Fresenius 2008, 2008H Troubleshooting guide

FRESENIUS 2008H |

HEMODIALYSIS SYSTEM |

TROUBLESHOOTING |

GUIDE |

Part Number 507082 Rev. B

FRESENIUS USA, INC.

2637 Shadelands Drive, Walnut Creek, CA 94598

800-227-2572 or 925-295-0200

TECHNICAL SUPPORT FOR HEMODIALYSIS SYSTEMS

Press 5 when the automated system answers.

AUTOMATED PHONE SYSTEM MENU

Press |

To Reach |

1 An individual 4-digit extension

5Technical Support

6Spare Parts Ordering

0 Operator

USEFUL EXTENSION AND FAX NUMBERS

Technical Support |

|

Receptionist X7003 |

FAX 925-988-1969 |

Technical Training |

|

Receptionist X7264 |

FAX 925-988-1969 |

Spare Parts |

|

Receptionist X7004 |

FAX 925-988-1969 |

REGIONAL EQUIPMENT SPECIALIST: __________________________________

FRESENIUS 2008H

HEMODIALYSIS SYSTEM

TROUBLESHOOTING

GUIDE

Part Number 507082 Rev B

Copyright 1998, 1999 Fresenius USA, Inc.

Fresenius 2008H Troubleshooting Guide

P/N 507082 Rev. B

TABLE OF CONTENTS |

|

USING THE TROUBLESHOOTING GUIDE........................................................................................................ |

1 |

THE 'ORDER' OF TROUBLESHOOTING ........................................................................................................... |

2 |

INITIAL CHECKS ................................................................................................................................................. |

3 |

SAFETY CHECKS ............................................................................................................................................... |

4 |

EQUIPMENT NEEDED........................................................................................................................................ |

4 |

SECTION 1 - FLOW ERRORS IN DIALYZE MODE............................................................................................ |

6 |

SECTION 2 - NO WATER.................................................................................................................................. |

23 |

SECTION 3 - FLOW ERRORS IN CLEANING PROGRAMS............................................................................ |

25 |

SECTION 4 - TEMPERATURE PROBLEMS..................................................................................................... |

33 |

SECTION 5 - CONDUCTIVITY PROBLEMS..................................................................................................... |

46 |

SECTION 6 - CONCENTRATE PUMP 'END OF STROKE' (EOS) ERRORS.................................................. |

52 |

SECTION 7 - COND OFFSET REF OR COND OFFSET FAILURES............................................................... |

54 |

SECTION 8 - FILLING PROGRAM PROBLEMS............................................................................................... |

55 |

SECTION 9 - TMP PROBLEMS ........................................................................................................................ |

57 |

SECTION 10 - PRESSURE HOLDING TESTS FAILING.................................................................................. |

60 |

SECTION 11 - NEGATIVE PRESSURE TESTS ............................................................................................... |

62 |

SECTION 12 - INDUCED POSITIVE PRESSURE TESTS ............................................................................... |

65 |

SECTION 13 - DEAERATION PROBLEMS ...................................................................................................... |

66 |

SECTION 14 - UF PUMP PROBLEMS.............................................................................................................. |

67 |

SECTION 15 - BLOOD LEAK PROBLEMS ....................................................................................................... |

69 |

SECTION 16 - CHECKING THE ACTUATOR BOARD CABLE ........................................................................ |

72 |

SECTION 17 - CHECKING THE SENSOR BOARD CABLE............................................................................. |

74 |

SECTION 18 - MANUAL BALANCING CHAMBER VALVE LEAK TESTS ....................................................... |

76 |

SECTION 19 - TESTING FOR A LEAKING BALANCING CHAMBER DIAPHRAGM....................................... |

79 |

Fresenius 2008H Troubleshooting Guide

P/N 507082 Rev. B

PREFACE

This troubleshooting guide has been developed with the help of many customers and Fresenius personnel. It is a combination of known techniques and excellent feedback from people that actually work with the equipment.

The intent of the 2008H Troubleshooting Guide is to provide you with an aid in the diagnosis of common problems. Since this document is only a guide and may not provide the most up-to-date solutions for every conceivable problem, we recommend contacting our Technical Services Support line should additional assistance be required.

WARNING: Before using this guide you must read pages 1 through 4 which outline Using the Troubleshooting Guide, Order of Troubleshooting, Initial Checks, Safety Checks and Equipment Needed. Never troubleshoot with a patient connected to the machine. If possible, remove the machine from the treatment area when it is being serviced. Always tag the machine to ensure it is not accidentally returned to service before the service work is completed.

Always fully test a machine (in accordance to the Technicians Manual P/N 490004 or Operators Manual P/N 490005) when maintenance and/or repairs have been completed. This is to include confirmation of conductivity, pH and Temperature with a calibrated device.

Should additional technical assistance be needed, technical support is provided 24 hours a day, seven days a week at our toll free number (800) 227-2572.

Fresenius 2008H Troubleshooting Guide

P/N 507082 Rev. B

USING THE TROUBLESHOOTING GUIDE

1.The equipment technician should have knowledge of clinical Hemodialysis and operational theory of the Fresenius system. A minimum of Level I training is necessary! Incorrect troubleshooting can result in injury or death to the troubleshooter and patient.

2.The equipment technician should have knowledge of the test equipment, especially the multimeter. Refer to the meter's operational manual as necessary.

3.The troubleshooting procedures are written in 'flow chart' style that systematically eliminates possible areas of failure. Read each procedure carefully before moving on. You will be prompted to the next procedure or to possible solutions. Pay careful attention to CAUTIONS and NOTES.

