KEYENCE IV Series User Manual

Vision Sensor

IV Series

User’s Manual

(Field Network)

Read this manual before use.

After you read this manual, keep it in a safe place for future reference.

1

2

3

4

5 A

256GB

Getting Started

EtherNet/IP

Cyclic communication

PROFINET

Data I/O communication

Reference program

Introduction

Introduction

Read this manual before using the product in order to achieve maximum performance. Keep this manual in a safe place after reading it so that it can be used at any time.

Symbols

The following symbols alert you to important messages.

Be sure to read these messages carefully.

It indicates a hazardous situation which, if not avoided, will result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

It indicates a situation which, if not avoided, could result in product damage as well as property damage.

It indicates cautions and limitations that must be followed during operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

It indicates the reference pages in this manual or the reference pages in separate manuals.

It indicates the reference pages in this manual or the reference pages in separate manuals.

Cautions

(1)Unauthorized reproduction of this manual in whole or part is prohibited.

(2)The contents of this manual may be changed for improvements without prior notice.

(3)An utmost effort has been made to ensure the contents of this manual are as complete as possible. If there are any mistakes or questions, please contact a KEYENCE office listed in the back of the manual.

(4)Regardless of item (3), KEYENCE will not be liable for any effect resulting from the use of this unit.

(5)Any manuals with missing pages or other paging faults will be replaced.

The company names and product names used in this manual are registered trademarks or the trademarks of their respective companies.

Safety Information for IV Series

Safety Information for IV Series

General Precautions

yyDo not use this product for the purpose to protect a human body or a part of human body. yyThis product is not intended for use as an explosion-proof product. Do not use this product in

hazardous location and/or potentially explosive atmosphere.

yyYou must verify that the IV Series are operating correctly in terms of functionality and performance before the start and the operation of the IV Series.

yyWe recommend that you take substantial safety measures to avoid any damage in the event of a problem occurring.

yyKEYENCE never warrants the function or performance of the IV Series if it is used in manner that differs from the IV Series specifications contained in this instruction manual or if the IV Series are modified by yourself.

yyWhen the IV Series is used in combination with other instruments, functions and performance may be degraded, depending on operating conditions and the surrounding environment.

yyDo not place the instruments, including peripherals, under the rapid temperature change. It may cause condensation and may damage instruments or peripherals.

yyRemove the power cable from the power supply if you do not use this product for a long time.

Safety precautions on LED product

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. Follow the instructions mentioned in this manual. Otherwise, injury to the human body (eyes and skin) may result.

yyDo not stare into the direct or specularly reflected beam.

yyDo not disassemble this product. The laser radiation emission from this product is not automatically stopped when it is disassembled.

yyDo not direct the beam at people or into areas where people might be present.

yyBe careful of the path of the LED beam. If there is a possibility that the operator may be exposed to the specular or diffuse reflections, block the beam by installing a protective enclosure.

yyInstall this product so that the path of the LED beam is not as the same height as that of human eye.

256GB |

1 |

Important Instructions

Important Instructions

Observe the following precautions to prevent malfunction of the IV Series and to ensure that it is used properly.

Precautions on use

yyThe power of this product and instruments connected to this product must be turned off when the cable is to be installed or removed. Failure to do so may cause an electric shock or a product damage.

yyUse this product in the correct supply voltage. Failure to do so may cause a product damage.

yyFor instructions

yyDo not turn OFF the power while setting the items or saving the settings. Otherwise, all or part of the setting data may be lost.

yyDo not let water, dust or oil stick to the camera/light of the sensor. Failure to do so may cause a malfunction.

yyWhen this product becomes dirty, do not rub it with a wet cloth, benzene, thinner, or alcohol. Doing so may change the color or shape of the unit.

yyIf the unit is heavily contaminated, disconnect all the cables including the power supply cable, wipe off the dirt with a cloth soaked with mild detergent, and then wipe with a soft dry cloth.

yyFor external master image registration

If the external master image registration is to be performed frequently, set [Write ROM when using Ext. Master Save] of the input option to [No] for nonvolatile memory protection of the internal sensor. When the option is set to [Yes], the nonvolatile memory is guaranteed to write for 100,000 times.

yyFor automatic focus function

yyAutomatic focus function is used for adjusting the focusing position at the time of installation. This will not activate during the operation.

yyFocusing position can be registered in each program. The program configurations are guaranteed to switch for 100,000 times. If the focusing position does not need to change for each program, set [Auto Focus Adjustment Position] to [Common] for extending the life-span.

yyDo not apply shock or vibration during the focusing position adjustment. Failure to do so may cause a product damage.

Measures to be taken when an abnormality occurs

In the following cases, turn the power OFF immediately. Using the IV Series in an abnormal condition could cause fire, electric shock, or malfunction.

Contact our office for repair.

yyIf water or debris enters the IV Series.

yyIf the IV Series is dropped or the case is damaged.

yyIf abnormal smoke or odor emanates from the IV Series.

2 |

- IV Series User’s Manual (Field Network) - |

Important Instructions

Precautions on installation

yyTo use this product correctly and safely, avoid installing it in the following locations. Failure to do so may cause fire, electric shock, or malfunction.

yyOutdoors

yyAltitude above 2000 m

yyLocations that are humid, dusty or poorly ventilated

yyLocations where the temperature is high such as those exposed to direct sunlight yyLocations where there are flammable or corrosive gases

yyLocations where the unit may be directly subjected to vibration or impact yyLocations where water, oil, or chemicals may splash onto the unit

yyTo improve the anti-noise feature, install the unit following the precautions below. Otherwise, a malfunction may occur.

yyMount the sensor onto the insulated attached mounting adapter. yyGround the FG cable (drain cable) of the sensor.

yyDo not mount the unit in a cabinet where high-voltage equipment is already installed. yyMount the unit as far from power lines as possible.

yySeparate the unit as far as possible from the devices that emit strong electric or magnetic field (such as solenoid or chopper).

yySeparate the I/O signal line from the power line or high-voltage line. yyFor power supply

yyNoise superimposed on the power supply could cause malfunction. Use a stabilized DC power supply configured with an isolation transformer.

yyWhen using a commercially available switching regulator, be sure to ground the frame ground terminal.

yyDevices including this unit are precision components. Do not apply shock or vibration. yyWhen connecting to a network, let engineers who are knowledgeable about networks handle it.

- IV Series User’s Manual (Field Network) - |

3 |

Precautions on Regulations and Standards

Precautions on Regulations and Standards

For IV-500C/IV-500CA/IV-500M/IV-500MA/IV-150M/IV-150MA/

IV-2000M/IV-2000MA

UL Certification

This product is a UL/C-UL Listed product. yyUL File No. E301717

yyCategory NRKH, NRKH7

Be sure to consider the following specifications when using this product as a UL/C-UL Listed Product. yyUse a power supply with Class 2 output defined in NFPA70 (NEC: National Electrical Code). yyPower supply/ External input/ Control output shall be connected to a single Class 2 source only. yyUse with an over current protection device which is rated 24 V or more and not more than 1A. yyEnclosure Type 1 (Based on UL50)

CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of the applicable EC Directive, based on the following specifications. Be sure to consider the following specifications when using this product in the Member State of European Union.

zzEMC Directive (2004/108/EC)

yyApplicable Standard EMI: EN60947-5-2, Class A EMS: EN60947-5-2

yyThe length of power I/O cable, Ethernet cable and Monitor cable must be less than or equal to 30m.

Remarks:

These specifications do not give any guarantee that the end-product with this product incorporated complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely responsible for the compliance on the end-product itself according to EMC Directive.

zzLow-Voltage Directive (2006/95/EC) yyApplicable Standard: EN62471

4 |

- IV Series User’s Manual (Field Network) - |

Version of the IV Series

Version of the IV Series

You can download the most recent operation software for the sensor (IV-150/500/2000) and IV-Navigator (IV-H1) from the KEYENCE web site.

