Page 1

96M1573

High-speed, High-accuracy

CCD Laser Displacement Sensor

LK-G Series

User’s Manual

Read this manual before using the system in order

to achieve maximum performance.

Keep this manual in a safe place for future

reference.

Page 2

Introduction

This Instruction Manual describes the basic operations and hardware functions of the LK-G

Series. Read this manual carefully to ensure the optimum performance and full function of the

LK-G Series before use.

Keep this manual in a safe place for future reference.

Be sure that the person who will finally operate this product receives this manual.

■

Symbols

These symbols alert you to matters concerning the prevention of human injury and product damage.

DANGER

Failure to follow the instructions may lead to death or serious injury.

WARNING

Failure to follow the instructions may lead to injury.

CAUTION

Failure to follow the instructions may lead to product damage or failure of the product.

Note

Provides additional information on proper operations that can be easily mistaken.

Reference

Provides advanced and useful information for operation.

Page 3

Safety Precautions

General Cautions

• At startup and during operation, be sure to monitor the functions and performance of

the LK-G Series.

• We recommend that you take substantial safety measures to avoid any damage in

the event of a problem occurring.

• Do not attempt to open or modify the LK-G Series or use it in any way other than as

described in the specifications. If the LK-G Series is modified or used other than as

described, the warranty will be voided.

• When the LK-G Series is used in combination with other devices, functions and

performance may be degraded, depending on the operating conditions and

surrounding environment.

• Do not use the LK-G Series for the purpose of protecting the human body.

• Do not allow the temperature to change sharply around the LK-G Series, including

the accessories. Otherwise, condensation may lead to malfunction.

WARNING

Follow the safety precautions below to ensure safe operation

• Apply the correct power voltage. Failure to do so may cause fire, electric shock, or

malfunction.

• Do not attempt to disassemble or modify the unit. Doing so may cause fire or electric

shock.

Handling abnormalities

Turn off the power immediately in the following cases. Using the unit in an abnormal

condition could cause fire, electric shock, or accident.

Contact the nearest KEYENCE office for repair.

• If liquid including water, chemicals or debris enters the unit.

• If the unit is dropped or the case is damaged.

• If abnormal smoke or odor is present.

LK-G-M-NO0-E

1

Page 4

CAUTION

Follow the safety precautions below to ensure safe operation

• Be sure to turn the power off when you plug/unplug the cable that leads to the unit

and its accessories. Not following this caution may result in damage.

• Do not turn off the power while setting items. The data being set or all the data may

be lost.

• Do not block the vent holes on the unit. Increase of internal temperature may cause

failure.

Installation environment

To use the LK-G Series correctly and safely, avoid installing it in the following locations;

doing so may lead to breakdown of the unit.

• Location that is humid, dusty or poorly ventilated

• Location with a high temperature such as a place exposed to direct sunlight

• Location where there are flammable or corrosive gases

• Location where the unit may be directly subjected to vibration or impact

• Location where water, oil or chemicals may splash onto the unit

• Location where static electricity is easily generated

Corrective action for noise

Do not install the LK-G Series near a power source or high-voltage cable, otherwise noise

may cause the LK-G Series to malfunction. Take corrective action for noise by using noise

filters, laying cables separately, and/or installing insulation on the controller and the

measuring unit. Use the single core shielded cable for the analog output cable.

Influence of ambient temperature

A change in the ambient temperature may cause the measurement to fluctuate. Be sure to

keep it stabilized. When the ambient temperature changes by 10 °C, it takes 60 minutes

for the distribution of internal temperature to equalize.

Operating ambient light intensity level

Do not use the LK-G Series near a lighting system that repeatedly and rapidly turns on

and off. If it is unavoidable to use the unit in such a place, install a light shielding board or

the like so that the light will not affect the measurement.

Warming up

Before using the LK-G Series, wait approximately 30 minutes after the power is turned on.

Otherwise, the measured value may gradually fluctuate because the circuit is not

immediately stable after the power is turned on.

2

LK-G-M-NO0-E

Page 5

Influence of dust or dirt

The measurement may fluctuate due to dirt, dust or fluid such as water or oil in the following cases:

• Adhesion on the protection glass: Blow the dirt off with clean air. If dirt persists, wipe

the glass surface gently using a soft cloth moistened with alcohol.

• Adhesion on the surface of the measuring target: Blow the dirt off with clean air or

wipe it off.

• Intrusion of floating or sprinkled dust or dirt into the light-axis range: In this case, take

corrective action with a protective cover or air purge.

Notes

Influence of vibration

When the measuring target is vibrating, the measured value may fluctuate. In this case,

increase the average number of times of measurement to achieve a more accurate value.

Measuring target

The measured value may fluctuate if the shapes or surfaces of the measuring targets vary. In

this case, use a known target and perform appropriate correction using the calibration function.

Handling

Do not wipe with a wet cloth, benzene, or thinner. Doing so may change the color or shape

of the unit. If the unit has much dirt on it, wipe it off with a cloth moistened with a mild

detergent, then wipe with a soft dry cloth.

Effect of atmospheric motions

Slow atmospheric motions may affect the measurement and result in fluctuation of the measured value.

In such a case, take the following countermeasures.

• Enclose the measurement portion with an appropriate enclosure.

•

Agitate the air between the measurement portion and the workpiece more strongly with a fan.

Precautions on CE Marking

The LK-G Series conforms to the EMC Directive subject to the conditions that the following

requirements are satisfied. In order to use this equipment in the EU countries, be sure that

the following requirements have already been satisfied beforehand.

The applicable standards are explained below.

LK-G-M-NO0-E

3

Page 6

EMI: EN61326, class A

EMS: EN61326

Length of the power cord that is connected to the Controller, and length of all input/output

cords must be limited to shorter than 30 m.

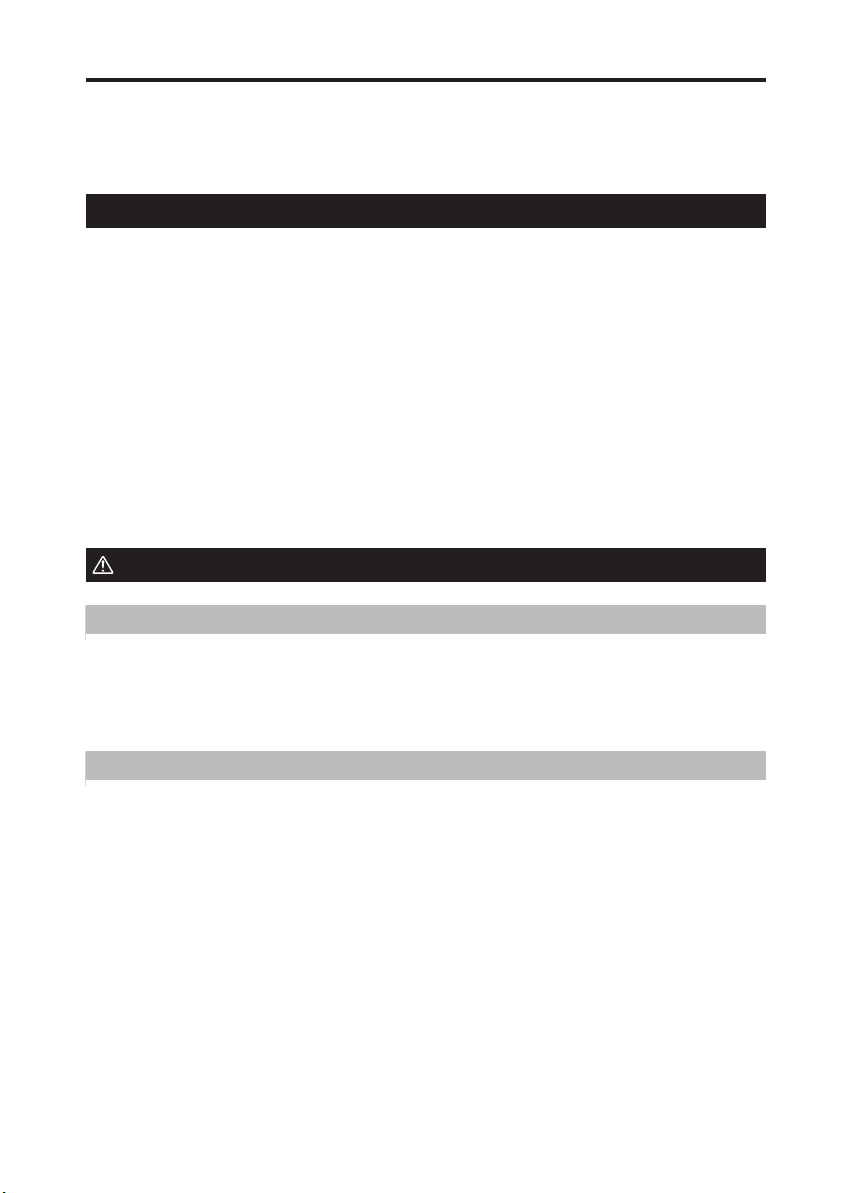

Precautions for Wiring

Part of the circuits between the inputs and output are internal common. Make sure that a

potential difference does not occur between internal common terminals due to a potential

difference between wires or external devices. Otherwise, it may cause malfunctions in the

unit or external devices.

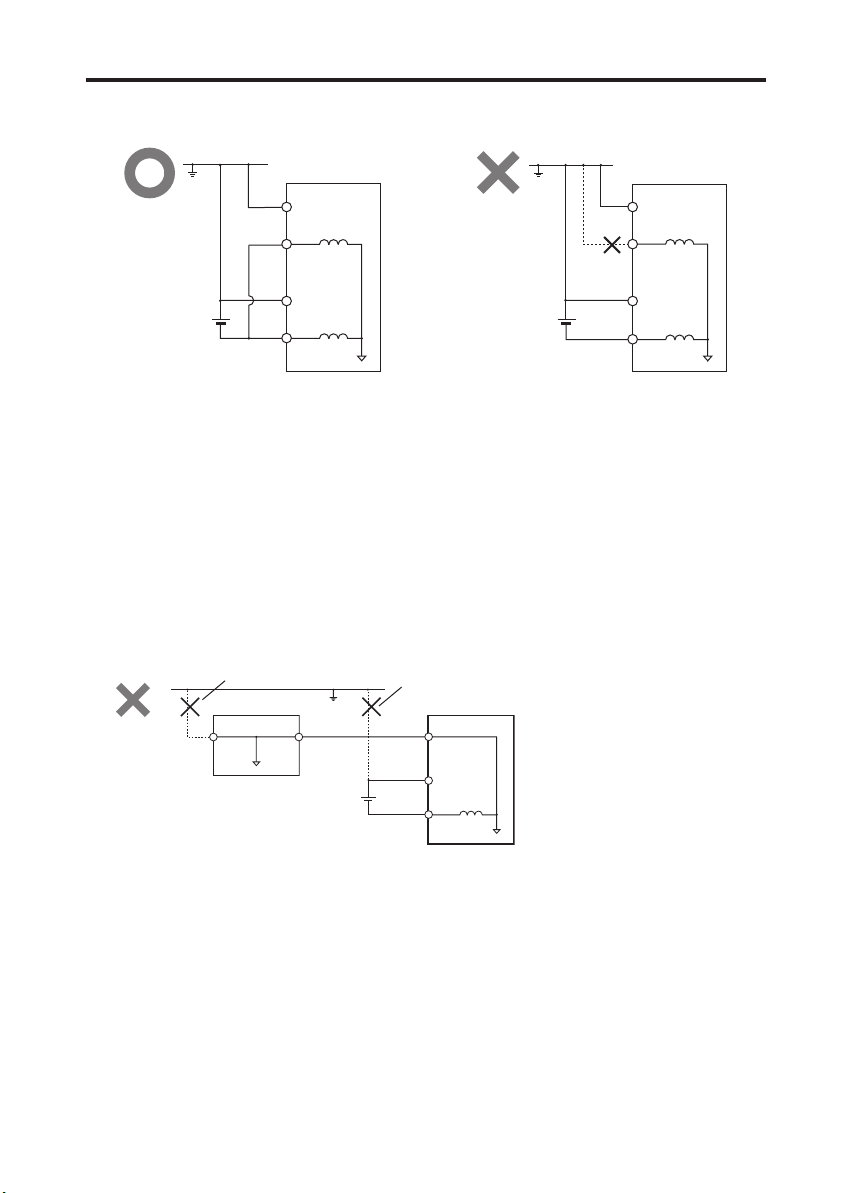

Examples of Wiring

LK-G3001V/LK-G3001(NPN type)

24 VDC (-), COM OUT (output COM), and COM IN (input COM) are all common via a

choke coil. Also, COM OUT and COM IN of the expansion connector are common via a

choke coil.

LK-G3001(V) LK-G3001(V)

DC24V

COM OUT

COM IN

DC24V(+)

DC24V(-)

COM OUT

COM IN

DC24V(+)

DC24V

DC24V(-)

The power supply (24 VDC) shorts via the

COM terminals, causing malfunctions.

