General ASH12UC, ASH12USCCW, AOH12USCC, ASH9UC, ASH9USCCW Installation Manual

...

SPLIT TYPE ROOM AIR CONDITIONER

INSTALLATION MANUAL

(PART NO. 9312853014-01)

This air conditioner uses new refrigerant HFC (R410A).

The basic installation work procedures are the same as conventional refrigerant (R22) models. However, pay careful attention to the following points:

(1)Since the working pressure is 1.6 times higher than that of conventional refrigerant(R22) models, some of the piping and installation and service tools are special.(See the table below.) Especially, when replacing a conventional refrigerant(R22) model with a new refrigerant R410A model, always replace the conventional piping and flare nuts with the R410A piping and flare nuts.

(2)Models that use refrigerant R410A have a different charging port thread diameter to prevent erroneous charging with conventional refrigerant(R22) and for safety. Therefore, check beforehand.[The charging port thread diameter for R410A is 1/2 threads per inch.]

(3)Be more careful that foreign matter (oil, water, etc.) does not enter the piping than with refrigerant(R22) models. Also, when storing the piping ,securely seal the opening by pinching, taping, etc.

(4)When charging the refrigerant, take into account the slight change in the composition of the gas and liquid phases, and always charge from the liquid phase side whose composition is stable.

Special tools for R410A

Tool name |

Contents of change |

|

|

|

|||

|

Pressure is high and cannot be measured with a conventional gauge. To prevent erroneous |

||||||

Gauge manifold |

mixing of other refrigerants, the diameter of each port has been changed. |

|

|||||

It is recommended the gauge with seals-0.1 to 5.3 MPa (-1 to 53 bar) for high pressure. |

|||||||

|

|||||||

|

-0.1 to 3.8 MPa (-1 to 38 bar) for low pressure. |

|

|

|

|

||

Charge hose |

To increase pressure resistance, the hose material and base size were changed. |

|

|||||

Vacuum pump |

A conventional vacuum pump can be used by installing a vacuum pump adapter. |

|

|||||

Gas leakage detector |

Special gas leakage detector for HFC refrigerant R410A. |

|

|

|

|||

Copper pipes |

|

|

|

|

|

|

|

It is necessary to use seamless copper pipes and it is desir- |

Table 1 Thicknesses of Annealed Copper Pipes |

||||||

able that the amount of residual oil is less than 40 mg/10m. |

|

|

|

|

|

||

|

|

Thickness (mm) |

|||||

Do not use copper pipes having a collapsed, deformed or |

|

|

|||||

Nominal |

Outer diameter |

R410A |

|

[ref.] R22 |

|||

discolored portion (especially on the interior surface). Other- |

|

||||||

diameter |

(mm) |

|

|||||

wise, the expansion value or capillary tube may become |

|

|

|

|

|

||

1/4 |

6.35 |

0.80 |

|

0.80 |

|||

blocked with contaminants. |

|

||||||

|

|

|

|

|

|||

3/8 |

9.52 |

0.80 |

|

0.80 |

|||

As an air conditioner using R410A incurs pressure higher than |

|

||||||

|

|

|

|

|

|||

|

|

|

|

|

|||

when using R22, it is necessary to choose adequate materi- |

|

|

|

|

|

||

als. |

|

|

|

|

|

|

|

Thicknesses of copper pipes used with R410A are as shown in Table1.Never us copper pipes thinner than 0.8mm even when it is available on the market.

WARNING

WARNING

(1)Do not use the existing (for R22) piping and flare nuts.

•If the existing materials are used, the pressure inside the refrigerant cycle will rise and cause breakage, injury, etc.(Use the special R410A materials.)

(2)When installing and relocating the air conditioner, do not mix gases other than the specified refrigerant(R410A) to enter the refrigerant cycle.

•If air or other gas enters the refrigerant cycle, the pressure inside the cycle will rise to an abnormally high value and cause breakage, injury, etc.

For authorized service personnel only.

WARNING

WARNING

(1)For the room air conditioner to operate satisfactory, install it as outlined in this installation manual.

(2)Connect the indoor unit and outdoor unit with the air conditioner piping and cords available standards parts. This installation manual describes the correct connections using the standard accessories and the parts specified in this installation manual.

(3)Have installation work done by authorized service personnel only.

(4)Never cut the power cord, lengthen or shorten the cord, or change the plug.

(5)Also do not use an extension cord.

(6)Plug in the power cord plug firmly. If the receptacle is loose, repair it before using the room air conditioner.

(7)Do not turn on the power until all installation work is complete.

●Be careful not to scratch the air conditioner when handling it.

