Page 1

Limitorque Actuation Systems

FCD LMENIM2312-00

Limitorque

®

Accutronix MX

Quick Mounting Instructions

Page 2

Page 3

3Accutronix MX Quick Mounting Instructions • LMENIM2312

Flow Control

Limitorque Actuation Systems

The Limitorque Accutronix MX is the technological leader

among electric actuators and the simplest device to install

and commission. Follow this simple step-by-step installation

guide to install the MX on all valve types. Refer to the

following documents for more set-up information:

• LMAIM2310, Quick Start-Up Instructions

calibration of valve position limits

• LMAIM2306, Installation and Operation Manual

complete installation instructions

Contents

Preparing the Stem Nut 4

Type “B” Bases: Torque-only Applications 4

Standard B4/B4E Base 4

Optional B1 Base (not applicable for MX-85 or -140) 5

Type “A” Bases: Thrust-only Applications 6

Standard A1/A1E Base 6

Type “BL” Drive: Splined-drive Applications (not applicable for MX-85 or -140) 11

Mechanical Installation of MX Actuator onto Valve or Gearbox 11

Mounting (Type “B” Bases): Torque-only 12

Removal (Type “B” Bases): Torque-only 12

Mounting (Type “A” Bases): Thrust-only 12

Removal (Type “A” Bases): Thrust-only 13

Checking the Settings 13

Page 4

4 LMENIM2312 • Accutronix MX Quick Mounting Instructions

Flow Control

Limitorque Actuation Systems

Preparing the Stem Nut

The Accutronix MX has two (2) basic base designs:

• Torque-only base, designated by a “B” prefix

• Thrust-only base, designated by an “A” prefix

Type “B” Bases: Torque-only Applications

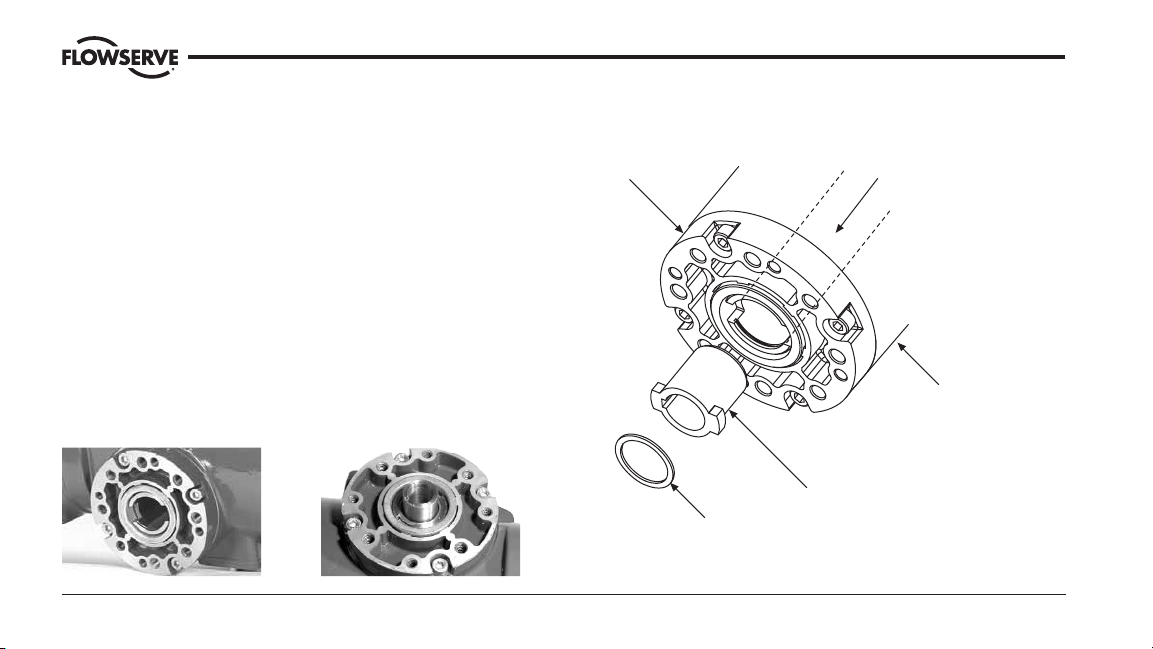

Standard B4/B4E Base

The standard MX actuator base is the B4 torque-only and includes a

mounting plate and steel torque nut, which may be machined to fit a

valve or gearbox.

A B4E torque nut can be provided and may be installed to allow for

extended stem acceptance.