4

LK-G-M-NO0-E

Page 7

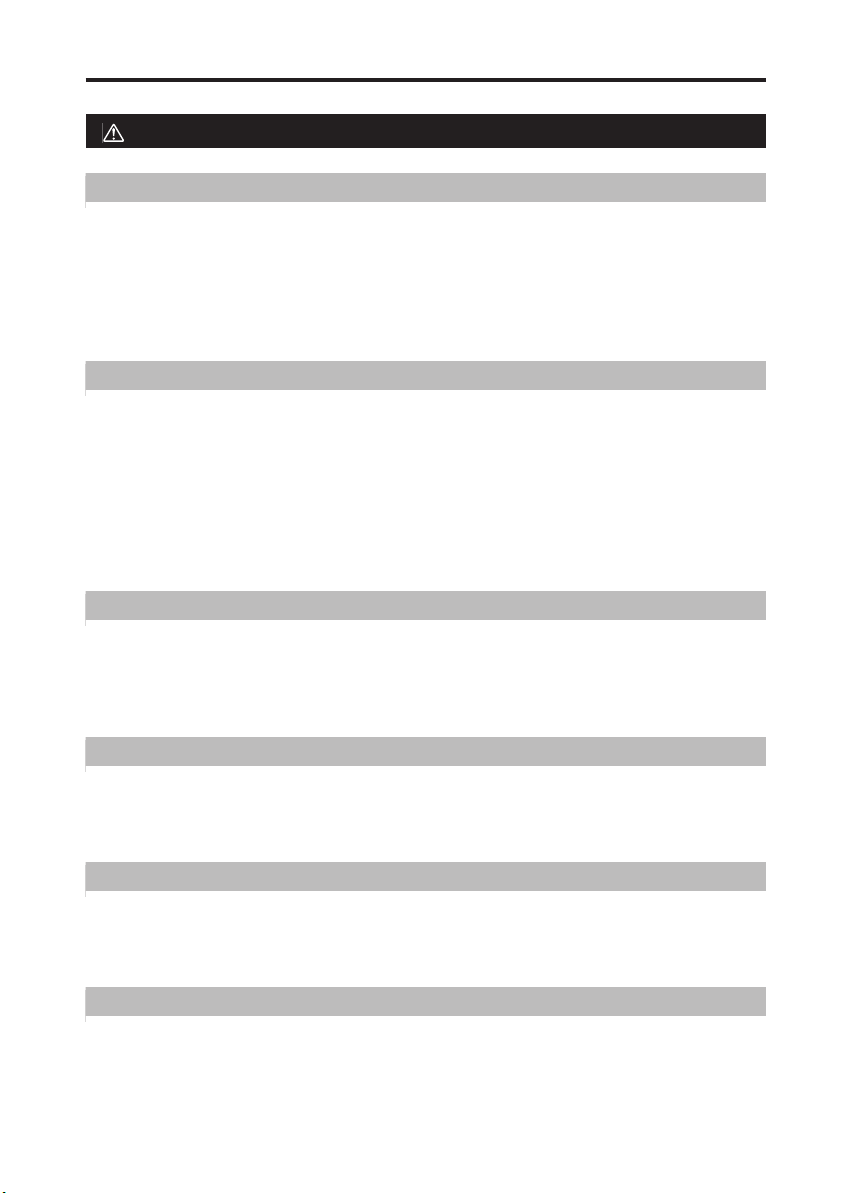

LK-G3001PV/LK-G3001P (PNP type)

24 VDC (-) and COM IN are common via a choke coil. Also, COM IN of the expansion

connector is common via a choke coil.

LK-G3001P(V)

COM OUT

LK-G3001P(V)

COM OUT

COM IN

DC24V(+)

DC24V(-)

DC24V

COM IN

DC24V(+)

DC24V

DC24V(-)

The power supply (24 VDC) shorts via the

COM terminals, causing malfunctions.

Common for all types

24 VDC (-), SG (GND) of USB, and SG (GND) of RS-232C are all common via a choke coil.

Make sure that a voltage potential difference does not occur with external devices such as

computers or PLC. If a voltage potential difference occurs, use the unit with insulation on

the LK-G power supply and the I/O terminals other than RS-232C and USB.

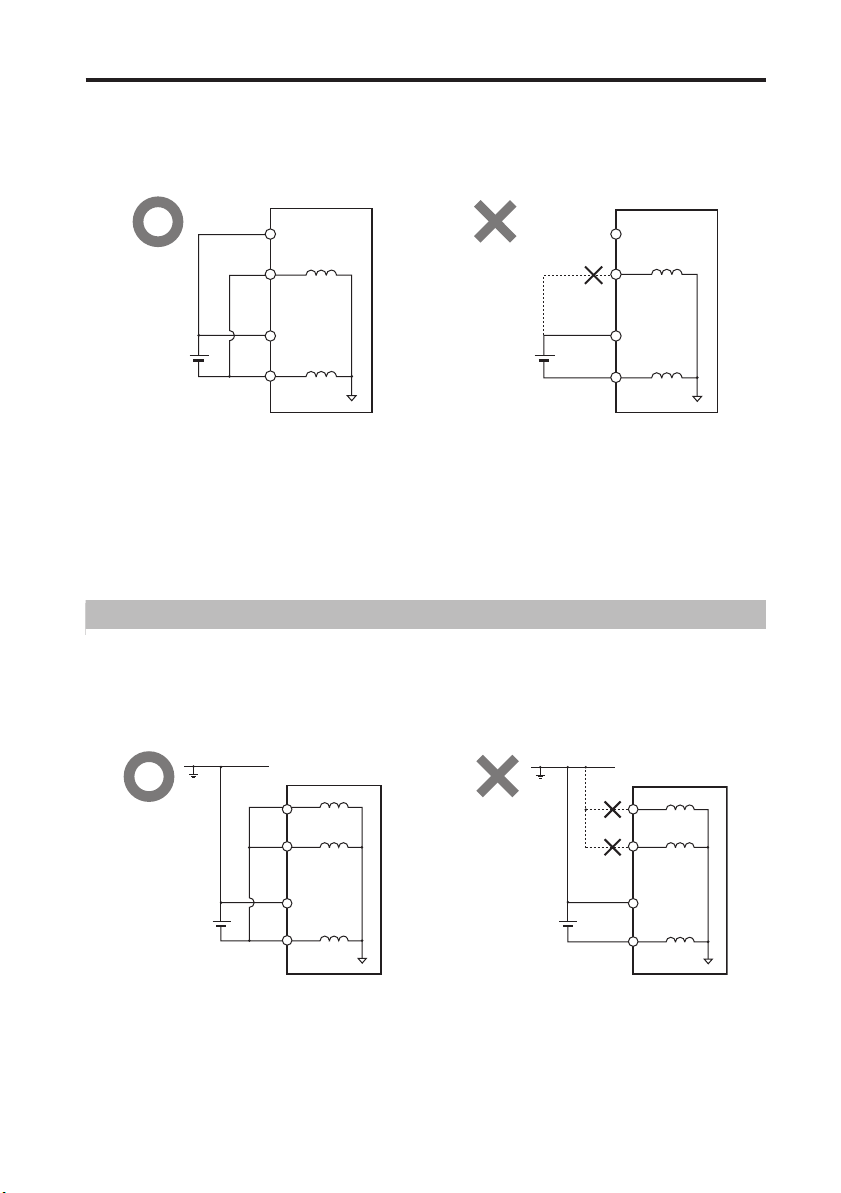

Precautions for a Positive Grounding Environment

When using a positive grounding environment, watch out for shorts through the COM

terminal.

LK-G3001V/LK-G3001 (NPN type)

GND

LK-G3001(V)

COM OUT

COM IN

GND

LK-G3001(V)

COM OUT

COM IN

DC24V

LK-G-M-NO0-E

DC24V(+)

DC24V(-)

DC24V(+)

DC24V

DC24V(-)

The power supply (24 VDC) shorts via the

COM terminals, causing malfunctions.

5

Page 8

LK-G3001PV/LK-G3001P (PNP type)

GND

LK-G3001P(V)

COM OUT

GND

LK-G3001P(V)

COM OUT

DC24V

COM IN

DC24V(+)

DC24V(

DC24V

-

)

COM IN

DC24V(+)

DC24V(

-

)

The power supply (24 VDC) shorts via the

COM terminals, causing malfunctions.

Precautions when connecting to computers or other external devices

When working in a positive grounding environment, when the LK-G is connected to a

computer through USB in order to use LK-Navigator or when establishing RS-232C

communication with a computer, take precautions to avoid shorts in between the SG

(GND) terminals for the computer and the LK-G.

24 VDC (-), SG (GND) of USB, and SG (GND) of RS-232C are all common via a choke coil.

Make sure that a voltage potential difference does not occur with external devices such as

computers or PLC. If a voltage potential difference occurs, use with insulation on the LK-G

power supply and the I/O terminals other than RS-232C and USB.

➀

Computer

GND

termin

al

RS-232C/

USB GND

GND

RS-232C/

USB cable

DC24V

➁

LK-G3001P(V)

RS-232/

USB GND

DC24V(

DC24V(+)

The power supply (24 VDC) shorts via

the SG (GND) terminals for LK-G and

the computer, causing malfunctions.

Insulate the computer (➀ in the figure)

and LK-G (➁ in the figure).

* The internal wiring in the computer,

PLC, or other device differs

depending on the device. For details,

refer to the instruction manual for each

-

)

device.

6

LK-G-M-NO0-E

Page 9

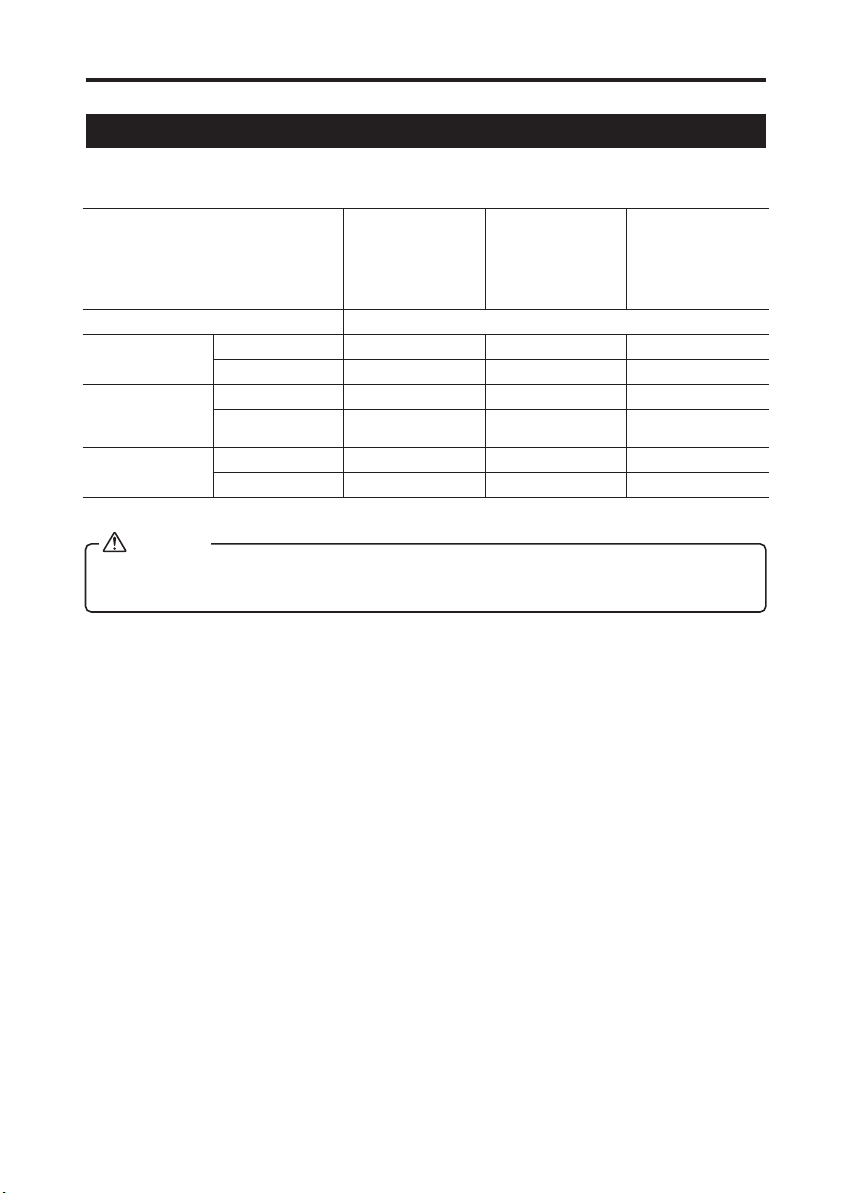

Safety Precautions on Laser Products

The models of the LK-G Series are classified in terms of laser class as follows:

Model LK-G35/LK-G30

Wavelength 650 nm

FDA (CDRH)

Part 1040.10

IEC60825-1:

1993 + A1:

1997 + A2: 2001

JIS C6802: 1997

Maximum output 4.8 mW 0.95 mW 0.3 mW

Class Class3a Class2 Class2

Maximum output 4.8 mW 0.95 mW 0.3 mW

Class

Maximum output 4.8 mW 0.95 mW 0.3 mW

Class Class 3A Class 2 Class 1

LK-G85/LK-G80

LK-G155/LK-G150

LK-G405/LK-G400

LK-G505/LK-G500

Class 3R Class 2

LK-G37/LK-G32

LK-G87/LK-G82

LK-G157/LK-G152

LK-G407/LK-G402

LK-G507/LK-G502

LK-G15/LK-G10

*

Class 1

*LK-G15/LK-G10 is a class 1 laser product according to IEC60825-1.

