Page 1

96M12230

Vision Sensor

IV-500C / IV-500CA /

IV-500M / IV-500MA /

IV-150M / IV-150MA /

IV-2000M / IV-2000MA

Instruction Manual

Read this manual before using the product in order to

achieve maximum performance.

Keep this manual in a safe place after reading it so that it

can be used at any time.

For details of functions, refer to the IV Series User's Manual

(Monitor) or the IV Series User's Manual (PC).

The IV Series User's Manual can be downloaded from the

KEYENCE web site:

http://www.keyence.com/

Symbols

The following symbols alert you to important messages.

Be sure to read these messages carefully.

It indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

It indicates a hazardous situation which, if

not avoided, could result in death or serious

injury.

It indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

It indicates a situation which, if not avoided,

could result in product damage as well as

property damage.

It indicates cautions and limitations that must

be followed during operation.

It indicates additional information on proper

operation.

It indicates tips for better understanding or useful

information.

Cautions

(1) Unauthorized reproduction of this manual in whole or

part is prohibited.

(2) The contents of this manual may be changed for

improvements without prior notice.

(3)

An utmost effort has been made to ensure the contents of

this manual are as complete as possible. If there are any

mistakes or questions, please contact a KEYENCE ofce

listed in the back of the manual.

(4) Regardless of item (3), KEYENCE will not be liable for

any effect resulting from the use of this unit.

(5) Any manuals with missing pages or other paging faults

will be replaced.

The company names and product names used in this

manual are registered trademarks or the trademarks of their

respective companies.

Safety Information for IV series

General Precautions

Do not use this product for the purpose to

protect a human body or a part of human body.

This product is not intended for use as an

explosion-proof product. Do not use this

product in a hazardous location and/or

potentially explosive atmosphere.

You must verify that the IV Series are

operating correctly in terms of functionality

and performance before the start and the

operation of the IV Series.

We recommend that you take substantial

safety measures to avoid any damage in the

event of a problem occurring.

KEYENCE never warrants the function or

performance of the IV Series if it is used in manner

that differs from the IV Series specications

contained in this instruction manual or if the IV

Series are modied by yourself.

When the IV Series is used in combination with

other instruments, functions and performance

may be degraded, depending on operating

conditions and the surrounding environment.

Do not place the instruments, including

peripherals, under rapid temperature

change. It may cause condensation and may

damage instruments or peripherals.

Remove the power cable from the power supply

if you do not use this product for a long time.

Safety precautions on LED product

Use of controls or adjustments or

performance of procedures other than those

specied herein may result in hazardous

radiation exposure. Follow the instructions

mentioned in this manual. Otherwise, injury to

the human body (eyes and skin) may result.

Do not stare into the direct or specularly

reected beam.

Do not disassemble this product. The laser

radiation emission from this product is not

automatically stopped when it is disassembled.

Do not direct the beam at people or into

areas where people might be present.

Be careful of the path of the LED beam.

If there is a possibility that the operator

may be exposed to the specular or diffuse

reections, block the beam by installing a

protective enclosure.

Install this product so that the path of the

LED beam is not as the same height as that

of human eye.

Important Instructions

Observe the following precautions to prevent malfunction of

the IV Series and to ensure that it is used properly.

Precautions on use

The power of this product and instruments

connected to this product must be turned off

when the cable is to be installed or removed.

Failure to do so may cause an electric shock

or a product damage.

Use this product in the correct supply voltage.

Failure to do so may cause a product damage.

1

IV Series (Sensor) - IM_E

Page 2

For instructions

Do not turn OFF the power while setting the

items or saving the settings. Otherwise, all

or part of the setting data may be lost.

Do not let water, dust or oil stick to the

camera/light of the sensor. Failure to do so

may cause a malfunction.

When this product becomes dirty, do not rub it with

a wet cloth, benzene, thinner, or alcohol. Doing so

may change the color or shape of the unit.

If the unit is heavily contaminated, disconnect

all the cables including the power supply cable,

wipe off the dirt with a cloth soaked with mild

detergent, and then wipe with a soft dry cloth.

For external master image registration

When the external master image registration is used

frequently, set "Write ROM when registering external

master" of the input option to "No" for nonvolatile

memory protection of the internal sensor. When the

option is set to "Yes", the nonvolatile memory is

guaranteed to write for 100,000 times.

For automatic focus function

Automatic focus function is used for adjusting

the focusing position at the time of installation.

This will not activate during the operation.

Focusing position can be registered in each

program. The program congurations are

guaranteed to switch for 100,000 times. If the

focusing position does not need to change

for each program, set "AF Adjustment Pos"

to "Common" for extending the life-span.

