Hitachi CS 33EB User Manual

Model

Modèle

Modelo

CS 33EB

Chain Saw

Tronçonneuse

Motosierra

SAFETY INSTRUCTIONS AND INSTRUCTION MANUAL

WARNING

WARNING

IMPROPER OR UNSAFE use of this power tool can result in death or serious bodily injury!

This manual contains important information about product safety. Please read and understand this manual BEFORE operating the power tool. Please keep this manual available for other users and owners before they use the power tool. This manual should be stored in safe place.

INSTRUCTIONS DE SECURITE ET MODE D’EMPLOI

AVERTISSEMENT

AVERTISSEMENT

Une utilisation INCORRECTE OU DANGEREUSE de cet outil motorisé peut entraîner la mort ou de sérieuses blessures corporelles !

Ce mode d’emploi contient d’importantes informations à propos de la sécurité de ce produit. Prière de lire et de comprendre ce mode d’emploi AVANT d’utiliser l’outil motorisé. Garder ce mode d’emploi à la disponibilité des autres utilisateurs et propriétaires avant qu’ils utilisent l’outil motorisé. Ce mode d’emploi doit être conservé dans un endroit sûr.

INSTRUCCIONES DE SEGURIDAD Y MANUAL DE INSTRUCCIONES

ADVERTENCIA

ADVERTENCIA

¡La utilización INAPROPIADA O PELIGROSA de esta herramienta eléctrica puede provocar lesiones graves o la muerte!

Este manual contiene información importante sobre la seguridad del producto. Lea y comprenda este manual ANTES de utilizar la herramienta eléctrica. Guarde este manual para que puedan leerlo otras personas antes de utilizar la herramienta eléctrica. Este manual debe ser guardado en un lugar seguro.

English

MEANINGS OF SYMBOLS

NOTE: Some units do not carry them.

Symbols

WARNING

The following show symbols used for the machine. Be sure that you understand their meaning before use.

It is important that you read, fully understand and observe the following safety precautions and warnings. Careless or improper use of the unit may cause serious or fatal injury.

Read, understand and follow all warnings and instructions in this manual and on the unit.

Always wear eye, head and ear protectors when using this unit.

Warning, kickback danger. Be careful of possible sudden and accidental upward and/or backward motion of the guide bar.

One-handed usage not permitted. While cutting, hold saw firmly with both hands with thumb firmly locked around front handle.

Contents |

|

WHAT IS WHAT? ................................................... |

3 |

WARNINGS AND SAFETY INSTRUCTIONS......... |

4 |

SPECIFICATIONS.................................................. |

7 |

ASSEMBLY PROCEDURES .................................. |

8 |

OPERATING PROCEDURES................................. |

9 |

MAINTENANCE ................................................... |

15 |

Parts breakdown |

|

2

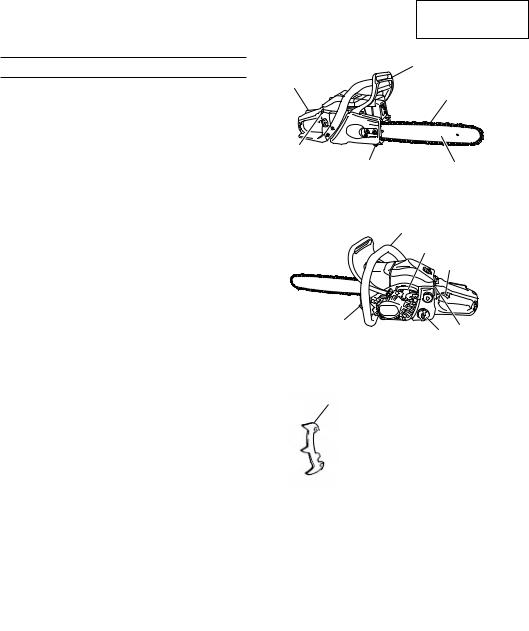

WHAT IS WHAT?

1.Throttle trigger: Device activated by the operatorʼs finger, for controlling the engine speed.

2.Throttle trigger lockout (Safety trigger): Device that prevents the accidental operation of the throttle trigger until manually released.

3.Ignition switch: Device for allowing the engine to be started or stopped.

4.Oil tank cap: For closing the oil tank.

5.Recoil starter: Pull handle to start the engine.

6.Front handle: Support handle located at or towards the front of the engine housing.

7.Fuel tank cap: For closing the fuel tank.

8.Choke control knob: Device for enriching the fuel/air mixture in the carburetor, to aid starting.

9.Guide bar: The part that supports and guides the saw chain.

10.Saw chain: Chain, serving as a cutting tool.

11.Chain brake (Front hand guard): Device for stopping or locking the chain.

12.Spiked bumper (optional): Device for acting as a pivot when in contact with a tree or log.

13.Chain catcher: device for restraining the saw chain.

14.Guide bar cover: Device for covering the guide bar and saw chain when the unit is not being used.

15.Combi box spanner: The tool for removing or installing a spark plug and tensioning the saw chain.

16.Handling instructions: Included with unit. Read before operation and keep for future reference to learn proper, safe techniques.

English

11

2

10

8

13 |

|

9 |

|

6 |

|

|

5 |

1 |

|

|

|

4 |

7 |

3 |

|

||

12 |

14 |

|

16

15

3

English

WARNINGS AND SAFETY

INSTRUCTIONS

Operator safety

○Always wear a safety face shield or goggles.

○Always use the gloves to reduce the e ects of vibration.

○Gloves should be used when sharpening chain.

○Always wear safety protective equipment such as jacket, trousers, gloves, helmet, boots with steel toe-caps and non-slip soles whenever you use a chain saw. For working in trees the safety boots must be suitable for climbing techniques. Do not wear loose clothing, jewelry, short pants, sandals or go barefoot.

Secure hair so it is above shoulder length.

○ Do not operate this tool when you are tired, ill or under the influence of alcohol, drugs or medication.

○Never let a child or inexperienced person operate the machine.