WARNING

Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

Cautions on class

3333a/3R/3A laser products

Observe the following instructions. Otherwise, injury to the human body (eyes and skin) may

result.

• Do not direct the laser beam at other persons.

• Never look at the laser beam through optical instruments such as a microscope,

magnifier or telescope.

• Make the laser path as short as possible and be sure to terminate the laser path with

a diffusion reflector or diffusion absorber so that the laser beam does not diffuse. (It

is recommended to install the protection enclosure.)

• Install the laser product so that the laser beam be located well above or below eye

level.

• Install the laser product carefully so that the laser beam is not unitentionally directed

at mirror- like surfaces.

• It is recommended to wear protective eye goggles.

• Do not disassemble the LK-G Series.

• Do not look directly at the laser beam.

LK-G-M-NO0-E

7

Page 10

Cautions on Class

Observe the following instructions. Otherwise, injury to the human body (eyes and skin)

may result.

• Do not direct the laser beam at other persons.

• Do not disassemble the LK-G Series.

• Do not stare at the laser beam.

Cautions on Class 1 laser products

• Do not look directly at the laser beam for an extended period of time.

• Do not disassemble the LK-G Series.

2222/ 2 laser products

8

LK-G-M-NO0-E

Page 11

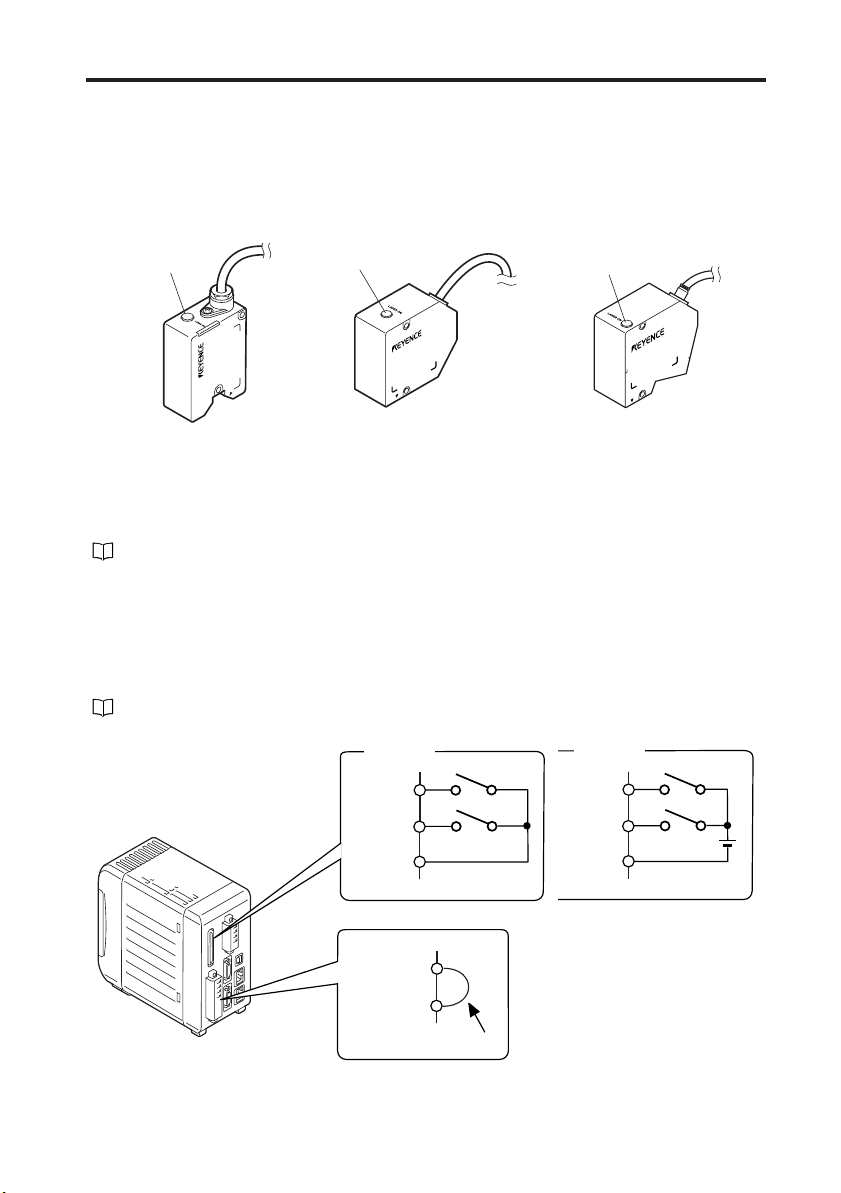

The LK-G Series is equipped with the following safety features based on IEC60825-1 and

L

CDRH Part 1040.10 (Safety of laser products).

■ Laser radiation emission warning indicator

Lights or flashes while the LK-G Series is in operation.

Laser emission

warning indicator

aser emission

warning indicator

Laser emission

warning indicator

■ Laser remote interlock connector

The laser beam stops radiation emission upon opening the circuit between the REMOTE

terminal and the COM IN terminal.

Refer to "12-pin I/O terminal block" (page 4-2) for connecting terminals.

■ Beam stop or attenuator

The laser beam stops radiation emission by the following operations :

• NPN type: Short-circuiting between the LASER OFF terminal and COM IN terminal.

• PNP type: Apply the voltage between the LASER OFF terminal and COM IN terminal.

Refer to "Expansion Connector" (page 4-5) for connecting terminals.

LK-G-M-NO0-E

NPN type

LASER

OFF A

LASER

OFF B

COM IN

REMOTE

COM IN

Short-circuiting wire

PNP type

LASER

OFF A

LASER

OFF B

COM IN

* The laser remote interlock

connector is delivered with the

wire for short-circuiting

installed.

9

Page 12

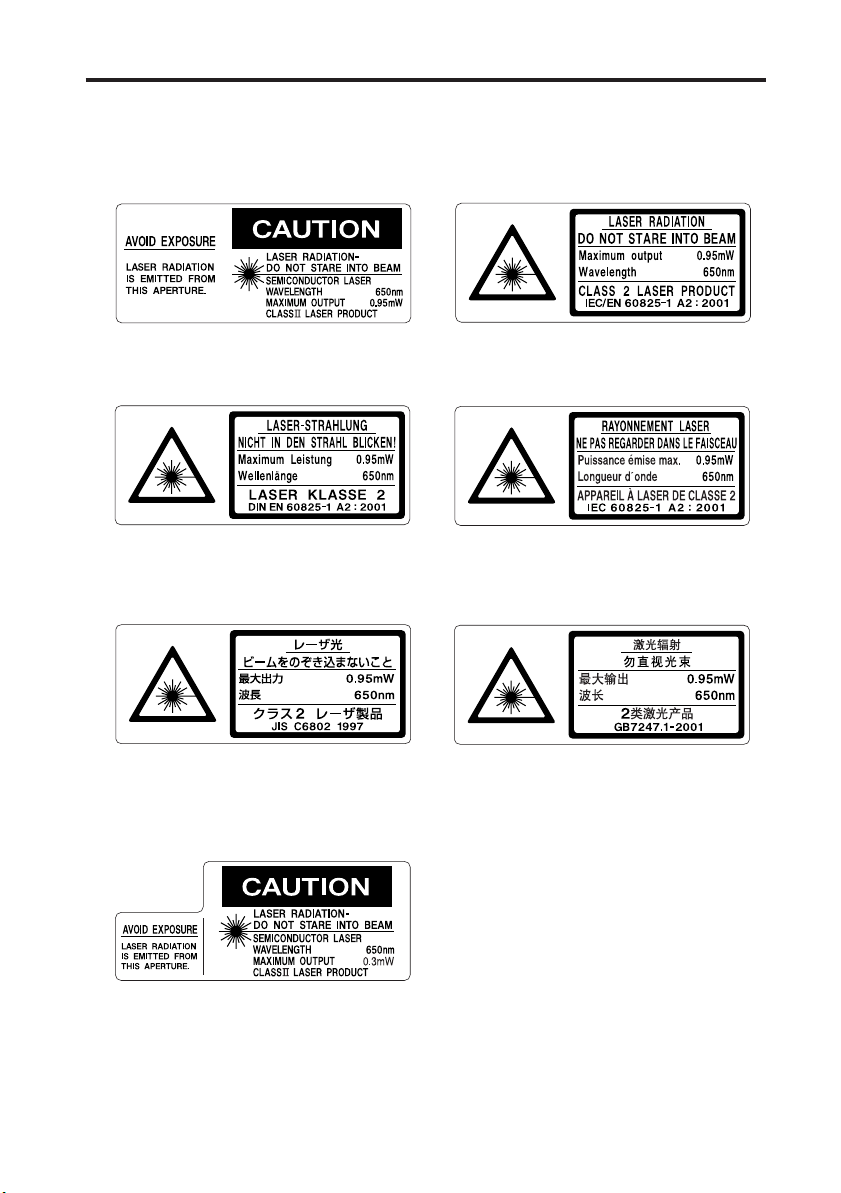

■ Warning labels

The contents of warning indications and locations for attaching warning labels are

described below.

The FDA (CDRH) warning labels are attached to the unit when shipped from the factory.

Labels other than the FDA (CDRH) label are supplied with the unit. Attach the other label(s)

to the locations as shown in the figure on page 9 according to the destinations of the

product.

Warning label are not supplied with LK-G15/LK-G10, because these models are IEC class

1 and JIS class 1 products.

■ Label contents

● LK-G35/LK-G30/LK-G85/LK-G80/LK-G155/LK-G150/LK-G405/LK-G400/LK-

G505/LK-G500

FDA (CDRH) IEC (English)

IEC (German) IEC (French)

JIS (Japanese) GB (Simplified Chinese)

10

LK-G-M-NO0-E

Page 13

● LK-G37/LK-G32/LK-G87/LK-G82/LK-G157/LK-G152/LK-G407/LK-G402/LK-

G507/LK-G502

FDA (CDRH) IEC (English)

IEC (German) IEC (French)

JIS (Japanese) GB (Simplified Chinese)

● LK-G15/LK-G10

FDA (CDRH)

LK-G-M-NO0-E

11

Page 14

■ Label attachment locations

● LK-G35/LK-G30/LK-G37/LK-G32

LK-G85/LK-G80/LK-G87/LK-G82

● LK-G155/LK-G150/LK-G157/LK-G152

LK-G405/LK-G400/LK-G407/LK-G402

LK-G505/LK-G500/LK-G507/LK-G502

● LK-G15/LK-G10

12

AVOID EXPOSURE

LASER RADIATION

IS EMITTED FROM

THIS APERTURE.

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

SEMICONDUCTOR LASER

WAVELENGTH

MAXIMUM OUTPUT

CLASS LASER PRODUCT

-

650nm

0.3mW

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

SEMICONDUCTOR LASER

WAVELENGTH

MAXIMUM OUTPUT

CLASS LASER PRODUCT

-

AVOID EXPOSURE

LASER RADIATION

650nm

IS EMITTED FROM

0.3mW

THIS APERTURE.

LK-G-M-NO0-E

Page 15

Organization of this Manual

Chapter

Before Use

1

Chapter

Operations and Functions

during Measurement

2

Chapter

Function Settings

3

Chapter

Input/Output

Terminals

4

Chapter

RS-232C

5

Chapter

Specifications

6

Describes cautions and preparations before use.

Describes the operations that can be performed during displacement measurement and their functions.

Describes the functions and setting procedures of the

Head settings, Output settings, Common settings, and

Environment settings.

Describes the specifications of the input/output

terminals and timing chart.

Describes the functions of the RS-232C interface

and the setting procedures.

Describes the specifications of the controller and the

head, outside dimensions, and characteristics.

1

2

3

4

5

6

Appendices

Appendices

Describes the troubleshooting methods, contents of

error messages and optional products.

