Page 1

Instruction

Manual

Laser Scan Micrometer

96M10280

LS-3100(W) Series

Page 2

S

AFETY

P

RECAUTIONS

This manual describes how to install the LS-3100(W) Series as well as its

operating procedures and precautions. Please read this manual carefully to

get the best from your LS-3100(W) Series.

Symbols

General Pecautions

The following symbols alert you to important messages. Be sure to read

these messages carefully.

WARNING

CAUTION

Note

• At startup and during operation, be sure to monitor the functions and

performance of the LS-3100(W) series.

• We recommend that you take substantial safety measures to avoid any

damage in the event a problem occurs.

• Do not open or modify the LS-3100(W) series or use it in any way other

than described in the specifications.

• When the LS-3100(W) series is used in combination with other instruments, functions and performance may be degraded, depending on

operating conditions and the surrounding environment.

Failure to follow instructions may lead to injury.

(electric shock, burn, etc.)

Failure to follow instructions may lead to product

damage.

Provides additional information on proper operation.

• Do not use the LS-3100(W) series for the purpose of protecting the

human body.

■ Best Management Practice for Perchlorate Materials — California

only

When you sell, manufacture and/or waste the products containing

perchlorate material in California, the following statement must appear on

the exterior of all outer shipping packages and on consumer packages,

based on California Code of Regulations.

“Perchlorate Material – special handling may apply, See

www.dtsc.ca.gov/hazardouswaste/perchlorate.”

Note: Alternative option is to indicate this statement on your MSDS or

manual accompanying with each product.

This product includes a CR coin type cell containing perchlorate material. If

you ship this product (or your product including this product) to California,

you must ensure to comply with this regulation.

Page 3

Unpacking

Check that the following items are included in your LS system package.

• Controller ....................................................................................... 1

• Scanning head ............................................................................... 1

• Laser beam cover (attached to scanning head) ............................ 1

• Connection cable ........................................................................... 3

• Power cable ................................................................................... 1

• Power switch key ........................................................................... 2

• Instruction manual ......................................................................... 1

• Laser beam axis alignment tool ..................................................... 1

1. Or number purchased.

2. LS-3033, 3060 only. (Not provided with LS-3033 SO)

WARRANTIES AND DISCLAIMERS

See page 97.

1.

1.

1.

1, 2.

96M10280

Page 4

CONTENTS

Chapter 1 Laser Safety Precautions 1

1-1. Classification ............................................................................................... 1

1-2. Warning Labels ...........................................................................................1

1-3. Label Location ............................................................................................. 2

1-4. Safety Consideration ................................................................................... 2

1-5. Safety Features Provided with the LS-3100 Series .................................... 3

1-6. Preparation for Operation ...........................................................................4

1-7. Connecting 2 Scanning Heads ...................................................................6

Chapter 2 Trial Operation 7

Chapter 3

Chapter 3 Quick Setup Procedures 8

3-1. Common Settings .......................................................................................9

Setting the Number of Measurements for Averaging ............................9

Tolerance Settings ..............................................................................10

3-2. Measurement Procedures ......................................................................... 10

Outer Diameter Measurements........................................................... 10

Gap Measurement 1 ...........................................................................11

Gap Measurement 2 ...........................................................................11

Measuring Roundness ........................................................................12

Measuring Eccentricity ........................................................................12

Measuring Target Displacement within the Measuring Range ........... 13

Measuring Edge Movement ................................................................13

3-3. Using LS-3100D(W) Controller with 2 Scanning Heads ...........................14

Chapter 4 Functions and Controls 15

4-1. Part Names ...............................................................................................15

Controller ..................................................................................................15

Scanning Heads ........................................................................................ 16

4-2. Indicators and Displays ............................................................................. 18

4-3. Panel Keys ................................................................................................ 19

Numeric Keys ............................................................................................ 19

SET Key .................................................................................................... 19

CLR Key .................................................................................................... 19

ENT Key .................................................................................................... 20

UP/DOWN Key .........................................................................................20

ZERO (Auto-Zero) Key .............................................................................20

HOLD Key ................................................................................................. 20

Page 5

AVE Key .................................................................................................... 21

Averaging Methods ........................................................................ 21

PRM Selector Key ..................................................................................... 22

Analog Voltage Range ................................................................... 22

LIMIT ...................................................................................................23

Tolerance Limits and Comparator Output ...................................... 24

DIGIT SUPPRESS ..............................................................................26

HOLD ..................................................................................................27

BAUD RATE ....................................................................................... 27

UNIT.................................................................................................... 27

BUZZER.............................................................................................. 28

HEAD2 ................................................................................................28

POSITION CHECK (Model: LS-3033/3060 only) ................................28

LIMIT (tolerance limits for 3-step differentiation) Key ...............................29

SEG (segment) Key ..................................................................................30

FNC (function) Key ...................................................................................32

Segment Selector ............................................................................... 32

Segment Check .................................................................................. 35

Output Channel ...................................................................................37

MODE, OFFSET, and LIMIT for CH2 ................................................. 39

MODE Key ................................................................................................40

CAL (calibration) Key ................................................................................41

DISP (subdisplay) Key ..............................................................................43

OFS (offset) Key ....................................................................................... 43

PROG (program) Key ...............................................................................45

Storing (SAVE) Settings...................................................................... 45

Retrieving (LOAD) Settings................................................................. 46

Table of I/O Terminals ........................................................................ 47

Analog Voltage Output ................................................................... 47

Comparator Output ........................................................................47

Program Selector Input Terminals ......................................................48

AUTO ZERO Terminals ......................................................................48

HOLD Terminal ...................................................................................48

Laser Emission Control Input Terminal ...............................................48

4-4. I/O Terminal .............................................................................................. 49

RS-232C I/O Terminal ..............................................................................49

36-pin Connector (Control I/O) .................................................................. 62

Input Signal .........................................................................................63

Output Signal ......................................................................................63

Functions of Terminal Blocks .................................................................... 63

Analog Voltage Output Terminals .......................................................63

Control Input Terminals....................................................................... 64

Control Output Terminals ....................................................................64

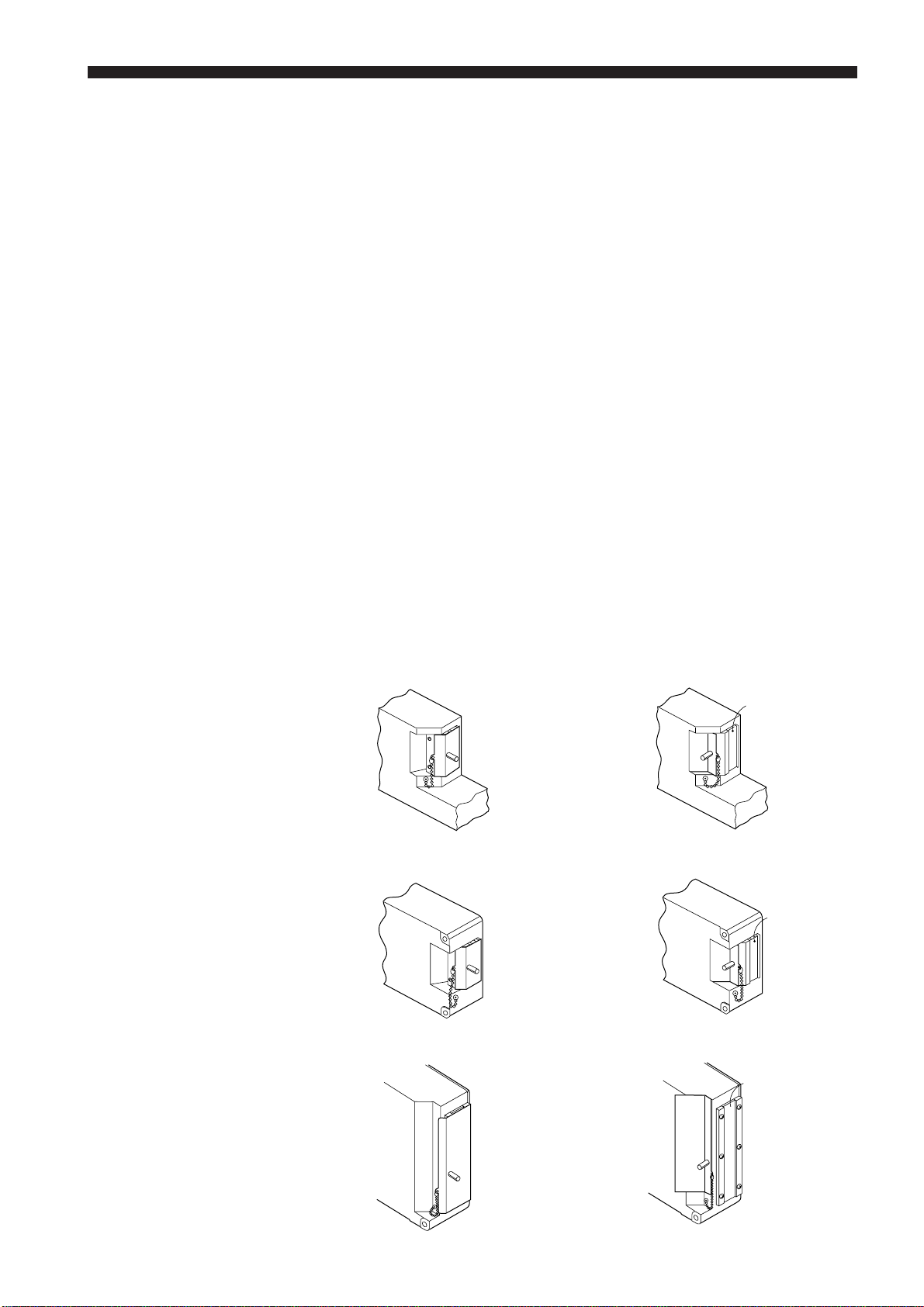

Chapter 5 Mounting Scanning Head 65

5-1. Alignment of Optical Axis (LS-3060 only) .................................................65

Allowance for Aligning Transmitter and Receiver ..................................... 65

5-2. Checking Alignment of Optical Axis (LS-3033 only) .................................66

Error Messages (For Models LS-3060 and LS-3033) ...............................67

Chapter 6 Optional Interface Boards 68

6-1. BCD Output ............................................................................................... 68

6-2. GP-IB Interface I/O ...................................................................................70

Page 6

Chapter 7 Hints on Correct Use 76

Chapter 8 Error Messages 78

H-Err .................................................................................................................. 78

P-Err .................................................................................................................. 78

CALIB ERROR .................................................................................................. 78

Chapter 9 Troubleshooting Guide 80

Troubleshooting Guide ...................................................................................... 80

Appendices 83

Appendix A Operating Principle ....................................................................... 83

Appendix B Characteristics ..............................................................................84

Measuring Area vs. Accuracy ................................................................... 84

Temperature Characteristics (Typical) ...................................................... 85

Appendix C Specifications................................................................................86

Controller ..................................................................................................86

Scanning Head .........................................................................................87

Appendix D Dimensions ................................................................................... 88

Appendix E Quick Reference Table .................................................................89

Modes (Functions) and Key Operations ...................................................89

Appendix F Key Flowcharts .............................................................................91

PRM (Parameter) ...................................................................................... 91

AVE (Average) ..........................................................................................92

SEG (Segment) ......................................................................................... 93

FNC (Function) .........................................................................................94

DISP (Display) ..........................................................................................95

MODE ....................................................................................................... 95

PROG (Program) ...................................................................................... 96

OFS (Offset) .............................................................................................. 96

LIMIT .......................................................................................................96

CAL (Calibration) ......................................................................................96

WARRANTIES AND DISCLAIMERS 97

Page 7

CHAPTER 1

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION-Laser radiation

when open.

DO NOT STARE

INTO BEAM.

LASER SAFETY PRECAUTIONS

1-1. Classification

Laser

FDA (CDRH) 21CFR

Class

Part 1040.10

IEC60825-1 Class 1

DIN EN 60825-1 Class 1

1-2. Warning Labels

1) Warning label

FDA Class II

CAUTION

LASER RADIATION-DO NOT

STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 0.5mW

CLASS II LASER PRODUCT

LS-3034 LS-3033 LS-3032 LS-3033 LS-3036 LS-3060

SO(8073)

Class I Class II

2) Aperture label

FDA Class II

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION-Laser radiation

when open.

DO NOT STARE

INTO BEAM.

1

Page 8

CHAPTER 1 Preparation for Measurement

CAUTION

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION-Laser radiation

when open.

DO NOT STARE

INTO BEAM.

AVOID EXPOSURE

1-3. Label Location

1-4 Safety Consideration

CAUTION

LASER RADIATION-DO NOT

STARE INTO BEAM

SEMICONDUCTOR LASER 670nm

MAXIMUM OUTPUT 0.5mW

CLASS II LASER PRODUCT

1) 2)

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION-Laser radiation

when open.

DO NOT STARE

INTO BEAM.

: Aperture

CAUTION

WARNING

Use of controls or adjustments or the performance of procedures other than

those specified herein may result in hazardous radiation exposure.

The possible health hazard is in exposing the eyes to the laser beam.

Damage to the eyes can occur if the operator stares directly into the beam.

Do not look directly at the laser beam.

Follow the safety precautions below to ensure operator safety:

• Operate the LS-3100(W) series only according to the procedures

described in this instruction manual.

Otherwise, injury may occur due to exposure to the laser beam.

• Do not disassemble the sensor head.

Laser emission from the LS-3100(W) series is not automatically stopped if

the sensor head is disassembled. If you disassemble the sensor head for

inspection or repair, you may be exposed to the laser beam. If the LS3100(W) series malfunctions, contact KEYENCE immediately.

• Do not look directly at the laser beam.

Looking directly at the laser beam may result in serious eye injury.

• Protective enclosure

We recommend that you install a protective enclosure around the sensor

head to prevent any person from getting near the sensor head during

operation.

• Protective goggles

We recommend that you wear protective goggles when using the LS3100(W) series.

2

Page 9

CHAPTER 1 Preparation for Measurement

1-5 Safety Features Provided with the LS-3100(W) Series

The LS-3100(W) series has the following safety features:

■ Laser ON alarm LED

Both the sensor head and the controller panel have a visible LED that lights

when laser is ready to be and is being emitted.

LEDs can be checked to see if they are lit even when you are wearing laser

protective glasses.

■ Delay of laser beam emission

To prevent an operator from being exposed to the laser beam, the laser

beam is emitted three seconds after the laser ON alarm LED lights.

■ Laser emission remote control input connector

The laser emission control connector is located on the rear panel of the

control unit. The laser can be turned on or off by a remote control signal

through this connector.

■ Key-operated power switch

The controller power switch can be locked using the attached key.

When the LS-3100(W) controller is OFF, the key can be removed.

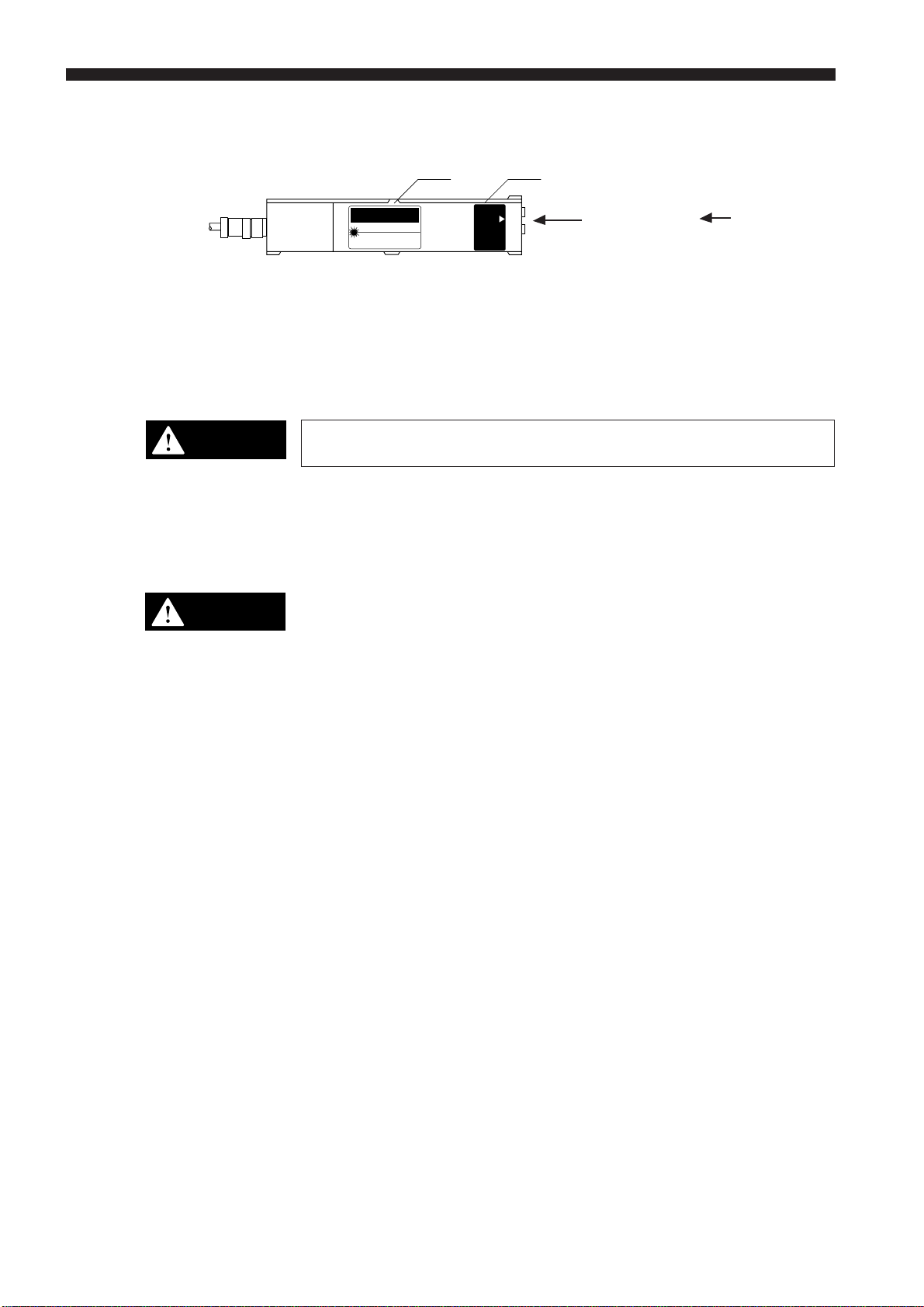

■ Laser beam shield

The sensor head transmitter comes with a laser beam shield.