Do not apply shock or vibration during the

focusing position adjustment . Failure to

do so may cause a product damage.

Measures to be taken when an abnormality occurs

In the following cases, turn the power OFF

immediately. Using the IV Series in an abnormal

condition could cause re, electric shock, or

malfunction. Contact our ofce for repair.

If water or debris enters the IV Series.

If the IV Series is dropped or the case is damaged.

If abnormal smoke or odor emanates from

the IV Series.

Precautions on installation

To use this product correctly and safely, avoid

installing it in the following locations. Failure to do

so may cause re, electric shock, or malfunction.

Outdoors

Altitude above 2000 m

Locations that are humid, dusty or poorly

ventilated

Locations where the temperature is high

such as those exposed to direct sunlight

Locations where there are ammable or

corrosive gases

Locations where the unit may be directly

subjected to vibration or impact

Locations where water, oil, or chemicals

may splash onto the unit

To improve the anti-noise feature, install

the unit following the precautions below.

Otherwise, a malfunction may occur.

Mount the sensor onto the insulated

attached mounting adapter.

Ground the FG cable (drain cable) of the sensor.

Do not mount the unit in a cabinet where

high-voltage equipment is already installed.

Mount the unit as far from power lines as possible.

Separate the unit as far as possible from the

devices that emit strong electric or magnetic

eld (such as solenoid or chopper).

Separate the I/O signal line from the power

line or high-voltage line.

For power supply

Noise superimposed on the power supply could

cause malfunction. Use a stabilized DC power

supply congured with an isolation transformer.

When using a commercially available

switching regulator, be sure to ground the

frame ground terminal.

Devices including this unit are precision

components. Do not apply shock or vibration.

When connecting to a network, let engineers

who are knowledgeable about networks

handle it.

Precautions on Regulations and Standards

UL Certication

This product is a UL/C-UL Listed product.

UL File No. E301717

Category NRKH, NRKH7

Be sure to consider the following specications when using

this product as a UL Listed product.

Use a power supply with Class 2 output dened in NFPA70

(NEC: National Electrical Code).

Power supply/ External input/ Control output shall be

connected to a single Class 2 source only.

Use with an over current protection device which is rated

24 V or more and not more than 1 A.

Enclosure Type 1 (Based on UL50)

CE Marking

Keyence Corporation has conrmed that this product

complies with the essential requirements of the applicable

EC Directive, based on the following specications. Be sure

to consider the following specications when using this

product in the Member State of European Union.

EMC Directive (2004/108/EC)

Applicable Standard EMI: EN60947-5-2, Class A

EMS: EN60947-5-2

The length of power/IO cable, Ethernet cable and

Monitor cable must be less than or equal to 30m.

Remarks:

These specications do not give any guarantee that the

end-product with this product incorporated complies with the

essential requirements of EMC Directive. The manufacturer

of the end-product is solely responsible for the compliance

on the end-product itself according to EMC Directive.

Low-Voltage Directive (2006/95/EC)

Applicable Standard: EN62471

Checking the Package Contents

Sensor

IV-500C

IV-500CA

Waterproof cap for Ethernet

connector x 1

Instruction Manual x 1 (This manual)

The mounting adapter is mounted on the monitor in the

default factory setting.

IV-150M

IV-150MA

Sensor x 1

IV-500M

IV-500MA

Mounting adapter x 1

Screw for mounting adapter x 1

Flathead screwdriver x1

(Manual focus type only)