4.Many of the troubleshooting procedures are performed at the DISTRIBUTION BOARD.

a)Inside the distribution board are several numerically identified 'male' connector positions. Male pins are arranged vertically and are numbered 1 through 5 (from top to bottom).

b)Each hydraulic component has a 5-pin female connector dedicated to numeric distribution board positions as specified in the HYDRAULIC FLOW DIAGRAM. For example, flow pump #21 plugs into position [P21, FLOW-P]. Valve 43 plugs into position [V43], etc. Except for the heater, acid pump, and bicarb pump, you can plug and unplug connectors into the distribution board with the power on.

NOTE: There are several unused positions including; x4 [PH-PR] (pH probe, optional), x13 [COND-POS] (on-line clearance, optional), x44 [NTC-POS] (on-line clearance, optional), V14, V15, x19 [AIR-SEP], V23 and x40 [V42]. Be CAREFUL not to accidentally plug a connector into one of these.

DISTRIBUTION BOARD

FEMALE CONNECTOR |

|

PIN 1 |

|

||

|

|

|

|

|

PIN 5 |

|

|

5. If unsuccessful please call Technical Services at 1-800- 2272572.

Fresenius 2008H Troubleshooting Guide |

Page 1 |

P/N 507082 Rev. B |

|

THE 'ORDER' OF TROUBLESHOOTING

Troubleshoot in the following order:

1.No Water

2.Flow Errors

3.Temperature

4.Conductivity

5.TMP

6.Blood Leak

7.Pressure Holding Test Failures

NOTE: Before beginning we recommend that you perform INITIAL CHECKS (page 3). This is especially important if someone has been working on the machine before you!

1.NO WATER (debug screen 5, !WATER = "1" either constantly or intermittently). Without water hydraulic operation is not possible.

2.FLOW ERRORS (debug screen 5, FLWERR = "1" either constantly or intermittently), will effect Temperature, Conductivity, TMP and Blood Leak. If a FLOW ERROR is present troubleshoot it before being concerned with any other alarms.

3.FLOW ERRORS turn the heater off and result in TEMPERATURE problems. Before troubleshooting any TEMPERATURE problem assure that the machine is free of flow errors (debug screen 5, FLWERR = "0" constantly).

4.CONDUCTIVITY is temperature compensated. Without stable temperature CONDUCTIVITY will not be stable. Before troubleshooting CONDUCTIVITY problems, assure that TEMPERATURE is normal and remaining constant from the main dialysis screen.

5.Before troubleshooting TMP problems assure that there are no flow errors present (debug screen 5, FLWERR = "0" constantly). Assure also that TEMPERATURE and CONDUCTIVITY are normal and remaining constant from the main dialysis screen.

6.Before troubleshooting PRESSURE HOLDING TEST FAILURES assure that there are no flow errors present (debug screen 5, FLWERR = "0" constantly). Assure also that TEMPERATURE and CONDUCTIVITY are normal and remaining constant from the main dialysis screen.

7.Before troubleshooting BLOOD LEAK problems assure that there are no flow errors present (debug screen 5, FLWERR = "0" constantly). Assure also that TEMPERATURE and CONDUCTIVITY are normal and remaining constant from the main dialysis screen.

FUNCTIONAL BOARD SOFTWARE DISCLAIMER

Functional board software may effect the TROUBLESHOOTING GUIDE. With the exception of CONDUCTIVITY PROBLEMS this guide is compatible with functional software up to 8.02

Page 2 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

INITIAL CHECKS

1.Turn the power OFF and slide the card cage forward. Check that all five boards are pushed down into the motherboard and are 'locked' in.

2.Check that the sensor and actuator cables are plugged tightly into *both ends. Check also for bare wires or other damage along their entire length.

* Both cables run into the distribution board and terminate at the SENSORS and ACTUATOR connectors respectively (see DISTRIBUTION BOARD diagram below).

3.Check that the power logic board cable is plugged tightly into the power logic board.

4.Check that the PGND (power ground) wire is plugged into the distribution board (see DISTRIBUTION BOARD diagram below).

5.Close the card cage. IMPORTANT NOTE! Do NOT troubleshoot with the card cage open! Turn the machine ON and return to the operating mode (DIALYSIS, RINSE, etc) where the problem is occurring.

6.Allow 10 minutes for stabilization.

ACTUATOR CABLE |

SENSOR CABLE |

MOTHER BOARD

POWER LOGIC

CABLE

CARD CAGE, TOP VIEW

SENSORS CONNECTOR |

ACTUATOR CONNECTOR |

PGND WIRE |

DISTRIBUTION BOARD |

|

Fresenius 2008H Troubleshooting Guide |

Page 3 |

P/N 507082 Rev. B |

|

SAFETY CHECKS

Before placing the machine back into service:

1.Remove all test equipment (jumpers, 'dummy' connectors, etc) from the distribution board and make sure that all hydraulic components are plugged in.

2.If you have been troubleshooting TEMPERATURE problems turn the heater breaker switch off and assure that the TEMP display falls to 33° C and that the bypass condition exists.

3.If you have been troubleshooting CONDUCTIVITY problems drop the acid and bicarb lines into water and assure that the COND display falls to 10.0 and that the bypass condition exists.

4.Check that AUDIO ALARMS are working properly.

5.Perform alarm and pressure holding tests.

EQUIPMENT NEEDED

-Fresenius gauge kit (part # 150034)

-Fresenius test (temperature) 'dummy connectors' (part # 190060)

-Graduated cylinder (1000 ml)

-Buret 0 - 25cc (part # 290104)

-60 ml syringe

-Flashlight

-Jumper wire

-Independently calibrated temperature, conductivity, and pressure meters

-Voltmeter (recommended Fluke "70" series)

-Clip-on meter leads (recommended Fluke TL24 Flexible test leads with AC80 pin grabbers) * Non-standard meter probes (recommended Fluke TP80 probes)

*Non-standard meter probes assure safe voltage measurement in 'tight' areas when shorting other pins or connectors is a concern. Fluke TP80 meter probes include a slip-on cap that fits over the lead to 'isolate' the measuring point and prevent shorting.

