GE GFD55GSSNWW User Manual

DRYERS |

|

|

|

SAFETY INFORMATION . . . . . . . |

. .3 |

|

USING THE DRYER |

|

|

WiFi Connect . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

Getting Started . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

Cycles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.7 |

|

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.8 |

|

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.8 |

|

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

CARE AND CLEANING . . . . . . . . . . |

11 |

|

INSTALLATION |

|

|

INSTRUCTIONS . . . . . . . . . . . . . . . . . . |

12 |

|

Reversing The Door Swing (Optional) . . |

30 |

|

Stacking (Optional) . . . . . . . . . . . . . . . . . . . |

32 |

|

TROUBLESHOOTING TIPS. . . . . |

36 |

|

LIMITED WARRANTY . . . . . . . . . . |

39 |

|

CONSUMER SUPPORT . . . . . . . . . |

40 |

|

Write the model and serial |

|

|

numbers here: |

|

|

Model #_________________ |

|

|

Serial # _________________ |

|

|

They are on the label on the front |

|

|

of the dryer behind the door. |

|

GE is a trademark of the General Electric Company. Manufactured under trademark license.

OWNER’S MANUAL &

INSTALLATION

INSTRUCTIONS

GFD85

GFD65

GFD55

GFV55

ENGLISH/FRANÇAIS/

ESPAÑOL

49-3000206 Rev 1

09-19 GEA

THANK YOU FOR MAKING GE APPLIANCES A PART OF YOUR HOME.

Whether you grew up with GE Appliances, or this is your first, we’re happy to have you in the family.

We take pride in the craftsmanship, innovation and design that goes into every GE Appliances product, and we think you will too. Among other things, registration of your appliance ensures that we can deliver important product information and warranty details when you need them.

Register your GE appliance now online. Helpful websites and phone numbers are available in the Consumer Support section of this Owner’s Manual. You may also mail in the pre-printed registration card included in the packing material.

2 |

|

49-3000206 Rev 1 |

|

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

|

To reduce the risk of fire, explosion, electric shock, or injury to persons when using your |

WARNING |

|

|

appliance, follow basic precautions, including the following: |

|

•Read all instructions before using the appliance.

•DO NOT dry articles that have been previously cleaned in, washed in, soaked in, or spotted with gasoline, dry-cleaning solvents, or other flammable or explosive substances, as they give off vapors that could ignite or explode.

•DO NOT place items exposed to cooking oils in your dryer. Items contaminated with cooking oils may contribute to a chemical reaction that could cause a load to catch fire. To reduce the risk of fire due to contaminated loads, the final part of the tumble dryer cycle occurs without heat (cool down period). Avoid stopping a tumble dryer before the end of the drying cycle unless all items are quickly removed and spread out so that the heat is dissipated.

•DO NOT allow children to play on or in this appliance. Close supervision of children is necessary when this appliance is used near children.

•Before the appliance is removed from service or discarded, remove the door to the drying compartment.

•DO NOT reach into the appliance if the drum is moving.

•DO NOT install or store this appliance where it will be exposed to the weather.

•DO NOT tamper with controls.

•DO NOT climb or stand on this unit.

•DO NOT repair or replace any part of this appliance or attempt any servicing unless specifically recommended in the user-maintenance instructions or in published user-repair instructions that you understand and have the skills to carry out.

•Follow all fabric care instructions and warnings to prevent melting of garments or damage to the appliance.

•DO NOT use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener or product.

•DO NOT dry articles containing foam rubber or similarly textured rubber-like materials.

•Clean lint screen before or after each load.

•DO NOT operate the dryer without the lint filter in place.

•DO NOT store combustible materials, gasoline or other flammable liquids near the dryer. Keep area around the exhaust opening and adjacent surrounding areas free from the accumulation of lint, dust and dirt.

•The interior of the appliance and exhaust duct should be cleaned periodically by qualified service personnel.

•Unplug the appliance or turn off the circuit breaker before servicing. Pressing the Power or Start/Pause pad DOES NOT disconnect power.

•DO NOT operate this appliance if it is damaged, malfunctioning, partially disassembled, or has missing or broken parts, including a damaged cord or plug.

•DO NOT spray any type of aerosol into, on or near dryer at any time. DO NOT use any type of spray cleaner when cleaning dryer interior. Hazardous fumes or electrical shock could occur.

•See “ELECTRICAL CONNECTION” located in the Installation Instructions for grounding instructions.

INFORMATION SAFETY

READ AND SAVE THESE INSTRUCTIONS

49-3000206 Rev 1 |

3 |

SAFETY INFORMATION

IMPORTANT SAFETY INFORMATION

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE

ADDITIONAL GAS DRYER WARNINGS

WARNING

WARNING

- Fire or Explosion Hazard

- Fire or Explosion Hazard

Failure to follow safety warnings exactly could result in serious injury, death, or property damage.

-DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS:

•DO NOT try to light any appliance.

•DO NOT touch any electrical switch; DO NOT use any phone in your building.

•Clear the room, building, or area of any occupants.

•Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•If you cannot reach your gas supplier, call the fire department.

-Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

4 |

49-3000206 Rev 1 |

Getting started

|

|

|

To reduce the risk of fire, electric shock, or injury to persons, read the IMPORTANT SAFETY |

|||

|

|

WARNING |

||||

|

|

INFORMATION before operating this appliance. |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING |

- Fire Hazard |

|

|

|

|

|

|

|

|

|

|

|

• |

Keep flammable materials and vapors, such as |

• DO NOT dry anything that has ever had any type of oil |

|||

|

|

gasoline, away from dryer. |

|

on it (including cooking oils). |

|

|

|

• DO NOT dry anything that has ever had anything |

• |

Items containing foam, rubber, or plastic must be dried |

|

||

|

|

flammable on it (even after washing). |

|

on a clothesline. |

|

|

|

• |

No washer can completely remove oil. |

• |

Failure to do so can result in death, explosion, or fire. |

|

|

|

|

|

|

|

|

|

Throughout this manual, features and appearance will vary from your model.

WiFi Connect (For customers in the United States only - on some models)

Your dryer is GE Appliances WiFi Connect enabled. |

WiFi Label Location |

|

Visit geappliances.com/connect and enter your model number to |

||

|

||

show you the proper steps to connect your appliance. |

|

|

Please visit GEAppliances.com/connect to learn more about |

|

|

connected appliance features, to learn what connected appliance |

|

|

app’s will work with your smartphone. |

|

|

WiFi Connectivity: For assistance with the appliance or the |

|

|

ConnectPlus network connectivity, please call GE Appliances at |

|

|

800.GE.CARES. |

|

DRYER THE USING

Quick Start:

Step 1

•Clean lint filter

•Loosely add items.

•Close door. NOTE: Dryer will not start with door open.

Step 2 |

Step 3 |

Step 4 |

• If the screen is dark, |

• Select a sensor dry cycle. |

• Press the Start/ |

press the Power pad |

(Defaults are set for each dry |

Pause pad. |

to “wake up” the |

cycle. These default settings |

|

display. |

can be changed. See the cycle |

|

|

descriptions for more information.) |

|

OR

•Select TIMED DRY and set Time, Temp and Level.

49-3000206 Rev 1 |

5 |

USING THE DRYER

Getting started

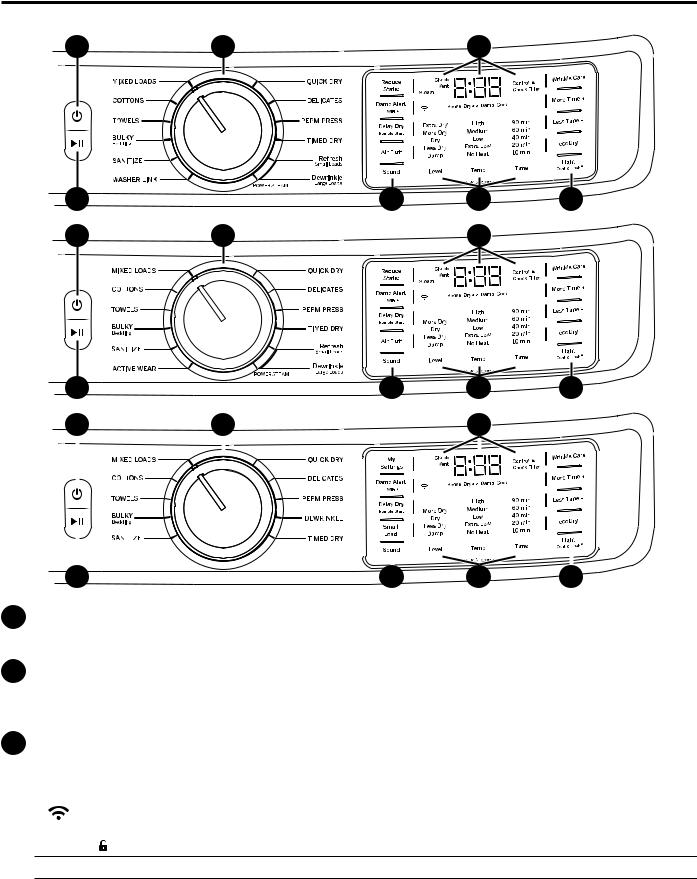

Features and appearance will vary.

A D

B

A D

|

C |

|

F |

E |

F |

|

C |

|

B F E F

A D C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

F |

E |

F |

||||||||||||

A |

Power |

|

|

|

|

|

|

|

||||||||

|

Press to “wake up” the display. If the display is active, press to put the dryer into idle mode. |

|||||||||||||||

|

NOTE: Pressing Power does not disconnect the appliance from the power supply. |

|

|

|

||||||||||||

B |

Start and Pause |

|

|

|

|

|

|

|

||||||||

|

Press Start to begin the cycle. NOTE: The door must be closed for the dryer to start the cycle. Pressing Start |

|||||||||||||||

again will pause the cycle, the Start light will blink and “Pause” will display. To continue the cycle, press Start again.

C |

Display and Status Lights |

|

The display shows the approximate time remaining until the end of the cycle and the dryer cycle status |

||

|

(Sense, Drying, Damp and Cool). |

|

|

In addition, the display will show: |

|

|

(WiFi) |

Will allow your appliance to communicate with your smartphone for remote appliance |

|

|

monitoring control and notifications. |

|

Controls |

The dryer is locked - will blink once if you press any pad or turn the cycle knob. |

Check Filter The Check Filter light will stay on for 15 seconds after the cycle stops.

Check Vent The Check Vent light indicates an issue has been found due to reduced airflow from a possible blocked or restricted vent. Checking and/or cleaning the vent system is recommended. See the,

“Check Vent” light is on in the Troubleshooting Tips section.