○Wear hearing protection. Pay attention to your surroundings.

Be aware of any bystanders who may be signaling a problem.

Remove safety equipment immediately upon shutting o engine.

○Wear head protection.

○Never start or run the engine inside a closed room or building.

Breathing exhaust fumes can kill.

○For respiratory protection, wear a protection mask while emitting the chain oil mist and dust from sawdust.

○Keep handles free of oil and fuel.

○Keep hands away from cutting equipment.

○Do not grab or hold the unit by the cutting equipment.

○When the unit turned o , make sure the cutting attachment has stopped before the unit is set down.

○When operation is prolonged, take a break from time to time so that you may avoid possible Hand-Arm Vibration Syndrome (HAVS) which is caused by vibration.

○The operator must obey the local regulations of cutting area.

WARNING

●Antivibration systems do not guarantee that you will not sustain Hand-Arm Vibration Syndrome or carpal tunnel syndrome.

Therefore, continual end regular users should monitor closely the condition of

their hands and fingers. If any of the above symptoms appear, seek medical advice immediately.

●Long or continuous exposure to high noise levels may cause permanent hearing impairment. Always wear approved hearing protection when operating a unit/machine.

●If you are using any medical electric/ electronic devices such as a pacemaker, consult your physician as well as the device manufacturer prior to operating any power equipment.

Unit/machine safety

○Inspect the entire unit/machine before each use. Replace damaged parts. Check for fuel leaks and make sure all fasteners are in place and securely tightened.

○Replace parts that are cracked, chipped or damaged in any way before using the unit/ machine.

○Make sure the side case is properly attached.

○Keep others away when making carburetor adjustments.

○Use only accessories as recommended for this unit/machine by the manufacturer.

○Never let the chain strike any obstacle. If the chain makes contact, the machine should be stopped and checked carefully.

○Make sure the automatic oiler is working. Keep the oil tank filled with clean oil. Never let chain run dry on the bar.

○All chain saw service, other than the items listed in the operatorʼs/ ownerʼs manual, should be performed by competent chain-saw service personnel. (For example, if improper tools are used to remove the flywheel or if an improper tool is used to hold the flywheel in order to remove the clutch, structural damage to the flywheel could occur and could subsequently cause the flywheel to burst.)

WARNING

●Never modify the unit/machine in any way. Do not use your unit/machine for any job except that for which it is intended.

●Never use chain saw without any safety equipment or that has faulty safety equipment. It could result in serious personal injury.

●Using guide bar/chain other than recommended by the manufacturer which are not approved, could result in a high risk of personal accidents or injury.

4

Fuel safety

○Mix and pour fuel outdoors and where there are no sparks or flames.

○Use a container approved for fuel.

○Do not smoke or allow smoking near fuel or the unit/machine or while using the unit/machine.

○Wipe up all fuel spills before starting engine.

○Move at least 3 m away from fueling site before starting engine.

○Stop engine before removing fuel cap.

○Empty the fuel tank before storing the unit/ machine. It is recommended that the fuel be emptied after each use. If fuel is left in the tank, store so fuel will not leak.

○Store unit/machine and fuel in area where fuel vapors cannot reach sparks or open flames from water heaters, electric motors or switches, furnaces, etc.

WARNING

Fuel is easy to ignite or get explosion or inhale fumes, so that pay special attention when handling or filling fuel.

Cutting safety

○Do not cut any material other than wood or wooden objects.

○For respiratory protection, wear an aerosol protection mask when cutting the wood after insecticide has been applied.

○Keep others including children, animals, bystanders and helpers outside the hazard zone. Stop the engine immediately if you are approached.

○Hold the unit/machine firmly with the right hand on the rear handle and the left hand on the front handle.

○Keep firm footing and balance. Do not overreach.

○Keep all parts of your body away from the mu er and cutting attachment when the engine is running.

○Keep Bar/Chain below waist level.

○Before felling a tree, the operator must be accustomed to the sawing techniques of the chain saw.

○Be sure to pre-plan a safe exit from a failing tree.

○While cutting, hold saw firmly with both hands with thumb firmly locked around front handle, and stand with feet well balanced and your body balanced.

○Stand to the side of the saw when cutting - never directly behind it.

English

○Always keep the spiked bumper face to a tree, because the chain may suddenly be drawn into a tree, if so equipped.

○When completing a cut, be ready to hold up the units as it breaks into clear, so it will not follow through and cut your legs, feet or body, or contact an obstruction.

○Be alert against kickback (when saw kicks up and back at operator). Never cut with the nose of the bar.

○When relocating to a new work area, be sure to shut o the machine and ensure that all cutting attachments are stopped.

○Never place the machine on the ground when running.

○Always ensure that the engine is shut o and any cutting attachments have completely stopped before clearing debris or removing grass from the cutting attachment.

○Always carry a first-aid kit when operating any power equipment.

○Never start or run the engine inside a closed room or building and/or near the inflammable liquid. Breathing exhaust fumes can kill.

Maintenance safety

○Maintain the unit/machine according to recommended procedures.

○Disconnect the spark plug before performing maintenance except for carburetor adjustments.

○Keep others away when making carburetor adjustments.

○Use only genuine HITACHI replacement parts as recommended by the manufacturer.

CAUTION

Do not disassemble the recoil starter. You may get a possibility of personal injury with recoil spring.

WARNING

Improper maintenance could result in serious engine damage or in serious personal injury.

Transport and storage

○Carry the unit/machine by hand with the engine stopped and the mu er away from your body.

○Allow the engine to cool, empty the fuel tank, and secure the unit/machine before storing or transporting in a vehicle.

○Empty the fuel tank before storing the unit/ machine. It is recommended that the fuel be emptied after each use. If fuel is left in the tank, store so fuel will not leak.

5

English

○Store unit/machine out of the reach of children.

○Clean and maintain the unit carefully and store it in a dry place.

○Make sure engine switch is o when transporting or storing.

○When transporting in a vehicle or storage, cover

chain with chain cover.

