HP 2000, 3000 x schematic

Agilent InfiniiVision

2000/3000 X-Series

Oscilloscopes

Service Guide

Notices

© Agilent Technologies, Inc. 2008-2011

No part of this manual may be reproduced in any form or by any means (including electronic storage and retrieval or translation into a foreign language) without prior agreement and written consent from Agilent Technologies, Inc. as governed by United States and international copyright laws.

Manual Part Number

75019-97015, July 2011

Print History:

75019-97012, January 2011

Available in electronic format only

Agilent Technologies, Inc.

1900 Garden of the Gods Road

Colorado Springs, CO 80907 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice, in future editions. Further, to the maximum extent permitted by applicable law, Agilent disclaims all warranties, either express or implied, with regard to this manual and any information contained herein, including but not limited to the implied warranties of merchantability and fitness for a particular purpose. Agilent shall not be liable for errors or for incidental or consequential damages in connection with the furnishing, use, or performance of this document or of any information contained herein. Should Agilent and the user have a separate written agreement with warranty terms covering the material in this document that conflict with these terms, the warranty terms in the separate agreement shall control.

defined in FAR 52.227-19(c)(1-2) (June 1987). U.S. Government users will receive no greater than Limited Rights as defined in FAR 52.227-14 (June 1987) or DFAR 252.227-7015 (b)(2) (November 1995), as applicable in any technical data.

Safety Notices

CAUTION

A CAUTION notice denotes a hazard. It calls attention to an operating procedure, practice, or the like that, if not correctly performed or adhered to, could result in damage to the product or loss of important data. Do not proceed beyond a CAUTION notice until the indicated conditions are fully understood and met.

A newer version of this manual may be available at

www.agilent.com/find/ 3000X-Series-manual

Microsoft ® is a U.S. registered trademark of Microsoft Corporation.

Technology Licenses

The hardware and/or software described in this document are furnished under a license and may be used or copied only in accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a U.S. Government prime contract or subcontract, Software is delivered and licensed as “Commercial computer software” as defined in DFAR 252.227-7014 (June 1995), or as a “commercial item” as defined in FAR 2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June 1987) or any equivalent agency regulation or contract clause. Use, duplication or disclosure of Software is subject to Agilent Technologies’ standard commercial license terms, and non-DOD Departments and Agencies of the U.S. Government will receive no greater than Restricted Rights as

WARNING

A WARNING notice denotes a hazard. It calls attention to an operating procedure, practice, or the like that, if not correctly performed or adhered to, could result in personal injury or death. Do not proceed beyond a WARNING notice until the indicated conditions are fully understood and met.

2000/3000 X-Series Oscilloscopes Service Guide

In This Service Guide

This book provides the service information for the Agilent 2000/3000 X- Series oscilloscopes. This manual is divided into these chapters:

1Characteristics and Specifications

This chapter contains a partial list of characteristics and specifications for the Agilent InfiniiVision

2000/3000 X- Series oscilloscopes.

2Testing Performance

This chapter explains how to verify correct oscilloscope operation and perform tests to ensure that the oscilloscope meets the performance specifications.

3Calibrating and Adjusting

This chapter explains how to adjust the oscilloscope for optimum operating performance.

4Troubleshooting

This chapter begins with suggestions for solving general problems that you may encounter with the oscilloscope. Procedures for troubleshooting the oscilloscope follow the problem solving suggestions.

5Replacing Assemblies

This chapter describes how to remove assemblies from the 2000/3000 X- Series oscilloscope.

6Replaceable Parts

This chapter describes how to order replaceable assemblies and parts for the Agilent 2000/3000 X- Series oscilloscopes. It includes diagrams and parts lists for hardware that you can order.

2000/3000 X-Series Oscilloscopes Service Guide |

3 |

7Safety Notices

At the front of the book you will find safety notice descriptions and document warranties.

Digital Channels

Because all of the oscilloscopes in the Agilent 2000/3000 X-Series have analog channels, the analog channel topics in this book apply to all instruments. Whenever a topic discusses the digital channels, that information applies only to Mixed-Signal Oscilloscope (MSO) models or DSO models that have been upgraded to an MSO.

