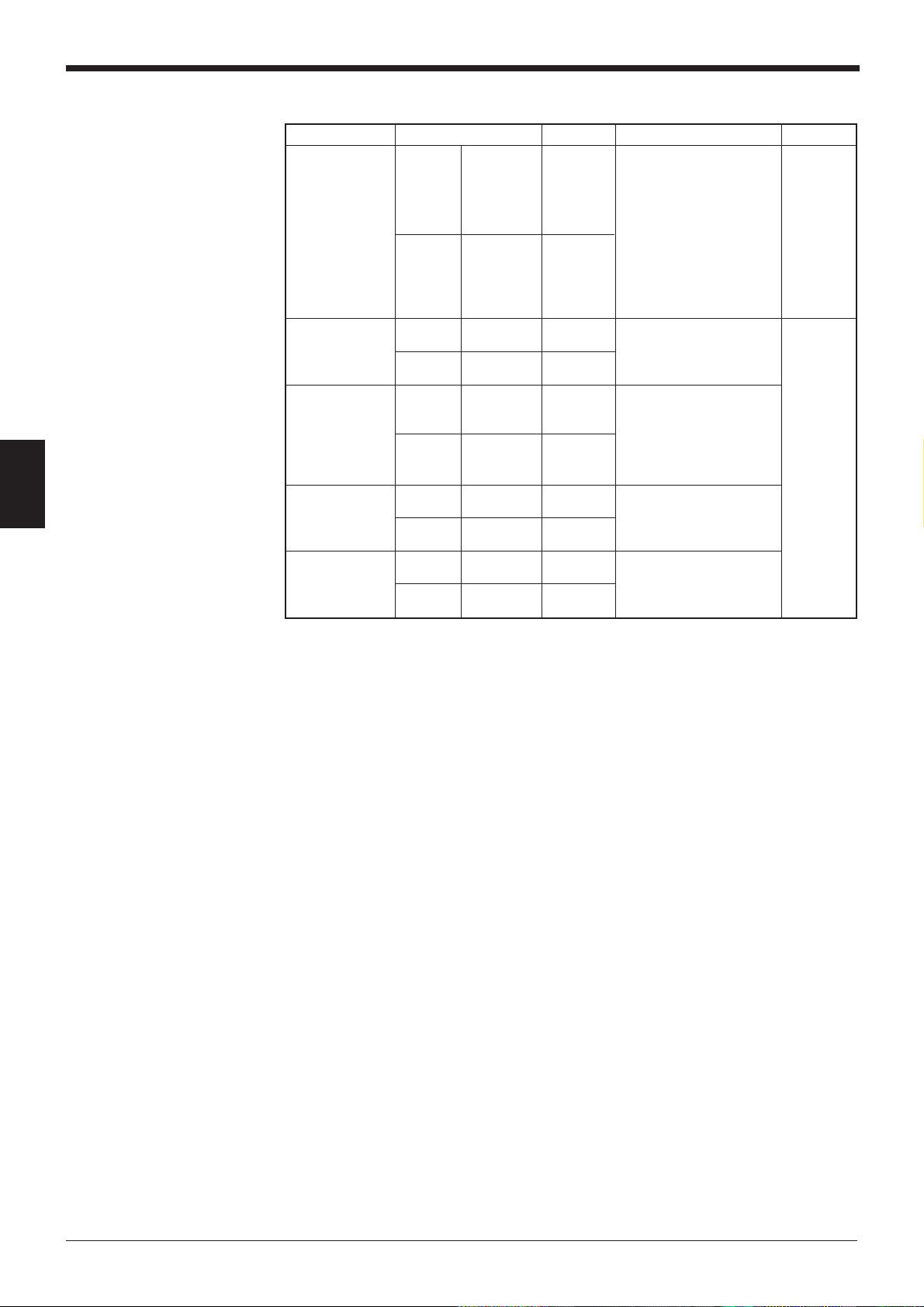

Interface selection RS-232C ON OFF OFF

RS-422A terminator OFF OFF

(Termination resistance: 100 Ω)ON ON

RS-485 terminator OFF OFF

(Termination resistance: 100 Ω)ON ON

Selection of READER port ON or OFF according

CS control method to the RS-232C port OFF

* The figure on the left shows the default settings.

DIP Switch No. 1 2 3 4 5 6

RS-422A OFF ON OFF

RS-485 multidrop OFF OFF ON

CS signal status.

Normally ON ON

22

Page 31

2.4.4 Terminals of I/O terminal block and wiring

TIM +12V OUT– COM OK NG SDA SDB SG RDA RDB

Chapter 2 Installation Procedure

Trigger

input

Symbol Description Signal direction

TIM Trigger input Input

+12 V OUT + terminal of power supply for sensor (12 VDC, 300 mA) Output

– terminal of power supply for sensor (0 V) Output

COM Common terminal for OK/NG output —

OK OK output Output

NG NG output Output

SDA + terminal for RS-422A data transmission/ Output,

RS-485 + terminal Input/Output

SDB – terminal for RS-422A data transmission/ Output,

RS-485 - terminal Input/Output

SG Signal ground —

RDA + terminal for RS-422A data reception Input

RDB – terminal for RS-422A data reception Input

Power supply

for sensors

(12 VDC, 300 mA)

OK/NG output

RS-422A/RS-485

Input

* Viewed from the left of the terminal block

• M3.0 screws are used for the terminal block.

• Use the following crimp terminals for connections.

2

Connecting trigger input

6.0 mm or

less

Round-shape

6.0 mm or

less

Fork-shape

The trigger input allows the BL series to start reading bar codes (turn on the laser

beam).

The trigger input is turned ON when 8.5 to 30 VDC input is activated between the

trigger input terminals.

The BL-U1 power supply for the sensor can be used as the input power supply.

TIM +12V OUT–

+

+

8.5~30VDC

Contact or

solid-state

23

Page 32

Chapter 2 Installation Procedure

Connecting OK/NG output

The OK/NG output is used to differentiate between acceptable and unacceptable

results based on the comparison with the preset data, and to indicate whether or

not the BL series successfully read bar codes.

The OK/NG output is an open-collector output.

COM OK NG

*Rated load: 30 V max. (100 mA)

2

I/O circuit diagram

Input circuit diagram

TIM

Load

Load

+

3.3KΩ

2.4

KΩ

Internal circuit

Output circuit diagram

Internal circuit

OK/NG

COM

Load

+

24

Page 33

2.4.5 Connecting RS-485

Incorrect Correct

BL-U1

BL-U1

For the RS-485 connections, use the “SDA” and “SDB” terminals provided on the

terminal block.

*

Chapter 2 Installation Procedure

BL-U1 BL-U1 BL-U1

SDA

SDB

SG

SDA

SDB

SG

SDA

SDB

SG

*

N-400

RS-485 +

RS-485 –

RS-485 SG

Recommended RS-485 cable

• 0.75 mm2 x 2 cores, shielded

• Up to thirty-one BL-U1 (BL series) units can be connected in multi-drop link

mode.