6 |

49-3000206 Rev 1 |

Getting started

D |

Drying |

Sensor cycles automatically determine fabric dryness. |

|

Cycles |

Timed cycles run for the selected time. |

|

MIXED LOADS |

For loads consisting of cottons and poly-blends. |

|

COTTONS |

For cottons and most linens. NOTE: ENERGY STAR® models are tested on COTTONS cycle |

|

|

with default settings (Temp setting on Low, Level setting on Dry, and ecoDry default on). |

|

TOWELS |

For most towels and linens. |

|

BULKY |

For large coats, bed spreads, mattress covers, sleeping bags, and similar large/bulky items such as |

|

|

blankets, comforters, jackets, and small rugs. |

|

SANITIZE |

This option reduces certain types of bacteria including: Staphylococcus aureus, Pseudomonas |

|

|

aeruginosa and Klebsiella pneumoniae. The anti-bacterial process occurs when high heat is used |

|

|

during a portion of the drying cycle; cool down also will be longer to protect you from a hot garment. |

|

|

NOTE: Do not use this cycle on delicate fabrics. |

|

WASHER |

When selected (and if connected to a compatible washer through WiFi communication) |

|

LINK (on |

the dryer receives load information from the washer to automatically make cycle, dryness, |

|

some models) |

temperature and time recommendations to optimize drying. |

|

ACTIVE |

Clothing worn for active sports exercise and some casual wear. Fabrics include new |

|

WEAR |

technology finishes and stretch fibers such as Spandex. Also for clothing labeled Easy Care or |

|

|

Perma Press: For wrinkle-free and permanent press items. |

|

QUICK DRY |

For small loads that are needed in a hurry, such as sport or school uniforms. Can also be used if the |

|

|

previous cycle left some items damp, such as collars or waistbands. NOTE: On some models, the time |

|

|

remaining in the cycle will show counting down in the display. |

|

DELICATES |

For delicate items, special-care fabrics and knits. |

|

PERM PRESS |

For wrinkle-free, permanent press and special sports items that need extra drying care. |

|

DEWRINKLE |

For removing wrinkles from items that are dry or slightly damp. This cycle is not recommended |

|

|

for delicate fabrics. |

|

STEAM |

For use with larger loads than STEAM Refresh. Ideal for loads left in the dryer for an extended time. |

|

Dewrinkle (on |

STEAM Dewrinkle is recommended for larger loads (9-13 garments). |

|

some models) |

NOTE: Steam cycles are not intended for use with towels. |

|

|

Important - the temperature setting must be set to High and water must be turned on before |

|

|

running the STEAM Dewrinkle cycle. |

|

STEAM |

For slightly wrinkled dry garments. Significantly reduces wrinkles. After the STEAM Refresh cycle, |

|

Refresh (on |

the unit will beep (if Sound is selected) and display “00.” |

|

some models) |

STEAM Refresh is recommended for small loads (3-5 garments). |

|

|

NOTE: Steam cycles are not intended for use with towels. |

|

|

NOTE: A single extremely light fabric item may need to have an additional item included in the |

|

|

STEAM Refresh cycle to achieve optimum results. |

|

|

Important - the temperature setting must be set to High and water must be turned on before |

|

|

running the STEAM Refresh cycle. |

TIMED DRY Use to set your own dry time. To use:

1.Turn cycle dial to TIMED DRY.

2.Increase the drying time by pressing the Time pad.

NOTE: This pad only increases the time. When max time is reached, pressing the pad again will reset the counter to the lowest setting.

3.Select the Temp.

4.Close the door.

5.Press Start/Pause pad.

DRYER THE USING

49-3000206 Rev 1 |

7 |

USING THE DRYER

Getting started

E Settings

Individual settings for cycle minutes (Time), dryness level (Level) and temperature (Temp) can be set from the minimum (lowest in column) to maximum (highest in column). In general, the higher up the column, the more energy will be used. NOTE: The selected cycle set Time can be further adjusted, in one minute increments, by pressing the More Time + and Less Time - pads.

Dryness Level - Selection only used for Sensor cycles. Timed cycles run for the selected time.

Extra Dry Use for heavy-duty fabrics or items that should be very dry, such as towels.

More Dry Use for heavy-duty or mixed type fabrics.

Dry Use for a normal dryness level suitable for most loads. This is the preferred cycle for energy savings.

Less Dry Use for lighter fabrics.

Damp For leaving items partially damp.

Temperature

High For regular to heavy cottons.

NOTE: STEAM Dewrinkle and STEAM Refresh require the High temperature setting.

Medium For synthetics, blends, delicates and items labeled permanent press.

Low For delicates, synthetics and items labeled tumble dry low.

Extra Low For lingerie and special-care fabrics.

No Heat For fluffing items without heat. For use only with the AIR FLUFF cycle.

F Options

Reduce Static (on some models)

When selected, the dryer will spray a mist of water onto the load, at the end of the drying cycle, to reduce static. This option is not available with BULKY, SANITIZE or STEAM cycles.

Damp Alert (Damp Alert/WiFi pad)

This option causes the dryer to beep when clothes have dried to a damp level. Remove items that you wish to hang dry. The Damp Alert will only beep when this option is selected (but the dry cycle will keep running). Removing clothes and hanging them when they are damp, can reduce the need to iron some items.

Delay Dry

Press the Delay Dry pad to set the delay start time in 1 hour increments up to 24 hours, and then back to clear (0 hours). After selecting the delay start time, press Start and the delay time will count down the time remaining until the cycle starts. NOTE: To set the amount of delay time faster, you can press and hold the Delay Dry pad.

Delay Dry for WiFi Connected Dryers

You have two options to set Delay Dry using your smartphone.

Option 1: Follow Delay Dry instructions. You can use the GE Appliances Laundry App to adjust the amount of time via your smartphone.

Option 2 - Remote Start: Set your dryer to “AP” using the Delay Dry pad. This allows you to use the GE Appliances Laundry App via your smartphone to start your dryer remotely at the time of your choosing. If the dryer is set to AP with no activity, it will start the dryer 24 hours later.

Air Fluff (on some models)

Provides 10 minutes of tumbling time with no heat. NOTE: On models without AIR FLUFF cycle, select TIMED DRY and set Temp to No Heat.

Sound

Use the Sound pad to change the volume of the pad presses and the end of cycle signal. Press the pad until you reach the desired volume or off. The clothes should be removed when the end of cycle signal goes off so wrinkles do not set in.

NOTE:

•Remove garments promptly at the sound of signal. Place clothes on hangers so wrinkles will not set in.

•Use the Sound especially when drying fabrics like polyester, knits and permanent press. These fabrics should be removed so wrinkles will not set in.

8 |

49-3000206 Rev 1 |

Getting started

FOptions (cont.)

Wrinkle Care

Use this option to minimize the wrinkles in clothes. It provides 1 hour of no-heat tumbling after the clothes are dry. If you are using the cycle Sound and you select the Wrinkle Care option, a signal will sound at the end of the drying time and several times during the Wrinkle Care cycle. This will remind you that it is time to remove the clothes.

More Time + / Less Time -

The selected cycle set Time can be further adjusted, in one minute increments, by pressing the More Time + and Less Time - pads.

ecoDry

Available for BULKY, TOWELS, COTTONS, MIXED LOADS, ACTIVE WEAR and DELICATES. When the ecoDry pad is pressed, cycle settings change to reduce the total energy consumption of the selected sensor cycle. NOTE: Cycle times will change when ecoDry is selected. The ecoDry option will default to on for COTTONS. For optimal energy savings, turn ecoDry on. For optimal drying times, turn ecoDry off. NOTE: Energy savings will vary across loads and cycles.

Light

The drum light will turn on if the Light pad is pressed or the door is opened. It will turn off when the door is shut, the Light pad is pressed again or after 5 minutes if the door is left open.

Small Load (on some models)

Select to use for a small load with any sensor cycle (except SANITIZE).

My Settings

As the cycle selector knob is turned, the Time (timed dry), Level (dryness level) and Temp (temperature) settings change to automatic pre-set default settings. If you desire a different setting, press the appropriate pad(s). Then press and hold the My Settings pad for 3 seconds and the dryer will “remember” these settings for that Knob Selection. In the future, when you turn the selector knob to that cycle, your settings will be automatically recalled. NOTE: Signal sound cannot be set for My Settings.

Control Lock

You can lock the controls to prevent any selections from being made. Or you can lock the controls after you have started a cycle. Children cannot accidentally start the dryer by touching pads with this option selected.

To lock/unlock the dryer controls, press and hold the Light pad for 3 seconds. The control lock icon will flash while locking/unlocking, stay on when locked, and turn off when unlocked.

NOTE: The Power pad can still be used when the machine is locked.

WiFi (Damp Alert/WiFi pad)

Press and hold the Damp Alert/WiFi pad for 3 seconds to activate.

DRYER THE USING

49-3000206 Rev 1 |

9 |

USING THE DRYER

Loading

Always follow fabric manufacturer’s care label when laundering.

Sorting and Loading Hints

|

|

|

|

|

|

|

|

|

|

|

WARNING |

- Fire Hazard |

|

|

|

|

|

|

|

|

|

|

|

|

• |

Keep flammable materials and vapors, such as |

• DO NOT dry anything that has ever had any type of oil |

||||

|

|

|

gasoline, away from dryer. |

|

on it (including cooking oils). |

|

|

|

• DO NOT dry anything that has ever had anything |

• |

Items containing foam, rubber, or plastic must be dried |

|

|||

|

|

|

flammable on it (even after washing). |

|

on a clothesline. |

|

|

|

• |

No washer can completely remove oil. |

• |

Failure to do so can result in death, explosion, or fire. |

|

||

|

|

|

|

|

|

|

|

As a general rule, if clothes are sorted properly for the washer, they are sorted properly for the dryer. Try also to sort items according to size. For example, do not dry a sheet with socks or other small items.

Do not add fabric softener sheets once the load has become warm. They may cause fabric softener stains. Bounce® Fabric Conditioner Dryer Sheets have been approved for use in this dryer when used in accordance with the manufacturer’s instructions.

Do not overload. This wastes energy and causes wrinkling.

Drying Rack (on some models)

A handy drying rack may be used for drying delicate items such as washable sweaters.

To install the drying rack, place the rack all the way into the dryer drum and fit its feet down and securely into place in the dryer.

NOTES:

• The drying rack must be used with the TIMED DRY cycle. Use with sensor cycles may result in damp items or extended cycle times.

• Do not use this drying rack when there are other clothes in the dryer.

• If your model did not come with a drying rack, order WE02X29449 on-line at GEApplianceparts.com, 24 hours a day or by phone at 877.959.8688 during normal business hours.

10 |

49-3000206 Rev 1 |

Care and cleaning

Interior and Duct

The interior of the appliance and exhaust duct should be cleaned once a year by qualified service personnel.

The Exhaust Duct: Inspect and clean the exhaust ducting at least once a year to prevent clogging. A partially clogged exhaust can lengthen the drying time.

Follow these steps:

1 Turn off electrical supply by disconnecting the plug from the wall socket.

2 Disconnect the duct from the dryer.

3 Vacuum the duct with the hose attachment and reconnect the duct.

The Exhaust Hood: Check with a mirror that the inside flaps of the hood move freely when operating. Make sure that there is no wildlife (birds, insects, etc.) nesting inside the duct or hood.

Exterior

Wipe or dust any spills or washing compounds with a damp cloth. Dryer control panel and finishes may be damaged by some laundry pretreatment soil and stain remover products. Apply these products away from the dryer. The fabric may then be washed and dried normally. Damage to your dryer caused by these products is not covered by your warranty.

