Page 1

Fanuc Focas Ethernet Driver

© 2021 PTCInc. All Rights Reserved.

Page 2

Fanuc Focas Ethernet Driver

Table of Contents

2

Fanuc Focas Ethernet Driver

Table of Contents

Fanuc FocasEthernet Driver

Overview

ExternalDependencies

Install aFocasLibrary

AdditionalSoftware Requirements

Setup

Channel Properties — General 9

Tag Counts 9

Channel Properties — Ethernet Communications 10

Channel Properties — Write Optimizations 10

Channel Properties — Advanced 11

Device Properties — General 12

Operating Mode 13

Tag Counts 13

Device Properties — Scan Mode 13

1

2

5

5

5

6

6

8

Device Properties — Timing 14

Device Properties — Auto-Demotion 15

Device Properties — Communications Parameters 16

Device Properties — Unsolicited Transfer Control 16

Device Properties — Unsolicited Data Areas 17

Device Properties — Redundancy 18

Unsolicited Messaging 19

Optimizing Communications

Data Types Description

AddressDescriptions

Series15i

Series16i

Series18i

Series21i

Power Mate i

Open

22

23

24

24

26

29

31

34

36

System Info Tags 39

Status Info Tags 39

www. ptc.com

Page 3

3

Tool Offset 43

Workpiece Zero Offset 45

Parameter Read Values 46

Alarm Values 46

Diagnostic Values 47

Path Values 47

Read Axis Data Values 48

Program Values 50

Program Name 50

Read Dynamic2 Data Values 51

Read Alarm Messages 52

Read Timer Data Values 52

Fanuc FocasEthernet Driver

Event LogMessages

AddressValidation

Address <address> is out of range for the specified device or register. 53

Array size is out of range for address <address>. 53

Array support is not available for the specified address:<address>. 53

Data Type <type> is not valid for device address <address>. 54

Device address <address> contains a syntax error. 54

Device address <address> is read only. 54

Missing address. 54

DeviceStatusMessages

Device <device name> is not responding. 55

Unable to write to <address> on device <device name>. 55

GeneralDriverMessages

Could not acquire library handle for device <channel.device>. FWLIBerror: <code>. 56

Could not read one or more vacant macros in range starting at <address> on device <device>. 56

Could not set request timeout for device <channel.device>. FWLIBerror: <code>. 57

Invalid XMLdocument. Reason: Error loading Unsolicited Data Areas for device <device-name>.

End address can not be less than start address for area <area-number>. 57

53

53

55

55

Invalid XMLdocument. Reason: Error loading Unsolicited Data Areas for device <device-name>.

Invalid area order or duplicate area number. 57

Invalid XMLdocument. Reason: Error loading Unsolicited Data Areas for device <device-name>.

Maximum size of area <area-number> is <size> bytes. 58

Read error occurred for address starting at <address> on device <channel.device>. FWLIBerror:

<code>. 58

Unable to start the Fanuc Focas Data Window Library services. 58

Write error occurred for address <address> on device <channel.device>.FWLIB error: <code>. 59

Fanuc FocasServer DeviceDriver Messages

www. ptc.com

59

Page 4

Fanuc Focas Ethernet Driver

Attempt to launch unsolicited message server failed. 60

Could not access necessary system resources for Fanuc Focas server device: <channel.device>. 61

Failed to connect Fanuc Focas server device <channel.device>.Could not acquire library handle.

FWLIBerror: <code>. 61

Failed to connect Fanuc Focas server device <channel.device>.Could not determine host IP

address. 61

Failed to connect Fanuc Focas server device <channel.device>.Could not set data area size. 62

Failed to connect Fanuc Focas server device <channel.device>.Could not set data area start

address. 62

Failed to connect Fanuc Focas server device <channel.device>.Could not set data area type. 63

Failed to connect Fanuc Focas server device <channel.device>.Could not set host IP. 63

Failed to connect Fanuc Focas server device <channel.device>.Could not set host port. 63

Failed to connect Fanuc Focas server device <channel.device>.Could not set message alive time. 64

Failed to connect Fanuc Focas server device <channel.device>.Could not set message retries. 64

Failed to connect Fanuc Focas server device <channel.device>.Could not set message timeout. 65

4

Failed to connect Fanuc Focas server device <channel.device>.Could not set messaging properties. FWLIBdata error <code>. 65

Failed to connect Fanuc Focas server device <channel.device>.Could not set messaging properties. FWLIBerror: <code>. 66

Failed to connect Fanuc Focas server device <channel.device>.Could not set number of data

areas. 66

Failed to connect Fanuc Focas server device <channel.device>.Could not set request timeout.

FWLIBerror: <code>. 67

Failed to connect Fanuc Focas server device <channel.device>.Could not set transmission control

PMCtype. 67

Failed to connect Fanuc Focas server device <channel.device>.Could not set transmission control

start address. 67

Failed to connect Fanuc Focas server device <channel.device>.Could not start messaging session.

FWLIBerror: <code>. 68

Installed version of Focas Data Window Library does not support unsolicited communication.

Device <device> deactivated. 68

Received CNC power down notification from unsolicited message server.Reconnecting Fanuc

Focas server devices. 69

Received CNC power up notification from unsolicited message server. 69

Received socket error notification from unsolicited message server. 69

Received unsolicited message server shutdown notification. 70

Unsolicited message server does not seem to be running. Attempting to launch. 70

Focas1 DataWindow Library Error Codes

API Calls

Index

www. ptc.com

71

73

74

Page 5

5

Fanuc Focas Ethernet Driver

Help version 1.073

CONTENTS

Overview

What is the Fanuc Focas Ethernet Driver?

Setup

How do I configure a device for use with this driver?

Optimizing Communications

How do I get the best performance from the Fanuc Focas Ethernet Driver?

Data Types Description

What data types does this driver support?

Address Descriptions

How do I address a data location on a Fanuc Focas device?

Fanuc FocasEthernet Driver

Error Descriptions

What error messages does the Fanuc Focas Ethernet Driver produce?

Overview

The Fanuc Focas Ethernet Driver provides a reliable way to connect Fanuc Focas Ethernet controllers to OPC

Client applications,including HMI, SCADA,Historian, MES,ERP, and countless custom applications. This

driver is intended for use with Fanuc Focas Computer Numerical Control (CNC)system.

For moreinformation on the additional software that is required for usewith this driver, refer to Additional

Software Requirements.

External Dependencies

This driver has external dependencies. For this driver to communicate with the hardware, the Fanuc CNC

Focas 1 / Ethernet Library (part number A02B-0207-K732) or Fanuc Focas 2 Library (part number A02B0207-K737) must be installed on the system. For more information, refer to Additional Software Require-

ments.

Note:The Focas 2 Library combines both Ethernet and HSSB capabilities and can be obtained from the

FANUC distributor or by calling 1-888-326-8287. Choose CNC, PARTS, place the order, and request the part

number.

www. ptc.com

Page 6

Fanuc Focas Ethernet Driver

Install a Focas Library

This driver requires a Focas library to communicate with the hardware, either FANUC CNCFocas 1 / Ethernet Library (part number A02B-0207-K732) or FANUCFocas 2 Library (part number A02B-0207-K737).

Only 32-bit DLLfiles are compatible with Fanuc Focas Ethernet Driver. Follow these steps to install a library:

1. Obtain a library from the distributor (typically Fwlib*.zip).

2. Move or paste the Fwlib* .zip file to the appropriate Windows system folder:

On a 64-bit Windows OS, the destination folder is C:\Windows\SysWOW64

On a 32-bit Windows OS, the destination folder is C:\Windows\System32

3. Once the zip file is in the appropriate destination folder, unzip / extract the contents of the Fwlib*.zip.

4. Verify the 32-bit DLLfiles are located in the folder;in particular FWLIB32.DLLand FWLIBE1.DLL,which

are used by the Fanuc Focas Ethernet Driver.

5. Restart the computer.

See Also: External Dependencies

6

Additional Software Requirements

Winsock

The host computer must have Winsock version 1.1 or later installed.This is normally done by default when

Windows is installed.

Focas 1 / HSSB or Focas 2 Library

This driver requires that either the FANUC CNCFocas 1 / Ethernet Library (part number A02B-0207-K732) or

FANUC Focas 2 Library (part number A02B-0207-K737) is installed on the system. Although the library does

not need to be installed to create a server project, the project will not run without it.This software may be

obtained from the FANUCdistributor or by calling 1-888-326-8287.

Note:The Focas 2 Library combines both Ethernet and HSSB capabilities.

Unsolicited Message Server

This driver requires that the unsolicited message server application "UMsgServ.exe" (version 1.0.0.1 or

later) is installed to use unsolicited messaging. This application is available from the distributor. For more

information, refer to the instructions below.

1. To start the installation, copy the executable file to the System folder.

2. Access the command prompt to type "UMsgServ.exe –Install." This causes the message server to

automatically launch every time the computer is started.

3. Once the message server is running, its icon is visible in the System Tray.

4. Next, configure the TCPport number on which the message server listens (in addition to the message timeout and the maximum number of CNCs). To do so, right-click the icon and then select Set-

ting.The default settings are as follows:

www. ptc.com

Page 7

7

l TCP Port Number:8196

l Message Timeout:30 seconds

l Maximum Number of CNCs: 32

Fanuc FocasEthernet Driver

5. To uninstall the message server, use the command prompt to type "UMsgServ.exe –Remove" and

then delete the executable file.

