Page 1

Vision Sensor

Getting Started

1

EtherNet/IP

2

Cyclic communication

3

PROFINET

4

256GB

IV Series

User’s Manual

(Field Network)

Read this manual before use.

After you read this manual, keep it in a safe place for future

reference.

Data I/O communication

5

Reference program

A

Page 2

Introduction

Introduction

Read this manual before using the product in order to achieve maximum performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

Symbols

The following symbols alert you to important messages.

Be sure to read these messages carefully.

It indicates a hazardous situation which, if not avoided, will result

in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

It indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

It indicates a situation which, if not avoided, could result in

product damage as well as property damage.

It indicates cautions and limitations that must be followed during operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

It indicates the reference pages in this manual or the reference pages in separate manuals.

Cautions

(1) Unauthorized reproduction of this manual in whole or part is prohibited.

(2) The contents of this manual may be changed for improvements without prior notice.

(3) An utmost effort has been made to ensure the contents of this manual are as complete as possible. If

there are any mistakes or questions, please contact a KEYENCE ofce listed in the back of the manual.

(4) Regardless of item (3), KEYENCE will not be liable for any effect resulting from the use of this unit.

(5) Any manuals with missing pages or other paging faults will be replaced.

The company names and product names used in this manual are registered trademarks or the trademarks

of their respective companies.

Page 3

Safety Information for IV Series

Safety Information for IV Series

General Precautions

Do not use this product for the purpose to protect a human body or a part of human body.

This product is not intended for use as an explosion-proof product. Do not use this product in

hazardous location and/or potentially explosive atmosphere.

You must verify that the IV Series are operating correctly in terms of functionality and

performance before the start and the operation of the IV Series.

We recommend that you take substantial safety measures to avoid any damage in the event of

a problem occurring.

KEYENCE never warrants the function or performance of the IV Series if it is used in manner

that differs from the IV Series specications contained in this instruction manual or if the IV

Series are modied by yourself.

When the IV Series is used in combination with other instruments, functions and performance

may be degraded, depending on operating conditions and the surrounding environment.

Do not place the instruments, including peripherals, under the rapid temperature change. It

may cause condensation and may damage instruments or peripherals.

Remove the power cable from the power supply if you do not use this product for a long time.

Safety precautions on LED product

Use of controls or adjustments or performance of procedures other than those specied herein

may result in hazardous radiation exposure. Follow the instructions mentioned in this manual.

Otherwise, injury to the human body (eyes and skin) may result.

Do not stare into the direct or specularly reected beam.

Do not disassemble this product. The laser radiation emission from this product is not

automatically stopped when it is disassembled.

Do not direct the beam at people or into areas where people might be present.

Be careful of the path of the LED beam. If there is a possibility that the operator may be

exposed to the specular or diffuse reections, block the beam by installing a protective

enclosure.

Install this product so that the path of the LED beam is not as the same height as that of human

eye.

256GB

1

Page 4

Important Instructions

Important Instructions

Observe the following precautions to prevent malfunction of the IV Series and to

ensure that it is used properly.

Precautions on use

The power of this product and instruments connected to this product must be turned off when

the cable is to be installed or removed. Failure to do so may cause an electric shock or a

product damage.

Use this product in the correct supply voltage. Failure to do so may cause a product damage.

For instructions

Do not turn OFF the power while setting the items or saving the settings. Otherwise, all or

part of the setting data may be lost.

Do not let water, dust or oil stick to the camera/light of the sensor. Failure to do so may cause

a malfunction.

When this product becomes dirty, do not rub it with a wet cloth, benzene, thinner, or alcohol.

Doing so may change the color or shape of the unit.

If the unit is heavily contaminated, disconnect all the cables including the power supply cable,

wipe off the dirt with a cloth soaked with mild detergent, and then wipe with a soft dry cloth.

For external master image registration

If the external master image registration is to be performed frequently, set [Write ROM when

using Ext. Master Save] of the input option to [No] for nonvolatile memory protection of the

internal sensor. When the option is set to [Yes], the nonvolatile memory is guaranteed to write

for 100,000 times.

For automatic focus function

Automatic focus function is used for adjusting the focusing position at the time of installation.

This will not activate during the operation.

Focusing position can be registered in each program. The program congurations are

guaranteed to switch for 100,000 times. If the focusing position does not need to change for

each program, set [Auto Focus Adjustment Position] to [Common] for extending the life-span.

Do not apply shock or vibration during the focusing position adjustment. Failure to do so may

cause a product damage.

Measures to be taken when an abnormality occurs

In the following cases, turn the power OFF immediately. Using the IV Series in an abnormal

condition could cause re, electric shock, or malfunction.

Contact our ofce for repair.

If water or debris enters the IV Series.

If the IV Series is dropped or the case is damaged.

If abnormal smoke or odor emanates from the IV Series.

2

- IV Series User’s Manual (Field Network) -

Page 5

Important Instructions

Precautions on installation

To use this product correctly and safely, avoid installing it in the following locations. Failure to

do so may cause re, electric shock, or malfunction.

Outdoors

Altitude above 2000 m

Locations that are humid, dusty or poorly ventilated

Locations where the temperature is high such as those exposed to direct sunlight

Locations where there are ammable or corrosive gases

Locations where the unit may be directly subjected to vibration or impact

Locations where water, oil, or chemicals may splash onto the unit

To improve the anti-noise feature, install the unit following the precautions below. Otherwise, a

malfunction may occur.

Mount the sensor onto the insulated attached mounting adapter.

Ground the FG cable (drain cable) of the sensor.

Do not mount the unit in a cabinet where high-voltage equipment is already installed.

Mount the unit as far from power lines as possible.

Separate the unit as far as possible from the devices that emit strong electric or magnetic

eld (such as solenoid or chopper).

Separate the I/O signal line from the power line or high-voltage line.

For power supply

Noise superimposed on the power supply could cause malfunction. Use a stabilized DC

power supply congured with an isolation transformer.

When using a commercially available switching regulator, be sure to ground the frame ground

terminal.

Devices including this unit are precision components. Do not apply shock or vibration.

When connecting to a network, let engineers who are knowledgeable about networks handle it.

- IV Series User’s Manual (Field Network) -

3

Page 6

Precautions on Regulations and Standards

Precautions on Regulations and Standards

For IV-500C/IV-500CA/IV-500M/IV-500MA/IV-150M/IV-150MA/ IV-2000M/IV-2000MA

UL Certication

This product is a UL/C-UL Listed product.

UL File No. E301717

Category NRKH, NRKH7

Be sure to consider the following specications when using this product as a UL/C-UL Listed Product.

Use a power supply with Class 2 output dened in NFPA70 (NEC: National Electrical Code).

Power supply/ External input/ Control output shall be connected to a single Class 2 source only.

Use with an over current protection device which is rated 24 V or more and not more than 1A.

Enclosure Type 1 (Based on UL50)

CE Marking

Keyence Corporation has conrmed that this product complies with the essential requirements of

the applicable EC Directive, based on the following specications. Be sure to consider the following

specications when using this product in the Member State of European Union.

EMC Directive (2004/108/EC)

Applicable Standard EMI: EN60947-5-2, Class A

EMS: EN60947-5-2

The length of power I/O cable, Ethernet cable and Monitor cable must be less than or equal to 30m.

Remarks:

These specications do not give any guarantee that the end-product with this product incorporated

complies with the essential requirements of EMC Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to EMC Directive.

Low-Voltage Directive (2006/95/EC)

Applicable Standard: EN62471

4

- IV Series User’s Manual (Field Network) -

Page 7

Version of the IV Series

Version of the IV Series

You can download the most recent operation software for the sensor (IV-150/500/2000) and IV-Navigator

(IV-H1) from the KEYENCE web site.

Please refer to the description on the homepage for the introduction method.

URL : http://www.keyence.com/

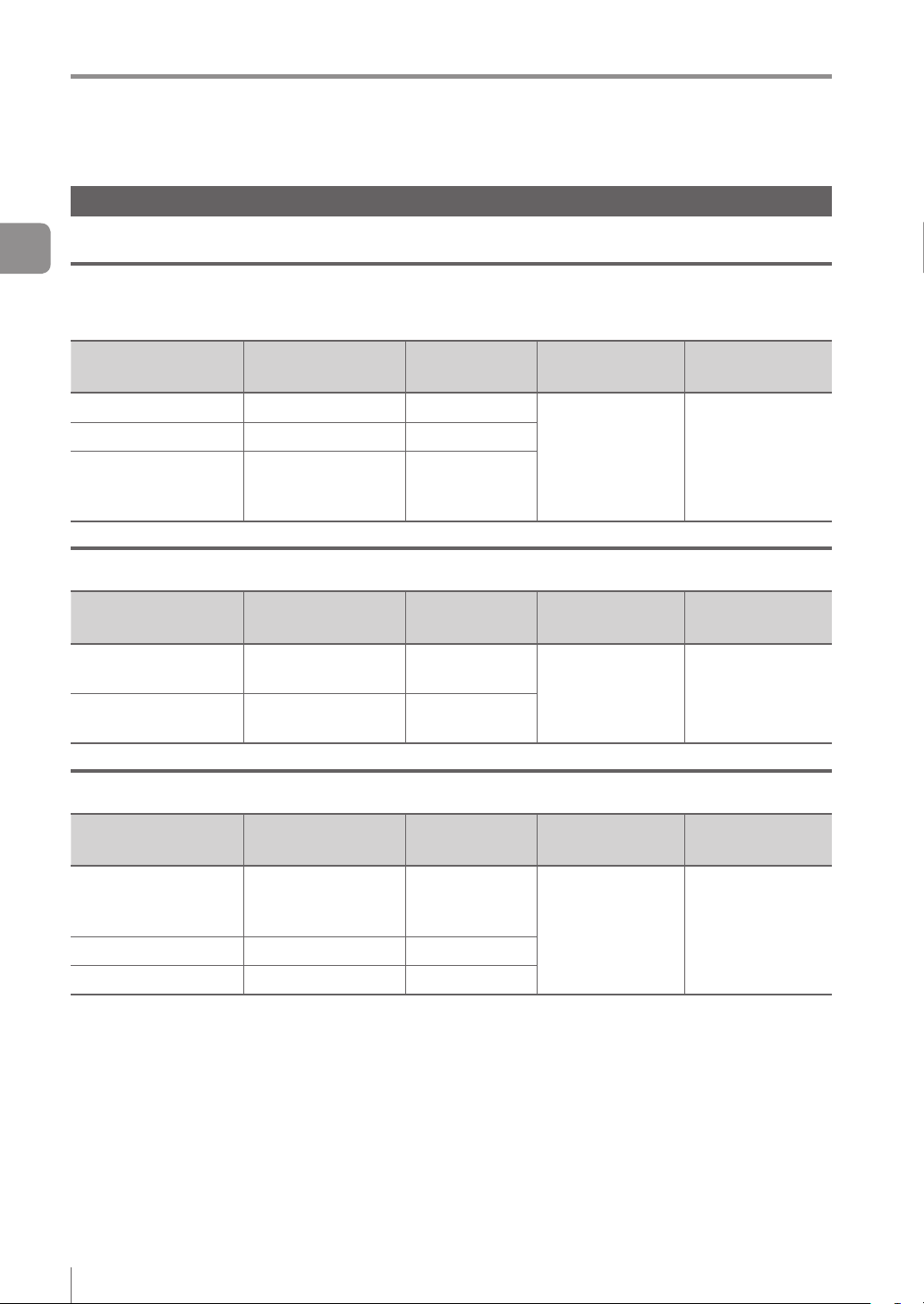

Operation software of the sensor (IV-150/500/2000)

Version Description

R1.00.00 The initial version.

R1.01.00 The processing time has been speeded up.

R1.10.00

R2.00.00

The processing time and the response time to program switching input have been

speeded up.

This is the version of this document.

The following functions have been added.

Logic output

Total status NG output

RUN output

FTP client function

Field network (EtherNet/IP, PROFINET)

Operation software of the monitor (IV-M30)

Version Description

R1.00.00 The initial version.

R1.01.01 Compatibility with Chinese (Simplied) / Chinese (Traditional).

R1.02.00 Compatibility with German.

R1.10.00 Compatibility with Tool Auto Tuning using a registration information le (*.ivt).

R2.00.00

This is the version of this document.

Compatibility with Italian / French / Spanish / Portuguese / Korean.

- IV Series User’s Manual (Field Network) -

5

Page 8

Version of the IV Series

IV-Navigator (IV-H1)

Version Description

R1.00.00 The initial version.

R1.01.00 Compatibility with German.

R1.02.00 Compatibility with Chinese (Simplied) / Chinese (Traditional).

The following functions have been added.

Addition of the IV-Simulator function

Addition of the image capture function to the operation of the [Save Image] button

R1.10.00

R2.00.00

Addition of the [Size] selection function to “Remove Outline”

Addition of the [Display Master Image] button to “Tool Auto Tuning”

Addition of the [Language] button (language selection) to the Activation Menu screen

This is the version of this document.

Compatibility with Italian / French / Spanish / Portuguese / Korean.

IVP-Convertor has been added.

6

- IV Series User’s Manual (Field Network) -

Page 9

Structure of This Manual

Structure of This Manual

1

2

3

4

5

A

Getting Started

EtherNet/IP

Cyclic communication

PROFINET

Data I/O communication

Reference program This chapter explains Reference program, etc.

This chapter explains the system congurations and

overview of IV Series.

This chapter describes the overview of EtherNet/IP and

the communication specications and functions of

the EtherNet/IP communication in the IV series.

This chapter describes the overview, setting method, data

allocation, and operating procedure of

the cyclic communication in the EtherNet/IP communication.

This chapter describes the overview of PROFINET and

the communication specications and functions of

the PROFINET communication in the IV series.

This chapter describes the overview, setting method, data

allocation, and operating procedure of

the data I/O communication in the PROFINET communication.

