Page 1

96M11549

CC-Link Communication

Unit for the LK-G5000 Series

Read this manual before use.

Keep this manual in a safe place for future reference.

User's Manual

LK-CC100

DeviceNet Communication Unit

LK-DN100

Page 2

NOTE

Introduction

This manual describes the basic operations and hardware functions of the LK-CC100 and

LK-DN100. Before using the LK-CC100 and LK-DN100, read this manual carefully to

ensure complete understanding so that you can take full advantage of these product's

performance and functions.

Keep this manual in a safe place for future reference.

Please deliver this manual to the end users of this product.

Symbols

The following symbols alert you to important messages concerning the prevention of

human injury and product damage.

DANGER

Failure to follow the instructions may lead to death or severe injury.

WARNING

Failure to follow the instructions may lead to injury (such as electric shock or burn).

CAUTION

Failure to follow the instructions may lead to property damage or product breakdown.

Provides additional information on proper operation.

Reference

Provides reference information or useful information about operation.

2

Page 3

Safety Precautions

General cautions

• At startup and during operation, be sure to monitor the functions and performance of

the LK-CC100 and LK-DN100.

• It is recommended that you take substantial safety measures to avoid any damage in

case of product failure.

• Do not modify the LK-CC100 or LK-DN100 or use it in any way other than as described

in the specifications. The warranty will be voided in such cases.

• When the LK-CC100 or LK-DN100 is used in combination with other devices, functions

and performance may be degraded depending on the operating conditions and

surrounding environment.

• Do not use the LK-CC100 or LK-DN100 for the purpose of protecting the human body.

• Do not allow the temperature to change sharply around the LK-CC100 or LK-DN100,

including the accessories. Otherwise, condensation may lead to a malfunction.

WARNING

Ensuring safe operation

• Use the proper power supply voltage as specified. Failure to do so may cause a fire,

electric shock, or malfunction.

• Do not attempt to disassemble or modify the unit. Doing so may cause a fire, electric

shock or unit malfunction.

Handling abnormal conditions

Turn off the power immediately in the following cases. Using the LK-CC100 or LK-DN100

in an abnormal condition could cause product breakdown.

Contact your nearest KEYENCE office for repair.

• If liquid or foreign matter enters the unit.

• If the unit is dropped or the housing is damaged.

• If smoke or an abnormal odor is emitted from the controller.

96M11549

3

Page 4

CAUTION

Ensuring safe operation

Do not block the vent holes on the unit. The rise in the internal temperature may cause

product failure.

Installation environment

To use the LK-CC100 or LK-DN100 properly and safely, avoid installing it in the following

locations. Doing so may lead to product breakdown.

• Location that is humid, dusty or poorly ventilated

• Location where the temperature becomes high, such as a place exposed to direct sunlight

• Location where there are flammable or corrosive gases

• Location where the product may be directly subjected to vibration or impact

• Location where water, oil or chemicals may splash onto the product

• Location where static electricity is readily generated

Influence of ambient temperature

Changes in the ambient temperature may cause the measurement to fluctuate. Be sure to

keep the temperature constant at all times. When the ambient temperature changes by 10 °C,

it takes about 60 minutes until the temperature inside the unit is uniformly distributed.

Other considerations

Handling

Do not wipe the unit with a wet cloth, benzene, or thinner. This may cause discoloration or

deformation of the housing. If the unit becomes dirty, wipe it off with a cloth moistened with

a mild detergent and then wipe with a soft dry cloth.

Precautions on CE Marking

The LK-CC100 and LK-DN100 conform to the CE marking directives under the conditions

that the following requirements are satisfied. Make sure these conditions are met if using

this device within the EU nations.

The applicable standards (EMC Directive) are listed below:

EMI : EN61326-1, Class A

EMS : EN61326-1

Limit the length of all input/output cables that are connected to the terminal panel of the

controller to 30 m or less.

4

Page 5

Contents

Introduction............................................... 2

Safety Precautions ................................... 3

General cautions ................................ 3

WARNING .......................................... 3

CAUTION ...........................................4

Other considerations ..........................4

Precautions on CE Marking ................ 4

Contents ................................................... 5

Chapter 1 Before Use

System Configuration ...........................1-2

Checking the Package Contents ..........1-3

LK-CC100

(CC-Link communication unit)..... 1-3

LK-DN100

(DeviceNet communication unit). 1-3

Part Names and Functions ...................1-4

CC-Link communication unit

LK-CC100 ................................... 1-4

DeviceNet communication unit

LK-DN100 ................................... 1-6

Mounting/Connecting the Units ............1-7

Connecting the communication unit

.. 1-7

Changing the CC-Link Communication Unit

Settings ...........................................2-7

Field network connection

specifications .............................. 2-7

Control using CC-Link .................... 2-8

Creating the Ladder Program .............2-19

Timing Diagrams ................................2-21

Chapter 3 Connecting to DeviceNet

Typical DeviceNet System

Configuration ..................................3-2

Typical system configuration using

DeviceNet ................................... 3-2

Special notes for using a DeviceNet

system......................................... 3-3

Connecting to the Field Network ..........3-4

Preparing the communication cable 3-4

Connecting the wiring cable ........... 3-5

Wiring to the DeviceNet controller

(LK-DN100)................................. 3-6

Changing the DeviceNet Communication

Unit Settings ...................................3-7

Field network connection

specifications .............................. 3-7

Control using DeviceNet ................. 3-9

Creating the Ladder Program .............3-18

Timing Diagrams ................................3-20

Chapter 2 Connecting to CC-Link

Typical CC-Link System Configuration .2-2

Typical system configuration using

CC-Link ....................................... 2-2

Special notes for using a CC-Link

system......................................... 2-3

Connecting to the Field Network ..........2-4

Preparing the communication cable

Connecting the wiring cable ........... 2-5

Wiring to the CC-Link controller

(LK-CC100)................................. 2-6

.. 2-4

Chapter 4 Specifications

Specifications .......................................4-2

CC-Link unit LK-CC100 .................. 4-2

LK-DN100 DeviceNet unit .............. 4-3

Dimensions ...........................................4-4

LK-CC100....................................... 4-4

LK-DN100....................................... 4-5

Appendices

Error Codes ......................................... A-2

Revision History ................................... A-6

5

Page 6

6

Page 7

Before Use1

System Configuration..........................................................1-2

Checking the Package Contents ........................................ 1-3

Part Names and Functions .................................................1-4

Mounting/Connecting the Units .........................................1-7

1

1-1

Page 8

1 Before Use

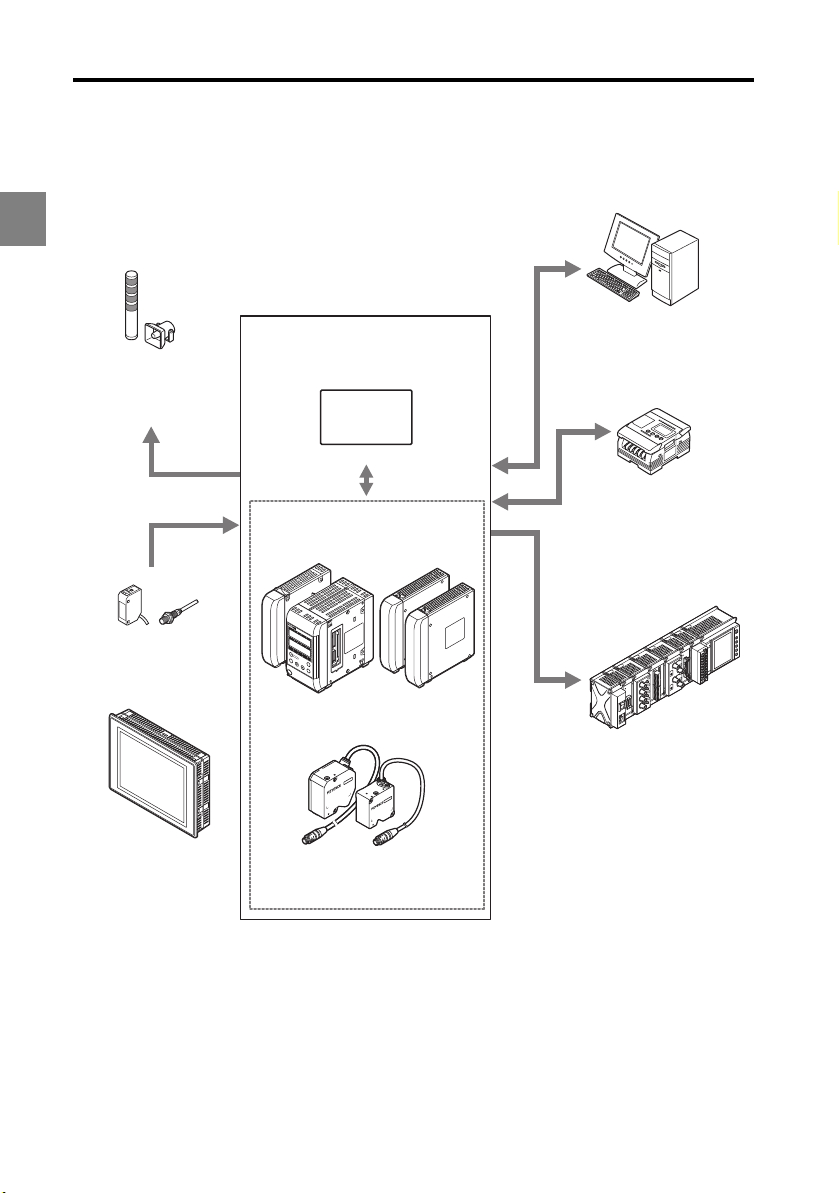

System Configuration

The LK-CC100 and LK-DN100 can be used along with commercially-available devices for

various purposes.

1

Enables control and measured

value reading through RS-232C

communication or the parallel

I/O board of the PC.

Indicator, buzzer

Issues an alarm depending

on the comparator result

output.

LK-G5000 Series

LK Navigator2

*2

Programmable logic controller

(PLC)

Enables synchronization control

of the measurement and

program number switching as

well as reading of control output

and measured values.

Recorder

Records the measurement

result.