IV-2000M

IV-2000MA

IV Series (Sensor) - IM_E

2

Page 3

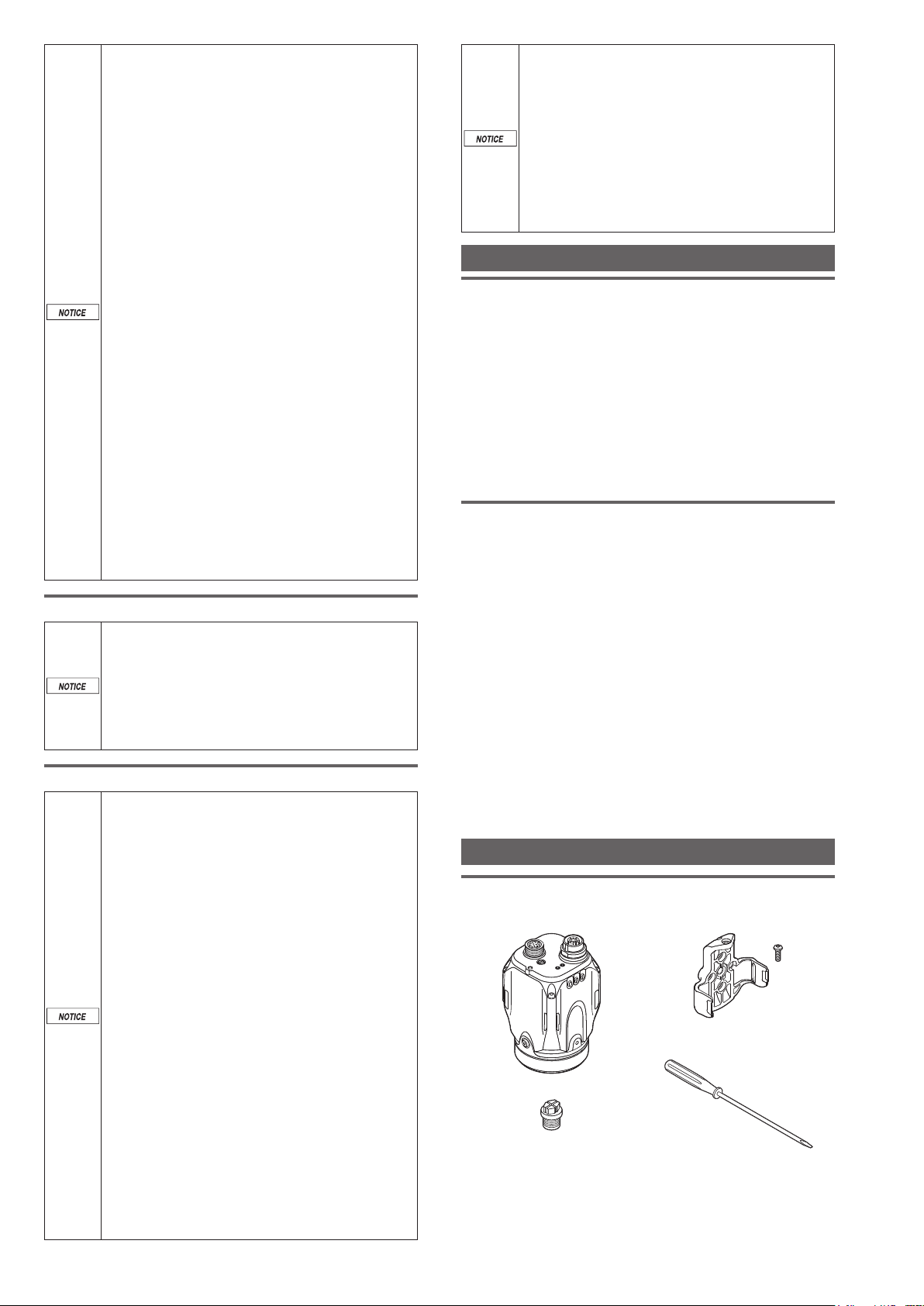

Optional parts for sensor

1

Dome attachment

IV-D10

Mounting screw x 2

Hexagon wrench

Dome attachment x 1

Polarized visible light lter attachment

OP-87436

Polarized visible light lter

attachment x 1

Infrared polarization lter attachment

OP-87437

Infrared polarization lter

attachment x 1

Power I/O cable (M12 12pin - strand wire)

OP-87440 (2m)

Power I/O cable (M12 12pin - strand wire) x 1

Mounting adapter

OP-87460

Mounting adapter x 1

Same as the accessories for sensor.

Optional parts in case of loss/damage.

Front cover (for replacement)

OP-87461

Front cover (for

replacement) x 1

Optional parts for replacement.

Bracket

OP-87685×1

OP-87441 (5m)

Mounting screw x 2

O-shaped ring

(Small x 2, Large x 1)

(L-shaped) x 1

Instruction Manual x 1

Mounting screw x 2

Instruction Manual x 1

Mounting screw x 2

Instruction Manual x 1

OP-87442 (10m)

