GE PT878 User Manual

GE

Sensing & Inspection Technologies Flow

TransPort® Model PT878

Portable Liquid Flowmeter

User’s Manual

910-219 Rev. F

November 2009

GE

Sensing & Inspection Technologies

TransPort® Model PT878

Portable Liquid Flowmeter

User’s Manual

910-219 Rev. F

November 2009

GESensingInspection.com

©2009 General Electric Company. All rights reserved.

Technical content subject to change without notice.

[no content intended for this page - proceed to next page]

ii

Preface

Information Paragraphs

• Note paragraphs provide information that provides a deeper understanding of

the situation, but is not essential to the proper completion of the instructions.

• Important paragraphs provide information that emphasizes instructions that

are essential to proper setup of the equipment. Failure to follow these

instructions carefully may cause unreliable performance.

• Caution! paragraphs provide information that alerts the operator to a hazardous

situation that can cause damage to property or equipment.

• Warning! paragraphs provide information that alerts the operator to a

hazardous situation that can cause injury to personnel. Cautionary information

is also included, when applicable.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county,

state and national codes, regulations, rules and laws related to

safety and safe operating conditions are met for each

installation.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual iii

Preface

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance

with local codes, standards, regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic

modes of operation. As equipment can move suddenly and

without warning, do not enter the work cell of this equipment

during automatic operation, and do not enter the work

envelope of this equipment during manual operation. If you do,

serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF

and locked out before you perform maintenance procedures on

the equipment.

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the

auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment

applicable to the auxiliary equipment. Examples include safety glasses, protective

headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the

equipment.

iv Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Preface

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Sensing & Inspection Technologies is an active participant in Europe’s

Waste Electrical and Electronic Equipment (WEEE) take-back initiative,

directive 2002/96/EC.

The equipment that you bought has required the extraction and use of

natural resources for its production. It may contain hazardous substances

that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment

and to diminish the pressure on the natural resources, we encourage you to

use the appropriate take-back systems. Those systems will reuse or recycle

most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling

systems, please contact your local or regional waste administration.

Visit http://www.gesensing.com/environment/weee.htm

for take-back

instructions and more information about this initiative.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual v

Preface

[no content intended for this page - proceed to next page]

vi Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Contents

Chapter 1. Features and Capabilities

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2.1 The Flowcell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.2.2 Electronics Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Chapter 2. Initial Setup

2.1 Making Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1.1 Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.2 Transducer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.3 Input/Output Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.4 The Infrared Wireless Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2 Caring for the PT878 Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.1 Charging and Storing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2.2 Replacing the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2.3 Disposing of Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Powering ON and OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 Using the Screen and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.1 Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4.2 Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 Obtaining On-Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual vii

Contents

Chapter 3. Programming Site Data

3.1 Entering the Program Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Entering Transducer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2.1 Parameters for Special Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.2 Confirming Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.3 Entering Pipe Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.4 Entering Pipe Lining Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.5 Entering Fluid Types and Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.6 Entering the Signal Path Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.6.1 Path Parameters for Clamp-On Transducers . . . . . . . . . . . . . . . . . . . . 40

3.6.2 Path Parameters for Wetted Transducers . . . . . . . . . . . . . . . . . . . . . . . 41

3.7 Entering the Energy Option Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.7.1 Entering Inputs in the Energy Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.7.2 Entering Custom Cp Data in the Energy Option . . . . . . . . . . . . . . . . . . 46

3.8 Entering Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.8.1 Entering General-Purpose Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . 50

3.8.2 Entering Analog Inputs in the Energy Option. . . . . . . . . . . . . . . . . . . . . 52

3.9 Entering the Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.10Entering the Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

3.11Entering User Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.11.1 Entering Correction Factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.11.2 Entering Reynolds Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

3.11.3 Entering a Calibration Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

viii Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Contents

Chapter 4. Creating and Managing Sites

4.1 The Site Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.1.1 Creating a New Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.1.2 Opening an Existing Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

4.1.3 Saving a Site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.1.4 Saving a Site with a Different Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.1.5 Refreshing a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.1.6 Renaming a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.1.7 Deleting a Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.1.8 Creating a Site Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

4.1.9 Printing a Current Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.1.10 Transferring a Site File to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.1.11 Transferring a Site File in Text Format to a PC . . . . . . . . . . . . . . . . . . . 84

4.1.12 Transferring a File from a PC to the PT878. . . . . . . . . . . . . . . . . . . . . . . 85

4.1.13 Listing Files by Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.1.14 Listing Files in Chronological Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Chapter 5. Displaying and Configuring Data

5.1 The Format Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

5.2 The View Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5.3 The Limits Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

5.4 The Measurement Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.5 Customizing the Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.5.1 Specifying the Number of Displayed Parameters . . . . . . . . . . . . . . . . 98

5.5.2 Customizing Softkeys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.6 Managing Files — The Drive Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

5.6.1 Transferring a File to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5.6.2 Transferring a File from a PC to the PT878. . . . . . . . . . . . . . . . . . . . . . 105

5.6.3 Refreshing a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.6.4 Deleting a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.6.5 Listing Files by Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.6.6 Listing Files in Chronological Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.7 Accessing Meter Data —The About Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual ix

Contents

Chapter 6. Programming Meter Settings

6.1 Entering the Meter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.2 Selecting Measurement Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.3 The Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

6.4 Entering Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.5 Changing Date and Time Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.6 Adjusting the Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

