Page 1

Instruction

Manual

High-speed Laser Scan Micrometer

96M12426

LS-5000 Series

Page 2

Safety Precautions

WARNING

CAUTION

CAUTION

This instruction manual describes the operation and function of the LS-5000 series.

Read this manual carefully to ensure safe use and maximum performance from

your LS-5000 series.

The LS-5000 series uses a semiconductor laser as the light source. Before using

the product, see “Laser Safety Precautions” on page 1 to learn the safe and correct

method of using the LS-5000 series.

Symbols

The following symbols alert you to important messages. Be sure to read these

messages carefully.

Failure to follow instruction may lead to injury. (electric

shock, burn, etc.)

Failure to follow instructions may lead to product damage.

General Precautions

Note:

• At startup and during operation, be sure to monitor the functions and performance of the LS-5000 series.

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the LS-5000 series or use it in any way other than

described in the specifications.

• When the LS-5000 series is used in combination with other instruments, functions and performance may be degraded, depending on operating conditions

and the surrounding environment.

• Do not use the LS-5000 series for the purpose of protecting the human body.

This is a class A (EN55011: EMI standard) product. In a domestic environment this

product may cause radio interference in which case the user may be required to

take adequate measures.

Provides additional information on proper operation.

i

Page 3

Checking the Contents of the Package

The LS-5000 series includes the following items. Be sure to check that no item is

missing or damaged.

■ LS-5501 Package

• Built-in display type controller: 1

• Instruction manual: 1

• AC power cables: 2

■ LS-5001 Package

• Separate type controller: 1

• Instruction manual: 1

• Communication cable (OP-26401 + OP-96368): 1

• LS-VIEWER Software (3.5-inch FD, Instruction manual): 1

■ LS-5041/5121 Package

• Scanning head (Transmitter, receiver and mounting base): 1

• Mounting brackets: 4

• ROM board: 1

1. Two types of AC power cables are provided with the built-in display model LS-5501. One is for 125

VAC and the other is for 250 VAC. Select either according to your local power supply type.

2. The serial nos. of both units should be identical.

1.

2.

2.

Warranty

Notice

See page 125.

• No part of this instruction manual may be reprinted or reproduced without the

prior written permission of KEYENCE CORPORATION.

• KEYENCE assumes no responsibility for the contents of this manual. No liability

is assumed for damages resulting from a program created by customers.

• The contents of this manual are subject to change without notice.

96M12426

ii

Page 4

Contents

Chapter 1 Laser Safety Precautions

Chapter 2 Before Using the LS-5000 Series

1.1 Classification .......................................................................................... 2

1.2 Warning Labels ...................................................................................... 2

1.3 Label Location ........................................................................................ 3

1.4 Safety Consideration .............................................................................3

1.5 Safety Features Provided with the LS-5000 Series ............................. 4

1.6 Preparation for Operation ..................................................................... 6

2.1 System Configuration and Connections ............................................. 8

2.1.1 System Configuration ................................................................................ 8

2.1.2 Connection Procedure .............................................................................. 9

2.2 Names and Functions of Indicators and Switches ...........................12

2.3 Part Names ........................................................................................... 13

Chapter 3 Quick Start Reference

3.1 Quick Start Reference ......................................................................... 16

3.1.1 Procedure for Starting Measurement ......................................................16

Chapter 4 Installation

4.1 Mounting the Scanning Head ............................................................. 18

4.2 Mounting the Controller ...................................................................... 19

Chapter 5 Outline of Measurements

5.1 Area/Segment/Edge .............................................................................22

5.2 Normal mode ........................................................................................22

5.2.1 DIA mode ................................................................................................ 23

5.2.2 T.EDGE (TOP EDGE) mode/B.EDGE (BOTTOM EDGE) mode ............ 23

5.2.3 SEG (m,n) mode ..................................................................................... 23

5.3 Pitch mode ............................................................................................ 24

iii

Page 5

Chapter 6 Normal mode

6.1 Normal Mode Screens ......................................................................... 24

6.2 Initial Screen ......................................................................................... 27

6.3 Setting Measuring Mode ..................................................................... 28

6.4 Setting Functions ................................................................................. 29

1 [HOLD] Hold Function...................................................................... 30

2 [ZERO] Auto-zero Function ............................................................. 31

3 [SCREEN] Screen Selection Function ............................................. 32

4 Limit Setup ....................................................................................... 35

5 [CALIB] Calibration Setup ................................................................ 36

6 [PROGRAM] Program Selection Function ....................................... 38

7 Area Setup ....................................................................................... 39

8 Calculation Setup ............................................................................. 41

9 Average ........................................................................................... 44

0 Measuring Mode ..............................................................................46

A Digit Suppression Function .............................................................. 54

B Offset Function ................................................................................ 55

C Analog Output Function ...................................................................57

D I/O Slot Setup .................................................................................. 59

E Inspection ........................................................................................ 60

F One-scan Mode ............................................................................... 62

G Program Selection Method Setup .................................................... 64

H Display Unit ...................................................................................... 65

I Area Check Function ....................................................................... 66

J Initialize ............................................................................................ 67

K Mode Change .................................................................................. 68

Chapter 7 Pitch Mode

7.1 Pitch Mode Screens ............................................................................. 70

7.2 Initial Screen ......................................................................................... 71

7.3 Setting Measurement ........................................................................... 72

7.4 Setting Functions ................................................................................. 72

1 Screen Selection Function ............................................................... 73

2 Limit Setup ....................................................................................... 75

3 Program Selection Function ............................................................76

4 Setting Number of Pitches ...............................................................77

5 Average ........................................................................................... 79

6 Digit Suppressing Function .............................................................. 80

7 Measuring Mode ..............................................................................81

8 Masking ...........................................................................................84

9 Mode Change .................................................................................. 85

iv

Page 6

Chapter 8 RS-232C I/O

8.1 RS-232C Communication Protocol .................................................... 88

8.2 Remote Control Function .................................................................... 90

8.3 Command List ......................................................................................97

Chapter 9 Expansion I/O Board

9.1 Control I/O Board ...............................................................................100

9.1.1 Part Names and Pin Assignment .......................................................... 100

9.1.2 I/O Terminal Operations ........................................................................ 101

9.1.3 Specifications ........................................................................................102

Chapter 10 Display System Setup

10.1 Display System Setup .....................................................................104

10.1.1 Adjusting Backlight Intensity ...............................................................104

10.1.2 Reversing Display ............................................................................... 105

10.1.3 Adjusting Contrast .............................................................................. 106

10.1.4 Setting Backlight OFF Time ................................................................ 107

10.1.5 Adjusting Buzzer Volume.................................................................... 108

10.1.6 Numeric Keys .....................................................................................109

10.2 Display Hardware Check Function ................................................. 110

10.3 Replacing Protective Sheet ............................................................. 111

10.4 Display Panel-lock Function ...........................................................112

Appendices

Appendix A Specifications ........................................................................114

Appendix B Initial Setting .......................................................................... 116

Appendix C Troubleshooting Guide ......................................................... 118

Appendix D Error Messages ...................................................................... 120

Appendix E Minimum Input Time and Output Response Time .............. 121

Appendix F Dimensions ............................................................................122

WARRANTIES AND DISLAIMERS 125

v

Page 7

Chapter 1

Laser Safety Precautions

1.1 Classification ........................................................................ 2

1.2 Warning Labels ..................................................................... 2

1.3 Label Location ...................................................................... 3

1.4 Safety Consideration ............................................................ 3

1.5 Safety Features Provided with the LS-5000 Series ........... 4

1.6 Preparation for Operation .................................................... 6

Page 8

Chapter 1 Laser Safety Precautions

CAUTION

1.1 Classification

1

1.2 Warning Labels

LS-5041 LS-5121

Laser FDA (CDRH) Part 1040.10 Class II Laser Product

Class IEC60825-1 Class 2 Laser Product

■ LS-5041

Warning label/Aperture label

FDA Class II IEC Class 2

IEC (French) Classe 2 DIN Klasse 2

■ LS-5121

Warning label/Aperture label

FDA Class II IEC Class 2

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

LASER RADIATIONDO NOT STARE INTO BEAM

SEMICONDUCTOR LASER

WAVELENGTH

OUTPUT

PULSE DURATION

CLASS II LASER PRODUCT

655nm

45µW

14µs

IEC (French) Classe 2 DIN Klasse 2

2

Page 9

1.3 Label Location

LS-5121T

SCANNING AREA

Aperture

CAUTION

■ LS-5041

■ LS-5121

Chapter 1 Laser Safety Precautions

Aperture

1

LS-5041T

SCANNING AREA

The IEC/DIN Warning labels are packed with the scanning head. Stick the Warning

labels on the scanning head or the vicinity where the scanning head is mounted in

order to be easily seen by the operators.

1.4 Safety Consideration

Use of controls or adjustments or the performance of procedures other than those

specified herein may result in hazardous radiation exposure.

The LS-5041 employ a visible semiconductor laser for its light source. The beam is

not harmful to the skin. The possible health hazard is in exposing the eyes to the

laser beam. Damage to the eyes occur if the operator stares directly into the beam.

3

Page 10

Chapter 1 Laser Safety Precautions

WARNING

1

Follow the safety precautions below to ensure operator safety:

• Operate the LS-5000 series only according to the procedures described in

this instruction manual.

Otherwise, injury may occur due to exposure to the laser beam.

• Do not disassemble the scanning head.

Laser emission from the LS-5000 series is not automatically stopped if the

scanning head is disassembled. If you disassemble the scanning head for

inspection or repair, you may be exposed to the laser beam. If the LS-5000

series malfunctions, contact KEYENCE immediately.

• Do not look directly into the laser beam.

Looking directly into the laser beam may result in serious eye injury.

• Protective enclosure

We recommend that you install a protective enclosure around the scanning

head to prevent any person from getting near the scanning head during operation.

• Protective goggles

We recommend that you wear protective goggles when using the LS-5000

series.

• You must stop all laser emissions before cleaning the laser aperture. Otherwise,

you may be exposed to the laser beam.

• Be aware of the optical axis of the laser beam.

If you may be exposed to a specularly-reflected or diffused laser beam, provide

an enclosure with reflectivity and thermal characteristics adequate to interrupt

the laser beam.

Install the LS-5041 so that the optical axis of the laser beam will not be at the

same height as your eyes when operating the LS-5000 series.

1.5 Safety Features Provided with the LS-5000 Series

The LS-5000 series comes with the following safety features:

• Laser emission remote control terminals

Rear of the LS-5001 Rear of the LS-5501

4

Laser emission remote

control input terminal

Laser emission remote

control input terminal

Page 11

Chapter 1 Laser Safety Precautions

LS-5041T

LS-5041T

LS-5041T

LS-5041T

LS-5121T

LS-5121T

• LASER ON alarm indicator

The scanning head has an LED which indicates that the laser beam is currently

being emitted or is about to start.

Even when you are wearing safety goggles, you can check whether the indicator is

lit or not.

Laser ON alarm indicator

• Laser beam shield

The LS-5000 series includes a laser beam shield which is to be attached to the

scanning head’s transmitter. Attach this shield when your eyes may be exposed to

the laser beam, for example during operation at the front of the scanning head.

■ LS-5041

Appearance with the laser

beam shield attached

Appearance with the laser

beam shield not attached

1

Laser beam shield

■ LS-5121

Appearance with the laser

beam shield attached

Appearance with the laser

beam shield not attached

* FDA safety standards do not require a laser beam shield to be provided with

Class II laser products. However, the shield should be used if necessary.

5

Page 12

CAUTION

1.6 Preparation for Operation

■ Suppressing noise interference

Be sure to isolate the connection cable from high-voltage or power lines. If the

connection cable is placed in the same conduit as these lines, the LS-5000 series

may malfunction due to noise interference.

■ Cooling fan

Do not block the cooling fan at the bottom of the LS-5501. If the cooling fan is

blocked, the LS-5501 may overheat and malfunction.

■ Operating environments

• Use the controller at an ambient temperature of 0°C to 45°C (32 to 113°F), No

freezing.

• Fluctuations in the ambient temperature cause measurement errors; therefore,

the ambient temperature should be kept constant. If the temperature changes

by 10°C (18°F), the LS-5000 series will take approximately 60 minutes until the

temperature distribution in the unit becomes even.

• Do not allow any substance which may refract the laser beam, such as water

and oil, to adhere to the scanning head.

* Blow dust off the protective glass using clean air. Wipe off any remaining dust

using a soft cloth moistened with alcohol.

Note 1: Measurement conditions

When the target oscillates, the measured value may fluctuate. The measurement

accuracy can be improved when the number of averaging measurements is set

higher.

Note 2: Target

When the target shape or luster varies, a measurement error may occur. In this

case, place a standard target in the measuring area and perform the calibration

using the [CALIB] key.

6

Page 13

Chapter 2

Before Using the LS-5000 Series

2.1 System Configuration and Connections ............................. 8

2.1.1 System Configuration .............................................................. 8

2.1.2 Connection Procedure ............................................................. 9

2.2 Names and Functions of Indicators and Switches .......... 12

2.3 Part Names .......................................................................... 13

Page 14

Chapter 2 Before Using the LS-5000 Series

LS-5501

I/O board (LS-B11)

ROM board

LS-5041/5121

Connection cable (option)

LS-C3: 3m

LS-C10: 10 m

LS-C50: 50 m

24 VDC

LS-5001

LS-5041/5121

Connection cable (option)

LS-C3: 3m

LS-C10: 10 m

LS-C50: 50 m

ROM

board

Expansion slots

Power

supply

I/O board (LS-B11)

Personal computer

LS-VIEWER

operating software

for Windows 95

2.1 System Configuration and Connections

The LS-5000 series includes the display unit, controller and scanning head.

This section describes the system configuration and connections of the LS-5000

series.

2.1.1 System Configuration

The LS-5000 series includes the display unit, controller and scanning head. The

controller can be used separately.

2

The LS-5000 series also offers I/Oboard, as well as a control unit which

incorporates the display unit and controller in a single body.

• Separate display type

• Built-in display type

Note: The scanning head and ROM board are calibrated as a pair. Be sure to

combine the units that have the same serial number.

8

Page 15

CAUTION

2.1.2 Connection Procedure

Frame cover Frame cover

Screws Screws

Frame cover Frame cover

Connecting the Scanning Head

Be sure to turn the power off before connecting the scanning head.

■ Connection of ROM Board

1. Remove the frame cover.

Chapter 2 Before Using the LS-5000 Series

LS-5001

2. Insert the ROM board.

LS-5001

Note: Insert the ROM board into HEAD 1 first.

LS-5501

LS-5501

2

3. Tighten the screws.

LS-5001

4. Re-attach the frame cover.

LS-5001

LS-5501

LS-5501

9

Page 16

Chapter 2 Before Using the LS-5000 Series

Transmitter Receiver

Transmitter Receiver

LS-C3 (3 m)

To ROM board

2

■ Connecting Transmitter and Receiver

1. Connect the cable between the transmitter and receiver.

Use the extension cable if necessary.

Extension cable between transmitter and receiver: OP-26540 (3 m)

OP-26816 (10 m)

2. Connect the cable between the transmitter and receiver to the scanning head

and ROM board. (This cable is optional.)

Connection cable

LS-C3 3 m

LS-C10 10 m

LS-C50 50 m

10

Page 17

Connecting I/O Board

CAUTION

Frame cover Frame cover

Screws Screws

Chapter 2 Before Using the LS-5000 Series

Be sure to turn the power off before connecting the I/O board.

1. Remove the frame cover.

LS-5501LS-5001

2

2. Insert the I/O board.

Note: Use the slot 1 first. When the slot 1 is used, use the slot 2.

LS-5001

3. Tighten the screws.

4. Re-attach the frame cover.

LS-5501

LS-5501LS-5001

LS-5501LS-5001

11

Page 18

Chapter 2 Before Using the LS-5000 Series

DISPLAY

DATA

LIMIT

SETUP

7 8 9

4 5 6

1 2 3

0 • –

ESCAPE

CANCEL

ENTER

5 • 0 0 0 0 –

ESCAPEENTER

2.2 Names and Functions of Indicators and Switches

This section describes the names and functions of the indicators and switches.

■ Names and Functions of Indicators and Switches

Display Name Description

Menu button Used to move to each function’s setup screen.

2

Setup/Select Used to set values or select settings.

button

Select button Used to select settings or programs.

Screen Select When you press the [Screen Select] button, you

button will move to the screen indicated on the button.

In the example on the left, you will move to the

DISPLAY DATA screen.

Numeric keys Used to set values.

[ENTER] key: Used to accept the setting.

[ESCAPE] key: Used to exit from the numeric keys

screen.

[CANCEL] key: Used to reset the preset value to

zero.

Sign key: Used to change the sign.

▲

[▲] [ ] keys: Used to move between setting

items.

■ Input Procedure Using Numeric Keys

Example: Enter “-5.0000”.

12

Page 19

2.3 Part Names

7

12

3

4

2

5 6

1

10

8

9

233

4

5

12

11

7

6

This section describes the part names of each model.

LS-5001 (Separate display type)

Front

1 I/O connector (LS-B11)

2 Analog output BNC connector (LS-B11)

3 Scanning head connecting port

4 DIP switch

5 Laser emission control input terminal

6 Program selection input terminal

7 Power supply terminal (24 VDC)

Chapter 2 Before Using the LS-5000 Series

2

LS-5501 (Built-in display type)

Front Rear

1 Measured value display and function setup/operating unit

2 I/O connector (LS-B11)

3 Analog output BNC connector (LS-B11)

4 Scanning head connecting port

5 DIP switch

6 Laser emission control input terminal

7 Program selection input terminal

8 Power supply switch

9 Power supply input

0 Fuse holder (250 V, 3.15 A)

A Expansion slot 1 for I/O board

B Expansion slot 2 for I/O board

13

Page 20

Chapter 2 Before Using the LS-5000 Series

1

2 3

4

5

676

LS-5041/5121 (Scanning head)

2

1 Laser ON alarm indicator

2 Transmitter (T)

3 Laser emission aperture

4 Receiver (R)

5 Connecting cable between scanning head and controller

6 Connecting cable between transmitter and receiver

7 Scanning head mounting frame

14

Page 21

Chapter 3

Quick Start Reference

3.1 Quick Start Reference ........................................................ 16

3.1.1 Procedure for Starting Measurement.....................................16

Page 22

Chapter 3 Quick Start Reference

3.1 Quick Start Reference

This section describes the procedures for starting measurement for trial operation.

