Page 1

WARNING

NOTICE

WARNING

NOTICE

WARNING

Laser emission

point

Laser warning and

explanation label

Class 2 (English) Class 1

Class 2 (included with the product in each language)

96M12738

All-Purpose Laser Sensor

LR-TB2000 Series

Instruction Manual

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

The following symbols alert you to important messages. Be sure to read these

messages carefully.

It indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

It indicates a situation which, if not avoided, could result in product

damage as well as property damage.

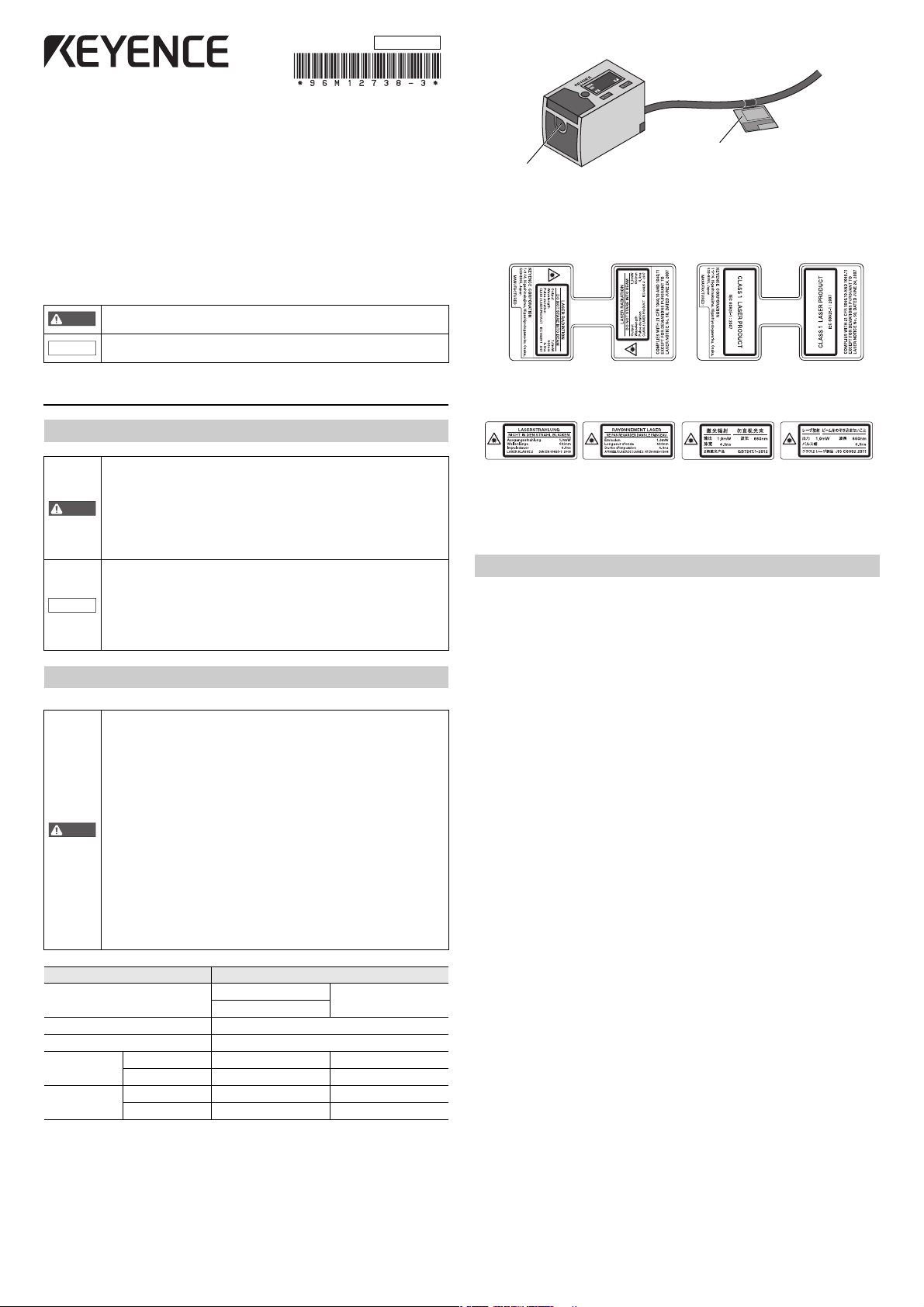

Laser warning and explanation labels

XX-XXXX

1567

1

1234

2

MODE

DISP

z Laser warning and explanation labels

• Attached to the cable

1 Introduction

Safety Information for LR-TB Series

• This product is only intended to detect object(s). Do not use this

product for the purpose to protect a human body or part of a human

body.

• This product is not intended for use as an explosion-proof product.

Do not use this product in a hazardous location and/or potentially

explosive atmosphere.

• This product uses DC power. The product may explode or burn if an

AC voltage is applied.

• Do not wire the cable along with power lines or high-tension lines,

as the sensor may malfunction or be damaged due to noise.

• When using a commercially available switching regulator, ground

the frame ground terminal and ground terminal.

• Do not use this product outdoors or in a location in which its

light-receiving surface will come in direct contact with stray ambient

light.

Safety Precautions on Laser Product

This product uses a semiconductor laser as its light source.

• Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

• Follow the instructions mentioned in this manual. Otherwise, injury

to the human body (eyes and skin) may result.

• Laser emission from this product is not automatically stopped when

it is disassembled. Do not disassemble this product.

• Precautions on Class 2 Laser Product

- Do not stare into the direct or specularly reflected beam.

- Do not direct the beam at people or into areas where people

might be present.

- Be careful of the path of the laser beam.