Cover is closed. Cover is open.

LS-3032/3034/3036LS-3032/3034/3036

LS-3033/3033SO(8073) LS-3033/3033SO(8073)

Laser emission

Laser emission

LS-3060LS-3060

Laser emission

3

Page 10

CHAPTER 1 Preparation for Measurement

1-6. Preparation for Operation

CAUTION

CAUTION

• Do not mount the scanning head to the place where a certain level of

electrical noise is applied or transferred. Isolate the scanning head if

electrical noise may be occured. Otherwise, laser diode may deteriorate

or become damaged.

• Although the LS controller has been thoroughly inspected before shipment, we kindly request that you check it upon purchase for any damage.

Contact the nearest KEYENCE distributor if your LS controller is damaged

in any way.

• Precision components are incorporated in the scanning head, therefore be

sure not to subject it to shocks.

• The scanning head has been precision set before shipment. Always keep

the casing closed to maintain the head's setting.

• The LS controller can operate normally at 0 to 45°C (32 to 113°F) [0 to

40°C (32 to 104°F) for LS-3036/3060] with no freezing and 35 to 85%RH

without condensation. Operation outside these ranges may result in

malfunction.

Do not connect or disconnect any cables while the power is ON. Otherwise,

the laser diode may deteriorate and/or may be damaged.

Note

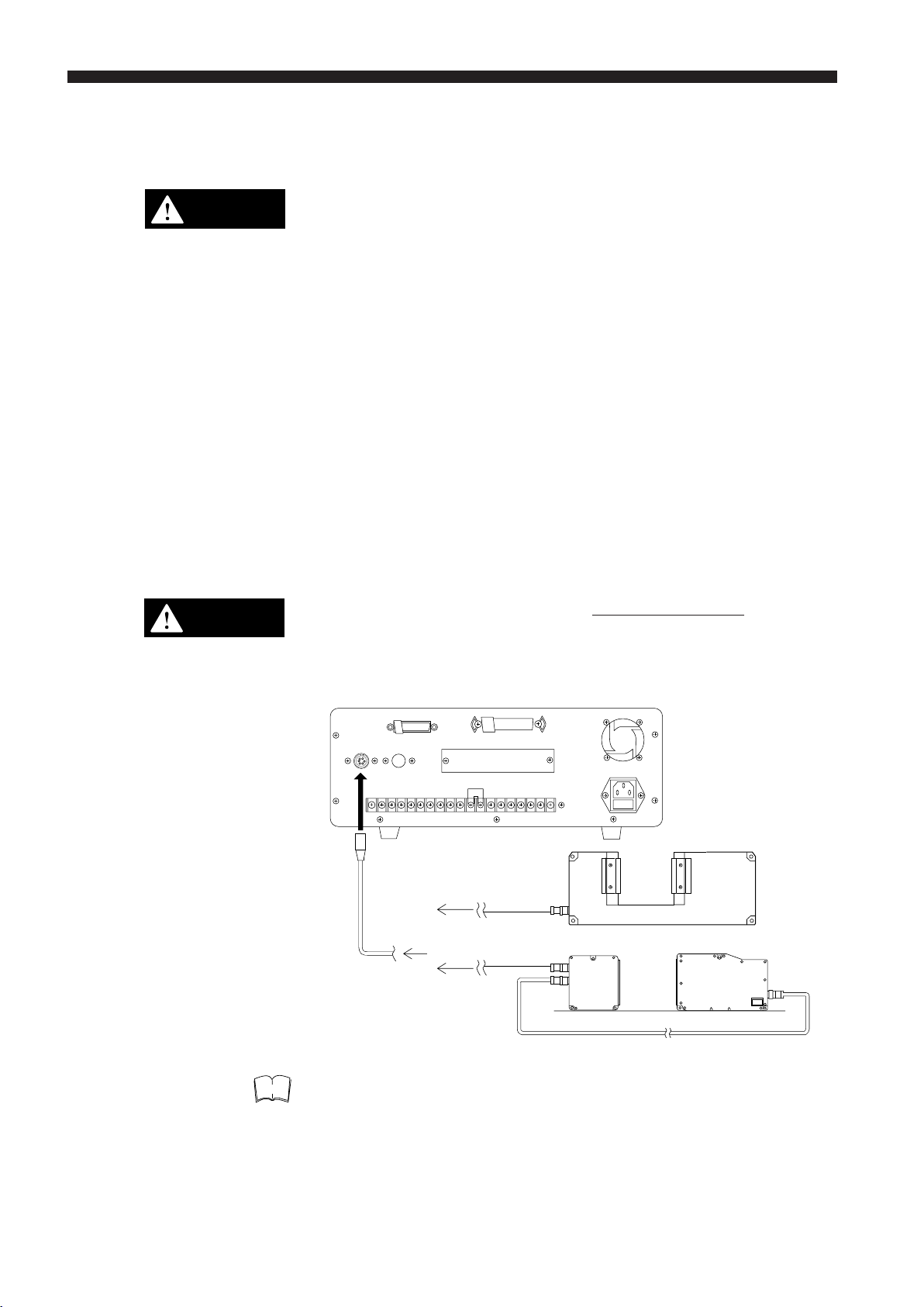

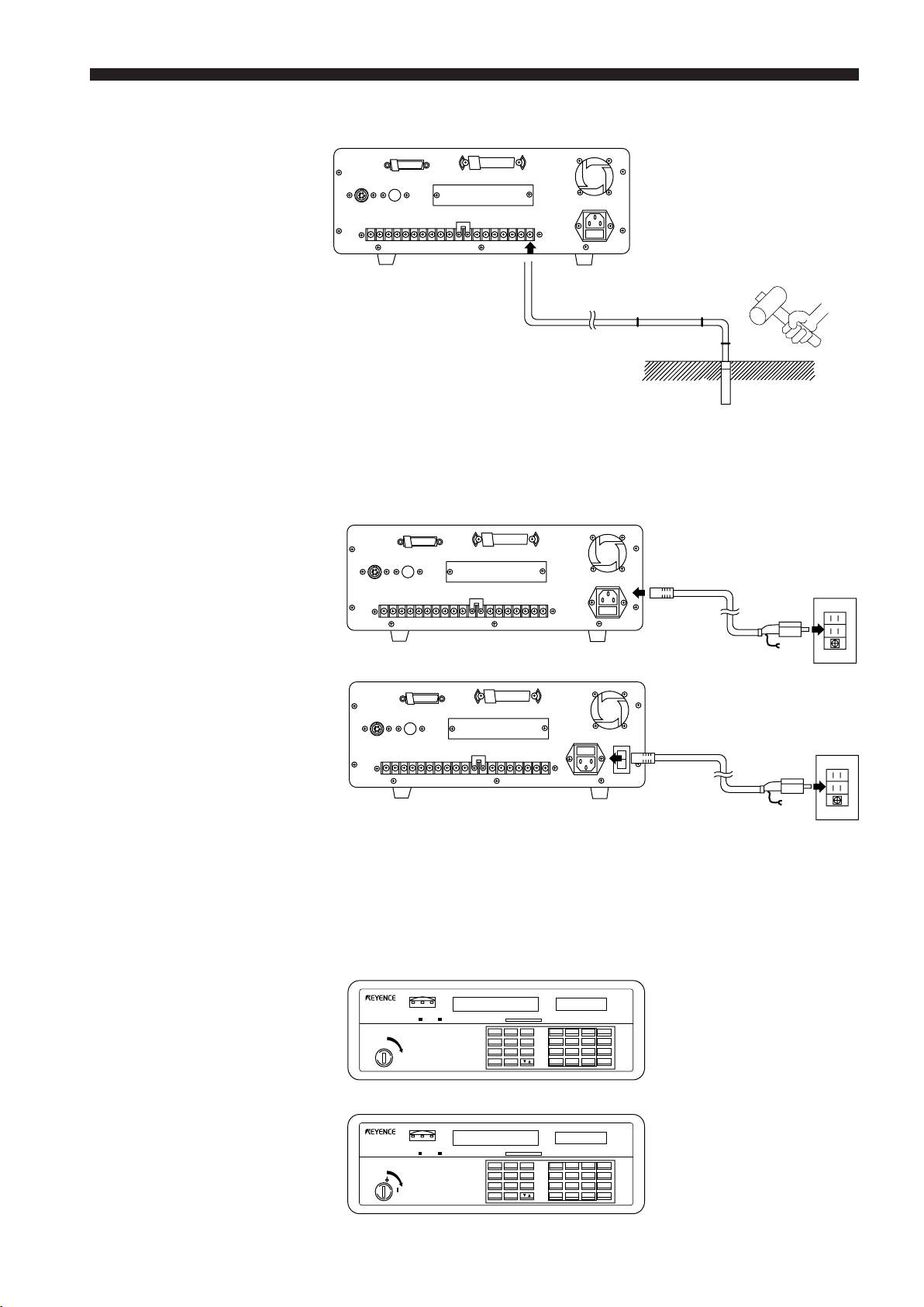

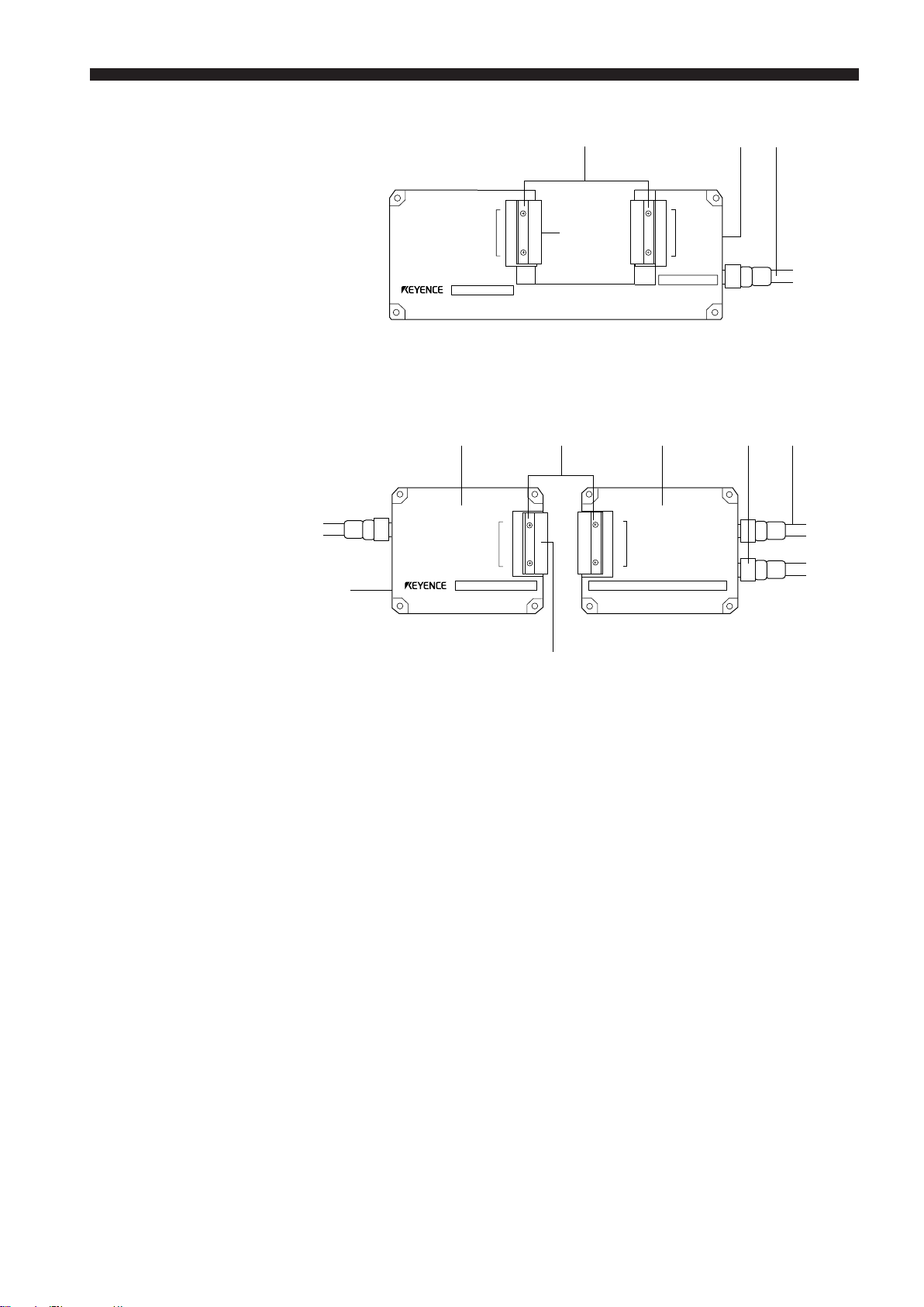

1. Connect the controller to the scanning head and the transmitter and

receiver using the supplied cables.

LS-3032, LS-3034, LS-3036

LS-3033, LS-3033 SO, LS-3060

The LS-3101(W) can be used with LS-3032, 3033, 3036 and 3060.

4

Page 11

CHAPTER 1 Preparation for Measurement

2. Ground the controller. (Except for models followed with “W”.)

Grounding the controller to the

grounding bar

3. Check first that the power switch of the controller is OFF, then connect it to

the outlet using the supplied power cable.

