Fresenius Pilot A2-CE2 Service manual

TECHNICAL MANUAL

TECHNICAL

MANUAL

PILOT A2, CE2 RS232 Events log

From serial n° 17730124 till ...

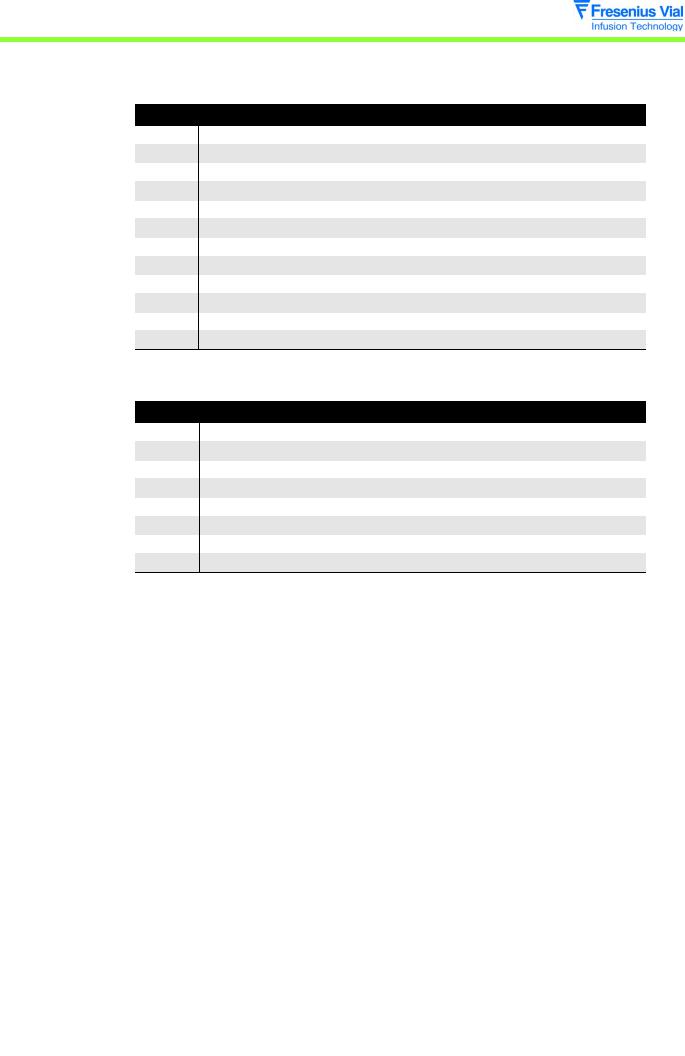

Revision table

TM Pilot A2 CE2 RS 232 Events Log_en : ref NT 1734

Date |

Revision |

Chapter |

Description |

|

|

|

|

03/04/03 |

0 |

All index "a" |

Creation |

|

|

|

|

08/01/07 |

1 |

index "b" |

New EMC standard, spare parts up date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 Overview ........................................................................................................... |

|

7 |

1.1 |

General .................................................................................................... |

7 |

1.2 |

Overview diagram ................................................................................. |

8 |

1.3 |

Precautions to be taken before use...................................................... |

9 |

1.4 |

Internal safety features .......................................................................... |

9 |

1.5 |

Technical characteristics ...................................................................... |

9 |

1.5.1 |

Electrical specifications .............................................................................................. |

9 |

1.5.2 |

Electronic specifications............................................................................................. |

9 |

1.5.3 |

Mechanical specifications .......................................................................................... |

9 |

1.5.4 |

Conformity and norms.............................................................................................. |

10 |

2 Description and operation ............................................................................. |

11 |

|

2.1 Physical description ............................................................................ |

11 |

|

2.1.1 The display board and the front panel...................................................................... |

12 |

|

2.1.2 |

CPU board ............................................................................................................... |

14 |

2.1.3 The power supply board and the battery.................................................................. |

17 |

|

2.1.4 Mechanical gear box unit ......................................................................................... |

20 |

|

2.1.5 |

Mechanical plunger unit ........................................................................................... |

20 |

2.2 Functional description ......................................................................... |

21 |

|

2.2.1 Syringe control and maintenance assembly ............................................................ |

21 |

|

2.2.2 |

Motorisation assembly ............................................................................................. |

21 |

2.2.3 |

External connection sub-assembly .......................................................................... |

21 |

3 Description of the menus .............................................................................. |

23 |

|

3.1 Configuration menu of the current operation parameters ............... |

23 |

|

3.1.1 |

Menu access ............................................................................................................ |

24 |

3.1.2 |

PAr1, configuration of the memorisation type ...................................................... |

25 |

3.1.3 |

PAr2, configuration of the syringe selection type ................................................. |

25 |

3.1.4 |

PAr3, |

|

|

configuration of the maximum flow rate that may be selected on the keyboard ...... |

26 |

3.1.5 |

PAr4, configuration of the list of syringes that may be selected........................... |

26 |

3.1.6 |

PAr5, configuration of the compulsory priming .................................................... |

27 |

3.1.7 |

PAr7, configuration of the KVO flow rate ............................................................. |

27 |

3.1.8 |

PAr9, configuration of the RS232 communication speed..................................... |

28 |

3.1.9 |

PArA, configuration of the empty syringe mode ................................................... |

28 |

3.1.10 |

PArb, configuration of the frequency of preventive checks .................................. |

29 |

3.1.11 |

PArC, configuration of the drug display mode ...................................................... |

29 |

3.1.12 |

PArd, configuration of the Flanges detection mode ............................................. |

30 |

3.1.13 |

PArF, configuration of the bolus flow memorisation mode ................................... |

30 |

3.1.14 |

PArG, configuration of the drugs list ..................................................................... |

31 |

3.1.15 |

PArJ, configuration of the mains disconnection signal......................................... |

32 |

3.1.16 |

PAr0, configuration of the date and time.............................................................. |

32 |

3.1.17 Typical syringe/details correspondence table .......................................................... |

33 |

|

PiloteCE2_A2_RS232horodaté_enTDM.fm |

3 |

|

|

3.2 Calibration menu.................................................................................. |

35 |

|

3.3 Service test menu ................................................................................ |

37 |

|

4 Preventive maintenance................................................................................. |

39 |

|

4.1 Recommendations ............................................................................... |

39 |

|

4.2 Maintenance schedule......................................................................... |

39 |

|

4.2.1 |

Preventive maintenance........................................................................................... |

39 |

4.2.2 |

Quality control .......................................................................................................... |

39 |

4.3 Checks .................................................................................................. |

41 |

|

4.3.1 |

Test access .............................................................................................................. |

41 |

4.3.2 |

Visual check ............................................................................................................. |

41 |

4.3.3 |

Running time and last servicing inspection date ...................................................... |

42 |

4.3.4 |

Indicator lights check................................................................................................ |

42 |

4.3.5 |

Keyboard check ....................................................................................................... |

43 |

4.3.6 |

Checking the battery voltage.................................................................................... |

44 |

4.3.7 |

Display of the last 10 alarms .................................................................................... |

44 |

4.3.8 |

Total operation time check ....................................................................................... |

46 |

4.3.9 |

TTL serial link test .................................................................................................... |

46 |

4.3.10 |

RS 232 serial link check........................................................................................... |

47 |

4.3.11 |

Checking the software version. ................................................................................ |

47 |

4.3.12 |

Checking the ADC.................................................................................................... |

48 |

4.3.13 |

Checking the position sensor ................................................................................... |

48 |

4.3.14 |

Buzzer test ............................................................................................................... |

49 |

4.3.15 |

Display of the calibration values............................................................................... |

49 |

4.3.16 |

Checking the syringe clamp ..................................................................................... |

49 |

4.3.17 |

Checking the syringe group number ........................................................................ |

50 |

4.3.18 |

Checking the list of syringes .................................................................................... |

50 |

4.3.19 |

Checking the disengagement................................................................................... |

50 |

4.3.20 |

Checking the flanges detection system.................................................................... |

50 |

4.3.21 |

Checking the syringe head detection system........................................................... |

51 |

4.3.22 |

Checking backpressure............................................................................................ |

52 |

4.3.23 |

Checking the pre-alarm and end of infusion alarm .................................................. |

52 |

4.3.24 |

Checking the linearity............................................................................................... |

53 |

4.3.25 |

Checking mains/battery operation............................................................................ |

53 |

4.3.26 |

Battery autonomy test .............................................................................................. |

54 |

4.3.27 |

Continuity test .......................................................................................................... |

54 |

4.3.28 |

Quality Control Certificate ........................................................................................ |