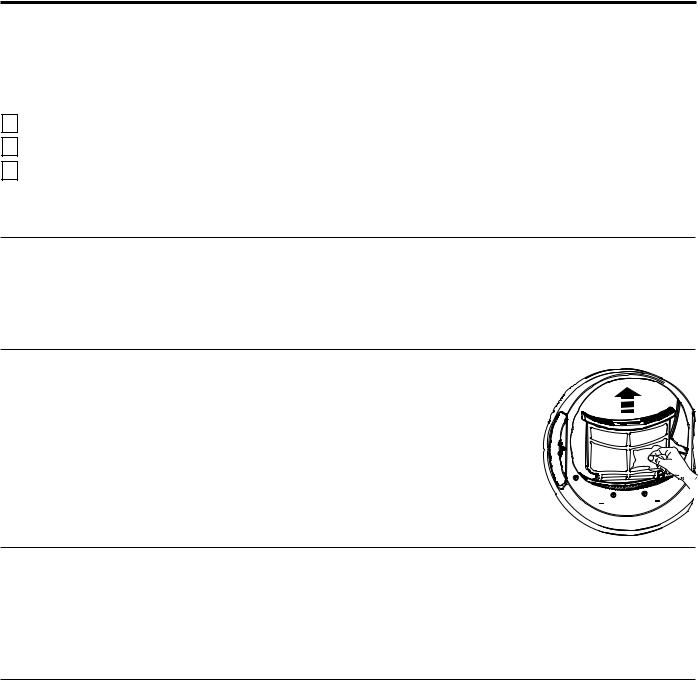

Lint Filter

Clean the lint filter before each use.

Remove by pulling straight up. Run your fingers across the filter. A waxy buildup may form on the lint filter from using dryer added fabric softener sheets.

To remove this buildup, wash the lint screen in warm, soapy water. Dry thoroughly and replace.

Vacuum the lint from the dryer lint filter area if you notice a change in dryer performance.

NEVER OPERATE THE DRYER WITHOUT ITS FILTER IN PLACE.

Stainless Steel

To clean stainless steel surfaces use a damp cloth with a mild, non-abrasive cleaner suitable for stainless steel surfaces. Remove the cleaner residue and then dry with a clean cloth.

The stainless steel used to make the dryer drum provides the highest reliability available in a GE Appliances dryer. If the dryer drum should be scratched or dented during normal use, the drum will not rust or corrode. These surface blemishes will not affect the function or durability of the drum.

Drum Light

The drum light is an LED light. Replacement must be done by a qualified technician.

CLEANING AND CARE

49-3000206 Rev 1 |

11 |

Installation |

Dryer |

Instructions |

|

If you have any questions, call GE Appliances at 800.GE.CARES (800.432.2737) or visit our Website at: GEAppliances.com

In Canada, call 800.561.3344 or visit www.GEAppliances.ca

BEFORE YOU BEGIN

Read these instructions completely and carefully.

• IMPORTANT– Save these instructions for local electrical inspector’s use.

• IMPORTANT– Observe all governing codes and ordinances.

•Install the clothes dryer according to the manufacturer’s instructions and local codes.

•Note to Installer – Be sure to leave these instructions with the Consumer.

•Note to Consumer – Keep these instructions for future reference.

•Clothes dryer installation must be performed by a qualified installer.

•This dryer must be exhausted to the outdoors.

•Before the old dryer is removed from service or discarded, remove the dryer door.

•Service information and the wiring diagram are located in the control console.

•Do not allow children on or in the appliance. Close supervision of children is necessary when the appliance is used near children.

•Proper installation is the responsibility of the installer.

•Product failure due to improper installation is not covered under the Warranty.

•Install the dryer where the temperature is above 50°F for satisfactory operation of the dryer control system.

•Remove and discard existing plastic or metal foil duct and replace with UL-listed duct.

If you are planning to stack the washer and dryer, order Stacking Kit number GFA28KITN to be used for this dryer. Kit sold separately.

WARNING

WARNING

- Risk of Fire

•Clothes dryer installation must be performed by a qualified installer.

•Install the clothes dryer according to these instructions and local codes.

•DO NOT install a clothes dryer with flexible plastic venting materials. If flexible metal (semi-rigid or foil-type) duct is installed, it must be UL-listed and installed in accordance with the instructions found in “Connecting the Dryer to House Vent” later in this manual. Flexible venting materials are known to collapse, be easily crushed and trap lint. These conditions will obstruct dryer airflow and increase the risk of fire.

•DO NOT install or store this appliance in any location where it could be exposed to water or weather.

•To reduce the risk of severe injury or death, follow all installation instructions.

•Save these instructions. (Installers: Be sure to leave these instructions with the customer.)

FOR GAS DRYERS ONLY

In the Commonwealth of Massachusetts, the following installation instructions apply:

•Installation must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by the State.

•If using a ball valve, it shall be a T-handle type.

•A flexible gas connector, when used, must not exceed 4 feet.

12 |

49-3000206 Rev 1 |

Installation Instructions

UNPACKING YOUR DRYER

Tilt the dryer sideways and remove the foam shipping pads by pulling at the sides and breaking them away from the dryer legs. Be sure to remove all of the foam pieces around the legs.

Remove the bag containing the literature.

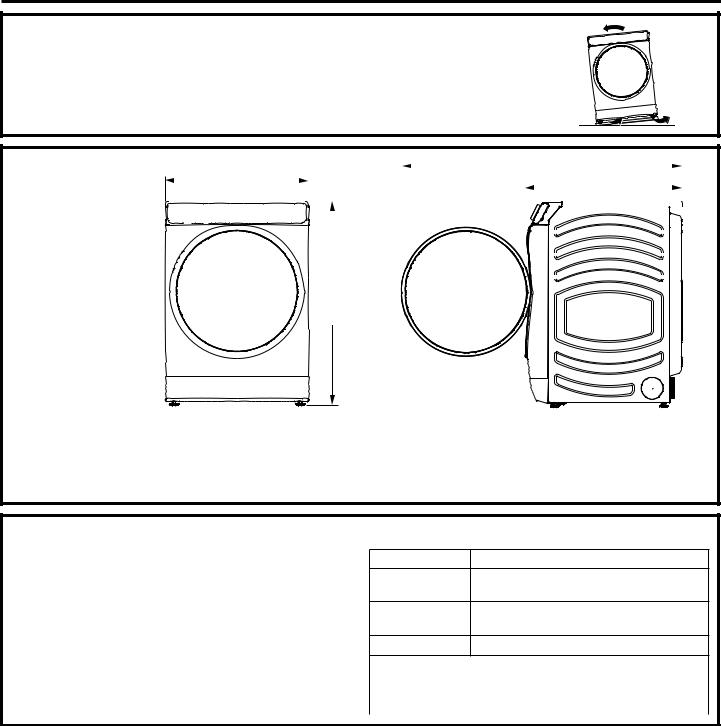

DRYER DIMENSIONS

|

|

|

|

|

|

|

|

54-1/4” (137.8 cm) |

|

|

|

|

|||||||||||

|

|

|

|

28” |

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

(71.2 cm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

31-3/8” (79.7 cm) |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*39-3/4” (101 cm)

Front View |

Side View |

*NOTE:

With leveling legs retracted: 39-3/4 (101 cm).

With leveling legs fully extended: 40-5/8 (103.1 cm).

With Optional Pedestal: 55-1/2” (141 cm) Min. - 56-5/8” (143.8 cm) Max. Stacked: 79-1/8” (201 cm).

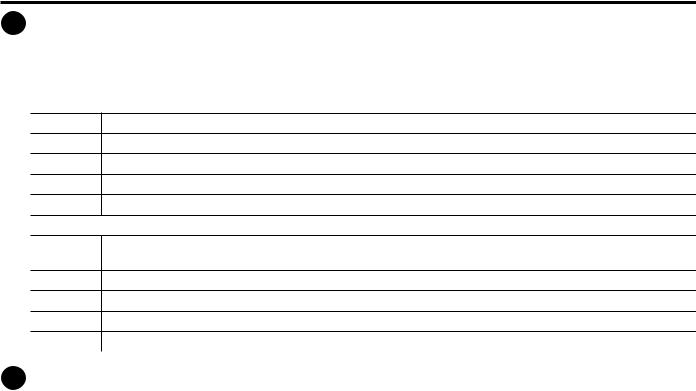

STEAM WATER HOSES (for steam dryer models only):

GE Appliances strongly recommends the use of factory specified parts. These hoses are manufactured and tested to meet GE Appliances specifications.

GE Appliances strongly recommends the use of new water supply hoses. Hoses degrade over time and need to be replaced every 5 years to reduce the risk of hose failures and water damage.

Parts and Accessories

Order on-line at GEApplianceparts.com, 24 hours a day or by phone at 877.959.8688 during normal business hours.

Part Number |

Accessory |

WE25X20060 Complete Kit (hoses, Y-adapter, washers) or

WE49X25794 Kit (Short hose, Y-adapter, washers) and

WE1M847 Long Hose

OR SEPARATELY

WE1M847 |

Long Hose and |

WE1M848 |

Short Hose |

ACCESSORIES: |

|

|

|

Part Number |

Accessory |

|

|

Order on-line at GEApplianceparts.com, 24 hours a day or |

GFP1528SNWW |

White Pedestal |

|

by phone at 877.959.8688 during normal business hours. |

|

|

|

GFP1528PNSN |

Satin Nickel Pedestal |

|

|

|

|

||

|

GFP1528PNRS |

Royal Sapphire Pedestal |

|

|

GFP1528PNDG |

Diamond Gray Pedestal |

|

|

GFA28KITN |

Stacking Kit for Dryer over Washer |

|

|

PM08X10085 |

Flexible Metal Dryer Transition Duct |

|

|

WE02X29449 |

Clothes Dryer Drying Rack |

|

|

|

|

|

49-3000206 Rev 1 |

13 |

Installation Instructions

REQUIREMENTS FOR ALCOVE OR CLOSET INSTALLATION

WARNING

WARNING

- Explosion Hazard

- Explosion Hazard

Keep flammable materials and vapors, such as gasoline, away from dryer.

Place dryer at least 18” (46 cm) above the floor for a garage installation.

Failure to do so can result in death, explosion, or fire.

•The dryer MUST be vented to the outdoors.

•Minimum clearance between dryer cabinet and adjacent walls or other surfaces is:

0” either side* 0” front

0” rear 0” top

*For improved performance, a 1/2” clearance is suggested on each side.

•The rear of the dryer should face a wall.

•Consideration must be given to provide adequate clearance for installation and service.

•Closet doors must be louvered or otherwise ventilated and have at least 60 square inches of open area. If the closet contains both a washer and a dryer, doors must contain a minimum of 120 square inches of open area.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT THE REAR OF THE DRYER, THE CONFIGURATION OF THE DUCTING MAY REQUIRE GREATER CLEARANCE.

Gas Dryers Only:

•No other fuel burning appliance shall be installed in the same closet as a gas dryer.

•The dryer must be disconnected from the gas supply piping during pressure testing at pressures greater than 1/2 psi (3.5 kPa).

•A 1/8 inch NPT minimum plugged tapping, accessible for test gauge connection, must be installed immediately upstream of the gas supply connection to the dryer.

MINIMUM CLEARANCE OTHER THAN ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and for air opening are: 0” both sides*, 0” rear and 0” top.

*For improved performance, a 1/2” clearance is suggested on each side.

The rear of the dryer should face a wall.

Consideration must be given to provide adequate clearance for installation and service.

MOBILE OR MANUFACTURED HOME INSTALLATION

•Installation MUST conform to the MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARD, TITLE 24, PART 3280 or STANDARD FOR MOBILE HOMES CAN/CSA-Z240 MH, or, when such standards are not applicable, with AMERICAN NATIONAL STANDARD FOR MOBILE HOME, ANSI/NFPA NO. 501B.

•The dryer MUST be vented to the outdoors.

•The exhaust vent MUST be securely fastened to a non-combustible portion of the mobile home.

•The vent MUST NOT be terminated beneath a mobile or manufactured home.

•The vent duct material MUST BE METAL.

•KIT 14-D346-33 MUST be used to attach the dryer securely to the structure.

•The vent MUST NOT be connected to any other duct, vent or chimney.

•DO NOT use sheet metal screws or other fastening devices which extend into the interior of the exhaust vent.