1

2

3

4

5

A

- IV Series User’s Manual (Field Network) -

7

Page 10

Contents

Contents

Introduction

Symbols

Cautions

Safety Information for IV Series..............................1

General Precautions ...........................................1

Safety precautions on LED product ....................1

Important Instructions .............................................2

Precautions on use .............................................2

Measures to be taken when an abnormality

occurs..................................................................2

Precautions on installation ..................................3

Precautions on Regulations and Standards ...........4

For IV-500C/IV-500CA/IV-500M/IV-500MA/

IV-150M/IV-150MA/IV-2000M/IV-2000MA ........... 4

UL Certication ................................................4

CE Marking ......................................................4

Version of the IV Series ..........................................5

Operation software of the sensor

(IV-150/500/2000) ...............................................5

Operation software of the monitor (IV-M30) ........5

IV-Navigator (IV-H1) ............................................ 6

Structure of This Manual ........................................7

Contents .................................................................8

Chapter 1 Getting Started

System Conguration ..........................................1-2

Basic congurations of IV-Series

Connecting the host device and

single sensor.................................................1-2

Connecting the host device and

multiple sensors

Overview of IV Series

IV Series...........................................................1-4

System conguration example......................1-4

Operation of the indicator light

............................................1-3

..........................................1-4

.....................1-2

......................1-5

Chapter 2 EtherNet/IP

Overview of EtherNet/IP ......................................2-2

What is EtherNet/IP?........................................2-2

EtherNet/IP communication specications and

functions in the IV series .....................................2-3

EtherNet/IP communication specications

in the IV series .................................................2-3

Overview of the Ethernet/IP

communications functions in the IV series .......2-3

List of supported PLCs .....................................2-4

Keyence PLC ................................................2-4

KV series ..............................................2-4

Rockwell Automation PLC ............................2-4

OMRON PLC ................................................2-4

Chapter 3 Cyclic communication

Overview of the cyclic communication.................3-2

What is cyclic communication? ........................3-2

Cyclic communication setting method .................3-3

Setting the IV series .........................................3-3

When settings on the monitor (IV-M30) ........3-3

When setting by IV-Navigator (IV-H1) ...........3-4

PLC settings .....................................................3-5

Establishing the connection ..........................3-5

Keyence KV series settings ..........................3-7

Rockwell Automation Control Logix series

settings

Data allocation in the cyclic communication

Input Assembly (IV series → PLC) .................3-10

Input Assembly parameter details ..................3-12

Output Assembly (PLC → IV series)

Output Assembly parameter details

Error code list

Warning code list ............................................3-23

Operating procedure of

the cyclic communication...................................3-26

Reading out the overall status result of

the IV series

(Handshake control [Disabled]) ......................3-26

Reading out the overall status result of

the IV series

(Handshake control [Enabled]).......................3-28

Switching the programs in the IV series

Registering a master image for

the IV series externally ...................................3-30

.........................................................3-8

Input Assembly Address 0:

Control result (response)

Input Assembly Address 1:

Control error result ..............................3-12

Input Assembly Address 2 to 3:

Handshake control/status/error result

Input Assembly Address 4 to 7:

Status result

Input Assembly Address 8 to 23:

Error/status/status result information

Input Assembly Address 24 to 51:

Statistics information

Input Assembly Address 52 to 71:

Position correction information ...........3-18

Input Assembly Address 72 to 391:

Tool information

Output Assembly Address 0 to 1:

Control request

Output Assembly Address 2 to 3:

Handshake control ..............................3-21

Output Assembly Address 4 to 11:

Program No. .......................................3-21

When a trigger is successful ...............3-26

When a trigger is unsuccessful ...........3-27

........................................3-15

..................................3-18

...................................3-20

.................................................3-22

....................3-12

...........................3-17

......3-10

...3-13

..3-16

..............3-19

...............3-20

.........3-29

8

- IV Series User’s Manual (Field Network) -

Page 11

Chapter 4 PROFINET

Overview of PROFINET ......................................4-2

What is PROFINET? ........................................4-2

PROFINET communication specications and

functions in the IV series .....................................4-3

IV series PROFINET communication

specications....................................................4-3

Specifying the IP address using

the DCP protocol ..............................................4-3

Overview of the PROFINET communication

functions in the IV series ..................................4-4

List of supported PLCs

Siemens PLC

Phoenix Contact PLC ...................................4-5

OMRON PLC ................................................4-5

.....................................4-5

................................................4-5

Chapter 5 Data I/O communication

Overview of the data I/O communication.............5-2

What is data I/O communication? ....................5-2

Data I/O communication setting method .............5-3

Setting the IV series .........................................5-3

When settings on the monitor (IV-M30) ........5-3

When setting by IV-Navigator (IV-H1) ...........5-4

Setting the device name...................................5-5

When settings on the monitor (IV-M30) ........5-5

When setting by IV-Navigator (IV-H1) ...........5-5

PLC settings .....................................................5-6

Establishing the data I/O communication .....5-6

Setting the Siemens TIA Portal .....................5-7

Setting the Siemens SIMATIC Manager .....5-11

Data allocations in

the data I/O communication...............................5-16

Control Modules (PLC → IV series) ...............5-16

Command Control ...............................5-16

Status Modules (IV series → PLC) ................5-17

Command Status Bits .........................5-17

Device Result Bits ...............................5-17

Device Status Words ..........................5-18

Device Statistics .................................5-18

Tool Result Modules (IV series→ PLC) ..........5-19

Position Adjust Result .........................5-19

Tool Result ..........................................5-19

Control Modules parameter details ................5-20

Command Control Address 0 to 1:

Control request ...................................5-20

Command Control Address 2 to 3:

Handshake control ..............................5-21

Command Control Address 4 to 11:

Program No. .......................................5-21

Status Modules parameter details..................5-22

Command Status Bits Address 0:

Control result (response) ....................5-22

Command Status Bits Address 1:

Control error result ..............................5-22

Command Status Bits Address 2 to 3:

Handshake control/status/error result

Device Results Bits Address 0 to 3:

Status result ........................................5-25

- IV Series User’s Manual (Field Network) -

...5-23

Contents

Device Status Words

Address 0 to 15:

Error/status/status result information

Device Statistics Address 0 to 27

(Statistics information) ........................5-27

Tool Result Modules parameter details ..........5-28

Position Adjust Result

Address 0 to 19

(Position correction information) .........5-28

Tool Result Address 0 to 19

(Tool information) ................................5-28

Error code list .................................................5-29

Warning code list ............................................5-30

Operating procedure of

the data I/O communication...............................5-32

Reading out the overall status result of

the IV series

(Handshake control [Disabled]) ......................5-32

When a trigger is successful ...............5-32

When a trigger is unsuccessful ...........5-33

Reading out the overall status result of

the IV series

(Handshake control [Enabled]).......................5-34

Switching the programs in the IV series .........5-35

Registering a master image for

the IV series externally ...................................5-36

...5-26

Appendices

Reference program (EtherNet/IP)....................... A-2

Handshake control [Disabled]

Keyence KV series ...................................... A-2

Description of the reference program

Rockwell Automation PLC

Description of the reference program

Handshake control [Enabled]

Keyence KV series ...................................... A-4

Description of the reference program

Rockwell Automation PLC ...........................A-5

Description of the reference program

Program switching........................................... A-6

Keyence KV series

Description of the reference program

Rockwell Automation PLC ...........................A-7

Description of the reference program

Reference program (PROFINET)

Index

Handshake control [Disabled] ......................... A-8

Siemens PLC ............................................... A-8

Description of the reference program

Handshake control [Enabled]

Siemens PLC

Description of the reference program

Program switching......................................... A-10

Siemens PLC

Description of the reference program

................................................................. A-12

...................................... A-6

............................................... A-9

............................................. A-10

......................... A-2

... A-2

........................... A-3

... A-3

.......................... A-4

... A-4

... A-5

... A-6

... A-7

....................... A-8

... A-8

.......................... A-9

... A-9

... A-10

9

Page 12

Contents

MEMO

10

- IV Series User’s Manual (Field Network) -

Page 13

1

Getting Started

This chapter explains the system congurations

and overview of IV Series.

System Conguration

Overview of IV Series ........................................1-4

.......................................1-2

1

Getting Started

- IV Series User’s Manual (Field Network) -

1-1

Page 14

System Conguration

System Conguration

1

Getting Started

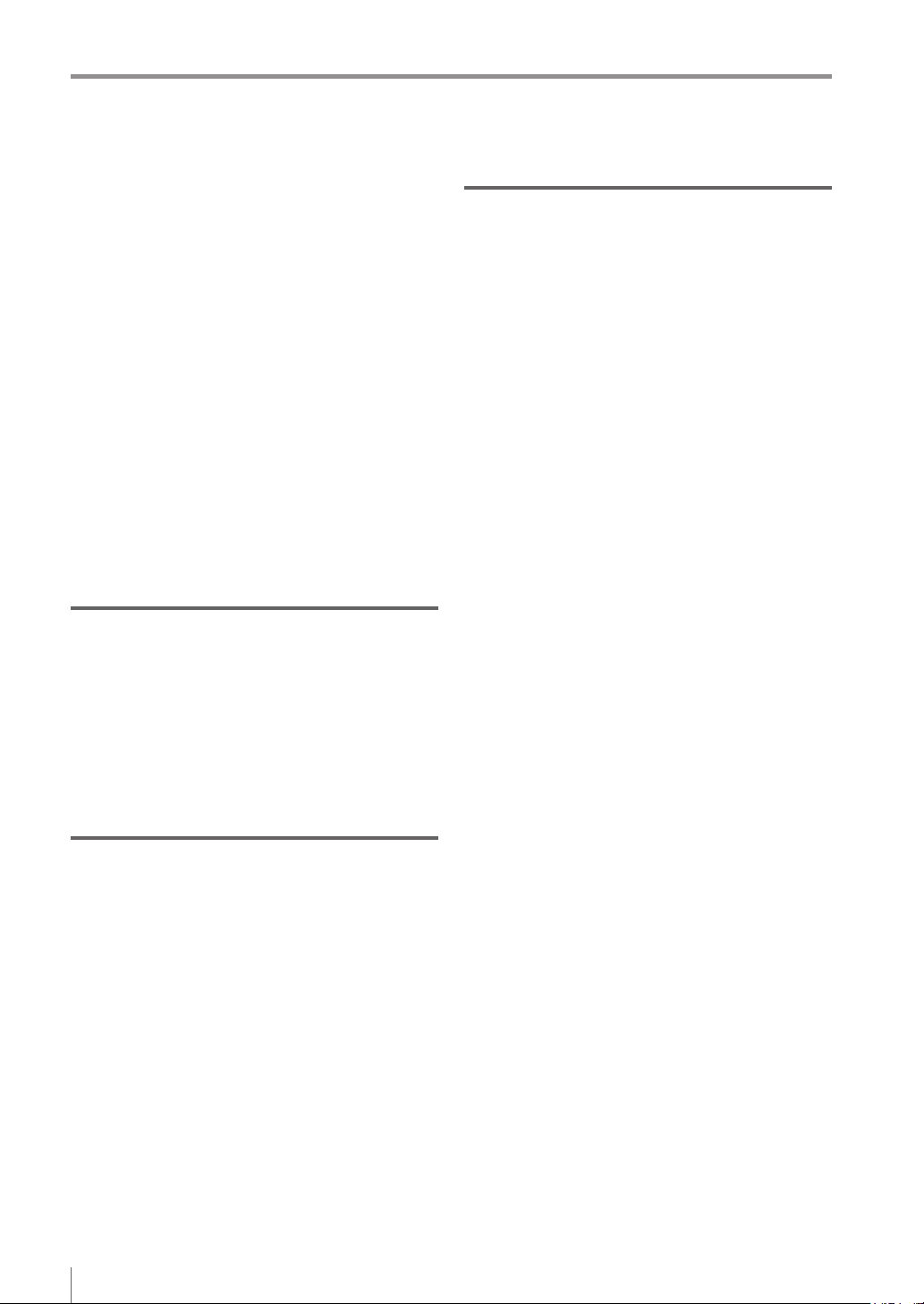

Basic congurations of IV-Series

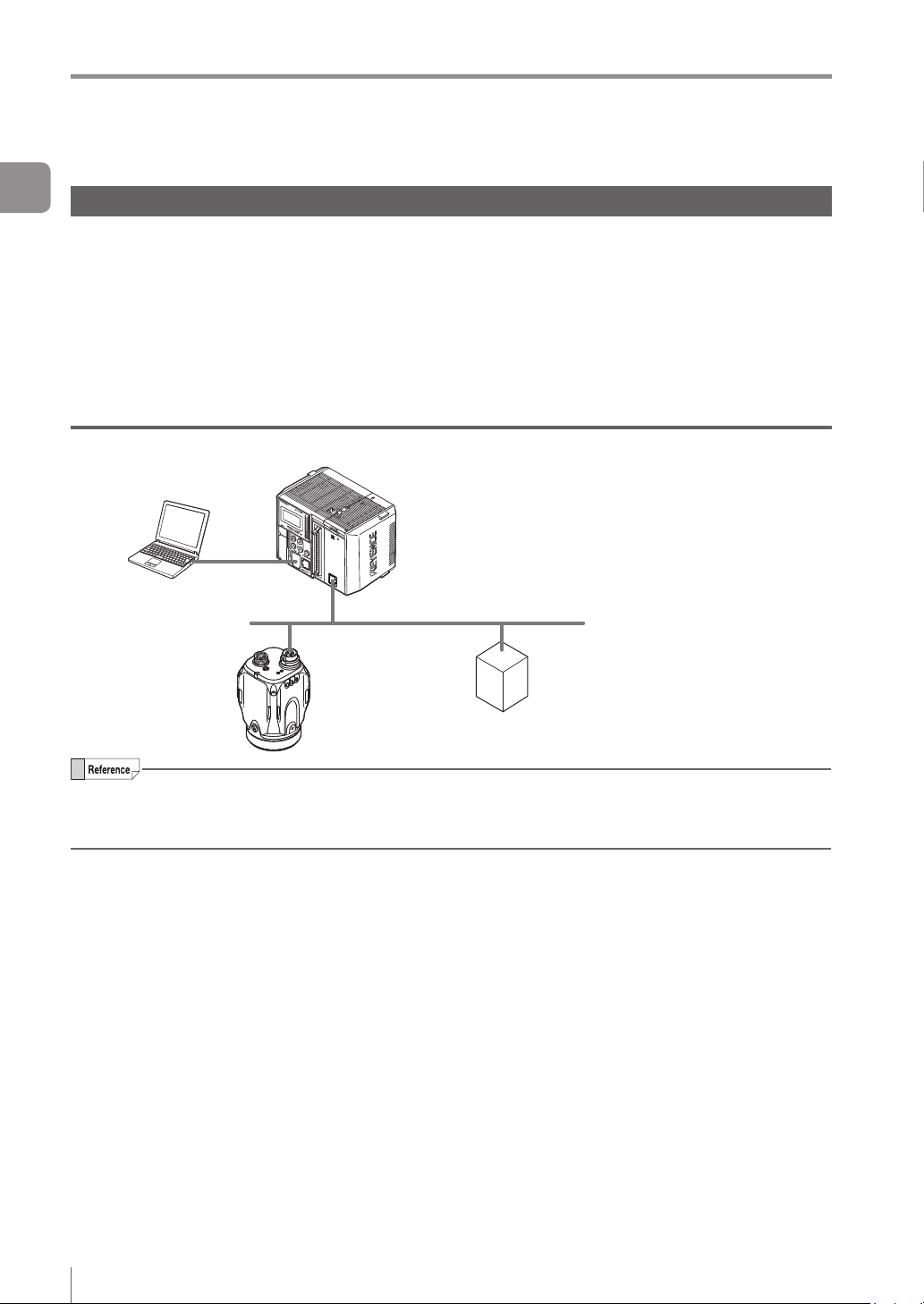

Connecting the host device and single sensor

IV Series

PLC or other host device

Ethernet cable

(2m/5m/10m)

In addition to the status result import,

the trigger control and switching

of the set program number can be

performed with the control output.