LK-G-M-NO0-E

13

Page 16

14

LK-G-M-NO0-E

Page 17

Table of Contents

Safety Precautions .................................. 1

General Cautions............................... 1

WARNING ..................................... 1

CAUTION ...................................... 2

Notes.................................................. 3

Precautions on CE Marking ............... 3

Precautions for Wiring................... 4

Safety Precautions on Laser Products

Organization of this Manual .................. 13

Table of Contents .................................. 14

Chapter 1 Before Use

System Configuration ........................... 1-2

Checking the Package Contents ......... 1-3

LK-G3001V/LK-G3001PV

(Single Unit Type Controller)........... 1-3

LK-G3001/LK-G3001P

(Separate Type Controller) ............. 1-3

LK-GD500

(Separate Type Controller) ............. 1-4

Head (LK-G15/LK-G10).................. 1-4

Head (Model other than LK-G15/

LK-G10) .......................................... 1-4

LK-GC2/GC5/GC10/GC20/GC30 ... 1-5

Identifying Part Names and Functions

Controller ........................................ 1-6

Head ............................................... 1-8

Installing and Connecting the Heads and

Optional Parts ...................................... 1-9

Installing the Head.......................... 1-9

Attaching the ND Filter (Option) ... 1-15

Installations Depending on the

Measurement Target..................... 1-16

Installing the Controller................. 1-17

Connection.................................... 1-22

Outline of Measurement and Settings 1-24

Switching Modes .......................... 1-24

..... 7

.... 1-6

Setting Mode................................. 1-25

Returning the LK-Series to the Factory

Default Settings .................................. 1-26

Chapter 2

Operations and Functions

during Measurement

Switching the Measurement

Value Displays .....................................2-2

Setting the Tolerance

Comparator Value ................................ 2-3

The Function of the

Tolerance Settings .......................... 2-3

Hysteresis .......................................2-5

Setting the Display Value Instantaneously

to Zero (Auto-Zero) ..............................2-6

Program Function ................................ 2-8

Switching Program Nos. ......................2-9

Performing Statistical Computation

with the Measurement Value .............. 2-10

Chapter 3 Function Settings

Measurement, Data Flow and

Functions ............................................. 3-2

Setting the Head .................................. 3-3

List of Functions and Function Nos

List of Default Values and Setting

Ranges............................................ 3-3

List of the Head Setting Screens ....3-4

Setting ABLE................................... 3-5

Setting the Measurement Mode

According to the Measuring

Target.............................................. 3-7

Specifying the Process When

Measurement is Not Possible

(Alarm Process) ..............................3-8

Automatically Teaching the Adjustment Range

of ABLE According to the Target

Setting the Mounting Mode........... 3-12

Setting the Conditions of the Measurement

Value Output ...................................... 3-13

.... 3-3

.......... 3-10

14

LK-G-M-NO0-E

Page 18

List of Functions and Function Nos

List of Default Values and Setting

Ranges ..........................................3-15

List of the OUT Setting Screens ....3-16

Calculating Between the Heads....3-18

Setting the Scaling for Measurement

(Calibration)...................................3-20

Stabilizing the Measurement by

Filtering..........................................3-22

Using the Hold Function

(Measurement Mode)....................3-25

Setting the Trigger Condition ........3-31

Measuring with Offset....................3-32

Setting the Unit and the Minimum

Display Unit ...................................3-33

Scaling the Analog Output ............3-34

Outputting the Analog Output Without

Holding..........................................3-36

Setting the Common Function ............3-37

List of Functions and Function Nos

List of Default Values and Setting

Ranges ..........................................3-37

List of the Common Function Setting

Screens .........................................3-38

Setting the Sampling Rate of

Measurement Value.......................3-39

Setting the Mutual Interference

Prevention Function.......................3-40

Setting the External Timing Input ..3-41

Setting the Output Form of the

Tolerance Comparator ..................3-42

Setting the Strobe Output Time .....3-43

Accumulating the Measurement Value in the

Memory (Data Storage Function)

Setting the Operations of the Equipment

(Environment Settings) .......................3-46

List of Functions and Function Nos

List of Default Values and Setting

Ranges ..........................................3-47

List of the Environment Setting Screens

.......................................................3-48

..3-13

.....3-37

.......3-44

.....3-46

Setting the Communication

Specifications of the RS-232C...... 3-49

Setting the Program Switching Method

...................................................... 3-50

Copying/Initializing the Program .. 3-51

Preventing Erroneous Operation on the

Panel (Panel Lock) ....................... 3-53

Reducing the Power Consumption

(Eco Mode)................................... 3-54

Chapter 4 Input/Output Terminals

Identifying Names and Functions of the

Input/Output Terminals ........................ 4-2

Functions of the Input/

Output Terminals ............................ 4-2

Functions of the Input and Output

Signals............................................ 4-7

Timing Chart ...................................... 4-13

Chapter 5 RS-232C

Specifications ...................................... 5-2

Pin Layout....................................... 5-2

Communication Specifications....... 5-2

Communication Performance and

Communication Mode in the

Measurement State ........................ 5-3

Overview of the Settings According to

External Devices............................. 5-3

Outputting Measurement Values and

Changing Settings through Commands

Connecting the PC or PLC Link Unit5-4

Mode Change Command............... 5-7

Measurement Control Command

Format ............................................ 5-8

Change Parameter Command ..... 5-13

Check Parameter Command Format

Timing Chart ................................. 5-21

Outputting Measurement Values in External

Synchronization ................................. 5-22

Environment Settings Parameters

.... 5-4

.. 5-20

... 5-22

LK-G-M-NO0-E

15

Page 19

Output........................................... 5-22

Timing Chart ................................. 5-23

Output Format............................... 5-24

ASCII Code Table (Reference) ..... 5-24

Chapter 6

Specifications of the LK-G

Series

Specifications ...................................... 6-2

Specifications of the Controller....... 6-2

Specifications of the Head.............. 6-4

Specifications of the Head-to-Controller

Cable ............................................ 6-15

Status Table.................................. 6-15

Response Delay Time................... 6-17

Outside Dimensions...................... 6-17

Characteristics ................................... 6-25

Spot Dimension............................. 6-25

Mutual Interference....................... 6-27

Appendices

Troubleshooting....................................A-2

Error Messages.....................................A-5

List of Optional Products ......................A-6

Index.....................................................A-8

16

LK-G-M-NO0-E

Page 20

17

LK-G-M-NO0-E

Page 21

Before Use1

Before Use1

This chapter describes the configuration of the LK-G Series, cautions

and required preparation before use. Be sure to read this section thoroughly before using the LK-G Series.

System Configuration ............................................................1-2

Checking the Package Contents ...........................................1-3

Identifying Part Names and Functions ..................................1-6

Installing and Connecting the Heads and Optional Parts......1-9

Outline of Measurement and Settings .................................1-24

Returning the LK-Series to the Factory Default Settings.....1-26

1

LK-G-M-NO1-E

1-1

Page 22

1 Before Use

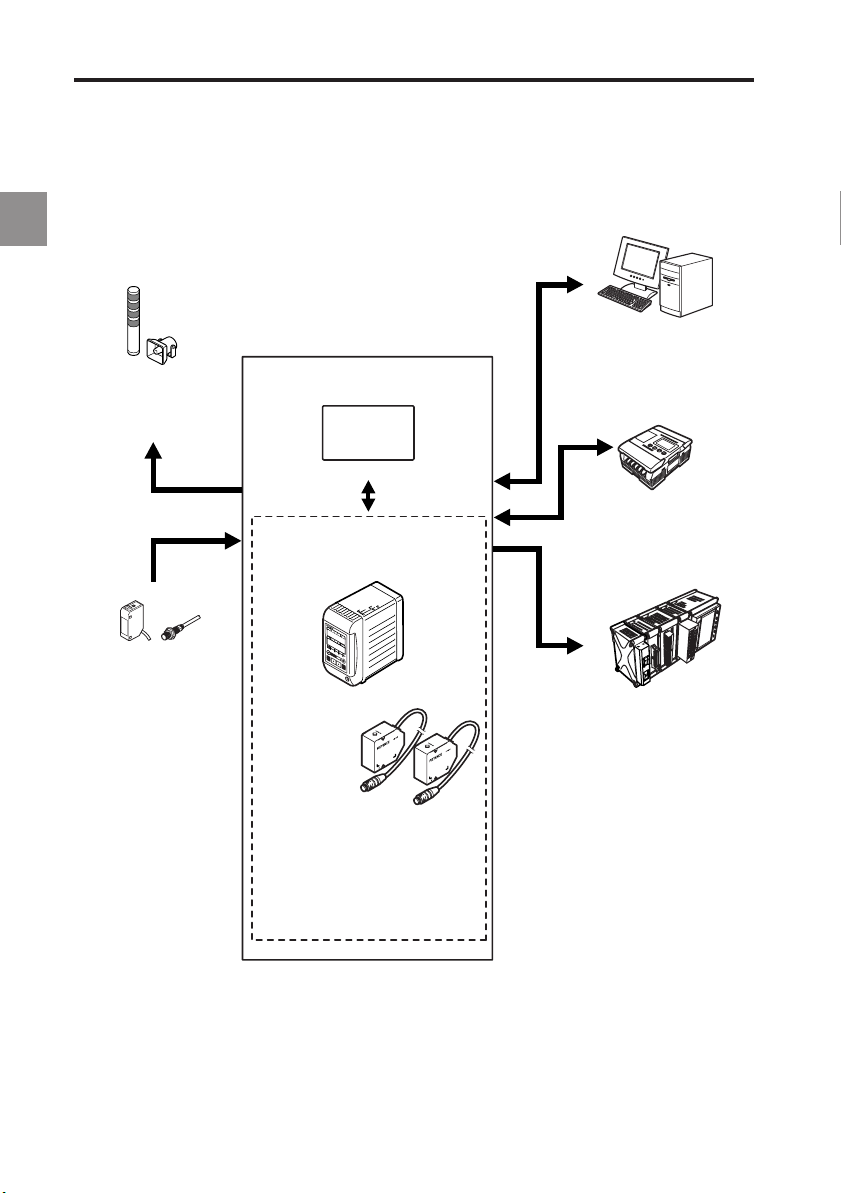

System Configuration

The LK-G Series can be used for various purposes in combination with commercially available

devices.

1

Indicator light/Buzzer

Issues an alarm depending on

the comparator result output.

Photoelectric/Proximity sensor

Transmits a signal to the

TIMING input when the target

is detected.

LK-G Series

LK Navigator

Setup support software (LK-H1W) *2

USB/RS-232C

*1

Controller

LK-G3001V/LK-G3001PV

LK-G3001/LK-G3001P

Head (two heads max.)

LK-G15/LK-G10

LK-G35/LK-G30

LK-G85/LK-G80

LK-G155/LK-G150

LK-G405/LK-G400

LK-G505/LK-G500

PC

Enables control and acquisition

of the measurement value from

the RS-232C or the parallel I/O

board.

Programmable controller

Enables timing control of the

measurement and the switching

of program No. as well as the

control output and the

measurement value acquisition.

Recorder

Records the measurement result.

*1: The controller (LK-G3001V/LK-G3001PV) can be separated into the display panel and the controller main

unit. You can also purchase them separately.

*2: For the details of the setup support software (LK-H1W) "LK-Navigator", refer to "LK-Navigator User’s

Manual" (The PDF file stored in the CD-ROM).

1-2

LK-G-M-NO1-E

Page 23

1 Before Use

Checking the Package Contents

The LK-G Series consists of the following models. Check if the parts and equipment listed

below are included in the package of the model you purchased before using the unit.

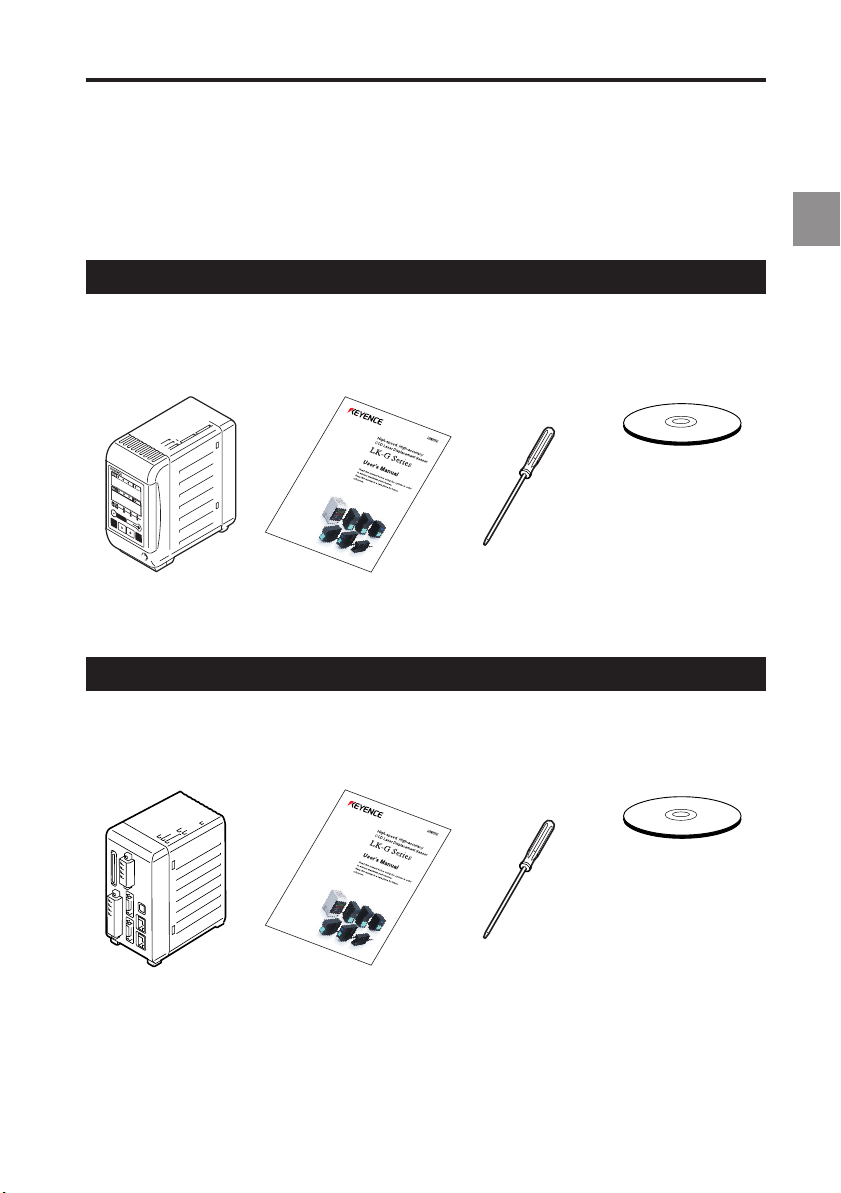

LK-G3001V/LK-G3001PV (Single Unit Type Controller)

