Page 1

Vision Sensor

Getting Started

1

Installation and

2

Connection

Basic Operation

3

Settings Navigator

4

(Setting the Judgment Condition)

206GB

IV Series

User’s Manual

(Monitor)

Read this manual before use.

After you read this manual, keep it in a safe place for future

reference.

Operating/Adjusting

5

Useful Features/

6

Various Functions

Controlling with

7

the Input/Output Line

Specications

8

Status Table,

A

Troubleshooting

Page 2

Introduction

Introduction

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

Symbols

The following symbols alert you to important messages.

Be sure to read these messages carefully.

It indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

It indicates a situation which, if not avoided, could result in

product damage as well as property damage.

It indicates cautions and limitations that must be followed during

operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

It indicates the reference pages in this manual or the reference pages in separate manuals.

Cautions

(1) Unauthorized reproduction of this manual in whole or part is prohibited.

(2)

The contents of this manual may be changed for improvements without prior notice.

(3) An utmost effort has been made to ensure the contents of this manual are as complete as possible.

If there are any mistakes or questions, please contact a KEYENCE ofce listed in the back of the

manual.

(4) Regardless of item (3), KEYENCE will not be liable for any effect resulting from the use of this unit.

(5) Any manuals with missing pages or other paging faults will be replaced.

The company names and product names used in this manual are registered trademarks or the trademarks

of their respective companies.

Page 3

Safety Information for IV Series

Safety Information for IV Series

General Precautions

Do not use this product for the purpose to protect a human body or a part of human body.

This product is not intended for use as an explosion-proof product. Do not use this product in

hazardous location and/or potentially explosive atmosphere.

You must verify that the IV Series are operating correctly in terms of functionality and performance

before the start and the operation of the IV Series.

We recommend that you take substantial safety measures to avoid any damage in the event of

a problem occurring.

KEYENCE never warrants the function or performance of the IV Series if it is used in manner that

differs from the IV Series specications contained in this instruction manual or if the IV Series are

modied by yourself.

When the IV Series is used in combination with other instruments, functions and performance

may be degraded, depending on operating conditions and the surrounding environment.

Do not place the instruments, including peripherals, under the rapid temperature change. It may

cause condensation and may damage instruments or peripherals.

Remove the power cable from the power supply if you do not use this product for a long time.

Safety precautions on LED product

Use of controls or adjustments or performance of procedures other than those specied herein

may result in hazardous radiation exposure. Follow the instructions mentioned in this manual.

Otherwise, injury to the human body (eyes and skin) may result.

Do not stare into the direct or specularly reected beam.

Do not disassemble this product. The laser radiation emission from this product is not

automatically stopped when it is disassembled.

Do not direct the beam at people or into areas where people might be present.

Be careful of the path of the LED beam. If there is a possibility that the operator may be exposed

to the specular or diffuse reections, block the beam by installing a protective enclosure.

Install this product so that the path of the LED beam is not as the same height as that of human eye.

206GB

1

Page 4

Important Instructions

Important Instructions

Observe the following precautions to prevent malfunction of the IV Series and to

ensure that it is used properly.

Precautions on use

The power of this product and instruments connected to this product must be turned off when

the cable is to be installed or removed. Failure to do so may cause an electric shock or a

product damage.

Use this product in the correct supply voltage. Failure to do so may cause a product damage.

For instructions

Do not turn OFF the power while setting the items or saving the settings. Otherwise, all or

part of the setting data may be lost.

Do not let water, dust or oil stick to the camera/light of the sensor. Failure to do so may cause

a malfunction.

The enclosure rating of the monitor (IV-M30) is IP40. This is not designed for water proof so be

careful to operate it.

When this product becomes dirty, do not rub it with a wet cloth, benzene, thinner, or alcohol.

Doing so may change the color or shape of the unit.

If the unit is heavily contaminated, disconnect all the cables including the power supply cable,

wipe off the dirt with a cloth soaked with mild detergent, and then wipe with a soft dry cloth.

For an LCD panel

Do not press the touch panel with the tip of your nail or anything that has a sharp tip such as

a pen or a screwdriver. Doing so may cause damage.

Do not apply shock to the touch panel or press it with excessive force. Doing so may cause

damage.

The LCD panel may have some dots that are always lit (bright dots) or ones that are always

unlit (black dots). This phenomenon is not a problem.

Due to the unique characteristics of an LCD, displaying the same image for a long time may

cause an afterimage.

For USB memory

Use products recommended by KEYENCE.

A USB memory device with a security function cannot be used.

Unplug the USB memory when turning on or off the power of IV Series.

Do not remove the USB memory while the USB is being written on. Otherwise, all or part of

the setting data may be lost or it may cause a damage.

For external master image registration

When the external master image registration is used frequently, set [Write ROM when using “Ext.

Master Save”?] of the input option to [No] for nonvolatile memory protection of the internal

sensor. When the option is set to [Yes], the nonvolatile memory is guaranteed to write for

100,000 times.

For automatic focus function

Automatic focus function is used for adjusting the focusing position at the time of installation.

This will not activate during the operation.

Focusing position can be registered in each program. The program congurations are guaranteed

to switch for 100,000 times. If the focusing position does not need to change for each program,

set [Auto Focus Adj Pos] to [Common] for extending the life-span.

Do not apply shock or vibration during the focusing position adjustment. Failure to do so may

cause a product damage.

2

- IV Series User's Manual (Monitor) -

Page 5

Important Instructions

Measures to be taken when an abnormality occurs

In the following cases, turn the power OFF immediately. Using the IV Series in an abnormal condition

could cause re, electric shock, or malfunction.

Contact our ofce for repair.

If water or debris enters the IV Series.

If the IV Series is dropped or the case is damaged.

If abnormal smoke or odor emanates from the IV Series.

Precautions on installation

To use this product correctly and safely, avoid installing it in the following locations. Failure to

do so may cause re, electric shock, or malfunction.

Outdoors

Altitude above 2000 m

Locations that are humid, dusty or poorly ventilated

Locations where the temperature is high such as those exposed to direct sunlight

Locations where there are ammable or corrosive gases

Locations where the unit may be directly subjected to vibration or impact

Locations where water, oil, or chemicals may splash onto the unit

To improve the anti-noise feature, install the unit following the precautions below. Otherwise, a

malfunction may occur.

Mount the sensor onto the insulated attached mounting adapter.

Ground the FG cable (drain cable) of the sensor.

Do not mount the unit in a cabinet where high-voltage equipment is already installed.

Mount the unit as far from power lines as possible.

Separate the unit as far as possible from the devices that emit strong electric or magnetic

eld (such as solenoid or chopper).

Separate the I/O signal line from the power line or high-voltage line.

For power supply

Noise superimposed on the power supply could cause malfunction. Use a stabilized DC

power supply congured with an isolation transformer.

When using a commercially available switching regulator, be sure to ground the frame ground

terminal.

Devices including this unit are precision components. Do not apply shock or vibration.

When connecting to a network, let engineers who are knowledgeable about networks handle it.

- IV Series User's Manual (Monitor) -

3

Page 6

Precautions on Regulations and Standards

Precautions on Regulations and Standards

For IV-500C/IV-500CA/IV-500M/IV-500MA/IV-150M/IV-150MA/ IV-2000M/IV-2000MA

UL Certication

This product is a UL/C-UL Listed product.

UL File No. E301717

Category NRKH, NRKH7

Be sure to consider the following specications when using this product as a UL/C-UL Listed Product.

Use a power supply with Class 2 output dened in NFPA70 (NEC: National Electrical Code).

Power supply/ External input/ Control output shall be connected to a single Class 2 source only.

Use with an over current protection device which is rated 24 V or more and not more than 1A.

Enclosure Type 1 (Based on UL50)

CE Marking

Keyence Corporation has conrmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specications. Be sure to consider the following

specications when using this product in the Member State of European Union.

EMC Directive (2004/108/EC)

Applicable Standard EMI: EN60947-5-2, Class A

EMS: EN60947-5-2

The length of power I/O cable, Ethernet cable and Monitor cable must be less than or equal to 30m.

Remarks:

These specications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to EMC Directive.

Low-Voltage Directive (2006/95/EC)

Applicable Standard: EN62471

4

- IV Series User's Manual (Monitor) -

Page 7

Precautions on Regulations and Standards

For IV-M30

UL Certication

This product is a UL/C-UL Listed product.

UL File No. E207185

Category NRAQ, NRAQ7

Be sure to consider the following specications when using this product as a UL/C-UL Listed Product.

Use a power supply with Class 2 output dened in NFPA70 (NEC: National Electrical Code).

This product is for use on a at surface of a Type 1 enclosure.

CE Marking

Keyence Corporation has conrmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specications. Be sure to consider the following

specications when using this product in the Member State of European Union.

EMC Directive (2004/108/EC)

Applicable Standard EMI: EN61326-1, Class A

EMS: EN61326-1

The length of Monitor power cable, Ethernet cable and Monitor cable must be less than or equal to 30m.

Remarks:

These specications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to EMC Directive.

- IV Series User's Manual (Monitor) -

5

Page 8

Version of the IV Series

Version of the IV Series

You can download the most recent operation software for the sensor (IV-150/500/2000) and the monitor

(IV-M30) from the KEYENCE web site.

Please refer to the description on the homepage for the introduction method.

URL : http://www.keyence.com/

Operation software of the sensor (IV-150/500/2000)

Version Description

R1.00.00 The initial version.

R1.01.00 The processing time has been speeded up.

R1.10.00

R2.00.00

The processing time and the response time to program switching input have been

speeded up.

This is the version of this document.

The following functions have been added.

Logic output

Total status NG output

RUN output

FTP client function

Field network (EtherNet/IP, PROFINET)

Operation software of the monitor (IV-M30)

Version Description

R1.00.00 The initial version.

R1.01.01 Compatibility with Chinese (Simplied) / Chinese (Traditional).

R1.02.00 Compatibility with German.

R1.10.00 Compatibility with Tool Auto Tuning using a registration information le (*.ivt).

R2.00.00

This is the version of this document.

Compatibility with Italian / French / Spanish / Portuguese / Korean.

6

- IV Series User's Manual (Monitor) -

Page 9

Structure of This Manual

This chapter explains the system conguration and overview

1

Getting Started

of IV Series, package contents, and names and functions of

each part.

Structure of This Manual

1

2

3

4

5

6

7

8

A

Installation and

Connection

Basic Operation

Settings Navigator

(Setting the Judgment Condition)

Operating/Adjusting This chapter explains how to operate and adjust the IV Series.

Useful Features/

Various Functions

Controlling with

the Input/Output Line

Specications This chapter explains specications and dimensions.

Appendices

This chapter explains how to mount the sensor and monitor,

and explains connection procedures.

This chapter explains the basic operation and operation ow

of the IV Series.

This chapter explains how to set the sensors using

the Settings Navigator.

This chapter explains the useful and detailed features.

This chapter explains how the input and output terminals

control each operation.

This chapter explains error messages and troubleshooting, etc.