Please refer to the description on the homepage for the introduction method. URL : http://www.keyence.com/

Operation software of the sensor (IV-150/500/2000)

Version |

Description |

|

|

|

|

R1.00.00 |

The initial version. |

|

|

|

|

R1.01.00 |

The processing time has been speeded up. |

|

|

|

|

R1.10.00 |

The processing time and the response time to program switching input have been |

|

speeded up. |

||

|

||

|

|

|

|

This is the version of this document. |

|

|

The following functions have been added. |

|

R2.00.00 |

yyLogic output |

|

yyTotal status NG output |

||

|

yyRUN output |

|

|

yyFTP client function |

|

|

yyField network (EtherNet/IP, PROFINET) |

Operation software of the monitor (IV-M30)

Version |

Description |

|

|

|

|

R1.00.00 |

The initial version. |

|

|

|

|

R1.01.01 |

Compatibility with Chinese (Simplified) / Chinese (Traditional). |

|

|

|

|

R1.02.00 |

Compatibility with German. |

|

|

|

|

R1.10.00 |

Compatibility with Tool Auto Tuning using a registration information file (*.ivt). |

|

|

|

|

R2.00.00 |

This is the version of this document. |

|

Compatibility with Italian / French / Spanish / Portuguese / Korean. |

||

|

||

|

|

- IV Series User’s Manual (Field Network) - |

5 |

Version of the IV Series

IV-Navigator (IV-H1)

Version |

Description |

|

|

|

|

R1.00.00 |

The initial version. |

|

|

|

|

R1.01.00 |

Compatibility with German. |

|

|

|

|

R1.02.00 |

Compatibility with Chinese (Simplified) / Chinese (Traditional). |

|

|

|

|

|

The following functions have been added. |

|

|

yyAddition of the IV-Simulator function |

|

R1.10.00 |

yyAddition of the image capture function to the operation of the [Save Image] button |

|

yyAddition of the [Size] selection function to “Remove Outline” |

||

|

||

|

yyAddition of the [Display Master Image] button to “Tool Auto Tuning” |

|

|

yyAddition of the [Language] button (language selection) to the Activation Menu screen |

|

|

|

|

|

This is the version of this document. |

|

R2.00.00 |

Compatibility with Italian / French / Spanish / Portuguese / Korean. |

|

|

IVP-Convertor has been added. |

|

|

|

6 |

- IV Series User’s Manual (Field Network) - |

Structure of This Manual

Structure of This Manual

1 |

Getting Started |

This chapter explains the system configurations and |

|

overview of IV Series. |

|||

|

This chapter describes the overview of EtherNet/IP and

2 EtherNet/IP the communication specifications and functions of the EtherNet/IP communication in the IV series.

3 |

|

This chapter describes the overview, setting method, data |

|

Cyclic communication |

allocation, and operating procedure of |

||

|

the cyclic communication in the EtherNet/IP communication.