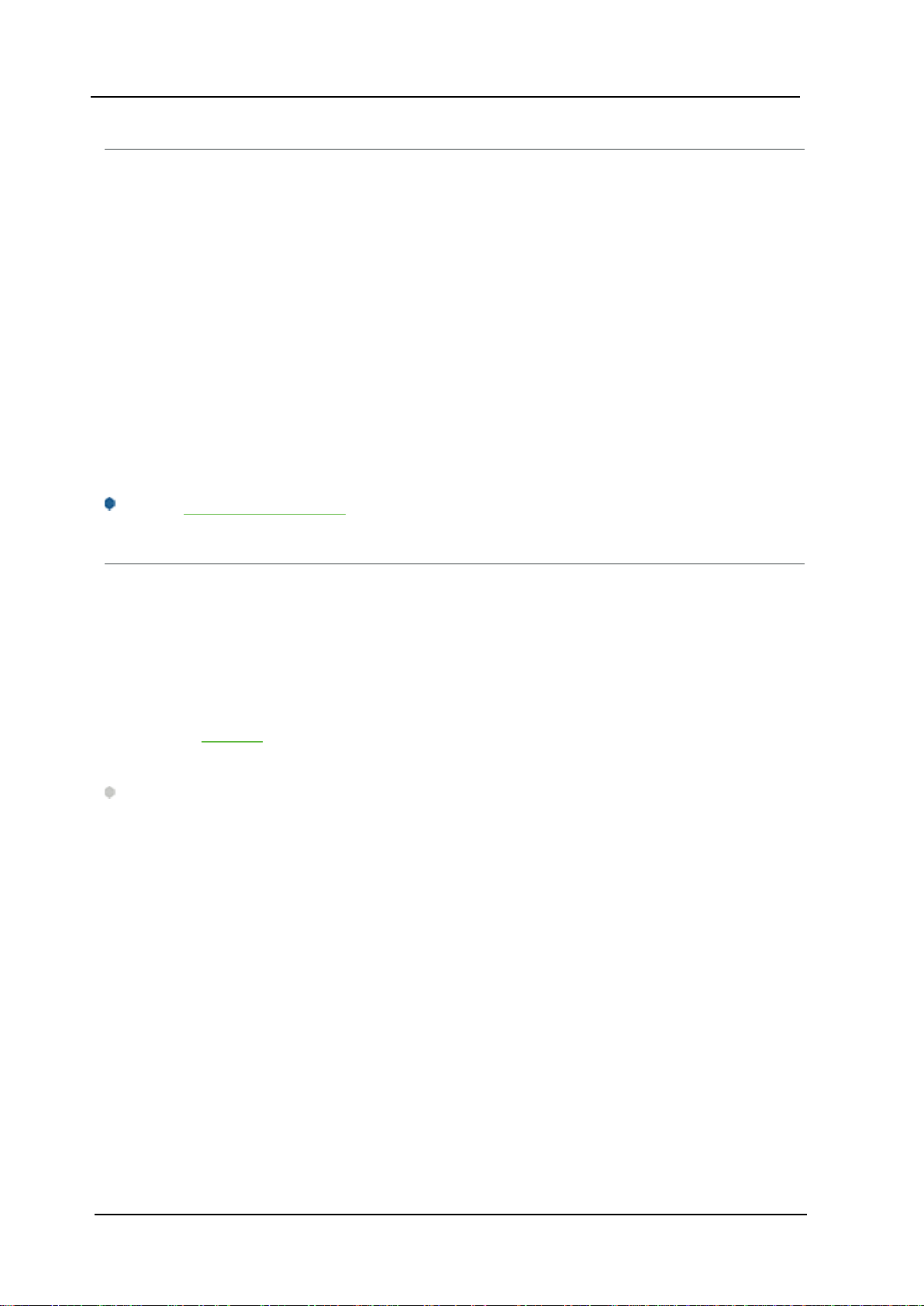

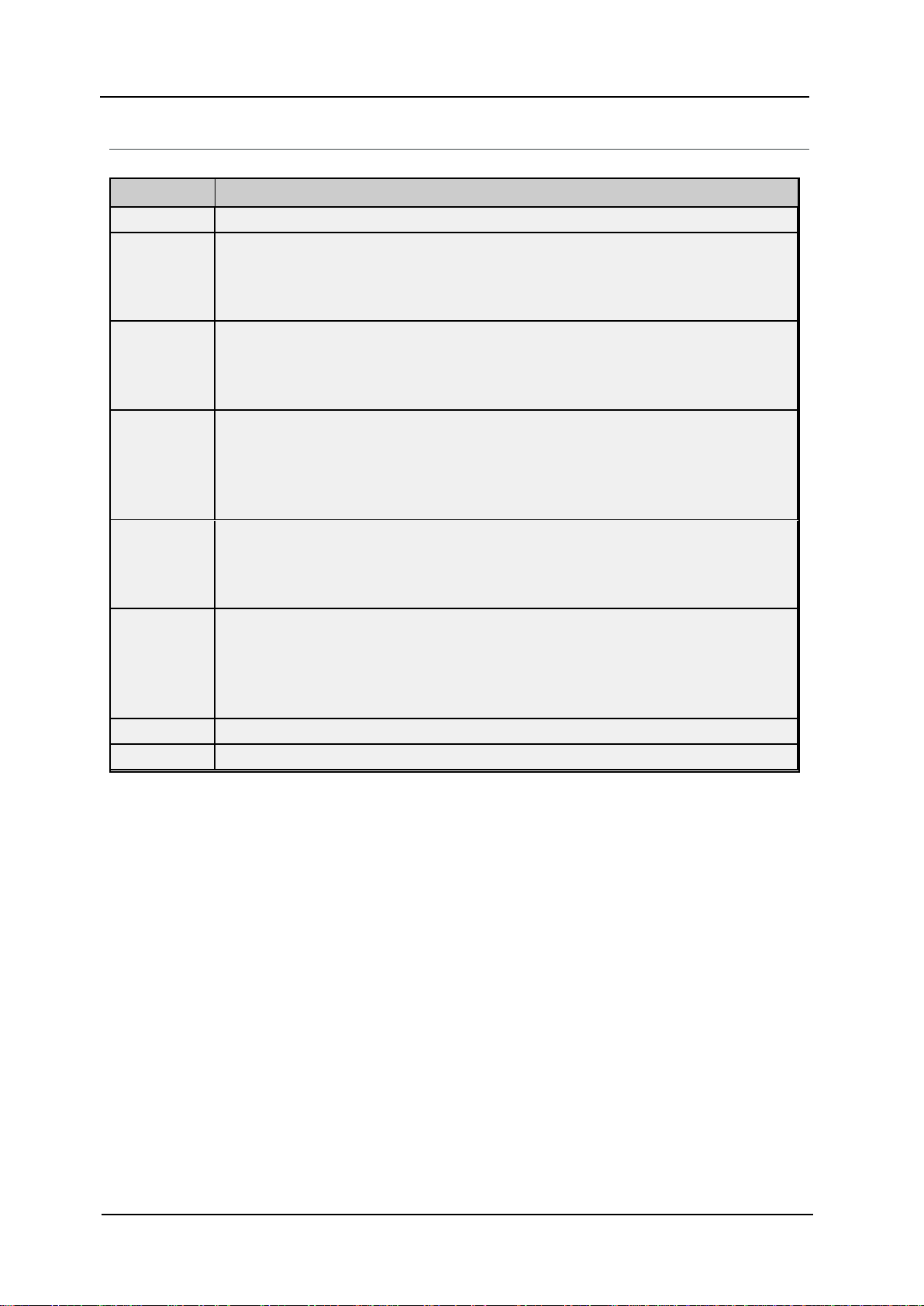

CNC Control Software

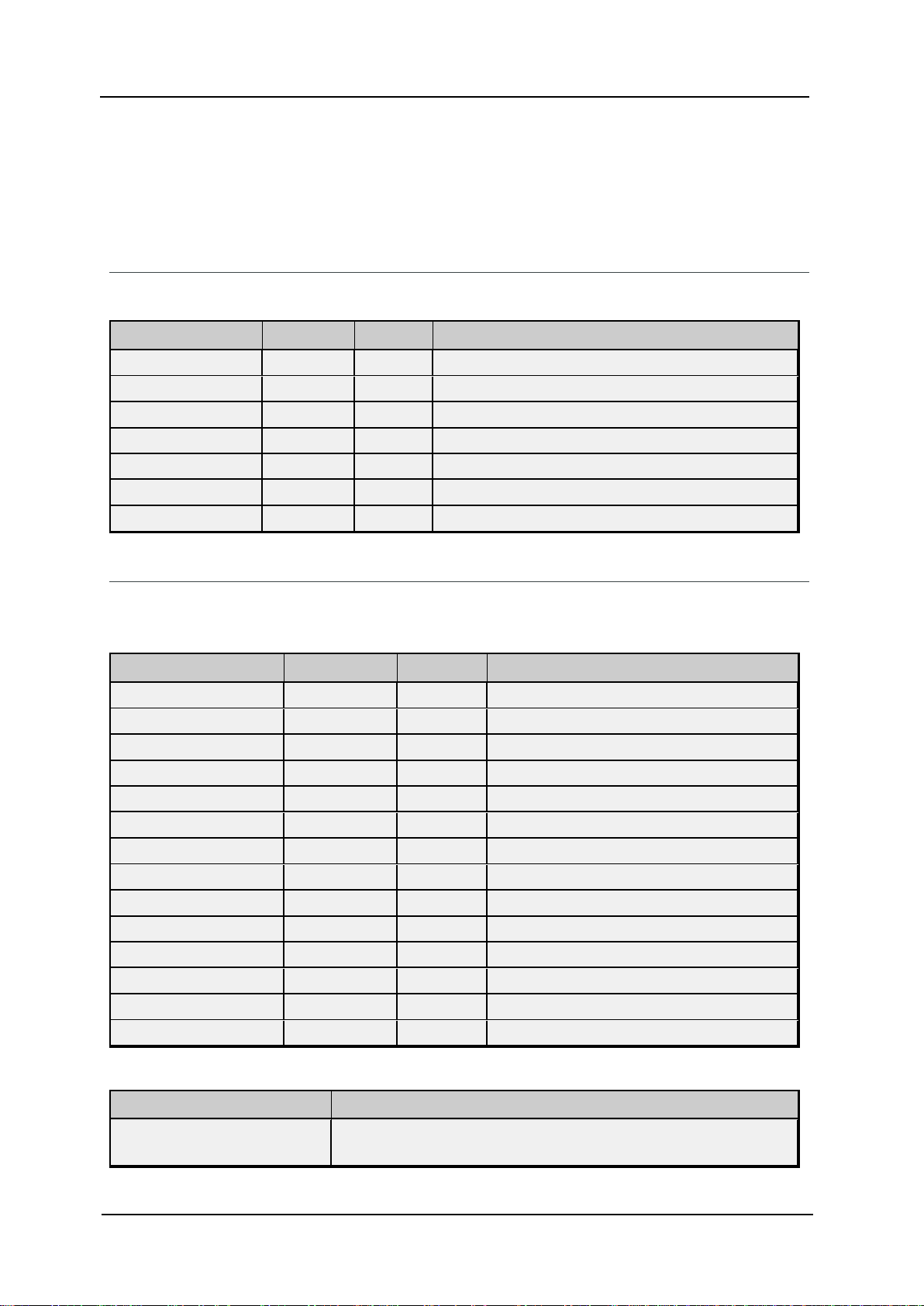

The table below displays the software that must be installed on the controller to use its unsolicited messaging capabilities.

Refer to FanucCNCdocumentation for other model compatibility.

Model Software

16i

18i

21i

B0F4/K1(M) or later

B0H1/P5(M) or later

DDF4/K1(M) or later

BDH1/P5(M) or later

BDF4/K1(M) or later

DDH1/P5(M) or later

Note:Set the CNCparameter 904, bit 4 to 1 for unsolicited messaging by using the controller’s pro-

gramming software.

Fast Ethernet Firmware

Firmware 6567/E2 or later (registered onto F-ROM of CNC) must be installed on the controller to use its unsolicited messaging capabilities.

Ladder

A ladder program must be created that constructs and controls the transmission of unsolicited messages to

use the controllers unsolicited messaging capabilities. For more information, refer to Unsolicited Mes-

saging.

www. ptc.com

Page 8

Fanuc Focas Ethernet Driver

Setup

Supported Devices

The Fanuc Focas Ethernet Driver can communicate to controllers that are compatible with the Focas 1 or

Focas 2 CNC / PMC data window control libraries. This includes, but is not limited to,the following:

Series 0i

Series 15

Series 15i

Series 16

Series 16i

Series 18

Series 18i

Series 21

Series 21i

Series 30i

Series 31i

Series 32i

Power Mate i

Open Addressing

8

Channel and Device Limits

The maximum number of channels supported by this driver is 256. The maximum number of devices supported by this driver is 20 per channel. Each device on the channel must be uniquely identified by its own IP

address.

Connect Timeout

Specify the amount of time that the driver waits for a connection to be made with a device. The connection

time depends on the network load and may vary with each connection attempt. The valid range is 1 to 60

seconds. The default setting is 3 seconds.