2

3

4

5

6

7

8

A

- IV Series User's Manual (Monitor) -

7

Page 10

Contents

Contents

Introduction

Symbols

Cautions

Safety Information for IV Series..............................1

General Precautions ...........................................1

Safety precautions on LED product ....................1

Important Instructions .............................................2

Precautions on use .............................................2

Measures to be taken when an abnormality

occurs..................................................................3

Precautions on installation ..................................3

Precautions on Regulations and Standards ...........4

For IV-500C/IV-500CA/IV-500M/IV-500MA/

IV-150M/IV-150MA/IV-2000M/IV-2000MA ........... 4

UL Certication ................................................4

CE Marking ......................................................4

For IV-M30 ..........................................................5

UL Certication ................................................5

CE Marking ......................................................5

Version of the IV Series ..........................................6

Operation software of the sensor

(IV-150/500/2000) ...............................................6

Operation software of the monitor (IV-M30) ........6

Structure of This Manual ........................................7

Contents .................................................................8

Chapter 1 Getting Started

System Conguration ..........................................1-2

Basic congurations of IV Series .....................1-2

Connecting the monitor and single sensor ...1-2

Connecting the monitor and

multiple sensors ............................................1-3

Overview of IV Series ..........................................1-4

IV Series...........................................................1-4

Using with the intelligent monitor (IV-M30) ...1-4

Using with the IV-Navigator (IV-H1) ..............1-5

Judgment processing ow................................1-6

Checking the Package Contents .........................1-8

Sensor ..............................................................1-8

Optional parts for the sensor ............................1-8

Dome attachment .........................................1-8

Polarized visible light lter attachment..........1-8

Infrared polarization lter attachment ...........1-8

Power I/O cable (M12 12pin - strand wire) ...1-9

Mounting adapter ..........................................1-9

Front cover (for replacement) .......................1-9

Bracket..........................................................1-9

Intelligent Monitor ...........................................1-10

Optional parts for the monitor.........................1-10

Monitor power cable

(M8 4pin - strand wire) ................................1-10

Protection sheet ..........................................1-10

USB memory (1GB) ....................................1-10

Stylus ..........................................................1-10

Wall mounting adapter ................................1-11

Panel mounting adapter..............................1-11

DIN mounting adapter.................................1-11

Communication Cable ....................................1-12

Monitor cable (M12 4pin - M12 4pin) ..........1-12

Ethernet cable (M12 4pin - RJ-45)..............1-12

Name and Function of Each Part ......................1-13

Sensor ............................................................1-13

Name and function of each part of

the sensor ...........................................1-13

Operation of the indicator light ............1-14

Monitor ...........................................................1-15

Chapter 2 Installation and Connection

Mounting the Sensor ...........................................2-2

Checking the view and installed distance ........2-2

Mounting the sensor.........................................2-4

Mounting the mounting adapter ....................2-4

Mounting on the wall .............................2-4

Mounting from the jig side .....................2-4

Mounting the sensor onto the mounting

adapter..........................................................2-4

Unmounting the sensor ....................................2-5

Mounting the attachment..................................2-6

Using the dome attachment ..........................2-6

Mounting the dome attachment ............2-6

Installed distance of the dome

attachment ............................................2-6

Using the polarizing lter attachment............2-7

Mounting the Monitor ...........................................2-8

Mounting to a wall ............................................2-8

Hanging on the hook.....................................2-8

Mounting with the wall mounting adapter .....2-8

Unmounting from the wall mounting adapter

Mounting to a panel........................................2-10

Mounting to a panel ....................................2-10

Panel cutting dimension..............................2-10

Mounting to the DIN rail .................................2-11

Mounting using DIN mounting adapter .......2-11

Unmounting from

the DIN mounting adapter...........................2-11

Cables ...............................................................2-12

Connecting the power I/O cable of

the sensor ......................................................2-12

Specication of I/O circuit and current of

the sensor ......................................................2-14

Input circuit .................................................2-14

No-voltage input

(When the NPN output is selected) ....2-14

Voltage input

(When the PNP output is selected) .....2-14

Output circuit...............................................2-14

When the NPN output is selected .......2-14

When the PNP output is selected .......2-14

Connecting the power cable of the monitor....2-15

Connecting the sensor and the monitor .........2-16

Connecting directly .....................................2-16

Connecting via network ..............................2-16

Connecting the monitor cable/

Ethernet cable.............................................2-17

...2-9

8

- IV Series User's Manual (Monitor) -

Page 11

Contents

Chapter 3 Basic Operation

Overview of Screen and Operation .....................3-2

Basic Operation Flow ..........................................3-4

Operation when the Power is Turned on .............3-5

Operation ow when the power is turned on ....3-5

Operation for initial startup of the monitor

(Direct Connection) ..........................................3-6

Operation for initial startup of the monitor

(Network Connection) ......................................3-7

Setting the network address of the monitor

Searching for a sensor to be connected .......3-8

Specifying sensor to be connected by IP

address .......................................................3-10

Operation for initial startup of the sensor .......3-11

Setting to the Factory Default ............................3-12

Initializing the sensor......................................3-12

Initializing the monitor ....................................3-13

Basic Operation for the Monitor .........................3-14

Editing the value with the slider......................3-14

Editing the tool window ..................................3-15

Inputting characters........................................3-16

Selecting the le in the USB memory.............3-17

...3-7

Chapter 4 Settings Navigator

(Setting the Judgment Condition)

Settings Navigator ...............................................4-2

Flow in the Settings Navigator .........................4-2

Basic Operation of the Settings Navigator...........4-3

Starting the Settings Navigator ........................4-3

Settings Navigator screen and operation ow

Displaying the Settings Navigator guide ..........4-5

Finishing the Settings Navigator ......................4-5

Finishing by completing all steps ..................4-5

Finishing without completing the step ...........4-5

1. Image Optimization (Clearly Image a Target)

Setting the Image Optimization ........................4-6

Main screen for the Image Optimization ..........4-7

Setting the Trigger Options ..............................4-8

Settings for the Trigger Options ....................4-8

Setting the Trigger Options .........................4-10

Auto Brightness Adjustment ...........................4-11

Focus Adjustment...........................................4-12

Focus adjustment for

the auto focusing type.................................4-12

Focus adjustment for

the manual focusing type ............................4-14

Extended functions for

the Image Optimization ..................................4-16

Items of extended functions for

the Image Optimization ...............................4-16

Imaging Area...............................................4-17

Advanced Brightness Adjustment ...............4-18

Lighting .......................................................4-18

Color Filters (color type only) ......................4-19

Digital Zoom (monochrome type only) ........4-19

2. Master Registration (Registering an Image

as a Reference for Judgment) ...........................4-20

Main screen for the Master Registration ........4-20

...4-4

...4-6

Registering the master image ........................4-21

Extended functions for

the Master Registration ..................................4-22

Items of extended functions for

the Master Registration...............................4-22

Master image registration from

the image history in the sensor ...................4-22

Registering from the image in

the USB memory ........................................4-24

When using a batch backup le

(*.iva) ..................................................4-24

When using an image capture le

(*.ivp) ..................................................4-25

Brightness correction ..................................4-26

3. Tool Settings

(Setting the Judgment Method for Targets) .......4-28

Selecting a tool according to

its intended purpose .......................................4-28

Types of tools .................................................4-28

Main screen for the Tool Settings ...................4-30

Adding/Editing/Deleting a tool ........................4-31

Adding a tool ...............................................4-31

Editing a tool ...............................................4-31

Deleting a tool .............................................4-31

Outline tool .....................................................4-32

Setting items for the Outline tool.................4-32

Setting the Outline tool ...............................4-33

Setting a search region .......................4-35

Settings for disabling outlines .............4-35

Setting a sensitivity .............................4-36

Extended functions for the Outline tool .......4-37

Rotation Range ...................................4-38

Search Algorithm ................................4-38

Tool Name ...........................................4-39

Color Area/Area tool .......................................4-40

Setting items for the Color Area/Area tool

Setting the Color Area/Area tool .................4-42

Mask settings ......................................4-45

Setting the upper limit .........................4-46

Extended functions of

the Color Area/Area tool .............................4-48

Advanced Color Extraction/

Advanced Brightness Extraction .........4-49

Tool Name ...........................................4-49

Fixed Reference Area .........................4-50

Position Adjustment tool .................................4-51

Setting items for

the Position Adjustment tool .......................4-52

Setting the Position Adjustment tool ...........4-53

Setting a search region .......................4-55

Settings for disabling outlines .............4-55

Setting a sensitivity .............................4-56

Extended functions for

the Position Adjustment tool .......................4-57

Rotation Range ...................................4-57

Extended functions for the Tool settings ........4-58

Items of extended functions for

the Tool settings ..........................................4-58

Copy Tool ....................................................4-58

...4-40

- IV Series User's Manual (Monitor) -

9

Page 12

Contents

4. Output Assignment

(Setting Details of Outputting to Output Line) ....4-60

Main screen for the Output Assignment .........4-60

Setting range of the Output Assignment ........4-60

Default value .......................................4-60

Setting the Output Assignment.......................4-61

Extended functions for

the Output Assignment ...................................4-62

Extended functions items for

the Output Assignment ...............................4-62

Logic Settings .....................................4-63

Total Status Conditions .......................4-65

Display Method of Extended Functions Menus

...4-66

Chapter 5 Operating/Adjusting

Starting an Operation ..........................................5-2

Turning on the power and

starting an operation ........................................5-2

Exiting the sensor settings and

starting an operation ........................................5-2

Overview of the Operation Screen ......................5-3

Names and Functions of the Operation Screen

Menu Screen ....................................................5-4

Switching the display to the full-screen mode

Enlarging the image display .............................5-6

Selecting the tool whose information to be

displayed ..........................................................5-6

Selecting the tool from

the pull-down menu ..............................5-6

Selecting the tool by tapping it on

the monitor ............................................5-6

Selecting a display method for tools ................5-7

Display methods for tools .............................5-7

For color type ........................................5-7

For monochrome type ...........................5-8

Displaying the statistical information ..............5-10

Displaying the statistical information...........5-10

Hiding the statistical information .................5-11

Displaying the histogram ................................5-12

Displaying the histogram ............................5-12

Hiding the histogram ...................................5-13

Adjusting Thresholds for Judgment ...................5-14

Tool Auto Tuning (Automatically

Adjusting the Judgment Condition)....................5-15

Using the images taken in

the Test mode .....................................5-15

Using the image history saved in

the sensor ...........................................5-15

Using the image les saved in

the USB memory ................................5-15

Operation ow for the Tool Auto Tuning .........5-16

Starting and nishing the Tool Auto Tuning ....5-16

Registering the OK/NG images to be used

for the Tool Auto Tuning .................................5-18

Registering the images taken in

the Test mode .............................................5-18

Registering the images from

the image history saved in the sensor ........5-20

...5-4

...5-5

Registering the images from

the le saved in the USB memory ..............5-22

Conrming or deleting the images

registered for the Tool Auto Tuning ................5-25

Tool Auto Tuning by

the previous registration information ..............5-26

Tool Auto Tuning by

the registration information le .......................5-28

Stabilizing the Judgment Process .....................5-32

Stabilizing the judgment process by

taking a clear image of the target ...................5-32

Imaging the target widely ............................5-32

Adjusting the installed distance (WD)

Using the digital zooming function ......5-32

Correcting the distorted images due to

the installation .............................................5-33

Achieving adequate image brightness ........5-33

If the brightness cannot be adjusted

in the Auto Brightness Adjustment ......5-33

If the brightness cannot be adjusted

due to uneven brightness ...................5-33

Achieving good focus..................................5-34

If good focus cannot be achieved by

the Auto Focus Adjustment .................5-34

Reducing the image blur .............................5-34

Reducing the shininess of the glossy or

metal surface ..............................................5-35

Using the Auto Brightness Adjustment

Using the dome attachment ................5-35

Using the polarizing lter attachment

Installing the sensor at an angle .........5-35

Adjusting the color tint (for color type only)