This chapter describes the overview of PROFINET and

4 PROFINET the communication specifications and functions of the PROFINET communication in the IV series.

5 |

|

This chapter describes the overview, setting method, data |

|

Data I/O communication |

allocation, and operating procedure of |

||

|

|||

|

|

the data I/O communication in the PROFINET communication. |

|

|

|

|

|

A |

Reference program |

This chapter explains Reference program, etc. |

|

|

|||

|

|

|

1

2

3

4

5 A

- IV Series User’s Manual (Field Network) - |

7 |

Contents

Contents

Introduction |

|

Symbols |

|

Cautions |

|

Safety Information for IV Series.............................. |

1 |

General Precautions............................................ |

1 |

Safety precautions on LED product..................... |

1 |

Important Instructions.............................................. |

2 |

Precautions on use.............................................. |

2 |

Measures to be taken when an abnormality |

|

occurs.................................................................. |

2 |

Precautions on installation................................... |

3 |

Precautions on Regulations and Standards............ |

4 |

For IV-500C/IV-500CA/IV-500M/IV-500MA/ |

|

IV-150M/IV-150MA/IV-2000M/IV-2000MA............ |

4 |

UL Certification................................................. |

4 |

CE Marking....................................................... |

4 |

Version of the IV Series........................................... |

5 |

Operation software of the sensor |

|

(IV-150/500/2000)................................................ |

5 |

Operation software of the monitor (IV-M30)......... |

5 |

IV-Navigator (IV-H1)............................................. |

6 |

Structure of This Manual......................................... |

7 |

Contents.................................................................. |

8 |

Chapter 1 Getting Started |

|

System Configuration........................................... |

1-2 |

Basic configurations of IV-Series...................... |

1-2 |

Connecting the host device and |

|

single sensor................................................. |

1-2 |

Connecting the host device and |

|

multiple sensors............................................ |

1-3 |

Overview of IV Series........................................... |

1-4 |

IV Series........................................................... |

1-4 |

System configuration example...................... |

1-4 |

Operation of the indicator light...................... |

1-5 |

Chapter 2 EtherNet/IP |

|

Overview of EtherNet/IP....................................... |

2-2 |

What is EtherNet/IP?........................................ |

2-2 |

EtherNet/IP communication specifications and |

|

functions in the IV series...................................... |

2-3 |

EtherNet/IP communication specifications |

|

in the IV series.................................................. |

2-3 |

Overview of the Ethernet/IP |

|

communications functions in the IV series........ |

2-3 |

List of supported PLCs..................................... |

2-4 |

Keyence PLC................................................ |

2-4 |

KV series............................................... |

2-4 |

Rockwell Automation PLC............................. |

2-4 |

OMRON PLC................................................. |

2-4 |

Chapter 3 Cyclic communication

Overview of the cyclic communication................. |

3-2 |

What is cyclic communication?......................... |

3-2 |

Cyclic communication setting method.................. |

3-3 |

Setting the IV series.......................................... |

3-3 |

When settings on the monitor (IV-M30)......... |

3-3 |

When setting by IV-Navigator (IV-H1)........... |

3-4 |

PLC settings..................................................... |

3-5 |

Establishing the connection........................... |

3-5 |

Keyence KV series settings........................... |

3-7 |

Rockwell Automation Control Logix series |

|

settings.......................................................... |

3-8 |

Data allocation in the cyclic communication....... |

3-10 |

Input Assembly (IV series → PLC)................. |

3-10 |

Input Assembly parameter details................... |

3-12 |

Input Assembly Address 0: |

3-12 |

Control result (response)..................... |

|

Input Assembly Address 1: |

3-12 |

Control error result.............................. |

|

Input Assembly Address 2 to 3: |

3-13 |

Handshake control/status/error result... |

|

Input Assembly Address 4 to 7: |

3-15 |

Status result........................................ |

|

Input Assembly Address 8 to 23: |

3-16 |

Error/status/status result information... |

|

Input Assembly Address 24 to 51: |

3-17 |

Statistics information........................... |

|

Input Assembly Address 52 to 71: |

3-18 |

Position correction information............ |

|

Input Assembly Address 72 to 391: |

3-18 |

Tool information................................... |

|

Output Assembly (PLC → IV series)............... |

3-19 |

Output Assembly parameter details................ |

3-20 |

Output Assembly Address 0 to 1: |

3-20 |

Control request.................................... |

|

Output Assembly Address 2 to 3: |

3-21 |

Handshake control.............................. |

|

Output Assembly Address 4 to 11: |

3-21 |

Program No......................................... |

|

Error code list.................................................. |

3-22 |

Warning code list............................................ |

3-23 |

Operating procedure of |

|

the cyclic communication................................... |

3-26 |

Reading out the overall status result of |

|

the IV series |

|

(Handshake control [Disabled])...................... |

3-26 |

When a trigger is successful............... |

3-26 |

When a trigger is unsuccessful........... |

3-27 |

Reading out the overall status result of |

|

the IV series |

|

(Handshake control [Enabled])....................... |

3-28 |

Switching the programs in the IV series......... |

3-29 |

Registering a master image for |

|

the IV series externally................................... |

3-30 |

8 |

- IV Series User’s Manual (Field Network) - |

Contents

Chapter 4 PROFINET

Overview of PROFINET....................................... |

4-2 |

What is PROFINET?......................................... |

4-2 |

PROFINET communication specifications and |

|

functions in the IV series...................................... |

4-3 |

IV series PROFINET communication |

|

specifications.................................................... |

4-3 |

Specifying the IP address using |

|

the DCP protocol.............................................. |

4-3 |

Overview of the PROFINET communication |

|

functions in the IV series................................... |

4-4 |

List of supported PLCs..................................... |

4-5 |

Siemens PLC................................................ |

4-5 |

Phoenix Contact PLC.................................... |

4-5 |

OMRON PLC................................................. |

4-5 |

Chapter 5 Data I/O communication

Overview of the data I/O communication............. |

5-2 |

What is data I/O communication?..................... |

5-2 |

Data I/O communication setting method.............. |

5-3 |

Setting the IV series.......................................... |

5-3 |

When settings on the monitor (IV-M30)......... |

5-3 |

When setting by IV-Navigator (IV-H1)........... |

5-4 |

Setting the device name................................... |

5-5 |

When settings on the monitor (IV-M30)......... |

5-5 |

When setting by IV-Navigator (IV-H1)........... |

5-5 |

PLC settings..................................................... |

5-6 |

Establishing the data I/O communication...... |

5-6 |

Setting the Siemens TIA Portal..................... |

5-7 |

Setting the Siemens SIMATIC Manager...... |

5-11 |

Data allocations in |

|

the data I/O communication............................... |

5-16 |

Control Modules (PLC → IV series)................ |

5-16 |

Command Control............................... |

5-16 |

Status Modules (IV series → PLC)................. |

5-17 |

Command Status Bits.......................... |

5-17 |

Device Result Bits............................... |

5-17 |

Device Status Words........................... |

5-18 |

Device Statistics.................................. |

5-18 |

Tool Result Modules (IV series→ PLC).......... |

5-19 |

Position Adjust Result.......................... |

5-19 |

Tool Result........................................... |

5-19 |

Control Modules parameter details................. |

5-20 |

Command Control Address 0 to 1: |

5-20 |

Control request.................................... |

|

Command Control Address 2 to 3: |

5-21 |

Handshake control.............................. |

|

Command Control Address 4 to 11: |

5-21 |

Program No......................................... |

|

Status Modules parameter details.................. |

5-22 |

Command Status Bits Address 0: |

5-22 |

Control result (response)..................... |

|

Command Status Bits Address 1: |

5-22 |

Control error result.............................. |

|

Command Status Bits Address 2 to 3: |

5-23 |

Handshake control/status/error result... |

|

Device Results Bits Address 0 to 3: |

5-25 |

Status result........................................ |

Device Status Words |

|

Address 0 to 15: |

|

Error/status/status result information... |

5-26 |

Device Statistics Address 0 to 27 |

5-27 |

(Statistics information)......................... |

|

Tool Result Modules parameter details........... |

5-28 |

Position Adjust Result |

|

Address 0 to 19 |

|

(Position correction information).......... |

5-28 |

Tool Result Address 0 to 19 |

5-28 |

(Tool information)................................. |

|

Error code list.................................................. |

5-29 |

Warning code list............................................ |

5-30 |

Operating procedure of |

|

the data I/O communication............................... |

5-32 |

Reading out the overall status result of |

|

the IV series |

|

(Handshake control [Disabled])...................... |

5-32 |

When a trigger is successful............... |

5-32 |

When a trigger is unsuccessful........... |

5-33 |

Reading out the overall status result of |

|

the IV series |

|

(Handshake control [Enabled])....................... |

5-34 |

Switching the programs in the IV series......... |

5-35 |

Registering a master image for |

|

the IV series externally................................... |

5-36 |

|

|

Appendices |

|

Reference program (EtherNet/IP)....................... |

A-2 |

Handshake control [Disabled].......................... |

A-2 |

Keyence KV series....................................... |

A-2 |

Description of the reference program.... |

A-2 |

Rockwell Automation PLC............................ |

A-3 |

Description of the reference program.... |

A-3 |

Handshake control [Enabled]........................... |

A-4 |

Keyence KV series....................................... |

A-4 |

Description of the reference program.... |

A-4 |

Rockwell Automation PLC............................ |

A-5 |

Description of the reference program.... |

A-5 |

Program switching........................................... |

A-6 |

Keyence KV series....................................... |

A-6 |

Description of the reference program.... |

A-6 |

Rockwell Automation PLC............................ |

A-7 |

Description of the reference program.... |

A-7 |

Reference program (PROFINET)........................ |

A-8 |

Handshake control [Disabled].......................... |

A-8 |

Siemens PLC............................................... |

A-8 |

Description of the reference program.... |

A-8 |

Handshake control [Enabled]........................... |

A-9 |

Siemens PLC............................................... |

A-9 |

Description of the reference program.... |

A-9 |

Program switching......................................... |

A-10 |

Siemens PLC............................................. |

A-10 |

Description of the reference program.... |

A-10 |

Index................................................................. |

A-12 |

- IV Series User’s Manual (Field Network) - |

9 |

Contents

MEMO

10 |

- IV Series User’s Manual (Field Network) - |

1

Getting Started

This chapter explains the system configurations and overview of IV Series.