Setting support software

(IV-H1)

Sensor

IV-500C

IV-500CA

IV-500M

IV-500MA

IV-150M

IV-150MA

IV-2000M

IV-2000MA

Photoelectric/

proximity sensor etc.

Sends the signal to the

trigger input when the

target is detected.

Power I/O cable

(2m/5m/10m)

(Optional)

Dome attachment

IV-D10

Polarizing lter attachment

OP-87436/OP-87437

24 VDC power

Indicator light/buzzer

etc.

Alarm can be output

by the status output

function.

1-2

- IV Series User’s Manual (Field Network) -

Page 15

System Conguration

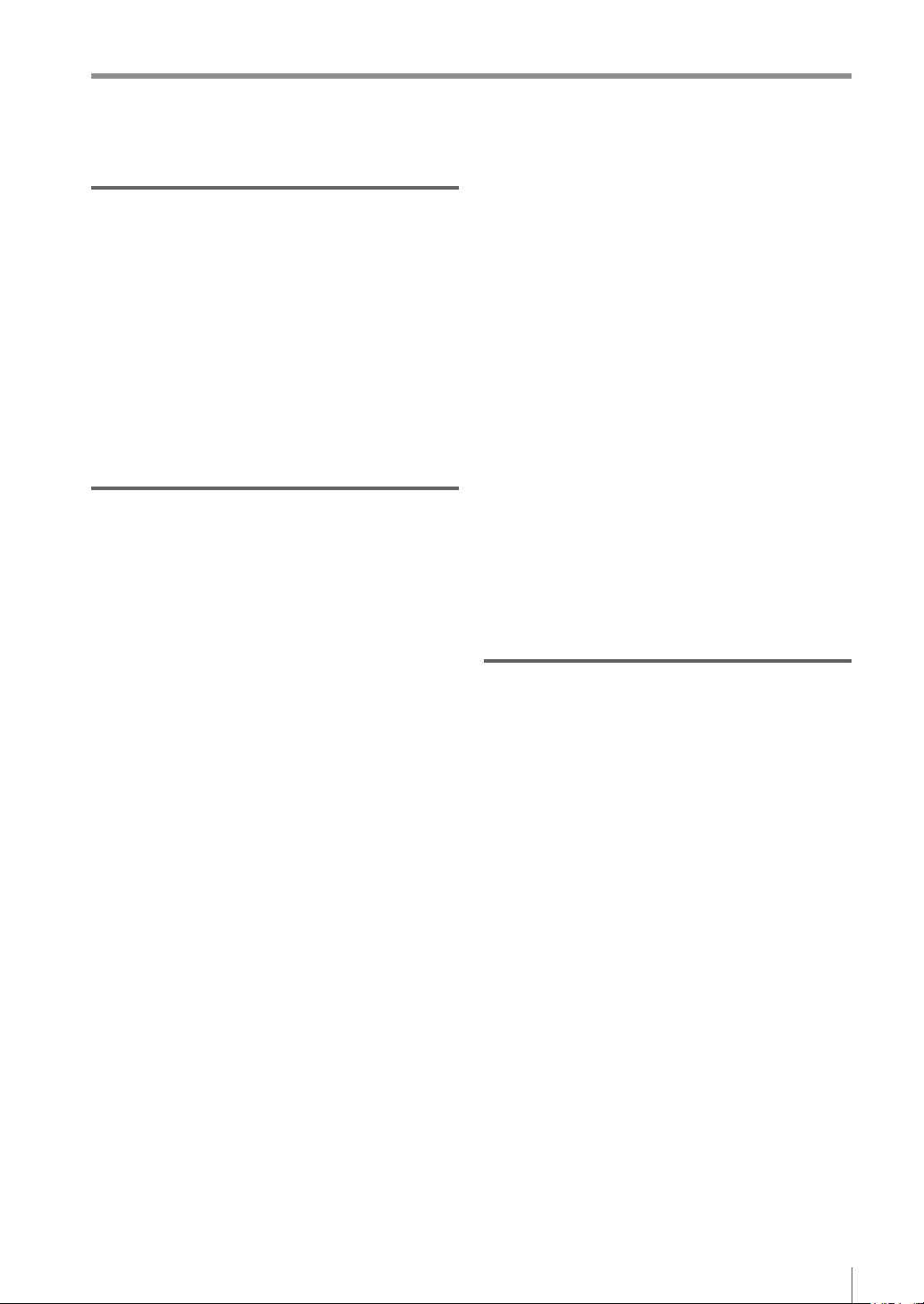

Connecting the host device and multiple sensors

PLC or other host device

Ethernet cable

(2m/5m/10m)

1

Getting Started

In addition to the status result import,

the trigger control and switching of the

set program number can be performed

with the control output.

Ethernet switch

Setting support software

(IV-H1)