Request Timeout

Specify the amount of time that the driver waits on a response from the device before giving up and going

on to the next request. Longer timeouts only affect performance when a device is not responding.The valid

range is 100 to 9999 milliseconds.The default setting is 1000 milliseconds.

Retry Attempts

Specify the number of times that the driver retries a message before giving up and going on to the next message.The valid range is 1 to 10. The default setting is 3.

www. ptc.com

Page 9

9

Fanuc FocasEthernet Driver

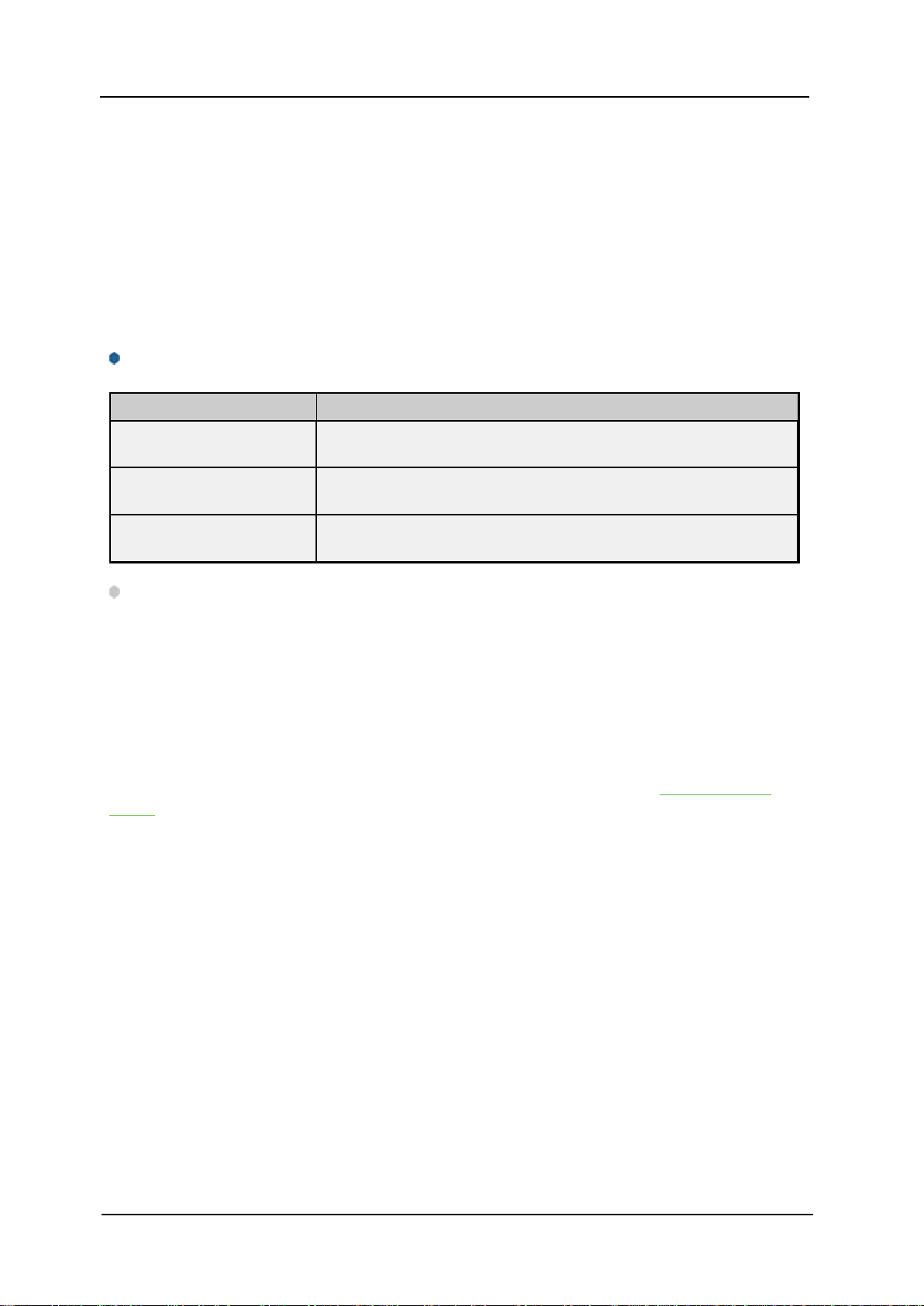

Channel Properties — General

This server supports the use of multiple simultaneous communications drivers. Each protocol or driver used

in a server project is called a channel. A server project may consist of many channels with the same communications driver or with unique communications drivers. A channel acts as the basic building block of an

OPClink. This group is used to specify general channel properties, such as the identification attributes and

operating mode.

Identification

Name: Specify the user-defined identity of this channel. In each server project,each channel name must be

unique. Although names can be up to 256 characters, some client applications have a limited display window

when browsing the OPC server's tag space. The channel name is part of the OPCbrowser information. The

property is required for creating a channel.

For information on reserved characters,refer to "How To... Properly Name a Channel, Device, Tag,and Tag

Group" in the server help.

Description: Specify user-defined information about this channel.

Many of these properties, including Description, have an associated system tag.

Driver: Specify the protocol / driver for this channel.This property specifies the device driver that was selected during channel creation. It is a disabled setting in the channel properties. The property is required for creating a channel.

Note:With the server's online full-time operation, these properties can be changed at any time. This

includes changing the channel name to prevent clients from registering data with the server. If a client has

already acquired an item from the server before the channel name is changed, the items are unaffected. If,

after the channel name has been changed, the client application releases the item and attempts to reacquire using the old channel name,the item is not accepted. Changes to the properties should not be made

once a large client application has been developed.Utilize proper user role and privilege management to

prevent operators from changing properties or accessing server features.

Diagnostics

Diagnostics Capture: When enabled, this option makes the channel's diagnostic information available to

OPCapplications. Because the server's diagnostic features require a minimal amount of overhead processing, it is recommended that they be utilized when needed and disabled when not. The default is disabled.

Note: This property is not available if the driver does not support diagnostics.

For moreinformation, refer to "Communication Diagnostics" and "StatisticsTags" in theserver help.

Tag Counts

www. ptc.com

Page 10

Fanuc Focas Ethernet Driver

Static Tags: Provides the total number of defined static tags at this level (device or channel). This information can be helpful in troubleshooting and load balancing.

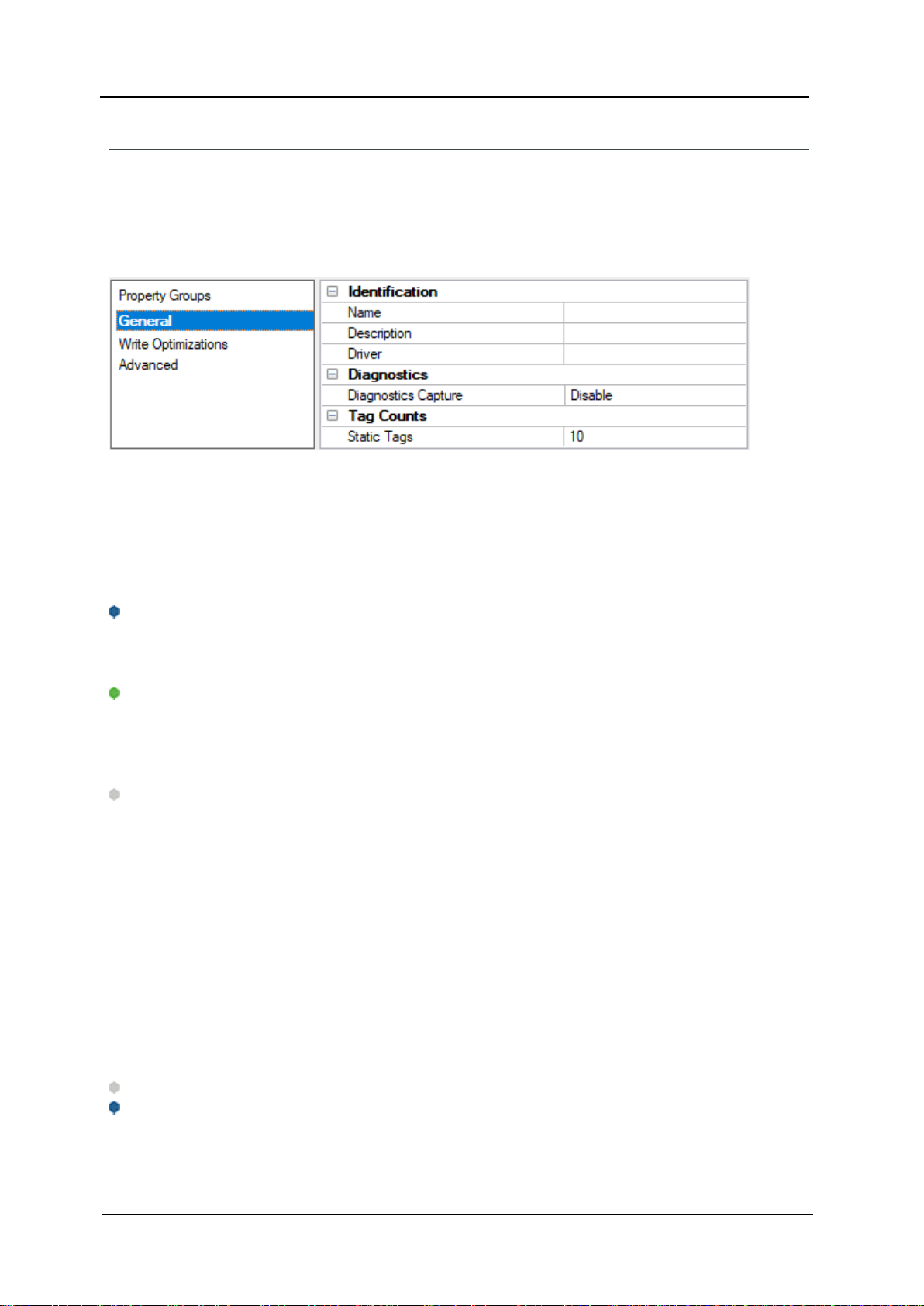

Channel Properties — Ethernet Communications

Ethernet Communication can be used to communicate with devices.

Ethernet Settings

Network Adapter: Specify the network adapter to bind.When left blank or Default is selected,the oper-

ating system selects the default adapter.