System Configuration |

........................................1-2 |

Overview of IV Series......................................... |

1-4 |

1

Started Getting

- IV Series User’s Manual (Field Network) - |

1-1 |

1

Started Getting

System Configuration

System Configuration

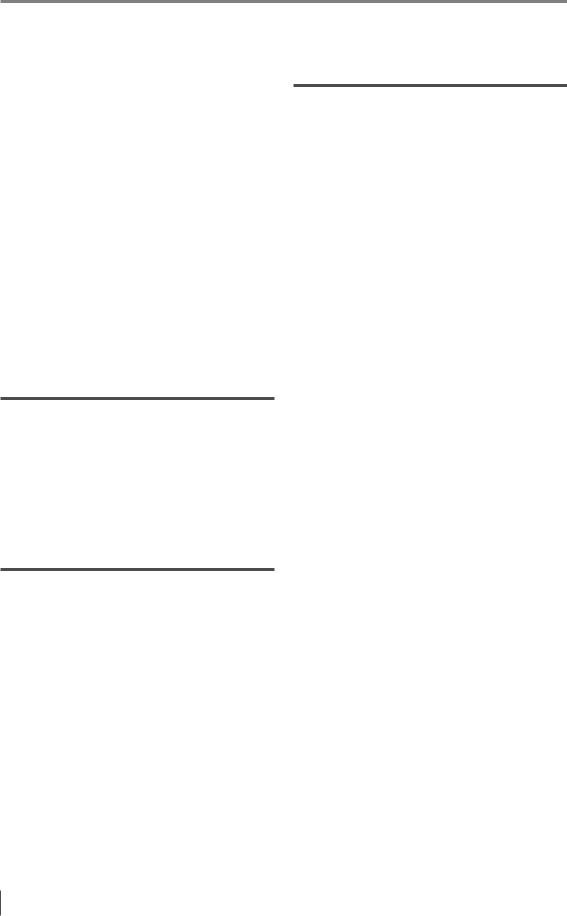

Basic configurations of IV-Series |

|

||

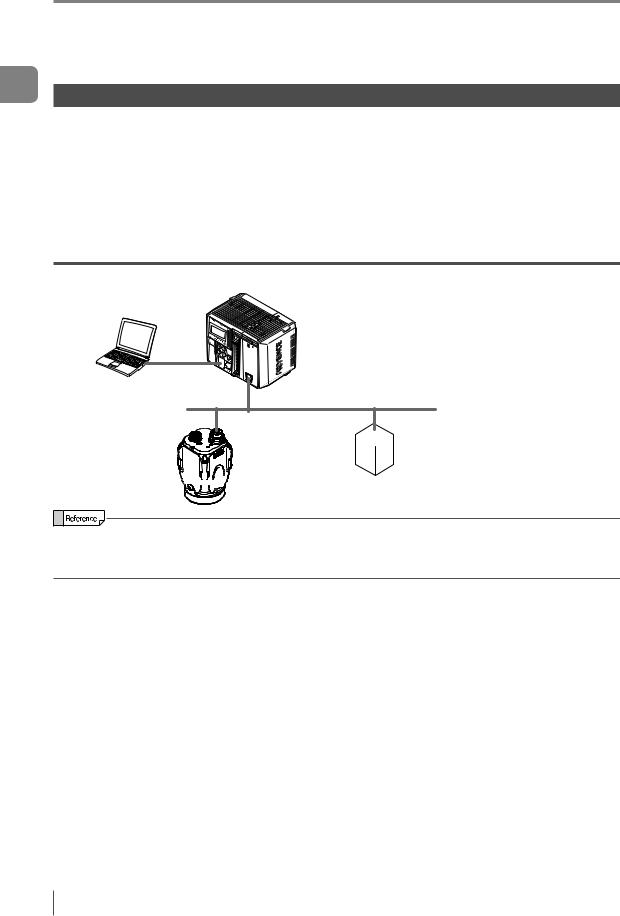

Connecting the host device and single sensor |

|||

PLC or other host device |

In addition to the status result import, |

||

the trigger control and switching |

|||

|

|

||

|

|

of the set program number can be |

|

|

|

performed with the control output. |

|

IV Series |

|

|

|

Ethernet cable |

|

|

|

(2m/5m/10m) |

|

|

|

|

|

Setting support software |

|

|

|

(IV-H1) |

|

Sensor |

Power I/O cable |

||

IV-500C |

|||

IV-500CA |

|

(2m/5m/10m) |

|

IV-500M |

|

|

|

IV-500MA |

(Optional) |

|

|

IV-150M |

Dome attachment |

|

|

IV-150MA |

IV-D10 |

|

|

IV-2000M |

Polarizing filter attachment |

||

IV-2000MA |

|||

OP-87436/OP-87437 |

|

||

|

|

||

|

|

24 VDC power |

|

Photoelectric/ proximity sensor etc.

Sends the signal to the trigger input when the target is detected.

Indicator light/buzzer etc.

Alarm can be output by the status output function.

1-2 |

- IV Series User’s Manual (Field Network) - |

System Configuration

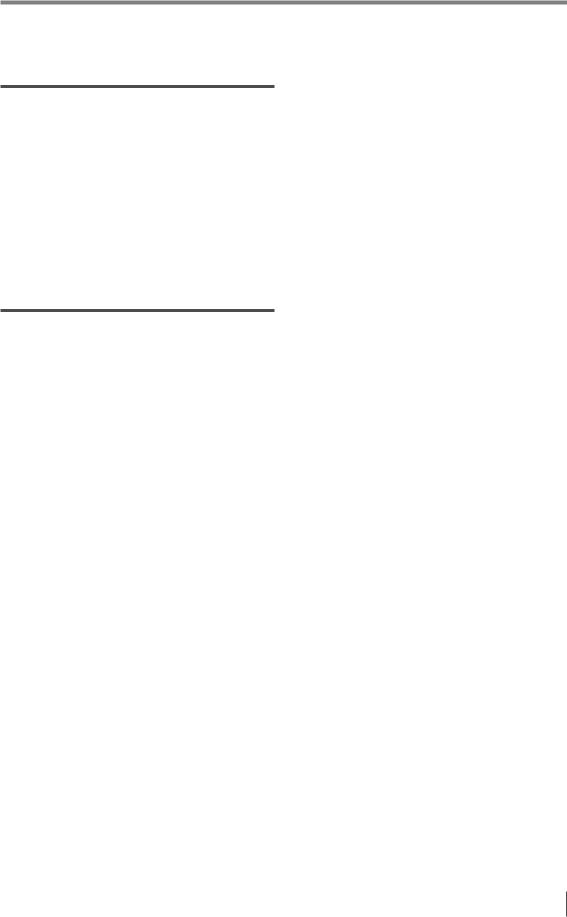

Connecting the host device and multiple sensors

In addition to the status result import, the trigger control and switching of the set program number can be performed

PLC or other host device

with the control output.

with the control output.

Ethernet switch

Ethernet cable

Ethernet cable

(2m/5m/10m)

Setting support software (IV-H1)

1

Started Getting

- IV Series User’s Manual (Field Network) - |

1-3 |

1

Started Getting

Overview of IV Series

Overview of IV Series

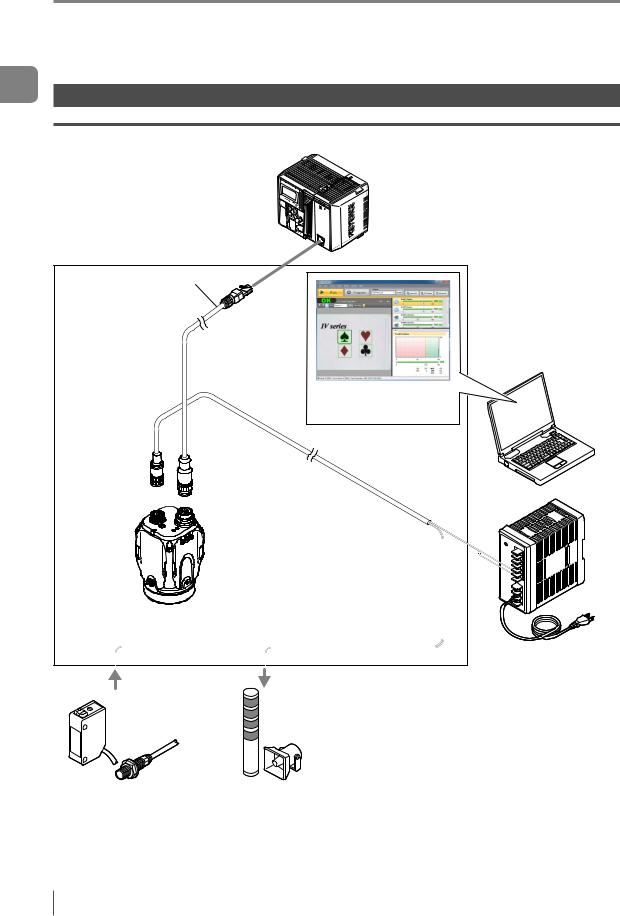

IV Series

The IV Series is an all-in-one “Vision Sensor” featuring a camera, a light, and a controller. This sensor can be attached easily so complicated detection operations such as detecting the shapes of parts with a photoelectric switch can be achieved easily.

Operation conditions settings require the IV Software, IV-Navigator (IV-H1) or

the intelligent monitor (IV M30). After setting is completed, the sensor can be operated independently. The IV Series operates as an EtherNet/IP communication adaptor or a PROFINET communication I/O device. With EtherNet/IP communication or PROFINET communication, the control output signal and status result, etc., can be input to the PLC as communication data.

System configuration example

PLC or other host device |

(EtherNet/IP communication scanner, |

PROFINET communication I/O controller) |

EtherNet/IP communication adapter,

EtherNet/IP communication adapter,

PROFINET communication I/O device

Sensor (this unit)

Sensor (this unit)

yyEtherNet/IP communication and PROFINET communication cannot be used simultaneously.

yyFor the details of installation, connection, and operation methods of the IV Series, refer to “IV Series User’s Manual (Monitor/PC Software)”.