If there is a possibility that the operator may be exposed to the

specular or diffuse reflections, block the beam by installing a

protective enclosure.

- Install this product so that the path of the laser beam is not as the

same height as that of human eye.

• Precautions on Class 1 Laser Product

- Do not stare into the direct or specularly reflected beam.

Item Description

Model

Wavelength 660 nm

Pulse width 4.3 ns

FDA(CDRH)

Part1040.10

JIS C 6802/

IEC 60825-1

* The laser classification for FDA (CDRH) is implemented based on IEC60825-1 in

accordance with the requirements of Laser Notice No.50.

Laser class* Class 2 laser product Class 1 laser product

Output 1.0 mW 390 μW

Laser class Class 2 laser product Class 1 laser product

Output 1.0 mW 390 μW

LR-TB2000

LR-TB2000C

LR-TB2000CL

• Included with the product

* For a Class 2 laser product, select from the warning and explanation labels included

in the package the appropriate warning and explanation label according to the country and region where the Class 2 laser product will be used. Then, affix the warning

and explanation label over top of the existing warning and explanation label on the

product.

Precautions on Regulations and Standards

CSA Certificate

LR-TB series complies with the following CSA and UL standards and has been certified by

CSA (Class 2252 06 / Class 2252 86).

• Applicable standard: CAN/CSA C22.2 No.61010-1

• Use the following power supply.

CSA/UL certified power supply that provides Class 2 output as defined in the CEC

(Canadian Electrical Code) and NEC (National Electrical Code), or CSA/UL certified power

supply that has been evaluated as a Limited Power Source as defined in CAN/ CSA-C22.2

No. 60950-1/UL60950-1

• Use this product at the altitude of 2000 m or less.

• Use this product at the level of overvoltage category I.

• Use this product at pollution degree 3.

• Indoor use only.

CE Marking

Keyence Corporation has confirmed that this product complies with the essential

requirements of the applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in a member state

of the European Union.

z EMC Directive (2004/108/EC)

• Applicable standard EMI : EN60947-5-2, Class A

z Low-voltage Directive (2006/95/EC)

• Applicable standard: EN61010-1, EN60825-1

• Use the power supply that has been evaluated as a Limited Power Source as defined in

IEC60950-1/EN60950-1.

• Use this product at the altitude of 2000 m or less.

• Use this product at the level of overvoltage category I.

• Use this product at pollution degree 3.

• Indoor use only

Remarks: These specifications do not give any guarantee that the end-product with this

product incorporated complies with the essential requirements of the EMC

Directive.

The manufacturer of the end-product is solely responsible for the compliance of

the end-product itself according to the EMC Directive.

