Fresenius 2008T Maintenance procedures

2008T HEMODIALYSIS

SYSTEM

PREVENTIVE MAINTENANCE PROCEDURES

Part Number 508033 Rev. M

FRESENIUS MEDICAL CARE

NORTH AMERICA

800-227-2572

Fresenius Medical Care North America

920 Winter St.

Waltham, MA 02451

Manufactured by: Fresenius USA, Inc. 4040 Nelson Avenue Concord, CA 94520

Page ii

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2008T HEMODIALYSIS SYSTEM

PREVENTIVE MAINTENANCE

PROCEDURES

Part Number 508033 Rev. M

INCLUDING

PREVENTIVE MAINTENANCE CHECKLISTS

SIX (6) MONTH AND ANNUAL/4000 HOUR

http://www.fmcna.com

Copyright 2008 – 2019 Fresenius Medical Care, All Rights Reserved.

Page iii

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2008T Preventive Maintenance Procedures

This document contains proprietary information of Fresenius USA, Inc. d/b/a Fresenius Medical Care North America and its affiliates (“Fresenius Medical Care”). The contents of this document may not be disclosed to third parties, copied, or duplicated in any form, in whole or in part, without the prior written permission of Fresenius Medical Care.

Fresenius Medical Care, the triangle logo, 2008, BlueStar, bibag and DIASAFE are trademarks of Fresenius Medical Care Holdings, Inc., or its affiliated companies. All other trademarks are the property of their respective owners.

Caution: US Federal law restricts this device to sale only by or on the order of a physician. Frequency, duration, and parameters of treatment are to be determined by the prescribing physician.

Installation, maintenance, calibration and other technical information may be found in the 2008T Technician’s Manual, P/N 490130.

Contact Fresenius Medical Care Technical Support for applicable Field Service Bulletins. The spare parts manual for the model 2008T and other information may be found on our web site at www.fmcna.com

Indications for Use: The 2008T hemodialysis machine is indicated for acute and chronic dialysis therapy in a healthcare facility.

Additional therapy options for patients receiving hemodialysis include: Isolated Ultrafiltration, Sustained Low Efficiency Dialysis (SLED), and low volume hemodialysis (patients weighing ≥ 20kg and ≤ 40 kg). This machine accommodates the use of both low flux and high flux dialyzers. The SLED therapy option is not to be used for patients weighing ≤ 40 kg. The 2008T

Hemodialysis Machine is not to be used for plasma replacement therapies, for patients weighing less than 20 kg, or for renal therapies using substitution fluid.

Conventions

Symbol Description

Warning! A warning is a statement that identifies conditions or actions that could result in personal injury or loss of life. Warnings found in this manual outside of this section are designated with the warning symbol.

Shock Hazard: A shock hazard warning refers to a risk of a possibly severe electrical shock due to improper use or handling of the equipment.

Caution: A caution is a statement that identifies conditions or actions that could result in damage to the machine.

Note: Notes are advisory comments or recommendations regarding practices or procedures.

Page iv

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

PREVENTIVE MAINTENANCE PROCEDURES |

|

|

|

TABLE OF CONTENTS |

|

1.0 INTRODUCTION............................................................................................................................................ |

1 |

|

1.1 |

SUPPLIES NEEDED.................................................................................................................... |

2 |

1.2 |

TEST EQUIPMENT NEEDED...................................................................................................... |

3 |

1.3 |

OPERATING MODES.................................................................................................................. |

4 |

1.4 |

FRONT PANEL CONTROLS ....................................................................................................... |

5 |

1.5 |

MEASURING FLUID VOLUMES.................................................................................................. |

7 |

2.0 SIX (6) MONTH PREVENTIVE MAINTENANCE ........................................................................................... |

8 |

|

2.1 |

FILTERS .................................................................................................................................... |

10 |

2.2 |

PRE-UF PUMP FILTER ............................................................................................................. |

10 |

2.3 |

UF PUMP CHECK VALVES....................................................................................................... |

11 |

2.4 |

HIGH VOLTAGE AC CONNECTIONS....................................................................................... |

11 |

2.5 |

UF PUMP................................................................................................................................... |

12 |

2.6 |

CONDUCTIVITY ........................................................................................................................ |

12 |

2.7 |

TEMPERATURE ........................................................................................................................ |