B4 base B4E base

Exploded view of B4/B4E base

Baseplate

Drive sleeve

Torque nut

Retaining ring

Accutronix MX

base

Page 5

5Accutronix MX Quick Mounting Instructions • LMENIM2312

Flow Control

Limitorque Actuation Systems

Disassembly

1. Remove the retaining ring (B4 base) or spiral-wound ring (B4E base)

that retains the torque nut in the drive sleeve.

2. Remove the torque nut. If the torque nut is difficult to remove, insert a

suitable device into the drive sleeve through bore and gently tap it

loose from the handwheel end.

3. Machine the torque nut to suit the valve stem or gearbox input shaft

(see LMASS2326, MX Performance and Dimensions for maximum

stem capacity). Ensure sufficient clearance for a smooth, sliding fit.

Reassembly

1. Clean the torque nut thoroughly and lightly grease.

2. Replace the torque nut in the drive sleeve. Ensure the torque nut

meshes with the drive lugs.

3. Refit the retaining ring (B4 base) or spiral-wound ring (B4E base).

Optional B1 Base (not applicable for MX-85 or -140)

An optional torque base assembly may be added to allow for a greater

stem acceptance. This base is supplied with a fixed bore and key as

defined by ISO 5210.

Disassembly

No disassembly is required since the torque nut has been machined to

an international standard. Clean the bore and lightly grease.

B1 base

Page 6

6 LMENIM2312 • Accutronix MX Quick Mounting Instructions

Flow Control

Limitorque Actuation Systems

Exploded view of B1 base

Type “A” Bases: Thrust-only Applications

Standard A1/A1E Base

The standard MX actuator thrust base is the A1 and may be bolted

directly to the actuator. The thrust base contains a bronze alloy thrust

nut that may be machined to suit the valve stem.

An A1E thrust nut can be provided and may be installed to reach

shorter stems.

A1 base

Socket head cap

screw (M8 x 20)

Torque nut,

(B1)

Pipe plug

Housing,

torque/

thrust

Bearing

Retainer, bearing

Pilot, torque/thrust

Socket head

cap screw (M4 x 8)

Socket head set screw

MX-05 B1 MX-40 B1

Pipe plug

Washer (M4)

Page 7

7Accutronix MX Quick Mounting Instructions • LMENIM2312

Flow Control

Limitorque Actuation Systems

Exploded view of A1/A1E base (MX-05/10/20/40 only)

Disassembly – Units MX-05/10/20/40

Refer to the figure at left.

Disassembly of the main housing from the base may be

recommended to allow the base to remain on the valve if the actuator

must be removed for service.

Pilot removal

MX-05/10: Remove the screw and washer holding the valve pilot to the

thrust base and remove pilot.

MX-20/40: Turn counterclockwise (CCW) and remove.

Thrust bearing and nut removal

1. Remove the first set of thrust washers and bearing.

2. Remove stem nut.

NOTE: The thrust washers, bearing, and stem nut may be removed at the

same time. The second set of thrust washers and bearing do not have to

be removed.

3. Machine the stem nut to suit the valve stem. Ensure sufficient

clearance to avoid unnecessary wear and heating during operation.

Housing

Socket head cap

screw

Socket head cap screw

Washer

Quad ring

Thrust washers

Pipe plug

Thrust base

standard nut

Thrust nut

Thrust washers

O-ring

Thrust

pilot

Quad ring

Needle bearings

Page 8

8 LMENIM2312 • Accutronix MX Quick Mounting Instructions

Flow Control

Limitorque Actuation Systems

Reassembly – Units MX-05/10/20/40

Refer to the figure on page 7.

1. Clean the stem nut, washers, and bearings thoroughly.

2. Slide the second set of thrust washers and bearing in place if removed.

NOTE: Order of assembly for thrust washers and bearing must be as

follows: washer, thrust bearing, washer.

Pilot installation

MX-05/10: Slide pilot into thrust base assembly and secure with washer

and screw. Tighten fully.

MX-20/40: Place pilot into thrust base and turn clockwise (CW) until

pilot is tight.

Disassembly – Unit MX-85

Refer to the figure on page 9.

Disassembly of the main housing from the base may be

recommended to allow the base to remain on the valve if the actuator

must be removed for service.

Thrust base mounting plate removal

Remove the six socket head cap screws holding the valve mounting

plate to the thrust base housing and remove mounting plate.

Thrust bearing and nut removal

1. Remove the first set of thrust washers and bearing.

2. Remove stem nut.

NOTE: The thrust washers, bearing, and stem nut may be removed at the

same time. The second set of thrust washers and bearing do not have to

be removed.

3. Machine the stem nut to suit the valve stem. Ensure sufficient

clearance to avoid unnecessary wear and heating during operation.

