Page 1

Setting and Support Software LS-H1W

for LS-7600/7000 Series

LS-Navigator

User’s Manual

Read this manual before using the system in order to obtain

full performance.

Keep this manual in a safe place for future reference.

96136E

Page 2

2

Safety Precautions

This manual describes the functions and usage for LS-Navigator, the setting and support software LS-H1W for

LS-7600/7000 series. Read this manual carefully before starting to use the software to ensure the optimum

performance and full functionality of the LS-Navigator. Keep this manual in a safe place for future reference.

Symbols

The following symbols and conventions alert you to important messages.

Symbol Description

WARNING

CAUTION

Note

Reference

Failure to follow instructions may lead to personal injury, such as burns or electric shock.

Failure to follow instructions may lead to product damage.

Provides additional information on proper operations that can be easily mistaken.

Provides advanced and useful information for operation.

General Cautions

• At startup and during operation, be sure to monitor the functions and performance of the software.

•

We recommend that you take substantial safety measures to avoid any damage in the event that a problem occurs.

• Do not modify the product or use it in any way other than described in the specifications.

• When the software is used in combination with other devices, functions and performance may be diminished,

depending on the operating conditions and surrounding environment.

Copyrights

• Windows 7, Vista, Windows XP, Windows 2000 Professional is the registered trademark of Microsoft Corporation, U.S.A.

• Pentium is the registered trademark of Intel Corporation, U.S.A.

• Other company names and product names are registered trademarks or trademarks of the respective companies.

For detailed operations for each controller (LK-7600/7500/7000), see the “User's Manual” for the

controller.

LS-Navigator-M-NO0-J

Page 3

Terms of the Software License Agreement

LS-Navigator is available to you provided that you agree with the following license agreement.

Read the following agreements carefully before using this software.

By using the LS-Navigator, you signify that you agree with the statements herein and the contract is accepted.

License agreement

1. License of use

KEYENCE grants the user the nonexclusive right to use this software in accordance with terms of this agreement.

2. Copyright

The copyright on the software and supplied documentation belong to KEYENCE Corporation. The user holds

only the license for its use.

3. Prohibited matter

The user may not copy this software and sell or distribute it to a third party. However, when using this software on

a computer that is connected to the KEYENCE product that was purchased with this software, this software may

be installed onto multiple computers for the same company. Also, you may copy this software for the purpose of

keeping backup copy for your personal use.

4. Escape clause

KEYENCE Corporation shall not be held liable by the user or a third party for any damages arising from the use

of the software.

5. Cancellation of contract

KEYENCE may terminate this agreement if the user fails to comply with the terms of this agreement. In such

event, the user must either return the software and all copies to KEYENCE or destroy.

LS-Navigator-M-NO0-E

96136E

1

Page 4

MEMO

2

LS-Navigator-M-NO0-E

Page 5

Organization of the Manual

Chapter

1

Chapter

2

Chapter

3

Chapter

4

Chapter

5

Appendix

LS-Navigator

Overview

Getting Started

Names and Functions

of Parts of the Window

Operation Flow from

Startup to Shutdown

Functions and

Operation Procedures

Appendix

This chapter describes the key functions, the conditions for use, and the system

environment for the LS-Navigator.

This chapter describes how to connect the computer and the controller, and how to

install or uninstall LS-Navigator.

This chapter describes the names and functions of each part of the LS-Navigator

window.

This chapter describes the basic flow of operations for the LS-Navigator from startup

to shutdown.

This chapter describes the operation procedures and the functions for each menu in the

LS-Navigator.

This chapter describes error messages and shortcut keys.

1

2

3

4

5

A

LS-Navigator-M-NO0-E

3

Page 6

MEMO

4

LS-Navigator-M-NO0-E

Page 7

Table of Contents

Safety Precautions

Terms of the Software License Agreement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

License agreement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Organization of the Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 1 LS-Navigator Overview

1-1 LS-Navigator Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Controller program setting function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Backup and restore functions for all controller settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Measurement value monitoring and control function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Function for transferring measurement values to an Excel sheet. . . . . . . . . . . . . . . . . . . . . . . 1-4

Setting conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 System Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Getting Started

2-1 Connecting the Controller and the Computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2-2 Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Example of installation on Windows XP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3 Uninstalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Example of uninstallation on Windows XP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Chapter 3 Names and Functions of Parts of the Window

3-1 Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Names and functions of parts of the main window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-2 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Command names and functions for each menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-3 Tool Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Names and functions of the tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Chapter 4 Operation Flow from Startup to Shutdown

4-1 Basic Flow of Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-2 Basic Procedures for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

LS-Navigator-M-NO0-E

Operation flow from startup to shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Basic procedures from startup to shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

5

Page 8

Chapter 5 Operating and Setting Functions

5-1 Setting and Changing the Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting and changing the connected controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5-2 Reading and Saving Setting Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Reading setting files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Saving setting files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5-3 Setting and Changing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5-4 Viewing the Measurement Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-5 Sending, Receiving, and Initializing Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Sending settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Receiving settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Initializing setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5-6 Backing up or Restoring All Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Backing up all settings for the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Restoring all settings for the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5-7 Setting RS-232C Communication Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5-8 Verifying and Changing the Program No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5-9 Transferring the Measurement Values t

5-10 Settin

g the Measurement Conditions for the Program . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Area settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Output settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Settings list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

o Excel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Appendix

1. Error Message List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

During operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-2

When starting up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

General application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

2. Shortcut Key List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

3. Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

6

LS-Navigator-M-NO0-E

Page 9

1

LS-Navigator Overview

This chapter describes the key functions, the setting conditions,

and the system environment for the LS-Navigator.

1-1 LS-Navigator Overview....................................... 1-2

1-2 System Environment .......................................... 1-5

LS-Navigator-M-NO1-E

1-1

Page 10

1-1 LS-Navigator Overview

This chapter describes the functions and setting conditions for the LS-Navigator.

1

Controller program setting function

1. Receives program settings for the controller on the computer and allows the user to verify the data.

2. Sends settings created on the computer to the controller and sets the program.

3. Reduces the time for settings with copy and paste functions when making settings for multiple controllers or

programs.

The following settings (parameters) for the controller can be verified and changed. Use the controller to change

parameters that are not listed.

Valid parametersDefault values

[OUT1] [OUT2]

[Limit settings]

Limit UPPER 1 1

STA N DA R D 1 0 1 0

LOWER -1 -1

HH 40 40

HI 30 30

LO 0 0

LL -10 -10

HOLD-H ON/OFF OFF OFF

Setting value

HOLD-L ON/OFF OFF OFF

Setting value0 0

00

[Output settings]

Calculation A1 +1 0

A2 0 +1

Averaging times 512 512

Measurement mode NormalNormal

Self-timing time 100 100

Offset 0 0

Analog output Scaling value 1000 1000

+10V = 30 30

-10V = 0 0

[Area 1] [Area 2]

[Area settings]

HeadHead 1 Head 1

Area settings Ar

Edge detection threshold 50 50

[Calibration settings]

Calibration T1-A 0 0

ea DIA DIA

SEG (start

SEG (end) +3E +3E

Area check OFF OFF

T2-A 0 0

T1-B 0 0

T2-B 0 0

) +2E +2E

1-2

LS-Navigator-M-NO1-E

Page 11

1-1 LS-Navigator Overview

Backup and restore functions for all controller settings

1. Reads and backs up the settings for all 16 programs on the controller (all of the parameters for limit settings,

calibration settings, area settings, and output settings) and the environment settings on the computer.

2. Restores the settings from the backup file created on the computer, in the event that the settings are erased

from the controller.

Note

There is no limit to the settings (parameters) that can be backed up or restored for the controller. Even parameters that

cannot be set by the program setting function can be backed up or restored.