6.7 Setting Backlight Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.8 Changing the Display Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

6.9 Changing Communications Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

6.10Resetting Forward and Reverse Totals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

6.11Setting Up User Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6.12Taking a Bitmap Capture of a Current Screen . . . . . . . . . . . . . . . . . . . . . . . . . 130

x Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Contents

Chapter 7. Logging Data

7.1 Entering the Logging Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

7.2 The Log Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.3 The File Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7.3.1 Setting up a New Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.3.2 Copying (Cloning) a Selected Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

7.3.3 Renaming a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7.3.4 Deleting a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

7.3.5 Deleting All Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

7.3.6 Refreshing the Log Manager Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

7.3.7 Printing a Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

7.3.8 Transferring a Log to a PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

7.4 The Log Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

7.4.1 Stopping (Pausing) a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

7.4.2 Restarting a Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

7.4.3 Ending a Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

7.4.4 Stopping All Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.4.5 Restarting All Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.4.6 Ending All Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.4.7 View All Sites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

7.5 The View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

7.5.1 Displaying Log Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

7.5.2 Displaying Log Data in Graphical Form. . . . . . . . . . . . . . . . . . . . . . . . . 150

7.5.3 Displaying Log Data in Spreadsheet Form . . . . . . . . . . . . . . . . . . . . . . 153

7.6 The Sort Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

7.6.1 Listing Logs by Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

7.6.2 Listing Logs in Chronological Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual xi

Contents

Chapter 8. Servicing the PT878

8.1 Entering the Service Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

8.2 Printing Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

8.3 Setting up the Thickness Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

8.4 Measuring Pipe Wall Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

8.4.1 Entering the Material and Soundspeed. . . . . . . . . . . . . . . . . . . . . . . . . 160

8.4.2 Measuring Thickness in Numeric Format . . . . . . . . . . . . . . . . . . . . . . . 162

8.4.3 Displaying the Receive Signal in Graphical Format . . . . . . . . . . . . . . 163

8.4.4 Calibrating the Thickness Gauge Transducer . . . . . . . . . . . . . . . . . . . 165

8.4.5 Calculating Velocity (Pipe Material Soundspeed) . . . . . . . . . . . . . . . . 168

8.5 Programming the Thickness Gauge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

8.6 Displaying Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8.7 Calibrating the Analog Output and Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.7.1 Calibrating the Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

8.7.2 Calibrating Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

8.8 Setting up Signal Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

8.8.1 Setting up Signal Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

8.8.2 Setting up Peak Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

8.8.3 Selecting the Transmit Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

8.9 Setting Error Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

8.10The Test Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

8.10.1 Testing the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

8.10.2 Testing the Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

8.10.3 Testing the Watchdog Timer Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

8.10.4 Setting Impulse Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

8.10.5 Taking Wave Samples for Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

8.10.6 Applying a Stored Signal for Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 192

8.10.7 Testing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

8.11Resetting to Factory Default Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

8.12Updating PT878 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

8.12.1 Updating Software Via IrOBEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

8.12.2 Updating Software Via IrCOMM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

xii Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Contents

Chapter 9. Diagnostics and Troubleshooting

9.1 Error Code Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

9.2 Displaying Diagnostic Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

9.3 Flowcell Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

9.3.1 Fluid Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

9.3.2 Pipe Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

9.4 Transducer Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

9.4.1 Wetted Transducer Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

9.4.2 Clamp-on Transducer Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

9.4.3 Relocating Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Chapter 10. Specifications

10.1Overall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

10.1.1 Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

10.1.2 Size/Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

10.1.3 Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

10.1.4 Flow Accuracy (Velocity, % of reading): . . . . . . . . . . . . . . . . . . . . . . . . . 213

10.2Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

10.3Operational Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

10.4Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

10.4.1 Clamp-On Ultrasonic Flow Transducers . . . . . . . . . . . . . . . . . . . . . . . . 217

10.4.2 Temperature Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

10.5Pipe Size and Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

10.5.1 Clamp-On Transducers: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

10.6Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual xiii

Contents

Appendix A. Menu Maps

Appendix B. Measuring P and L Dimensions

Appendix C. Temperature Transmitter Installation

C.1 Guidelines for RTD Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

C.2 Mounting RTDs on the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

C.2.1 Assembling the Clamping Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

C.2.2 Mounting the RTD to the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

C.3 Making Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

C.3.1 Connecting the RTD to the 4 to 20-mA Transmitter . . . . . . . . . . . . . 246

C.3.2 Connecting the Transmitter to the PT878. . . . . . . . . . . . . . . . . . . . . . . 247

Appendix D. Ultrasonic Thickness Gauge Theory of Operation

D.1 Factors Affecting Performance and Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . 250

D.1.1 Transducer Positioning/Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

D.1.2 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

D.1.3 Taper or Eccentricity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

D.1.4 Acoustic Properties of the Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Appendix E. Material Safety Data Sheet for Couplant

E.1 Product Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

E.2 Hazardous Ingredients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

E.3 Physical Data (nominal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

E.4 Fire and Explosion Hazard Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

E.5 Reactivity Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

E.6 Health Hazard and First Aid Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

E.7 Storage and Handling Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

E.8 Control Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Appendix F. Establishing IR Communications

Appendix G. Glossary

xiv Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Chapter 1. Features and Capabilities

Chapter 1. Features and Capabilities

The TransPort® Model PT878 is a transit-time flowmeter which combines

all the features of a full-size flowmeter with the advantages of a portable

instrument.