- IV Series User’s Manual (Field Network) -

1-3

Page 16

Overview of IV Series

Overview of IV Series

1

Getting Started

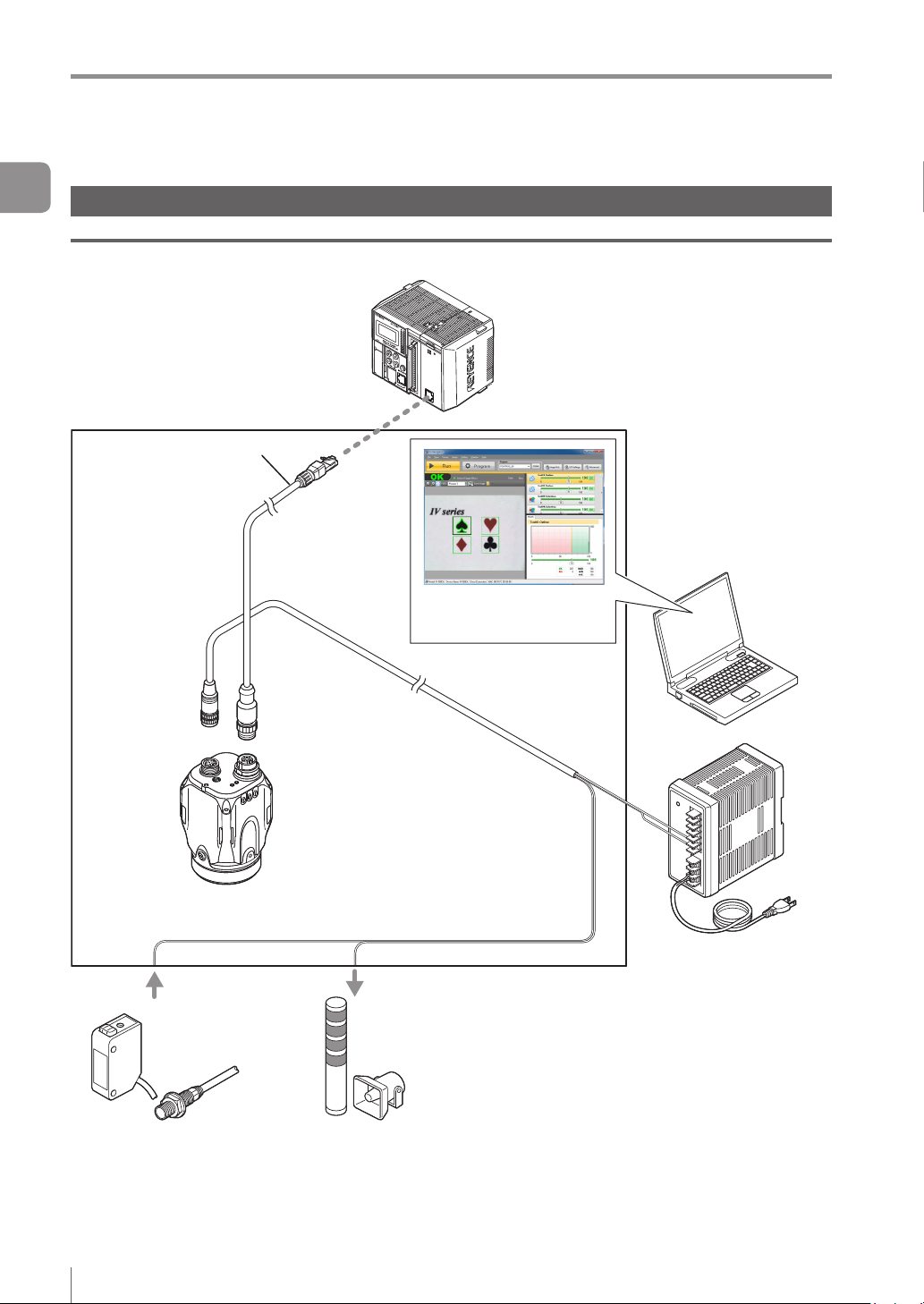

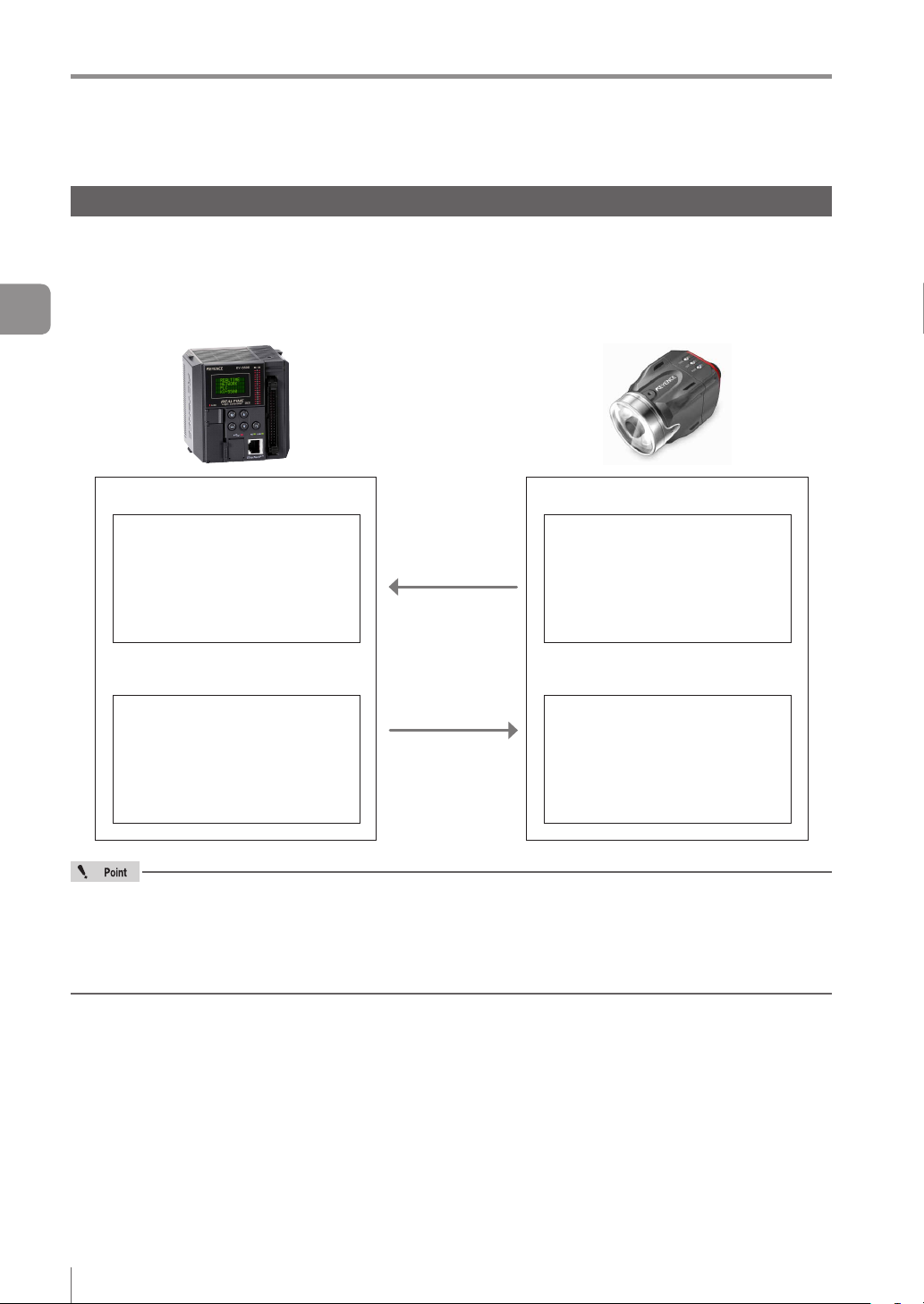

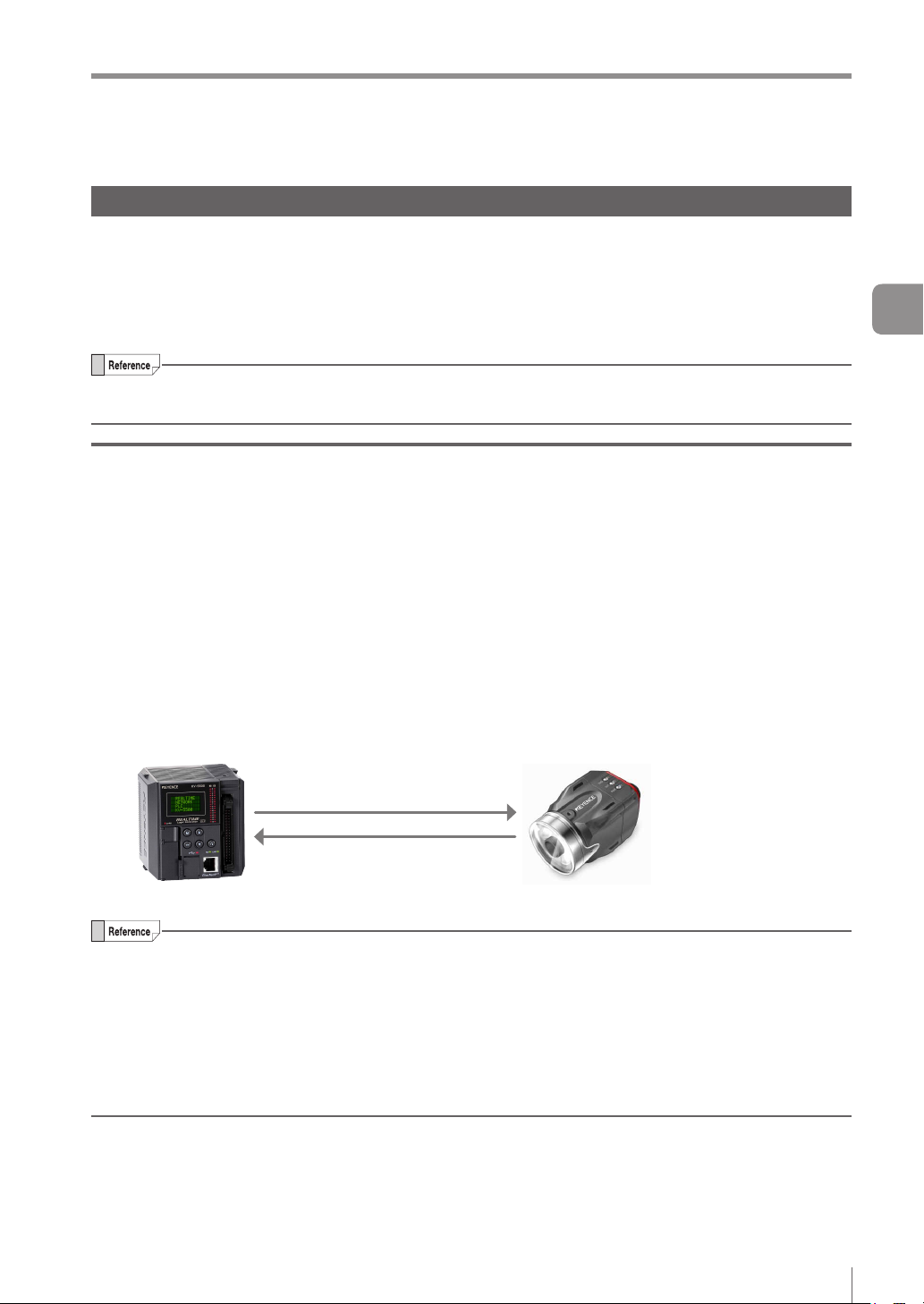

IV Series

The IV Series is an all-in-one “Vision Sensor” featuring a camera, a light, and a controller. This sensor

can be attached easily so complicated detection operations such as detecting the shapes of parts with a

photoelectric switch can be achieved easily.

Operation conditions settings require the IV Software, IV-Navigator (IV-H1) or

the intelligent monitor (IV-M30). After setting is completed, the sensor can be operated independently.

The IV Series operates as an EtherNet/IP communication adaptor or a PROFINET communication I/O device.

With EtherNet/IP communication or PROFINET communication, the control output signal and status result,

etc., can be input to the PLC as communication data.

System conguration example

PLC or other host device

(EtherNet/IP communication scanner,

PROFINET communication I/O controller)

EtherNet/IP communication adapter,

PROFINET communication I/O device

Sensor (this unit)

EtherNet/IP communication and PROFINET communication cannot be used simultaneously.

For the details of installation, connection, and operation methods of the IV Series, refer to “IV Series

User’s Manual (Monitor/PC Software)”.

1-4

- IV Series User’s Manual (Field Network) -

Page 17

Overview of IV Series

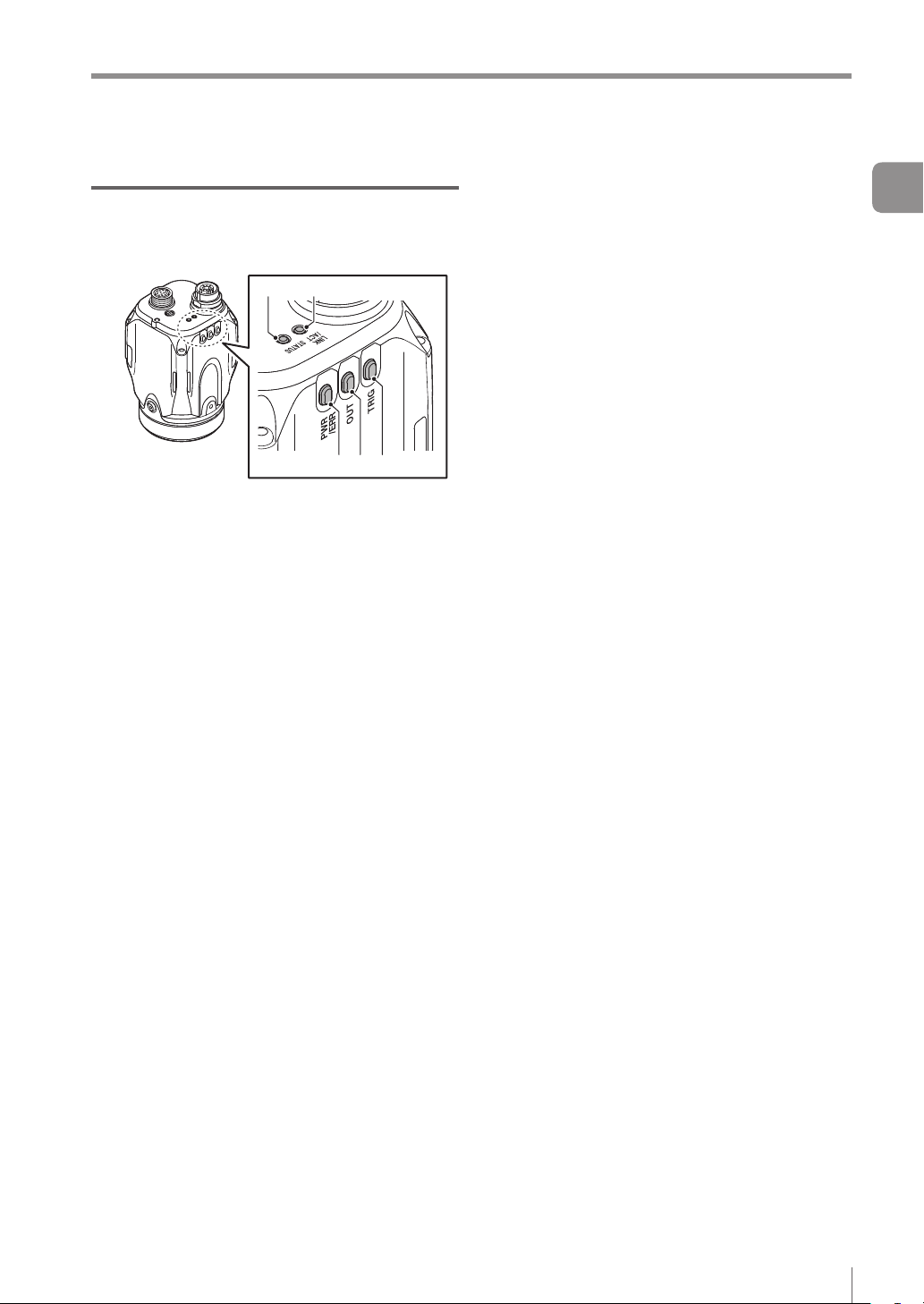

Operation of the indicator light

Details on operations of the indicator light are

shown below.

4 5

1 2 3

1 PWR/ERR

Indicates the power supplying status to the

sensor and the error status of the sensor.

Green (ON)

Green (Blink)

Red (ON)

Red (Blink)

Orange (Blink)

(OFF)

2 OUT

Indicates the comprehensive result.

Green

.................. Comprehensive result is “NG”.

Red

(OFF)

Standby status until the rst

Orange (Blink)

...... Operating.

.... Setting processing. Operation

is stopped. Blinks once a

second.

.......... Unrecoverable error has

occurred.

....... Recoverable error has

occurred.

...

Flash LED has been required on

the PROFINET communication

I/O controller. Blinks 4 times

with a period of about a second.

............... Power is not supplied.

Adjusting the focusing position

(

manual focus only).

............... Comprehensive result is “OK”.

............... Setting processing.

judge nishes after starting the

operation or after switching

the program number.

...

Indicates the focusing status

while adjusting the focusing

position with the blinking speed

(manual focus type only).

Flash LED has been required on

the PROFINET communication

I/O controller. Blinks 4 times

with a period of about a second.

3 TRIG

Green light lights up (one-shot) according to

input of the internal or external trigger.

Orange (Blink)

4 STATUS

Indicates the connecting status to the PC.

Green (ON)

Green (Blink)

Red (Blink)

Red (ON)

............... IP address is not assigned.

(OFF)

Orange (Blink)

5 LINK/ACT

Indicates the linking status within PC or

Ethernet switch.

Green (ON)

Green (Blink)

...............

(OFF)

...

Flash LED has been required on

the PROFINET communication

I/O controller. Blinks 4 times

with a period of about a second.

......

Normally connected with monitor,

PC, EtherNet/IP communication

scanner, or PROFINET

communication I/O controller.

.... IP address has been retrieved

but the sensor is not correctly

connected with

EtherNet/IP communication

scanner, or PROFINET

communication I/O controller.

....... Timeout has occurred at the

communication with EtherNet/

IP communication scanner.

.......... IP address coincides with

another device.

Not correctly connecting with

PC.

..

Indicates the focusing status

while adjusting the focusing

position with the blinking speed

(manual focus type only).

...... Normally linked.

.... Normally linked, and the data

is sending/receiving.

Sensor is not normally linked.

monitor, PC,

1

Getting Started

- IV Series User’s Manual (Field Network) -

1-5

Page 18

Overview of IV Series

1

Getting Started

MEMO

1-6

- IV Series User’s Manual (Field Network) -

Page 19

2

EtherNet/IP

This chapter describes the overview of EtherNet/IP

and the communication specications and functions

of the EtherNet/IP communication in the IV series.

2

EtherNet/IP

Overview of EtherNet/IP

EtherNet/IP communication specications

and functions in the IV series...........................2-3

....................................2-2

- IV Series User’s Manual (Field Network) -

2-1

Page 20

Overview of EtherNet/IP

Overview of EtherNet/IP

EtherNet/IP is an open industrial networking standard developed and maintained by the ODVA (Open

2

DeviceNet Vendor Association, Inc.). All supported devices can use the communication network regardless

EtherNet/IP

of the vendor.

Ethernet and an industrial protocol have been combined and standardized as EtherNet/IP (Industrial Protocol).

Communication is achieved by combining a protocol called CIP (Common Industrial Protocol) and the TCP/

IP and Ethernet. This allows the network to be shared and used with standard Ethernet.

To start the Ethernet/IP communication, one device needs to open a communication line called a "connection"

for the other device. The device that will open a connection is referred to as the "scanner", and the device

whose connection will be opened is referred to as the "adapter" (IV series is an adapter device).

The EtherNet/IP communication offers the following two types of communications: Cyclic communication

for sending and receiving data periodically (Implicit communication), and message communication for

sending and receiving commands/responses at arbitrary timings.

In the cyclic communication, you can set the RPI (Request Packet Interval: communication cycle) based

on the priority of the data to be sent/received, enabling sending/receiving of data with adjusted overall

communication load. Various data including the control output, status result import, trigger control and

switching to the set program No. can be communicated without a ladder program.

In the message communication, you can send/receive the required commands and responses at the required

timings. The message communication is used for applications requiring no punctuality unlike the cyclic

communication, such as for reading and writing the adapter device settings.

What is EtherNet/IP?

The IV series supports cyclic communication (Implicit communication).

EtherNet/IP

communication

scanner

(Communication cycle: 5 ms)

High-speed

EtherNet/IP

communication

adapter

Low-speed (Communication cycle: 1000 ms)

Normal

(Communication

cycle: 100 ms)

EtherNet/IP

communication

adapter

EtherNet/IP

communication

adapter

2-2

- IV Series User’s Manual (Field Network) -

Page 21

EtherNet/IP communication specications and functions in the IV series

EtherNet/IP communication specications and

functions in the IV series

This section describes the overview of the EtherNet/IP communication functions supported in the IV series.

EtherNet/IP communication specications in the IV series

Cyclic communication

(Implicit messages)

Number of

connections

16

Overview of the Ethernet/IP communications functions in the IV series

The following shows the list of functions that can be used to control the IV series using the EtherNet/IP

communication.

Function Content

Trigger input Executes a trigger input for the sensor.

Program switching Executes a program switching for the sensor.

External master registration Executes an external master registration for the sensor.

Error clear input Executes an error clear.

Read out status Allows you to check the unit status (Imaging, RUN, BUSY, Error).

Read overall status result Reads out the overall status result.

Read judgment processing time Reads out the judgment processing time.

Read each tool’s status result Read each tool’s status result

Read statistics information

Reads out the number of triggers issued that generated a trigger

error and the number of trigger errors.

2

EtherNet/IP

If you are switching programs using the EtherNet/IP communication, set the [Switching method] option

to [Monitor/PC]. For details of the setting, refer to the “IV Series User’s Manual (Monitor / PC Software)”.

If the master registration will be executed using the EtherNet/IP communication, set the [Write to ROM

at external master reg.] option to [No]. For details of the setting,refer to the “IV Series User’s Manual

(Monitor / PC Software)”.

- IV Series User’s Manual (Field Network) -

2-3

Page 22

EtherNet/IP communication specications and functions in the IV series

Check the instruction manual of each PLC for details of the setting methods.