1

Controller User’s Manual Screwdriver

LK-G3001V/ (this manual): 1 : 1

LK-G3001PV: 1

LK-G3001/LK-G3001P (Separate Type Controller)

Controller User’s Manual Screwdriver

LK-G3001/ (this manual): 1

LK-G3001P/: 1

Packed separately

LK-H1W (

• Setup support

• Setup support

USB cable (3m)

Packed separately

LK-H1W (

• Setup support

• Setup support

USB cable (3m)

CD-ROM)

software

"LK-Navigator"

software

User’s Manual

(PDF file)

CD-ROM)

software

"LK-Navigator"

software

User’s Manual

(PDF file)

LK-G-M-NO1-E

1-3

Page 24

1

1 Before Use

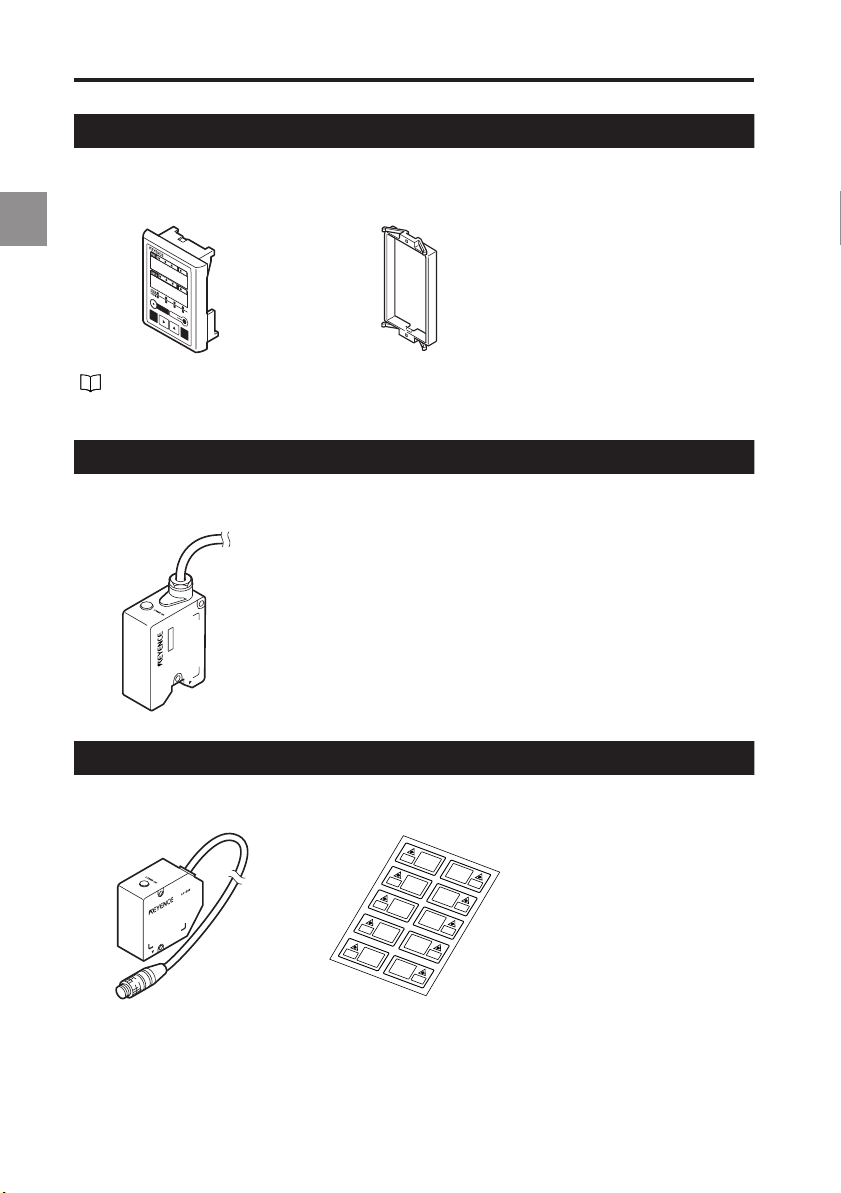

LK-GD500 (Separate Type Controller)

Display panel Panel attachment ring

LK-GD500: 1 : 1

The communication cable between the controller and the separate type display panel is

sold separately. Refer to page A-6 for details.

Head (LK-G15/LK-G10)

Head: 1

LK-G10

Head (Model other than LK-G15/LK-G10)

Head: 1 Laser sticker sheet: 1

1-4

LK-G-M-NO1-E

Page 25

1 Before Use

LK-GC2/GC5/GC10/GC20/GC30

Head-to-controller cable: 1

LK-GC2 : 2-m cable

LK-GC5 : 5-m cable

LK-GC10 : 10-m cable

LK-GC20 : 20-m cable

LK-GC30 : 30-m cable

* We have thoroughly inspected the package contents before shipment. However, in the

event of defective or broken items, contact your nearest KEYENCE office (address

listed in the end of this manual).

For the optional products,refer to "List of Optional Products"(page A-6).

1

LK-G-M-NO1-E

1-5

Page 26

1 Before Use

Identifying Part Names and Functions

This section describes the name and function of each part.

1

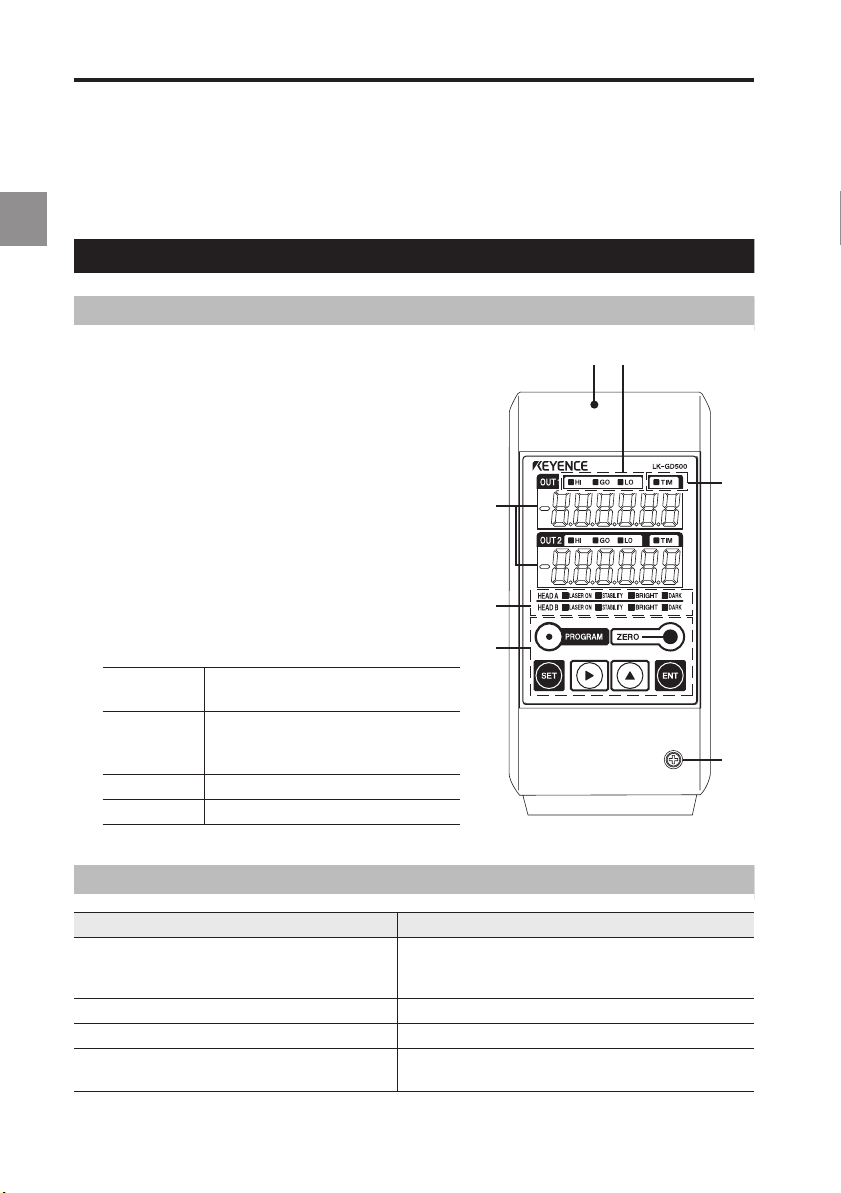

Controller

Display panel

1 Display panel fixing case

14

2 Display panel fixing screw

3 Measurement value indicators

Display the measurement value, tolerance

comparator value, and various statistical results.

The setting items are displayed during setting.

Green: Within the tolerance Red: Outside the tolerance

4 Comparator output indicator

3

5

Lights during the comparator output (HI, GO, or LO).

5 Timing input indicator

Lights when the timing signal is being input.

6 Head status display indicator

Displays the laser emission status and the

measurement status.

LASER ON Laser emission LED. Lights while

STABILITY

BRIGHT

DARK

the LK-G Series is in operation.

Lights in green or orange within the

measurement range. Lights in red outside

the measurement range, alarm, or laser-off.

Lights at the exceeding light intensity alarm.

Lights at the light intensity shortage alarm.

6

7

2

7 Operation keys

Displays and descriptions of the measurement value indication

Display Description

Numerical value (±999999)

FFFFFF (HI output: ON. Monitor output: + 10.8 V) Displayed when the value exceeds the display range.

–FFFFFF (LO output: ON. Monitor output: –10.8 V)

- - - - - -

(HI, GO and LO outputs: OFF. Monitor output: –10.8 V)

Displays the measurement result in numerical value.

The display unit, decimal point position, and minimum

display unit vary depending on the settings.

Displayed when the value drops below the display range.

Displayed during the comparator standby state.

1-6

LK-G-M-NO1-E

Page 27

Operation keys

Key Function

1 Before Use

• During measurement it calls the Program switch mode.

• During measurement it calls the Tolerance setting mode.

• When pressed for one second, it calls the Operation setting mode.

• During setting it cancels the setting content and returns to the previous setting.

• During measurement it calls the Statistics display mode.

• During setting it determines the content.

• During measurement it sets the measurement value to zero.

• When pressed for three seconds it cancels auto-zero.

When pressed for three seconds while inputting the value, it initializes the selected item.

•

•

During setting it switches the display to the next setting item.

• While inputting the value it shifts one digit right.

• When pressed for one second or more it shifts in higher speed.

During measurement it changes the display for OUT1, OUT2 or both at the same time.

•

• During setting it switches the setting content.

• While inputting the value it switches symbols or sets numerical values.

• When pressed for one second or more it shifts in higher speed.

Terminal panel

1 RS-232C connector

Establishes communication with a PC or a PLC.

Refer to "Pin Layout" (page 5-2).

2 USB connector

Used when connecting the PC via USB.

Refer to "LK-Navigator User’s Manual" for details.

3 6-pin terminal block

Refer to "6-pin I/O terminal block" (page 4-4).

4 Expansion connector

Refer to "Expansion connector" (page 4-5).

5 Head connectors

6 Laser emission LED.

Lights while the LK-G series operates.

7 Display panel connector

Connects the communication cable between the display

panel and the controller.

8 12-pin terminal block

Refer to "12-pin I/O terminal block" (page 4-2).