FLUKE TP80 METER PROBES (WITH SLIP ON CAP)

Page 4 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

SHUNT DOOR

HANSEN

CONNECTORS

EXTERNAL FLOW

INDICATOR #75

DIALYSATE LINE

FILTER #73

UF PUMP #22

BALANCING

CHAMBER #68

VALVE #25

Note: On Later version, Valve 25 may be on the front side of hydraulics

DIALYSATE PRESSURE  TRANSDUCER #9

TRANSDUCER #9

REGULATOR #78

FLOW PUMP #21

UPPER POWER

SUPPLY

HEATER BREAKER

SWITCH

ON/OFF SWITCH

DISTRIBUTION BOARD (INSIDE COVER)

HEATER CONNECTOR

INPUT WATER

INPUT WATER

FILTER

FILTER

FILTER

VENT LINE

VENT LINE

DRAIN LINE CONDUCTIVITY CELL #7

DRAIN LINE CONDUCTIVITY CELL #7

NTC #2

NTC #3

CFS TRANSDUCER #10

ORIFICE #48

LOADING PRESSURE

REGULATOR #65

VALVE 39

DEAERATION PUMP #29

DIAGRAM A REAR VIEW

Fresenius 2008H Troubleshooting Guide |

Page 5 |

P/N 507082 Rev. B |

|

SECTION 1 - FLOW ERRORS IN DIALYZE MODE

F- 1.0.0 CHECK LOADING PRESSURE

a)Assure that the vent tube is not 'pinched' (see diagram A, page 5) .

b)Insert a *loading pressure gauge TIGHTLY into the ACETATE/ACID port. Peak pressure?

1) |

0 to 10 psi |

Call up debug screen 5. If !WATER = "1" proceed to NO WATER (page 23) |

|

|

otherwise proceed to F- 2.0.0 |

2) |

17 to 25 psi |

Allow two minutes (if necessary) for the symptoms to appear. See F- 3.0.0 |

3) |

Greater than |

Attempt to calibrate loading pressure to +19 psi peak per CALIBRATION |

|

25 psi |

PROCEDURES, section 2.13. If not successful a bad loading pressure |

|

|

regulator #65 is indicated (see diagram A, page 5). |

* If the gauge does not read 0 psi at atmosphere compensate for this during loading pressure checks.

F- 2.0.0 CHECK FOR A RUNNING DEAERATION PUMP

Make sure that flow is on (FLOW ON/OFF LED is off). Depending upon the pump:

1. Motors with brushes The deaeration pump's motor shaft can be accessed from the front side of the machine (see FRONT VIEW diagram below). If the shaft is *rotating the pump is running. Is the deaeration pump running?

Yes |

See F- 14.0.0 |

(page 12). |

No |

See F- 18.0.0 |

(page 16) to check the DEAERATION PUMP. |

* Rotation is CCW (from the front of the machine). If rotating CW the motor is running backwards

2.Motors without brushes Remove the CLEAR tubing from the deaeration pump's input nozzle (see REAR VIEW diagram below). If the pump is running you will hear 'gurgling'. Is the deaeration pump running?

Yes |

See F- 14.0.0 |

(page 12). |

No |

See F- 18.0.0 |

(page 16) to check the DEAERATION PUMP. |

DEAERATION MOTOR SHAFT (WITH BRUSHES)

DEAERATION

INPUT NOZZLE

FRONT VIEW |

REAR VIEW |

Page 6 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

F- 3.0.0 CHECK DEBUG ERRORS

CAUTION Do NOT attempt to reset other alarms during this check!

Call up debug screen 5 and watch !WATER and FLWERR for two minutes. Proceed accordingly:

1)!WATER and FLWERR = "0" constantly. See F- 3.0.1

2)!WATER = "1" constantly or intermittently. See NO WATER (page 23).

3)FLWERR = "1" constantly or intermittently. See F- 4.0.0

F- 3.0.1 FLOW ERROR NOT PRESENT

-If COND is CONSTANTLY high. Watch FLWERR for several minutes. If it goes to "1" see F- 4.0.0

-If COND is drifting from normal to high. Wait until the BYPASS LED is off and watch FLWERR for 30 seconds. If it goes to "1" see F- 6.0.0.

-If conductivity remains normal. If FLWERR remains " 0" constantly a flow error is not indicated.

-If conductivity remains low and FLWERR remains "0" a flow error is NOT present.

F- 4.0.0 CHECK FOR FILLING PROGRAM

Call up debug screen 7. Is FILACT "1" or "0"?

"1" |

See F- 4.0.1 |

"0" |

See F- 5.0.0 |

F- 4.0.1 FILLING PROGRAM PRESENT

a)At the top of chamber #69 is a two-pin female connector that plugs onto two male probes (see diagram, below). Unplug both sides of the connector and connect the female ends together. FILACT should now = 0.

b)Return to debug screen 5 and watch for 3 minutes. Does FLWERR go to "0" and REMAIN?

Yes |

See F- 4.0.2. |

No |

Plug the female connector back onto the probes and see F- 5.0.0. |

TWO-PIN FEMALE

CONNECTOR

MALE PROBES

CHAMBER # 69

FLOW PUMP

MOTOR SHAFT

FRONT VIEW

Fresenius 2008H Troubleshooting Guide |

Page 7 |

P/N 507082 Rev. B |

|

F- 4.0.2 CHECK FLOW PUMP

From the front side of the machine you can see the flow pump's motor shaft (see FRONT VIEW diagram, previous page). Turn the flow off. Is the shaft rotating?

Yes |

Replace the actuator board. |

No |

See F- 16.0.0 (page 14). |

F- 5.0.0 CHECK FOR A *VALVE ERROR

Proceed with this step ONLY if FILACT and !WATER are both = "0" continuously.