13 |

2.8 |

ALARM OPERATION AND PRESSURE HOLDING TESTS...................................................... |

14 |

2.9 |

VERIFY PH ................................................................................................................................ |

16 |

2.10 |

POWER FAILURE ALARM ........................................................................................................ |

16 |

2.11 |

FINAL CHECKS ......................................................................................................................... |

17 |

3.0 ANNUAL (4000 HOUR) PREVENTIVE MAINTENANCE ............................................................................ |

18 |

|

3.1 |

FILTERS AND O-RINGS............................................................................................................ |

18 |

3.2 |

PRE-UF PUMP FILTER ............................................................................................................. |

19 |

3.3 |

UF PUMP CHECK VALVES....................................................................................................... |

19 |

3.4 |

DIAPHRAGM PUMPS................................................................................................................ |

19 |

3.5 |

HEATER ELEMENT................................................................................................................... |

20 |

3.6 |

HIGH VOLTAGE AC CONNECTIONS....................................................................................... |

20 |

3.7 |

DEAERATION MOTOR BRUSHES ........................................................................................... |

21 |

3.8 |

INLET WATER PRESSURE REGULATOR ............................................................................... |

22 |

3.9 |

ONLINE CLEARANCE TEST (IF APPLICABLE) ....................................................................... |

23 |

3.10 |

DEAERATION AND LOADING PRESSURE.............................................................................. |

26 |

3.11 |

FLOW RELIEF PRESSURE....................................................................................................... |

27 |

3.12 |

CONCENTRATE (ACID) AND BICARBONATE PUMPS ........................................................... |

28 |

3.13 |

UF PUMP................................................................................................................................... |

28 |

3.14 |

CONDUCTIVITY ........................................................................................................................ |

28 |

3.15 |

TEMPERATURE ........................................................................................................................ |

28 |

3.16 |

VOLT HI LO DETECT ................................................................................................................ |

28 |

3.17 |

BLOOD LEAK AND DIMNESS................................................................................................... |

29 |

3.18 |

ARTERIAL, VENOUS AND TRANSMEMBRANE PRESSURE.................................................. |

30 |

3.19 |

DIALYSATE FLOW .................................................................................................................... |

33 |

3.20 |

HEPARIN PUMP........................................................................................................................ |

33 |

3.21 |

BLOOD PUMP ........................................................................................................................... |

36 |

3.22 |

LEVEL DETECTOR ................................................................................................................... |

38 |

3.23 |

ALARM OPERATION AND PRESSURE HOLDING TESTS...................................................... |

40 |

3.24 |

VERIFY PH ................................................................................................................................ |

40 |

3.25 |

RINSE CHECKS ........................................................................................................................ |

41 |

3.26 POWER FAILURE ALARM AND BATTERY REPLACEMENT .................................................. |

42 |

|

3.27 |

BLOOD PRESSURE MODULE.................................................................................................. |

43 |

3.28 |

INSPECT DIALYSATE LINES.................................................................................................... |

47 |

3.29 |

FINAL CHECKS ......................................................................................................................... |

47 |

4.0 REBUILDING THE DIAPHRAGM PUMPS .................................................................................................. |

48 |

|

4.1 |

REBUILDING THE ULTRAFILTRATION PUMP ........................................................................ |

48 |

4.2 |

REBUILDING THE CONCENTRATE (ACID) AND BICARBONATE PUMPS ............................ |

51 |

4.3 |

TESTING CONCENTRATE (ACID) AND BICARBONATE PUMPS........................................... |

53 |

PREVENTIVE MAINTENANCE CHECKLIST SIX (6) MONTH ............................................................................ |

56 |

|

PREVENTIVE MAINTENANCE CHECKLIST ANNUAL/4000 HOUR.................................................................. |

58 |

|

|

|

Page v |

|

2008T Preventive Maintenance Procedures |

|

|

P/N 508033 Rev. M |

|

General Warnings

Refer to the “General Warning” section in the 2008T Hemodialysis Machine Operator’s Manual (P/N 490122) for a complete listing of general warnings.

Warning! Never perform maintenance when a patient is connected to the machine. If possible, remove the machine from the treatment area when it is being serviced. Label the machine to ensure it is not accidentally returned to clinical use before the service work is completed. Always fully test the machine when maintenance is completed. Confirm dialysate conductivity and pH level before returning the machine to clinical use.