• The total extension length of the RS-485 cable must be within 1.2 km.

• Turn ON the equipment terminator (termination resistance: 100 Ω) at both ends

of the RS-485 connection (marked with * in the above diagram).

• Turn ON/OFF the BL-U1 terminator using the terminator switch. (See p. 22.)

• Turn ON/OFF the N-400 terminator using the terminator switch. (See p. 6.)

Note: Be sure not to connect the RS-485 cable using the terminal block.

2

Note 1: Do not place the RS-485 cable in the same conduit as a power cable.

Note 2: Do not branch the RS-485 connection as shown below.

Incorrect

(Connection with branch)

BL-U1 BL-U1

N-400 N-400

Correct

(Connection without branch)

BL-U1BL-U1

*

BL-U1

BL-U1

* Terminator ON

*

25

Page 34

Chapter 2 Installation Procedure

2.5 Using Connection Test Mode

This section describes the procedure for performing a connection test after the N400 and the BL series (N-48 or BL-U1) are connected with the RS-485 cable.

Note: To use the connection test mode, ensure that the settings of the connected

BL series and those of the N-400 are switched to “multidrop link” mode.

1) When you press and hold the N-400 test switch for approximately 2 seconds

after the power to all devices is turned ON, the connection test mode is acti-

2

vated. The N-400 displays the ID number of the device being tested. If the

devices are properly connected, the ID number is automatically incremented.

2) If any device is not connected or is improperly connected, the ID number

corresponding to the device flashes.

To go to the next step during the connection test, press the test switch once.

Example 1

When ten BL series (ID Nos. 1 to 10) are connected:

The displayed ID number automatically changes from “1” to “10”, and then “11”

will flash if the connection test result is “OK”.

Example 2

When fourteen BL series (ID Nos. 3 to 16) are connected:

When “1” flashes, press the test switch once. When “2” flashes, press the test

switch again. The displayed number changes from “3” to “16”, and then “17” will

flash if the connection test result is “OK”.

3) If an ID number of any BL series flashes, the BL series unit is not properly

connected. After checking the following points, perform the connection test

again.

• Check that the RS-485 communication parameters (baud rate, data length,

parity and stop bit length) of the N-400 match to those of the BL series.

• Check that the BL series is set to “multi-drop link” mode.

• Check that all cables are properly connected. Ensure that the connections are

not branched and that no cables are connected using the terminal block. (

See pp. 19, 20 and 25.

• Check that the equipment terminators at both ends of the connection are ON

and the terminators of other equipment are OFF.

• Check that the BL series’ ID numbers are properly assigned. Make sure that the

same ID number is not assigned to different devices.

)

➮

26

4) Pressing and holding the test switch for approximately 2 seconds again resets

the connection test mode.

Page 35

2.6 Mounting Procedure

2.6.1 Operating environment precautions

Chapter 2 Installation Procedure

CAUTION

This unit is a precision instrument and you must take care in choosing the

operating environment.

■ Ambient environments

Do not install the unit in place as shown below

• The unit is exposed to direct sunlight, or the ambient temperature may fall

below 0°C (32°F) or exceed 50°C (122°F);

• The relative humidity may exceed the range of 35 to 85%, or condensation may

occur due to rapid temperature changes;

• Corrosive gas or inflammable gas is present, or a high level of dust, salt, iron

particles or soot is present;

• The unit is subject to vibration or impact;

•Water, oil or chemicals may splash the unit;

•A strong magnetic field or electric field is generated.

• Do not place the cables in the same conduit as a power cable.

2

■ In-panel installation

To mount the N-400 in a panel, carefully observe the following instructions.

• Provide enough ventilation space.

• If the ambient temperature may fall below 0°C (32°F) or exceed 50°C (122°F),

provide a fan or air conditioner.

• Do not mount this unit in a panel where a high voltage device is installed.

• Place this unit as far away from power lines as possible.