Photoelectric sensors,

proximity sensors

Use to send timing input signals

when the measurement object is

detected.

Dedicated touch panel

LK-HD1001

Setup support software (LK-H2)

USB/RS-232C/

Ethernet

Head expansion unit

LK-HA100

OUT1

HIGOLO

LK-HD500

OUT2

TIM

HIGOLO TIM

HEAD1

HEAD2

LASER ON

LASER ON

S

TABILITY

S

TABILITY

BRIGHT D

P

R

O

BRIGHT

G

R

A

ARK

M

D

ARK

SET

ZE

RO

ENT

Controller

LK-G5001V/LK-G5001PV

*1

Expansion unit

LK-CC100

LK-DN100

Head (12 heads max.)

*1: The single unit type controller (LK-G5001V/LK-G5001PV) can be separated into the display panel

and controller unit. They can also be purchased separately.

The single unit type controller is labeled as LK-HD500 on the display panel side and as LK-G5001

or LK-G5001P on the terminal panel side.

*2: Refer to the LK-Navigator 2 User's Manual (the PDF file is on the CD-ROM) for further details on the

setup support software (LK-H2) LK-Navigator 2.

1-2

Page 9

Checking the Package Contents

MS

NS

10

(

FG

)

LK-D

N100

1

B R

A

TE

V

+

CAN H

SHIELD

CAN L

V

-

STATION No.

LK-CC100 (CC-Link communication unit)

1 Before Use

CC-Link communication unit

LK-CC100: 1

User's Manual: 1 Resistors

• 110 1/2W: 2

• 130 1/2W: 2

100

LK-CC

L RUN

SD

RD

L ERR

10

STATION No.

1

TE

A

B R

MODE

)

FG

(

SLD

DG

DB

DA

LK-DN100 (DeviceNet communication unit)

DeviceNet communication unit

LK-DN100: 1

User's Manual: 1 Metal-film resistor

121 1% 1/4W: 2

Screwdriver: 1

Screwdriver: 1

1

The package contents have been carefully inspected; however, if any component is

defective or damaged, contact your nearest KEYENCE office (address listed at the end of

this manual).

1-3

Page 10

1 Before Use

Part Names and Functions

This section describes the name and functions of each component.

1

CC-Link communication unit LK-CC100

L RUN (Operating status) indicator

• Lit: Data communication between the master and local

stations (when lit green).

• Unlit: Data communications timed out (indicator will

light up again when data is received normally).

SD (Send data) indicator

• Lit: Sending data.

RD (Receive data) indicator

• Lit: Receiving data.

L ERR (error) indicator

• Lit: A communications error exists (when lit red).

LK-CC100

L RUN

L ERR

3

2

4

1

0

9

7

8

3

2

4

1

0

9

7

8

3

2

4

1

0

9

7

8

5

4

6

3

7

2

1

0

F

B

E

C

D

SD

RD

5

10

6

5

1

6

STATION No.

5

B RATE

6

8

9

MODE

A

(FG)

SLD

DG

DB

A

D

• Flashing at regular intervals: Station number or

communication speed change detected while power

was on.

• Flashing irregularly: Terminator (terminating resistor) is set incorrectly, or noise is

affecting the unit or CC-Link dedicated cable.

• Unlit: Communications are normal.

STATION No. setting switch

Sets the station number (setting range: 1 to 64). x10 indicates the tens place, x1 indicates

the ones place.

B RATE setting switch

Sets the baud rate. The baud rate settings can be set as follows.

0: 156 kbps, 1: 625 kbps, 2: 2.5 Mbps, 3: 5 Mbps, 4: 10 Mbps

MODE setting switch

Sets the communication mode. The communication mode settings can be set as follows.

햲

햳

햴

햵

햶

햷

햸

햹

햺

Switch setting Multiple Station Ver si on Remark

0 1 1 - Not supported (Disables control input, tolerance comparison

and readout of measurement values for any OUT).

1 1 2 1.1 Disables control input, tolerance comparison and readout of

measurement values for OUT03 and higher.

2 1 3 1.1 Disables control input, tolerance comparison and readout of

measurement values for OUT05 and higher.

1-4

Page 11

1 Before Use

Switch setting Multiple Station Ve rsi on Remark

3 1 4 1.1 Disables control input, tolerance comparison and readout of

measurement values for OUT07 and higher.

4 2 1 2.0 Disables control input or tolerance comparison for any OUT,

and disables readout of measurement values for OUT3 and

higher.

5 2 2 2.0 Disables control input or tolerance comparison for OUT05

and on, and disables readout of measurement values for

OUT07 and higher.

6 2 3 2.0 Disables control input or tolerance comparison for OUT09

and on, and disables readout of measurement values for

OUT11 and higher.

7 2 4 2.0 Unused.

8 4 1 2.0 Disables control input or tolerance comparison for OUT03

and on, and disables readout of measurement values for

OUT07 and higher.

9 4 2 2.0 Disables control input and tolerance comparison for OUT11

and higher.

A 4 3 2.0 Unused.

B 4 4 - Cannot be used due to stress placed on network.

C 8 1 2.0 Disables control input and tolerance comparison for OUT07

and higher.

D 8 2 2.0 Unused.

E 8 3 - Cannot be used due to stress placed on network.

F 8 4 - Cannot be used due to stress placed on network.

1

Connector

Termina l bl ock

Ter minal name Function

FG Functional ground terminal.

Ground to a ground resistance of 100 ohms or less.

SLD Shield.

Connect shield wire from the dedicated CC-Link cable supporting Ver. 1.10

(OP-79426, OP-79427, etc.).

DG Communication ground

DB Communication signal Low

DA Communication signal High

1-5

Page 12

1 Before Use

DeviceNet communication unit LK-DN100

MS (Status) indicator

Displays the status of the LK-DN100.

• Lit green: Normal operation.

1

LK-DN100

MS

NS

• Lit red: An unrecoverable alarm exists (caused when

3

2

wrong switches are selected at start up).

• Flashing red: A recoverable alarm exists (can be

caused by turning the rotary switch after start up). Reset

4

1

5

0

10

6

9

7

8

3

2

4

1

5

0

1

6

9

7

Node Address

8

5

4

6

3

7

2

8

1

Data

9

0

A

F

B

Rate

E

C

D

error by returning the switch where it was at start up.

+

• Unlit: The power is OFF.

NS (Network status) indicator

Displays the status of the network communication.

• Lit green: Slave unit is online and connected to the

V

CAN H

SHIELD

CAN L

V

-

(FG)

master unit.

• Flashing green: Slave unit is online but not connected

to the master unit.

• Lit red: Indicates the bus is off, a duplicate node address exists, or the wrong switches

were selected at start up.

• Flashing red: 1 or more connections have timed out.

• Alternately flashing red and green: A network access error exists.

• Unlit: The power is OFF.

Node Address (node address setting) switch

Sets the node address (setting range: 0 to 63, default setting: 63). x10 indicates the tens

place, x1 indicates the ones place.

햲

햳

햴

햵

햶

햷

햸

Data Rate (baud rate) setting switch

Sets the baud rate. The baud rate settings can be set as follows.

0: 125 kbps, 1: 250 kbps, 2 (default): 500 kbps

Connector

Terminal block

Terminal name Wire color Function

V+ Red Communication power supply (24 VDC input)

CAN_H White Communication signal High

Shield Exposed Shield

CAN_L Blue Communication signal Low

V- Black Communication power supply (0 VDC input)

F.G. terminal

1-6

Page 13

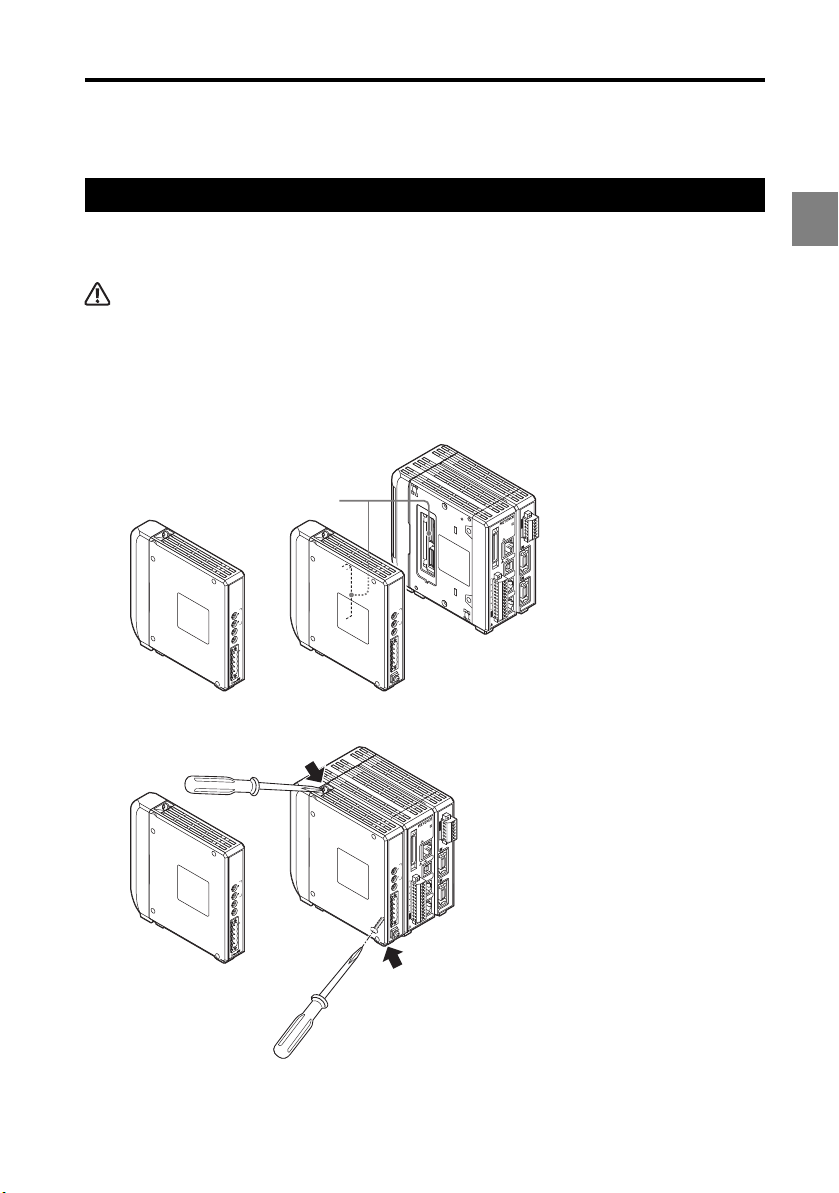

Mounting/Connecting the Units

Connecting the communication unit

1 Before Use

Connect the LK-CC100 CC-Link communication unit or the LK-DN100 DeviceNet

communication unit to the controller.