UL61010-1

EMS : EN60947-5-2

1

Page 2

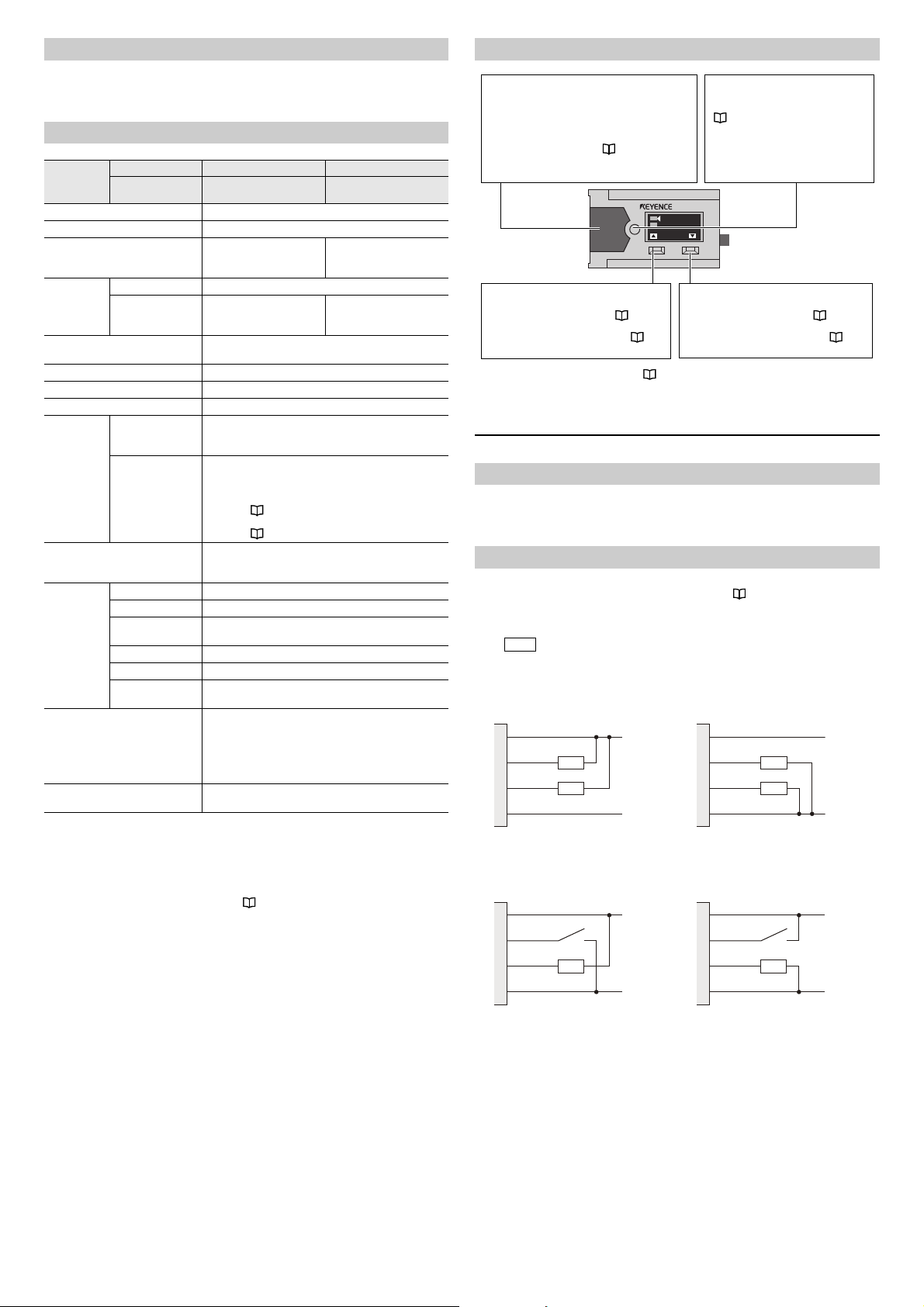

Package Contents

Indicator

Output 1 ON : Orange*

Output 1 OFF : Green*

Error : Flashing red

* The indicator flashes when two conditions below

are met;

• Stability output tur ns ON ( page 9).

• Output 1 turns OFF when output logic is N.O. or

turns ON when output logic is N.C.

[SET] Button

The operation of this button varies

depending on the detection mode

( page 4).

Example: 2-point calibration

1. Press this button with no workpiece

present.

2. Press this button with a workpiece

present.

[DISP/S] Button

Pressed for 1 second or less:

Changes the setting value ( page 6)

Held for 3 seconds or more:

Switches to the display screen ( page

7)

[MODE/T] Button

Pressed for 1 second or less:

Changes the setting value ( page 6)

Held for 3 seconds or more:

Switches to the setting screen ( page

8)

Load (input device)

1, brown

4, black

2, white

3, blue

20 ... 30 V

0 V

1, brown

4, black

2, white

3, blue

20 ... 30 V

0 V

1, brown

4, black

2, white

3, blue

20 ... 30 V

0 V

1, brown

4, black

2, white

3, blue

20 ... 30 V

0 V

• Main unit

• Instruction manual

• Laser warning and explanation labels (LR-TB2000/TB2000C only)

Specifications

Part Functions

Model

Detectable distance

Spot diameter Approx. 4 mm

Response time

Light source

Mutual interference prevention

function

Timer OFF/OFF delay/ON delay/One-shot

Power voltage 20 to 30 VDC, including 10% ripple (P-P), Class 2 or LPS

Current consumption 45 mA or less (without load)

*4*5

I/O

Protection circuit

Environmental

resistance

Material

Weight

Cable LR-TB2000 -

Cable with

connector M12

*1

Type Red laser (660 nm)

Laser class

Control output

External input

Enclosure rating IP65/IP67 (IEC60529)

Ambient light Incandescent lamp/Sunlight: 100000 lux or less

Ambient

temperature

Ambient humidity 35 to 85%RH (no condensation)

Shock resistance 1000m/s2 in X, Y, Z axis directions respectively 6 times

Vibration resistance

LR-TB2000C LR-TB2000CL

60 to 2000 mm

1 ms/10 ms/25 ms/

100 ms/1000 ms

selectable

Class 2 laser product

IEC60825-1,FDA(CDRH)

Part1040.10

4 units (when using the interference prevention function)

NPN open collector/PNP open collector selectable

residual voltage: 2 V or less, N.O./N.C. selectable

Short-circuit current: 1 mA or less for both NPN and PNP

For the applied voltage, see the wiring diagrams

Protection against reverse power connection,

power supply surges, output overcurrent, output surge,

10 to 55 Hz Double amplitude 1.5 mm in the X, Y, Z axis

Case: Zinc die cast (Nickel chrome plating), I

and buttons: PES, Lens cover and display: PMMA

M12 connector (only for the cable with connector M12 type):

Cable type: Approx. 125 g (Including cable)

Cable with connector M12 type: Approx. 85 g

*2

30 VDC or less, 50 mA or less,

Transmission OFF / Tuning /

Reference surface update selectable

( page 2 in the instruction manual).

For the input times, see the time charts

( page 3 in the instruction manual).

and reverse output connection

-20 to +55°C (no freezing)

directions respectively, 2 hours

(scratch-resistant coating specifications),

Cable bushing: PBT, Cable: PVC,

TPE, PBT, Nickel-plated brass

2 ms/20 ms/50 ms/

200 ms/2000 ms

selectable

Class 1 laser product

IEC60825-1,FDA(CDRH)

Part1040.10

*2

*3

ndicator cover

*1 The range for displayable distance is from 50 to 2200.

*2 The laser classification for FDA (CDRH) is implemented based on IEC60825-1 in

accordance with the requirements of Laser Notice No.50.

*3 145mA or less (with load)

*4 You can select the I/O from the following combinations.

Control output × 2, control output + external input

(For details on the setting method, see page 3 of the instruction manual.)

*5 IO-Link specification v.1.1/COM2 (38.4 kbps) is supported.

You can download a setup file from the KEYENCE website (http://www.keyence.com).

If you are using the product in an environment in which you cannot download files

over the Internet, contact your nearest KEYENCE office.

XX-XXXX

1

2

1567

1234

DISP MODE

For a more detailed explanation, see "Switching between Display Screens" (page 7).

2 Installation and Wiring

Installation

• Tightening torque for the mounting holes: 0.63 N·m (M3 screw)

• If the detecting object has a mirrored surface, install the sensor in a position where

specular reflection will not penetrate the optical receiver.

Wiring

With the LR-TB Series, you can select the functions of the I/O wires (black and white) from

the combinations shown below during the initial settings. "3 Initial Settings" (page 3)

Independently isolate any I/O wires that you will not use.