2

EtherNet/IP

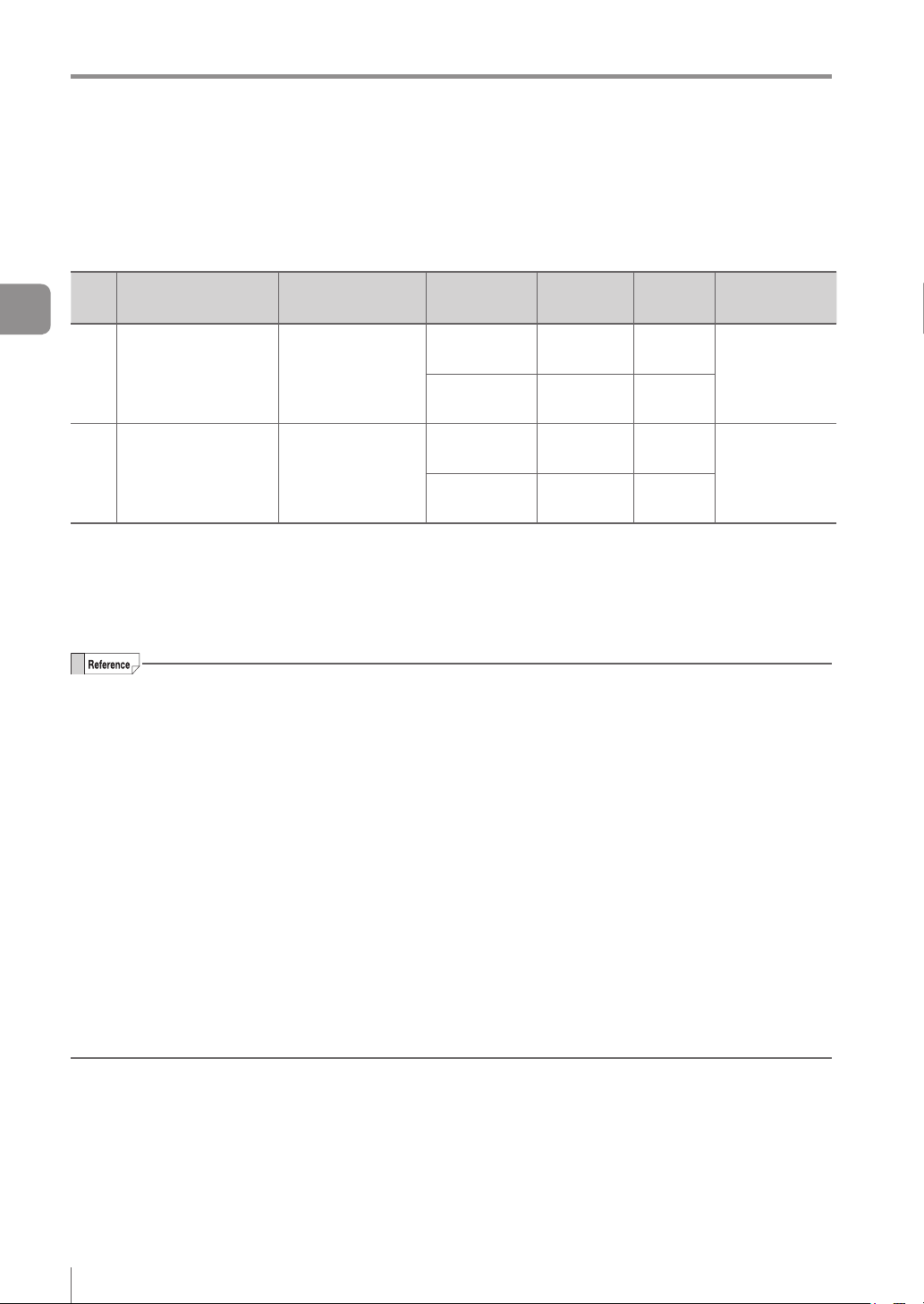

Keyence PLC

List of supported PLCs

KV series

PLC model

KV-3000 KV-EP21V Ver.2 or later

KV-5000 KV-EP21V Ver.2 or later

KV-5500

EtherNet/IP

communication unit

(Built-in port or KV-

EP21V)

Rockwell Automation PLC

PLC model

1756 ControlLogix

1769 CompactLogix

EtherNet/IP

communication unit

1756-ENBT

1756-EN2T

(Built in the unit)

OMRON PLC

PLC model

EtherNet/IP

communication unit

Firmware

version

Ver.2 or later

Firmware

version

Ver.13 or later

Ver.13 or later

Firmware

version

Software used

KV STUDIO Ver.6.0 or later

Software used

RSLogix5000 Ver.13 or later

Software used

Version of the

software used

Version of the

software used

Version of the

software used

-

SYSMAC CJ2

SYSMAC CJ1 CJ1W-EIP21 V1.0 or later

SYSMAC CS1 CJ1W-EIP21 V1.0 or later

2-4

(Built-in port or

CJ1W-EIP21)

- IV Series User’s Manual (Field Network) -

V1.0 or later

CX-One Ver.3.0 or later

Page 23

3

Cyclic

communication

This chapter describes the overview, setting

method, data allocation, and operating procedure

of the cyclic communication in the EtherNet/IP

communication.

3

Cyclic communication

Overview of the cyclic communication

Cyclic communication setting method ............3-3

Data allocation in the cyclic communication

Operating procedure of

the cyclic communication...............................3-26

...........3-2

...3-10

- IV Series User’s Manual (Field Network) -

3-1

Page 24

Overview of the cyclic communication

Overview of the cyclic communication

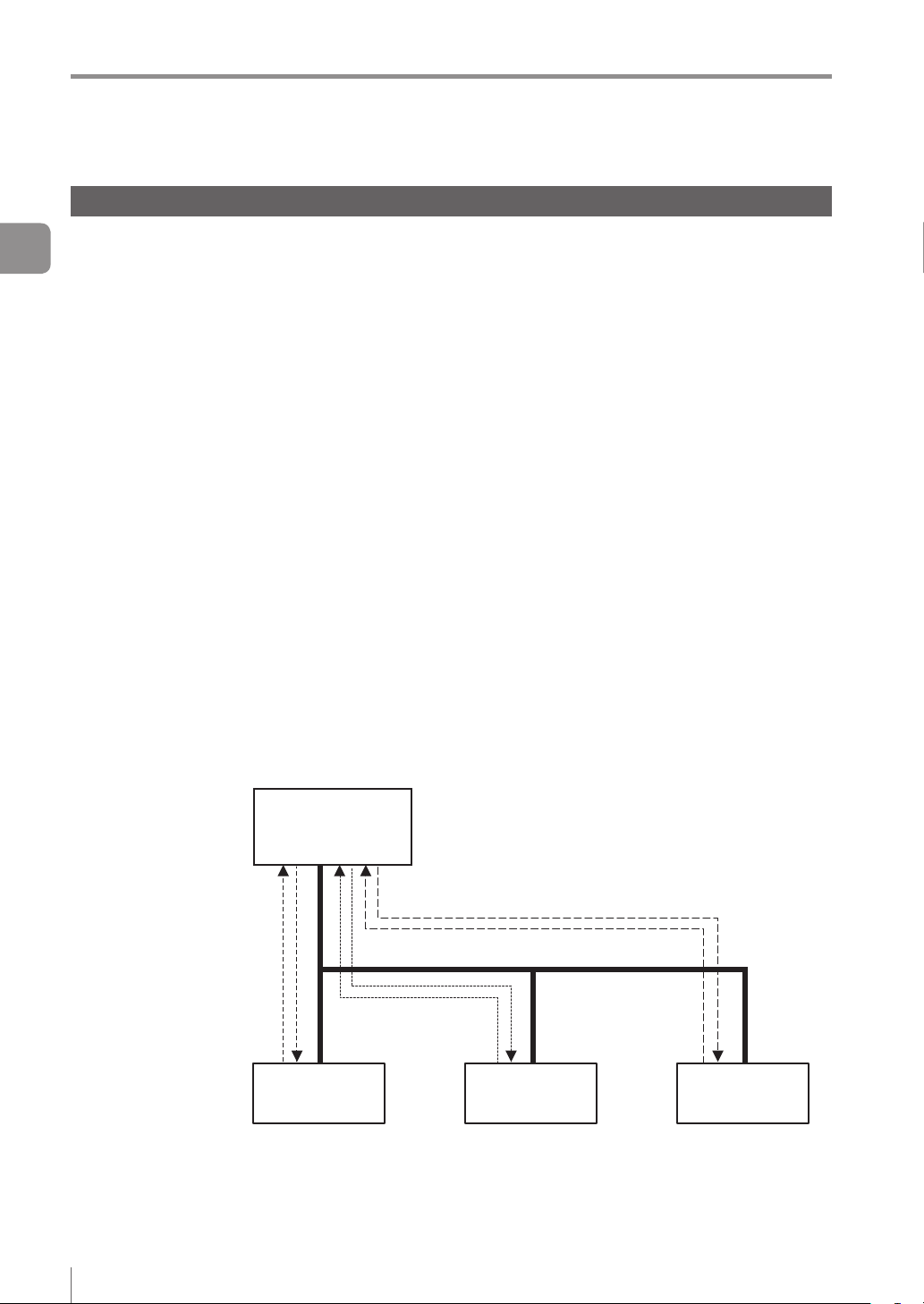

What is cyclic communication?

This function enables cyclic (i.e. in xed intervals) data communications with the EtherNet/IP devices.

This function provides high-speed control with several to several tens of milliseconds.

The communication can be controlled by referencing and updating the variables in the PLC, making it easy

3

to control the programs on the PLC side.

Cyclic communication

Input Area

Status result

Control/status/error result

Statistics information

Tool information

RPI

(Communication

Output Area

Trigger control

External master image

registration control

Program switching control

Handshake control

Communication settings for the cyclic communication, such as the RPI (communication cycle) and the

data size, will be congured on the PLC side.

In a network with many connected devices (including the EtherNet/IP devices), a network delay and/

or packet loss may occur when there is a heavy load on the network. Conduct a thorough verication

before the operation.

cycle)

Output data

Status result

Control/status/error result

Statistics information

Tool information

Input data

Trigger control

External master image

registration control

Program switching control

Handshake control

3-2

- IV Series User’s Manual (Field Network) -

Page 25

Cyclic communication setting method

Cyclic communication setting method

This following explains the setting method when

using the cyclic communication.

To control the IV series using the EtherNet/IP

communication, select [Network connection] for

the sensor connection setting. When connected

directly, the eld network settings will be greyed

out and disabled.

If you have modied the protocol settings, the

connection with the sensor will be terminated

and then restarted.

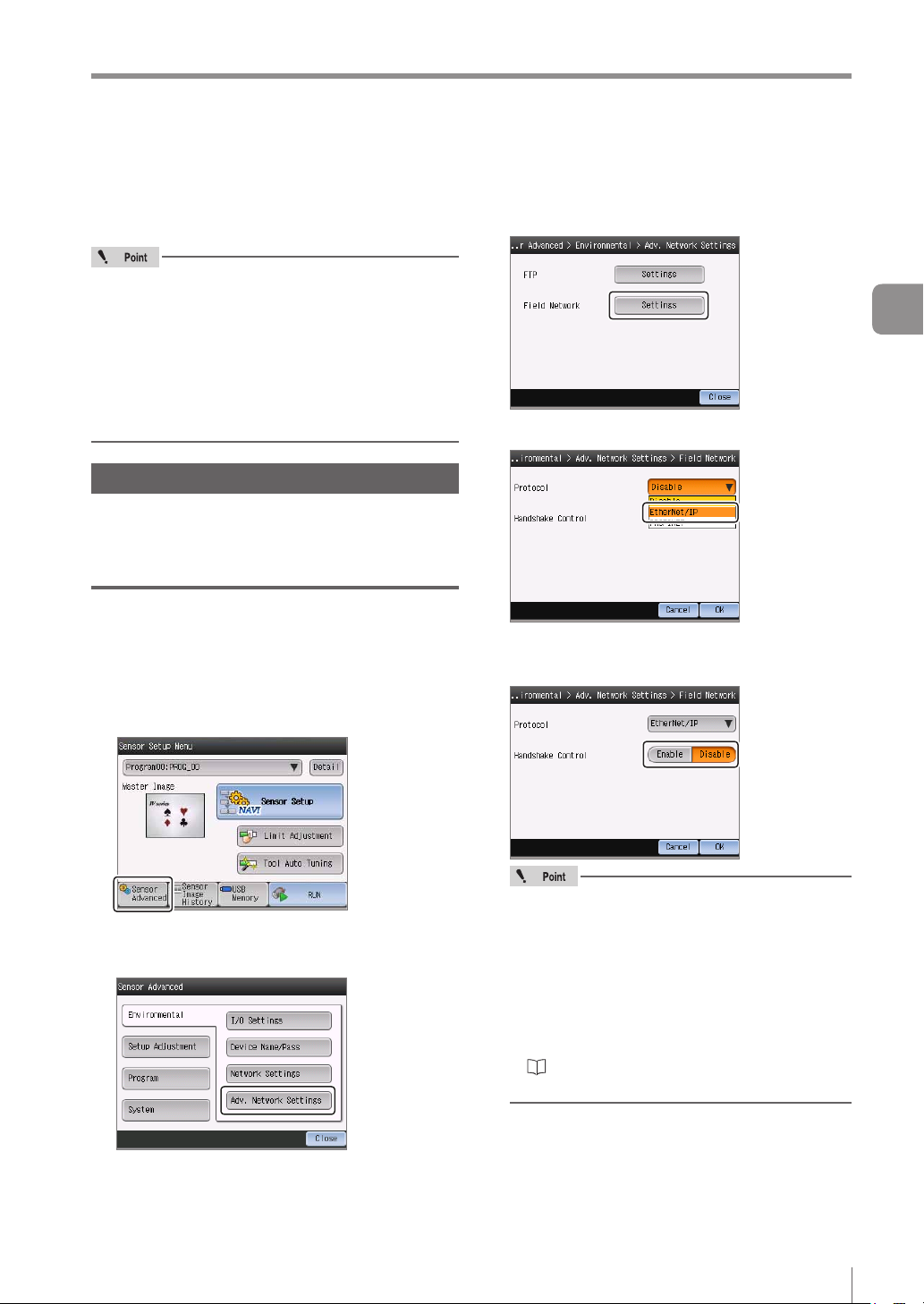

Setting the IV series

You can congure the following settings for the IV

series using the monitor (IV-M30) or IV-Navigator

(IV-H1).

When settings on the monitor (IV-M30)

Set the eld network settings of the sensor to

[EtherNet/IP].

Tap the [Sensor Advanced] button on the

1

Sensor Setup Menu screen.

Tap the [Settings] button in the “Field

3

Network”.

Select [Ethernet/IP] for the protocol.

4

To enable the handshake control, select

5

[Enable].

3

Cyclic communication

Tap the [Environmental] button, and then

2

the [Adv. Network Settings] button.

- IV Series User’s Manual (Field Network) -

When the protocol is set as [Disable],

this setting item is shaded and cannot be

selected.