If situations occur which are not covered in this manual, take care and use common sense. Contact HITACHI dealer if you need assistance. Pay special attention to statements preceded by the following words:

WARNING

Indicates a strong possibility of severe personal injury or loss of life, if instructions are not followed.

CAUTION

Indicates a possibility of personal injury or equipment damage, if instructions are not followed.

NOTE

Helpful information for correct function and use.

6

|

|

|

|

English |

|

SPECIFICATIONS |

|

|

|

|

|

Model |

CS33EB (30P) |

CS33EB (35P) |

CS33EB (40P) |

CS33EB |

|

Type of equipment |

|

Chain saw, portable |

|

||

Engine Size (cu. in.) |

|

1.96 (32.2 ml) |

|

||

Spark Plug |

|

NGK BPM-6A or equivalent |

|

||

Fuel Tank Capacity (US pint) |

|

0.74 (350 ml) |

|

||

Chain Oil Tank Capacity (US pint) |

|

0.53 (250 ml) |

|

||

Dry Weight (lbs) |

|

8.4 (3.8 kg) |

|

||

(Without guide bar and chain) |

|

|

|||

|

|

16 |

|

||

Guide bar length (in.) |

12 (300 mm) |

14 (350 mm) |

— |

||

(400 mm) |

|||||

|

|

|

|

||

Chain pitch (in.) |

|

3/8 (9.52 mm) |

|

||

Chain gauge (in.) |

|

0.05 (1.27 mm) |

|

||

Sound pressure level |

|

92 |

|

||

LpA (dB (A)) |

|

|

|||

by ISO 22868 |

|

110 |

|

||

Sound power level |

|

|

|||

Lw measured (dB (A)) |

|

|

|

|

|

by ISO 22868 |

|

113 |

|

||

Sound power level LwA (dB (A)) |

|

|

|||

by 2000/14/EC |

|

|

|

|

|

Vibration level (m/s2) |

|

|

|

|

|

by ISO 22867 |

8.5 |

9.2 |

9.7 |

— |

|

Front handle |

|||||

Rear handle |

8.0 |

6.7 |

6.7 |

— |

|

Max. engine power |

|

1.2/9,500 |

|

||

by ISO 7293 (kW) |

|

|

|||

|

|

|

|

||

Max. engine speed (min-1) |

|

12,500 |

|

||

Idle engine speed (min-1) |

|

3,100 |

|

||

Specific fuel consumption (g/kWh) |

|

500 |

|

||

Type of chain |

|

91VG |

|

||

|

(Oregon) |

|

|||

|

|

|

|||

Max. chain speed (m/sec) |

|

23.8 |

|

||

Sprocket (number of teeth) |

|

|

6 |

|

|

NOTE: Equivalent noise level/vibration levels are calculated as the time-weighted energy total for noise/ vibration levels under various working conditions with the following time distribution: 1/3 idle, 1/3 full, 1/3 racing speed.

* All data subject to change without notice.

7

English

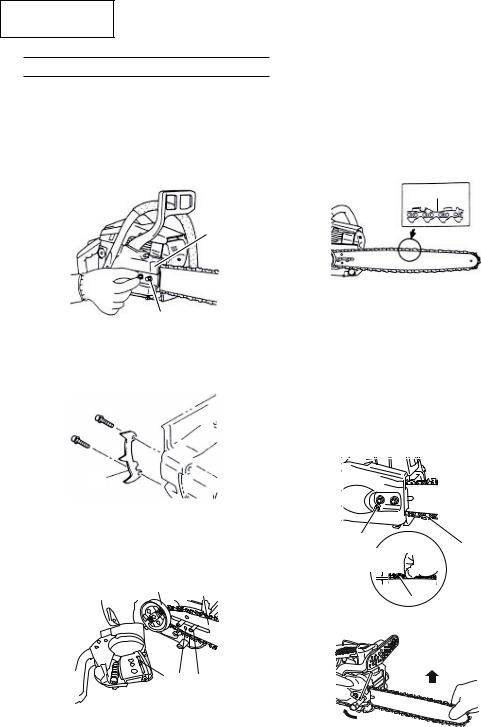

ASSEMBLY PROCEDURES

WARNING

Never try to start engine without side case securely fastened.

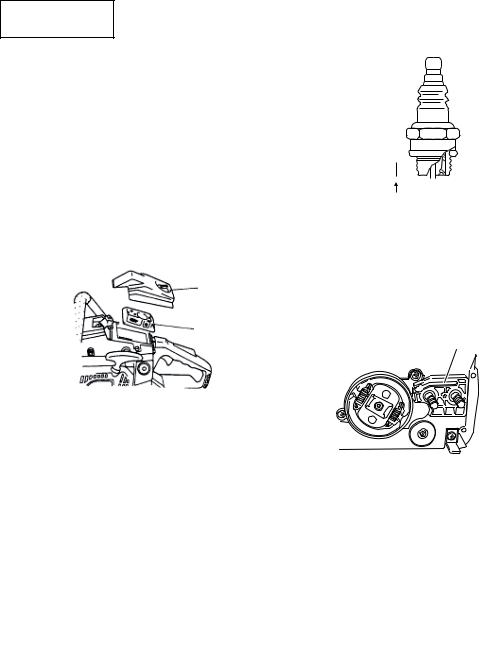

1.Remove chain bar clamp nuts (1).