55 |

4.4 Flow rate control .................................................................................. |

57 |

|

4.4.1 |

Measurement with a computer................................................................................. |

57 |

4.4.2 |

Measurement with scales......................................................................................... |

59 |

4.4.3 |

Measurement using a test tube................................................................................ |

61 |

4.5 Cleaning and disinfecting ................................................................... |

63 |

|

4.6 Storage.................................................................................................. |

64 |

|

|

44 |

PiloteCE2_A2_RS232horodaté_enTDM.fm |

|

|

|

5 |

Diagnostic ....................................................................................................... |

|

65 |

|

5.1 |

Troubleshooting guide ....................................................................... |

65 |

|

5.2 |

Error messages .................................................................................... |

67 |

6 |

Operation sheets ............................................................................................ |

71 |

|

|

N°1, Procedure: Display and central unit boards .................................... |

73 |

|

|

N°2, Procedure: Syringe clamp ................................................................. |

75 |

|

|

N°3, Procedure: Syringe detection system .............................................. |

77 |

|

|

N°4, Procedure: Motor + Opto + Disk ........................................................ |

83 |

|

|

N°5, Procedure: Dynamometer sensor ..................................................... |

85 |

|

|

N°6, Procedure: Plunger advance control potentiometer ....................... |

91 |

|

|

N°7, Procedure: |

|

|

|

|

Plunger cover and/or disengagement lever + anti-siphon arm .... |

.. 93 |

|

N°8, Procedure: Power supply board........................................................ |

95 |

|

|

N°9, Procedure: Battery door and battery ................................................ |

97 |

|

|

N°10, Procedure: Plug holder wired .......................................................... |

99 |

|

|

N°11, Procedure: Ribbon cable winding kit............................................ |

101 |

|

|

N°12, Procedure: Syringe head detection plunger kit ........................... |

105 |

|

|

N°13, Procedure: Centering ring kit ........................................................ |

109 |

|

|

N°14, Procedure: Flex circuit and tube kit .............................................. |

113 |

|

|

N°15, Procedure: Upper and lower cases ............................................... |

119 |

|

7 |

Calibration..................................................................................................... |

|

123 |

|

7.1 |

Calibration procedure ........................................................................ |

123 |

|

7.1.1 |

Calibration access.................................................................................................. |

123 |

|

7.1.2 EtA.4 Calibration of the 3 battery voltage levels................................................ |

124 |

|

|

7.1.3 EtA.6 Calibration of the position sensor. ........................................................... |

124 |

|

8 |

Spare parts catalogue .................................................................................. |

125 |

|

|

8.1 |

Upper case .......................................................................................... |

125 |

|

8.2 |

Lower case .......................................................................................... |

127 |

|

8.3 |

Plunger unit ........................................................................................ |

129 |

|

8.4 |

Mechanical Gear box ......................................................................... |

133 |

|

8.5 |

Labels .................................................................................................. |

135 |

PiloteCE2_A2_RS232horodaté_enTDM.fm |

5 |

|

|

|

66 |

PiloteCE2_A2_RS232horodaté_enTDM.fm |

|

|

|

1 Overview

1.1 General

The Pilot A2 RS 232 Events log is a syringe pump intended for the infusion of intravenous agents at a accurate, low flow rate. The wide choice of syringes, the use of the universally recognised control symbols and the synoptic display of the alarms contribute to making the Pilot A2 RS 232 Events log easy to use. The adjustable occlusion detection, the correct positioning detection and the overall syringe protection system guarantee optimum safety.

Its technical characteristics, the flow range from 0.1 to 400 ml/hr (configured at 200 ml/hr) and its excellent accuracy (+1% on the device) contribute to making the Pilot A2 RS 232 Events log, the ideal instrument for medical services.

The Pilot A2 RS 232 Events log is equipped with a 16ko-EEPROM enabling the memorization of 896 events. These events are available for consultation through the ISCTRL maintenance software, 4.1 and upper version.