Reducing the effect of

illumination variation ...................................5-36

Stabilizing by correcting

the misaligned target position ........................5-36

Tool settings ........................................5-36

Processing during an operation ..........5-36

Stabilizing the position adjustment .................5-37

Basic adjustments ...............................5-37

If the target tilts and the position

adjustment becomes unstable ............5-37

If the position adjustment becomes

unstable due to the effect of

the unwanted outlines .........................5-37

If the outline of the reference target

cannot be detected .............................5-38

Stabilizing the Outline tool..............................5-38

Basic adjustments ...............................5-38

If the outline cannot be detected

when the target becomes

out of position .....................................5-38

If the detection becomes unstable

due to the effect of the unwanted

outline other than the target ................5-38

If the target tilts and the outline

cannot be detected .............................5-39

If the match rate difference

between the high and

low-quality-targets is small ..................5-39

...5-32

...5-35

...5-35

...5-36

10

- IV Series User's Manual (Monitor) -

Page 13

Contents

If the outline of the target cannot

be detected .........................................5-39

Stabilizing the Color Area/Area tool ...............5-39

Basic adjustments ...............................5-39

If the color you wish to judge cannot

be extracted ........................................5-39

If the area search becomes

unstable due to unwanted colors

Shortening the Processing Time........................5-40

being extracted ...................................5-39

For the processing time..................................5-40

Flow of the internal process ................5-40

Shortening the imaging processing time ........5-41

Selecting the tool............................................5-41

Shortening the processing time of each tool ..5-41

Shortening the processing time of

the Outline tool............................................5-41

Shortening the processing time of

the Color Area/Area tool .............................5-42

Shortening the processing time of

the position adjustment ...............................5-42

Chapter 6

Useful Features/Various Functions

List of the Useful Features...................................6-2

Useful features while running ...........................6-2

Useful features during installation/adjustment

Displaying the Sensor Setup Menu Screen .........6-7

Changeover for a Target (Program Functions) ....6-8

Overview of the program functions ..................6-8

Things can be performed with

the program functions ......................................6-8

Preparing the program functions ......................6-9

Preparation ow ............................................6-9

Preparation procedures ................................6-9

Using the program functions

(changing over) ..............................................6-10

When the [Monitor/PC] is selected in

the Program Switch Method .......................6-10

When the [External IN] is selected in

the Program Switch Method .......................6-11

Editing a program name .................................6-12

Copying a program.........................................6-12

Initializing a program ......................................6-13

Sensor Image History (Conrming

the Images whose Status Result is NG) ............6-14

Displaying the Sensor Image History screen

Displaying from the run screen ...........6-14

Displaying from

the Sensor Setup Menu screen ..........6-14

Loading and conrming the saved images.....6-15

Clearing the saved images.............................6-16

Changing the logging conditions of

the image history ............................................6-17

Saving the Sensor Settings and Images to

a USB Memory ..................................................6-18

Installing/Removing the USB memory ...........6-18

Installing the USB memory .........................6-18

Removing the USB memory .......................6-18

...6-4

...6-14

Displaying the USB Memory screen ..............6-18

Displaying from the run screen ...........6-18

Displaying from

the Sensor Setup Menu screen ..........6-18

Saving the sensor settings or

the image history ............................................6-19

Backing up in a batch .................................6-19

Saving the image history individually ..........6-20

Transferring the settings backed up in

the USB memory to the sensor ......................6-21

Capturing the monitor screen and

saving to the USB memory ............................6-23

Enabling the screen capturing function.......6-23

Capturing the screen ..................................6-23

Folder composition and le naming rules.......6-24

Setting the Extended Functions of the Sensor

Sensor advanced settings ..............................6-25

Environmental .............................................6-25

Setup Adjustment........................................6-25

Program ......................................................6-25

System ........................................................6-25

I/O Settings ....................................................6-26

Input Settings ..............................................6-26

Output Settings ...........................................6-27

Polarity ........................................................6-28

I/O Monitor ..................................................6-28

Device settings ...............................................6-29

Device Name ..............................................6-29

Password Lock ...........................................6-30

Network Settings ............................................6-31

Advanced Network Settings ...........................6-32

FTP .............................................................6-32

FTP Destination Settings ....................6-33

Transfer Condition Settings ................6-34

Transfer Destination Folder Settings

Field Network ..............................................6-37

Tilt Correction .................................................6-38

Rotate 180° ....................................................6-40

White Balance (for color type only) ................6-41

Program Switch Method .................................6-42

Auto Focus Adjustment Position

(auto focus type only) .....................................6-42

Sensor Information .........................................6-43

Initializing the sensor......................................6-44

Updating the sensor .......................................6-44

Setting the Advanced Monitor Information.........6-45

Monitor Settings .............................................6-45

Sensor Connect ..........................................6-45

Monitor Device Settings ..............................6-45

Monitor Environment...................................6-45

System ........................................................6-45

Sensor Connect .............................................6-46

When directly connecting with the sensor ..6-46

When connecting with the sensor

via a network...............................................6-46

Network Settings ............................................6-48

Display Settings .............................................6-49

Touch Screen Lock.........................................6-50

Language .......................................................6-51

Time ...............................................................6-51

...6-25

...6-35

- IV Series User's Manual (Monitor) -

11

Page 14

Contents

Backlight.........................................................6-52

Touch Panel Calibration .................................6-52

Monitor Information ........................................6-53

Initialize Monitor .............................................6-53

Update Monitor...............................................6-53

Chapter 7

Controlling with Input/Output Line

Controlling Timing of Judgment with Triggers......7-2

External trigger .................................................7-2

Internal trigger ..................................................7-3

Operating in the shortest cycle .....................7-3

Importing the Status Output.................................7-4

Importing the total status /

total status NG output ......................................7-4

Importing the individual status output of

each detection tool / logic.................................7-5

Changing the timing of the status output..........7-6

Cancelling One-Shot output..........................7-6

Changing Over ....................................................7-7

Registering the Master Image .............................7-8

Clearing Errors ..................................................7-10

Operations when Power of the Sensor is

Turned on ..........................................................7-11

Input Response Time.........................................7-12

Response time for the switch program

input ............................................................7-12

Response time for the external master

registration input .........................................7-12

Response time for the error clear input ......7-12

Description for symbols ..............................7-12

Chapter 8 Specications

Specications ......................................................8-2

Sensor ..............................................................8-2

Intelligent Monitor .............................................8-4

Dimensions ..........................................................8-6

Sensor ..............................................................8-6

Optional parts for the sensor ............................8-7

Dome attachment .........................................8-7

Polarizing lter attachment ...........................8-8

Power I/O cable ............................................8-8

Mounting adapter ..........................................8-8

Front cover....................................................8-8

Bracket..........................................................8-9

Intelligent Monitor ...........................................8-10

Optional parts for the monitor.........................8-12

Monitor power cable ...................................8-12

Protection sheet ..........................................8-12

Stylus ..........................................................8-12

Wall mounting adapter ................................8-12

Panel mounting adapter..............................8-12

DIN mounting adapter.................................8-12

Connection Cable...........................................8-13

Monitor cable ..............................................8-13

Ethernet cable.............................................8-13

Appendices

Status Table ........................................................ A-2

Status table ..................................................... A-2

Displaying and outputting the status result ..... A-4

Displaying and outputting the status result

at the time of position adjustment ................... A-4

Matching Rate of the Outline Tool and

Position Adjustment Tool .................................... A-5

Matching rate at the time of protrusion............ A-5

Cut-off process of the matching rate ............... A-5

Settings List ........................................................ A-6

RUN screen (menu display OFF) .................... A-6

RUN screen (menu display ON)...................... A-6

Sensor Setup Menu screen............................. A-7

Monitor Settings screen .................................. A-9

Sensor Advanced screen .............................. A-11

Sensor Setup screen..................................... A-14

1. Image Optimization ................................ A-14

2. Master Registration................................ A-15

3. Tool Settings .......................................... A-15

4. Output Assignment ................................ A-18

Troubleshooting ................................................ A-19

Error Messages ................................................ A-22

Checking errors by observing

the PWR/ERR indicator light of the sensor ... A-22

Conrming error messages of the monitor .... A-24

Remedy when the Monitor cannot

be Connected with the Sensor ......................... A-28

Remedy when direct connection is

unavailable .................................................... A-28

Remedy when connection via

a network is unavailable ................................ A-29

Conrming the status by observing

the indicator light of the sensor ..................... A-32

LINK/ACT (link/activity) indicator light ........ A-32

STATUS indicator light ............................... A-33

Conrming the status by observing

the SENSOR indicator light of the monitor .... A-34

Other methods of conrming a network

connection ..................................................... A-35

Conrming the existence of

the sensor from the monitor ....................... A-35

If the displayed conrmation

result is “NG” ...................................... A-35

Conrming/Setting the IP address of

the monitor ................................................. A-36

Conrming/Setting the IP address of

the sensor .................................................. A-37

Conrming the router settings.................... A-37

Remedy when data transfer via

FTP is unavailable ..................................... A-38

Initializing the Network Settings

(IP Reset Switch) .............................................. A-40

Settings after initialization ............................. A-40

Connecting method after initialization ........... A-40

For direct connection ......................... A-40

For network connection ..................... A-40

Initializing the network settings ..................... A-40

12

- IV Series User's Manual (Monitor) -

Page 15

Maintenance ..................................................... A-41

Attaching the protection sheet....................... A-41

Replacing the front cover .............................. A-41

Index ................................................................. A-42

Contents

- IV Series User's Manual (Monitor) -

13

Page 16

Contents

MEMO

14

- IV Series User's Manual (Monitor) -

Page 17

1

Getting Started

This chapter explains the system congurations

and overview of IV Series, how to check package

contents, and the name and function of each part.

System Conguration .......................................1-2

Overview of IV Series ........................................1-4

Checking the Package Contents ......................1-8

Name and Function of Each Part ...................1-13

1

Getting Started

- IV Series User's Manual (Monitor) -

1-1

Page 18

System Conguration

System Conguration

1

Getting Started

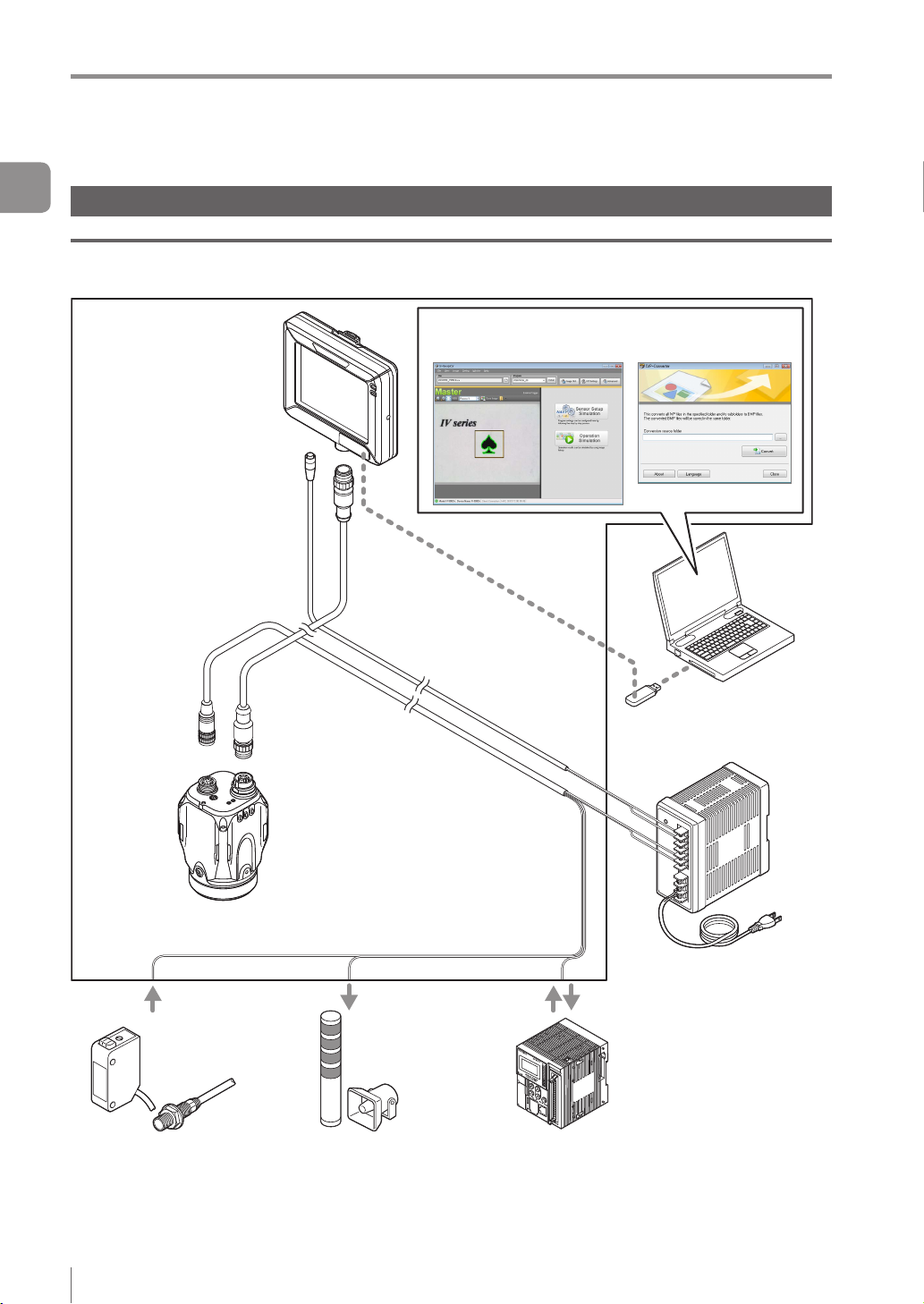

Basic congurations of IV Series

Connecting the monitor and single sensor

IV Series

Intelligent Monitor

IV-M30

Monitor power cable

(2m/5m/10m)

Ethernet communication

Simulator

(IV-Navigator) IVP-Converter

Monitor cable

(2m/5m/10m/20m)

Sensor

IV-500C

IV-500CA

IV-500M

IV-500MA

IV-150M

IV-150MA

IV-2000M

IV-2000MA

Photoelectric/

proximity sensor etc.