Abbreviated instructions for pressing a series of keys

Instructions for pressing a series of keys are written in an abbreviated manner. Instructions for pressing Key1, then pressing Softkey2, then pressing Softkey3 are abbreviated as follows:

Press [Key1] & Softkey2 & Softkey3.

The keys may be front panel keys, or softkeys, which are located directly below the oscilloscope display.

4 |

2000/3000 X-Series Oscilloscopes Service Guide |

Contents

In This Service Guide |

3 |

|

Figures |

9 |

|

Tables |

13 |

|

1 Characteristics and Specifications 15 |

||

Power Requirements |

16 |

|

Measurement Category |

17 |

|

Measurement Category 17

Measurement Category Definitions 17

Transient Withstand Capability 18

Environmental Conditions |

19 |

Specifications |

20 |

|

|

Contact us |

21 |

|

|

2 Testing Performance |

23 |

||

Overview |

24 |

|

|

List of Test Equipment |

25 |

||

Conventions |

26 |

|

|

To construct the test connector (for use with MSO models only) 27

To test digital channels (MSO models only) 29

To verify digital channel threshold accuracy (MSO models only) 30

When to Test 30

2000/3000 X-Series Oscilloscopes Service Guide |

5 |

Contents

What to Test 30 |

|

|

Verifying Test Results |

30 |

|

To verify DC vertical gain accuracy |

35 |

|

To verify dual cursor accuracy 42 |

|

|

To verify analog bandwidth (-3 dB) |

49 |

|

To verify time base accuracy |

55 |

|

To verify trigger sensitivity |

57 |

|

|

Test Internal Trigger Sensitivity (all models) |

58 |

|

||||

|

Test External Trigger Sensitivity |

60 |

|

|

|||

|

Agilent 2000 X-Series Oscilloscopes Performance Test Record |

63 |

|||||

|

Agilent 3000 X-Series Oscilloscopes Performance Test Record |

65 |

|||||

3 |

Calibrating and Adjusting |

67 |

|

|

|

|

|

|

User Calibration |

69 |

|

|

|

|

|

|

To perform User Cal |

69 |

|

|

|

|

|

|

User Cal Status |

72 |

|

|

|

|

|

4 |

Troubleshooting |

73 |

|

|

|

|

|

|

Solving General Problems with the Oscilloscope |

74 |

|

||||

|

If there is no display |

74 |

|

|

|

|

|

|

If there is no trace display |

75 |

|

|

|

||

|

If the trace display is unusual or unexpected |

75 |

|

||||

|

If you cannot see a channel |

76 |

|

|

|||

|

Verifying Basic Operation |

77 |

|

|

|

|

|

|

To power-on the oscilloscope |

77 |

|

|

|||

|

To perform hardware self test |

78 |

|

|

|||

|

To perform front panel self test |

78 |

|

|

|||

|

To verify default setup |

79 |

|

|

|

|

|

|

To perform an Auto Scale on the Probe Comp signal 80 |

|

|||||

|

To compensate passive probes |

81 |

|

|

|||

6 |

2000/3000 X-Series Oscilloscopes Service Guide |

Contents

|

Troubleshooting Internal Assemblies |

83 |

|

|

|||

|

Equipment Required for Troubleshooting Internal |

|

|||||

|

Assemblies |

83 |

|

|

|

|

|

|

To prepare for internal assembly troubleshooting |

84 |

|||||

|

Flowchart for Troubleshooting Internal Assemblies |

87 |

|||||

|

System Board Drawings |

88 |

|

|

|

|

|

|

To check the system board power supply test points |

90 |

|||||

|

To check the interboard supply connector voltages |

91 |

|||||

|

To check the line filter board AC output |

93 |

|

||||

|

To check the power switch |

95 |

|

|

|

||

|

To check the power supply DC output |

96 |

|

||||

|

To check the display supplies |

97 |

|

|

|

||

|

To check the keyboard supplies |

98 |

|

|

|||

|

To check the fan |

99 |

|

|

|

|

|

5 |

Replacing Assemblies 101 |

|

|

|

|

|

|

|

To remove the front panel knobs |

104 |

|

|

|||

|

To remove the bucket assembly |

105 |

|

|

|

||

|

To remove the power supply shield |

107 |

|

|

|||

|

To remove the rear deck assembly |

110 |

|

|

|||

|

To remove the acquisition board |

117 |

|

|

|

||

|

To remove the front panel assembly |