●After installation, explain correct operation to the customer, using the operating manual.

●Let the customer keep this installation manual because it is used when the air conditioner is serviced or moved.

●The maximum length of the piping is 15 m. The maximum height difference of the piping is 8 m, if the units are further apart than these, correct operation can not be guaranteed.

STANDARD ACCESSORIES

The following installation accessories are supplied.

Use them as required.

Name and Shape Q’ty |

Name and Shape Q’ty |

Wall hook bracket |

Drain pipe |

|

(including drain packing) |

|

(Reverse cycle type only) |

1 |

1 |

Remote |

Cloth tape |

control |

|

unit |

|

1 |

1 |

Battery |

Tapping screw |

2 |

8 |

One set of following parts are necessary in istallation of this product.

Name

Connection pipe assembly

Connection cord (3-conductor)

Wall pipe

Decorative tape

Vinyl tape

Wall cap

Saddle

Drain hose

Tapping screws

Sealant

ELECTRICAL REQUIREMENT

Always make the air conditioner power supply a special branch circuit and provide a special switch and receptacle. Do not extend the power cord.

SELECTING THE MOUNTING POSITION

Decide the mounting position with the customer as follows:

1. INDOOR UNIT

(1)Install the indoor unit level on a strong wall which is not subject to vibration.

(2)The inlet and outlet ports should not be obstructed : the air should be able to blow all over the room.

(3)Install the unit near an electric outlet or special branch circuit.

(4)Do not install the unit where it will be exposed to direct sunlight.

(5)Install the unit where connection to the outdoor unit is easy.

(6)Install the unit where the drain pipe can be easily installed.

(7)Take servicing, etc. into consideration and leave the spaces shown in (Fig. 2). Also install the unit where the filter can be removed.

2. OUTDOOR UNIT

(1)If possible, do not install the unit where it will be exposed to direct sunlight. (If necessary, install a blind that does not interfere with the air flow.)

(2)Do not install the unit where a strong wind blows or where it is very dusty.

(3)Do not install the unit where people pass.

(4)Take you neighbors into consideration so that they are not disturbed by air blowing into their windows or by noise.

(5)Provide the space shown in Fig. 2 so that the air flow is not blocked. Also for efficient operation, leave open three of the four directions front, rear, and both sides.

WARNING

WARNING

Install at a place that can withstand the weight of the indoor and outdoor units and install positively so that the units will not topple or fall.

CAUTION

CAUTION

(1)Do not install where there is the danger of combustible gas leakage.

(2)Do not install near heat sources.

(3)If children under 10 years old may approach the unit, take preventive measures so that they cannot reach the unit.

(4)Install the indoor unit on the wall where the height from the floors more than 230 cm.