•Provide an opening with a free area of at least 25 square inches for introduction of outside air into the dryer room.

•See the sections for electrical connection information.

14 |

49-3000206 Rev 1 |

Installation Instructions

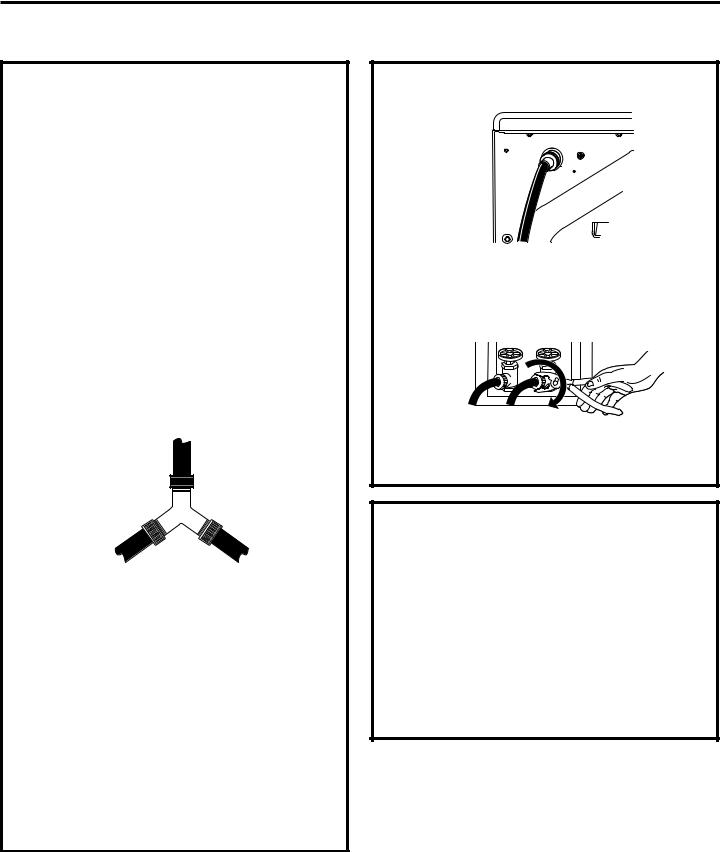

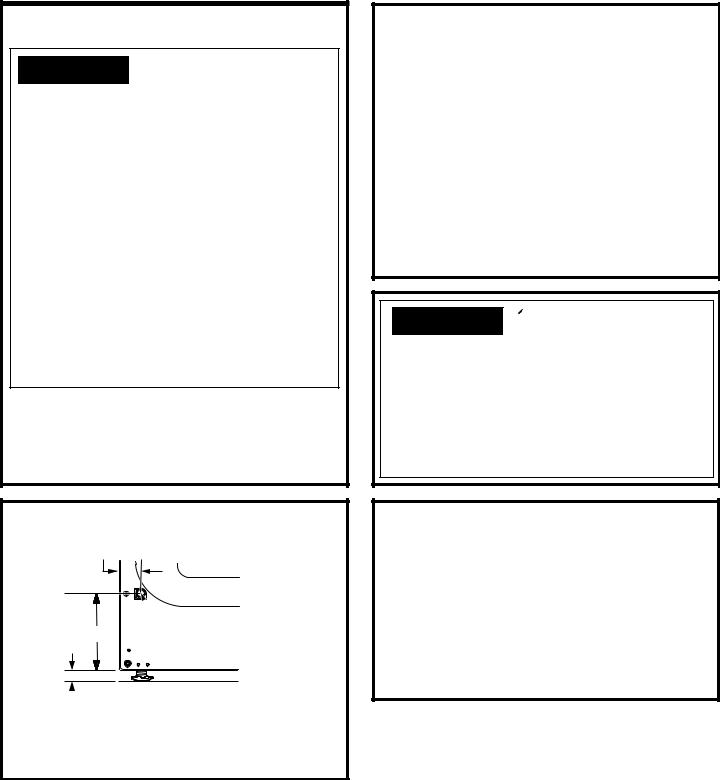

CONNECTING INLET HOSES (for steam dryer models only)

CONNECTING INLET HOSES

To produce steam, the dryer must connect to the cold water supply. Since the washer must also connect to the cold water, a “Y” connector is inserted to allow both inlet hoses to make that connection at the same time.

NOTE: Use new inlet hoses; never use old hoses.

1. Turn the cold water faucet off. Remove the washer inlet hose from the washer fill valve connector (cold).

2. Ensure the rubber flat washer is in place and attach one female coupling of the short hose provided onto the washer fill valve connector. Tighten by hand until firmly seated.

3. Attach one male end of the “Y” connector to the other female coupling of the short hose. Ensure the rubber flat washer is in place. Tighten by hand until firmly seated.

4. Insert the filter screen in the coupling of the washer’s inlet hose. If a rubber flat washer is already in place remove it before installing the filter screen. Attach this coupling to one male end of the ‘’Y’’ connector. Tighten by hand until firmly seated.

5. Ensure the rubber flat washer is in place and attach a 4 ft. to 6 ft. long water inlet hose (may need to be purchased separately) to one male end of the ‘’Y’’ connector. Tighten by hand until firmly seated.

6. Ensure the rubber flat washer is in place and attach the other end of the dryer’s long inlet hose to the fill valve connector at the bottom of the dryer back panel. Tighten by hand until firmly seated.

CONNECTING INLET HOSES (cont.)

7. Using pliers, tighten all the couplings with an additional two–thirds turn.

NOTE: Do not overtighten. Damage to the couplings may result.

8. Turn the water faucet on.

9. Check for leaks around the ‘’Y’’ connector, faucet and hose couplings.

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42 in. (107 cm) of your washer’s water inlet. The faucets MUST be 3/4 in. (1.9 cm) garden hose-type so inlet hoses can be connected. Water pressure MUST be between 10 and 120 pounds per square inch. Your water department can advise you of your water pressure.

NOTE: A water softener is recommended to reduce buildup of scale inside the steam

generator if the home water supply is very hard.

49-3000206 Rev 1 |

15 |

Installation Instructions

CONNECTING A GAS DRYER (skip for electric dryers)

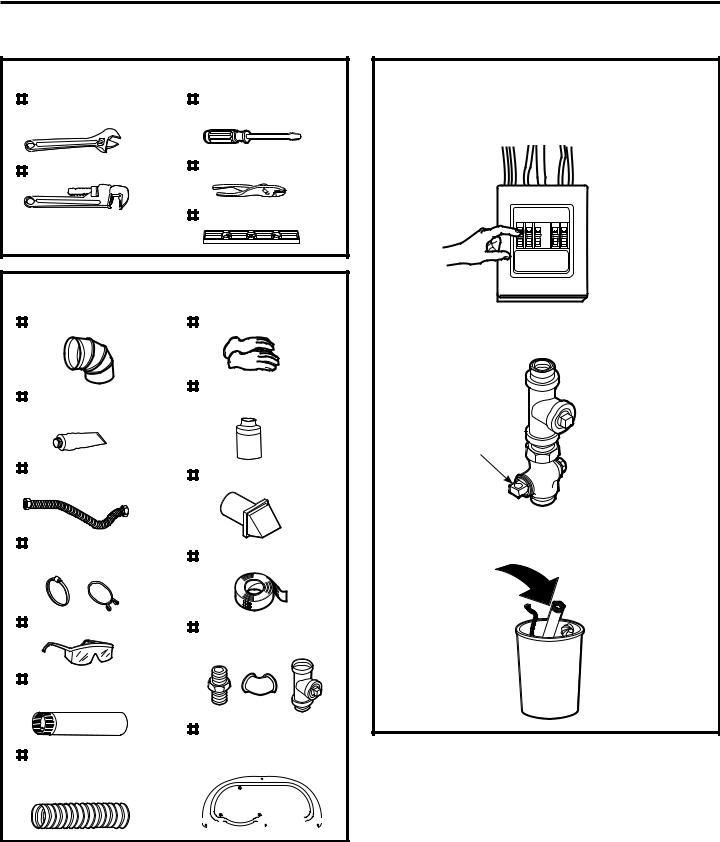

TOOLS YOU WILL NEED

Ŷ 10” Adjustable |

Ŷ Flat-blade |

wrenches (2) |

screwdriver |

Ŷ 8” Pipe wrench |

Ŷ Slip-joint pliers |

|

Ŷ Level |

MATERIALS YOU WILL NEED

Ŷ 4” dia. metal elbow |

Ŷ Gloves |

ŶPipe compound or PTFE tape

ŶFlexible gas line connector

ŶDuct clamps (2) or Spring clamps (2)

ŶSafety glasses

Ŷ4” dia. metal duct (recommended)

Ŷ4” dia., UL-listed flexible metal duct (if needed)

ŶSoap solution for leak detection

ŶExhaust hood

ŶDuct tape

ŶGas pipe adapters (2), elbow and pipe plug

ŶAccess Panel (Kit WE16X29317) (if needed)

•Before beginning the installation, turn off the circuit breaker(s) or remove the dryer’s circuit fuse(s) at the electrical box. Be sure the dryer

cord is unplugged from the wall.

•Turn the dryer’s gas shut-off valve in the supply line to the OFF position.

Shut-off

Valve

•Disconnect and discard old flexible gas connector and ducting material.

16 |

|

|

|

|

|

|

|

|

|

|

|

|

49-3000206 Rev 1 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Installation Instructions

CONNECTING A GAS DRYER (cont.)

GAS REQUIREMENTS

WARNING

WARNING

- Explosion Hazard

- Explosion Hazard

•Use a new CSA International approved flexible gas supply line. Never reuse old flexible connectors.

•Install an individual manual shut-off valve within 6ft. of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.

•Securely tighten all gas connections.

•If connected to LP gas, have a qualified person make sure gas pressure DOES NOT exceed 13” water column.

•Examples of a qualified person include: licensed heating personnel, authorized gas company personnel, and authorized service personnel.

•Failure to do so can result in death, explosion, or fire.

•The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/ NFPA 54, or the Natural Gas and Propane Installation Code, CSA B149.1.

GAS SUPPLY

•A 1/8” National Pipe Taper thread plugged tapping, accessible for test gauge connection, must be installed immediately upstream of the gas supply connection to the dryer. Contact your local gas utility should you have questions on the installation of the plugged tapping.

•Supply line is to be 1/2” rigid pipe and equipped with an accessible shutoff within 6 feet of, and in the same room with, the dryer.

•Use pipe thread compound appropriate for natural or LP gas or use PTFE tape.

•Connect flexible metal connector to dryer and gas supply.

WARNING

WARNING

- Fire Hazard

- Fire Hazard

FOR USE WITH NATURAL GAS ONLY

Dryer as produced by manufacturer is to be used only with a natural gas supply. A manufacturersupplied conversion kit is required to convert this dryer for propane gas supply. Use propane gas conversion kit WE25M87. Conversion must be made by properly trained and qualified personnel in accordance with local codes and ordinances.

DRYER GAS SUPPLY CONNECTION

1-5/8”

3/8” NPT MALE 5-3/4” THREAD GAS

3/8” NPT MALE 5-3/4” THREAD GAS

SUPPLY

NOTE: Add to vertical dimension the

NOTE: Add to vertical dimension the

GLVWDQFH EHWZHHQ FDELQHW ERWWRP WR ÀRRU

You must use with this dryer a flexible metal connector (listed connector ANSI Z21.24 / CSA 6.10). The length of the connect shall not exceed 4 ft.

