Page 1

Using the Air Purge Unit

96M12695

DANGER

WARNING

CAUTION

NOTICE

NOTICE

Important

At the time of shipping, the air purge unit is attached to the sensor head. By

using the air purge unit, you can reduce the dirt on the transmitter and

receiver caused by water, dust and other debris.

LS-9006D/LS-9030D

Instruction Manual

Read this manual before using the product in order to achieve maximum

performance.

Keep this manual in a safe place after reading it so that it can be used at

any time.

Introduction

This Instruction Manual provides the hardware information of the LS-9006D/

LS-9030D.

When reading the information pertaining to the usage methods and the

WARRANTIES AND DISCLAIMERS” section, be sure to also read the

“

corresponding parts of the “LS-9000 Series User's Manual.”

Keep this manual in a safe place for future reference.

Ensure that the end user of this product receives this manual.

■ Safety precautions on laser products

z Symbols

The following symbols alert you to important messages. Be sure to read

these messages carefully.

It indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

It indicates a situation which, if not avoided, could result in

product damage as well as property damage.

It indicates cautions and limitations that must be followed

Important

during operation.

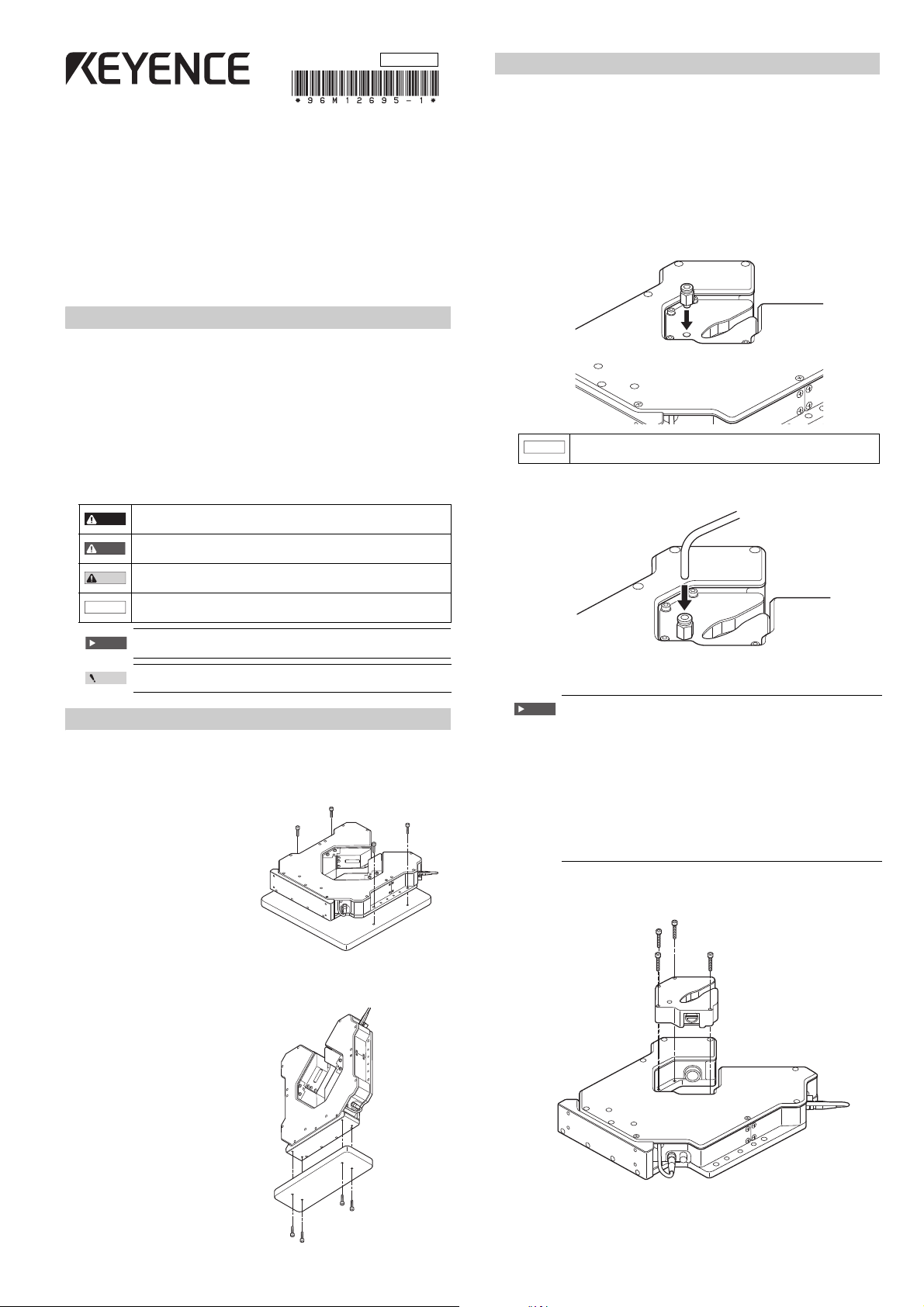

■ How to use the air purge unit

zLS-9006D

To use LS-9006D’s air purge unit, prepare the following off-the-shelf items:

•PC6-M5 (PISCO fitting) (Recommended)

• Air tube (Outer diameter