Screw for mounting

adapter x 1

Hexagon wrench

(L-shaped) x 1

Instruction

Manual x 1

Mounting screw for

bracket + Nut x 1

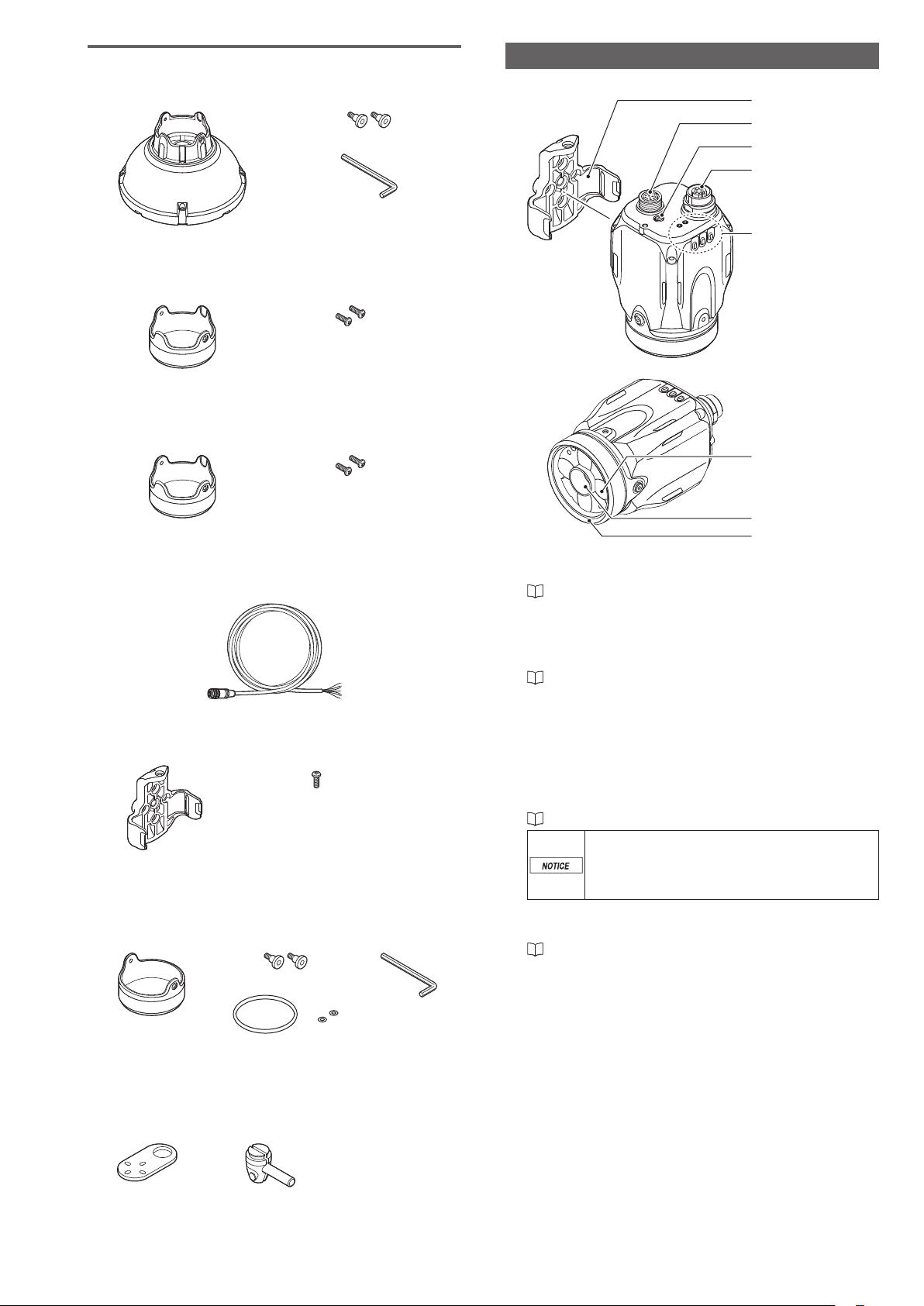

Name and function of each part

Name and function of each part of sensor

2

3

4

5

6

7

8

1 Sensor mounting adapter

Use this for mounting and xing the sensor.

“Mounting” (Page 4)

2 Connector for power I/O cable

Connector for connecting a power I/O cable.

Use this for supplying power to the sensor and for

connecting with external devices.

“Cables” (Page 6)

3 Focusing position adjustment screw

(manual focus type only)

Adjusts the focus of displayed images.

4 Connector for monitor cable/Ethernet cable

Connector for connecting a monitor cable or Ethernet

cable. Use this for connecting the monitor, PC, or Ethernet

switch.

“Cables” (Page 6)

When the cable is not connected, attach

the waterproof cap for Ethernet connector

to maintain enclosure rating.

Tightening torque : 0.45 to 0.55 N·m

5 Indicator light

Indicates the operating status of the sensor.

“Operation of the indicator light” (Page 4)

6 Built-in light

LED light that illuminates the object.

7 Camera

Images the object.

8 Front cover

Protects the camera and built-in lights.

The front cover is protected by the protection sheet (blue)

in the default factory setting.

Remove the sheet when the sensor is to be used.

Front cover for replacement is provided for maintenance.

Bracket A x 1

Bracket B x 1

Screw for mounting

adapter x 4

3

IV Series (Sensor) - IM_E

Page 4

Operation of the indicator light

600

Details on operations of indicator light are shown below.

4 5

1 2 3

1 PWR/ERR

Indicates the power supplying status to the sensor and

error status of the sensor.