Sends the signal to the trigger

input when the target is detected.

(Optional)

Dome attachment

IV-D10

Polarizing lter attachment

OP-87436/OP-87437

Power I/O cable

(2m/5m/10m)

Indicator light/buzzer etc.

Alarm can be output by the

status output function.

USB memory

DC24V power

PLC

PLC can control the trigger input

and the status output function, and

can switch the program number.

1-2

- IV Series User's Manual (Monitor) -

Page 19

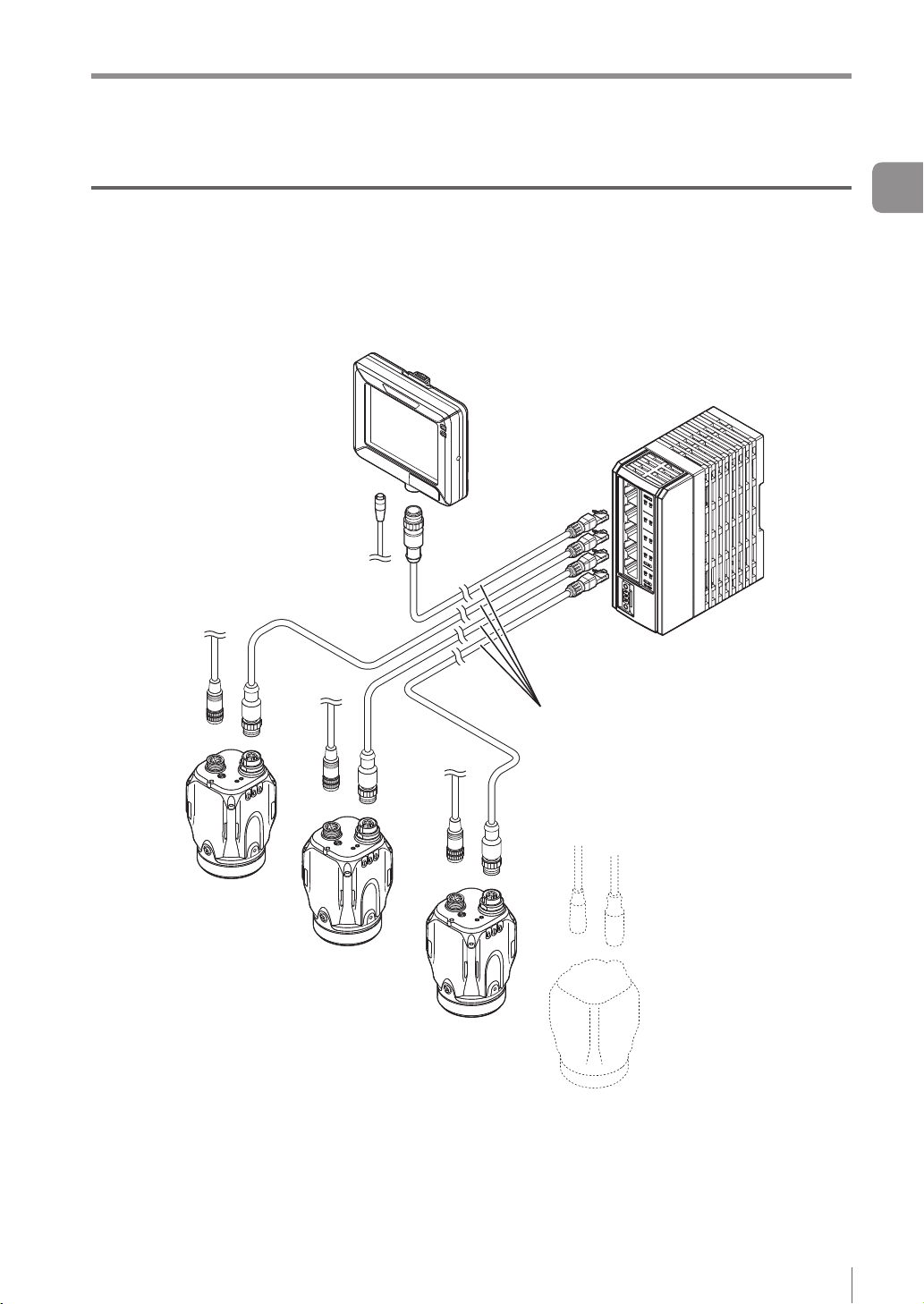

System Conguration

Connecting the monitor and multiple sensors

When the network is connected, the intelligent monitor (IV-M30) can be connected by selecting a single

sensor from among multiple sensors.

* Each sensor requires the power I/O cable.

* IV-M30 requires the power cable.

* A single monitor cannot be connected with multiple sensors at the same time.

Ethernet switch

Ethernet cable

(2m/5m/10m)

1

Getting Started

- IV Series User's Manual (Monitor) -

1-3

Page 20

Overview of IV Series

Overview of IV Series

1

Getting Started

IV Series

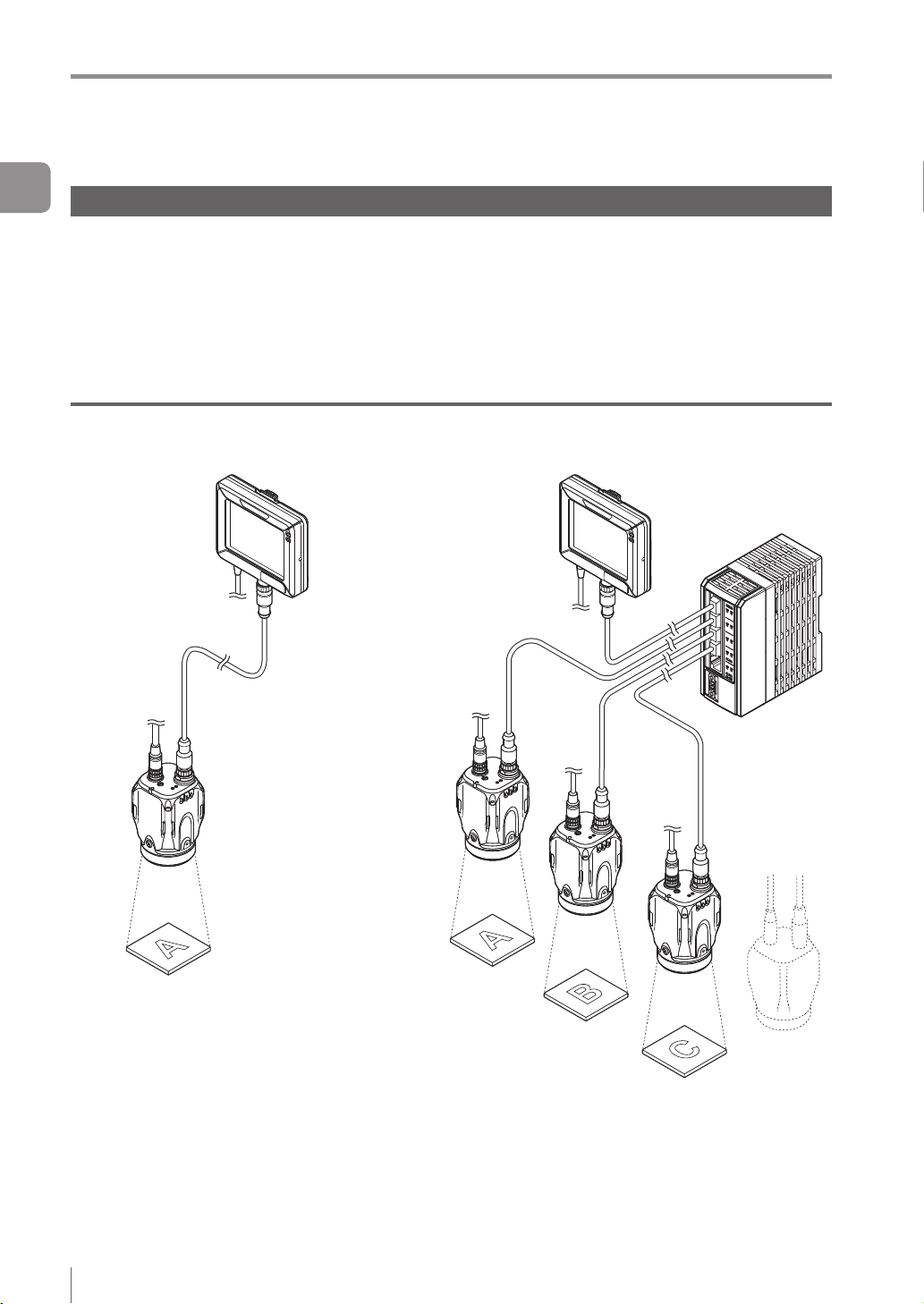

The IV Series is an all-in-one “Vision Sensor” featuring a camera, a light, and a controller. This sensor

can be attached easily so complicated detection operations such as detecting the shapes of parts with a

photoelectric switch can be achieved easily.

Operation condition settings require the intelligent monitor (IV-M30) or the IV software IV-Navigator (IV-H1).

After setting is completed, the sensor can be operated independently.

The sensor with monitor and the sensor with PC are connected via an Ethernet so network connection with

multiple sensors besides direct single connection can be performed.

Using with the intelligent monitor (IV-M30)