1

3

6

4

8

5

2

1

7

LK-G-M-NO1-E

1-7

Page 28

1 Before Use

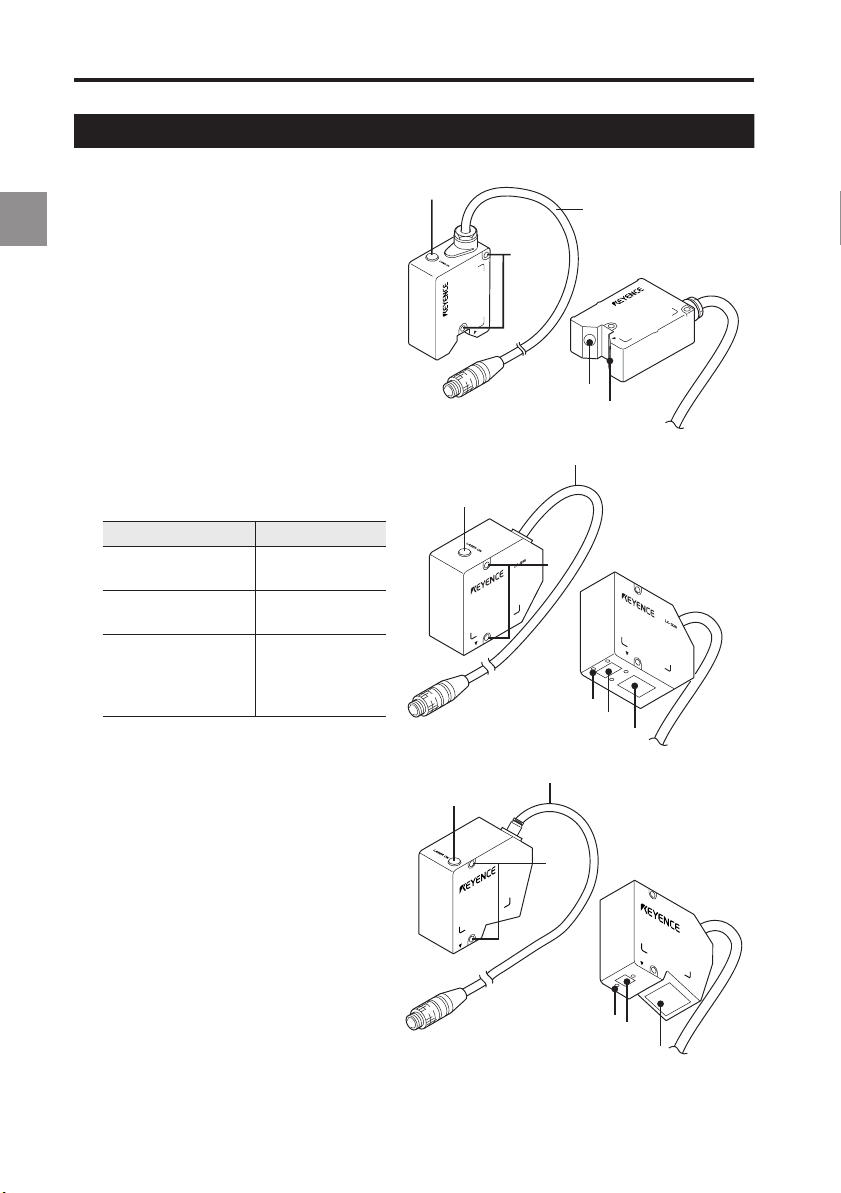

Head

1 Sensor (emitter)

Emits the laser beam for measurement. It

1

is protected with a glass cover.

2 Sensor (receiver)

Receives the laser beam for measurement. It is protected with a glass window.

3 Attachment holes for the ND filter

Used for attaching the ND filter (LK-F1/

LK-F2).

4 Installation holes

5 Connecting cable

Connected to the head-to-controller

cable.

6 Laser radiation emmission LED

Lights or flashes while the LK-G Series is

in operation.

Status LED

Center of the

measurement range

Within the

measurement range

Outside the

measurement range

Alarm

Laser off

Lights in green

Lights in orange

Flashes in

orange

6

4

6

5

2

1

5

4

3

1

2

1-8

5

6

4

3

1

2

LK-G-M-NO1-E

Page 29

1 Before Use

Installing and Connecting the Heads and Optional Parts

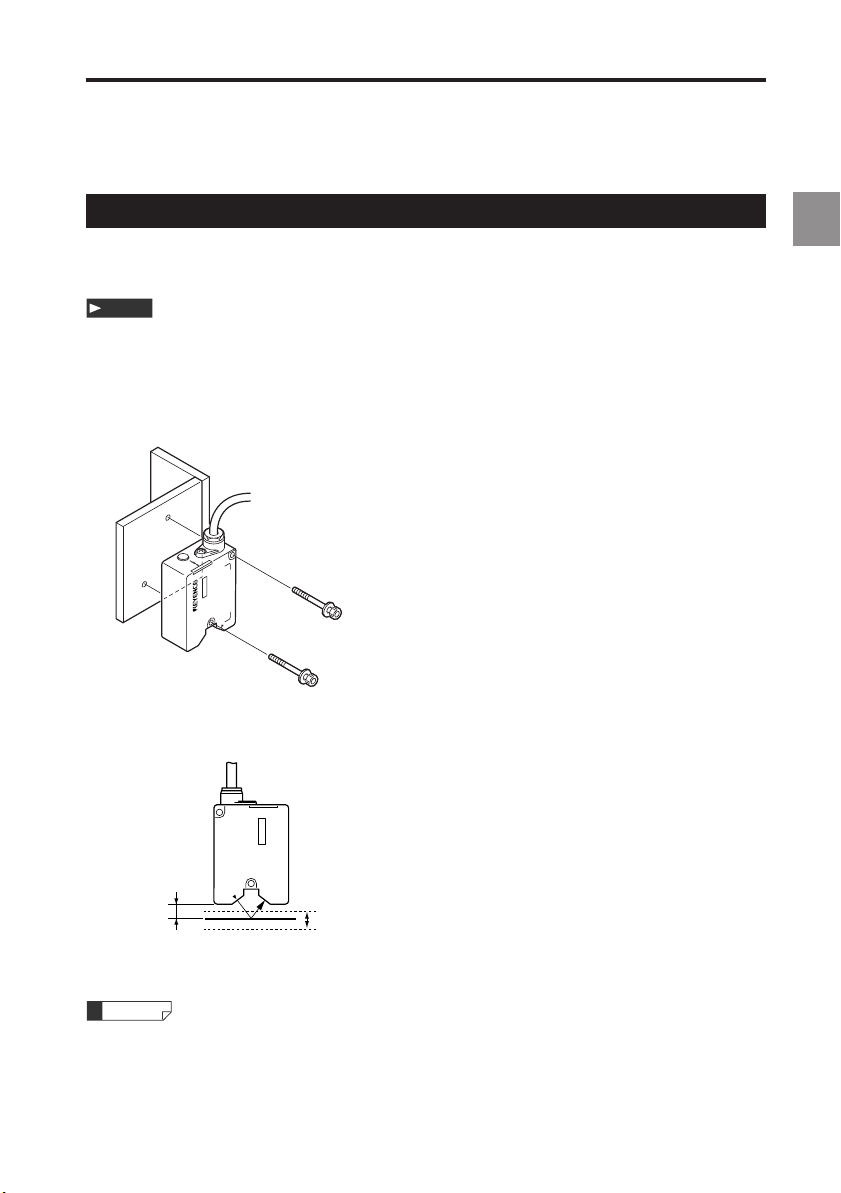

Installing the Head

Adjust the distance between the head and the measuring target, and fix the head with the

screws at the two installation holes.

Note

Insulated mounting is recommended when using the head under the positive grounding

environment.

■ LK-G15/LK-G10

• Installation procedure

LK-G10

M4r35 mm or more

The measurement range is shown in the figure below.

1

LK-G10

Reference

distance

10 mm

Reference

distance

0 mm

+1mm

Measurement range

–1 mm

(–0.37mm)

* The value inside the parentheses ( ) is when the sampling rate is 20 µs.

Reference

The laser emission LED at both diffuse reflection and specular reflection lights in green

within ±0.05 mm of the reference position, and lights in orange in the other positions in the

measurement range.

LK-G-M-NO1-E

1-9

Page 30

1 Before Use

■ LK-G35/LK-G30/LK-G37/LK-G32

• Installation procedure

1

M4r35 mm or more

The measurement range is shown in the figure below.

• Diffuse reflection setup • Specular reflection setup

Reference

distance

30 mm

Reference

distance

0 mm

+5mm

Measurement range

–5 mm

(–1.8 mm)

Reference

distance

23.5 mm

Reference

distance

0 mm

40°

+4.5mm

Measurement range

–4.5mm

(–1.6 mm)

* The value inside the parentheses ( ) is when the sampling rate is 20 µs.

Reference

• The laser emission LED at both diffuse reflection and specular reflection lights in

green within ±0.25 mm of the reference position, and lights in orange in the other

positions in the measurement range.

1-10

LK-G-M-NO1-E

Page 31

■ LK-G85/LK-G80/LK-G87/LK-G82

• Installation procedure

LK-G85

M4r45 mm or more

The measurement range is shown in the figure below.

• Diffuse reflection setup • Specular reflection setup

1 Before Use

1

Reference

distance

80 mm

Reference

distance

0 mm

LK-G85

+15mm

Measurement range

–15 mm

(+9mm)

Reference

distance

75.2 mm

Reference

distance

0 mm

17°

LK-G85

+14mm

Measurement range

–14mm

(+8.7mm)

* The value inside the parentheses ( ) is when the sampling rate is 20 µs. Note that the

measurement range narrows, disabling measurements at the reference position.

Reference

• The laser emission LED at both diffuse reflection and specular reflection lights in

green within ±0.75 mm of the reference position, and lights in orange in the other

positions in the measurement range.

• Select the mounting mode ( page 3-12) according to the installation conditions.

Note

The measurement range when measuring a mirror surface or a glass surface at the time of

specular reflection setup is between +14 (NEAR side) to –8.2 mm (FAR side). When the

sampling rate is 20 µs, the value becomes +14 (NEAR side) to +8.7 mm (NEAR side).

LK-G-M-NO1-E

1-11

Page 32

1 Before Use

■ LK-G155/LK-G150/LK-G157/LK-G152

• Installation procedure

1

LK-G150

M4r40 mm or more

The measurement range is shown in the figure below.

• Diffuse reflection setup • Specular reflection setup

Reference

distance

150 mm

Reference

distance

0 mm

LK-G150

+40mm

Measurement range

–40 mm

(+22mm)

Reference

distance

147.5 mm

Reference

distance

0 mm

17°

LK-G150

+39mm

Measurement range

–39mm

(+22mm)

* The value inside the parentheses ( ) is when the sampling rate is 20 µs. Note that the

measurement range narrows, disabling measurements at the reference position.

Reference

• The laser emission LED at both diffuse reflection and specular reflection lights in

green within ±2 mm of the reference position, and lights in orange in the other

positions in the measurement range.

• Select the mounting mode ( page 3-12) according to the installation conditions.

Note

The measurement range when measuring a mirror surface or a glass surface at the time of

specular reflection setup is between +39 (NEAR side) to –24 mm (FAR side). When the

sampling rate is 20 µs, the value becomes +39 (NEAR side) to +22 mm (NEAR side).

1-12

LK-G-M-NO1-E

Page 33

■ LK-G405/LK-G400/LK-G407/LK-G402

• Installation procedure

LK-G405

M4r45 mm or more

The measurement range is shown in the figure below.

• Diffuse reflection setup • Specular reflection setup

1 Before Use

1

Reference

distance

400 mm

Reference

distance

0 mm

LK-G405

+100mm

Measurement range

–100mm

(+70mm)

Reference

distance

398 mm

Reference

distance

0 mm

17°

LK-G405

+99mm

Measurement range

–99mm

(+70mm)

* The value inside the parentheses ( ) is when the sampling rate is 20 µs. Note that the

measurement range narrows, disabling measurements at the reference position.

Reference

• The laser emission LED at both diffuse reflection and specular reflection lights in

green within ±5 mm of the reference position, and lights in orange in the other

positions in the measurement range.

• Select the mounting mode ( page 3-12) according to the installation conditions.

Note

When using LK-G405/G400/G407/G402, select function No. G-1 or G-0 (page 33).

The measurement range when measuring a mirror surface or a glass surface at the time of

specular reflection setup is between +72 (NEAR side) to –50 mm (FAR side). When the

sampling rate is 20 µs, the value becomes +72 (NEAR side) to +70 mm (NEAR side).

LK-G-M-NO1-E

1-13

Page 34

1 Before Use

■ LK-G505/LK-G500/LK-G507/LK-G502

• Installation procedure

1

LK-G505

M4r45 mm or more

The measurement range is shown in the figure below.

• Diffuse reflection setup • Specular reflection setup

Reference

distance

500 mm

Reference

distance

0 mm

LK-G505

+250mm

Measurement range

–500mm

(+125mm)

(+230mm)

*1

*2

Reference

distance

497.5 mm

Reference

distance

0 mm

17°

LK-G505

+249mm

Measurement range

–498mm

(+125mm)

(+230mm)

*1

*2

*1 The value inside the parentheses ( ) is when the sampling rate is 50 µs.

*2 The value inside the parentheses ( ) is when the sampling rate is 20 µs.

Note that the measurement range narrows in either case, disabling measurements at the

reference position.

Reference

• The laser emission LED at both diffuse reflection and specular reflection lights in

green within ±12.5 mm of the reference position, and lights in orange in the other

positions in the measurement range.

• Select the mounting mode ( page 3-12) according to the installation conditions.

Note

When using LK-G505/G500/G507/G502, select function No. G-1 or G-0 (page 33).

The measurement range when measuring a mirror surface or a glass surface at the time of

specular reflection setup is between +173 (NEAR side) to +49.5 mm (NEAR side). When the

sampling rate is 50 µs, the value becomes +173 (NEAR side) to +125 mm (NEAR side). Note

that the measurement is disabled when the sampling rate is 20 µs.

1-14

LK-G-M-NO1-E

Page 35

1 Before Use

Attaching the ND Filter (Option)

If the head is installed for specular reflection and and the measurement target is a shiny

mirror or glass surface, the measurement accuracy may deteriorate. In such a case,

attach the ND filter (LK-F1) to ensure accurate measurement.