Green (ON)

Green (Blink)

...... Operating.

.... Setting processing. Operation is

stopped. Blinks once a second.

Red (ON) .......... Unrecoverable error has occurred.

Red (Blink)

(OFF)

....... Recoverable error has occurred.

............... Power is not supplied.

Adjusting the focusing position (manual

focus only).

2 OUT

Indicates the comprehensive results.

............... Comprehensive result is "OK".

Green

.................. Comprehensive result is "Fail".

Red

............... Setting processing.

(OFF)

Standby status until the rst judge

nishes after starting the operation or

after switching the program number.

Orange (Blink)

... Indicates the focusing status while

adjusting the focusing position with

the blinking speed (manual focus type

only).

3 TRIG

Green light lights up (one-shot) according to input of the

internal or external trigger.

4 STATUS

Indicates the connection status within the monitor.

Green (ON)

...... Normally connected with monitor or

PC.

Green (Blink)

.... IP address has been retrieved but the

sensor is not correctly connected with

monitor or PC.

............... IP address is not assigned.

(OFF)

Sensor is

not correctly connected with monitor or

PC.

Orange (Blink)

... Indicates the focusing status while

adjusting the focusing position with

the blinking speed (manual focus type

only).

5 LINK/ACT

Indicates the linking status within monitor or Ethernet

switch.

Green (ON)

Green (Blink)

...... Normally linked.

.... Normally linked, and the data is

sending/receiving.

............... Sensor is not normally linked.

(OFF)

Mounting

Ground (functional ground) the drain cable

(FG) of the power I/O cable.

Mount and insulate the sensor. Use the

attached mounting adapter to insulate.

Sensor case has been grounded. If the

sensor is not insulated, electric potential and

noises may cause a damage or malfunction.

Do not place the sensor in the environment

that exceeds the limit of sensor's resistance

to the environment, or environment that

propagates the vibration directly to the

sensor. Those may cause a damage or

malfunction.

Manual focus type needs to adjust the

focusing position after installed. Reserve

enough space to adjust and install it.

At the time of installation, it is better to

enable the position or direction adjustment

of the sensor by installing the adjustment

system at the sensor mounting area.

View and optical axis have individual

differences. Adjust the position by checking

the actual image at the time of installation.

Place the sensor where no ambient light has

effect. Ambient light includes solar light,

lights of other devices, and photoelectric

sensors. Also, be careful when the light

intensity of the ambient light changes. Use

the shield to protect when the location

cannot be changed.

Place the sensor where no object can block

out the internal light or the view of the

sensor.

Detection may become unstable due to the

lights if multiple sensors are placed nearby

each other. Delay the timing of external

trigger inputs or use the shield to avoid

interference.

Checking the view and installed distance

For IV series, installed distance between the view and object

is different depending on the type of the sensor. Check the

type of the sensor to be used and its view, and place it in the

proper distance.

View H

Indicator light

View V = View H x 0.75

(H : V = 4 : 3)

Standard-range type (color / monochrome)

500

View V

Installed distance WD

IV Series (Sensor) - IM_E

400

300

200

150

100

Installed distance WD (mm)

50

0

5025 70 100 150130 200 250

210

View H (mm)

4

Page 5

Short-range type

2500

150

100

50

Mounting the sensor onto the mounting adapter

Mount the sensor to the left and right stopper on

1

the mounting adapter.

Sensors cannot be mounted on the side with the

indicator light.

Indicator light

Installed distance WD (mm)

0

Long-rang type

2000

1500

1000

500

300

Installed distance WD (mm)

0

The value of View H and V will be a half of the value on

the gures above when using the digital zooming function

(monochrome type only).

10 20 30 4012 36

View H (mm)

10045 200 300 400

View H (mm)

Mounting the mounting adapter

Use the mounting adapter (accessory or OP-87460) to

mount the sensor.

The mounting adapter is mounted on the

sensor in the default factory setting. Remove

it from the sensor.

“Unmounting the sensor” (Page 5)

Push the sensor to the

stopper of xing screw

Push until you hear the clicking

sound from the both side stoppers

Fix the mounting adapter and sensor using the

2

attached screws.

Screw : M3 x 1

Use the attached screws.

Tightening torque : 0.45 to 0.55 N·m

Mounting on the wall

Screw : M3 x 4

Use the commercially available screws which have head

thickness of 3 mm or lower.

Tightening torque : 1.0 N·m or lower

Mounting from the jig side

Screw : M4 x 4

Use the commercially available screws.

Tightening torque : 1.5 N·m or lower

Remove the protection

sheet (blue)

Unmounting the sensor

Dismount the screw.

1

Pull out the stopper of the mounting adapter and

2

unmount the sensor.