This section describes the TransPort features and general system, and

explains the theory of operation.

1.1 Overview

The PT878 measures the flow rate of acoustically conductive single-phase

fluids. This includes most clean liquids, sewage, some slurries, some

oil/water mixtures, and liquids with a small percentage of entrained gas

bubbles. The flowmeter provides one linear (0/4-20 mA) analog output of

flow velocities or volumetric flow rate of these fluids, measuring velocities

from ±0.03 to ±12 m/sec (±0.1 to ±40 ft/sec), along with one selectable

frequency output or pulsed totalizer output.

The PT878 also provides two 4 to 20-mA analog inputs in order to connect

temperature transmitters to measure energy flow rate of liquids. Energy

flow rate may be calculated for water, glycol, and water/glycol mixtures.

The PT878 has the ability to store site data in files which can be accessed at

a later time. Within the Main Menu, a set of forms (windows) asks you all

the necessary setup information for a particular site. Once the necessary

questions are answered, you simply save the information to a file.

The PT878 stores these files and other data in non-volatile memory, which

retains the information even if power is off. The flowmeter itself runs on

rechargeable or alkaline batteries for up to 10 hours.

This small lightweight flowmeter displays measurements in both numeric

and graphical form on a EL-backlit, 240 x 200 pixel LCD graphic screen.

The PT878 also has the capability of logging over 100,000 flow data points

internally.

Using an infrared communications port, the PT878 can transmit or print

logged data, as well as real time data and other stored data. It is also

computer-programmable via GE’s PanaView™ software.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 1

Chapter 1. Features and Capabilities

1.1 Overview (cont.)

To assist you, the PT878 is fully equipped with context-sensitive on-line

help which is accessible at any time by simply pressing the “?” (Help) key.

Internal diagnostic and troubleshooting features help is olate and remedy

common flowcell and transducer problems.

The PT878 operates with all standard GE transducers - wetted, clamp-on,

®

hybrids (Pan-Adapta

plug), and buffered styles.

A built-in ultrasonic thickness gauge capability measures the pipe wall

thickness when used with the optional thickness transducer.

1.2 System Description

The PT878 is one part of the flowmeter system. The flowmeter system

consists of two essential subsystems: the flowcell and the electronics

package (the PT878).

1.2.1 The Flowcell

The flowcell is that part of the system that uses ultrasonic pulses to

interrogate the flow. It consists of the flowcell pipe and the transducers.

A. FLOWCELL PIPE - The flowcell can either be created in the existing

piping (for example, by inserting wetted transducers into the pipe, or

clamping non-wetted transducers onto the pipe), or inserted as a

substitute pipe section (spoolpiece). The flowcell must provide

mechanical support for the transducers and assure stable fluid conditions

for accurate flow measurement.

B. TRANSDUCERS - The transducers convert electrical energy into

ultrasonic pulses when in a transmit cycle, and convert the ultrasonic

pulses back to electrical energy when in a receive cycle. In other words,

they act like loudspeakers when transmitting the signal and microphones

when receiving it. In the PT878 system, each transducer acts as both a

receiver and transmitter, since a series of ultrasonic pulses are alternately

sent upstream and then downstream through the flowcell.

2 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Chapter 1. Features and Capabilities

1.2.2 Electronics Package

The PT878 consists of circuits that generate, receive, and measure the travel

time of the ultrasonic pulses. It also contains a microcomputer that controls

operation and calculates flow measurement parameters. Specific circuits

function as follows:

• TRANSMIT SIGNAL GENERATOR - The transmit signal generator,

under control of the microcomputer and timing circuit, synthesizes the

signal that drives the transmitter.

• TRANSMITTER - The transmitter amplifies the signals from the

transmit signal generator to a signal that drives the transmit transducer.

• RECEIVER - The receiver amplifies the received signals to a level

suitable for the data acquisition circuitry.

• DATA ACQUISITION - The data acquisition circuitry digitizes the

received signal and stores it in a buffer for processing by the

microcomputer.

• TIMING CIRCUIT - The timing circuit generates the transmitter

frequency, receive window, controls the data acquisition circuit and the

direction of the transmission.

• MICROCOMPUTER - The microcomputer controls the PT878

flowmeter’s operation and calculates flow measurements derived from

the transmitted and digitized received signals. Also, the microcomputer

continually checks for faults and allows the use of built-in diagnostics for

troubleshooting.

• INPUT/OUTPUT - The input/output circuitry allows the flowmeter to

indicate the measured flow with the 0/4-20 mA current loop, and to

output to a printer or other remote device. The digital output supports

frequency or pulse output, as well as use as a gate input; it can also act as

a test point for triggering an oscilloscope from the transmit or receive

window.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 3

Chapter 1. Features and Capabilities

1.3 Theory of Operation

The PT878 is a transit-time ultrasonic flowmeter. When ultrasonic pulses

are transmitted through a moving liquid, the pulses that travel in the same

direction as the fluid flow (downstream) travel slightly faster than the pulses

that travel against the flow (upstream). The PT878 uses various digital

signal processing techniques, including cross-correlation, to determine

transit times and then uses the transit times to calculate flow velocity.

During operation, two transducers serve as both ultrasonic signal generators

and receivers. When mounted on a pipe, they are in acoustic communication

with each other, so that each transducer can receive ultrasonic signals

transmitted by the other transducer. Each transducer thus functions as a

transmitter generating a certain number of acoustic pulses, and as a receiver

for an identical number of pulses.