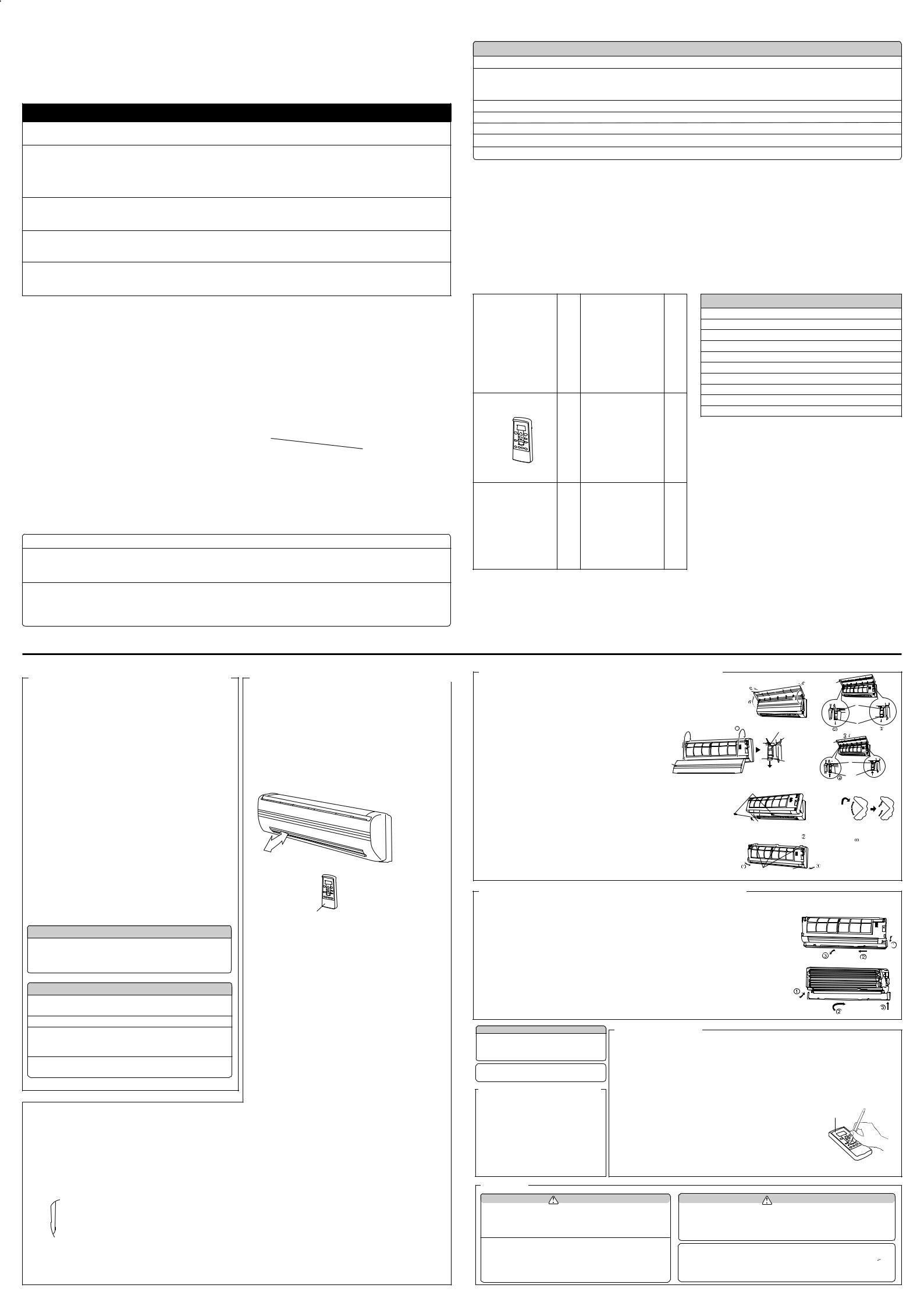

[Indoor unit piping direction]

The piping can be connected in the five directions indicated by 1,

2, 3, 4, and 5 in (Fig. 1). When the piping is connected in direction 2 or 5, cut along the piping groove in the side of the under cover with a hacksaw.

When connecting the piping in direction 3, cut a notch in the thin wall at the front bottom of the under cover.

INSTALLATION DIAGRAM OF

INDOOR AND OUTDOOR UNITS

Fig. 2

[INDOOR UNIT]

|

|

|

Wall hook |

12 cm or over |

bracket |

||

|

|

|

6 cm or over |

|

|

|

12 cm or over |

|

|

|

|

|

|

|

|

Wall cap

150 cm or over

230 cm or over

Remote

control unit

Connection Cord

Conform to Type245 IEC57

[OUTDOOR UNIT] 60 cm or over

5 cm or over

10 cm or over

60 cm or over

25 cm or over

Fig. 1 |

|

|

|

Fig. 3 |

|

|

|

|

|

|

|

|

|

50 cm |

|

(Rear) |

|

5 Left |

|

|

|

|

outlet |

cm |

|

|

|

|

|

|

|

4 Left rear |

|

26.5 |

|

|

|

|

|

2 Right |

1 Rear outlet |

outlet |

|

|

outlet |

|

|

|

|

|

3 Bottom outlet |

|

|

|

FRONT PANEL REMOVAL AND INSTALLATION

The intake grille removal |

|

|

Grill |

|

||

(1) |

Open the intake grille. |

|

Intake grille |

|

||

|

|

|

Fixing axle |

|||

(2) |

Pull down the knob. |

|

|

|

||

|

|

|

|

|||

(3) |

Open the intake grille , and lift the intake grille upward ,until the axle at the top of |

|

|

|||

|

the intake grille is removed. |

|

|

|

|

|

The intake grille installation |

|

|

Fixing axle |

Knob |

||

|

|

Mounting shaft |

|

|||

(1) |

The fixing axle of the intake grille is installed on the front panel. |

|

Grill |

|

||

(2) |

Push the knob up to the position. |

|

|

|

||

|

|

|

|

|||

(3) |

Lay down the intake grille. |

Intake grille |

|

Knob |

Fixing axle |

|

|

|

|

|

|||

The front panel removal |

|

|

|

Knob |

||

(1) |

Turn the wind guide and remove two screws at two sides of air outlet. |

|

|

|||

|

Fixing screw (2 position) |

|

||||

(2) |

Take out the air outlet part of the front panel, then lift the whole front panel up to |