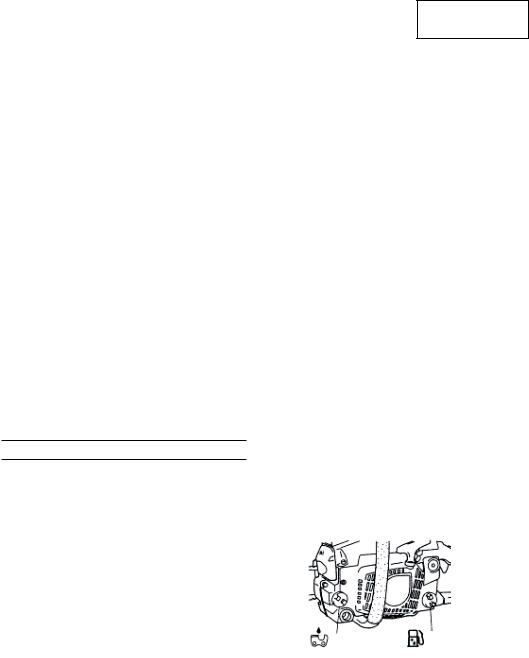

2.Remove the side case (2) as pinching the rear part of the side case (2). (Fig. 1)

2

1

Fig. 1

*In case of installing the spiked bumper (3), install the spiked bumper (3) (if so equipped) to the unit with two screws. (Fig. 2)

3

Fig. 2

3.Install the chain bar (4) onto the bolts (5), then push it toward the sprocket (6) as far as it will go. Make sure that the boss of chain tension adjust bolt (7) fits into the hole of the bar (8). (Fig. 3)

6 4

NOTE

Slightly move the bar back and forth and make sure the chain tension boss (7) fits into the hole

(8) in the bar properly. (Fig. 3)

4.Confirm the direction of saw chain (9) is correct as in the figure, and align the chain on the sprocket. (Fig. 4)

9

Fig. 4

5.Guide the chain drive links into the bar groove all around the bar.

6.Install the side case (2) onto the bolts (5).

Then tighten the clamp nuts (1) temporarily. (Fig. 1)

7.Raise the bar end, and tighten the chain (9) by turning the tension adjustment bolt (10) clockwise. To check proper tension, lightly lift up the center of chain and there should be about 0.02 – 0.04 ″ (0.5 – 1.0 mm) clearance between bar and edge of drive link (11). (Fig. 5, 6)

10 |

9 |

|

0.02 – 0.04 ″ |

||

|

||

(0.5 – 1 mm) |

|

11 Fig. 5

7 8 5

Fig. 3

Fig. 6

8

CAUTION

PROPER TENSION IS EXTREMELY IMPORTANT

8.Raise the bar end and securely tighten the chain bar clamp nuts with the combi box spanner. (Fig. 6)

9.A new chain will stretch so adjust the chain after a few cuts and watch chain tension carefully for the first half hour of cutting.

NOTE

Check the chain tension frequently for optimum performance and durability.

CAUTION

●When the chain is excessively tightened, the bar and chain will be damaged rapidly. Conversely, when the chain is excessively loosened, it may get out of the groove in the bar.

●Always wear gloves when touching the chain.

WARNING

During operation, hold chain saw firmly with both hands. A single hand operation may cause serious injury.

OPERATING PROCEDURES

Fuel (Fig. 7)

Fig. 7

WARNING

●The chain saw is equipped with a two-stroke engine. Always run the engine on fuel, which is mixed with oil. Provide good ventilation, when fueling or handling fuel.

●Fuel contains highly flammable and it is possible to get the serious personal injury when inhaling or spilling on your body. Always pay attention when handling fuel. Always have good ventilation when handling fuel inside building.

English

Fuel

○Always use branded 89 octane unleaded gasoline.

○Use genuine two-cycle oil or use a mix between 25:1 to 50:1, please consult the oil bottle for the ratio or HITACHI dealer.

○Only for the state of California at 50:1.

○If genuine oil is not available, use an anti-oxidant added quality oil expressly labeled for air-cooled 2-cycle engine use (JASO FC GRADE OIL or ISO EGC GRADE). Do not use BIA or TCW (2-stroke water-cooling type) mixed oil.

○Never use multi-grade oil (10 W/30) or waste oil.

○Always mix fuel and oil in a separate clean container.

Always start by filling half the amount of gasoline, which is to be used.

Then add the whole amount of oil. Mix (shake) the fuel mixture. Add the remaining amount of gasoline. Mix (shake) the fuel-mix thoroughly before filling the fuel tank.

Fueling

WARNING (Fig. 8)

●Always shut o the engine before refueling.

●Slowly open the fuel tank (12), when filling up with fuel, so that possible overpressure disappears.

●Tighten the fuel cap carefully, after fueling.

●Always move the unit at least 10 ft. (3 m) from the fueling area before starting.

●Always wash any spilled fuel from clothing immediately with soap.

●Be sure to check any fuel leaking after refueling.

13 |

12 |

Fig. 8

Before fueling, clean the tank cap area carefully, to ensure that no dirt falls into the tank. Make sure that the fuel is well mixed by shaking the container, before fueling.

9

English

Chain oil (Fig. 8)

Fill up with chain oil (13). Always use good quality chain oil. When the engine is running, the chain oil is automatically discharged.

NOTE

When pouring fuel (12) or chain oil (13) into the tank, place the unit with cap side up. (Fig. 8)

Starting (Fig. 9, 10)

CAUTION

Before starting, make sure chain brake is disengaged (if so equipped) and that the bar/ chain does not touch anything.

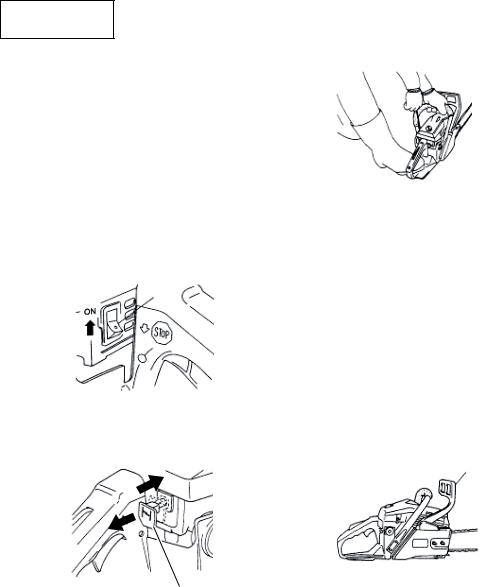

1. Set ignition switch (14) to ON position. (Fig. 9)

14

Fig. 9

2.Pull the choke lever (15) down to choked position (Fig. 10). This will automatically lock the throttle in starting position. (Fig. 9)

15

Fig. 10

3.Pull recoil starter briskly, taking care to keep the handle in your grasp and not allowing it to snap back. (Fig. 9)

4.When you hear first ignition, return the choke to run position. (Fig. 10)

5.Pull recoil starter briskly again in the aforementioned manner. (Fig. 11)

After engine starts, make sure the chain brake is disengaged.