CAUTION

Turn off the power of the LK-G5000 Series before connecting the communication unit. Otherwise, you

may suffer a shock or damage the unit.

Connect the communication unit by aligning its connector to the connector on

1

the left side of the LK-G5000.

You need to remove the sticker attached to the left side of the LK-G5000 beforehand.

Connector

LK-CC100

L RUN

SD

RD

L ERR

10

STATION No.

1

ATE

B R

MODE

)

FG

(

SLD

DG

LK-CC100

DB

DA

or

LK-DN100

Secure the communication unit by tightening the two connecting screws.

2

LK-DN100

MS

NS

10

STATION No.

1

B RATE

+

V

CAN H

SHIELD

CAN L

V

)

FG

(

Screw position

LK-G5000

)

V

(

)

A

(

0V

)

1

V

(

LASER ON

)

A

(

0V

21

22

2

23

1

1

24

2

25

ETHERNET

3

26

LK-DN100

4

27

5

MS

28

6

29

7

30

8

31

HEAD

NS

2

9

32

10

33

11

34

12

35

13

36

14

LK-CC100

RUN

L

SD

RD

L ERR

10

STATION No.

1

ATE

B R

MODE

)

FG

(

SLD

DG

DB

DA

LK-CC100

or

LK-DN100

37

15

38

USB

16

39

17

40

18

19

20

10

STATION No.

1

HEAD

1

RS-232C

TE

A

B R

COM INZERO 1TIMING 1GOLASER 1DC 24V

+

V

DISPLAY

CAN H

SHIELD

CAN L

V

)

FG

(

LK-G5000

)

V

(

)

A

(

0V

)

1

V

(

LASER ON

)

A

(

0V

21

22

2

23

1

1

24

2

25

ETHERNET

3

26

4

27

5

28

6

29

7

30

8

31

HEAD

2

9

32

10

33

11

34

12

35

13

36

14

37

15

38

USB

16

39

17

40

18

19

20

HEAD

1

RS-232C

COM INZERO 1TIMING 1GOLASER 1DC 24V

AY

DISPL

1

Screw position

Tightening torque

Limit the tightening torque to 0.7 Nm or less.

1-7

Page 14

1

1 Before Use

1-8

Page 15

Connecting to CC-Link2

Typical CC-Link System Configuration............................. 2-2

Connecting to the Field Network....................................... 2-4

Changing the CC-Link Communication Unit Settings..... 2-7

Creating the Ladder Program ...........................................2-19

Timing Diagrams .............................................................. 2-21

2

2-1

Page 16

2 Connecting to CC-Link

Host device: PLC, etc.

(CC-Link master unit)

LK-G5001

+

LK-CC100

LK-G5001

+

LK-CC100

LK-G5001

+

LK-CC100

Terminator

connection

for KV-CL20,

etc.

RS-232C/USB/Ethernet

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LASER ON

ETHERNET

USB

DISPL

AY

R

S-232C

H

EA

D

1

(

V

)

(

A

)

0V

(

V

)

(

A

)

0V

COM INZERO 1TIMING 1GOLASER 1DC 24V

1

H

EA

D

LK-G5000

2

L

R

UN

SD

RD

L ERR

10

LK-CC100

1

B R

A

TE

SLD

DG

DB

DA

MODE

STATION No.

(

FG

)

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LASER ON

ETHERNET

USB

DISPLA

Y

R

S

-232C

H

EA

D

1

(

V

)

(

A

)

0V

(

V

)

(

A

)

0V

COM INZERO 1TIMING 1GOLASER 1DC 24V

1

H

EA

D

LK-G5000

2

L

R

UN

SD

RD

L ERR

10

LK-CC100

1

B R

A

TE

SLD

DG

DB

DA

MODE

STATION No.

(

FG

)

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LASER ON

ETHERNET

USB

DISPLA

Y

R

S-232C

H

EA

D

1

(

V

)

(

A

)

0V

(

V

)

(

A

)

0V

COM INZERO 1TIMING 1GOLASER 1DC 24V

1

H

EA

D

LK-

G5000

2

L

R

UN

SD

RD

L ERR

10

LK-CC100

1

B R

A

TE

SLD

DG

DB

D

A

MODE

STATION No.

(

FG

)

LK-H02*/H05*

series head

LK-H02*/H05*

series head

Terminator

Max. connections:

64 units

LK-H02*/H05*

series head

PC for setup

Typical CC-Link System Configuration

Typical system configuration using CC-Link

2

2-2

Page 17

2 Connecting to CC-Link

Special notes for using a CC-Link system

Take note of the following when using the LK-CC100 in a CC-Link network.

• The LK-CC100 is a network controller for CC-Link Ver. 2.00 or Ver. 1.10. If using the LKCC100 on a CC-Link Ver. 2.00 network, it must be connected to a master device

compatible with CC-Link Ver. 2.00. The LK-CC100 operates as a Ver. 1.10 unit when the

extended cyclic setting is set to single. It operates as a Ver. 2.00 unit at double or faster.

• CC-Link supports up to 64 connected devices. The actual number of devices that can

be connected is limited by the number of stations each unit occupies. Refer to the

manual for the master device used on the CC-Link to determine the number of stations

occupied and the maximum number of devices that can be connected.

• The maximum total length of the entire CC-Link network is 1.2 km (at 156 kbps). Refer to

the following table for the relation between communication speed and maximum cable

length.

2

Communication speed Cable length between

stations

156 kbit/s 20 cm min. 1,200 m

625 kbit/s 900 m

2.5 M bit/s 400 m

5 M bit/s 160 m

10 M bit/s 100 m

• Connect the LK-CC100 using the dedicated CC-Link cable (Ver. 1.10 or higher).

• Always connect a terminator (110 ohms 1/2W) between DA - DB on the units at both

ends of the CC-Link.

• The setup support software LK-Navigator 2 (LK-H2) cannot be used to display received

light waveforms through the CC-Link.

Maximum total cable

length

Precautions on CC-Link settings

• The parameters for the LK-CC100 should be set to match the CC-Link master unit. Set

using the STATION No. setting switch, B RATE setting switch, and MODE setting switch.

• Refer to the manual for the CC-Link master unit for details on how to set it.

NOTE

The number of stations occupied must be set according to the data read/write size.

2-3

Page 18

2 Connecting to CC-Link

Approx. 8 mm

Twist conductor strands together

Connecting to the Field Network

To connect to the master device or network controller on the field network using a

multidrop connection, or to connect other slave devices, connect a communication cable

that supports each field network to the field network connector.

2

Preparing the communication cable

Use a communication cable dedicated for CC-Link (Ver. 1.10 or higher).

Remove the sheath (outer insulation) from the cable.

1

Approx. 50 mm

Sheath (outer insulation)

Carefully remove about 50 mm from the end of the dedicated cable so as not to

damage the braided shield wires.

Prepare the shield.

2

Aluminum polyester laminated tape

Carefully unravel the braided shield wires. Inside the shield is a single exposed

drain wire (twisted or loose). Twist this with the unraveled shield wire and cover it

with an insulation tube.

Strip the insulation from the signal lines.

3

Shield (braided shield wire)

Twisted shield wireInsulation tube

Being careful not to damage the signal lines, remove the aluminum polyester

laminated tape and filling, and strip about 8 mm from each signal line.

Twist the exposed conductor strands to keep them together.

2-4

Page 19

2 Connecting to CC-Link

Connecting the wiring cable

Connect the prepared wiring cable to the field network connector (terminal block).

Reference

The field network connector is designed for multidrop connection of slave devices.

Insert each signal line into the holes in the connector.

1

Insert into corresponding connector

NOTE

Before inserting the communication cable, loosen the connector clamp screws.

Secure each signal line by tightening the clamp screws on the side of the

2

connector.

2

Secure by tightening clamp screw

Wiring varies depending on the network controller.

Insert the applicable signal lines into the connector.

2-5

Page 20

2 Connecting to CC-Link

SLD

DG

DB

DA

(FG)

NOTE

Wiring to the CC-Link controller (LK-CC100)

The LK-CC100 field network connector (terminal block) is to be wired as explained below.

Terminal name Funct ion

FG Functional ground terminal.

SLD Shield.

2

DG Communication ground

DB Communication signal Low

DA Communication signal High

• To connect the CC-Link controller to the CC-Link, use the CC-Link dedicated cable (Ver. 1.10 or

higher).

• At each CC-Link station connection, connect the cable shield to FG.

Ground to a ground resistance of 100 ohms or less.

Connect shield wire from the dedicated CC-Link cable

supporting Ver. 1.10 (OP-79426, OP-79427, etc.).

Typical connection

Refer to the manual for the CC-Link master unit for wiring details.

Master station

Terminator Terminator

LK-CC100 Other unit Other unit

Connecting terminators

A terminator must be connected to both ends of the

trunk line. The terminators must be connected to

reduce signal reflection and stabilize communication.

Terminator resistance: 110 ohms, 1/2W

• The terminators must be connected, otherwise, the CC-Link

will not communicate properly.

• If using the CC-Link dedicated high-performance cable,

use a 130 ohm, 1/2W resistor.

2-6

Other unit LK-CC100

DB

Terminator

DA

(FG)

SLD

DG

DB

DA

Page 21

2 Connecting to CC-Link

Changing the CC-Link Communication Unit Settings

This section explains the principle and operation of the CC-Link communication unit (LKCC100).