Shock Hazard: Refer servicing to qualified personnel. The electrical source must be 120 volts, 60 Hz, single phase. The outlet must be a three-conductor type with a hospital-grade receptacle and a ground fault interrupter. Test the polarity and ground integrity before installation and ensure it is maintained thereafter. Failure to do so may result in electrical shock to the operator or patient

Warning! Calibration procedures must be performed using primary standards or by using standards that are regularly calibrated in a program traceable to the National Institute of Standards and Technology (National Bureau of Standards)

Warning! Calibrate the Level Detector module for the model of venous line being used. During calibration ensure the filter inside the drip chamber is below the sensor heads. Also verify that the venous clamp fully occludes the line when closed.

Improper functioning of the level detector may be caused by a clot of blood.

Warning! Failure to install, operate and maintain this equipment according to the manufacturer’s instructions may cause injury or death to the patient or the operator. If this equipment is modified, appropriate inspection and testing must be conducted to ensure continued safe use of the equipment. Substitution of a component different from that supplied may result in measurement errors.

Warning! Use of this equipment adjacent to or stacked with other equipment should be avoided because it could result in improper operation. If such use is necessary, this equipment and the other equipment should be observed to verify that they are operating normally.

Warning! Only Original Equipment Manufacturer (OEM) Fresenius Medical Care parts should be used in the repair or upgrade of the Fresenius Medical Care 2008T Hemodialysis System. Although, parts may look similar to parts in various vendor catalogs or brick and mortar stores the 2008T Hemodialysis System uses parts that have been specified and tested in accordance to ANSI/AAMI/ISO guidelines. The use of non-OEM parts will void your warranty and may cause patient harm.

Note: This document is written for the 2008T Hemodialysis Systems using software versions 1.04 or later.

Page vi

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

1.0INTRODUCTION

Preventive Maintenance for the 2008T Hemodialysis System is simple and straightforward.

Scheduled maintenance is performed based on timed intervals or number of hours a machine is operated, whichever comes first. The time and hour intervals are as follows:

Machines without Extended Life Pump Components3

•Six (6) months

•Annually or after 4000 hours of operation

Machines with Extended Life Pump Components3

•Six (6) months

•Annually or after 4000 hours of operation

•Concentrate (acid), Bicarbonate & UF Pumps with extended life components3 are rebuilt every 2 years or after 8000 hours of operation.

2008T BlueStar™ Premium Machines

2008T BlueStar Premium machine are equipped with extended life components3 and can be identified by the 2008T BlueStar logo (shown below) on the keyboard.

•Six (6) months

•Annually or after 4000 hours of operation

•Concentrate (acid), Bicarbonate & UF Pumps with extended life components3 are rebuilt every 2 years or after 8000 hours of operation.

The maintenance procedures have been devised to require a minimum of time while ensuring that the machine is maintained in optimum operating condition.

Included in the Preventive Maintenance procedures are tests to verify normal machine operation. Should the machine fail to pass any of these tests, repair or re-calibrate as needed, then repeat the tests until the specifications are met before returning the machine to service.

Checklists are provided in the back of this manual to record the work done. Make copies of these checklists as needed. Your initials on the checklist certifies that each procedure has been completed and that the machine is performing according to the specifications given.

3 Refer to Sections 4.1 and 4.2 on how to recognize extended life pump components.

Page 1

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

1.1SUPPLIES NEEDED

A number of small parts must be available to perform the Preventive Maintenance (PM). Kits are available that include the necessary parts needed, except for the 9-Volt battery that must be replaced annually. An NEDA 1604AC heavy-duty (alkaline type) battery is required.

Machines without Extended Life Pump Components3 o 2008T Annual PM Kit (part number 191108)

Machines with Extended Life Pump Components3

o 2008T BlueStar Premium One Year PM Kit (part number 191175) o 2008T BlueStar Premium Two Year PM Kit (part number 191174)

2008T BlueStar Premium1 Machines

•2008T BlueStar Premium One Year PM Kit (part number 191175)

•2008T BlueStar Premium Two Year PM Kit (part number 191174)

Note: The 2008T BlueStar Premium Two Year PM Kit includes all of the items in the 2008T BlueStar Premium One Year PM Kit along with the necessary extended life components3 to rebuild the concentrate (acid), bicarbonate and UF pumps every 2 years or 8000 hours.