Fig. 11

NOTE

If engine does not start, repeat procedures from 2 to 5.

6.After starting engine, allow the engine about 2–3 minutes to warm up before subjecting it to any load.

Chain brake operation (Fig. 12)

Chain brake (16), if so equipped, is designed to activate in an emergency such as kick-back action. Please check to verify that it works properly before use.

Application of brake is made by moving the front guard towards the bar. During the chain brake operation, even if the throttle lever is pulled, the engine speed does not increase and the chain does not turn. To release the brake, pull up the chain brake lever.

16

16

Fig. 12

How to confirm:

1)Turn o the engine.

2)Holding the chain saw horizontally, release your hand from the front handle, hit the tip of the guide bar to a stump or a piece of wood, and confirm brake operation. Operating level varies by bar size.

10

In case the brake is not e ective, ask our dealer for inspection and repairs. If the engine keeps rotating at high speed with the brake engaged, the clutch will overheat causing trouble.

When the brake engages during operation, immediately release the throttle lever to stop the engine.

WARNING

Do not carry the machine with the engine running.

Stopping (Fig. 13)

Decrease engine speed, and push ignition switch (14) to stop position.

14

Fig. 13

WARNING

KICKBACK DANGER (Fig. 14)

17

Fig. 14

One of the most severe dangers when working with a chain saw is the possibility of kickback. Kickback may occur when the upper tip of the guide bar touches an object, or when the wood closes in and pinches the saw chain in the cut. Tip contact in some cases may cause a lightning fast reverse reaction, kicking the guide bar up and back toward you. Pinching the saw chain along the top of the guide bar may also push the guide bar rapidly back

English

towards you. Either of these reactions may cause you to lose control of the saw which could result in serious personal injury. Even though your saw has safety built into its design, you should not rely on these safety features exclusively. Know where your bar tip is at all times. Kickback does occur if you allow the kickback zone (17) of the bar to touch an object. Do not use that area. Kickback from pinching is caused by a cut closing and pinching the upper side of the guide bar. Study your cut and make sure it will open as you cut through. Maintain control when the engine is running by always keeping a firm grip on the saw with your right hand on the rear handle, your left hand on the front handle and your thumbs and fingers encircling the handles. Always hold the saw with both hands during operation and cut at high engine speed.

WARNING

●Do not overreach or cut above shoulder height.

●Use extra caution when felling, and do not use the saw in a nose-high position or above shoulder height.

CHAIN CATCHER

The chain catcher is located on the power head just below the chain to further prevent the possibility of a broken chain striking the chain saw user.

WARNING

Do not stand in-line with chain when cutting.

BASIC TECHNIQUES FOR MAKING FELLING, LIMBING AND BUCKING CUTS

The intention of the following information is to provide you with the general introduction to wood cutting techniques.

WARNING

● This information does not cover all specific situations, which may depend on di erences in terrain, vegetation, kind of wood, form and size of trees, etc. Consult your servicing dealer, forestry agent or local forestry schools for advice on specific woodcutting problems in your area. This will make your work more e cient and safer.

● Avoid cutting in adverse weather conditions, such as dense fog, heavy rain, bitter cold, high winds, etc.

Adverse weather is often tiring to work in and creates potentially dangerous conditions such as slippery ground.

11

English

High winds may force the tree to fall in an unexpected direction causing property damage or personal injury.

CAUTION

Never use a chain saw to pry or for any purpose for which it is not intended.

WARNING

●Avoid stumbling on obstacles such as stumps, roots, rocks, branches and fallen trees. Watch out for holes and ditches. Be extremely cautious when working on slopes or uneven ground.

Shut o the saw when moving from one work place to another.

Always cut at wide open throttle. A slow moving chain can easily catch and force the saw to jerk.

●Never use the saw with only one hand.

You cannot control the saw properly and you may lose control and injure yourself severely.

Keep the saw body close to your body to improve control and reduce strain.

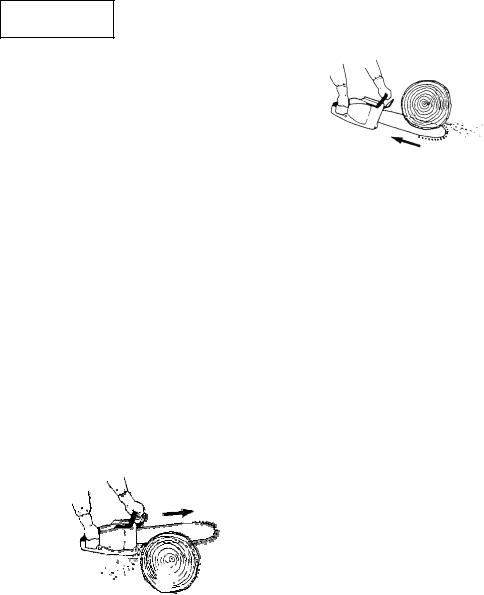

When cutting with the bottom part of the chain the reactive force will pull the saw away from you towards the wood you are cutting.

The saw will control the feeding speed and sawdust will be directed towards you. (Fig. 15)

Fig. 15

●When cutting with the upper part of the chain the reactive force will push the saw towards you and away from the wood you are cutting. (Fig. 16)

12

Fig. 16

●There is a risk of kickback if the saw is pushed far enough so that you begin to cut with the nose of the bar.

The safest cutting method is to cut with the bottom part of the chain. Sawing with the upper part makes it much more di cult to control the saw and increases the risk of kickback.

●In case the chain locked, immediately release the throttle lever.

If the throttle lever keeps rotating at high speed with the chain locked, the clutch will overheat causing trouble.