Turning direction |

||||

|

remove it. |

|

|

|

|

|

The front panel installation |

|

Lift up |

|

|

||

|

|

|

|

|||

(1) |

Firstly fit the lower part of the front panel to the air outlet part and insert its |

|

Font panel |

Before turning |

||

|

lower edge into the slot of the under cover. |

|

|

Top hole Bracket |

||

|

|

|

After turning |

|||

(2) |

Insert three hooks on the upper side of the front panel into the slot of bracket. |

|||||

|

Turning wind |

|||||

(3) |

Turn the wind guide, tighten the screws, and then turn the wind guide back to its |

|

||||

|

guide |

|||||

|

origial position. |

|

|

|

|

|

Top hook Under cover Fig. 4

THE UNDER COVER REMOVAL AND INSTALATION

The under cover removal should be done after the panel has been removed beforehand, or the parts may Fig. 5 be damaged.

The under cover should be installed before the fixing of the panel, or it may result in poor installation.

The under cover removal

(1) While pressing the joint part between the right part of the under cover and the bracket, pull it out of the slot.

(2) Hold two sides of the under cover and slide it to the left. Make sure its lower part getting out of the slot.

(3)Turn the right part of the under cover lower-left to separate the left slot of the under cover from the bracket.

The under cover installation

(1) Hold two sides of the under cover and align it to the side of the bracket.Firstly match the left slot on the under cover to the bracket.

(2) Make five slots on the under cover fit into the fixing plate of the body, then slide it to the right until the left side of the under cover align to the bracket.

(3) Push the right part of the under cover inward to make the slot and bracket engaged with each other completely.

CAUTION

CAUTION

Install the front panel and intake grille securely. If installation is imperfect, the front panel or intake grille may fall off and cause injury.

Be sure that the top hole of the front panel is hooked securely to the hook of the base.

CUSTOMER GUIDANCE

Explain the following to the customer in accordance with the operating manual:

(1)Starting and stopping method, operation switching, temperature adjustment, timer, air flow switching, and other remote control unit operations.

(2)Air filter removal and cleaning, and how to use the air louvers.

(3)Give the operating and installation manuals to the customer.

TEST RUNNING

●Perform test operation and check items 1 and 2 below.

●For the test operation method, refer to the operating manual.

●The outdoor unit, may not operate, depending on the room temperature. In this case, press the test run button on the remote control unit while the air conditioner is running, (Point the transmitter section of the remote control unit toward the air conditioner and press the test run button with the tip of a ball-point pen, etc.)

●To end test operation, press the remote control unit START/STOP button.

(When the air conditioner is run by pressing the test run button, the OPERATION indicator lamp and TIMER indicator lamp will simultaneously flash slowly.)

Fig. 6

1. |

INDOOR UNIT |

Transmitter |

(1) |

Is operation of each button on the remote control unit normal? |

section |

|

(2)Does each lamp light normally?

(3)Do the air flow-direction louver operate normally?

(4)Is the drain normal?

2. OUTDOOR UNIT |

Test run |

|

(1) Is there any abnormal noise and vibration during operation? |

||

button |

||

|

(2)Will noise, wind, or drain water from the unit disturb the neighbors?

(3)Is there any gas leakage?

POWER

|

WARNING |

|

|

CAUTION |

|

(1) |

The rated voltage of this product is 230 V AC 50 Hz. |

|

(1) |

The power source capacity must be the sum of the air conditioner current and the current |

|

(2) |

Before turning on the power, check if the voltage is within the 220 V -10 % to |

|

of other electrical appliances. When the current contracted capacity is insufficient, change |

||

|

240 V +10 % range. |

|

|

the contracted capacity. |

|

(3) |

Always use a special branch circuit and install a special receptacle to supply |

|

|

||

(2) |

When the voltage is low and the air conditioner is difficult to start, contact the power |

||||

power to the room air conditioner. |

company the voltage raised. |

|

(4)Use a circuit breaker and receptacle matched to the capacity of the air condi-

|

tioner. |

NOTE: These equipment shall be connected to a suitable mains network with a main |

(5) |

Do not extend the power cord. |

impedance less than the following: 0. 424Ω |

(6) |

Perform wiring work in accordance with standards so that the air condi- |

The product is intended for use only in premises having a service current capacity 100A |

|

tioner can be operated safely and positively. |

per phase,supplied from a distribution network having a nominal voltage of 230 V, and |

(7) |

Install a leakage circuit breaker in accordance with the related laws and regu- |

instruct the user to determine in consulation with the supply authority, if necessary, that |

|

lations and electric company standards. |

the service current capacity at the interface point is sufficient for the equipment. |

Loading...

Loading...