• LK-G35/LK-G30/LK-G37/LK-G32

LK-G85/LK-G80/LK-G87/LK-G82

• LK-G155/LK-G150/LK-G157/LK-G152

LK-G405/LK-G400/LK-G407/LK-G402

LK-G505/LK-G500/LK-G507/LK-G502

1

ND filter

LK-F1

Mounting screw x 4

(M1.6 x 3 countersink-head screw)

ND filter

LK-F2

Mounting screw x 2

(M1.6 x 3 countersink-head screw)

LK-G-M-NO1-E

1-15

Page 36

1 Before Use

Installations Depending on the Measurement Target

Measuring distance

Use the head as close to the reference distance as possible. Doing so stabilizes

the detection.

1

Target shape

The installation of the head in the orientations indicated by the circle in the figures below is

recommended.

Near the wall surface

Height-difference measurement

LK-G35

(a) (b)

LK-G35

Displacement in a hole

LK-G35 LK-G35

1-16

LK-G-M-NO1-E

Page 37

Installing the Controller

Install the controller to the DIN rail, or fix it with screws.

1 Before Use

Caution on the orientation of the LK-G Series

Install the controller in the orientations shown in the following figures with a circle. Do not install

it upside down.

Be sure to leave 30 mm of clearance or more above the

controller, and 10 mm or more on each side.

In addition, for ensuring the safe connection of the cord,

30mm

leave 65 mm space or more in front of the terminal panel of

the controller.

mm

10

10

mm

When installing the controllers side-by-side, make sure

there is a clearance of 10 mm or more between the

controllers and 30 mm or more of clearance above them.

30mm 30mm

1

10

mm

10

mm

CAUTION

• Do not cover the ventilation holes on the top and bottom of the controller. The heat

may stay inside causing a malfunction.

• When the temperature in the controller panel rises to over 50 °C, decrease the

ambient temperature below 50 °C by introducing forced cooling air or by securing

more room around the system.

LK-G-M-NO1-E

10

mm

1-17

Page 38

1 Before Use

Installing the LK-G3001V/LK-G3001PVLK-G3001PV (single unit type controller)

Install it on its bottom.

1

Installing the LK-G3001/LK-G3001P and LK-GD500 (separate type controller)

M4 screw x 4 (screw depth 6 mm)

Display panel (LK-GD500)

Display panel

Panel attachment

ring

Control panel

Insert the display panel

from the front, and fix it with

the panel attachment ring.

When removing the display

panel, while pushing up the two

cutouts of the attachment ring

with a flat-head screwdriver

and push out the display panel.

Controller (LK-G3001/LK-G3001P)

• Installing on a DIN rail • Installing on its bottom

Two cutouts

M4 screw x 4

(screw depth 6 mm)

1-18

LK-G-M-NO1-E

Page 39

Separating the single unit type controller

Disconnect the display panel cable from the display panel connector on the

1

controller’s terminal panel.

Remove the display panel cable from the guide on the bottom of the controller.

Loosen the display panel fixing screw.

2

Reference

The display panel fixing screw does not drop from the display panel fixing case.

Remove the display panel fixing case from the controller.

3

(1)

Remove the

display panel

fixing case in

the directions

of the arrows.

(2)

1 Before Use

1

While pushing (1) and (2) outward in this order, push the display panel to

4

remove the panel attachment ring.

Panel attachment ring

(1)

(2)

Remove the display panel from the display panel fixing case.

5

LK-G-M-NO1-E

Panel attachment

ring

(3)

1-19

Page 40

1

1 Before Use

Combining the separate type controller

Install the display panel by aligning it with the two protrusions on the display

1

panel fixing case.

Display Panel

Two protrusions

Display panel fixing case (optional)

Fix the display panel with the panel attachment ring, and connect the 30-cm display

2

cable (optional).

Panel attachment ring

Two claws

Fix the cable by fitting it along the guide.

Align the three claws of the display panel fixing case with the controller.

3

Display panel fixing case

Three claws

Controller

1-20

LK-G-M-NO1-E

Page 41

1 Before Use

Install the display panel fixing case along the groove on the controller.

4

Slide the front panel

in the direction of the arrow.

CAUTION

Be sure to check the orientation of the claws on the connector side before installation.

Otherwise, the claws break and cause malfunction.

Fix the display panel fixing case by tightening the display panel fixing screw.

5

Route the display panel cable along the guide, and connect it to the display

6

panel connector on the rear of the controller.

1

LK-G-M-NO1-E

1-21

Page 42

1

1 Before Use

Connection

CAUTION

• Be sure to turn off the power of the controller before connecting/disconnecting

cables. Failure to do so may cause malfunction.

• Ensure that the orientation of the connector is correct. Otherwise the pin could break

and may lead to system malfunction.

• Part of each input/output circuit of the LK-G Series is internally common. Be sure that

no potential difference is generated between the common terminals due to the

potential difference between wires or external devices.

Refer to "Precautions for Wiring" (page 4) for details.

Display Panel

Display panel cable

(30 cm/3 m/10 m)

(in the case of the separate type controllers)

Head-to-controller cable

(2 m/5 m/10 m/20 m/30 m)

24 VDC power supply

Head B

Head A

■ Connecting the head

Connect the connector of the head-to-controller cable to the head connector A or B on the

controller’s terminal panel. Check that a click sound is heard indicating that they are

securely fixed. When removing it, pull it out while pressing the buttons on both sides of the

connector. Up to two heads can be connected at the same time.

1-22

LK-G-M-NO1-E

Page 43

1 Before Use

■ Connecting the display panel

In the case of the separate type controller, the display panel cable is used for connecting the

controller to the display panel.

Reference

The LK-G series can be operated without the display panel. In addition, the operation from

a PC is possible by using the "LK-Navigator" software.

■ Connecting the power

Connect the 24V DC power to the terminals 1 and 2 of the 12-pin terminal block.

Reference

KEYENCE CA-U3 is recommended for the 24V DC power supply.

■ Connecting the terminal block

The steps to connect the wires to the terminal block are as follows:

Remove the terminal block from the controller.

1

Loosen the two screws with a screwdriver and pull it out.

Loosen the screws on the terminal with a screwdriver, and insert the lead wires

2

into the terminal block.

Approximately 6.5mm of the insulation should be striped from both wires.

Tighten the lead wires with the screwdriver.

3

After tightening them, pull the lead wires lightly to confirm that they are securely

fixed.

1

Install the terminal block to the controller.

4

LK-G-M-NO1-E

1-23

Page 44

1 Before Use

Outline of Measurement and Settings

1

Switching Modes

The LK-G has the following modes :

* Program switch mode : Switches between stored programs

* Tolerance setting mode : Sets “Hi” and “Lo” limits

* Setting mode : Used for setup of various functions and settings

* Measurement mode : Performs measurement

Press the [SET] key for one second.

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

Setting mode

HI GO LO

OUT1

HI GO LO

OUT2

Sets the functions such as the head

and the measurement process.

Chapter 3 "Function Settings"

(page 3-1)

Press the [SET] key.Press the [PROGRAM] key.

Tolerance setting modeProgram switch mode

HI GO LO

OUT1

HI GO LO

OUT2

TIM

TIM

TIM

TIM

1-24

The parameters can easily be changed if

necessary when calling up the program.

Chapter 2 "Operations and Functions during

Measurement" -"Program Function" (page 2-8)

The upper limit, lower limit, or

hysteresis can be set in the

Tolerance setting mode.

LK-G-M-NO1-E

Page 45

1 Before Use

Setting Mode

In the Setting mode, every time the key is pressed, the setting content advances in this

order : Head Setting

→

OUT Settings → Common Settings → Environment Settings.

PROG.0 to 7

Head Settings

OUT1

OUT2

HI GO LO

HI GO LO

TIM

key

TIM

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

1

OUT1

OUT2

key

HI GO LO

HI GO LO

TIM

TIM

key

Environment Settings

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

OUT Settings

HI GO LO

OUT1

HI GO LO

OUT2

TIM

key

TIM

key

Common Settings

HI GO LO

key

OUT1

OUT2

HI GO LO

PROG.0 to 7

Eight programs can be switched among Program Nos. 0 to 7 in the LK-G Series. You can register a set of

parameters as a program according to the measurement process or the measuring target. The set parameters

can easily be changed, if necessary, when calling up the desired program.

Head setting : The functions regarding sensing for stable detection can be set.

Setting contents : ABLE, Measurement mode, ALARM warning, ABLE calibration

Refer to "Setting the Head" (page 3-3).

OUT settings: The functions regarding data processing can be set.

Setting contents : Calculation method, Scaling, Filter, Measurement mode, Trigger, Offset, Minimum

display unit, Analog scaling, Analog through

Refer to "Setting the Conditions of Measurement Value Output" (page 3-13).

Common settings :

Setting contents : Sampling rate, Mutual interference prevention, Timing synchronization, Comparator

The common functions regarding the head setting and the OUT setting can be set

output format, Strobe time, Data storage

Refer to "Setting the Common Settings" (page 3-37).

Environment settings : The operating environment of the LK-G series can be set.

Setting contents : RS-232C, Setting selection, Program, Panel lock, Eco mode

Refer to "Setting the Operations of the Equpement (Enviroment Settings)" (page 3-46).

TIM

TIM

.

LK-G-M-NO1-E

1-25

Page 46

1 Before Use

Returning the LK-Series to the Factory Default Settings

1

You can initialize the controller and return the settings to the default settings when shipped from

the factory.

While pressing the key, turn on the power.

1

The measurement value indication shows “

nt".

When you press the key again, the settings are initialized and the measure

2

ment state is established.

The settings return to the default setting when shipped from the factory.

Refer to "Chpater 3 Function Settings" (page 3-1).

-

1-26

LK-G-M-NO1-E

Page 47

Operations and Functions during

Operations and Functions during

Measurement

Measurement

2

2

This chapter describes the operations that can be performed during displacement measurement and their functions.

Switching the Measurement Value Displays..........................2-2

Setting the Tolerance Comparator Values .............................2-3

Setting the Display Value Instantaneously to

Zero (Auto-Zero)....................................................................2-6

Program Function..................................................................2-8

Switching Program Nos.........................................................2-9

Performing Statistical Computation with

the Measurement Value.......................................................2-10

2

LK-G-M-NO2-E

2-1

Page 48

2 Operations and Functions during Measurement

Switching the Measurement Value Displays

This section describes how to switch the measurement value display contents.

During measurement, the following three types of display can be switched. Press the key

to switch displays.

2

• OUT1 signal display

• OUT2 signal display

• OUT1/OUT2 dual display

Displays OUT1 and OUT2 at the same time (default)

OUT1

HI GO LO

TIM

HI GO LO

OUT2

Displays OUT1 only Displays OUT2 only

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

Reference

The display type is retained for every program No.

TIM

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

2-2

LK-G-M-NO2-E

Page 49

2 Operations and Functions during Measurement

Setting the Tolerance Comparator Value

This section describes how to read the tolerance comparator display, and its

setting procedure.

The Function of the Tolerance Settings

HIGH and LOW comparator tolerance values can be set. The measured value can be

displayed and output in 3 steps: when exceeding the HI comparator value (HI), when the value

drops below the LOW comparator value (LOW), and when the value is between the HI and

LOW comparator values (GO).

Comparator status Range Display

HIGH HI comparator value <

GO

LOW Measurement value < LO

Comparator

standby state

Measurement value

LO comparator value

Measurement value HI

comparator value

comparator value

When the comparator output format is normal, the comparator output is as follows.

Refer to "Setting the Output Form of the Tolerance Comparator" (page 3-42) for the

comparator output form.

Display value

HI comparatator value

LO comparator value

HI output

GO output

LO output

ON

OFF

ON

OFF

ON

OFF

HI LED lights, and the measurement value is

displayed in red.

GO LED lights, and the measurement value is

displayed in green.

LO LED lights, and the measurement value is

displayed in red.

No LED lights, and the measurement value is

displayed as ------.

t

2

Reference

The comparator result of tolerance is outputted from the 12-pin I/O terminal block and the

expansion connector on the controller’s terminal panel.

Refer to "Functions of the Input/Output Terminals" (page 4-2) for the external terminals.

LK-G-M-NO2-E

2-3

Page 50

2 Operations and Functions during Measurement

OUT1

HI GO LO TIM

OUT1

HI GO LO TIM

Note

Measurement stops while the setting is in progress.

■ Setting Procedures for tolerance comparator values.

2

Press the key.

1

Enters the tolerance setting mode.

For changing the OUT No. to be set, press the key.

Press the key, and set the value with the and keys.

2

As an example, the tolerance on the HI side of OUT1 is set to

4.0000.

Press the key, and set the value with the and keys.

3

As an example, the tolerance on the LO side of OUT1 is set

to -4.0000.

Confirm the data by pressing the key, and press the

4

key to return to the measurement state.

OUT1

OUT2

OUT1

OUT2

OUT1

OUT2

Setting procedure of numerical values

A numerical value can be set by the following key operations.

You can set the digit of a flashing number. When all digits are flashing, you can set symbols.

• When the key is pressed, the digit that flashes after all

the digits flash shifts to the right. When pressed for one

second or more it shifts in higher speed.