Overview

01_011b_en.fm |

7 |

|

|

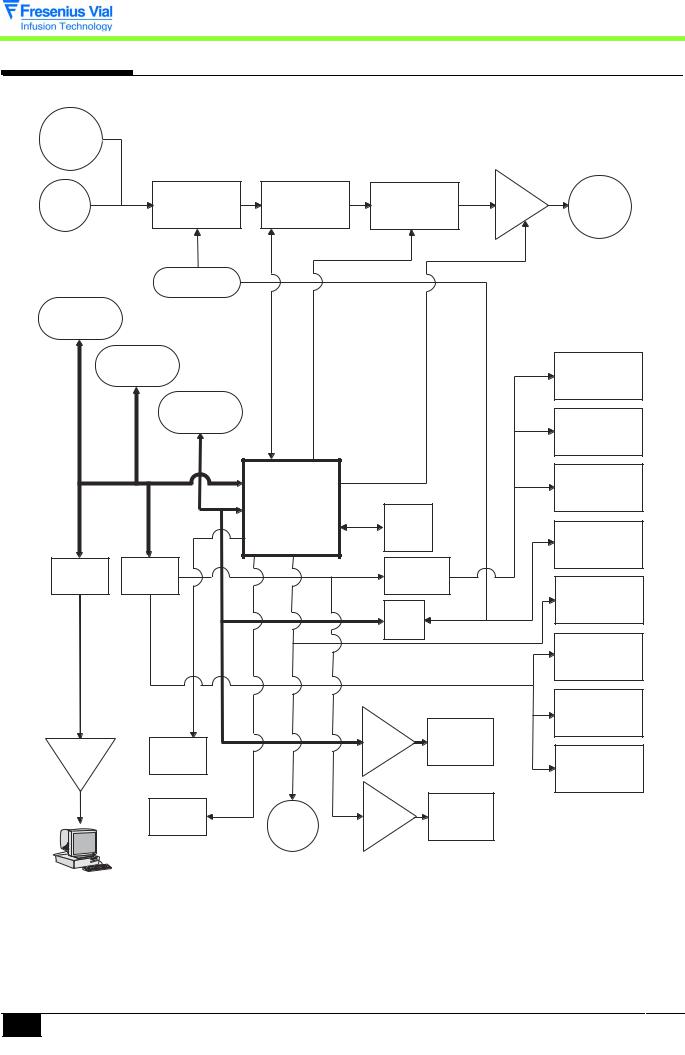

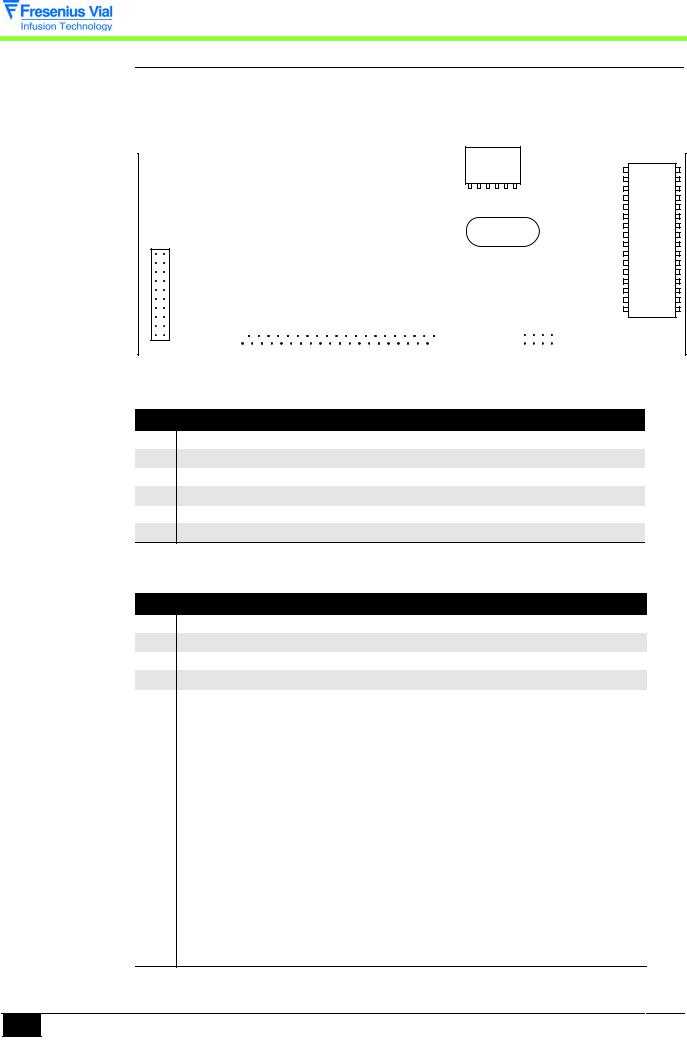

1.2 Overview diagram

Ext |

|

|

|

|

|

|

12/15 V |

|

|

|

|

|

|

15 W |

|

|

|

|

|

|

|

|

|

DC-DC |

Motor |

Step by |

|

230 V |

Power supply |

ON / OFF |

step |

|||

converter |

driver |

|||||

|

|

|

motor |

|||

|

|

|

|

|

||

|

Battery |

|

|

|

|

|

EPROM |

|

|

|

|

|

|

128K x 8 |

|

|

|

|

|

|

|

RAM |

|

|

|

Motor speed |

|

|

8K x8 |

|

|

|

||

|

|

|

|

sensor |

||

|

|

|

|

|

||

|

EEPROM |

|

|

|

|

|

|

512 |

|

|

|

Syringue body |

|

|

|

|

|

|

||

|

|

|

|

|

sensor |

|

|

BUS |

|

|

|

Antisiphon |

|

|

|

|

|

|

||

|

SPI |

CPU |

|

|

sensor |

|

|

|

|

|

|||

|

|

Watch |

|

|

||

|

|

|

|

|

||

|

|

|

dog |

|

Displacement |

|

|

|

|

|

|

transducer |

|

UART |

Interface |

|

Opto |

|

|

|

bus |

|

interface |

|

|

||

|

|

|

Nurse call |

|||

|

|

|

|

|

||

|

|

|

|

|

(option) |

|

|

|

|

ADC |

|

|

|

|

|

|

|

|

Occlusion |

|

|

|

|

|

|

switch |

|

|

|

|

|

|

Disengagement |

|

|

|

|

|

|

switch |

|

|

|

|

LCD |

LCD |

|

|

|

|

|

display |

|

||

RS 232 |

Keyboard |

|

driver |

|

||

|

|

|

||||

|

|

|

|

Flanges switch |

||

|

|

|

|

|

||

|

Master |

|

LED |

LED |

|

|

|

Buzzer |

driver |

display |

|

||

|

|

|

||||

Overview |

|

|

|

|

|

|

8 |

|

|

|

|

01_011b_en.fm |

1.3 Precautions to be taken before use

The symbol ! in the concise instrument instructions guide of the device recommends that the operator’s guide should be read complelety in accordance with standard EN 60601-1.

Fresenius Vial may in no case be held responsible for medical problems or any other problems resulting from inadequate use of the equipment.

Refer to the User’s instructions for further details.

1.4 Internal safety features

As soon as it is switched ON, the device activates a continuous function inspection system. Any internal failure or any problem related to the operating procedure in progress is detected immediately. Nevertheless, abnormal operation of the equipment with no obvious cause must always be reported to the qualified technicians in your establishment or our After Sales service.

In case of single fault condition, an alarm is activated for any flow rate deviation of ± 5% in comparison with the normal flow rate.

A second check activates an alarm in the event of deviation of 1 ml in comparison with the anticipated infused volume, or if a flow rate deviation of ± 20% is identified. The alarm is triggered by the most rapidly detected deviation.

The Pilot A2 Events log is fitted with an internal battery to continue operation in the event of a power cut. Furthermore, a safety fuse protects the mains from further disturbance.

1.5Technical characteristics

1.5.1Electrical specifications

!Power supply: 230 V - 50-60 Hz.

!Max. consumption : 23 VAC.

!Fuse F2: 100 mAT 250 V IEC 127.

!Battery: 6 V - 1,1 / 1,3 Ah.

!External power supply: 12 - 15 V DC -15 W.

1.5.2 Electronic specifications

The Pilot syringe pump is fitted with 3 circuit boards:

!Motor power supply and control board.

!CPU board.

!Keyboard display board.

1.5.3 Mechanical specifications

!Overall dimensions H x W x D: 120 x 330 x 155 mm.

!Weight: approximately 2,2 kg.

Overview

01_011b_en.fm |

9 |

|

|

|

1.5.4 Conformity and norms |

|

|

|

|

|

Conform to the 93/42/CE Medical Directive. |

IP34 Protection against |

0459 |

|

splashing liquid. |

Safety of Electro |

Conform to EN/IEC 60601-1 and EN/IEC 60601-2-24 |

Protection against |

Medical |

|

leakage current: CF type. |

Equipements |

|

|

EMC |

Conform to EN/IEC 60601-1-2 (first edition) and EN/IEC |

Protection against electric |

(ElectroMagnetic |

60601-2-24 |

shocks: class II. |

Compatibility) |

|

|

Since 2001,electromagnetic compatibility standards have evolued.

Pilot A2 RS 232 Events log that serial number is higher than 18908961 with EN/IEC 60601-1-2 (second édition) and EN/IEC 60601-2-24 complies standards.

Detailed information concerning electromagnetic compatibility is available in the chapter "Guidance and manufactureris declaration on EMC" of the User Manual.

Overview

|

10 |

01_011b_en.fm |

|

|

|

2Description and operation

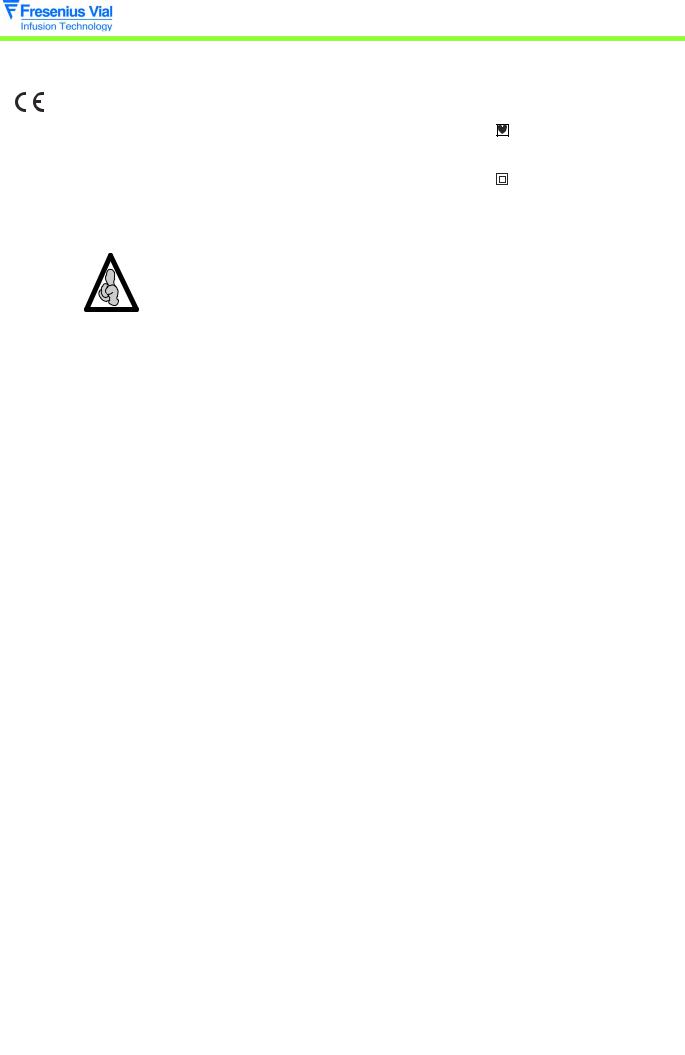

2.1Physical description

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Flanges switch |

|

|

|

Flanges positioning groove |

|

|||

|

|

Syringe clamp |

|

|

|

Plunger disengagement |

|||||||

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

||||||||

|

Upper case |

|

|

|

control |

|

|

|

|||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

Anti-siphon arm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lower case |

Front control panel |

|

The Pilot A2 Events log is fitted with an upper case and a lower case.

!The upper case holds the syringe clamp and contains:

"A display board associated with the front control panel.

"A CPU board.

!The lower case contains:

"A power supply board and a battery.

"A mechanical base unit.

"A plunger unit.