27

Page 36

Chapter 2 Installation Procedure

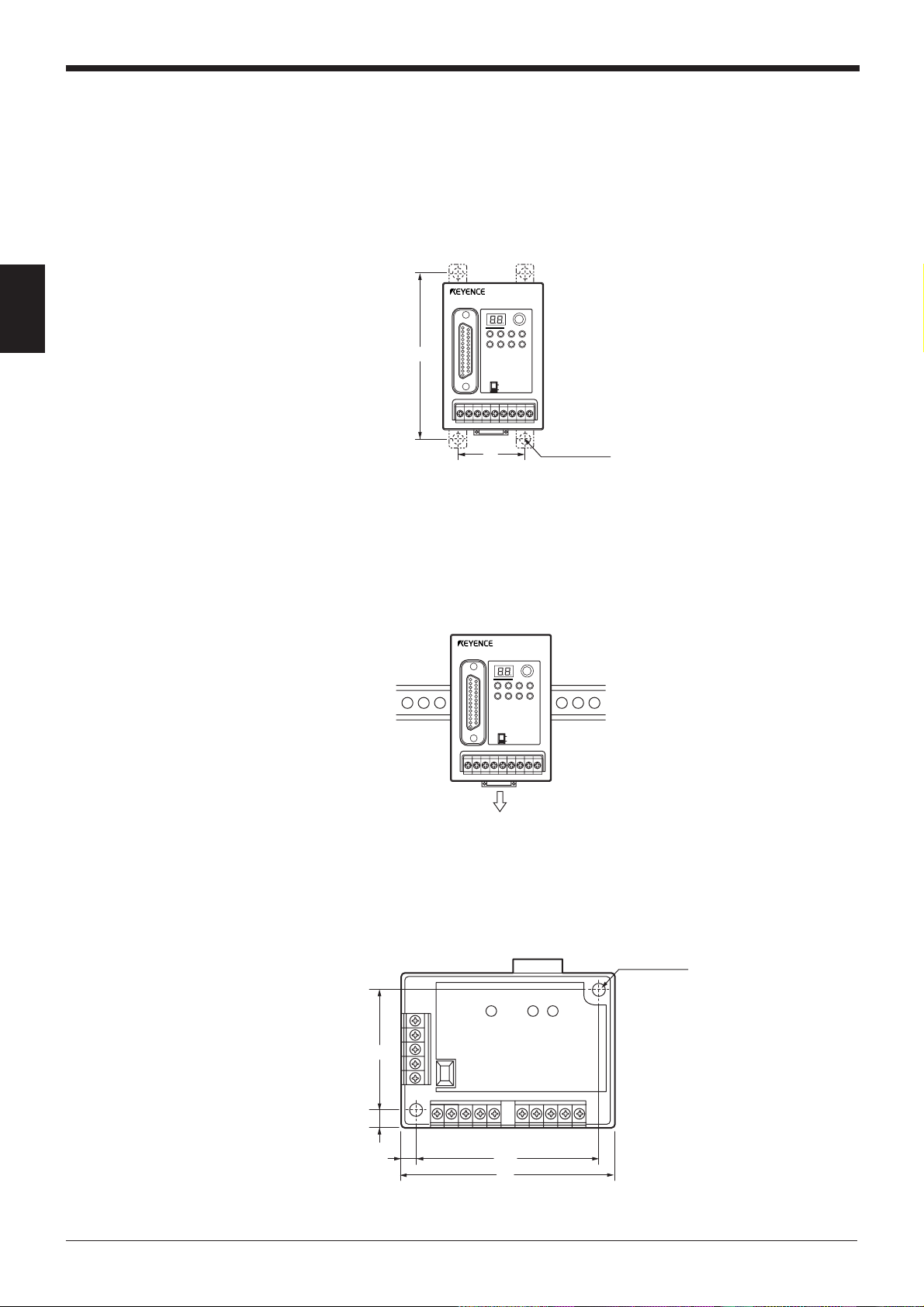

2.6.2 Mounting N-400

Direct mounting

2

To mount the N-400, you can use one of the following two methods:

Pull the brackets provided at four positions on the rear of the N-400, and fix them

with screws.

N-400

TEST

RS-232C

CS RS

SD RD

RD

SD

POWER TIMING

TERMINATOR

RS-455

ON

OFF

100

DIN-rail mounting

2.6.3 Mounting N-48

40

4 x ø5

mounting hole

To mount the N-400 on a DIN-rail, press the unit against the DIN rail until it clicks.

To remove the unit, pull the hook in the direction indicated by arrow.

N-400

TEST

RS-232C

CS RS

SD RD

RD

SD

POWER TIMING

RS-455

TERMINATOR

ON

OFF

28

To mount the N-48, use the mounting hole.

POWER SD RD

43.2

5.9

5.9

63.2

75

4 x ø5

mounting hole

Page 37

2.6.4 Mounting BL-U1

To mount the BL-U1, you can use one of the following two methods:

Positions of direct mounting

Pull the brackets provided at four positions on the rear of the BL-U1, and fix them

with screws.

Chapter 2 Installation Procedure

4 x ø5

DIN-rail mounting

98

150

1. Hook the BL-U1 in the groove of the DIN rail from the top, and press the bottom

of the BL-U1 against the DIN rail until it clicks.

2. Make sure that the DIN-rail mounting hook is set in condition “A”. If it is not,

push it inward.

3. To remove the BL-U1 from the DIN rail, pull the hook so that it is set in condition

“B”.

4. To mount the unit on the DIN rail again, restore the hook to condition “A”.

2

AB

29

Page 38

Chapter 2 Installation Procedure

2

30

Page 39

Chapter 3

N-400 Setup Procedure

3.1 Installing Setup Software ...................................................32

3.2 Setup Software Operating Procedure ...............................34

3.2.1 Operating procedure..............................................................34

3.2.2 Description on each setup screen .........................................35

3.2.3 Outline of operation ...............................................................36

3.3 Details of Operating Procedure ........................................38

3.3.1 Setting procedure ..................................................................38

3.3.2 Reading/Saving/Printing File .................................................44

3.4 Sending/Receiving Settings ..............................................48

3.5 Using Terminal ....................................................................52

3.6 List of Error Messages .......................................................55

Page 40

Chapter 3 N-400 Setup Procedure

3.1 Installing Setup Software

The N-400 includes the setup software for the Windows version only.

The operating environments and the procedure for installing this setup software

are described below.

■ Hardware requirments

• IBM PC/AT 100% compatible

CPU: 80386 or higher

Memory: 4 MB or more

Floppy disk drive: 3.5 inch floppy disk drive (1.44 Mb compatible)

Serial port: A minimum of one RS-232C port is required.

■ OS requirements

3

Installation procedure

• MS-Windows 3.1 or MS-Windows 95

1. Insert the N-400 setup software system disk into the floppy drive.

2. Perform the following procedure.

•Windows 3.1:

Execute “Run” in the icon menu of the program manager.

•Windows 95:

Select “Run” from the "Start" menu.

3. Run the “SETUP” file from the floppy disk drive.

(This step is common to both the Windows 3.1 and Windows 95.)

Type in as follows:

A: \SETUP

32

Page 41

Chapter 3 N-400 Setup Procedure

4. The N-400 setup software installer starts. Follow the instructions in the install

window. (Typically, the installation procedure can be completed simply by

pressing [Next (N)] twice.)

5. The setup software is normally installed in the following directory:

C: \KEYENCE\N400

If this directory is correct, click on [Next (N)]. If you wish to change the directory,

click on [Browse (R)..], and select the desired directory.

6. When installation starts, the file copy process is displayed as a graph. When the

installation is completed, the following message appears.

7. For Windows 3.1, double-click on the [N400] icon in the [KEYENCE] group to

start the setup software.

For Windows 95, start the program from the "Start" menu.

3

33

Page 42

Chapter 3 N-400 Setup Procedure

3.2 Setup Software Operating Procedure

3.2.1 Operating procedure

To set up the N-400 using the setup software, follow the procedure below.

1. Connect the N-400 to the host computer using the RS-232C cable.

➮

For the recommended cable, see 2.2.2 Connecting RS-232C.

2. Start the N-400 setup software.

3. Select a setup item, and set it to the desired condition.

4. Before sending the updated settings to the N-400, click on [COM PORT] to

match the communication parameters of the personal computer with the current

3

settings of the N-400.

The default settings of the N-400 are as follows:

• Baud rate: 9600 bit/s

• Data length: 7 bit

• Parity: Even

• Stop bit length: 1 bit

Immediately after you purchase the N-400, set [COM PORT] to the above

settings.

If you do not know the current settings of the N-400, press the N-400 test switch

for approximately 5 seconds. When the N-400 displays “S0(50)”, the N-400 is

automatically set to the above settings. The N-400 can communicate with the

host computer if the “COM PORT” settings are same as the above.

5. Click on [Transfer] to send the updated settings to the N-400.

(The current settings of the N-400 can also be read.)

6. Select [FILES] to save or print the settings, as required.

7. After the setup procedure is completed, click on [Exit] to close the setup software.

34

Page 43

3.2.2 Description on each setup screen

Chapter 3 N-400 Setup Procedure

▼

▲

Displays the name of the setup file

currently being edited. If the file has

been read from the setup file, the file

name is specified as “File: ...”. If the

file has been read from the N-400, the

file name is marked with “N-400”. If

the file name is the initial setting,

“default” is displayed.

If the file name has been changed

from the initial setting (the condition

immediately after it is read from the

file), “changed” is displayed.