1 Refer to Section 1.0 on how to recognize a 2008T BlueStar Premium machine.

3 Refer to Sections 4.1 and 4.2 on how to recognize extended life pump components.

Page 2

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

1.2TEST EQUIPMENT NEEDED

In addition, the following test equipment is needed:

Warning! Test equipment used must be maintained and/or calibrated per the test equipment manufacturer’s requirements. In particular, the dialysate meter must meet the specifications listed below. Refer to the test equipment's' operator's manual, or contact the manufacturer for calibration and maintenance requirements. Failure to properly maintain and calibrate test equipment could lead to improper calibration and/or failure of the device to meet its specifications.

Warning! Disinfect the machine internally and externally and check all pressure transducer protectors for contamination before working on the machine.

•2008T Calibration Procedures (part number 508032).

•Test Kit (part number 150034), which contains two pressure gauges with fittings and hoses for measuring loading pressure and deaeration pressure.

•Dialysate meter to measure dialysate pressure, temperature and conductivity at the ends of the dialysate lines. The meter must be capable of making pressure measurements from -250mmHg to +400mmHg with an accuracy of at least ±3mmHg. The temperature function of this meter must be accurate within 0.2°C from 20°C to 45°C and must be capable of measuring dialysate temperatures up to 85°C with an accuracy of at least ±4.0°C. The conductivity function of this meter must be accurate to within 0.1mS over a range of 12mS to 17mS at a temperature of 25°C.

•Stopwatch with a resolution to 0.01 second and an accuracy of 0.01% or better.

•Buret, 25ml capacity with 0.1ml graduations (part number 290104).

•Graduated cylinder: 1000ml capacity with a tolerance of 5.0ml at 1000ml or better.

•Syringe, 60cc capacity. Tolerance is not important; the syringe is not used for volume measurements.

•Tubing for Buret tip, 24” long (part number 545325-10). Use on the tip of the Buret.

•Resistor Plug Set for OLC Testing (part number 190168).

The following equipment is also required to test the blood pressure module:

•Dummy Cuff (part number 370090). The Dummy Cuff contains two air chambers with calibrated volumes.

•Mercury manometer or equivalent pressure meter accurate to within 1mmHg at pressures up to 330mmHg.

Page 3

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

1.3OPERATING MODES

The following preventive maintenance procedures contain instructions to place the 2008T into Dialysis Mode and Service Mode.

To place the machine in Service Mode, turn the machine power On and wait for the message Press CONFIRM for Service Mode to appear. Once it appears, press the [CONFIRM] key and the message will change to Machine in Service Mode. After the System Initializing process is complete, the machine will be in Service Mode.

If the [CONFIRM] key is not pressed when the Press CONFIRM for Service Mode message is on the screen, the screen will change and the message Machine in Dialysis Mode will appear. After the System Initializing process is complete, the machine will be in Dialysis Mode.

Page 4

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

1.4FRONT PANEL CONTROLS

The front panel consists of four areas, the display screen, the key pad, a full keyboard and a touch pad. The display screen is the area under the glass in the center of the front panel. The key pad is to the right of the display screen and contains membrane keys. Note the keyboard and touch pad fold down 90 degrees from under the display screen and key pad.

Throughout the preventive maintenance procedures, whenever a key is to be pressed, the appropriate key name is surrounded by square brackets as in the following example:

Press the [CONFIRM] key and the screen will change.

In this example, the [CONFIRM] key on the touch pad should be pressed.

Touch Pad Operation

The touch pad is designed to allow the user to move an arrow around on the display screen. To select a button during a procedure, use the touch pad to move the arrow over the button on the screen. Tap the touch pad to select the on screen button.

Depending on the type of button, the screen will change. Data boxes are also displayed on the display screen. The following describes the type of buttons and data boxes that will be encountered during the preventive maintenance process.

Data Button

A yellow data button is used to enter a measured volume or value. When the yellow area of the data button is selected, it will change to a darker yellow. The data can be changed using the [▲] and [▼] keys or the value can be entered using the number keys. Once the data is entered, press the [CONFIRM] key and the data button changes back to light yellow. The [Escape] key can be pressed when the data button is dark yellow to abort the data entry and return it to light yellow. The entered data does not get stored until the [CONFIRM] key is pressed.

Some data buttons will change the screen and the data entry will be performed on the new screen.

A gray data button means the button is not active and selecting it will have no effect.

Page 5

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

Screen Button

Blue rectangles on the display screen are screen buttons. By selecting the blue area of the screen button the display will either change to another screen or the selection of an option will change. A screen button is not active if it is gray.