Out1+Out2

z NPN z PNP

Input+Out1

z NPN z PNP

2

Page 3

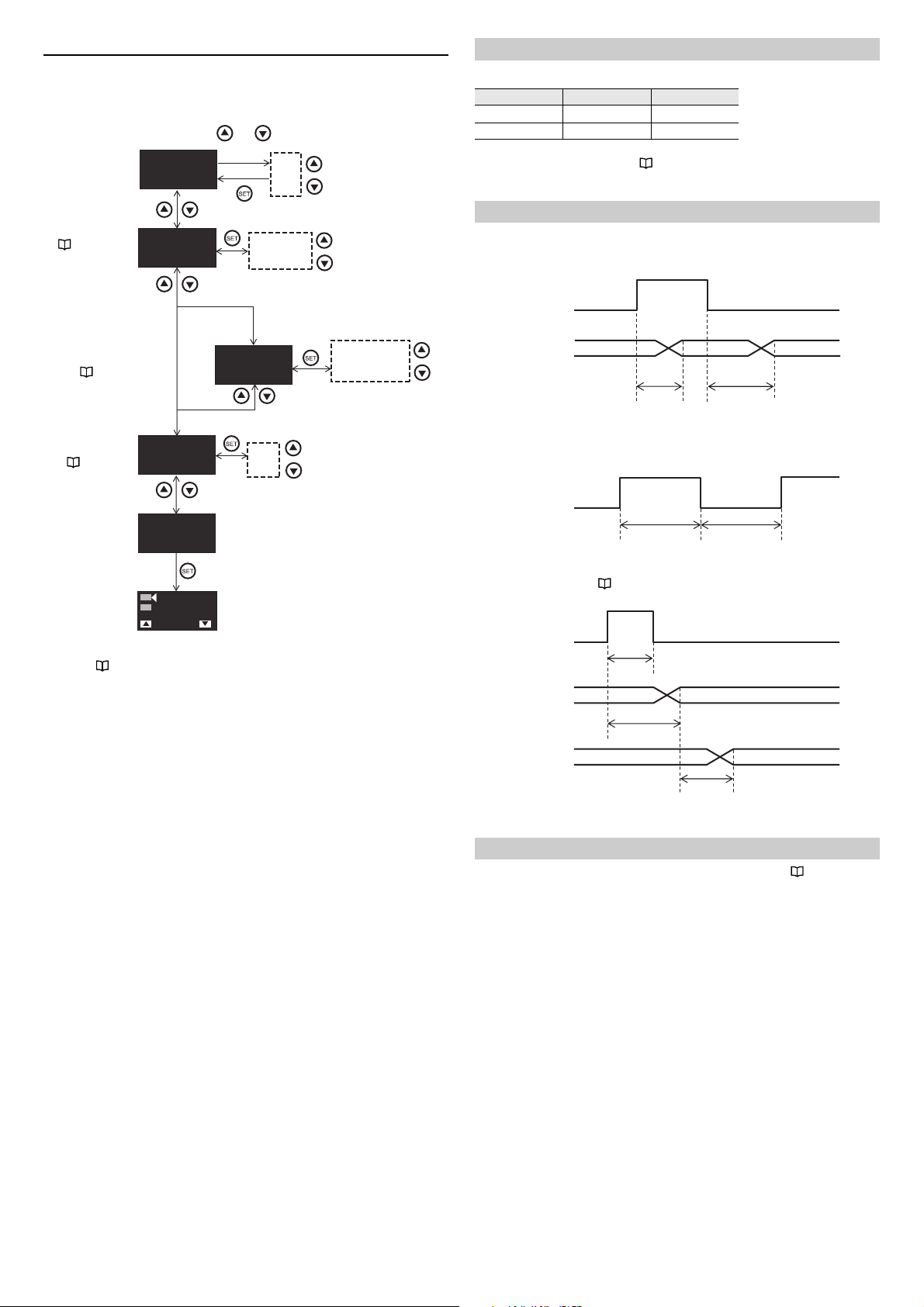

3 Initial Settings

3-1. I/O Selection

( page 3)

3-2. External Input

Selection

( page 3)

3-3. NPN/PNP

Selection

( page 3)

Input

ON

> 60 ms

> 60 ms

OFF

Updated reference surface

Updated output

Input

ON

> 5 ms

< 60 ms

Response

time

OFF

When you turn on the LR-TB Series for the first time after you purchase it or when you have

initialized the LR-TB Series, the following initial settings must be configured.

Display Units

and

Press for 3 seconds or more

mm

inch

feet

Out1+Out2

Input+Out1

Select I/O

Out1+Out2

Start Config.

Out1+Out2

Input+Out1

3-1. I/O Selection

Select from the following table the functions assigned to the I/O wires (black and white).

Options Black Wire White Wire

Out1 + Out2 Output 1 Output 2

Input + Out1 External input Output 1

The functions assigned to output 1, output 2, and external input can be changed after you

finish configuring the initial settings. "6 Detailed Settings" (page 8).

3-2. External Input Selection

Transmission OFF [Laser Off]

The laser beam transmission is stopped.

ON

Input

OFF

Select Input

Laser Off

Select Output

NPN

End Config.

1

2

1234

500

•

After you have finished configuring the initial settings, you will not be able to reconfigure the

unit, I/O, or NPN/PNP selection. To change any of these settings, you will have to initialize the

product. "Initialization" (page 7).

RUN

NPN

PNP

Laser Off

Tuning

DATUM Preset

Transmission TransmissionOFF

< 5 ms < 50 ms

External Calibration [Tuning]

When selected, this external input performs the same function as pressing the [SET]

button.