HOST MODE:

• Sets auto-polling mode (multi-drop link) and multi-head scan mode

• Sets the interference suppression function in multi-head mode

• Sets read mode, measuring method and trigger input in multi-head mode

• Sets a read error code and trigger ON/OFF commands in multi-head mode

PROTOCOL:

• Sets the handshaking protocol

• Sets the header and delimiter

• Sets the PLC link

3

ID SETUP:

• Registers the ID number of the connected BL Bar Code Reader

RS-232C:

• Sets the baud rate, data length, stop bit length and parity for the RS-232C

communication

• Setting the RTS/CTS protocol

RS-485:

• Sets the baud rate, data length, stop bit length and parity for the RS-485 communication

FILES:

• Saves, reads or prints settings

COM PORT:

• Sets the communication parameters (baud rate, etc.) of the host computer

according to the settings of the N-400 before communication starts between the

N-400 and host computer.

TRANSFER:

• Sends updated settings to the N-400, or reads the current settings of the N-400.

MONITOR:

• Checks if the N-400 can operate normally.

EXIT:

• Quits the N-400 setup software.

35

Page 44

Chapter 3 N-400 Setup Procedure

3.2.3 Outline of operation

This section describes the basic operations of the N-400 setup software.

To enter settings, place the mouse pointer on the item to be changed, and click the

left mouse button.

Mouse pointer

3

Clicking on

Clicking on

Clicking on

• • •

Used to select the item to be changed.

Used to select any of several options.

The selected item is marked with • .

Used to select whether to enable or disable this function.

To enable this function, the mark is checked with “√”. (For the Windows Ver. 3.1,

it is checked with “x”.)

Clicking on

➞

Used to select any of several options.

36

Page 45

Entering a value

Entering characters

Chapter 3 N-400 Setup Procedure

After clicking in the frame, enter a value using the keyboard.

If the entered value exceeds the setting range, an error message is displayed.

(

➮

See p. 55.

When you click in the frame labeled “ASC”, you can enter characters using the

keyboard.

When you click in the frame labeled “HEX”, you can enter characters using hexadecimal numbers (00 to 7F). This function is used to enter control characters (00 to

21h ASCII codes, such as [CR] and [STX]).

)

3

37

Page 46

Chapter 3 N-400 Setup Procedure

3.3 Details of Operating Procedure

3.3.1 Setting procedure

HOST MODE

In the HOST MODE, select “Multi-drop link” or “Multi-head scan”.

3

1. If you select “Multi-head scan” mode, the following setup items appear. The

following steps are effective for “Multi-head scan” mode only.

2. To use the “Interference Suppression” function, the following setup items

appear.

38

“TIMER” indicates the reading time of each BL series in the interference suppression mode. Enter a value using the keyboard.

3. “Data-send” is displayed only when “Read mode” is set to “Single”.

4. Enter a read error code using the keyboard. The read error code can be

changed to any eight character string. Set this code so that it conforms to the

read error code of the connected BL series.

Normally, you should use the default setting (ERROR) without changing it (as

well as the BL series’ read error code).

Page 47

5. When you click on [Trigger setup], you can set the trigger input in multi-head

mode.

➮

Tips

MULTI-DROP LINK (Multi-drop link mode): p. 58

➮

MULTI-HEAD SCAN (Multi-head scan mode): p. 86

➮

Interference Suppression: p. 95

➮

Read mode: pp. 89 to 90

➮

Data-send: p. 92

➮

Read error code: p. 93

TRIGGER SETUP (only when Multi-head scan is selected)

The Trigger Setup screen is used to set the trigger input for Multi-head scan mode.

Chapter 3 N-400 Setup Procedure

3

Tips

1. Set “Trigger Input/Signal Type” to “Level” or “One-shot”.

If you select “One-shot”, the one shot input time is displayed.

2. Enter the “Command for Trigger ON” and “Command for Trigger OFF” using the

keyboard. These commands can be changed to any eight character string. Set

these commands so that they conform to the trigger ON/OFF commands of the

connected BL series.

Normally, you should use the default settings (LON and LOFF) without changing them (as well as the BL series’ trigger ON/OFF commands).

➮

Trigger Input/Signal Type: p. 91

➮

Command for Trigger ON, Command for Trigger OFF: p. 72

39

Page 48

Chapter 3 N-400 Setup Procedure

PROTOCOL (when "Use PLC" is disabled)

The PROTOCOL screen is used to set “Handshaking protocol” and various items

to enable the "Use PLC".

3

1. When “Use PLC” is disabled, set the “Handshaking protocol” as shown above.

2. Select “Header” and “Delimiter” from the displayed items. You can change the

read data format by setting these items. If you select “Custom”, the following

screen appears. These items can be set to any five character string using the

keyboard.

Note: When customizing the header and delimiter, you modify them based on the

previously selection. When selecting "custom," if you currently use "CR", "0D"

appears in hex and "." in ASCII (It is not a period but stands for "CR"). If "none"

was used previously, nothing appears.

3. Normally, the ID number of the BL series that executed reading is not added to

the read data in multi-head scan mode. However, you can set “Add ID” so that

the ID number is added to the read data.

4. “Checksum” can be added to read data to check incompatible data translation

between the N-400 and the host computer. Normally, this function is not necessary.