Data Box

This type of box shows selected data or data the machine is measuring. During the preventive maintenance process this type of box is used to verify a value or selection.

Page 6

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

1.5MEASURING FLUID VOLUMES

Several of the following procedures require measuring fluid volumes using graduated cylinders and laboratory burets. When making these measurements do the following:

•Make certain the container is clean and dry before collecting the fluid to be measured. Two drops of fluid are approximately 0.1ml, which is enough to affect the accuracy of critical measurements.

•Ensure that no items such as thermometers or tubing are allowed to come in contact with the fluid in the graduate. Such items will change the calibration of the graduate and affect the accuracy of measurements. Both the total volume indicated and the amount of fluid indicated by each increment on the graduated scale will be incorrect. For example, if a graduate is calibrated in 1ml increments, a piece of tubing in contact with the fluid will cause each increment to be less than 1ml, depending upon the total volume of the tubing that penetrates into the fluid.

•Surface tension causes the fluid to curve into a meniscus (See Figure 1). Measure the volume at the bottom of the meniscus curve as shown.

BOTTOM OF

MENISCUS

CURVE

Figure 1. Meniscus Curve.

Page 7

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2.0SIX (6) MONTH PREVENTIVE MAINTENANCE

Perform the following Preventive Maintenance procedures every six (6) months of machine operation.

Make copies of the Six (6) Month Preventive Maintenance Checklist provided in the back of this manual and use them to record the maintenance done.

Note: When performing an Annual Preventive Maintenance do not perform the six (6) month procedures below first. Go directly to Section 3 and perform the annual procedures described there.

While performing the following procedures, check the floor of the hydraulic unit and all surfaces for moisture that might indicate a leak. Locate and correct any leaks detected. Clean the floor of the hydraulic unit so that future leaks will be readily apparent. Also, check all electrical connectors that can be reached to be sure they are fully seated and there is no strain on the electrical cables.

Page 8

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

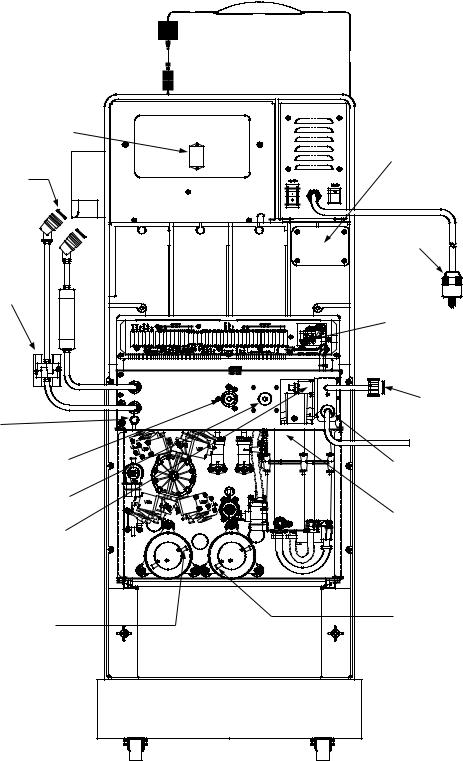

9-VOLT BATTERY |

|

|

|

BLOOD PRESSURE |

|

DIALYSATE LINE |

MODULE |

|

CONN. O-RINGS |

|

|

P/N M42674 |

|

|

|

STRAIN |

|

|

RELIEF |

|

DIALYSATE |

|

|

INLINE FILTER |

HEATER |

|

P/N 650113 |

||

CONNECTIONS |

||

|

||

|

INLET WATER FILTER |

|

REDUNDANT |

P/N 330636 |

|

|

||

GROUND |

|

|

UF PUMP |

DRAIN PORT |

|

ADJUSTMENT |

||

BICARBONATE PUMP |

HEATER ELEMENT |

|

|

||

INLET PRESSURE |

P/N 250169 |

|

REGULATOR |

|

|

CONCENTRATE (ACID) |

|

|

PUMP BEHIND INLET |

|

|

PRESSURE REGULATOR |

|

|

FLOW PUMP |

DEAERATION PUMP |

|

INLET |

||

OUTLET |

|

Figure 2. 2008T Hemodialysis System, Rear View.

Page 9

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2.1FILTERS

Clean filters as follows. Replace any filters that appear damaged or corroded.