Controller (rear view)

LS-3100 Series

Grounding the

controller through the

grounding outlet

LS-3100(W) Series

I

O

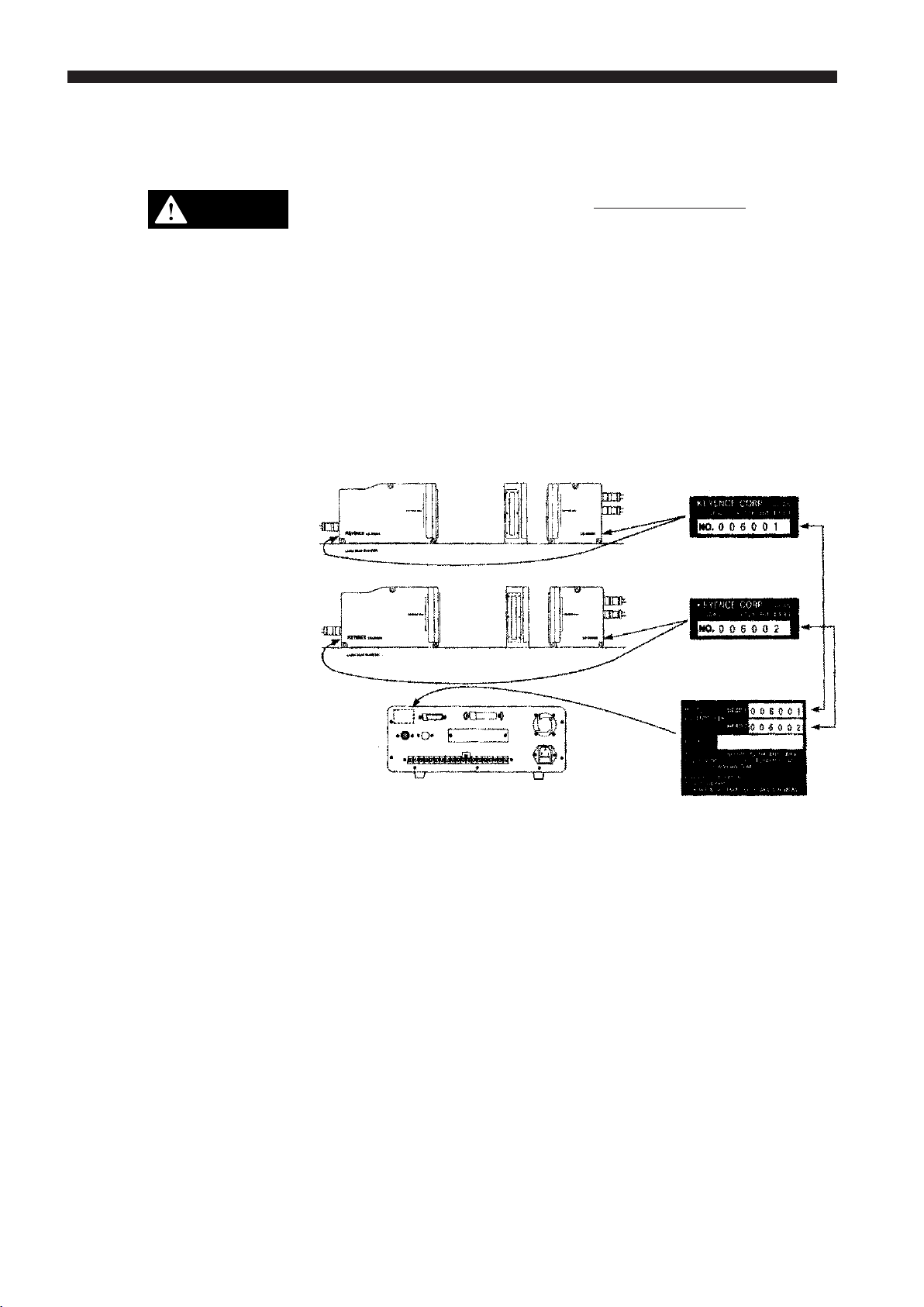

4. Check that laser can be safely emitted, then turn the power switch ON.

Allow the controller to warm-up for approximately 30 minutes after the

laser emission indicator LED has lit.

With the LS-3100(W) series, first turn on the POWER switch (at the rear),

and then turn on the LASER switch (on the front panel).

Controller (front view)

LS-3100 Series

LIMT

HIGH GO LOW

1 2

LASER LASER

LS

LASER SCAN DIAMETER

• OFF

• ON

POWER

OFFSET ZERO HOLD LOCK POSITION

LS-3100(W) Series

LIMT

HIGH GO LOW

1 2

LASER LASER

LS

LASER SCAN DIAMETER

•

•

LASER

OFFSET ZERO HOLD LOCK POSITION

SEG SETMODE

AVE LIMIT OF S

PRM FNC CAL

PROG DISP

SEG SETMODE

AVE LIMIT OF S

PRM FNC CAL

PROG DISP

mm

inch

7

8

9

ZERO

4

5

6

HOLD

1

2

3

CLR

0

.

+/-

ENT

mm

inch

7

8

9

ZERO

4

5

6

HOLD

1

2

3

CLR

0

.

+/-

ENT

5

Page 12

CHAPTER 1 Preparation for Measurement

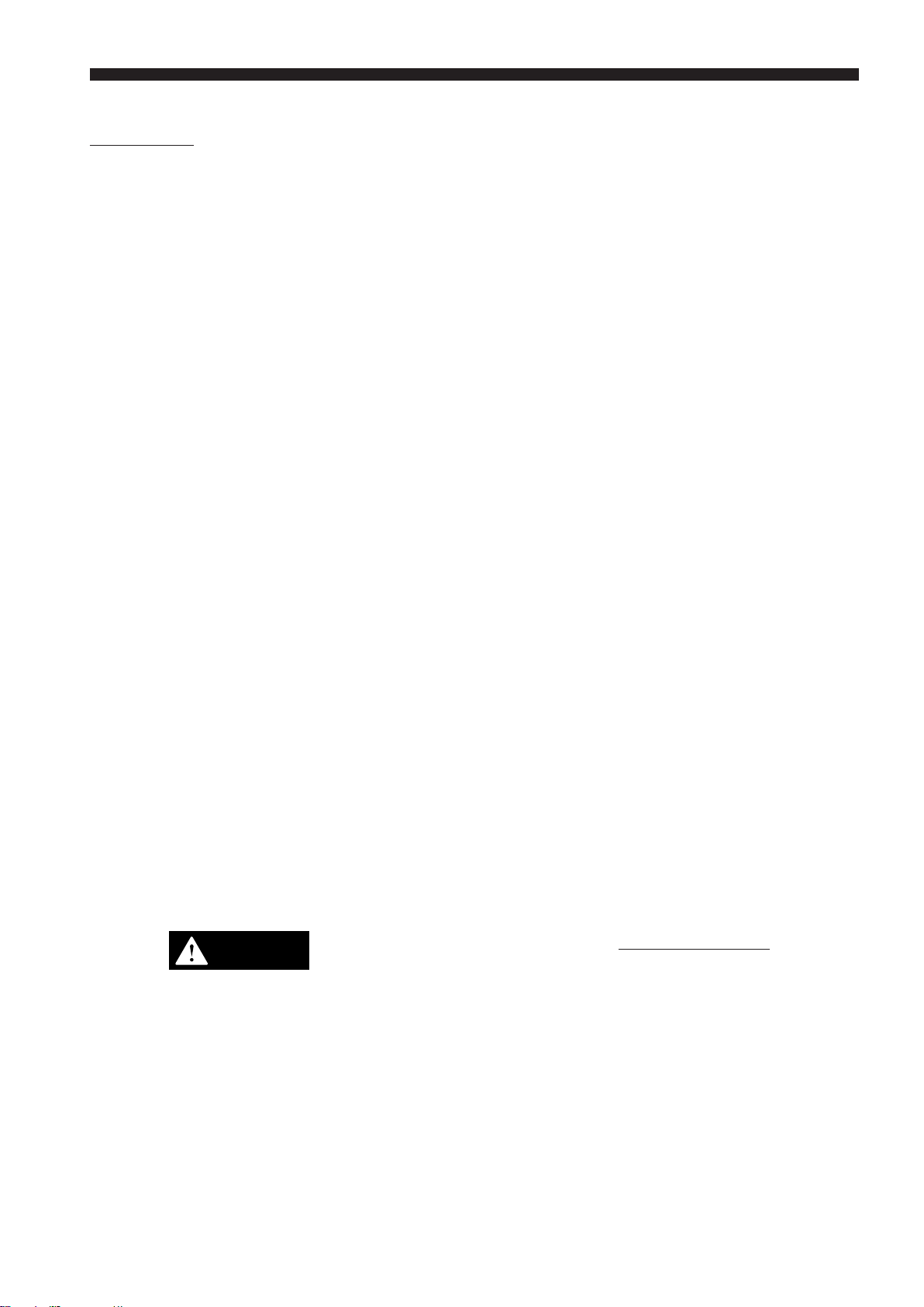

1-7. Connecting 2 Scanning Heads

CAUTION

Do not connect or disconnect any cables while the power is ON. Otherwise,

the laser diode may deteriorate and/or may be damaged.

Note the following for connecting 2 scanning heads to the controller:

• These heads have been factory-set for use either as the HEAD1 or

HEAD2. Incorrect connection of the scanning heads will, therefore, result

in malfunction. To prevent this, first check the serial No. of each scanning

head, then check the serial No. of the HEAD1 and HEAD2 on the back of

the controller for correct connection. Each of the scanning heads must be

connected respectively to the HEAD1 or HEAD2 connector on the back of

the controller.

Connect the correct scanning

head to the HEAD1 or HEAD2

connector.

Serial No.

Serial No.

Next, follow the steps (1) through (4) on P4. and 5.

6

Page 13

CHAPTER 2

TRIAL OPERATION

1. Connect the controller and scanning head(s). Make sure that the optical

axis of the transmitter and receiver are aligned before turning the power

ON. Aligning the optical axis is not necessary, however, when using the

single-body type scanning head or when the transmitter and receiver are

secured on the detachable frame.

2. Laser emission starts in approximately 5 seconds.

3. Make sure that the target is correctly positioned in the measurement area.

The measured value will be displayed shortly.

4. The LS controller has been adjusted to the following factory-settings:

Ref.

• DIA: Outer diameter measuring mode. ............................................... P.32

• 1024: Number of measurements for averaging .................................. P.21

• MOVE: Averaging method .................................................................. P.21

CAUTION

Therefore, the displayed value was measured in the above settings. Read

this manual carefully to use the desired settings on your LS controller. To

change each setting, see the table of contents for the corresponding page

No. Some of the most frequently-used operations are given below with the

reference page Nos.

Ref.

• Changing the measurement position of targets .................................. P.32

• Changing the number of measurements for averaging ....................... P.21

• Changing the measurement mode (NORMAL, P-P, PEAK, BOTTOM)P.40

• Measuring two values at a time .......................................................... P.32

• Using two scanning heads to measure (X+Y)/2 .................................. P.32

Do not connect or disconnect any cables while the power is ON. Otherwise,

the laser diode may deteriorate and/or may be damaged.

7

Page 14

CHAPTER 3 Quick Setup Procedures

CHAPTER 3

QUICK SETUP PROCEDURES

The LS Series is a multi-function, versatile laser scan micrometer. This

chapter describes the procedures for setting the LS-3100(W)/3101(W) by

illustrating typical applications.

This chapter covers the procedures needed to make measurements after the

memory is initialized (after "MEMORY INITIALIZED" is displayed).

Initializing Current Settings ........................................................................... 8

How to Use This Chapter ..............................................................................9

Common Settings .........................................................................................9

Setting the Number of Measurements for Averaging ............................... 9

Tolerance Settings .................................................................................10

Initializing Current

Settings

Measurement Procedures .......................................................................... 10

Outer Diameter Measurements .............................................................. 10

Gap Measurement 1 ..............................................................................11

Gap Measurement 2 ..............................................................................11

Measuring Roundness ...........................................................................12

Measuring Eccentricity ...........................................................................12

Measuring Target Displacement within the Measuring Range ..............13

Measuring Edge Movement ...................................................................13

Using LS-3100D(W) Controller with 2 Scanning Heads .............................14

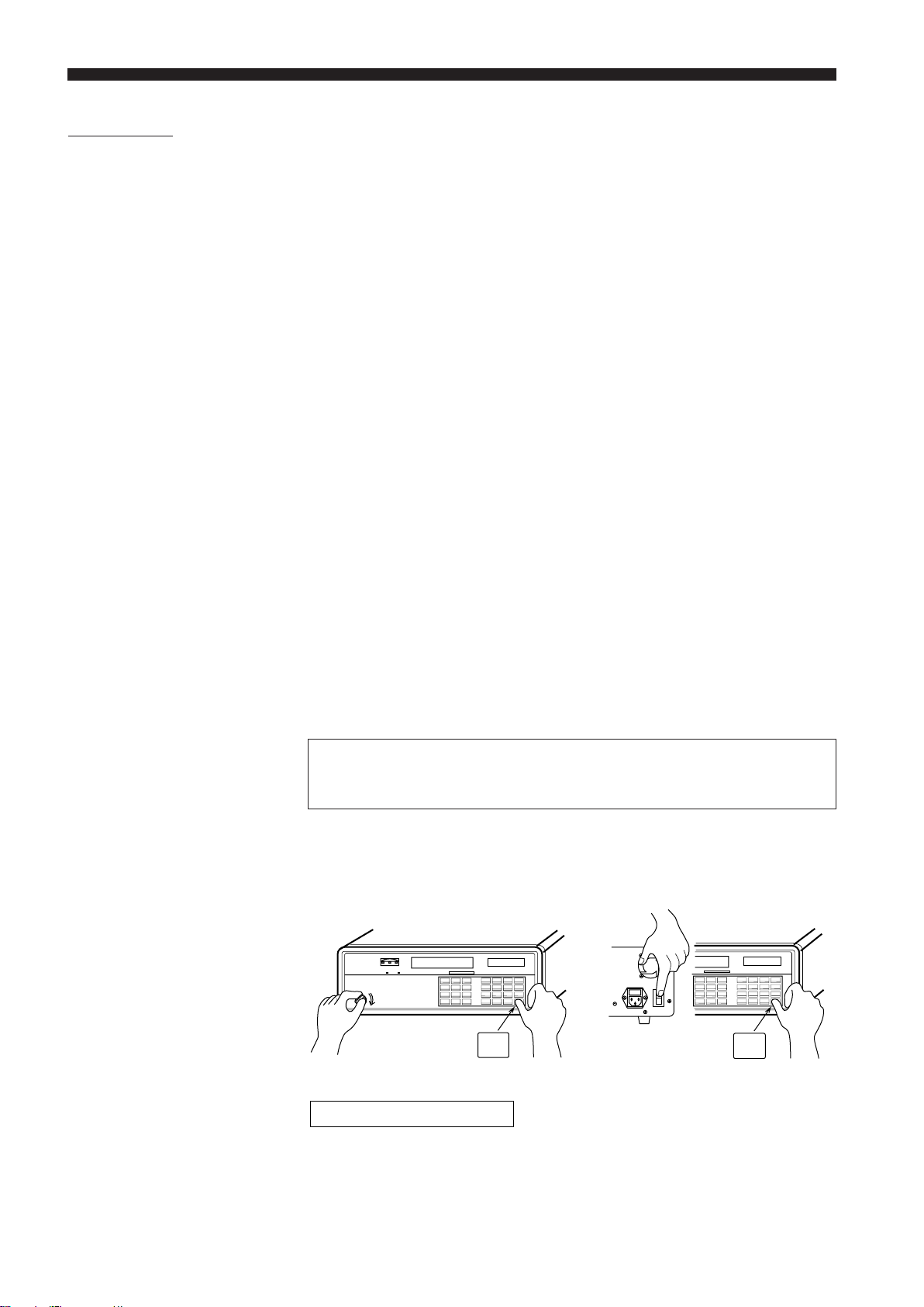

Once a setup is completed, do not initialize the setting again unless

you need to change them. (When initialized, all the current settings

are cleared.)