The flowmeter measures the time interval between transmission and

reception of the ultrasonic signals in both directions. When the liquid in the

pipe is not flowing, the transit-time downstream equals the transit-time

upstream. When the liquid is flowing, the transit-time downstream is less

than the transit-time upstream. The difference between the downstream and

upstream transit-times is proportional to the velocity of the flowing liquid,

and its sign indicates the direction of flow.

4 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Chapter 2. Initial Setup

Chapter 2. Initial Setup

Before making measurements, you must prepare the PT878 for operation.

This includes the following procedures:

• Making Electrical Connections

• Charging and/or Replacing Batteries

• Powering On and Off

• Using the Screen and Keypad

• Obtaining On-Line Help

Figure 1 below shows the PT878 in its standard soft case (a) and in the

optional solid case (b). In the solid case, the interior is structured for optimal

protection of the PT878 and its accessories.

(a) (b)

Figure 1: The PT878 and Accessories

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 5

Chapter 2. Initial Setup

2.1 Making Electrical Connections

Before making measurements with the PT878, you must make all the

necessary connections to the unit. This section describes how to connect the

following:

• Power

• Transducers

• Input/Output

• Infrared Interface

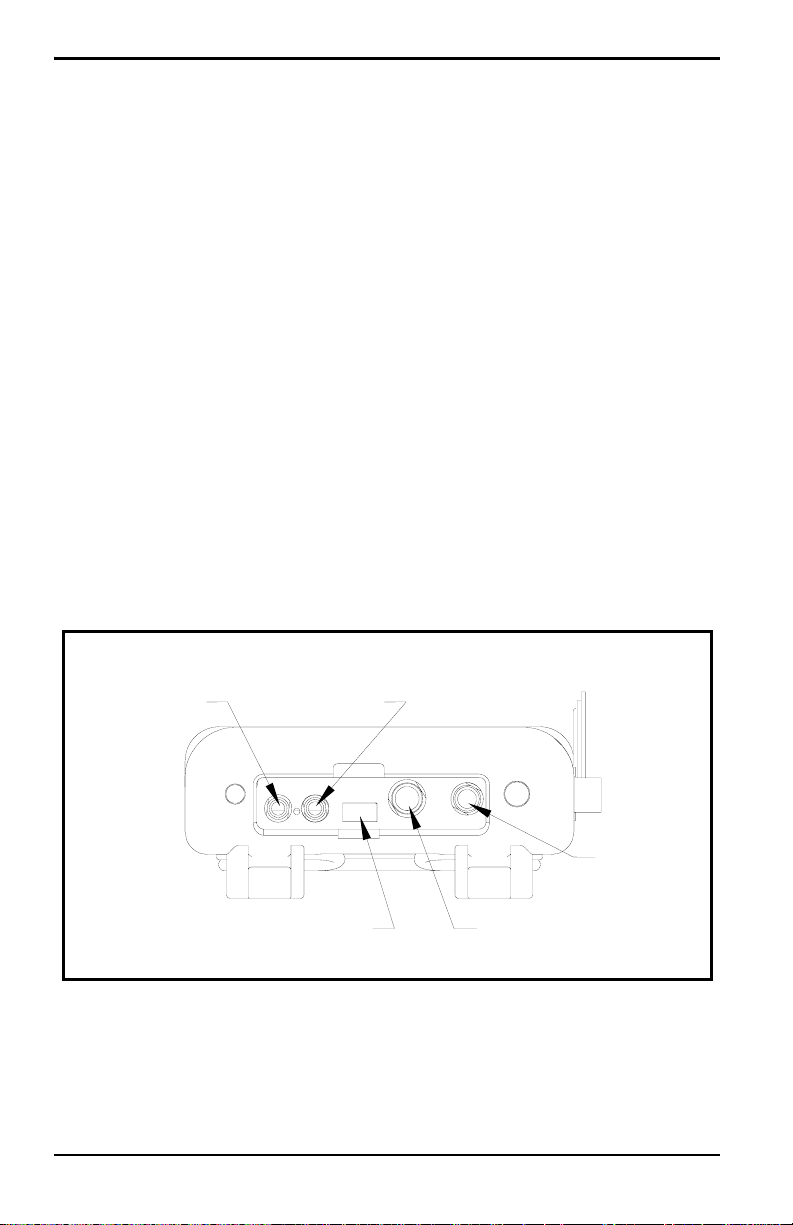

Make all connections to the top of the PT878 unit as shown in Figure 2

below. Please note that you need to make the proper power and transducer

connections only. The other connections are required for particular

functions, but are not necessary for basic operation.

Note: For a listing of Input/Output connections, see Table 1 on page 8.

Transducer

Upstream

Infrared Transceiver

Downstream

Power

Input/Output

Figure 2: Connection Locations

6 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Chapter 2. Initial Setup

2.1.1 Power Connections

The PT878 is powered by either a 100-120/200-260 VAC wall mount

plug-in module, or by 5 internal C

-size NiCad high-energy rechargeable

s

batteries or by a pack of 3.0 Ahr NiMH batteries. (An optional power

supplement, part #703-1283, uses 6 AA alkaline batteries.) When you

receive the PT878, the batteries are not charged; therefore, to make remote

measurements using the batteries, follow the instructions on page 9 to

charge the batteries. In either case, you must connect the power cord to the

appropriate terminal as shown in Figure 2 on page 6.