122 |

|

|

|||

|

To remove the display assembly |

129 |

|

|

|

||

|

Replacing a 75019-68712 Display Assembly 131 |

|

|||||

|

To remove the fan assembly |

134 |

|

|

|

|

|

|

To remove the power supply |

136 |

|

|

|

||

|

To remove the line filter board |

139 |

|

|

|

||

6 |

Replaceable Parts |

145 |

|

|

|

|

|

|

Ordering Replaceable Parts |

146 |

|

|

|

|

|

2000/3000 X-Series Oscilloscopes Service Guide |

7 |

Contents

Listed Parts |

146 |

|

Unlisted Parts |

146 |

|

Direct Mail Order System 146 |

||

Exchange Assemblies |

147 |

|

Exploded Views |

148 |

|

Replaceable Parts List |

150 |

|

7 Safety Notices |

157 |

|

Warnings 157 |

|

|

To clean the instrument |

158 |

|

Safety Symbols |

159 |

|

Index 161

8 |

2000/3000 X-Series Oscilloscopes Service Guide |

Figures

Figure 1. Constructing the 8-by-2 Connector 28 |

|

|

|||

Figure 2. Setting Up Equipment for Digital Channel Threshold |

|

||||

Accuracy Test |

32 |

|

|

|

|

Figure 3. Setting up Equipment for DC Vertical Gain Accuracy |

|

||||

Test |

39 |

|

|

|

|

Figure 4. Using a Blocking Capacitor to Reduce Noise |

41 |

|

|||

Figure 5. Setting up Equipment for Dual Cursor Accuracy Test |

46 |

||||

Figure 6. Using a Blocking Capacitor to Reduce Noise |

48 |

|

|||

Figure 7. Setting Up Equipment for Analog Bandwidth (-3 dB) |

|

||||

Verification Test |

51 |

|

|

|

|

Figure 8. Setting Up Equipment for Internal Trigger Sensitivity |

|

||||

Test |

58 |

|

|

|

|

Figure 9. Setting Up Equipment for 4-Channel External Trigger |

|

||||

Sensitivity Test |

61 |

|

|

|

|

Figure 10. User Calibration cable for 2-channel oscilloscope |

70 |

||||

Figure 11. User Calibration cable for 4-channel oscilloscope |

71 |

||||

Figure 12. Default setup screen 80 |

|

|

|

||

Figure 13. Example pulses |

82 |

|

|

|

|

Figure 14. Setup for troubleshooting internal assemblies 85 |

|

||||

Figure 15. System Board Test Points - Top Side, Left |

89 |

|

|||

Figure 16. System Board Test Points - Top Side, Right |

89 |

|

|||

Figure 17. Line filter board interboard supply connector J108 |

92 |

||||

Figure 18. Verify line filter board AC output |

94 |

|

|

||

Figure 19. Verify power switch operation |

95 |

|

|

||

Figure 20. Location of the Fan Connector |

100 |

|

|

||

Figure 21. Removing the front panel knobs |

104 |

|

|

||

Figure 22. Removing the bucket screws |

105 |

|

|

||

Figure 23. Removing bucket assembly 106 |

|

|

|||

Figure 24. Removing the power supply shield screw |

107 |

|

|||

2000/3000 X-Series Oscilloscopes Service Guide |

9 |

Figures

Figure 25. Unclipping the power supply shield right side |

108 |

||

Figure 26. Removing the power supply shield - lift and pull |

|||

|

out 109 |

|

|

Figure 27. Removing the BNC nuts and washers |

110 |

|

|

Figure 28. |

Removing the top rear deck screws 111 |

|

|

Figure 29. |

Removing the bottom right rear deck screw |

111 |

|

Figure 30. |

Removing the bottom left rear deck screw |

112 |

|

Figure 31. |

Removing the bottom rear deck screws |

112 |

|

Figure 32. Removing the option module guide to acquisition board screw 113

Figure 33. Disconnecting the interboard supply cable from the

|

acquisition board |

114 |

Figure 34. |

Lifting front bezel latch 115 |

|

Figure 35. Separating the rear and front decks 116 |

||

Figure 36. |

Rear and front decks separated 116 |

|

Figure 37. |

Removing the T6 screws (4 channel version) 117 |

|

Figure 38. |

Disconnecting keyboard and display cables from |

|

|

acquisition board |

118 |

Figure 39. Disconnecting display inverter cable from acquisition

|

board 119 |

|

Figure 40. |

Acquisition board mounting screw locations |

120 |

Figure 41. |

Acquisition board removed from front deck |

121 |

Figure 42. |