From DIALYZE MODE return to debug screen 5. Watch VLVERR VERY carefully for two full minutes. If a valve error is present VLVERR 'blinks' momentarily to "1" (about every 60 seconds). If a valve error is present VLVERR goes to "1" for ONLY a second. If you look away you may miss it! Does VLVERR ever 'blink' "1"?

Yes |

See F- 5.0.1 |

No |

See F- 6.0.0 |

* VALVE ERRORS indicate either high or low current in a particular 'valve circuit'.

F- 5.0.1 LOCATING THE VALVE ERROR

Listen carefully in the area of the hydraulics (you may need to remove them from the machine). You should be able to hear a continuous, dull, 'thudding'. Proceed step-by-step and follow the given instructions.

1)From DIALYZE MODE open the shunt door. If the 'thudding' stops a VALVE 25 is causing the error. Note this (valve 25 is the problem) and see TROUBLESHOOTING VALVE ERRORS (page 30). If the 'thudding' continues proceed to step 2.

2)Turn the flow off. If the 'thudding' stops a BALANCING CHAMBER VALVE is causing the error. Note this (balancing chamber valve is the problem) and see TROUBLESHOOTING VALVE ERRORS (page 30). If the 'thudding' continues proceed to step 3.

3)The 'thudding' continues with the shunt door open and flow off. VALVE 30 or 26 is causing the error. Note this (valve 30 or 26 is the problem) and see TROUBLESHOOTING VALVE ERRORS (page 30). Troubleshoot BOTH valves.

Page 8 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

F- 6.0.0 CHECK FLOW ERROR 'IN BYPASS'

Open the shunt door to cause bypass. Return to debug screen 5 and watch FLWERR for one full minute. Does FLWERR go to "0" constantly or does it still = "1" (either constant or intermittent)?

"0" constantly |

See F- 6.0.1 |

Still = "1" |

Close the shunt door and see F- 7.0.0 |

F- 6.0.1 CHECK FLOW ERROR 'OUT OF BYPASS'

a)Leave the shunt door open and return to the main DIALYSIS screen.

b)Allow TEMP and COND to become normal.

c)Close the shunt door (bypass LED should turn off) and return to debug screen 5. Wait 30 seconds. Does FLWERR = "1"?

Yes |

See F- 17.0.0 (page 15). |

No |

A flow error is not indicated. |

F- 7.0.0 CHECK FOR A RUNNING FLOW PUMP

CAUTION Do NOT attempt to reset other alarms during this check!

a)At this time NOTE if FLWERR = "1" constantly or intermittently for future use.

b)From the FRONT of the machine you can see the flow pump's motor shaft (see FRONT VIEW diagram below). If the shaft *rotating?

Yes |

See F- 8.0.0 |

No |

See F- 18.0.0 (page 16) to check the FLOW PUMP. |

* Rotation is CCW (from the front of the machine). If rotating CW the motor is running backwards

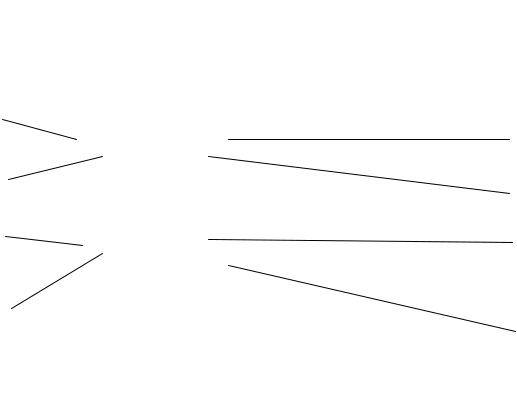

FLOW PUMP

MOTOR SHAFT

FLOW PUMP

OUTPUT NOZZLE

FRONT VIEW |

REAR VIEW |

Fresenius 2008H Troubleshooting Guide |

Page 9 |

P/N 507082 Rev. B |

|

F- 8.0.0 CHECK FLOW PUMP CONTROL

Turn the flow off and check the flow pump's motor shaft again. Still rotating?

Yes |

Replace the actuator board (pump driver (IC18) possibly shorted). |

|

No |

a) |

Turn the flow on. |

|

b) |

FLWERR may = "0" for a few seconds after turning flow on. Ignore this! As noted |

previously (step F- 7.0.0) was FLWERR = "1" constant or intermittent?

Constant |

See F- 10.0.0 |

Intermittent |

See F- 9.0.0 |

F- 9.0.0 CHECK FOR NO WATER

Turn the flow on and call up debug screen 5 and carefully watch !WATER for two minutes. Does !WATER go to "1" at any time during this time interval?

Yes |

See NO WATER (page 23). |

No |

See F- 9.0.1 |

F- 9.0.1 CHECK FLOW PUMP PRESSURE

a)Tee a pressure gauge between the flow pump's output nozzle and the WHITE tubing (see REAR VIEW diagram, previous page).

b)Turn the flow on at a 500 flow rate. Does pressure peak to 14 psi or greater?

Yes |

See F- 13.0.0 (page 12) |

No |

Three possibilities: 1) Bad actuator board; 2) Bad flow pump head; 3) Bad flow pump motor. |

F- 10.0.0 CHECK DRAIN FLOW

a)Having a bucket handy and go to end of the drain line. Hold it UP, at a 45 degree angle, over the bucket. CAUTION! Holding the drain line lower than 45 degrees makes this test invalid!

b)Watch for 20 seconds. Flow may be intermittent and this is normal. Is there any flow through the drain line?

Yes |

See F- 10.1.0 |

No |

See F- 11.0.0 |

Page 10 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

F- 10.1.0 DETERMINING DRAIN FLOW

Normal Fresenius drain output 'pulses' in 30 ml increments, stops completely, and then 'pulses' out again. Is drain flow 'pulsing' or 'continuous' (never stops)?

