HP 1707B Service manual

m

r-

0

b

F

P

OPERATING AND

SERVICE

MANUAL

OSCILLOSCOPE

1707B

~-

-

_-

-

HEWLETT

PACKARD

.

OPERATING AND SERVICE MANUAL

MODEL

1707B

OSCILLOSCOPE

4

SERIALS

PREFIXED:

1410A

Refer to Section

VI1

for instruments with the following

standard options:

002,007,011,012,015,602,607,611

and

631.

H

EWLETT-PAC KA

R

D

COMPANY/COLO RA DO SPRINGS DIV

IS1

ON

1900

GARDEN

OF

THE GODS ROAD, COLORADO SPRINGS, COLORADO, U.S.A.

Manual

Part

Number 01707-90916

Microfiche Number 01 707-908 16

PRINTED: APRIL

1974

SAFETY

SUMMARY

The following general safety precautions must be observed during all phases of operation, service, and repair

of this instrument. Failure to comply with these precautions

or

with specific warnings elsewhere

in

this

manual violates safety standards of design, manufacture, and intended use of the instrument. Hewlett-

Packard Company assumes no liability for the customer's failure to comply with these requirements.

GROUND THE INSTRUMENT.

To minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

ground. The instrument is equipped with a three-conductor ac power cable. The power cable

must either be plugged into an approved three-contact electrical outlet

or

used with a three-

contact to two-contact adapter with the grounding wire (green) firmly connected to an elmtrical

ground (safety ground) at the power outlet. The power jack and mating plug of the-power cable

meet International Electrotechnical Commission

(IEC)

safety standards.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do

not operate the instrument

in

the presence of flammable gases

or

fumes. Operation of any

electrical instrument in such an environment constitutes a definite safety hazard.

KEEP

AWAY

FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel.

Do

not replace components with

power ca ble connected. Under certain conditions, dangerous voltages may exist even with the

power cable removed.

To

avoid injuries, always disconnect power and discharge circuits before touching them.

DO NOT SERVICE

OR

ADJUST ALONE.

Do

not attempt internal service

or

adjustment unless another person, capable of rendering first

aid and resuscitation, is present.

USE CAUTION WHEN EXPOSING

OR

HANDLING THE CRT.

Breakage of

the

cathode-ray tube (CRT) causes

a

high-velocity scattering of glass fragments

(implosion). To prevent

CRT

implosion, avoid rough handling or jarring of the instrument.

Handling of the

CRT

shall be done only by qualified maintenance personnel using approved

safety mask and gloves.

DO NOT SUBSTITUTE PARTS

OR

MODIFY INSTRUMENT.

Because of

the

danger of introducing additional hazards,

do

not install substitute parts

or

perform any

un-

authorized modification to the instrument. Return the instrument to a Hewlett-Packard Sales and Service

Office for service and repair to ensure that safety features are maintained.

DANGEROUS PROCEDURE WARNINGS.

Warnings, such as the example below, precede potentially dangerous procedures throughout this

manual. Instructions contained in the warnings must be followed.

Dangerous voltages, capable of causing death, are present in this instrumezt.

Use

extreme

caution when handling, testing, and adjusting.

I

Model

1707H

TABLE

OF

CONTENTS

J

I

I

Section Page

I

GENERAL INFORMATION

..............

1-1

1.1

.

1.4

.

1.5

.

1.7

.

1-1

1

.

1.17

.

1.20 .

1.22 .

1.24 .

1.26 .

1.30 .

Introduction

......................

1-1

Description

.......................

1

.

1

Introduction

..................

1-1

Vertical Circuits

..............

1-1

Horizontal Circuits

............

1-1

Cathode-ray Tube

.................

1-5

Warranty

......................... 1-5

Accessories Furnished

............ 1-5

Accessories Available

.............

1-5

Instrument and Manual

Identification

................... 1-5

Inquiries

..........................

1-5

I1 INSTALLATION .........................

2-1

2.1

.

2.3 .

2.6 .

2.7

.

2-1

1

.

2.13

.

2- 15 .

2.17 .

2.19 .

Introduction

...................... 2-1

Initial Inspection

.................

2-1

Preparation for Use

............... 2-1

Power Requirements

..........

2-1

Three-conductor AC Power

Cable

.......................

2-1

DC

Plug

......................

2-2

Battery Installation

...........

2-2

Claims

............................

2-2

Repacking for Shipment

.......... 2-2

I11 OPERATION

.............................

3-1

3.1

.

Introduction

......................

3-1

3.3

.

Controls and Connectors

..........

3-1

3.5

.

Beam Finder

....................

3-1

3.7

.

Scale Illumination

.............. 3-1

3.9

.

Trace Align

.....................

3-1

3.11

.

Calibrator

...................... 3-1

3.13

.

Focus and Astigmatism

.........

3-1

3.15

.

Coupling

........................

3-1

3.17

.

Display

.........................

3-4

3.24

.

Trig

............................

3-4

3.26

. B

Polarity

...................... 3-4

3.28

.

Sweep Display

..................

3-4

3.30

.

Ext

Horiz Input

................. 3-4

3.32

.

Main Sweep

.................... 3-4

3.34

.

Mixed Sweep

...................

3-4

3.36

.

Delayed Sweep

.................. 3-4

3.38

.

Time/Div

....................... 3-4

3.40

.

Vernier

.........................

3-4

3.42 .

Trigger Level

...................

3-4

3.44

.

Trigger Holdoff

3-4

3.46 .

Slope

............................ 3.4

.................

Section Page

3.48 .

3.51 .

3.54 .

3.56 .

3.58

.

3.59

.

3.61

.

3.63

.

3.65 .

3.67

.

3.69 .

3.71 .

3.73

.

3.75 .

3.77 .

3.80 .

Sweep Mode

....................

3-5

Trigger Selection

................

3-5

Magnetic Interference

............. 3-5

Battery Recharge Operation

....... 3-5

Preoperational Adjustments

.......

3-5

Initial Turn.on

..................

3-5

Focus and Astigmatism Adjust

.. 3-6

Operating Procedures

.............

3-6

Operators Performance Check

..... 3-6

Operating Information

............

3-7

Auto Versus

Norm

..............

3-7

Auto Versus

Trig

...............

3-7

AC Versus DC

.................. 3-7

Mixed Sweep

....................

3-7

Delayed Sweep

..................

3-7

Line Sync

....................... 3-7

IV PRINC11’1,ES OF OPERATION

...........

4-1

4.1

.

4.3

.

4.6 .

4.8

.

4-

10

.

4-12

4.14

.

4-

16

.

4.21 .

4.24 .

4.27

.

Introduction ......................

4-1

Block Diagram Discussion

.......

4-1

Input Attenuator

..............

4-1

Vertical I’rcamplifier

..........

4-1

1)cllay

I.ine

....................

4-1

Vertical Output Amplifier

.....

4-1

Trigger Circuits

...............

4-1

M

ai

n

In t egr

a

t

o

r

...............

4

.

1

Holdoff and Comparator

......

4-2

I

)el ay ed Integra tor

............

4-2

‘l’iming Sequence

..............

4-;3

4..31

.

Horizontal Mode Assembly

....

4-:3

‘1

-;

35

.

4.41

.

4.44

.

4.46

.

4.48

.

4.53 .

4.79

.

4.81

.

4.86

.

4.104 .

4-1 19 .

4.124

.

4- 130

.

4.148 .

4.156 .

4.158 .

4.162

.

4.165 .

4.174 .

I.

ow

Voltage Power

Supply

....

4-;j

High Voltage Power Supply

...

4-3

Gate Amplifitr

................

4-4

Detailed Circuit Theory

..........

4-4

Input Attenuators

.............. 4-4

Vertical Preamplifier

...........

4-4

Delay Line

.....................

4-6

Vertical Output Amplifier

...... 4-6

Trigger Circuits

................

4-6

Main Integrator

................

4-8

Holdoff and Comparator

......

4-10

Delayed Integrator

............ 4-10

Horizontal Mode

..............

4-11

Gate Assembly

.................

4-13

Calibrator

.....................

4-14

Horizontal Preamplifier and

Output Assemblies

...........

4-14

Indicator Drivers

..............

4-14

Low Voltage Power

Supply

.......................

4-14

High Voltage Power

Supply

.......................

4-16

111

Table of Contents

Model 1707B

TABLE

OF

CONTENTS

(Cont’d)

Section Page

V

PERFORMANCE: CHECK AND

A1)JUS’I’ME:NTS

.......................

5-1

5.1

.

5.3

.

5.5

.

5.8

.

5.10

.

5-

12

.

5.13

.

5.18

.

5.23

.

5.28

.

5.33

.

5.38

.

5.43

.

5.48

.

5.53

.

5.58

.

5.63

.

5.68

.

5.73

.

5-78

.

5.83

.

5.88

.

5.93

.

5.98

.

5.103

.

5.108

.

5-113

.

5.118

.

5.123

.

5.128

.

5-133

.

5.138

.

5.142

.

5.143

.

5.148

.

5.153

.

5.157

.

5.162

.

5.167

.

5.172

.

5.177

.

5.181

.

5-

185

.

Introduction

......................

5-1

Test Equipment

...................

5-1

Performance Check

...............

5-1

Front-panel Adjustments

..........

5-

1

Front-panel Settings

..............

5-1

Performance Tests

................

5-1

Deflection Factor

.............

5-1

Rise time

.....................

5-2

Handwidth

....................

5-3

A+B Mode

......................

5-3

Alt Mode

.......................

5-4

Chop Mode

.....................

5-4

Single Sweep

...................

55

Auto

Trig

Recovery Time

........

5-5

Z

Axis

Sensitivity

...............

56

Beam Finder

....................

5-6

Coupling Switch

................

5-6

Input Resistance

................

5-7

Common Rejection Ratio

(CMRR)

......................

5-8

Main

Sweep Time

...............

5-8

Delay Time Accuracy

..........

5-10

Delay Time Linearity

..........

511

Delay Jitter

....................

5-12

Main Triggering

...............

5-13

Delayed Triggering

............

5-14

Main Trigger Level Range and

Polarity

......................

5-15

Delayed Trigger Level Range

and Polarity

.................

5-16

Ext Horizontal Bandwidth

....

5-16

Ext Horizontal Deflection

Factor

......................

5-17

Calibrator

.....................

5-17

Adjustments

.....................

5-19

Adjust Procedures

................

5-19

Adjustment

..................

5-19

Adjustment

..................

5-19

Y-Axis

Alignment

..............

520

Adjustment

..................

5-20

DC

Adjustment

.............

5-21

Trigger Sensitivity

.............

5-21

Sweep Length Adjustment

.....

5-22

Adjustment

..................

523

Delayed Sweep Time

............

5-9

Low

Voltage Power Supply

High

Voltage Power Supply

Intensity Limit Adjustment

....

5-20

Gate Amplifier Response

Trigger Amplifier Balance and

Position Centering Adjustment

.

5-22

Main Sweep Timing

Section Page

5.190

.

5.195

.

5.200

.

5.205

.

5.210

.

5-2

15

.

5.220

.

5.225

.

5.230

.

Delayed Sweep Time

Adjustment

..................

5-23

X10 Gain Adjustment

..........

524

Mag Centering Adjustment

....

524

Calibrator Adjustment

.........

5-25

Ext

Horiz

Gain Adjust

.........

5-26

Adj

............................

5.26

Ext Horiz Input Compensation

.

5-25

Low-frequency Pulse Response

Input Capacitance and Attenuator

High-frequency Pulse

Compensation Adjustment

. .

5-26

Response Adj

...............

5-27

VI REPI.ACEAH1.

E

PARTS

.................

6-1

6.1

.

Introduction

......................

6-1

6.3

.

Ordering Information

.............

6-1

VI1

MAZNUAI. CHANGES AN!)

OP‘I’IONS

....

7-1

7.1

.

Introduction

......................

7-1

7.3

.

Manual Changes

..................

7-1

7.5

.

Special Options

...................

7-1

7.9

.

Standard Options

.................

7-1

VI11 SCHEMATICS ANI) TROUH1.E:

.

SHOOTING

............................

8-1

8.1

.

8.3

.

8.8

.

8-

12

.

8-

1.5

.

8-

17

.

8.22

.

8.27

.

8.29

.

8-:3

1

.

8..n

.

8..35 .

8437

.

8.42

.

8.44

.

8.46

.

8.48

.

Introduction

......................

8-1

Schematics

.......................

8-1

Reference Designations

...........

8-1

Component

I.

ocations

.............

8-1

Preventive Maintenance

..........

8-1

Mechanical Inspection

........

8-1

Switch Maintenance

..........

8-2

Repair and Replacement

..........

8-2

CRT Removal and Replace-

ment

........................

8-2

Vertical Amplifier Module

Removal and Replacement

. . 8-3

Delay line Removal and

Replacement

................ 8-3

Attenuator Removal

and

Replacement

................

8-3

Removal and Replacement

of

Assemblies in Horizontal

Amplifier Module

...........

8-5

Power

S

u

p p

1

y

Mod

u

1

e

Removal and Replacement

8-5

Power

Supply

Module

IXs-

assembly and Reassembly

. .

8-5

Semiconductor Removal and

Replacement

................

8-6

At

t

e

n

u

a

t

o

r Ser vi c

i

n

g

..........

8-6

iv

Model 1707B

TABLE

OF

CONTENTS (Cont'd)

Table of Contents

List of Illustrations

)

Section Page Section Page

8.50

.

Circuit Hoards

.....................

8.52

.

Hoard Connect ions

.............

8-6

8-6

8.62

.

Soldering

Tool.

Solder. and

Aids

.........................

8-7

8.64

.

Heat Sink Removal

............

8.8

8.66

.

Troubleshooting

...................

8.8

8.69

.

DC Voltages

...................

8.8

Waveforms

....................

8.8

.........................

Test Points

....................

8.8

8.60

.

Service Kit

.....................

8.7

8.75

.

Circuit Checking

...............

8.9

8.54

.

Servicing Etched Circuit

Hoards

.......................

8.6

8.56

.

Integrated Circuit Replace- 8-7 1

.

ment 8.6 8.73

.

LIST

OF

ILLUSTRATIONS

Figure Title Page Figure Title Page

.

...............

1.1 Model 1707R Oscilloscope 1-0 5.12

.

Main Triggering

Test

Setup

............

5.13

5.13

.

5.14

.

5.15

.

Delayed Triggering Test Setup

.........

5.14

Main Trigger Level Range and Polarity

Delayed Trigger Level Range and

1.2

.

Instrument Serial Number

............

1-5

1.3

.

Service Kit for HP 1700-series

Test Setup

...........................

5.15

2.1

.

Rear Panel Power Module

...............

2-1 Polarity Test Setup

................

5-16

1-6

Oscilloscopes

.......................

.

...............

2.2 Battery Pack Installation 2-2 5-16

.

EXT Horizontal Bandwidth

Test Setup

...........................

5.17

................

3.1

.

Controls and Connectors 3-2

Sweep Combinations

....................

3-5

517

.

EXT

Horizontal Deflection Factor

3.2

.

1

3.3

.

DC BAL Adjust

.........................

3-8 Test Setup

...........................

5.17

3.4

.

CALAdjust

.............................

3-9

Operation

............................

3-10

Delayed Sweep

.........................

3-11

Mixed Sweep

...........................

3-12

3.5

.

3.6

.

3.7

.

Algebraic Addition and Differential

4.1

.

4.2

.

Timing Sequence

........................

4-2

Gate Schmitt Trigger

...............

4-7

Step-by-step operation of the

518

.

5-19

.

6-1

.

6-2

.

8.1

.

8.2

.

8.3

.

8.4

.

Calibrator Test Setup

..................

5.18

Adjustment

..........................

529

Knob Locator

...........................

6-2

Mechanical

Parts

Locator

...............

6-3

Vertical Module Mechanical Parts

Removal

..............................

8-4

Attenuator Removal

....................

8-4

Semiconductor Terminal Identification

. .

8-7

Component Identification. Interior Front

and rear Panel

.....................

8-23

8.5

.

Component and Assembly Locations

.

8-23

8.6

.

Identification

......................

8-24

4.3

.

reset Multivibrator 4-9

4.4

.

Blanking Sequence

...................

4-12

Step-by-step operation of the Set-

..................

Vertical Module A5 Component

5.1

.