Release the bezel clips from the front deck |

122 |

Figure 43. |

All bezel clips released 123 |

Figure 44. |

HINT: When reinstalling bezel, align ground terminal |

|

first 123 |

|

Figure 45. |

Gently lift front deck from bezel |

124 |

Figure 46. |

Disconnect the keyboard cable |

125 |

Figure 47. |

Disconnect the softkey board cable 126 |

Figure 48. |

Unclip the softkey board from the bezel 127 |

Figure 49. |

Remove the softkey keypad from the bezel |

127 |

Figure 50. |

Unclip the keyboard board from the bezel |

128 |

Figure 51. |

Remove the keyboard keypad from the bezel |

128 |

Figure 52. |

Removing the display assembly 129 |

|

10 |

2000/3000 X-Series Oscilloscopes Service Guide |

Figures

Figure 53. Display assembly removed 130

Figure 54. The 75019-68712 display assembly has a bracket under two of the retaining screws 131

Figure 55. |

Disassembling the 75019-68712 display assembly 132 |

Figure 56. |

Separating the 75019-68712 display mounting |

|

bracket 133 |

|

Figure 57. |

Removing the 75019-61606 display cable 133 |

|

Figure 58. |

Disconnecting fan power cable |

134 |

Figure 59. |

Removing fan assembly 135 |

|

Figure 60. |

Disconnecting the AC cable |

136 |

Figure 61. Disconnecting the interboard supply cable from the line filter board 137

Figure 62. Disconnecting the DC cable from the line filter

|

board 137 |

|

|

|

Figure 63. Removing the power supply |

138 |

|

||

Figure 64. Removing the option module guide |

139 |

|||

Figure 65. Disconnecting the ground wire |

140 |

|

||

Figure 66. Removing the line filter board screws |

141 |

|||

Figure 67. |

Removing the line filter board |

142 |

|

|

Figure 68. |

Removing the power switch extender |

143 |

||

Figure 69. |

Exploded View 1 of 2 |

148 |

|

|

Figure 70. |

Exploded View 2 of 2 |

149 |

|

|

2000/3000 X-Series Oscilloscopes Service Guide |

11 |

Figures

12 |

2000/3000 X-Series Oscilloscopes Service Guide |

Tables

Table 1. List of test equipment |

25 |

|

|

|

Table 2. Conventions |

26 |

|

|

|

Table 3. Materials required to construct the test connectors |

27 |

|||

Table 4. Equipment Required to Test Digital Channel Threshold |

|

|||

Accuracy |

31 |

|

|

|

Table 5. Threshold Accuracy Voltage Test Settings |

33 |

|

||

Table 6. DC Vertical Gain Accuracy Test Limits 35 |

|

|||

Table 7. Equipment Required to Verify DC Vertical Gain |

|

|||

Accuracy |

36 |

|

|

|

Table 8. Settings Used to Verify DC Vertical Gain Accuracy, |

|

|||

2000 X-Series Models |

37 |

|

|

|

Table 9. Settings Used to Verify DC Vertical Gain Accuracy, |

|

|||

3000 X-Series Models |

38 |

|

|

|

Table 10. Equipment Required to Verify Dual Cursor Accuracy |

43 |

|||

Table 11. Settings Used to Verify Dual Cursor Accuracy, |

|

|||

2000 X-Series Models |

44 |

|

|

|

Table 12. Settings Used to Verify Dual Cursor Accuracy, |

|

|||

3000 X-Series Models |

45 |

|

|

|

Table 13. Analog Bandwidth (-3 dB) Test Limits |

49 |

|

||

Table 14. Equipment Required to Verify Analog Bandwidth |

|

|||

(-3 dB) 50 |

|

|

|

|

Table 15. Equipment Required to Verify Time Base Accuracy |

55 |

|||

Table 16. Equipment Required to Verify Trigger Sensitivity 57 |

|

|||

Table 17. Equipment Required to Troubleshoot the |

|

|

||

Oscilloscope |

83 |

|

|

|

Table 18. Replaceable Parts |

150 |

|

|

|

2000/3000 X-Series Oscilloscopes Service Guide |

13 |

Tables

14 |

2000/3000 X-Series Oscilloscopes Service Guide |

Agilent InfiniiVision 2000/3000 X-Series Oscilloscope

Service Guide

1

Characteristics and Specifications

Power Requirements 16

Measurement Category 17

Environmental Conditions 19

Specifications 20

Contact us 21

This chapter contains a partial list of characteristics and specifications for the Agilent InfiniiVision

2000/3000 X- Series oscilloscopes.