NOTE

Always keep the spiked bumper face to a tree, because the chain may suddenly be drawn into a tree.

FELLING

Felling is more than cutting down a tree. You must also bring it down as near to an intended place as possible without damaging the tree or anything else. Before felling a tree, carefully consider all conditions which may e ect the intended direction, such as:

Angle of the tree. Shape of the crown. Snow load on the crown.

Wind conditions. Obstacles within tree range (e.g., other trees, power lines, roads, buildings, etc.).

WARNING

●Always observe the general conditions of the tree. Look for decay and rot in the trunk which will make it more likely to snap and start to fall before you expect it.

●Look for dry branches, which may break and hit you when you are working.

Always keep animals and people at least twice the tree length away while felling. Clear away shrubs and branches from around the tree.

Prepare a path of retreat away from the felling direction.

BASIC RULES FOR FELLING TREES

Normally the felling consists of two main cutting operations, notching and making the felling cut. Start

making the upper notch cut on the side of the tree facing the feeling direction. Look through the kerf as you saw the lower cut so you do not saw too deep into the trunk. The notch should be deep enough to create a hinge of su cient width and strength. The notch opening should be wide enough to direct the fall of the tree as long as possible. Saw the felling cut from the other side of the tree between one and two inches (3–5 cm) above the edge of the notch. (Fig. 17)

18

19

21 20 Fig. 17

18.Felling direction

19.45° minimum notch opening

20.Hinge

21.Felling cut

Never saw completely through the trunk. Always leave a hinge.

The hinge guides the tree. If the trunk is completely cut through, you lose control over the felling direction.

Insert a wedge or a felling lever in the cut well before the tree becomes unstable and starts to move. This will prevent the guide bar from binding in the felling cut if you have misjudged the falling direction. Make sure no people have come into the range of the falling tree before you push it over.

FELLING CUT, TRUNK DIAMETER MORE THAN TWICE GUIDE BAR LENGTH

Cut a large, wide notch. Then cut a recess into the center of the notch. Always leave a hinge on both sides of the center cut. (Fig. 18)

English

Complete the felling cut by sawing around the trunk as in the Fig. 19.

Fig. 19

WARNING

These methods are extremely dangerous because they involve the use of the nose of guide bar and can result in kickback.

Only properly trained professionals should attempt these techniques.

LIMBING

Limbing is removing the branches from a feller tree.

WARNING

A majority of kickback accidents occur during Iimbing.

Do not use the nose of the guide bar. Be extremely cautious and avoid contacting the log, other limbs or objects with the nose of the guide bar. Be extremely cautious of limbs under tension. They can spring back towards you and cause loss of control resulting in injury. (Fig. 20)

Fig. 20

Stand on the left side of the trunk. Maintain a secure footing and rest the saw on the trunk. Hold the saw close to you so that you are in full control of it. Keep well away from the chain. Move only when the trunk is between you and the chain. Watch out for spring back of limbs under tension.

Fig. 18 |

13 |

|

English

LIMBING THICK BRANCHES

When limbing thick branches, the guide bar may get pinched easily. Branches under tension often snap up, so cut troublesome branches in small steps. Apply the same principles as for cross cutting. Think ahead and be aware of the possible consequences of all your actions.

CROSS CUTTING/BUCKING

Before starting to cut through the log, try to imagine what is going to happen. Look out for stresses in the log and cut through it in such a manner that the guide bar will not get pinched.

CROSS CUTTING LOGS, PRESSURE ON TOP

Take a firm stance. Begin with an upper cut. Do not cut too deeply, about 1/3 of the log diameter is enough. Finish with a bottom cut.

The saw cuts should meet. (Fig. 21)

24

2225

26

23

27

Fig. 21

22.Relieving cut

23.Cross cut

24.Pressure on top

25.Pressure side

26.Tension side

27.Relative depth of saw cuts

THICK LOG, LARGER THAN GUIDE BAR LENGTH

Begin by cutting on the opposite side of the log. Pull the saw towards you, followed by previous procedure. (Fig. 22)

Fig. 22

If the log is lying on the ground make a boring cut to avoid cutting into the ground. Finish with a bottom cut. (Fig. 23)

Fig. 23

WARNING

KICKBACK DANGER

Do not attempt a boring cut if you are not properly trained. A boring cut involves the use of the nose of the guide bar and can result in kickback.

CROSS CUTTING LOGS, PRESSURE ON BOTTOM

Take a firm stance. Begin with a bottom cut. The depth of the cut should be about 1/3 of the log diameter.

Finish with an upper cut. The saw cuts should meet. (Fig. 24)

30

29

31

32

28

33

Fig. 24

28.Relieving cut

29.Cross cut

30.Pressure on bottom

31.Tension side

32.Pressure side

33.Relative depth of saw cuts

THICK LOG, LARGER THAN GUIDE BAR LENGTH

Begin by cutting on the opposite side of the log. Pull the saw towards you, followed by previous procedure. Make a boring cut if the log is close to the ground. Finish with a top cut. (Fig. 25)

14

Fig. 25

WARNING

KICKBACK DANGER

Do not attempt a boring cut if you are not properly trained. A boring cut involves the use of the nose of the guide bar and can result in kickback. (Fig. 26)

Fig. 26

IF THE SAW GETS STUCK

Stop the engine. Raise the log or change its position, using a thick branch or pole as a lever. Do not try to pull the saw free. If you do, you can deform the handle or be injured by the saw chain if the saw is suddenly released.

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION CONTROL DEVICES AND SYSTEM MAY BE PERFORMED BY ANY NONROAD ENGINE REPAIR ESTABLISHMENT OR INDIVIDUAL.