ADJUSTING FOR ELEVATION

•Gas clothes dryers input ratings are based on sea level operation and need not be adjusted for operation at or below 2000 ft. elevation. For operation at elevations above 2000 ft., input ratings should be reduced at a rate of 4 percent for each 1000 ft. above sea level.

•Installation must conform to local codes and ordinances or, in their absence, the NATIONAL FUEL GAS CODE, ANSI Z223.

49-3000206 Rev 1 |

17 |

Installation Instructions

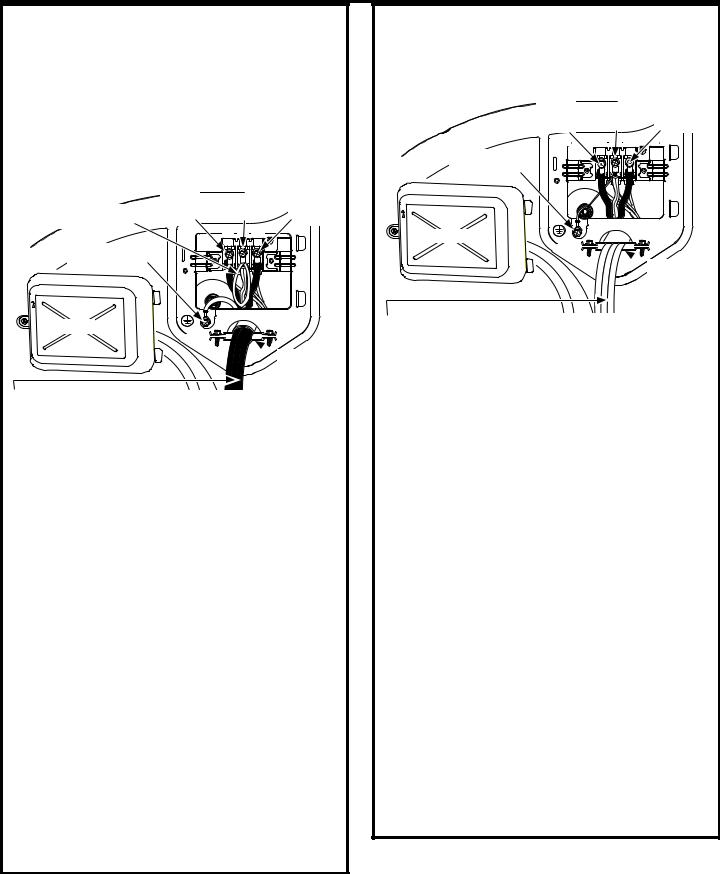

CONNECTING A GAS DRYER (cont.)

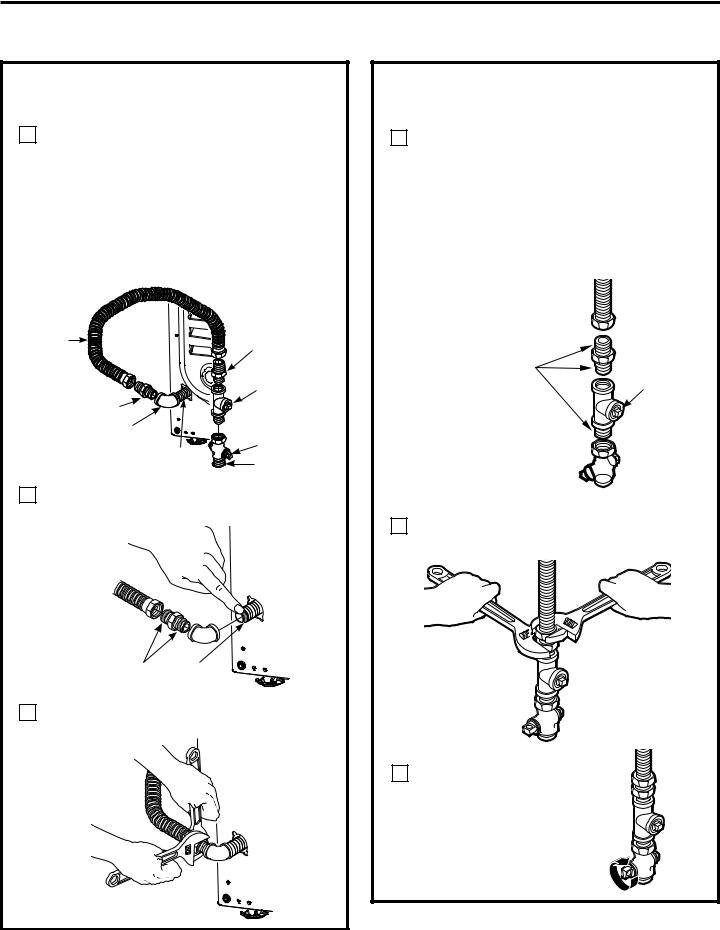

CONNECTING THE DRYER TO THE GAS SUPPLY

AInstall a female 3/8” NPT elbow at the end of the dryer gas inlet.

Install a 3/8” flare union adapter to the female elbow.

IMPORTANT: Use a pipe wrench to securely hold on to the end of the dryer gas inlet to prevent twisting the inlet.

NOTE: Apply pipe compound or PTFE tape to the threads of the adapter and dryer gas inlet.

New Metal |

|

Adapter |

|

Flexible Gas |

|

||

Line Connector |

|

1/8” NPT |

|

|

|

||

|

|

Pipe Plug for |

|

Adapter |

|

Checking Gas |

|

Elbow |

|

Inlet Pressure |

|

|

|

||

Items not supplied |

3/8” NPT |

Shut-Off Valve |

|

Pipe size at |

|||

|

|

||

|

|

least 1/2” |

BAttach the flexible metal gas line connector to the adapter.

Apply pipe compound to the adapter and dryer gas inlet.

CTighten the flexible gas line connection, using two adjustable wrenches.

CONNECTING THE DRYER TO

THE GAS SUPPLY (cont.)

DInstall a 1/8” NPT plugged tapping to the dryer gas line shut-off valve for checking gas inlet pressure.

Install a flare union adapter to the plugged tapping.

NOTE: Apply pipe compound or PTFE tape to the threads of the adapter and plugged tapping.

Apply pipe compound |

|

or PTFE tape to all |

|

male threads. |

Plugged |

|

Tapping |

Shut-Off

Valve

ETighten all connections, using two adjustable wrenches. Do not overtighten.

F Open the gas shut-off valve.

18 |

49-3000206 Rev 1 |

Installation Instructions

CONNECTING A GAS DRYER (cont.)

TEST FOR LEAKS

Never use an open flame to test for gas leaks.

Check all connections for leaks with soapy solution or equivalent.

Apply a soap solution. The leak test solution must not contain ammonia, which could cause damage to the brass fittings.

If leaks are found, close the valve, retighten the joint and repeat the soap test.

Open Gas

Valve

ELECTRICAL CONNECTION INFORMATION FOR GAS DRYERS

WARNING

WARNING

- Electrical Shock Hazard

- Electrical Shock Hazard

Plug into a grounded 3 prong outlet. DO NOT remove ground prong. DO NOT use an adapter.

DO NOT use an extension cord.

Failure to do so can result in death, fire or electrical shock.

•Circuit – Individual properly polarized and grounded 15 or 20 amp circuit breaker or time-delay fuse.

•Power Supply – 2-wire plus ground, 120 Volt, single phase, 60 Hz, alternating current.

•Outlet Receptacle – Properly grounded 3-prong receptacle to be located

so the power cord is accessible when the dryer is in an installed position.

If a 2-prong receptacle is present, it is the owner’s responsibility to have a licensed electrician replace

it with a properly grounded 3-prong grounding type receptacle.

ELECTRICAL CONNECTION INFORMATION FOR GAS DRYERS (cont.)

•Dryer must be electrically grounded in accordance with local codes and ordinances, or in the absence of local codes, with the latest edition of the NATIONAL ELECTRICAL CODE, ANSI/NFPA NO. 70 or CANADIAN ELECTRICAL CODE, CSA C22.1. Check with a licensed electrician if you are not sure that the dryer is properly grounded.

GROUNDING INSTRUCTIONS

This dryer must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. This dryer uses a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Improper connection of the

WARNING equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded. DO NOT modify the plug on the power supply cord. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded. DO NOT modify the plug on the power supply cord. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

•If required by local codes, an external 18 gauge or larger copper ground wire (not provided) may be added. Attach to dryer cabinet with a #8-18 x ½” sheet metal screw (available at any hardware store) to rear of dryer as illustrated.

Ground

Screw

49-3000206 Rev 1 |

19 |

Installation Instructions

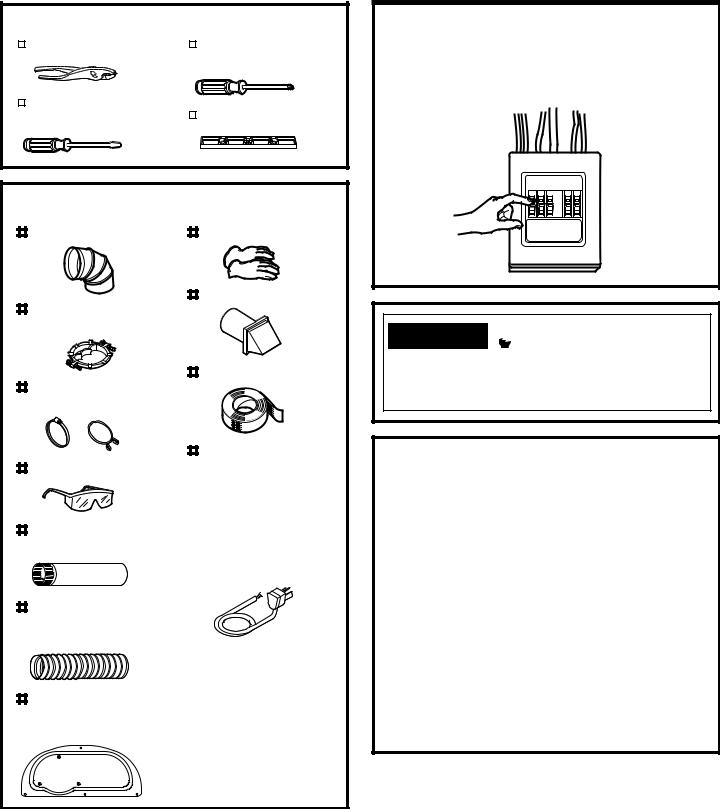

CONNECTING AN ELECTRIC DRYER

(Skip for gas dryers and if your dryer already has a power cord attached)

TOOLS YOU WILL NEED

Slip-joint pliers |

Phillips |

|

screwdriver |

Flat-blade |

Level |

screwdriver |

MATERIALS YOU WILL NEED

Ŷ4” dia. metal elbow

ŶMetal strain relief clamp (UL recognized)

Ŷ4” Duct clamps (2) or 4” spring clamps (2)

ŶSafety glasses

Ŷ4” dia. metal duct (recommended)

Ŷ4” dia., UL-listed flexible metal duct (if needed)

ŶAccess Panel (Kit WE16X29317) (if needed)

ŶGloves

ŶExhaust hood

ŶDuct tape

ŶDryer power cord kit (not provided with dryer)

UL rated 120/240V, 30A with 3 or 4 prongs. Identify the plug type as per the house receptacle before purchasing line cord.

Stacking installations may require a power cord up to 6 feet in length.

Before making the electrical connection, turn off the circuit breaker(s) or remove the dryer’s circuit fuse(s) at the electrical box. Be sure the dryer cord is unplugged from the wall. NEVER LEAVE THE ACCESS COVER OFF THE TERMINAL BLOCK.