40

Tips

➮

Handshaking protocol: pp. 65 and 66

➮

Header, Delimiter: p. 61

➮

Checksum: pp.133 and 134

Page 49

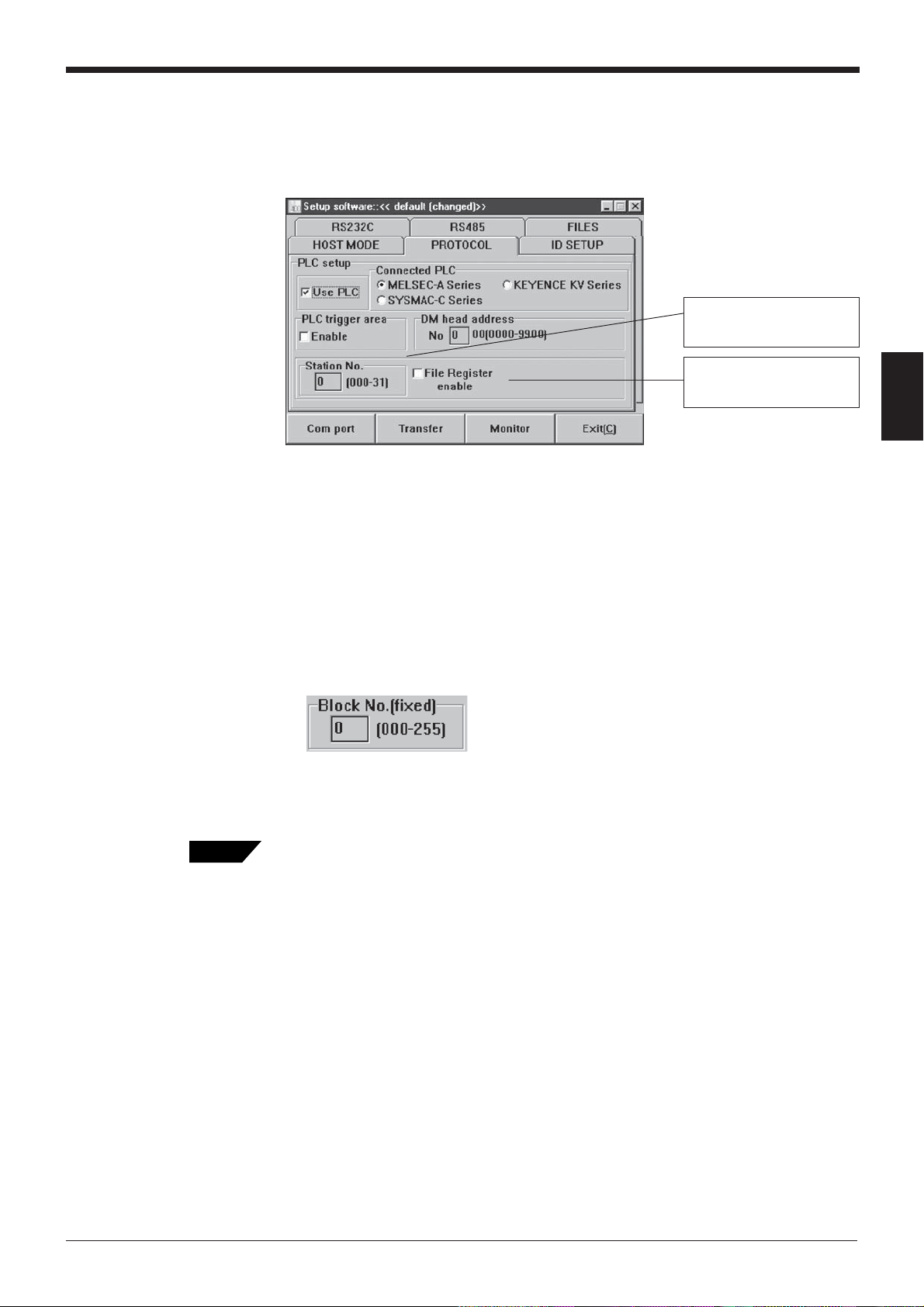

PROTOCOL (when "Use PLC" is enabled)

To enable the "Use PLC", set each item as follows:

S018

Chapter 3 N-400 Setup Procedure

The setting of the station

number is not displayed

▼

▼

when “KV Series” is selected.

The setting of the file register

is displayed only when

“MELSEC-A” is selected.

3

Tips

1. Set “Connected PLC”, “DM head address” and “Station No.”.

To set “DM head address”, enter a value (0000 to 9900) using the keyboard.

2. To send a trigger signal to the BL series when the PLC link is enabled, set

“PLC trigger area”.

3. To use “File Register”, set “File Register” to “Enable”. When “File Register” is

enabled, the following screen appears. The “File Register” can be used with

the Mitsubishi MELSEC-A series only.

Enter the block number (000 to 255) of the file register using the keyboard.

➮

PLC link: p. 100

➮

PLC trigger area: p. 106

➮

DM head address: p. 106

➮

File register: p. 101

41

Page 50

Chapter 3 N-400 Setup Procedure

ID SETUP

3

The ID SETUP screen is used to register the ID numbers of the connected BL

series. When you register the ID numbers in multidrop link mode, polling automatically starts when the N-400 starts up. To perform manual polling, skip the ID

SETUP.

RS-232C

Tips

➮

Auto polling: p. 61

➮

Manual polling: p. 62

The RS-232C screen is used to set the RS-232C communication parameters for

the N-400. Set these parameters so that they conform to those of the host computer or PLC.

42

Tips

1. Setting “RTS/CTS” is disabled when “Use PLC” is selected.

➮

RTS/CTS: p. 66

Page 51

RS-485

Chapter 3 N-400 Setup Procedure

The RS-485 screen is used to set the RS-485 communication parameters for the

N-400. Set these parameters so that they conform to those of the connected BL

series.

3

Note: We recommend that you set the baud rate to “38400 bits/s” to increase the

processing speed, since the RS-485 communication between the N-400 and the

BL series transfers a large volume of data.