When the data handshake control is set

as [Enabled], the status result will not be

updated until [Result acquisition complete

notice] (“Address2, Bit0” of Output Assembly)

is input.

“Operating procedure of the cyclic

communication” (Page 3-26)

After the setting is completed, tap the [OK]

6

button.

3-3

Page 26

Cyclic communication setting method

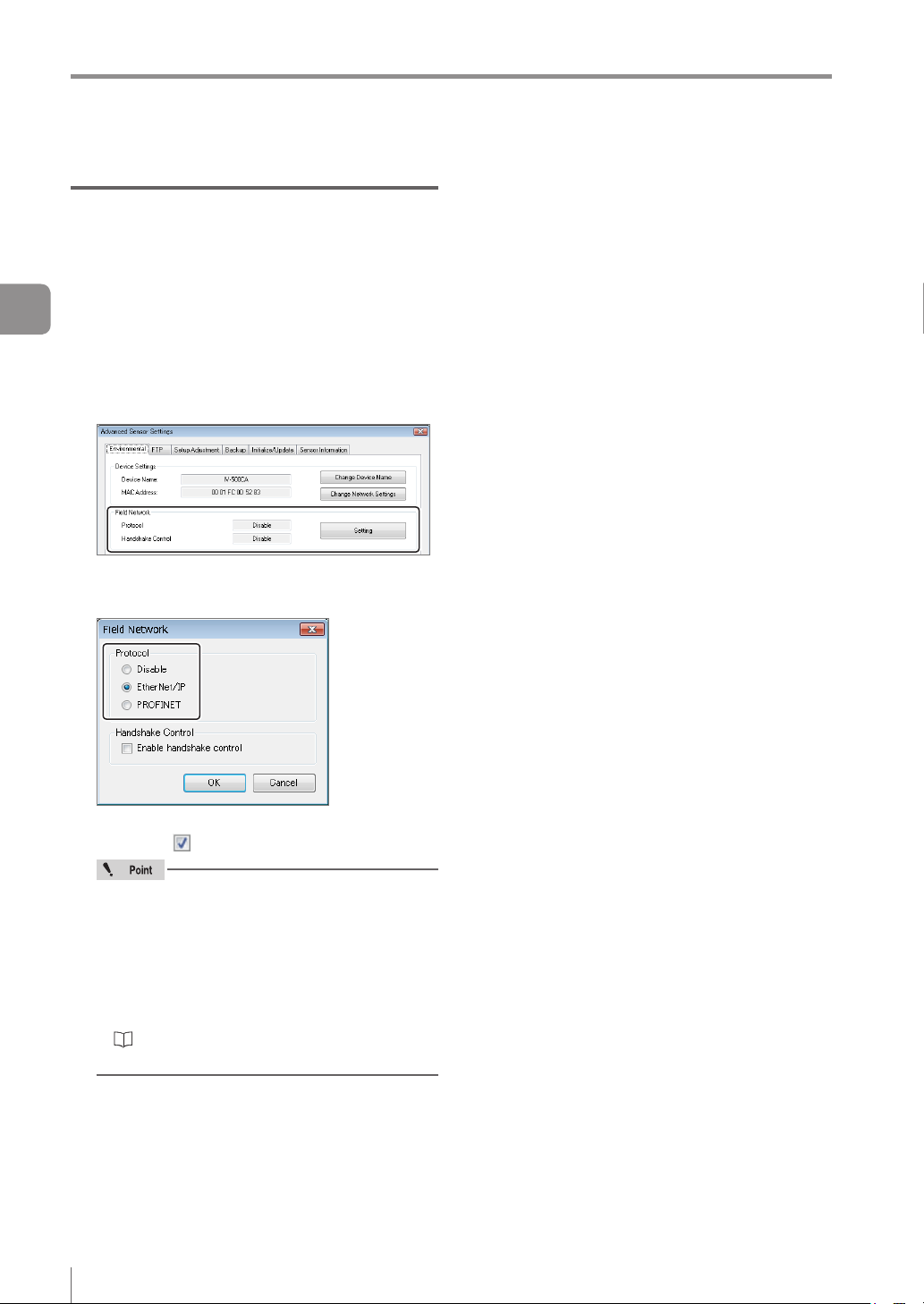

When setting by IV-Navigator (IV-H1)

Set the eld network settings of the sensor to

[EtherNet/IP].

Display the Advanced Sensor Settings

3

1

Cyclic communication

screen.

Select the [Environmental] tab, and then

2

click the [Setting] button under [Field

network].

Select [EtherNet/IP] in [Protocol] for the

3

eld network.

To enable the handshake control, check this

check box .

When the protocol is set as [Disable],

this setting item is shaded and cannot be

selected.

When the data handshake control is set as

[Enabled], the status result will not be updated

until [Result acquisition complete notice]

(“Address2, Bit0” Output Assembly) is input.

“Operating procedure of the cyclic

communication” (Page 3-26)

After the setting is completed, click the

4

[OK] button.

The system returns to the main screen in

[Program].

Click the [OK] button.

5

3-4

- IV Series User’s Manual (Field Network) -

Page 27

Cyclic communication setting method

PLC settings

You can set the following settings for the PLC:

(1)

Set the connection to be used for the cyclic communication.

(2)

Set the device to be used for the cyclic communication.

For details of the setting, refer to the instruction manual of each PLC.

If you are using the Keyence KV series, (1) and (2) can be set automatically simply by making a selection

in KV STUDIO.

Establishing the connection

In the cyclic communication, one device opens a logical communication circuit called a “connection” for the

other device; and data communication will become possible if the open is successful.

The device that will open a connection is referred to as the “scanner”, and the device whose connection

will be opened is referred to as the “adapter”.

(IV series is an adapter device)

In the EtherNet/IP communication, a connection must be opened from the scanner when the cyclic

communication is started.

3

Cyclic communication

The communication is started in the following procedure:

(1) The scanner requests a connection open request to the adapter.

(2) Compatibility will be checked on the adapter side.

(3) A connection will open if no error is encountered in the compatibility check.

(1) Connection open request

(2) Compatibility check

(3) Connection open

Scanner Adapter device

A compatibility check is used to check whether the device set by the scanner and the IV series are in

match with one another, in order to prevent the scanner from communicating with a wrong device when

it communicates with the IV series.

Communication settings for the cyclic communication, such as the communication cycle (RPI) and the

data size, will be congured on the scanner side.

In a network with many connected devices (including the EtherNet/IP devices), a network delay and/

or packet loss may occur when there is a heavy load on the network. Conduct a thorough verication

before the operation.

- IV Series User’s Manual (Field Network) -

3-5

Page 28

Cyclic communication setting method

There are many types of connections, and the connection available for each device are dened in the EDS

le.

The following shows the list of connections that are available in the IV series.

3

No Connection name Application type I/O

Cyclic communication

Monitor Data And

External Input

1

(Monitor/External

input)

Monitor Data (Input

2

Only)

(Monitor data)

When using the Keyence KV series (EtherNet/IP communication scanner), the names of the connections

with the IV series will be “Monitor/External Input” and “Monitor Data”. The relationship of each connection

name is as described below.

1 : Monitor Data And External Input → Monitor/External input

2 : Monitor Data (Input Only) → Monitor data

The trigger timings of each connection are controlled by the cyclic communications; and both the point-

to-point and Multicast connection types are supported.

If you wish to open “Exclusive Owner” and “Input Only” connections simultaneously, set the connection

type to “Multicast” and match the RPI and the size.

The details of each application type are as described below.

[Exclusive Owner]

This connection allows you to congure the data transmission from the scanner to the IV series, and

vice versa.

This connection type is used when the scanner will not only monitor the data of the IV series but also

provide external input to the IV series.

It is not possible for multiple scanners to open "Exclusive Owner" connections for a single IV series

unit.

[Input Only]

This connection only allows you to congure the data transmission from the IV series to the scanner.

This connection is used when the scanner will only monitor the data of the IV series.

Multiple scanners can simultaneously open “Input Only” connections for a single IV series unit.

If connections will be opened simultaneously from multiple scanners, set the connection type to

“Multicast” and match the RPI and the size.

Exclusive Owner

Input Only

This unit

→ Scanner

Scanner

→ This unit

This unit

→ Scanner

Scanner

→ This unit

Assembly

Instance

64H (100) 2 to 392

65H (101) 2 to 12

64H (100) 2 to 392

FEH (254) 0

Size

(bytes)

RPI

5 to 10000ms

5 to 10000ms

3-6

- IV Series User’s Manual (Field Network) -

Page 29

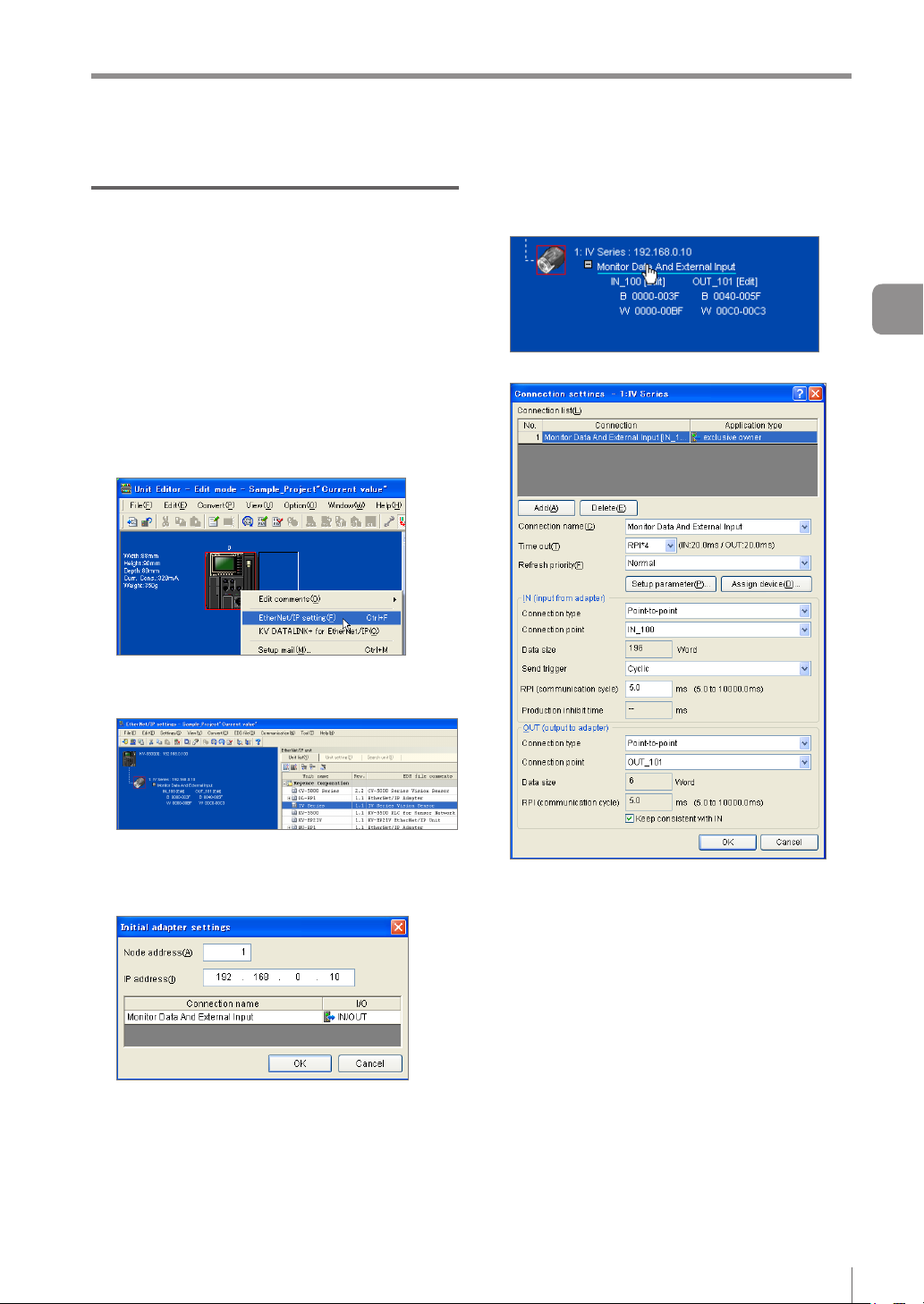

Keyence KV series settings

This following explains the setting method when

using KV-5500.

For details of the required setting, such as the unit

conguration for the PLC and the KV STUDIO

settings for connecting with the PC, refer to the “KV

STUDIO User’s Manual” and the “KV-EP21V User’s

Manual”.

Right-click KV-5500 in the unit editor of

1

KV STUDIO, and then select [EtherNet/IP

setting].

Cyclic communication setting method

Modify the settings as necessary.

4

Click the connection name in the scan list.

The [Connection settings] screen will appear.

3

Cyclic communication

Drag [IV Series] from the Unit list and add

2

it to the scan list.

Set the Node address and IP address

3

for the IV series on the [Initial adapter

settings] screen.

Connection name

Select [Monitor/External input] or [Monitor data].

RPI (communication cycle)

You can set the cyclic communication cycle.

Connection type

Select [Point-to-point] or [Multicast].

Save the settings and close [EtherNet/IP

5

settings] and the unit editor.