NOTE

This manual describes only those functions and settings of the CC-Link master device necessary for

communicating with the LK-CC100. Refer to the manual supplied with the master device for details on

functions and settings between the CC-Link master device and a PLC.

Field network connection specifications

Master settings

To connect the LK-CC100 to the CC-Link master, it is necessary to configure the slave

attribute and memory allocation settings.

Slave attributes

Register the LK-CC100 to the CC-Link master unit as a remote device station.

You can also set this by importing a CSP file into the software for the master unit (ladder

programming software, CC-Link setting software).

Memory allocation settings

In order to exchange data between the LK-CC100 and CC-Link master unit, the memory

allocation must be set using the software for the master unit (ladder programming

software, CC-Link setting software).

Reference

• The RX, RY, RWw, and RWr communicated over the CC-Link is stored in the master unit's buffer

memory.

• When multiple slaves are being used, the memory is allocated automatically for each slave

according to the specified starting address. You can view the memory allocation information for

each slave in the CC-Link setting software.

• CSP files can be downloaded from the KEYENCE website.

http://www.keyence.co.jp/

2

2-7

Page 22

2 Connecting to CC-Link

Control using CC-Link

This section explains how to use a PLC to control the LK-CC100 configured for a CC-Link

network.

NOTE

This section describes only those functions and settings of the CC-Link master station necessary for

communicating with the LK-CC100. Refer to the manual supplied with the CC-Link master station and

2

PLC for details on functions and settings of each device.

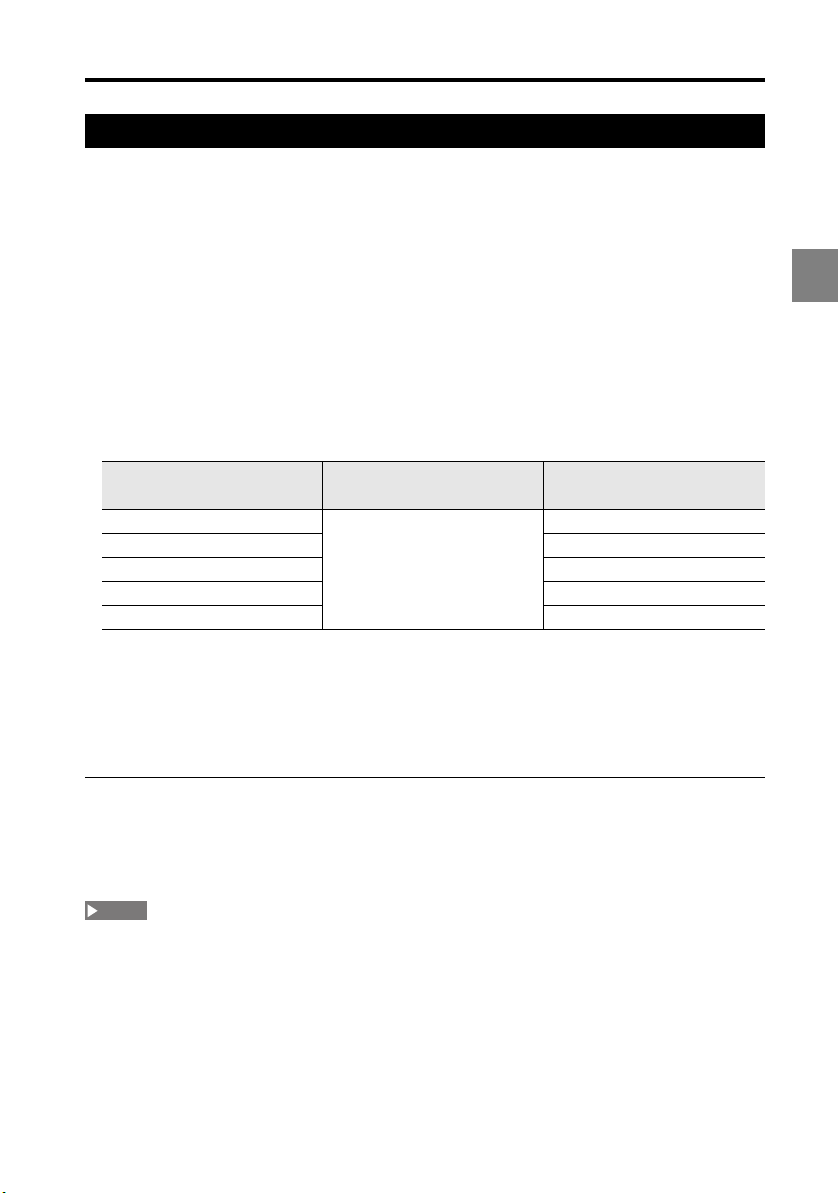

Operation and memory configuration with CC-Link

On a CC-Link network, the LK-CC100 operates as a slave station (remote device station)

to the CC-Link master station connected via the network cable.

• The buffer memory inside the LK-CC100 is linked to remote I/O and remote registers on

the CC-Link master station according to the memory configuration illustrated below.

• Control the system by setting and programming (2-14) according to this memory

configuration.

Memory configuration

Buffer memory inside the LK-CC100 is linked as shown here.

Read buffer

Write buffer

2-8

Buffer memory

Read control buffer

Read data buffer

Write control buffer

Write data buffer

CC-Link master station

RY (remote outputs)

RWw (remote registers)

RX (remote inputs)

RWr (remote registers)

Page 23

2 Connecting to CC-Link

RY (Remote outputs)

RY (remote outputs) are control signals sent from the CC-Link master station to the LK-CC100.

LKCC100

Read

control

buffer

Signal

direction

CC-Link master station

RY

(Remote outputs)

RY (n+0) CHG_PRG_REQ • Requests to change to the program

RY (n+1) System reserved

RY (n+2) SYNC_TIM_ON_REQ • Requests synchronized timing ON at

RY (n+3) System reserved

RY (n+4) SYNC_TIM_OFF_REQ • Requests synchronized timing OFF at

RY (n+5) System reserved

RY (n+6) SYNC_ZERO_ON_REQ • Requests synchronized zero ON at the

RY (n+7) System reserved

RY (n+8) SYNC_ZERO_OFF_REQ • Requests synchronized zero OFF at

RY (n+9) System reserved

RY (n+10) SYNC_RESET_REQ • Requests synchronized reset at the

RY (n+11) System reserved

RY (n+12) System reserved

RY (n+13) System reserved

RY (n+14) System reserved

RY (n+15) System reserved

RY (n+16*m+0) System reserved

RY (n+16*m+1) System reserved

RY (n+16*m+2) System reserved

Signal name Explanation

number stored in SET_PRG_NUM at

the rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

the rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

the rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

the rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

2

2-9

Page 24

2 Connecting to CC-Link

LKCC100

Read

control

buffer

2

Signal

direction

CC-Link master station

RY

(Remote outputs)

RY (n+16*m+3) OUTm_TIM_ON_REQ • Requests timing ON to OUTm at the

RY (n+16*m+4) System reserved

RY (n+16*m+5) OUTm_TIM_OFF_REQ • Requests timing OFF to OUTm at the

RY (n+16*m+6) System reserved

RY (n+16*m+7) System reserved

RY (n+16*m+8) OUTm_ZERO_ON_REQ • Requests zero ON to OUTm at the

RY (n+16*m+9) System reserved

RY (n+16*m+10) OUTm_ZERO_OFF_REQ • Requests zero OFF to OUTm at the

RY (n+16*m+11) System reserved

RY (n+16*m+12) System reserved

RY (n+16*m+13) OUTm_RESET_REQ • Requests reset to OUTm at the rising

RY (n+16*m+14) System reserved

RY (n+16*m+15) System reserved

RY (n+16*13+0) System reserved

.

.

.

Signal name Explanation

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

edge from OFF (0) ON (1).

• Ends the request at the falling edge

from ON (1) OFF (0).

System reserved

• n: varies according to the station number of the LK-CC100.

• m (1 to 12): corresponds to the OUT number. m = 1 for OUT01, m = 2 for OUT02, etc.

2-10

Page 25

2 Connecting to CC-Link

RWw (Remote registers)

RWw (remote registers) refers to the area where parameters sent from the CC-Link master

station to the LK-CC100 are stored.

LKCC100

Read

data

buffer

n: varies according to the station number of the LK-CC100.

Signal

direction

CC-Link master station

RY

(Remote outputs)

RWw (n+0) SET_PRG_NUM Sets the program selection number from

RWw (n+1) System reserved

.

.

.

Signal name Explanation

0 to 7.

System reserved

RY (Remote inputs)

RX (remote inputs) refers to the area where LK-CC100 statuses and responses to RY

(remote output) control signals are stored.

LKCC100

Write

control

buffer

Signal

direction

CC-Link master station

RY

(Remote outputs)

RX (n+0) CHG_PRG_ACQ Turns ON (1) when the program number

RX (n+1) CHG_PRG_ERR Turns ON (1) when an error occurs during

RX (n+2) SYNC_TIM_ON_ACQ Turns ON (1) when the synchronized

RX (n+3) SYNC_TIM_ON_ERR Turns ON (1) when an error occurs during

RX (n+4) SYNC_TIM_OFF_ACQ Turns ON (1) when the synchronized

RX (n+5) SYNC_TIM_OFF_ERR Turns ON (1) when an error occurs during

RX (n+6) SYNC_ZERO_ON_ACQ Turns ON (1) when the synchronized zero

RX (n+7) SYNC_ZERO_ON_ERR Turns ON (1) when an error occurs during

RX (n+8) SYNC_ZERO_OFF_ACQ Turns ON (1) when the synchronized zero

RX (n+9) SYNC_ZERO_OFF_ERR Turns ON (1) when an error occurs during

RX (n+10) SYNC_RESET_ACQ Turns ON (1) when the synchronized

RX (n+11) SYNC_RESET_ERR Turns ON (1) when an error occurs during

RX (n+12) System reserved

Signal name Explanation

changeover process completes.

the program number changeover

process.

timing ON process completes.

the synchronized timing ON process.

timing OFF process completes.

the synchronized timing OFF process.

ON process completes.

the synchronized zero ON process.

OFF process completes.

the synchronized zero OFF process.

reset process completes.

the synchronized reset process.