For a full list of Agilent InfiniiVision 2000/3000 X- Series oscilloscopes characteristics and specifications see the data sheets.

The data sheets are available at

www.agilent.com/find/2000XSeries or

www.agilent.com/find/3000XSeries.

15

1 Characteristics and Specifications

Power Requirements

Line voltage, frequency, and power:

•~Line 100120 Vac, 50/60/400 Hz

•100240 Vac, 50/60 Hz

•100 W max

16 |

2000/3000 X-Series Oscilloscopes Service Guide |

Characteristics and Specifications |

1 |

Measurement Category

Measurement Category

|

The InfiniiVision 2000/3000 X- Series oscilloscope is intended |

|

|

to be used for measurements in Measurement Category I. |

|

WARNING |

Use this instrument only for measurements within its specified |

|

measurement category. |

||

|

Measurement Category Definitions

Measurement category I is for measurements performed on circuits not directly connected to MAINS. Examples are measurements on circuits not derived from MAINS, and specially protected (internal) MAINS derived circuits. In the latter case, transient stresses are variable; for that reason, the transient withstand capability of the equipment is made known to the user.

Measurement category II is for measurements performed on circuits directly connected to the low voltage installation. Examples are measurements on household appliances, portable tools and similar equipment.

Measurement category III is for measurements performed in the building installation. Examples are measurements on distribution boards, circuitbreakers, wiring, including cables, busbars, junction boxes, switches, socketoutlets in the fixed installation, and equipment for industrial use and some other equipment, for example, stationary motors with permanent connection to the fixed installation.

Measurement category IV is for measurements performed at the source of the lowvoltage installation. Examples are electricity meters and measurements on primary overcurrent protection devices and ripple control units.