1.Inlet Water Filter in the inlet connector of the water supply (See Figure 2, pg. 9).

Warning! After cleaning or replacing the inlet filter screen, disinfect the water inlet line as described in the Operator’s manual and in accordance with your Unit Policy.

2. Filters in the concentrate (acid) and bicarbonate connectors (See Figure 3).

FILTER INSERT P/N 566307

Figure 3. Concentrate (acid) and Bicarbonate Connector Assemblies.

3.Clean the Dialysate Inline filter (See Figure 2, pg. 9).

2.2PRE-UF PUMP FILTER

Inspect the Pre-UF Pump filter for leaks or distortion. Replace the Pre-UF Pump Filter if leakage or distortion is found.

Caution: Do not attempt to disassemble the Pre-UF Pump Filter. If not properly reassembled, the Pre-UF Pump filter may leak. A leak in the hydraulic system at this location may affect the operation of the machine or cause fluid loss from the patient.

Page 10

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2.3UF PUMP CHECK VALVES

Caution: If a check valve is replaced, ensure it is oriented correctly to allow fluid flow in the proper direction.

Inspect the UF pump Output check valves (one at the UF pump output and the other downstream at the UF Sample Port). Replace any that show signs of wear, damage or leaking.

2.4HIGH VOLTAGE AC CONNECTIONS

Shock Hazard: Dangerous high voltage is present at the connections accessed in this procedure when the machine is operating. Ensure the machine's power plug is disconnected from the wall outlet before proceeding.

1.Remove power from the machine then check and tighten the 8-pin heater connections next to the distribution board (See Figure 2, pg. 9). Check heater block AC connections for signs of arcing or melting.

2.If applicable, inspect the power plug for loose or frayed wires. Ensure the strain relief is securely fastened.

3.Inspect the entire length of the power cord (from plug to strain relief) for nicks or cuts in the insulation and replace if necessary (part number 150425).

4.Confirm that the strain relief is tightly secured to the power supply chassis.

5.At the strain relief, locate the black, white and green wires from the power cord (inside the power supply chassis). Follow the black and white wires to the main power switch. Attached to the main power switch are four (4) wires (2 black and 2 white). Look for loose connections, cracked insulation, and signs of overheating, such as discolored or melted insulation. Replace wires with Power Supply Wire Kit (part number 190411).

6.Inspect the main power switch and verify that its operation is smooth (no grinding or sticky operation) and that the wires are not crossed.

Page 11

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

Shock Hazard: Do not operate the machine if the resistance is greater than

0.2ohm. A shock hazard to operators and patients could exist.

7.With a digital multimeter, measure the resistance between the round (ground) pin on the power plug and the redundant ground terminal on the machine (See Figure 2, pg. 9). Verify that the resistance is less than

0.2ohm. If the value is above 0.2 ohm, measure the internal resistance of your meter by shorting the leads together, then subtract this value from the resistance measured between the power plug ground pin and the redundant ground terminal on the machine to obtain the true ground resistance.

8.Record the measured value on either the Six (6) Month Preventive Maintenance Checklist or the Annual/4000 Hour Preventive Maintenance Checklist depending upon which is being performed.

9.Perform the electrical safety checks required by local codes, facility procedure and the Joint Commission on Accreditation of Healthcare Organizations.

2.5UF PUMP

Calibrate the UF Pump Volume (Refer to the 2008T Calibration Procedures – part number 508032.)

Record the measured value on the Six (6) Month Preventive Maintenance Checklist.

2.6CONDUCTIVITY

Verify that the dialysate conductivity measured by the internal cell in the machine agrees with an external conductivity meter within 0.1mS/cm and within 0.4mS/cm of TCD as follows:

1.Connect an external conductivity meter to the dialysate lines.

2.With the machine in Dialysis Mode and flow ON, compare the value shown on the external conductivity meter with the conductivity shown on the Display screen. They must be within 0.1mS/cm of each other.

3.With the machine in Dialysis Mode and flow ON, compare the value shown for TCD with the conductivity shown on the Display screen. They must be within 0.4mS/cm of each other.

4.Record the measured value on either the Six (6) Month Preventive Maintenance Checklist or the Annual/4000 Hour Preventive Maintenance Checklist depending upon which is being performed.