2

2-11

Page 26

2 Connecting to CC-Link

2

LKCC100

Write

control

buffer

Signal

direction

CC-Link master station

RY

(Remote outputs)

RX (n+13) CHG_PRG_ENBLE Turns ON (1) when program changeover

RX (n+14) READY_FLAG • Turns ON (1) when the controller is not

RX (n+15) SYSTEM_ERR_FLAG • Turns ON (1) when the controller or

RX (n+16*m+0) OUTm_LO Turns ON (1) when the comparator output

RX (n+16*m+1) OUTm_GO Turns ON (1) when the comparator output

RX (n+16*m+2) OUTm_HI Turns ON (1) when the comparator output

RX (n+16*m+3) OUTm_TIM_ON_ACQ Turns ON (1) when the timing ON process

RX (n+16*m+4) OUTm_TIM_ON_ERR Turns ON (1) when an error occurs during

RX (n+16*m+5) OUTm_TIM_OFF_ACQ Turns ON (1) when the timing OFF

RX (n+16*m+6) OUTm_TIM_OFF_ERR Turns ON (1) when an error occurs during

RX (n+16*m+7) OUTm_TIM_STATE Turns ON (1) when the timing for OUTm is

RX (n+16*m+8) OUTm_ZERO_ON_ACQ Turns ON (1) when the zero ON process

RX (n+16*m+9) OUTm_ZERO_ON_ERR Turns ON (1) when an error occurs during

RX (n+16*m+10) OUTm_ZERO_OFF_ACQ Turns ON (1) when the zero OFF process

RX (n+16*m+11) OUTm_ZERO_OFF_ERR Turns ON (1) when an error occurs during

RX (n+16*m+12) OUTm_ZERO_STATE Turns ON (1) when the zero for OUTm is

RX (n+16*m+13) OUTm_RESET_ACQ Turns ON (1) when the reset process

RX (n+16*m+14) OUTm_RESET_ERR Turns ON (1) when an error occurs during

Signal name Explanation

is possible.

in setting mode, communicating,

running, Able Tuning, or setting scaling

from measurement data.

• When OFF (0), the ***-ERR

corresponding to the ***-REQ turns ON

(1).

expansion unit has a system error.

• When ON (1), all signals except

SYSTEM_ERR_NO become invalid.

for OUTm is LO.

for OUTm is GO.

for OUTm is HI.

for OUTm completes.

the timing ON process for OUTm.

process for OUTm completes.

the timing OFF process for OUTm.

ON.

for OUTm completes.

the zero ON process for OUTm.

for OUTm completes.

the zero OFF process for OUTm.

ON.

completes for OUTm.

the reset process for OUTm.

2-12

Page 27

2 Connecting to CC-Link

LKCC100

Write

control

buffer

Signal

direction

CC-Link master station

RY

(Remote outputs)

RX (n+16*m+15) System reserved

RX (n+16*13+0) System reserved

.

.

.

Signal name Explanation

System reserved

• n: varies according to the station number of the LK-CC100.

• m (1 to 12): corresponds to the OUT number. m = 1 for OUT01, m = 2 for OUT02, etc.

• ***-ACQ and ***-ERR turn OFF (0) at the falling edge of ***-REQ from ON(1) OFF(0).

RWr (Remote registers)

RWr (remote registers) refers to the area where the statuses of LK-CC100 are stored.

LKCC100

Write

data

buffer

• n: varies according to the station number of the LK-CC100.

• m (1 to 12): corresponds to the OUT number. m = 1 for OUT01, m = 2 for OUT02, etc.

Signal

direction

CC-Link master station

RY

(Remote outputs)

RWr (n+0) CUR_PRG_NUM Stores the current program selection

RWr (n+1) SYSTEM_ERR_NO Stores the system error number when the

RWr (n+2) COUNTER_LO Stores the unsigned 32-bit counter value.

RWr (n+3) COUNTER_HI

RWr

(n+2*(m+1)+0)

RWr

(n+2*(m+1)+1)

RWr

(n+2*(13+1)+0)

.

.

.

Signal name Explanation

number from 0 to 7.

SYSTEM_ERR_FLAG turned ON (1).

Increments the count each time a

measurement value is acquired from the

controller.

OUTm_LO Stores the measurement value for OUTm.

OUTm_HI

System reserved

System reserved

* This register assumes the following

values in these instances:

Comparator standby = 0xFFF00000

Alarm = 0x000FFFFF

- Range over = 0xFFF00001

+ Range over = 0x000FFFFE

2

2-13

Page 28

2 Connecting to CC-Link

Setting and programming

The following settings and program are required to control the LK-CC100 using CC-Link.

2

Set communication

conditions

Set data size

Ladder program

Set the LK-CC100 communication speed and slave ID (station number).

Calculate and set the data size required for communication. Refer to

"Link" (Page 2-14) for details.

On the CC-Link master station, set the link area for the LK-CC100.

Create a program according to the settings.

Using handshake signals, create a program to receive command

signals and operation result data for commands from the host PLC.

Execute program

Communication condition settings

Set the communication speed and slave ID (station number) on the LK-CC100 using the

STATION No. setting switch and B RATE setting switch.

• Slave ID (station number): set to the same number as the slave ID (station number)

assigned to the LK-CC100 in the CC-Link.

• Baud rate: Set to the same speed as the baud rate (communication speed) in the CCLink.

Refer to the manual for the CC-Link master station for details on setting the CC-Link

master station.

Data size settings

Set the write size and read size of the memory to be linked in the CC-Link using the MODE

setting switch. This is set as a combination of the "number of stations occupied" and the

"extended cyclic multiple". Use the table below to calculate.

Occupies 1 station Occupies 2 stations Occupies 3 stations Occupies 4 stations

x1 Setting impossible RX/RY: 64 bits

x2 RX/RY: 32 bits

RWw/RWr: 16 bytes

x4 RX/RY: 64 bits

RWw/RWr: 32 bytes

x8 RX/RY: 128 bits

RWw/RWr: 64 bytes

RWw/RWr: 16 bytes

RX/RY: 96 bits

RWw/RWr: 32 bytes

RX/RY: 192 bits

RWw/RWr: 64 bytes

RX/RY: 384 bits

RWw/RWr: 128 bytes

RX/RY: 96 bits

RWw/RWr: 24 bytes

RX/RY: 160 bits

RWw/RWr: 48 bytes

RX/RY: 320 bits

RWw/RWr: 96 bytes

Setting impossible Setting impossible

RX/RY: 128 bits

RWw/RWr: 32 bytes

RX/RY: 224 bits

RWw/RWr: 64 bytes

Setting impossible

2-14

Page 29

2 Connecting to CC-Link

Memory allocation example

This example shows how to make the following settings.

Memory allocation

This example assumes the CC-Link master station has the following memory allocation

settings.

KEYENCE PLC Mitsubishi Electric

RX (remote input) refresh device R32000 X1000 Bits

RWw (remote register) refresh

device

RX (remote output) refresh device R33000 Y1000 Bits

RWr (remote register) refresh device DM10500 D2000 Words (16

DM10700 D1000 Words (16

PLC

Operation

This example performs the following measurements and control inputs.

• Measurement acquisition from OUT1 to OUT4

• Control inputs for OUT1 to OUT4

• Program change

Reference

• The data memory allocated in the PLC must be set larger area than the CC-Link communication

size.

• For example, to communicate X bytes from the PLC to the LK-CC100, and Y bytes from the LKCC100 to the PLC, allocate X bytes or more PLC data memory for output, and Y bytes or more for

input. Otherwise, an error will occur if not enough memory is allocated.

Device units

bits)

bits)

2

2-15

Page 30

2 Connecting to CC-Link

Example for a KEYENCE PLC

LK-CC100 Signal

direction

Read control buffer R32000 CHG_PRG_REQ

2

Read data buffer DM10700 SET_PRG_NUM

Write control buffer R33000 CHG_PRG_ACQ

CC-Link master station

Device Signal name

R32001

R32002 SYNC_TIM_ON_REQ

R32003

R32004 SYNC_TIM_OFF_REQ

R32005

R32006 SYNC_ZERO_ON_REQ

R32007

.

.

.

R32408 OUT4_ZERO_ON_REQ

R32409

R32410 OUT4_ZERO_OFF_REQ

R32411

R32412

R32413 OUT4_RESET_REQ

R32414

R32415

R33001 CHG_PRG_ERR

R33002 SYNC_TIM_ON_ACQ

R33003 SYNC_TIM_ON_ERR

R33004 SYNC_TIM_OFF_ACQ

R33005 SYNC_TIM_OFF_ERR

R33006 SYNC_ZERO_ON_ACQ

R33007 SYNC_ZERO_ON_ERR

.

.

.

R33408 OUT4_ZERO_ON_ACQ

R33409 OUT4_ZERO_ON_ERR

R33410 OUT4_ZERO_OFF_ACQ

R33411 OUT4_ZERO_OFF_ERR

R33412 OUT4_ZERO_STATE

R33413 OUT4_RESET_ACQ

R33414 OUT4_RESET_ERR

R33415

.

.

.

.

.

.

2-16

Page 31

2 Connecting to CC-Link

LK-CC100 Signal

direction

Write data buffer DM10500 CUR_PRG_NUM

CC-Link master station

Device Signal name

DM10501 SYSTEM_ERR_NO

DM10502 COUNTER_LO

DM10503 COUNTER_HI

DM10504 OUT1_LO

DM10505 OUT1_HI

.

.

.

DM10510 OUT4_LO

DM10511 OUT4_HI

Example for a Mitsubishi Electric PLC

LK-CC100 Signal

direction

Read control buffer Y1000 CHG_PRG_REQ

Read data buffer D1000 SET_PRG_NUM

CC-Link master station

Device Signal name

Y1001

Y1002 SYNC_TIM_ON_REQ

Y1003

Y1004 SYNC_TIM_OFF_REQ

Y1005

Y1006 SYNC_ZERO_ON_REQ

Y1007

.

.

.

Y1048 OUT4_ZERO_ON_REQ

Y1049

Y104A OUT4_ZERO_OFF_REQ

Y104B

Y104C

Y104D OUT4_RESET_REQ

Y104E

Y104F

2

.