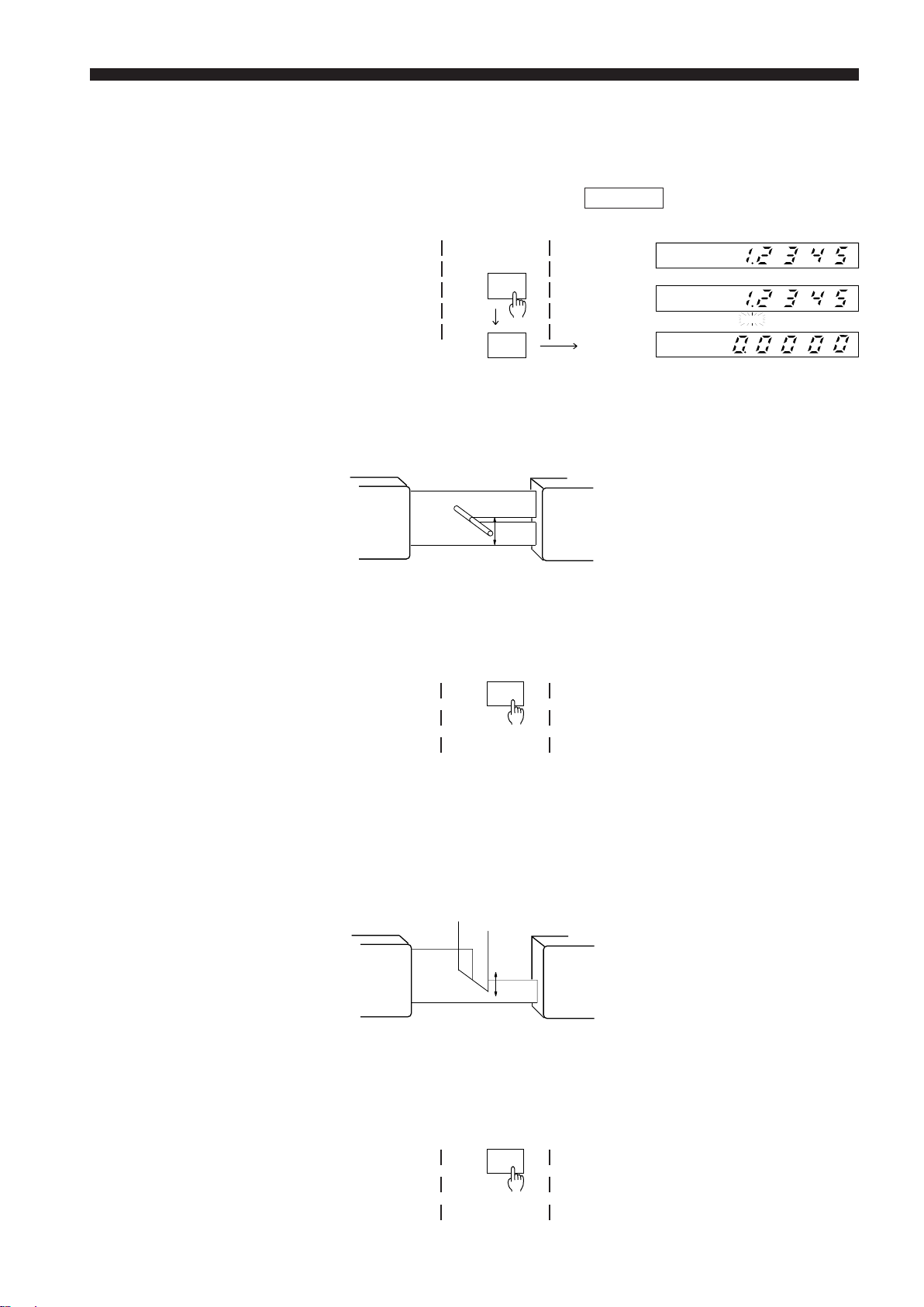

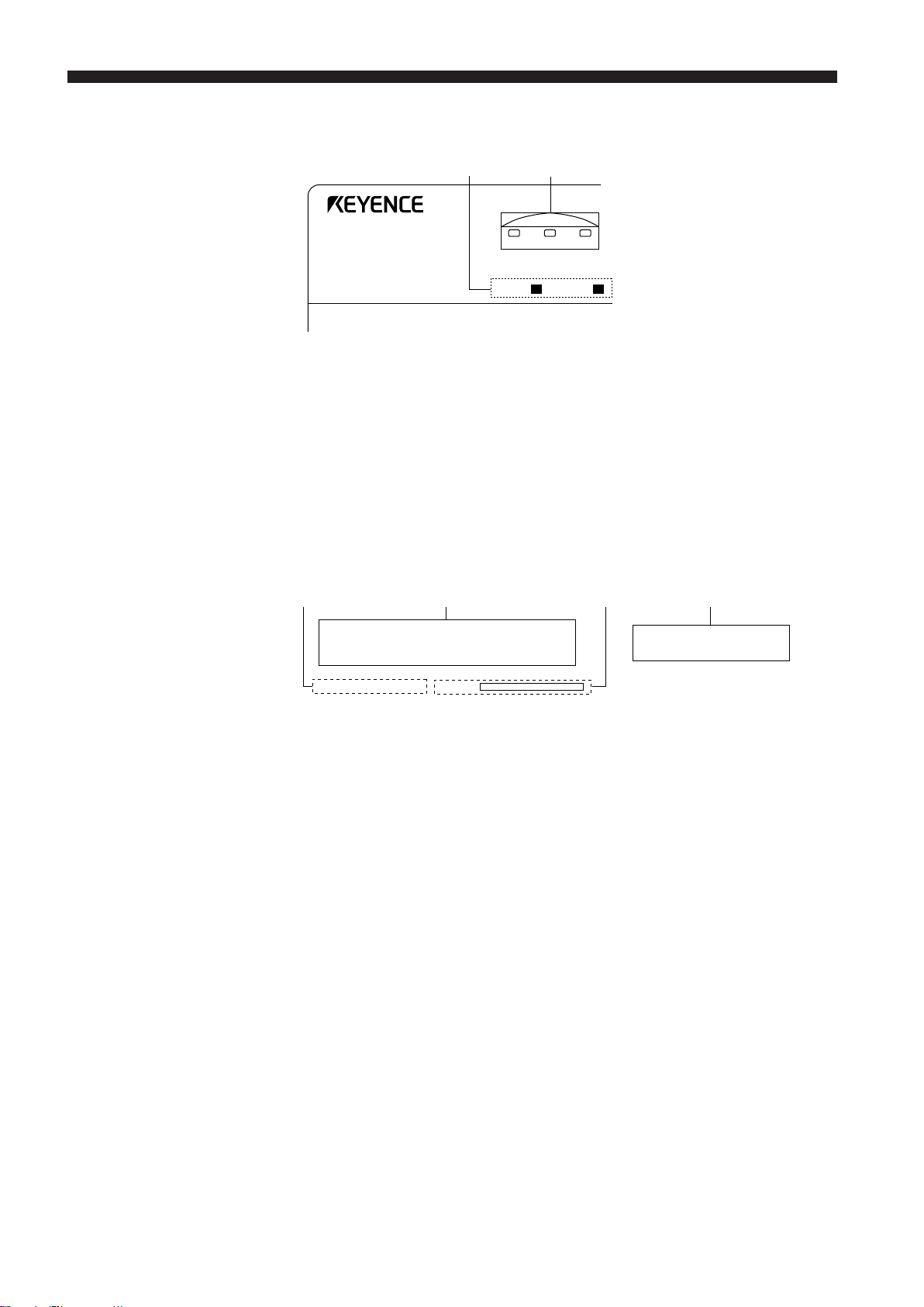

Turn the power switch "ON" while pressing ENT.

LS-3100 Series LS-3100(W) Series

ON

ENT

"MEMORY INITIALIZED" is displayed on the sub-display.

MIENMIOTRIY

All prior settings are cleared and memory initialization is completed.

AL I ZED

ENT

8

Page 15

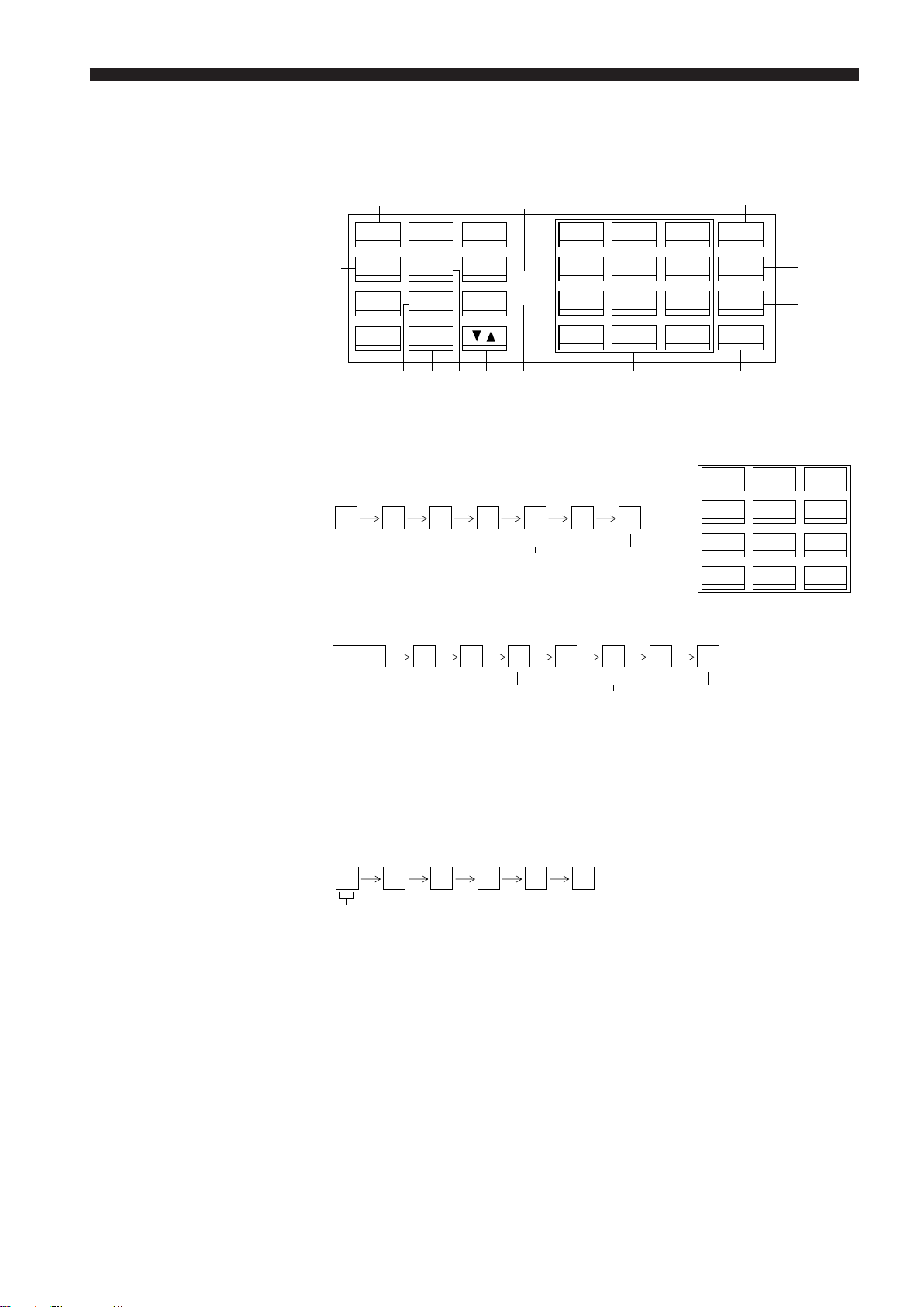

How to Use This Chapter

CHAPTER 3 Quick Setup Procedures

3-1. Common Settings

Setting the Number of Measurements for Averaging

The switches on the left

side of the front panel

are shown on the left

side of the pages in this

chapter.

The switches on the

right side of the front

panel are shown at the

center of the pages in

this chapter.

See page 93 for Measurement Procedures.

AVE

SET

SET

SET

.

.

.

.

AVE 1M0O2V4

AVE

AVE 2

AVE 4

E

S I MPL1E

All massages on the

sub-display are shown

on the right side of the

pages in this chapter.

512

256

128

64

32

16

8

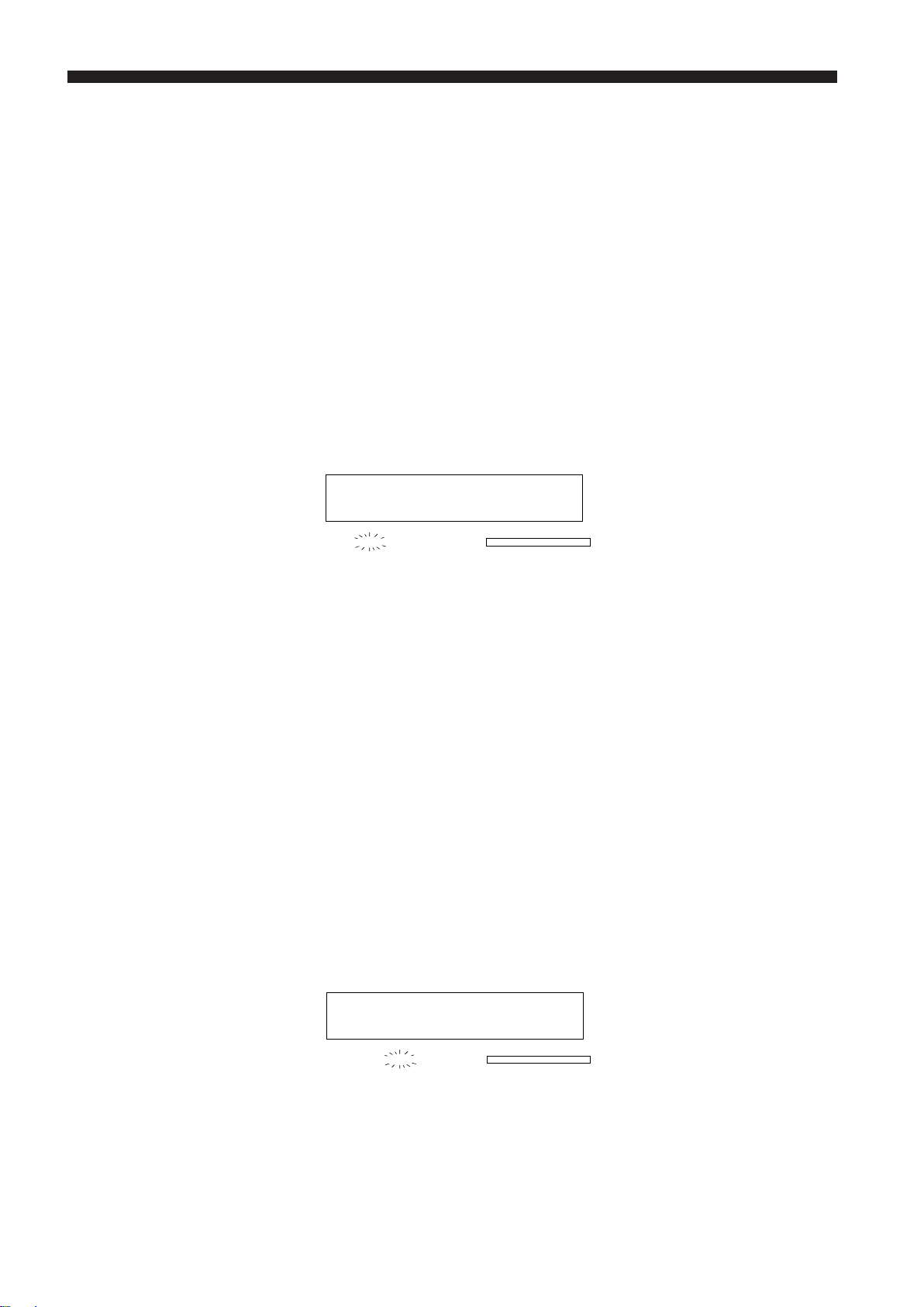

• After initialization, the number of measurements for averaging is automatically set to 1024. "----" appears on the main display for about 3 seconds,

even after a workpiece has entered the measurement range.

• The sampling time required for one measurement is 2.5 m sec. The

sampling time then required for 1024 measurements is 2.56 sec. (2.5 x

1024). The time required to display an averaged measurement changes

depending on the number of measurements being made.

If highly accurate measurement is needed, select 512 or higher as the

number of measurements for averaging.

9

Page 16

CHAPTER 3 Quick Setup Procedures

Tolerance Settings

The following procedure shows how to set the upper limit to 10.5 mm, and

lower limits to 9.5 mm.

LIMIT

OK

1

0

.

5

ENT

9

.

5

ENT

HLIO=

=–6600..00000000

HLIO==[

HLIO==[

HLIO=

HLIO=

HLIO=

HLIO=

HLIO=

HLIO=

HLIO=

HLIO=

–60 . 00010

–60 . 001000

[

=

–60 . 01000.0

[

=

–60 .1000.050

=

–1600..50000000

10 . 5000

=[

10 . 5000

=[

10 . 50090

=[

10 . 5090.0

=[

109..5500000

=

]

]

]

]

]

]

9

]

.

]

5

0

▲

" " moves

to the "LO"

position

For details on tolerance setting for 7-step differentiation, refer to pages 23

through 26.

3-2. Measurement Procedures

Outer Diameter Measurements

■ Applications

• Measuring piston outer diameter

• Measuring flat cable width

•Measuring capacitor outer diameter

■ Setting

After "MEMORY INITIALIZED" is displayed, the segment mode is automatically set to DIA (outer diameter measurement).

For details on AVERAGE setting, refer to "AVERAGE", and for details on

tolerance setting, refer to "Tolerance Settings" shown above.

RT

10

• The number of measurements for averaging is set to 1024 after settings

are initialized.

"----" appears on the display for about 3 seconds, even after a target is

placed within the measuring range.

• In the DIA mode, "----" appears on the main display when no workpiece is

within the measuring range.

Page 17

CHAPTER 3 Quick Setup Procedures

Gap Measurement 1

(When part of the target is

outside the optical axis)

Gap Measurement 2

(When all of the target is

within the optical axis)

■ Applications

• Measuring gap between rollers in a copy machine

• Measuring gap between magnet roller and doctor blade

TR

■ Setting

1. Initialize settings ("MEMORY INITIALIZED" is displayed.)

2.

SEG

SET

OK

SEG D I A

S EG E DGE1

■ Applications

• Measuring pitch of capacitor leads

• Measuring pitch of IC leads

1

TR

2

3

4

5

6

■ Setting

1. Initialize settings ("MEMORY INITIALIZED" is displayed.)

2.

SEG

SET

SET

SET

3

.