Reference surface update [DATUM Preset]

When the detection mode ( "4 Detection Mode" [page 4]) is set to "DATUM mode," this

external input updates the reference surface.

3-3. NPN/PNP Selection

You can select between NPN outputs or PNP outputs. For details, see "Wiring" (page

2).

3

Page 4

4 Detection Mode

1567

1234

XX-XXXX

DISP MODE

1

2

A-A

0

ON

ON

N.O.

N.C.

OFF

OFF

Hys.

Hys.

A: Setting value

Hys: Hysteresis ( page 10)

Reference surface

Reference surface

Press the set button for 1 second or less.

Press and hold the set button for 3 seconds or more.

Completion

1567

1234

XX-XXXX

DISP MODE

1

2

Hys.

ON

ON

A

0

2000

N.O.

N.C.

OFF

OFF

A: Setting value

Hys: Hysteresis ( page 10)

Press the set button for 1 second or less.

Setting value

Press the set button for 1 second or less.

Completion

The LR-TB Series has four output modes and three detection modes.

Output Mode ( page 9) Detection Mode

Standard (default value) [Standard]

Window [Window] 4-3. Window mode

Stability [Stability] ( page 9)

Error [Error] ( page 9)

When the output modes for Out1 & Out2 are either [Standard] or [Window], the detection

modes can only be set in the below combinations.

[Out1] / [Out2] = [DATUM]/ [DATUM], [Distance]/ [Distance], [Distance]/ [Window],

[Window]/ [Distance], [Window]/ [Window]

4-1. DATUM Mode (FGS)

Operation

• In this mode, the change in position from a reference surface (which has a value of 0) is

displayed.

• This mode is useful in detecting the passage of workpieces in front of a stationary

background.

4-1. DATUM mode (FGS)

4-2. Distance mode (BGS)

4-2. Distance Mode (BGS)

Operation

• In this mode, the distance from the sensor is displayed.

Setting

• Set the detection mode to [Standard], which is the default value. "6 Detailed

Settings" (page 8)

• For details on setting output 2, see " 4-5. Switching Out1/Out2" (page 6)

Setting

• Set the output mode to [Standard], which is the default mode. "6 Detailed Settings"

(page 8)

• For details on setting output 2, see " 4-5. Switching Out1/Out2" (page 6).

• In DATUM mode, a "±" is displayed in front of the setting value.

1

XX-XXXX

1

2

2

DISP MODE

DISP MODE

1567

1234

XX-XXXX

1

2

1567

1234

z

2-point calibration

1

2

N.O.

OFF

N.C.

OFF

ON

ON

DISP MODE

DISP MODE

DISP MODE

XX-XXXX

1

2

1567

1234

XX-XXXX

1

2

1567

1234

XX-XXXX

1

2

1567

1234

N.O.

N.C.

-A

A

ON

OFF

ON

OFF

4

Page 5

z

1567

1234

XX-XXXX

DISP MODE

1

2

1

2

1567

1234

XX-XXXX

DISP MODE

1

2

1567

1234

XX-XXXX

DISP MODE

1

2

N.O.

N.C.

ON

OFF

ON

OFF

Press and hold the set button

for 3 seconds or more.

Completion

Press and hold the set button

for 3 seconds or more.

The object is detected while

the button is pressed.

1

1567

1234

XX-XXXX

DISP MODE

1

2

N.O.

N.C.

1567

1234

XX-XXXX

DISP MODE

1

2

ON

OFF

ON

OFF

Press and hold the set button

for 3 seconds or more.

Completion

Hys: Hysteresis ( page 10)

1567

1234

XX-XXXX

DISP MODE

1

2

1

2

1567

1234

XX-XXXX

DISP MODE

1

2

1567

1234

XX-XXXX

DISP MODE

1

2

ON

NEARFAR

ON

N.O.

N.C.

OFF

OFF

Completion

Press the set button for 1 second or less.

Press the set button for 1 second or less.

Full auto calibration

Use this function when the movement of detected objects cannot be stopped.

4-3. Window Mode

Operation

• In this mode, the distance from the sensor is displayed.

• You can assign setting values to the upper and lower limits.

2000

ON

N.O.

OFF

ON

N.C.

OFF

Hys. Hys.

Setting

• Set the detection mode to [Window]. "6 Detailed Settings" (page 8)

• For details on setting output 2, see " 4-5. Switching Out1/Out2" (page 6).

z

2-point calibration

Use this function to detect objects inside a range of specific upper and lower limits.

NEARFAR

0

XX-XXXX

1

2

1567

1234

DISP MODE

z

1-point calibration

Use this function to enable the installation of detected objects at the upper limit that you

do not want to detect.

5

Page 6

z

Press and hold the set button for 3 seconds or more.

Completion

RUN

1567

1234

XX-XXXX

DISP MODE

1

2

1...9999

1567

1234

1

2

1567

1234

1

2

Press the [DISP/S] or the [MODE/T] button

(for 1 second or less).

3 seconds

XX-XXXX

DISP MODE

RUN

FAR

NEAR

1567

1234

1789

1

2

N

N

F

1567

1234

1789

1

2

F

N

F

1567

1234

1789

1

2

N

F

1567

1234

1789

1

2

N

F

1...9999

Press the [DISP/S] or the [MODE/T] button

(for 1 second or less).

3 seconds 3 seconds

Press the [DISP/S] or the [MODE/T] button

(for 1 second or less).

3 seconds

3 seconds 3 seconds

1567

1234

XX-XXXX

DISP MODE

1

2

1567

1234

1

2

Out2 1456

S

Out1 1234

Out1 1234

Out2 1456

S

1567

1456

1

2

1567

1456

1

2

RUN

1567

1234

1

2

RUN

Press the [DISP/S] or the [MODE/T] button

(for 1 second or less).