All digits flash

OUT1

HI GO LO

HI GO LO

HI GO LO

HI GO LO

HI GO LO

HI GO LO

HI GO LO TIM

TIM

TIM

TIM

TIM

TIM

TIM

• When the key is pressed, the value increments.

When pressed for one second or more, the value advances

in higher speed.

Reference

When the key is pressed for three seconds, the setting returns to the default value.

2-4

LK-G-M-NO2-E

Page 51

2 Operations and Functions during Measurement

Hysteresis

If the measurement value is fluctuating around the tolerance comparator value, the comparator

output may repeatedly turn on and off. By setting a hysteresis, a gap may be generated

between the detected value and the return value of the tolerance comparator, thus avoiding this

phenomenon. When the comparator output format is normal, the comparator output is as

follows. Hysteresis is not set by default when shipped from the factory.

Refer to "Setting the Output Form of the Tolerance Comparator" (page 3-42) for the

comparator output form.

2

Dispaly value

HI comparator value

LO comparator value

HI ouptput

GO ouptput

LO ouptput

ON

OFF

ON

OFF

ON

OFF

Detection

Return

Note

Measurement stops while the setting is in progress.

■ Setting procedures of hysteresis

Press the key.

1

Enters the tolerance setting mode.

Pressing the key twice shows the Hysteresis setting

2

screen.

"

kYS-1" sets OUT1, and "kYS-2" sets OUT2.

Press the key, and set the value with the and keys.

3

In this example, the hysteresis of OUT1 is set to "0.1000".

OUT1

OUT2

OUT1

OUT2

OUT1

OUT2

Hysteresis

HI GO LO

HI GO LO

HI GO LO

HI GO LO

HI GO LO

HI GO LO

t

TIM

TIM

TIM

TIM

TIM

TIM

Confirm the data by pressing the key, and press the

4

key to return to the measurement state.

LK-G-M-NO2-E

2-5

Page 52

2 Operations and Functions during Measurement

Setting the Display Value Instantaneously to Zero (Auto-Zero)

This section describes the auto-zero function, which is used for referencing

zero-point position.

2

Operation of the key or others resets the present displayed value to "

considering this zero position as a reference, the increase and decrease are displayed in ±

(positive/negative). This function can be used for reference zero-point positioning when a

workpiece is changed.

The example below uses the auto-zero function by using the 150-µm target as a reference.

Display

0.0000

". By

150 µm

0

New reference point

Note

Auto-zero cannot be set at comparator standby state (displayed as "------") and overrange state. However, cancellation of auto-zero is possible.

Reference

• The auto-zero value is stored according to program No. and OUT.

• The auto-zero value is retained even if the power is turned off.

• When the measurement mode is other than normal, the comparator standby state ("---

---") is established after auto-zero is set.

• Adjusting a master workpiece by using the offset function (auto offset function)

When the offset value is set to the size of the master workpiece, enabling the auto-zero

will set the numerical value to the size of the master workpiece (offset value).

Refer to "Measuring with Offset" (page 3-32).

• Auto-zero is set for the measurement value that underwent a measurement mode

process ( page 3-25).

Positive

indication

Negative

indication

2-6

LK-G-M-NO2-E

Page 53

■ Operations from the display panel

2 Operations and Functions during Measurement

Measure the target to be used as a reference.

1

Assume that "

Press the key.

2

The measurement value display becomes zero.

Reference

1.2345" is displayed.

OUT1

OUT2

OUT1

OUT2

HI GO LO

HI GO LO

HI GO LO

HI GO LO

• If you enable the auto-zero function for either OUT1 or OUT2 independently, the

measurement value display mode must be set to the single display.

• If you enable the auto-zero function for both OUT1 or OUT2 at the same time, the

measurement value display mode must be set to the dual display.

Refer to "Switching the Measurement Value Displays" (page 2-2) for switching the

measurement value display.

• The measurement value at the moment when the key is released is set as

0.0000".

"

• Pressing the key for three seconds cancels auto-zero.

■ Input from the ZERO terminal

Auto-zero is activated for OUT1 when ZERO1 (Terminal 10) on the 12-pin terminal block

receives an input and for OUT2 when ZERO2 (terminal 8) on the expansion connector

receives an input. Ensure that the turn-on time does not exceed two seconds.

• NPN type : OFF when opened/ON when short-circuited with COM (No.12)

• PNP type : OFF when opened/ON when the voltage is applied

TIM

TIM

TIM

2

TIM

Reference

The measurement value at the turning-on moment is set as "

0.0000".

If the ZERO1 terminal or the ZERO2 terminal is turned on for two seconds or more, autozero is canceled.

■ RS-232C interface

You can send the command from the external devices by using the RS-232C interface to set or

cancel the auto-zero function.

Refer to "Chapter 5 RS-232C" (page 5-1).

LK-G-M-NO2-E

2-7

Page 54

2 Operations and Functions during Measurement

Program Function

Eight Programs can be switched among Program Nos. 0 to 7 in the LK-G Series. Register the

setting contents that correspond to a measuring target as programs in advance. By calling up

a program as desired, you can easily change between targets.

2

Head Settings

HI GO LO TIM

OUT1

HI GO LO TIM

OUT1

OUT Settings

HI GO LO TIM

OUT1

HI GO LO TIM

OUT1

Common Settings

HI GO LO TIM

OUT1

Program No.

PRG0

PRG1

PRG2

PRG3

PRG4

PRG5

PRG6

Note

[Environment Settings] is not saved in the program.

2-8

PRG7

LK-G-M-NO2-E

Page 55

2 Operations and Functions during Measurement

Switching Program Nos.

This section describes the Program No. switch function, which can easily change the operation

settings.

■ Display panel

Press the key.

1

The program selection screen appears.

Select a program No. by using the key.

2

Press the key to register it, and return to the measurement state.

3

■ External input terminal

Program No. can be changed by using the P1, P2, and P3 of the expansion connector.

Refer to "Expansion Connector" (page 4-5).

■ RS-232C interface

You can send the command from the external devices by using the RS-232C interface to

switch program Nos.

Refer to "Chapter 5 RS-232C" (page 5-RS-232C).

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

2

Note

The method of switching the program Nos. varies depending on the setting of "Setting the

Program Switching Method" (page3-50) in the Environment settings.

Function No. Selection item Operation method

b-0""PANEL"

"

"

b-1"

LK-G-M-NO2-E

E T

""

Panel operation/RS-232C interface

External terminal input

2-9

Page 56

2 Operations and Functions during Measurement

Performing Statistical Computation with the Measurement Value

Statistical computation with the measurement value can be performed. The data to be used for

the statistical computation is the one held in each measurement mode. OUT1 and OUT2 can

perform statistical computation independently.

2

Refer to "Using the Hold Function (Measurement Mode)" (page 3-25).

Up to 90000 statistical data can be acquired. If the number exceeds 90000, the statistical

computation stops.

The statistical computation is performed and the statistical data is updated continuously.

The statistical data is cleared under the following six conditions:

• When the key is pressed for three seconds

• When moving to the Measurement mode from the Setting mode, Tolerance Settings

mode, Program Change mode, or Communication mode

• When the statistics clearing command is received via the RS-232C interface

• When the clearing operation is performed on "LK-Navigator" software

• When a program No. is switched

• When the power is turned off

The upper OUT1 display shows the name of the statistical data, and the lower OUT2 display

shows the statistical data.

The statistical data consists of the following 11 items.

OUT1 display Name of statistical data Description

M-Sk

M-SLo

M-AvG

M-toP

M-bot

M-d F

M-Std

M- no

M- H

M- Go

M- Lo

* M is displayed as "1" at OUT1, and as "2" at OUT2.

Tolerance upper limit Displays the upper limit of the tolerance setting.

Tolerance lower limit Displays the lower limit of the tolerance setting.

Average value Displays the average value of the measurement data.

Maximum value Displays the maximum value of the measurement data.

Minimum value Displays the minimum value of the measurement data.

Maximum value –

minimum value

Standard deviation Displays the standard deviation of the measurement data.

Number of all data Displays the number of all the measurement data.

Number of tolerance HI

data

Number of tolerance

GO data

Number of tolerance

LO data

Displays the difference between the maximum value and

the minimum value.

Displays the number of data that exceed the upper limit of

the tolerance.

Displays the number of data found within the tolerance

range.

Displays the number of data that are below the lower limit

of the tolerance.

2-10

LK-G-M-NO2-E

Page 57

2 Operations and Functions during Measurement

■ Setting procedures of statistical data

Press the key to change the screen to show the single display.

1

Set the OUT No. of which statistical data is to be displayed.

Press the key.

2

The screen changes to the statistical data

display.

The upper limit of the tolerance setting is

displayed.

Press the key and check the statistical data in order.

3

For details of the displaying order, refer to page 2-10.

Press the key to return to the measurement value display.

4

Note

When displaying both OUT1 and OUT2 during measurement, the statistics cannot be displayed.

Reference

• The measurement and statistical computation are performed even when the statistical

data are displayed.

• In the statistics display screen, if no key operation is performed for 60 seconds, the

screen returns to the measurement state.

Name of statistical

data

Statistical data

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

2

LK-G-M-NO2-E

2-11

Page 58

2 Operations and Functions during Measurement

2

MEMO

2-12

LK-G-M-NO1-E

Page 59

Function Settings3

Function Settings3

This chapter describes the functions of the LK-G Series and the setting

procedures.

Measurement, Data Flow and Functions ..............................3-2

Setting the Head....................................................................3-3

Setting the Conditions of the Measurement Value Output

Setting the Common Functions ...........................................3-37

Setting the Operations of the Equipment

(Environment Settings)........................................................3-48

.......3-13

3

LK-G-M-NO3-E

3-1

Page 60

3 Function Settings

Measurement, Data Flow and Functions

The LK-G Series can connect two heads. Each head can perform measurement individually,

and the measurement values between the heads can be calculated.

Data flow of the head A

Sampling

Data flow of the head B

Sampling

Alarm processing

Scaling

Head A measurement value

FilteringFiltering

Auto-zero

Offset

Tolerance comparator

OUT 1 measurement valueOUT 2 measurement value

3

Alarm processing

Scaling

Head B measurement value

Calculation between the data of heads

Data flow of OUT 2 data

Measurement mode Measurement mode

Auto-zero

Offset

Tolerance comparator

The functions of the LK-G Series can be categorized into the following four groups.

Head Settings The functions related to stable detection are set.

OUT Settings The functions related to data processing are set.

Common Settings The common functions related to the Head settings and the OUT settings

Environment Settings The operating environment of the LK-G Series is set.

are set.

Data flow of OUT 1 data

■ Function and function display

Function

Function display

3-2

OUT1

OUT2

HI GO LO

HI GO LO

TIM

TIM

LK-G-M-NO3-E

Page 61

3 Function Settings

Setting the Head

This section describes the settings related to the sensing for stable detection.

List of Functions and Function Nos.

Function Function Function No. Reference page

Function

display

A

Light intensity

adjustment

able Auto

b

Measurement

mode

EAS

Alarm process

ALAr

d

ABLE

calibration

aBle-t STart/stop

e

Mounting

mode

oUnt d FF-S rr-S

0 1 2 3 4

AUTO MANUAL 3-5

anual

Normal

nor al

Count setting ([oUnT, 0 to 999, 8)

Level (

START/STOP 3-10

Diffuse

reflection

Translucent

object

Transparent

object

KAlF-t tran-i tran-2

LEVEL, 0 to 9, 4 )

Mirror

reflection

Transparent

object 2

Multi-reflective

object

rs

3-7

3-8

3-12

3

* The shaded cells are set by default.

List of Default Values and Setting Ranges

Function Item Settable range Default value Remarks

A

b

[

d

e

LK-G-M-NO3-E

ABLE Auto/Manual AUTO

Upper limit of control 1 to 99 99

Lower limit of control 1 to 99 1

Measurement mode

Number of times of processing

Level 0 to 9 4

ABLE calibration START/STOP -

Mounting mode Diffuse reflection / Mirror reflection Diffuse

Normal / Translucent object / Transparent object

/ Transparent object 2 / Multi-reflective object

0 to 999 8

Normal

reflection

3-3

Page 62

3 Function Settings

List of the Head Setting Screens

3

Head Settings ABLE

HI GO LO TIM

OUT1

HI GO LO TIM

OUT1

OUT2

Measurement mode

OUT2

Alarm process

OUT2

HI GO LO

HI GO LO

HI GO LO

TIM HI GO LO

TIM

Auto

OUT2

Manual

HI GO LO

OUT2

Normal

HI GO LO

OUT2

Translucent object

HI GO LO

OUT2

Transparent object

HI GO LO

OUT2

Transparent object 2

HI GO LO

OUT2

Multi-reflective object

HI GO LO

OUT2

Number of times of

TIM

processing

HI GO LO

OUT2

TIM

TIM

TIM

TIM

TIM

TIM

TIM

TIM

3-4

ABLE calibration

HI GO LO

OUT2

Mounting mode

HI GO LO

OUT2

Level

HI GO LO

OUT2

TIM

TIM

Diffuse reflection

HI GO LO

OUT2

Mirror reflection

HI GO LO

OUT2

TIM