3.1.1 Procedure for Starting Measurement

3

Connect the controller and scanning head.

▲

Turn the power on.

▲

Align the optical axis of the transmitter and

receiver.

▲

The 5001 series starts laser emission in

approximately 5 seconds, at which time the

measurement begins.

▲

Place a target in the measuring area.

▲

The measured value is soon displayed.

For information on the connection

procedure, see p. 8.

• When the transmitter and receiver are

fixed to the scanning head mounting

frame, optical axis alignment is not

necessary.

• For information on the scanning head

mounting allowance, see p. 18.

For information on checking the optical

axis, see p. 60 and 61.

For information on the measuring area,

see p. 115.

The factory setting for the number of

averaging measurements is 768 for DIA

mode.

Before changing the measuring mode or the number of averaging measurements,

read this instruction manual thoroughly for the correct settings.

For setting items, see the table of contents.

The following is reference page numbers for typical operations.

• Changing the DIA mode to EDGE mode ............................................... p.39, 40

• Changing the number of averaging measurements ............................... p.44, 45

• Changing the measuring mode ........................................................... p.46 to 51

• Simultaneous measurement ........................................................................p.32

• (X + Y)/2 measurement using two scanning heads ............................... p.41, 42

16

Page 23

Chapter 4

Installation

4.1 Mounting the Scanning Head ............................................18

4.2 Mounting the Controller ..................................................... 19

Page 24

Chapter 4 Installation

Transmitter Receiver

Transmitter Receiver

Within ±1 mm

Within ±1 mm

Transmitter Receiver

Transmitter Receiver

Within ±1 mm

Within ±1 mm

Receiver

Receiver

Within ±0.25° Within ±0.25°

Within ±0.25° Within ±0.25°

Transmitter

Transmitter

Receiver

Transmitter

Transmitter

Receiver

4.1 Mounting the Scanning Head

The LS-5000 series comes with the transmitter and receiver fixed to the scanning

head mounting frame. To use the LS-5000 series with the transmitter and receiver

removed from the mounting frame, mount the scanning head so that the following

specifications are met. This will eliminate measurement errors caused by optical

axis misalignment.

Allowance for Mounting the Scanning Head

■ Horizontal deviation of transmitter and receiver positions

4

■ Inclination of transmitter and receiver

* Values in parentheses are for the LS-5121.

Note: For information on the optical axis checking function, see “Head Inspection”

on p. 60.

18

Page 25

4.2 Mounting the Controller

DIN rail

LS-5121T

SCANNING AREA

LS-5121R

SCANNING AREA

This section describes how to mount the controller (LS-5001).

Mounting the LS-5001

The LS-5001 can be mounted to a DIN rail.

Hook the upper claw first, and then press the controller against the DIN rail until it

clicks.

Chapter 4 Installation

4

Mounting the Scanning Head Front Protection Cover (For LS-5121)

Application example of front protection cover

Transmitter

The LS-5121 transmitter and receiver come with a protection cover for the scanning head.

Mount the cover as shown in order to prevent the front glass of the scanning head

from being scratched or broken.

Receiver

19

Page 26

Chapter 4 Installation

4

20

Page 27

Chapter 5

Outline of Measurements

5.1 Area/Segment/Edge ............................................................ 22

5.2 Normal Mode ....................................................................... 22

5.2.1 DIA Mode ............................................................................... 23

5.2.2 T.EDGE (TOP EDGE) Mode /

B.EDGE (BOTTOM EDGE) Mode ......................................... 23

5.2.3 SEG (m,n) Mode .................................................................... 23

5.3 Pitch Mode ........................................................................... 24

Page 28

Chapter 5 Outline of Measurements

Edge 0

Edge 1

Edge 2

Edge 3

Edge 4

Edge 5 (n-1)

Edge 6 (n)

Photodiode for synchronization

Laser

scanning

direction

Target

Transmitter Receiver

Photodiode for synchronization

Transmitter Receiver

Roller

Rotating

This width can be

measured when

SEG(m,n) is set to (0,2) in

Normal mode.

5.1 Area/Segment/Edge

When a target is placed in the measuring area, there are areas where the laser

beam is received (laser beam enters the receiver), and where the laser beam is

interrupted by the target (shadow of the target is projected on the receiver). The

border between the light and dark areas is called “EDGE”. Each section divided by

the edge is called a “SEGMENT”. The measurement "AREA" is determined by two

edges and includes all "SEGMENTS" between these two edges.

* The edge number is counted in the laser scanning direction starting at T.EDGE

(top edge).

5

5.2 Normal Mode

Note: EDGE 0

The position of the photodiode for synchronization is called “EDGE 0”.

EDGE 0 can be used as a reference point during roller oscillation measurement or

sheet edge control. (No reference edge is required.)

Example: Roller oscillation measurement

➮

For the setting procedure, see p. 39.

The LS-5000 series has two measuring modes; NORMAL and PITCH. NORMAL

mode provides four types of measurement3: “DIA”, “T.EDGE (Top Edge)”,

“B.EDGE (Bottom Edge)” and “SEG(m,n)”.

The function of each mode is described below. Select the mode that suits your

measurement condition.

DIA mode

Measurement of outer diameter

of rod or electric wire

22

T.EDGE/B.EDGE modes

Measurement of gap

between rollers or position

of target

edge

SEG(m,n) mode

Setting the measurement

position to measure inner

diameter using

a bearing

Page 29

5.2.1 DIA Mode

Photodiode for synchronization

Laser

scanning

direction

Target

Measured

width

Transmitter Receiver

Photodiode for synchronization

Target

Measured

width

Transmitter Receiver

Photodiode for synchronization

Target

The T.EDGE mode

measures this width.

The B.EDGE mode

measures this width.

Transmitter Receiver

Photodiode for synchronization

Target

Both the T.EDGE and B.EDGE

modes measure this width.

Transmitter Receiver

Photodiode for synchronization

Target

This width is measured

when SEG(3,4) is set.

Transmitter Receiver

0

1

2

3

4

5

6

Chapter 5 Outline of Measurements

Example: Outer diameter measurement using a rod or transparent object

The width between the lower edge of the first light segment and the top edge of the

last light segment is measured.

• When one target is measured

• When several targets are measured

5.2.2 T.EDGE (TOP EDGE) Mode / B.EDGE (BOTTOM EDGE) Mode

Example: Measurement of a gap between rollers

T.EDGE: Measures the width of the first light segment.

B.EDGE: Measures the width of the last light segment.

5.2.3 SEG (m,n) Mode

Example: Inner diameter measurement using a bearing

When two edges are specified, the width between these edges is measured.

5

* (m,n) indicates any number between 0 and 254. “m” should be smaller than “n”.

Note: DIA mode

Since DIA mode is basically intended for outer diameter measurement of a rod,

transparent tube or other round surface, the measurement error due to the round

surface is calibrated.

To perform outer diameter measurement of a round target, select DIA mode.

23

Page 30

Chapter 5 Outline of Measurements

LASER ON DISPLAY DATA PITCH P. 1

HEAD1OKMax

Min

0.5010

0.4990

HEAD2OKMax

Min

0.6010

0.5990

HEAD3OKMax

Min

0.7020

0.6980

HEAD4OKMax

Min

0.8020

0.7980

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAM OPTIONS

DISPLAY

DATA

Pitch

Optical axis

5.3 Pitch Mode

➮

For the setting procedure, see p. 72.

Pitch mode enables pitch measurement using connector pins or IC leads.

This mode measures each center-to-center pitch, and displays the maximum and

minimum values.

5

Note 1: When Pitch mode is selected, only one measurement can be performed

with one scanning head.

Note 2: When Pitch mode is selected, the comparator output is activated as shown

below:

HI3 = Alarm output

HI2 = Disabled

HI1 = Output when the measured value exceeds the upper/lower limit.

GO = Output when the measured value is within the upper/lower limit.

LO1: Disabled

LO2: Disabled

LO3: Disabled

24

The analog output and RS-232C output are activated as shown below.

Analog output: Held at +10V.

RS-232C output: Output according to the command.

➮

See p. 97.

Page 31

Chapter 6

Normal Mode

6.1 Normal Mode Screens ........................................................ 26

6.2 Initial Screen ....................................................................... 27

6.3 Setting Measuring Mode .................................................... 28

6.4 Setting Functions ............................................................... 29

1 [HOLD] Hold Function .................................................... 30

2 [ZERO] Auto-zero Function ............................................ 31

3 [SCREEN] Screen Selection Function ........................... 32

4 Limit Setup ..................................................................... 35

5 [CALIB] Calibration Setup .............................................. 36

6 [PROGRAM] Program Selection Function ..................... 38

7 Area Setup ..................................................................... 39

8 Calculation Setup ........................................................... 41

9 Average .......................................................................... 44

0 Measuring Mode............................................................. 46

A Digit Suppression Function ............................................ 54

B Offset Function ............................................................... 55

C Analog Output Function.................................................. 57

D I/O Slot Setup ................................................................. 59

E Inspection ....................................................................... 60

F One-scan Mode .............................................................. 62

G Program Selection Method Setup .................................. 64

H Display Unit .................................................................... 65

I Area Check Function ...................................................... 66

J Initialize .......................................................................... 67

K Mode Change ................................................................. 68

Page 32

Chapter 6 Normal Mode

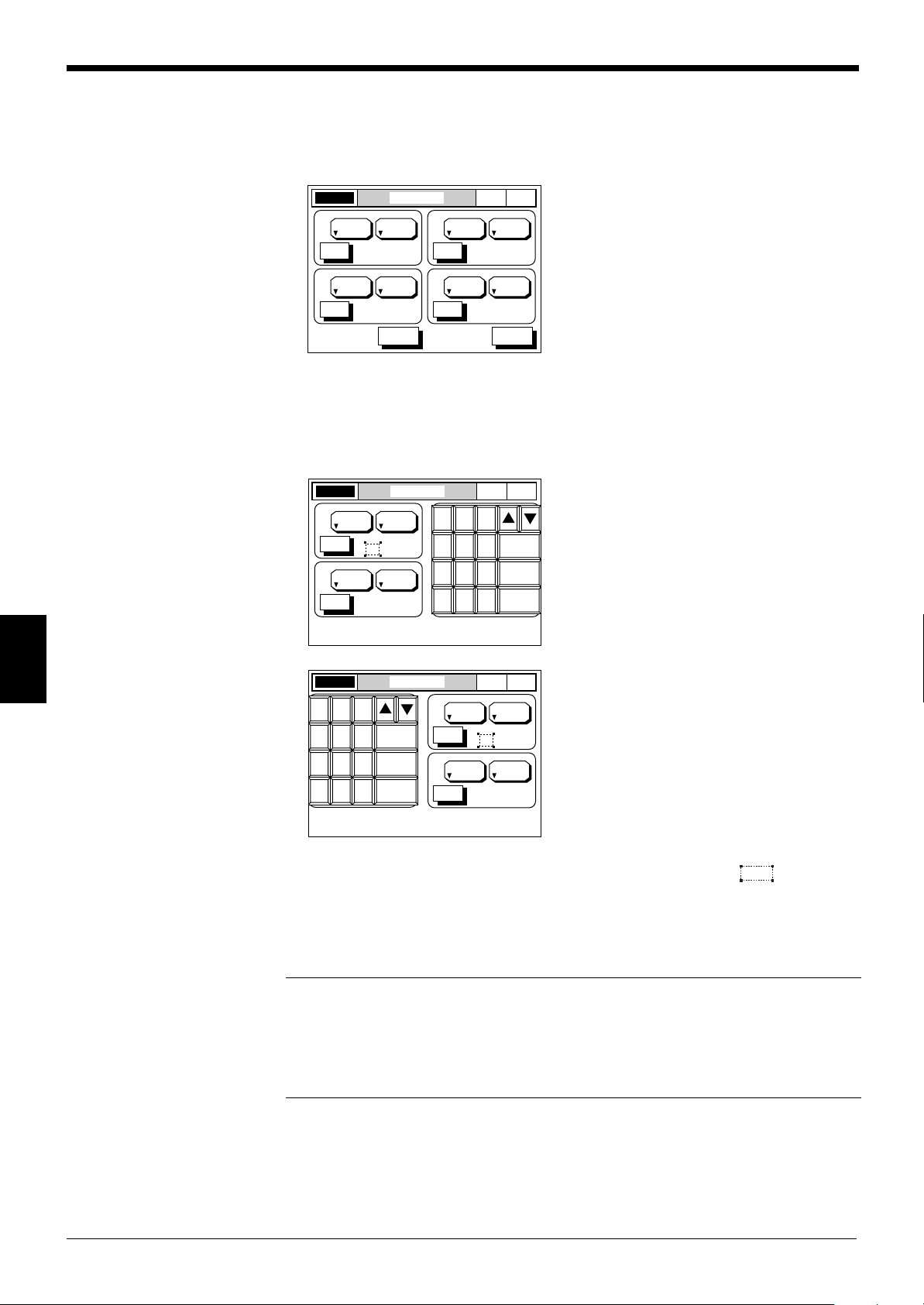

LASER ON SCREEN

NOR

MAL

P. 1

DISPLAY DATA

DISPLAY DATA

DISPLAY GRAPH

DISPLAY GRAPH

ONOUT1

SET SET

OFFOUT2

OUT1

OFFOUT3

OFFOUT4

LASER ON DISPLAY GRAPHOUT1

NOR

MAL

P. 1

SETUP SCREEN

40.0000

0.0000

DATA: 25.77110

AREA

OUT1

OUT4

OUTPUT

INSPECT

UTILITY

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 HI3

HI1 20.0000

LO1 15.0000

OFF

OFF

ZERO

HOLD

SCREEN

SCREEN

DISPLAY

DATA

DISPLAY

DATA

LIMIT

SET UP

PROGRAMCALIB

OPTIONS

54.21595

LASER ON SELECT OUTPUT

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SET UP

LIMIT

SET UP

PROGRAMCALIB

OPTIONS

OUT1

OUT2

OUT3

OUT4

Select Output No. to set the limits.

LASER ON AREA SETUP

NOR

MAL

P. 1

DIAHEAD1

( 2, 3)

ESCHELP

SET

HEAD No.

EDGE No.

A1

SEGMENT

DIAHEAD2

( 2, 3)

SET

HEAD No.

EDGE No.

A2

SEGMENT

SEGMENT

SEGMENT

DIAHEAD3

( 2, 3)

SET

HEAD No.

EDGE No.

A3

DIAHEAD4

( 2, 3)

SET

HEAD No.

EDGE No.

A4

OUTPUT MODEOUT1LASER ON P. 1

+A1 OFF OFF OFF

AREA1 AREA2 AREA3 AREA4

100

AVERAGE

CALCULATE

1 (0.833ms)

MEASURING MODE

SELF-TIMING

INTERVAL (ms)

NORMAL

DIGIT

SUPPRESS

NONE

ESCHELP NEXT

NOR

MAL

HEAD1

HEAD4

LASER ON CALIBRATE AREA

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SET UP

PROGRAMCALIB

CALIB

PROGRAM

OPTIONS

OPTIONS

AREA1

AREA2

AREA3

AREA4

Select Area No. to calibrate.

LASER ON OUTPUT MODE

NOR

MAL

P. 1

OUT1

OUT2

OUT3

I/O SLOT

SETUP

OUT4

ESC

Select Output to set.

LASER ON I/O SLOT SETUP

NOR

MAL

P. 1

I/O OUT1

OUT2

OUT1

OUT2

SLOT1 CH1

I/O

I/O

I/O

CH2

SLOT2 CH1

CH2

ESC

I/O SLOT SETUP

LASER ON SELECT PROGRAM No.

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SET UP

PROGRAMCALIB

OPTIONS

Selected program No.

1

5 87642 31

13 1615141210 119

LASER ON INSPECT

NOR

MAL

P. 1

HEAD1

HEAD2

HEAD3

HEAD4

ESC

Select Head to inspect.

INSPECTHEAD1LASER ON P. 1

BEAM INTENSITY

HEAD R

: OK

: OKOPTICAL AXIS

ESC

NOR

MAL

LASER ON OPTIONS

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SET UP

PROGRAMCALIB OPTIONS

AREA

OUTPUT

INSPECT

UTILITY

Select Option to setup.