5-2

.

5.3

.

5-4

.

55

.

5-6

.

5-7

.

58

.

59

.

5-10

.

5-11

.

Deflection Factor Test Setup

............

5-2

Rise time Test Setup

....................

5-3

Bandwidth Test Setup

.................

33

A+B

Mode Test Setup

..................

5-4

Input Resistance Test Setup

.............

5-7

CMRR Test Setup

.......................

5-8

Main Sweep Time Test Setup

............

5-8

Delayed Sweep Time Test Setup

........

5.10

Delay Time Accuracy Test Setup

.......

5.10

Delay Jitter Test Setup

.................

5.12

Delay Time Linearity Test Setup

.......

5.11

8.7

.

8-8

.

8-9

.

8-10

.

8.11

.

8.12

.

8.13

.

8-14

.

8-15

.

Horizontal Module A6 Component

Identification

......................

8-24

Main Block Diagram

.................

8-25

Power Supply Block Diagram

........

8-27

Attenuator Component Identification

.

8-28

Attenuator Schematic

................

8-29

Vertical Preamplifier Assembly A5A4

Component Identification

..........

830

Vertical Preamplifier Assembly

A5A4

..............................

8-31

Vertical Preamplifier Assembly

A5A4

................................

8.33

Vertical Preamplifier Assembly A5A4

Component Identification

............

8.34

V

List of Illustrations

List

of

Tables

LIST

OF

ILLUSTRATIONS

(Cont‘d)

Model

1707B

Figure Title Page

Figure Title Page

8.16

.

8.17

.

8.18

.

8.19

.

8.20

.

8-21

.

8.22

.

8.23

.

8.24

.

8.25

.

8.26

.

8.27

.

8-28

.

8.29

.

8.30

.

8.31

.

Table

1.1

.

1.2

.

5.1

.

5.2

.

5.3

.

5.4

.

5.5

.

5.6

.

5.7

.

5.8

.

5.9

.

6.1

.

vi

Vertical Preamplifier A5A4 and Vertical

Output Amplifier A5A5

..............

8.35

Vertical Preamplifier A5A4

............

8.37

Trigger Assembly A6A2 Com-

ponent Identification

.................

8.38

Trigger Assembly A6A2

................

8.39

Trigger Assembly A6A2

................

8.41

Component Identification

............

8-42

Component Identification

............

8.42

Main Integrator A6A3

.................

8.43

Component Identification

............

8.44

Horizontal Mother Board A6A1

Main Integrator A6A3

Main Sweep Time Assembly A6A5

Main Sweep Time Assembly A6A5

.....

8.45

Delayed Integrator A6A4 Component

Identification

........................

8.46

Delayed Integrator A6A4

...............

8.47

Delayed Sweep Time Assembly A6A6

Component Identification

............

8.48

A6A6

................................

8-49

Component Identification

............

8.50

Delayed Sweep Time Assembly

Holdoff and Comparator A6A7

Holdoff and Comparator A6A7

.........

8-51

8.32

.

8.33

.

8-34

.

8.35

.

8-36

.

8.37

.

8.38

.

8.39

.

8.40

.

8.41

.

8.42

.

8.43

.

8.44

.

8.45

.

8.46

.

8.47

.

8.48

.

8.49

.

8.50

.

LIST

OF

TABLES

Title Page Table

6.2

.

Model 1707H Accessories Available

. .

1-5/14? 6.3

.

Specifications

...........................

1-2

7.1

.

Recommended Test Equipment

..........

5-0

Ileflection Factor Accuracy

..............

5-2

Main Sweep Performance Check

........

5-9

Delayed Sweep Performance Check

....

5-11

Performance Check Record

.........

5.18a

Power Supply Voltage Limits

..........

‘5-19

Main Sweep Time Adjustments 5-23 8.4

.

Ilelayed Sweep Time Adjustments

......

5-24

Square-wave Adjustment

.............

5-27

Capacitance Adjustment

.............

5-27

8.1

.

8.2

.

8.3

.

.........

8.5

.

Abbreviations for Replaceable Parts

8.6

.

List

...................................

6-1

Horizontal Mode Assembly A6A8

Component Identification

............

8.52

EXT Horizontal Amplifier Assembly A8.

Component Identification

............

8.52

Horizontal Mode Assembly A6A8

......

8.53

Horizontal Preamplifier Assembly A6A9

Component Identification

............

8.54

Horizontal Output Amplifier Assembly

A6A10 Component Identification

.....

8.54

Horizontal Preamplifier and Output

Assemblies A6A9 and A6A10

........

8.55

Gate Assembly A4 Component

Identification

........................

8.56

Gate Assembly A4

...................

High Voltage Oscillator A3A4

Component Identification

..........

High Voltage Oscillator A3A4

........

Line Rectifier A2 Component

Identification

......................

Low Voltage Mother Board A3A1

Component Identification

..........

Power Input and Line Filters

.........

Low Voltage Converter Assembly

A3A2 Component Identification

....

Low Voltage Converter Assembly

A3A2

..............................

Line Rectifier and Filter A3A3

Component Identification

..........

Line Rectifier and Filter A3A3

.......

Horizontal Mother Board A6A1

......

Horizontal Preamplifier A6A9

Voltage Distribution

...............

a57

8-58

8-59

a60

8-60

8-61

a62

8-63

864

a65

8-67

868

Title Page

Replaceable Parts

.......................

6-5

List of Manufacturers’ Code

..........

6-25

Model 1707H Standard Options

..........

7-2

Etched Circuit Soldering Equipment

.....

8-8

Model 1707H Assembly Locations

.......

8-9

Schematic Notes

.......................

8-10

Troubleshooting Low Voltage

Power Supply

......................

8-11

Troubleshooting High Voltage Power

Troubleshooting Vertical

Supply.

CRT.

Gate

.................

8-13

Deflection

..........................

8-16

Model

1707B

Table

List of Tables

LIST

OF

TABLES

(Cont’d)

8-7.

8-8.

8-9.

8-

10.

8-1 1.

8-

12.

8-13.

8-14.

8-15.

8-16.

8-17.

Title Page Table Title Page

Troubles hooting Horizontal

..........

8-

19

Troubleshooting Time Base

..........

8-20

Block Diagram Measurement

Conditions

..........................

.8-24

Schematic

4

Measurement Con-

ditions and Waveforms..

...........

8-31

Schematic

5

Measurement Con-

ditions and Waveforms..

...........

8-32

Schematic

6

Measurement Con-

ditions and Waveforms..

...........

83-34

Schematic 7 Measurement Con-

8-18.

Schematic 12 Measurement Con-

ditions and Waveforms..

...........

8-46

8-19. Schematic

13

Measurement Con-

8-20. Schematic

14

Measurement Con-

ditions..

...........................

8-48

ditions and Waveforms..

...........

8-50

8-21. Schematic

15

Measurement Con-

ditions and Waveforms.

............

8-52

8-22. Schematic 16 Measurement Con-

ditions and Waveforms..

...........

8-54

...........

8-23. Schematic 17 Measurement Con-

8-24. Schematic

18

Measurement Con-

ditions and Waveforms.. 8-36

ditions and Waveforms..

...........

8-38

ditions and Waveforms..

...........

8-40

ditions and Waveforms.

ditions and Waveforms.

Schematic

8

Measurement Con-

Schematic 9 Measurement Con-

............

............

8-56

8-58

Schematic 10 Measurement Con- 8-25. Schematic 19 Measurement Con-

ditions and Waveforms..

...........

843 ditions..

...........................

8-60

Schematic

11

Measurement Con- 8-26. Schematic 20 Measurement Con-

ditions..

...........................

8-44 ditions and Waveforms..

...........

8-62

vii

i

Gcncral Information

Model 1707B

1707-PO01

<.*

-"

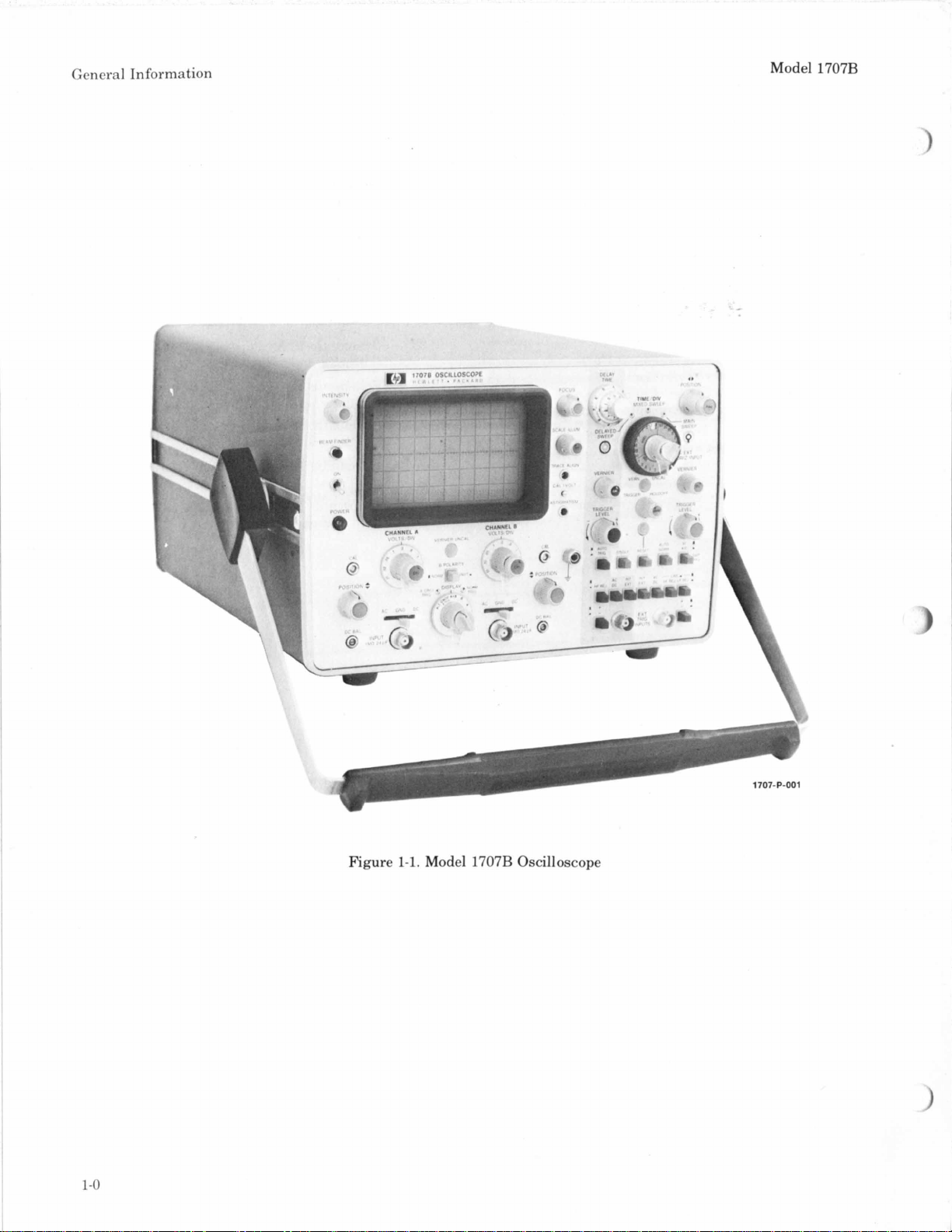

Figure

1-1.

Model 1707B Oscilloscope

1-0

Model 1707B

1

I

h

General Information

SECTION

I

GENERAL INFORMATION

i

1-1.

INTRODUCTION.

1-2.

This

manual provides operating and service

information for the Hewlett-Packard Model 1707B

Oscilloscope (figure

1-1).

This manual

is

divided into

eight sections, each covering

a

specific topic or

aspect of the instrument. All schematics are located

at

the rear of the manual.

Also

located

at

the rear of

the manual are instruction cards located

in

an

envelope attached to the inside back cover. These

cards explain the function of each instrument control.

The card

is

designed to fit the inside lid of the front

panel storage cover.

1-3. This section contains

a

description of Model

1707B. Instrument specifications are listed in table

1-1.

Table 7-2 lists the options available for Model

1707B.

1-4.

DESCRl PTION.

1-5.

INTRODUCTION.

1-10. With the dual-trace feature, displays can be

obtained on either channel A or B, channels A

and B together, channels A

+

B, and channels A

-

B. Simultaneous display of two signals

is

possible

in either chop or alternate mode of operation. During

chop operation, channels are switched

at

an approxi-

mate rate of 400-kHz during each sweep. In the

alternate mode of operation, the signal applied to

each channel

is

displayed on alternate sweeps.

Triggering

is

selectable from either A ONLY TRIG

or NORM TRIG position. In the NORM TRIG position,

the instrument triggers on the displayed signal.

In the A ONLY TRIG position, the instrument

triggers on the signal applied to channel A.

1-11.

HORIZONTAL CIRCUITS.

1-12. The horizontal circuits provide four types of

sweep displays. The displays are main sweep, mixed

sweep, delayed sweep and external horizontal input.

1-13.

Operation of the delayed sweep while in the

main sweep mode provides trace intensification.

The amount of intensification width depends on the

delayed front panel settings. In the delayed mode,

the intensified portion is displayed across the entire

CRT.

1-6. The Model 1707B

is

a

general-purpose, wide-

band oscilloscope designed for bench or field service.

The Model 1707B operates from an ac line, dc line

or optional battery pack. The optional ,rechargable

nickel cadmium batteries provide up

to

4% hours of

operation and require

a

recharge time of approxi-

mately

14

hours. A carrying handle provides ease

of transportation and

is

adjustable, allowing the

Model 1707B to be placed at an angle for viewing

the CRT.

1-14.

Sweep speed settings from 0.1 usec/div to

2 sec/div (main sweep) and 0.1 usec/div to

0.2 sec/div (delayed sweep) are available in

a

1,

2,

5

sequence. Vernier controls allow continuous adjust-

ment between steps and extend the slowest sweep

to

5

sec/div (main sweep) and

0.5

sec/div (delaved

i

1-7.

VERTICAL CIRCUITS.

1-8.

Vertical bandwidth

is

75

MHz with

a

rise time

less than 4.7 ns. Maximum vertical deflection factor

is

10 mV/div. The Model 1707B contains two identical

vertical amplifiers for single or dual channel

operation. Each channel offers

a

choice of ac or

dc coupling. Common mode rejection

is

at

least .40

dB

at 10 mV/div, and

20

dB

for the rest of the

deflection ranges.

1-9. Nine calibrated switch settings provide

a

deflection factor range from 10 mV/div to

5

V/div in

a

1, 2,

5

sequence. The vertical verniers permit

continuous adjustment between calibrated steps and

extend the least sensitive deflection factor

(5

V/

div) to

at

least 12.5 V/div.

>I

sweep). Using the magnifier function, the fastest

sweep speed can be expanded to 10 ns/div. The

mixed sweep function provides for simultaneous

display of an input waveform and an expanded

portion of the waveform.

The delayed circuits are

calibrated, permitting accurate time difference meas-

urements to be made.

1-15.

The main and delayed trigger circuits have

provisions for either internal or external operation.

Choice of trigger coupling

is

provided; ac/dc,

high

frequency reject, and low frequency reject. The

delayed trigger circuit does not have low frequency

reject trigger coupling.

1-16.

An external horizontal input allows the use of

an external signal to drive the horizontal deflection

plates of the CRT.