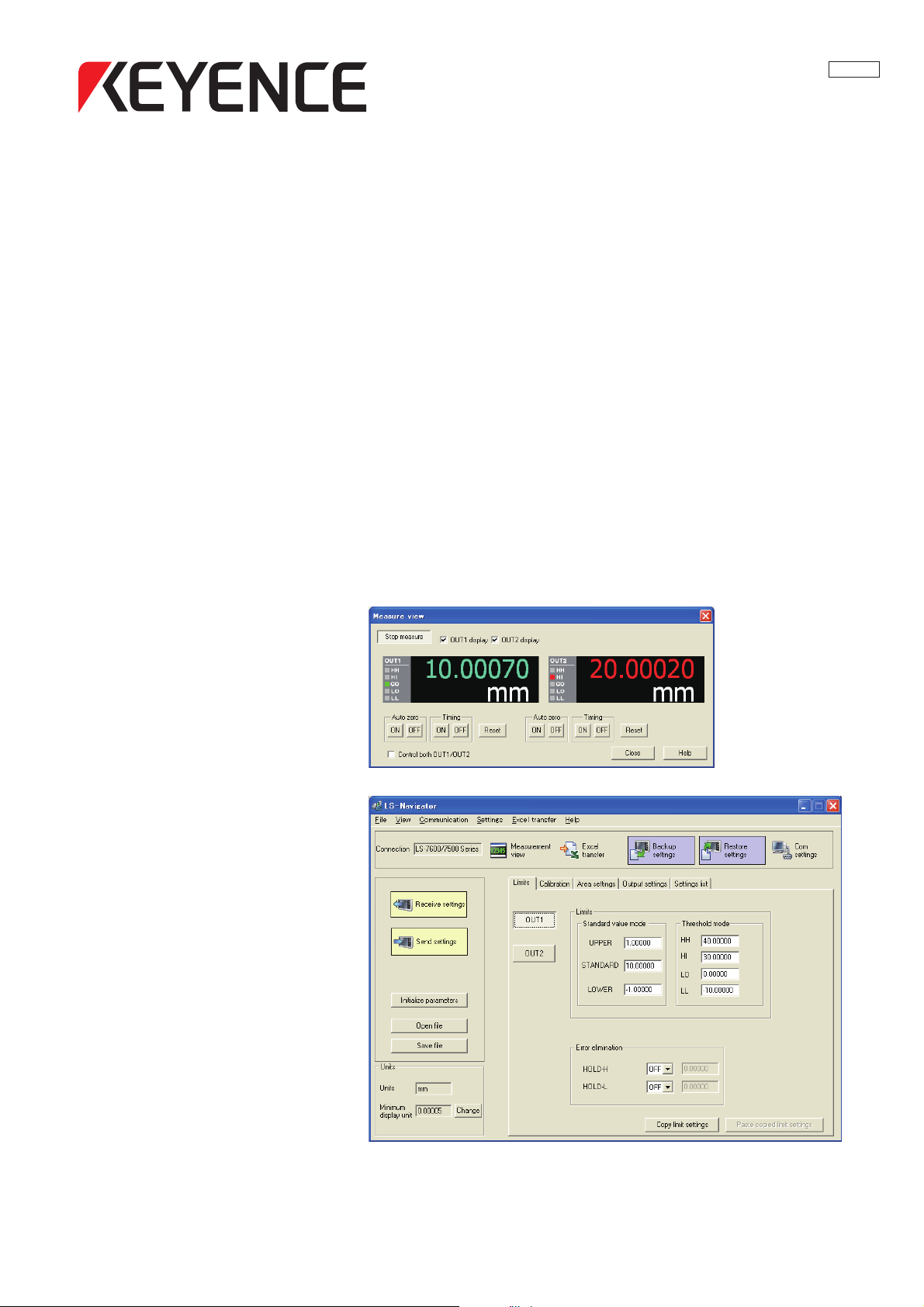

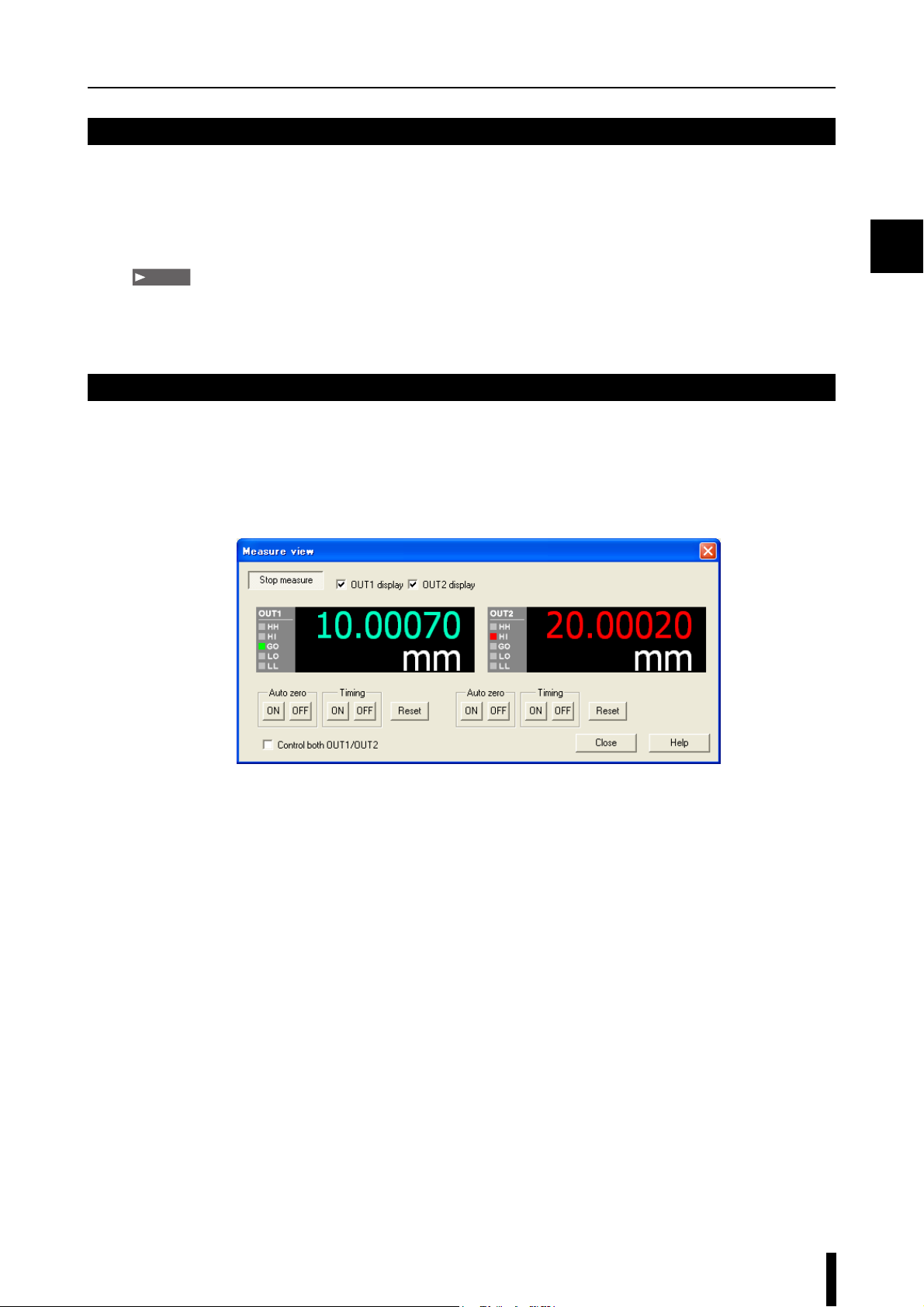

Measurement value monitoring and control function

The measurement values or judgment results that are measured on the controller can be monitored in real time on

the computer. The view can be selected from OUT1 display, OUT2 display, or simultaneous display of OUT1 and

OUT2. The value can be controlled by using auto-zero, timing, or the reset button.

1

Example of the measurement view menu

LS-Navigator-M-NO1-E

1-3

Page 12

1

1-1 LS-Navigator Overview

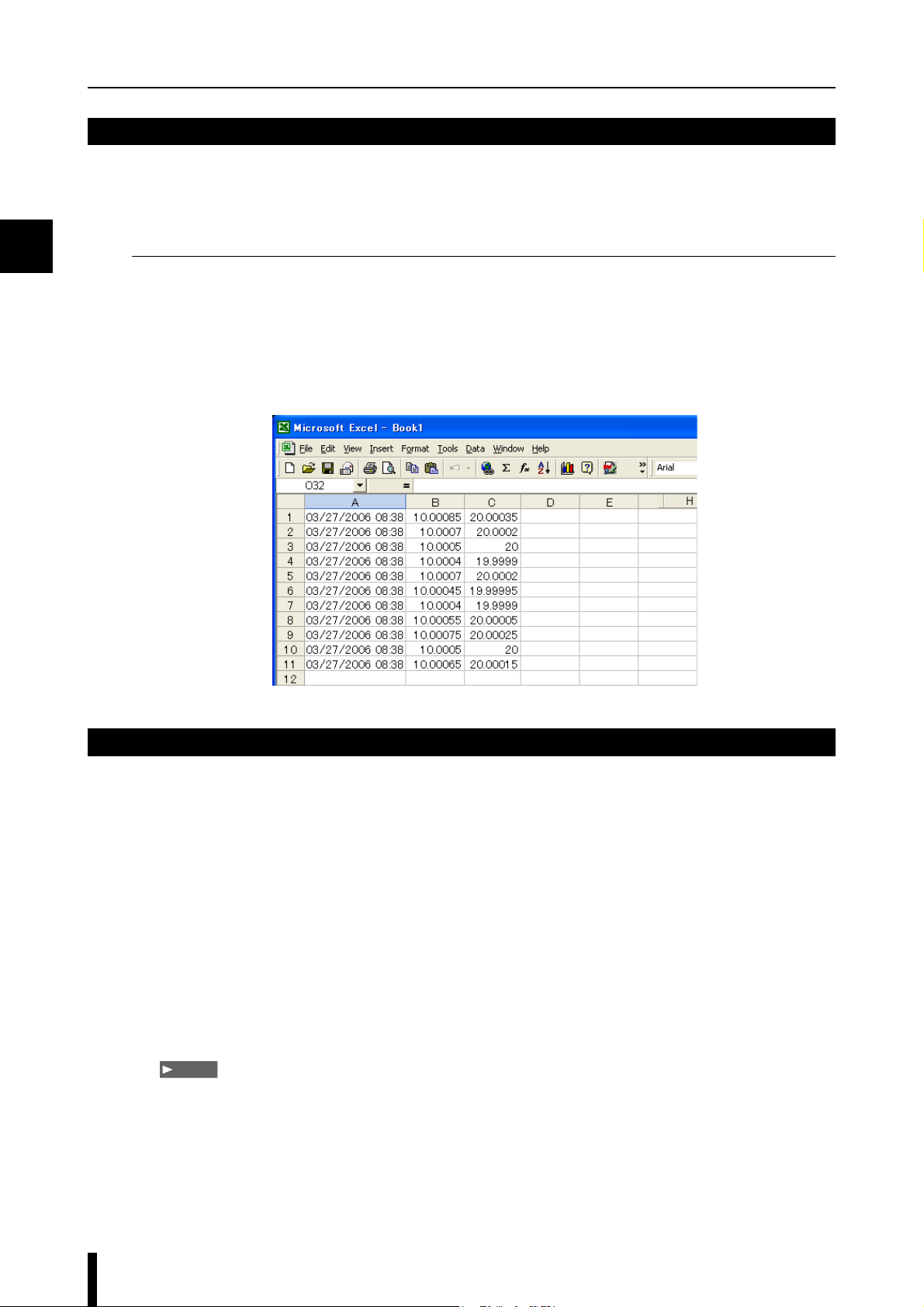

Function for transferring measurement values to an Excel sheet

The measured values that are received from the controller can be transferred to an Excel sheet with the

specifications from the specified logging method

Logging methods

1. Click logging : Transfers the measurement values when the button is clicked.

2. Timer logging : Transfers the measurement values at specified intervals.

3. External trigger logging: Transfers the measurement values when the controller communication setting is

[Printer Mode] and a trigger (timing input) is entered from the controller.

Example of transfer to an Excel sheet

Setting conditions

Operations that use LS-Navigator require certain setting conditions.

Set the following conditions before using the software.

1. Switch the controller to [Measurement] mode when communicating between the computer and the controller.

2. The connected model selected on the LS-Navigator (computer) must be the same as the controller model (LS-

7600/LS-7500/LS-7000 series).

3. The connected model selected on the LS-Navigator (computer) must be the same as the controller model (LS-

7600/LS-7500/LS-7000 series).

4. The settings for [Units] ([D-UNIT]) and [Minimum display unit] ([D-RES]) must be the same for the LS-

Navigator (computer) and the controller (LS-7600/LS-7500/LS-7000 series).

5. [PANEL] must be set for [P-SELECT] in the environment settings for the controller.

[NORMAL] must be set for [D-MODE].

Note

When [Ext trig logging] is selected as the method for transferring the measurement value to the Excel sheet, select

[PRINTER1] or [PRINTER2] for [D-MODE].

6. When [TERMINAL] is set for [P-SELECT] in the environmental settings for the controller, the selected

program number cannot be sent or read. Also, backup and restore functions cannot be executed for all of the

settings.

1-4

LS-Navigator-M-NO1-E

Page 13

1-2 System Environment

The following system requirements are necessary to use LS-Navigator.

CPU Pentium III 400 MHz or greater

Compatible OS

Memory capacity 64 MB or greater

Display VGA (800 x 600 pixels) or greater, 256 colors or greater

Hard drive space 10 MB or greater

Interface RS-232C (serial port) interface built-in

Excel Excel 2010/2007/2003/2002/2000

*1 Home Premium, Professional, and Ultimate editions each are supported.

*2 Ultimate, Business, Home Premium, and Home Basic editions each are supported. For Windows Vista, Ver.

1.2 or above are supported.

*3 Professional and Home Edition editions each are supported.

Windows 7

Windows Vista

Windows XP

Windows 2000 Professional

*1

*2

*3

1

LS-Navigator-M-NO1-E

1-5

Page 14

1

MEMO

1-6

LS-Navigator-M-NO1-E

Page 15

2

Getting Started

This chapter describes how to connect the computer and the controller,

and how to install or uninstall LS-Navigator.