Pulsing |

See F- 13.0.0 (next page). |

Continuous |

Three possibilities: 1) Partial restriction to drain (check the drain line first for |

|

restrictions); 2) Balancing chamber valve remaining open (run automated valve leak |

|

test from SERVICE/DIAGNOSTICS); 3) Leaking balancing chamber diaphragm (see |

|

TESTING FOR A LEAKING BALANCING CHAMBER DIAPHRAGM). |

F- 11.0.0 CHECK FLOW TO (DRAIN) VALVE 30

CAUTION! During this procedure there will be spillage. Move the hydraulics away from the cabinet to prevent spillage into the cabinet!

a)Turn the flow off and remove the INPUT tube from valve 30 (see TOP VIEW diagram below). Point it AWAY from the hydraulics.

b)Turn the flow on. Is there good 'pulsing' flow here?

Yes |

Turn flow off and attach the tubing to valve 30. See F- 11.1.0 |

|

No |

See F- 12.0.0 |

|

|

INPUT TUBE |

VALVE 30 |

TOP VIEW

REAR OF MACHINE

F- 11.1.0 CHECK VALVE 30

a)Turn the flow on.

b)Remove the drain line from the back of the machine. Is there good 'pulsing' flow here?

Yes |

The drain line is restricted. |

No |

A problem is indicated with VALVE 30 or the actuator board. NOTE this and see |

|

TROUBLESHOOTING VALVES (page 29). |

Fresenius 2008H Troubleshooting Guide |

Page 11 |

P/N 507082 Rev. B |

|

F- 12.0.0 CHECK FLOW TO FLOW PUMP

Proceed with this step if you are VERY sure that VLVERR (debug screen 5) is always "0".

Place the machine into RINSE and remove the CLEAR tube from the flow pump's INPUT nozzle (see diagram below). Good flow here?

Yes |

A problem is indicated with VALVE 26 or the actuator board. NOTE this and see |

|

TROUBLESHOOTING VALVES (page 29). |

No |

Replace the actuator board. If the flow error continues there may be two bad valves |

|

(remaining closed) on the balancing chamber. |

DEAERATION PUMP

INPUT NOZZLE

FLOW PUMP

INPUT NOZZLE

REAR VIEW

F- 13.0.0 CHECK CFS SIGNAL

Making sure that flow is on call up debug screen 11 and watch ACFS (in vdc). SIX possibilities:

1)Constant flow error and ACFS remaining between 3 and 7. See F- 21.0.0 (page 20).

2)Constant flow error and ACFS remaining between 8 and 11. See F- 23.0.0 (page 22).

3)Constant flow error and ACFS remaining between 0 and 3. See F- 20.0.0 (page 18).

4)Intermittent flow error and ACFS remaining between 3 and 7. See F- 21.0.0 (page 20).

5)Intermittent HIGH FLOW error. Call up debug screen 10 and watch CFS for a couple of minutes. If CFS intermittently 'bounces' to about 10 replace the CFS transducer (#10). If the problem continues check for a bad connection at the sensor board cable on both sides (especially the distribution board side, unplug the cable and check the male pins for corrosion ). There may also be an intermittent open in the sensor cable or a problem with the sensor or actuator boards.

6)Intermittent flow error and ACFS 'bouncing' (about every 9 seconds) from between 0 and 3 to about 5. A problem is indicated with a BALANCING CHAMBER VALVE. See F- 19.0.0 (page 16).

F- 14.0.0 LOW LOADING PRESSURE, DEAERATION PUMP RUNNING

NOTE: This procedure checks for water in the hydroblock and proper float functional.

a)Stop the deaeration pump by unplugging it from distribution board position P20, DEAR-P.

b)If you haven't done so remove the CLEAR (input) tube from the deaeration pump's nozzle (see REAR VIEW diagram, above). Is there flow from the tube?

Yes |

See F- 14.0.1 |

No |

See F- 15.0.0 |

Page 12 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

F- 14.0.1 CHECK INCOMING WATER

Allow this flow to continue for about three minutes (you may need a bucket). You should hear water entering the hydroblock in cycles as the float falls and rises. Does flow remain continuous?

Yes |

See F- 14.0.2 |

No |

See F- 15.0.0 |

F- 14.0.2 CHECK LOADING PRESSURE REGULATOR

a)Plug the deaeration pump back into the distribution board (P20, DEAR-P) and assure that it starts running i.e. the motor shaft rotates. Allow one minute and check if loading pressure returns to normal (19 ± 1 psi). If it does there may be an intermittent problem with the float. Continue to part b otherwise.

b)Tightly clamp the solid tubing between the loading pressure regulator and the hydroblock (see diagram below). Is there a drastic increase of loading pressure?

Yes |

A problem is indicated with the loading pressure regulator. |

No |

A problem is indicated with the deaeration pump head. |

F- 15.0.0 CHECK HYDROBLOCK

a)Clamp the vent tube and remove the orifice from the hydroblock (see diagram below). Check if it is plugged. If plugged this is the problem.

b)Re-install the orifice and REMOVE the clamp from the vent tube.

c)Turn the power off.

d)Loosen (but don't remove) the screws that mounts the float into the hydroblock (see diagram below). CAUTION Don't pull on the float's wiring harness or you may break it! Carefully remove the float from the hydroblock.

FLOAT (FULLY DOWN ON SHAFT)

HEATER

VENT TUBE

HYDROBLOCK

ORIFICE

LOADING PRESSURE

REGULATOR

SOLID TUBING

(CLAMP HERE)

e)Unplug the float from distribution board position FLOAT-SW. Check inside the distribution board for bent broken or corroded male pins.

Fresenius 2008H Troubleshooting Guide |

Page 13 |

P/N 507082 Rev. B |

|

f)Very carefully open the cover on the female connector (see diagram below). Note that pins 2 and 5 are missing. Clip meter leads onto pins 1 and 3 (pin 1 = top of the 100 ohm resistor, pin 3 = middle pin). CAUTION! Be careful to clip onto the correct pins!