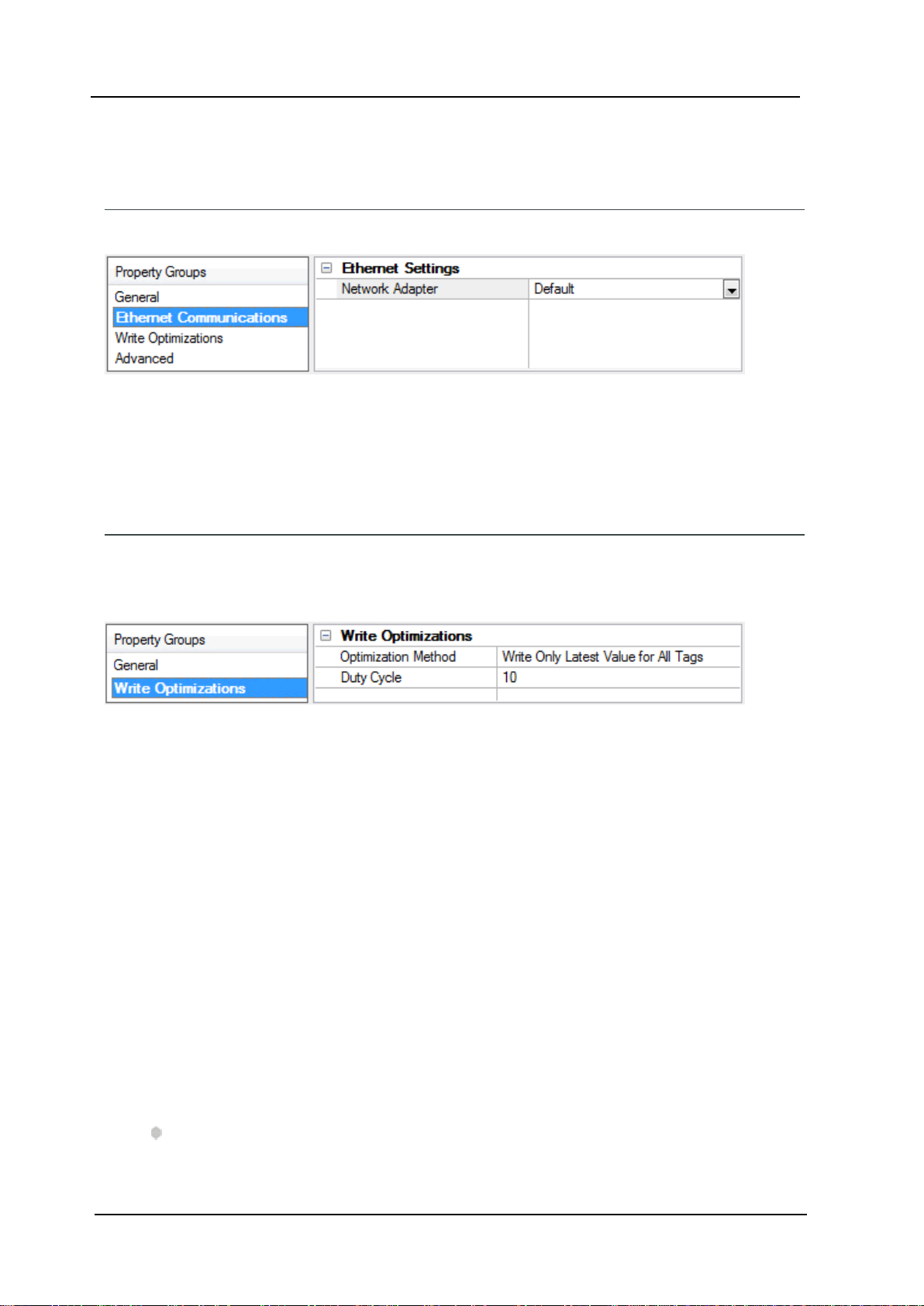

Channel Properties — Write Optimizations

10

The server must ensure that the data written from the client application gets to the device on time. Given

this goal, the server provides optimization properties to meet specific needs or improve application responsiveness.

Write Optimizations

Optimization Method: Controls how write data is passed to the underlying communications driver. The

options are:

l Write All Values for All Tags: This option forces the server to attempt to write every value to the

controller. In this mode,the server continues to gather write requests and add them to the server's

internal write queue. The server processes the write queue and attempts to empty it by writing data

to the device as quickly as possible. This mode ensures that everything written from the client applications is sent to the target device. This mode should be selected if the write operation order or the

write item's content must uniquely be seen at the target device.

l Write Only Latest Value for Non-Boolean Tags:Many consecutive writes to the same value can

accumulate in the write queue due to the time required to actually send the data to the device. If the

server updates a write value that has already been placed in the write queue, far fewer writes are

needed to reach the same final output value. In this way, no extra writes accumulate in the server's

queue. When the user stops moving the slide switch, the value in the device is at the correct value at

virtually the same time. As the mode states, any value that is not a Boolean value is updated in the

server's internal write queue and sent to the device at the next possible opportunity. This can greatly

improve the application performance.

Note:This option does not attempt to optimize writes to Boolean values.It allows users to optimize

www. ptc.com

Page 11

11

Fanuc FocasEthernet Driver

the operation of HMIdata without causing problems with Boolean operations, such as a momentary

push button.

l Write Only Latest Value for All Tags: This option takes the theory behind the second optimization

mode and applies it to all tags. It is especially useful if the application only needs to send the latest

value to the device. This mode optimizes all writes by updating the tags currently in the write queue

before they are sent. This is the default mode.

Duty Cycle: is used to control the ratio of write to read operations. The ratio is always based on one read for

every one to ten writes. The duty cycle is set to ten by default,meaning that ten writes occur for each read

operation. Although the application is performing a large number of continuous writes, it must be ensured

that read data is still given time to process. A setting of one results in one read operation for every write

operation. If there are no write operations to perform, reads are processed continuously. This allows optimization for applications with continuous writes versus a more balanced back and forth data flow.

Note:It is recommended that the application be characterized for compatibility with the write optimization

enhancements before being used in a production environment.

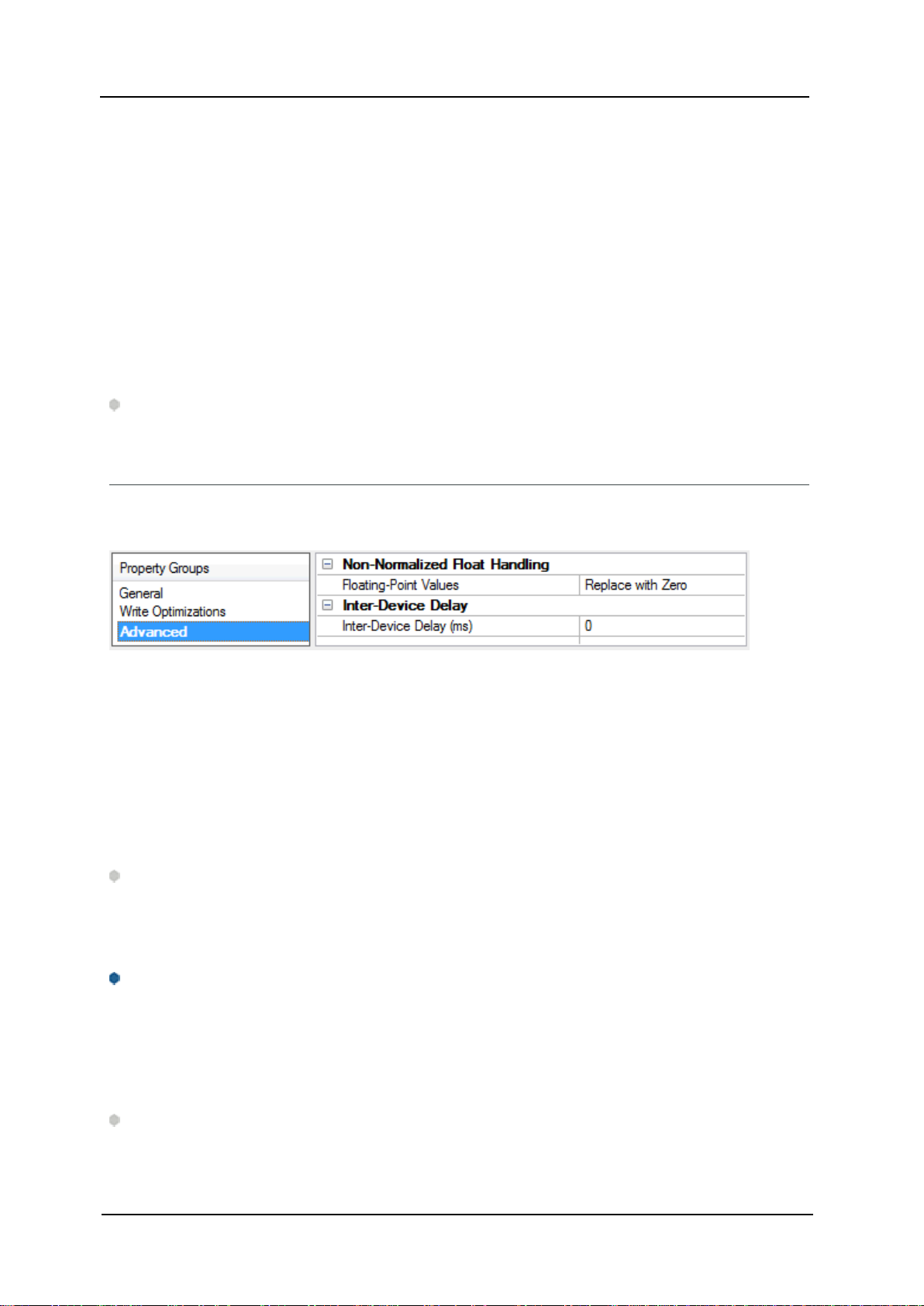

Channel Properties — Advanced

This group is used to specify advanced channel properties.Not all drivers support all properties; so the

Advanced group does not appear for those devices.

Non-Normalized Float Handling:A non-normalized value is defined as Infinity, Not-a-Number (NaN), or as

a Denormalized Number. The default is Replace with Zero. Drivers that have native float handling may

default to Unmodified. Non-normalized float handling allows users to specify how a driver handles non-normalized IEEE-754 floating point data.Descriptions of the options are as follows:

l Replace with Zero: This option allows a driver to replace non-normalized IEEE-754 floating point val-

ues with zero before being transferred to clients.

l Unmodified: This option allows a driver to transfer IEEE-754 denormalized, normalized, non-num-

ber, and infinity values to clients without any conversion or changes.

Note: This property is disabled if the driver does not support floating-point values or if it only supports the

option that is displayed. According to the channel's float normalization setting, only real-time driver tags

(such as values and arrays) are subject to float normalization. For example,EFM data is not affected by this

setting.

For moreinformation on the floating-point values, refer to "How To ... Work with Non-Normalized FloatingPoint Values" in theserver help.

Inter-Device Delay: Specify the amount of time the communications channel waits to send new requests to

the next device after data is received from the current device on the same channel.Zero (0) disables the

delay.