WARNING! To ensure the safe operation of the PT878, you must

install and operate it as described in this manual. In

addition, be sure to follow all applicable safety codes and

regulations for installing electrical equipment in your

area. The PT878 and its transducers are designed for use

only in general-purpose locations.

2.1.2 Transducer Connections

The transducer cables connect to the PT878 with LEMO® coaxial type

connectors. Each color-coded cable should have a collar labeled

UPSTREAM or DOWNSTREAM. Make transducer cable connections to

the top of the flowmeter as shown in Figure 2 on page 6. Because there are

various types of transducers and installations, transducer installation is

discussed separately in the Liquid Transducer Installation Guide (916-055).

2.1.3 Input/Output Connections

The PT878 provides one 0/4-20 mA current output and two 4 to 20-mA

analog inputs with switchable 16-V supply for loop- powered temperature

transmitters. It also supports digital, frequency, and totalizer outputs.

Connect the inputs/outputs using a LEMO

Figure 2 on page 6. The pin numbers for the connector and the color code

for the standard input/output cable are shown in Table 1 on page 8.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 7

®

multi-pin connector as in

Chapter 2. Initial Setup

2.1.3 Input/Output Connections (cont.)

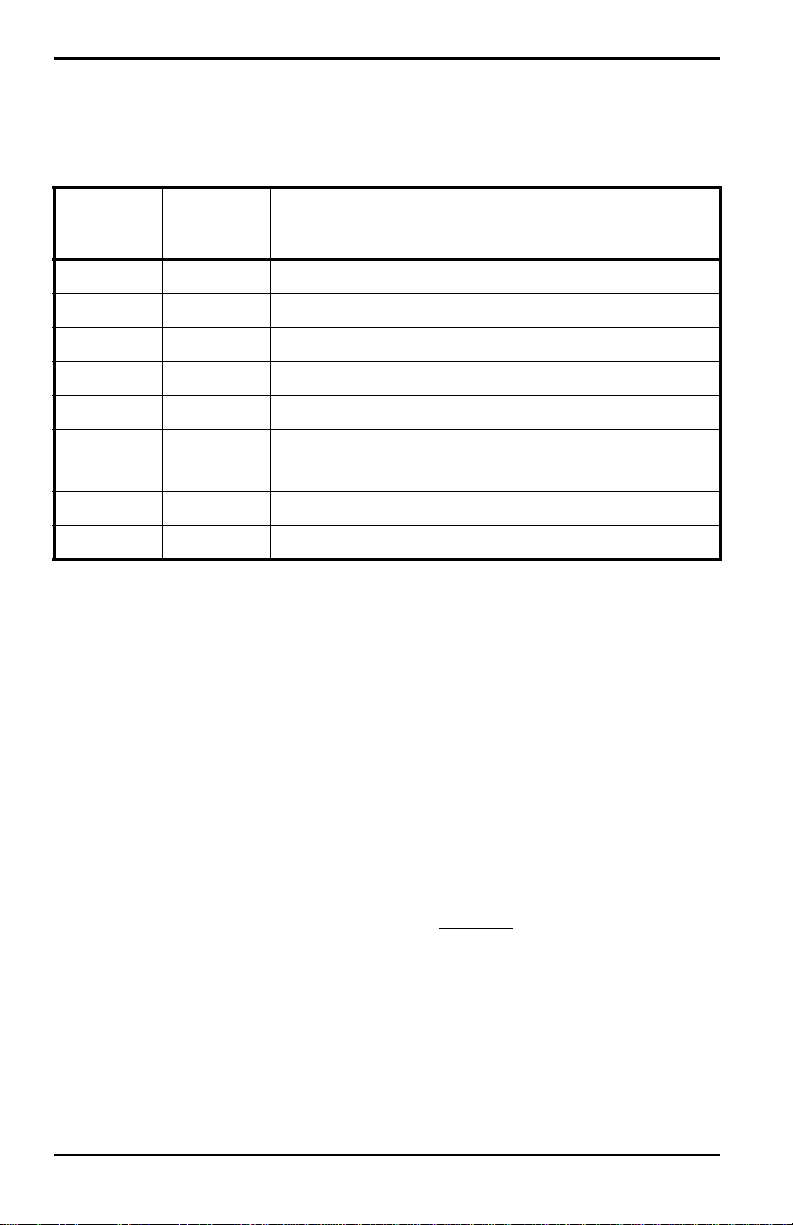

Table 1: Cable Assembly for Analog Inputs/Outputs

Pin

Number

Wire

Color Description

1 Black Analog Out 1

2 Red 16 V (switched)

3 White Supply or Return Temperature (Input A)

4 Yellow Supply or Return Temperature (Input B)

5 Green Analog Ground

6 Orange Digital Output (frequency output, pulse totalizer,

diagnostic output or calibration gate)

7 Blue Digital Ground

8 Violet Receive Monitor

2.1.4 The Infrared Wireless Interface

The PT878 comes equipped with an internal infrared transceiver (shown in

Figure 2 on page 6) that enables communication between the meter and

other IR devices, particularly the IR ports or dongles (IR to RS232 adapters)

of Windows

They can also program the meter using the optional PanaView software

interface. The PT878 was designed for use with products that comply to the

IrDA protocol. For more information on establishing IR communications

between the PT878 and your PC, refer to Appendix F.