Description and operation

02_008b_en.fm |

11 |

|

|

Description and operation

12

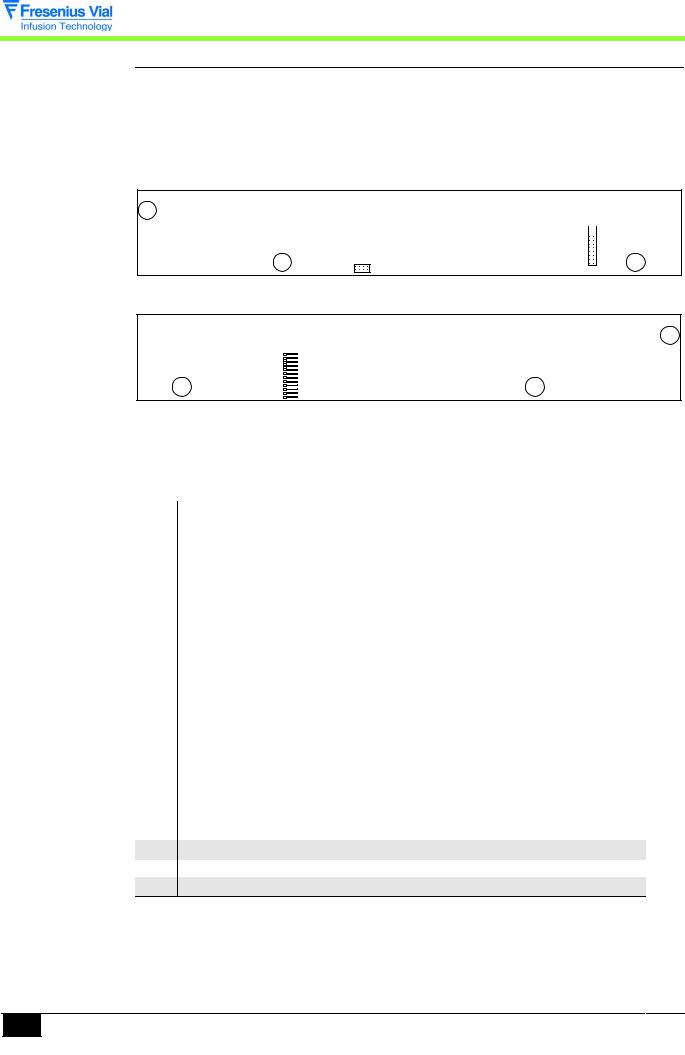

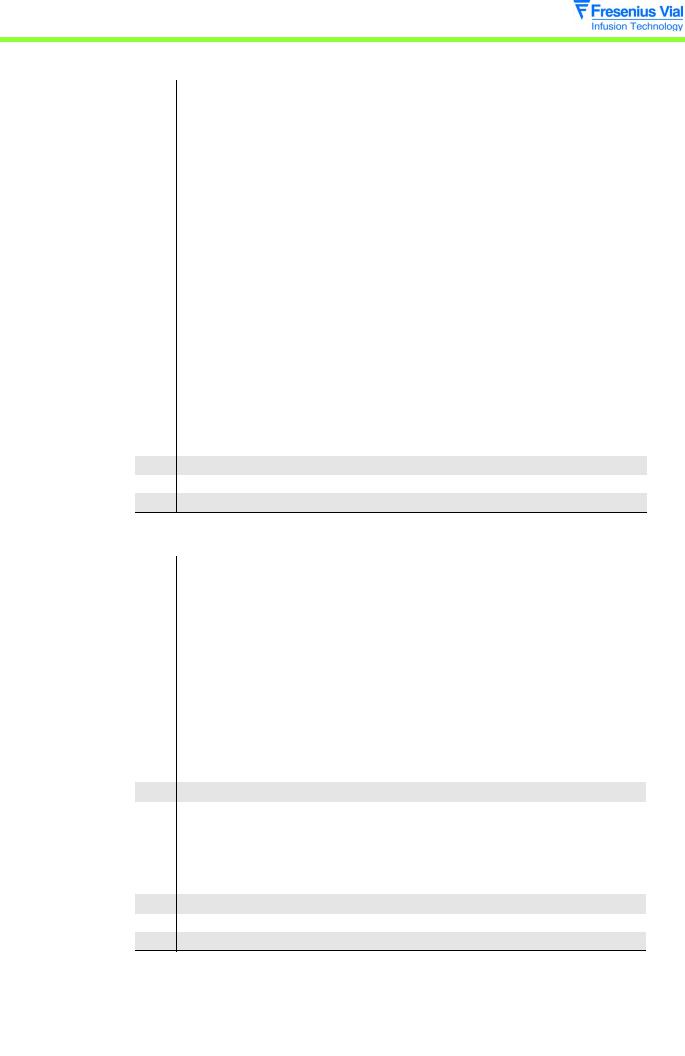

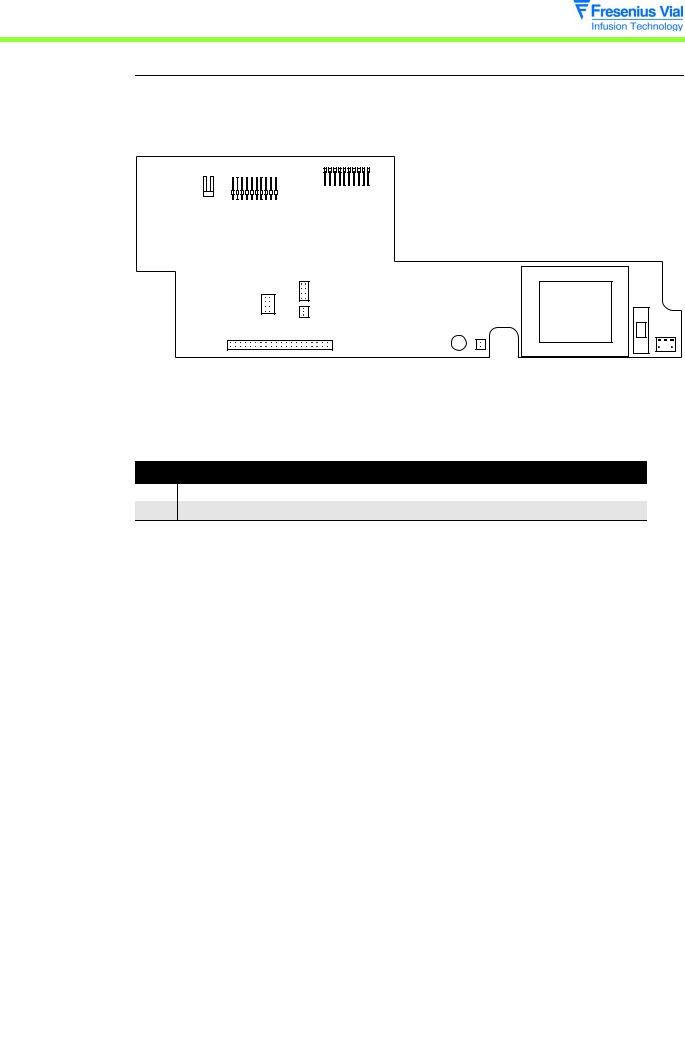

2.1.1 The display board and the front panel

The display board is mounted under the front control panel and is fitted with all the organs required for man-machine interaction.

!Keyboard interface.

!Control lamps and overview diagrams.

!7-segment display units.

J1

J1

J3

Solder side display board.

J2

Component side display board.

This board is connected to the different parts of equipment by means of connectors.