Note: This property is not available for all drivers, models, and dependent settings.

www. ptc.com

Page 12

Fanuc Focas Ethernet Driver

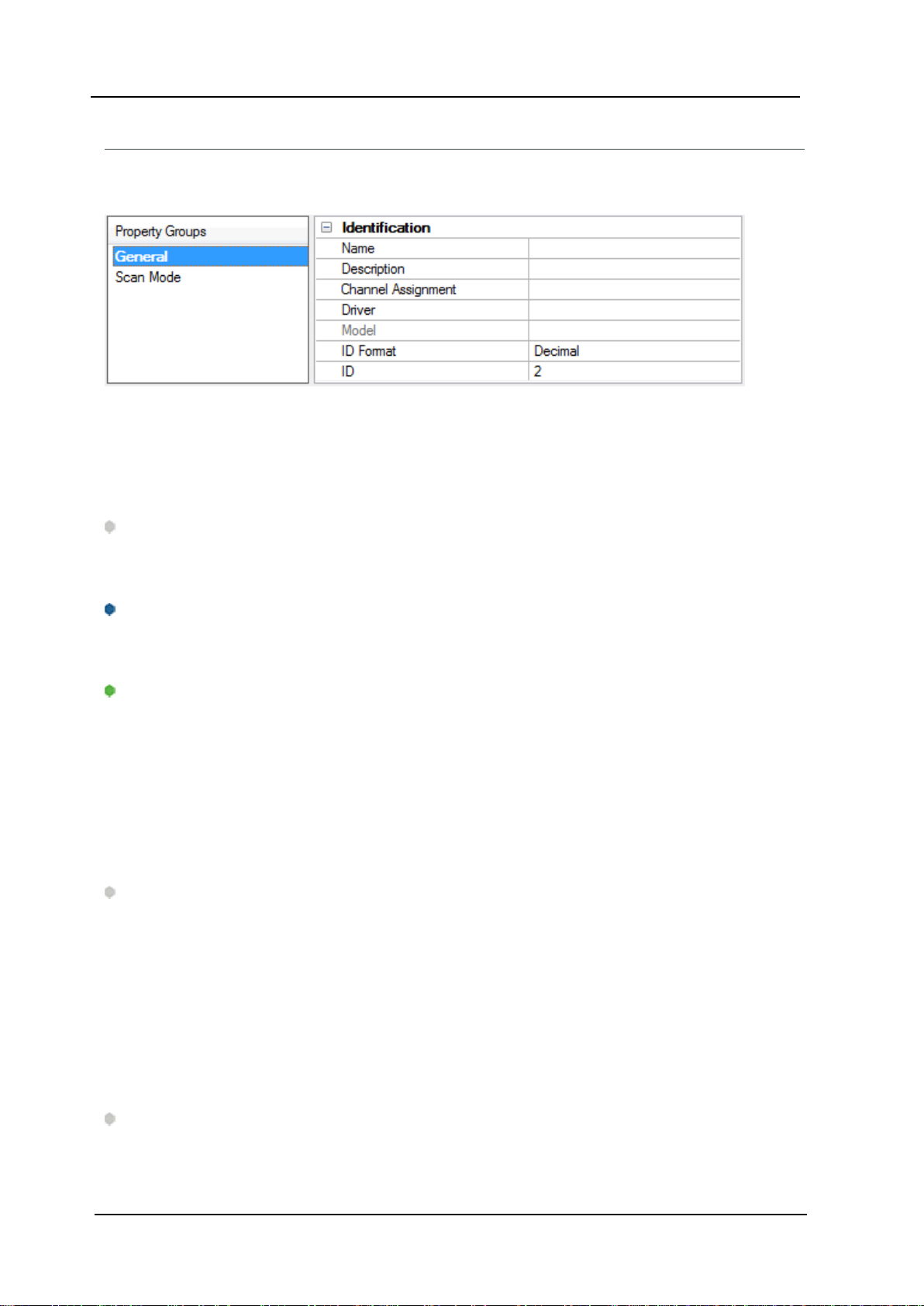

Device Properties — General

A device represents a single target on a communications channel.If the driver supports multiple controllers,

users must enter a device ID for each controller.

Identification

Name: Specify the name of the device. It is a logical user-defined name that can be up to 256 characters

long and may be used on multiple channels.

Note:Although descriptive names are generally a good idea, some OPCclient applications may have a

limited display window when browsing the OPCserver's tag space. The device name and channel name

become part of the browse tree information as well. Within an OPCclient, the combination of channel name

and device name would appear as "ChannelName.DeviceName".

For moreinformation, refer to "How To... Properly Namea Channel, Device,Tag,and TagGroup" in server

help.

12

Description: Specify the user-defined information about this device.

Many of these properties,including Description, have an associated system tag.

Channel Assignment: Specify the user-defined name of the channel to which this device currently belongs.

Driver: Selected protocol driver for this device.

Model: Specify the type of device that is associated with this ID. The contents of the drop-down menu

depend on the type of communications driver being used. Models that are not supported by a driver are disabled. If the communications driver supports multiple device models, the model selection can only be

changed when there are no client applications connected to the device.

Note: If the communication driver supports multiple models,users should try to match the model selection to the physical device. If the device is not represented in the drop-down menu, select a model that conforms closest to the target device.Some drivers support a model selection called "Open," which allows users

to communicate without knowing the specific details of the target device.For more information, refer to the

driver help documentation.

ID: Specify the device's driver-specific station or node. The type of ID entered depends on the communications driver being used. For many communication drivers, the ID is a numeric value. Drivers that support a Numeric ID provide users with the option to enter a numeric value whose format can be changed to

suit the needs of the application or the characteristics of the selected communications driver. The format is

set by the driver by default. Options include Decimal, Octal, and Hexadecimal.

Note:If the driver is Ethernet-based or supports an unconventional station or node name,the device's

TCP/IPaddress may be used as the device ID. TCP/IPaddresses consist of four values that are separated by

periods, with each value in the range of 0 to 255. Some device IDs are string based. There may be additional

www. ptc.com

Page 13

13

properties to configure within the ID field, depending on the driver. For moreinformation, refer to the driver's

help documentation.

Fanuc FocasEthernet Driver

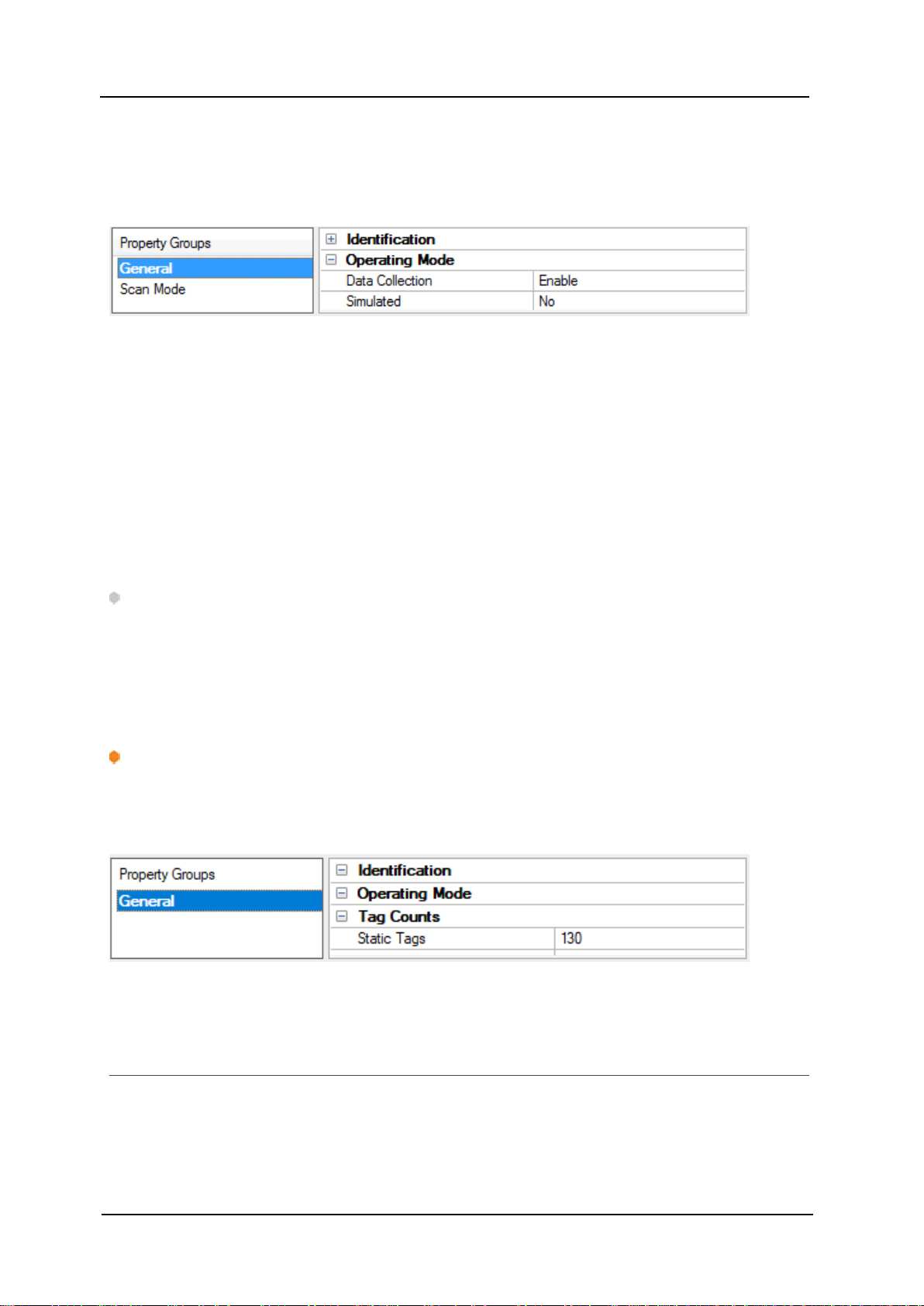

Operating Mode

Data Collection: This property controls the device's active state. Although device communications are

enabled by default, this property can be used to disable a physical device. Communications are not attempted when a device is disabled. From a client standpoint, the data is marked as invalid and write operations

are not accepted. This property can be changed at any time through this property or the device system tags.

Simulated: Place the device into or out of Simulation Mode. In this mode, the driver does not attempt to

communicate with the physical device, but the server continues to return valid OPCdata.Simulated stops

physical communications with the device, but allows OPCdata to be returned to the OPCclient as valid data.

While in Simulation Mode, the server treats all device data as reflective:whatever is written to the simulated

device is read back and each OPCitem is treated individually. The item's memory map is based on the group

Update Rate. The data is not saved if the server removes the item (such as when the server is reinitialized).

The default is No.

Notes:

1. This System tag (_Simulated) is read only and cannot be written to for runtime protection. The System

tag allows this property to be monitored from the client.

2. In Simulation mode, the item's memory map is based on client update rate(s) (Group Update Rate for

OPCclients or Scan Rate for native and DDEinterfaces). This means that two clients that reference

the same item with different update rates return different data.

Simulation Mode is for test and simulation purposes only. It should never be used in a production envir-

onment.

Tag Counts

Static Tags: Provides the total number of defined static tags at this level (device or channel). This inform-

ation can be helpful in troubleshooting and load balancing.