®

-based PCs. Users can send and receive site and log data.

Note: The dongle connection is RS232. The configuration options are either

RS232 or IRDa. Selecting the RS232 does not

link the meter to the

dongle. IrDa must be selected for the link to work.

• To transfer files between the PT878 and PC, see Managing Files — the

Drive Manager on page 102.

• To transfer a log from the PT878 to a PC, see page 144.

8 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Chapter 2. Initial Setup

2.2 Caring for the PT878 Batteries

The PT878 comes with self-contained, built-in rechargeable batteries to

support portable operation. For optimum performance, these batteries

require a minimum of maintenance.

CAUTION! Use only GE-approved batteries and desktop chargers.

These chargers are designed to maximize battery life.

Using other batteries or chargers voids the warranty and

may cause damage.

IMPORTANT: For CE compliance, the PT878 is classified as a

battery-powered device, not to be used with the AC

adaptor.

2.2.1 Charging and Storing the Batteries

When you receive the PT878, you will need to initially charge the batteries.

Also, the battery may need recharging if it has not been used for a long

period of time. The batteries must be charged up to 8 hours to receive the

maximum charge. When fully charged, the batteries provide 8 to 10 hours

of continuous operation. An internal battery gauge indicates the remaining

power in the batteries.

To charge the batteries, simply plug the AC power module cord into the

power jack (shown in Figure 2 on page 6) and be sure the battery pack is

installed. When the PT878 is plugged into line voltage, the internal battery

charger automatically charges the batteries, whether the PT878 is on or off.

If the PT878 is on, the Battery icon in the upper right corner of the screen

indicates battery status (as shown in Table 2 on page 10).

Note: For version 1B of the PT878 software, you must also press the red

power key in the upper right corner of the keypad. (See page 110 to

determine your software version.)

For optimal run time, charge the batteries only in temperatures from 50°F to

104°F (10°C to 40°C). Otherwise, the batteries will not be properly charged

and will have a significantly reduced run time.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 9

Chapter 2. Initial Setup

2.2.1 Charging and Storing the Batteries (cont.)

Store the batteries at temperatures from –4°F to 131°F (–20°C to 55°C) for

periods of less than one month, or from 32°F to 104°F (0°C to 40°C) for

longer periods. (If you are transporting them for two days or less, the

batteries can withstand temperatures from –40°F to 158°F (–40°C to 70°C).

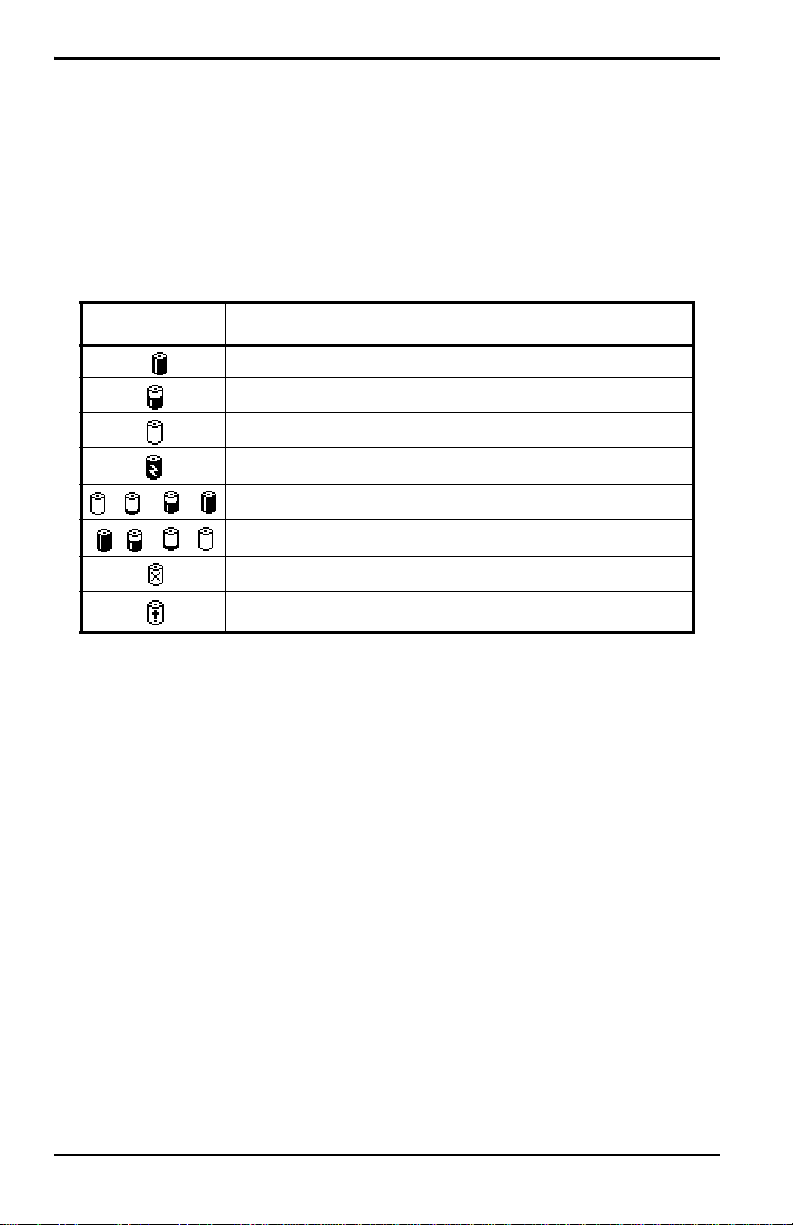

Table 2: Battery Status Icons

Icon Battery Status

Full battery

Partially full battery

Empty battery

Fully charged battery, connected to AC power

Charging battery

Discharging battery

Failure/missing battery

Notification to check battery form (see page 114)