φ6)

1 Attach the fitting on the air purge unit.

Recommended tightening torque: 1 to 1.5 N・m

If you use an L-shaped fitting, make sure that the threaded

portion will not become loose due to twisting of the tube.

2 Insert the air tube into the fitting.

It indicates additional information on proper operation.

Point

Mounting the Head

■ Mounting method

zUsing the top mounting holes

Secure the head by inserting the provided hexagon socket bolts (M6 x

L25) through the mounting holes on the base surface and tightening them.

Maximum tightening torque value

• LS-9006D: 5.2 N・m

• LS-9030D

zUsing the bottom mounting holes

Secure the head using the mounting holes located on the bottom panel of

the base (M6 12 mm deep).

Maximum tightening torque value

• LS-9006D: 5.2 N・m

• LS-9030D

: 5.2 N・m

LS-9030D mounting example

: 5.2 N・m

LS-9030D mounting example

• Supply air flow rate:

20L/min to 40L/min

• Air pressure:

Approx. 60 kPa

The air pressure is measured before the air purge. The

pressure will vary depending on the point of measurement.

Be sure to check the performance based on the air flow.

• Be sure to use clean, dry air.

• The air purge performance and the measurement accuracy of

the sizer can be affected by the usage environment and/or the

condition of the air source. Determine the specifications for

the air source and the glass cleaning schedule in accordance

with the actual operating conditions.

When cleaning the receiver, remove the air purge unit that is secured

with four screws as shown below.