Page 12

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2.7TEMPERATURE

Verify that the actual dialysate temperature measured by an external temperature meter agrees with the display screen within 0.3°C at 37°C and 39°C as follows:

1.Connect the dialysate lines to an external temperature meter.

2.Place the machine in Dialysis Mode with concentrate (acid) in the system. Clear any alarms.

3.Select2 the Temperature button. The button label will change to Temp. Setting. The value now displayed on this button is the temperature set point. Adjust the temperature set point to exactly 37.0 then press the [CONFIRM] key. The button will change back and now reads the actual temperature of the dialysate again. Wait until this value stabilizes. It will settle very close to the value set, depending upon inlet water temperature and other conditions.

4.After the temperature of the dialysate stabilizes, compare the temperature shown on the Temperature button with the temperature shown on the external temperature meter connected to the dialysate lines. The two readings must be within 0.3°C of each other.

5.Record the measured value on either the Six (6) Month Preventive Maintenance Checklist or the Annual/4000 Hour Preventive Maintenance Checklist depending upon which is being performed.

6.Repeat steps 3 and 4 with the temperature set to 39.0°C. Verify that the actual temperature reported on the front panel display screen and the

external temperature meter is within 0.3°C of each other after the temperatures stabilize again.

7.Record the measured values on either the Six (6) Month Preventive Maintenance Checklist or the Annual/4000 Hour Preventive Maintenance Checklist depending upon which is being performed.

2 Refer to Section 1.4 on the use of screen buttons.

Page 13

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

2.8ALARM OPERATION AND PRESSURE HOLDING TESTS

For 2008T BlueStar Premium1 machines, this is an optional test.

Verify the automatic alarms produce the responses shown in Table 1 and the machine passes the automatic pressure holding test as follows:

1.Place the dialysate lines in the shunt and close the door.

Warning! The use of a “test drip chamber” or “dummy drip chamber” must never be used on the treatment floor. It must only be used in a controlled technical environment.

2.Place a venous chamber filled with water in the holder on the level detector module.

3.Place the machine in Dialyze mode and start the blood pump. Clear all blood and water alarms.

4.Select2 the Test & Options button. On this screen select2 the Both Tests button. Press the [CONFIRM] key to start.

5.Observe the machine stepping through the following alarm tests and ensure that each alarm produces all of the responses shown in Table 1.

1Refer to Section 1.0 on how to recognize a 2008T BlueStar Premium machine.

2Refer to Section 1.4 on the use of screen buttons.

Page 14

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

Table 1. Alarm Tests.

ALARM TEST |

|

RESPONSE |

|

|

|

|

|

Air Detector |

1. |

Red visual alarm |

|

2. |

Venous clamp closes |

||

|

|||

|

3. |

Blood pump stops |

|

|

|

|

|

Blood Leak |

1 |

Red visual alarm |

|

2. |

Venous clamp closes |

||

|

|||

|

3. |

Blood pump stops |

|

|

|

|

|

Arterial Pressure |

1. |

Red visual alarm |

|

2. |

Venous clamp closes |

||

|

|||

|

3. |

Blood pump stops |

|

|

|

|

|

Venous Pressure |

1. |

Red visual alarm |

|

2. |

Venous clamp closes |

||

|

|||

|

3. |

Blood pump stops |

|

|

|

|

|

TMP |

1. |

Red visual alarm |

|

2. |

Venous clamp closes |

||

|

|||

|

3. |

Blood pump stops |

|

|

|

|

|

9-Volt Battery |

|

Passes if battery voltage is greater than 7.0 |

|

|

volts under a load of 22Ω. |

||

|

|

||

|

|

|

|

Optical Detector |

1. |

Lower venous alarm limit rises to 10mmHg |

|

|

causing a venous pressure alarm |

||

|

|

||

|

2. |

Venous clamp closes |

|

|

3. |

Blood pump stops |

|

|

|

|

|

Temperature |

1. |

Red visual alarm |

|

2. |

Yellow visual bypass |

||

|

|||

|

3. |

Machine in Bypass mode (no flow through the |

|

|

|

dialysate flow indicator). |

|

|

|

|

|

Conductivity |

1. |

Red visual alarm |

|

2. |

Yellow visual bypass |

||

|

|||

|

3. |

Machine in Bypass mode (no flow through the |

|

|

|

dialysate flow indicator). |

|

|

|

|

Page 15

2008T Preventive Maintenance Procedures

P/N 508033 Rev. M

Loading...

Loading...