2.2.2 Replacing the Batteries

CAUTION! Replace batteries only with the specified rechargeable

batteries. The battery charges when the unit is off. Do not

attempt to recharge non-rechargeable batteries.

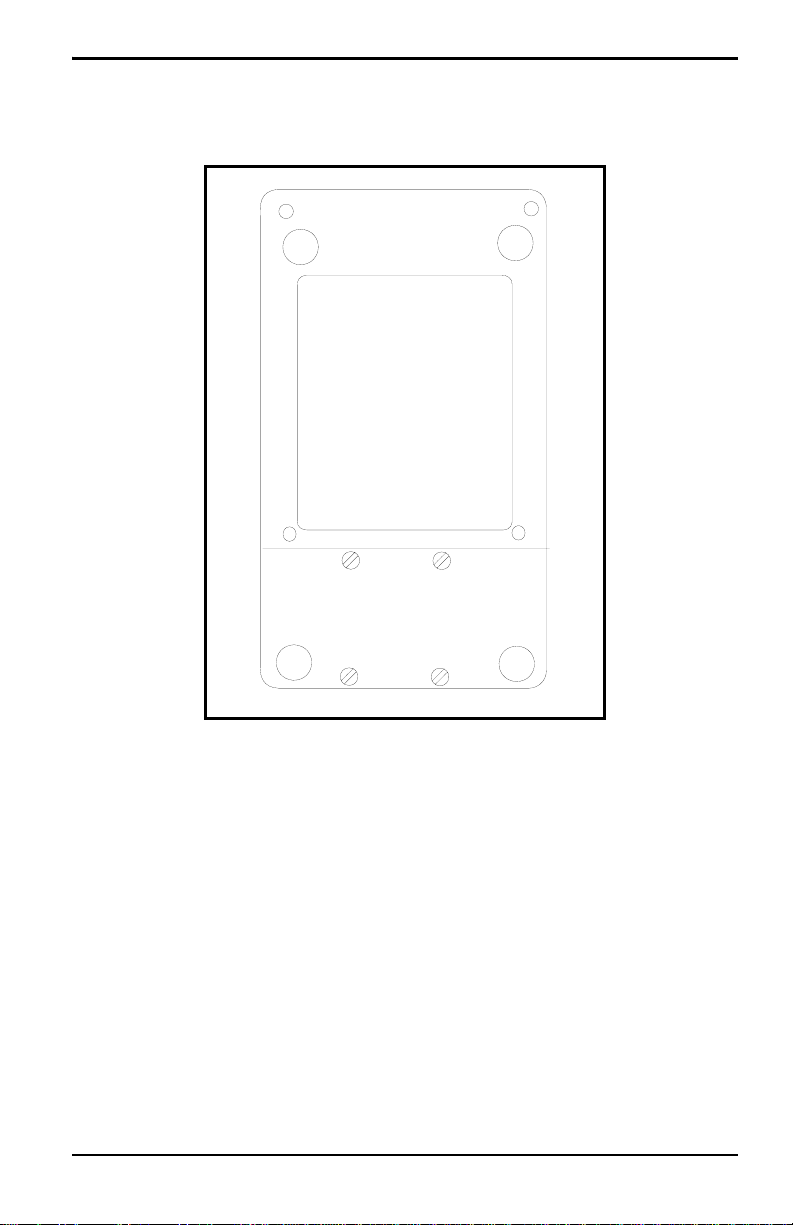

If you need to replace the rechargeable batteries, use the recommended 3.0

Ahr NiMH batteries (part number 200-081). While the batteries can be

recharged up to 600 times, it is best to replace them when they no longer

provide acceptable performance. T o replace the batteries, remove the rubber

boot, open the panel located on the back of the PT878 unit, disconnect the

batteries, and replace with new ones (see Figure 3 on page 11).

10 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

2.2.2 Replacing the Batteries (cont.)

Battery Location

(behind panel)

Chapter 2. Initial Setup

Figure 3: Battery Location

To further extend the battery power on the PT878, the GE Part #705-1283

option uses 6 AA alkaline batteries.

2.2.3 Disposing of Batteries

CAUTION! Never dispose of the batteries by incineration. Do not

attempt to disassemble or short-circuit the batteries. For

safety. do not handle a damaged or leaking battery.

IMPORTANT: Be sure to dispose of your battery properly. In some areas,

battery disposal in business or household trash may be

prohibited. For safe disposal options, contact your nearest

GE-authorized service center.

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 11

Chapter 2. Initial Setup

2.3 Powering ON and OFF

To operate the PT878, the power cord must be plugged into line voltage or

the battery must be charged as described previously.

IMPORTANT: For CE compliance, the PT878 is classified as a

battery-powered device, not to be used with the AC adapter.