43

Page 52

Chapter 3 N-400 Setup Procedure

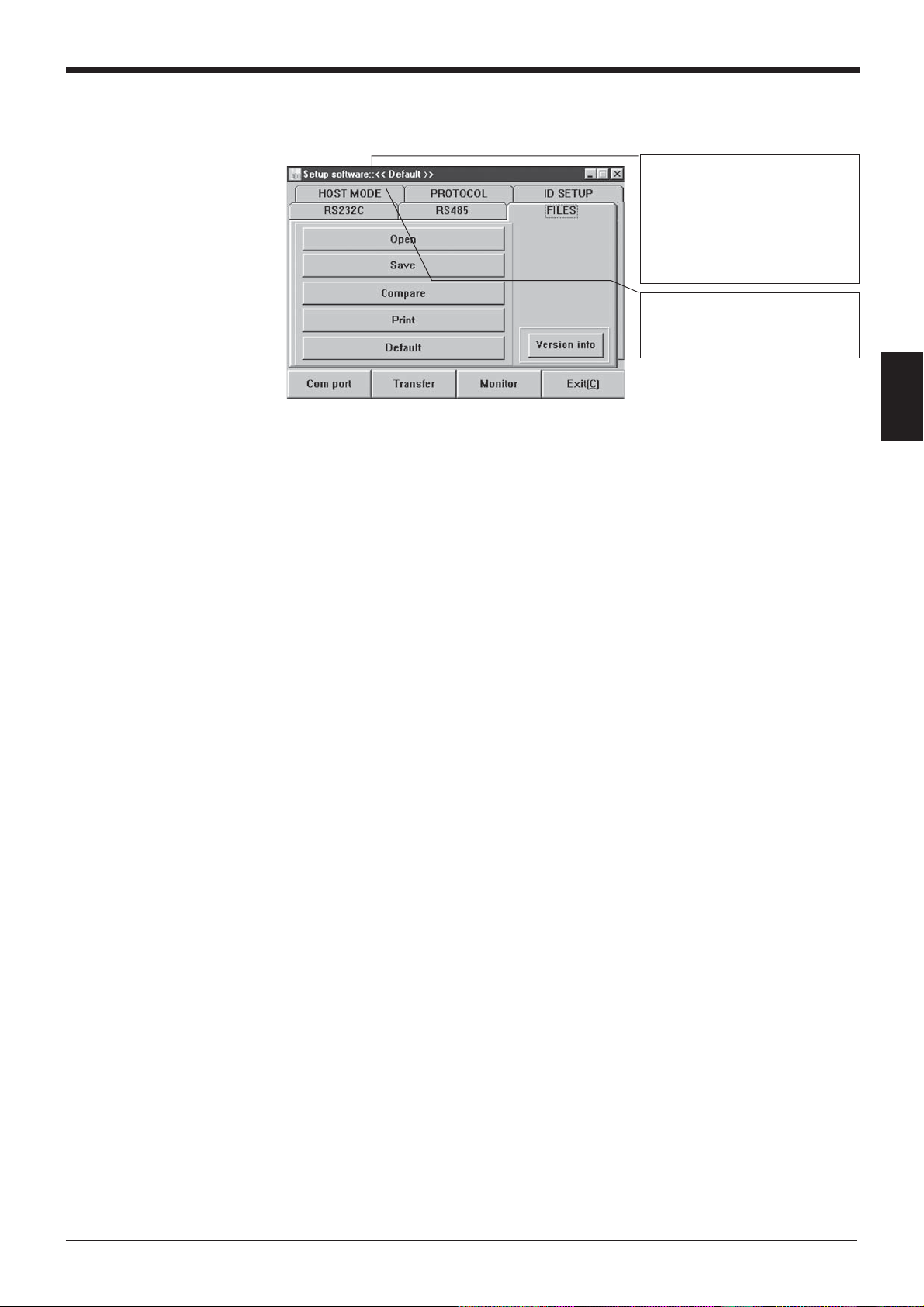

3.3.2 Reading/Saving/Printing File

The FILES screen is used to save updated settings in a file, to read a saved setting

file, and to print the contents of a setting file.

3

• Open: Reads a saved setting file.

• Save: Saves updated settings in a file.

• Compare: Compares the settings currently edited with a file previously saved.

• Print: Prints contents of a setting file.

• Default (Initialize settings): Restores updated settings to the default settings.

• Version info: Displays the version information of this software.

Reading a previously saved setting file

1. To read a previously saved setting file, click on [Open]. The following screen will

appear.

44

2. When you click on [OK] after selecting a file, the selected file can be opened.

Page 53

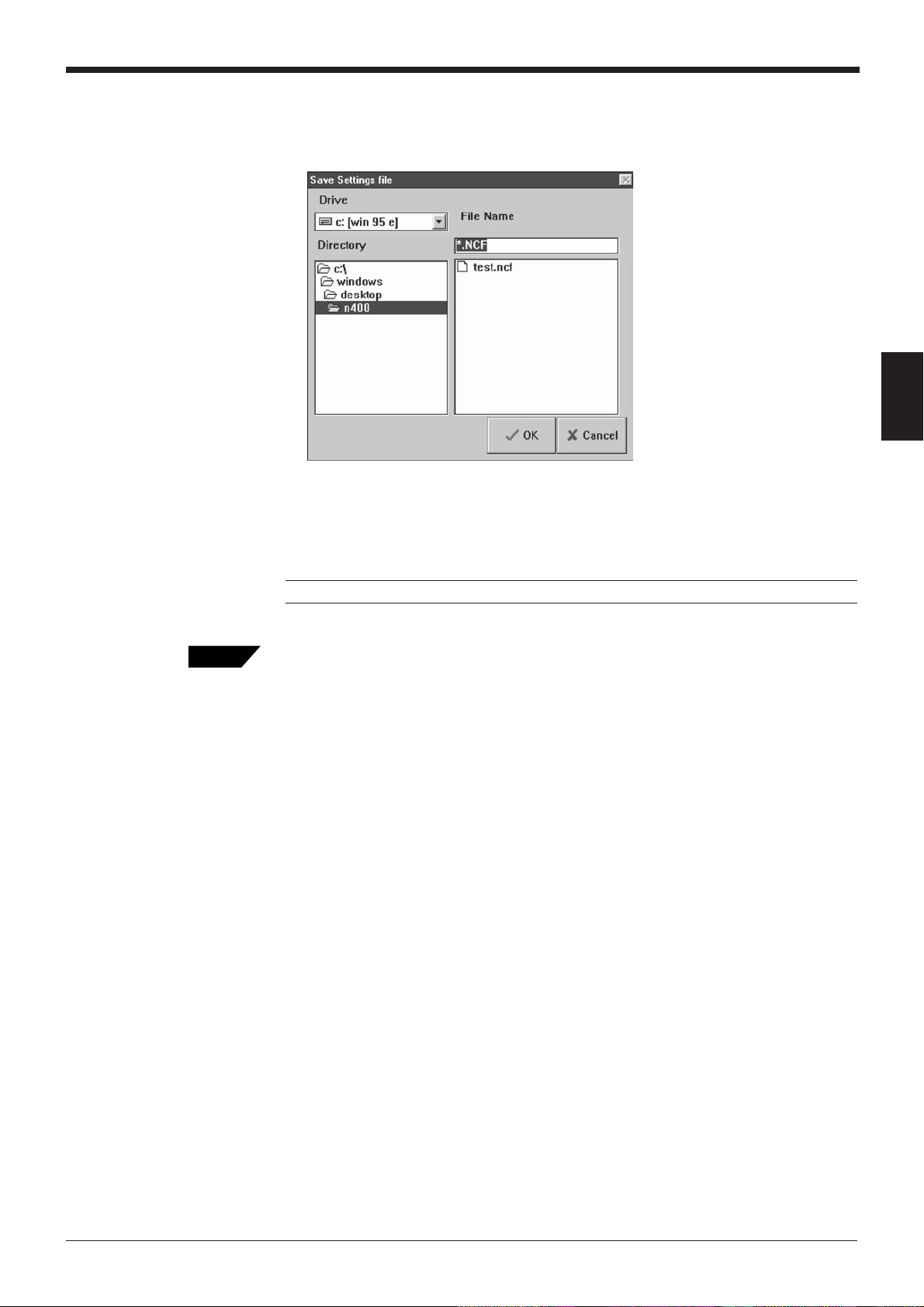

Saving updated settings in a file

1. To save updated settings in a file, click on [Save]. The following screen will

appear.

2. Click on the file name entry field, and enter a file name using the keyboard.

Specify a file name within eight characters. Be sure to add the extension “NCF”.

After entering the file name, click on [OK] to save the file.

Chapter 3 N-400 Setup Procedure

3

Tips

Note: This software cannot accept a long file name in Windows 95.

When the saved setting file is sent to the N-400, the name of the file is simultaneously sent to the N-400. When you read the settings of the N-400 using this

software, the file name is also read. It is convenient for maintenance since you can

find the file that stores the settings.

To enter a file name, use alphanumerics (letters and numbers) only. Otherwise, the

file name cannot be sent to the N-400, because it can only recognize alphanumerics. To send a file name, be sure to enter the file name using alphanumerics and

then save it. (If the file name is not saved, it cannot be sent to the N-400.)

45

Page 54

Chapter 3 N-400 Setup Procedure

Comparing the settings currently edited with a saved file

1. To compare the settings currently edited with the setting file previously saved,

click on [Compare].

3

2. Select a file to be compared, and click on [OK]. Then, the system compares the

selected file with the settings currently edited, and displays the result.