English

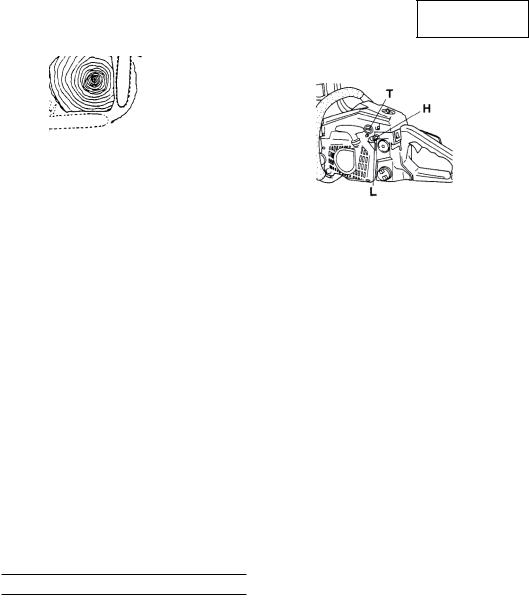

Carburetor adjustment (Fig. 27)

Fig. 27

WARNING

Never start the engine without the complete clutch cover.

Otherwise the clutch can come loose and cause personal injuries.

In the carburetor, fuel is mixed with air. When the engine is test run at the factory, the carburetor is adjusted. A further adjustment may be required, according to climate and altitude. The carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air filter is clean. When the idle speed is correct, the cutting attachment will not rotate. If adjustment is required, close (clockwise) the T-screw, with the engine running, until the cutting attachment starts to rotate. Open (counterclockwise) the screw until the cutting attachment stops. You have reached the correct idle speed when the engine runs smoothly in all positions well below the rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed adjustment, contact HITACHI dealer.

WARNING

When the engine is idling the cutting attachment must under no circumstances rotate.

NOTE

Some models sold in areas with strict exhaust emission regulation do not have high and low speed carburetor adjustments. Such adjustments may allow the engine to be operated outside of their emission compliance limits. For these models, the only carburetor adjustment is idle speed.

15

English

If you are not familiar with this type of adjustment, please ask for assistance from your HITACHI dealer.

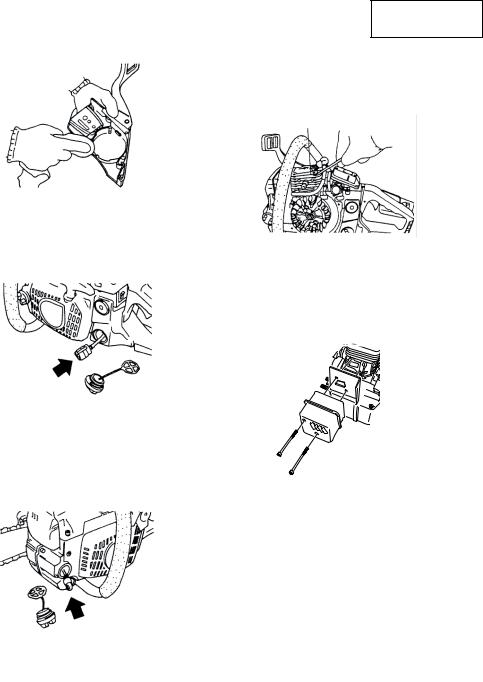

Air filter (Fig. 28)

The air filter (34) must be cleaned from dust and dirt in order to avoid:

○Carburetor malfunctions.

○Starting problems.

○Engine power reduction.

○Unnecessary wear on the engine parts.

○Abnormal fuel consumption.

Clean the air filter daily or more often if working in exceptionally dusty areas.

Cleaning the air filter

Remove the air filter cover (35) and the filter (34).

35

34

Fig. 28

Rinse them in warm soap suds. Check that the filter is dry before reassembly. An air filter that has been used for some time cannot be cleaned completely. Therefore, it must regularly be replaced with a new one. A damaged filter must always be replaced.

Spark plug (Fig. 29)

The spark plug condition is influenced by:

○An incorrect carburetor setting.

○Wrong fuel mixture (too much oil in the gasoline)

○A dirty air filter.

○Hard running conditions (such as cold weather). These factors cause deposits on the spark plug electrodes, which may result in malfunction and starting di culties. If the engine is low on power, di cult to start or runs poorly at idling speed, always check the spark plug first. If the spark plug is dirty, clean it and check the electrode gap. Readjust if necessary. The correct gap is 0.024″ (0.6 mm). The spark plug should be replaced after about 100 operation hours or earlier if the electrodes are badly eroded.

0.024 ″

(0.6 mm)

(0.6 mm)

Fig. 29

NOTE

In some areas, local law requires using a resistor spark plug to suppress ignition signals. If this machine was originally equipped with resistor spark plug, use same type of spark plug for replacement.

Oiler port (Fig. 30)

Clean the chain oiler port (36) whenever possible. 36

Fig. 30

Guide bar (Fig. 31)

Before using the machine, clean the groove and oiler port (37) in the bar with the special gauge o ered as an optional accessory.

37

Fig. 31

Side case (Fig. 32)

Always keep the side case and drive area clean of saw dust and debris. Periodically apply oil or grease to this area to protect from corrosion as some trees contain high levels of acid.

16

Fig. 32

Fuel filter (Fig. 33)

Remove the fuel filter from the fuel tank and thoroughly wash it in solvent. After that, push the filter into the tank completely.

Fig. 33

NOTE

If the filter is hard due to dust and dirt, replace it.

Chain oil filter (Fig. 34)

Remove the oil filter and thoroughly wash it in solvent.

Fig. 34

Cleaning the cylinder fins (Fig. 35)

When wood chips are caught between cylinder fins (38), the engine may overheat, resulting in lower output. To avoid this, always keep cylinder fins and fan case clean.

English

Every 100 operating hours, or once a year (more often if conditions require), clean fins and external surfaces of engine of dust, dirt and oil deposits which can contribute to improper cooling.

38

Fig. 35

Cleaning the mu er (Fig. 36)

Remove the mu er and spark arrestor, if so equipped, and clean out any excess carbon from the exhaust port or mu er inlet every 100 hours of operation.