Maximum tightening torque for securing the unit: 1.5 N

・m

1

E LS-9006D/LS-9030D

Page 2

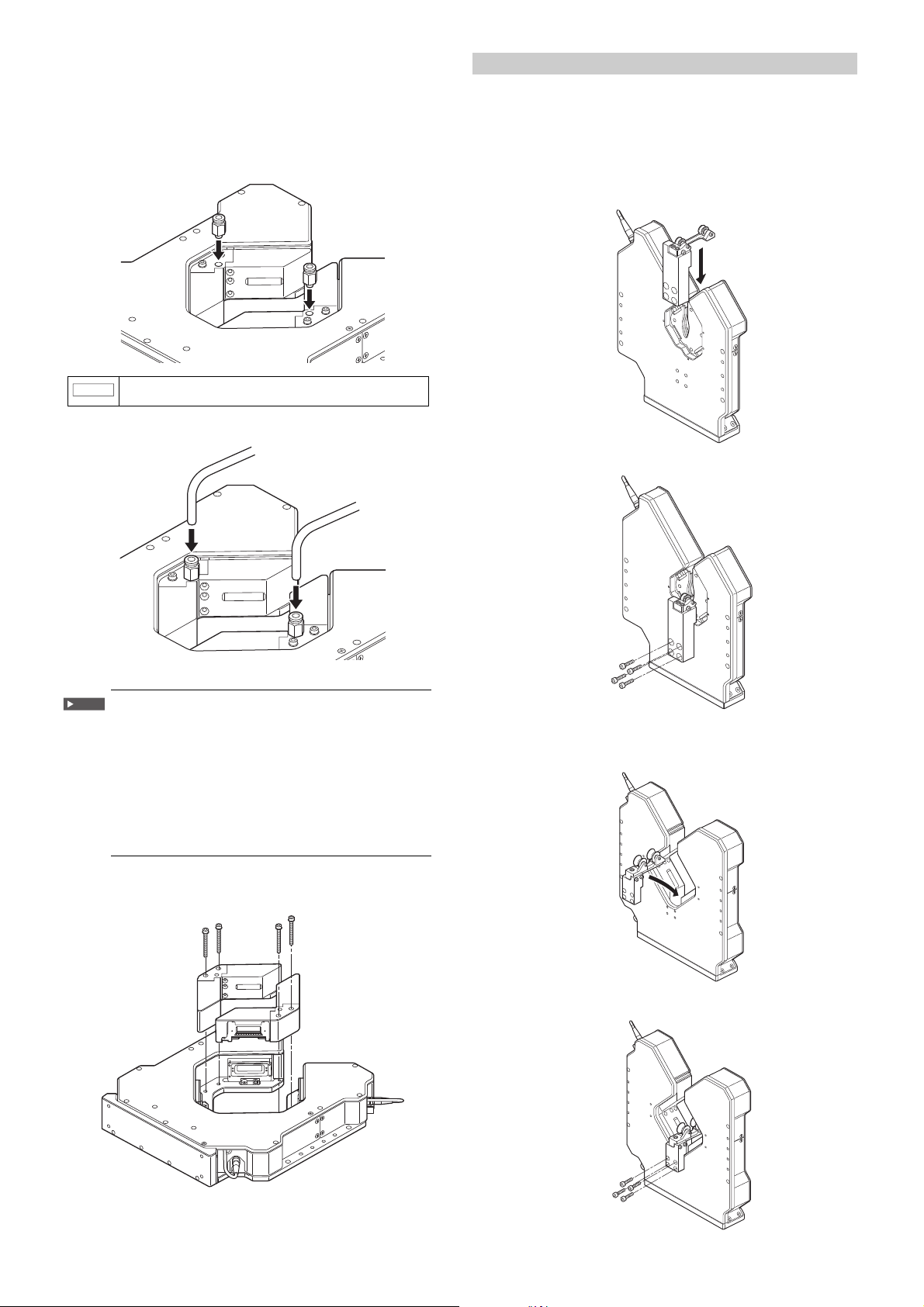

LS-9030D

NOTICE

z

To use LS-9030D’s air purge unit, prepare the following off-the-shelf items:

•PC6-M5 (PISCO fitting) (Recommended)

• Air tube

(Outer diameter φ6)

1 Remove the set screw from the inlet to which the fitting will be

attached. (2 mounting points)

Recommended tightening torque: 1 to 1.5 N・m

If you use an L-shaped fitting, make sure that the threaded

portion will not become loose due to twisting of the tube.

2 Insert the air tube into the fitting.

Using the Pulley Jig

The following describes how to mount the pulley unit to the casing. The

compatible combinations for pulley models and sensor heads are shown

below.

• LS-9006D : OP-87750

• LS-9030D : OP-87749

■ For LS-9006D

1 Place the jig into the notched section of air purge unit.

2 Secure it using the provided hexagon socket bolts (M5 x L15).

• Supply air flow rate:

Important

When cleaning the receiver, remove the air purge unit that is secured

with four screws as shown below.

Maximum tightening torque for securing the unit: 1.5 N

40L/

min to 80L/min (20 L/min to 40L/min per unit)

• Air pressure:

Approx. 40 kPa.

The air pressure is measured before the air purge. The

pressure will vary depending on the point of measurement.

Be sure to check the performance based on the air flow.

• Be sure to use clean, dry air.

• The air purge performance and the sizer’s measurement

accuracy can be affected by the usage environment and/or

the condition of the air source. Determine the specifications

for the air source and the glass cleaning schedule in

accordance with the actual operating conditions.