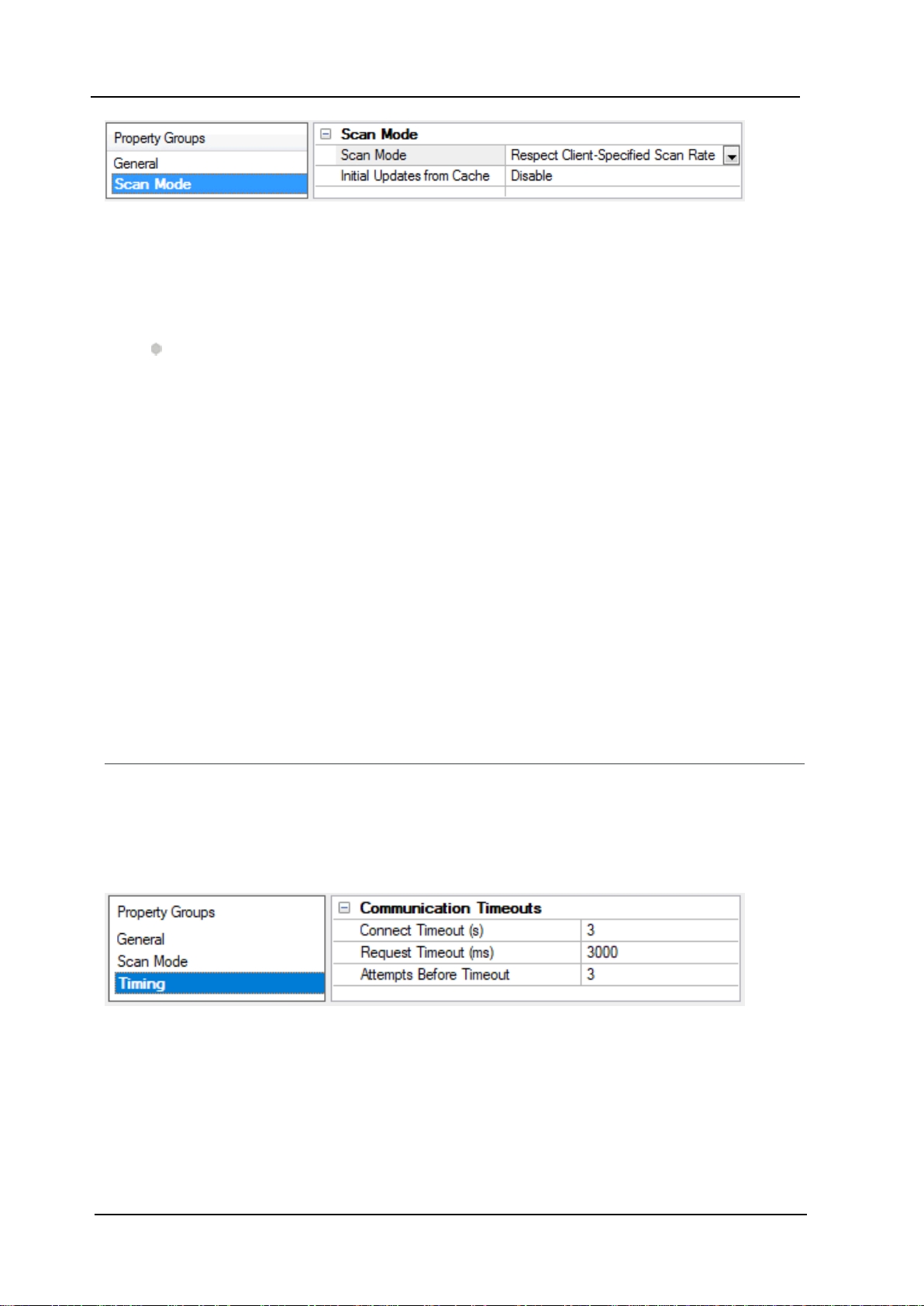

Device Properties — Scan Mode

The Scan Mode specifies the subscribed-client requested scan rate for tags that require device communications. Synchronous and asynchronous device reads and writes are processed as soon as possible;

unaffected by the Scan Mode properties.

www. ptc.com

Page 14

Fanuc Focas Ethernet Driver

Scan Mode: Specify how tags in the device are scanned for updates sent to subscribing clients.Descriptions

of the options are:

l Respect Client-Specified Scan Rate: This mode uses the scan rate requested by the client.

l Request Data No Faster than Scan Rate: This mode specifies the value set as the maximum scan

rate.The valid range is 10 to 99999990 milliseconds.The default is 1000 milliseconds.

Note: When the server has an active client and items for the device and the scan rate value is

increased, the changes take effect immediately. When the scan rate value is decreased, the changes

do not take effect until all client applications have been disconnected.

l Request All Data at Scan Rate: This mode forces tags to be scanned at the specified rate for sub-

scribed clients. The valid range is 10 to 99999990 milliseconds. The default is 1000 milliseconds.

l Do Not Scan, Demand Poll Only: This mode does not periodically poll tags that belong to the

device nor perform a read to get an item's initial value once it becomes active. It is the OPCclient's

responsibility to poll for updates, either by writing to the _DemandPoll tag or by issuing explicit device

reads for individual items. For more information, refer to "Device Demand Poll" in server help.

l Respect Tag-Specified Scan Rate: This mode forces static tags to be scanned at the rate specified

in their static configuration tag properties. Dynamic tags are scanned at the client-specified scan

rate.

14

Initial Updates from Cache: When enabled,this option allows the server to provide the first updates for

newly activated tag references from stored (cached) data. Cache updates can only be provided when the

new item reference shares the same address, scan rate,data type,client access,and scaling properties. A

device read is used for the initial update for the first client reference only. The default is disabled; any time a

client activates a tag reference the server attempts to read the initial value from the device.

Device Properties — Timing

The device Timing properties allow the driver's response to error conditions to be tailored to fit the application's needs. In many cases, the environment requires changes to these properties for optimum performance. Factors such as electrically generated noise, modem delays, and poor physical connections can

influence how many errors or timeouts a communications driver encounters. Timing properties are specific

to each configured device.

Communications Timeouts

Connect Timeout: This property (which is used primarily by Ethernet based drivers) controls the amount of

time required to establish a socket connection to a remote device. The device's connection time often takes

longer than normal communications requests to that same device.The valid range is 1 to 30 seconds. The

default is typically 3 seconds, but can vary depending on the driver's specific nature. If this setting is not supported by the driver,it is disabled.

www. ptc.com

Page 15

15

Note:Due to the nature of UDP connections, the connection timeout setting is not applicable when com-

municating via UDP.

Request Timeout: Specify an interval used by all drivers to determine how long the driver waits for a

response from the target device to complete. The valid range is 50 to 9,999,999 milliseconds (167.6667

minutes). The default is usually 1000 milliseconds,but can vary depending on the driver. The default timeout

for most serial drivers is based on a baud rate of 9600 baud or better. When using a driver at lower baud

rates,increase the timeout to compensate for the increased time required to acquire data.

Attempts Before Timeout: Specify how many times the driver issues a communications request before considering the request to have failed and the device to be in error. The valid range is 1 to 10.The default is typically 3, but can vary depending on the driver's specific nature. The number of attempts configured for an

application depends largely on the communications environment. This property applies to both connection

attempts and request attempts.

Fanuc FocasEthernet Driver

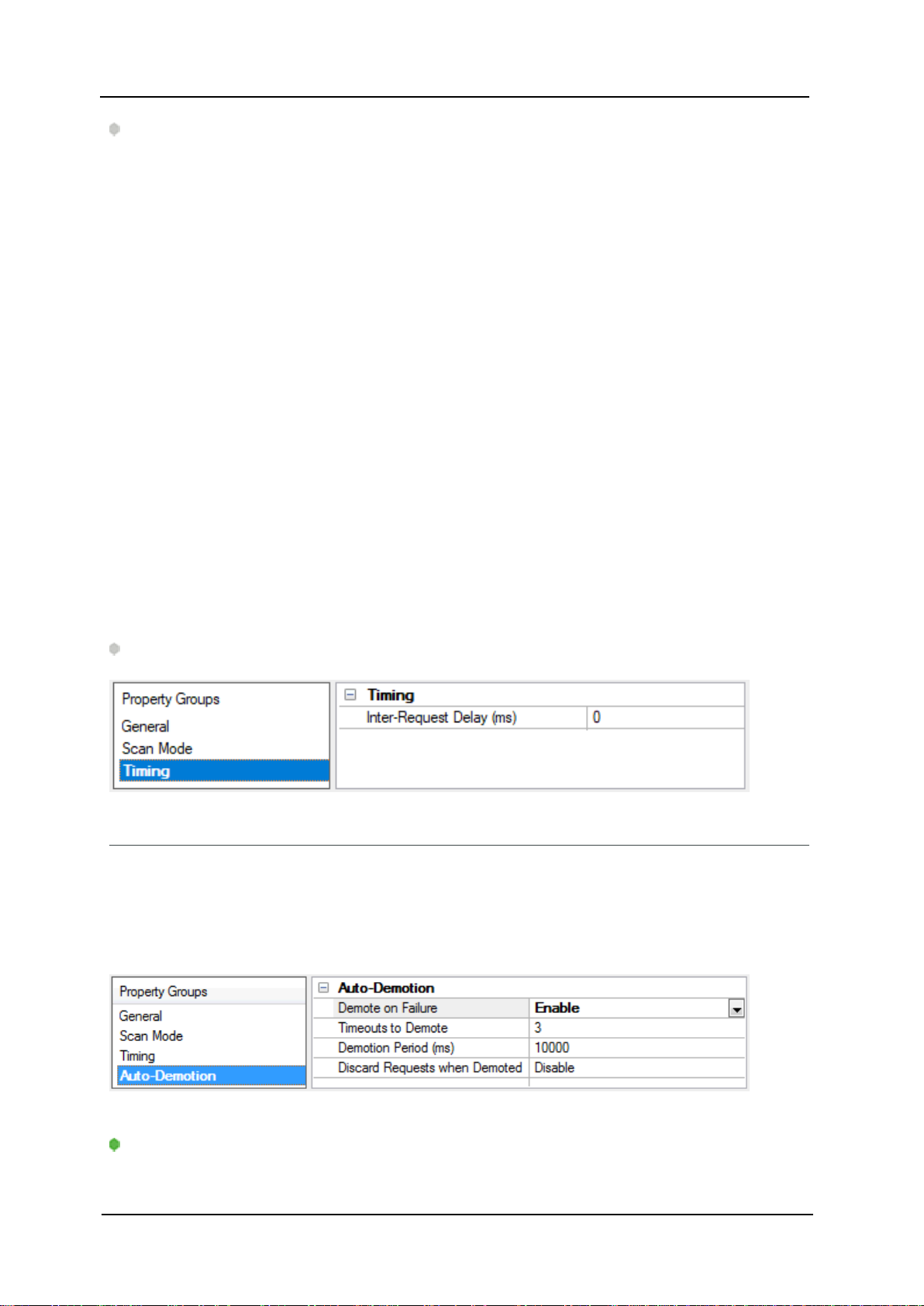

Timing

Inter-Request Delay: Specify how long the driver waits before sending the next request to the target

device. It overrides the normal polling frequency of tags associated with the device, as well as one-time

reads and writes. This delay can be useful when dealing with devices with slow turnaround times and in

cases where network load is a concern.Configuring a delay for a device affects communications with all

other devices on the channel. It is recommended that users separate any device that requires an interrequest delay to a separate channel if possible.Other communications properties (such as communication

serialization) can extend this delay. The valid range is 0 to 300,000 milliseconds;however, some drivers may

limit the maximum value due to a function of their particular design. The default is 0, which indicates no

delay between requests with the target device.

Note:Not all drivers support Inter-Request Delay. This setting does not appear if it is not available.

Device Properties — Auto-Demotion

The Auto-Demotion properties can temporarily place a device off-scan in the event that a device is not

responding.Byplacing a non-responsive device offline for a specific time period, the driver can continue to

optimize its communications with other devices on the same channel.After the time period has been

reached, the driver re-attempts to communicate with the non-responsive device. If the device is responsive,

the device is placed on-scan; otherwise, it restarts its off-scan time period.

Demote on Failure: When enabled, the device is automatically taken off-scan until it is responding again.

Tip:Determine when a device is off-scan by monitoring its demoted state using the _AutoDemoted sys-

tem tag.

www. ptc.com

Page 16

Fanuc Focas Ethernet Driver

Timeouts to Demote: Specify how many successive cycles of request timeouts and retries occur before the

device is placed off-scan. The valid range is 1 to 30 successive failures. The default is 3.