PIN 1 (TOP PIN)

100 OHM RESISTOR PIN 2 (MISSING) PIN 3 (MIDDLE PIN)

PIN 5 (MISSING)

FEMALE FLOAT DISTRIBUTION

BOARD CONNECTOR

g)With the float FULLY DOWN on the shaft you should read approximately 100Ω, FULLY UP an 'open' (OL). Move the float FULLY UP and DOWN twenty times while watching the transition on the meter. It should go from OL to 100Ω everytime! If the float checks out good see F- 15.0.1

F- 15.0.1 CHECK INCOMING WATER

a)Plug the float's connector back into the distribution board (position FLOAT-SW).

b)Hold the float in its FULLY UP position. Turn the power on and wait until the SELECT PROGRAM screen is up.

c)Looking into the hydroblock's float cavity turn the power on. CAUTION Avoid overflow during this step! Move the float to its FULLY DOWN position. Is the water level rising?

Yes |

See F- 15.0.2 |

No |

Two possibilities: 1) *Bad sensor board cable; 2) Bad actuator board. |

*The sensor cable can be checked for continuity. Note that you are checking the FLOAT connection and see CHECKING THE SENSOR BOARD CABLE (page 74).

F- 15.0.2 CLEARING AN AIR LOCK

a)Connect a 60 ml syringe to the clear INPUT tubing of the deaeration pump and draw on it. You may have to pull five or six syringes full of air before water flows continuously by itself. If you are not able to make water flow continuously it may be indicative of a 'stripped' orifice.

b)Re-connect the INPUT tubing to the deaeration pump and plug the deaeration pump back into the distribution board (P20, DEAR-P). Assure that it starts running i.e. the motor shaft rotates. Allow a few minutes for loading pressure to return to normal. NOTE: Recurring air locks may be indicative of a bad deaeration pump head, motor or a 'stripped' orifice.

F- 16.0.0 TROUBLESHOOTING 'FILLING PROGRAM' FLOW ERRORS

During FILLING PROGRAMS the dialysate pressure transducer #9 determines the presence of flow.

a)Plug the connector back onto the probes.

b)Remove the dialysate lines from the shunt door and drop them into a bucket of water on the floor.

c)IMPORTANT Close the shunt door.

Page 14 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

d) Call up debug screen 9 and wait 30 seconds. Is PDIA between 4.0 and 6.0 vdc?

Yes |

See F- 16.0.1 |

No |

See TM- 2.0.1, TMP PROBLEMS (page 58). |

F- 16.0.1 CHECK VALVE 43

CAUTION! During this procedure there will be spillage. Move the hydraulics away from the cabinet to prevent damage.

a)Place the machine into RINSE.

b)Clamp and remove the tubing from the valve 43's output nozzle (see diagram below).

VALVE 43 |

OUTPUT NOZZLE |

HYDRAULICS, TOP VIEW

c)Call up debug screen 20. When V43= 1 the actuator board is sending a signal to open valve 43. This occurs every two minutes for several seconds. When V43= 1 is there flow from valve 43's nozzle?

Yes |

Flow errors sometimes occur if a FILLING PROGRAM is prolonged. |

No |

A problem is indicated with VALVE 43 or the actuator board. NOTE this and see |

|

CHECKING VALVES (page 28). |

F- 17.0.0 TROUBLESHOOTING FLOW ERRORS 'OUT OF BYPASS'

A problem is indicated in the 'out of bypass' circuit which includes the external dialysate filter (73), valves 24 and 25. CAUTION! There will be spillage during this procedure. Make sure the card cage is closed!.

a)Place the machine into RINSE.

b)Open the shunt door and remove the RED dialysate line. Is there flow from the shunt door?

Yes |

a) Stop RINSE by pulling the red concentrate connector from its port |

|

|

b) Check the external dialysate line filter #73 (see diagram A, page 5). If the filter is clean a |

|

|

problem is indicated with VALVE 25 or the actuator board. NOTE this and see |

|

|

TROUBLESHOOTING VALVES (page 29). |

|

No |

A problem is indicated with VALVE 24, the actuator board or actuator cable. NOTE this and |

|

|

see CHECKING VALVES (page 28). |

|

|

Fresenius 2008H Troubleshooting Guide |

Page 15 |

|

P/N 507082 Rev. B |

|

F- 18.0.0 TROUBLESHOOTING PUMPS

Proceed ONLY with the pump of interest.

a)Make sure that flow is on and the proper flow rate is selected as directed in the table below.

b)Unplug the noted pump from the distribution board. Check, inside the distribution board, for bent, broken, or corroded male pins.

c)Measure dc voltage, inside the distribution board, between male pins 1 and 5 (top and bottom).

|

DISTRIBUTION |

FLOW |

VOLTAGE |

|

|

PUMP |

BOARD |

RATE |

BAD |

||

RANGE |

|||||

|

POSITION |

(ml/min) |

|

||

|

|

|

|||

|

|

|

|

|

|

|

|

|

16 vdc or greater |

Replace the pump head |

|

DEAERATION |

P20, DEGAS-P |

500 |

|

|

|

|

Two Possibilities: |

||||

|

|

|

|

||

|

|

|

Less than 16 vdc |

1. 1Actuator cable |

|

|

|

|

|

2. Actuator board |

|

|

|

|

12 vdc or greater |

Replace the pump head |

|

FLOW |

P21, FLOW-P |

800 |

|

|

|

|

Two Possibilities: |

||||

|

|

|

|

||

|

|

|

Less than 12 vdc |

1. 2Actuator cable |

|

|

|

|

|

2. Actuator board |

1The actuator cable can be checked for continuity. Note that you are checking DEAERATION PUMP connections and see CHECKING THE ACTUATOR BOARD CABLE (page 72).

2The actuator cable can be checked for continuity. Note that you are checking FLOW PUMP connections and see CHECKING THE ACTUATOR BOARD CABLE (page 72).