3 seconds 3 seconds

An arrow will be displayed next to the setting value to be changed when tuning

or calibration is implemented.

1-point calibration

Use this function when you cannot move detected objects away from the center of the

detection range.

1

XX-XXXX

1

2

1567

1234

DISP MODE

When [Out2] mode is set to [Standard] or [Window]

XX-XXXX

1

2

1567

1234

DISP MODE

FAR

ON

N.O.

OFF

ON

N.C.

OFF

4-4. Manual Tuning

NEAR

DISP MODE

S

Out1 1234

Out2 1456

S

Out1 1234

Out2 1456

[Standard]

1

1567

2

F

N

F

1567

1234

1789

[Window]

1234

1789

1...9999

RUNRUN

[Standard]

1

XX-XXXX

1

2

1567

1234

2

1567

1

2

1567

1234

1234

1

2

N

1567

N

F

1...9999

1234

1789

FARNEAR

1

2

N

F

4-5. Switching Out1/Out2

The initial [Out2] mode is [Stability]. "6 Detailed Settings" (page 8)

When [Out2] mode is set to [Standard] or [Window], the setting below could be

manipulated.

When the detection mode is set to [Window]

6

Page 7

5 Useful Functions

9999

Input Password

0000

0000

...

1567

1234

XX-XXXX

DISP MODE

1

2

1567

1234

XX-XXXX

DISP MODE

1

2

Press these buttons at the same time

for 3 seconds or more.

If necessary, enter the password to

release the lock.

Lock

Unlock

"3 Initial Settings" (page 3)

1567

1234

XX-XXXX

DISP MODE

1

2

Initialize ?

No

Initialize ?

Yes

While pressing the [MODE/T] button,

press the [SET] button five times.

1234

1789

1

2

Use the I/O selection to change what is displayed here.

" 3-1. I/O Selection" (page 3).

(1): Output 1 (displayed in gray when OFF)

(2): Output 2 (displayed in gray when OFF)

IN: External input (displayed in gray when OFF)

An arrow will be displayed next to the setting value to be

changed when tuning or calibration is implemented.

Current value

Setting value

(the display of which

can be changed)

The indicator will turn grey while the

[DISP /S] button is pressed.

The indicator will turn grey while the

[MODE /T] button is pressed.

1567

1234

XX-XXXX

DISP MODE

1

2

1567

1234

1

2

1567

1234

1789

1

2

P

B

1567

1

2

Simple

Display

S

Bar

Display

S

Peak Bottom

Display

S

Standard

Display

S

1567

MIN

1

2

MAX

Press the [DISP /S] button

(for 3 seconds or more).

Current value

Setting value

Current value

Peak val ue*

Bottom value*

Current value

Bar

Current value

Key Lock

To require a password to release the key lock, see " 6-11. Password" (page 10).

Switching between Display Screens

You can select between four different displays.

Display screen

How to switch the display

Initialization

Initialization resets the product to its factory default settings. After initialization, you will

have to configure the "3 Initial Settings" (page 3).

Using the shortcut keys to execute the initialization

Using the setting menu to execute the initialization

On the "Initialize?" screen, select "Yes". "6 Detailed Settings" (page 8)

* When the output changes from ON to OFF, the bottom value is reset to the current

value.

When the output changes from OFF to ON, the peak value is reset to the current

value.

7

Page 8

6 Detailed Settings

3-1. I/O Selection

( page 3)

6-1. Response Time

( page 9)

6-2. Output 1 Logic

( page 9)

6-3. Output 1 Mode

( page 9)

6-4. Output 1 Timer

( page 9)

6-2. Output 2 Logic

( page 9)

6-3. Output 2 Mode

( page 9)

6-4. Output 2 Timer

( page 9)

6-5. Hysteresis

( page 10)

6-8. Output Hold

( page 10)

6-9. Screen

Brightness

( page 10)

6-11. Password

( page 10)

6-12. Initialization

( page 10)

6-10. Interference

Prevention

( page 10)

6-6. Received Light

Sensitivity

( page 10)

6-7. Input Function

( page 10)

You can complete settings by holding down the

button.

3 seconds

Advanced Settings

The values shown on the display screen are the initial values.

1

2

1567

1234

A

Out1+Out2

Input+Out1

B

Menu

Response Time

25ms

1000 ms

100 ms

25 ms

10 ms

1 ms

*

1

Hysteresis

Standard

Custom

Standard

Custom

Output1 Logic

N.O.

Output1 Mode

Standard

Output1 Timer

Off

Output2 Logic

N.O.

Output2 Mode

Stability

Timer1 Setting

B

Stability or Error

Output2 Timer

Adv. Settings

End

1

2

1567

1234

Off

Off

*1 The LR-TB2000CL has the following response times.

2000 ms

200 ms

50 ms

20 ms

2 ms

Off

10 ms

Off

Timer2 Setting

10 ms

On

RUN

N.O.

N.C.

Standard

Window

Off

Off-delay

On-delay

One shot

N.O.

N.C.

Standard

Window

Stability

Error

Off

Off-delay

On-delay

One shot

Off

On

9999 ms

...

1 ms

9999 ms

...

1 ms

Sensitivity

A

Output Hold

Brightness

Interference

Channel

Password Lock

Initialize?

End

1

2

1567

1234

Hys. Value

High

B

Off

30%

Off

On

Enter Password

No

RUN

0000

10

High

Mid

Low

Off

On

100%

30%

Display Off

Channel 4

Channel 3

Channel 2

Channel 1

Off

On

No

Yes

9999

...