2-1 Connecting the Controller and the Computer ..... 2-2

2-2 Installing ............................................................. 2-3

2-3 Uninstalling......................................................... 2-6

LS-Navigator-M-NO2-E

2-1

Page 16

2

2-1

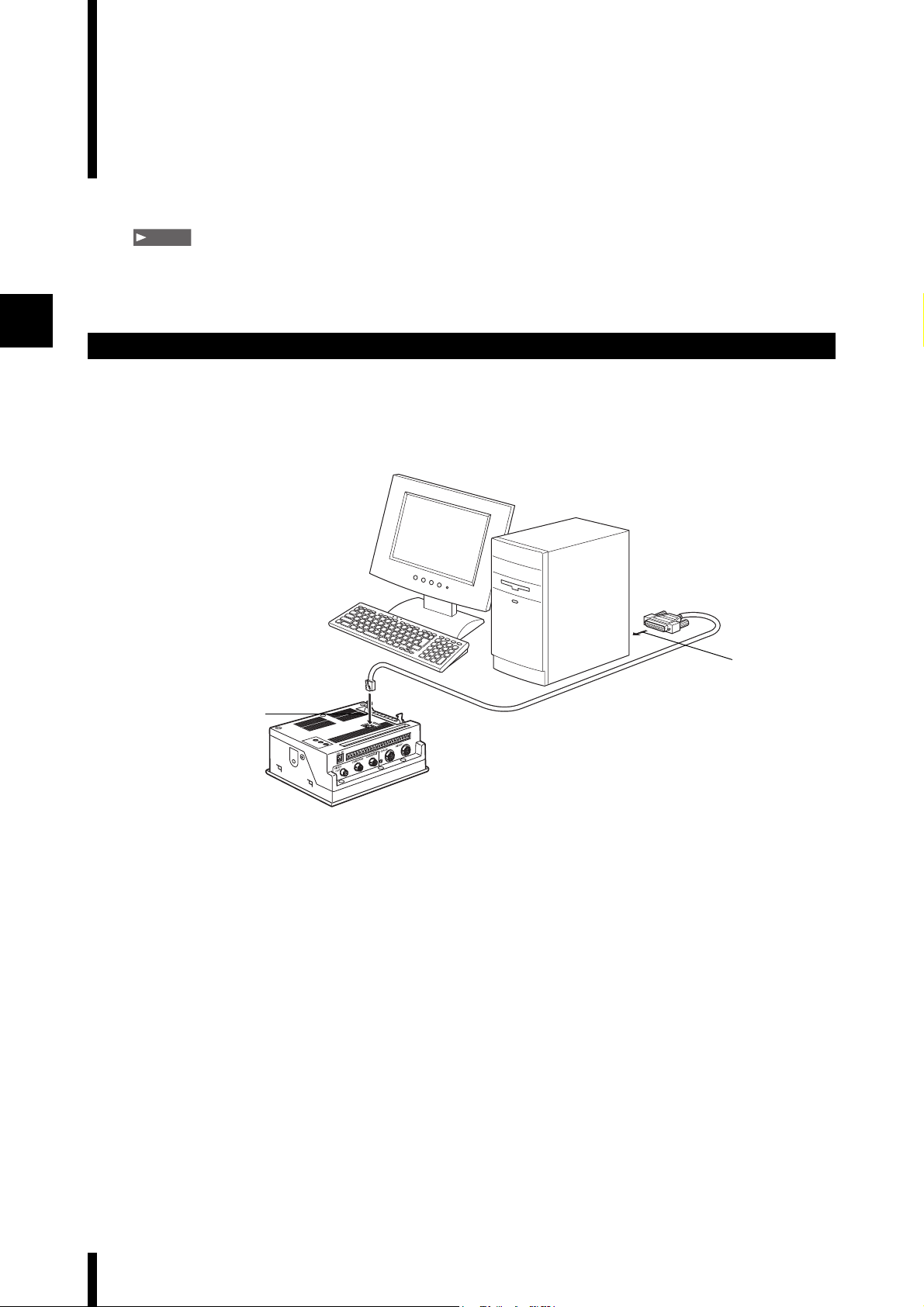

This section describes how to connect the controller and the computer by using RS-232C.

Note

This operation varies depending on the location and direction of the RS-232C port on the computer. Refer to the manual

that comes with the computer when connecting the RS-232C cord.

Connecting the Controller and the Computer

Connecting

Connect the controller (LS-7600/7500/7000) and the computer by using RS-232C.

Use the cord OP-35382 (D-sub 9-pin) or OP-25253 (D-sub 25-pin) for connection.

Connection diagram

Computer

2

RS-232C cord

1

Controller

• LS-7600 series

• LS-7500 series

• LS-7000 series

Connect to the RS-232C connector for the

1

controller by using the cord OP-35382 (D-

sub 9-pin) or OP-25253 (D-sub 25-pin).

Connect to the RS-232C port for the

2

computer by using the cord OP-35382 (D-

sub 9-pin) or OP-25253 (D-sub 25-pin).

This procedure describes and example when

using OP-25253 (D-sub 25-pin).

OP-35382 (D-sub 9-pin)

or

OP-25253(D-sub 25-pin)

2-2

LS-Navigator-M-NO2-E

Page 17

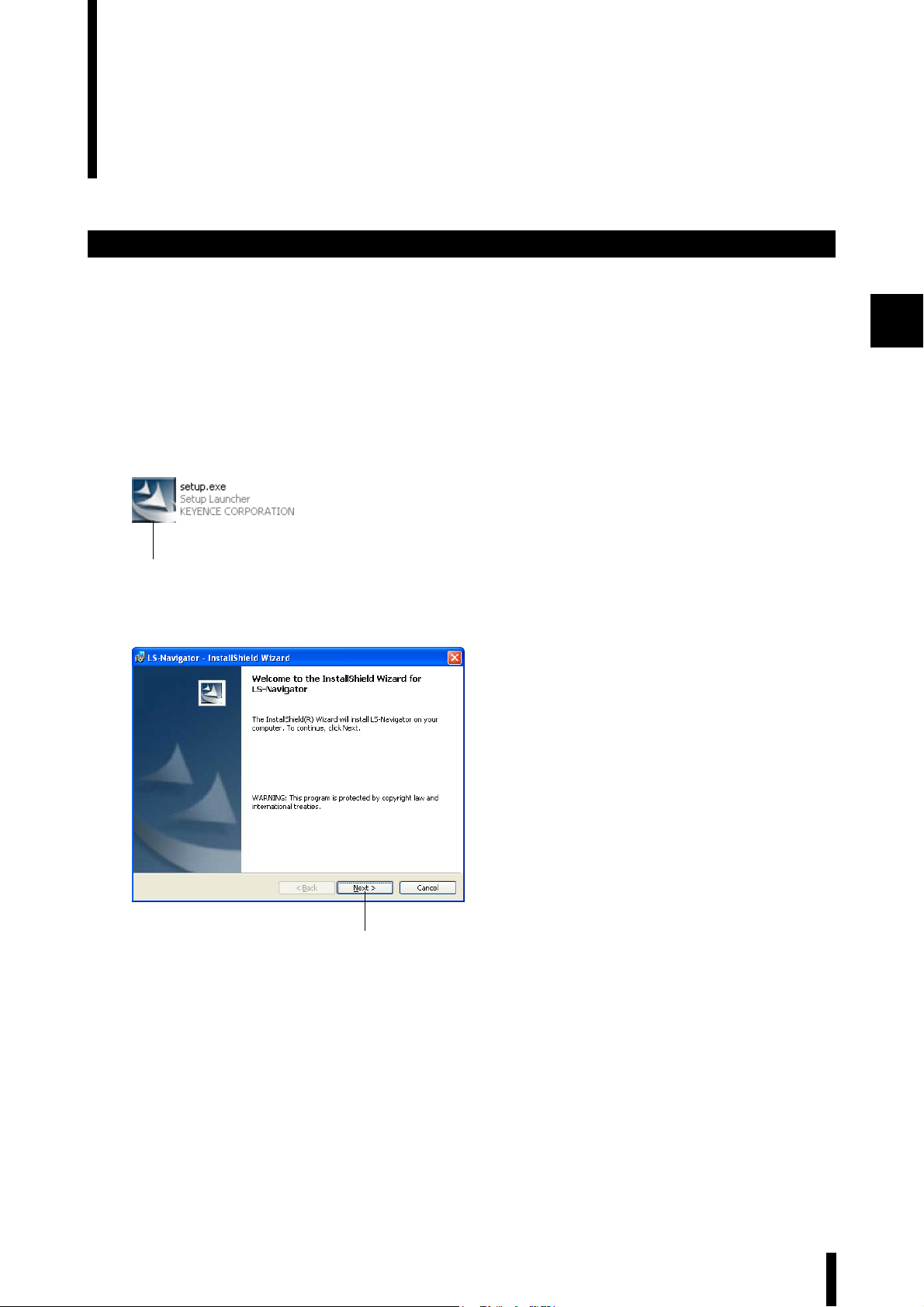

2-2 Installing

This section describes the procedures for installing LS-Navigator to a computer.

Example of installation on Windows XP

This procedure describes how to install the software on Windows XP.

• Close all active applications before starting the installation.

• When installing on Windows 7, Windows Vista, Windows XP Professional Edition or Windows 2000

Professional, log in with a user name that has Administrator rights.

Insert the CD that contains this software

1

into the CD-ROM drive of the computer.

Double click on [setup.exe] in the [LS-

2

Navigator Installer] folder.

The installation software starts up and the

“Welcome” window for the InstallShield Wizard

2

appears.

2

Click on the [Next] button.

3

The [Customer Information] dialog appears.