MODE

CHANGE

Normal

-> Pitch

LASER ON UTILITY

NOR

MAL

P. 1

AREA CHECK

INITIALIZE

ON

PANEL

mm

ONE-SCAN MODE

PROGRAM SELECT

DISPLAY UNIT

ESC

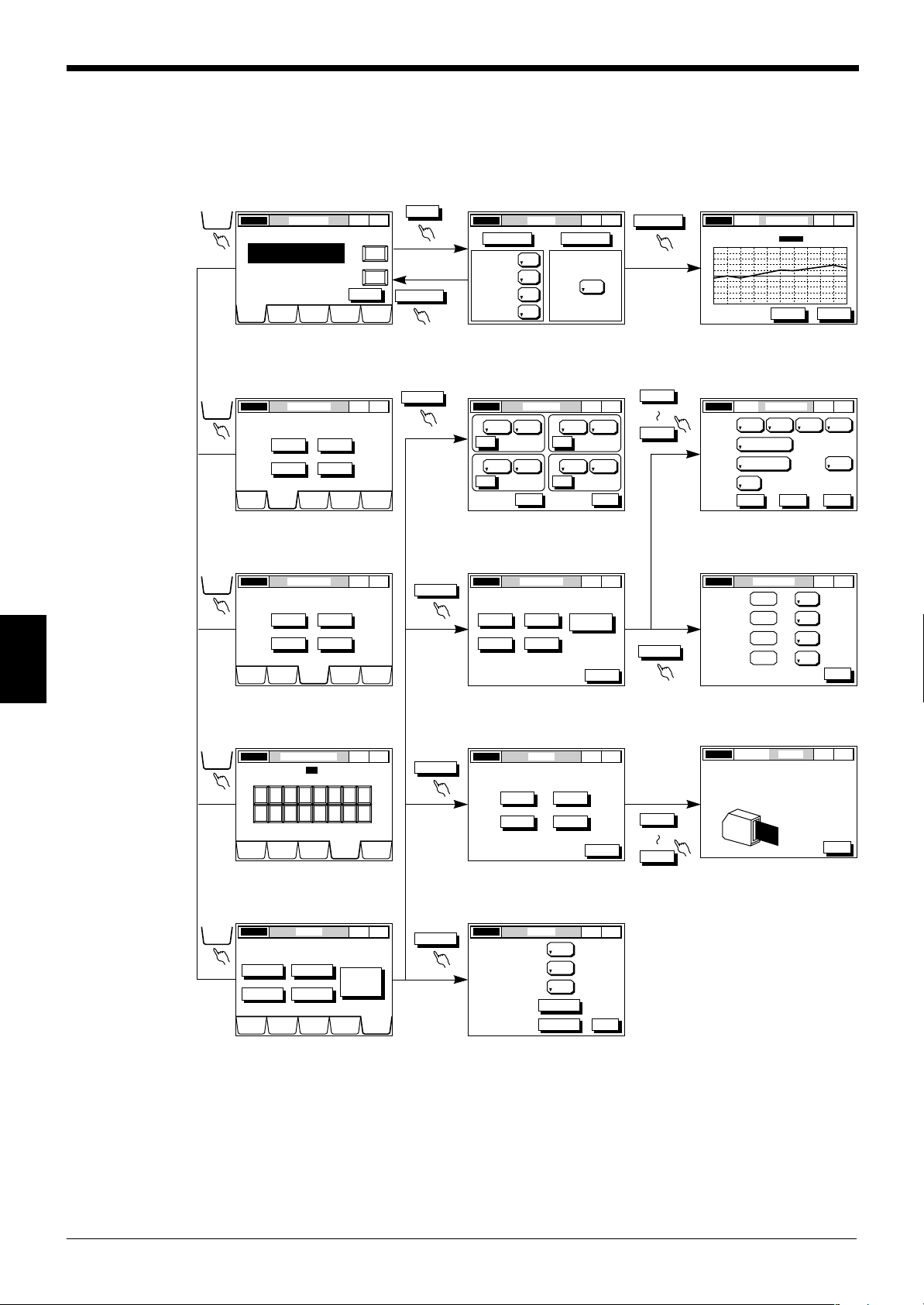

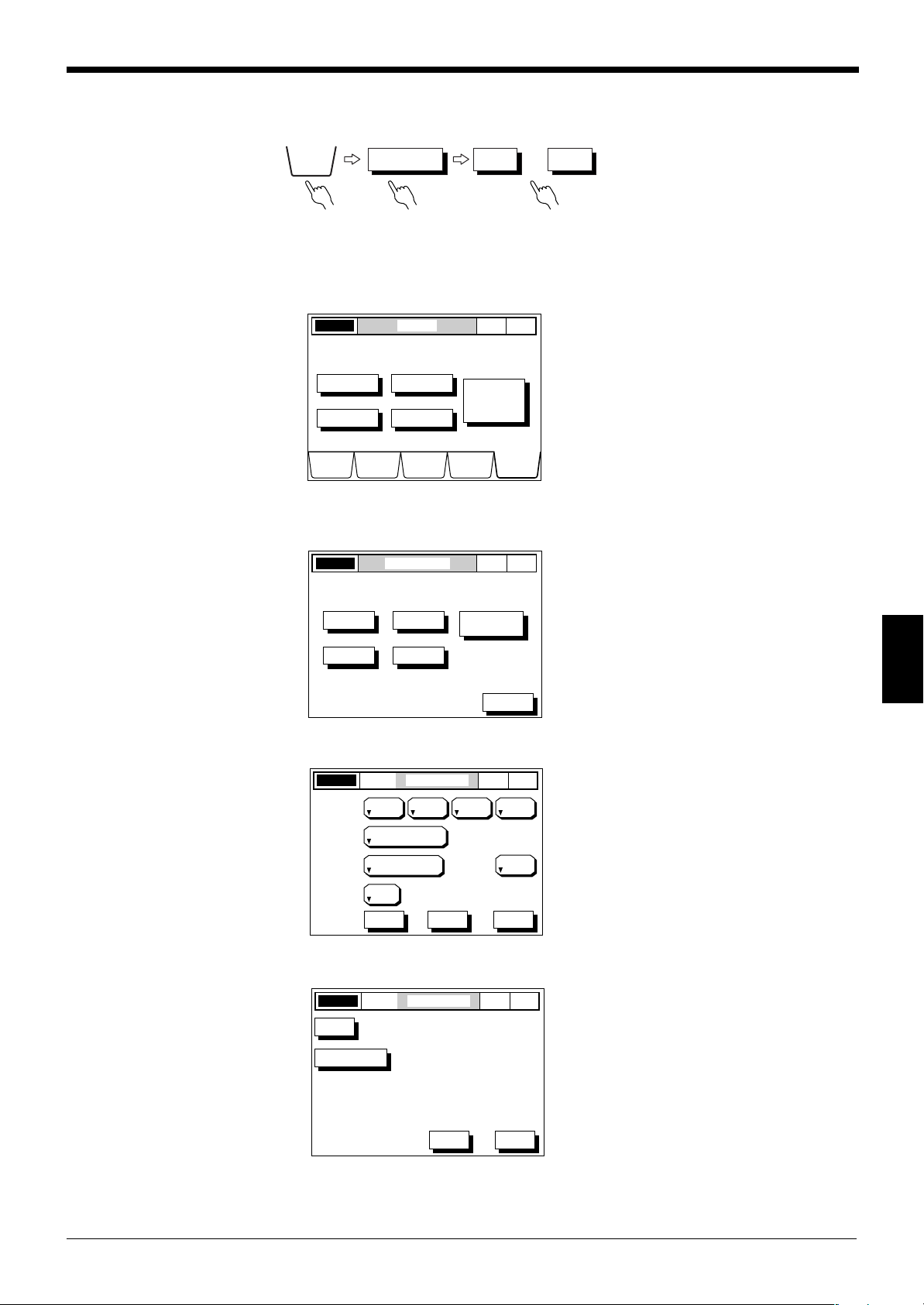

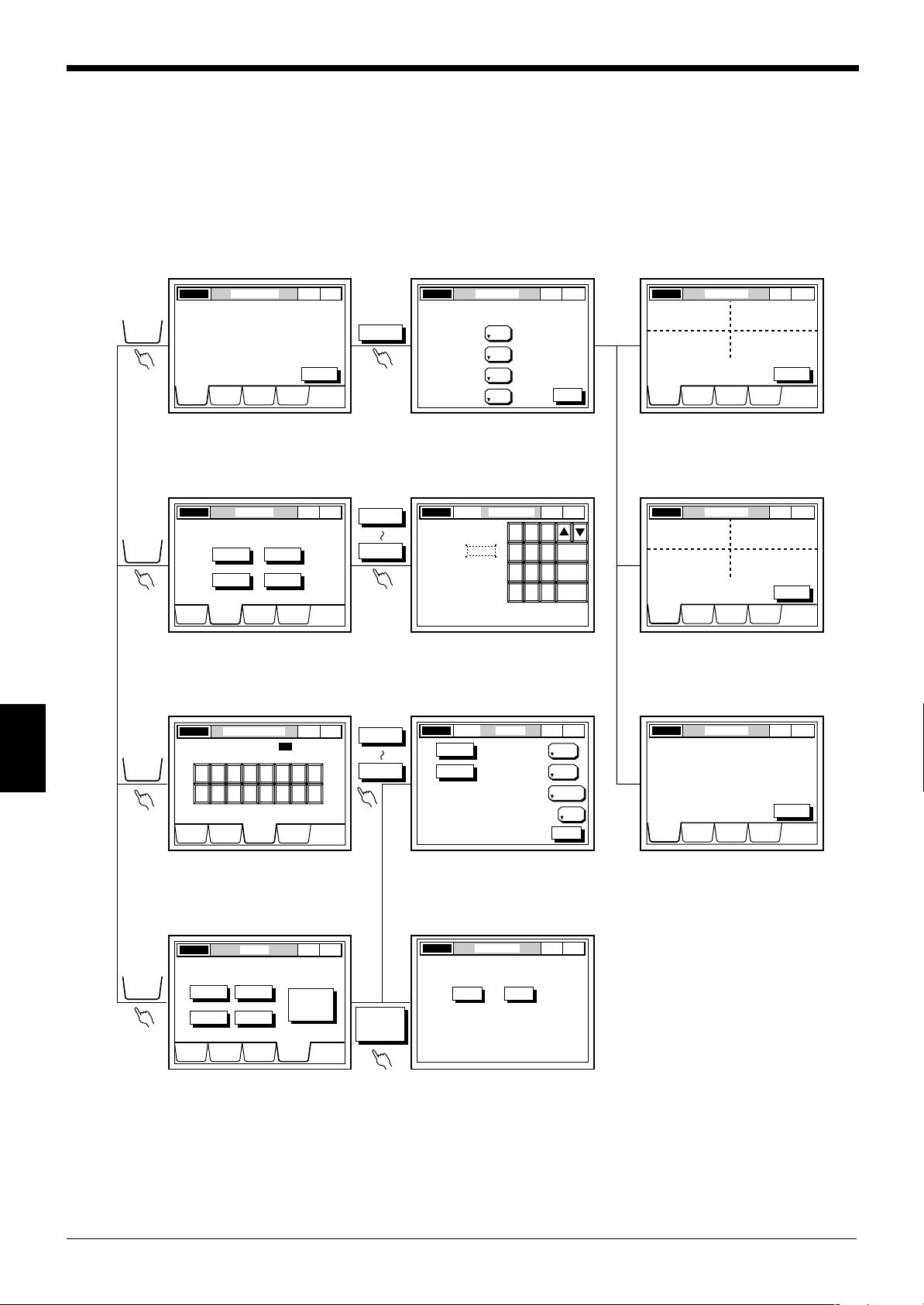

6.1 Normal Mode Screens

DISPLAY DATA screen

➮

See p.30.

LIMIT SETUP screen

➮

See p.35.

CALIBRATE screen

SCREEN SELECT screen DISPLAY GRAPH screen

➮

See p. 33.

➮

See p. 33.

AREA SETUP screen OUTPUT MODE screen

➮

See p.41-58.

I/O SLOT SETUP screen

➮

See p.39.

OUTPUT MODE screen

6

➮

See p.36.

SELECT PROGRAM NO.

screen

➮

See p.38.

OPTIONS screen

➮

See p.39.

➮

See p.41.

INSPECT screen

➮

See p.60.

UTILITY screen

➮

See p.62-68.

➮

See p.59.

HEAD INSPECT screen

➮

See p.60.

26

Page 33

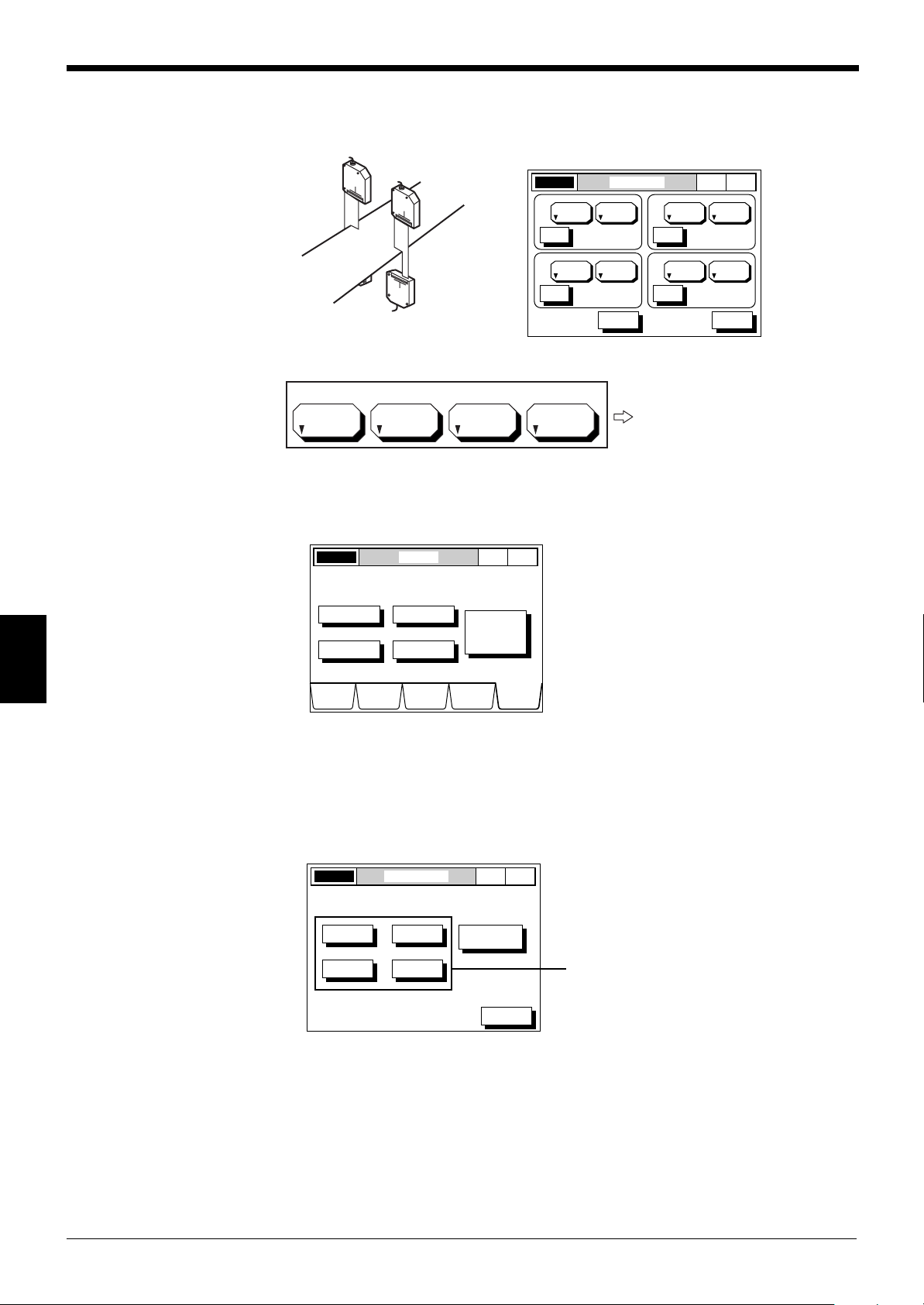

6.2 Initial Screen

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT2 54.21595

HI1 20.0000

LO1 15.0000

HI3

OFF OFF

ZERO HOLD

OUT3 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT4 54.21595

HI1 20.0000

LO1 15.0000

HI3

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

Chapter 6 Normal Mode

Displays the measured

value, comparator output

and upper/lower limits

(HI1, LO1) for OUT1.

Auto-zero switch

Laser ON/OFF

status

To the DISPLAY

DATA screen

To the LIMIT

SETUP screen

Screen title

To the CALIB

screen

Measuring

mode

To the

SELECT

PROGRAM

NO. screen

Program No.

Hold switch

Screen

selecting

switch

To the

OPTION S

screen

6

27

Page 34

Chapter 6 Normal Mode

LASER ON AREA SETUP

NOR

MAL

P. 1

DIAHEAD1

( 2, 3)

ESCHELP

SET

HEAD No.

EDGE No.

A1

SEGMENT SEGMENT

SEGMENT SEGMENT

DIAHEAD2

( 2, 3)

SET

HEAD No.

EDGE No.

A2

DIAHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A3

DIAHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A4

AREA

OPTIONS

A3

A4

A1

A2

DIAHEAD2

( 2, 3)

SET

HEAD No.

EDGE No.

A2

SEGMENT

Set the measurement mode

[DIA, T.EDGE, B.EDGE, SEG(m,n)].

(AREA SETUP

screen)

A2 (Measuring area 2)

Set the scanning

head number (1 to 4).