1-1

General Information Model 1707B

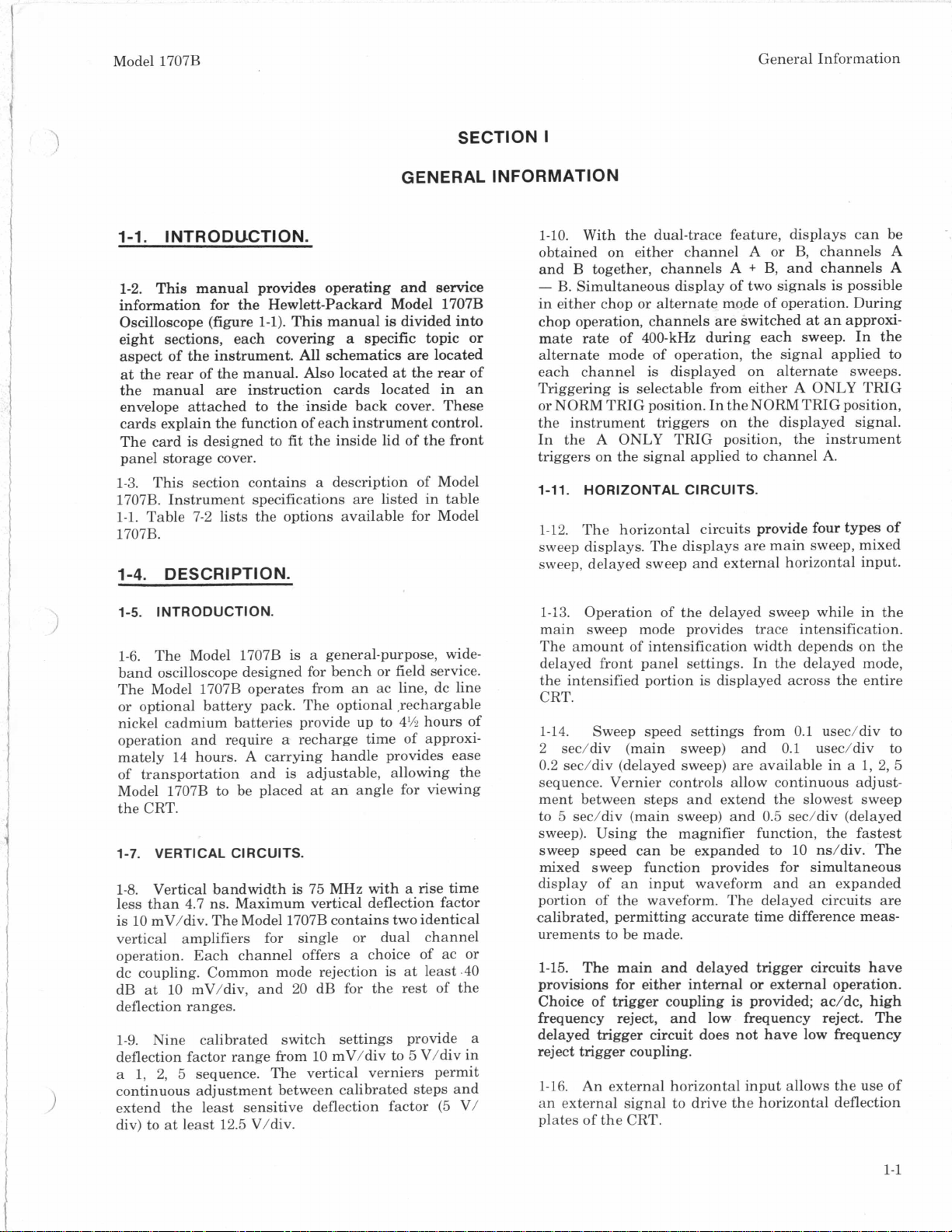

Table

1-1.

Specifications

IERTICAL AMPLIFIERS

MODES OF OPERATION:

channel A; channel B;

channels A and B displayed alternately on

successive sweeps (alt); channels

A

and B

displayed by switching between channels

at approximately 400-kHz rate with blanking

during switching (chop); channel A

+

channel

B

(algebraic addition).

EACH CHANNEL

(2)

Bandwidth:

(Direct or with Model 10006B

probe, 3-dB down from 50-kHz, 6-div ref-

erence signal from terminated 5@ohm

source.)

DC-COUPLED: dc

to

75 MHz.

AC-COUPLED: lower limit

is

approxima-

Risetime:

<4.7

ns

direct or

with

Model 10006B

probe, 10%

to

90%

points with 6 div input

step from terminated 50-ohm source.

tely

10

Hz.

DEFLECTION FACTOR

Ranges:

from 10 mV/div to

5

V/div

(9

ranges)

in 1,

2,

5

sequence;

*3%

accuracy with

vernier in calibrated position.

Vernier:

continuously variable between all

ranges, extends maximum deflection factor

to

at

least 12.5 V/div.

Polarity:

NORM or INVT selectable on chan-

nel B.

Signal Delay:

input signals are delayed

suf-

ficiently

to

view leading edge of input

signals without advanced external trigger.

Input

RC

1

megohm

*2%,

shunted by approxi-

mately

24

pF.

Input Coupling:

AC, DC or GND selectable.

GND position disconnects signal input and

grounds amplifier input.

MAXIMUM INPUT

AC-coupled:

*600V (dc

+

pk ac);

rms

ac <350V,

5

V/div

to

20 mV/div; <150V

at

10 mV/div

(10 kHz or less).

DC-coupled:

<350V (rms)

5

V/div to

20

mV/div;

<150V

at

10 mV/div (10 kHz or less).

A

+

B OPERATION

Amplifier:

bandwidth and deflection factors

are unchanged; channel B may be inverted

for A

-

B operation.

Common Mode (A

-

B)

FREQUENCY: dc to

1

MHz.

REJECTION RATIO:

at

least

40

dB

on 10

mV/div;

at

least

20

dB on all other ranges

with verniers set for optimum rejection.

Common-mode signal amplitude equivalent

to 30 div.

TR

I

G GE

RI

N

G

Normal Trigger:

on displayed signal.

A only trigger:

on signal from channel A.

MAIN TIME BASE

SWEEP

Ranges:

from 0.1 usec/div to 2 sec/div (23

ranges) in 1,

2,

5

sequence; *3% accuracy

with vernier

in

calibrated position.

Vernier:

continuously variable between all

ranges, extends slowest sweep to

at

least

5

sec/div; vernier uncalibrated light

in-

dicates when vernier

is

not in

CAL

position.

Magnifier:

expands all sweep by factor of 10

and extends fastest sweep to 10 ns/div;

accuracy *5% (including

3%

accuracy of

time base).

SWEEP MODE

Normal:

sweep

is

triggered by internal or

external signal.

Automatic:

bright baseline displayed in absence

of input signal; triggering

is

same

as

normal

above 40 Hz.

Single:

in

normal mode, sweep occurs once

with same triggering

as

normal; reset push-

button

arms sweep and lights indicator; in

auto mode, sweep occurs once each time

RESET pushbutton

is

pressed.

TRIGGER1 NG

Internal:

dc to

35

MHz on signals causing 0.5

div or more vertical deflection, increasing to

1

div

at

75 MHz in all display modes except

chop; dc

to

400 kHz in chop mode.

External:

dc

to

35

MHz on signals 50 mV p-p

or more, increasing to 100 mV p-p at 75 MHz.

External Input RC:

approximately

1

megohm

shunted by approximately 27 pF.

1-2

Model

1707B

General Information

Table

1-1.

Specifications (Cont’d)

Level and Slope

INTERNAL

at

any point on vertical wave-

form displayed.

EXTERNAL continuously variable from

+12V

to

-1.2V on either slope of trigger

signal. Maximum input, *lOOV.

Coupling:

AC, DC, LF REJ, or HF REJ.

AC: attenuates signals below approximately

LF REJ: attenuates signals below approxi-

HF REJ: attenuates signals above approxi-

20 Hz.

mately 15 kHz.

mately 30 kHz.

TRIGGER HOLDOFF:

time between sweeps

continuously variable.

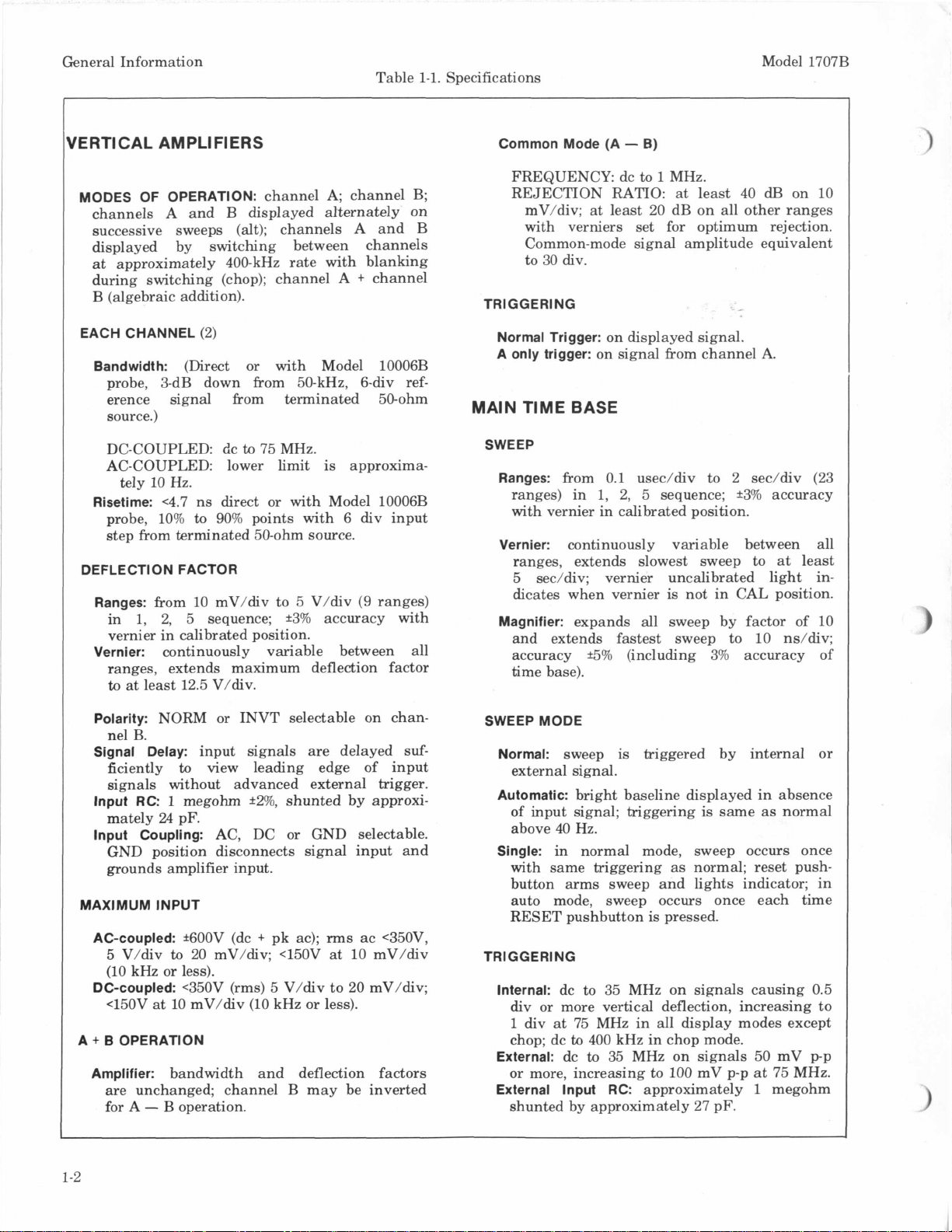

DELAYED TIME BASE

TRACE INTENSIFICATION:

intensifies

that

part

of main time base to be expanded to full

screen in delayed time base mode. Rotating

time base switch from OFF position activates

intensified mode.

SWEEP

Ranges:

0.1 usec/div to

0.2

sec/div

(20

ranges)

in 1,

2,

5

sequence;

*3%

with vernier

in

cali-

brated position.

Vernier:

continuously variable between all

ranges, extends slowest sweep to 0.5 sec/div.

Magnifier:

expands all sweeps by

a

factor of

10 and extends fastest sweep to 10 ns/div;

accuracy *5% (including

3%

accuracy of

time base).

SWEEP MODE

Trigger:

delayed sweep

is

armed

at

end of

Auto:

delayed sweep

is

automatically triggered

delay period.

at end of delay period.

TRIGGERING

Internal:

same

as

main time base.

External:

same

as

main time base. Input RC

is

approximately

1

megohm shunted by

approximately

27

pF.

Level and Slope

INTERNAL

at

any point on vertical wave

form displayed.

EXTERNAL continuously variable from

+1.2V

to

-1.2V on either slope of trigger

signal.

Coupling:

selectable, AC, DC, or HF REJ. AC

attenuates signals below approximately

20

Hz. HF REJ attenuates signals above approxi-

mately 30 kHz.

DELAY (Before start of delayed sweep.)

Time:

continuously variable from

0.1

usec to

Time Jitter:

<0.005%

(1

part

in

20,000)

of

Calibrated delay Accuracy:

fl%;

linearity,

*O.Wo.

2

sec.

maximum delay

in

each sweep.

MIXED SWEEP

Combines main and delayed sweeps into

one display. Sweep

is

started by main time

base and

is

completed by faster delayed

time base.

EXTERNAL HORIZONTAL INPUT

BANDWIDTH:

dc

to

1

MHz.

COUPLl NG:

dc.

DEFLECTION FACTOR:

X1;

1

V/div.

VERNIER:

1O:l

vernier provides continuous

DYNAMIC RANGE:

beam may be positioned to

MAXIMUM INPUT

*lOOV.

INPUT RC:

1

megohm shunted by approximately

X10;

0.1

V/div.

adjustment between ranges.

left edge of CRT with

0

to -5V input.

30

pF.

CATHODE-RAY TUBE AND CONTROLS

TYPE:

post-accelerator, 22.2-kV accelerating

potential; aluminized

P31

phosphor (other

phosphors available, refer to options).

GRATICULE:

6

X 10 div internal graticule; each

major division consists of

5

subdivisions on

major axes;

1

div

=

1

cm.

TRACE ALIGN:

aligns

trace with horizontal

grati-

cule line.

BEAM FINDER:

returns trace to CRT regardless

of settings of vertical, horizontal, or intensity

controls.

INTENSITY MODULATION:

+4V, dc to

1

MHz,

blanks trace of any intensity. Input R equals

1000 ohms

*lo%.

Maximum Input: lOV (dc plus pk ac).

GENERAL

CALI B RAT0

R

Type:

1

kHz

*lo%

square wave.

Voltage:

1V

pp

*l%.

1-3

General Information

Model 1707B

Table

1-1.

Specifications (Cont'd)

NOTE:

DIMENSIONS IN INCHES

AND

(MILLIMETERS)

TOP

c

1

1-

14 3/8(365.1)

-1

MAX PROJECTION (1701A)

15 5/16(388.9)

MAX PROJECTION (1701A)

15 9/16(395.31

c

20 7/8 (530.2)

c

3

1/8

7

15

3/4 (400.1)

-

(79.4)

ID

POWER REQUIREMENTS

AC Line:

115V or 230V *20%, 48 to 440 Hz.

DC Line:

11.5V

to

36V.

Battery (optional)

OPERATING TIME: up

to

4.5 hours.

RECHARGE TIME: 14

hr

minimum charging

time for

a

fully discharged battery.

LOW BATTERY INDICATOR: power light

flashes

to

indicate that batteries are dis-

charged and further operation may dam-

age battery.

RECHARGING: batteries are recharging

whenever POWER MODE switch

is

set to

switch

off,

full charge

is

applied; with

POWER switch ON, trickle charge

is

applied.

a-

13 3/8(339.7)

b--11 15/64(286.1)

-4

7 21/64

(1 86.1)

7

53/64

I

(198.0)

WEIGHT

Without Panel Cover:

net, 24 lb

(11

kg); ship-

ping, 35 lb (15.9 kg).

With Panel Cover and Accessories:

net, 27 lb

(12.3 kg); shipping,

38

lb (17.2 kg).

With Panel Cover, Accessories, and Battery

Pack:

net, 35 lb (16 kg); shipping, 46 lb

(20.9 kg).

DI MENS1 ONS:

refer to outline drawing.

ENVIRONMENT (Oscilloscope operates within

specifications over following ranges):

temperature 0°C to +55"C; humidity, to 95%

relative humidity

to

40°C; altitude, to 15,000

ft;

vibration, in three planes for 15 min each

with 0.010-inch excursion,

10

to 55 Hz.

ACCESSORIES FURNISHED:

blue contrast filter,

Model 10115A; front panel storage cover,

Model 10101B; two Model 10006B probes;

and one ac power cord with right angle plug.

1-4

General Information

Model 1707B

1-17. CATHODE-RAY TUBE.

1-18. The Model 1707B uses

a

post-accelerator CRT

with

a

nonglare, rectangular faceplate. An internal

graticule

is

located on the same plane

as

the display

to eliminate parallax errors. The CRT

has

approxi-

mately 22 -kV accelerating potential, and 6 vertical

by 10 horizontal divisions. Each division

is

a

square

centimeter.