Demotion Period:Indicate how long the device should be placed off-scan when the timeouts value is

reached. During this period,no read requests are sent to the device and all data associated with the read

requests are set to bad quality. When this period expires,the driver places the device on-scan and allows for

another attempt at communications. The valid range is 100 to 3600000 milliseconds. The default is 10000

milliseconds.

Discard Requests when Demoted: Select whether or not write requests should be attempted during the

off-scan period.Disable to always send write requests regardless of the demotion period. Enable to discard

writes; the server automatically fails any write request received from a client and does not post a message

to the Event Log.

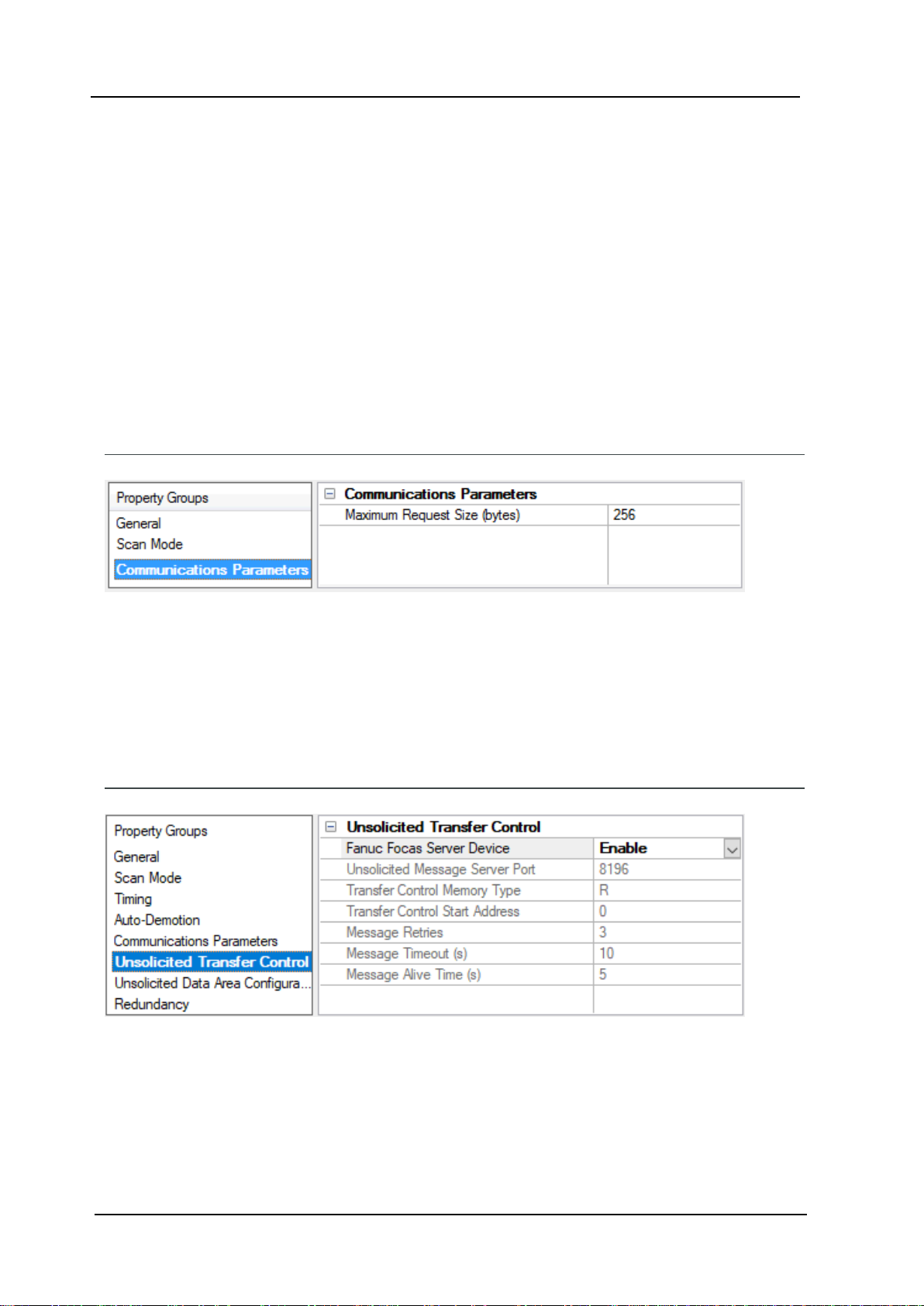

Device Properties — Communications Parameters

16

TCP/IP Port: Specify the TCP/IPport number that the remote device is configured to use. The default setting

is 8193.

Maximum Request Size: Specify the number of bytes that may be requested from a device at one time.To

refine the driver's performance, configure the request size to one of the following settings:8,16, 32, 64, 128,

256,or 512 bytes. The default setting is 256 bytes.

Device Properties — Unsolicited Transfer Control

Fanuc Focas Server Device: This option should be enabled if the device receives unsolicited data from the

CNC. All tags belonging to a Fanuc Focus Server device read data cached in the driver,not directly from the

CNC. The Fanuc Focus Server device's tags displays a value of zero until it receives its first unsolicited data

update.When disabled, all tags belonging to the device read and write directly to the CNC.The default setting is disabled.

www. ptc.com

Page 17

17

Unsolicited Message Server Port: Specify the port that the unsolicited message server application has

been configured to use. The default setting is 8196.

Transfer Control Memory Type:Specify the registers' PMC memory type for unsolicited message transfer

control. Options include R(internal relay) and E(extended relay). The default setting is R.

Transfer Control Start Address:Specify the start address of the registers used for unsolicited message

transfer control. The valid range is 0 to 7999,although the actual range of valid addresses depends on the

hardware. The default setting is 0.

Message Retries: Specify the number of times that the CNCshould retry sending unsolicited messages. The

valid range is 0 to 10.The default setting is 3.

Message Timeout: Specify the unsolicited message timeout,which is the amount of time that the CNC waits

for the driver to respond to an unsolicited message. The valid range is 0 to 30.The default setting is 10

seconds.

Message Alive Time: Specify the unsolicited message alive time,which is the amount of time that the CNC

retains an unsolicited message for the driver to read. This setting must be less than the message timeout.

The valid range is 0 to 30.The default setting is 5 seconds.

Fanuc FocasEthernet Driver

See Also:Unsolicited Messaging

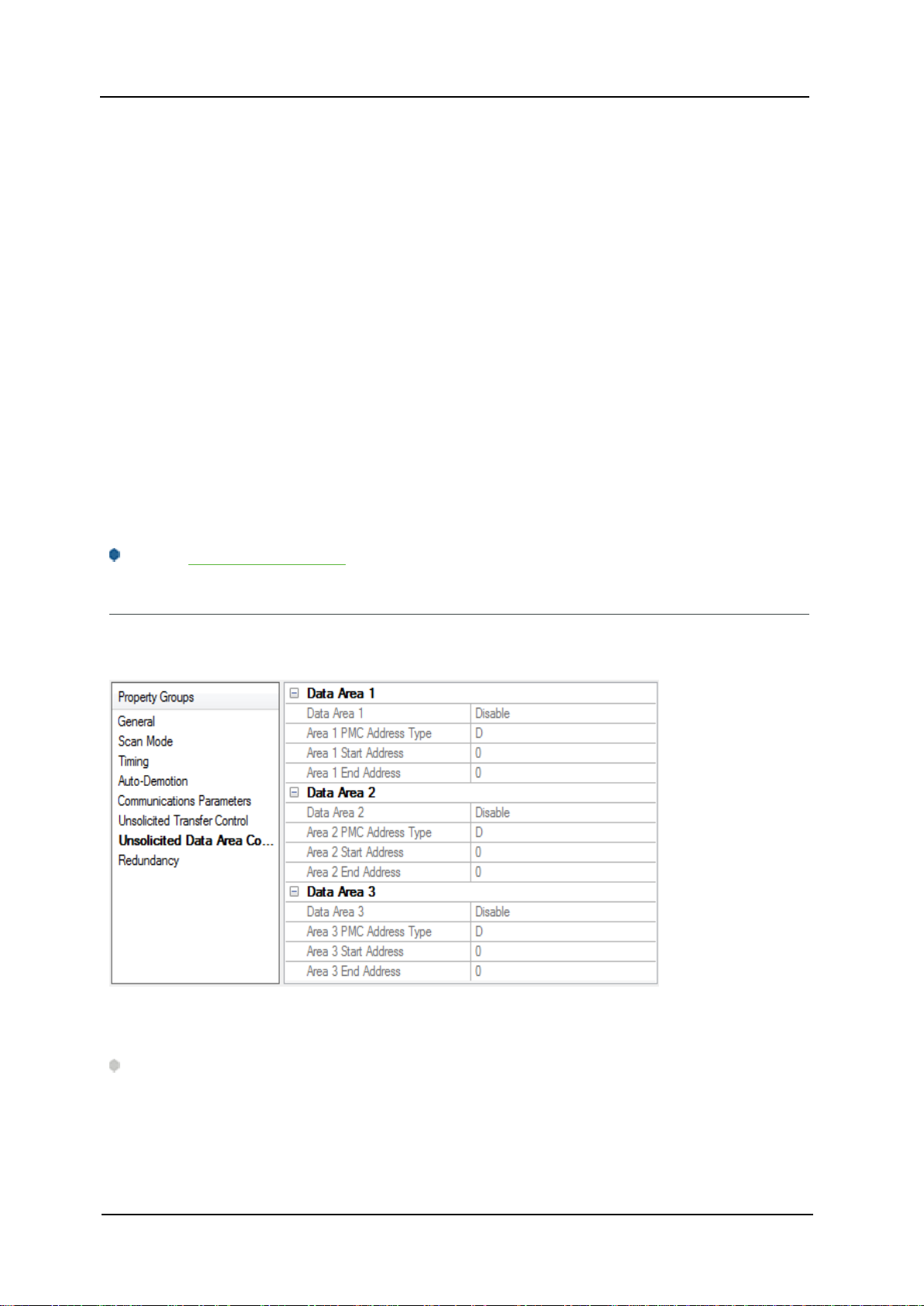

Device Properties — Unsolicited Data Areas

Users can configure up to three areas in PMCmemory for unsolicited messaging. These areas' data content

is sent to the driver in each unsolicited message. As such, these areas should be made as small as possible.

Data Area n

Note:All tags that are created for a Fanuc Focus server device are validated according to the configured

data areas.For example, if a Fanuc Focus Server device is configured with a single area with D1000 to

D1100, then a tag with address D1000 would be valid,but tags with addresses D1101 or C0001 would be

invalid. All tags belonging to a Fanuc Focus Server device are Read Only.

www. ptc.com

Page 18

Fanuc Focas Ethernet Driver

l Data Area n:When enabled,this data area is in use.

l PMC Address Type:Specify the area's PMCaddress type. The default setting is D. Supported types

include the following:

l G:Signal to PMC->CNC

l F:Signal to CNC->PMC

l Y:Signal to PMC->machine

l X: Signal to machine->PMC

l A:Message demand

l R:Internal relay

l T:Changeable timer

l K:Keep relay

l C:Counter

l D:Data table

l Start Address:Specify an area's start address.The valid range is 0 and 7999,although the actual

range of valid addresses depends on the hardware. The default setting is 0.

l End Address:Specify an area's end address. The valid range is 0 and 7999,although the actual

range of valid addresses depends on the hardware. The total number of bytes must not exceed 1430,

1414, or 1398 for areas 1, 2, or 3 respectively. The default value is 0.