OUTPUT MODEOUT1LASER ON P. 1

+A1 OFF OFF OFF

AREA1 AREA2 AREA3 AREA4

100

AVERAGE

CALCULATE

1 (0.833ms)

MEASURING MODE

SELF-TIMING

INTERVAL (ms)

NORMAL

DIGIT

SUPPRESS

NONE

ESCHELP NEXT

NOR

MAL

OUTPUT

OPTIONS

Digit

Calculation

No. of Averaging

Measurements

Measurement

mode

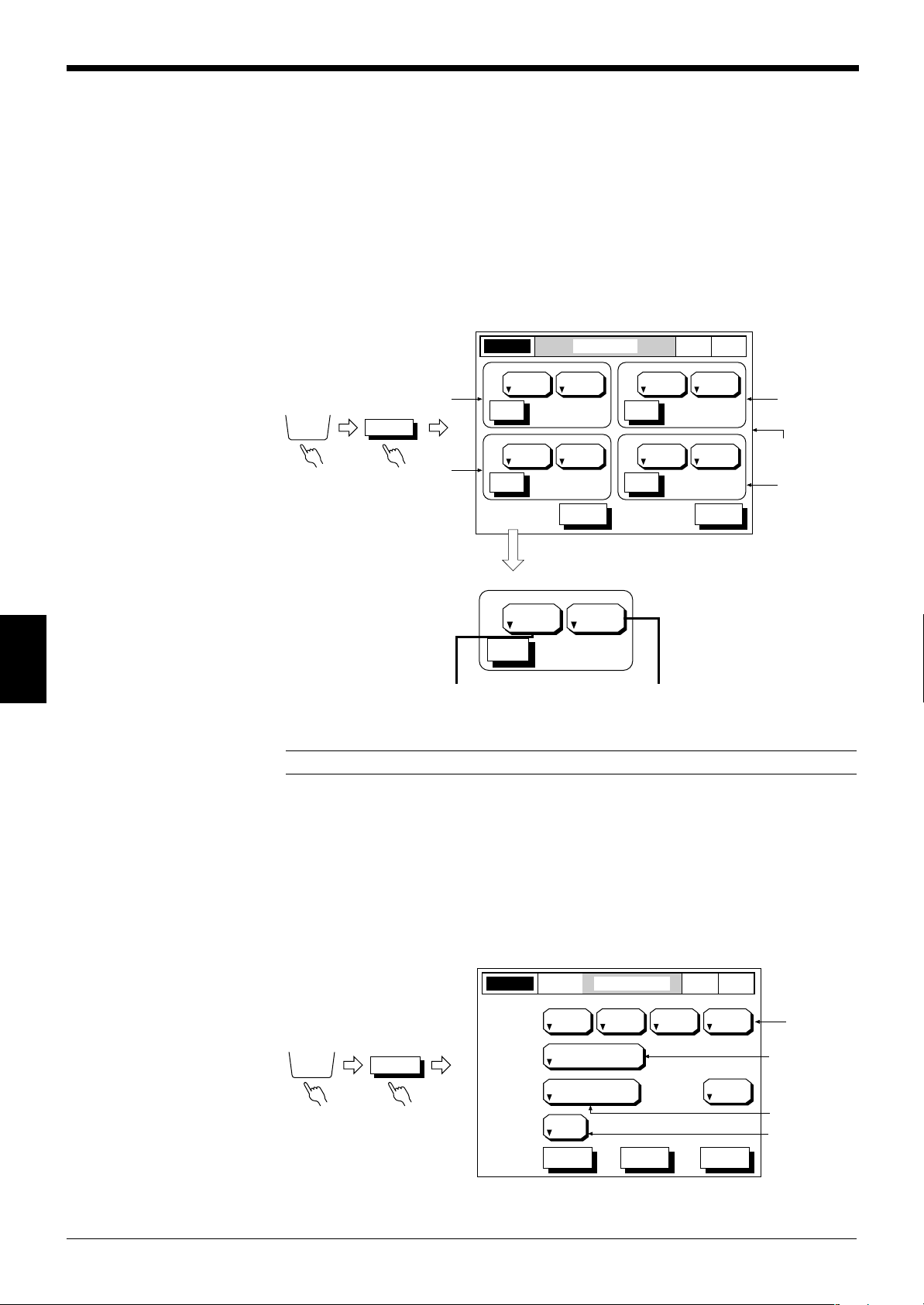

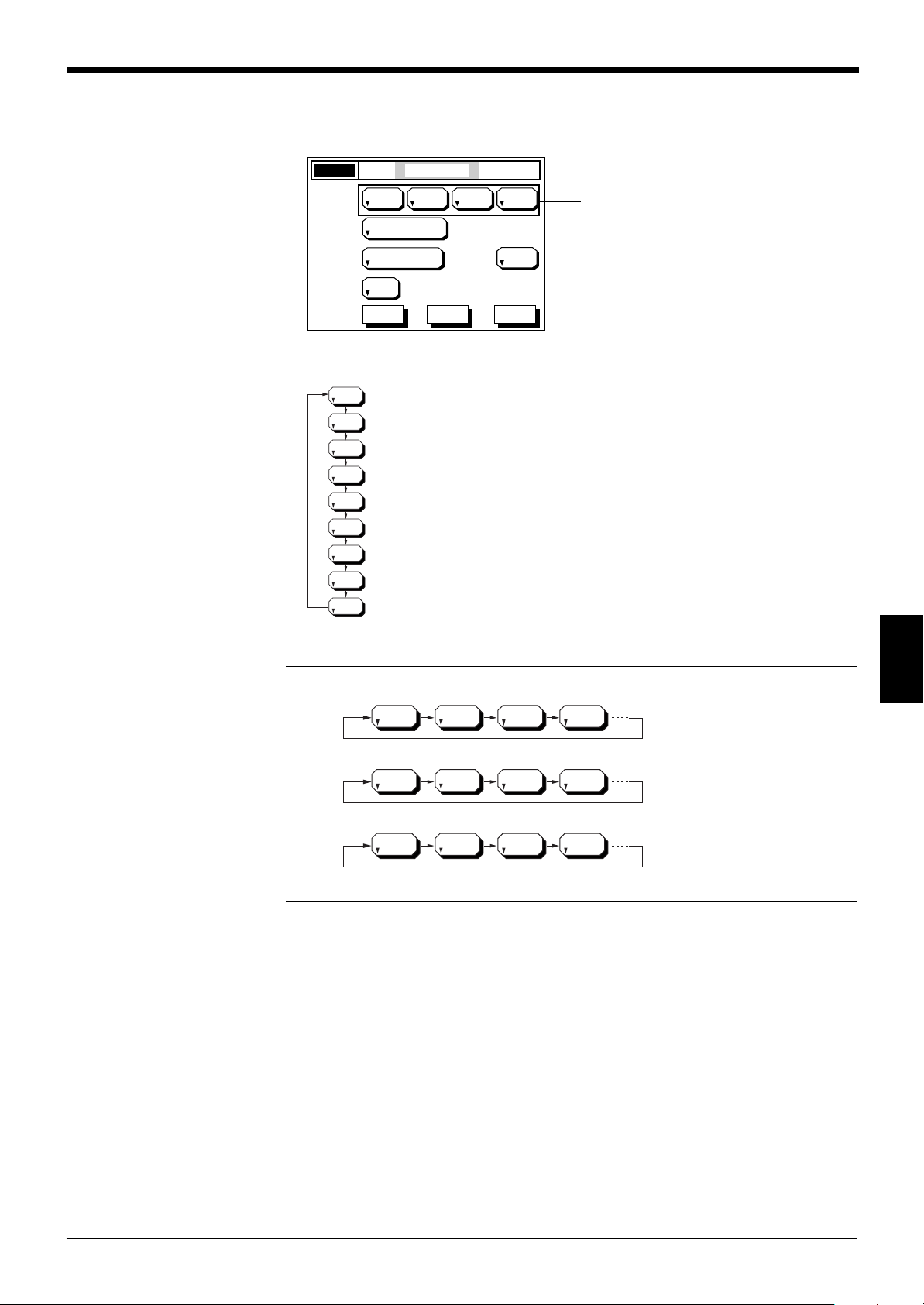

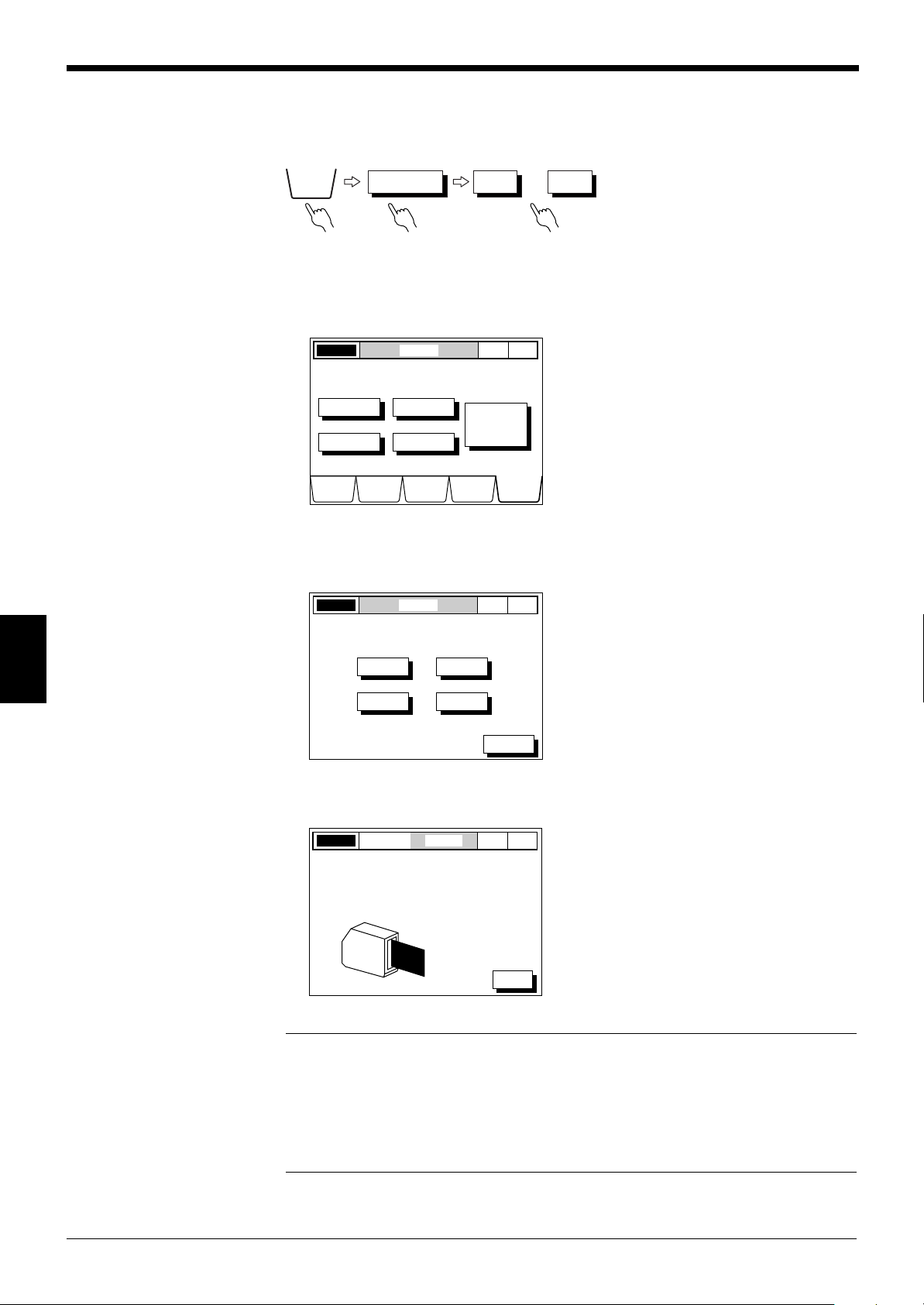

6.3 Setting Measuring Mode

Setting Scanning Head and Measurement

1. Setting Measuring Area

The LS-5000 series can simultaneously perform four measurements and outputs

with one scanning head, and different measurements and outputs with four scanning heads.

The place for which the measurement condition is set is called the “measuring

area” (A1 to A4), where the scanning head number and measuring mode can be

set.

(➮ See note.)

6

28

Note: The LS-5002 and 5502 can only control a single scanning head.

2. Setting Output Mode

The LS-5000 series can accept measurement data from multiple scanning heads

and perform calculations on the data for displaying and outputting the comparator

result.

Using the preset measuring area (A1 to A4), you can set various calculation and

measuring modes, as well as the number of averaging measurements as shown

below.