J1 connector to CPU board

Pin |

Description |

|

1 |

SEG1 display matrix |

Line 1 |

2 |

SEG2 display matrix |

Line 2 |

3 |

SEG3 display matrix |

Line 3 |

4 |

SEG4 display matrix |

Line 4 |

5 |

SEG5 display matrix |

Line 5 |

6 |

SEG6 display matrix |

Line 6 |

7 |

SEG7 display matrix |

Line 7 |

8 |

SEG8 display matrix |

Line 8 |

9 |

COL1 display matrix |

Column 1 |

10 |

COL2 display matrix |

Column 2 |

11 |

COL3 display matrix |

Column 3 |

12 |

FAIL LED control |

Fail |

13 |

COL/DIG 9 LED type control |

" |

14 |

LIG1 keyboard interface |

Line 1 |

15 |

LIG2 keyboard interface |

Line 2 |

16 |

LIG3 keyboard interface |

Line 3 |

17 |

LDSECT lighting control |

Mains LED |

18+5V power supply

19VBAT power supply

20GND power supply

02_008b_en.fm

J2 connector to keyboard

Pin Description

1Column 1

2Column 2

3Column 3

4Column 4

5Column 5

6Column 6

7Line 1

8Line 2

9Line 3

10Ton

11Toff

12Gnd power supply

J3 connector to CPU board

Pin Description

1Ton ON key

2Toff OFF key

3SI SPI bus

4Clk SPI bus

5CSLCD SPI bus

6Buzz BUZZER control

7Vbat power supply

8Gnd power supply

Description and operation

02_008b_en.fm |

13 |

|

|

Description and operation

14

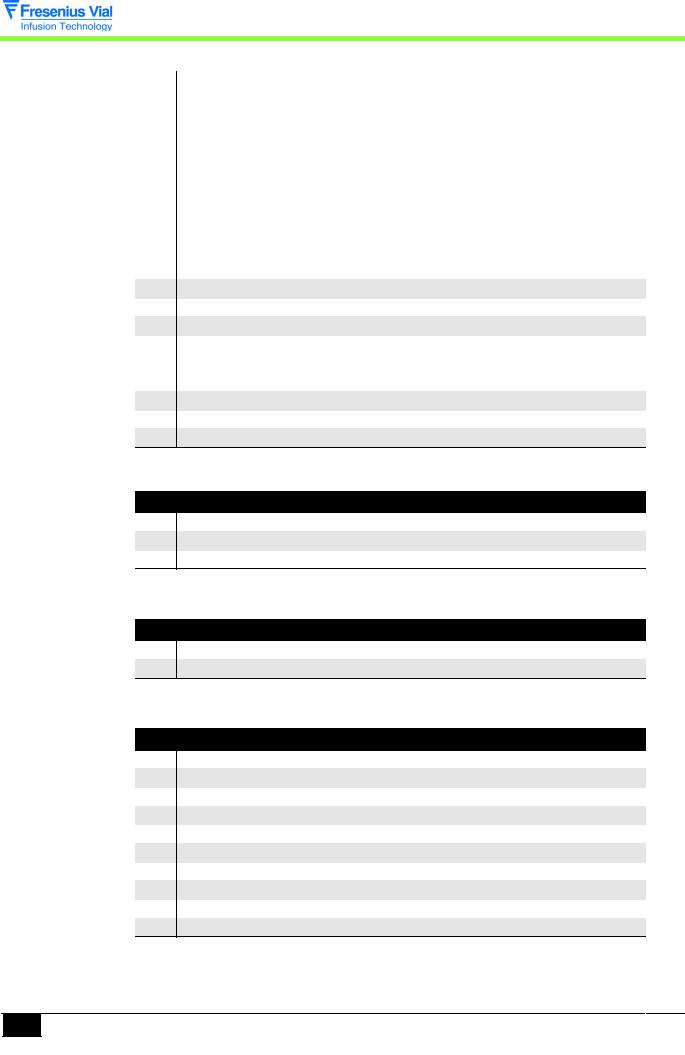

2.1.2 CPU board

The CPU board holds an 80C32 microprocessor. It is mounted and connected to the display board through J4 and J5 connectors.

A ribbon cable connects this to a power supply board by means of a connector J3.

J2

J4

J3 |

|

J5 |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|

|

|

CPU board

J2 connector: to flanges detection switch and syringe detection opto-electronic sensor

Pin Description

1Ground

2Flanges contact

3Opto anode diode +5V

4Common points between cathode LED , opto 1 and opto 2 transistor emitters.