WARNING

WARNING

- Electrical Shock Hazard

- Electrical Shock Hazard

Disconnect power supply before servicing. Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

POWER CORDS

GE Appliances strongly recommends the use of factory specified parts. Select the power cord to fit your installation requirements.

Part Number |

Type |

Length |

Amperage |

WX9X2 |

3-Prong |

4 Feet |

30 |

WX9X3 |

3-Prong |

5 Feet |

30 |

WX9X4 |

3-Prong |

6 Feet |

30 |

WX9X18 |

4-Prong |

4 Feet |

30 |

WX9X19 |

4-Prong |

5 Feet |

30 |

WX9X20 |

4-Prong |

6 Feet |

30 |

Order on-line at GEApplianceparts.com today, 24 hours a day or by phone at 877.959.8688 during normal business hours. In Canada, visit your local GE Appliances parts distributor or call 800.661.1616 or

GEAppliances.ca/en/products/parts-filters-accessories.

20 |

49-3000206 Rev 1 |

Installation Instructions

ELECTRICAL CONNECTION INFORMATION FOR ELECTRIC DRYERS

For electrical connections using a power cord:

WARNING

WARNING

- Fire Hazard

- Fire Hazard

Use a new UL-listed 240V 30 amp dryer power supply cord with closed ring terminals or spade terminals with upturned ends.

Use a UL-listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center terminal.

Ground wire (green or bare wire) must be connected to green ground connector.

Connect remaining two supply wires to remaining two terminals.

Securely tighten all electrical connections. Replace the terminal block cover.

Failure to do so can result in death, fire or electrical shock.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected dryer: This dryer must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. This dryer uses a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Improper connection of the

WARNING equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded. DO NOT modify the plug on the power supply cord. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

WARNING equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded. DO NOT modify the plug on the power supply cord. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

WARNING

WARNING

- Electrical Shock Hazard

- Electrical Shock Hazard

TO PREVENT ELECTRIC SHOCK, DISCONNECT POWER BEFORE SERVICING.

This dryer should be connected to an individual branch circuit with 10 gauge copper wire minimum through a 30 amp fuse or circuit breaker. DO NOT fuse neutral.

Use copper conductors only.

ELECTRICAL CONNECTION INFORMATION FOR ELECTRIC DRYERS

For direct wire connections:

WARNING

WARNING

- Fire Hazard

- Fire Hazard

Use 10 gauge copper wire. Use a UL-listed strain relief.

Disconnect power before making electrical connections.

Connect neutral wire (white or center wire) to center terminal.

Ground wire (green or bare wire) must be connected to green ground connector.

Connect remaining two supply wires to remaining two terminals.

Securely tighten all electrical connections. Replace the terminal block cover.

Failure to do so can result in death, fire or electrical shock.

GROUNDING INSTRUCTIONS

For a permanently connected dryer: This dryer must be connected to a grounded metal, permanent wiring system, or an equipment-grounding conductor must be run with the circuit conductors and connected to the equipment-grounding terminal on the appliance.

Improper connection of the

WARNING equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded.

WARNING equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician, or service representative or personnel, if you are in doubt as to whether the appliance is properly grounded.

SAVE THESE INSTRUCTIONS

WARNING

WARNING

- Electrical Shock Hazard

- Electrical Shock Hazard

TO PREVENT ELECTRIC SHOCK, DISCONNECT POWER BEFORE SERVICING.

This dryer should be connected to an individual branch circuit with 10 gauge copper wire minimum through a 30 amp fuse or circuit breaker. DO NOT fuse neutral.

Use copper conductors only.

49-3000206 Rev 1 |

21 |

Installation Instructions

CONNECTING AN ELECTRIC DRYER (cont.)

CONNECTING DRYER USING 4-WIRE CONNECTION (MUST BE USED FOR MOBILE HOME INSTALLATION)

NOTE: Since January 1, 1996, the National Electrical Code requires that new constructions use a 4-wire connection to an electric dryer. A 4-wire cord must also be used where local codes do not permit grounding through the neutral. 3-wire connection is NOT for use on new construction.

|

Black |

White |

Black |

|

Dryer’s White Strap |

or Red |

or Red |

||

Wire |

||||

Looped to Neutral (N) |

Wire |

L1 N L2 |

Wire |

|

|

|

|

||

Green wire from |

|

|

|

|

power cord |

|

|

|

Cover

Metal Strain

Metal Strain

Relief

Clamp UL

4 #10 AWG minimum copper conductors or 120/240V 30A power supply cord kit marked for use with dryers and provided with closed loop or spade terminals with upturned ends (not supplied).

1.Turn off the circuit breaker(s) (30 amp) or remove the dryer’s circuit fuse at the electrical box.

2.Be sure the dryer cord is unplugged from the wall receptacle.

3.Remove the power cord cover located at the lower back.

4.Remove green ground screw and retain for use in Step 7. Leave one end of the short white strap loose until Step 6. Remove center screw (marked

N)in terminal block.

5.Place the UL-recognized metal strain relief clamp to power cord entry hole. Bring power cord through strain relief clamp.

6.Connect power cord as follows:

A.Connect the 2 hot lines to the outer screws of the terminal block (marked L1 and L2).

B.Connect the neutral (white) line and the loose end of the short white strap to the center of the terminal block (marked N).

7.Attach ground wire of power cord with the green ground screw (hole to left of strain relief clamp). Tighten all terminal block screws (3) securely.

8.Properly secure power cord to strain relief clamp.

9.Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE TERMINAL BLOCK.

CONNECTING DRYER USING 3-WIRE CONNECTION

If required, by local code, install external ground (not provided) to grounded metal, cold water pipe, or other established ground determined by a qualified electrician.

Black |

White |

Black |

or Red |

or Red |

|

Wire |

Wire |

Wire |

L1 N L2

L1 N L2

Ground

White Strap

Cover

Metal Strain

Metal Strain

Relief

Clamp UL

3 #10 AWG minimum copper conductors or 120/240V 30A power supply cord kit marked for use with dryers and provided with closed loop or spade terminals with upturned ends (not supplied).

3-wire Connection

Not for use in Canada.

DO NOT use for Mobile Home Installations. NOT for use on new construction.

NOT for use on recreational vehicles.

NOT for use in areas where local codes prohibit grounding through the neutral conduction.

1.Turn off the circuit breaker(s) (30 amp) or remove the dryer’s circuit fuse at the electrical box.

2. Be sure the dryer cord is unplugged from the wall receptacle.

3.Remove the power cord cover located at the lower back.

4.Place the UL-recognized metal strain relief clamp to power cord entry hole. Bring power cord through strain relief clamp.

5.Connect power cord as follows:

A.Connect the 2 hot lines to the outer screws of the terminal block (marked L1 and L2).

B.Connect the neutral (white) line to the center of the terminal block (marked N).

6. Be sure ground white strap is connected to green ground screw on cabinet rear. Tighten all terminal block screws (3) securely.

7.Properly secure power cord to strain relief clamp.

8.Reinstall the cover.

NEVER LEAVE THE COVER OFF OF THE TERMINAL BLOCK.

22 |

49-3000206 Rev 1 |

Installation Instructions

EXHAUSTING THE DRYER

WARNING

WARNING

- Fire Hazard

- Fire Hazard

This dryer MUST be vented to the outdoors.

Use only 4” rigid metal ducting for the home exhaust duct.

Use only 4" rigid metal, UL-listed flexible metal, or UL-listed metal foil dryer transition duct to connect the dryer to the home exhaust.

DO NOT use any plastic to vent the dryer, this includes the home exhaust duct, dryer transition duct, or within the dryer.

DO NOT use flexible metal or metal foil ducting for a home exhaust duct or within the dryer.

DO NOT exhaust into a chimney, kitchen exhaust, gas vent, wall, ceiling, attic, crawl space, or concealed space of a building.

DO NOT install a screen in or over the exhaust duct.

DO NOT install a booster fan in the exhaust duct.

DO NOT use duct longer than specified in the exhaust length table.

Failure to follow these instructions can result in death or fire.

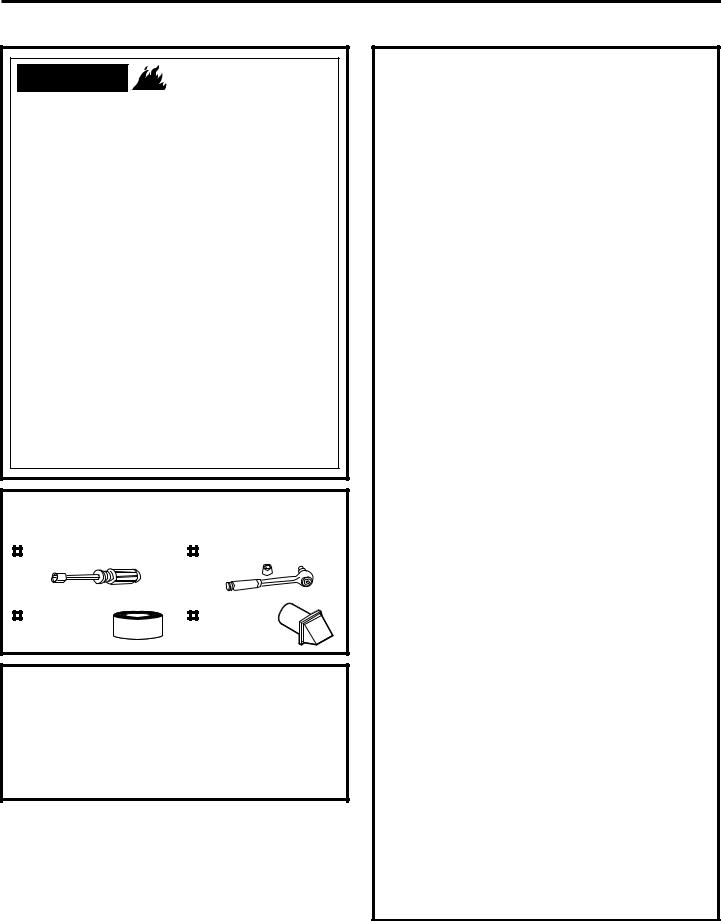

TOOLS AND MATERIALS YOU WILL NEED TO INSTALL EXHAUST DUCT

Ŷ 1/4" Socket & Nut Driver |

Ŷ 1/4" Socket & Wrench |

Ŷ Duct tape or |

Ŷ Vent hood |

duct clamp |

|

PARTS AVAILABLE FROM GEAPPLIANCEPARTS.COM OR LOCAL SERVICE ORGANIZATIONS

WE16X29317 Dryer Venting Kit PM8X85 Outdoor exhaust hood WX08X10130 4” Dryer exhaust clamp

CONNECTING THE DRYER TO HOUSE VENT

RIGID METAL TRANSITION DUCT

•For best drying performance, a rigid metal transition duct is recommended.

•Rigid metal transition ducts reduce the risk of crushing and kinking.

UL-LISTED FLEXIBLE METAL CLOTHES DRYER TRANSITION DUCT

•If rigid metal cannot be used, then UL-listed flexible metal clothes dryer transition duct (GE Appliances part – PM08X10085) can be used.

•Never install transition duct in walls, ceilings, floors or other enclosed spaces.

•Total length of transition duct should not exceed 8’ (2.4 m).

•For many applications, installing elbows at both the dryer and the wall is highly recommended (see illustrations in next section). Elbows allow the dryer to sit close to the wall without kinking and/or crushing the transition duct, maximizing drying performance.