Page 35

Chapter 6 Normal Mode

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OFF OFF

ZERO HOLD

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

Button

Tag

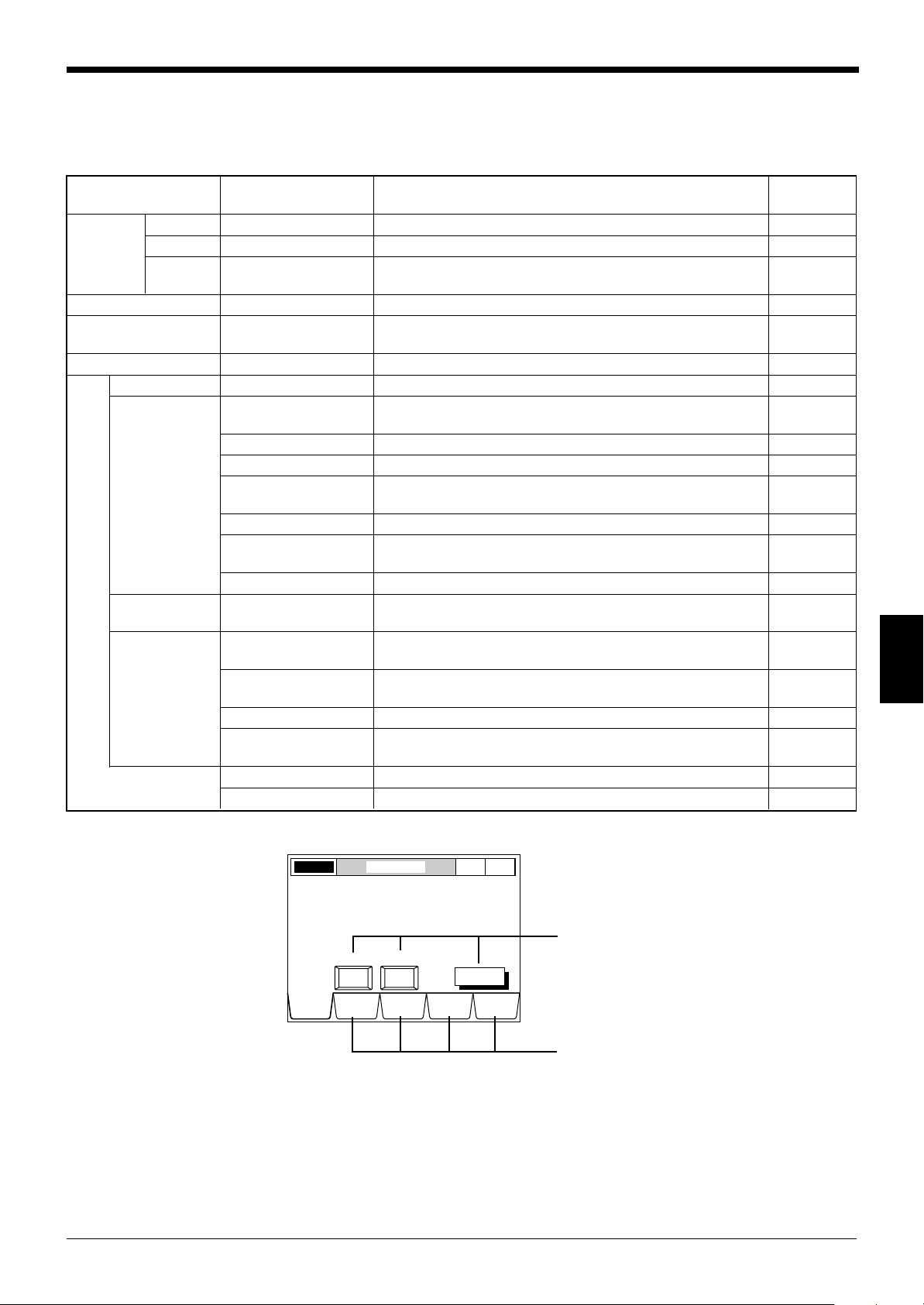

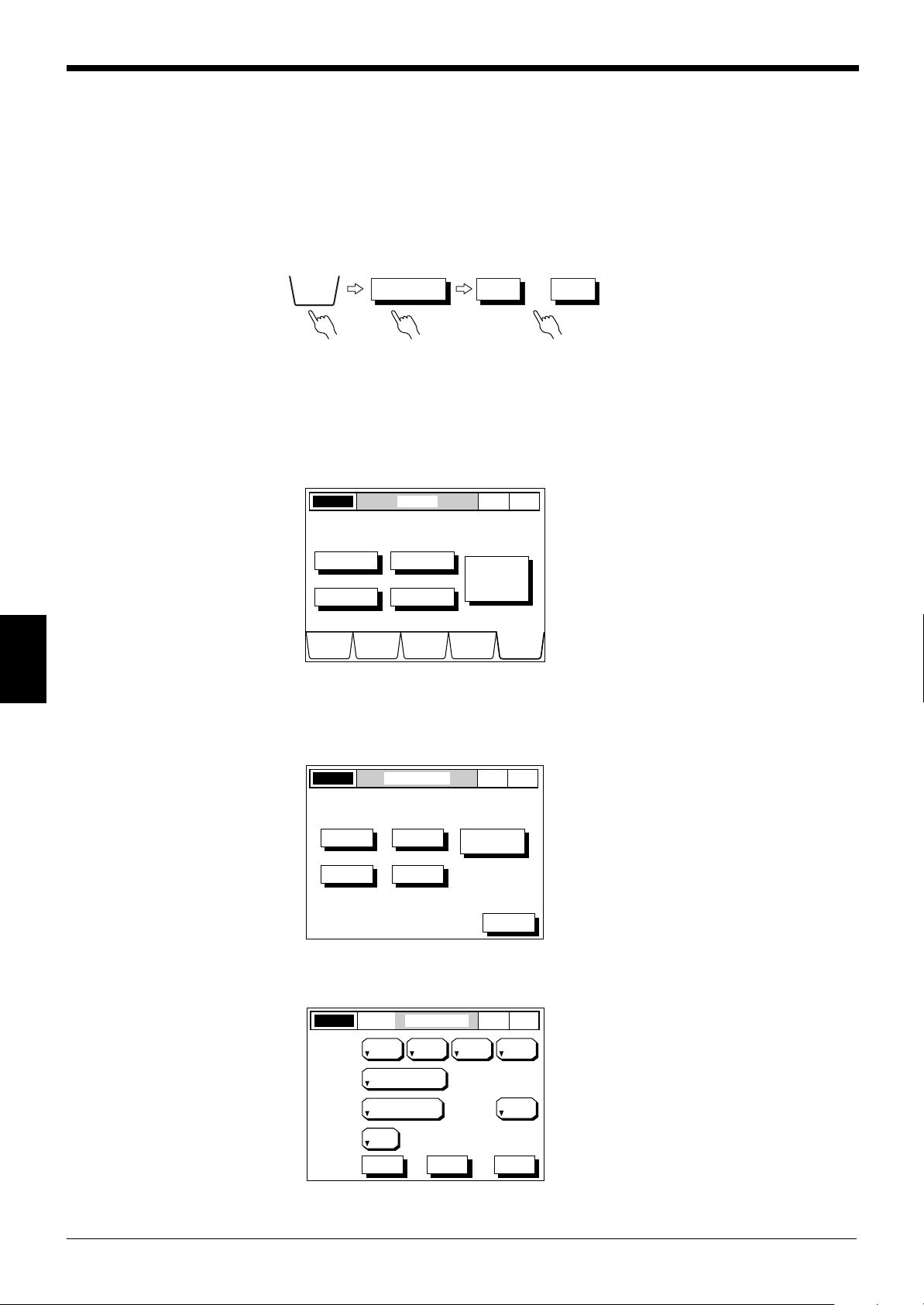

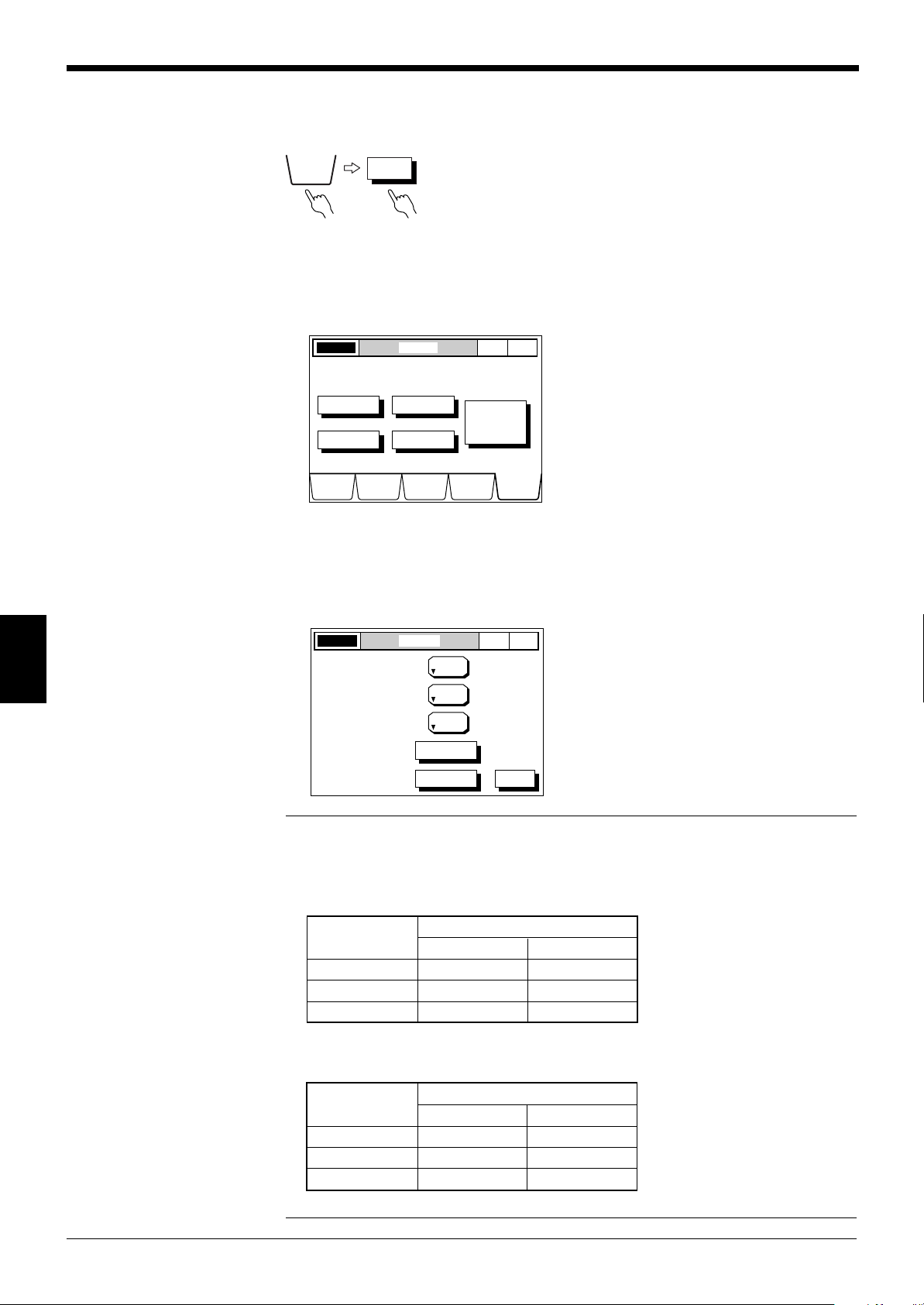

6.4 Setting Functions

Names and functions

Tag/Button Function Description Reference

page

DISPLAY HOLD Hold A measured value can be held or reset. 30

DATA ZERO Auto-zero A measured value can be instantaneously reset to “0.000”. 31

SCREEN Screen Selection The DISPLAY DATA screen or DISPLAY GRAPH screen 32 to 34

can be selected.

LIMIT SETUP Limit Setup 7 level tolerance limits can be set for each output. 35

CALIB Calibration Setup Minute measurement fluctuations caused by a change in the 36

target surface condition or target inclination can be corrected.

PROGRAM Program Selection Measurement data is stored and called as programs. 38

AREA Area Setup DIA, T.EDGE, B.EDGE or SEG(m,n) can be selected. 39

OUTPUT Calculation Setup Calculation can be performed with each measuring area 41

(A1 to A4).

Average Measurement results can be averaged. 44

M. Mode Nine measuring modes are provided. 46 to 53

Offset Any value can be added to or subtracted from the displayed 55

value.

Digit Sets the number of digits after the decimal point. 54

Analog Output An analog voltage (within ±10 V) proportional to the displayed 57

value can be output.

I/O Slot Setup Expansion I/O boards can be set. 59

INSPECT Inspect The scanning head conditions (optical axis, intensity) can 60

OPTIONS

UTILITY One-Scan Function Data obtained with only one surface of the 12-surface polygon 62

Program Selection The program selection method (front panel or rear terminals) 64

Display Unit The display units can be selected (“mm” or “inch”). 65

Area Check The number of edges in the measuring area can be 66

Initialize All settings are reset to the initial values. 67

Mode Change Normal mode or Pitch mode can be selected. 68

be checked.

mirror becomes effective.

can be selected.

checked.

6

29

Page 36

Chapter 6 Normal Mode

DISPLAY

DATA

OFF

HOLD HOLD

ON

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT2 54.21595

HI1 20.0000

LO1 15.0000

HI3

OFF OFF

ZERO HOLD

OUT3 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT4 54.21595

HI1 20.0000

LO1 15.0000

HI3

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT2 54.21595

HI1 20.0000

LO1 15.0000

HI3

OFF ON

ZERO HOLD

OUT3 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT4 54.21595

HI1 20.0000

LO1 15.0000

HI3

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

11

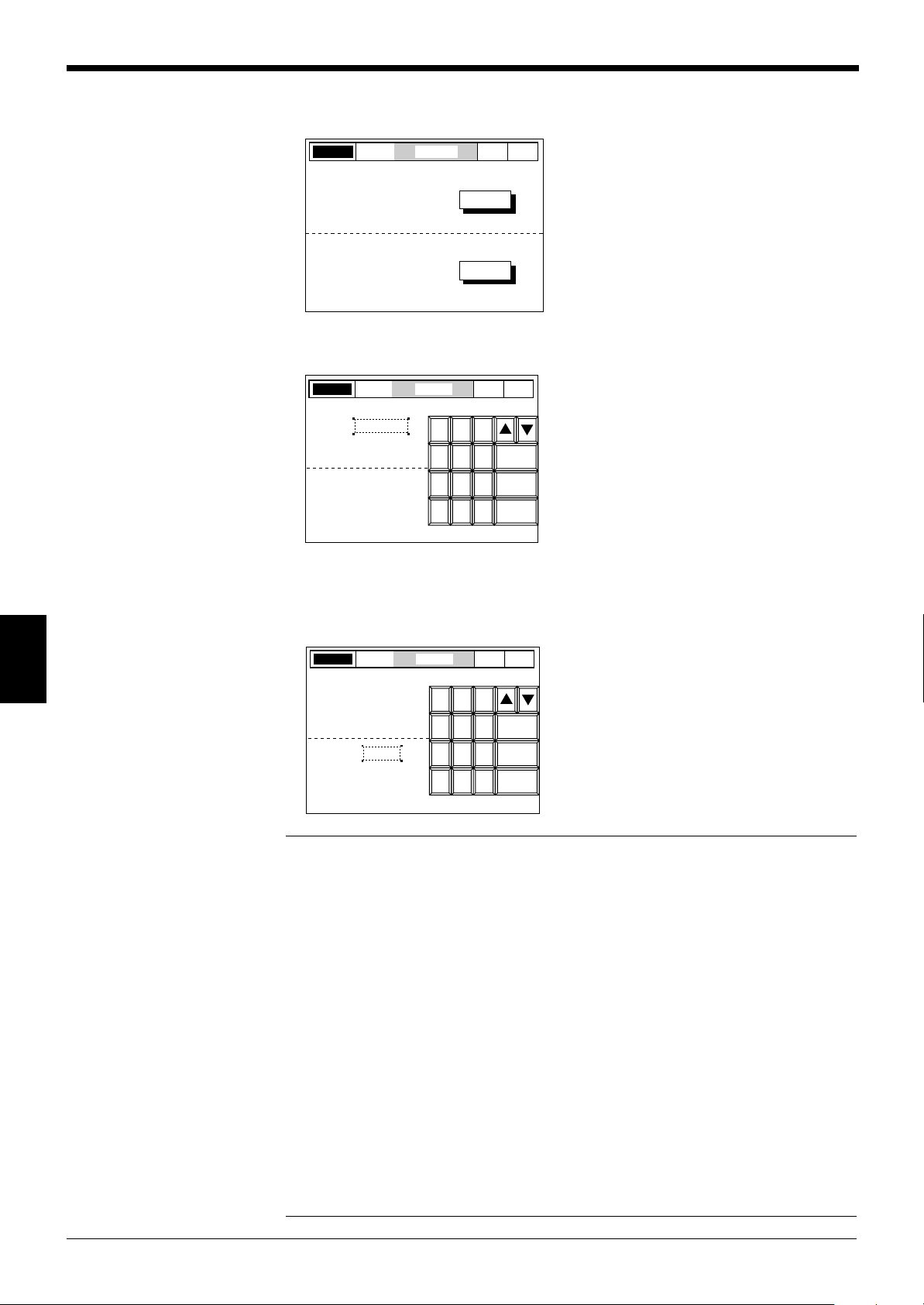

1 [HOLD] Hold Function

11

The hold function allows the displayed value and output value to be held or reset

regardless of the measuring mode.

■ Setting Procedure

1. Select the DISPLAY DATA screen.

Press the [DISPLAY DATA] button. The screen shown below is displayed.

6

2. Set the hold function.

Press the [HOLD OFF] button. [HOLD OFF] is changed to [HOLD ON].

Note: The hold function cannot be set separately for each output from this screen.

To set this function separately for each output, send the hold signal from the

control I/O board (Option). (Short-circuit the Tim input terminal and the GND

terminal.)

30

Page 37

22

DISPLAY

DATA

OFF

ZERO ZERO

ON

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT2 54.21595

HI1 20.0000

LO1 15.0000

HI3

OFF OFF

ZERO HOLD

OUT3 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT4 54.21595

HI1 20.0000

LO1 15.0000

HI3

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 0.00000

0.00000

0.00000

0.00000

HI1 20.0000

LO1 15.0000

LO1

OUT2

HI1 20.0000

LO1 15.0000

LO1

OFF

ON

ZERO HOLD

OUT3

HI1 20.0000

LO1 15.0000

LO1

OUT4

HI1 20.0000

LO1 15.0000

LO1

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB OPTIONS

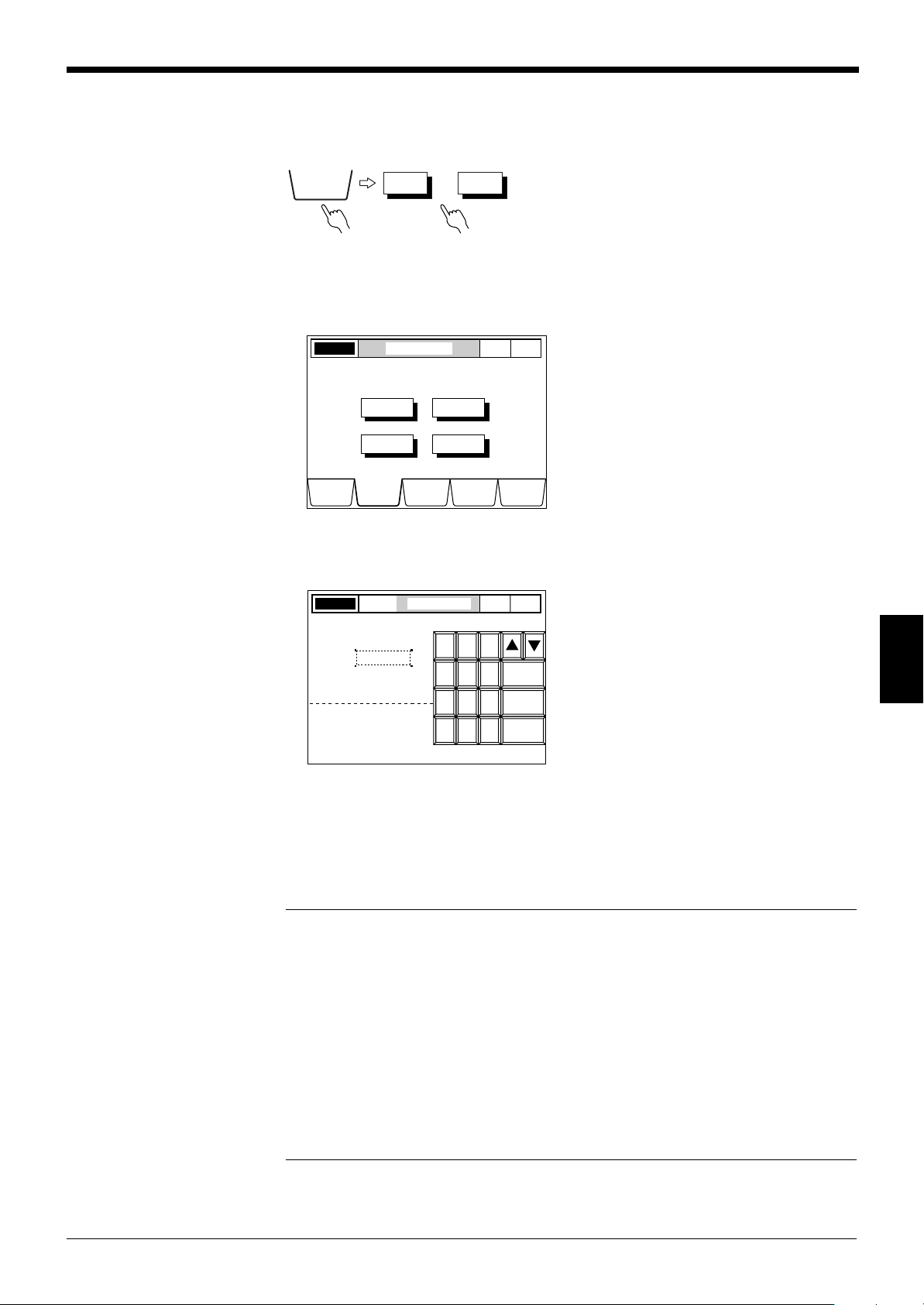

2 [ZERO] Auto-zero Function

22

The auto-zero function can instantaneously reset the displayed value to “0.0000”.

This function simplifies zero-point adjustment when targets are changed over.

■ Setting Procedure

1. Select the DISPLAY DATA screen.

Chapter 6 Normal Mode

Press the [DISPLAY DATA] button. The screen below is displayed.

2. Set the auto-zero function.

Press the [ZERO OFF] button. [ZERO OFF] is changed to [ZERO ON].

The following two methods will also activate the auto-zero input.

• Short-circuit the auto-zero input terminal and the GND terminal of the control I/O

board (Option).

The auto-zero function can be set separately for each output.

• Send a command through the RS-232C board from external equipment such as

a computer.

You can reset the auto-zero function by sending the command.

➮

See p. 93.

Note 1: The auto-zero function cannot be reset with the control I/O input.

6

Note 2: When the displayed value is “- - - - -”, the auto-zero function cannot be

activated.

Note 3: When the auto-zero function is activated from the front panel, all outputs

are simultaneously reset to “0.0000”.