Matched Not matched

46

Page 55

Chapter 3 N-400 Setup Procedure

Printing contents of a setting file

1. To print settings, click on [Print]. The following screen will appear.

2. Adjust “Printer Setup” as required, and click on [OK]. Printing will then start.

Restoring the settings currently edited to the default (initial) settings

3

1. To restore the settings currently being edited to the default settings, click on

[Default (Initialize settings)].

2. If you try to initialize the settings currently being edited without saving them, the

following message appears. If you wish to execute initialization, click on [OK].

Note: The initialization procedure described in this section is used to initialize the

settings being edited with the setup software. The settings on the N-400 cannot be

initialized.

47

Page 56

Chapter 3 N-400 Setup Procedure

3.4 Sending/Receiving Settings

Sending updated settings to the N-400

To send updated settings to the N-400, perform the following procedure.

1. Press and hold the N-400 test switch for five seconds. When the N-400 displays

“S0 (50)”, the communication parameters are temporarily set as follows:

• Baud rate: 9600 bits/s

• Step bit length: 1 bit

• Data length: 7 bits

• PLC link: Disabled

• Parity: Even

3

Tips

If you know the current communication parameter settings of the N-400, this step is

not necessary. You can send data to the N-400 by setting the communication

parameters of the host computer using [COM PORT] so that they conform to the

current settings of the N-400. However, if PLC link is enabled, you cannot send

data to the N-400 without performing this step because the handshaking protocol is

set for PLC link only.

2. Click on [COM PORT] to set the communication parameters of the host computer according to the values listed in the step 1. (above procedure). Select an

RS-232C port, and click on [OK].

3. Click on [Send setting (Save in N-400 EEP-ROM]. The updated settings are

then sent to the N-400.

48

Page 57

Chapter 3 N-400 Setup Procedure

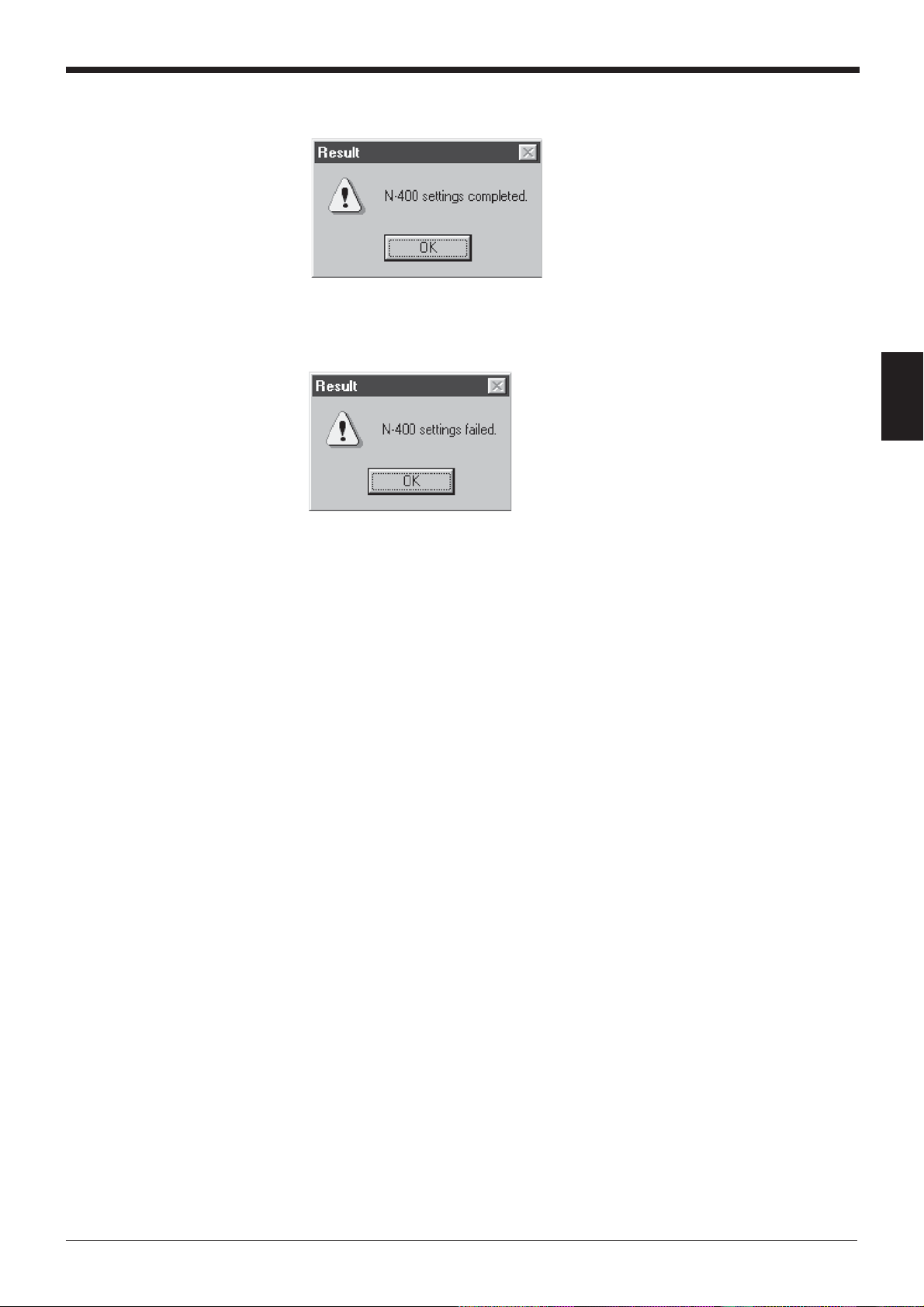

4. If the settings were successfully sent to the N-400, the following message

appears.

If the host computer failed to send the data to the N-400, the following message

appears.

3

If this message is displayed, check the following points:

• Check that [COM PORT] is set to the values listed in step 1. when the N-

400 displays “S0 (50)”.

• Check that the power to the N-400 is ON.

• Check that the RS-232C cable pin assignment of the N-400 is the same as

that of the host computer.