For details on mounting hole dimensions, refer

to “Dimensions” (Page 8).

Pull out the

stopper

5

IV Series (Sensor) - IM_E

Page 6

Cables

Connecting the power I/O cable of the sensor

Adjust the pins of the connector for the power I/O

1

cable and pin connection of the cable connector,

and connect the cable to the sensor.

Selecting PNP output

When PNP is selected in I/O format

Brown (DC24V)

Pink/Yellow/

Light Blue/Purple/

Green/Red

(IN)

Black/White/Gray/

Orange

(OUT)

OUT

External device

(PNP)

DC24V

IN

Adjust the pins and the

pin connection

Tighten the connector by turning the screw-on

2

connector in the clockwise direction.

Tightening torque of the screws needs to be 1.0 to 1.5 N·m.

When connecting the connector, insert it

without tipping and tighten it well. If the

tightening is weak, it may cause a bad

connection and vibration can loosen the

connector. Also, the enclosure rating may

not be maintained with loose connection.

* Indication is retightening approximately

90° to 120° with tools such as pliers

after tightening with hands.

Wire each cable according to its intended purpose.

3

Selecting NPN output

When NPN is selected in I/O format

Brown (DC24V)

Black/White/Gray/

Orange

(OUT)

Pink/Yellow/

Light Blue/Purple/

Green/Red

(IN)

Blue (0V)

Drain wire (FG)

External device

Load

IN

DC24V

OUT

(NPN)

Blue (0V)

Drain wire (FG)

Black (OUT1) / White (OUT2) /

Gray (OUT3) / Orange (OUT4)

Pink (IN1 : External trigger) / Yellow (IN2) /

Light Blue (IN3) / Purple (IN4) /Green (IN5)

/ Red (IN6)

Use it by assigning the optional function to

OUT1 to OUT4 and IN2 to IN6.

Wiring

color

Brown DC24V - + side of power

Blue 0V -

Black OUT1

White OUT2 BUSY (N.O.)

Gray OUT3 Error (N.O.)

Orange OUT4 OFF

Pink IN1

Yellow IN2 OFF

Light Blue

Purple IN4 OFF

Green IN5 OFF

Red IN6 OFF

Drain FG - Insulated frame

Cable

specication

Name

IN3 OFF

The output assignment, N.O./N.C., and input line

assignment can be changed. For details, refer to

the User's Manual.

Assigning

default value

Total judge

(N.O.)

External

trigger ↑

Brown/Blue/Black/White/Gray/Orange

: AWG25

Pink/Yellow/Light Blue/Purple/Green/

Red : AWG28

With braided shield cable (with drain cable)

Load

Description

- side of power

GND of input-output cable

Output assignable

function

Total Status

Tot.StatusNG

RUN

BUSY

Error

Pos. Adj.

Judge result of each

tool (Tool 1 to Tool 16)

Result of the logical

operation of each tool

(Logic 1 to Logic 4)

OFF (not used)

Set external trigger.

Activation timing (↑) or

deactivation timing (↓)

can be set.

Input assignable function

Program bit0 to bit4

Clear error

External master

OFF (not used)

Black (OUT1) / White (OUT2) /

Gray (OUT3) / Orange (OUT4)

Pink (IN1 : External trigger) / Yellow (IN2) /

Light Blue (IN3) / Purple (IN4) / Green (IN5)

/ Red (IN6)

Use it by assigning the optional function to

OUT1 to OUT4 and IN2 to IN6.

IV Series (Sensor) - IM_E

Individually insulate the non-used input-

output cables.

For input cables of this sensor, connect with

non-contact output (transistor output/SSR

output). For contact output (relay output),

incorrect input may be operated due to the

contact bouncing in the system.

6

Page 7

Circuit Diagram

DC24V

DC24V

Input circuit

No-voltage input (When NPN output is selected)

When NPN is selected in I/O format, the circuit becomes

no-voltage input circuit. External power supply is not

necessary.

ON voltage : 2 V or lower

OFF current : 0.1 mA or lower

ON current : 2 mA (short circuit)

+3.3V

Main circuit

* Pink (IN1 : External trigger) / Yellow (IN2) / Light Blue (IN3) /

Purple (IN4) / Green (IN5) / Red (IN6)

Use by assigning the optional functions to IN2 to 6

Voltage input (When PNP output is selected)

When PNP is selected in I/O format, the circuit becomes

voltage input circuit.