1-19. A type

P31

phosphor

is

used in the standard

CRT. Other types of phosphors are available by

special order. Refer to Section VI1 for further infor-

mation about optional and special-order modifi-

cations.

NOTE

Due to phosphor burn sensitivity,

instruments with

a

P-11

phosphor do

not have the intensified function of

the beam finder.

1-20. WARRANTY.

1

CAUTION

3

The warranty may be void for instru-

ments having

a

mutilated serial number

tag.

1-21. The instrument is certified and warranted

as

stated in the front of this manual. The CRT

is

covered by

a

separate warranty. The CRT warranty

and warranty claim form

is

located

at

the rear of

this manual. Should the CRT fail

within

the time

specified on the CRT warranty page, complete the

warranty claim form and return

it

with the defective

CRT. The procedure for returning

a

defective CRT

is

described on CRT warranty page.

1-22. ACCESSORIES FURNISHED.

1-23. Accessories furnished are listed in table

1-1.

I

1-24. ACCESSORIES AVAILABLE.

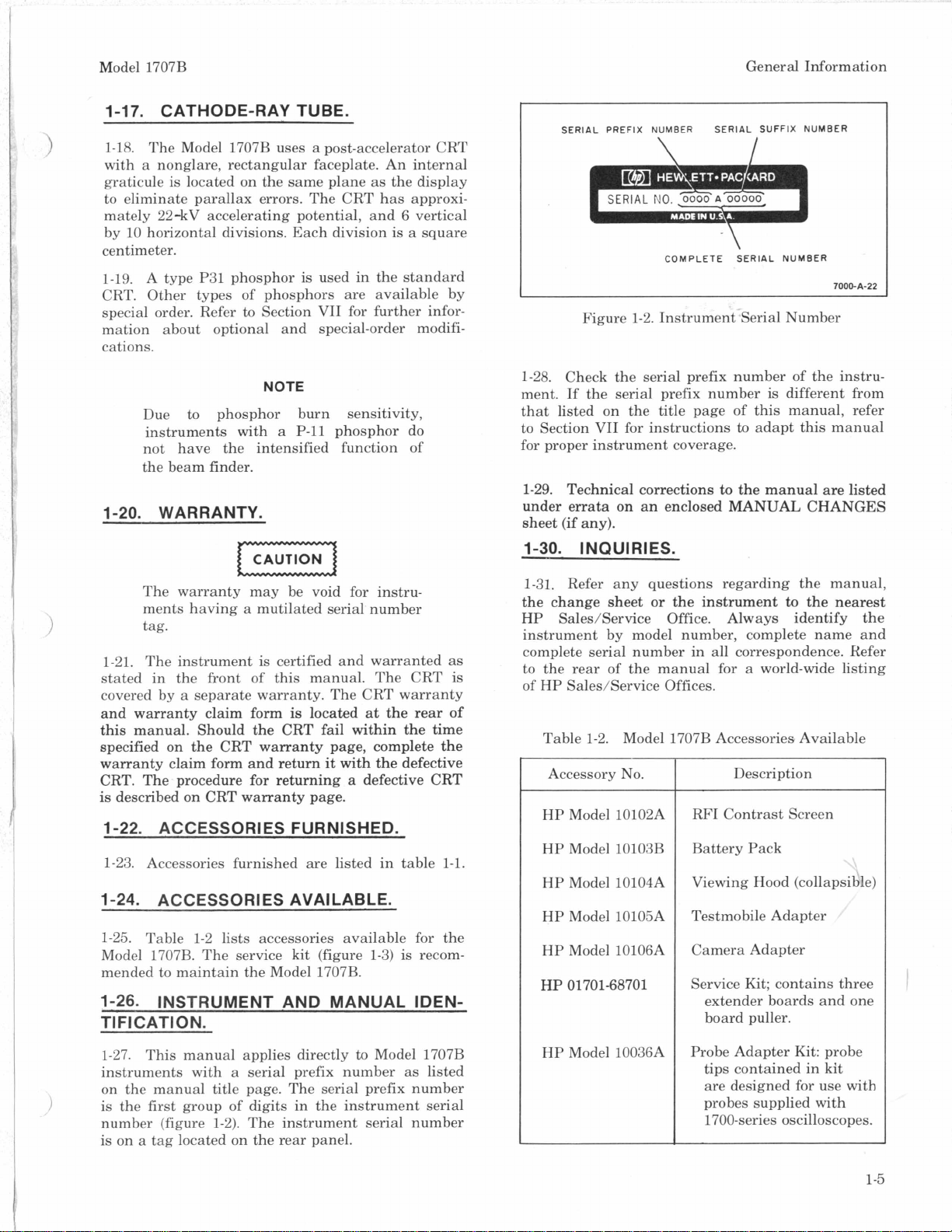

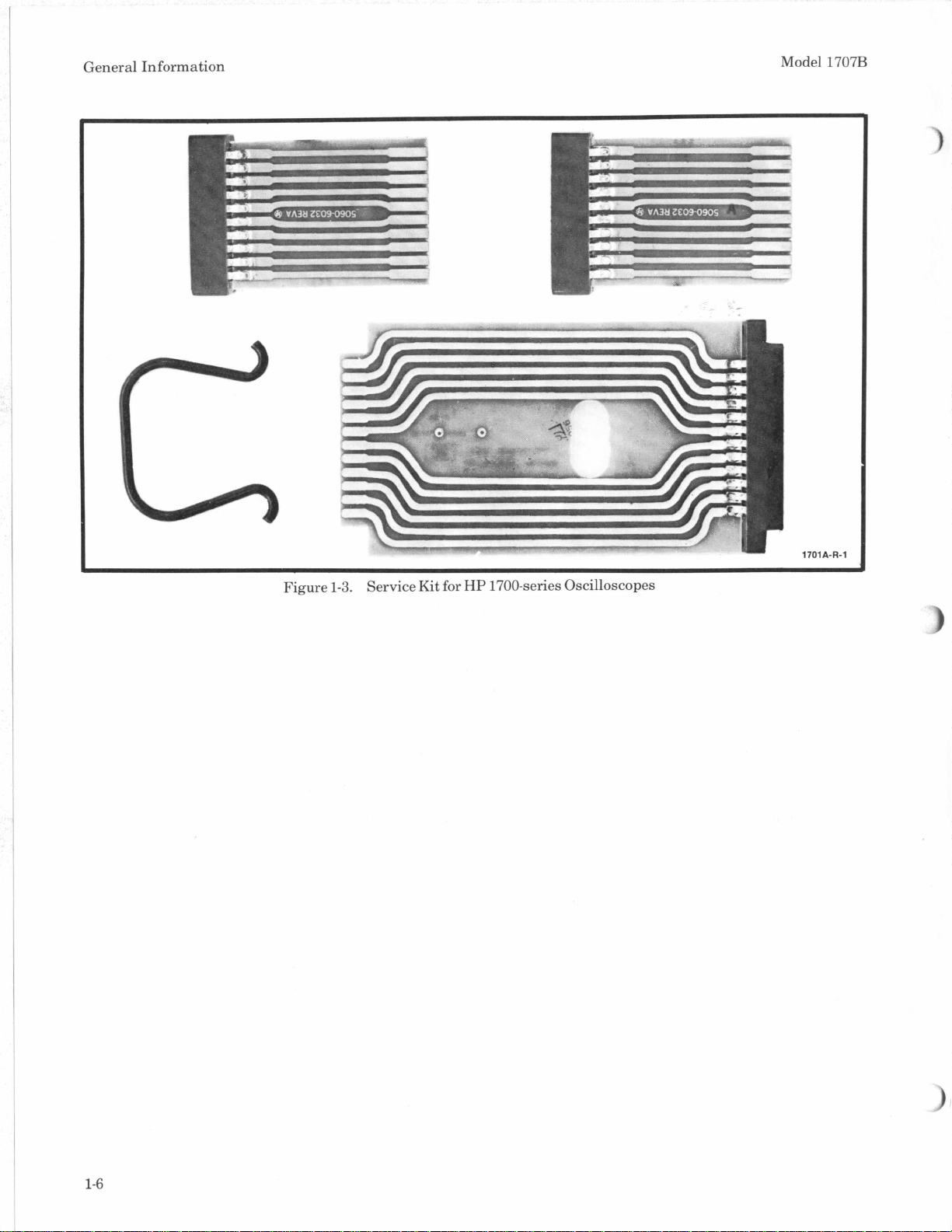

1-25. Table 1-2 lists accessories available for the

Model 1707B. The service kit (figure

1-3)

is

recom-

mended to maintain the Model 1707B.

1-26. INSTRUMENT AND MANUAL IDEN-

TI

FI

CAT1 ON.

1-27. This manual applies directly to Model 1707B

instruments with

a

serial prefix number

as

listed

on the manual title page. The serial prefix number

is

the first group of digits in the instrument serial

number (figure 1-2). The instrument serial number

is

on

a

tag located on the rear panel.

SERIAL PREFIX NUMBER SERIAL SUFFIX NUMBER

rZBirn*h

SERIAL

rJG

0000

A

00000

-\

COMPLETE SERIAL NUMBER

7000-A-22

I

Figure 1-2. Instrument Serial Number

1-28. Check the serial prefix number of the instru-

ment. If the serial prefix number

is

different from

that listed on the title page of this manual, refer

to Section VI1 for instructions

to

adapt this manual

for proper instrument coverage.

1-29. Technical corrections to the manual are listed

under errata on an enclosed MANUAL CHANGES

sheet (if any).

1-30. INQUIRIES.

1-31.

Refer any questions regarding the manual,

the change sheet or the instrument to the nearest

HP Sales/Service Office. Always identify the

instrument by model number, complete name and

complete serial number in all correspondence. Refer

to the rear of the manual for

a

world-wide listing

of HP SaledService Offices.

Table 1-2. Model 1707B Accessories Available

1

Accessory No.

I

Description

I

HP Model 10102A

HP Model 10103B

HP Model 10104A

HP Model 10105A

HP Model 10106A

HP

01701-68701

HP Model 10036A

RFI Contrast Screen

Battery Pack

Viewing Hood (collapsible)

Testmobile Adapter

Camera Adapter

Service Kit; contains three

extender boards and one

board puller.

Probe Adapter Kit: probe

tips contained in kit

are designed for use with

probes supplied with

1700-series oscilloscopes.

1-5

Gen era1

In

form ation

Model

1707B

1701A-R-1

Figure

1-3.

Service

Kit

for

HP

1700-series Oscilloscopes

I

1-6

Model 1707B

2-1. INTRODUCTION.

2-2. This section contains instructions for perform-

ing an initial inspection of the Model 1707B. Instal-

lation procedures and precautions are presented

in step-by-step order. The procedures for making

a

claim for warranty repairs and for repacking the

instrument for shipment are also described

in

this

section.

2-3.

INITIAL INSPECTION.

2-4. The instrument was inspected mechanically and

electrically before shipment. Upon receipt, inspect

it

for damage that may have occurred in transit.

Check for broken knobs, bent or broken connectors,

and dents or scratches. If damage

is

found, refer

to the claims paragraph in this section. Retain the

packing material for possible future use.

Installation

SECTION

II

I

NSTALLATI

0

N

Voltages are present inside instrument

when power switch

is

off and ac power

cord connected.

)

2-5. Check the electrical performance of the instru-

ment immediately after receipt. Refer to Section V

for the performance check procedure. The perform-

ance check will determine whether or not the instru-

ment

is

operating within the specifications listed in

table

1-1.

Initial performance and accuracy of the

instrument are certified

as

stated

in

the front of

this manual. If the instrument does not operate

as

specified, refer to the claims paragraph

in

this

section.

2-6.

PREPARATION FOR USE.

2-7.

POWER REQUIREMENTS.

2-8.

The Model

1707B

can operate from either

an

ac or dc power source. For ac operation, the Model

1707B requires

115-

or 230-volt *20%, single phase,

48- to 440-Hz source that can deliver

50

volt-amperes.

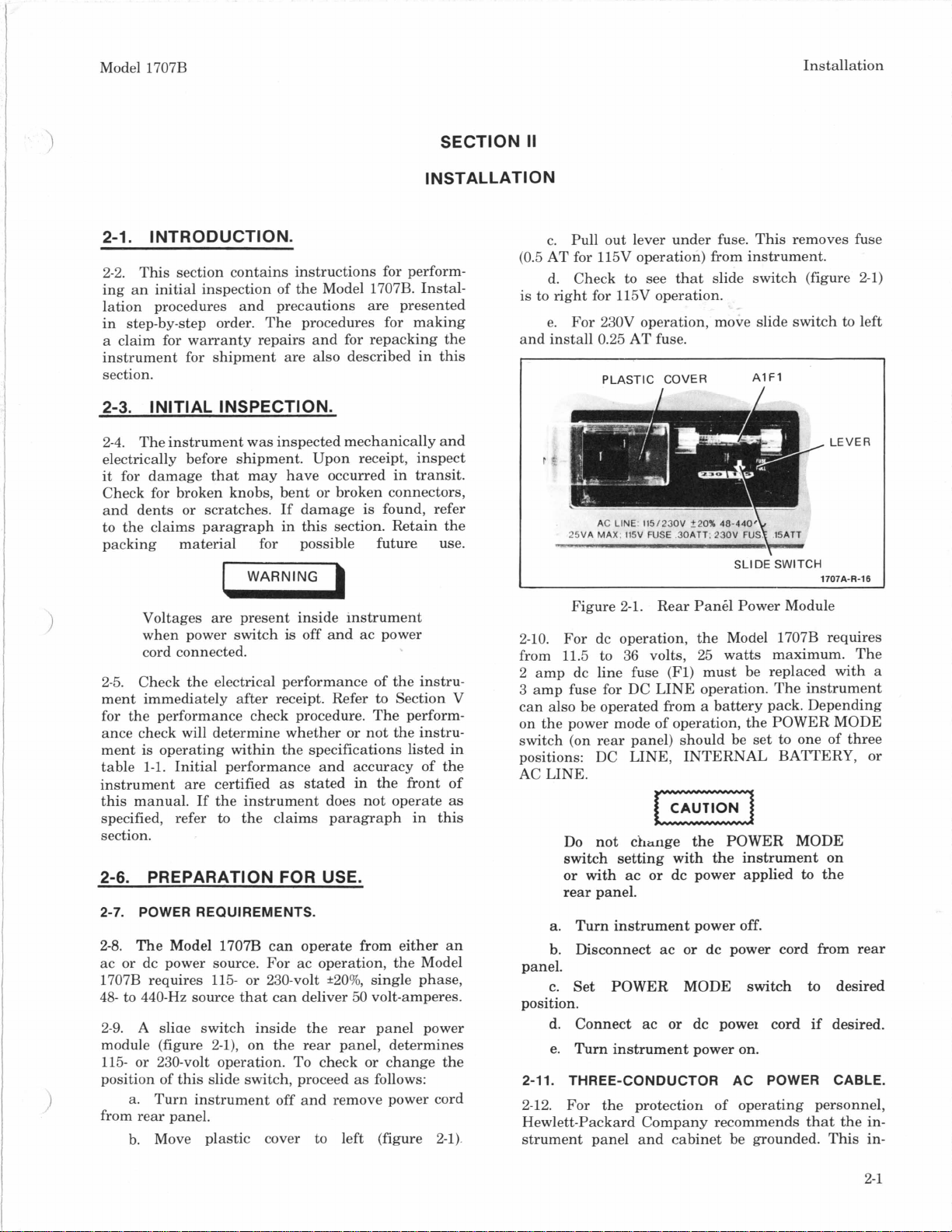

2-9. A sliae switch inside the rear panel power

module (figure 2-1), on the rear panel, determines

115- or 230-volt operation. To check or change the

position of this slide switch, proceed

as

follows:

1

a.

Turn instrument off and remove power cord

from rear panel.

b. Move plastic cover to left (figure 2-1).

c. Pull out lever under fuse. This removes fuse

d. Check to see

that

slide switch (figure 2-1)

e.

For 230V operation, move slide switch to left

(0.5 AT for 115V operation) from instrument.

is

to right for 115V operation.

and install 0.25 AT fuse.