- IV Series User’s Manual (Field Network) -

3-7

Page 30

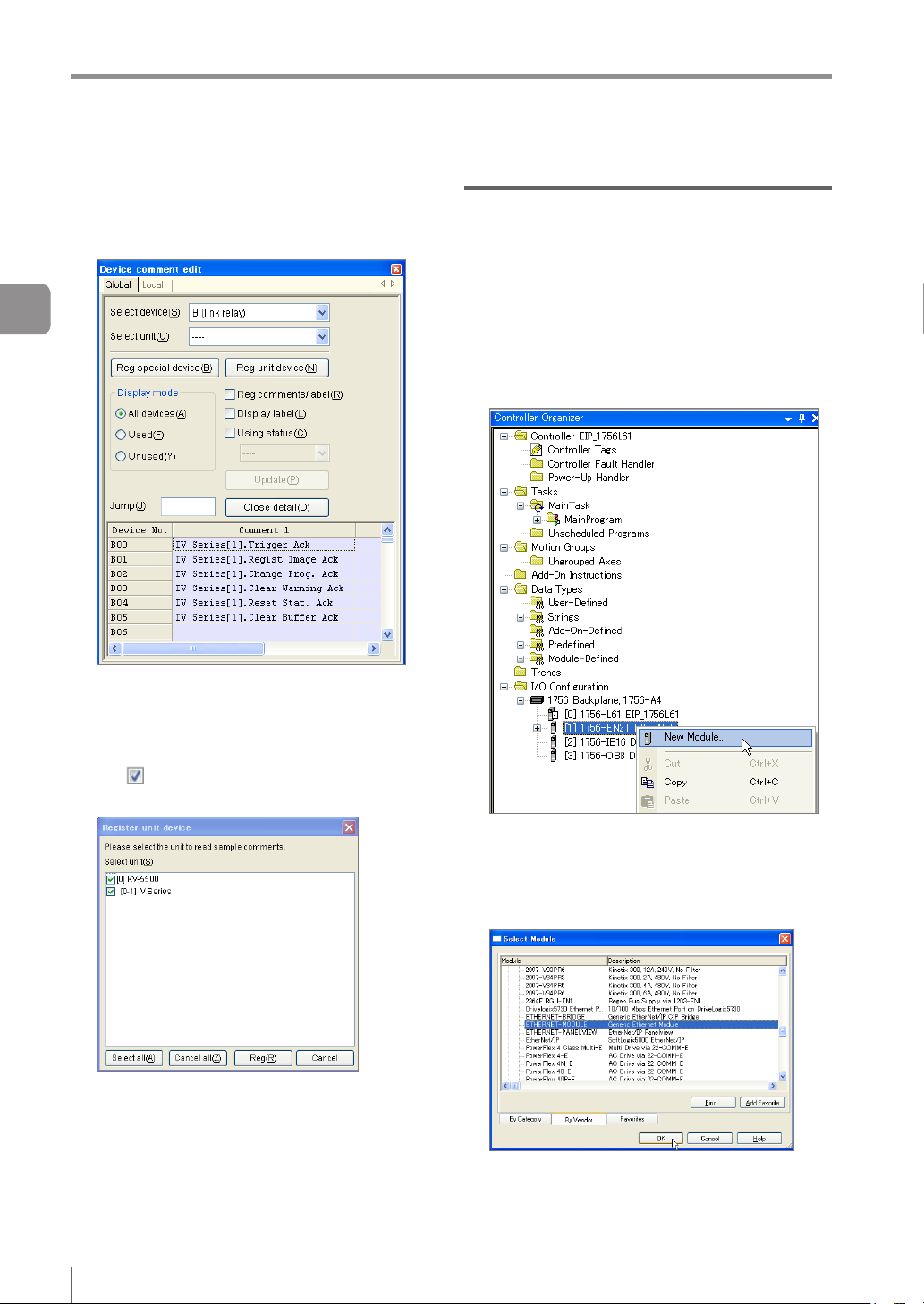

Cyclic communication setting method

Select [Device comment edit window]

6

from the [Edit] menu in KV STUDIO.

The [Device comment edit] screen will appear.

Rockwell Automation Control Logix series settings

This following explains the setting method when

using a Control Logix PLC.

3

Cyclic communication

Click [Details].

The [Register unit device] screen will appear.

Make sure that the [IV Series] checkbox is

7

ON

in the [Select unit] eld, and then

click the [Reg] button.

Select the EtherNet/IP communication unit

1

to be connected with the IV series in

the I/O conguration of RsLogix5000, and

then right-click to select [New Module].

The [Select Module] screen will appear.

Select [PLC Transfer] from the [Monitor/

8

Simulator] menu of KV STUDIO.

3-8

- IV Series User’s Manual (Field Network) -

Click the [+] button next to Communications,

2

and then select EtherNET-MODULE (Generic

Ethernet Module) and click the [OK] button.

The [New Module] screen will appear.

Page 31

Modify the settings as necessary.

3

Name (Device name)

You can assign a desired name. The following

tags will be generated based on the entered

names and used for the data sent and received

in the cyclic communication.

(Device name): I

(Device name): O

(Device name): C

Comm Format

You can enter a desired format. Due to the

structure of the assembly object, programming

will be easier with a format that supports a

2-byte alignment.

IP Address

You can enter the IP address of the IV series.

Input (Assembly Instance)

Enter “100”.

Input (Size)

You can enter the Input Assembly size of the IV

series.

Output (Assembly Instance)

Enter “101”.

Output (Size)

You can enter the Output Assembly size for the

IV series.

Conguration (Assembly Instance)

Enter “1”.

Conguration Size

Enter “0”.

..... Information received from

the IV series

... Information to be sent to

the IV series

... Not used.

Cyclic communication setting method

Setting the Comm Format option to [Input

Data] will enable you to establish cyclic

communication with multiple PLCs using the

“Input only” connection.

To set the Comm Format to [Input Data],

perform the following settings on each PLC.

Item Setting contents

Comm Format Input Data-INT

Input

(Assembly Instance)

Input (Size)

Output

(Assembly Instance)

Output (Size)

If communications with multiple PLCs

will be established using the “Input Only”

connection, set the connection type to

“Multicast”.

For details of the Input Assembly and Output

Assembly sizes for the IV Series, refer to

“EtherNet/IP communication specications in

the IV series” (Page 2-3) .

Set the RPI (communication cycle) for the

4

cyclic communication.

Make sure to set a value longer than or equal to 5 ms.

Download the settings to the PLC.

5

The EtherNet/IP communication will be enabled

when you switch to online after downloading the

settings.

100

Input Assembly size

of the IV series

254

Output Assembly size

for the IV series

3

Cyclic communication

- IV Series User’s Manual (Field Network) -

3-9

Page 32

Data allocation in the cyclic communication

Data allocation in the cyclic communication

Input Assembly (IV series → PLC)

Input Assembly are devices that write responses from the IV series to the PLC.

The device map of the data allocated for the Input Assembly is as shown below.

These parameters output the statuses, status results and statistics information of the IV series.

3

For details of each parameter, refer to “Input Assembly parameter details” (Page 3-12).

Cyclic communication

Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 Reserved by system

1 Reserved by system

2 Reserved by system

3

Error Warning

4 Reserved by system

5 Reserved by system

Tool 8 Tool 7 Tool 6 Tool 5 Tool 4 Tool 3 Tool 2 Tool 1

6

7

Tool 16 Tool 15 Tool 14 Tool 13 Tool 12 Tool 11 Tool 10 Tool 9

8 - 9

10 - 11

12 - 13

14 - 15

16 - 17

18 - 19

20 - 21

22 - 23

24 - 25

26 - 27

28 - 29

30 - 31

32 - 35

36 - 39

40 - 43

44 - 47

48 - 51

52 - 53

Buffer

clear

response

Ready RUN

Buffer

overrun

LOGIC4 LOGIC3 LOGIC2 LOGIC1

Number of remaining buffers (Unsigned 16-bit integer)

Current program No. (Unsigned 16-bit integer)

Program No. during judgment (Unsigned 16-bit integer)

Processing time (Unsigned 16-bit integer)

Processing time MAX (16-bit unsigned integer)

Processing time MIN (Unsigned 16-bit integer)

Processing time AVE (Unsigned 16-bit integer)

Number of triggers (Unsigned 32-bit integer)

Number of OKs (Unsigned 32-bit integer)

Number of NGs (Unsigned 32-bit integer)

Number of trigger errors (Unsigned 32-bit integer)

Position correction score (Unsigned 16-bit integer)

Statistics

reset

response

Error NO. (Unsigned 16-bit integer)

Warning No. (Unsigned 16-bit integer)

Checksum (Unsigned 16-bit integer)

Result NO. (Unsigned 16-bit integer)

Reserved by system

Reserved by system

Warning

clear

response

Imaging

status

Reserved by system

Program

switching

response

Program

switching

failed

BUSY

Master

registration

response

Master

registration

failed

Result

update

complete

Position

correction

Trigger

response

Trigger

failed

Result

available

Overall

judgment

3-10

- IV Series User’s Manual (Field Network) -

Page 33

Data allocation in the cyclic communication

Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

54 - 55

56 - 57

58 - 59

60 - 71

72 - 73

74 - 75

76 - 77

78 - 79

80 - 81

82 - 91

92 - 391

Position correction score MAX (Unsigned 16-bit integer)

Position correction score MIN (Unsigned 16-bit integer)

Position correction score Lower threshold (Unsigned 16-bit integer)

Reserved by system

Tool 1 score (Unsigned 16-bit integer)

Tool 1 score MAX (Unsigned 16-bit integer)

Tool 1 score MIN (Unsigned 16-bit integer)

Tool 1 lower threshold (Unsigned 16-bit integer)

Tool 1 upper threshold (Unsigned 16-bit integer)

Reserved by system

Tool 2 to 16 (Same as Tool 1)

The start address of tool number “n” is 72 + (n-1) x 20

3

Cyclic communication

- IV Series User’s Manual (Field Network) -

3-11

Page 34

Data allocation in the cyclic communication

Input Assembly parameter details

Input Assembly Address 0: Control result (response)

The Bits at Address 0 of the Input Assembly have the following functions:

3

Cyclic communication

Address Bit Item Content Data content

0

Input Assembly Address 1: Control error result

The Bits at Address 1 of the Input Assembly have the following functions:

Address Bit Item Content Data content

1

0 Trigger response

Master image registration

1

response

Program switching

2

response

3 Warning clear response

4 Statistics reset response

5 Buffer clear response Stores the buffer clear response.

6 to 7 Reserved by system --- ---

0 Trigger failed

Master image registration

1

failed

2 Program switching failed

3 to 7 Reserved by system --- ---

Stores the external trigger

response.

Stores the master image

registration response.

Stores the program switching

response.

Stores the warning clear

response.

Stores the statistics reset

response.

This bit is output when the

external trigger is unsuccessful.

This bit is output when the

master image registration is

unsuccessful.

This bit is output when

the program switching is

unsuccessful.

0 : OFF

1 : ON

0 : OFF

1 : ON

0 : OFF

1 : ON

0 : OFF

1 : ON

0 : OFF

1 : ON

0 : OFF

1 : ON

0 : 1 : The external trigger

0 : 1 :

0 : 1 : Program switching

has failed.

Master image

registration has failed.

has failed.

3-12

- IV Series User’s Manual (Field Network) -

Page 35

Data allocation in the cyclic communication

Input Assembly Address 2 to 3: Handshake control/status/error result

The Bits at Address 2 to 3 of the Input Assembly have the following functions:

Address Bit Item Content Data content

0 : The status

0 Result available

1 Result update complete

2 BUSY

2

3 Imaging

4 RUN

5 Ready

6 to 7 Reserved by system --- ---

0 to 4 Reserved by system --- ---

5 Buffer overrun status

3

6 Warning status

7 Error status

This bit is output when the

status result can be acquired.

This bit switches the ON/OFF

statuses when the status result

is updated.

This bit is output when the unit

is unable to accept new trigger

inputs, such as while performing

imaging, processing a judgment,

registering an external master

image, switching programs, etc.

This bit is output while the unit

is performing imaging operation.

This bit is output when the unit

is “RUN” and no system errors

have occurred.

This bit is output when the

start-up sequence of this unit

completes after power-on.

If handshake control is

[Enabled], this bit is output when

an overrun of the status result

has occurred.

This bit outputs the warning

status of the unit.

This bit outputs the error status

of the unit.

result cannot be

acquired.

1 : The status result

can be acquired.

0 <=> 1:

The statuses will

be switched when

the status result is

updated.

0 : The unit is not in

busy status.

1 : The unit is in busy

status.

0 : The unit is not

performing imaging

operation.

1 : The unit is

performing imaging.

0 : The unit is not in

operation.

1 : The unit is

operating normally.

0 : The start-up has

not completed yet.

1 : The start-up has

completed.

0

: No buffer overrun

has occurred.

1 : The buffer is in

overrun status.

0 : The unit is not in

warning status.

1 : The unit is in

warning status.

0 : The unit is not in

error status.

1 : The unit is in error

status.

3

Cyclic communication

- IV Series User’s Manual (Field Network) -

3-13

Page 36

Data allocation in the cyclic communication

By monitoring whether the unit is in “Imaging” status, you can determine whether the target object or

the unit can be moved before completion of the image processing.

“BUSY” and “Imaging” statuses may be skipped in some cyclic frequency settings. It is therefore

necessary to take the imaging condition into consideration when setting the cyclic frequency.

3

Cyclic communication

Warning statuses can be cleared from the EtherNet/IP communication. For the warning details, refer to

the warning code. The rst occurred warning code will be displayed.

When two or more warnings are issued, all subsequent warnings after the rst warning will be saved in

the history. If you clear the warnings, the warning code of the highest priority warning will be displayed.

Warning

Warning clear

Warning No.

Error statuses cannot be cleared from the EtherNet/IP communication. For the error details, refer to the

Warning code 1 00 Warning code 2

error code. The error code of the highest priority error will be displayed.

The buffer overrun status can be cleared using a warning clear.

3-14

- IV Series User’s Manual (Field Network) -

Page 37

Data allocation in the cyclic communication

Input Assembly Address 4 to 7: Status result

The Bits at Address 4 to 7 of the Input Assembly have the following functions:

Address Bit Item Content Data content

0 Overall judgment

1 Position correction

4

5 0 to 7 Reserved by system --- ---

6

7

2 Logic 1 Displays the result of Logic 1. 0 : NG 1 : OK

3 Logic 2 Displays the result of Logic 2. 0 : NG 1 : OK

4 Logic 3 Displays the result of Logic 3. 0 : NG 1 : OK

5 Logic 4 Displays the result of Logic 4. 0 : NG 1 : OK

6 to 7 Reserved by system --- ---

0 Tool 1 Displays the result of Tool 1. 0 : NG 1 : OK

1 Tool 2 Displays the result of Tool 2. 0 : NG 1 : OK

2 Tool 3 Displays the result of Tool 3. 0 : NG 1 : OK

3 Tool 4 Displays the result of Tool 4. 0 : NG 1 : OK

4 Tool 5 Displays the result of Tool 5. 0 : NG 1 : OK

5 Tool 6 Displays the result of Tool 6. 0 : NG 1 : OK

6 Tool 7 Displays the result of Tool 7. 0 : NG 1 : OK

7 Tool 8 Displays the result of Tool 8. 0 : NG 1 : OK

0 Tool 9 Displays the result of Tool 9. 0 : NG 1 : OK

1 Tool 10 Displays the result of Tool 10. 0 : NG 1 : OK

2 Tool 11 Displays the result of Tool 11. 0 : NG 1 : OK

3 Tool 12 Displays the result of Tool 12. 0 : NG 1 : OK

4 Tool 13 Displays the result of Tool 13. 0 : NG 1 : OK

5 Tool 14 Displays the result of Tool 14. 0 : NG 1 : OK

6 Tool 15 Displays the result of Tool 15. 0 : NG 1 : OK

7 Tool 16 Displays the result of Tool 16. 0 : NG 1 : OK

Displays the overall status

result.