Input maximum rating : 26.4 V

ON voltage : 15 V or higher

ON current : 2 mA (for 24V)

OFF current : 0.2 mA or lower

Brown

IN1 - IN6

*

0V

Blue

Output circuit

When NPN output is selected

When NPN is selected in I/O format, the circuit becomes

open collector N

PN output circuit

Maximum rating : 26.4 V, 50 mA

Remaining voltage : 1.5 V or lower

Main circuit

* Black (OUT1) / White (OUT2) / Gray (OUT3) / Orange (OUT4)

Use by assigning the optional functions to OUT1 to OUT4

When PNP output is selected

Overcurrent

When PNP is selected in I/O format, the circuit becomes

open collector

PNP output circuit

Maximum rating : 26.4 V, 50 mA

Remaining voltage : 2 V or lower

.

DC24V

Brown

Load

OUT1 - OUT4

*

protection circuit

0V

Blue

.

DC24V

Brown

Brown

IN1 - IN6

*

Main circuit

0V

Blue

* Pink (IN1 : External trigger) / Yellow (IN2) / Light Blue (IN3) /

Purple (IN4) / Green (IN5) / Red (IN6)

Use by assigning the optional functions to IN2 to 6

OUT1 - OUT4

*

Main circuit

* Black (OUT1) / White (OUT2) / Gray (OUT3) / Orange (OUT4)

Use by assigning the optional functions to OUT1 to OUT4

Overcurrent

protection circuit

0V

Blue

Load

7

IV Series (Sensor) - IM_E

Page 8

Dimensions

(102)

0.4 112.5

93

56

Sensor

IV-500C / IV-500CA / IV-500M / IV-500MA / IV-150M / IV-150MA / IV-2000M / IV-2000MA

R50

52

R50

50

56

WD reference surface

32.4

57.4

0.4

50

20

81.5

58

45.5 25

Mounting

adapter

Power I/O cable

OP-87440 (2m) / OP-87441 (5m) / OP-87442 (10m)

45

φ15

φ6.7

2000

5000

10000

120 5

150

180

5

5

1/4-20UNC

(Depth 6mm)

4-M4

(Depth 6mm)

10.5 10.5

(108)

Focusing position adjustment screw

610.5

(MF type only)

3-M3

(Depth 6mm)

20.5

41

Bracket

OP-87685

50

IV Series (Sensor) - IM_E

(99)

48.4

31.6

99

58

19.6

41

82.5

8

Page 9

Specications

Model IV-500C IV-500CA IV-500M IV-500MA IV-150M IV-150MA IV-2000M IV-2000MA

Installed distance Standard distance (50 to 500 mm)

Short range (50 to 150 mm)

Installed distance 50 mm :

View

Installed distance 50 mm : 25 (H) x 18 (V) mm

to

Installed distance 500 mm : 210 (H) x 157 (V) mm

12 (H) x 9 (V) mm

to

Installed distance 150 mm :

36 (H) x 27 (V) mm

Image sensor 1/3 inch color CMOS 1/3 inch monochrome CMOS

Pixel 752 (H) x 480 (V)

Focus adjustment Manual Auto

*1

Manual Auto

*1

Manual Auto

Exposure time 1/10 to 1/50,000 1/10 to 1/25,000 1/20 to 1/25,000 1/10 to 1/25,000

Lights

Tools

Amplier type White LED Red LED Infrared LED

Lighting method

Type Outline search, Color area

Number

Pulse lighting/DC lighting is switchable

*7

*2

Detection tools : 16 tools, Position adjustment tool : 1 tool

, Area*8, Position adjustment

Switch settings (programs) 32 programs

Image

history

Numbers 100 images

*3

Condition NG only/All is selectable

*4

300 images

*5

OFF/Statistics/Histograms is switchable

Statistics : Processing time (latest value, MAX, MIN, AVE), numbers of OKs, numbers of NGs,

Analysis information

Other functions

Indicators

*6

trigger numbers, trigger errors, judge results list by tools

Histograms :

Histogram, matching degree (latest value, MAX, MIN, AVE), numbers of OKs, numbers of NGs

HDR, HighGain, Color lters*7, Digital zoom*8, Brightness correction, Tilt correction, White balance*7,

Mask outline, Mask area, Test run, ToolAutoTune, Input monitor, Output test, Security settings, Simulator

PWR/ERR, OUT, TRIG, STATUS, LINK/ACT

No-voltage input/voltage input is switchable

Input

For no-voltage input

For voltage input

:

ON voltage 2V or lower, OFF current 0.1mA or lower, ON current 2mA (short circuit)

:

Maximum input rating 26.4V, ON voltage 15V or higher, OFF

lower, ON current 2mA (for 24V)

Inputs 6 inputs (IN1 to IN6)

Function

IN1 : External trigger, IN2 to IN6 : Enable by assigning the optional functions

Assignable functions :