•Avoid resting the duct on sharp objects.

UL-LISTED FLEXIBLE METAL (FOIL-TYPE) TRANSITION DUCT

•In special installations, it may be necessary to connect the dryer to the home exhaust vent using flexible metal (foil-type) transition duct. UL– LISTED universal flexible dryer transition duct (GE Appliances parts – PM8X73 or WX8X73) may be used ONLY in installations where rigid metal or flexible metal transition ducting cannot be used AND where a 4” diameter can be maintained throughout the entire length of the transition duct.

•In Canada and the United States, only transition ducts that comply with “UL 2158A STANDARD FOR CLOTHES DRYER TRANSITION DUCT” shall be used.

•Avoid resting the duct on sharp objects.

•For best drying performance:

1.Slide one end of the duct over the clothes dryer outlet pipe.

2.Secure the duct with a clamp.

3.With the dryer in its permanent position, extend the duct to its full length. Allow 2” of duct to overlap the exhaust pipe. Cut off and remove excess duct. Keep the duct as straight as possible for maximum airflow.

4.Secure the duct to the exhaust pipe with the other clamp.

49-3000206 Rev 1 |

23 |

Installation Instructions

EXHAUSTING THE DRYER (cont.)

• DO cut duct as short |

• DO use elbows |

as possible and |

when turns are |

install straight into |

necessary. |

wall. |

|

|

Elbows |

• DO NOT bend |

• DO NOT use |

• DO NOT |

• DO NOT |

or collapse |

excessive |

crush duct |

set dryer |

ducting. |

exhaust |

against |

on duct. |

Use elbows |

length. Cut |

the wall. |

|

if turns are |

duct as short |

|

|

necessary. |

as possible. |

|

|

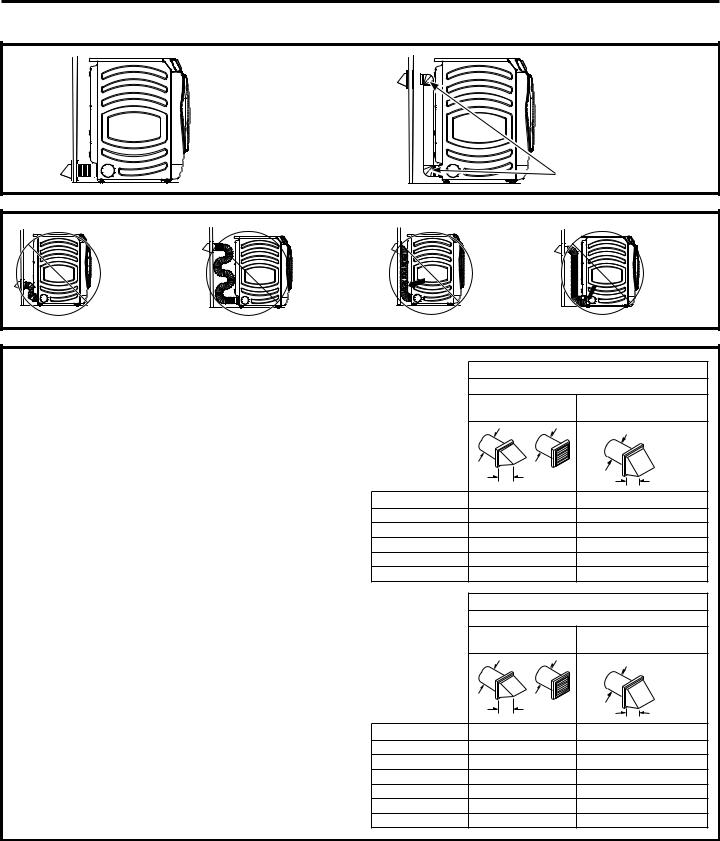

EXHAUST LENGTH

Using exhaust longer than specified length will:

•Increase the drying times and the energy cost.

•Reduce the dryer life.

•Accumulate lint, creating a potential fire hazard.

The correct exhaust installation is YOUR RESPONSIBILITY.

Problems due to incorrect installation are not covered by the warranty.

The MAXIMUM ALLOWABLE length of the exhaust system depends upon the type of duct, number of turns, the type of exhaust hood (wall cap) and all conditions noted on the chart.

•Internal elbows added for side or bottom vent conversions must be included in the total elbow count.

•Any elbow greater than 45° should be treated as a 90° elbow; one elbow of 45° or less may be ignored.

•Two 45° elbows will be treated like one 90° elbow.

•For the side exhaust installations, add one 90° elbow to the chart.

•For every additional 90° elbow, reduce the allowable vent system length by 10 feet.

•When calculating the total vent system length, you must add all the straight portions and elbows of the system (including the transition duct).

EXHAUST |

RECOMMENDED MAXIMUM LENGTH |

||||

|

Exhaust Hood Types |

|

|||

LENGTH |

Recommended |

Use only for short run |

|||

FOR |

installations |

||||

4" DIA. |

4" DIA. |

||||

NORMAL |

4" DIA. |

||||

VENT |

|

|

|

|

|

MODELS |

|

4" |

|

2-1/2" |

|

No. of 90° Elbows |

Rigid Metal |

Rigid Metal |

|||

0 |

|

90 Feet |

60 Feet |

||

1 |

|

60 Feet |

45 Feet |

||

2 |

|

45 Feet |

35 Feet |

||

3 |

|

35 Feet |

25 Feet |

||

4 |

|

25 Feet |

15 Feet |

||

EXHAUST |

RECOMMENDED MAXIMUM LENGTH |

||||

|

Exhaust Hood Types |

|

|||

LENGTH |

Recommended |

Use only for short run |

|||

FOR |

installations |

||||

4" DIA. |

4" DIA. |

||||

LONG |

4" DIA. |

||||

|

|

|

|||

VENT |

|

|

|

|

|

MODELS |

|

4" |

|

2-1/2" |

|

No. of 90° Elbows |

Rigid Metal |

Rigid Metal |

|||

0 |

|

200 Feet |

175 |

Feet |

|

1 |

|

185 Feet |

165 |

Feet |

|

2 |

|

175 Feet |

155 |

Feet |

|

3 |

|

165 Feet |

145 |

Feet |

|

4 |

|

155 Feet |

135 |

Feet |

|

5 |

|

145 Feet |

125 |

Feet |

|

24 |

49-3000206 Rev 1 |

Installation Instructions

EXHAUSTING THE DRYER (cont.)

EXHAUST SYSTEM CHECKLIST

HOOD OR WALL CAP

•Terminate in a manner to prevent back drafts or entry of birds or other wildlife.

•Termination should present minimal resistance to the exhaust airflow and should require little or no maintenance to prevent clogging.

•Wall caps must be installed at least 12” above ground level or any other obstruction with the opening pointed down.

SEPARATION OF TURNS

•For best performance, separate all turns by at least 4 ft. of straight duct, including distance between last turn and dampened exhaust hood (wall cap).

SEALING OF JOINTS

•All joints should be tight to avoid leaks. The male end of each section of duct must point away from the dryer.

•Duct joints should be made airand moisture-tight by wrapping the overlapped joints with duct tape or aluminum tape.

•Do not assemble ductwork with any fasteners that extend into the duct. These fasteners can accumulate lint, creating a potential fire hazard.

•Horizontal runs should slope down towards the outdoors 1/4” per foot.

•Provide an access for inspection and cleaning of the exhaust system, especially at turns and joints. Exhaust system shall be inspected and cleaned at least once a year.

INSULATION

•Ductwork that runs through an unheated area or is near air conditioning should be insulated to reduce condensation and lint build-up.

BEFORE YOU BEGIN

•Remove and discard existing plastic or metal foil duct and replace with UL-listed duct.

•Remove any lint from the wall exhaust opening.

Wall

Internal

Duct

Opening

Check that exhaust

Check that exhaust

hood damper

opens and closes

freely.

STANDARD REAR EXHAUST

We recommend that you install your dryer before installing your washer. This will permit direct access for easier exhaust connection.

Slide the end of the exhaust duct on the back of the dryer and secure with duct tape or a hose clamp.

Duct

NOTE: We strongly recommend using rigid metal exhaust duct. However, if flexible ducting is used it must be UL-Listed metal, not plastic.

•For straight line installation, connect the dryer exhaust to the external exhaust hood using duct tape or clamp.

Wall Side

Duct Tape

Duct Tape

Dryer

Side

RECOMMENDED CONFIGURATION TO MINIMIZE EXHAUST BLOCKAGE

Using duct elbows will prevent duct kinking and collapsing.

Wall

Transition

Ducting

49-3000206 Rev 1 |

25 |

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE VENTING

WARNING

WARNING

- Fire Hazard

- Fire Hazard

Disconnect dryer from electrical supply. Wear gloves and arm guards.

Close the back opening with the access panel included in kit WE16X29317.

Failure to do so may result in fire, electrical shock or lacerations.

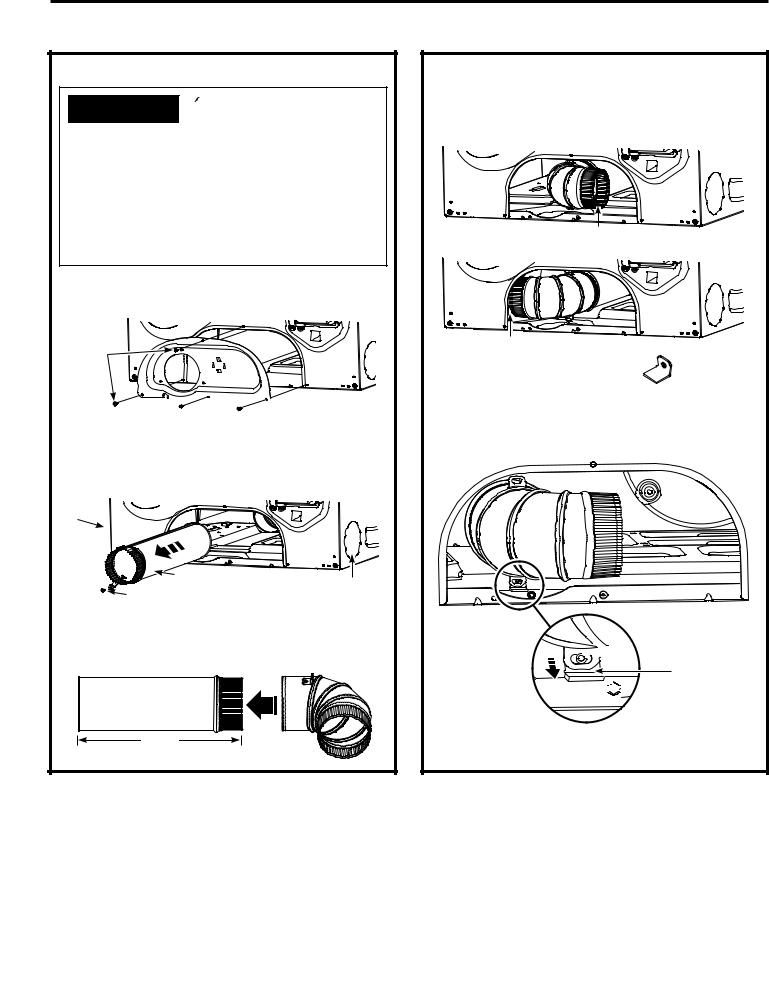

•Remove the 4 screws that secure the access panel and save. Remove the access panel.

Remove 4 screws and save

Access Panel

Access Panel

•Detach and remove the right or left side knockout as desired. Remove the screw that secures the dryer exhaust duct and save. Pull the exhaust duct out of the dryer.