2000/3000 X-Series Oscilloscopes Service Guide |

17 |

1 Characteristics and Specifications

Transient Withstand Capability

CAUTION |

Maximum input voltage for analog inputs |

|

CAT I 300 Vrms, 400 Vpk; transient overvoltage 1.6 kVpk |

||

|

||

|

with 10073C 10:1 probe: CAT I 500 Vpk, CAT II 400 Vpk |

|

|

with N2862A/B or N2863A/B 10:1 probe: 300 Vrms |

|

|

|

|

|

Do not exceed 5 Vrms in 50 Ω mode (3000 X-Series oscilloscopes only). |

|

CAUTION |

||

Input protection is enabled in 50 Ω mode, and the 50 Ω load will |

||

|

||

|

disconnect if greater than 5 Vrms is detected. However, the input could |

|

|

still be damaged, depending on the time constant of the signal. The 50 |

|

|

Ω input protection mode only functions when the oscilloscope is |

|

|

powered on. |

|

|

|

|

|

Maximum input voltage for logic channels: |

|

CAUTION |

||

±40 V peak CAT I; transient overvoltage 800 Vpk |

||

|

||

|

|

18 |

2000/3000 X-Series Oscilloscopes Service Guide |

Characteristics and Specifications |

1 |

Environmental Conditions

Environment |

Indoor use only. |

|

|

Ambient |

Operating 0 °C to +55 °C; non-operating –40 °C to +71 °C |

temperature |

|

|

|

Humidity |

Operating: Up to 80% RH at or below +40 °C. Up to 45% RH up |

|

to +50 °C. |

|

Non-operating: Up to 95% RH up to +40 °C. Up to 45% RH up to |

|

+50 °C. |

|

|

Altitude |

Operating and non-operating to 4,000 m (13,123 ft) |

|

|

Overvoltage |

This product is intended to be powered by MAINS that comply |

Category |

to Overvoltage Category II, which is typical of cord-and-plug |

|

connected equipment. |

|

|

Pollution |

The InfiniiVision 2000/3000 X-Series oscilloscopes may be |

Degree |

operated in environments of Pollution Degree 2 (or Pollution |

|

Degree 1). |

|

|

Pollution |

Pollution Degree 1: No pollution or only dry, non-conductive |

Degree |

pollution occurs. The pollution has no influence. Example: A |

Definitions |

clean room or climate controlled office environment. |

|

Pollution Degree 2. Normally only dry non-conductive pollution |

|

occurs. Occasionally a temporary conductivity caused by |

|

condensation may occur. Example: General indoor |

|

environment. |

|

Pollution Degree 3: Conductive pollution occurs, or dry, |

|

non-conductive pollution occurs which becomes conductive |

|

due to condensation which is expected. Example: Sheltered |

|

outdoor environment. |

|

|

2000/3000 X-Series Oscilloscopes Service Guide |

19 |

1 Characteristics and Specifications

Specifications

Please see the InfiniiVision 2000/3000 X- Series Oscilloscopes Data Sheet for complete, upto- date specifications and characteristics.

To download a copy of the data sheet please visit:

www.agilent.com/find/2000XSeries or

www.agilent.com/find/3000XSeries.

Or go to the Agilent home page at www.agilent.com and search for 2000/3000 X-Series oscilloscopes data sheet.

To order a data sheet by phone, please contact your local

Agilent office. A contact list is provided on the next page.

The most upto- date list is available at:

www.agilent.com/find/contactus

20 |

2000/3000 X-Series Oscilloscopes Service Guide |

Characteristics and Specifications |

1 |

Contact us

Americas

Canada (877) 894-4414

Latin America 305 269 7500

United States (800) 829-4444

Asia Pacific

Australia 1 800 629 485

China 800 810 0189

Hong Kong 800 938 693

India 1 800 112 929

Japan 81 426 56 7832

Korea 080 769 0800

Malaysia 1 800 888 848

Singapore 1 800 375 8100

Taiwan 0800 047 866

Thailand 1 800 226 008

Europe

Austria 0820 87 44 11 Belgium 32 (0) 2 404 93 40 Denmark 45 70 13 15 15 Finland 358 (0) 10 855 2100 France 0825 010 700 Germany 01805 24 6333* *0.14€/minute

Ireland 1890 924 204

Italy 39 02 92 60 8484 Netherlands 31 (0) 20 547 2111 Spain 34 (91) 631 3300 Sweden 0200-88 22 55 Switzerland (French)

44 (21) 8113811 (Opt 2) Switzerland (German) 0800 80 53 53 (Opt 1)

United Kingdom 44 (0) 7004 666666 Other European countries: www.agilent.com/find/contactus

2000/3000 X-Series Oscilloscopes Service Guide |

21 |

1 Characteristics and Specifications

22 |

2000/3000 X-Series Oscilloscopes Service Guide |

Agilent InfiniiVision 2000/3000 X-Series Oscilloscope

Service Guide

2

Testing Performance

Overview 24 |

|

|

|

List of Test Equipment 25 |

|

|

|

To construct the test connector (for use with MSO models only) |

27 |

||

To test digital channels (MSO models only) 29 |

|

||

To verify digital channel threshold accuracy (MSO models only) |

30 |

||

To verify DC vertical gain accuracy |

35 |

|

|

To verify dual cursor accuracy |

42 |

|

|

To verify analog bandwidth (-3 dB) |

49 |

|

|

To verify time base accuracy |

55 |

|

|

To verify trigger sensitivity 57 |

|

|

|

Agilent 2000 X-Series Oscilloscopes Performance Test Record |

63 |

||

Agilent 3000 X-Series Oscilloscopes Performance Test Record |

65 |

||

This chapter explains how to verify correct oscilloscope operation and perform tests to ensure that the oscilloscope meets the performance specifications.

23

2 Testing Performance

Overview

To completely test and troubleshoot MSO models, create and use the test connector accessory as described in this chapter.

•The test connector is only required for oscilloscopes that have the MSO option licensed (enabled).

•The connector is used in the digital channel threshold accuracy test.

•The test connector keeps electrical distortion to a minimum and makes it easy for you to connect the oscilloscope probes to function generators and measurement equipment.

Let the Equipment Warm Up Before Testing

For accurate test results, let the test equipment and the oscilloscope warm up 30 minutes before testing.