1-4 |

- IV Series User’s Manual (Field Network) - |

Overview of IV Series

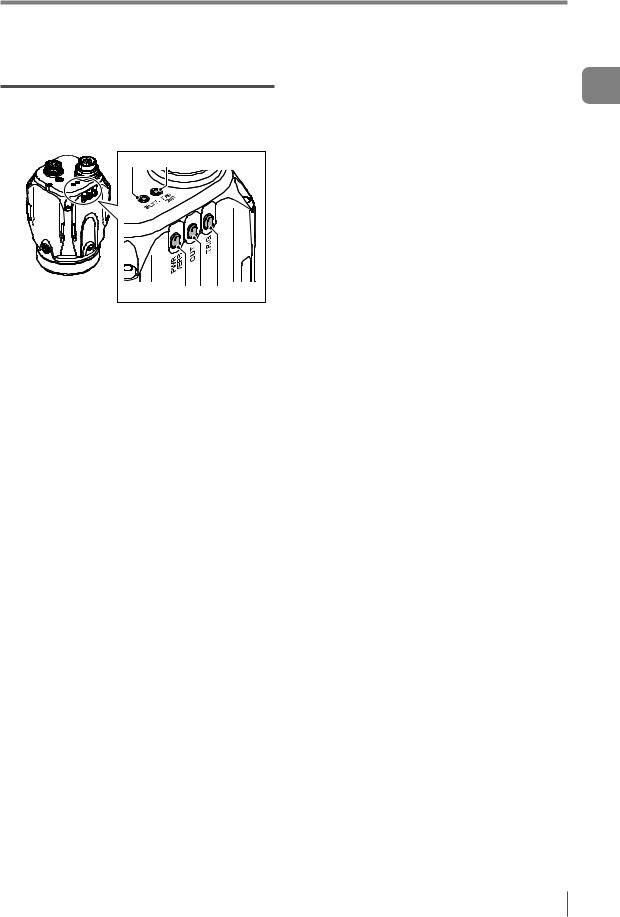

Operation of the indicator light

Details on operations of the indicator light are shown below.

4 5

1 2 3

1PWR/ERR

Indicates the power supplying status to the

sensor and the error status of the sensor.

yyGreen (ON)....... |

Operating. |

yyGreen (Blink).... |

Setting processing. Operation |

|

is stopped. Blinks once a |

|

second. |

yyRed (ON).......... |

Unrecoverable error has |

|

occurred. |

yyRed (Blink)........ |

Recoverable error has |

|

occurred. |

yyOrange (Blink)... |

Flash LED has been required on |

|

the PROFINET communication |

|

I/O controller. Blinks 4 times |

|

with a period of about a second. |

yy(OFF)................ |

Power is not supplied. |

|

Adjusting the focusing position |

|

(manual focus only). |

2OUT

Indicates the comprehensive result.

yyGreen................ |

Comprehensive result is “OK”. |

yyRed................... |

Comprehensive result is “NG”. |

yy(OFF)................ |

Setting processing. |

|

Standby status until the first |

|

judge finishes after starting the |

|

operation or after switching |

|

the program number. |

yyOrange (Blink).... |

Indicates the focusing status |

|

while adjusting the focusing |

|

position with the blinking speed |

|

(manual focus type only). |

|

Flash LED has been required on |

|

the PROFINET communication |

|

I/O controller. Blinks 4 times |

|

with a period of about a second. |

3TRIG

Green light lights up (one-shot) according to input of the internal or external trigger. yyOrange (Blink)...Flash LED has been required on

the PROFINET communication

I/O controller. Blinks 4 times with a period of about a second.

4STATUS

Indicates the connecting status to the PC.

yyGreen (ON).......Normally connected with monitor,

PC, EtherNet/IP communication scanner, or PROFINET communication I/O controller.

yyGreen (Blink)....IP address has been retrieved but the sensor is not correctly connected with monitor, PC, EtherNet/IP communication scanner, or PROFINET communication I/O controller.

yyRed (Blink)........Timeout has occurred at the communication with EtherNet/

IP communication scanner. yyRed (ON)..........IP address coincides with

another device. yy(OFF)................IP address is not assigned.

Not correctly connecting with

PC.

yyOrange (Blink)..Indicates the focusing status while adjusting the focusing position with the blinking speed (manual focus type only).

5LINK/ACT

Indicates the linking status within PC or

Ethernet switch.

yyGreen (ON).......Normally linked.

yyGreen (Blink)....Normally linked, and the data is sending/receiving.

yy(OFF)................Sensor is not normally linked.

1

Started Getting

- IV Series User’s Manual (Field Network) - |

1-5 |

Overview of IV Series

MEMO

1

Started Getting

1-6 |

- IV Series User’s Manual (Field Network) - |

2

EtherNet/IP

This chapter describes the overview of EtherNet/IP and the communication specifications and functions of the EtherNet/IP communication in the IV series.

Overview of EtherNet/IP.................................... |

2-2 |

EtherNet/IP communication specifications |

|

and functions in the IV series........................... |

2-3 |

2

EtherNet/IP

- IV Series User’s Manual (Field Network) - |

2-1 |

2

EtherNet/IP

Overview of EtherNet/IP

Overview of EtherNet/IP

What is EtherNet/IP?

EtherNet/IP is an open industrial networking standard developed and maintained by the ODVA (Open

DeviceNet Vendor Association, Inc.). All supported devices can use the communication network regardless of the vendor.

Ethernet and an industrial protocol have been combined and standardized as EtherNet/IP (Industrial Protocol). Communication is achieved by combining a protocol called CIP (Common Industrial Protocol) and the TCP/ IP and Ethernet. This allows the network to be shared and used with standard Ethernet.

To start the Ethernet/IP communication, one device needs to open a communication line called a "connection" for the other device. The device that will open a connection is referred to as the "scanner", and the device whose connection will be opened is referred to as the "adapter" (IV series is an adapter device).

The EtherNet/IP communication offers the following two types of communications: Cyclic communication for sending and receiving data periodically (Implicit communication), and message communication for sending and receiving commands/responses at arbitrary timings.

In the cyclic communication, you can set the RPI (Request Packet Interval: communication cycle) based on the priority of the data to be sent/received, enabling sending/receiving of data with adjusted overall communication load. Various data including the control output, status result import, trigger control and switching to the set program No. can be communicated without a ladder program.

In the message communication, you can send/receive the required commands and responses at the required timings. The message communication is used for applications requiring no punctuality unlike the cyclic communication, such as for reading and writing the adapter device settings.

The IV series supports cyclic communication (Implicit communication).

EtherNet/IP communication scanner

Low-speed (Communication cycle: 1000 ms)

High-speed

(Communication cycle: 5 ms)

Normal

(Communication cycle: 100 ms)

EtherNet/IP |

|

EtherNet/IP |

|

EtherNet/IP |

communication |

|

communication |

|

communication |

adapter |

|

adapter |

|

adapter |

2-2 |

- IV Series User’s Manual (Field Network) - |

EtherNet/IP communication specifications and functions in the IV series

EtherNet/IP communication specifications and functions in the IV series

This section describes the overview of the EtherNet/IP communication functions supported in the IV series.