.

.

.

.

.

2-17

Page 32

2 Connecting to CC-Link

LK-CC100 Signal

direction

Write control buffer X1000 CHG_PRG_ACQ

2

Write data buffer D2000 CUR_PRG_NUM

CC-Link master station

Device Signal name

X1001 CHG_PRG_ERR

X1002 SYNC_TIM_ON_ACQ

X1003 SYNC_TIM_ON_ERR

X1004 SYNC_TIM_OFF_ACQ

X1005 SYNC_TIM_OFF_ERR

X1006 SYNC_ZERO_ON_ACQ

X1007 SYNC_ZERO_ON_ERR

.

.

.

X1048 OUT4_ZERO_ON_ACQ

X1049 OUT4_ZERO_ON_ERR

X104A OUT4_ZERO_OFF_ACQ

X104B OUT4_ZERO_OFF_ERR

X104C OUT4_ZERO_STATE

X104D OUT4_RESET_ACQ

X104E OUT4_RESET_ERR

X104F

D2001 SYSTEM_ERR_NO

D2002 COUNTER_LO

D2003 COUNTER_HI

D2004 OUT1_LO

D2005 OUT1_HI

.

.

.

D2010 OUT4_LO

D2011 OUT4_HI

.

.

.

.

.

.

2-18

Page 33

2 Connecting to CC-Link

Creating the Ladder Program

Acquiring measurement data, tolerance comparator results, various

statuses (auto-zero, timing, system error), and program number settings

Create the ladder program as follows.

Check the status.

1

Verify the SYSTEM_ERR_FLAG is OFF and READY_FLAG is ON.

Store the counter value.

2

Store the current counter value (COUNTER_LO and COUNTER_HI).

Check for counter value updates.

3

Wait until the current counter value, stored in Step 2, changes.

Acquire data.

4

Acquire the required data.

NOTE

The counter value will be updated twice after any of the following has happened to the controller: start

up, set, an able tuning performed, a set scaling from a measurement data, or a complete

communication has been performed

2

2-19

Page 34

2 Connecting to CC-Link

Reference

Programming a control input

Create the ladder program as follows.

Check the status.

1

• Verify the SYSTEM_ERR_FLAG is OFF and READY_FLAG is ON.

• To request a program change, verify CHG_PRG_ENBLE is ON.

2

• Verify ***_ACQ is OFF.

Set the control parameter.

2

To request a program change, store the program number in SET_PRG_NUM.

Send the control input request.

3

Change the request signal to control ***_REQ from OFF -> ON.

The request is sent to the LK-CC100 at the rising edge of ***_REQ.

Check the control input status.

4

When the LK-CC100 receives the control input and completes the execution

requested, ***_ACQ turns ON.

When ***_ACQ turns ON, verify ***_ERR and make sure the request was processed

normally.

Check the control input result.

5

• For a program change request, wait for CUR_PRG_NUM to change.

• For a control request that causes ***_STATE to change, wait for ***_STATE to

change.

• For all other requests, wait for input response time (T2).

Refer to the LK-G5000 series User's Manual for details on input response time (T2).

Disable the control input request.

6

Disable the control input request by changing ***_REQ from ON OFF.

Store the counter value.

7

Store the current counter value (COUNTER_LO and COUNTER_HI).

Check for counter value updates.

8

Wait until the current counter value, stored in Step 7, changes.

Acquire data.

9

Acquire the required data.

2-20

Page 35

Timing Diagrams

This is the timing diagram for a control input.

•OUT: Master slave

•IN: Slave master

• Internal: Internal processing at the slave

2 Connecting to CC-Link

NOTE

• Control inputs that do not have the ***_STATE flag follow the same timing except that the ***_STATE

flag is omitted.

• The X axis shows the correct timing but not the exact time.

Normal timing (status change from OFF ON)

Verify ***_ACQ is OFF, then turn ***_REQ ON.

1 ***_REQ OUT

2 Internal

processing

3 ***_ACQ

4 ***_ERR IN

5 ***_STATE IN

IN

Abnormal timing (error, status stays ON)

1 ***_REQ OUT

Verify ***_ACQ is OFF, then turn ***_REQ ON.

Issue the next ***_REQ after

verifying ***_ACQ has gone LO.

2

2 Internal

processing

3 ***_ACQ IN

4 ***_ERR IN

5 ***_STATE IN

***_ACQ turns ON after

***_ERR changes state.

***_ERR changes to the OFF state at the

same time ***_ACQ turns OFF.

***_STATE does not change if ***_ERR goes to HI

because no processing is performed.

2-21

Page 36

2 Connecting to CC-Link

Internal processing time

***_REQ ON ***_ACQ ON

t

The following table describes time t for each command.

2

Control input Signal name t

Program change input CHG_PRG_REQ 200 ms + number of expansion units x 130 ms

Timing input SYNC_TIM_ON_REQ

Zero input SYNC_ZERO_ON_REQ

Reset input SYNC_RESET_REQ

Counter update interval = 45 ms

Reference

The response speed becomes slower than the figures in the table during communication with the LKNavigator 2 setup support software or during communication with the RS-232C port.

SYNC_TIM_OFF_REQ

OUT_TIM_ON_REQ

OUT_TIM_OFF_REQ

SYNC_ZERO_OFF_REQ

OUT_ZERO_ON_REQ

OUT_ZERO_OFF_REQ

OUT_RESET_REQ

60 ms

2-22

Page 37

Connecting to DeviceNet3

Typical DeviceNet System Configuration......................... 3-2

Connecting to the Field Network....................................... 3-4

Changing the DeviceNet Communication Unit Settings . 3-7

Creating the Ladder Program ...........................................3-18

Timing Diagrams .............................................................. 3-20

3

3-1

Page 38

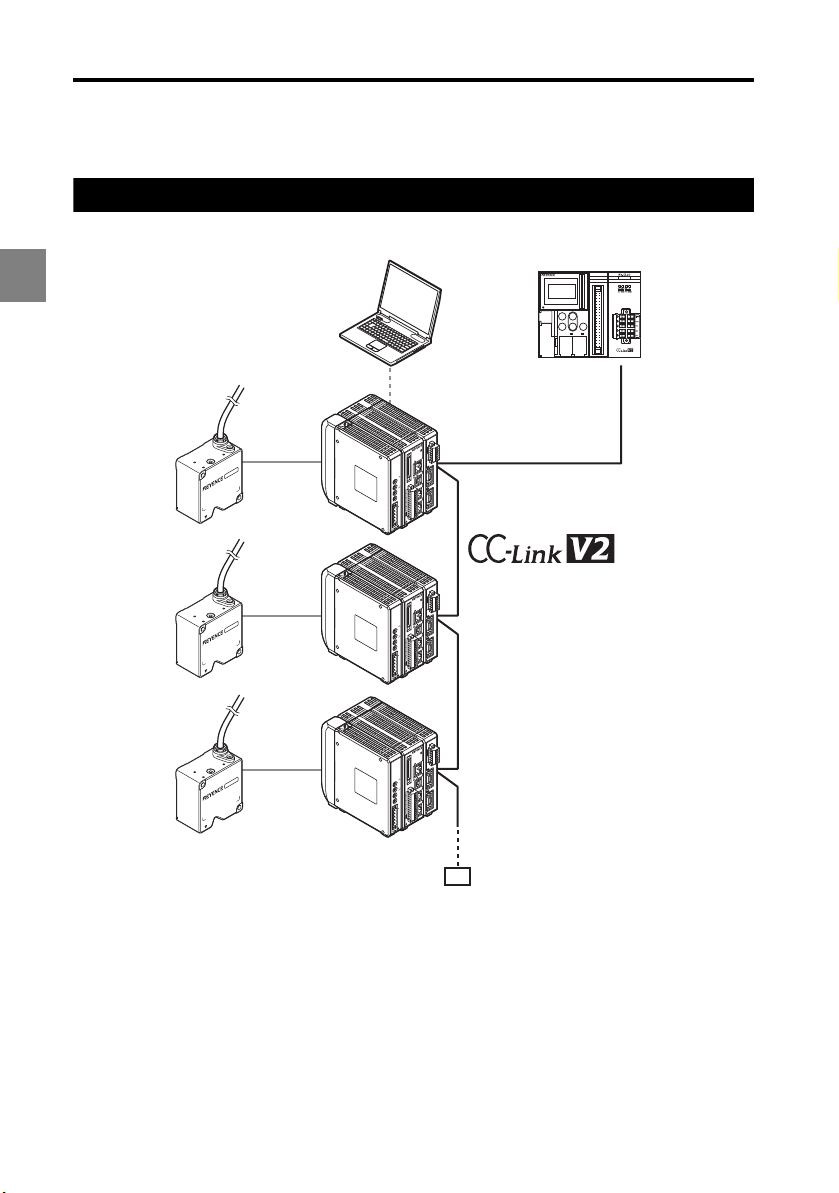

3 Connecting to DeviceNet

Terminator

connection

for KV-DN20,

etc.

Communication

power supply

PC for setup

Host device: PLC, etc.

(DeviceNet master unit)

LK-G5001

+

LK-DN100

LK-G5001

+

LK-DN100

LK-G5001

+

LK-DN100

Terminator

Max. connections: 64 units

(Including master node)

RS-232C/USB/Ethernet

LK-H02*/H05*

series head

LK-H02*/H05*

series head

LK-H02*/H05*

series head

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LASER ON

ETHERNET

USB

DISPL

A

Y

R

S-232C

H

EA

D

1

(

V

)

(

A

)

0V

(

V

)

(

A

)

0V

COM INZERO 1TIMING 1GOLASER 1DC 24V

1

H

EA

D

LK-

G5000

2

MS

NS

10

(

FG

)

LK-DN100

1

B RA

TE

V

+

CA

N H

SH

IELD

C

AN

L

V

-

STATION No.

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LASER ON

ETHERNET

USB

DISPL

AY

R

S-232C

H

EA

D

1

(

V

)

(

A

)

0V

(

V

)

(

A

)

0V

COM INZERO 1TIMING 1GOLASER 1DC 24V

1

H

EA

D

LK-

G5000

2

MS

NS

10

(

FG

)

LK-DN100

1

B RA

TE

V

+

C

AN

H

SH

IELD

C

AN

L

V

-

STATION No.