Verifying Test Results

During the tests, record the readings in the Performance Test Record on page 63. To verify whether a test passes, verify that the reading is within the limits in the Performance Test Record.

If a performance test fails

If a performance test fails, first perform the User Cal procedure. Press the following keys to access User Cal: [Utility]→Service→Start User Cal.

24 |

2000/3000 X-Series Oscilloscopes Service Guide |

Testing Performance |

2 |

List of Test Equipment

|

|

Below is a list of test equipment and accessories required to |

|

|

|

perform the performance test verification procedures. |

|

Table 1 |

List of test equipment |

|

|

|

|

|

|

|

|

|

Recommended Model/ |

Equipment |

|

Critical Specifications |

Part Number |

|

|

|

|

Test connector, 8-by-2* |

See page 27 for instructions on building test connector. |

n/a |

|

|

|

|

|

Digital Multimeter |

0.1 mV resolution, 0.005% accuracy |

Agilent 34401A |

|

|

|

|

|

Power Splitter |

Outputs differ by 0.15 dB |

Agilent 11667B |

|

|

|

|

|

Oscilloscope Calibrator |

DC offset voltage of -5.5 V to 35.5 V, 0.1 V resolution |

Fluke 5820A |

|

|

|

25 MHz—500 MHz sine wave, 5 ppm |

|

|

|

|

|

Signal Generator |

25 MHz, 100 MHz, 350 MHz, 500 MHz, and 1 GHz |

Agilent N5181A |

|

|

|

sine waves |

|

|

|

|

|

Power Meter |

1 GHz ±3% accuracy |

Agilent N1914A |

|

Power Sensor |

1 GHz ±3% accuracy |

Agilent E9304A or |

|

|

|

|

N8482A |

|

|

|

|

BNC banana cable |

BNC (m) to dual banana |

Pomona 2BC-BNC-36 or |

|

|

|

|

Agilent 11001-66001 |

|

|

|

|

BNC cable (qty 3) |

BNC - BNC, 48” length |

Agilent 10503A† |

|

Cable |

|

Type N (m) 609.6 mm (24 in.) |

Agilent 11500B |

|

|

|

|

Probe cable* |

No substitute |

Agilent N6450-60001 |

|

|

|

|

(16-channel) or Agilent |

|

|

|

N6459-60001 |

|

|

|

(8-channel)† |

Adapter |

|

BNC(f) to banana(m) |

Agilent 1251-2277† |

Adapter |

|

BNC Tee (m) (f) (f) |

Agilent 1250-0781† or |

|

|

|

Pomona 3285 |

|

|

|

|

*Required only for testing digital channels of oscilloscopes that have the MSO option.

Most parts and equipment are available at www.agilent.com. See respective manufacturer’s websites for their equipment.

† These parts available at www.parts.agilent.com at the time this manual was published.

2000/3000 X-Series Oscilloscopes Service Guide |

25 |

2 Testing Performance

Table 1 List of test equipment (continued)

|

|

Recommended Model/ |

Equipment |

Critical Specifications |

Part Number |

|

|

|

Adapter |

Type N (m) to BNC (m) |

Agilent 1250-0082 or Pomona 3288 with Pomona 3533

Blocking capacitor and shorting cap |

Note: if a BNC blocking capacitor is not available use an |

Agilent 11742A + |

|

SMA blocking capacitor. |

Pomona 4288 + |

|

|

Pomona 5088 |

|

|

|

Adapter (qty 3) |

N(m) to BNC(f) |

Agilent 1250-0780 |

|

|

|

50 Ohm Feedthrough Termination |

50Ω BNC (f) to BNC (m) |

Agilent 0960-0301 |

|

|

|

*Required only for testing digital channels of oscilloscopes that have the MSO option.

Most parts and equipment are available at www.agilent.com. See respective manufacturer’s websites for their equipment.

† These parts available at www.parts.agilent.com at the time this manual was published.

Conventions

The following conventions will be used when referring to oscilloscope models throughout this chapter.