PLASTIC COVER A1

F1

LEVER

~

SLIDE

SWITCH

1707A-R-16

Figure 2-1. Rear Pan61 Power Module

2-10. For dc operation, the Model 1707B requires

from

11.5

to 36 volts, 25 watts maximum. The

2 amp dc line fuse

(Fl)

must be replaced with

a

3

amp fuse for DC LINE operation. The instrument

can also be operated from

a

battery pack. Depending

on the power mode of operation, the POWER MODE

switch (on rear panel) should be set to one of three

positions: DC LINE, INTERNAL BATTERY, or

AC LINE.

Do not change the POWER MODE

switch setting with the instrument on

or

with

ac or dc power applied

to

the

rear panel.

a.

Turn instrument power

off.

b.

Disconnect ac or dc power cord from rear

panel.

c. Set POWER

MODE

switch to desired

position.

d.

Connect ac or dc powei cord if desired.

e. Turn instrument power on.

2-11.

THREE-CONDUCTOR AC POWER CABLE.

2-12. For the protection of operating personnel,

Hewlett-Packard Company recommends that the

in-

strument panel and cabinet be grounded. This

in-

2-1

Installation

Model 1707B

strument

is

equipped with

a

three-conductor ac power

cable that, when connected to an appropriate re-

ceptacle, grounds the instrument through the

offset pin. The power jack and mating plug of the

power cord meet International Electro-technical

Commission (IEC) safety standards. To preserve

this

protection feature when operating from

a

two-

contact outlet, use

a

three-conductor to two-conductor

adapter, and connect the adapter wire to ground

at

the power outlet.

2-13.

DC

PLUG.

2-14. A dc jack

is

provided for operating from

a

dc

line. The cable used for the dc power cord should

be 2 wire (grounded) and must be able to carry

2.5A of current with

a

voltage loss of less than

1

volt.

2-15.

BATTERY INSl’ALLATION.

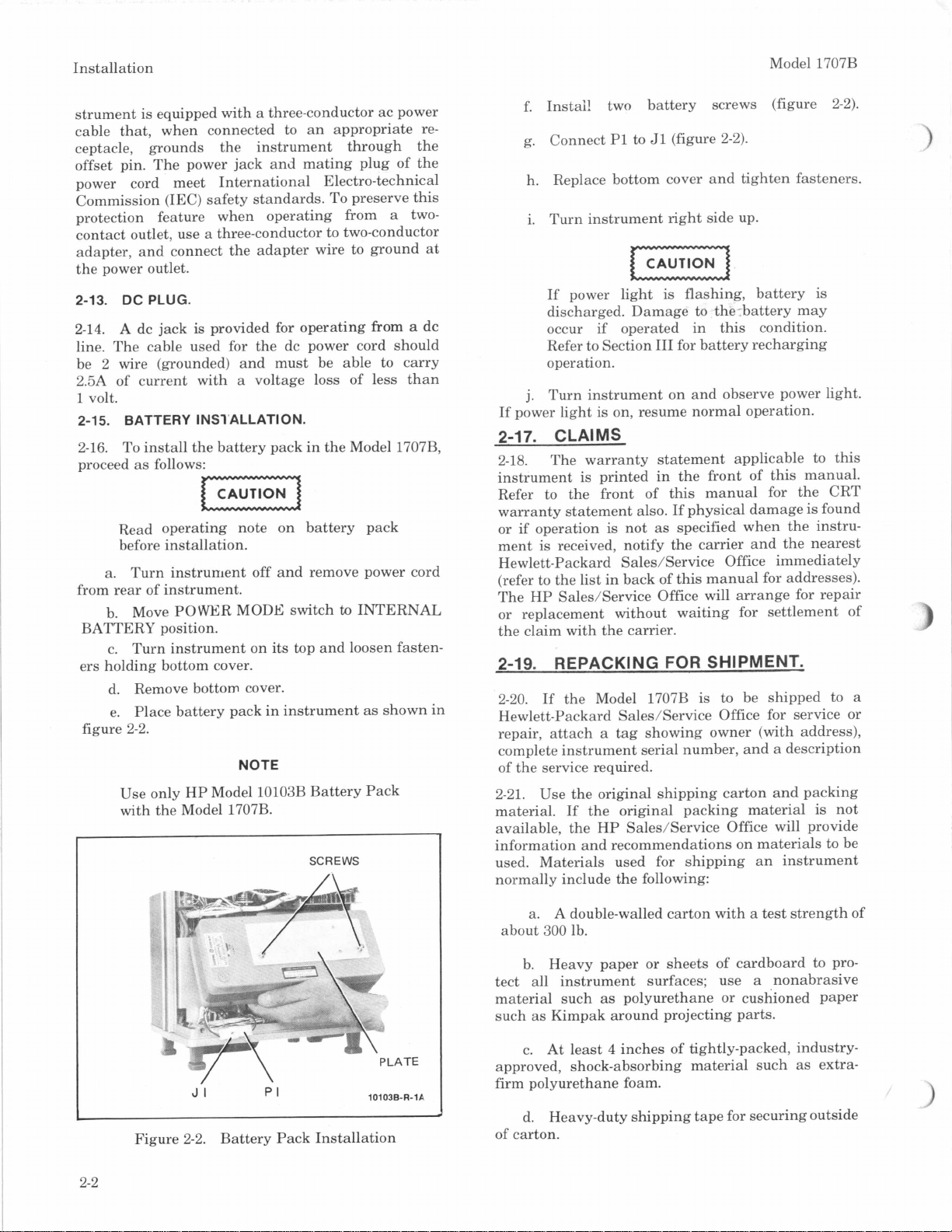

2-16. To install the battery pack in the Model 1707B,

proceed

as

follows:

Read operating note on battery pack

before inst all ation.

a.

Turn instrument off and remove power cord

Move POWER MODE switch

to

INTERNAL

Turn instrument on

its

top and loosen fasten-

from rear of instrument.

BATTERY position.

ers holding bottom cover.

b.

c.

d. Remove bottom cover.

e.

figure 2-2.

Place battery pack in instrument

as

shown

in

NOTE

Use only HP Model 10103B Battery Pack

with the Model 1707B.

SCREWS

10103B-R-IA

JI

PI

Figure 2-2. Battery Pack Installation

f. Instal! two battery screws (figure 2-2).

g.

Connect

P1

to

Jl

(figure 2-2).

h. Replace bottom cover and tighten fasteners.

i.

Turn instrument right side up.

If power light

is

flashing, battery

is

discharged. Damage to the:battery may

occur if operated in this condition.

Refer to Section

I11

for battery recharging

operation.

j.

Turn instrument on and observe power light.

If power light

is

on, resume normal operation.

2-17.

CLAIMS

2-18. The warranty statement applicable to

this

instrument

is

printed

in

the front

of

this

manual.

Refer to the front of

this

manual for the CRT

warranty statement also. If physical damage

is

found

or if operation

is

not

as

specified when the instru-

ment

is

received, notify the carrier and the nearest

Hewlett-Packard Sales/Service Office immediately

(refer to the list in back of this manual for addresses).

The

HP

Sales/Service Office will arrange for repair

or replacement without waiting for settlement of

the claim with the carrier.

2-19.

REPACKING

FOR

SHIPMENT,

2-20. If the Model 1707B

is

to be shipped to

a

Hewlett-Packard Sales/Service Office for service or

repair, attach

a

tag showing owner

(with

address),

complete instrument serial number, and

a

description

of the service required.

2-21. Use the original shipping carton and packing

material. If the original packing material

is

not

available, the HP Sales/Service Office will provide

information and recommendations on materials to be

used. Materials used for shipping

an

instrument

normally include the following:

a.

A double-walled carton with

a

test strength of

about

300

lb.

b.

Heavy paper or sheets of cardboard to pro-

tect all instrument surfaces; use

a

nonabrasive

material such

as

polyurethane or cushioned paper

such

as

Kimpak around projecting parts.

c. At least

4

inches of tightly-packed, industry-

approved, shock-absorbing material such

as

extra-

firm polyurethane foam.

d.

of carton.

Heavy-duty shipping tape for securing outside

2-2

Model 1707B

Operation

SECTION

111

OPERATION

3-1.

I

NTR

0

D

U

CTI ON.

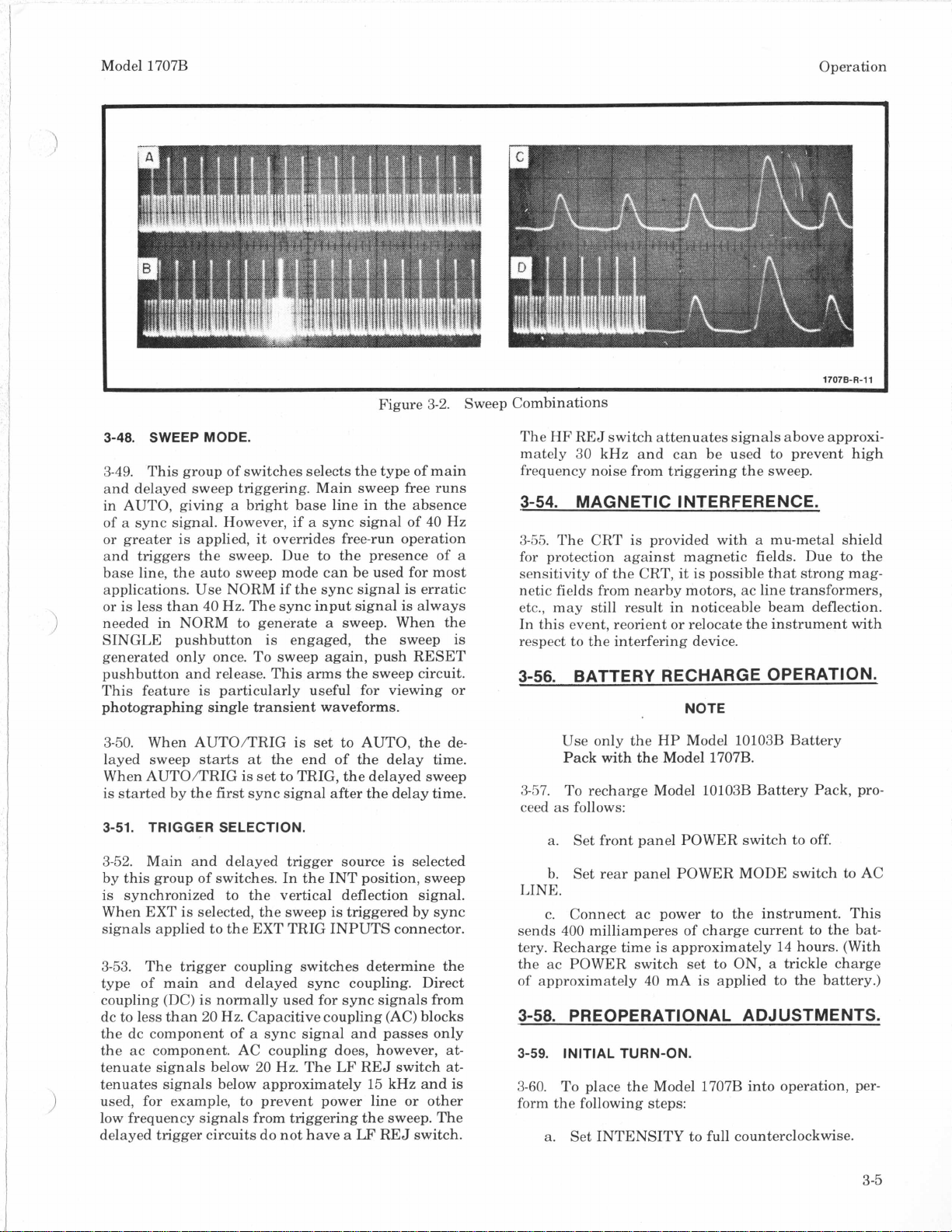

3-1 1. CALIBRATOR.