31

Page 38

Chapter 6 Normal Mode

LASER ON DISPLAY DATA

NOR

MAL

P. 1

OUT1 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT2 54.21595

HI1 20.0000

LO1 15.0000

HI3

OFF OFF

ZERO HOLD

OUT3 54.21595

HI1 20.0000

LO1 15.0000

HI3

OUT4 54.21595

HI1 20.0000

LO1 15.0000

HI3

SCREEN

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

DISPLAY

DATA

SCREEN DISPLAY DATA DISPLAY GRAPHor

OUT1 54.21595 H13 OUT3 5421595 H13

HI

LO

OUT2 54.21595 H13 OUT4 5421595 H13

HI

LO

HI

LO

HI

LO

200000

200000

200000

200000

200000

200000

200000

200000

33

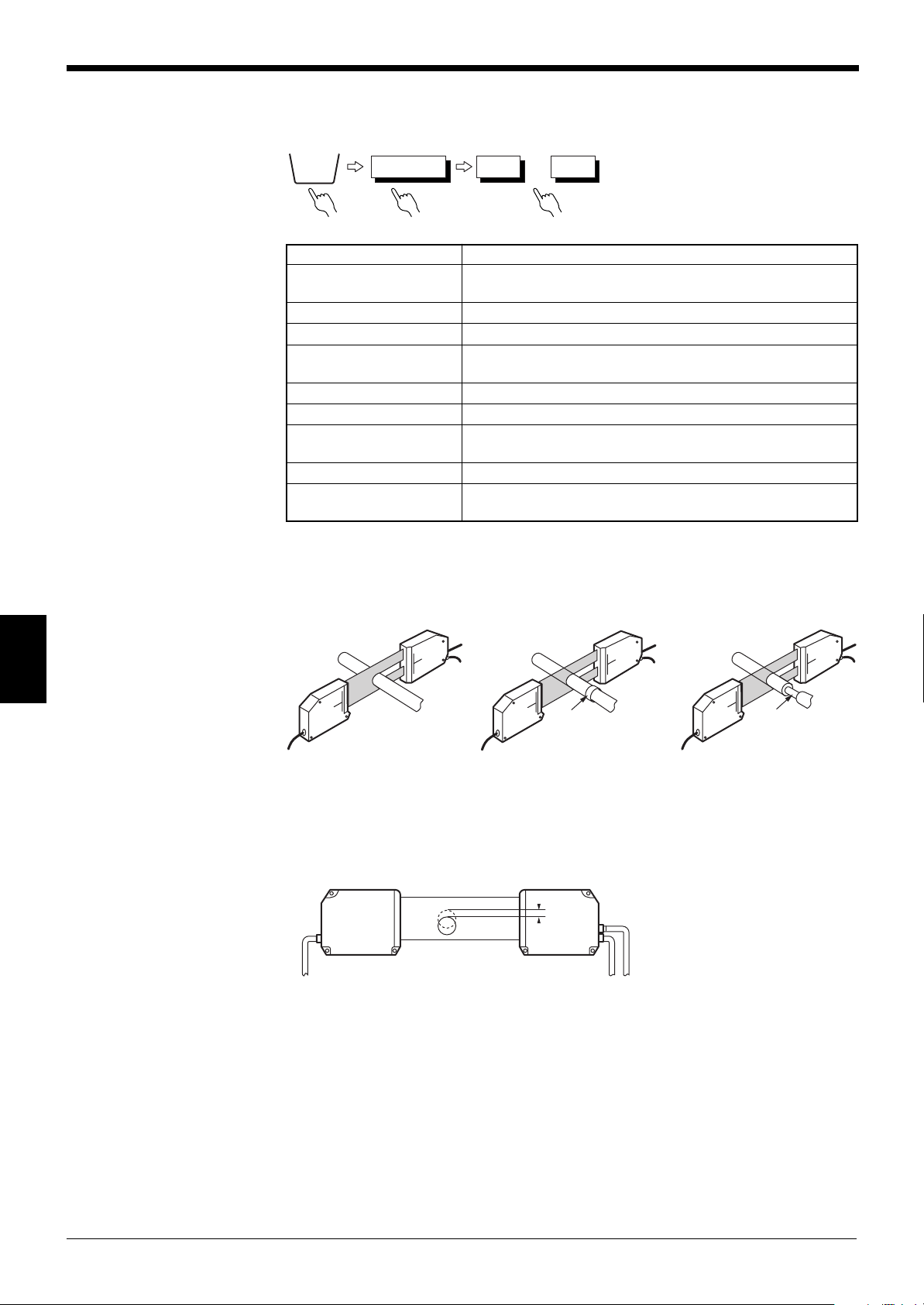

3 [SCREEN] Screen Selection Function

33

The screen selection function allows you to select the DISPLAY DATA screen (1 to

4 data displays) or the DISPLAY GRAPH screen.

<DISPLAY DATA>

Example 1: When several scanning heads are used

6

<DISPLAY GRAPH>

Example 2: Measurement of wire’s outer diameter

■ Setting Procedure <DISPLAY DATA>

1. Select the DISPLAY DATA screen.

Press the [DISPLAY DATA] button. The screen shown below is displayed.

32

2. Select the SCREEN SELECT screen.

Press the [SCREEN] button.

Page 39

Chapter 6 Normal Mode

OUT1 OUT2 OUT3 OUT4

LASER ON SCREEN

NOR

MAL

P. 1

DISPLAY DATA DISPLAY GRAPH

ONOUT1

SET SET

OFFOUT2

OUT1

OFFOUT3

OFFOUT4

LASER ON DISPLAY GRAPHOUT1

NOR

MAL

P. 1

SETUP SCREEN

40.0000

0.0000

DATA: 25.77110

LASER ON SCREEN

NOR

MAL

P. 1

DISPLAY DATA DISPLAY GRAPH

ONOUT1

SET SET

OFFOUT2

OUT1

OFFOUT3

OFFOUT4

3. Set the output to be displayed. (

➮

For setting outputs, see p.41.

)

Turn ON the output to be displayed.

If an output is not to be displayed, press the [ON] button once to turn it OFF.

4. Return to the DISPLAY DATA screen.

Press the [DISPLAY DATA] button to return to the DISPLAY DATA screen.

■ Setting Procedure <DISPLAY GRAPH>

1. Perform steps 1 and 2 described on the previous page to go to the SCREEN

SELECT screen shown below.

2. Select “DISPLAY GRAPH”.

Select the output to be graphically displayed.

OUT1 to OUT4 are switched in the above order.

Press the [DISPLAY GRAPH] button.

3. Perform “GRAPH SETUP”.

Press the [SETUP] button.

6

33

Page 40

Chapter 6 Normal Mode

LASER ON SETUPOUT1

NOR

MAL

P. 1

RANGE

TIME

MAX:

MIN:

40.0000

0.0000

SAMPLING

FREQ:

NO. OF DATA:

1 X 0.1S

100

SETUPOUT2LASER ON

NOR

MAL

P. 1

87

5 64

2 31

0

9

ENTER

CANCEL

ESCAPE

MAX: 40.0000

MIN:

SAMPLING

FREQ:

NO. OF DATA:

0.0000

1 X 0.

100

SETUPOUT1LASER ON

NOR

MAL

P. 1

87

5 64

2 31

. -0

9

ENTER

CANCEL

ESCAPE

MAX: 40.0000

MIN:

SAMPLING

FREQ:

NO. OF DATA:

0.0000

1 X 0.

100

4. Set the range of GRAPH display.

Perform “RANGE SETUP”. Press the [RANGE] button.

6

Select the item from MAX or MIN using the [▲] [ ] arrow keys.

▲

Enter a value using the numeric keys and press [ENTER].

Press [ESCAPE] to complete the entry.

Press [CANCEL] to cancel the entry. The

value returns to the previous value.

5. Perform “TIME SETUP”.

Press the [TIME] button. Select the item from SAMPLING FREQ or NO. OF

DATA using the [▲] [ ] arrow keys. Enter a value using the numeric keys and

▲

press [ENTER].

Press [ESCAPE] to complete the entry.

Press [CANCEL] to cancel the entry. The

value returns to the previous value.

34

Note 1: Range Setup

The maximum and minimum range setup values are as follows:

Max.: 999.9999 (9.99999)

Min.: -99.9999 (-0.99999)

* Values in ( ) are the maximum and minimum values displayed in inches.

When the displayed value exceeds the above range, “OVER” is displayed and the

entered value cannot be accepted.

Note 2: Time Setup

The maximum and minimum values for the sampling frequency and the number of

displayed data are as follows:

Sampling frequency

Max.: 30000 x 0.1 s (3000 s) Min.: 1 (0.1 s)

Number of displayed data

Max.: 600 Min.: 2

When the sampling frequency or the number of displayed data exceeds the above

range, “OVER” is displayed and the entered value cannot be accepted.

Note 3: The above maximum and minimum values are independent of tolerance

limits.

Page 41

44

OUT1 • • • OUT4

LIMIT

SETUP

LASER ON SELECT OUTPUT

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

OUT1

OUT2

OUT3

OUT4

Select Output No. to set the limits.

LIMIT SETUPOUT1LASER ON

NOR

MAL

P. 1

87

5 64

2 31

. -0

9

ENTER

CANCEL

ESCAPE

HI3 30.0000

HI2 25.0000

HI3 20.0000

LO1 15.0000

LO2 10.0000

LO3 5.0000

4 Limit Setup

44

Chapter 6 Normal Mode

7-level-tolerance-limits can be set separately for four outputs. (

setting output

.)

➮

See p.41 for

■ Setting Procedure

1. Select the LIMIT SETUP screen.

Press the [LIMIT SETUP] button. The screen shown below is displayed.

2. Set tolerance limits.

Press the button corresponding to the output for which you wish to set tolerance

limits.

6

Select a desired tolerance limit using the [▲]/[ ] arrow keys.

Enter a value using the numeric keys, and press [ENTER].

Press [ESCAPE] to complete the entry.

Press [CANCEL] to cancel the entry. The value returns to the previous value.

Note 1: When a measured value exceeds the tolerance range, the measured value

is displayed in reverse. The differentiation result corresponding to the tolerance

limits is output from the display unit and the control I/O (option) board.

Note 2: Tolerance limits must conform to the following condition:

HI3 > HI2 > HI1 > LO3 > LO2 > LO1

Otherwise, the tolerance value cannot be entered. (The “ERR” message appears

on the display and the entered value cannot be accepted.)

Note 3: The maximum and minimum tolerance limit values are as follows:

Max.: 999.9999 (9.99999)

Min.: -99.9999 (-0.99999)

* Values in ( ) are the maximum and minimum values displayed in inches.

▲

35

Page 42

Chapter 6 Normal Mode

AREA1CALIB • • • AREA4

CALIBRATEAREA2LASER ON

NOR

MAL

P. 1

DATA

54.21595

ESC

CALIBRATE

RESET

LASER ON CALIBRATE AREA

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

AREA1

AREA2

AREA3

AREA4

Select Segment No. to calibrate.

CALIBRATEAREA1LASER ON

NOR

MAL

P. 1

87

5 64

2 31

.0

9

ENTER

CANCEL

ESCAPE

TARGET1 0.0000

DATA 54.21595

TARGET1 0.0000

Enter calibration

values for targets

1 and 2, and press

OK.

OK

55

5 [CALIB] Calibration Setup

55

Minute measurement fluctuations caused by a change in the target surface condition or target inclination can be corrected with each AREA. (

AREA.

)

➮

See p.39 for setting

■ Setting Procedure

1. Select the CALIBRATE AREA screen.

Press the [CALIB] button. The screen shown below is displayed.

6

2. Press the button corresponding to the area for which you wish to perform

calibration.

Press the [RESET] button to reset the calibration. The calibration value is reset

to the factory setting.

Press the [CALIBRATE] button to go to the CALIBRATE screen.

36

3. Insert sample workpiece 1 to check the measured value.

Enter the value of sample workpiece 1 using the numeric keys, and accept the

value by pressing the [ENTER] button.

Page 43

Chapter 6 Normal Mode

4. Insert sample workpiece 2 to check the measured value.

Enter the value of sample workpiece 2 using the numeric keys, and accept the

value by pressing the [ENTER] button.

When you press the [OK] button, the calibration is performed and a message

regarding the calibration result is displayed.

Input Conditions

Workpiece 1 < Workpiece 2

0.5 ≤ Span ≤ 2

If the above conditions are not satisfied, the “Calibration Error” message is

displayed.

When the above conditions are satisfied, the “Calibration OK” message is

displayed.

6

37

Page 44

Chapter 6 Normal Mode

P1 P2 P3 P4 GND

• • •

PROGRAM

1 16

LASER ON SELECT PROGRAM No.

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB

OPTIONS

Selected program No.

1

5 87642 31

13 1615141210 119

66

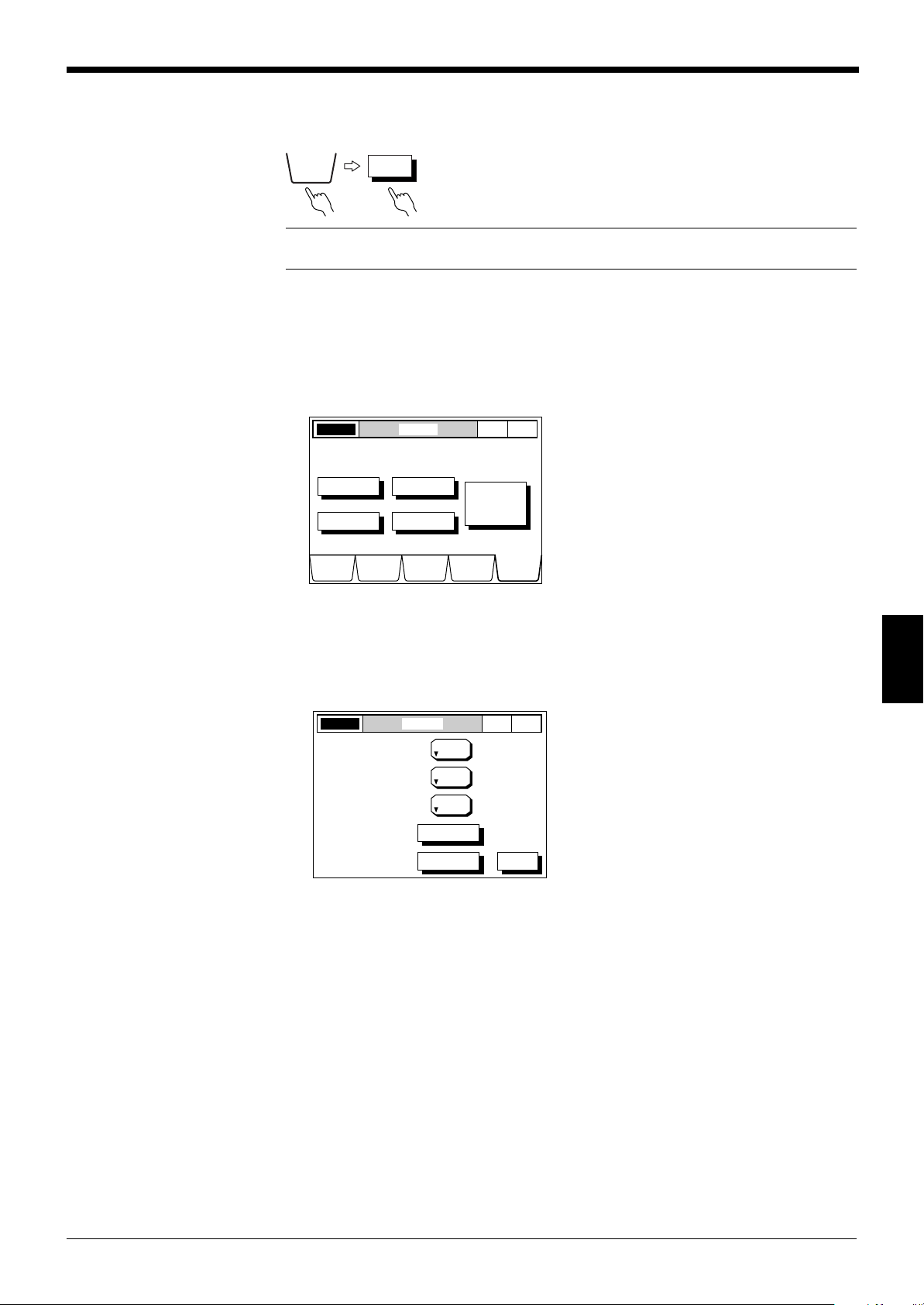

6 [PROGRAM] Program Selection Function

66

The LS-5000 series can store all measurement conditions as a program. Up to 16

programs can be stored and loaded easily.

■ Setting Procedure

1. Select the SELECT PROGRAM NO. screen.

Press the [PROGRAM] button.

2. Select a program number.

Press the button corresponding to the program number to be loaded.

6

38

Note 1: When the program selection method is set to the rear terminals, the

program number cannot be switched on the front panel.

➮

See p. 63.

Note 2: To switch a program number using the rear terminals, change the combination of the following four terminals and GND terminal.

Terminal No.