・m

■ For LS-9030D

1 Place the jig into the notched section of air purge unit.

2 Secure it using the provided hexagon socket bolts (M5 x L15).

E LS-9006D/LS-9030D

2

Page 3

Using the Display Panel Support

The following describes how to mount the display panel support (OP-87757)

to the casing.

■ Common to LS-9006D/LS-9030D

1 Mount the display panel support to the display panel (LS-D1000) using

the provided bolts (M4 x L10).

Maximum tightening torque for securing the unit: 0.75 N・m

2 Mount the display panel support to the casing using the provided

bolts (M5 x L12).

Specifications

Model LS-9006D LS-9030D

Measurement target

Minimum object sensitivity 0.04 mm 0.3 mm

Repeatability

Measurement position

accuracy

Sampling frequency*

Light source InGaN green LED

Monitor function Unavailable

Environment

resistance

Sensor head protection

ructure

st

Material Aluminum

Weight Approx. 4.8 kg Approx. 9 kg

*1 A ± 2σ margin of error when measuring the outer diameter of φ1.0 mm round

bars in the center of the measurement area with the average measurement

number set as 2048 times.

*2 A ± 2

*3 Margin of error when a moving

*4 Margin of error when a moving

*5 The sampling frequency will vary according to the number of OUTs that have

σ margin of error when measuring the outer diameter of φ10 mm round

bars in the center of the measurement area with the average measurement

number set as 2048 times.

measurement area.

measurement area.

been

set and the use of the mutual interference prevention function.

5

Operating

ambient

temperature

Operating

mbient

a

humidity

Ambient

uminance

l

Vibration

r

esistance

Impact

esistance

r

φ0.04 mm 〜 φ6 mm φ0.3 mm 〜 φ30 mm

1

μm*

±0.03

3

μm*

±0.5

16000 times/sec

0 to + 50ºC

20 to 85% RH

o condensation)

(N

Incandescent lamp/Fluorescent lamp:

10 to 55 Hz, double amplitude 1.5 mm;

IP67 (including the connector part)

φ1.0 mm round bar is measured in the

φ10 mm round bar is measured in the

3000 lx or less

2 hrs in X, Y and Z directions

15 G/6 ms

±0.1 μm*

±2 μm*

2

4

The panel support can be mounted on either side of the casing.

zAir purge unit

Model OP-87751

Material Aluminum

Weight Approx. 1500 g

OP-87752

Approx. 400 g

zTarget holder pulley

Model OP-87749

Material Aluminum (Main unit), SUS (Pulley part)

Weight Approx. 300 g

OP-87750

zDisplay panel support

Model OP-87757

No. of mountable display panels 1

Material Steel

Weight

Approx. 250

g

3

E LS-9006D/LS-9030D

Page 4

Characteristics

Zero point

*1

180

89

±1.5μm

±0.5μm

Y-axis head

receiver

X-axis head

receiver

±0.5

±0.5

2

4

2

4

6

6

X-axis

measurement area

Y-axis

measurement area

Unit: mm

Unit: mm

■ Measurement range and accuracy

zLS-9006D

zLS-9030D

Zero point

±0.5

200

*1

Y-axis head

receiver

X-axis head

receiver

±0.5

145

* Zero point is the intersection of the optical center of each X and Y axis

measurement range.

X-axis

measurement area

Y-axis

measurement area

30

30

20

10

±2μm

±5μm

10

20

* Zero point is the intersection of the optical center of each X and Y axis

measurement range.

■ Temperature characteristics

The following shows the typical examples of the temperature characteristics.

zLS-9006/LS-9006M/LS-9006D (X-axis, Y-axis)

Temperature 0°C 10°C 20°C 30°C 40°C 50°C

Drift

-

0.18-0.06 0.00 0.08 0.12 0.19

Unit: μm

*Whenaφ1roundbarismeasuredinthecenterofthemeasurementarea

(20ºCasreference)

zLS-9030/LS-9030M/LS-9030D (X-axis, Y-axis)

Temperature 0°C 10°C 20°C 30°C 40°C 50°C

Drift 0.28 0.14 0.00

*Whenaφ10roundbarismeasuredinthecenterofthemeasurement

area(20ºCasreference)