Table 2 Conventions

Models |

Referred to as: |

|

|

MSO-X /DSO-X 2002A, MSO-X /DSO-X 2004A |

70 MHz Models |

|

|

MSO-X /DSO-X 2012A, MSO-X /DSO-X 2014A |

100 MHz Models |

MSO-X /DSO-X 3012A, MSO-X /DSO-X 3014A |

|

|

|

MSO-X /DSO-X 2022A, MSO-X /DSO-X 2024A |

200 MHz Models |

MSO-X /DSO-X 3024A |

|

|

|

MSO-X /DSO-X 3032A, MSO-X /DSO-X 3034A |

350 MHz Models |

|

|

MSO-X /DSO-X 3052A, MSO-X /DSO-X 3054A |

500 MHz Models |

|

|

26 |

2000/3000 X-Series Oscilloscopes Service Guide |

Testing Performance |

2 |

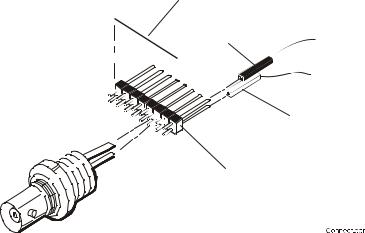

To construct the test connector (for use with MSO models only)

Agilent 2000/3000 X- Series oscilloscopes that have digital channels enabled require the test connector described below. Follow the steps to build the test connector.

Table 3 |

Materials required to construct the test connectors |

||

|

|

|

|

Description |

|

Recommended Part |

Qty |

|

|

|

|

BNC (f) Connector |

Agilent 1250-1032 or |

1 |

|

|

|

Pomona 4578 |

|

|

|

|

|

Berg Strip, 8-by-2 |

3M .100” x .100” Pin |

1 strip, cut to length (8x2) |

|

|

|

Strip Header or similar |

|

|

|

|

|

Jumper wire

1Obtain a BNC connector and an 8- by- 2 section of Berg strip. A longer strip can be cut to length using wire cutters.

2On one side of the Berg strip, solder a jumper wire to all of the pins (shown in Figure 1 on page 28).

3On the other side of the Berg strip, solder another jumper wire to all of the pins.

4Solder the center of the BNC connector to a center pin on one of the rows on the Berg strip.

5Solder the ground tab of the BNC connector to a center pin on the other row on the Berg strip.

2000/3000 X-Series Oscilloscopes Service Guide |

27 |

2 Testing Performance

Jumper (2)

Ground Lead

(from scope’s MSO cable)

Signal Lead

(from scope’s MSO cable)

8 x 2 Berg Strip

BNC Panel Mount Connector

BNC Panel Mount Connector

Figure 1 Constructing the 8-by-2 Connector

28 |

2000/3000 X-Series Oscilloscopes Service Guide |

Testing Performance |

2 |

To test digital channels (MSO models only)

The acquisition system testing provides confidence that the acquisition system is functioning correctly. It does not, however, check a particular specification.

1Disconnect all probes from the circuit under test and from any other input source.

2Using probe leads and grabbers, connect digital channels D0, D1, D2, and D3 to the Probe Comp signal on the center of the front panel.

3Press the [AutoScale] key.

If four square waves appear, the acquisition system is functioning correctly.

If the square waves do not appear, go to the “Troubleshooting” chapter. Then return here to finish testing the digital channels.

4Disconnect the digital channels from the calibration point.

5Use steps 2 and 3 to test the following sets of digital channels. After you test one set of digital channels, remove them before connecting the next set.

•D4, D5, D6, D7

•D8, D9, D10, D11 (on 3000 X- Series models)

•D12, D13, D14, D15 (on 3000 X- Series models)

2000/3000 X-Series Oscilloscopes Service Guide |

29 |

2 Testing Performance

To verify digital channel threshold accuracy (MSO models only)

This test verifies the digital channel threshold accuracy specification of the Agilent 2000/3000 X- Series oscilloscopes.

Threshold accuracy test limits: ±(100 mV + 3% of threshold setting)

When to Test

You should perform this test every 12 months or after 2000 hours of operation, whichever comes first.

What to Test

Use these instructions to test the threshold settings of digital channels D7D0. Then, use the same instructions to test digital channels D15D8 (on 3000 X- Series).

Verifying Test Results

After each threshold test, record the voltage reading in the Performance Test Record on page 63. To verify whether a test passes, verify that the voltage reading is within the limits in the Performance Test Record.

30 |

2000/3000 X-Series Oscilloscopes Service Guide |

Loading...

Loading...