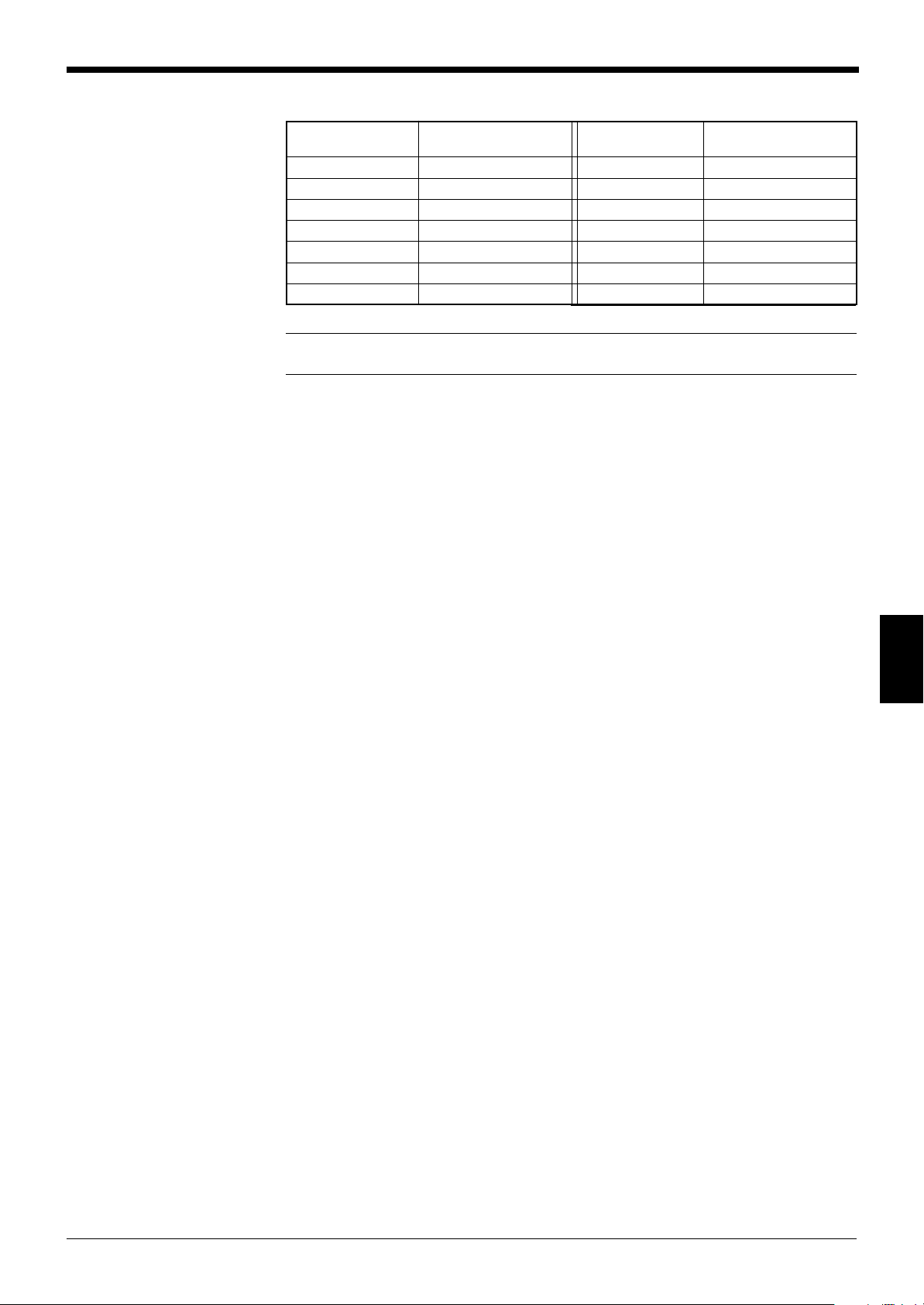

Program No. P1 P2 P3 P4

1 OFF OFF OFF OFF

2ONOFF OFF OFF

3 OFF ON OFF OFF

4ONONOFF OFF

5 OFF OFF ON OFF

6ONOFF ON OFF

7 OFF ON ON OFF

8ONONONOFF

9 OFF OFF OFF ON

10 ON OFF OFF ON

11 OFF ON OFF ON

12 ON ON OFF ON

13 OFF OFF ON ON

14 ON OFF ON ON

15 OFF ON ON ON

16 ON ON ON ON

ON: This terminal and the GND terminal are short-circuited.

OFF: This terminal is open.

Note 3: The system setup for the display unit (

➮

see p. 104

) cannot be stored by

the program function.

Page 45

77

LASER ON OPTIONS

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB OPTIONS

AREA

OUTPUT

INSPECT

UTILITY

Select Option to setup.

MODE

CHANGE

Normal

-> Pitch

LASER ON AREA SETUP

NOR

MAL

P. 1

DIAHEAD1

( 2, 3)

ESCHELP

SET

HEAD No.

EDGE No.

A1

SEGMENT SEGMENT

SEGMENT SEGMENT

DIAHEAD2

( 2, 3)

SET

HEAD No.

EDGE No.

A2

DIAHEAD3

( 2, 3)

SET

HEAD No.

EDGE No.

A3

DIAHEAD4

( 2, 3)

SET

HEAD No.

EDGE No.

A4

HEAD1 HEAD2 HEAD3 HEAD4

DIA

T. EDGE B. EDGE

SEG

OPTIONS

AREA

7 Area Setup

77

Chapter 6 Normal Mode

The scanning head (Head 1 to Head 4) and measuring mode (DIA, T.EDGE,

B.EDGE, SEG(m,n))can be selected for a measuring area. Up to 4 areas can be

set at the same time. (

➮

see p. 22 for Area.

)

■ Setting Procedure

1. Select the OPTIONS screen.

Press the [OPTIONS] button.

2. Select the AREA SETUP screen.

Press the [AREA] button.

3. Set the scanning head number.

When you press the [HEAD No.] button, the scanning head number is switched

in the following order.

4. Set the segment.

When you press the [SEGMENT] button, the segment is switched in the following order.

6

Note 1: The edge number setting is effective only when “SEG” is selected as the

SEGMENT.

Note 2: When either of DIA, T.EDGE, or B.EDGE is selected for a scanning head,

SEG cannot be selected for the same head. Also, when SEG is selected, DIA,

T.EDGE, and B.EDGE cannot be selected for the same head.

Note 3: When only one scanning head is connected, the head number remains

“HEAD 1” even if the head number button is pressed.

39

Page 46

Chapter 6 Normal Mode

LASER ON AREA SETUP

NOR

MAL

P. 1

SEGHEAD1

( 2, 3)

ESCHELP

SET

HEAD No. SEGMENT

SEGMENT SEGMENT

SEGMENT

EDGE No.

A1

SEGHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A2

SEGHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A3

SEGHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A4

LASER ON AREA SETUP

NOR

MAL

P. 1

SEGHEAD1

( 2 , 3)

SET

HEAD No.

EDGE No.

A1

SEGMENT

SEGMENT

SEGHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A2

87

5 64

2 31

. -0

9

ENTER

CANCEL

ESCAPE

( 2 , 3)

LASER ON AREA SETUP

NOR

MAL

P. 1

SEGHEAD1

SET

HEAD No.

EDGE No.

A3

SEGMENT

SEGMENT

SEGHEAD1

( 2, 3)

SET

HEAD No.

EDGE No.

A4

87

5 64

2 31

. -0

9

ENTER

CANCEL

ESCAPE

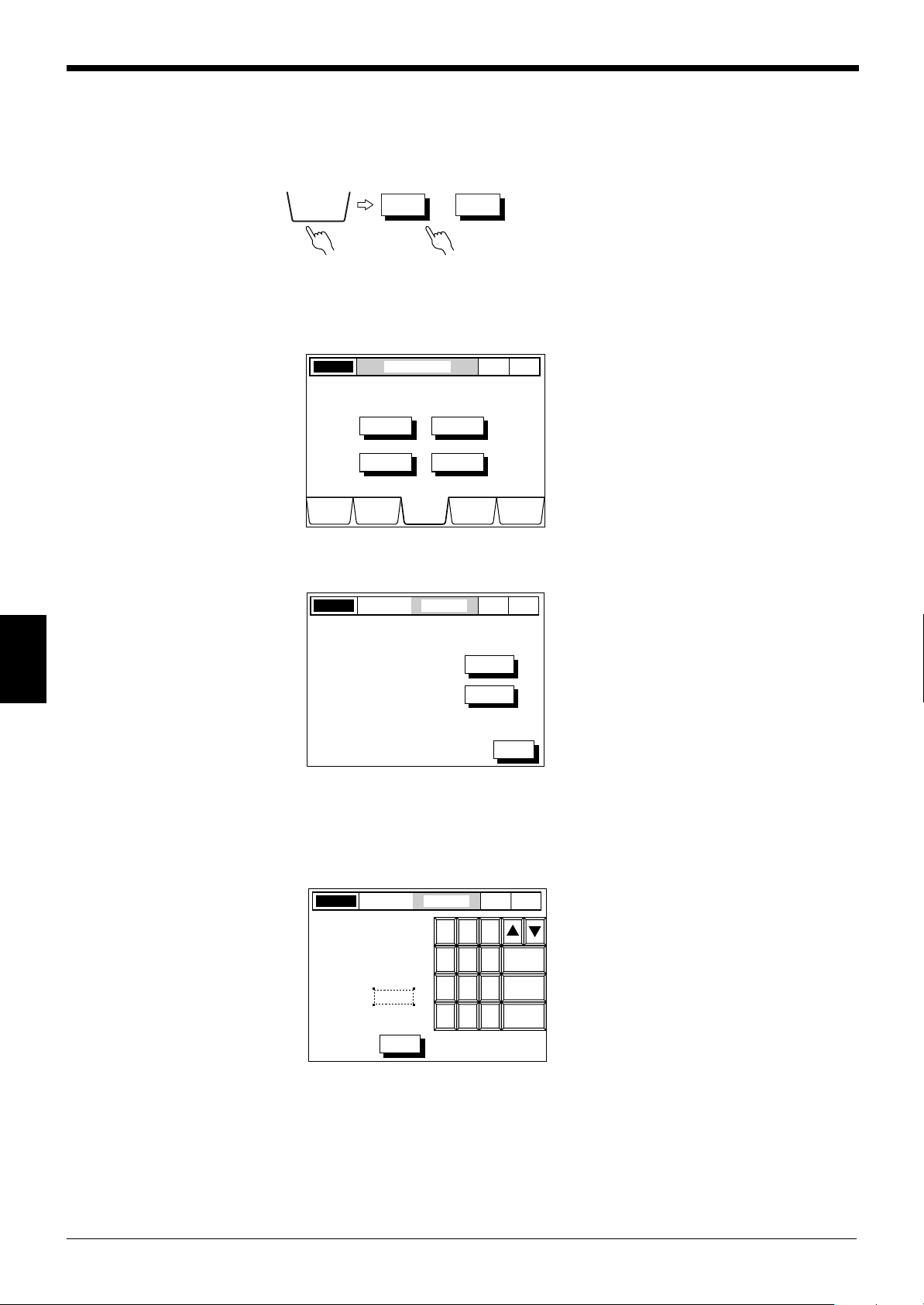

■ Procedure for Setting Edge Number (Only when SEG is selected.)

1. Select the AREA SETUP screen.

Perform steps 1 and 2 described on the previous page to go to the screen

shown below.

2. Set the EDGE number.

Press the [SET] button corresponding to the area for which you wish to set the

edge number.

6

You can enter a value in the space indicated by the dotted line .

Enter a value using the numeric keys, and press [ENTER] key.

Press [ESCAPE] to complete the entry.

Press [CANCEL] to cancel the entry. The value returns to the previous value.

Note 1: The edge number (m,n) must conform to the condition: m < n.

When “m” is larger than “n”, the “ERR” message is displayed and the entered value

cannot be accepted.

Note 2: When you press the [HELP] button, descriptions about the measuring mode

(DIA, T.EDGE/B.EDGE and SEG) are displayed on the screen.

40

Page 47

88

OPTIONS

OUTPUT OUT1 • • • OUT4

OUTPUT MODEOUT1LASER ON P. 1

+A1 +A2 +A3 OFF

AREA1 AREA2 AREA3 AREA4

500

AVERAGE

CALCULATE

1 (0.833ms)

MEASURING MODE

SELF-TIMING

INTERVAL (ms)

NORMAL

DIGIT

SUPPRESS

NONE

ESCHELP NEXT

NOR

MAL

+A1 +A2 –A3 OFF

AREA1 AREA2 AREA3 AREA4

LASER ON AREA SETUP

NOR

MAL

P. 1

EDGEI

EDGEI

HEAD1

( 2, 3)

ESCHELP

SET

HEAD No.

EDGE No.

A1

SEGMENT

HEAD2

( 2, 3)

SET

HEAD No.

EDGE No.

A2

SEGMENT

DIAHEAD3

( 2, 3)

SET

HEAD No.

EDGE No.

A3

SEGMENT

DIAHEAD4

( 2, 3)

SET

HEAD No.

EDGE No.

A4

SEGMENT

+A1/2 +A2/2 OFF OFF

AREA1 AREA2 AREA3 AREA4

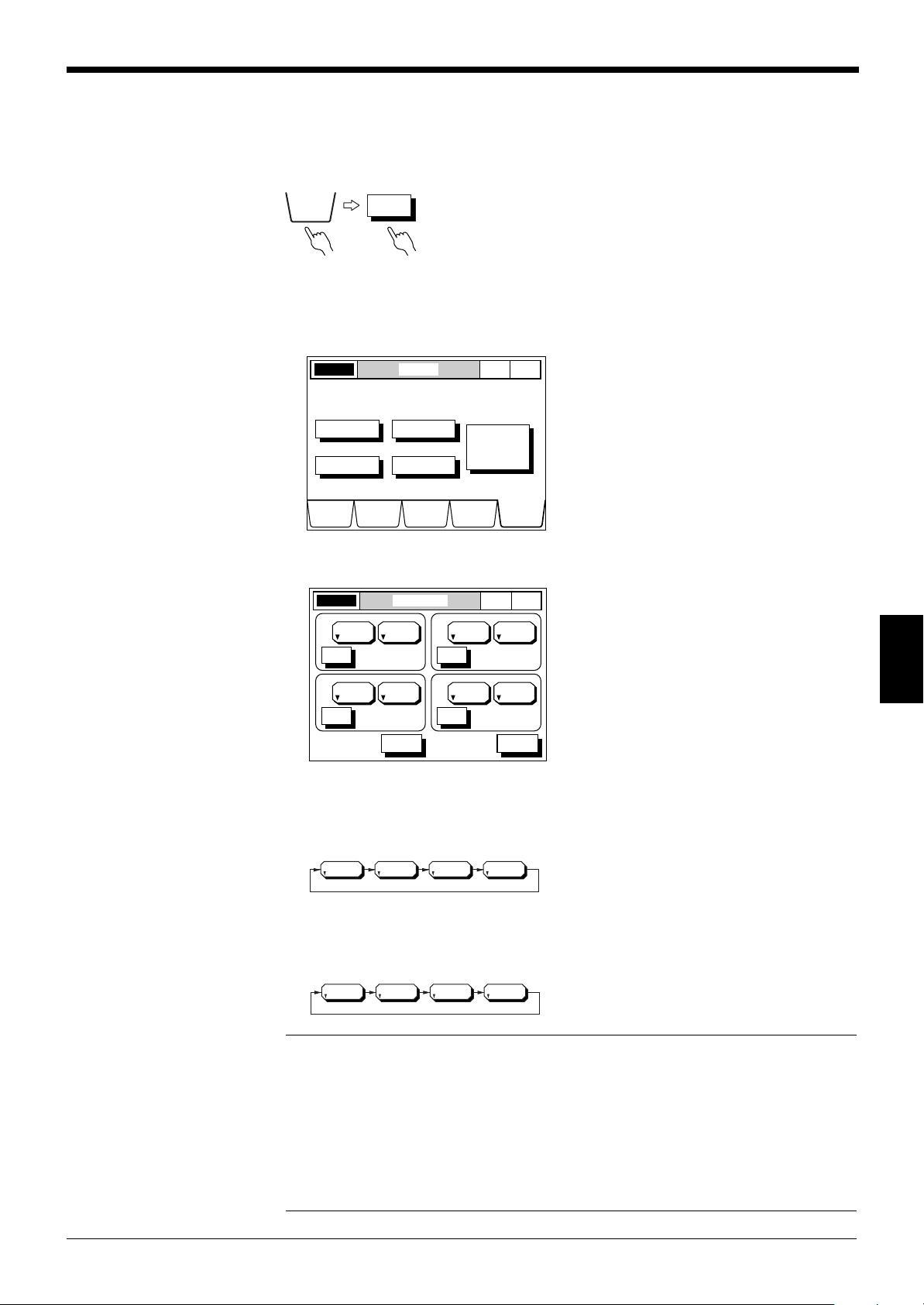

8 Calculation Setup

88

Chapter 6 Normal Mode

The following calculation modes can be set for the area (A1 to A4) specified on the

AREA SETUP screen. Addition and subtraction using data of several areas can be

set.

■ Calculation for each area

OFF : The measured value is not used for calculation.

+A# : The measured value is output without changes.

+A#/2 : The measured value is multiplied by “1/2”.

+A#/3 : The measured value is multiplied by “1/3”.

:

–A#/4 : The measured value is multiplied by “-1/4”.

* A# indicates either of A1 to A4.

Calculation using data of several areas

Calculation setup

When the calculation modes are set as shown above, the calculation result of

“+A1+(+A2)+(-A3)” is output.

[Example 1]

When two scanning heads are installed along two axes, the average value of the

wire’s outer diameter is output.

[AREA SETUP]

6

Setting Status

1/2 of the outer diameters

measured with HEAD 1 and

HEAD 2 are added.

41

Page 48

Chapter 6 Normal Mode

LASER ON AREA SETUP

NOR

MAL

P. 1

EDGEI

EDGEI

HEAD1

( 2, 3)

ESCHELP

SET

HEAD No.

EDGE No.

A1

SEGMENT

HEAD2

( 2, 3)

SET

HEAD No.

EDGE No.

A2

SEGMENT

DIAHEAD3

( 2, 3)

SET

HEAD No.

EDGE No.

A3

SEGMENT

DIAHEAD4

( 2, 3)

SET

HEAD No.

EDGE No.

A4

SEGMENT

–A1 –A2 OFF OFF

AREA1 AREA2 AREA3 AREA4

LASER ON OPTIONS

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB OPTIONS

AREA

OUTPUT

INSPECT

UTILITY

Select Option to setup.

MODE

CHANGE

Normal

-> Pitch

LASER ON OUTPUT MODE

NOR

MAL

P. 1

OUT1

OUT2

OUT3

I/O SLOT

SETUP

OUT4

ESC

Select Output to set.

[Example 2]

Two scanning heads are used to measure a sheet width.

[AREA SETUP]

Setting Status

The measured values of HEAD

1 and HEAD 2 are both multiplied by “-1”, and the resulting

values are added.

■ Setting Procedure

1. Select the OUTPUT MODE screen.

Press the [OPTIONS] button. The screen shown below is displayed.

6

2. Select the output number to be set.

Press the [OUTPUT] button.

Press the button corresponding to the output number for which calculation setup

is to be performed.