EtherNet/IP communication specifications in the IV series

Cyclic communication |

Number of |

16 |

|

(Implicit messages) |

connections |

||

|

|||

|

|

|

Overview of the Ethernet/IP communications functions in the IV series

The following shows the list of functions that can be used to control the IV series using the EtherNet/IP communication.

|

|

Function |

Content |

|

|

|

|

|

|

Trigger input |

Executes a trigger input for the sensor. |

|||

|

|

|

|

|

Program switching |

Executes a program switching for the sensor. |

|||

|

|

|

|

|

External master registration |

Executes an external master registration for the sensor. |

|||

|

|

|

|

|

Error clear input |

Executes an error clear. |

|||

|

|

|

|

|

Read out status |

Allows you to check the unit status (Imaging, RUN, BUSY, Error). |

|||

|

|

|

|

|

Read overall status result |

Reads out the overall status result. |

|||

|

|

|

|

|

Read judgment processing time |

Reads out the judgment processing time. |

|||

|

|

|

|

|

Read each tool’s status result |

Read each tool’s status result |

|||

|

|

|

|

|

Read statistics information |

Reads out the number of triggers issued that generated a trigger |

|||

error and the number of trigger errors. |

||||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yyIf you are switching programs using the EtherNet/IP communication, set the [Switching method] option to [Monitor/PC]. For details of the setting, refer to the “IV Series User’s Manual (Monitor / PC Software)”. yyIf the master registration will be executed using the EtherNet/IP communication, set the [Write to ROM at external master reg.] option to [No]. For details of the setting,refer to the “IV Series User’s Manual (Monitor / PC Software)”.

2

EtherNet/IP

- IV Series User’s Manual (Field Network) - |

2-3 |

EtherNet/IP communication specifications and functions in the IV series

2

EtherNet/IP

List of supported PLCs

Check the instruction manual of each PLC for details of the setting methods.

Keyence PLC |

|

|

|

|

|

KV series |

|

|

|

|

|

|

|

|

|

|

|

PLC model |

EtherNet/IP |

Firmware |

Software used |

Version of the |

|

communication unit |

version |

software used |

|||

|

|

||||

|

|

|

|

|

|

KV-3000 |

KV-EP21V |

Ver.2 or later |

|

|

|

|

|

|

|

|

|

KV-5000 |

KV-EP21V |

Ver.2 or later |

KV STUDIO |

Ver.6.0 or later |

|

|

|

|

|||

|

- |

|

|||

|

|

|

|

||

KV-5500 |

(Built-in port or KV- |

Ver.2 or later |

|

|

|

|

EP21V) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Rockwell Automation PLC |

|

|

|

||

|

|

|

|

|

|

PLC model |

EtherNet/IP |

Firmware |

Software used |

Version of the |

|

communication unit |

version |

software used |

|||

|

|

||||

|

|

|

|

|

|

1756 ControlLogix |

1756-ENBT |

Ver.13 or later |

|

|

|

1756-EN2T |

|

|

|||

|

|

RSLogix5000 |

Ver.13 or later |

||

|

|

|

|||

1769 CompactLogix |

- |

Ver.13 or later |

|||

|

|

||||

(Built in the unit) |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

OMRON PLC |

|

|

|

|

|

|

|

|

|

|

|

PLC model |

EtherNet/IP |

Firmware |

Software used |

Version of the |

|

communication unit |

version |

software used |

|||

|

|

||||

|

- |

|

|

|

|

SYSMAC CJ2 |

(Built-in port or |

V1.0 or later |

|

|

|

|

CJ1W-EIP21) |

|

CX-One |

Ver.3.0 or later |

|

|

|

|

|||

SYSMAC CJ1 |

CJ1W-EIP21 |

V1.0 or later |

|

|

|

|

|

|

|

|

|

SYSMAC CS1 |

CJ1W-EIP21 |

V1.0 or later |

|

|

|

|

|

|

|

|

|

2-4 |

- IV Series User’s Manual (Field Network) - |

3

Cyclic communication

This chapter describes the overview, setting method, data allocation, and operating procedure of the cyclic communication in the EtherNet/IP communication.

Overview of the cyclic communication............ |

3-2 |

Cyclic communication setting method............ |

3-3 |

Data allocation in the cyclic communication... |

3-10 |

Operating procedure of |

|

the cyclic communication............................... |

3-26 |

3

communication Cyclic

- IV Series User’s Manual (Field Network) - |

3-1 |

Overview of the cyclic communication

Overview of the cyclic communication

3

communication Cyclic

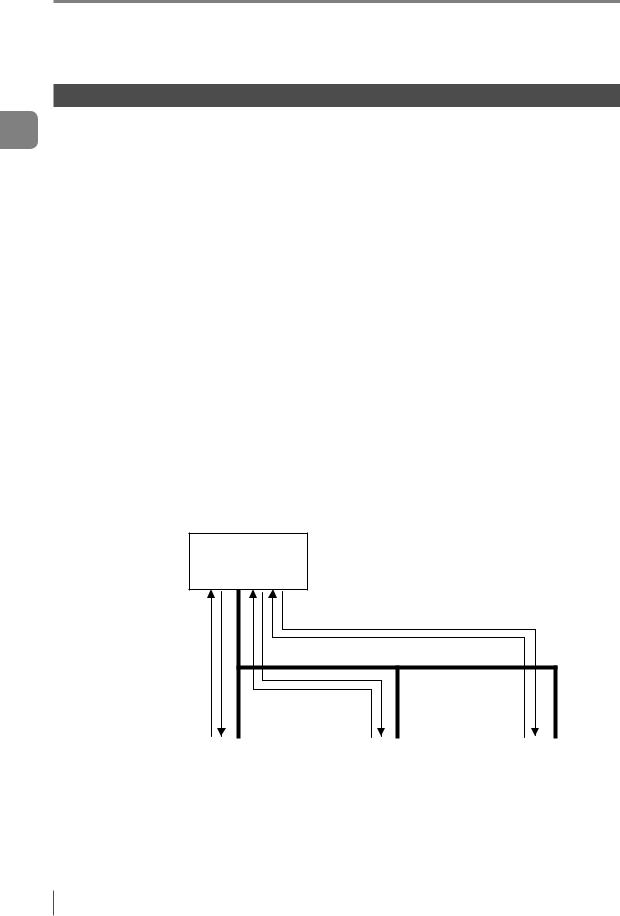

What is cyclic communication?

This function enables cyclic (i.e. in fixed intervals) data communications with the EtherNet/IP devices.

This function provides high-speed control with several to several tens of milliseconds.

The communication can be controlled by referencing and updating the variables in the PLC, making it easy to control the programs on the PLC side.

Input Area

yyStatus result yyControl/status/error result yyStatistics information yyTool information

Output Area

yyTrigger control yyExternal master image registration control

yyProgram switching control yyHandshake control

|

|

|

|

Output data |

||

|

|

|

|

|

|

|

|

|

|

|

|

yyStatus result |

|

|

|

|

|

|

yyControl/status/error result |

|

|

|

|

|

|

yyStatistics information |

|

|

|

|

|

|

|

|

|

|

|

|

|

yyTool information |

|

|

RPI |

|

|

|

||

|

|

|

||||

(Communication |

|

|

|

|||

|

cycle) |

Input data |

||||

|

|

|

|

|

yyTrigger control |

|

|

|

|

|

|

yyExternal master image |

|

|

|

|

|

|

registration control |

|

|

|

|

|

|

yyProgram switching control |

|

|

|

|

|

|

yyHandshake control |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

yyCommunication settings for the cyclic communication, such as the RPI (communication cycle) and the data size, will be configured on the PLC side.

yyIn a network with many connected devices (including the EtherNet/IP devices), a network delay and/ or packet loss may occur when there is a heavy load on the network. Conduct a thorough verification before the operation.

3-2 |

- IV Series User’s Manual (Field Network) - |

Cyclic communication setting method

Cyclic communication setting method

This following explains the setting method when using the cyclic communication.

yyTo control the IV series using the EtherNet/IP communication, select [Network connection] for the sensor connection setting. When connected directly, the field network settings will be greyed out and disabled.

yyIf you have modified the protocol settings, the connection with the sensor will be terminated and then restarted.