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

2

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

LASER ON

ETHERNET

USB

DISPL

AY

R

S-232C

H

EA

D

1

(

V

)

(

A

)

0V

(

V

)

(

A

)

0V

COM INZERO 1TIMING 1GOLASER 1DC 24V

1

H

EA

D

LK-G5000

2

MS

NS

10

(

FG

)

LK-DN100

1

B RA

TE

V

+

C

AN

H

SH

IELD

C

A

N

L

V

-

STATION No.

Typical DeviceNet System Configuration

Typical system configuration using DeviceNet

3

3-2

Page 39

3 Connecting to DeviceNet

Special notes for using a DeviceNet system

Take note of the following when using the LK-DN100 in a DeviceNet network.

• DeviceNet supports up to 64 connected devices. This includes the master, slaves, and

configurable devices.

• The maximum total length of the entire DeviceNet network is 500 m (at 125 kbps). Refer

to the following table for the relation between communication speed and maximum

cable length.

Typ e of

cable

Thick cable 500 kbit/s 100 m 6 m 36 m 8 A

Thin cable 500 kbit/s 100 m 36 m 3 A

• Connect the LK-DN100 using the dedicated 5-wire cable for DeviceNet. KEYENCE will

not guarantee performance if any other cable is used.

• Always connect a terminator (121 ohms, 1% 1/4W metal-film resistor) at both ends of the

trunk line.

• Do not connect any non-DeviceNet components along communication line. Otherwise,

signal reflection and other problems may cause communication failures.

• Only one point on the network must be ground to a ground resistance of 100 ohms or

less. If a ground resistance of 100 ohms or less is not available, do not connect the FG

to the V- on the communication power supply to avoid problems caused by noise.

• Do not connect the shield to multiple locations on the network.

Communication

speed

250 kbit/s 250 m 78 m

125 kbit/s 500 m 156 m

250 kbit/s 100 m 78 m

125 kbit/s 100 m 156 m

Max. length

of network

Branch

lengths

Tot a l b ra nc h

length

Current

capacity

3

Precautions on DeviceNet settings

• Set the LK-DN100 parameters according to the DeviceNet master unit using the Node

Address setting switch and Data Rate setting switch.

• Refer to the manual for the DeviceNet master unit for details on how to set it.

NOTE

When wiring the LK-DN100, use connectors, cables, T-splitters, and terminators that comply with

published ODVA (Open DeviceNet Vendor Association, Inc.) specifications.

3-3

Page 40

3 Connecting to DeviceNet

Connecting to the Field Network

To connect to the master device or network controller on the field network using a

multidrop connection, or to connect other slave devices, connect a communication cable

that supports each field network to the field network connector.

Preparing the communication cable

Use a 5-wire communication cable dedicated for DeviceNet.

3

Remove the sheath (outer insulation) from the cable.

1

Sheath

6 mm max.

Braided shield wires

Remove about 70 mm from the end of the cable.

Leave 6 mm or less of the braided shield exposed.

Cover with a shrink tube.

2

Sheath

Cover the exposed conductors and sheath with a shrink tube cut to about 40 mm.

Strip the insulation from each conductor.

3

Strip about 8 mm from the end of each conductor.

Approx. 40 mm

Shrink tube

Approx. 70 mm

Insulated conductor

Approx. 8 mm

3-4

Page 41

3 Connecting to DeviceNet

Connecting the wiring cable

Connect the prepared wiring cable to the field network connector (terminal block).

Reference

The field network connector is designed for multidrop connection of slave devices.

Insert each signal line into the holes in the connector.

1

Insert into corresponding connector

NOTE

Before inserting the communication cable, loosen the connector clamp screws.

Secure each signal line by tightening the clamp screws on the side of the

2

connector.

3

Secure by tightening clamp screw

Wiring varies depending on the network controller.

Insert the applicable signal lines into the connector.

3-5

Page 42

3 Connecting to DeviceNet

D

NOTE

Wiring to the DeviceNet controller (LK-DN100)

The LK-DN100 field network connector (terminal block) is to be wired as explained below.

Termina l

name

V+ Red Communication power supply (24 VDC input)

CAN_H White Communication signal High

SHIELD Exposed Shield

CAN_L Blue Communication signal Low

3

V- Black Communication power supply (0 VDC input)

NOTE

Connect the cable by matching the color of the wires to the colors on the sticker affixed to the

DeviceNet connector.

Wire

color

Fun ctio n

Typical connection

Refer to the manual for the DeviceNet master unit for wiring details.

Master node

Terminator Terminator

+

V

CAN H

SHIELD

CAN L

-

V

LK-DN100 Other unit Other unit

Connecting terminators

A terminator must be connected to both ends of the

trunk line. The terminators must be connected to

reduce signal reflection and stabilize communication.

Terminator resistance: metal-film resistor 121 ohms,

1%, 1/4W

The terminators must be connected, otherwise, DeviceNet will

not communicate properly.

3-6

Other unit LK-DN100

CAN H

Terminator

CAN L

+

V

CAN H

SHIEL

CAN L

-

V

Page 43

3 Connecting to DeviceNet

Changing the DeviceNet Communication Unit Settings

This section explains the principle and operation of the DeviceNet controller (LK-DN100).

NOTE

This manual describes only those functions and settings of the DeviceNet master device necessary for

communicating with the LK-DN100. Refer to the manual supplied with the master device for details on

functions and settings between the DeviceNet master device and a PLC.

Field network connection specifications

Slave attributes

Notes on device profiles (attribute files for DeviceNet)

The table below shows the contents of the device profile.

General data Vendor name KEYENCE Corporation

Vendor ID 367

Device profile name Generic

Profile No. 0

Product catalog number 3000

Product revision 1.1

Physical conformance data Maximum network power

consumption

Connector type Open-ended screw connector

Physical layer insulation support Yes

Support LED Module, Network

MAC ID setting Node Address switch

Default MAC ID 63

Transmission baud rate setting Data Rate switch

Support transmission rate 125 kbps, 250 kbps, 500 kbps

Communication data Predefined Master/Slave Group 2-only server

Connection Set support

UCMM and message group

support

Message splitting support for

sending

-

N/A

Compatible

3

3-7

Page 44

3 Connecting to DeviceNet

Reference

Master settings

To connect the LK-DN100 to the DeviceNet master, it is necessary to configure the slave

attribute and memory allocation settings.

Slave attributes

Set the slave settings for communication format, I/O size, etc., on the master. The master

can also be set by reading an EDS file for the LK-DN100 using the master setting

software.

Memory allocation settings

3

This setting affects non-programmed data exchange between the slave and master. Use

the master setting software to set the memory allocation.

EDS files can be downloaded from the KEYENCE website.

http://www.keyence.co.jp/

3-8

Page 45

3 Connecting to DeviceNet

Control using DeviceNet

This section explains how to use a PLC to control the LK-DN100 configured for the

DeviceNet network.

NOTE

This section describes only those functions and settings of the DeviceNet master unit necessary for

communicating with the LK-DN100. Refer to the manual supplied with the DeviceNet master unit and

PLC for details on functions and settings of each device.

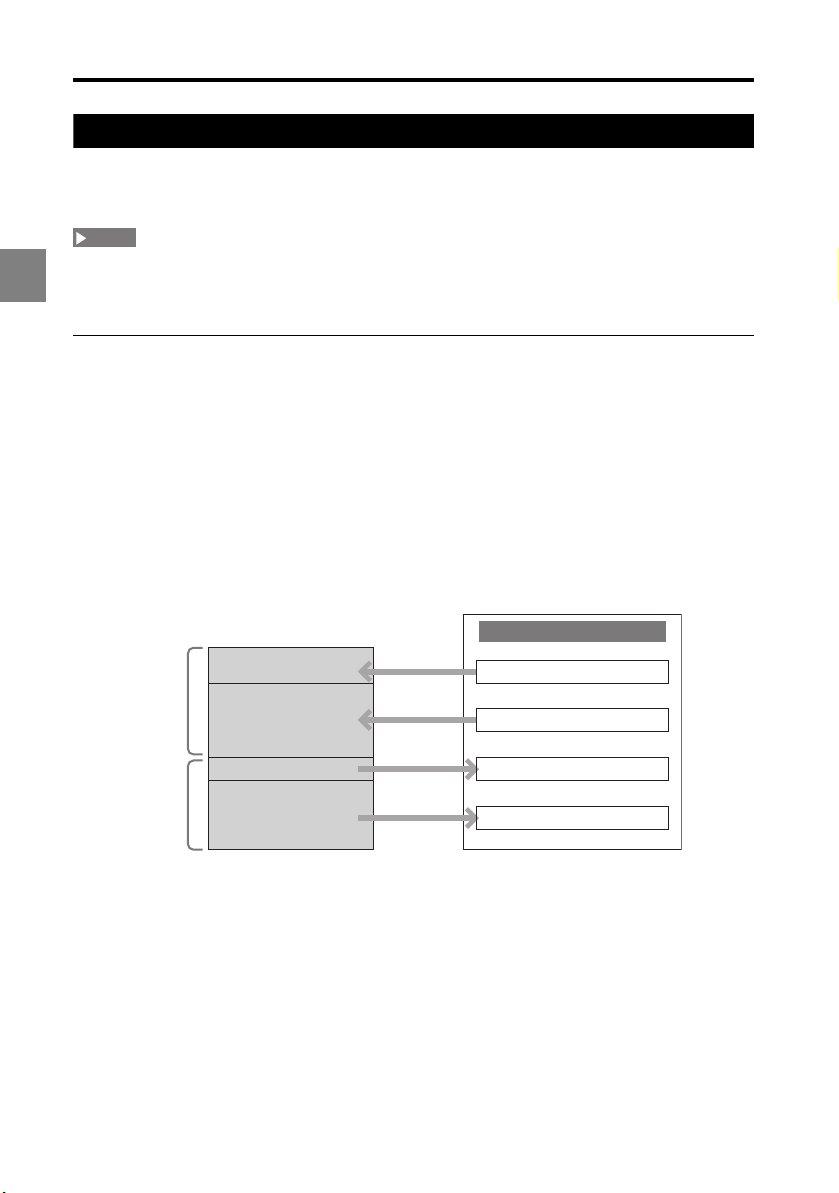

Operation and memory configuration with DeviceNet

On the DeviceNet network, the LK-DN100 operates as a slave to the DeviceNet master

unit connected via the network cable.