Power I/O

Direct connection

Functions of monitor

Setting the sensor

Monitoring the

operation screen

Monitoring the

statistical information

Reading the image

history

Network connection

Ethernet switch

1-4

Functions of sensor

Camera

Light

Image detection

I/O

Saving the image history

- IV Series User's Manual (Monitor) -

Page 21

Overview of IV Series

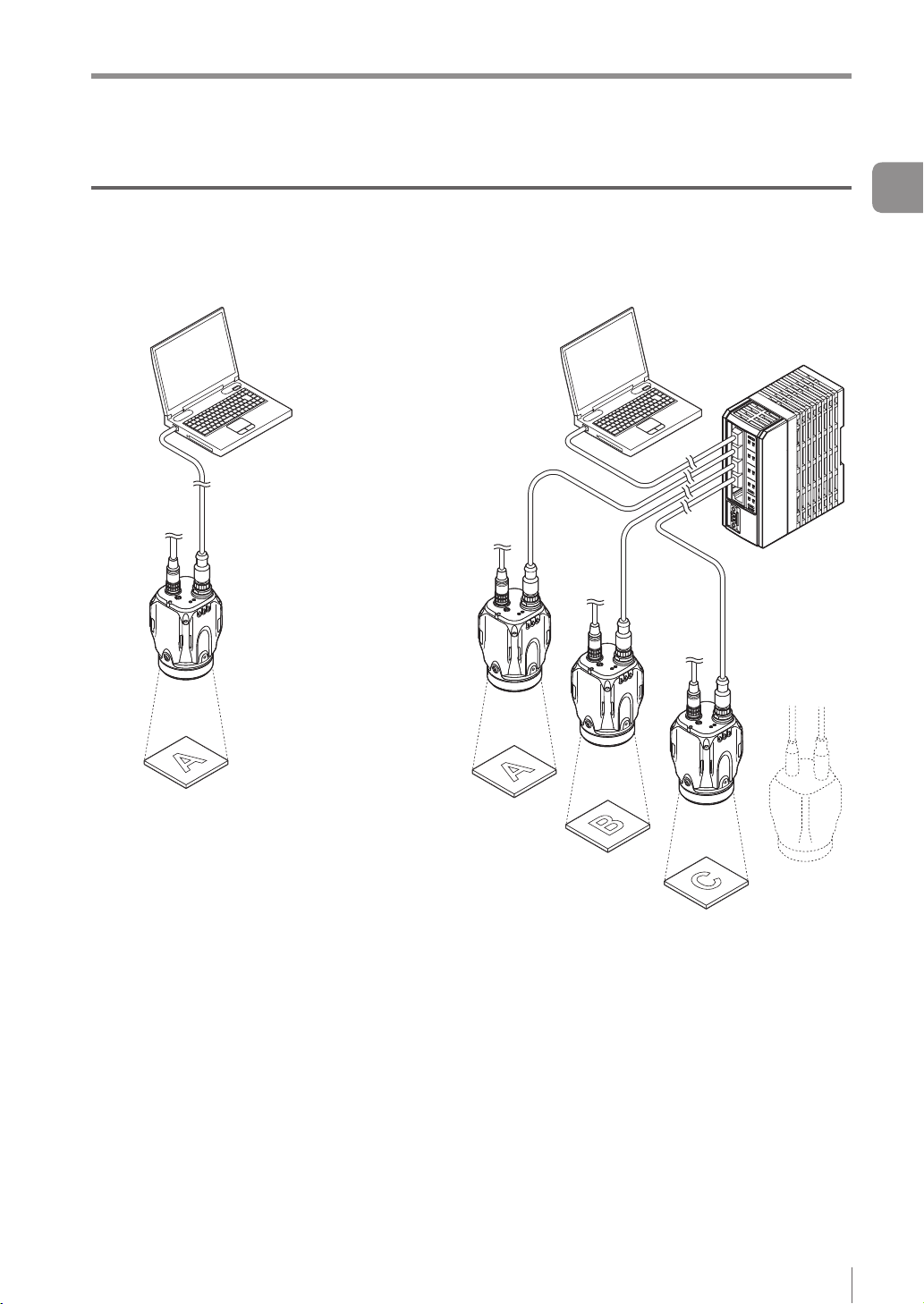

Using with the IV-Navigator (IV-H1)

The IV-Navigator has the same functions as the intelligent monitor (IV-M30).

For details of operations using the IV-Navigator, refer to “IV Series User's Manual (PC Software)”.

Direct connection

Power I/O

Functions of sensor

Functions of IV-Navigator

Setting the sensor

Monitoring the operation

screen

Monitoring the statistical

information

Reading the image history

Simulator

Camera

Light

Image detection

I/O

Saving the image history

Network connection

Ethernet switch

1

Getting Started

- IV Series User's Manual (Monitor) -

1-5

Page 22

Overview of IV Series

1

Getting Started

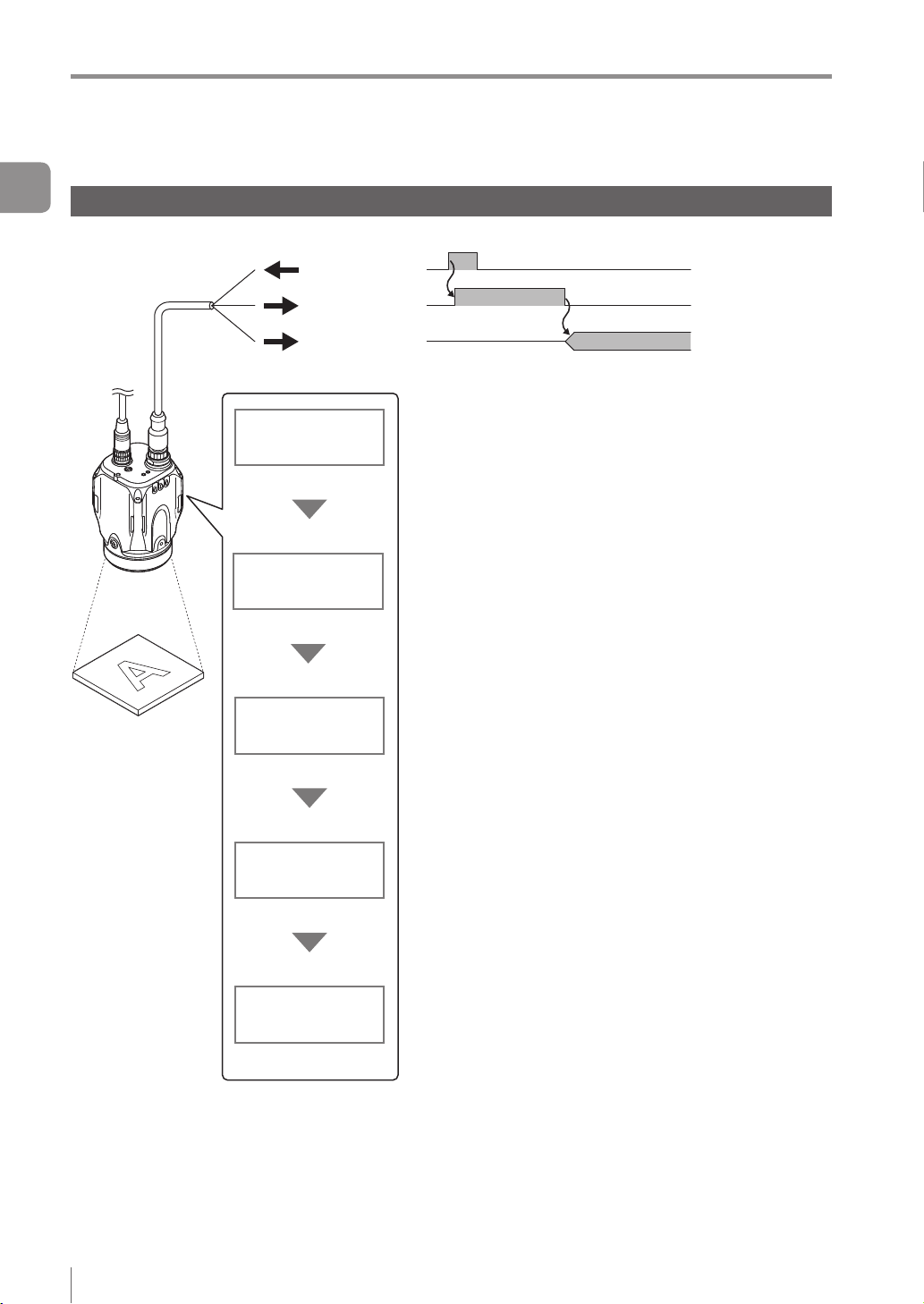

Judgment processing ow

This section describes the basic judgment processing ow of this device.

Trigger input

BUSY output

Total status

output

Trigger input

Imaging

Tool processing

Status output

Inputs the imaging startup signal by synchronizing to the

target position from a photoelectric switch or PLC.

Also, the trigger can be input at a regular interval with an

internal trigger function.

Light up the built-in light and image the target by using the

CMOS image sensor. BUSY output function turns ON.

According to the settings of a detection tool, the image of the target

is scanned for detecting whether a target is high or low quality.

Up to 16 detection tools can be set. Also, misaligned

positions of the target can be corrected by using the

position adjustment tool.

After the detection process is completed, the BUSY output

function turns OFF.

Outputs the status results.

When the total status result is OK, the total status output

is ON.

When the total status result is NG, the total status NG

output is ON.

1-6

Save images

- IV Series User's Manual (Monitor) -

Saves the image to the image history memory in the sensor.

Conditions for saving the image can be selected from “NG

only” or “All”.

Color type can save 100 images, and monochrome type

can save 300 images.

Page 23

MEMO

Overview of IV Series

1

Getting Started

- IV Series User's Manual (Monitor) -

1-7

Page 24

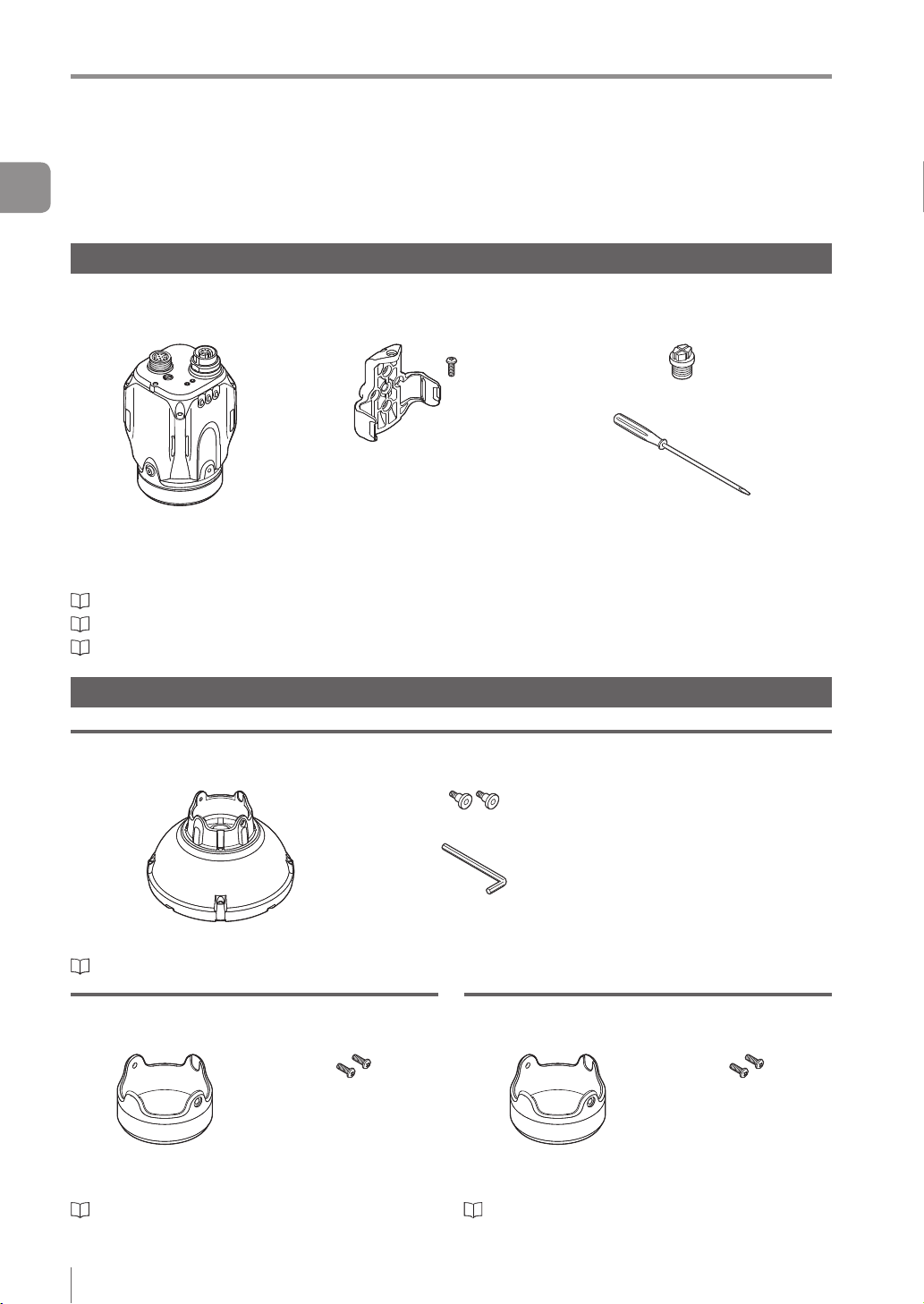

Checking the Package Contents

Checking the Package Contents

1

IV Series are constructed by each following model. Check that all the following packed items are packed

Getting Started

for each model you purchased before using.

Sensor

IV-500C

IV-500CA

The mounting adapter is mounted with the sensors in the

default factory setting.