5Opto 1 transistor collector

6Opto 2 transistor collector

J3 connector to power supply board

Pin Description

1+5V

2Gnd

3+Vbat

4Gnd

5 |

Phase A |

Motor control |

6 |

Phase B |

Motor control |

7 |

Phase C |

Motor control |

8 |

Phase D |

Motor control |

9 |

I signal |

Motor control |

10 |

Boost signal |

Motor control |

11 |

Sopt1 |

Opto rotation motor output |

|

|

|

12 |

Sopt2 |

Opto anti-siphon |

13 |

Apinf |

Nurse call independent of the buzzer |

|

|

signal |

14 |

Cdopt1 |

Opto rotation motor control output |

15 |

Cdopt2 |

Opto anti-siphon module control |

16 |

Off |

Signal off key pressed |

17 |

Sect |

Mains power supply on signal |

|

|

|

18 |

Cdalim |

Power cut signal |

02_008b_en.fm

J3 connector to power supply board

Pin |

Description |

|

19 |

Ldsect |

Mains LED control |

20 |

Cts |

Clear to send |

21 |

Deb/off |

Disengagement signal |

22 |

Rts request to send |

Request to send |

23 |

Occ/off |

Occlusion signal |

24 |

Buz |

Nurse call relay control |

25 |

Eoc |

End Of adc conversion |

26 |

Csadc |

Selection spi adc bus |

27 |

Clk |

Clock spi adc bus |

28 |

Si |

Data in spi adc bus |

29 |

So |

Data out spi adc bus |

30 |

Cdana |

Analogue sensor power supply control |

31 |

Rx2 |

Receive data TTL |

32 |

Tx2 |

Transmit data TTL |

33 |

Txd1 |

Transmit data TTL |

34 |

Rxd1 |

Receive data TTL |

35 |

Ton |

ON key |

36 |

Toff |

OFF key |

37 |

+Vbat |

Power supply |

38Gnd

39+5V

40Gnd

J4 connector to display board

Pin |

Description |

|

1 |

Seg1 display matrix |

Line 1 |

2 |

Seg2 display matrix |

Line 2 |

3 |

Seg3 display matrix |

Line 3 |

4 |

Seg4 display matrix |

Line 4 |

5 |

Seg5 display matrix |

Line 5 |

6 |

Seg6 display matrix |

Line 6 |

7 |

Seg7 display matrix |

Line 7 |

8 |

Seg8 display matrix |

Line 8 |

9 |

Col1 display matrix and keyboard |

Column 1 |

10 |

Col2 display matrix and keyboard |

Column 2 |

11 |

Col3 display matrix and keyboard |

Column 3 |

12Fail diode fail control

13Rdcrt current reduction control

14 |

Lig1 keyboard interface |

Line 1 |

15 |

Lig2 keyboard interface |

Line 2 |

16 |

Lig3 keyboard interface |

Line 3 |

17Ldsect mains LED control

18+5V power supply

19Vbat power supply

20Gnd power supply

02_008b_en.fm |

15 |

|

|

Description and operation

J5 connector to display board

Pin Description

1Ton ON key

2Toff OFF key

3Si spi bus

4Clk spi bus

5Cslcd spi bus

6Buzz buzzer control

7Vbat power supply

8Gnd power supply

Description and operation

|

16 |

02_008b_en.fm |

|

|

|

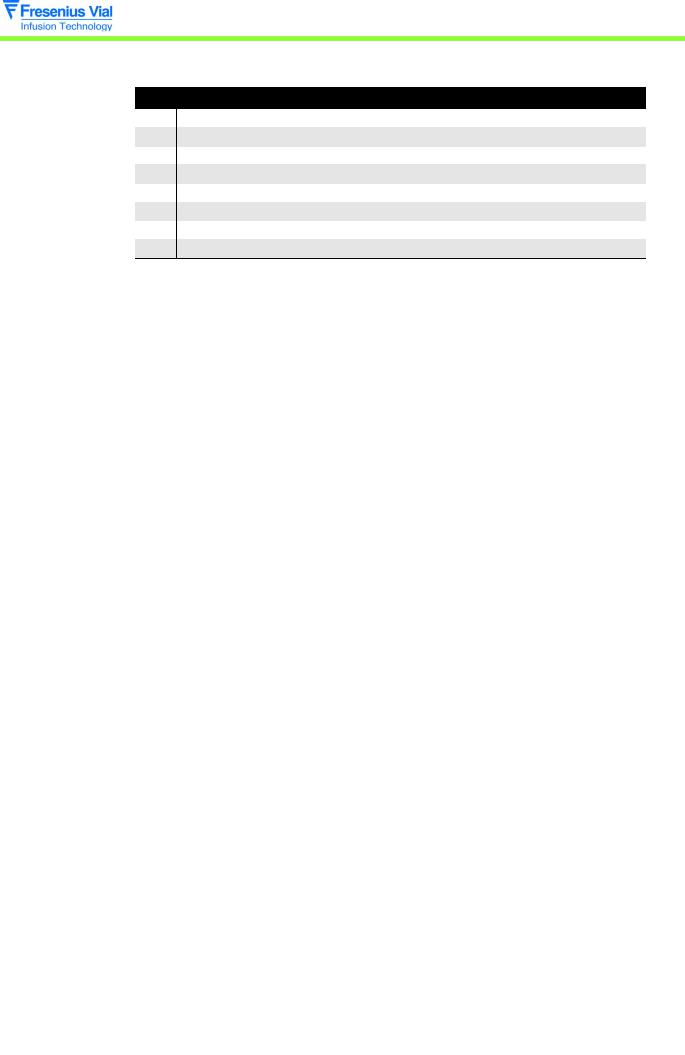

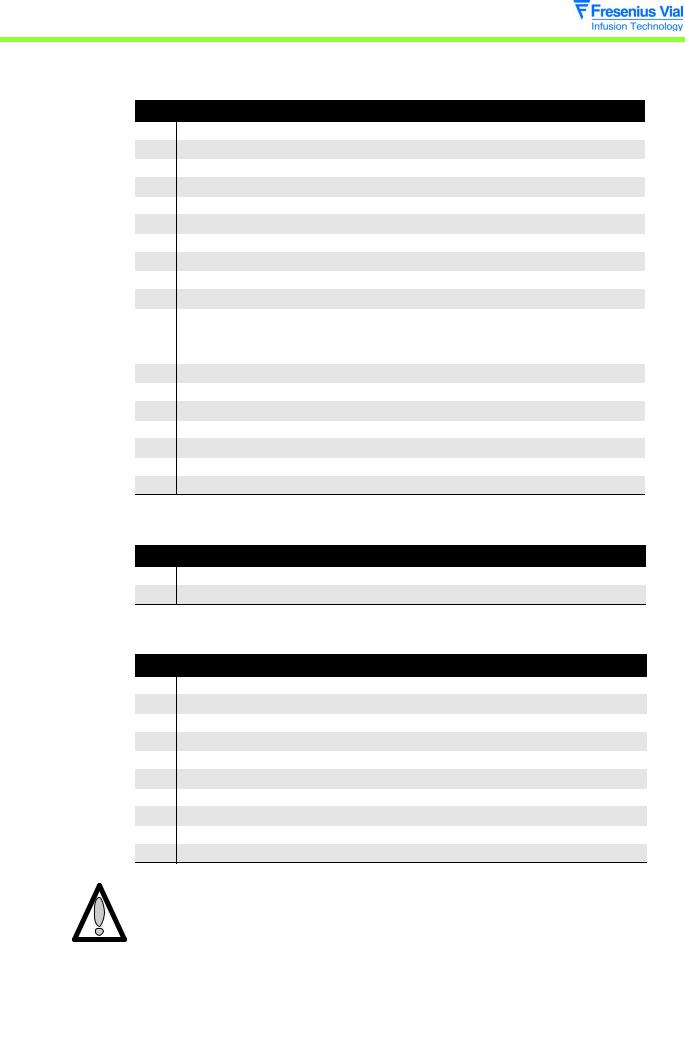

2.1.3 The power supply board and the battery

The power supply board is mounted on the lower case. It allows to supply the electronic parts using the network 230 V AC or the external 12 / 15 DC. It also charges the 1.1 or 1.3 Ah battery.

|

J6 |

J7 |

J8 |

|

J5 |

J9 |

F2 |

|

J3 |

|||

|

|

||

|

J4 |

J1 |

|

J2 |

F1 |

|

Power supply board.

This board is connected to the different parts of equipment by means of connectors.

J1 connector to mains

Pin Description

1Neutral

2Phase

J2 connector to CPU board

|

Pin |

Description |

|

|

1 |

+5V controlled power supply |

|

|

|

|

2 |

Gnd power supply |

|

|

3 |

+Vbat power supply |

|

|

|

|

4 |

Gnd power supply |

|

|

5 |

Phase A |

Motor control |

||

|

6 |

Phase B |

Motor control |

|

7 |

Phase C |

Motor control |

||

|

8 |

Phase D |

Motor control |

|

9 |

I signal |

Motor control |

||

|

10 |

BOOST signal |

|

|

11 |

Sopt1 |

Opto rotation module output |

||

|

12 |

Sopt2 |

Opto anti-siphon module output |

|

13 |

N.U |

|

|

|

|

14 |

Cdopt1 |

Opto rotation module control |

|

15 |

Cdopt2 |

Opto anti-siphon module control |

||

|

16 |

Off |

Off key pressed on the ON/OFF button |

|

17 |

SECT |

Mains supply presence signal |

||

|

18 |

CDALIM |

Power cut signal |

|

19 |

LDSECT |

Mains LED control |

||

|

20 |

CTS |

Clear to send |

|

21 |

DEB/OFF |

Disengagement signal active at 0 |

||

|

|

|

|

|

02_008b_en.fm |

|

|

17 |

|

|

|

|

|

|

Description and operation

Description and operation

18

J2 connector to CPU board

Pin |

Description |

|

22 |

RTS |

Request to send |

23 |

OCC/OFF |

Occlusion signal active at 0 |

24 |

BUZ |

Nurse call relay control |

25 |

EOC |

End of ADC conversion |

26 |

CSADC |

Selection bus SPI ADC |

27 |

CLK |

Clock bus SPI ADC |

|

|

|

28 |

SI |

Data IN bus SPI ADC |

29 |

SO |

Data out bus SPI ADC |

30 |

CDANA |

Analogue sensor power supply control |

|

|

|

31RX2 receive data TTL

32TX2 transmit data TTL

33TXD1 transmit data TTL

34RXD1 receive data TTL

35 |

Toff |

OFF key |

36 |

Ton |

ON key |

37 |

+Vbat |

Power supply |

38Gnd

39+5V

40Gnd

J3 connector to potentiometer

Pin Description

1Vref

2Centre point

3Gnd

J4 connector to internal battery

Pin Description

1+ battery

2- battery

J5 connector to motor

Pin Description

1+Vbay

2+Vbat

3Phase D

4Phase C

5Phase B

6Phase A

7Opto rotation anode diode /+5V

8Opto rotation cathode diode

9Opto rotation transistor collector

10GND/ opto rotation transistor emitter

02_008b_en.fm

J6 connector to RS232 and Master plugs

Pin Description

1TX1

2+5V

3RX1

4Gnd

5Interface validation

6Nurse call relay common point

7Nurse call relay normally open

8Nurse call relay normally closed

9CD ON external on

10CD OFF external off

11 |

I-OPTON |

Motor control output |

12 |

I-SECT |

Mains led |

13 |

+Vbat |

External power supply plug |

14RX2

15TX2

16Gnd

17CTS

18RTS

19BUZ

20NC

J7 connector to external DC power supply

Pin Description

1± external power supply

2± external power supply

J8 connector to disengagement micro-switch, force sensor and anti-siphon switch

Pin Description

1Not used

2Micro-switch input/output

3Micro-switch input/output

4Not used

5Opto anti-siphon cathode diode

6Opto anti-siphon anode diode/+5V

7Opto anti-siphon transistor collector

8Disengagement micro-switch on

9Disengagement micro-switch off

10Gnd

Do not forget to dismount the ribbon cable holder on the power supply board before extracting the mechanical assembly from the housing (risk of breaking the ribbon cable).

02_008b_en.fm |

19 |

|

|

Description and operation

J9 connector, test points

Pin Description

1GND

2Position sensor output

3Battery discharge control output

4Amplified force sensor output

5Cd coupler power supply 0-5V

6Motor control opto output

7Force and position sensor reference voltage

8Piston head detection opto output

9Control/APIN F

10Control/APIN F

2.1.4 Mechanical gear box unit

The mechanical base unit is composed of a motor-reducer block driving a screw-and-nut unit. At the shaft end, the motor receives a control panel associated with an opto-electronic switch.

The mechanical base unit also accommodates a potentiometer fitted with a rack pinion system.

2.1.5 Mechanical plunger unit

The mechanical plunger unit is mounted onto the mechanical gear box. The gear box ensures the displacement movement of the plunger through a screw / nut system.

The plunger is fitted with a disengagement control allowing to separate this from the screw- and-nut system.

Description and operation

|

20 |

02_008b_en.fm |

|

|

|

2.2 Functional description

From a functional point of view, the Pilot A2 Events Log is composed of three subassemblies:

!A syringe position control and maintenance assembly.

!A motorisation assembly.

!An external connection assembly.

2.2.1 Syringe control and maintenance assembly

The syringe if fitted into the upper case and held in position by means of a syringe clamp.

Detection of the syringe size (60 cc or 20 cc) is carried out by two opto-electronic sensors mounted onto the syringe clamp.

The flanges switch ensures the syringe flanges are correctly positioned in the groove. Associated with an opto-electronic sensor, the anti-siphon arm controls the piston position.

Composed of a micro-switch fitted to the plunger, an anti-occlusion system triggers an alarm whenever force on the piston is excessive.

2.2.2 Motorisation assembly

This sub-assembly moves the piston in the syringe.

It is put into motion by means of a motor-reducer unit associated with a screw-and-nut system.

A motor rotation disk mounted on the shaft end of the motor and associated with an optoelectronic sensor controls the rotation.

A potentiometer controls the plunger movement by means of a rack pinion system.

A micro-switch allows for control of the disengagement device.

2.2.3 External connection sub-assembly

The Pilot A2 Events log has three connectors located at the rear end of the lower case:

!A 12-15 V DC, 15 W type external power supply connector.

!An RS 232 connector.