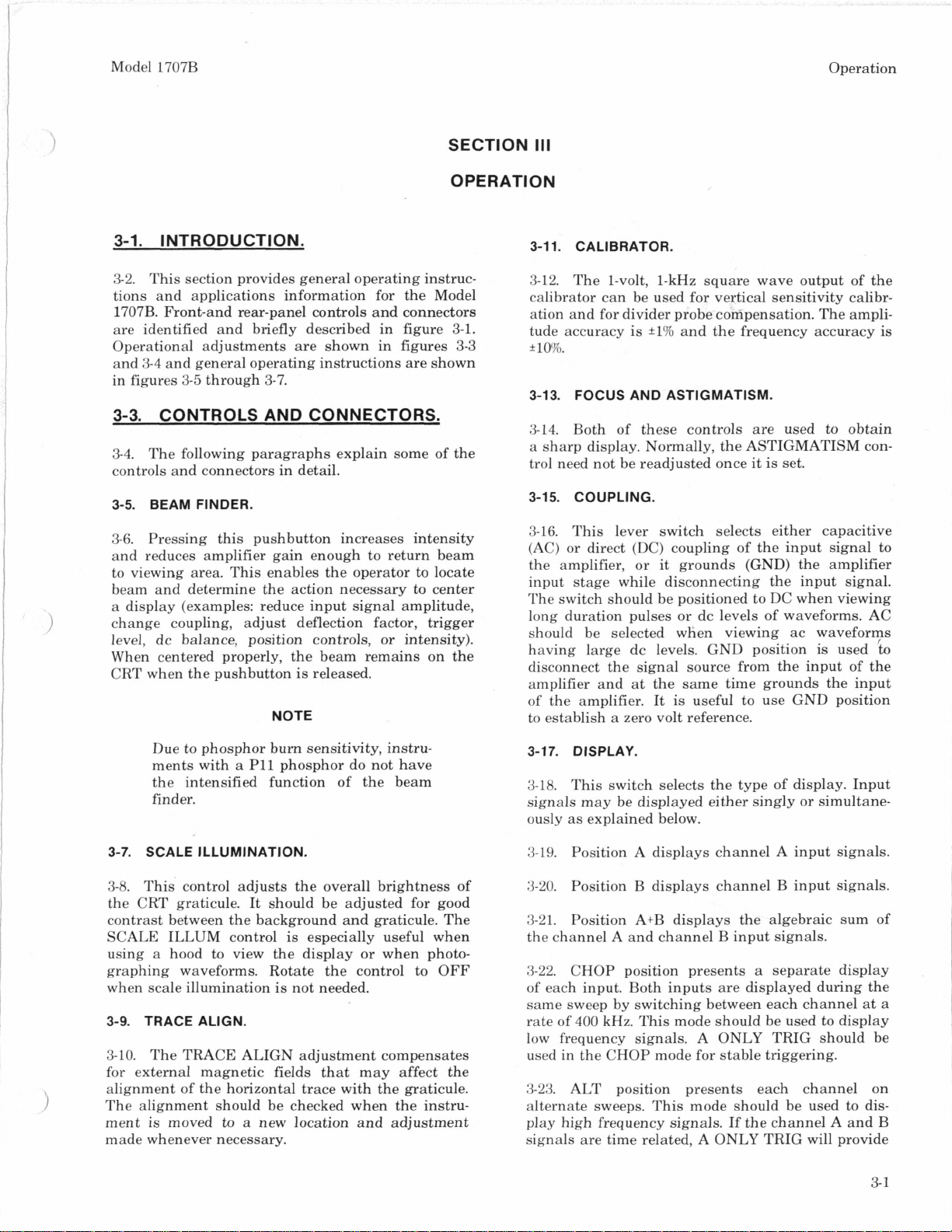

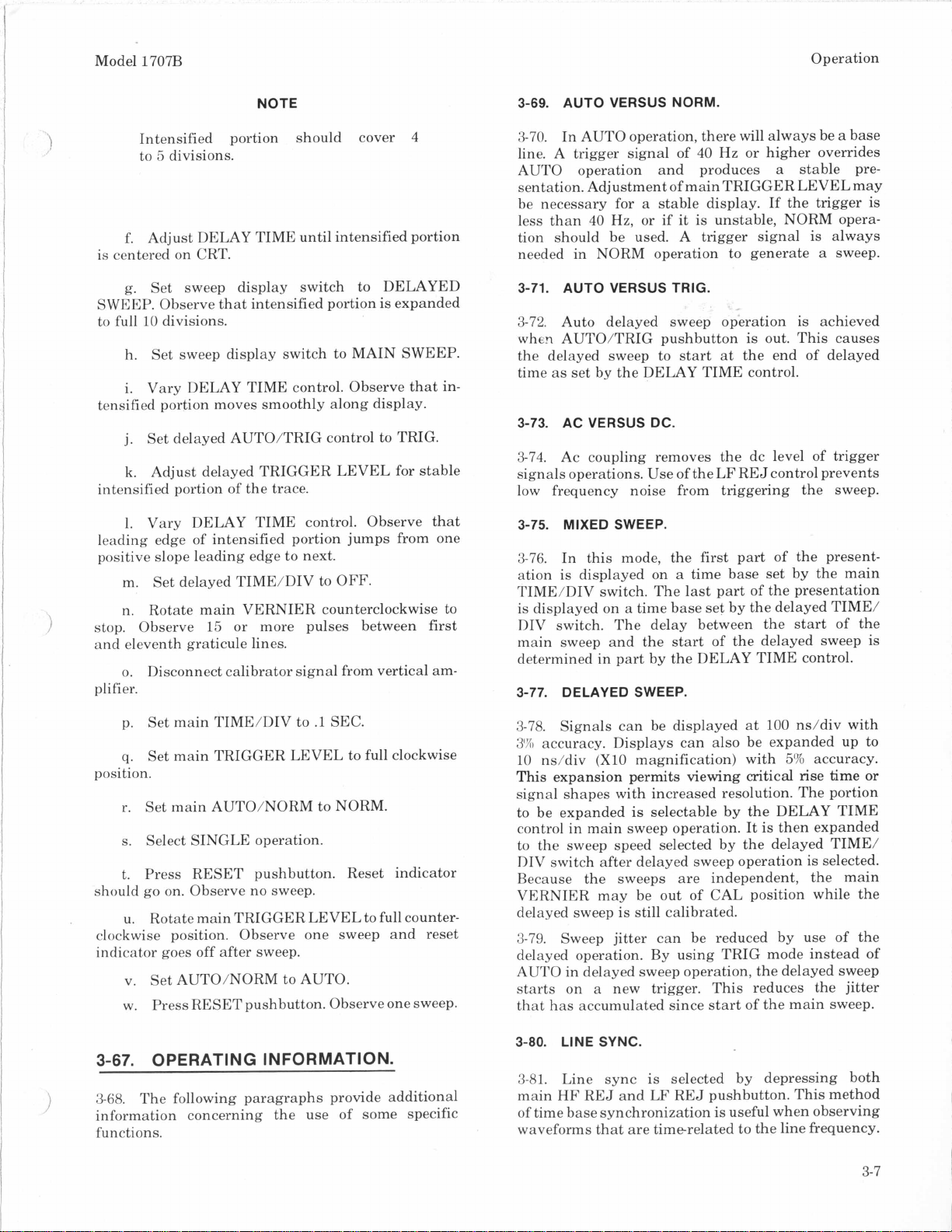

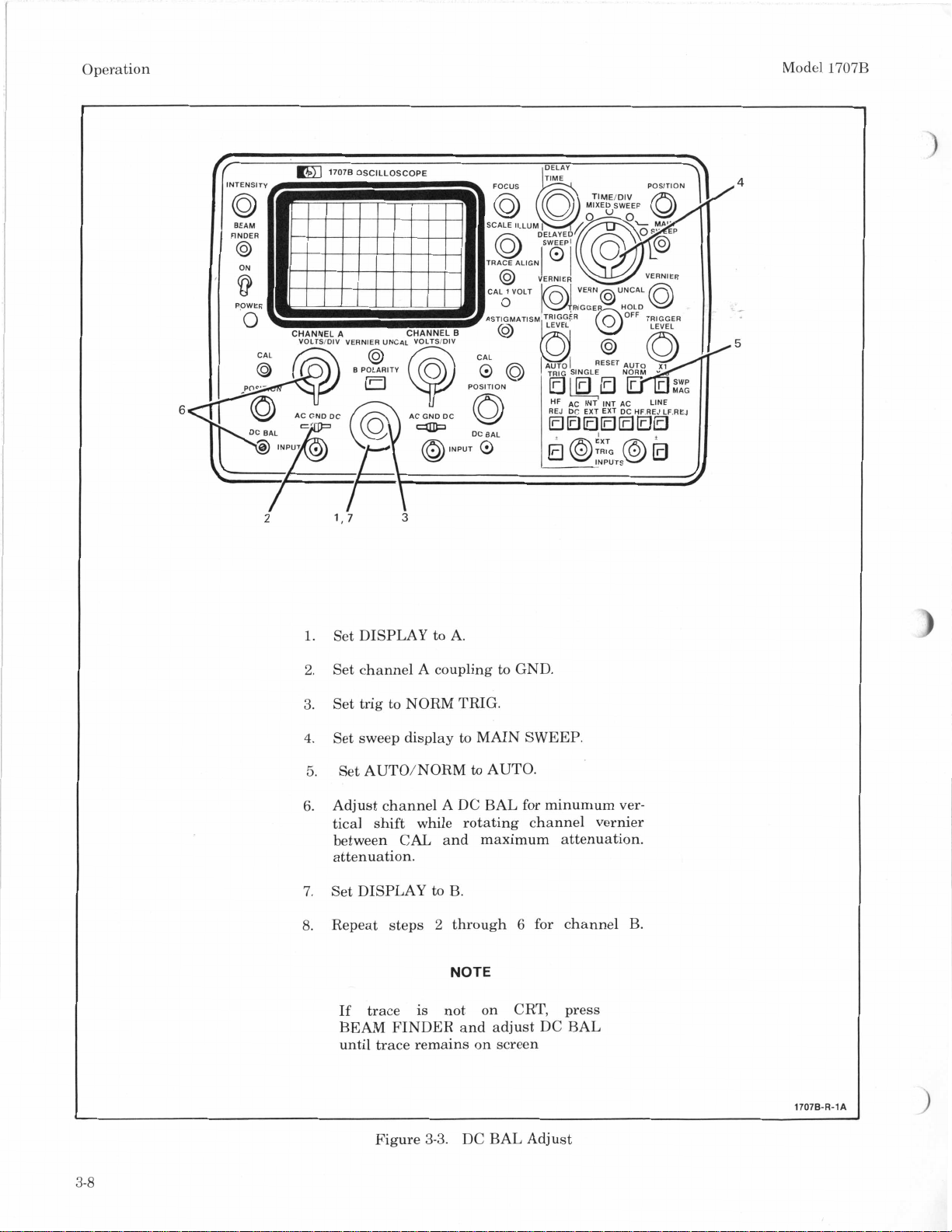

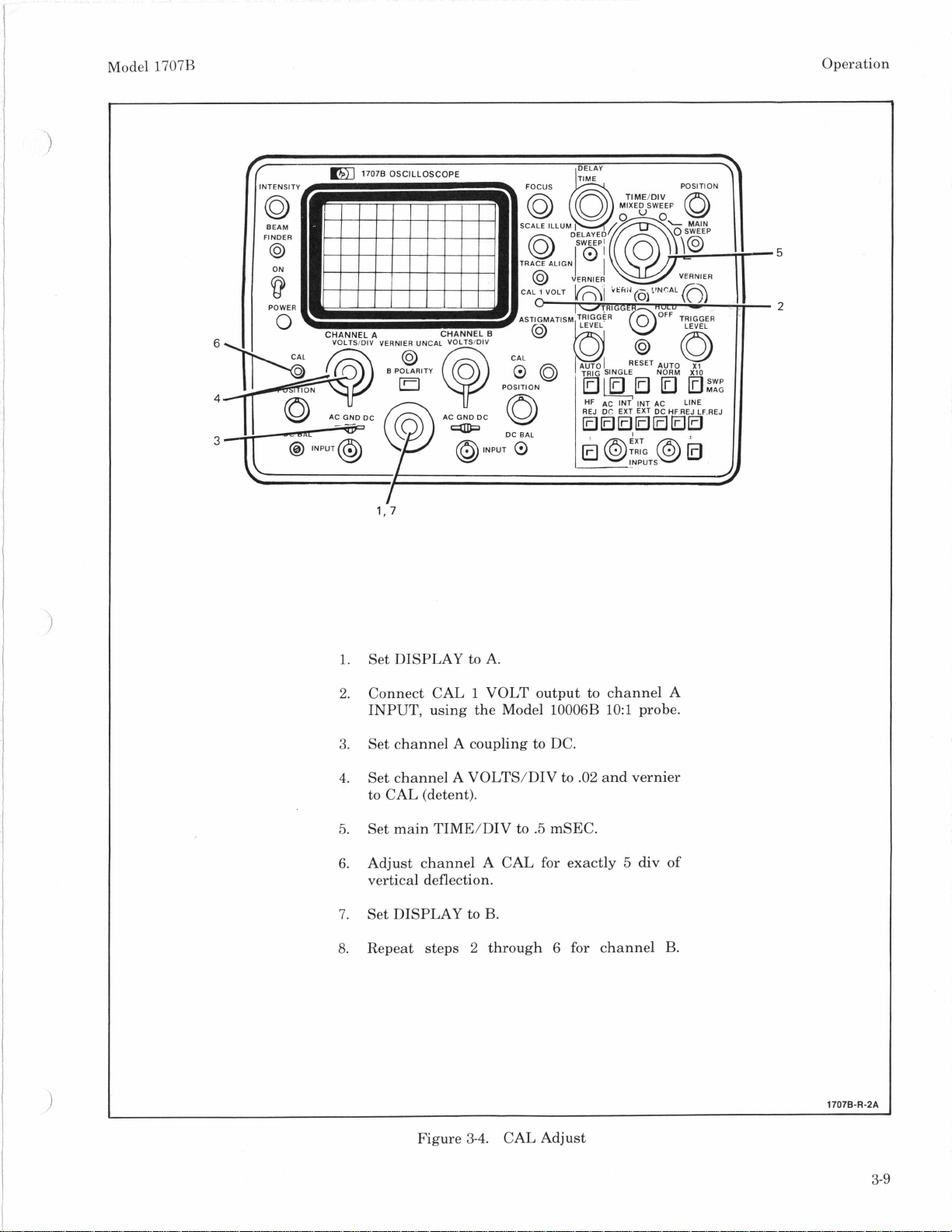

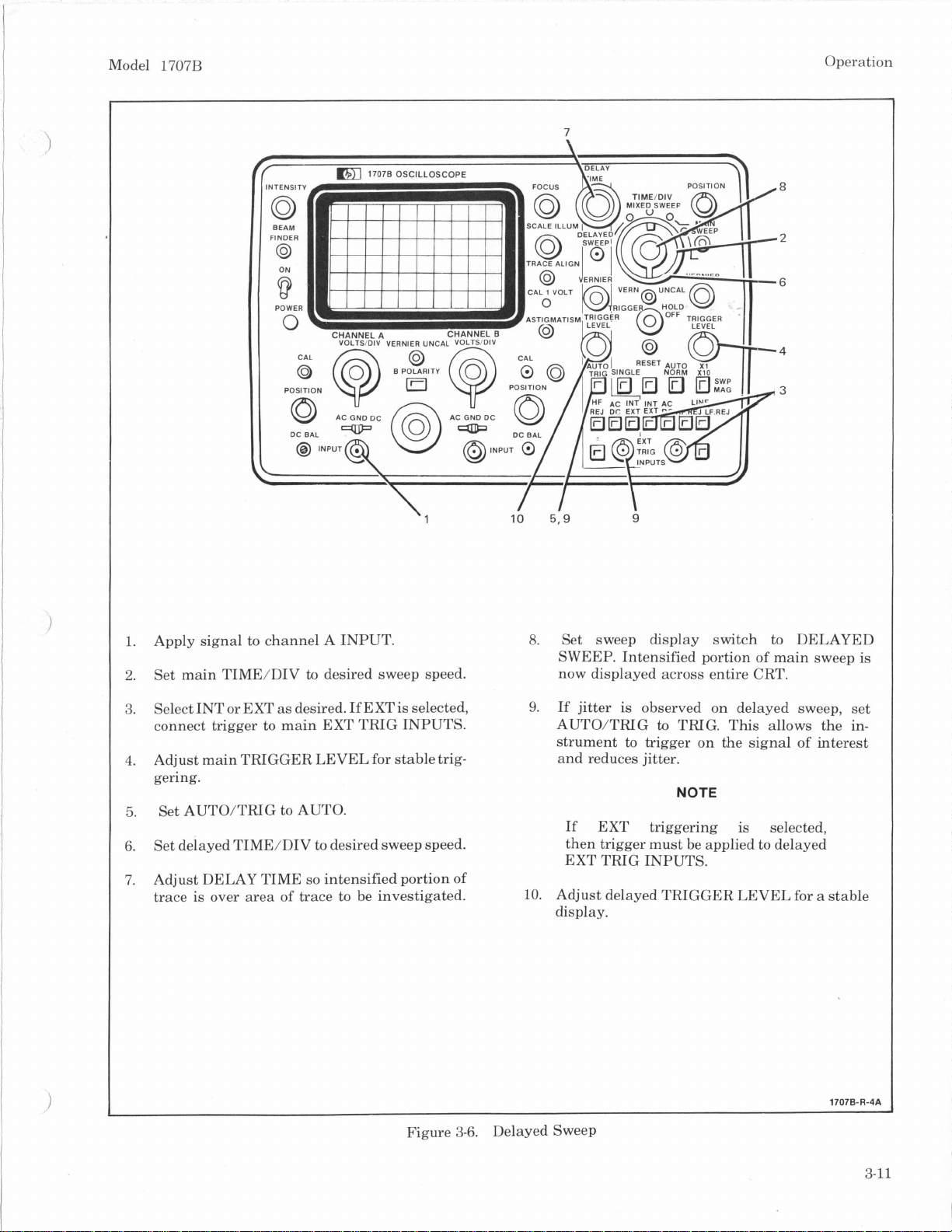

3-2. This section provides general operating instruc-

tions and applications information for the Model

1707B. Front-and rear-panel controls and connectors

are identified and briefly described in

figure

3-1.

Operational adjustments are shown in figures

3-3

and 3-4 and general operating instructions are shown

in figures

3-5

through 3-7.

3-3.

CONTROLS AND CONNECTORS.

3-4. The following paragraphs explain some of the

controls and connectors in detail.

3-5. BEAM FINDER.

3-6. Pressing this pushbutton increases intensity

and reduces amplifier gain enough to return beam

to viewing area. This enables the operator to locate

beam and determine the action necessary to center

a

display (examples: reduce input signal amplitude,

change coupling, adjust deflection factor, trigger

level, dc balance, position controls, or intensity).

When centered properly, the beam remains on the

CRT when the pushbutton

is

released.

NOTE

Due to phosphor burn sensitivity, instru-

ments with

a P11

phosphor do not have

the intensified function of the beam

finder.

3-7. SCALE ILLUMINATION.

3-8.

This control adjusts the overall brightness of

the CRT graticule.

It

should be adjusted for good

contrast between the background and graticule. The

SCALE ILLUM control

is

especially useful when

using

a

hood to view the display or when photo-

graphing waveforms. Rotate the control to OFF

when scale illumination

is

not needed.

3-9. TRACE ALIGN.

3-10. The TRACE ALIGN adjustment compensates

for external magnetic fields that may affect the

alignment of the horizontal trace with the graticule.

The alignment should be checked when the instru-

ment is moved to

a

new location and adjustment

made whenever necessary.

3-12. The 1-volt, l-kHz square wave output of the

calibrator can be used for vertical sensitivity calibr-

ation and for divider probe compensation. The ampli-

tude accuracy

is

*l%

and the frequency accuracy

is

*

10'70.

3-13. FOCUS AND ASTIGMATISM.

3-14. Both of these controls are used to obtain

a

sharp display. Normally, the ASTIGMATISM con-

trol need not be readjusted once

it

is

set.

3-15. COUPLING.

3-16. This lever switch selects either capacitive

(AC) or direct (DC) coupling of the input signal to

the amplifier, or it grounds (GND) the amplifier

input stage while disconnecting the input signal.

The switch should be positioned to

DC

when viewing

long duration pulses

or

dc levels of waveforms. AC

should be selected when viewing ac waveforms

having large dc levels. GND position

is

used

to

disconnect the signal source from the input of the

amplifier and at the same time grounds the input

of

the amplifier.