“Name and Function of Each Part” (Page 1-13)

“Mounting the Sensor” (Page 2-2)

“Cables” (Page 2-12)

Optional parts for the sensor

IV-150M

IV-150MA

Sensor x 1

IV-500M

IV-500MA

Mounting adapter x 1

Screw for mounting

adapter x 1

IV-2000M

IV-2000MA

Waterproof cap for Ethernet connector x 1

Flathead screwdriver x 1

(Manual focus type only)

Instruction Manual x 1

Dome attachment

IV-D10

Mounting screw x 2

Hexagon wrench

Dome attachment x 1

“Using the dome attachment” (Page 2-6)

(L-shaped) x 1

Polarized visible light lter attachment

OP-87436

Mounting screw x 2

Instruction Manual x 1

Polarized visible light

lter attachment x 1

“Using the polarizing lter attachment” (Page 2-7)

Instruction Manual x 1

Infrared polarization lter attachment

OP-87437

Mounting screw x 2

Instruction Manual x 1

Infrared polarization

lter attachment x 1

“Using the polarizing lter attachment” (Page 2-7)

1-8

- IV Series User's Manual (Monitor) -

Page 25

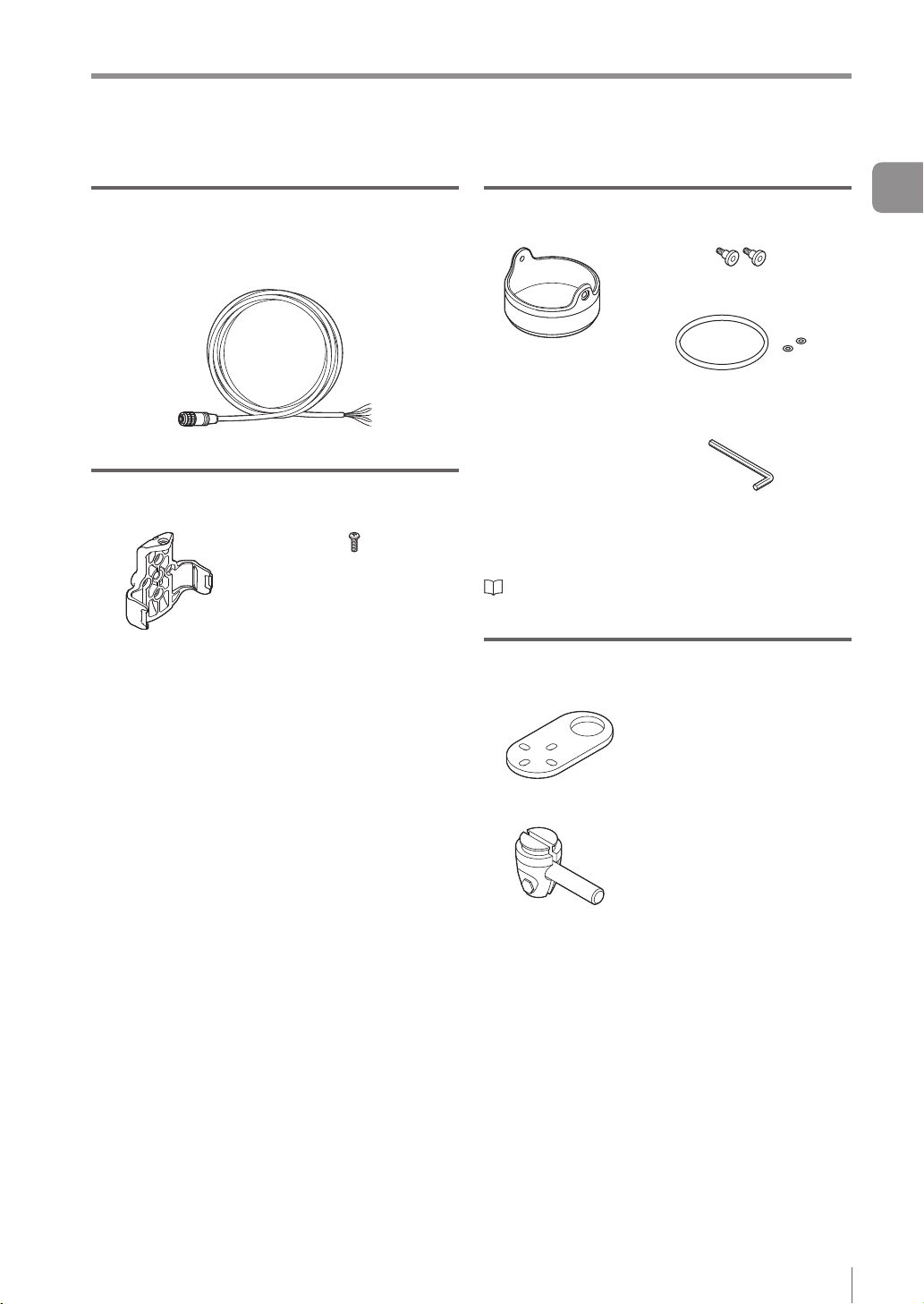

Checking the Package Contents

Power I/O cable (M12 12pin - strand wire)

OP-87440 (2m)

OP-87441 (5m)

OP-87442 (10m)

Power I/O cable (M12 12pin - strand wire) x 1

Mounting adapter

OP-87460

Screw for the mounting

adapter x 1

Mounting adapter x 1

Same as accessories for the sensor.

Optional parts in case of loss/damage.

Front cover (for replacement)

OP-87461

Mounting screw x 2

Front cover (for

replacement) x 1

Optional parts for replacement.

“Replacing the front cover” (Page A-41)

O-shaped ring

(Small x 2, Large x 1)

Hexagon wrench (L-shaped) x 1

Instruction Manual x 1

Bracket

OP-87685

Screw for the bracket and

nut x 1

1

Getting Started

Bracket A x 1

Bracket B x 1

- IV Series User's Manual (Monitor) -

Mounting screw x 4

1-9

Page 26

Checking the Package Contents

1

Getting Started

Intelligent Monitor

IV-M30

“Name and Function of Each Part” (Page 1-13)

“Mounting the Monitor” (Page 2-8)

“Cables” (Page 2-12)

Optional parts for the monitor

Monitor power cable (M8 4pin - strand wire)

OP-87443 (2m)

OP-87444 (5m)

OP-87445 (10m)

Monitor x 1

Stylus x 1

String for hanging the stylus x 1

USB memory (1GB)

OP-87502

Wall mounting adapter x 1

Screw for the adapter x 2

Hexagon nut x 2

Instruction Manual x 1

Starting Guide x 1

USB memory x 1

Monitor power cable (M8 4pin - strand wire)

Protection sheet

OP-87463

Protection sheet x 1

“Attaching the protection sheet” (Page A-41)

1-10

- IV Series User's Manual (Monitor) -

Stylus

OP-87462

String for hanging the

stylus x 1

Stylus x 1

Same as accessories for monitors.

Optional parts in case of loss/damage.

Page 27

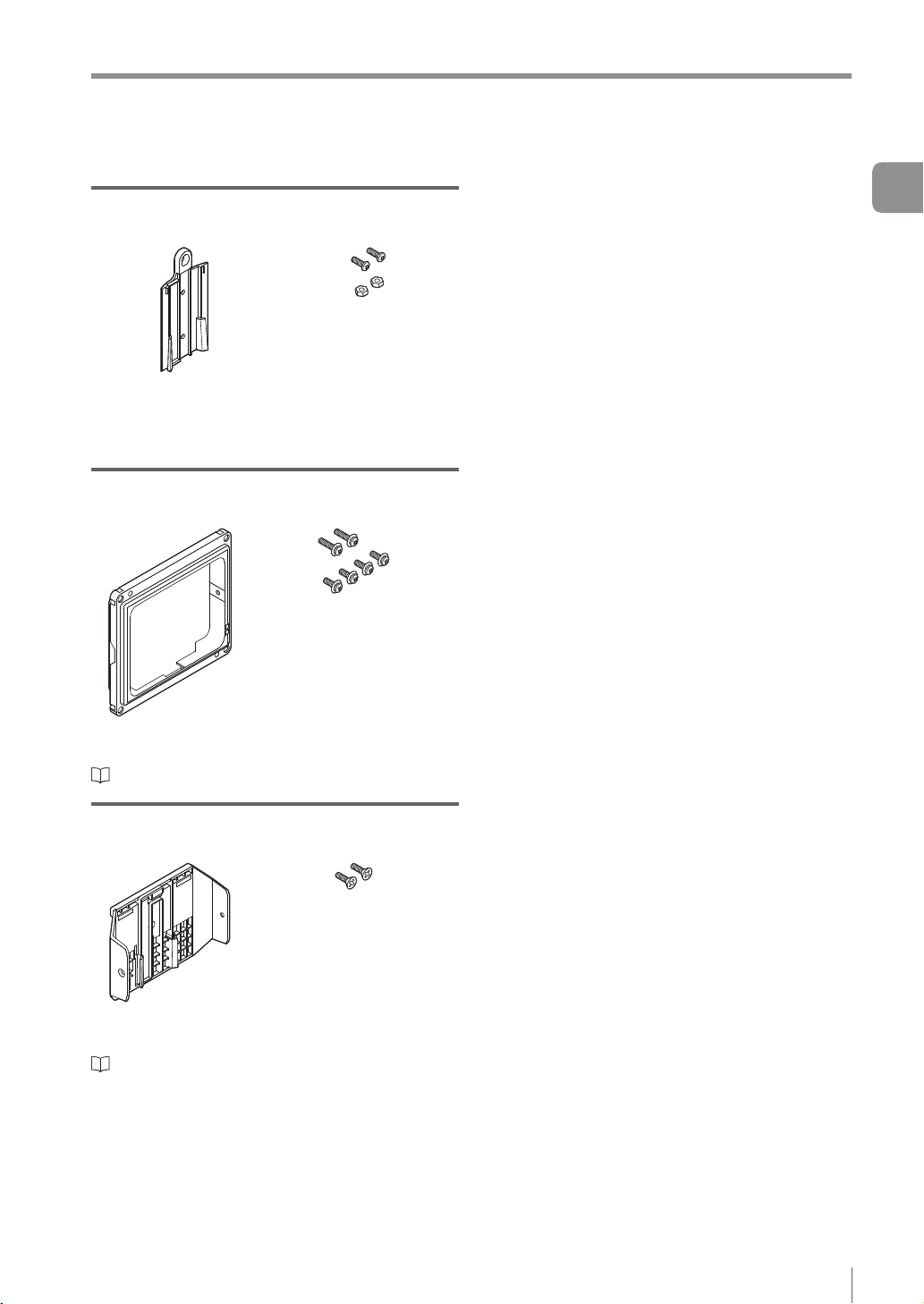

Checking the Package Contents

Wall mounting adapter

OP-87464

Screw for the adapter x 2

Hexagon nut x 2

Wall mounting adapter x 1

Same as accessories for monitors.

Optional parts in case of loss/damage.

Panel mounting adapter

OP-87465

Mounting screw (lateral) x 2

Mounting screw (front) x 4

1

Getting Started

Panel mounting

adapter x 1

“Mounting to a panel” (Page 2-10)

DIN mounting adapter

OP-87466

Mounting screw (lateral) x 2

DIN mounting

adapter x 1

“Mounting to the DIN rail” (Page 2-11)