0

9999

...

0000

Input Function

Laser Off

Laser Off

Tuning

DATUM Preset

8

Page 9

A

ON

OFF

ON

N.O.

N.C.

FAR

NEAR

OFF

ON

OFF

ON

N.O.

N.C.

OFF

ON

OFF

ON

N.O.

N.C.

OFF

ON

OFF

ON

N.O.

N.C.

OFF

Timer OFF

Off Delay

On Delay

One Shot

Timer time

6-1. Response Time

Longer response times lead to more stable detection.

LR-TB2000/TB2000C

Example) Chart during DATUM mode

XX-XXXX

1234

1567

2

1

DISP MODE

Detecting

distance

[mm]

White Paper (Reflectivity: 90%)

Response Time [ms]

1 10 25 100 1000

1000±9±4±3±3±3

2000 ±25 ±7 ±6 ±3 ±3

Repetition Accuracy[mm] (Typical) (Under stable temperature)

Repetition Accuracy[mm] (Typical) (Under stable temperature)

Detecting

distance

[mm]

Gray Paper (Reflectivity: 18%)

Response Time [ms]

1 10 25 100 1000

1000 ±26 ±7 ±6 ±3 ±3

2000 ±69 ±21 ±13 ±6 ±4

LR-TB2000CL

Detecting

distance

[mm]

1000 ±10 ±5 ±3 ±3 ±3

2000 ±26 ±8 ±7 ±5 ±3

Detecting

distance

[mm]

1000 ±26 ±9 ±6 ±3 ±3

2000 ±71 ±22 ±15 ±9 ±5

Repetition Accuracy[mm] (Typical) (Under stable temperature)

White Paper (Reflectivity: 90%)

Response Time [ms]

2 20 50 200 2000

Repetition Accuracy[mm] (Typical) (Under stable temperature)

Gray Paper (Reflectivity: 18%)

Response Time [ms]

2 20 50 200 2000

NEAR

Distance

mount of

received light

(workpiece >

background)

Stability

output

(N.O.)

FAR

OFF

ON

5 cycles

Setting value

Amount of

received light

threshold (fixed)

Error [Error]

Output is activated when an error occurs. When the error is cleared, the output is also

automatically reset. For causes of errors, see " Error Display" (page 10).

6-4. Timer

This function can be used to delay the timing with which the sensor output is switched.

• Off delay [Off-delay]

• On delay [On-delay]

• One shot [One shot]

6-2. Output Logic

Select N.O. or N.C. for the output logic. For details, see "4 Detection Mode" (page 4).

6-3. Output Mode

Standard [Standard]

The output is activated according to the detecting distance. For details, see "4 Detection

Mode" (page 4).

Window [Window]

The output is activated according to the detecting distance. For details, see " 4-3.

Window Mode" (page 5).

Stability [Stability]

This function can be used to check whether there has been a decrease in the amount of

light received due to problems such as dirt on the detected surface.

z When the I/O selection is [Out1 + Out2]

Output is activated if the amount of light received falls below the threshold (fixed value)

during the observation period.

Detection Mode Observation Period

DATUM

Distance Detected value < setting value

Window

Negative setting value < detected value

< positive setting value

LOW-side setting value < detected value

< HIGH-side setting value

9

Page 10

6-5. Hysteresis

FAR

NEAR

ON

OFF

ON

N.O.

N.C.

OFF

Hysteresis

Setting value

B

1000 2000

A

Hysteresis

Detecting

distance

Unit: mm

Response Time (ms) A(mm) B(mm)

25 to 2000 15 20

10, 20 30 40

1, 2 60 80

NEAR

00

ON

N.O.

)

OFF

NEAR

ON

(

N.O.

)

OFF

Display Display

Distance

display

Distance

display

SettingSetting

DistanceDistance

Output Output

Hysteresis is the difference between the value at which the output turns ON and the value

at which the output turns OFF.

• With [Standard], the hysteresis varies depending on the response time and the

detecting distance.

6-10. Interference Prevention

With the LR-TB Series, you can prevent the effect of mutual interference by changing the

laser emission channel. If you are using multiple LR-TB Series units in close proximity to

each other, set each one to have a different laser emission channel.

6-11. Password

If you set this to [ON], you can set a personal identification number that must be entered to

release the " Key Lock" (page 7). You can set the personal identification number to a

value from 0 to 9999.

6-12. Initialization

Initialize the sensor settings. You can also use the shortcut keys to execute the

initialization. "Initialization" (page 7)

After initialization, you will have to configure the "3 Initial Settings" (page 3).

7Other

Error Display

• With [Custom], you can specify an arbitrary value regardless of the detecting distance.

• For details on the operation differences between the detection modes, see "4

Detection Mode" (page 4).

6-6. Received Light Sensitivity

By lowering the received light sensitivity level, you can reduce the number of times that

malfunctions such as the following occur.

• Detections of dirt and mist between the sensor and the detected object.

• Detections of translucent objects when passing through translucent objects to detect

the target.

You cannot change the received light sensitivity when " 6-1. Response Time" (page 9)

is set to [1ms/10ms]/[2ms/20ms].

6-7. Input Function

For details, see " 3-2. Exter nal Input Selection" (page 3).

6-8. Output Hold

This function holds the display value and the output status that were in use immediately

prior to the LR-TB Series becoming unable to receive light.

When Output Hold is OFF When Output Hold is ON

Error Display Cause and Remedy

NEAR*

- - - -*

Over Current

Laser Error

EEPROM Error

System Error

* When Output mode is set to [Error], while “Near” or “- - - -” is on display, the output would not

switch.