-

0.07-0.25

-

0.4

Unit: μm

E LS-9006D/LS-9030D

4

Page 5

Dimensions

4 x φ7

Measuring position

(Mounting hole)

4 x M6

Effective depth 12

M5 Effective depth 8

Fitting mounting screw

(85)

(85)

260

240

8

10

47

180

18

93

87

316

22.5

2417

89±0.5

180±0.5

78

147

24

134

Air purge unit*

1

Zero point*

2

R22

R22

Measuring position

Airpurgeunit*

1

20

215

69.6

220.4

62

(85)

(85)

140

360

130

255

316

13

330

20

40

13.5

145±0.5

200±0.5

Zero point*

2

36

R22

R22

33.9

2 x M5 Effective depth 8

Fitting mounting screw

4 x M6

Effective depth 12

4 x φ7

(Mounting hole)

100°

9

6

18

88

23 54

108

106.9

(115)

22.5

(3.5)

20

20

36

8

8

4 x φ5.4

φ16 φ16

Spot facing φ11

Depth 20

44

79.4

(1.8)

39

141

32.7

32.7

141

39

Fitting mounting screw

M5 Effective depth 8

■ Sensor head

zLS-9006D

■ Target holder pulley

Unit: mm

zOP-87749 (For LS-9030D)

Unit: mm

27.5

*1 Air purge unit is removable

*2 Zero point is the intersection of the optical center of each X and Y axis

measurement range.

zLS-9030D

100°

17

15

19

4 x φ5.8

Spot facing φ11 Depth13.5

77

167

24

7

38

zOP-87750 (For LS-9006D)

(5.5)

φ24

96

36 40

φ24

85.8

(97.8)

*1 Air purge unit is removable

*2 Zero point is the intersection of the optical center of each X and Y axis

measurement range.

■ Air purge unit

zOP-87751 (For LS-9030D)

5

Unit: mm

E LS-9006D/LS-9030D

Page 6

Copyright (c) 2013 KEYENCE CORPORATION. All rights reserved.

12695E 1093-1 96M12695 Printed in Japan

zOP-87752 (For LS-9006D)

29.2

10

88

88

21

20.4

Fitting mounting screw

M5 Effective depth 8

90

63

75

90

75

74

5211

26

(8)

Mounting hole for

LS-D1000

Mounting hole

4 x φ4.8

3 x φ5.5

35°

(Range of motion)

35°

(Range of motion)

■ Display Panel Support

zOP-87757

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were used

merely to illustrate the general type and quality of the Products and not to

represent that the Products would necessarily conform to said models or

samples. Any Products found to be defective must be shipped to KEYENCE

with all shipping costs paid by Buyer or offered to KEYENCE for inspection

and examination. Upon examination by KEYENCE, KEYENCE, at its sole

option, will refund the purchase price of, or repair or replace at no charge any

Products found to be defective. This warranty does not apply to any defects

resulting from any action of Buyer, including but not limited to improper

installation, improper interfacing, improper repair, unauthorized modification,

misapplication and mishandling, such as exposure to excessive current,

heat, coldness, moisture, vibration or outdoors air. Components which wear

are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products.

They are only suggestions, and it is Buyer's responsibility to ascertain the

fitness of the Products for Buyer’s intended use. KEYENCE will not be

responsible for any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are

not to be used internally in humans, for human transportation, as safety

devices or fail-safe systems, unless their written specifications state

otherwise. Should any Products/Samples be used in such a manner or

misused in any way, KEYENCE assumes no responsibility, and additionally

Buyer will indemnify KEYENCE and hold KEYENCE harmless from any

liability or damage whatsoever arising out of any misuse of the Products/

Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE

LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING

FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF

INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF PROFITS,

LOSS OF SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED

GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY MATTER

ARISING OUT OF OR IN CONNECTION WITH THE USE OR INABILITY

TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS

AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD PARTY’S

CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In

some jurisdictions, some of the foregoing warranty disclaimers or damage

limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to

a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written

information provided to Buyer pertaining to the Products/Samples.

E 1101-3

E LS-9006D/LS-9030D

6

Loading...

Loading...