4

SEG D I A

S EG E DGE1

S EG E DGE2

SEG [ 2 , 3]

SEG [ 3 , 3 ]

SEG [ 3 , 3 ]

SEG [ 3 , 4 ]

OK

ENT

SEG [ 3 , 4 ]

11

Page 18

CHAPTER 3 Quick Setup Procedures

Measuring

Roundness

(When target is rotating)

■ Applications

• Detecting uneven rubber roller in a copying machine

• Detecting uneven rubber roller on a printer

RT

■ Setting

1. Initialize settings ("MEMORY INITIALIZED" is displayed.)

2.

MODE

SET

OK

MODE NO MA L

MOD E P–P

R

When the measurement mode is set to "P-P", the displayed value is

retained until HOLD is pressed or until an external signal is input through

the hold synchronous input terminal.

Measuring

Eccentricity

(When target is rotating)

3. Resetting displayed values (When 1. 2 3 4 5 appears on the main

display)

HOLD

HOLD

HOLD

The displayed

Main display

value is reset

to "0".

■ Applications

• Measuring eccentricity of rubber rollers

• Measuring shaft eccentricity for automobile

RT

■ Setting

1. Initialize settings ("MEMORY INITIALIZED" is displayed.)

12

2.

SEG

SET

MODE

SET

OK

SEG D I A

S EG E DGE 1

MODE NOMA L

MODE P–P

Page 19

CHAPTER 3 Quick Setup Procedures

When the measurement mode is set to "P-P", the displayed value is

retained until HOLD is pressed or until an external signal is input through

the hold synchronous input terminal.

3. Resetting displayed values (When 1. 2 3 4 5 appears on the main

display)

HOLD

Measuring Target Displacement within the Measuring Range

Main display

HOLD

The displayed

value is reset

to "0".

■ Applications

•Measuring disk head movement

• Measuring camera lens movement

TR

–

+

■ Setting

1. Initialize settings ("MEMORY INITIALIZED" is displayed.)

Follow the same procedure as that for "Gap Measurement 1".

To reset the current value to "0", press ZERO.

ZERO

HOLD

Measuring Edge Movement

To reset the displayed value to "0" again, press ZERO twice.

■ Applications

•Measuring paper feed for copying machines

• Controlling sheet edges

• Measuring dot printer wire movement

TR

+

–

■ Setting

1. Initialize settings ("MEMORY INITIALIZED" is displayed.)

Follow the same procedure as that for "Gap Measurement 1".

To reset the current value to "0", press ZERO.

ZERO

To reset the displayed value to "0" again, press ZERO twice.

13

Page 20

CHAPTER 3 Quick Setup Procedures

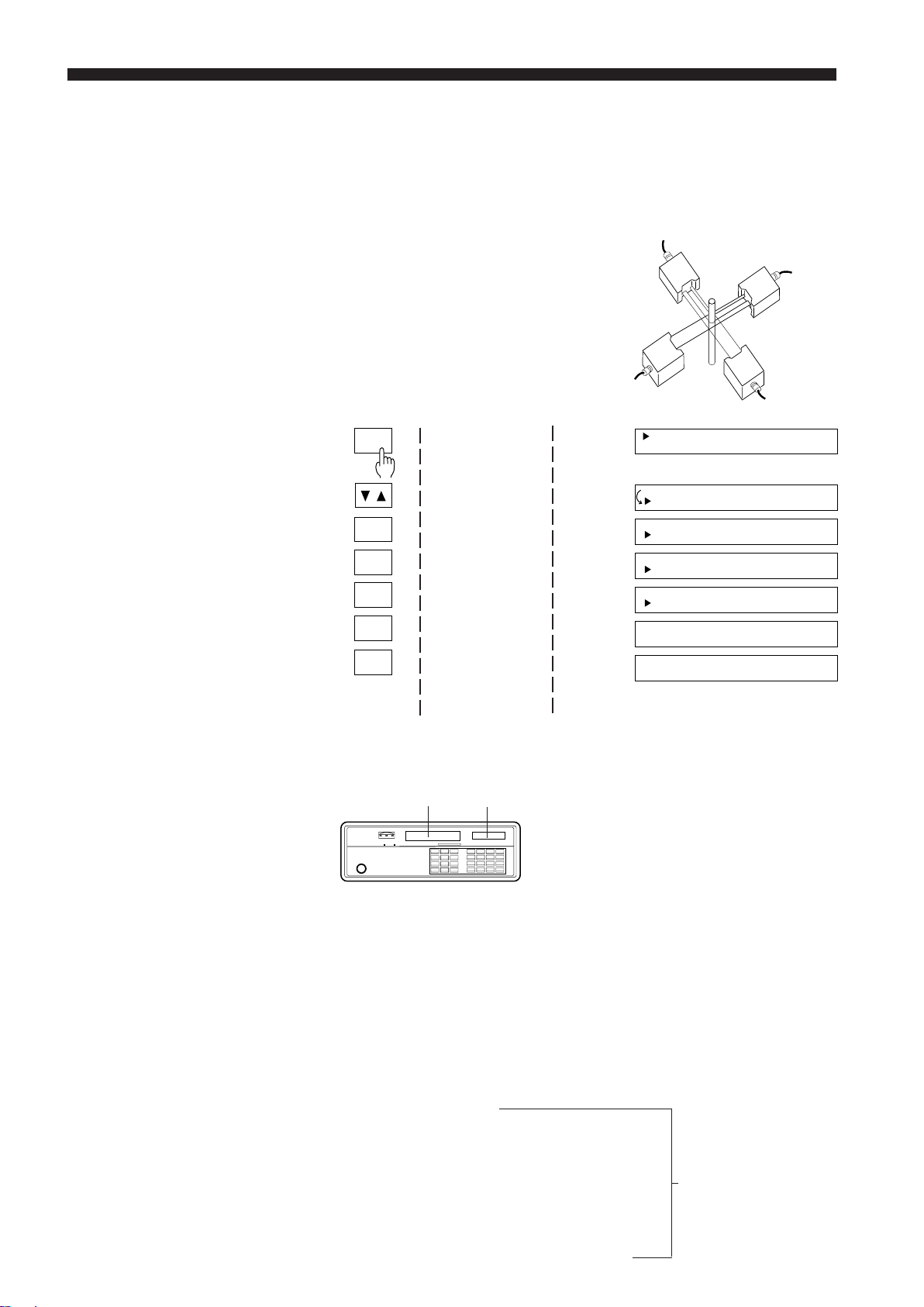

3.3 Using LS-3100D(W) Controller with 2 Scanning Heads

Measuring Outer Diameters in the X and Y Axes

The LS-3100D(W) uses 2 scanning heads for this measurement.

■ Applications

• Measuring outer diameter of coated wire

in the X and Y axes

• Measuring outer diameter of extrusion

molded parts

■ Setting

1. Initialize settings

2.

FNC

SET

SET

SET

DISP

DISP

XY==DDIIA

XY==DDIIA

XY==DEIDA

XY==DEIDA

XY==D2I:A

DNIOA

CNHO2R--

A

A

GE1

GE2

D IA

RMA L

AVE1 024

----------

14

OK

In the above setup, measurements from scanning head 1 are displayed on

the main display, and measurements from scanning head 2 are displayed on

the sub-display.

Measurement value in Y-axis Measurement value in X-axis

For details on tolerance setting, refer to p.23-26, 39, 40, 43 in this manual.

This appendix does not cover all of the LS-3100(W) functions. In addition to

the applications covered in this appendix, the LS-3100(W) can be used for

several other types of measurements.

For more details on functions and measurements, read chapter 4. (A cross

reference between this appendix and chapter 4 is given below.)

Setting number of measurements for averaging .......... p.21

Tolerance settings ........................................................ p.23-26, 39, 40, 43

Measuring outer diameter

Gap measurement 1

Gap measurement 2

Measuring roundness

Measuring eccentricity p.30-32, 40-41, 89-96

Measuring target displacement

within the measuring range

Measuring edge movement

Measuring outer diameter in the X and Y axes

Page 21

CHAPTER 4

FUNCTIONS AND CONTROLS

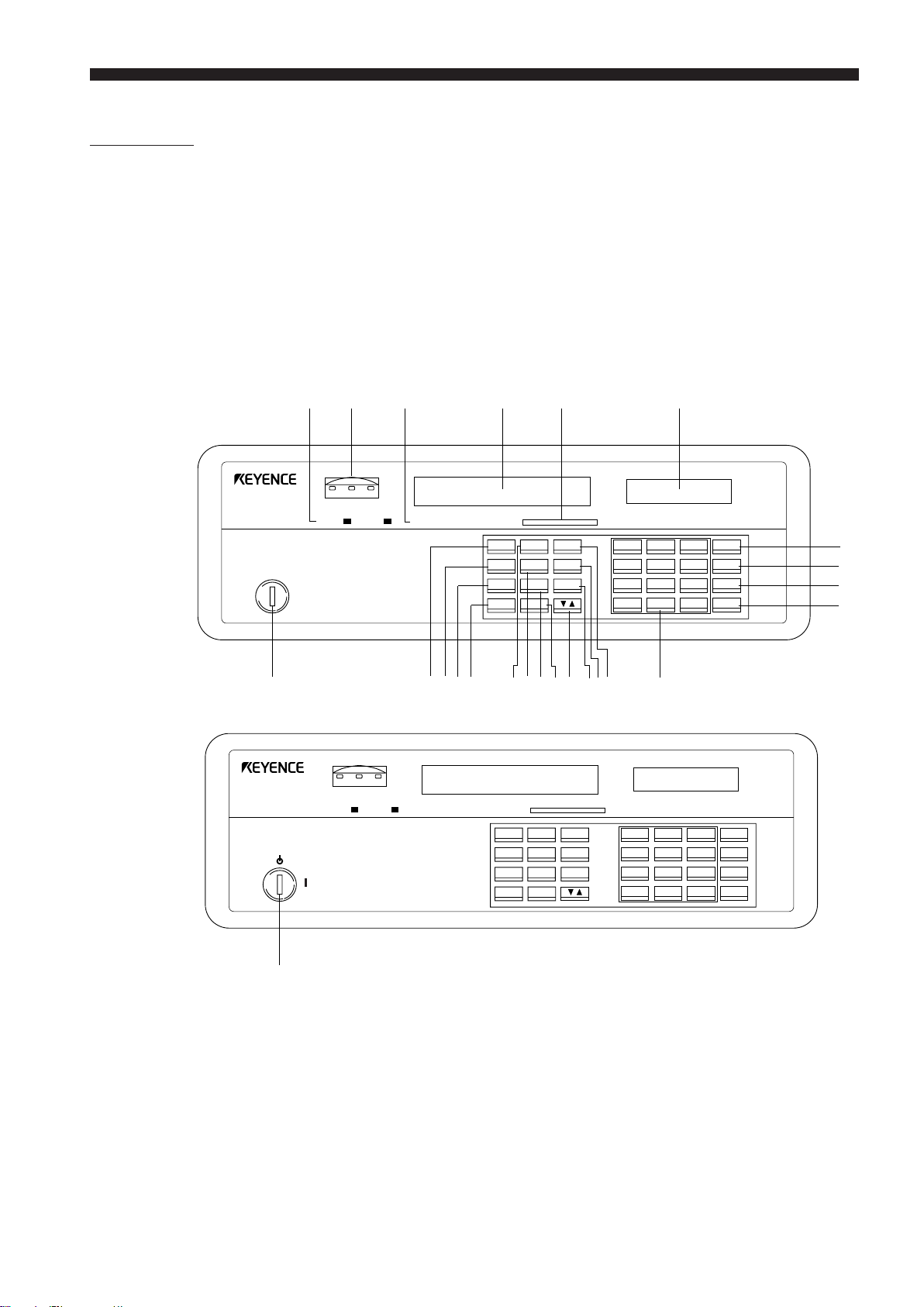

4-1. Part Names

Controller

Model: LS-3100(W)/3100D(W)

Front Panel

LS-3100 Series

LS-3100(W) Series

12 3 45 6

LS

LASER SCAN DIAMETER

• OFF

• ON

POWER

7

LS

LASER SCAN DIAMETER

•

•

LASER

LIMT

HIGH GO LOW

1 2

LASER LASER

LIMT

HIGH GO LOW

1 2

OFFSET ZERO HOLD LOCK POSITION

LASER LASER

OFFSET ZERO HOLD LOCK POSITION

SEG SETMODE

AVE LIMIT OFS

PRM FNC CAL

PROG DISP

SEG SETMODE

AVE LIMIT OFS

PRM FNC CAL

PROG DISP

mm

inch

7

8

9

ZERO

4

5

6

HOLD

1

2

3

CLR

0

.

+/-

ENT

I

H GF E D C BA0 98

mm

inch

J

7

8

9

ZERO

4

5

6

HOLD

1

2

3

CLR

0

.

+/-

ENT

K

L

M

N

7

1 Laser emission indicator LED

2 Comparator output LEDs

3 Current setting indicator

4 Main display (CH1)

5 Target position indicator

6 Subdisplay (CH2)

7 Key-operated power switch

(LS-3100(W) Series: Key-operated

laser switch)

8 SEGMENT key

9 AVERAGE key

(for number of measurements)

0 PARAMETER key

A PROGRAM key

B MODE key

C LIMIT key (for 3-level

comparator output only)

D FUNCTION key

E SUBDISPLAY key

F UP/DOWN key

G CALIBRATION key

H OFFSET key

I SET key

J Numeric keys

K AUTO ZERO key

L HOLD key

M CLEAR key

N ENTER key

15

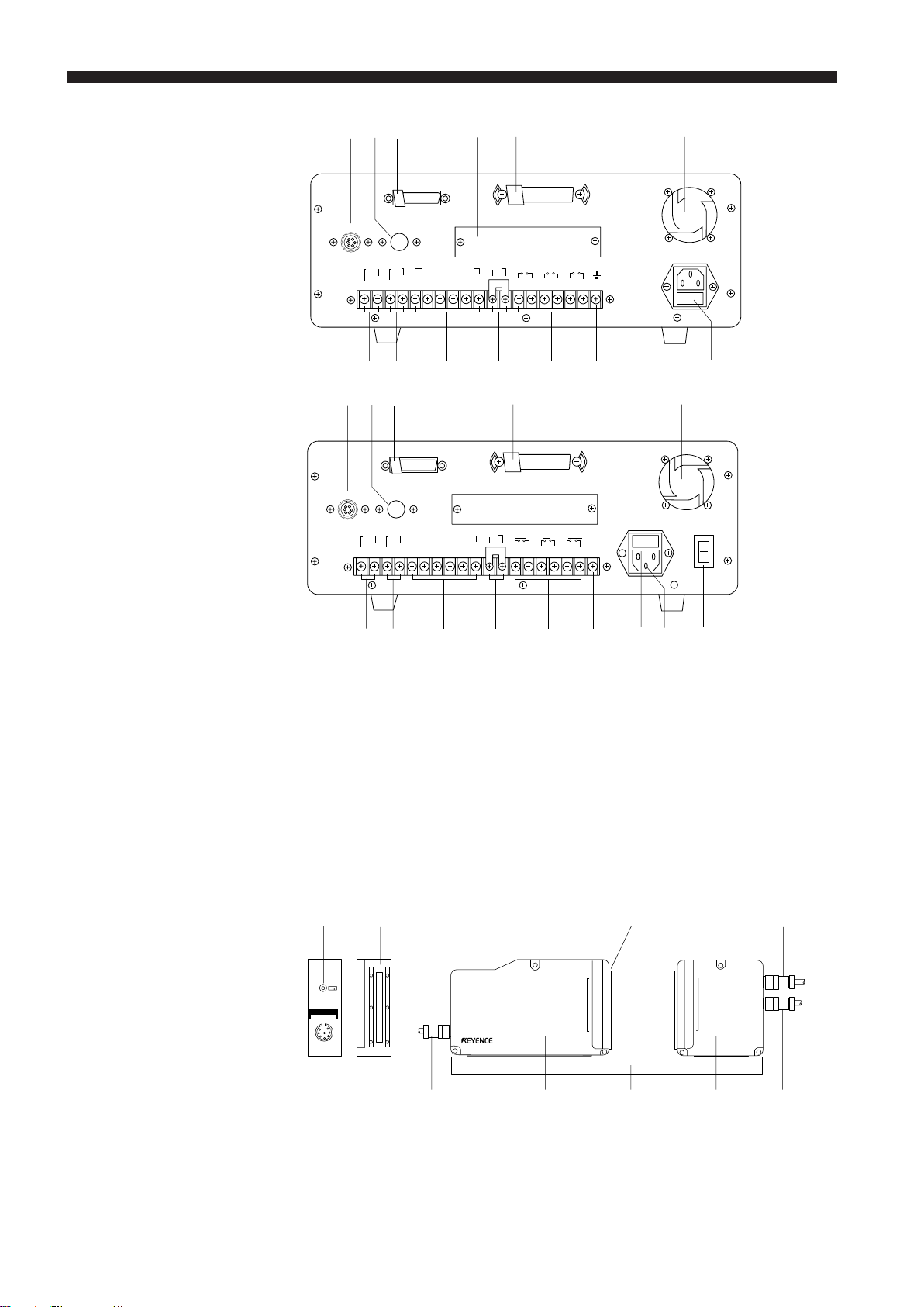

Page 22

CHAPTER 4 Functions and Controls

ST

WXYZ [\

ST

Back Panel

Model: LS-3100

Model: LS-3100(W)

PQ

O

RS - 232C

HEAD 1 HEAD 2

TIMMON

OV GND P1 P2 P 3 P4 P5 GND

1 23 4 5 6 7 8 9 10

UV

PQ

O

RS - 232C

HEAD 1 HEAD 2

TIMMON

OV GND P1 P2 P 3 P4 P5 GND

1 23 4 5 6 7 8 9 10

PROGRAM SELECT

PROGRAM SELECT

R

CONTROL I/O

LASAER

REMOTE

13 14 15 16 17 18 1911 12

R

LASAER

REMOTE

13 14 15 16 17 18 1911 12

LOWGOHIGH

CONTROL I/O

LOWGOHIGH

85~264V AC

2A

85~264V AC POWER

O

2A

I

Scanning Heads

Model: LS-3060

UV WXYZ[

O SCANNING HEAD connector port

P SCANNING HEAD connector port

(for second scanning head)

Q RS-232C connector port

R Expansion I/O port (for optional

BCD or GP-IB interface board)

S 36-pin connector port

(Control I/O port)

T Cooling fan

U Analog voltage output terminals

1. Not used for the LS-3100(W) series.

18

THIS PRODUCT..... ...