Description and operation

02_008b_en.fm |

21 |

|

|

Description and operation

|

22 |

02_008b_en.fm |

|

|

|

3 Description of the menus

3.1 Configuration menu of the current operation parameters

The configuration menu enables users to adapt the Pilot to the specific needs of each department. It provides access to the menus allowing for customisation of the parameters associated with current operation modes.

Fresenius Vial recommends users to implement the selected configuration procedures in the presence of a member of its qualified personnel or a member of the technical department.

It is possible to exit the configuration mode at any time by pressing the OFF key.

This menu enables users to:

!PAr1: select the type of flow rate memorisation.

!PAr2: select the syringe selection mode.

!PAr3: modify the maximum flow rates which can be selected using the keyboard.

!PAr4: configure the list of syringes that can be selected.

!PAr5: select the compulsory priming.

!PAr7: select the KVO flow rate.

!PAr9: select the RS232 communication speed.

!PArA: select the empty syringe mode.

!PArb: select the frequency of preventive checks.

!PArC: select the drug display mode.

!PArd: choose whether or not to activate the flanges detection mode.

!PArF: select the Bolus memorisation mode.

!PArG: enter the list of drugs.

!PArJ: choose whether or not to activate the mains disconnection signal.

!PAr0: enter the current date and time.

Description of the menus

03.2_008b_en.fm |

23 |

|

|

3.1.1 Menu access

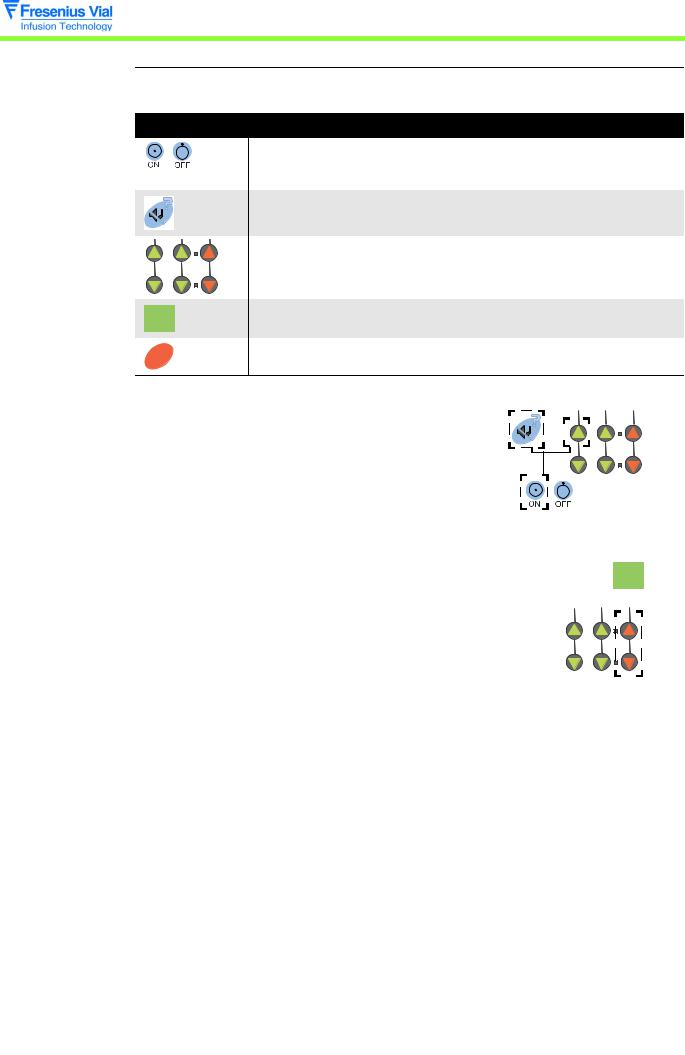

Useful keys

Key |

Function |

|

ON, is used to switch the machine ON. |

|

OFF, is used to switch the machine off when pressed for over three |

|

seconds. |

|

SILENCE ALARM, is used to access the configuration mode of the |

|

current operation parameters. |

|

The selection keys allow to scroll the figures and letters on the tenths, |

|

units, tens segments etc. |

OK |

CONFIRM, is used to validate a choice. |

|

|

|

STOP, is used to cancel the current configuration. |

STOP

Switch to configuration mode.

! Press "SILENCE ALARM" and "TENS" simultaneously. ! Maintain this position while pressing "ON".

!When PAr is shown on the display unit, release the selection of "SILENCE ALARM" and "TENS"

then validate within three seconds by pressing "CONFIRM".

!PAr1 is shown by default.

! Switching from PAr1 to PArO is carried out using the "tenths" keys.

OK

Description of the menus

|

24 |

03.2_008b_en.fm |

|

|

|

3.1.2 PAr1, configuration of the memorisation type

This configuration enables users to choose whether or not to memorise the infusion flow rate when the Pilot is shut down.

! PAr1, press "CONFIRM" |

OK |

|

"If MEM, the flow rate is memorised when the Pilot is shut down, this value will be displayed by default when the machine is next switched on.

"If noME, the flow rate is not memorised, the default

value is 00.0 each time the machine is switched on.

# Select the memorisation type using the selection keys.

" By validating once again, the type is memorised and it is

possible to select another configuration . |

OK |

|

|

||

The modification may be cancelled by pressing the "STOP" key. |

|

|

STOP |

||

|

||

It is possible to exit the configuration mode at any time by pressing the |

|

|

|

||

"OFF" key. |

|

3.1.3 PAr2, configuration of the syringe selection type |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This configuration enables users to choose the type of syringe selection. |

|

|

|

|

|

|

|

|

|

|

|||

! PAr2, press "CONFIRM" |

|

|

|

|

|

OK |

|||||||

|

|

|

|

|

|

|

|

|

|||||

" If SEL3, automatic validation of the only syringe that |

|

|

|

|

|

|

|

|

|

|

|||

may be selected. |

|

|

|

|

|

|

|

|

|

|

|||

" If SEL4, when the Pilot is switched on, the user should |

|

|

|

|

|

|

|

|

|

|

|||

select the type of syringe installed. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

# Choose the selection type using the selection keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

" By validating once again, the type is memorised and it is

possible to select another configuration . |

OK |

When mode SEL3 is selected, and if there is a choice of more than one syringe, the Pilot automatically moves onto the configuration of the list of syringes that may be selected PAr4 when the machine is next switched on.

The modification may be cancelled by pressing the "STOP" key.

STOP

It is possible to exit the configuration mode at any time by pressing the "OFF" key.

03.2_008b_en.fm |

25 |

|

|

Description of the menus

Description of the menus

26

3.1.4 PAr3, configuration of the maximum flow rate that may be selected on the keyboard

This configuration enables users to choose the maximum flow rate that may be selected using |

||||||||||||||||

the keyboard for each type of syringe. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Syringe type |

Min. flow rate (ml/hr) |

Max. flow rate (ml/hr) |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50/60 cc |

0,1 |

400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 cc |

|

0,1 |

275 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! Par3, press "CONFIRM" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

OK |

|

||||||

" Select the syringe type using the keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

# |

20c, 20 ml. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

# |

50c, 50 ml. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

" Press "CONFIRM" |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

OK |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

# Select the maximum flow rate using the keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

" By validating once again, the maximum flow rate is |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

memorised and it is possible to select another |

|

|

|

|

|

|

|

|

|

OK |

||||||

configuration . |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

The modification may be cancelled by pressing the "STOP" key. |

|

|

||||||||||||||

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

STOP |

|

|||

It is possible to exit the configuration mode at any time by pressing the |

|

|

||||||||||||||

|

||||||||||||||||

"OFF" key. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.1.5 PAr4, configuration of the list of syringes that may be selected

This configuration enables users to choose whether or not it may be selected for each type of active syringe.

! PAr4, press "CONFIRM" |

OK |

|

|

|

|

"The LED of the syringe to be configured flashes.

#If SEL, this type of syringe may be selected when the Pilot is switched on.

#If noSE, this type of syringe may not be selected

when the Pilot is switched on. " Make your choice using the keys.

|

|

|

|

|

|

|

|

|

|

|

! Press "CONFIRM" to memorise the modification. |

|

|

|

|

||||||

|

OK |

|||||||||

" The LED of the configured syringe is: |

|

|

|

|||||||

|

|

|

||||||||

# |

Lit up is it may be selected. |

|

|

|||||||

# |

Off if it may not be selected. |

|

|

|||||||

03.2_008b_en.fm

Details of the syringe are displayed

when the "tenths" keys are pressed (see chapter 3.1.17 "Typical syringe/details correspondence table").

The modification may be cancelled by pressing the "STOP" key.

STOP

It is possible to exit the configuration mode at any time by pressing the "OFF" key.