• The buffer memory inside the LK-DN100 is linked to link memory in the DeviceNet

master unit according to the memory configuration illustrated below.

• Set and program (3-15) according to this memory configuration.

Memory configuration

Buffer memory inside the LK-DN100 is linked as shown here.

Link memory

Output control buffer

Output data buffer

Input control buffer

Input data buffer

Read buffer

Write buffer

Buffer memory

Read control buffer

Read data buffer

Write control buffer

Write data buffer

3

3-9

Page 46

3 Connecting to DeviceNet

Output control buffer

The output control buffer refers to control signals sent from the DeviceNet master node to

the LK-DN100.

3

LKDN100

Read

control

buffer

Signal

direction

DeviceNet master node

Offset Signal name Explanation

Bit (0) CHG_PRG_REQ • Requests to change to the program

number stored in SET_PRG_NUM at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (1) System reserved

Bit (2) SYNC_TIM_ON_REQ • Requests synchronized timing ON at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (3) System reserved

Bit (4) SYNC_TIM_OFF_REQ • Requests synchronized timing OFF at

the rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (5) System reserved

Bit (6) SYNC_ZERO_ON_REQ • Requests synchronized zero ON at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (7) System reserved

Bit (8) SYNC_ZERO_OFF_REQ • Requests synchronized zero OFF at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (9) System reserved

Bit (10) SYNC_RESET_REQ • Requests synchronized reset at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (11) System reserved

Bit (12) System reserved

Bit (13) System reserved

Bit (14) System reserved

Bit (15) System reserved

Bit (16*m+0) System reserved

Bit (16*m+1) System reserved

Bit (16*m+2) System reserved

3-10

Page 47

3 Connecting to DeviceNet

LKDN100

Read

control

buffer

Signal

direction

DeviceNet master node

Offset Signal name Explanation

Bit (16*m+3) OUTm_TIM_ON_REQ • Requests timing ON to OUTm at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (16*m+4) System reserved

Bit (16*m+5) OUTm_TIM_OFF_REQ • Requests timing OFF to OUTm at the

rising edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (16*m+6) System reserved

Bit (16*m+7) System reserved

Bit (16*m+8) OUTm_ZERO_ON_REQ • Requests zero ON to OUTm at the rising

edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (16*m+9) System reserved

Bit (16*m+10) OUTm_ZERO_OFF_REQ • Requests zero OFF to OUTm at the rising

edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (16*m+11) System reserved

Bit (16*m+12) System reserved

Bit (16*m+13) OUTm_RESET_REQ • Requests reset to OUTm at the rising

edge from OFF (0) ON (1).

• Ends the request at the falling edge from

ON (1) OFF (0).

Bit (16*m+14) System reserved

Bit (16*m+15) System reserved

m (1 to 12): corresponds to the OUT number. m = 1 for OUT01, m = 2 for OUT02, etc.

3

3-11

Page 48

3 Connecting to DeviceNet

Output data buffer

The output data buffer refers to the area where parameters sent from the DeviceNet

master node to the LK-DN100 are stored.

LKDN100

Read

data

buffer

A word is 16 bits.

Signal

direction

DeviceNet master node

Offset Signal name Explanation

Word (14) SET_PRG_NUM Sets the program selection number from 0

to 7.

Word (15) System reserved

3

Input control buffer

The input control buffer refers to the area where LK-DN100 statuses and responses to the

output control buffer control signals are stored.

LKDN100

Write

control

buffer

Signal

direction

DeviceNet master node

Offset Signal name Explanation

Bit (0) CHG_PRG_ACQ Turns ON (1) when the program number

changeover process completes.

Bit (1) CHG_PRG_ERR Turns ON (1) when an error occurs during

the program number changeover process.

Bit (2) SYNC_TIM_ON_ACQ Turns ON (1) when the synchronized timing

ON process completes.

Bit (3) SYNC_TIM_ON_ERR Turns ON (1) when an error occurs during

the synchronized timing ON process.

Bit (4) SYNC_TIM_OFF_ACQ Turns ON (1) when the synchronized timing

OFF process completes.

Bit (5) SYNC_TIM_OFF_ERR Turns ON (1) when an error occurs during

the synchronized timing OFF process.

Bit (6) SYNC_ZERO_ON_ACQ Turns ON (1) when the synchronized zero

ON process completes.

Bit (7) SYNC_ZERO_ON_ERR Turns ON (1) when an error occurs during

the synchronized zero ON process.

Bit (8) SYNC_ZERO_OFF_ACQ Turns ON (1) when the synchronized zero

OFF process completes.

Bit (9) SYNC_ZERO_OFF_ERR Turns ON (1) when an error occurs during

the synchronized zero OFF process.

Bit (10) SYNC_RESET_ACQ Turns ON (1) when the synchronized reset

process completes.

Bit (11) SYNC_RESET_ERR Turns ON (1) when an error occurs during

the synchronized reset process.

Bit (12) System reserved

Bit (13) CHG_PRG_ENBLE Turns ON (1) when program changeover is

possible.

3-12

Page 49

3 Connecting to DeviceNet

LKDN100

Write

control

buffer

Signal

direction

DeviceNet master node

Offset Signal name Explanation

Bit (14) READY_FLAG Turns ON (1) when the controller is not in

setting mode, communicating, running,

Able Tuning, or setting scaling from

measurement data.

Bit (15) SYSTEM_ERR_FLAG • Turns ON (1) when the controller or

expansion unit has a system error.

• When ON (1), all signals except

SYSTEM_ERR_NO become invalid.

Bit (16*m+0) OUTm_LO Turns ON (1) when the comparator output

for OUTm is LO.

Bit (16*m+1) OUTm_GO Turns ON (1) when the comparator output

for OUTm is GO.

Bit (16*m+2) OUTm_HI Turns ON (1) when the comparator output

for OUTm is HI.

Bit (16*m+3) OUTm_TIM_ON_ACQ Turns ON (1) when the timing ON process

for OUTm completes.

Bit (16*m+4) OUTm_TIM_ON_ERR Turns ON (1) when an error occurs during

the timing ON process for OUTm.

Bit (16*m+5) OUTm_TIM_OFF_ACQ Turns ON (1) when the timing OFF process

for OUTm completes.

Bit (16*m+6) OUTm_TIM_OFF_ERR Turns ON (1) when an error occurs during

the timing OFF process for OUTm.

Bit (16*m+7) OUTm_TIM_STATE Turns ON (1) when the timing for OUTm is

ON.

Bit (16*m+8) OUTm_ZERO_ON_ACQ Turns ON (1) when the zero ON process for

OUTm completes.

Bit (16*m+9) OUTm_ZERO_ON_ERR Turns ON (1) when an error occurs during

the zero ON process for OUTm.

Bit (16*m+10) OUTm_ZERO_OFF_ACQ Turns ON (1) when the zero OFF process

for OUTm completes.

Bit (16*m+11) OUTm_ZERO_OFF_ERR Turns ON (1) when an error occurs during

the zero OFF process for OUTm.

Bit (16*m+12) OUTm_ZERO_STATE Turns ON (1) when the zero for OUTm is

ON.

Bit (16*m+13) OUTm_RESET_ACQ Turns ON (1) when the reset process

completes for OUTm.

Bit (16*m+14) OUTm_RESET_ERR Turns ON (1) when an error occurs during

the reset process for OUTm.

Bit (16*m+15) System reserved

• m (1 to 12): corresponds to the OUT number. m = 1 for OUT01, m = 2 for OUT02, etc.

• ***-ACQ and ***-ERR turn OFF (0) at the falling edge of ***-REQ from ON(1) OFF(0).

3

3-13

Page 50

3 Connecting to DeviceNet

Input data buffer

The input data buffer refers to the area where the statuses of LK-DN100 are stored.

LKDN100

Write

data

buffer

3

• A word is 16 bits.

• m (1 to 12): corresponds to the OUT number. m = 1 for OUT01, m = 2 for OUT02, etc.

Signal

direction

DeviceNet master node

Offset Signal name Explanation

Word (14) CUR_PRG_NUM Stores the current program selection

Word (15) SYSTEM_ERR_NO Stores the system error number when the

Word (16) COUNTER_LO Stores the unsigned 32-bit counter value.

Word (17) COUNTER_HI

Word

(2*(m+8)+0)

Word

(2*(m+8)+1)

OUTm_LO Stores the measurement value for OUTm.

OUTm_HI

number from 0 to 7.

SYSTEM_ERR_FLAG turned ON (1).

• Increments the count each time a

measurement value is acquired from the

controller.

• Count does not increment if

READY_FLAG is OFF (0).

* This register assumes the following values

in these instances:

Comparator standby = 0xFFF00000

Alarm = 0x000FFFFF

- Range over = 0xFFF00001

+ Range over = 0x000FFFFE

3-14

Page 51

3 Connecting to DeviceNet

Setting and programming

The following settings and program are required to control the LK-DN100 using

DeviceNet.

Set communication

conditions

Set data size

Ladder program

Execute program

Communication condition settings

Set the communication speed and slave ID (node address) on the LK-DN100 using the

Node Address switch and Data Rate setting switch.

• Slave ID (MAC ID): set to the same number as the slave ID (node address) assigned to

the LK-DN100 in the DeviceNet.

• Baud rate: Set to the same speed as the baud rate (communication speed) in the

DeviceNet. Refer to the manual for the DeviceNet master unit for details on setting the

DeviceNet master unit.

Data size settings:

• Write size: 16 words

• Read size: 42 words

Set the LK-DN100 communication speed and slave ID (node address).

Calculate and set the data size required for communication. Refer to

"Data size settings:".

On the DeviceNet master node, set the link area for the LK-DN100.

Create a program according to the settings.