CONFORMS

LS-3060T

LASAER SCAN DIAMETER

]\

V Hold synchronous input terminal

W Program selector input terminals

X Laser emission control input

terminals

Y Comparator output terminals

Z Earth ground terminal

[ Power cable receptacle

\ Fuse holder (2A)

] POWER switch

(LS-3100(W) series only)

SCANNING AREA SCANNING AREA

1.

78

LS-3060R

16

26 3 4 56

1 Laser emission indicator LED

2 Protective cover glass

3 Transmitter (T)

4 Detachable frame

5 Receiver (R)

6 8-pin connector cable between

(T) and (R)

7 6-pin connector cable between

the controller and the scanning

head

8 Laser aperture

Page 23

CHAPTER 4 Functions and Controls

Model: LS-3032/3034/3036

Model: LS-3033/3033 SO

9 E0

SCANNING AREA SCANNING AREA

LS-3032

A9 CD

SCANNING AREA SCANNING AREA

F

B

E

LS-3033T

LS-3033R

F

9 Protective cover glass

To prevent lens from being damage or dust from accumulating on the lens

surface (Spares are available for replacement.)

0 Connector cable between the controller and the scanning head (3 m)

A Transmitter (T)

B Receiver (R)

C 6-pin connector cable between the controller and the scanning head

D 8-pin connector cable between (T) and (R)

E Laser emission indicator LED

F Laser aperture

17

Page 24

CHAPTER 4 Functions and Controls

4-2. Indicators and Displays

1

2

LIMIT

HIGH GO LOW

11

1 Laser Emission

11

Indicator LEDs

22

2 Comparator Output

22

LEDs

LS

LASER SCAN DIAMETER

Light when laser is being or about to be emitted from the scanning head.

Only LED [1] lights when one scanning head is used. Both LED [1] and LED

[2] light when two scanning heads are used.

Three LEDs, HIGH, LOW, and GO, are provided. HIGH and LOW light

respectively when the measured value is above the preset upper limit and

below the preset lower limit. GO lights when the measured value is within the

range between these two limits.

3 4 56

OFFSET ZERO HOLD LOCK POSITION

LASER LASER 1 2

mm

inch

33

3 Current Setting

33

Indicator

44

4 Main Display

44

(Channel 1)

55

5 Target Position

55

Indicators

66

6 Subdisplay

66

(Channel 2)

Lights when one of OFFSET, AUTO-ZERO, HOLD, or PANEL LOCK has

been selected.

Shows a measured value.

Indicate where the target is located in the measurement area.

Shows preset values when only one scanning head is used. It shows a

measured value when two scanning heads are used.

A measured value is displayed in 8 digits and updated 10 times per second.

18

Page 25

4-3. Panel Keys

CHAPTER 4 Functions and Controls

11

1 Numeric Keys

11

A

SEG SETMODE

8

AVE LIMIT OFS

9

PRM FNC CAL

G

PROG DISP

B

C 2F

D50E

7

4

1

0

1

8

5

2

.

9

6

3

+/-

6

ZERO

HOLD

CLR

ENT

4

7

3

Enter numbers, a decimal point, and + or - sign. See the following examples:

• Entering +10.0000

10

.

0000

May be defaulted

7

4

1

0

8

5

2

.

9

6

3

+/-

• Entering -10.0000

22

2 SET Key

22

+ / -

10 . 0000

May be defaulted

"+" and "-" alternate each time +/- is pressed. Note that the "+" sign is not

displayed. This key can be pressed to select a positive or negative number

as long as you have only up to 3-digit integers.

• Entering 0.1234

0.1234

May be defaulted

• When you first enter any number by using numeric keys, [ ] appears

on both sides of this number. This indicates that the key input can be

accepted. Any incorrect entry can be deleted using CLR only in this mode.

Changes parameter, setting, and ON/OFF status.

33

3 CLR Key

33

Deletes the desired number. Press ENT to regain the initial data.

19

Page 26

CHAPTER 4 Functions and Controls

44

4 ENT Key

44

55

5 UP/DOWN Key

55

66

6 ZERO (Auto-Zero)

66

Key

Registers the desired number.

Turn ON the power while pressing and holding ENT to return to the factory

settings.

➪

See P.89 to P.96 for the factory settings.

When making certain settings, two of the following items, value, mode or ON/

OFF status, appear at the same time on the subdisplay (CH2). Press this key

to move the cursor up and down to change one of the preset value or status.

Resets the displayed value to "0".

1. Press ZERO to reset the displayed and output values to 0.0000 mm or

0.0000 inch. The "ZERO" indicator below the main display lights when this

key is pressed. From this moment, the main display will only show the

changes in measured value based on the value that has been reset.

mm

inch

OFFSET ZERO HOLD LOCK POSITION

2. Press ZERO again to cancel this mode. The "ZERO" indicator goes out

when this key is pressed.

77

7 HOLD Key

77

• This function is available only for the measured value appearing on the

main display (CH1). Use FNC to reset the measured value on the

subdisplay (CH2) to 0.

➪

See P.39

• This key is invalid when the measurement mode is set to "P-P". At this

time, press HOLD to reset the measured value.

➪

See P.20

• It is also possible to remotely reset the measured value or cancel this

mode by sending a signal through one of the control I/O connector pins.

➪

See P.43

Holds the displayed and output values.

1. Press HOLD to hold the displayed and output values just before this key is

pressed. The "HOLD" indicator below the main display lights when this

key is pressed.

mm

inch

OFFSET ZERO HOLD LOCK POSITION

20

2. Press HOLD again to cancel this mode. The "HOLD" indicator goes out

when this key is pressed.

• If the measurement mode is set to "P-P", "PEAK", or "BOTTOM", the

previously measured value is reset when this mode is cancelled.

• It is possible to use this mode only on the main (CH1) display or on both

the main and subdisplay (CH2). To do this, choose the desired mode

using PRM.

Page 27

CHAPTER 4 Functions and Controls

88

8 AVE Key

88

(Selector key for number

of measurements for

averaging and averaging

method)

Sets the desired number of measurements and averaging method.

1. Use AVE to display the current number and method.

2. To change the number of measurements, use UP/DOWN to move the

cursor up. Then, use SET to specify the number. Each time you press

SET, the number will increment in the following order: "1, 2, 4, 8 ••••• 512,

and 1024". Note also that the number of measurements is set automatically to the currently displayed number. Therefore, you do not need to

press any other key to finalize this number.

AVE

1024

MOV E

3. To change the measurement method, use UP/DOWN to move the cursor

down. Then, use SET to change the averaging method. Each time you

press SET, SIMPLE and MOVE display alternately.

AVE

1024

SIMPLE

See the timing diagrams below for the difference between these two

methods.

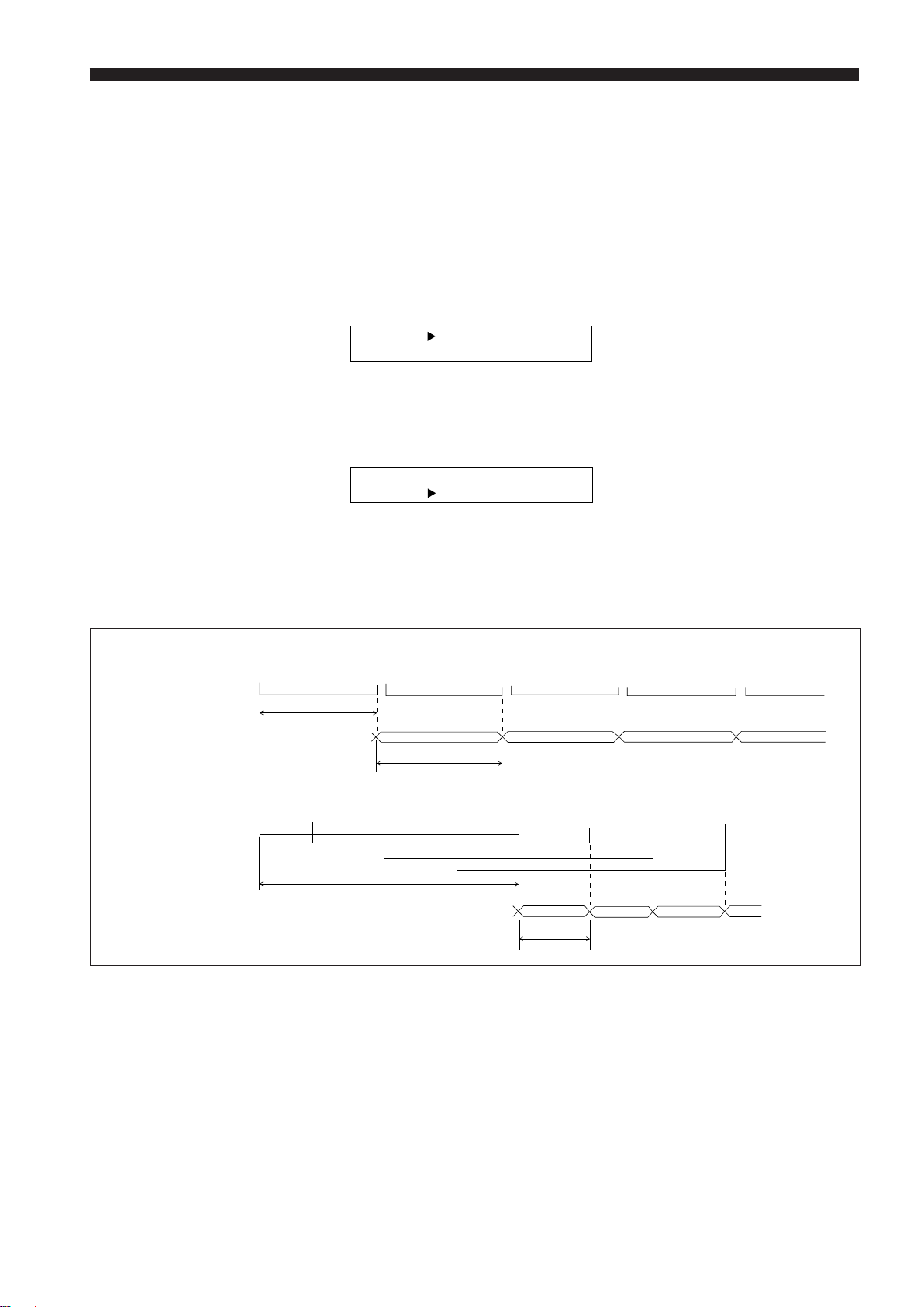

Averaging Methods

Number of samplings

SIMPLE averaging

(Number: 32)

Output cycle of measured value

Number of samplings

MOVE averaging

(Number: 32)

Out put cycle of measured value

1, 2, 3, • • • • • • • 30, 31, 32, 33, 34, 35, • • • • • • 62, 63, 64,65, 66, 67, • • • 94, 95, 96, 97, 98, 99, • • • 126, 127, 128, 129, 130, 131, • • •

1

2.5 ms x number of measurements

2.5 ms x number of measurements

1, 2, • • 7, 8, 9, 10, • • 15, 16,17, 18, • • 23, 24, 25,26, • • 31, 32, 33, 34, • 39, 40, 41, 42, • 47, 48, 49, 50, • 55, 56, 57, 58, • •

2.5 ms x number of measurements

1

23 4

2 34

1

1

20 ms

2

3

23

4

4

* MOVE is valid only when the number of measurements is set to a number

between 16 and 1024.

21

Page 28

CHAPTER 4 Functions and Controls

99

9 PRM Selector

99

Key

Analog Voltage Range

Displays sequentially the following 9 items: preset analog range, "LIMIT",

"DIGIT SUPPRESS", "HOLD", "BAUD RATE", "UNIT", "BUZZER", "HEAD2",

and "POSITION CHECK". Display the desired item first and make the

necessary changes. See the instructions below for making settings in each

item.

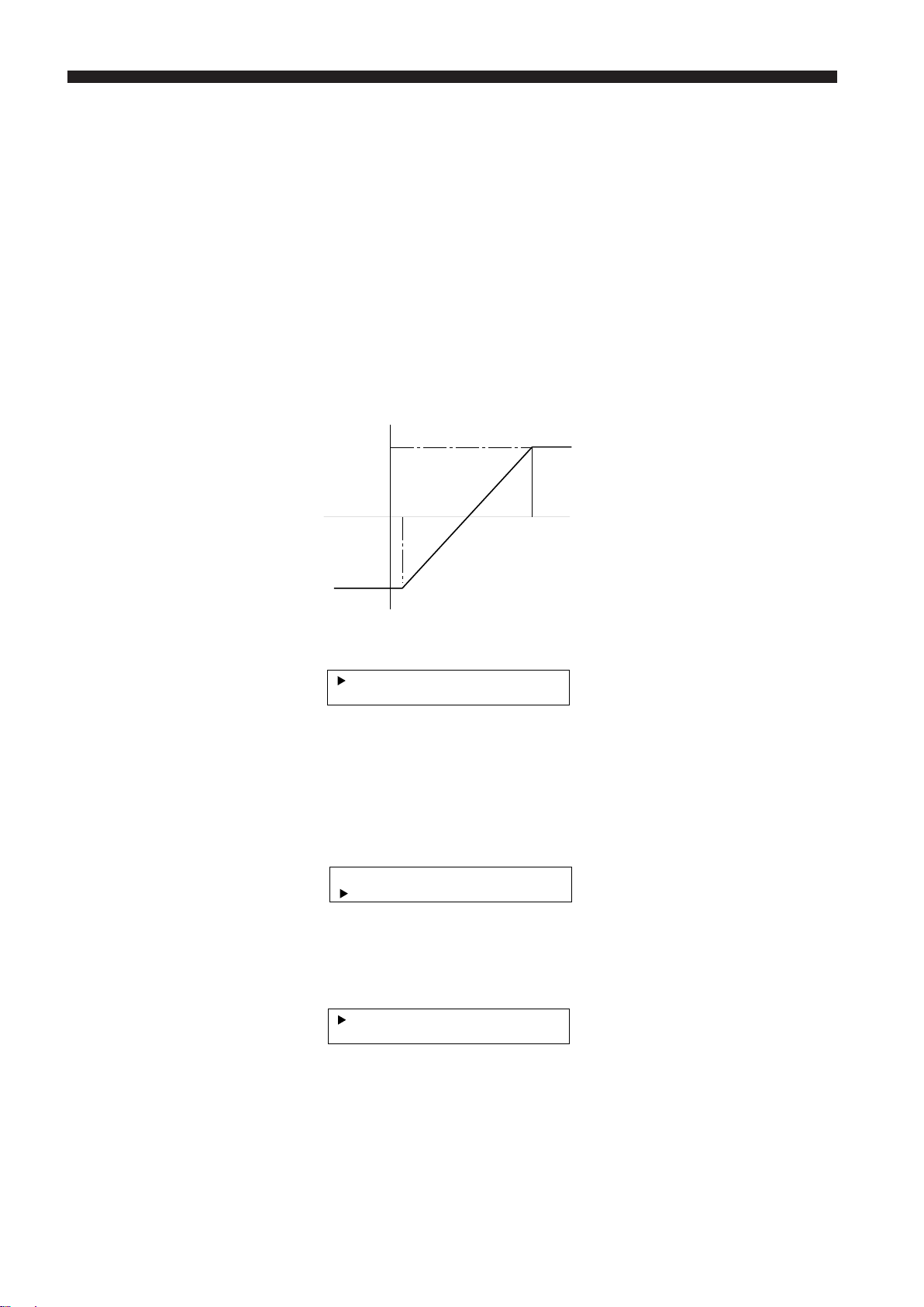

In this mode, measured value is converted into an analog voltage between

-6 V and +6 V. Match the desired measurement range and the above voltage

range. By matching these ranges, the measured value can be converted into

its corresponding voltage.