F- 19.0.0 TROUBLESHOOTING BALANCING CHAMBER VALVES

A balancing chamber valve may be remaining open or closed at all times.

a)Check that all balancing chamber valves are plugged into the distribution board at their proper positions (V31 through V38). If ok proceed.

b)Turn the power off and swap in a good actuator board.

c)Put the machine back into dialyze mode. Call up debug screen 5 and watch FLWERR for several minutes. If the flow error is still intermittent see F- 19.0.1.

Page 16 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

VALVE 34 |

|

|

(BEHIND VALVE 32) |

VALVE 33 |

|

|

(BEHIND VALVE 31) |

|

VALVE 32 |

VALVE 31 |

|

|

||

VALVE 37 |

VALVE 36 |

|

(BEHIND VALVE 35) |

||

|

||

VALVE 35 |

|

|

|

VALVE 38 |

|

|

(BEHIND VALVE 36) |

HYDRAULICS, REAR VIEW

F- 19.0.1 CHECKING VALVES 36 AND 38

NOTE: The previous actuator board is good.

a)Turn the machine off and then back on. Wait until the SELECT PROGRAM screen is up.

b)IMPORTANT! Do NOT place the machine into dialyze mode. From SELECT PROGRAM is there flow to the drain?

Yes |

Using a metal clamp tightly clamp the solid tubing at balancing chamber valve 36 (see |

|

diagram, above). If flow stops replace valve 36. If not replace valve 38. |

No |

See F- 19.0.2 |

F- 19.0.2 CHECKING VALVE 32

Unplug valves 32 and 36 from the distribution board (V32 and V36). Plug 36 into 32's position and visa versa. If there is flow to the drain replace valve 32. If not carefully plug both valves back into their proper distribution positions and see F-19.0.3

F- 19.0.3 CHECKING VALVE 34

Unplug valves 34 and 38 from the distribution board (V34 and V38). Plug 34 into 38's position and visa versa. If there is flow to the drain replace valve 34. If not carefully plug both valves back into their proper distribution board positions and see F-19.0.4.

Fresenius 2008H Troubleshooting Guide |

Page 17 |

P/N 507082 Rev. B |

|

F- 19.0.4 CHECKING FOR CLOSED BALANCING CHAMBER VALVES

Place the machine into dialyze mode and TIGHTLY clamp the clear tubing at valve 31 (see diagram, above). From debug screen 5, does FLWERR now go constant "1"?

Yes |

Referencing the flow diagram, the problem is a valve in the right-side balancing chamber. |

|

See F- 19.0.5 |

No |

FLWERR remains intermittent. Referencing the flow diagram, the problem is a valve in the |

|

left-side balancing chamber. See F- 19.0.6 |

F- 19.0.5 'RIGHT-SIDE' VALVE BAD

a)Turn the power off and unplug valves 37 and 34 from the distribution board (positions V37 and V34).

b)Plug valve 37 into 34's position (V34), leaving valve 34 unplugged.

c)IMPORTANT! Do NOT place the machine into dialyze mode. From SELECT PROGRAM check drain flow. Is there strong flow to the drain?

Yes |

Note that either valve 38 or 34 is not opening and see F- 19.0.7 |

No |

Note that either valve 37 or 33 is not opening and see F- 19.0.7 |

F- 19.0.6 'LEFT-SIDE' VALVE BAD

a)Turn the power off and unplug valves 35 and 32 from the distribution board (positions V35 and V32).

b)Plug valve 35 valve 32's position (V32), leaving valve 32 unplugged.

c)IMPORTANT! Do NOT place the machine into dialyze mode. From SELECT PROGRAM check drain flow. Is there strong flow to the drain?

Yes |

Note that either valve 32 or 36 is not opening and see F- 19.0.7 |

No |

Note that either valve 35 or 31 is not opening and see F- 19.0.7 |

F- 19.0.7 CHECK FOR A 'MECHANICALLY STICKING' VALVE

a)Check the noted valve's distribution board connector position for bent, broken or corroded male pins.

b)Carefully plug all valves back into their proper distribution board position.

c)Place the machine into dialyze mode and call up debug screen 7. FILACT MUST = "0" to continue.

d)If the valve bodies are clear check the valve plungers for movement and replace the one that is not moving. If the valve bodies are solid, swap one of the valves and check for flow errors.

F- 20.0.0 ACFS BETWEEN 0 AND 3

The CFS transducer is acting like a 'short'. Turn flow off. Does ACFS go to between 3 and 7?

Yes |

IMPORTANT turn flow on and return to F- 7.0.0 (the CFS transducer is good). |

No |

See F- 20.0.1 |

Page 18 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

F- 20.0.1 CHECK CFS CIRCUIT

Unplug the CFS transducer from the distribution board (position CFS). Check, for bent, broken or corroded male pins. Is ACFS between 8 and 11?

Yes |

See F- 20.0.2 |

No |

ACFS remains between 0 and 3. See F- 20.0.7 |

F- 20.0.2 CHECK SENSOR BOARD CFS VALUE

Leave the transducer unplugged and call up debug screen 10. Is CFS between 8 and 11?

Yes |

See F- 20.0.3 |

No |

Replace the sensor board. |

F- 20.0.3 CHECK FOR A LEAKING BALANCING CHAMBER VALVE

a)Plug the CFS transducer back into the distribution board and assure that ACFS returns to between 0 and 3.

b)Turn the flow on and push SET to return to the DIALYSIS screen. Is TMP pegged at +60?

Yes |

See F- 20.0.4 |

No |

Replace the CFS transducer (see diagram, next page). |

F- 20.0.4 CHECK FOR A LEAKING BALANCING CHAMBER VALVE

a)Push and release the RESET button on the front panel. The message "ADJUST TMP?" appears.

b)Immediately push and HOLD the RESET button. After the "ADJUSTING TMP" message is gone does TMP return to +60 or remain relatively stable?