3

LS-Navigator-M-NO2-E

2-3

Page 18

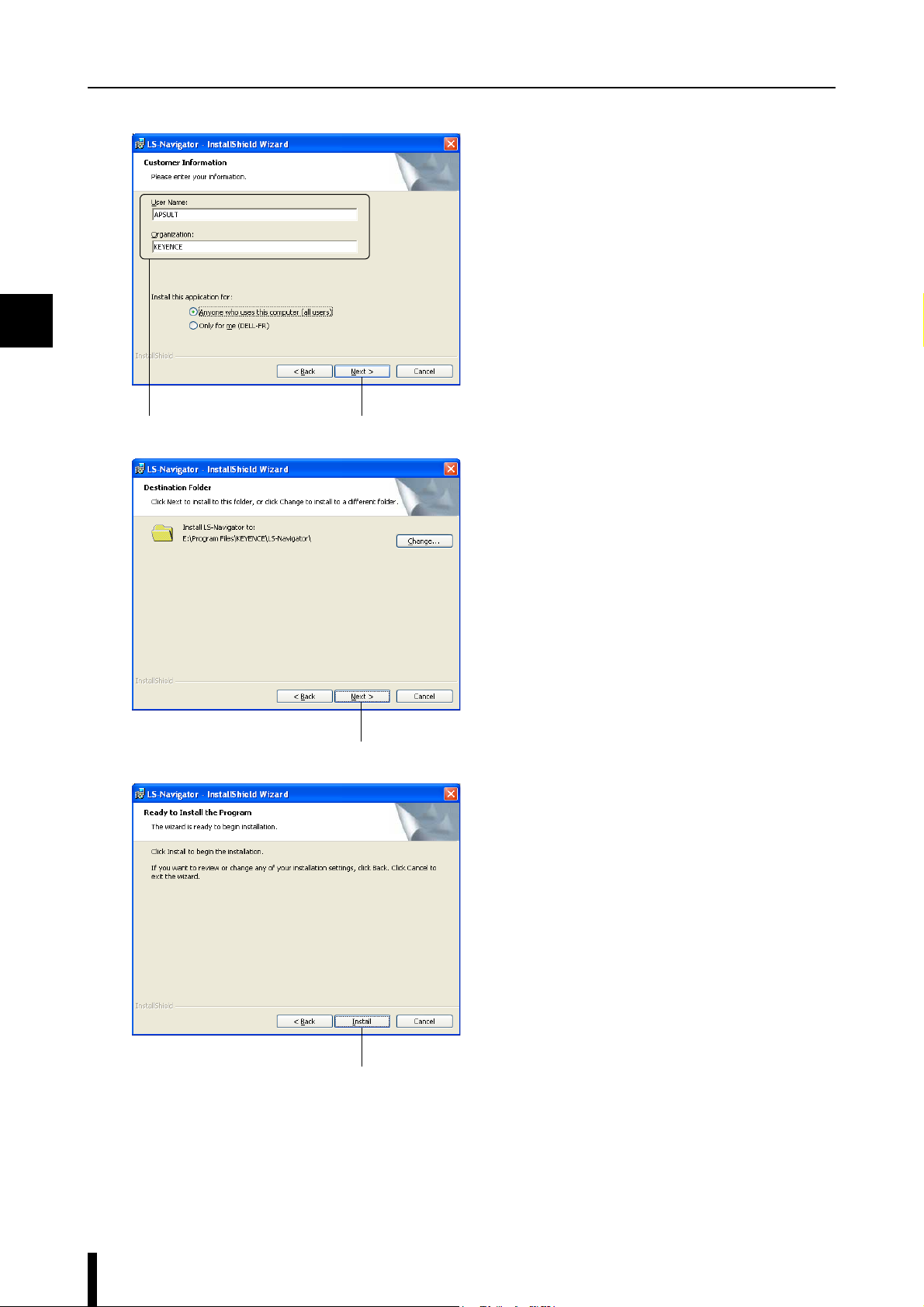

2

2-2 Installing

Enter the information into [User Name] and

4

[Company Name], and then click on the

[Next] button.

The [Destination Folder] dialog appears.

•

The default setting installs the software to "C:\Program

Files\KEYENCE\LS-Navigator".

• To install the software to a different folder, click

on the [Change] button and select the folder in the

[Change Current Destination Folder] dialog.

44

Click on the [Next] button.

5

A window appears with the message that the

program is ready to be installed.

5

Click on the [Install] button.

6

6

2-4

LS-Navigator-M-NO2-E

Page 19

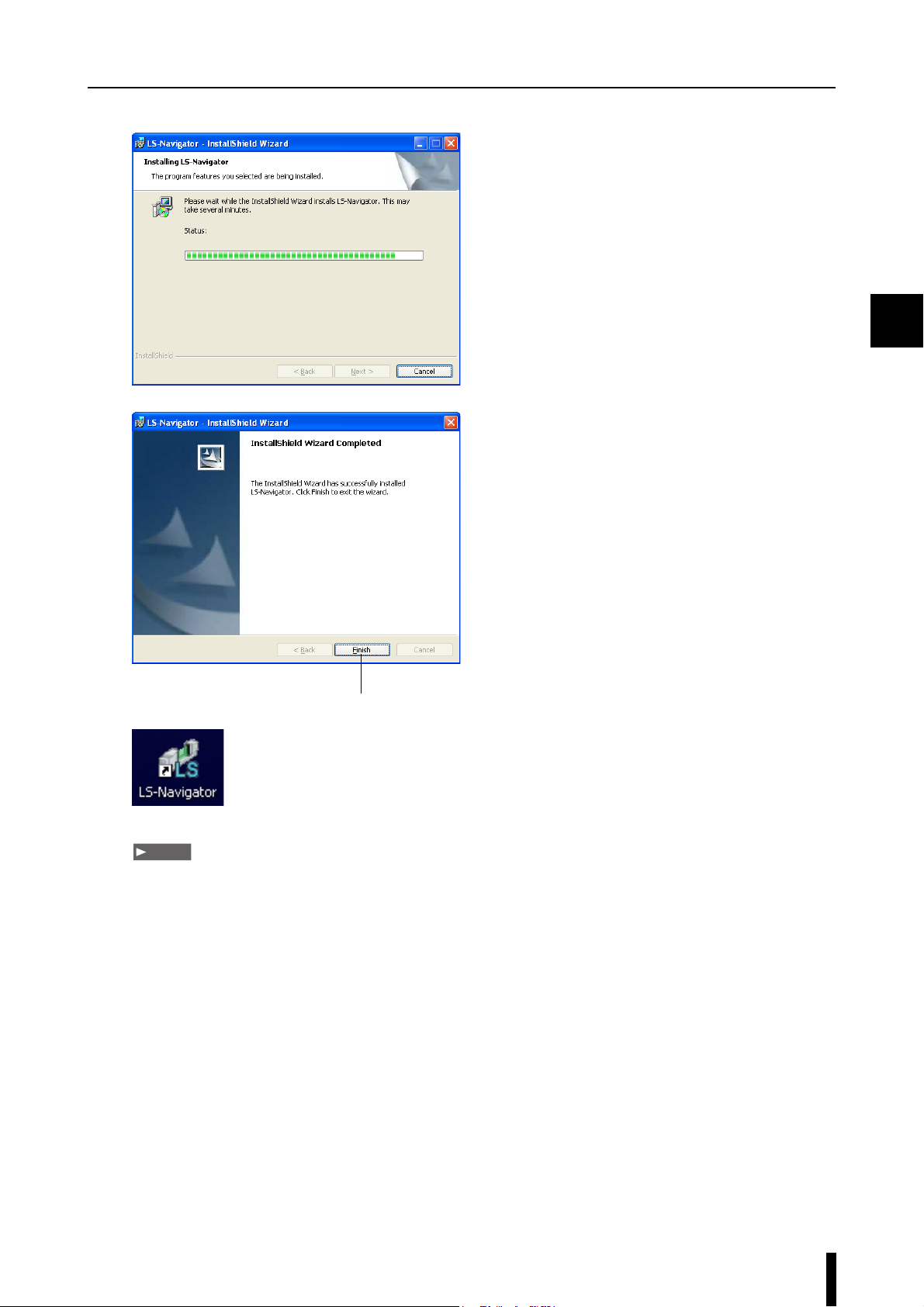

The program is installed.

7

When installation finishes, the

8

[InstallShield Wizard Completed] window

appears. Click on the [Finish] button to

complete the process.

An [LS-Navigator] shortcut appears on the

Desktop, and [LS-Navigator] appears under

[KEYENCE Applications] in the Windows

[Start] menu.

2-2 Installing

2

8

Note

The help file for this software was created in PDF file format. The viewing software Adobe Reader from Adobe Systems

Incorporated must be installed onto your computer to use the help file. We recommend using version 7.0 or greater. You

can download the latest version of Adobe Reader for free from the Adobe Systems Incorporated web site: http://

www.adobe.com

LS-Navigator-M-NO2-E

2-5

Page 20

2

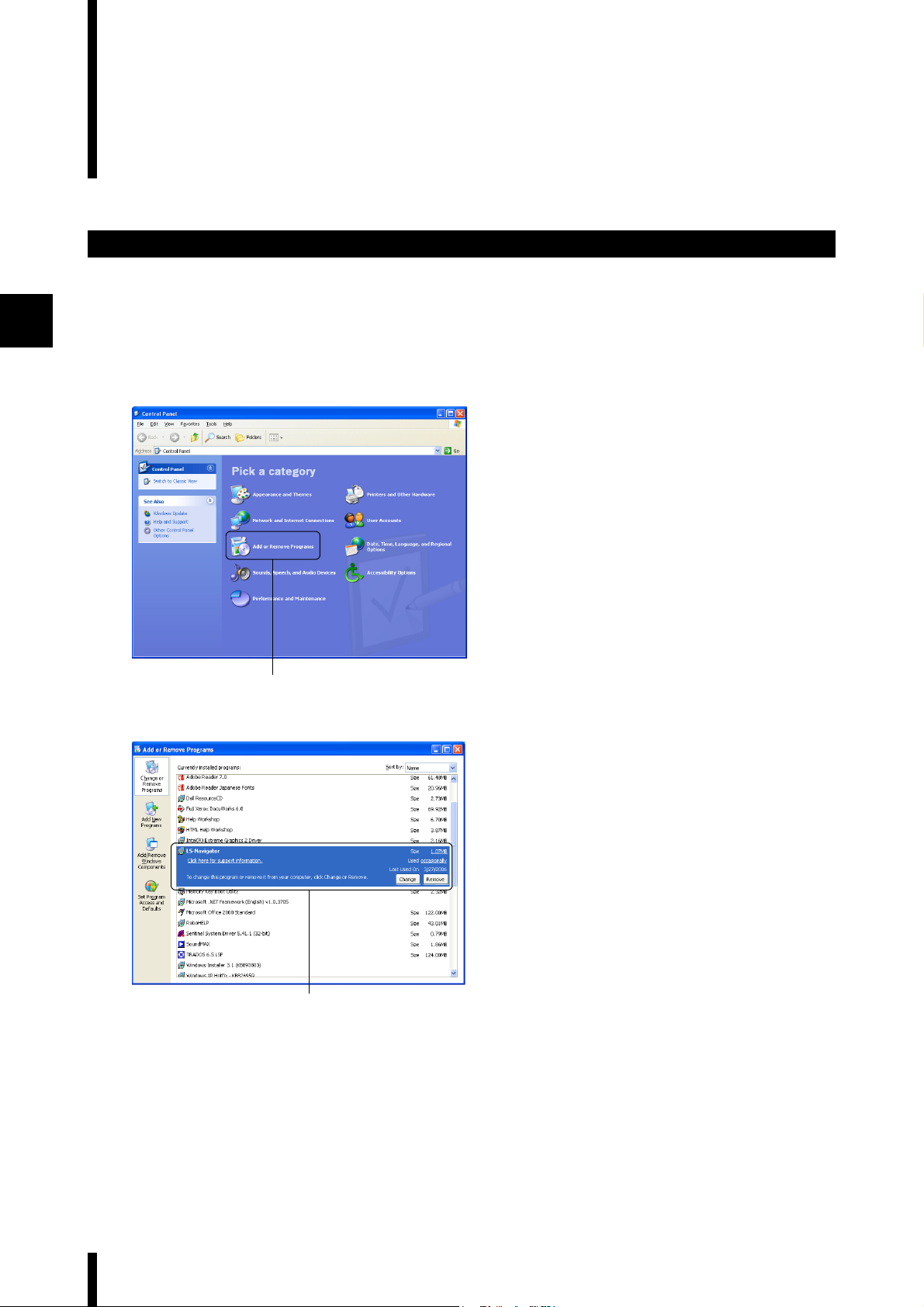

2-3 Uninstalling

This section describes the procedures for uninstalling LS-Navigator from a computer.

Example of uninstallation on Windows XP

This procedure describes how to uninstall the software on Windows XP.

• Close all active applications before starting the uninstall process.

• When uninstalling on Windows 7, Windows Vista, Windows XP Professional Edition or Windows 2000

Professional, log in with a user name that has Administrator rights.

Double click on [Add or Remove Programs]

1

in the Control Panel.

The [Add or Remove Programs] window appears.

1

Select [LS-Navigator] and click on

2

[Remove].

The [Add or Remove Programs] dialog appears.