Determine the upper and lower limits (m) and (n) as shown below. These

values correspond respectively to +6 V and -6 V. This automatically determines the conversion rate of the measurement range against the voltage

range.

Voltage

+6V

n

0

m

Measured value

-6V

1. Use PRM to display the analog voltage range as shown below. UP/DOWN

is not used in this mode.

+6

=

- =-

V6

60. 0V000

0. 0000

6

2. Enter the desired value in mm or inch that corresponds to +6 V.

3. Press ENT to register.

4. When ENT is pressed, the cursor moves down to the second line and the

current preset value corresponding to -6 V disappears.

+6

=

-=

V6

20. 0V000

5. Enter the desired value in mm or inch that corresponds to -6 V.

6. Press ENT to register and finish.

+6

=

-=

V6

20. 0V000

0. 0000

22

7. Use CLR to delete incorrect data and enter the correct one if required.

Page 29

CHAPTER 4 Functions and Controls

[]

[]

[]

[]

[]

[]

[]

Example of Operation You are to measure the diameter of round bars. The reference diameter is 10

mm, and you wish to convert a difference of 1 mm into 1 V.

In this case, first set 100.000 mm to 0 V. Then, to represent each 1 mm

change in diameter from the reference by 1 V, set the reference plus 6 mm to

+6 V and the reference minus 6 mm to -6 V. That is, +6 V = 16 mm and -6 V

= 4 mm.

Step Key operation Display

1 Use PRM to display analog

voltage range.

2 Press "1".

3 Press "6".

4 Press ".".

5 Press "0" four times.

6 Press ENT

7 Press "4".

8 Press ".".

+6

=

- =-

V6

+6

V

=

-=

+6V

-=

+6V

-=

+6V

-=

+6V

-=

+6V

-=

+6V

-=

-

V6

=

-

V6

=

-

V6

=

-

V6

=

V6

=

V6

=

V6

60. 0V000

0. 0000

6

6 . 0000

0

6 . 0000

0

6 . 0000

0

1 . 00006

6 . 0000

0

1 . 00006

1 . 00006

1 . 00006

1

1.

6

4

4

1

6

.

LIMIT

Note

Note

9 Press "0" four times.

10 Press ENT.

V

=

+6

-=

V6

+6V

=

-=

V6

1 . 00006

4 . 0000

1 . 00006

4 . 0000

• The LS controller is factory-set to +6 V = 60 mm and -6 V = - 60 mm.

•A range of 0.024 mm to 240 mm can be specified.

• Make sure that the value corresponding +6 V is greater than that for -6 V.

• When your reference value is an integer with no decimals, steps 4, 5, 8

and 9 can be omitted.

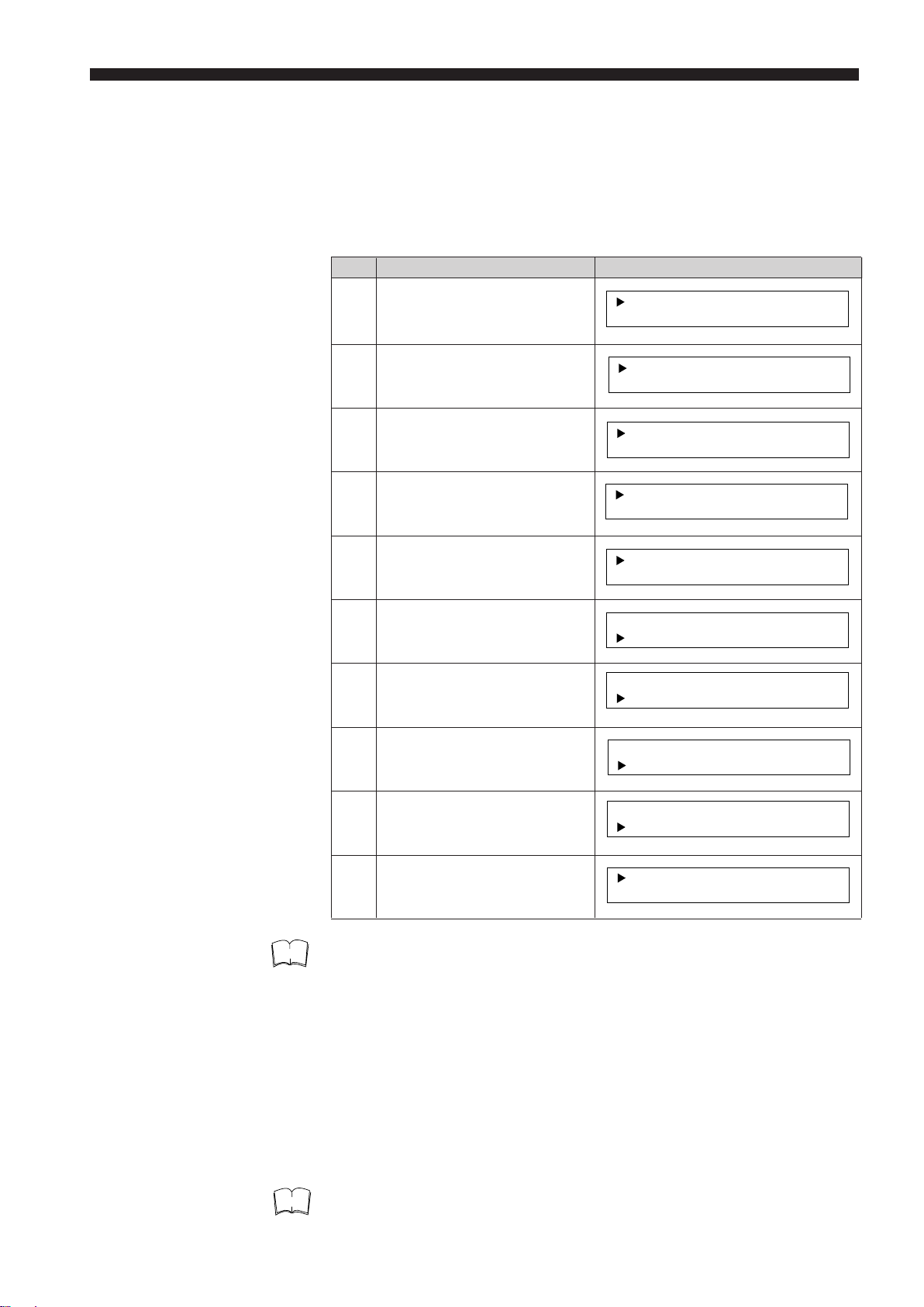

You can set the following 3 parameters in LIMIT:

• 3-step or 7-step differentiation

• Tolerance limits when 7-step differentiation is selected

• Comparator output type; Relay or open-collector (if the measured value is

above the upper limit or below the lower limit).

• Use FNC to set the tolerance limits for the measured value appearing on

the subdisplay (CH2). ➪

See P.32

23

Page 30

CHAPTER 4 Functions and Controls

Tolerance Limits and

Comparator Output

■ 3-step differentiation

Choose the 3-step differentiation first, then set the tolerance limits using

LIMIT. When "ON" appears on the display, the comparator output is sent

through each of the relays and open-collectors (HIGH, GO, or LOW).

➪

See P.63, 64

Tolerance limit Condition Output

(Relay) (Open-collector)

HI < X HIGH HI1 (CH1)

HI

HI ≥ X ≥ LO GO GO (CH1)

LO

X < LO LOW LO1 (CH1)

Note: X represents a measured value.

■ 7-step differentiation

Choose the 7-step differentiation first, then set the tolerance limits using

PRM. When "ON" appears on the display, the comparator output is sent

through each of the relays and open-collectors (HI3, HI2, HI1, GO, LO1,

LO2, or LO3).

➪

See P.63

Tolerance limit Condition Output

(Relay) (Open-collector)

HI3 < X HIGH HI3 (CH1)

HI3

HI3 ≥ X > HI2 HIGH HI2 (CH1)

HI2

HI2 ≥ X > HI1 HIGH HI1 (CH1)

HI1

HI1 ≥ X ≥ LO1 GO GO (CH1)

LO1

LO1 > X ≥ LO2 LOW LO1 (CH1)

LO2

LO2 > X ≥ LO3 LOW LO2 (CH1)

LO3

LO3 > X LOW LO3 (CH1)

Note: X represents a measured value.

• It is possible to set the tolerance limits for both 3-step and 7-step differentiation. However, only the tolerance limits of the type of differentiation you

have selected are valid. Therefore, the comparator output is sent according to these limits.

24

• In 7-step differentiation, measured values can be correctly checked only

when the values assigned to the tolerance limits meet the following

condition: HI3>HI2>HI1>LO1>LO2>LO3

Page 31

CHAPTER 4 Functions and Controls

Procedure ■ Switching between 3-step and 7-step differentiations

1. Use PRM to display "LIMIT" (on the subdisplay).

2. To switch between two types of differentiation, use UP/DOWN to move the

cursor up.

I MILTON7CL ASSES

3. Each time you press SET, "7 CLASSES" and "3 CLASSES" are displayed

alternately. Choose the desired type of differentiation.

■ Turning comparator output function ON/OFF

1. Use PRM to display "LIMIT" (on the subdisplay).

2. Use UP/DOWN to move the cursor down.

I MILTON7CL ASSES

3. Each time you press SET, "ON" and "OFF" are displayed alternately.

4. Display "ON" to obtain the comparator output function, or "OFF" to cancel

this output function.

■ Setting tolerance limits (3-step differentiation)

1. First select 3-step differentiation as mentioned above, then use LIMIT to

set the tolerance limits.

➪

See P.29

2. If you press PRM after having set the tolerance limits, "DIGIT SUPPRESS"

will be displayed.

■ Setting tolerance limits (7-step differentiation)

1. First select 7-step differentiation as mentioned above, then use PRM to

set the tolerance limit.

2. "HI1" and "LO1" will appear on the subdisplay. Use UP/DOWN to move

the cursor up for HI1 or down for LO1.

I MILTON7CL ASSES

3. Enter the desired values and press ENT to register.

4. Press PRM.

5. "HI2" and "LO2" will appear on the subdisplay. Enter the desired values

and press ENT to register.

H2

I

LO

=2-

.

30 000.

0

0

30=000

6. Press PRM to display "HI3" and "LO3", enter the desired values, and

press ENT to register.

25

Page 32

CHAPTER 4 Functions and Controls

Example of Operation

You are to measure the diameter of round bars. The reference diameter is

10 mm. You wish to perform a 7-step differentiation with the following tolerance limits: ±0.1 mm, ±0.2 mm, ±0.3 mm.

Step Key operation Display

1 Press PRM to display

"LIMIT".

I MILTON3CL ASSES

2 Use UP/DOWN to move

cursor up.

3 Use SET to display "7

CLASSES".

I MILTON3CL ASSES

I MILTON7CL ASSES

4 Press PRM to display "HI1"

and "LO1".

H1

I

LO

-

=1-

10 000.

.

0

0

10=000

5Enter 10.1000 for HI1 and

9.9000 for LO1, then press

ENT.

I

H1

LO

=

=1

10

00

1

..

9

.

0

009

0

6 Press PRM again to display

30=000

"HI2" and "LO2".

I

H2

LO

=2-

.

30 000.

0

0

DIGIT SUPPRESS

7Enter 10.2000 for HI2 and

9.8000 for LO2, then press

ENT.

H2

I

LO

=

=2

10

00

2

..

9

.

0

008

0

8 Press PRM again to display

"HI3" and "LO3".

I

H3

LO

=3-

.

60 000.

0

0

60=000

9Enter 10.3000 for HI3 and

9.7000 for LO3, then press

ENT.

H3

I

LO

=

=3

10

..

9.007

00

3

0

0

Deletes fractions from measured value on the display. DIGIT SUPPRESS is

useful when there is a relatively large difference from one measured value to

another. The possibly applicable cases are listed below.

• When the number of measurements for averaging is set to a small number

• When the target is vibrating

•When it is not necessary to obtain precise measurements

This prevents errors involved in reading measured values.

26

• This function can be used for both the main display and subdisplay. It

becomes invalid when the subdisplay is used to show measured values in

P-P, PEAK, or BOTTOM mode.

• Although fractions are not displayed, the target is measured down to

0.0001 mm and comparator output sent based on these measured values.

Page 33

CHAPTER 4 Functions and Controls

Procedure

HOLD

Procedure

1. Use PRM to display "DIGIT SUPPRESS" (on the subdisplay).

IG

I T

UDS0PPRESS CH2 0

CH1

2. Use UP/DOWN to move the cursor up or down, then use SET to choose

how many fractions you wish to delete. Each time you press SET, the

subdisplay will show "0", "1", "2", "3", "4", and "0" again.

3. Note that they represent the number of digits to be deleted starting from

the rightmost (smallest) fraction.

Selects whether to use HOLD function (see P.20) only for CH1 or for both

CH1 and CH2.

1. Use PRM to display "HOLD" (on the subdisplay).

C1

OLD

H

H

2. Each time you press SET, "CH1" and "CH2" are displayed alternately.

Display "CH1" only for CH1 or "CH2" for both CH1 and CH2.

BAUD RATE

Procedure

UNIT

Procedure

Selects the data transmission speed via RS-232C interface.

1. Use PRM to display "BAUD RATE" (on the subdisplay).

T1

B

AUD

EA R 2 00

2. Each time you press SET, the baud rate will increment from 75 to 19200.

Display the desired choice.

Selects the unit of measurement between mm and inch.

1. Use PRM to display "UNIT" (on the subdisplay).

NIT

mUm

2. Use SET to display "mm" or "inch".

The unit selected in this mode will be applied to other values such as

tolerance limits and calibration values.

27

Page 34

CHAPTER 4 Functions and Controls

BUZZER

Turns ON/OFF the beep during panel key operation.

Procedure 1. Use PRM to display "BUZZER" (on the subdisplay).

UZZ NBOER

2. Use SET to display "ON" or "OFF".

HEAD2

Procedure

Selects whether to use two scanning heads or not.

1. Each time you press SET, "ON" and "OFF" are displayed alternately.

2. Display "ON" to use two scanning heads or "OFF" to use just one head.

EADHN2O

The controller must be equipped with the optional PC board for the second

scanning head. If not, an error message "H2-Err" appears on the main

display. In such a case, display "HEAD2 OFF" (on the subdisplay). This will

cause "H-Err" to appear on the main display. Then, turn OFF the power

once, then turn it ON again. You can now perform measurements using only

the first scanning head (HEAD1).

POSITION CHECK

(Model: LS-3033/3060 only)

Procedure

Checks whether the transmitter and receiver are aligned in terms of the

optical axis of the laser. This alignment is required when these units are

removed from the detachable frame during operation.

➪

See "Mounting Scanning Head" in Chapter 5 on P.65 for details.

1. Use PRM to display "POSITION CHECK".

EADH1

OS TP IOI N CHECK

2. Align the transmitter and receiver in terms of the optical axis.

3. When two scanning heads are used, press PRM again to display

"HEAD2" above "POSITION CHECK", and align the second set of

transmitter and receiver.

H2

EAD

OS TP IOI N CHECK

28

Page 35

CHAPTER 4 Functions and Controls

[]

00

0 LIMIT

00

(Tolerance limits

for 3-step

differentiation)

Key

This key is used to set the tolerance limits (upper and lower) for measured

values on the main display (CH1). If the measured value is above the upper

or below the lower limit, the comparator output is sent through the corresponding relay and open-collector.

➪

See P.24 for the relationship between the tolerance limits and types of output obtained.

• Use FNC to set the tolerance limits for the subdisplay (CH2).

➪

See P.39

Procedure 1. Use LIMIT to display the current tolerance limits.

2. HI and LO represent respectively the upper and lower limits.

3. Use UP/DOWN to move the cursor up or down.

HI

LO= - 60 . 0000

60. 0=000

4. Enter the desired tolerance limits.

Make sure that the value for HI is greater than that for LO.

5. Press ENT to register.

Example of Operation

6. Use UP/DOWN again to move the cursor, and enter another tolerance

limit.

7. Use CLR to delete any incorrect entry.

You are to measure the diameter of round bars. The reference diameter is

10 mm. You wish to perform a 3-step differentiation with the tolerance limits

of ±0.1 mm (upper limit=10.1 mm, lower limit=9.9 mm).