Setting the IV series

You can configure the following settings for the IV series using the monitor (IV-M30) or IV-Navigator

(IV-H1).

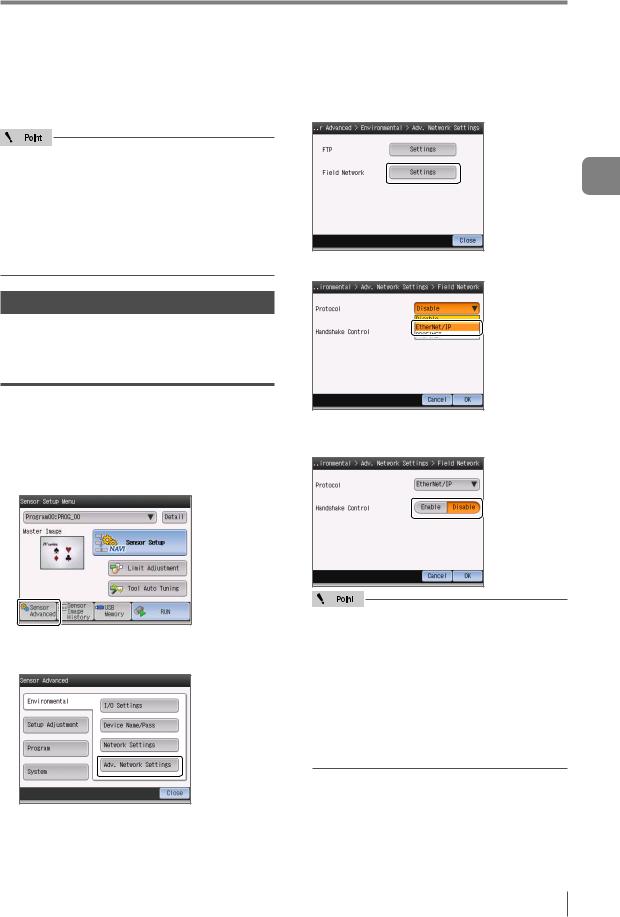

When settings on the monitor (IV-M30)

Set the field network settings of the sensor to [EtherNet/IP].

1 Tap the [Sensor Advanced] button on the Sensor Setup Menu screen.

2 Tap the [Environmental] button, and then the [Adv. Network Settings] button.

3 Tap the [Settings] button in the “Field Network”.

4 Select [Ethernet/IP] for the protocol.

5 To enable the handshake control, select [Enable].

yyWhen the protocol is set as [Disable], this setting item is shaded and cannot be selected.

yyWhen the data handshake control is set as [Enabled], the status result will not be updated until [Result acquisition complete

notice] (“Address2, Bit0” of Output Assembly) is input.

“Operating procedure of the cyclic communication” (Page 3-26)

“Operating procedure of the cyclic communication” (Page 3-26)

6 After the setting is completed, tap the [OK] button.

3

communication Cyclic

- IV Series User’s Manual (Field Network) - |

3-3 |

Cyclic communication setting method

3

communication Cyclic

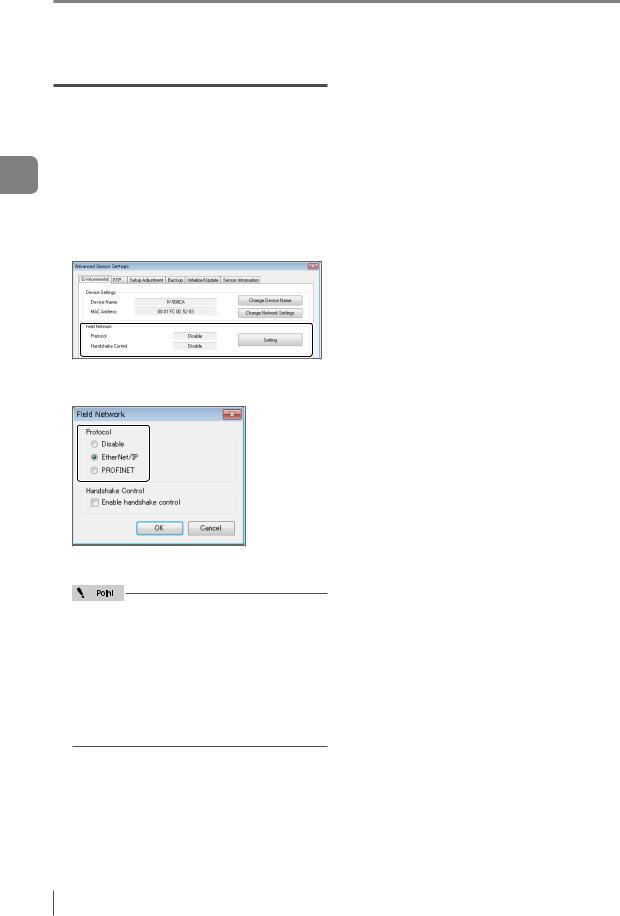

When setting by IV-Navigator (IV-H1)

Set the field network settings of the sensor to [EtherNet/IP].

1 Display the Advanced Sensor Settings screen.

2

3 Select [EtherNet/IP] in [Protocol] for the field network.

To enable the handshake control, check this check box  .

.

yyWhen the protocol is set as [Disable], this setting item is shaded and cannot be selected.

yyWhen the data handshake control is set as

[Enabled], the status result will not be updated until [Result acquisition complete notice] (“Address2, Bit0” Output Assembly) is input.

“Operating procedure of the cyclic communication” (Page 3-26)

“Operating procedure of the cyclic communication” (Page 3-26)

4 After the setting is completed, click the [OK] button.

The system returns to the main screen in

[Program].

5 Click the [OK] button.

3-4 |

- IV Series User’s Manual (Field Network) - |

Cyclic communication setting method

PLC settings

You can set the following settings for the PLC:

(1)Set the connection to be used for the cyclic communication.

(2)Set the device to be used for the cyclic communication.

For details of the setting, refer to the instruction manual of each PLC.

If you are using the Keyence KV series, (1) and (2) can be set automatically simply by making a selection in KV STUDIO.

Establishing the connection

In the cyclic communication, one device opens a logical communication circuit called a “connection” for the other device; and data communication will become possible if the open is successful.

The device that will open a connection is referred to as the “scanner”, and the device whose connection will be opened is referred to as the “adapter”.

(IV series is an adapter device)

In the EtherNet/IP communication, a connection must be opened from the scanner when the cyclic communication is started.

The communication is started in the following procedure:

(1)The scanner requests a connection open request to the adapter.

(2)Compatibility will be checked on the adapter side.

(3)A connection will open if no error is encountered in the compatibility check.

(1)Connection open request

(2) Compatibility check

(3) Connection open

|

Scanner |

Adapter device |

|

|

|

|

|

|

|

|

|

|

|

|

|

yyA compatibility check is used to check whether the device set by the scanner and the IV series are in match with one another, in order to prevent the scanner from communicating with a wrong device when it communicates with the IV series.

yyCommunication settings for the cyclic communication, such as the communication cycle (RPI) and the data size, will be configured on the scanner side.

In a network with many connected devices (including the EtherNet/IP devices), a network delay and/ or packet loss may occur when there is a heavy load on the network. Conduct a thorough verification before the operation.

3

communication Cyclic

- IV Series User’s Manual (Field Network) - |

3-5 |

Cyclic communication setting method

3

communication Cyclic

There are many types of connections, and the connection available for each device are defined in the EDS file.

The following shows the list of connections that are available in the IV series.