Follow the on-screen directions to

2

If the program is not uninstalled after performing steps 1 to 3, continue on and perform the following steps 4 to 6.

Step 4: Insert the CD that contains the software into the drive and double click on [setup.exe] in the [LS-

Navigator Installer] folder. A window appears to confirm uninstallation for LS-Navigator.

3

uninstall the software.

2-6

Step 5: Click on the [Remove] button.

A window appears to confirm completion of the uninstallation.

Step 6: Click on the [Finish] button to complete the process.

LS-Navigator-M-NO2-E

Page 21

3

Names and Functions of

Parts of the Window

This chapter describes the names and functionsof each part of the LS-Navigator window.

3-1 Main Window...................................................... 3-2

3-2 Menu Bar............................................................ 3-3

3-3 Tool Bar .............................................................. 3-5

LS-Navigator-M-NO3-E

3-1

Page 22

3-1 Main Window

This section describes the main window.

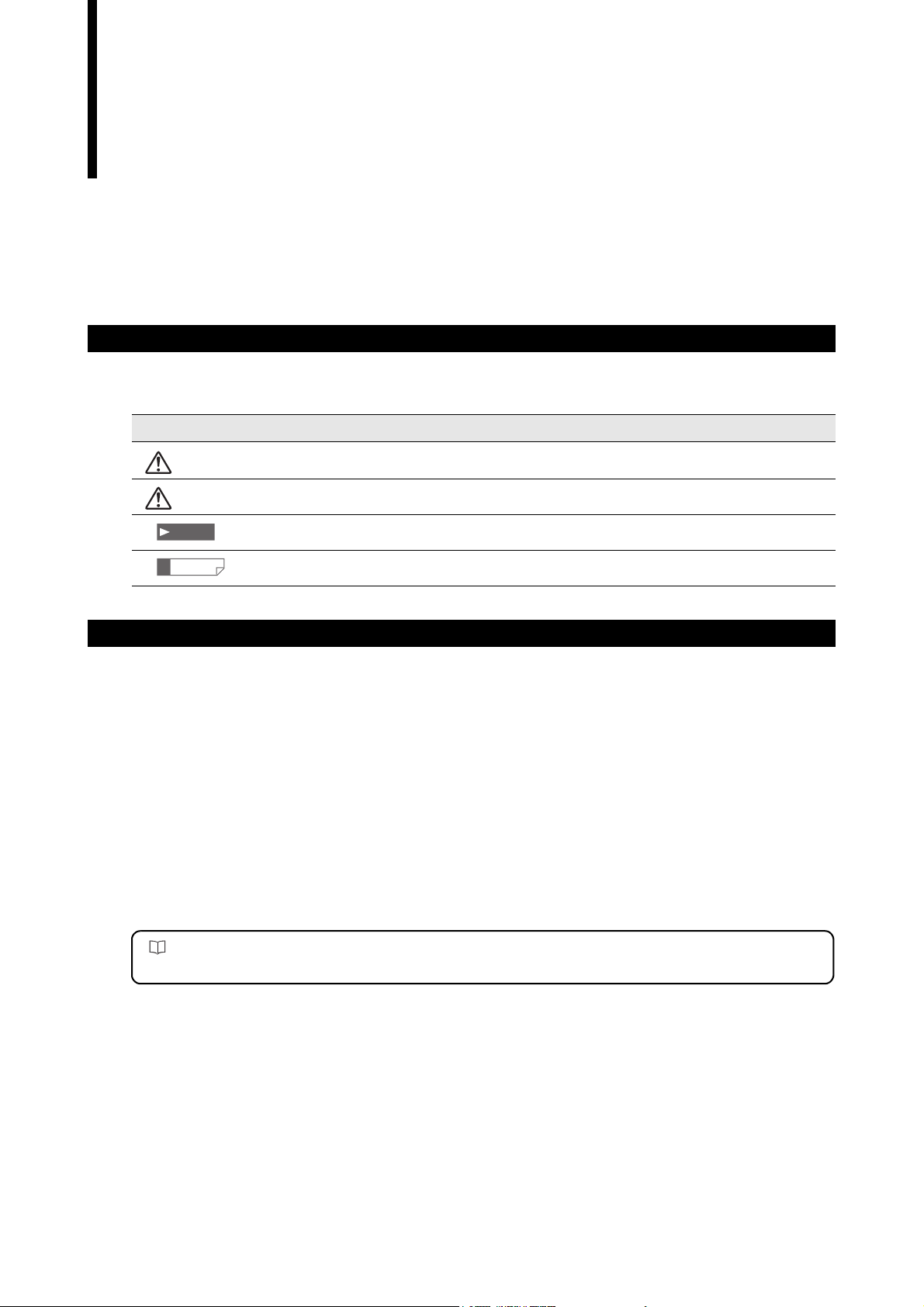

Names and functions of parts of the main window

3

Communication and file

operation area

Initializes parameters, opens or

saves setting files, and receives

or sends controller parameters.

Menu bar

Displays the operational

menus for LS-Navigator.

Too l bar

Displays the connected

model and buttons for

frequently used menus.

Program setting area

Set the parameters for [Limits],

[Calibration], [Area settin

[Outpu

t settings], and then check

the settings in [Settings list].

For more details, see "Setting

the Program" (Page 5-18).

gs], and

3-2

Unit setting area

Set and change the units and minimum

display unit for the selected program.

For more details, see “Setting and

Changing Units” (Page 5-5).

Copy and paste

Copies and pastes the parameters for each

of the measurement condition settings.

LS-Navigator-M-NO3-E

Page 23

3-2 Menu Bar

This section describes the command names and the functions for each menu in the menu bar.

Command names and functions for each menu

File menu

Command name Function Reference page

Open file Reads a saved setting file for the

controller.

Save file Saves a setting file for the

controller.

Exit Exits LS-Navigator. Page 4-5

View menu

Page 5-3

Page 5-4

3

Communication menu

Command name Function Reference page

Measure view Displays the measurement value

for the controller.

Command name Function Reference page

Send settingsSends parameters set on the

computer to the controller.

Receive settings Receives setting parameters for

the controller on the computer.

Backup settingsSaves all of the program setting

parameters for the controller on

the computer as a backup file.

Restore settings Restores all of the program setting

parameters for the controller from

a backup file saved on the

computer.

Page 5-6

Page 5-7

Page 5-8

Page 5-10

Page 5-11

LS-Navigator-M-NO3-E

3-3

Page 24

3

3-2 Menu Bar

Settings menu

Command name Function Reference page

Change connection Change the model of the

Communication

settings

Change program

No.

verification

Option Sets whether to display the

connected controller (LS-7600/LS-

7500 series or LS-7000 series).

Reference

•Changing the connected model

sets the following setting data to

the default values: Limit settings,

Calibration settings, Area

settings, and Output settings.

•Changing the connected model

also changes the extension for

the backup file.

Sets the communication

conditions for the RS-232C

connection that connects the

computer

Switches and verifies the program

No. for the connected controller.

“Welcome” message at startup.

and the controller.

Page 5-2

Page 5-12

Page 5-18

-

Excel transfer menu

Help

Command name Function Reference page

Start logging Performs settings for transferring

measurement values to an Excel

sheet or settings for the logging

method.

Command name Function Reference page

View help Displays this manual as a PDF file. -

AboutDisplays the version of LS-

Navigator.

Page 5-19

-

3-4

LS-Navigator-M-NO3-E

Page 25

3-3 Tool Bar

This section describes the names and functions of each tool in the tool bar.

Names and functions of the tools

Tool bar

Connection

Tool name Function Reference page

Connection Displays the model of the currently

connected controller.

3

Page 5-2

Measurement view

Excel transfer

Backup settings

Tool name Function Reference page

Measurement view Displays the measurement values

acquired from the controller in the

[Measure view] window.

Tool name Function Reference page

Excel transfer Records the measurement values

Tool name Function Reference page

Backup

settings

acquired from the controller in an

Excel sheet.

Saves all of the settings for the

controller on the computer as a

backup file.

Page 5-6

Page 5-19

Page 5-10

LS-Navigator-M-NO3-E

3-5

Page 26

3

3-3 Tool Bar

Restore settings

Communication settings

Tool name Function Reference page

Restore settings Restores all of the settings for the

Tool name Function Reference page

Communication

settings

controller from a backup file saved

on the computer.

Sets the communication

conditions for the RS-232C

connection that connects the

computer and the controller.

Page 5-11

Page 5-12

3-6

LS-Navigator-M-NO3-E

Page 27

4

Operation Flow from Startup

to Shutdown

This chapter describes the basic flow of operations for the LS-Navigator from startup to shutdown.

4-1 Basic Flow of Operations.................................... 4-2

4-2 Basic Procedures for Operation ......................... 4-3

LS-Navigator-M-NO4-E

4-1

Page 28

4

4-1 Basic Flow of Operations

The following chart shows the flow of operations for the LS-Navigator from startup to shutdown.

Operation flow from startup to shutdown

Connect the controller and the computer by using RS-232C.

Page 2-2

Start up the controller and set it to [Measurement] mode.

Next, start up the computer.

Page 1-4

Start up LS-Navigator.

Page 4-3

select the model for the controller that is connected to the computer and

When [Read controller

settings] is selected

Set the same RS-232C communication

conditions and settings as used on the

controller.

The settings are read from the

In the main window, the software can be used to display measurement

In the [Select the settings to display at startup] dialog,

choose the setting contents to read.

Page 5-12

controller.

Page 4-4

values, set programs on the controller, backup settings,

and send or receive setting files. Page 4-5

Page 4-4

When [Read from file] or [Start with

defaults] are selected, the software

reads the default values or the data

saved to a file.

Page 4-4

Set the same RS-232C communication

conditions and settings as used on the

controller.

Page 5-12

4-2

Exit LS-Navigator.

Page 4-5

LS-Navigator-M-NO4-E

Page 29

4-2 Basic Procedures for Operation

This chapter describes the basic procedures for operation for the LS-Navigator from startup to shutdown.

Basic procedures from startup to shutdown

Run LS-Navigator by double clicking on the

1

[LS-Navigator] shortcut icon on the

Desktop or by clicking on [All Programs] in

the Start menu and selecting [LSNavigator] from [KEYENCE Application].

The “Welcome” message appears. This message

indicates that there are restrictions on the

parameters that can be set on the software.

Note

Uncheck the box next to [Show this message on next

startup] to skip this message on the next startup.

For the parameters that can be set, see Page 1-2.

Click on the [Close] button.

2

The [Select the settings to display at startup]

window appears.

4

LS-Navigator-M-NO4-E

2

4-3

Page 30

4-2 Basic Procedures for Operation

Select the model of the controller

3

connected to the computer from the

following options.

LS-7000 Series, LS-7600/LS-7500 Series

Note

The model of the controller connected to the

computer must be the same as the model selected in

this window on LS-Navigator.

Select the method for reading the setting

4

contents from the following options.

Read controller settings, Read from file, Start

with defaults

4

4

3

■ When [Read controller settings] is

selected

After the [Communicating...] message appears,

the [Parameter update results] message is

displayed. Click on the [OK] button to display the

main window.

Note

When selecting [Read controller settings], click on

the [Communication Settings] button and change the

values in the [Communication settings] dialog so that

the values for the RS-232C communication

conditions on the software are the same as on the

controller. Click on the [Comm check] button to check

whether the RS-232C communication conditions are

the same on the controller and the computer.