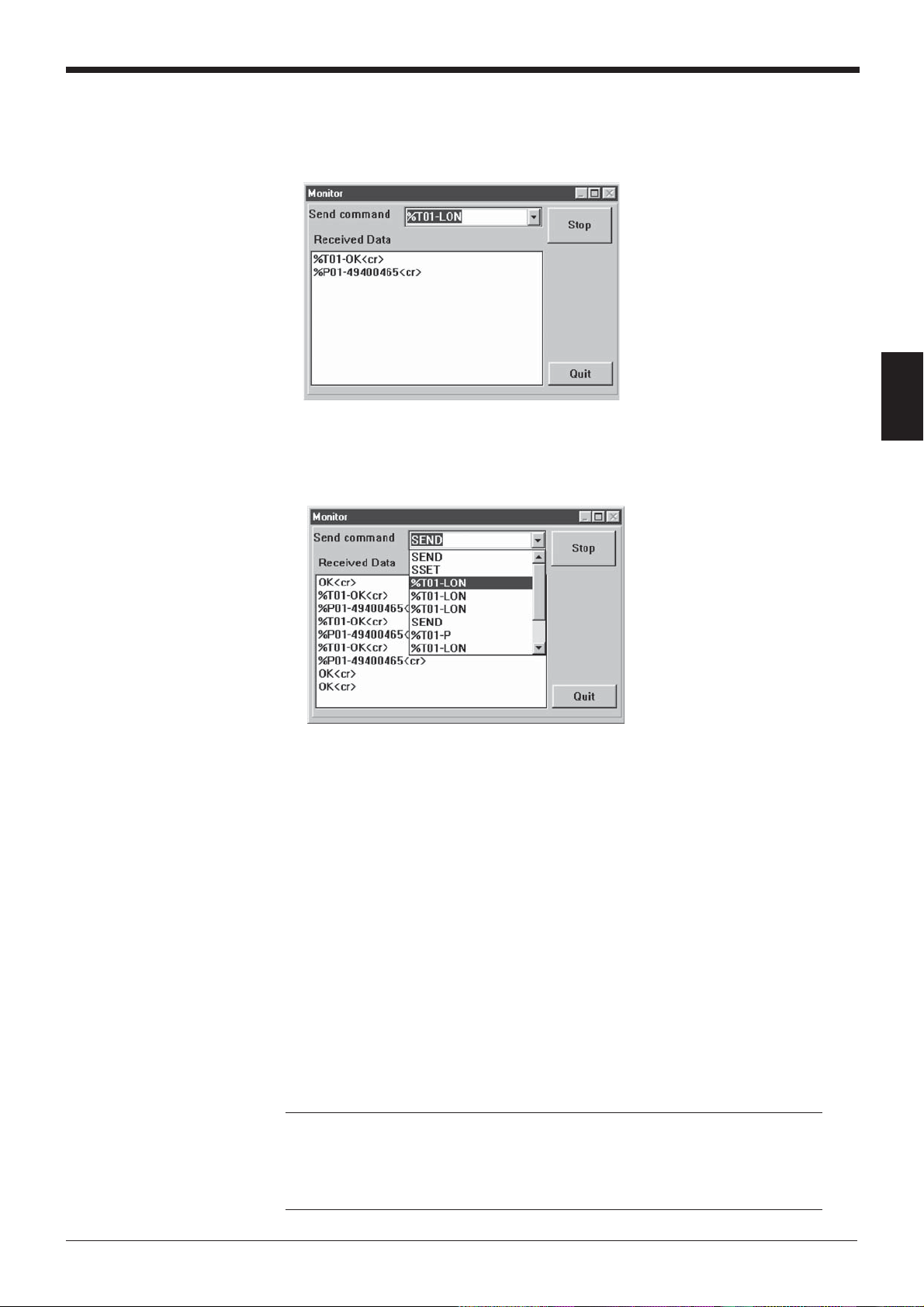

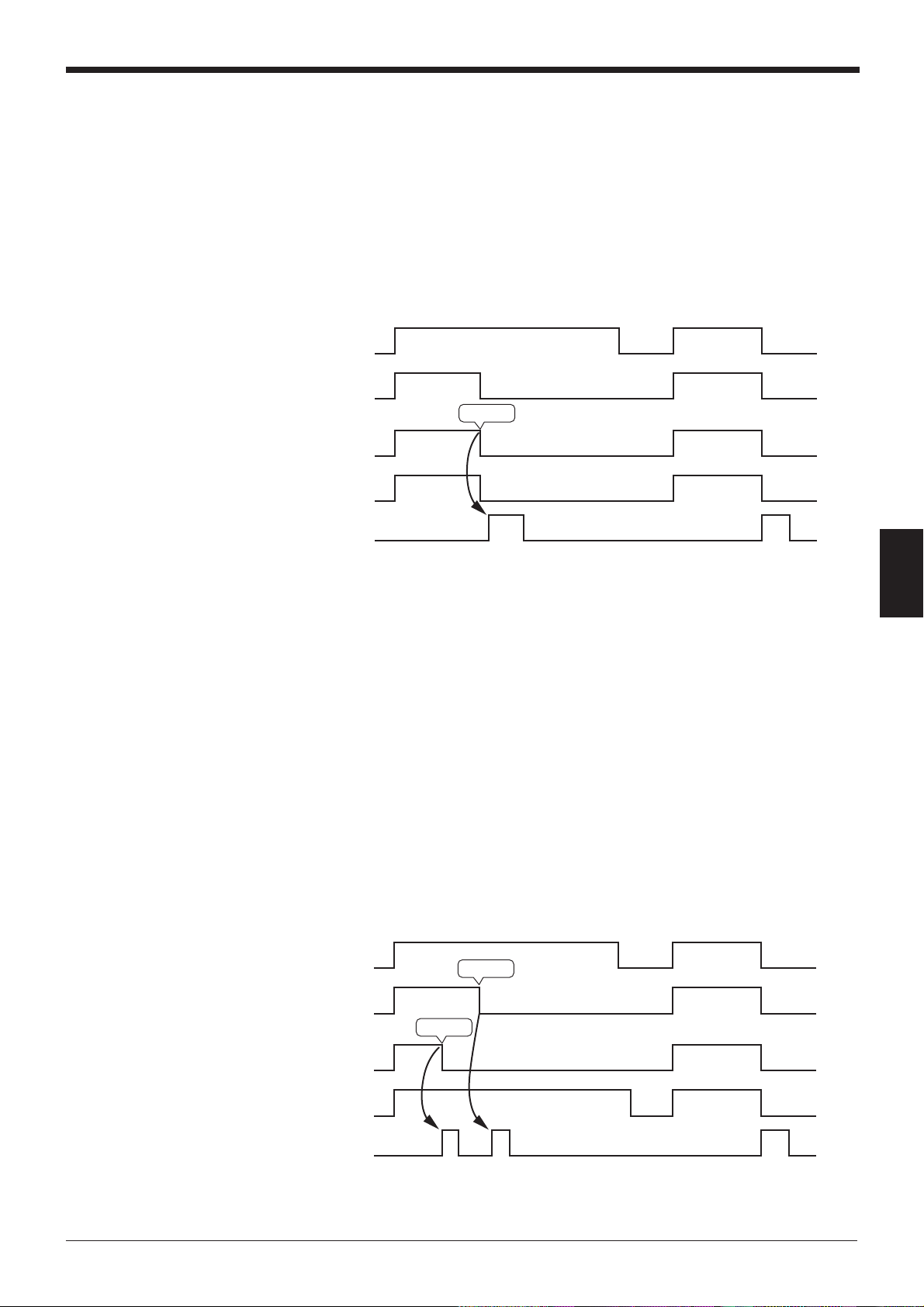

5. After the settings are sent, press the N-400 test switch once to reset the “S0