Page 9

9Accutronix MX Quick Mounting Instructions • LMENIM2312

Flow Control

Limitorque Actuation Systems

Exploded view of thrust base (MX-85 only)

Reassembly – Unit MX-85

Refer to the figure at left.

1. Clean the stem nut, washers, and bearing(s) thoroughly.

2. Slide the second set of thrust washers and bearing in place if removed.

3. Install stem nut.

4. Install first set of thrust washers and bearing.

NOTE: Order of assembly for thrust washers and bearing must be as

follows: washer, thrust bearing, washer.

Thrust baseplate installation

Mount baseplate to thrust base housing and install the six socket head cap

screws to the proper torque per the table below.

Mechanical Installation of MX

Screw Size Torque (ft-lb)

M8 or 5/16inch 12-14

M10 or 3/8inch 25-30

M12 or 1/2inch 40-50

M16 or 5/8inch 90-100

M20 or 3/4inch 180-200

10-3

10-12

10-15

10-2

10-17

10-14

10-13

Section A-A

View shown

with standard nut

with extended nut

Section A-A

View shown

10-12

10-14

10-10

10-13

A

10-11

10-1

A

Page 10

10 LMENIM2312 • Accutronix MX Quick Mounting Instructions

Flow Control

Limitorque Actuation Systems

Exploded view of thrust base (MX-140 only)

NOTE: Screw mounting torque for both mounting thrust base to main

housing and thrust baseplate to thrust base housing.

Disassembly – Unit MX-140

Refer to the figure at left.

Disassembly of the main housing from the base may be

recommended to allow the base to remain on the valve if the actuator

must be removed for service.

Pilot removal

Remove the two screws and washers holding the valve pilot to the thrust

base and remove pilot.

Thrust bearing and nut removal

1. Remove the first set of thrust washers and bearing.

2. Remove stem nut.

NOTE: The thrust washers, bearing, and stem nut may be removed at the

same time. The second set of thrust washers and bearing do not have to

be removed.

10-10

10-1

10-13

10-12

10-14

10-3

10-14

10-13

10-12

10-15

10-6

10-7

10-2

10-11

10-8

Section A-A

View shown with

standard nut

Section B-B

View shown with

extended nut

A

B

B

A

Page 11

11Accutronix MX Quick Mounting Instructions • LMENIM2312

Flow Control

Limitorque Actuation Systems

3. Machine the stem nut to suit the valve stem. Ensure sufficient

clearance to avoid unnecessary wear and heating during operation.

Reassembly – Unit MX-140

Refer to the figure on page 10.

1. Clean the stem nut, washers, and bearing(s) thoroughly.

2. Slide second set of thrust washers and bearing in place if removed.

3. Install stem nut.

4. Install first set of thrust washers and bearing.

NOTE: Order of assembly for thrust washers and bearing must be as

follows: washer, thrust bearing, washer.

Pilot installation

Slide pilot into thrust base assembly and secure with the two washers

and screws. Tighten fully.

Type “BL” Drive: Splined-drive Applications

(Not applicable for MX-85 or -140)

Steel alloy splined nuts are provided to a standard involute spline

category for rising and rotating stem valves per customer requirements.

Disassembly and reassembly is the same as the B4 base and the torque

nut. See Type “B” Bases: Torque-only Applications section.

Mechanical Installation of MX

Actuator onto Valve or Gearbox

NOTE: Refer to LMAIM2314, MX Maintenance and Spare Parts for

more detailed instructions.

Before installing the actuator onto a valve or gearbox, check the

following to ease installation:

• Verify mounting flange is suited dimensionally to mate with the

actuator base. Ensure that it is perpendicular to the valve stem or

gearbox input shaft.

• Ensure the stem nut mates with the valve stem or input shaft. For

screwed nuts, it is advisable to run the stem nut down the entire length

of the stem to check for tightness. Keyed or splined shafts should

exhibit a smooth, sliding fit with the key installed.

Page 12

12 LMENIM2312 • Accutronix MX Quick Mounting Instructions

Flow Control

Limitorque Actuation Systems

• Ensure there is adequate engagement of the stem nut with the valve

stem or input shaft when mounted. Generally, the minimum length of

engagement is 1.5 times the diameter of the stem.

• Verify mounting studs or bolts are the correct length to suit the

thickness of the mounting plate.

• Verify hardware specifications for English style: socket head cap screw

per ASTM A 574 and ANSI 18.3. Hex head cap screw per SAE J429

Grade 5.

• Verify hardware specifications for metric style: hex and socket head

cap screws per Property Class 12.9.

• Clean and lubricate the valve stem or input shaft.