For more details, see “Setting RS-232C

Communicatio

manual.

■ When [Read from file] is selected

The [Open] dialog appears. Select the file to load

and click on the [Open] button to display the

main window.

For more details, see “Reading setting files”

(Page 5-3).

n Conditions” (Page 5-12) in this

4-4

■ When [Start with defaults] is selected

The [Select the settings to display at startup]

window disappears and the main window is

displayed.

LS-Navigator-M-NO4-E

Page 31

Main window

4-2 Basic Procedures for Operation

Perform necessary actions such as

5

displaying the measurement values,

sending or receiving setting files, setting

the measurement conditions for the

program, or backing up and saving the

settings.

For more details, see “Chapter 5: Operating and

Setting Functions” (Page 5-1).

4

Select [Exit] from the [File] menu to exit LS-

6

Navigator.

6

LS-Navigator-M-NO4-E

4-5

Page 32

4

MEMO

4-6

LS-Navigator-M-NO4-E

Page 33

5

Operating and Setting

Functions

This chapter describes how to operate the functions and perform settings in the LS-Navigator.

5-1 Setting and Changing the Connection................ 5-2

5-2 Reading and Saving Setting Files ......................5-3

5-3 Setting and Changing Units................................ 5-5

5-4 Viewing the Measurement Value ........................ 5-6

5-5 Sending, Receiving, and Initializing Settings...... 5-7

5-6 Backing up or Restoring All Settings ................ 5-10

5-7 Setting RS-232C Communication Conditions...5-12

5-8 Verifying and Changing the Program No. ......... 5-18

5-9 Transferring the Measurement Values to Excel 5-19

5-10 Setting the Measurement Conditions for the

Program............................................................ 5-22

LS-Navigator-M-NO5-E

5-1

Page 34

5

5-1

This section describes how to set and change the controller connected to the computer.

Setting and changing the connected controller

Setting and Changing the Connection

Select [Change connection] from the

1

1

[Settings] menu.

A message appears to confirm changing the

model.

Click on the [OK] button.

2

The [Model selection] dialog appears.

2

Select the model to set.

3

For this example, select LS-7600/LS-7500 series.

43

Click on the [OK] button.

4

The connected model is changed and

[Connection] in the tool bar changes to [LS-7600/

LS-7500 Series].

Example of the [Connection] display

5-2

LS-Navigator-M-NO5-E

Page 35

5-2 Reading and Saving Setting Files

This section describes how to read setting files from the computer and save files to the computer.

Reading setting files

Select [Open file] from the [File] menu.

1

1

1

Or click on the [Open file] button in the

communication and file operation area.

The [Open] dialog appears.

5

Select a setting file (extension: *.lsc) and

2

click on the [Open] button.

The setting file is read.

2

LS-Navigator-M-NO5-E

5-3

Page 36

5-2 Reading and Saving Setting Files

Saving setting files

Select [Save file] from the [File] menu.

1

Or click on the [Save file] button in the

1

1

parameter settings area.

The [Save As] dialog appears.

Enter a file name and click on the [Save]

2

button.

The setting file is saved.

5

2

5-4

LS-Navigator-M-NO5-E

Page 37

5-3 Setting and Changing Units

Set the same values for [Units] and [Minimum display unit] on LS-Navigator as for the controller

program.

Click on the [Change] button in the unit

1

setting area.

The [Unit setting] dialog appears.

1

Use the pull-down menu to set the values

2

for [Units] and [Minimum display unit] the

same as in the controller.

Reference

Yo u can check the settings for [Units] and [Minimum

display unit] in the controller by looking at [Option]

settings in [Setting] mode.

See the “Minimum Display Unit” section in the

“User’s Manual” for each controller.

5

LS-Navigator-M-NO5-E

32

Click on the [OK] button to complete the

3

settings.

The set information appears in the unit setting

area.

5-5

Page 38

5

5-4 Viewing the Measurement Value

The measurement values that are measured on the controller can be monitored in real time on the computer.

Note

The communication settings for the computer and the controller must be set correctly for this function to operate.

The settings can be verified by clicking on the [Comm check] button in the [Communication settings] menu. This menu

can be displayed by clicking on the [Com settings] button on the tool bar.

See “Setting RS-232C Communication Conditions” (Page 5-12) in this manual.

Select [Measure view] from the [View]

1

1

1

menu.

Or click on the [Measurement view] icon on

the tool bar.

The [Measure view] window appears.

Click on the [Start measure] button in the

2

[Measure view] window.

The measurement values from the controller

appear in the [Measure view] window.

2

1 2

4 5

1. Switches between starting and stopping acquisition of the measurement value.

2. When a check mark is placed in the box, the measurement value for [OUT1] on the controller is displayed.

3. When a check mark is placed in the box, the measurement value for [OUT2] on the controller is displayed.

4. Displays the level of the limit judgment.

5. Turns on or off the [Auto zero] function.

See the “Automatic Zero Function” section in the “User’s Manual” for each controller.

6. Turn this option on to control both OUT1 and OUT2 simultaneously.

7. Turns on or off [Timing].

Use with the measurement mode function to control the measurement.

8. Resets the measurement values.

6

3

8

7

5

7

34

8

5-6

LS-Navigator-M-NO5-E

Page 39

5-5

This section describes how to send and receive setting files between the computer and

controller, as well as how to initialize them.

Sending settings

Sending, Receiving, and Initializing Settings

Select [Send settings] from the

1

1

[Communication] menu.

Or click on the [Send settings] button in

the communication and file operation area.

The [Send] dialog appears.

Select either [Current program No.] or

2

[Specify the program No.] and select a

program No. from the pull down menu.

Click on the [OK] button, and the

3

[Communicating] dialog appears.

32

When the communication is complete, the

[Parameter update results] window appears and

the sent parameters are displayed.

5

LS-Navigator-M-NO5-E

5-7

Page 40

5-5 Sending, Receiving, and Initializing Settings

4

Click on the [Close] button to complete the

4

process.

5

Receiving settings

Select [Receive settings] from the

1

[Communication] menu.

1

Or click on the [Receive settings] button in

the communication and file operation area.

The [Receive] dialog appears.

Select either [Current program No.] or

2

[Specify the program No.] and select a

program No. from the pull down menu.

Click on the [OK] button, and the

3

[Communicating...] dialog appears.

5-8

32

LS-Navigator-M-NO5-E

Page 41

5-5 Sending, Receiving, and Initializing Settings

When the communication is complete, the

[Parameter update results] window appears and

the received parameters are displayed.

Click on the [Close] button to complete the

4

process.

4

Initializing setting parameters

This section describes how to initialize setting parameters read by LS-Navigator.

1

Click on the [Initialize parameters] button

1

in the parameter settings area.

A message appears to confirm that all of the

parameters will be initialized.

5

LS-Navigator-M-NO5-E

Click on the [OK] button to initialize all of

2

the setting parameters on the LSNavigator

Reference

The setting parameters on the controller are not

initialized. Send the settings to initialize the setting

parameters on the controller.

2

.

5-9

Page 42

5-6

This section describes how to back up or restore all 16 programs and environment setting

information for the controller.

Backing up all settings for the controller

Backing up or Restoring All Settings

Select [Backup settings] from the

1

[Communication] menu.

Or click on the [Backup settings] icon on

the tool bar.

1

1

The [Save As] dialog appears.

5

Enter a file name and click on the [Save]

2

button.

The [Communicating...] dialog appears and the

software begins backing up the setting parameters

for the controller. After the backup finishes, the

backup completion message appears.

The backup files use the following extensions.

• For LS-7600/7500 : .lsbh

• For LS-7000 : .lsbs

2

Click on the [OK] button to complete the

3

process.

5-10

3

LS-Navigator-M-NO5-E

Page 43

Restoring all settings for the controller

1

1

5-6 Backing up or Restoring All Settings

Select [Restore settings] from the

1

[Communication] menu.

Or click on the [Restore settings] icon on

the tool bar.

The [Open] dialog appears.

Enter the name of the backup file that you

2

want to restore and click the [Open] button.

The [Communicating...] dialog appears and the

software begins backing up the settings for the

controller. After the restoration finishes, the

restoration completion message appears.

5

2

Click on the [OK] button to complete the

3

process.

3

LS-Navigator-M-NO5-E

5-11

Page 44

5

5-7

This section describes how to set the same RS-232C communication conditions on LS-

Navigator as used on the connected controller.

Setting RS-232C Communication Conditions

The software can check the following RS-

1

232C communication conditions for the

controller environment settings.

• Baud rate ([BAUDRATE])

• Stop bit ([STOPBIT])

• Data length ([D-LENGTH])

• Data mode ([D-MODE])

• Data send mode ([D-SEND])

Use the following procedure to check the RS232C communication conditions.

For the LS-7600/7500 series

Press and hold the [ESCAPE] button while in

[Setting] mode for at least three seconds, and then

check the settings in the [Environment settings]

menu that appears.

For more details, see “Environment Settings” in

the “User’s Manual” for the LS-7600/7500 series.

For the LS-7000 series

Press the [FUNC] key once during [Program]

view, and then check the settings in the [RS232C] view that appears.

For more details, see “RS-232C” in the “User’s

Manual” for the LS-7000 series.

Select [Communication settings] from the

2

[Settings] menu.

2

2

Or click on the [Com settings] icon on the

tool bar.

The [Communication settings] dialog appears.

5-12

LS-Navigator-M-NO5-E

Page 45

5-7 Setting RS-232C Communication Conditions

Click on the [Setting wizard] button in the

3

[Communication settings] dialog.

[Setting Wizard] is different for the LS-7600/

7500 series and the LS-7000 series starting from

step 4.

3

For the LS-7600/7500 series

For the LS-7000 series

Click on the [Next] button.

4

A confirmation message on the [Setting Wizard]

asks whether the RS-232C cable is connected to

the communication port.

4

5

LS-Navigator-M-NO5-E

4

5-13

Page 46

5-7 Setting RS-232C Communication Conditions

5

For both the LS-7600/LS-7500 series and

the LS-7000 series

5

For the LS-7600/7500 series

Select the port for RS-232C

5

communication.

Select between COM1 to COM8 from the pulldown menu.

Select the serial port number on the computer for

the connected controller.

Click on the [Next] button.

6

A message appears on the [Setting Wizard],

instructing the user to switch the controller to the

environment settings display. Use the following

procedure to display the environment settings for

the controller.

For the LS-7000 series

■ For the LS-7600/7500 series

Press and hold the [ESCAPE] button for at least

three seconds while in [Setting] menu of the

controller. The controller switches to the

environment settings display.

■ For the LS-7000 series

Press the [PROG] key while pressing the [FUNC]

6

key in the sub-display menu for the controller.

The display switches to [PROG]. Press the

[FUNC] key to switch the display to [RS-232C].

5-14

6

LS-Navigator-M-NO5-E

Page 47

For the LS-7600/7500 series

5-7 Setting RS-232C Communication Conditions

Click on the [Next] button.

7

A message appears on the [Setting Wizard],

instructing the user to set the same values as

shown for the communication settings on the

controller.

The communication settings for the LS-7600/7500

series and the LS-7000 series are different in the

following manner.

(1)

(2)

(3)

(4)

6

(1) Set the same value for [Baud rate] as displayed on the controller.