+60 See F- 20.0.5

Stable Replace the CFS transducer (see diagram, next page).

F- 20.0.5 CHECK FOR A LEAKING BALANCING CHAMBER VALVE

a)Place the machine into SERVICE/DIAGNOSTICS.

b)Select and enter #11 VALVE LEAK TEST. Wait until the "READY" message appears.

c)Push SET TWICE to start the test. Is a leaking valve indicated?

Yes |

Note the leaking valve and see F- 20.0.6 |

No |

Replace the CFS transducer (see diagram, next page). |

Fresenius 2008H Troubleshooting Guide |

Page 19 |

P/N 507082 Rev. B |

|

F- 20.0.6 CHECK FOR SHORTED VALVE DRIVER

a)Unplug the NOTED valve from the distribution board.

b)Measure dc voltage, inside the distribution board, between male pins 1 and 5 (top and bottom). One volt or greater?

Yes |

Replace the actuator board. |

No |

Replace the indicated leaking valve. |

F- 20.0.7 TROUBLESHOOTING THE CFS CIRCUIT

Leave the transducer unplugged for now and call up debug screen 10. Is CFS also between 0 and 3?

Yes |

See F- 22.0.0 |

No |

Between 8 and 11. Replace the actuator board. |

F- 21.0.0 ACFS BETWEEN 3 AND 7

The CFS transducer is not switching the balancing chamber valves properly.

Clamp the solid tubing between the output of the CFS transducer and regulator #78 (see diagram below). Does ACFS go to below 2 now?

Yes |

Replace regulator #78 (see diagram below). |

No |

See F- 21.0.1 |

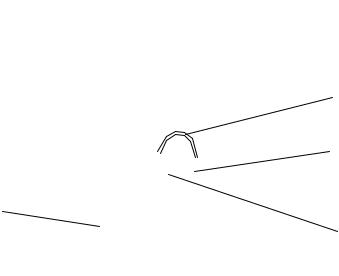

CLAMP TUBING HERE

CFS TRANSDUCER

FLOW PUMP OUTPUT

NOZZLE

REGULATOR #78

REAR VIEW

Page 20 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

F- 21.0.1 CHECK FLOW PUMP PRESSURE

1)Remove the clamp.

2)Turn the flow off and tee a psi gauge between the flow pump's output nozzle and the SOLID tubing (see diagram on previous page).

3)Turn the flow on at a 500 flow rate. Does pressure peak to 14 psi or greater?

Yes |

See F- 21.0.2 |

No |

Three possibilities: 1) Bad actuator board; 2) Bad flow pump head; 3) Bad flow pump motor. |

F- 21.0.2 CHECK CFS CIRCUIT

Unplug the CFS transducer from the distribution board (position CFS) and check for bent, broken or corroded male pins. Is ACFS between 8 and 11?

Yes |

See F- 21.0.3 |

No |

ACFS remains between 3 and 7. See F- 21.0.4 |

F- 21.0.3 CHECK SENSOR BOARD CFS VALUE

Leave the CFS transducer unplugged and call up debug screen 10. Is CFS between 8 and 11? Yes a) Plug the CFS transducer back into distribution board (position x10, CFS).

|

b) If CFS remains between 3 and 7 and the flow error is still present there are four |

|

possibilities: 1) Bad actuator board; 2) Bad flow pump head; 3) Bad flow pump motor |

|

motor; Bad CFS transducer (see diagram, previous page). |

No |

Replace the actuator board. |

F- 21.0.4 TROUBLESHOOTING THE CFS CIRCUIT

Leave the transducer unplugged for now and call up debug screen 10. Is CFS also between 3 and 7?

Yes |

See F- 22.0.0 |

No |

Between 8 and 11. Replace the actuator board. |

F- 22.0.0 CHECK SENSOR BOARD CABLE

a)Turn the power off and unplug the 34-pin ribbon cable from the top of the sensor board [card cage, smallest board, right hand side].

b)Turn the power on.

c)Push the SET button ONCE to enter the VERIFY CONCENTRATE screen

d)Call up debug screen 11. Is CFS between 8 and 11 now?

Yes |

Unplug both sides of the 34-pin ribbon cable from the sensor and distribution board's |

|

|

SENSORS connector. Look for bent male pins inside each connector. If ok replace the 34-pin |

|

|

ribbon cable. |

|

No |

Three possibilities: 1) Bad sensor board; 2) Bad actuator board; |

3) Bad functional board; |

|

Fresenius 2008H Troubleshooting Guide |

Page 21 |

|

P/N 507082 Rev. B |

|

F- 23.0.0 ACFS BETWEEN 8 AND 11

An CFS transducer is acting 'open'. There are several possibilities that may cause this symptom. Call up debug screen 10. Is CFS also reading between 8 and 11?

Yes |

See F- 23.0.1 |

No |

Replace the actuator board. |

F- 23.0.1 CHECK CFS TRANSDUCER FOR AN 'OPEN'

a)Unplug the CFS transducer from distribution board position CFS. Check, inside the distribution board, for bent, broken or corroded male pins.

b)Plug the 34 degree Fresenius temperature 'dummy connector' into the CFS's distribution board position (CFS). Does CFS go to between 0 and 2?

Yes |

1Replace the CFS transducer (see diagram, page 20). |

No |

Two possibilities: 1) 2Bad sensor board cable; 2) Bad sensor board. |

1Before replacing the transducer, check if there is a pig tail extension in the cable between the transducer and the distribution board. If present make sure it is plugged in properly using the 'key' on the pig tail connector. The pig tail is not present in all cases.

2The sensor cable can be checked for continuity. Note that you are checking CFS TRANSDUCER connections and see CHECKING THE SENSOR BOARD CABLE (page 74) .

Page 22 |

Fresenius 2008H Troubleshooting Guide |

|

P/N 507082 Rev. B |

Loading...

Loading...