Step Key operation Display

1 Press LIMIT to display

current tolerance limits.

HI

LO= - 60 . 0000

60. 0=000

2 Enter tolerance limit.

10. 1=000

[

HI

LO= - 60 . 0000

]

3 Press ENT to register.

10. 1=000

10. 1=000

4 Press UP/DOWN to move

cursor.

HI

LO= - 60 . 0000

HI

LO= - 60 . 0000

5Enter another tolerance

limit.

6 Press ENT to register.

HI

LO= - 9 . 9000

HI

LO= 9. 9000

10. 1=000

10. 1=000

29

Page 36

CHAPTER 4 Functions and Controls

AA

A SEG (Segment)

AA

Key

Definition of Segment

Note

Targets placed within the measurement area interrupt the passage of the

laser beam, thus creating a light-dark pattern. The border between the light

and dark regions is referred to an "edge". Also, each dark or light region

separated by the edge is called a "segment".

Transmitter Receiver

Edge1

Edge2

Edge3

by laser

Direction of scanning

Targets

Edge4

Edge5 (X-1)

Edge6 (X)

The desired pair of edges is to be selected from those shown above, and the

distance between these two edges measured.

• The edges are numbered in the order that they are scanned by the laser

(from top to bottom).

• The desired pair from among up to 126 edges can be selected.

Description

4 types of segment pairs, DIA, EDGE1, EDGE2, (m,n), can be measured.

The description of measurement for each pair is given below.

DIA: This mode is applicable to measurement of targets’ outer diameters. In

the above figure, the distance between edge 2 and edge (X-1) is measured.

When there is only one target, its outer diameter is measured. When there

are two or more targets, the distance between the upper edge of the upper

most target to the lower edge of the lower most target is measured.

EDGE1: The width of the uppermost region where the laser is not interrupted by the target is measured. This mode is applicable to measurement of

changes in targets’ diameters. In the above figure, the distance between

edge 1 and edge 2 is measured.

EDGE2: The width of the lowermost region where the laser is not interrupted

by the target is measured. In the above figure, the distance between edge

(X-1) and edge X is measured.

(m,n): The distance between two desired edges is measured. When measuring two or more targets, this mode is applicable to measurement of the

outer diameter of each target or to measurement of the gap between two

targets.

In (m,n) mode, both "m" and "n" represent the edge numbers ranging from 1

to 126. Make sure that the number specified for "n" is greater than that for

"m".

30

Page 37

CHAPTER 4 Functions and Controls

Procedure

1. Press SEG to display the current segment pair (on the subdisplay).

SEG D I A

2. Each time you press SET, the subdisplay will sequentially show "DIA",

"EDGE1", "EDGE2", "(m,n)", then "DIA" again. Display the desired segment pair. You do not need to press any other key. (When two scanning

heads are used, the subdisplay will sequentially show "DIA", "EDGE1",

"EDGE2", "(m,n)", "2:DIA", "2:EDGE1", "2:EDGE2", "2:(m,n)", and "DIA"

again.)

3. To measure the distance between two desired edges, select the (m,n)

mode.

S E G ( 5, 2 )

4. Use SET to display "(m,n)" first.

SEG ( ,

)

nm

5. Enter the desired edge numbers.

➪

See the example of operation given below for details.

6. Press ENT to register.

Example of Operation You are to measure the gap between two round bars (between edges 3 and

4). Suppose that the currently registered edges are 2 and 3.

Step Key operation Display

1 Press SEG.

SEG D I A

2 Use SET to display current

edges (2 and 3).

SEG ( 2 , 3 )

3 Press "3".

SEG ( 3 , 3 )

4 Press ".".

SEG ( 3 , 3 )

5 Press "4".

SEG ( 3 , 4 )

6 Press ENT.

SEG ( 3 , 4 )

31

Page 38

CHAPTER 4 Functions and Controls

Note

• If you enter invalid numbers (other than 1 through 126) and press ENT,

the initial edge numbers will remain on the subdisplay.

• Basically, two numbers are entered in this mode. If by mistake you enter

the larger number on the left and smaller number on the right, and press

ENT, the smaller number will appear on the left and larger number on the

right.

S E G ( 4, 3 )

ENT

S E G ( 3, 4 )

• Clear objects can be used as targets only in DIA, EDGE1, and EDGE2

modes, but not in SEG (m,n) mode.

• Use CLR to delete any incorrect values.

• In the above example operation, if you need to change only the first edge

number, that is, from 2 to 1, follow only steps 1, 2, 3, and 6.

BB

B FNC (Function)

BB

Key

Segment Selector

• Similarly, if you need to change only the second edge number, that is,

from 3 to 5, follow only steps 1, 2, 4, 5, and 6.

Is used for the following settings:

• Segment selector

Selection of measurement points (2-point simultaneous measurement)

• Segment check

Inhibiting output of measurements obtained under abnormal conditions

• Output channel

Selection of output channel for displaying measured values X and Y and

calculation of equations using these values

• MODE, OFFSET, and LIMIT for CH2

Selection of mode for CH2, offset value, and tolerance limit

Description of each setting is given below.

In this mode, two segments are to be specified for simultaneous 2-point

measurement. Just as with the SEG key, any of four types of segments can

be specified respectively for segment selectors X and Y. (See P.30.) By

selecting two different segments, the LS controller can measure two different

segments at the same time.

32

Page 39

CHAPTER 4 Functions and Controls

Procedure 1:

Measuring 2 Segments with 1

Scanning Head

1. Use FNC to display the current segments for X and Y.

X D

=

Y=

IIADA

2. Use UP/DOWN to move the cursor up.

3. Each time you press SET, "DIA", "EDGE1", "EDGE2", "(m,n)", and "DIA"

will sequentially appear on the right of "X=". Display the desired segment.

* "m" and "n" in (m,n) represent two desired edge numbers.

X

=I

DA

DG

EI

EY=

4. When you have selected "(m,n)", enter the desired edge numbers, and

press ENT to register.

➪

See P.31.

Once you select "(m,n)" for X, "(m,n)" will be automatically selected for Y.

X

Y

(

= 2, 3

(

=

1, 2

)

)

5. Use UP/DOWN to move the cursor down.

X

Y

(

= 2, 3

(

=

1, 2

)

)

Example of Operation

6. Repeat steps 3 and 4.

You are to measure the outer diameter and eccentricity of the round bars

using one scanning head.

Edge 1

Y

Edge 2

X

Edge 3

Edge 4

Transmitter

Receiver

Step Key operation Display

1 Use FNC to display current

X D

Y=

=

IIADA

segments.

2 Use UP/DOWN to move

X D

cursor up.

Y=

=

IIADA

3 Use SET to display:

(1) "X= DIA"

(2) "X= (m,n)". Enter 2 for

"m" and 3 for "n", and press

ENT.

X D

=

Y=

X

= 2, 3

Y

=

(

(

IIADA

1, 2

(To be continued)

)

)

33

Page 40

CHAPTER 4 Functions and Controls

Procedure 2:

Using 2 Scanning Heads

4 Use UP/DOWN to move

cursor down.

X D

=

Y=

X

= 2, 3

Y

=

(

(

IIADA

1, 2

5 When you have selected

X

=I

"DIA" in step 3, use SET to

display

DA

DG

EY=

EI

"Y= EDGE1".

When you have selected

"(m,n)" in step 3, enter 1 for

X

Y

(

=

1, 2

(

= 2, 3

"m" and 2 for "n", and press

ENT.

Press PRM first, and check that "HEADS2 ON" is displayed on the

subdisplay.

1. Use FNC to display current segments.

2. Use UP/DOWN to move cursor up.

)

)

)

)

Example of Operation

3. Each time you press SET, the subdisplay will sequentially show "DIA",

"EDGE1", "EDGE2", "(m,n)", "2:DIA", "2:EDGE1", "2:EDGE2", "2:(m,n)",

and "DIA" again. Display the desired segment.

* "m" and "n" in (m,n) represent two desired edge numbers.

* "2:" in "2:DIA", for example, represents the second scanning head.

4. When you have selected "(m,n)", enter the desired numbers, and press

ENT to register.

➪

See P.31.

X

Y

(

= 2, 3

(

=

1, 2

)

)

5. Use UP/DOWN to move the cursor down.

X

Y

(

=

1, 2

(

= 2, 3

)

)

6. Repeat steps 3 and 4.

Measuring the outer diameter of 2 round bars at the same time using 2

scanning heads

Step Key operation Display

1 Use FNC to display current

X D

segments.

=

Y=

IIADA

34

2 Use UP/DOWN to move

cursor up.

3 Use SET to display "X=

DIA"

X

Y=

X

Y=

D

=

IIADA

D

=

IIADA

(To be continued)

Page 41

4 Use UP/DOWN to move

cursor down.

CHAPTER 4 Functions and Controls

X D

=

Y=

IIADA

5 Use SET to display

Note

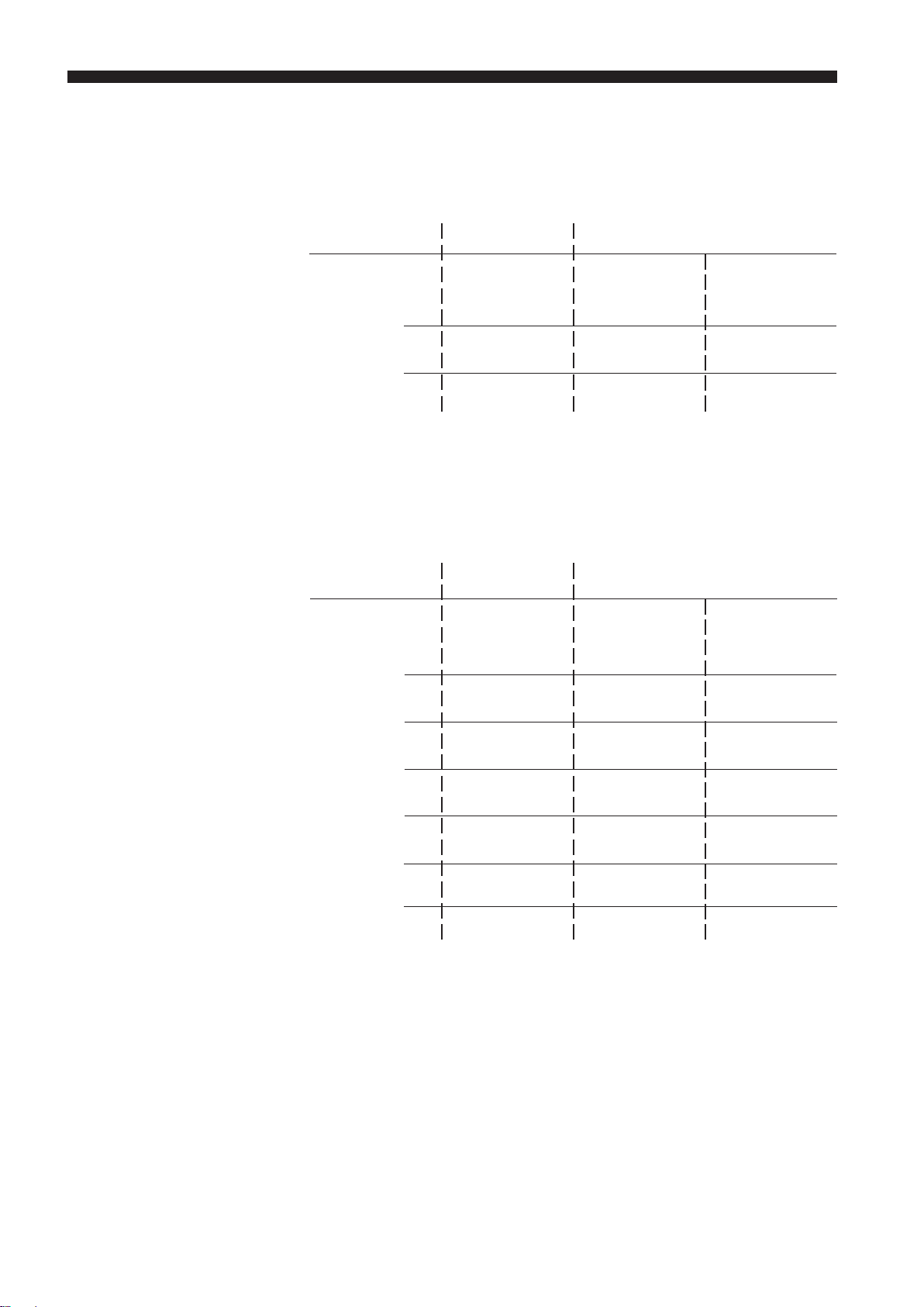

• Some combinations of segments cannot be used with the LS controller.

See the table below. ("✓" indicates valid combinations.)

DIA EDGE1 EDGE2 (m,n) 2: DIA 2: EDGE1 2: EDGE2 2: (m,n)

DIA

EDGE1

EDGE 2

✓

✓

✓

(m,n)

2: DIA

2: EDGE 1

Segment selector Y

2: EDGE 2

2: (m,n)

✓

✓

✓

✓

• Even when you have selected the segments using segment selectors X

and Y, these segments will be replaced by those selected using SEG.

When using SEG, be sure to select the same segments again.

"Y=2:DIA".

X

Y=

IIADA:2

D

=

Segment selector X

✓✓ ✓ ✓ ✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

Segment Check

This mode is applicable to segment mode (m,n). In this mode, you are to

register the number of segments. If the number of segments detected during

measurement is not the same as the registered one, error message " - - - - "

will appear. When this happens, the measured value is ignored.

This prevents incorrect measurements due to dust, drops of oil, or any other

particles on the scanning head. The error message will also appear when

the target is displaced from the measurement area.

•Non-clear targets are being measured.

1

2

3

4

5

6

ReceiverTransmitter

Segment selectors

X=(2. 3)

Y=(4. 5)

The registered number of edges is 6. If more than 6 edges are detected due

to dust as shown below, " - - - - - " will be displayed.

Floating dust

1

2

3

4

5

6

7

ReceiverTransmitter

* The segment check mode does not function with segment pairs in the

DIA, EDGE1, and EDGE2 modes.

35

Page 42

CHAPTER 4 Functions and Controls

Procedure Check first that segment pair, (m,n), has been selected.

1. Use FNC to display "X SEG CHECK OFF".

SCEGX HECK OF F

4

2. Use SET to display "ON" on the right of "SEG CHECK" to activate the

segment check mode.

SCEGX HE CK ON

4

* When the currently selected segment pair is DIA, EDGE1, or EDGE2, "Y

SEG CHECK" will be displayed.

3. Enter the correct number of edges.

4. Press ENT to register.

5. Press FNC to display "Y SEG CHECK OFF".

6. Repeat steps 3 and 4.

Example of Operation

You are to measure the outer diameter of two round bars at the same time

using one scanning head. You need to use the segment check mode to

prevent incorrect measurements. In this case, the number of edges is 6.

1

2

3

4

5

6

ReceiverTransmitter

Segment selectors

X=(2. 3)

Y=(4. 5)

Step Key operation Display

1 Use FNC to display "X SEG

CHECK OFF".

SCEGX HECK OF F

4

2 Press SET.

SCEGX HE CK ON

4

3 Enter "6".

4 Press ENT to register.

SCEGX HECK ON

SCEGX HECK ON

[]

6

6

36

5 Press FNC.

6 Press SET.

7 Press "6".

8 Press ENT to register.

SCEGY HECK OF F

4

SCEGY HECK ON

4

SCEGY HE CK ON

SCEGY HECK ON

[

]

6

6

Page 43

CHAPTER 4 Functions and Controls

Output Channel

The LS controller is equipped with two output channels (CH1 and CH2)

having their own displays and output terminals for simultaneous 2-point

measurement.

In this mode, you are to select which output channel to display or output

each of the measured values for X and Y. You can also choose to select the

equation containing X and Y as variables and obtain the result.

Types of output for CH1 and CH2

Channel Display Output

Main display

3 comparator LEDs (HI,

GO, LO)

CH1

3-step comparator output (relay)

➪

See P.64.

7-step comparator output

(control I/O)

Analog voltage output

RS-232C

BCD (option)

GP-IB (option)

➪

➪

See P.49.

➪

See P.62.

See P.68.

➪

See P.70.

➪

See P.47.

Subdisplay 3-step comparator output

CH2

(control I/O)

➪

See P.62.

RS-232C

GP-IB (option)

* For the subdisplay you can use DISP to display the current settings,

measured value for CH1 in one of the measurement modes, or measured

value for CH2. Therefore, the subdisplay may not show the measured

value of the segment you have selected. However, the comparator output

and the BCD output will be sent based on the measured value of the

segment selected using the segment selectors.