Select among 1200, 2400, 4800, 9600, 19200, 36400, 57600, or 115200 from the pull-down menu.

(2) Set the same value for [Parity] as displayed on the controller.

Select among NONE, ODD, or EVEN from the pull-down menu.

(3) Set the same value for [Stop bit] as displayed on the controller.

Select between 1 and 2 from the pull-down menu.

(4) Set the same value for [Data length] as displayed on the controller.

Select between 7 and 8 from the pull-down menu.

5

LS-Navigator-M-NO5-E

5-15

Page 48

5

5-7 Setting RS-232C Communication Conditions

For the LS-7000 series

The following steps describe the different methods for checking each of the communication conditions on the

controller

(1) Baud rate

Press the [ENT] key on the controller to switch the display

to [BAUDRATE].

Set the same value for [Baud rate] as displayed on the

controller.

Select among 1200, 2400, 4800, 9600, 19200, 36400,

57600, or 115200 from the pull-down menu.

(2) Parity

Press the [FUNC] key on the controller to switch the display

to [PARITY].

Set the same value for [Parity] as displayed on the

controller.

Select among NONE, ODD, or EVEN from the pull-down

menu.

(3) Stop bit

(4) Data length

Press the [FUNC] key on the controller to switch the display

to [STOPBIT].

Set the same value for [Stop bit] as displayed on the

controller.

Select between 1 and 2 from the pull-down menu.

Press the [FUNC] key on the controller to switch the display

to [D-LENGTH].

Set the same value for [Data length] as displayed on the

controller.

Select between 7 and 8 from the pull-down menu.

5-16

LS-Navigator-M-NO5-E

Page 49

5-7 Setting RS-232C Communication Conditions

Check that the [D-MODE] setting on the

8

controller is [NORMAL], and then click on

the [Next] button on the [Setting Wizard].

For the LS-7600 series

For the LS-7000 series

After checking all of the messages, click on

9

the [End] button.

The display returns to the [Communication

settings] window. Use the following procedure to

check the [D-MODE] setting for the controller.

■ For the LS-7600/7500 series

Press and hold the [ESC] button for at least three

seconds while in [Setting] menu of the controller.

Check the [D-MODE] setting in the

[Environment Setting] menu that appears.

■ For the LS-7000 series

Press the [FUNC] key four times in the [RS-232C

display] menu for the controller. Press the [▲]

9

and [▼] keys to select [D-MODE] and check the

setting.

5

10

9

Switch the controller to [Measurement]

10

mode and click on the [Comm check]

button in the [Communication settings]

dialog for LS-Navigator.

The “Connection status OK” message appears

and settings are completed.

LS-Navigator-M-NO5-E

5-17

Page 50

5

5-8

This section describes how to change and verify the program No. that is read by the computer.

Verifying and Changing the Program No.

Select [Change program No. verification]

1

from the [Settings] menu.

The [Change program No. verification] dialog

1

appears.

Note

For the LS-7600/7500 series, the displayed value for

program No. is “00 to 15”.

For the LS-7000 series, the displayed value for

program No. is “0-9, A-F”.

To verify the program No. that is currently being read,

click on the [Check] button.

To c h ange the program No., select the program No.

to read from the pull-down menu

and click on the [Run] button.

Note

When switching the program number, [PANEL] must be set for [P-SELECT] in the environment settings for the controller.

For more details, see the “Details of Environment Settings” section in the “User’s Manual” for each controller.

5-18

LS-Navigator-M-NO5-E

Page 51

5-9

This section describes how to transfer measurement values that are read from the controller to

an Excel sheet.

Transferring the Measurement Values to Excel

Select [Start logging] from the [Excel

1

1

1

transfer] menu.

Or click on the [Excel transfer] icon on the

tool bar.

The [Logging] dialog appears.

Set the appropriate values for the transfer

2

items, the transferring sheet name, the

logging method, and any other required

parameters.

Select the items to transfer to the Excel sheet.

Items that can be transferred: Date (mdyhms),

OUT1, OUT2

Set the name of the Excel sheet to

transfer information to, and set the cell to

start writing.

Set the logging method and logging

cycle (seconds).

From the pull-down menu, select

one of the following three types of

logging methods: [Click logging],

[Timer logging], and [Ext trig

logging].

When [Timer logging] is selected,

set [Logging cycle]. The cycle can

be set in 1 second intervals from 1

to 600 seconds.

When [Ext trig logging] is selected,

select [PRINTER1] or [PRINTER2]

for [D-MODE].

3

5

LS-Navigator-M-NO5-E

5-19

Page 52

5-9 Transferring the Measurement Values to Excel

For click logging

For timer logging

Click on the [Start logging] button.

3

The dialog for the selected logging method

appears.

Data is transferred to the Excel sheet every time

the [Measurement value output] button is clicked.

5

After clicking on the [Start output] button, data is

transferred to the Excel sheet at the intervals set

in [Logging cycle].

The [Start output] button changes to the

[Outputting...] button.

5-20

LS-Navigator-M-NO5-E

Page 53

For trigger logging

PRINTER1

Tr ansfers only the

measurement values.

PRINTER2

Tr ansfers the measurement

values and the limit

judgment results.

5-9 Transferring the Measurement Values to Excel

After clicking on the [Start receiving data]

button, data is transferred to the Excel sheet every

time there is a timing input from the input

terminal on the controller.

The data outputs as seen to the left with [D-

MODE] settings.The [Start receiving data] button

changes to the [Standby...] button.

Note

・ When performing trigger logging, set the same settings

for LS-Navigator and [D-MODE] in the controller, and

then select [PRINTER1] or [PRINTER2].

・ [D-SEND] on the controller can be set to “S1: Output

All Measured Values” or “S2: Output NG Measured

Valued”.

・ To stop trigger logging and return the LS-Navigator to

normal operations, set [D-MODE] in the controller to

[NORMAL].

For more details, see the “Connecting to

Printers” section in the “Userís Manual” for

each controller.

5

Example of transfer to an Excel sheet

(for timer logging)

Click on the [Measurement value output],

4

[Start output], or [Start receiving data]

button in the dialog.

The measurement values are transferred to the

Excel sheet.

Note

Measurement values cannot be transferred if the

Excel file is being used for other applications.

To stop the timer logging, click on the

5

[Outputting...] button.

To stop external trigger logging, click on

the [Standby...] button.

Note

The output cycle for timer logging uses the internal

clock in the computer.

Cumulative errors in the internal clock may lead to

errors in the output cycle.

LS-Navigator-M-NO5-E

5-21

Page 54

5-10

This section describes how to set the measurement conditions for [Limits], [Calibration], [Area

settings], and [Output settings].

Setting the Measurement Conditions for the Program

Limits

Click on the [Limits] tab in the program

1

setting area.

The [Limits] window appears.

Set [Limits] for OUT1 and OUT2.

2

5

Set the standard value, as well as the

upper and lower limits for the deviation.

The measurement is judged as one of

three levels: HI, GO, or LO.

1

Select the output (OUT1

or OUT2).

Copies the limit settings from

OUT1 or OUT2 and pastes

them into OUT1 or OUT2.

Set the upper limits and lower limits with

absolute values. The measurement is judged

as one of five levels: HH, HI, GO, LO, or LL.

Reference

The range for each parameter depends on the

settings for [Units] and [Minimum display unit].

If dust or foreign objects become attached to

the measurement target, the displayed

measurement value may become extremely

inaccurate. If dust or foreign objects become

attached to the measurement target, the

displayed measurement value may become

extremely inaccurate

set on, measurement values that exceed the

upper limit for errors (HOLD-H) or fall below the

lower limit for errors (HOLD-L) are automatically

detected and eliminated. Select [ON] from the

pull-down menu and enter the upper limit or

lower limit for errors in the text box.

. When this para

meter is

5-22

Note

・ Use the controller to change settings in limit mode.

For more details, see the “Tolerance Settings” section in the “User’s Manual” for each controller.

・ Set the same values for [Units] and [Minimum display unit] in the settings for the controller and LS-Navigator. (Refer to

Page 5-5.)

LS-Navigator-M-NO5-E

Page 55

Calibration

5-10 Setting the Measurement Conditions for the Program

Click on the [Calibration] tab in the

1

program setting area.

The [Calibration] window appears.

Set [Logic calibration] for area 1 and area

2

2.

1

Enter the values for two points (target 1 and target

2) on the workpiece.

The values are displayed as follows:

Before calibration After calibration

FirstT1-A: Displayed

Second T2-A: Displayed

The value for calibration span is automatically

calculated after the above values are entered.

The calibration span is display

value.

value for target 1

before calibration

value for target 2

before calibration

T1-B: Displayed

value for target 1

after calibration

T2-B: Displayed

value for target 2

after calibration

ed as a ref

erence

5

Select the area (area 1 or

area 2).

Copies the calibration settings

from area 1 or area 2 and pastes

them into area 1 or area 2.

Note

When setting the calibration mode, enter values

that meet the following relationship:

T1-A < T2-A and T1-B < T2-B

Set the values so that the calibration span is

greater than 0.5 and smaller than 2.0.

Note

These settings are effective when [Calibration

Settings] for the controller is set to logic calibration

mode.

For more details, see the “Calibration Settings”

section in the “User’s Manual” for each controller.

LS-Navigator-M-NO5-E

5-23

Page 56

5

5-10 Setting the Measurement Conditions for the Program

Area settings

1

Click on the [Area settings] tab in the

1

program setting area.

The [Area settings] window appears.

Set which area of the target to measure.

2

Select the head (head 1 or head 2) to use

for measurement.

Select [ON] or [OFF] from the pull-down

menu. When the parameter is set to [ON],

set the total number of edges for

measurement. When the value has a

different number of edges, the

measurement value becomes invalid. This

prevents the output of measurement values

that are incorrect due to dust or oil on the

measurement head.

Parameter range: 2 to 127

Set two areas

(area 1 or area

2) on the

measurement

target.

Select the measurement method from the pull-down menu.

Measurement

method

DIA Set this method when measuring the outer diameter of a round bar or a transparent body. This method

T- E D G E Set this method when measuring the gap between rollers or when setting a position. T-EDGE measures the

E Set this

B-EDG

SEG Set this method when measuring the inner diameter of a disk or when measuring pitch.

Set the detection threshold value

when measuring a target that has high

transparency. Enter a value into the

text box.

Parameter range: 10 to 99%

Type of measurement

measures the target from the first falling edge (an edge where a bright portion becomes dark) to the last

rising edge (an edge where a dark portion becomes bright).

width of the first bright portion on the top of the target.

method when measuring the gap between rollers or when setting a position. B-EDGE measures the

width of the last bright portion on the top of the target.

This method measures the width between two specified edges: the start edge where measurement is

started and the end edge where measurement is finished.

Parameter range: 0, ±1 to ±127, E or P

Copies the calibration settings from area 1

or area 2 and pastes them into area 1 or

area 2.

5-24

LS-Navigator-M-NO5-E

Page 57

Output settings

5-10 Setting the Measurement Conditions for the Program

Click on the [Output settings] tab in the

1

program setting area.

The [Output settings] window appears.

Various processes are performed on the

2

values measured from area 1 and area 2,

and these results are output as OUT1 and

OUT2.

1

When the measurement mode is set to

[Self-timing hold] mode, set the selftiming time.