No |

Connection name |

Application type |

I/O |

Assembly |

Size |

RPI |

|

Instance |

(bytes) |

||||||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Monitor Data And |

|

This unit |

64H (100) |

2 to 392 |

|

|

|

External Input |

|

→ Scanner |

|

|||

1 |

Exclusive Owner |

|

|

5 to 10000ms |

|||

(Monitor/External |

Scanner |

65H (101) |

2 to 12 |

||||

|

input) |

|

→ This unit |

|

|||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Monitor Data (Input |

|

This unit |

64H (100) |

2 to 392 |

|

|

|

|

→ Scanner |

|

||||

2 |

Only) |

Input Only |

|

|

5 to 10000ms |

||

|

|

|

|||||

Scanner |

|

|

|||||

|

(Monitor data) |

|

FEH (254) |

0 |

|

||

|

|

→ This unit |

|

||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

When using the Keyence KV series (EtherNet/IP communication scanner), the names of the connections with the IV series will be “Monitor/External Input” and “Monitor Data”. The relationship of each connection

name is as described below. |

|

||

1: Monitor Data And External Input |

→ Monitor/External input |

||

2: Monitor Data (Input Only) |

→ Monitor data |

||

|

|

|

|

|

|

|

|

|

|

|

|

yyThe trigger timings of each connection are controlled by the cyclic communications; and both the point- to-point and Multicast connection types are supported.

yyIf you wish to open “Exclusive Owner” and “Input Only” connections simultaneously, set the connection type to “Multicast” and match the RPI and the size.

yyThe details of each application type are as described below.

[Exclusive Owner]

yyThis connection allows you to configure the data transmission from the scanner to the IV series, and vice versa.

yyThis connection type is used when the scanner will not only monitor the data of the IV series but also provide external input to the IV series.

yyIt is not possible for multiple scanners to open "Exclusive Owner" connections for a single IV series unit.

[Input Only]

yyThis connection only allows you to configure the data transmission from the IV series to the scanner. yyThis connection is used when the scanner will only monitor the data of the IV series.

yyMultiple scanners can simultaneously open “Input Only” connections for a single IV series unit. yyIf connections will be opened simultaneously from multiple scanners, set the connection type to

“Multicast” and match the RPI and the size.

3-6 |

- IV Series User’s Manual (Field Network) - |

Cyclic communication setting method

Keyence KV series settings

This following explains the setting method when using KV-5500.

For details of the required setting, such as the unit configuration for the PLC and the KV STUDIO settings for connecting with the PC, refer to the “KV STUDIO User’s Manual” and the “KV-EP21V User’s Manual”.

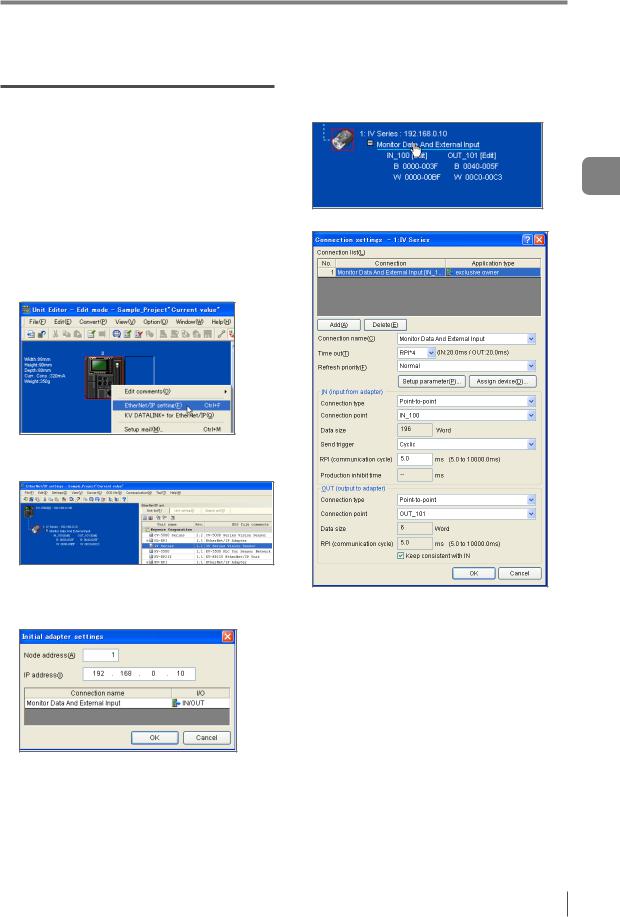

1 Right-click KV 5500 in the unit editor of KV STUDIO, and then select [EtherNet/IP setting].

2 Drag [IV Series] from the Unit list and add it to the scan list.

3 Set the Node address and IP address for the IV series on the [Initial adapter settings] screen.

4 Modify the settings as necessary.

Click the connection name in the scan list.

The [Connection settings] screen will appear.

zzConnection name

Select [Monitor/External input] or [Monitor data]. zzRPI (communication cycle)

You can set the cyclic communication cycle. zzConnection type

Select [Point-to-point] or [Multicast].

5 Save the settings and close [EtherNet/IP settings] and the unit editor.

3

communication Cyclic

- IV Series User’s Manual (Field Network) - |

3-7 |

Cyclic communication setting method

3

communication Cyclic

6 Select [Device comment edit window] from the [Edit] menu in KV STUDIO.

The [Device comment edit] screen will appear.

Click [Details].

The [Register unit device] screen will appear.

7 Make sure that the [IV Series] checkbox is ON  in the [Select unit] field, and then click the [Reg] button.

in the [Select unit] field, and then click the [Reg] button.

8 Select [PLC Transfer] from the [Monitor/ Simulator] menu of KV STUDIO.

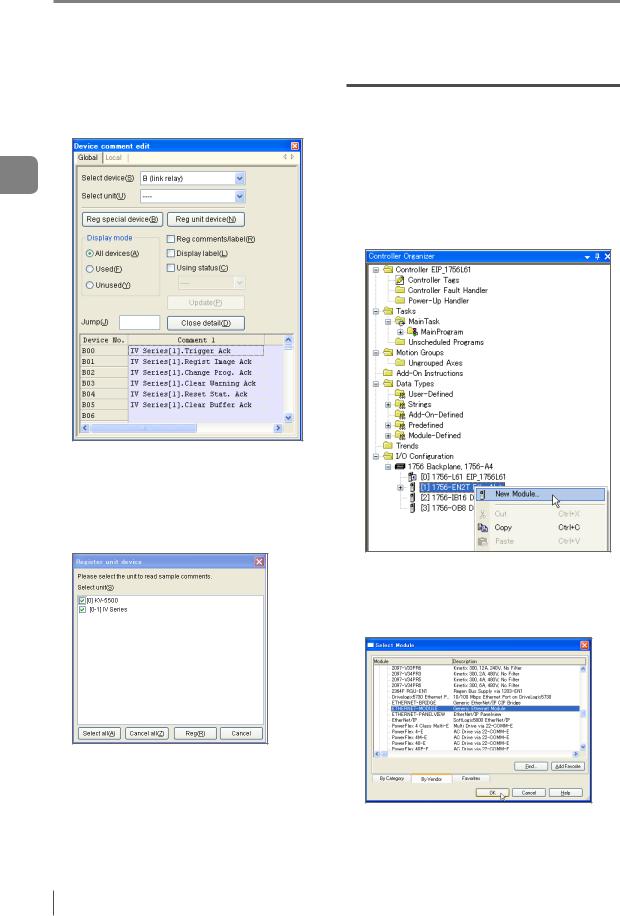

Rockwell Automation Control Logix series settings

This following explains the setting method when using a Control Logix PLC.

1 Select the EtherNet/IP communication unit to be connected with the IV series in

the I/O configuration of RsLogix5000, and then right-click to select [New Module].

The [Select Module] screen will appear.

2 Click the [+] button next to Communications, and then select EtherNET-MODULE (Generic Ethernet Module) and click the [OK] button.

The [New Module] screen will appear.

3-8 |

- IV Series User’s Manual (Field Network) - |

Loading...

Loading...