It

is

useful to use GND position

to establish

a

zero volt reference.

3-17. DISPLAY.

3-18. This switch selects the type of display. Input

signals may be displayed either singly or simultane-

ously

as

explained below.

3-19.

Position A displays channel A input signals.

3-20. Position

B

displays channel B input signals.

3-21.

the channel A and channel B input signals.

Position A+B displays the algebraic sum of

3-22. CHOP position presents

a

separate display

of

each input. Both inputs are displayed during the

same sweep by switching between each channel

at

a

rate of

400

kHz, This mode should be used to display

low frequency signals. A ONLY TRIG should be

used in the CHOP mode for stable triggering.

3-23. ALT position presents each channel on

alternate sweeps. This mode should be used to dis-

play high frequency signals. If the channel A and B

signals are time related, A ONLY TRIG will provide

3-

1

Operation Model

1707B

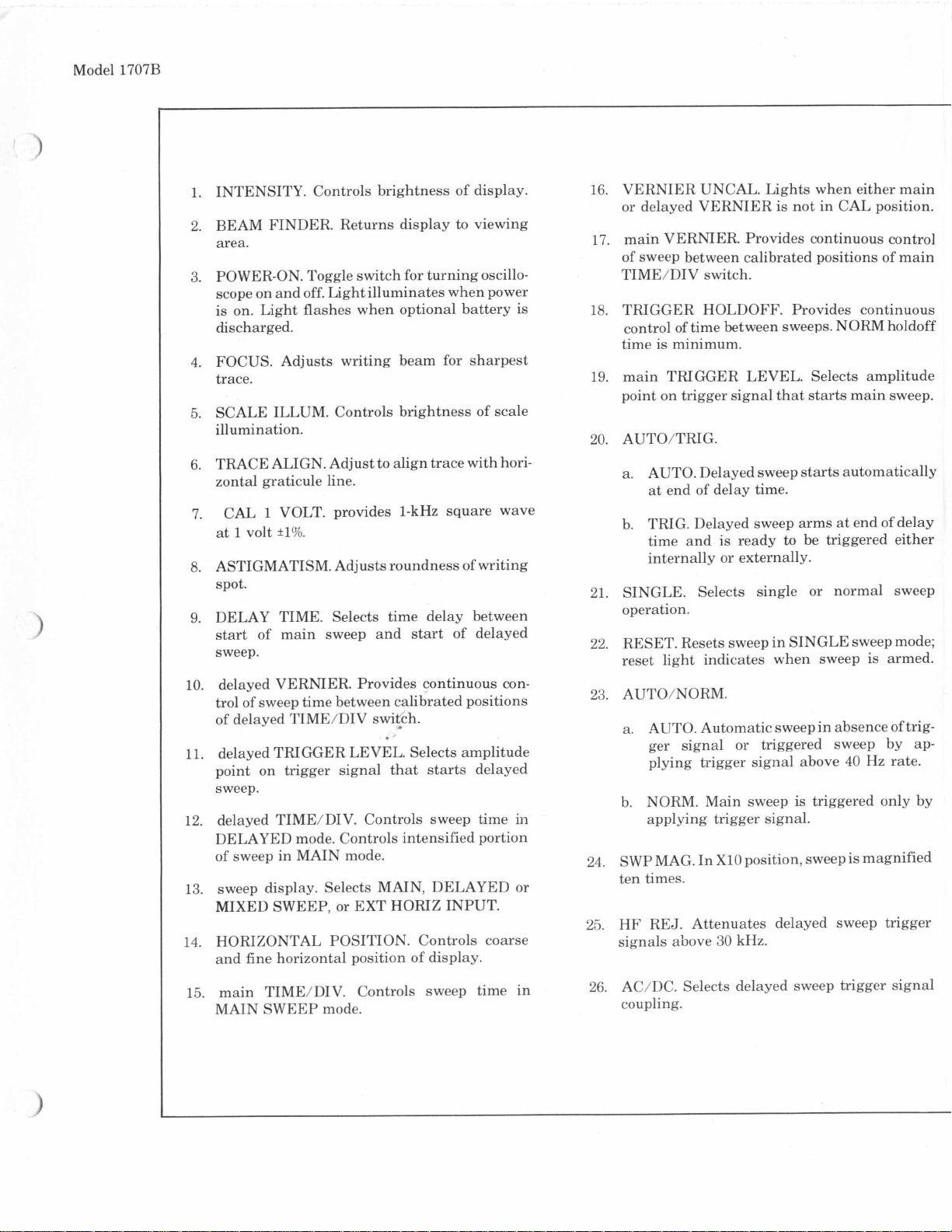

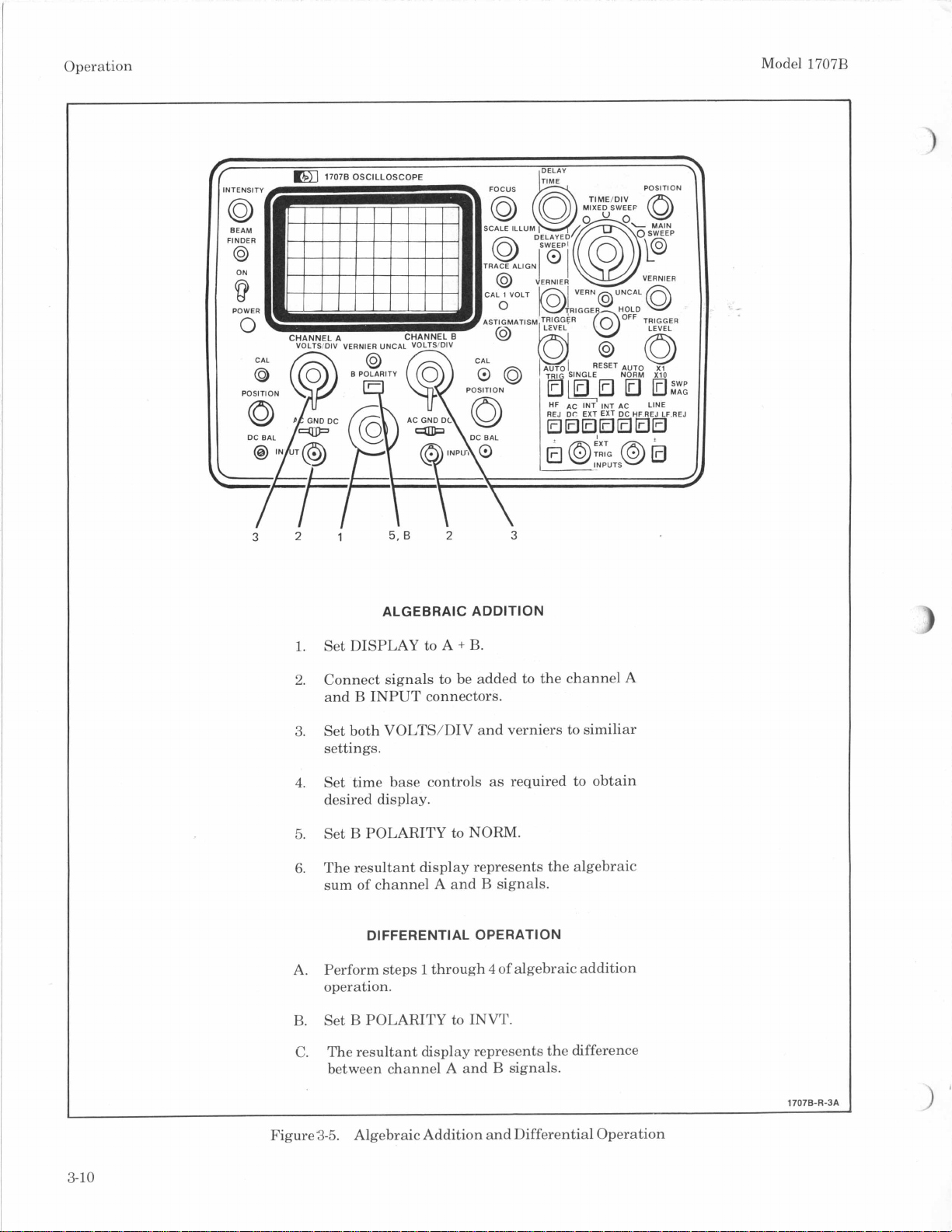

1-3

4-8 9-1 1 12 13 14

15

16

17

18

46

45

44

43

42 41 40 39 38 37 36 35 34 33 32

\\

El

\\.

'ORIZ INPUT

@

c

1.

3. APPLY AC POWER

TO

INSTRUMENT.

SET FRONT PANEL POWER SWITCH TO OFF.

2.

SET

FRONT

PANEL

POWER

MODE

SWITCH

TO

AC.

POWER

MODE

c-3

INTERNALBATTERY

[~y,lnrj

~

AC LINE

5/230

0'0

48-440

53 52 51 50

19

20-

25-

/

49

-24

-31

Figure

31.

Controls and Connectors

3-2

e'

I

a

Model

1707B

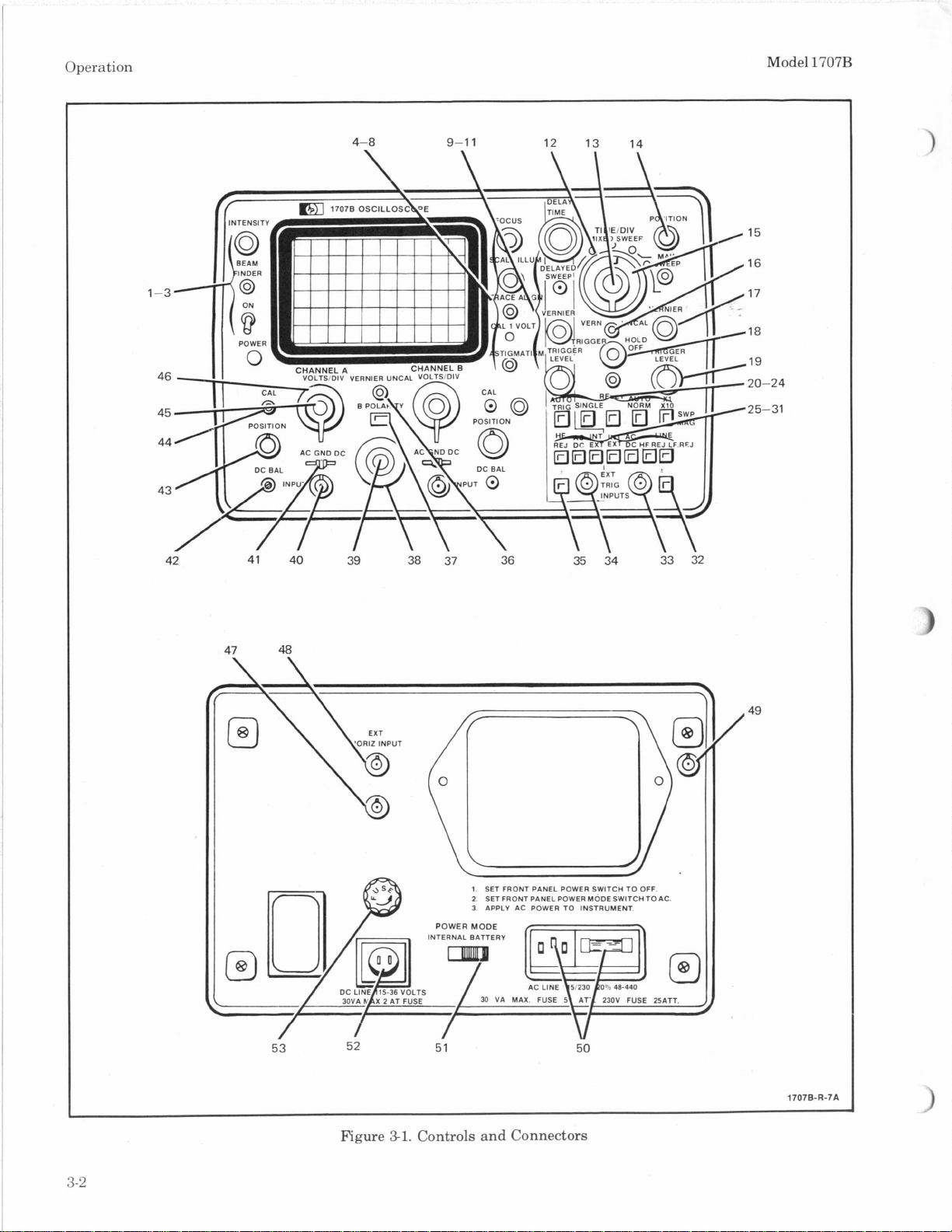

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

INTENSITY. Controls brightness of display.

BEAM FINDER. Returns display to viewing

area.

POWER-ON. Toggle switch for turning oscillo-

scope on and off. Light illuminates when power

is

on. Light flashes when optional battery

is

discharged.

FOCUS. Adjusts writing beam for sharpest

trace.

SCALE ILLUM. Controls brightness of scale

illumination.

TRACE ALIGN. Adjust to align trace with hori-

zontal graticule line.

CAL

1

VOLT. provides

1-kHz

square wave

at

1

volt

*I%.

ASTIGMATISM. Adjusts roundness of writing

spot.

DELAY TIME.

Selects time delay between

start

of main sweep and

start

of delayed

sweep.

delayed VERNIER. Provides continuous con-

trol of sweep time between calibrated positions

of delayed TIME/DIV switch.

delayed TRIGGER LEVEL. Selects amplitude

point on trigger signal that

starts

delayed

sweep.

delayed TIME/DIV. Controls sweep time

in

DELAYED mode. Controls intensified portion

of sweep in MAIN mode.

sweep display. Selects MAIN, DELAYED or

MIXED SWEEP, or EXT HORIZ INPUT.

HORIZONTAL POSITION. Controls coarse

and fine horizontal position of display.

main TIME/DIV. Controls sweep time in

MAIN SWEEP mode.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

VERNIER UNCAL. Lights when either main

or delayed VERNIER

is

not in CAL position.

main VERNIER. Provides continuous control

of sweep between calibrated positions of main

TIME/DIV switch.

TRIGGER HOLDOFF. Provides continuous

control of time between sweeps. NORM holdoff

time

is

minimum.

main TRIGGER LEVEL. Selects amplitude

point on trigger signal that

starts

main sweep.

AUTO/TRIG.

a.

AUTO. Delayed sweep

starts

automatically

at

end of delay time.

b. TRIG. Delayed sweep arms

at

end of delay

time and

is

ready to be triggered either

internally or externally.

SINGLE. Selects single or normal sweep

operation.

RESET. Resets sweep

in

SINGLE sweep mode;

reset light indicates when sweep

is

armed.

AUTO/NORM.

a.

AUTO. Automatic sweep in absence of trig-

ger signal or triggered sweep by

ap-

plying trigger signal above

40

Hz rate.

b. NORM. Main sweep

is

triggered only by

applying trigger signal.

SWP

MAG. In XI0 position, sweep

is

magnified

ten times.

HF REJ. Attenuates delayed sweep trigger

signals above 30 kHz.