[OUTPUT] button

42

Page 49

Chapter 6 Normal Mode

OFF

–A1/4

+A1

+A1/2

+A1/3

+A1/4

–A1

–A1/2

–A1/3

OFF +A2 +A2/2 +A2/3

OFF +A3 +A3/2 +A3/3

OFF +A4 +A4/2 +A4/3

For AREA 2

For AREA 3

For AREA 4

OUTPUT MODEOUT1LASER ON P. 1

+A1 OFF OFF OFF

AREA1 AREA2 AREA3 AREA4

100

AVERAGE

CALCULATE

1 (0.833ms)

MEASURING MODE

SELF-TIMING

INTERVAL (ms)

NORMAL

DIGIT

SUPPRESS

NONE

ESCHELP NEXT

NOR

MAL

3. Set the calculation modes.

Every time you press the [CALCULATE] button, the setting changes as shown

below. (For AREA 1)

[CALCULATE] button

OFF: Calculation is set to OFF.

+A1: The measured value is output without changes.

+A1/2: The measured value is multiplied by “1/2”.

+A1/3: The measured value is multiplied by “1/3”.

+A1/4: The measured value is multiplied by “1/4”.

Note:

–A1: The measured value is multiplied by “–1”.

–A1/2: The measured value is multiplied by –1/2”.

–A1/3: The measured value is multiplied by “–1/3”.

–A1/4: The measured value is multiplied by “–1/4”.

6

43

Page 50

Chapter 6 Normal Mode

OPTIONS

OUTPUT OUT1 • • • OUT4

LASER ON OPTIONS

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB OPTIONS

AREA

OUTPUT

INSPECT

UTILITY

Select Option to setup.

MODE

CHANGE

Normal

-> Pitch

LASER ON OUTPUT MODE

NOR

MAL

P. 1

OUT1

OUT2

OUT3

I/O SLOT

SETUP

OUT4

ESC

Select Output to set.

OUTPUT MODEOUT1LASER ON P. 1

+A1 OFF OFF OFF

AREA1 AREA2 AREA3 AREA4

100

AVERAGE

CALCULATE

1 (0.833ms)

MEASURING MODE

SELF-TIMING

INTERVAL (ms)

NORMAL

DIGIT

SUPPRESS

NONE

ESCHELP NEXT

NOR

MAL

99

9 Average

99

The number of averaging measurements can be set based on the application as

follows.

• Increase the number of averaging measurements:

To average fluctuations in measured values to obtain stable data

• Reduce the number of averaging measurements:

To increase high speed differentiation speed

■ Setting Procedure

1. Select the OPTIONS screen.

Press the [OPTIONS] button.

2. Select the OUTPUT MODE screen.

Press the [OUTPUT] button.

6

3. Set the number of averaging measurements.

Press the button corresponding to the output number for which the number of

averaging measurements is to be set.

Press the [AVERAGE] button and set a number of averaging measurements.

44

Page 51

Chapter 6 Normal Mode

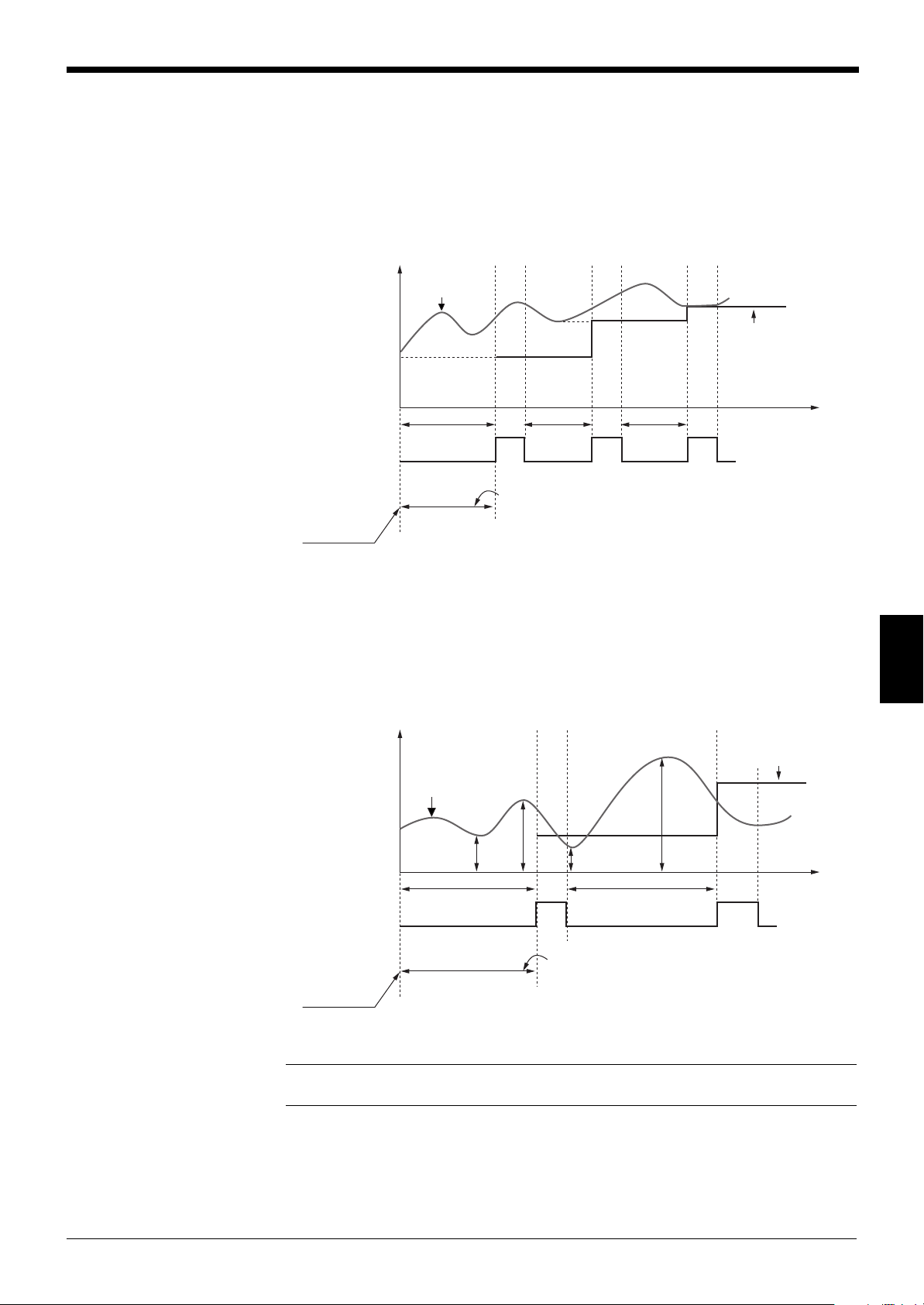

[Relationship between number of averaging measurements and averaging time]

No. of averaging Averaging time

measurements

1 0.833 ms

2 1.67 ms

4 3.33 ms

8 6.67 ms

12 10 ms

24 20 ms

48 40

Note: The averaging time is not the same as output response time.

➮

For output response time, see p. 121.

No. of averaging Averaging time

measurements

96 80 ms

192 160 ms

384 320 ms

768 640 ms

1538 1.28 s

3072 2.56 s

6144 5.12 s

6

45

Page 52

Chapter 6 Normal Mode

Measures

this diameter.

Measures

this diameter.

Measures

this width.

OPTIONS

OUTPUT OUT1 • • • OUT4

00

0 Measuring mode

00

The LS-5000 series provides the following nine measuring modes.

Mode Description

Normal The measured value and comparator output are displayed/

output at any time.

Peak hold The maximum value during a specified period is measured.

Bottom hold The minimum value during a specified period is measured.

Difference hold The difference between the maximum and minimum values

during a specified period is measured.

Auto peak hold The maximum measured value is retained.

Auto bottom hold The minimum measured value is retained.

Auto difference hold The difference between the maximum and minimum values is

retained.

Sample hold The instantaneous value at a specified time is measured.

Self-timing Automatic measurement without using external synchronous

input. Only with DIA or SEG (m, n).

6

[Applications of each mode]

• Normal mode

Used for normal continuous measurement.

• Difference hold

• Auto difference hold

• Peak hold

• Auto peak hold

Used to measure the maximum value of the target.

• Bottom hold

• Auto bottom hold

Used to measure the

minimum value of the

target.

46

Page 53

Chapter 6 Normal Mode

LASER ON OPTIONS

NOR

MAL

P. 1

DISPLAY

DATA

LIMIT

SETUP

PROGRAMCALIB OPTIONS

AREA

OUTPUT

INSPECT

UTILITY

Select Option to setup.

MODE

CHANGE

Normal

-> Pitch

LASER ON OUTPUT MODE

NOR

MAL

P. 1

OUT1

OUT2

OUT3

I/O SLOT

SETUP

OUT4

ESC

Select Output to set.

NORMAL PEAK BOTTOM DIFFERENCE

AUTO-DIFFERENCE AUTO-BOTTOM AUTO-PEAK SELF-TIMING SAMPLE

OUTPUT MODEOUT1LASER ON P. 1

+A1 OFF OFF OFF

AREA1 AREA2 AREA3 AREA4

100

AVERAGE

CALCULATE

1 (0.833ms)

MEASURING MODE

SELF-TIMING

INTERVAL (ms)

NORMAL

DIGIT

SUPPRESS

NONE

ESCHELP NEXT

NOR

MAL

500 1000 10 50 100 200

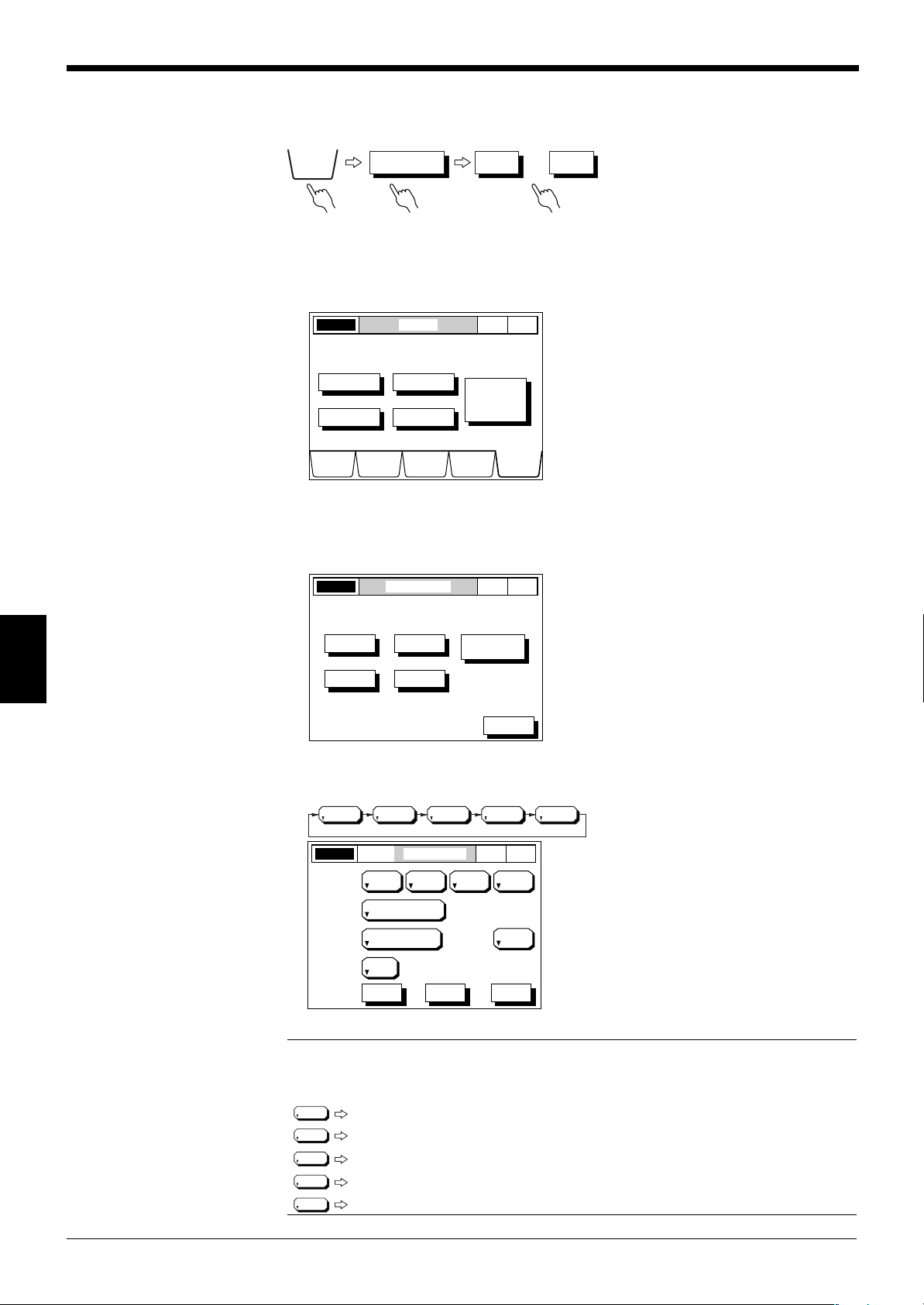

■ Setting Procedure

1. Select the OPTIONS screen.

Press the [OPTIONS] button.

2. Select the OUTPUT MODE screen.

Press the [OUTPUT] button.

Press the button corresponding to the output number for which the measuring

mode is to be set.

3. Set the measuring mode.

Press the [MEASURING MODE] button to set the measuring mode.

Every time the [MEASURING MODE] button is pressed, the indication changes

in the above order.

[When the self-timing mode is selected] [Only with DIA or SEG (m, n)]

4. Set the self-timing interval.

Press the [SELF-TIMING INTERVAL] button to set the self-timing interval.

Every time the [SELF-TIMING INTERVAL] button is pressed, the setting

changes in the following order.

6

47

Page 54

Chapter 6 Normal Mode

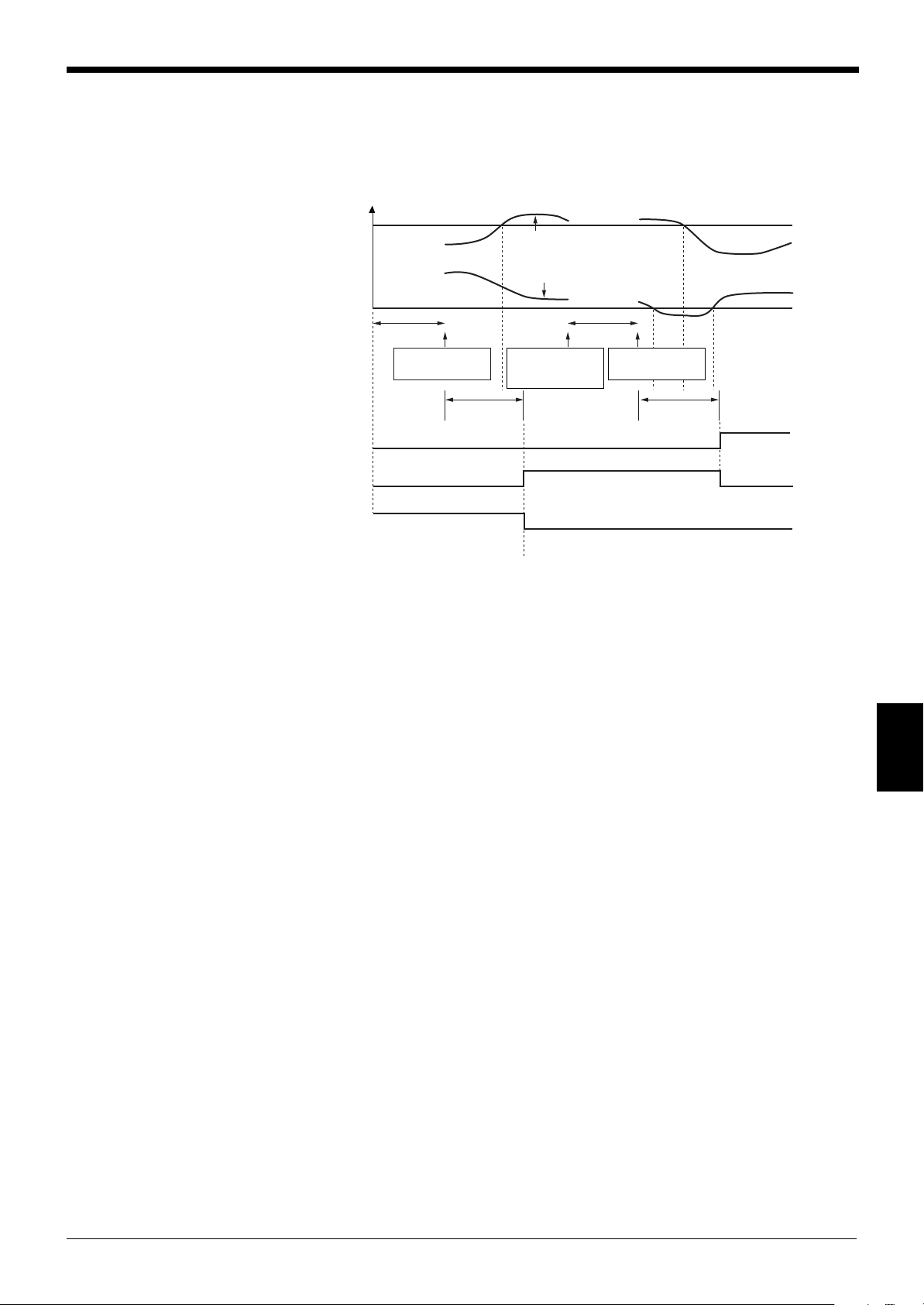

* When the synchronous input is ON, the displayed value/comparator output is retained.

Preset upper limit

Displayed value

Preset lower limit

HI OUT

ON

OFF

ON

OFF

ON

OFF

ON

OFF

GO OUT

LO OUT

Synchronous

input

(t)

Internal

measurement

Measured

value

ON

OFF

Synchronous

input

Power-ON or

RESET input

(t)

After the power-ON or RESET input is activated,

“-----” is displayed until the synchronous input is turned ON.

Peak hold value

Sampling

period

Sampling

period

Sampling