- IV Series User's Manual (Monitor) -

1-11

Page 28

Checking the Package Contents

1

Getting Started

Communication Cable

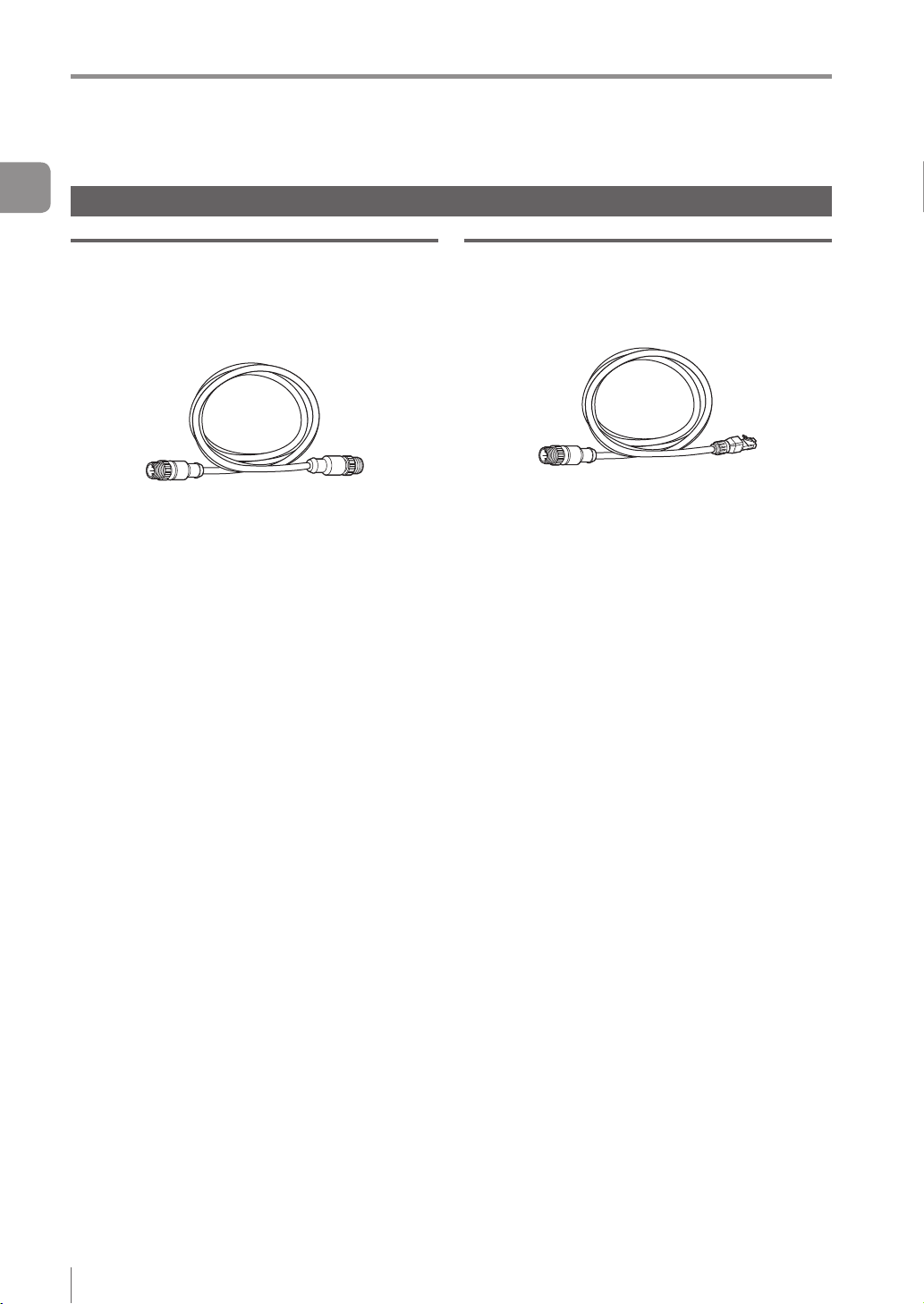

Monitor cable (M12 4pin - M12 4pin)

OP-87450 (2m)

OP-87451 (5m)

OP-87452 (10m)

OP-87453 (20m)

Monitor cable (M12 4pin - M12 4pin) x 1

Ethernet cable (M12 4pin - RJ-45)

OP-87457 (2m)

OP-87458 (5m)

OP-87459 (10m)

Ethernet cable (M12 4pin - RJ-45) x 1

1-12

- IV Series User's Manual (Monitor) -

Page 29

Name and Function of Each Part

1

2

3

4

5

6

7

8

Name and Function of Each Part

Sensor

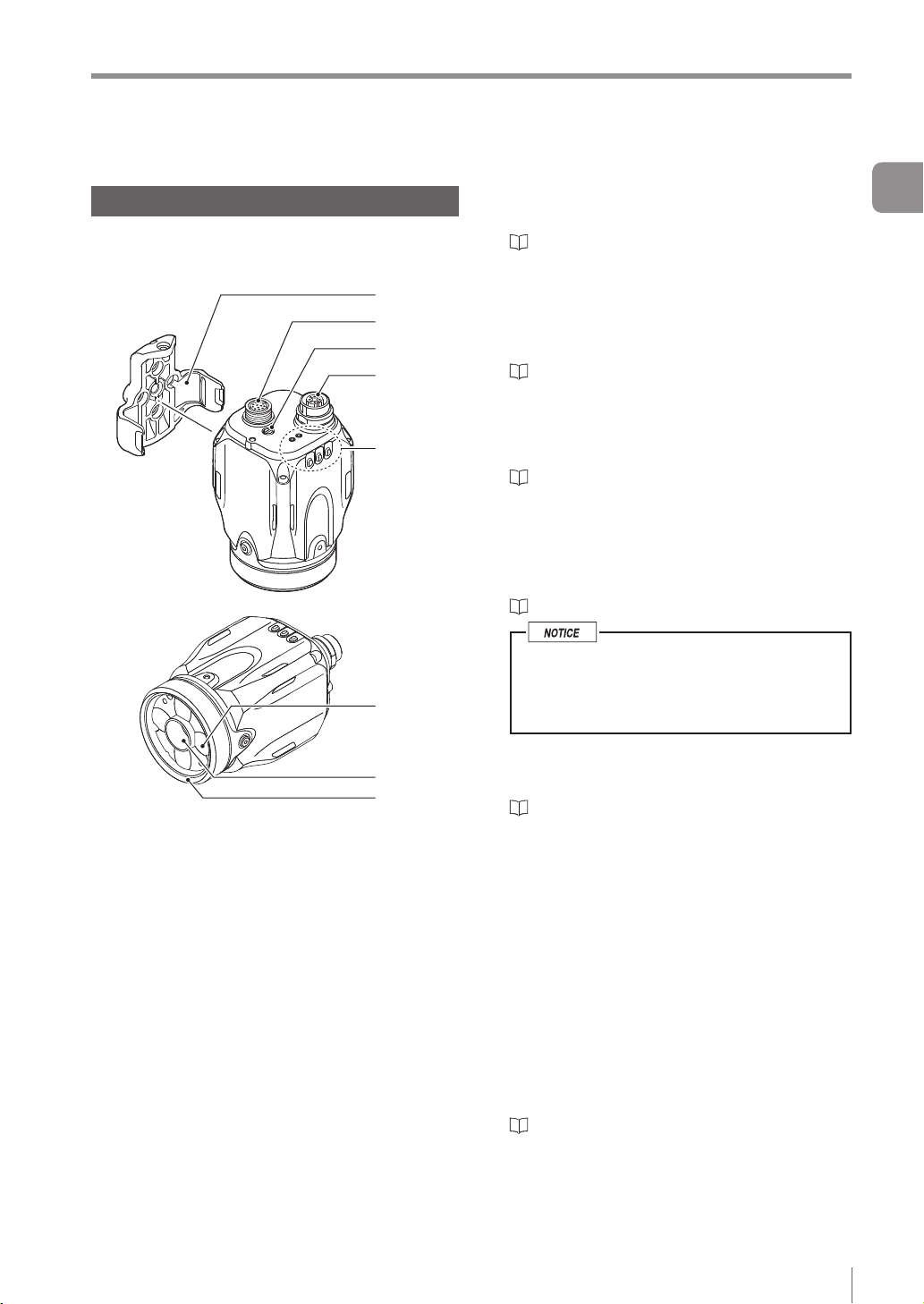

Name and function of each part of the

sensor

1 Mounting adapter

Use this for mounting and xing the sensor.

“Mounting the Sensor” (Page 2-2)

2 Connector for power I/O cable

Connector for connecting the power I/O cable.

Use this for supplying the power to the sensor

and for connecting with external devices.

“Cables” (Page 2-12)

3 Focusing position adjustment screw

(manual focus type only)

Adjusts the focus of the displayed image.

“Focus Adjustment” (Page 4-12)

4 Connector for monitor cable/Ethernet cable

Connector for connecting a monitor cable or

Ethernet cable. Use this for connecting the

monitor, PC, or Ethernet switch.

“Cables” (Page 2-12)

When the cable is not connected, attach

the waterproof cap for Ethernet connector

to maintain enclosure rating.

Tightening torque : 0.45 to 0.55 N·m

1

Getting Started

5 Indicator light

- IV Series User's Manual (Monitor) -

Indicates the operating status of the sensor.

“Operation of the indicator light” (Page 1-14)

6 Built-in light

LED light that illuminates the target

7 Camera

Images the object.

8 Front cover

Protects the camera and built-in lights.

The front cover is protected by the protection

sheet (blue) in the default factory setting. Remove

the sheet when the sensor is to be used.

Front cover for replacement is provided for

maintenance.

“Replacing the front cover” (Page A-41)

1-13

Page 30

Name and Function of Each Part

1

Getting Started

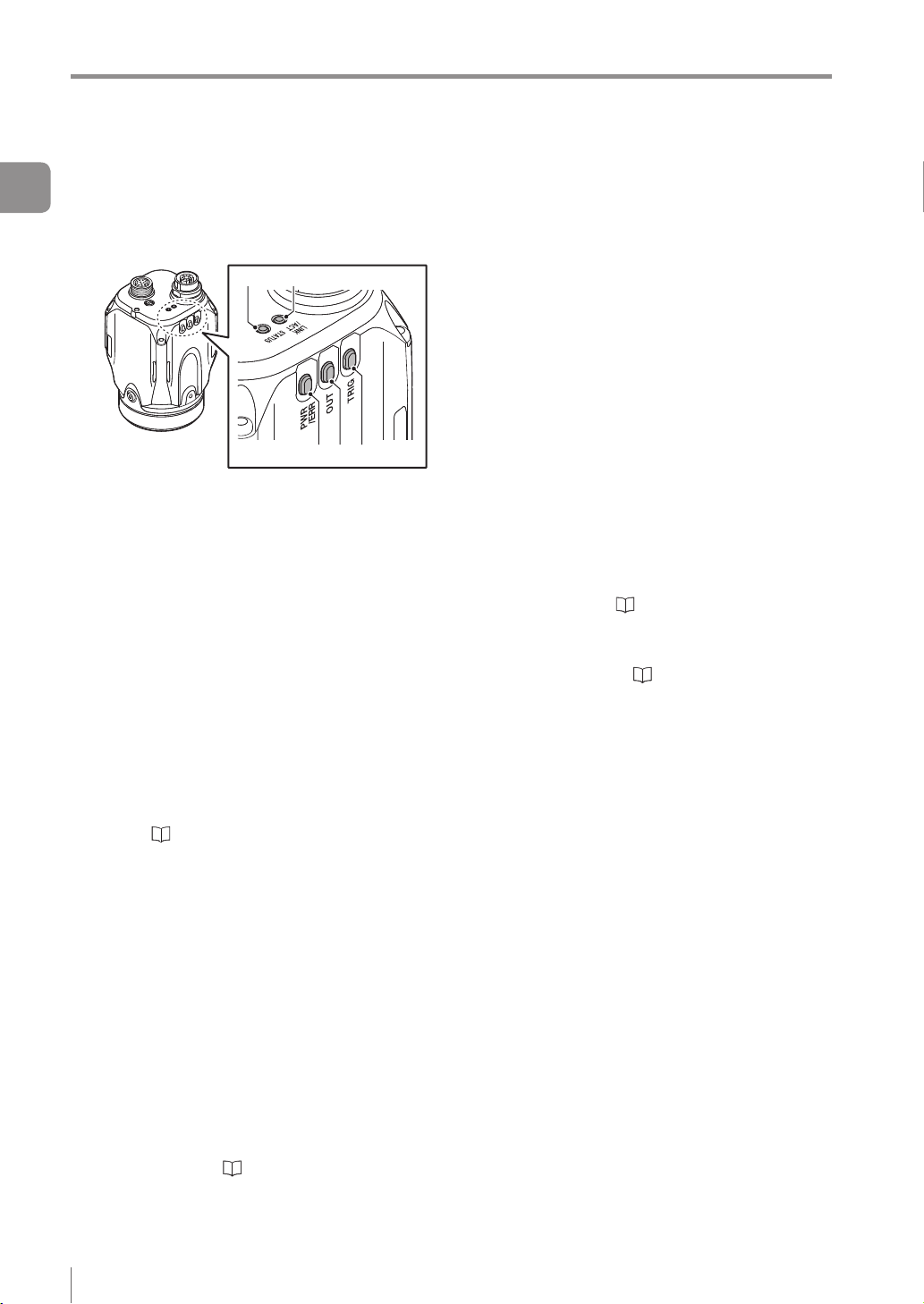

Operation of the indicator light

Details on operations of the indicator light are

shown below.

1 PWR/ERR

Indicates the power supplying status to the

sensor and the error status of the sensor.