The detected object is not within the detectable range (the detected

object is too close).

Light reflected from the detected object could not be received.

• The amount of light received from the detected object is low.

• The detected object is not within the detectable range of the LR-TB (the

detected object is too far away).

An overcurrent is flowing through the output wire.

• Check whether the output wire is connected correctly.

• Check whether the output wire is in contact with other wires.

A laser diode error has occurred.

• If you cannot fix the problem by restarting the product, the product must

be replaced.

1) Settings have been rewritten more than 1,000,000 times.

• The memor y has reached the end of its service life.

2) A recording memory error has occurred.

• If you cannot fix the problem by restarting the product, the product must

be replaced.

An internal system error has occurred.

• If you cannot fix the problem by restarting the product, the product must

be replaced.

Output When an Error Occurs

Error Display

NEAR ON OFF

- - - - OFF ON

Over Current

Laser Error

EEPROM Error

System Error

*1 When Output mode is set to [Error], despite the setting of N.O. or N.C., LR-T would remain

*2 When Output mode is set to [Error], LR-T would turn ON with N.O. and turn OFF with N.C.

*1

*2

*2

*2

OFF to protect the output circuit.

Output ON or OFF

N.O. N.C.

OFF OFF

OFF ON

The same as during normal operation

OFF ON

6-9. Screen Brightness

You can set the operation to perform when no button operations are performed for a set

length of time.

Item Description

100% The display brightness is always kept at 100%.

30% (default value)

Display Off After a certain length of time elapses, the display is turned OFF.

• If you use the LR-TB Series for a long period of time, the display brightness will

decrease.

• If you set this to [100%], the display brightness will decrease at a faster rate.

After a certain length of ti me elapses, the display brightness is set to

30%.

10

Page 11

11

Page 12

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any models

or samples were shown to Buyer, such models or samples were used merely to

illustrate the general type and quality of the Products and not to represent that

the Products would necessarily conform to said models or samples. Any

Products found to be defective must be shipped to KEYENCE with all shipping

costs paid by Buyer or offered to KEYENCE for inspection and examination.

Upon examination by KEYENCE, KEYENCE, at its sole option, will refund the

purchase price of, or repair or replace at no charge any Products found to be

defective. This warranty does not apply to any defects resulting from any action of

Buyer, including but not limited to improper installation, improper interfacing,

improper repair, unauthorized modification, misapplication and mishandling, such

as exposure to excessive current, heat, coldness, moisture, vibration or outdoors

air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products.

They are only suggestions, and it is Buyer's responsibility to ascertain the fitness

of the Products for Buyer’s intended use. KEYENCE will not be responsible for

any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not to

be used internally in humans, for human transportation, as safety devices or

fail-safe systems, unless their written specifications state otherwise. Should any

Products/Samples be used in such a manner or misused in any way, KEYENCE

assumes no responsibility, and additionally Buyer will indemnify KEYENCE and

hold KEYENCE harmless from any liability or damage whatsoever arising out of

any misuse of the Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL EXPRESS,

IMPLIED, AND STATUTORY WARRANTIES, INCLUDING, WITHOUT

LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY

RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE

TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT, INCIDENTAL,

PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING,

WITHOUT LIMITATION, ANY DAMAGES RESULTING FROM LOSS OF USE,

BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR

INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST

OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR

TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF OR IN

CONNECTION WITH THE USE OR INABILITY TO USE THE PRODUCTS,

EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED

OF A POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER

CLAIM AGAINST BUYER. In some jurisdictions, some of the foregoing warranty

disclaimers or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a

third party, Buyer must provide such third party with a copy of this document, all

specifications, manuals, catalogs, leaflets and written information provided to

Buyer pertaining to the Products/Samples.

KEYENCE CORPORATION

1-3-14, Higashi-Nakajima, Higashi-Yodogawa-ku,

Osaka, 533-8555, Japan

PHONE: +81-6-6379-2211

AUST RIA

Ph: +43 22 36-3782 66-0

BELGIUM

Ph: +32 1 528 1222

BRAZIL

Ph: +55-11-3045-4011

CANADA

Ph: +1-905-366-7655

CHINA

Ph: +86-21-68757500

CZECH REPUBLIC

Ph: +420 222 191 483

FRANCE

Ph: +33 1 56 37 78 00

GERMANY

Ph: +49 6102 36 89-0

Specifications are subject to change without notice.

Copyright (c) 2013 KEYENCE CORPORATION. All rights reserved.

12738E 1034-3a 96M12738 Printed in Japan

HONG KONG

Ph: +852-3104-1010

HUNGARY

Ph: +36 1 802 73 60

INDIA

Ph: +91-44-4299-4192

INDONESIA

Ph: +62-21-2939-8766

ITALY

Ph: +39-02-6688220

KOREA

Ph: +82-31-789-4300

MALAYSIA

Ph: +60-3-2092-2211

MEXICO

Ph: +52-81-8220-7900

www.keyence.com

NETHERLANDS

Ph: +31 40 20 66 100

POLAND

Ph: +48 71 36861 60

ROMANIA

Ph: +40 269-232-808

SINGAPORE

Ph: +65-6392-1011

SLOVAKIA

Ph: +421 2 5939 6461

SLOVENIA

Ph: +386 1-4701-666

SWITZERLAND

Ph: +41 43-45577 30

TAIWAN

Ph: +886-2-2718-8700

12

E 1101-3

THAILAND

Ph: +66-2-369-2777

UK & IRELAND

Ph: +44-1908-696900

USA

Ph: +1-201-930-0100

VIETNAM

Ph: +84-4-3760-6214

A6WW1-MAN-1044

Loading...

Loading...