Parameter range: 1 to 9999 ms

This parameter can only be set during

[Self-timing hold] mode.

Calculations are performed using the

measurement values obtained from

measuring the two areas set in [Area

settings].

Select a value from the pull-down menu.

Valid settings:

0, +1, +1/2, -1, -1/2

Set the number of times for averaging from

the pull-down menu.

Set a larger value to average variations in

more

the measurement value and pro

stable result. Set a smaller value to

measure at high speeds.

Valid number of times for averaging:

1, 2, 4, 8, 16, 32, 64, 128, 256, 512, 1024,

2048, 4096

Select the method for output. Some methods

output the raw measurement value, while

others continuously measure a changing

value using a timing and output the maximum

or minimum values. Select the measurement

mode from the pull-down menu. The modes

as divided according to target and conditions

for measurement.

Valid measurement modes:

Normal, peak hold, bottom hold, peak-topeak hold, average hold, auto peak hold,

auto bottom hold, auto peak-to-peak hold,

sample hold 1, sample hold 2, self-timing

hold

For more details, see “Measuring Mode”

in the “User’s Manual” for each controller.

vide a

5

LS-Navigator-M-NO5-E

5-25

Page 58

5

5-10 Setting the Measurement Conditions for the Program

Copies the output settings from OUT1 or

OUT2 and pastes them into OUT1 or OUT2.

The entered value is added to or subtracted from the measurement

value.

When an offset value is set while using the auto zero function, the

offset appears on the display momentarily.

Valid range:

With the defaults, the range is -99.99999 to 99.99999 mm.

Reference

The offset value changes according to the units and the minimum

display unit setting.

For more details, see the sections “Display Unit” and “Minimum

Display Unit” in the “User’s Manual” for each controller.

Analog voltage is output for the measurement value.

For standard value mode: When the limit mode is

standard value, the standard value is represented by 0

V, and the output voltage is greater or smaller

depending on the deviation. Select one of the following

values from the pull-down menu.

Valid values:

1, 2, 5, 10, 20, 50, 100, 200, 500, 1000, 2000, 5000,

10000 µm/V

Threshold m

mode, set the measurement valu

output at +10 V and -10 V. These values determine the

scaling for the output.

Set the measurement values so that the absolute

value of their difference satisfies the conditions of the

following for mula.

Absolute value of { (Measurement value for +10 V) (Measurement value f

value for X changes depending on the minimum

The

display unit setting.

The following chart indicates the relationship between

X and the minimum display unit.

Minimum display unit (mm) X (mm)

0.00001, 0.00002, 0.00005 0.02

0.0001, 0.0002 0.2

0.001, 0.01, 0.1 2

0.01, 0.02, 0.05 20

0.1, 0.2 200

1 2000

For more details, see the “Analog Output Settings”

section in the “User’s Manual” for each controller.

Set the same values for [Units] and [Minimum display

unit] in the settings f

(Refer to Page 5-5.)

ode: When the limit mode is threshold

or -10V) } X

or the controller and LS-Navi

es that you want to

>_

gator.

5-26

Settings list

1

Click on the [Settings list] tab in the

1

program setting area.

A list of the set parameters appears in the

[Settings list] window.

Copy the settings to clipboard. Paste the

2

settings in another application, such as

Excel.

Reference

The parameters that have been changed from their

default values are displayed in blue.

2

LS-Navigator-M-NO5-E

Page 59

A

Appendix

This chapter describes error messages and shortcut keys.

1Error Message List .............................................A-2

2 Shortcut Key List ................................................A-4

3 Index...................................................................A-5

LS-Navigator-M-APP-E

A-1

Page 60

A

1 Error Message List

This section describes information about the displayed error messages that appear when an error occurs.

During operation

During data communication

Error message Cause Reference page

Failed to communicate. Communication is not possible when the

No response from the

controller.

controller is in setting mode.

Check whether the PC and controller have

the same communication settings.

Check whether the controller D-MODE

settings are correct.

Check the communication settings. The communication settings are not the

Check whether the cables are connected

correctly.

This port number is invalid.

Choose another port.

Process failed to finish correctly.

Restart the application.

Set the same values for units and

minimum display unit in the controller

settings and LS-Navigator settings.

Settings cannot be transferred if the units

are not the same.

the method for switching p

Set

settings in “PANEL”.

This backup file includes the dual head

mode in the setting contents. Check that

the connected model is LS-7600.

rogram

The controller is in setting mode. Page 1-4

The communication settings are not the

same on the PC and the controller.

The controller D-MODE settings are not

correct.

same on the PC and the controller.

The cables are not connected correctly. Page 2-2

An invalid port is selected. Page 5-12

When the data transfer process

finish.

The units for the controller and the LS-

Navigator are different.

The setting is not “PANEL”. Page 1-4

The backup file includes dual head mode

in the settings.

fails to

Page 5-12

Page 5-17

Page 5-12

Page 4-3

Page 5-5

Page 5-10

A-2

During Excel transfer

Error message Cause Reference page

Select at least one item to transfer. No items are selected for transfer. Page 5-19

Failed to output to Excel. Excel is being used. Page 5-19

Enter the sheet name to transfer items to. A sheet name for transferring items is not entered. Page 5-19

The following cannot be used in the name: Invalid characters are used in the sheet name. Page 5-19

The cell position is not set correctly. An invalid cell position is select

The loggi

Set the logging cycle between 1 and 600. The cycle is set in an invalid range. Page 5-19

No further information can be written. The system is attempting to write in an invalid range for

Enter up to 31 letters for the sheet name.

ng method is not selected correctly. The logging method is not selected correctly. Page 5-19

Excel.

On the logging menu, the [Start logging] button was

pressed when more than 31 letters were entered for the

sheet name. (Every character is treated the same as one

letter.)

ed. Page 5-19

Page 5-19

Page 5-19

LS-Navigator-M-APP-E

Page 61

1 Error Message List

Saving and reading settings

Error message Cause Reference page

The file name is too long. The file path name is too long. (The maximum path

name length is 255 characters.)

Failed to read the file.

Check that the correct file is set.

The file may be corrupted. Page 5-3

The file may be an incorrect type of data.Page 5-3

Page 5-4

Output settings

Error message Cause Reference page

Set the value for scaling within the range. Set the value for scaling within the range.

See the “Analog Output Settings” section in the “User’s

Manual” for each controller.

Page 5-26

Limit settings

Error message Cause Reference page

The upper limit must be larger than the lower limit. The lower limit is larger than the upper limit. Page 5-22

The value exceeds the standard value + upper limit. Set

the value between ( ) and ( ).

* The values displayed within the parentheses ( ) vary

depending on the units and the minimum display unit.

The HH setting must be larger than the HI setting.

The LO setting must be larger than the LL setting.

The HOLD-H value must be larger than the HOLD-L

value.

The value exceeds the setting range for standard value

per limit.

+ up

Se

e the “Units, Default Minimum Values, and Setting

Ranges” section in the “User’s Manual” for each

controller.

The HI setting is larger than the HH setting.

The LL setting is larger than the LO setting.

The HOLD-L value is larger than the HOLD-H value. Page 5-22

Page 5-22

-

Page 5-22

Page 5-22

A

Settings list

Error message Cause Reference page

Failed to copy to the clipboard. When the Windows OS fails to copy to the clipboard. Page 5-26

Reference: An error message may be displayed from the Windows OS.

When starting up

Error message Cause Reference page

Start with defaults.Appears when related files start up automatically and

the reading process fails.

Page 4-3

General application

Error message Cause Reference page

The HELP file cannot be opened. When the PDF HELP file cannot be opened because

the HELP file does not exist or Adobe Reader is not

installed.

-

LS-Navigator-M-APP-E

A-3

Page 62

A

2 Shortcut Key List

This section provides the shortcut keys that can be used on LS-Navigator.

Menu Submenu Shortcut keys Operation

File Open file Ctrl + O Opens a saved setting file.

Save file Ctrl + S Saves the settings as a file.

View Measure view F10 + V + V Switches between showing and hiding the

Communication Send settings F10 + C + SSends the information set on LS-Navigator to the

Receive settings F10 + C + L

Backup settings F10 + C + B Saves all of the settings on the connected controller to

Restore settings F10 + C + R Replaces all of the settings on the connected

Settings Change connection F10 + S + G Changes the model of the connected controller.

Communication settings F10 + S + C Performs the communication settings.

Change program No. verification F10 + S + P Switches and verifies the program No. for the

ption F

O

Excel Transfer Start logging F10 + E + S Tr ansfers the logging data to an Excel file.

Help View help F1 Runs help.

About F10 + H + A Displays the version of LS-Navigator.

10 + S + O Sets whether to display the “Welcome” message at

measurement view window.

controller.

Loads controller settings into LS-Navigator.

a file.

controller with the data from a backup file.

connected controller.

startup.

A-4

LS-Navigator-M-APP-E

Page 63

3 Index

A

Analog voltage . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Area settings . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Auto zero function . . . . . . . . . . . . . . . . . . . . . . 5-6

B

Backup settings . . . . . . . . . . . . . . . . . . . 3-5, 5-10

Baud rate . . . . . . . . . . . . . . . . . . . . . . . 5-15, 5-16

B-EDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

C

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Change connection . . . . . . . . . . . . . . . . . . . . . 5-2

Change program No. verification . . . . . . . . . . 5-18

Click logging . . . . . . . . . . . . . . . . . . . . 5-19, 5-20

Communication and file operation area . . . . . . 3-2

Communication menu . . . . . . . . . . . . . . . . . . . 3-3

Communication settings . . . . . . . . . . . . 3-6, 5-12

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Copy and paste . . . . . . . . . . . . . . . . . . . . . . . . 3-2

D

Data length . . . . . . . . . . . . . . . . . . . . . 5-15, 5-16

DIA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

H

Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

I

Initialize parameters . . . . . . . . . . . . . . . . . . . . 5-9

Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

L

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Logging cycle . . . . . . . . . . . . . . . . . . . . . . . . 5-19

M

Measure view . . . . . . . . . . . . . . . . . . . . . .3-5, 5-6

Measurement mode . . . . . . . . . . . . . . . . . . . 5-25

Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . .3-2, 3-3

Minimum display unit . . . . . . . . . . . . . . . . . . . 5-5

O

Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Open file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Output settings . . . . . . . . . . . . . . . . . . . . . . . 5-25

P

A

E

Error message . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Excel transfer . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Excel Transfer menu . . . . . . . . . . . . . . . . . . . . 3-4

External trigger logging . . . . . . . . . . . . . . . . . 5-19

F

File menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

LS-Navigator-M-APP-E

Parameter settings area . . . . . . . . . . . . . . . . . 5-4

Parity . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15, 5-16

Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Program setting area . . . . . . . . . . . . . . . . . . . 3-2

R

Receive settings . . . . . . . . . . . . . . . . . . . . . . . 5-8

Restore settings . . . . . . . . . . . . . . . . . . .3-6, 5-11

RS-232C communication conditions . . . . . . . 5-12

A-5

Page 64

A

3 Index

S

Save file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

SEG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Send settings . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Setting wizard . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Settings list . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Settings menu . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Shortcut key . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Standard value mode . . . . . . . . . . . . . . . . . . 5-26

Start logging . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Start measure . . . . . . . . . . . . . . . . . . . . . . . . . 5-6