Program switching, Clear error, External master image registration

Open collector output NPN/PNP is switchable, N.O./N.C. is switchable

Output

For open collector NPN output : Maximum rating 26.4V 50mA, remaining voltage 1.5V or lower

For open collector PNP output : Maximum rating 26.4V 50mA, remaining voltage 2V or lower

Outputs 4 outputs (OUT1 to OUT4)

Enable by assigning the optional functions

Function

Assignable functions : Total judge result, RUN, BUSY, Error, Position adjustment result, Judge

result of each tool, Result of the logical operation of each tool

Standard 100BASE-TX/10BASE-T

Ethernet

*10

Connector M12 4pin connector

Network function FTP client, EtherNet/IP, PROFINET

Power voltage DC 24V ± 10% (including ripple)

Rating

Environmental

resistance

Consumption

current

Ambient

temperature

Relative humidity

0.6 A or less

0 to +50°C (No freezing)

35 to 85%RH (No condensation)

Vibration 10 to 55 Hz, 1.5 mm double amplitude, 2 hours each for X, Y, and Z axes

Shock resistance

Enclosure rating

500m/s2 6 different directions in 3 times

*11

IP67

Material Main unit case : Aluminum die-casting, Packing : NBR, Front Cover : Acrylic, Mounting adapter : POM

Weight Approx. 270 g

*1 The focusing position can be automatically adjusted at the time of installation. Deactivated during the operation. The focusing

position can be registered by programs.

*2 Tools can be installed by programs.

*3 Saves to the memory in the sensor.

The images saved in the sensor can be backed up to the USB memory installed to the intelligent monitor (IV-M30) or to the

PC by the software for IV (IV-H1).

*4 When using the FTP client function ; 70 pictures

*5 When using the FTP client function ; 210 pictures

*6 This can be displayed on the intelligent monitor (IV-M30) or by the software for IV (IV-H1).

*7 Color type only.

*8 Monochrome type only.

*9 This function can be used with the software for IV (IV-H1).

*10 This is for connection with the intelligent monitor (IV-M30) or the software for IV (IV-H1).

*11 Except when polarized lter attachment (OP-87436/OP-87437) is mounted.

Long range (300 to 2000 mm)

Installed distance 300 mm :

45 (H) x 33 (V) mm

Installed distance 2000 mm :

300 (H) x 225 (V) mm

*1

Manual Auto

current

to

*1

*9

0.2mA or

9

IV Series (Sensor) - IM_E

Page 10

Warranties and Disclaimers

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were

used merely to illustrate the general type and quality of the Products and not

to represent that the Products would necessarily conform to said models or

samples. Any Products found to be defective must be shipped to KEYENCE

with all shipping costs paid by Buyer or offered to KEYENCE for inspection and

examination. Upon examination by KEYENCE, KEYENCE, at its sole option,

will refund the purchase price of, or repair or replace at no charge any Products

found to be defective. This warranty does not apply to any defects resulting from

any action of Buyer, including but not limited to improper installation, improper

interfacing, improper repair, unauthorized modication, misapplication and

mishandling, such as exposure to excessive current, heat, coldness, moisture,

vibration or outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products.

They are only suggestions, and it is Buyer's responsibility to ascertain the

tness of the Products for Buyer’s intended use. KEYENCE will not be

responsible for any damages that may result from the use of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not

to be used internally in humans, for human transportation, as safety devices or

fail-safe systems, unless their written specications state otherwise. Should any

Products/Samples be used in such a manner or misused in any way, KEYENCE

assumes no responsibility, and additionally Buyer will indemnify KEYENCE and

hold KEYENCE harmless from any liability or damage whatsoever arising out of

any misuse of the Products/ Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL EXPRESS,

IMPLIED, AND STATUTORY WARRANTIES, INCLUDING, WITHOUT

LIMITATION, THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF PROPRIETARY

RIGHTS, ARE EXPRESSLY DISCLAIMED. IN NO EVENT SHALL KEYENCE

AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY PERSON OR ENTITY

FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY

DAMAGES RESULTING FROM LOSS OF USE, BUSINESS INTERRUPTION,

LOSS OF INFORMATION, LOSS OR INACCURACY OF DATA, LOSS

OF PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF

SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY

MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR

INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS

AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD PARTY’S

CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST BUYER. In some

jurisdictions, some of the foregoing warranty disclaimers or damage limitations

may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a

third party, Buyer must provide such third party with a copy of this document, all

specications, manuals, catalogs, leaets and written information provided to

Buyer pertaining to the Products/Samples.

E 1101-3

IV Series (Sensor) - IM_E

Copyright (c) 2012 KEYENCE CORPORATION. All rights reserved.

12230E 1122-1 96M12230 Printed in Japan

10

Loading...

Loading...