Displays the position correction

result.

0 : NG 1 : OK

0 : NG 1 : OK

3

Cyclic communication

If the position correction/logic/tool is not set, the data content will be “0”.

If the status result of the tool is either “trigger standby” (no judgment) or “judgment not possible”, the

data content will be OFF (0).

- IV Series User’s Manual (Field Network) -

3-15

Page 38

Data allocation in the cyclic communication

Input Assembly Address 8 to 23: Error/status/status result information

z

The Bits at Address 8 to 23 of the Input Assembly have the following functions:

Address

3

Cyclic communication

8 to 9 UINT Error code

10 to 11 UINT Warning code

12 to 13 UINT

14 to 15 UINT Checksum

16 to 17 UINT Current program No.

18 to 19 UINT

20 to 21 UINT Result No.

22 to 23 UINT Processing time

* UINT : Unsigned 16-bit integer

UDINT : Unsigned 32-bit integer

Data

type*

Item Content Data content

Number of remaining

buffers

Program No. during

judgment

Displays the currently occurring

error code.

Displays the currently occurring

warning code.

Displays the number of status

results that can be buffered, if

handshake control is [Enabled].

Displays the current sensor

setting status using an arbitrary

5-digit integer.

Displays the current program

No.

Displays the program No. of the

latest judgment process.

Displays the judgment process

counts.

Displays the processing time of

the latest judgment process.

0 to 128

0 to 128

0 to 10

0 to 65535

0 to 31

0 to 31

0 to 32767

0 to 10000

yThe unit of processing time is msec.

yIf two or more errors are occurring at the same time, the error code of the highest priority error will be

displayed.

“Error code list” (Page 3-22)

yThe rst occurred warning code will be displayed.

“Warning code list” (Page 3-23)

yA checksum can be used to monitor whether the sensor settings have been modied by a third party.

yThe checksum will remain unchanged even if you switch programs.

yThe checksum will remain unchanged even if you change the IP address, subnet mask, default gateway

or port number of the IV series.

yFor the number of remaining buffers, refer to “Reading out the overall status result of the IV series

(Handshake control [Enabled])” (Page 3-28).

yThe upper limit value of the result No. is 32767. If the maximum value is exceeded, it will go back to 0

and start counting up again.

yThe result No. will also count the judgment process counts that were skipped due to the cyclic

frequency setting.

3-16

- IV Series User’s Manual (Field Network) -

Page 39

Data allocation in the cyclic communication

Input Assembly Address 24 to 51: Statistics information

The Bits at Address 24 to 51 of the Input Assembly have the following functions:

Address

24 to 25 UINT Processing time MAX

26 to 27 UINT Processing time MIN

28 to 29 UINT Processing time AVE

30 to 31 --- Reserved by system --- ---

32 to 35 UDINT Number of triggers

36 to 39 UDINT Number of OKs

40 to 43 UDINT Number of NGs

44 to 47 UDINT Number of trigger errors

48 to 51 --- Reserved by system --- ---

* UINT : Unsigned 16-bit integer

UDINT : Unsigned 32-bit integer

Data

type*

Item Content Data content

Displays the maximum

processing time value.

Displays the minimum

processing time value.

Displays the average processing

time value.

Displays the total number of

triggers issued.

Displays the total number of

triggers issued whose overall

status result was “OK”.

Displays the total number of

triggers issued whose overall

status result was “NG”.

Number of triggers issued that

generated a trigger error

0 to 10000

0 to 10000

0 to 10000

0-999999999

0-999999999

0-999999999

0-999999999

3

Cyclic communication

The unit of processing time is msec.

The maximum number of triggers is 999999999. If the maximum value is exceeded, it will go back to 0

and start counting up again.

The maximum value for the number of OK triggers, number of NG triggers, and the number of trigger

errors is 999999999. The value will stop updating when the upper limit value is reached.

A reset will occur in the following conditions:

When [Statistics reset] is input

When a tool is added/deleted/copied

When the enable/disable status of the upper threshold value for the color area/area tool or the setting

scale has been changed via user operation or tool auto-tuning

When a tool auto-tuning is started with two or more tools other than the position correction tool set

When the sensor is switched OFF

When the program is switched

When a correction for the sensor is started

When the sensor is initialized

- IV Series User’s Manual (Field Network) -

3-17

Page 40

Data allocation in the cyclic communication

Input Assembly Address 52 to 71: Position correction information

The Bits at Address 52 to 71 of the Input Assembly have the following functions:

Address

3

Cyclic communication

52 to 53 UINT

54 to 55 UINT

56 to 57 UINT

58 to 59 UINT

60 to 71 --- Reserved by system --- ---

* UINT : Unsigned 16-bit integer

UDINT : Unsigned 32-bit integer

Data

type*

Item Content Data content

Position correction tool

matching rate

Position correction tool

matching rate MAX

Position correction tool

matching rate MIN

Position correction tool

threshold

Stores the matching rate of the

position correction tool.

Stores the maximum matching

rate value of the position

correction tool.

Stores the minimum matching

rate value of the position

correction tool.

Stores the threshold value of the

position correction tool.

0 to 100

0 to 100

0 to 100

0 to 100

Maximum and minimum matching rate values of the position correction tool will be reset in the same

manner as the statistics information.

If the position correction tool is not set, the data content will be “0”.

Input Assembly Address 72 to 391: Tool information

The Bits at Address 72 to 391 of the Input Assembly have the following functions:

Address

72 to 73 UINT Tool 1 matching rate

74 to 75 UINT

76 to 77 UINT Tool 1 matching rate MIN

78 to 79 UINT Tool 1 lower limit value

80 to 81 UINT Tool 1 upper limit value

82 to 91 --- Reserved by system --- ---

Thereafter, the information of tool 2, 3, ... 16 will be assigned for each 20-byte Address of Input Assembly.

* UINT : Unsigned 16-bit integer

UDINT : Unsigned 32-bit integer

Data

type*

Item Content Data content

Tool 1 matching rate MAX

Stores the matching rate of Tool

1.

Stores the maximum matching

rate value of Tool 1.

Stores the minimum matching

rate value of Tool 1.

Stores the lower threshold value

of Tool 1.

Stores the upper threshold

value of Tool 1.

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

Maximum and minimum matching rate values of the tool will be reset in the same manner as the

statistics information.

If the tool is not set, the data content will be “0”.

If the upper threshold value of the tool is not set, the data content of the tool’s upper limit value will be

“65535”.

3-18

- IV Series User’s Manual (Field Network) -

Page 41

Data allocation in the cyclic communication

Output Assembly (PLC → IV series)

Output Assembly are devices that write instructions from the PLC to the IV series.

The device map of the data allocated for the Output Assembly is as shown below.

These parameters are responsible for the control instructions for the IV series, clearing of warnings and

handshake control.

For details of each parameter, refer to “Output Assembly parameter details” (Page 3-20).

Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

0 Reserved by system

1 Reserved by system

2 Reserved by system

3 Reserved by system

4 - 5 Program No.

6 - 11 Reserved by system

Buffer

clear

request

Statistics

reset

request

Warning

clear

request

Program

switching

request

Master

registration

request

Trigger

request

Result

acquisition

complete

notication

3

Cyclic communication

- IV Series User’s Manual (Field Network) -

3-19

Page 42

Data allocation in the cyclic communication

Output Assembly parameter details

Output Assembly Address 0 to 1: Control request

The Bits at Address 0 to 1 of the Output Assembly have the following functions:

3

Cyclic communication

Address Bit Item Content Data content

0

1 0 to 7 Reserved by system --- ---

The following will occur when a buffer clear is requested:

If handshake control is [Enabled]

The current status result will be cleared.

The status result in the buffer will be cleared.

The result available bit will become OFF (0).

The number of remaining buffers will become “10”.

If the handshake control is [Disabled]

The current status result will be cleared.

The result available bit will become OFF (0).

If you are switching programs using the EtherNet/IP communication, set the [Switching method] option

to [Monitor/PC]. For details of the setting, refer to the “IV Series User’s Manual (Monitor / PC Software)”.

Buffer overrun and warning statuses will not be cleared even if you execute a buffer clear request.

0 Trigger request Requests the external trigger. 0 : OFF 1 : ON

Master image registration

1

request

Program switching

2

request

3 Warning clear request Requests a warning clear. 0 : OFF 1 : ON

4 Statistics reset request Requests a statistics reset. 0 : OFF 1 : ON

5 Buffer clear request Requests a buffer clear. 0 : OFF 1 : ON

6 to 7 Reserved by system --- ---

Requests a master image

registration.

Requests a program switching. 0 : OFF 1 : ON

0 : OFF 1 : ON

3-20

- IV Series User’s Manual (Field Network) -

Page 43

Data allocation in the cyclic communication

Output Assembly Address 2 to 3: Handshake control

The Bits at Address 2 to 3 of the Output Assembly have the following functions:

Address Bit Item Content Data content

Result acquisition

0

2

1 to 7 Reserved by system --- ---

3 0 to 7 Reserved by system --- ---

A result acquisition completion notice is used when handshake control is [Enabled].

Updating of the status result will be permitted when you request a result acquisition completion notice.

For details, refer to “Reading out the overall status result of the IV series (Handshake control [Enabled])”

(Page 3-28).

Output Assembly Address 4 to 11: Program No.

The Bits at Address 4 to 11 of the Output Assembly have the following functions:

Address

4 to 5 UINT Program No.

6 to 11 --- Reserved by system --- ---

Data

type

complete notication

Item Content Data content

Permits the updating of the

status result.

Stores the program No. when a

program switching is requested.

0: OFF 1: ON

0 to 31

3

Cyclic communication

- IV Series User’s Manual (Field Network) -

3-21

Page 44

Data allocation in the cyclic communication

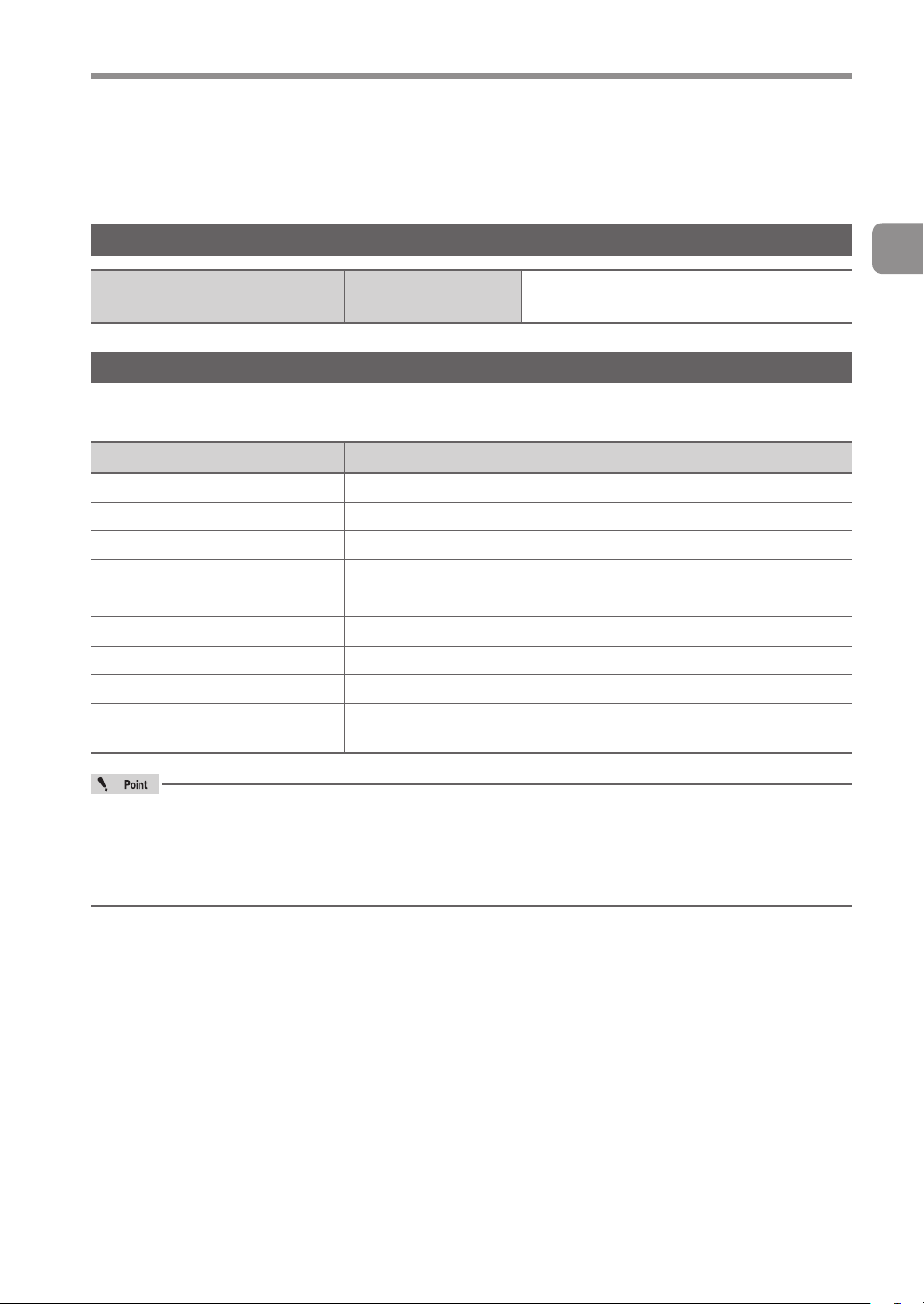

Error code list

The following shows the list of error codes that are generated in the IV series.

Error

code

3

Cyclic communication

0 No error --- ---

1 - 32

75

76

81-128 System error

Program No. xx

corruption error

Non-volatile memory

error

(EEPROM)

Non-volatile memory

error

(FLASHROM)

Content Cause Countermeasure

A data error has

occurred in program No.

xx.

The data corruption may

have occurred due to a

power-off while writing

settings data and/or due

to noise.

A data error has

occurred.

The data corruption may

have occurred due to a

power-off while writing

settings data and/or due

to noise.

An error may have

occurred in the sensor.

Initialize the program No. xx.

Switch on the power back ON.

Do not switch off the unit while the

settings are being saved.

If the error persists, contact your

nearest KEYENCE ofce.

Initialize the settings of this unit.