Green (ON) ...... Operating.

Green (Blink) .... Setting processing. Operation

Red (ON) .......... Unrecoverable error has

Red (Blink) ....... Recoverable error has

(OFF) ............... Power is not supplied.

For countermeasures when an error occurred,

refer to “Error Messages” (Page A-22).

2 OUT

Indicates the comprehensive result.

Green ...............

Red ..................

(OFF) ............... Setting processing.

Standby status until the rst

Orange (Blink) ..

“Focus adjustment for

4 5

1 2 3

is stopped. Blinks once a

second.

occurred.

occurred.

Adjusting the focusing position

(

manual focus only).

Comprehensive result is “OK”.

Comprehensive result is “NG”.

judge nishes after starting the

operation or after switching

the program number.

Indicates the focusing status

while adjusting the focusing

position with the blinking speed

(manual focus type only).

the manual focusing type”

(Page 4-14)

3 TRIG

Green light lights up (one-shot) according to

input of the internal or external trigger.

4 STATUS

Indicates the connection status within the monitor.

Green (ON) ...... Normally connected with

monitor.

Green (Blink) .... IP address has been retrieved

but the sensor is not correctly

connected with monitor.

(OFF) ............... IP address is not assigned.

Sensor is not correctly

connected with monitor.

Orange (Blink) ..

When the sensor cannot correctly connect with

the monitor, refer to “Remedy when the

Monitor cannot be Connected with the Sensor”

(Page A-28).

5 LINK/ACT

Indicates the linking status within monitor or

Ethernet switch.

Green (ON) ...... Normally linked.

Green (Blink) .... Normally linked, and the data

(OFF) ...............

Indicates the focusing status

while adjusting the focusing

position with the blinking speed

(manual focus type only).

“Focus adjustment for the

manual focusing type” (Page 4-14)

is sending/receiving.

Sensor is not normally linked.

1-14

- IV Series User's Manual (Monitor) -

Page 31

Name and Function of Each Part

10

Monitor

21

1 Power connector

Connects the monitor power cable.

“Cables” (Page 2-12)

2 Connector for the monitor cable/Ethernet

cable

Connector for connecting the monitor cable or

Ethernet cable. Used when connecting with the

sensor or Ethernet switch.

“Cables” (Page 2-12)

3 Unlock button

Push this button when dismounting the monitor from

the wall mounting adapter or DIN mounting adapter.

“Unmounting from the wall mounting adapter”

(Page 2-9)

“Unmounting from the DIN mounting adapter”

(Page 2-11)

4 Indicator light (PWR)

Indicates the operating status of the monitor.

3

4

5

6

7

8

9

Green (ON) ...... The power is turned ON.

Red (ON) ..........

Red (Blink) ....... Recoverable error occurred to

(OFF) ............... The power is turned OFF.

For countermeasures when an error occurred,

refer to

5 Indicator light (SENSOR)

Indicates the connecting status to the sensor.

Green (ON) ...... Connected normally to the

Green

(Slowly blinks)

(OFF) ............... It is not properly connected

If the monitor cannot correctly connect with the

sensor, refer to “Remedy when the Monitor

cannot be Connected with the Sensor” (Page A-28).

6 LCD monitor/Stylus

Displays the operation screen and setup screen.

Operates by touching the screen with the stylus.

7 USB connecting connector

Connector for connecting the USB memory.

Connector is protected by the cover.

“Saving the Sensor Settings and Images to a

USB Memory” (Page 6-18)

8 Stylus

Used to operate the touch-screen.

9 Stylus holder

Stores the stylus.

10

Strap holder

Holds the strap or hangs the stylus.

“Error Messages” (Page A-22).

1

Getting Started

Unrecoverable error occurred

to the sensor or monitor.

the sensor or monitor.

sensor.

... Linked normally but it is not

properly connected to the

sensor.

because it did not link

normally.

- IV Series User's Manual (Monitor) -

1-15

Page 32

Name and Function of Each Part

1

Getting Started

MEMO

1-16

- IV Series User's Manual (Monitor) -

Page 33

2

Installation and

Connection

This chapter explains how to mount the sensor and

monitor, and explains connection procedures.

2

Installation and Connection

Mounting the Sensor .........................................2-2

Mounting the Monitor ........................................2-8

Cables ...............................................................2-12

- IV Series User's Manual (Monitor) -

2-1

Page 34

Mounting the Sensor

Mounting the Sensor

Ground (functional ground) the drain cable

2

Installation and Connection

(FG) of the power I/O cable.

Mount and insulate the sensor. Use the

attached mounting adapter to insulate.

Sensor case has been grounded. If the sensor

is not insulated, the electric potential and

noises may cause a damage or malfunction.

Do not place the sensor in the environment

that exceeds the limit of sensor's resistance

to the environment, or environment that

propagates the vibration directly to the

sensor. Those may cause a damage or

malfunction.

Checking the view and installed distance

For IV Series, installed distance between the view

and object is different depending on the type of the

sensor. Check the type of the sensor to be used

and its view, and place it in the proper distance.

View H

Indicator light

View V

Manual focus type needs to adjust the focusing

position after installed. Reserve the enough

space to adjust and install it.

At the time of installation, it is better to enable

the position or direction adjustment of the

sensor by installing the adjustment system at

the sensor mounting area.

View and optical axis have individual differences.

Adjust the position by checking the actual image

at the time of installation.

Place the sensor where no ambient light has

effect. Ambient light includes solar light, lights of

other devices, and photoelectric sensors. Also,

be careful when the light intensity of the ambient

light changes. Use the shield to protect when the

location cannot be changed.

Place the sensor where no object can block out

the internal light or the view of the sensor.

Detection may become unstable due to the

lights if multiple sensors are placed nearby each

other. Delay the timing of external trigger or use

the shield to avoid interference.

Installed distance

WD

View V = View H x 0.75

(H : V = 4 : 3)

The indicator light of

the sensor side is the

front surface of an

image.

2-2

- IV Series User's Manual (Monitor) -

Page 35

Standard range type (color/monochrome)

100

200

150

300

400

500

600

250

210

100

150

10 20 30 4012 36

1500

1000

2000

2500

10045 200 300 400

Installed distance WD (mm)

50

0

Short range type

5025 70 100 150130 200

View H (mm)

Mounting the Sensor

2

Installation and Connection

50

Installed distance WD (mm)

0

View H (mm)

Long range type

500

300

Installed distance WD (mm)

0

View H (mm)

The value of View H and V will be a half of the

value on the gures above when using the digital

zooming function (monochrome type only).

- IV Series User's Manual (Monitor) -

2-3

Page 36

Mounting the Sensor

Mounting the sensor

2

Mounting the mounting adapter

Installation and Connection

Use the mounting adapter (accessory or OP-87460)

to mount the sensor.

The mounting adapter is mounted with the sensors

in the default factory setting. Remove it from the

sensor.

“Unmounting the sensor” (Page 2-5)

Mounting on the wall

Screw : M3 x 4

Use the commercially available screws which

have head thickness of 3 mm or lower.

Tightening torque : 1.0 N·m or lower

Mounting the sensor onto the mounting adapter

Mount the sensor to the left and right

1

stopper on the mounting adapter.

Sensors cannot be mounted on the side with the

indicator light.

Indicator light

Push the sensor to the

stopper of the xing screw

Mounting from the jig side

Screw : M4 x 4

Use the commercially available screws.

Tightening torque : 1.5 N·m or lower

For details on mounting hole dimensions, refer to

“Dimensions” (Page 8-6).

2-4

- IV Series User's Manual (Monitor) -

Push until you hear the clicking sound from

the both side stoppers

Fix the mounting adapter and sensor

2

using the attached screws.

Screw : M3 x 1

Use the attached screws.

Tightening torque : 0.45 to 0.55 N·m

Remove the

protection sheet

Page 37

Unmounting the sensor

Mounting the Sensor

Dismount the screw.

1

Pull out the stopper of the mounting

2

adapter and unmount the sensor.

Pull out the

stopper

2

Installation and Connection

- IV Series User's Manual (Monitor) -

2-5

Page 38

Mounting the Sensor

Mounting the attachment

2

Using the dome attachment

Installation and Connection

Dome attachment can be used for the standard

range type and short range type sensor.

Do not remove the front cover of the sensor.

Use the dome attachment at a correct

installation distance. Failure to do so may lose

the effect of the dome attachment.

Adjust the brightness with the dome attachment

mounted.

“Auto Brightness Adjustment” (Page 4-11)

For the color type, adjust the white balance with

the dome attachment mounted.

“White Balance (for color type only)” (Page 6-41)

Fix the dome attachment with attached

2

dedicated screws.

Screw : Dedicated screw x 2

Use the attached dedicated screws.

Tightening torque : 0.25 to 0.35 N·m

Mounting the dome attachment

Mount the attachment by aligning the

1

concave part of the dome attachment with

the mounting screw of the front cover of

the sensor.

Screw hole for

mounting the

Front cover

mounting screw

Concave part

attachment

Concave part

Installed distance of the dome

attachment

62 to 112 mm from the front face of the sensor

(0 to 50 mm from the front face of the dome attachment)

Sensor type

Standard range type

Short range type

Installed distance

from the front face

of the sensor

62 to 112 mm

Target

(0 to 50 mm)

2-6

- IV Series User's Manual (Monitor) -

Page 39

Using the polarizing lter attachment

Do not remove the front cover of the sensor.

There are the polarized visible light lter

attachment (OP-87436) and the infrared

polarization lter attachment (OP-87437). Use

the correct polarization lter attachment in

accordance with the illuminant of the sensor light.

Failure to do so may lose the effect.

Adjust the brightness with the polarization lter

attachment mounted.

“Auto Brightness Adjustment” (Page 4-11)

For the color type, adjust the white balance with

the polarization lter attachment mounted.

“White Balance (for color type only)” (Page 6-41)

Mount the attachment by aligning the

1

concave part of the polarizing lter

attachment with the mounting screw of

the front cover of the sensor.

Mounting the Sensor

Fix the polarizing lter attachment with

2

the attached dedicated screws.

Screw : M2.5 x 2

Use the attached dedicated screws.

Tightening torque : 0.25 to 0.35 N·m

Remove the protection

sheet (blue)

2

Installation and Connection

Front cover

mounting screw

Concave part

Screw hole for

mounting the

attachment

Concave part

- IV Series User's Manual (Monitor) -

2-7

Page 40

Mounting the Monitor

Mounting the Monitor

Mounting to a wall

Use the wall mounting adapter (accessories or OP-

2

87464).

Installation and Connection

Hang it on the hook with the wall mounting adapter

mounted to the monitor, or mount the monitor to the

wall mounting adapter mounted on the wall.

Hanging on the hook

For operation take the monitor from the hook and

operate it while holding it in your hands.

Mount the monitor to the wall mounting

1

adapter by aligning the stopper of the wall

mounting adapter to the groove on the

rear monitor.

Slide the monitor down all the way, and conrm

that the monitor is locked.

Mounting with the wall mounting adapter

The monitor can be operated by the following

methods.

Unhang to pick up the monitor from the hook and

operate it.

Operate it while mounted on the wall.

Mount the wall mounting adapter to the wall.

1

Mounting by creating a screw hole in the wall

Screw : M3 x 2

Use commercially available screws.

Tightening torque : 0.27 to 0.33 N·m

Mounting by creating a plated through

hole on the panel

Screw : M3 x 2, Nut : M3 x 2

Use the attached screws and nuts.

Tightening torque : 0.27 to 0.33 N·m

Stopper

Hang the monitor on the hook.

2

2-8

- IV Series User's Manual (Monitor) -

Page 41

Mount the monitor to the wall mounting

2

adapter by aligning the stopper of the wall

mounting adapter to the groove on the

rear monitor.

Slide the monitor down all the way, and conrm

that the monitor is locked.

Mounting the Monitor

Unmounting from the wall mounting adapter

Unlock the monitor from the wall mounting adapter

by pulling toward the unlock button. And slide up to

unmount the monitor mounted to the adapter.

Unlock

2

Installation and Connection

Stopper

- IV Series User's Manual (Monitor) -

2-9

Page 42

Mounting the Monitor

3.5

+1

+1

Mounting to a panel