• Ensure adequate lifting facilities and slings are available at the

installation site.

NOTE: Do not use the handwheel to lift the actuator.

Mounting (Type “B” Bases): Torque-only

Refer to the figures on pages 4-6.

1. Ensure the torque nut is secured inside the actuator drive sleeve with

the retaining ring.

2. Lower the actuator onto the valve or gearbox stem. Align the stem nut

key and keyway with the valve or gearbox stem key seat.

3. Verify that the actuator and valve mounting adapter flanges mate

correctly.

4. Secure the actuator to the valve mounting adapter with mounting bolts.

Removal (Type “B” Bases): Torque-only

Refer to the figures on pages 4-6.

1. Remove the bolts that secure the actuator to the valve mounting

adapter. If type B1 base is used in addition to the standard type B4

baseplate, you may leave the B1 base attached to the actuator and

remove as a unit.

2. Lift the actuator from the actuator mounting adapter.

Mounting (Type “A” Bases): Thrust-only

Refer to the figures on pages 6-8.

1. The following are two options for mounting the type “A” base

actuator:

a. If the type “A” thrust base was removed from the valve mounting

adapter, replace the thrust base onto the valve mounting adapter.

Page 13

13Accutronix MX Quick Mounting Instructions • LMENIM2312

Flow Control

Limitorque Actuation Systems

Ensure the thrust base stem nut has the lugs positioned upward to

engage with the drive sleeve slots when the actuator is reinstalled.

Rotate the bronze nut while holding the base steady.

or

b. If the thrust base is installed on the valve mounting adapter,

proceed to step two.

2. Lower the actuator along the threaded valve stem and onto the valve

mounting plate. Ensure the thrust base stem nut lugs properly engage

and align with the drive sleeve slots.

3. Install the bolts to secure the actuator to the thrust base assembly.

Removal (Type “A” Bases): Thrust-only

1. Remove the bolts that secure the actuator to the thrust base

assembly.

2. Remove the type “A” thrust base by removing the bolts that secure

the actuator to the valve mounting adapter.

or

Leave the type “A” thrust base mounted to the valve mounting adapter

until ready to remount the actuator. The thrust base will maintain valve

position provided that the valve stem threads are locking.

3. Lift the complete actuator from the thrust base.

Checking the Settings

When the assembly of the actuator to the valve is complete, the actuator

position limits may be set. Please refer to LMAIM2310, Quick Start-Up

Instructions, for calibration of valve/actuator position limits.

Page 14

Page 15

Page 16

©2006 Flowserve Corporation, Irving, Texas, USA. Flowserve and Limitorque are registered trademarks of Flowserve Corporation. FCD LMENIM2312-00

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly

selected, this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser

or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide

specific data and warnings for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for

the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read

and understand the Installation and Maintenance (I & M) instructions included with the product, and train its employees and

contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative

purposes only and should not be considered certified or as a guarantee of satisfactory results by reliance thereon. Nothing

contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and

information contained herein are subject to change without notice. Should any question arise concerning these provisions, the

purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

FLOWSERVE CORPORATION

FLOW CONTROL DIVISION

Limitorque Actuation Systems

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA 24506-1318

Phone: 434 528 4400

Facsimile: 434 845 9736

www.flowserve.com

For more information about Flowserve Corporation, visit www.flowserve.com or call USA 1 800 225 6989.

USA

Flowserve Limitorque

5114 Woodall Road

Lynchburg, VA 24506

Phone: 434-528-4400

Fax: 434-845-9736

China

Limitorque Asia - Beijing

Room B803

Han Wei Plaza

No. 7 Guang Hua Road,

Chao Yang District

Beijing 100004, P.R. China

Phone: 8610 6561 2701

FAX: 8610 6561 2702

Singapore

Limitorque Asia PTD

12, Tuas Avenue 20

Singapore 638824

Phone: 065 6862 3332

Fax: 065 6862 4940

Canada

Flowserve Flow Control

120 Vinyl Court

Woodbridge, Ontario

L4L 4A3

Canada

Phone: 905 856 8568

Fax: 905 856 7905

EMA

Limitorque EMA

Abex Road

Newbury, Berkshire

RG14 5EY

United Kingdom

Phone: 44 1635 46999

Fax: 44 1635 36034

Japan

Nippon Gear Co., Ltd

Asahi Seimei Building

9th Floor

1-11-11 Kita-Saiwai

Nishi-Ku

Yokohama-Shi,

Japan 220-0004

Phone: 81 45 326 2065

Fax: 81 45 320 5962

Flow Control

Limitorque Actuation Systems

Printed in USA.

Loading...

Loading...