To comply with CE certification, do not operate the meter

with the charger plugged in.

T o turn the PT878 on, press the red button in the upper-right-hand corner of

the keypad. Immediately upon power up the PT878 emits a short beep and

displays a “PCI Loader” message. It then validates the instrument

programming, and then displays the GE logo and the software version and

emits a long beep. If the meter fails any of these tests, contact the factory.

WARNING! If the meter fails the backup battery test, you must send

the unit back to the factory for a battery replacement.

Make sure you keep the batteries charged until you are

ready to ship the unit back to the factory. Before shipping,

print out all the log and site data, or transfer it to your PC.

12 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Chapter 2. Initial Setup

2.3 Powering ON and OFF (cont.)

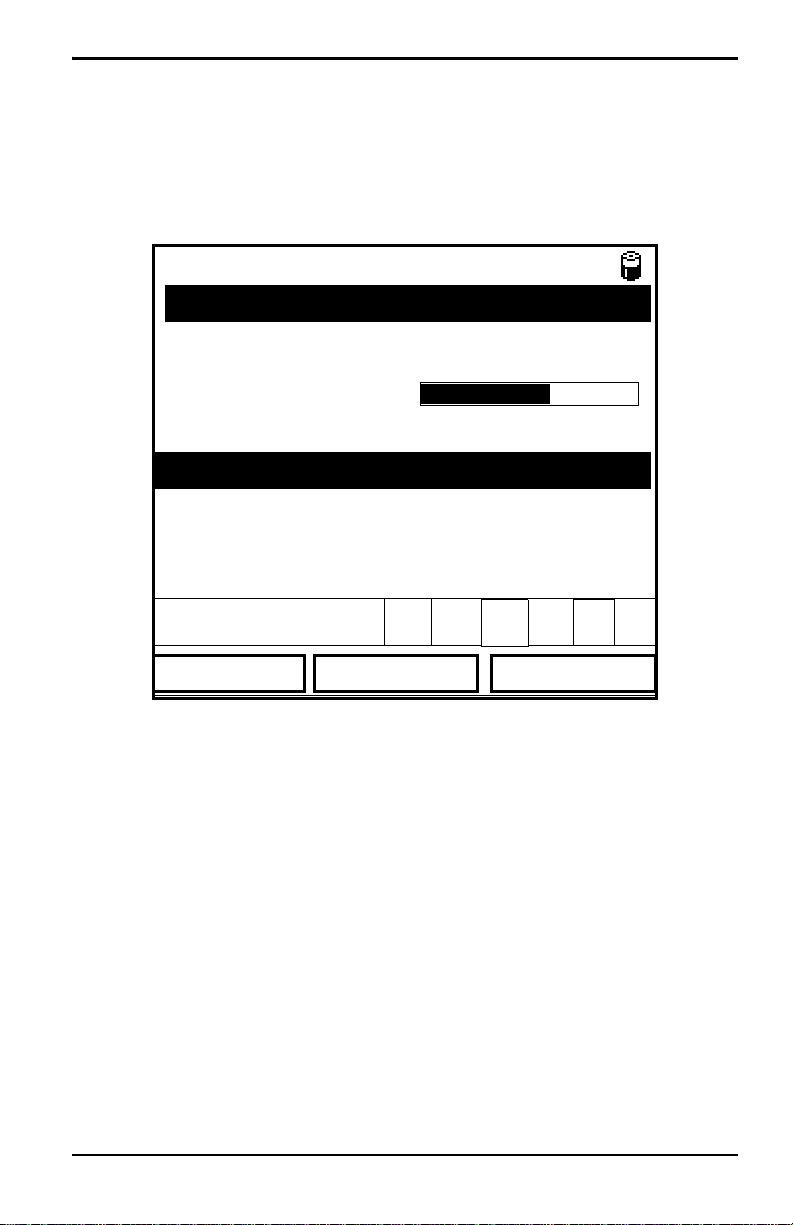

After the meter conducts all the self checks, the screen then appears similar

to the one shown in Figure 4 below.

ABC.SIT

Velocity, ft/s

0.00

Delta-T, ns

E0: No Errors

Figure 4: Screen After Powering ON

0.10

2000/11/30 09:53 AM

Signal, dB

32

Volume, l/s

0.0

Transport® Model PT878 Portable Liquid Flowmeter User’s Manual 13

Chapter 2. Initial Setup

2.3 Powering ON and OFF (cont.)

To turn the PT878 off, press the red key for 3 seconds. The screen now

appears similar to Figure 5 below.

Velocity, ft/s

SHUTDOWN: Meter OFF

Signal, dB

SLEEP: Meter Idle

CANCEL: Resume Operations

Delta-T, ns

Shutdown

Figure 5: Shutdown Menu

Three options are available:

Sleep

Volume, l/s

Resume

• Press [F1] to shut down the PT878, turning it completely off.

• Press [F2] to send the PT878 into sleep mode. In this mode, some of the

power supplies shut down, but the PT878 remains in a standby mode.

Users can resume taking measurements immediately by pressing the

power button.

• Press [F3] to cancel the command and return the PT878 to normal

operation.

If the PT878 locks up, you can reset it by holding the power key (the red key

in the upper right corner) for 15 seconds.

14 Transport® Model PT878 Portable Liquid Flowmeter User’s Manual

Loading...

Loading...