Right knockout

Exhaust Duct |

Left Knockout |

|

Remove screw and save |

||

|

•Locate the 12-1/2” exhaust duct and elbow duct from the kit and assemble together. Apply duct tape around the joint to eliminate leaks between ducts.

12-1/2"

SIDE VENTING (cont.)

•Insert and connect the elbow/exhaust duct assembly to the blower housing and orient the elbow for either left or right venting.

Left Venting

Right Venting

• Locate the bracket from the kit.

•Remove the adhesive liner from the bottom of the bracket and position it behind the elbow duct tab.

•Press down firmly to secure the bracket to the bottom of the dryer.

Elbow Duct Tab

Elbow Duct Tab

Bracket

Saved Screw

Saved Screw

•Using one of the screws from earlier, secure the elbow duct tab to the bracket.

26 |

49-3000206 Rev 1 |

Installation Instructions

EXHAUSTING THE DRYER (cont.)

SIDE VENTING (cont.)

For LEFT venting:

•Locate the 15-1/2” exhaust duct from the kit.

•Insert exhaust duct through knockout opening on the LEFT side of dryer.

•Assemble exhaust duct to elbow duct.

•Wrap the joint with duct tape to avoid air leaks.

Left

Venting

For RIGHT venting:

•Locate the 9-1/2” exhaust duct from the kit.

•Insert exhaust duct through knockout opening on the RIGHT side of dryer.

•Assemble exhaust duct to elbow duct.

•Wrap the joint with duct tape to avoid air leaks.

Right

Venting

•Install the new access panel from the kit.

•Secure access panel with 4 screws saved from earlier.

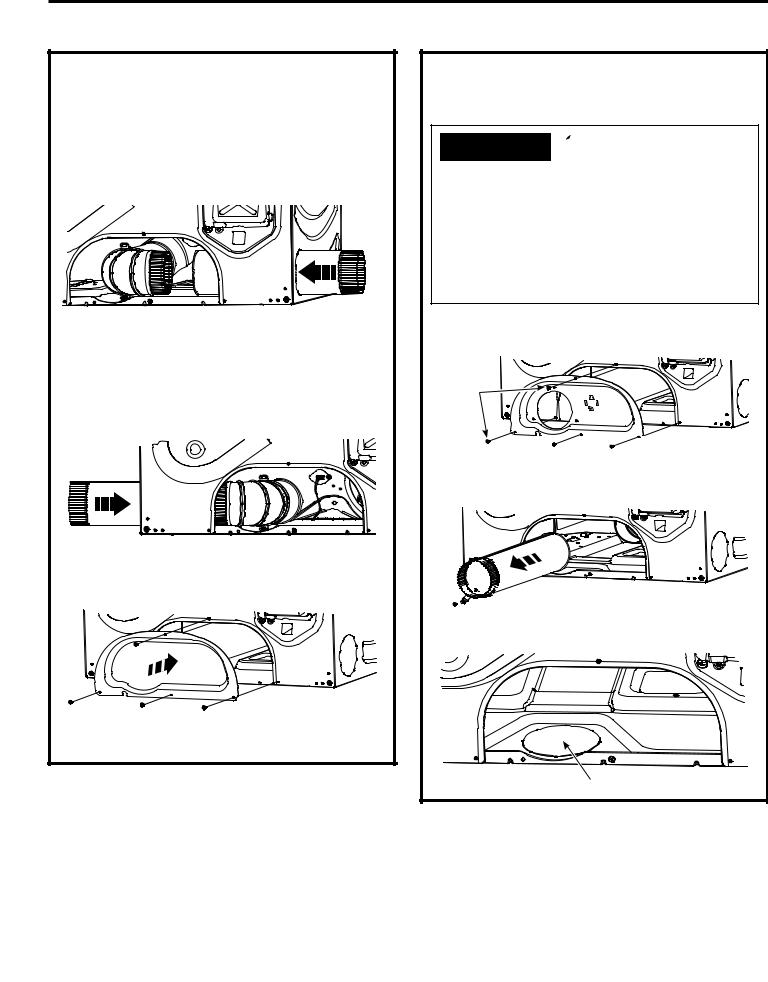

BOTTOM VENTING

Dryer Exhaust to the bottom of cabinet for Gas and Electric models WITHOUT Built-In Pedestal™.

WARNING

WARNING

- Fire Hazard

- Fire Hazard

Disconnect dryer from electrical supply. Wear gloves and arm guards.

Close the back opening with the access panel included in kit WE16X29317.

Failure to do so may result in fire, electrical shock or lacerations.

•Remove the 4 screws that secure the access panel and save. Remove the access panel.

Remove 4 screws and save

Access Panel

Access Panel

•Remove the screw that secures the dryer exhaust duct and save. Pull the exhaust duct out of the dryer.

Exhaust Duct

Exhaust Duct

Remove screw and save

Remove screw and save

• Detach and remove the bottom knockout.

NEVER LEAVE THE BACK OPENING WITHOUT

THE ACCESS PANEL.

Botom Knockout

49-3000206 Rev 1 |

27 |

Installation Instructions

EXHAUSTING THE DRYER (cont.)

BOTTOM VENTING (cont.)

•Locate the 12-1/2” exhaust duct and elbow duct from the kit and assemble together. Apply duct tape around the joint to eliminate leaks between ducts.

12-1/2"

•Insert and connect the elbow/exhaust duct assembly to the blower housing and insert the elbow through the bottom knockout.

BOTTOM VENTING (cont.)

•Install the new access panel from the kit.

•Secure access panel with 4 screws saved from earlier.

NEVER LEAVE THE BACK OPENING WITHOUT THE ACCESS PANEL.

28 |

49-3000206 Rev 1 |

Installation Instructions

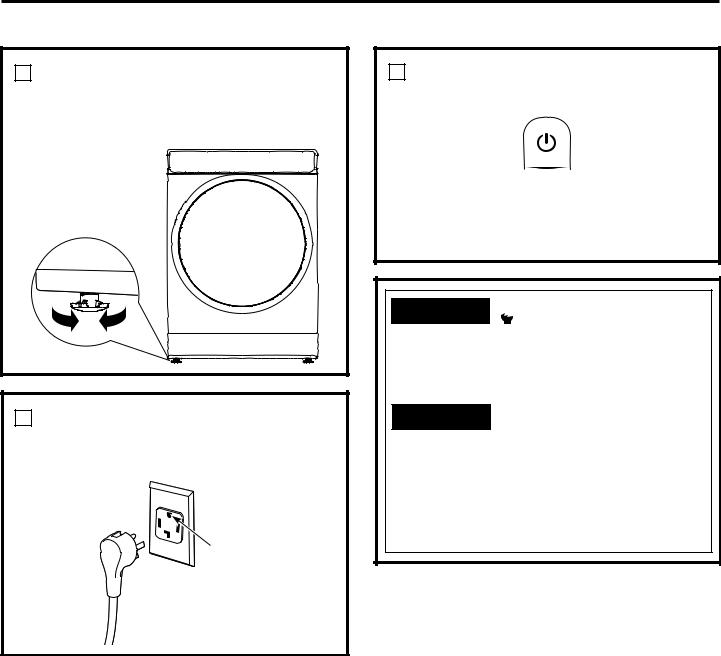

FINAL SETUP

1 LEVEL THE DRYER

Stand the dryer upright near the final location and adjust the four leveling legs at the corners to ensure that the dryer is level from side to side and front to rear.

Lower Raise

2 PLUG DRYER IN

NOTE: Stacking installations may require a power cord up to 6 feet in length.

Ensure proper ground exists before use.

3 DRYER START-UP

Press the Power pad.

NOTE: If the dryer has been exposed to temperatures below freezing for an extended period of time, allow it to warm up before pressing Power. Otherwise, the display will not come on.

The dryer is now ready for use.

WARNING

WARNING

- Electrical Shock Hazard

- Electrical Shock Hazard

Disconnect power supply before servicing. Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING - Shock Hazard

WARNING - Shock Hazard

Certain internal parts are intentionally not grounded and may present a risk of electric shock only during servicing.

Service personnel – DO NOT contact the following parts while the appliance is energized: water valve, door switch, electronic board, igniter, thermostats, flame detector.

49-3000206 Rev 1 |

29 |

Installation Instructions

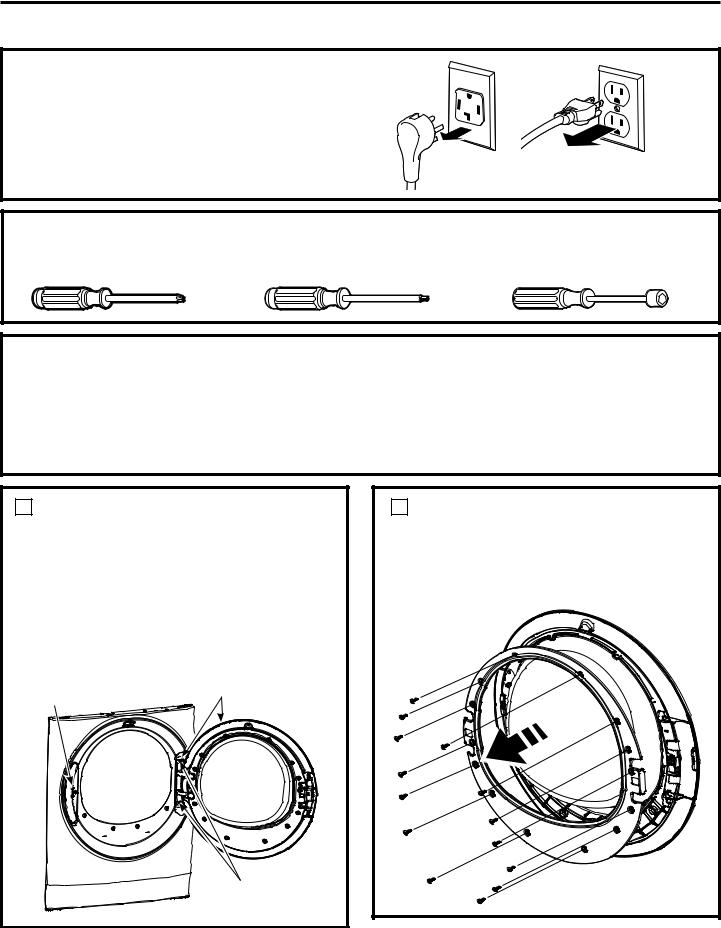

REVERSING THE DOOR SWING (Optional)

BEFORE YOU START

Unplug the dryer from its electrical outlet.

TOOLS YOU WILL NEED

Phillips-head screwdriver T-25 torx driver 1/4” nut driver

IMPORTANT NOTES

• Handle parts carefully to avoid scratching paint. |

• |

Once you begin, do not move the cabinet until |

|

• Provide a non-scratching work surface for the door. |

|

door-swing reversal is completed. |

|

• |

These instructions are for changing the hinges from the |

||

• Set screws down by their related parts to avoid using |

|||

|

right side to the left side—if you ever want to switch them |

||

them in the wrong places. |

|

||

|

back to the right side, follow these same instructions and |

||

|

|

||

|

|

reverse all references to the left and right. |

1REMOVE THE STRIKE PLATE AND DOOR ASSEMBLY

•Open the dryer door.

•Remove the two screws from the strike plate using a T-25 torx driver.

•Remove the strike plate and set it aside.

•While supporting the door, remove the two screws from the hinge in the dryer face using a 1/4” nut driver.