3.1.6 PAr5, configuration of the compulsory priming

This configuration enables users to choose whether or not priming is compulsory after selection of a syringe.

! PAr5 is displayed.

" Press "CONFIRM" |

OK |

|

#If PurG, compulsory priming, pressing "BOLUS" during start-up is compulsory to switch to selection of the flow rate.

#If noPu, priming is not compulsory, the flow rate

may be selected upon start-up straight after validation of the syringe.

" Make your choice using the keys.

"By validating once again, the configuration is memorised and it is possible to select another configuration .

The modification may be cancelled by pressing the "STOP" key.

It is possible to exit the configuration mode at any time by pressing the "OFF" key.

OK

STOP

3.1.7 PAr7, configuration of the KVO flow rate

This configuration enables users to choose whether or not to activate the switching to KVO flow rate.

! PAr7, press "CONFIRM" |

OK |

|

|

|

|

"If KVO, KVO flow activated, the infusion continues at 1,0 ml/hr (or at the same flow rate if this is under 1,0 ml/hr) when the volume infused reaches the limit volume.

"If noKV, no KVO flow, infusion stops with a limit volume alarm when the infused volume reaches the limit volume.

"Make your choice using the keys.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

03.2_008b_en.fm |

27 |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

Description of the menus

Description of the menus

28

" By validating once again, the configuration is memorised

and it is possible to select another configuration . |

OK |

|

|

||

The modification may be cancelled by pressing the "STOP" key. |

|

|

STOP |

||

|

||

It is possible to exit the configuration mode at any time by pressing the |

|

|

|

||

"OFF" key. |

|

3.1.8 PAr9, configuration of the RS232 communication speed

This configuration enables the user to select the communication speed of the RS232 link.

! PAr9, press "CONFIRM" |

OK |

"If 19K2, speed at 19200 Bauds.

"If 19K2, speed at 9600 Bauds.

"If 4800, speed at 4800 Bauds.

" Make your choice using the keys.

" By validating once again, the configuration is memorised

and it is possible to select another configuration . |

OK |

|

The modification may be cancelled by pressing the "STOP" key. |

|

|

STOP |

||

|

||

It is possible to exit the configuration mode at any time by pressing the |

|

|

|

||

"OFF" key. |

|

3.1.9 PArA, configuration of the empty syringe mode

This configuration enables users to choose whether or not to activate using the empty syringe mode.

! PArA, press "CONFIRM" |

OK |

|

"If SVId, empty syringe mode activated.

"If SVId, empty syringe mode deactivated.

" Make your choice using the keys.

" By validating once again, the configuration is memorised

and it is possible to select another configuration . |

OK |

|

|

||

The modification may be cancelled by pressing the "STOP" key. |

|

|

STOP |

||

|

||

It is possible to exit the configuration mode at any time by pressing the |

|

|

|

||

"OFF" key. |

|

03.2_008b_en.fm

3.1.10 PArb, configuration of the frequency of preventive checks

This configuration enables users to select the maintenance frequency which lies between 1 and 9999 hours.

! PArb, press "CONFIRM" |

OK |

|

||||||||||||||

|

|

|

|

|

|

|||||||||||

" The current value is displayed. |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

" Display the new frequency value using the keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

" By validating once again, the new frequency is |

|

|

|

|

|

|

||||||||||

memorised and it is possible to select another |

|

|

|

|

|

|

||||||||||

OK |

|

|||||||||||||||

configuration . |

|

|||||||||||||||

|

|

|

|

|

|

|||||||||||

The modification may be cancelled by pressing the "STOP" key. |

|

|

|

|

|

|

|

|||||||||

|

STOP |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

It is possible to exit the configuration mode at any time by pressing the "OFF" |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

||||||||||

key. |

|

|

|

|

|

|

||||||||||

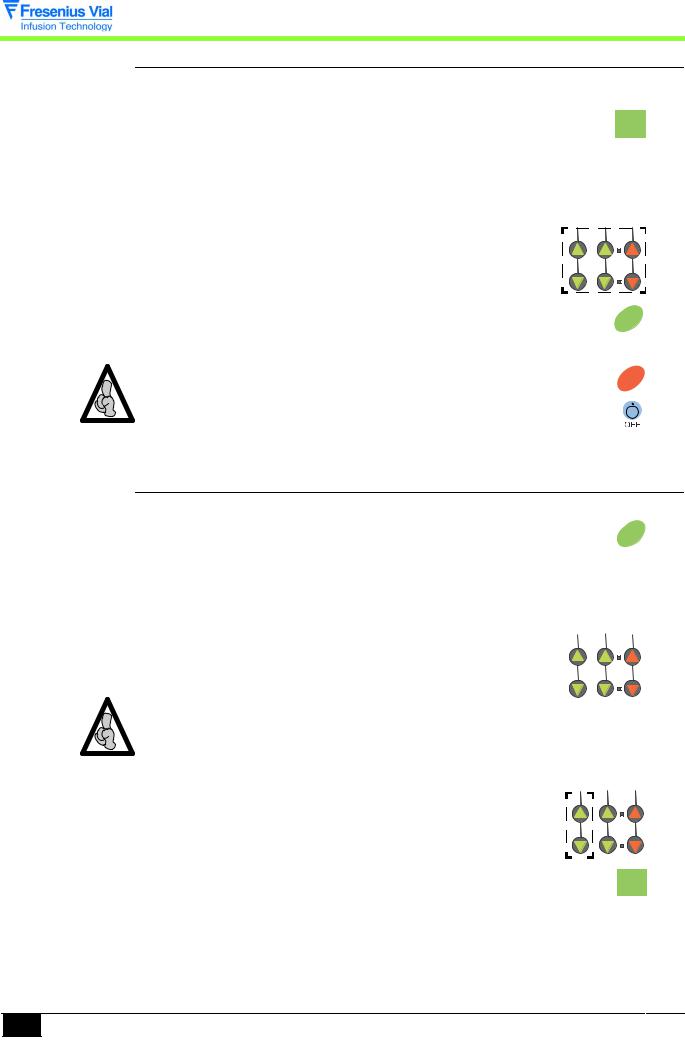

3.1.11 PArC, configuration of the drug display mode

This configuration enables users to choose whether or not to display the first four letters of the name of the drug used.

! PArC, press "CONFIRM" |

OK |

|

|

|

|

"If drUG, display activated, after validation of the syringe type, the operator should select the name of the drug used out of the choice of 15 names.

"If nodr, display deactivated, the Pilot does not offer a choice of drug names.

" Make your choice using the keys.

"By validating once again, the configuration is memorised and it is possible to select another configuration .

If The modification may be cancelled by pressing the "STOP" key.

It is possible to exit the configuration mode at any time by pressing the "OFF" key.

OK

STOP

Description of the menus

03.2_008b_en.fm |

29 |

|

|

Description of the menus

30

3.1.12 PArd, configuration of the Flanges detection mode

This configuration enables users to choose whether or not to activate the syringe flanges position check.

! PArd, press "CONFIRM" |

OK |

|

"If AiLE, detection activated, inappropriate positioning of the flanges is signalled by means of an alarm.

"If noAL, no detection, the inappropriate positioning of the flanges is not checked.

" Make your choice using the keys.

" By validating once again, the configuration is memorised

and it is possible to select another configuration . |

OK |

|

|

|

|

The modification may be cancelled by pressing the "STOP" key. |

|

|

STOP |

|

|

|

|

|

It is possible to exit the configuration mode at any time by pressing the "OFF" |

|

|

|

|

|

key. |

|

|

3.1.13 PArF, configuration of the bolus flow memorisation mode

This configuration enables users to select the bolus flow memorisation mode.

! PArF, press "CONFIRM" |

|

OK |

|||||||||||

|

|

|

|

|

|||||||||

" If MEM, bolus memorised, upon start-up of the Pilot, the |

|

|

|

|

|

||||||||

|

|

|

|

|

|||||||||

bolus flow given corresponds to the last selected. |

|

|

|

|

|

||||||||

" Si noME, bolus not memorised, upon start-up of the |

|

|

|

|

|

||||||||

Pilot, the bolus flow given is that defined by default. |

|

|

|

|

|

||||||||

" Make your choice using the keys. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If the "not memorised" mode is selected, the bolus default value must be defined.

" If the noMEis selected, the 50 cc LED lights up and the

bolus flow is displayed. |

|

|

# |

Using the keys, enter the bolus value to be defined by |

|

|

default for a 50 cc syringe. |

|

# |

Press "CONFIRM" to memorise it |

OK |

|

||

03.2_008b_en.fm

Loading...

Loading...