26. AC/DC. Selects delayed sweep trigger signal

coupling.

i

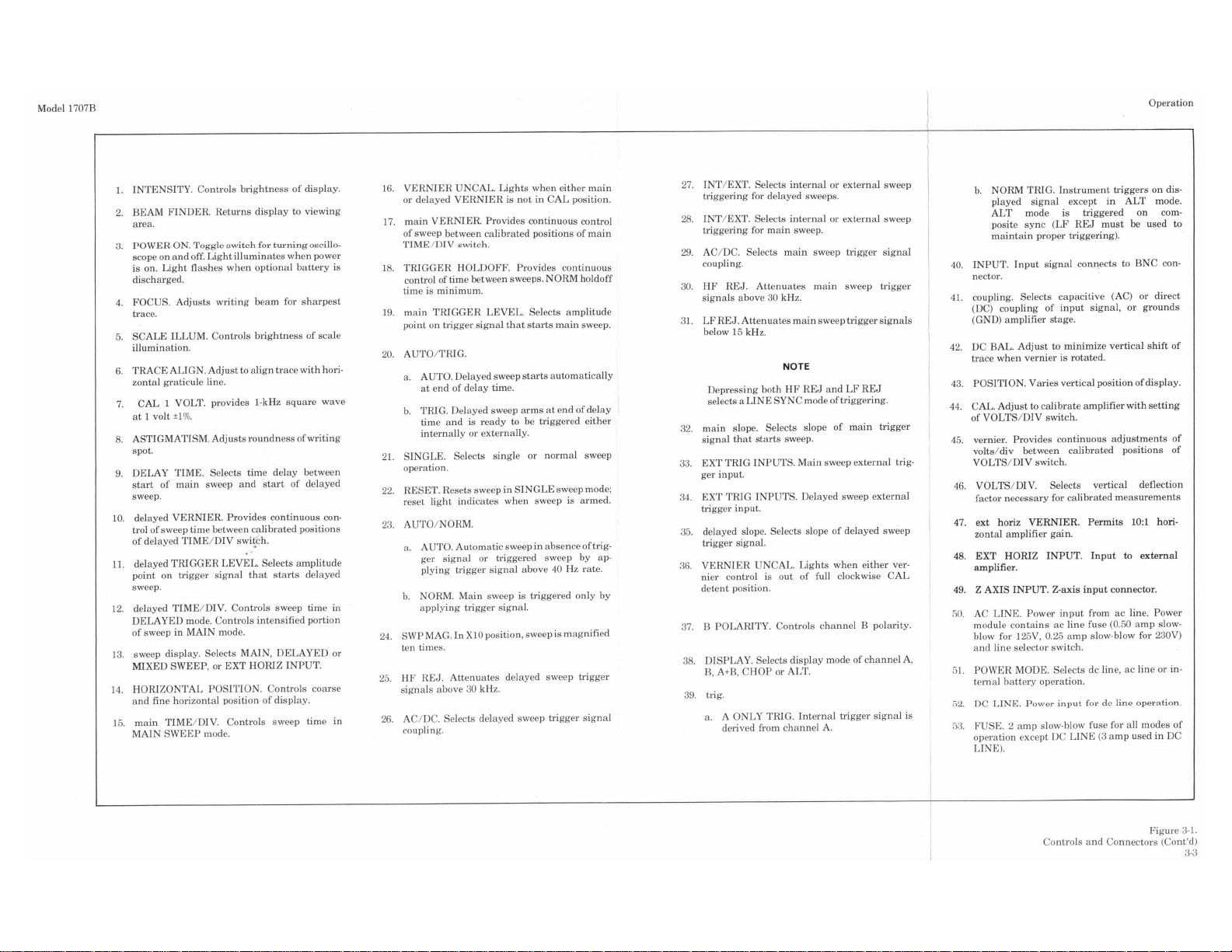

Operation

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

INT/EXT. Selects internal or external sweep

triggering for delayed sweeps.

INT/EXT. Selects internal or external sweep

triggering for main sweep.

AC/DC. Selects main sweep trigger signal

coupling.

HF RE

J.

Attenuates main sweep trigger

signals above 30 kHz.

LF REJ. Attenuates main sweep trigger signals

below

15

kHz.

NOTE

Depressing both HF REJ and LF REJ

selects

a

LINE SYNC mode of triggering.

main slope. Selects slope of main trigger

signal that

starts

sweep.

EXT TRIG INPUTS. Main sweep external trig

ger input.

EXT TRIG INPUTS. Delayed sweep external

trigger input.

delayed slope. Selects slope of delayed sweep

trigger signal.

VERNIER UNCAL. Lights when either ver-

nier control

is

out of full clockwise CAL

detent position.

B

POLARITY. Controls channel B polarity.

DISPLAY. Selects display mode of channel A,

B,

A+B, CHOP or ALT.

trig.

a.

A ONLY TRIG. Internal trigger signal

is

derived from channel A.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

b. NORM TRIG. Instrument triggers on dis-

played signal except in ALT mode.

ALT mode

is

triggered on com-

posite sync (LF REJ must be used to

maintain pro per triggering)

.

INPUT. Input signal connects to BNC con-

nector.

coupling. Selects capacitive (AC) or direct

(DC) coupling of input signal, or grounds

(GND) amplifier stage.

DC BAL. Adjust to minimize vertical shift of

trace when vernier

is

rotated.

POSITION. Varies vertical position of display.

CAL. Adjust to calibrate amplifier with setting

of VOLTS/DIV switch.

vernier. Provides continuous adjustments

of

volts/div between calibrated positions of

VOLTS/DIV switch.

VOLTS/DIV. Selects vertical deflection

factor necessary for calibrated measurements

ext horiz VERNIER. Permits

1O:l

hori-

zont

a1

amplifier gain.

EXT HORIZ INPUT. Input to external

amplifier.

Z AXIS INPUT. Z-axis input connector.

AC LINE. Power input from ac line. Power

module contains ac line fuse (0.50 amp slow-

blow for 125V, 0.25 amp slow-blow for 230V)

and line selector switch.

POWER MODE. Selects dc line, ac line or in-

tern

a1

battery operati on.

DC LINE. Power input for dc line operation.

FUSE.

2

amp slow-blow fuse for all modes of

operation except DC LINE

(3

amp used in DC

LINE).

Figure

3-1.

Controls and Connectors (Cont’d)

3-3

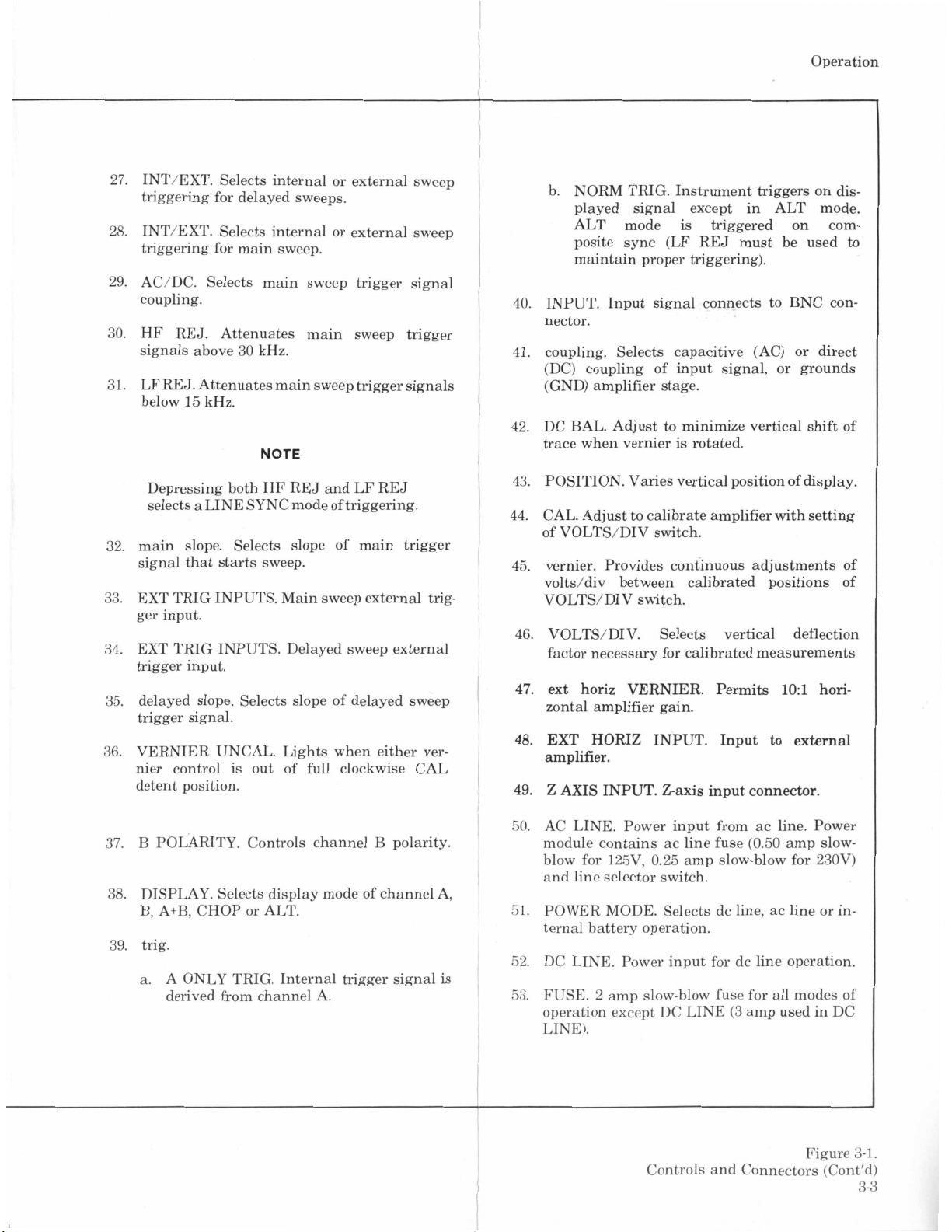

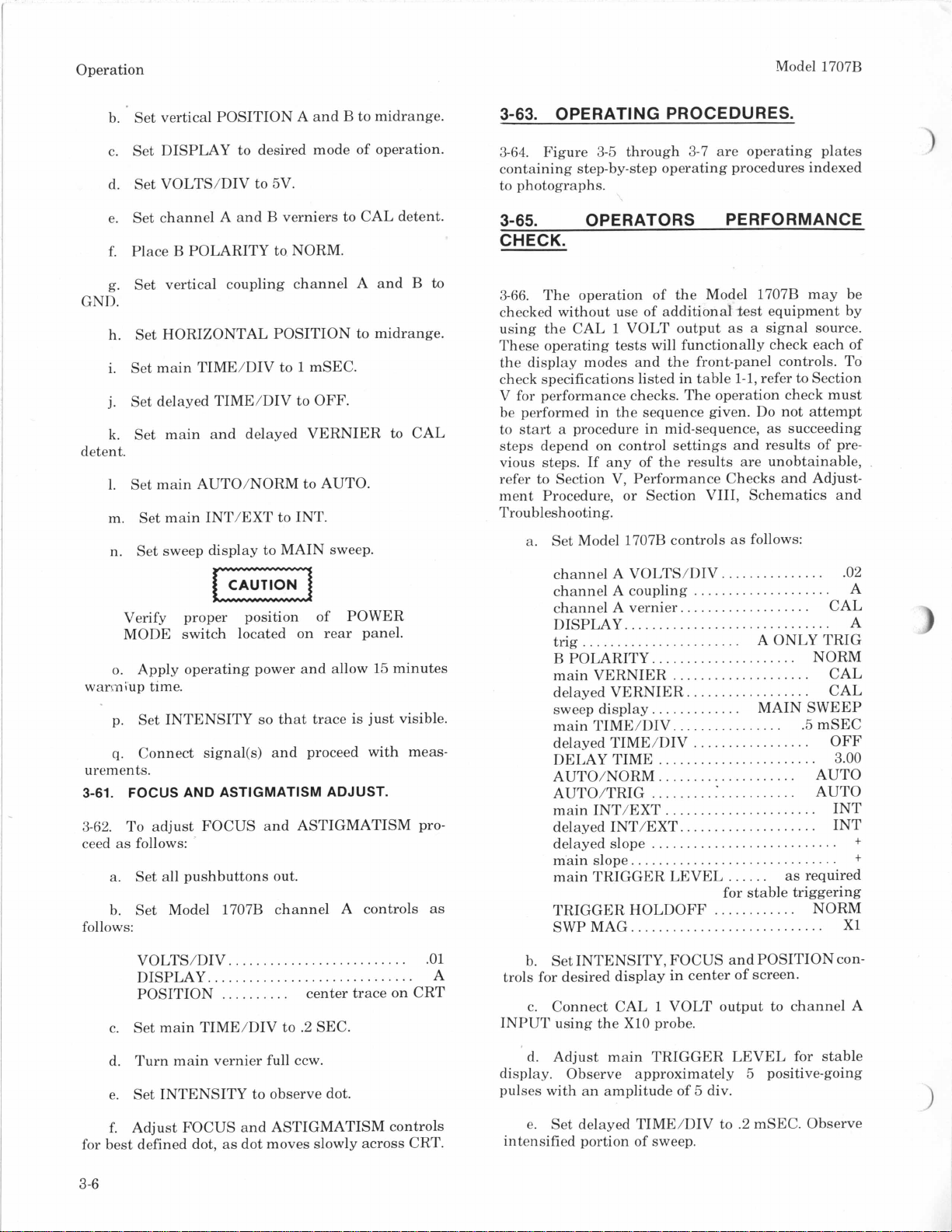

Operation

Model

1707B

the most stable triggering. If the two signals are

not time related, then NORM TRIG should be used.

3-24. TRIG.

3-25. This switch selects the signal to be used

as

the internal trigger signal. In A ONLY TRIG position,

the signal on channel A is used

as

the internal

trig-

ger signal. In NORM TRIG position, the instrument

triggers on the signal being displayed, except in ALT

mode. In ALT mode, the instrument triggers on the

composite sync signal and LF REJ trigger coupling

should be used to maintain stable triggering.

3-26.

B

POLARITY.

3-27. This switch inverts the channel B display

180 degrees. This switch can also be used to present

an A-B display. Set DISPLAY to A+B mode. Put

R

POLARITY switch in INVT position. Display

observed is A-B.

3-28. SWEEP DISPLAY.

3-29. This switch, mounted concentric to the main

and delayed TIME/DIV controls, determines the hori-

zontal sweep display modes. Modes are EXT HORIZ

INPUT, MAIN SWEEP, MIXED SWEEP and DE-

LAYED SWEEP. The function of each mode is

as

fol-

lows:

3-30. EXT

HORIZ

INPUT.

3-31.

driven by an external source.

In this mode, the CRT horizontal plates are

3-32. MAIN SWEEP.

3-33. In this mode, the main sweep sets

a

time

base reference €or the vertical signal. Main sweep

controls are mounted on the right side of the front

panel, and sweep speed

is

selected by main TIME/

DIV. If delayed TIME/DIV is set to OFF, sweep

intensity is uniform. However, any other setting

of delayed ’I’IME/DIV causes the sweep to intensify

during the time that the delayed sweep is generated.

This

feature makes it possible to select

a

point of

interest on the main sweep time base before viewing

in the delayed sweep mode.

3-34. MIXED SWEEP.

3-35. In this mode, the first portion of signal

is

referenced to the main time base and the expanded

portion is referenced to the delayed time base.

Turning the

DELAY

TIME control varies the amount

of display controlled by the delayed time base.

3-36. DELAYED SWEEP.

3-37. Main sweep is not displayed in this mode.

The sweep speed

is

controlled by delayed TIME/

DIV.

3-38. TIME/DIV.

3-39. Main and delayed TIMEIDIV switches

determine the amount of time to sweep horizontally

one graticule division. Both switches are concentric

and interlocked

so

the delayed sweep

is

always

faster than the main sweep, Mairi sweep speeds are

selectable by main TIME/DIV in 23 ranges from 0.1

usecldiv to 2 sec/div. Twenty ranges of delayed

sweep speeds from 0.1 usec/div to 0.2 sec/div are

provided by delayed TIME/DIV. By using the

SWP

MAG switch,

a

display can be expanded 10

times, increasing the fastest sweep to 10 ns/div.

3-40. VERNIER.

3-41.

Sweep speeds are calibrated to the TIME/DIV

switch when both the main and delayed VERNIER

controls are set fully clockwise to the CAL detent

position. As the VERNIER controls are turned

counterclockwise, the VERNIER UNCAL indicator

lights and sweep speeds decrease. The main VER-

NIER control extends the slowest sweep to

at

least

5

sec/div. The vernier controls are useful for making

continuous adjustments of sweep speed, however,

TIME/DIV readings are uncalibrated.

3-42. TRIGGER LEVEL.

3-43. These controls select the point on the sync

signal that starts the sweep. Triggering point is

adjustable

at

any level on the displayed signal in

INT position.

In the EXT position, the triggering

point is adjustable from +1.2V to -1.2V along the

sync signal. Delayed TRIGGER LEVEL has no

function when AUTO/TRIG

is

set to AUTO.

3-44. TRIGGER HOLDOFF.

3-45. This adjustment

is

a

dual purpose control.

When the control is rotated out of detent position,

the first portion of the control acts

as

a

high

frequency stability control.

This

prevents double

trig-

gering on

high

frequency waveforms.

As

the control

is

rotated further out of detent position,

it

functions

as

a