Fig. 36

For long-term storage

Drain all fuel from the fuel tank. Start and let engine run until it stops. Repair any damage which has resulted from use. Clean the unit with a clean rag, or the use of high pressure air hose. Put a few drops of two-cycle engine oil into the cylinder through the spark plug hole, and spin the engine over several times to distribute oil.

Cover the unit and store it in a dry area.

CHAIN SHARPENING

Parts of a cutter (Fig. 37, 38)

WARNING

●Gloves should be used when sharpening chain.

●Be sure to round o the front edge to reduce the chance of kickback or tie-strap breakage.

17

English

40 39

41 |

|

|

|

|

|

42 |

|

|

|

47 |

|

43 |

44 |

45 |

46 |

||

|

|||||

|

|

Fig. 37 |

|

|

|

|

48 |

49 |

|

|

|

|

|

|

50 |

|

51

Fig. 38

39.Top plate

40.Working corner

41.Side plate

42.Gullet

43.Heel

44.Chassis

45.Rivet hole

46.Toe

47.Depth gauge

48.Correct angle on top plate (degree of angle depends on chain type)

49.Slightly protruding “hook” or point (curve on nonchisel chain)

50.Top of depth gauge at correct height below top plate

51.Front of depth gauge rounded o

LOWERING DEPTH GAUGES WITH A FILE

1)If you sharpen your cutters with a file holder, check and lower the depth.

2)Check depth gauges every third sharpening.

3)Place depth gauge tool on cutter. If depth gauge projects, file it level with the top of the tool. Always file from the inside of the chain toward an outside cutter. (Fig. 39)

Fig. 39

4)Round o front corner to maintain original shape of depth gauge after using depth gauge tool. Always follow the recommended depth gauge setting found in the maintenance or operator manual for your saw. (Fig. 40)

Fig. 40

GENERAL INSTRUCTIONS FOR FILING CUTTERS

File (52) cutter on one side of the chain from the inside out. File on forward stroke only. (Fig. 41)

52

52 |

52 |

Fig. 41

5) Keep all cutters the same length. (Fig. 42)

Fig. 42

6)File enough to remove any damage to cutting edges (side plate (53) and top plate (54)) of cutter. (Fig. 43)

18

53 |

54 |

|

Fig. 43 |

SHARPENING ANGLES FOR SHARPENING SAW CHAIN

1. Part Number |

91VG |

|

2. |

Pitch |

3/8″ |

3. Depth Gauge Setting |

0.025″ |

|

4. |

Side Plate Filing Angle |

80° |

|

|

|

5. Top Plate Angle |

30° |

|

6. |

File Guide Angle |

90° |

Maintenance schedule

Below you will find some general maintenance instructions. For further information please contact HITACHI dealer.

Daily maintenance

○Clean the exterior of the unit.

○Clean the chain oil filter port.

○Clean the groove and oil filter port in the guide bar.

○Clean the side case of saw dust.

○Check that the saw chain is sharp.

○Check that the bar nuts are su ciently tightened.

○Make sure that the chain transport guard is undamaged and that it can be securely fitted.

○Check that nuts and screws are su ciently tightened.

Especially inspect the bolt of mu er and ensure that they are properly tightened before starting engine. Should any of the bolts be loose, retighten them immediately. Failure to do so could result in serious hazard.

○Check the tip of the bar. Please exchange it for the new one when it is worn out.

○Check the band of chain brake. Please exchange it for the new one when it is worn out.

Weekly maintenance

○Check the starter, especially cord and return spring.

○Clean the exterior of the spark plug.

○Remove the spark plug and check the electrode gap. Adjust it to 0.024″ (0.6 mm) or change the spark plug.

English

○Clean the cooling fins on the cylinder and check that the air intake at the starter is not clogged.

○Clean the air filter.

Monthly maintenance

○Rinse the fuel tank with gasoline, and clean fuel filter.

○Clean chain oil filter.

○Clean the exterior of the carburetor and the space around it.

○Clean the fan and the space around it.

○Clean the mu er of carbon.

NOTE

When ordering the parts to your nearest dealer, please use the item numbers showing on the parts breakdown section in this instruction.

MODEL |

|

LENGTH- |

CHAIN NO. |

|

NO. |

BAR NO. |

|||

TYPE |

||||

OREGON |

|

|

||

|

|

|

||

CS33EB |

26779 |

12″(300 mm) |

91VG-045X |

|

|

26780 |

14″(350 mm) |

91VG-052X |

|

|

160NDEA041 |

16″(400 mm) |

91VG-057X |

19

Français

SIGNIFICATION DES SYMBOLES

REMARQUE : Certains appareils n’en sont pas pourvus.

Symboles

ATTENTION

Les symboles suivants sont utilisés pour l’outil. Bien se familiariser avec leur signification avant d’utiliser l’outil.

Il est essentiel que vous lisiez et compreniez parfaitement les consignes de sécurité et autres avertissements suivants et que vous les observiez strictement. L’utilisation inattentive ou inadéquate de cette machine risque de provoquer des blessures graves ou fatales.

Lisez, comprenez et suivez toutes les instructions et tous les avertissements donnés dans ce manuel et sur le produit.

Utilisez toujours des lunettes de protection ainsi qu’une protection pour la tête et les oreilles lorsque vous utilisez ce produit.

Portez une attention particulière aux phénomènes de rebond. Prenez garde aux mouvements possibles soudains et accidentels du guide-chaîne de votre tronçonneuse.

L’utilisation d’une tronçonneuse avec une seule main n’est pas autorisée. Lorsque vous coupez avec votre machine, tenir celle-ci fermement avec les deux mains, le pouce enserrant la poignée avant.

Sommaire |

|

DESCRIPTION ..................................................... |

21 |

PRÉCAUTIONS ET CONSIGNES DE |

|

SÉCURITÉ....................................................... |

22 |

SPÉCIFICATIONS................................................ |

25 |

MONTAGE ........................................................... |

26 |

UTILISATION........................................................ |

27 |

ENTRETIEN ......................................................... |

34 |

Liste des pièces détachées |

|

20

Loading...

Loading...