18

See Also: Unsolicited Messaging

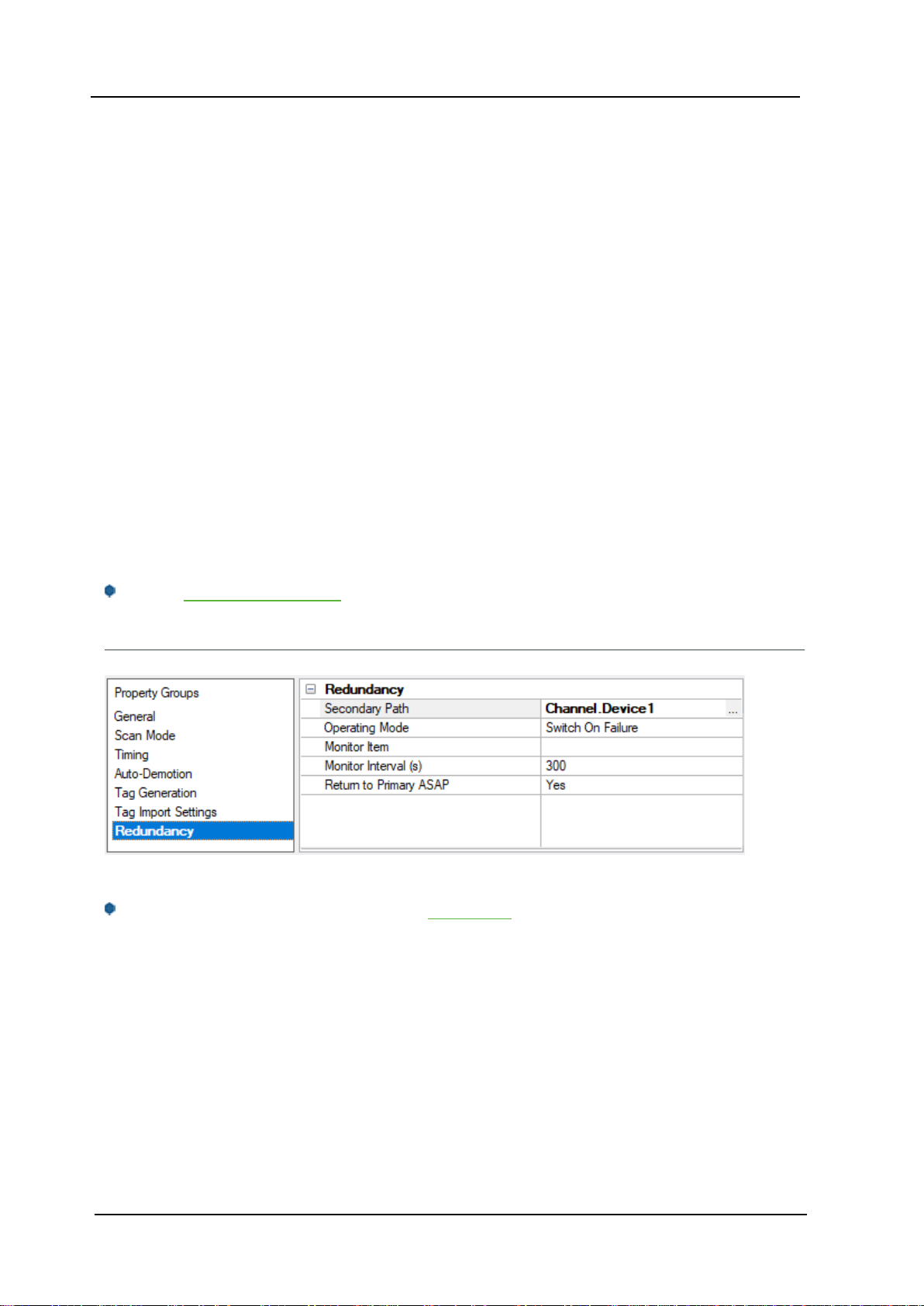

Device Properties — Redundancy

Redundancy is available with the Media-Level Redundancy Plug-In.

Consult thewebsite,a salesrepresentative,or the user manual for more information.

www. ptc.com

Page 19

19

Fanuc FocasEthernet Driver

Unsolicited Messaging

Before configuring a system for unsolicited messaging, it is important that users understand how the various hardware and software components work together to transfer data. These components include one or

more CNCcontrollers equipped with Fast Ethernet communications boards, firmware that supports unsolicited messaging, and a ladder program. To receive unsolicited data,a host computer must be equipped

with the OPCserver, its Fanuc Focas Ethernet Driver, the Focas 1 Data Window Library software, and the

Unsolicited Message Server. Data can be read from the OPCserver with OPCor DDEclient applications running on the host or remote computer. For more information, refer to Additional Software Requirements.

During an unsolicited messaging session, the controller is only in direct communication with the Unsolicited

Message Server.The message server notifies the driver when the controller makes a request to send unsolicited data. The Focas 1 Data Window Library allows the driver to receive the unsolicited data via the message server,and also enables direct communications with the controllers for starting and ending unsolicited

messaging sessions.

Note:If unsolicited messaging is not used, the driver uses the library to issue read and write requests directly to the controller. It is possible to simultaneously use both types of communication with a controller by

creating a Fanuc Focus Server and a non-server device in the OPCserver project.

Unsolicited Data Transmission

Ladder programs coordinate the transfer of unsolicited data from their respective controllers and must be

tailored to each application. For more information on unsolicited data transmission, refer to theinstructions

below.

1. To start, the ladder program places the message contents in a designated area of the PMCmemory.

Once the message is prepared, the ladder controls the data transmission by setting and monitoring

bits in the Unsolicited Transfer Control area of PMC memory.

2. To trigger the unsolicited message transmission,the ladder sets the "REQ" (request to send) transfer

control bit. The controller sends an "Unsolicited data ready" notification to the message server immediately after.

3. The message server relays the notification to the driver, which then responds by issuing a "Read

unsolicited message" command to the message server.

4. The driver receives the unsolicited message data in response to this command,and then replies to

the data ready notification with a response code indicating success or failure. The message server

then passes this response code to the controller.

5. When the controller receives the response code,it copies it to the "RES_CODE" memory area. The

controller sets the "RES" (response ready) bit to indicate that the transaction completed immediately

after.

Note:The ladder program must be designed to detect when the RESbit has been set.Once it

detects that the RESbit has been set, it can read the response code and react as needed. If the data

fails to reach the driver,the controller will place its own response code that describes the problem in

RES_CODEand set the RESbit.

6. Once the ladder has read the response code, it must clear the REQbit to ready the system for the

next message.

PMCMemory

www. ptc.com

Page 20

Fanuc Focas Ethernet Driver

The PMC memory area included in unsolicited messages is defined with the Fanuc Focas Ethernet Driver.

The driver transfers these area properties to the controller at the start of an unsolicited messaging session.

Data from the range of all areas is included each time an unsolicited message is sent. As such, these areas

should be made as small as possible.The ladder program must be written to use the exact address ranges

specified in the driver configuration.

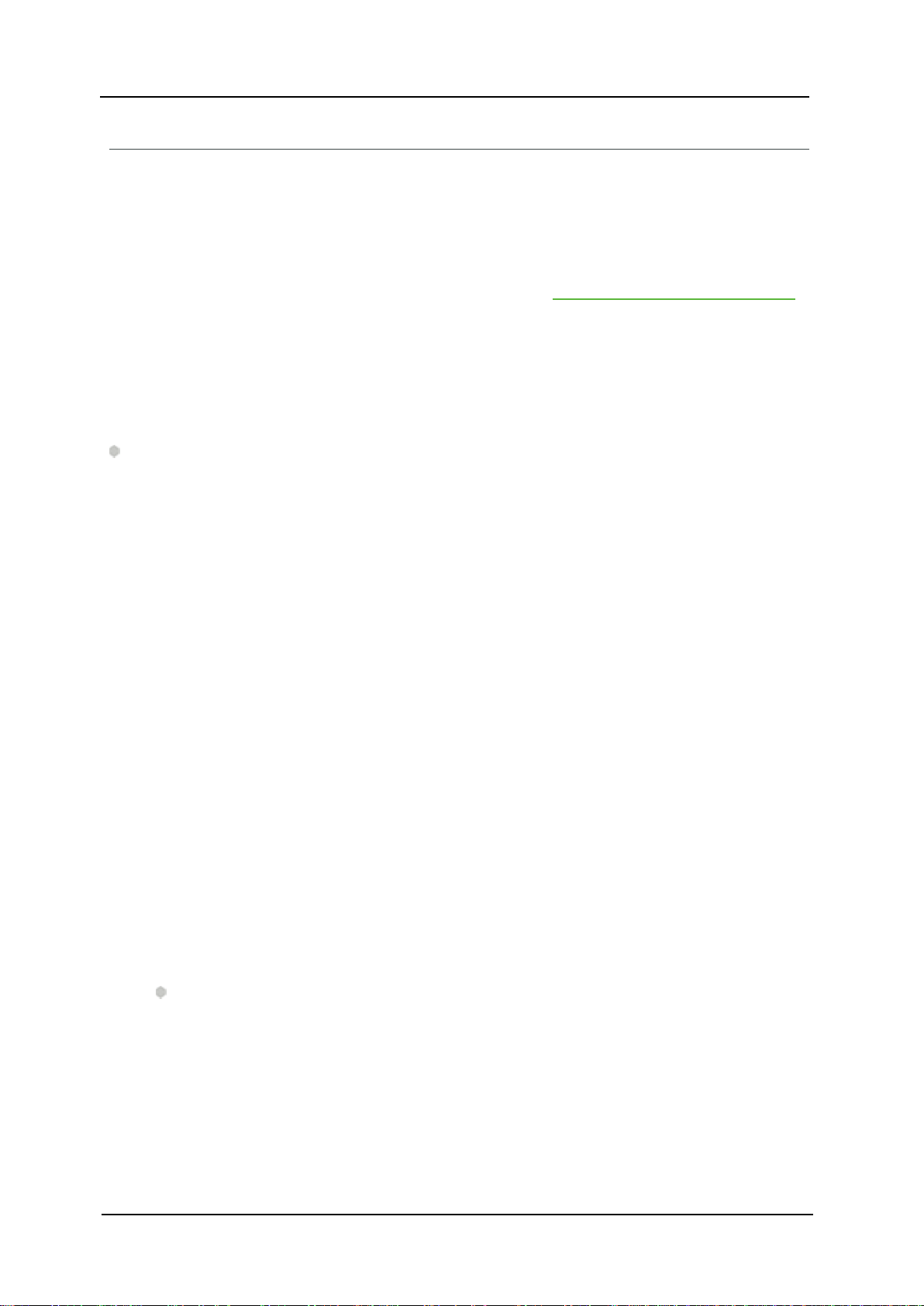

Unsolicited data transmission is coordinated between the ladder program and communications board via 2

bytes of PMC Ror Ememory. This transfer control area is defined with the Fanuc Focas Ethernet Driver . The

transfer control area properties are then sent to the controller along with the data area properties when an

unsolicited messaging session starts. The ladder program must be written to use the specific addresses specified in the driver configuration. The various bits in the transfer control area,with starting address xxxx,

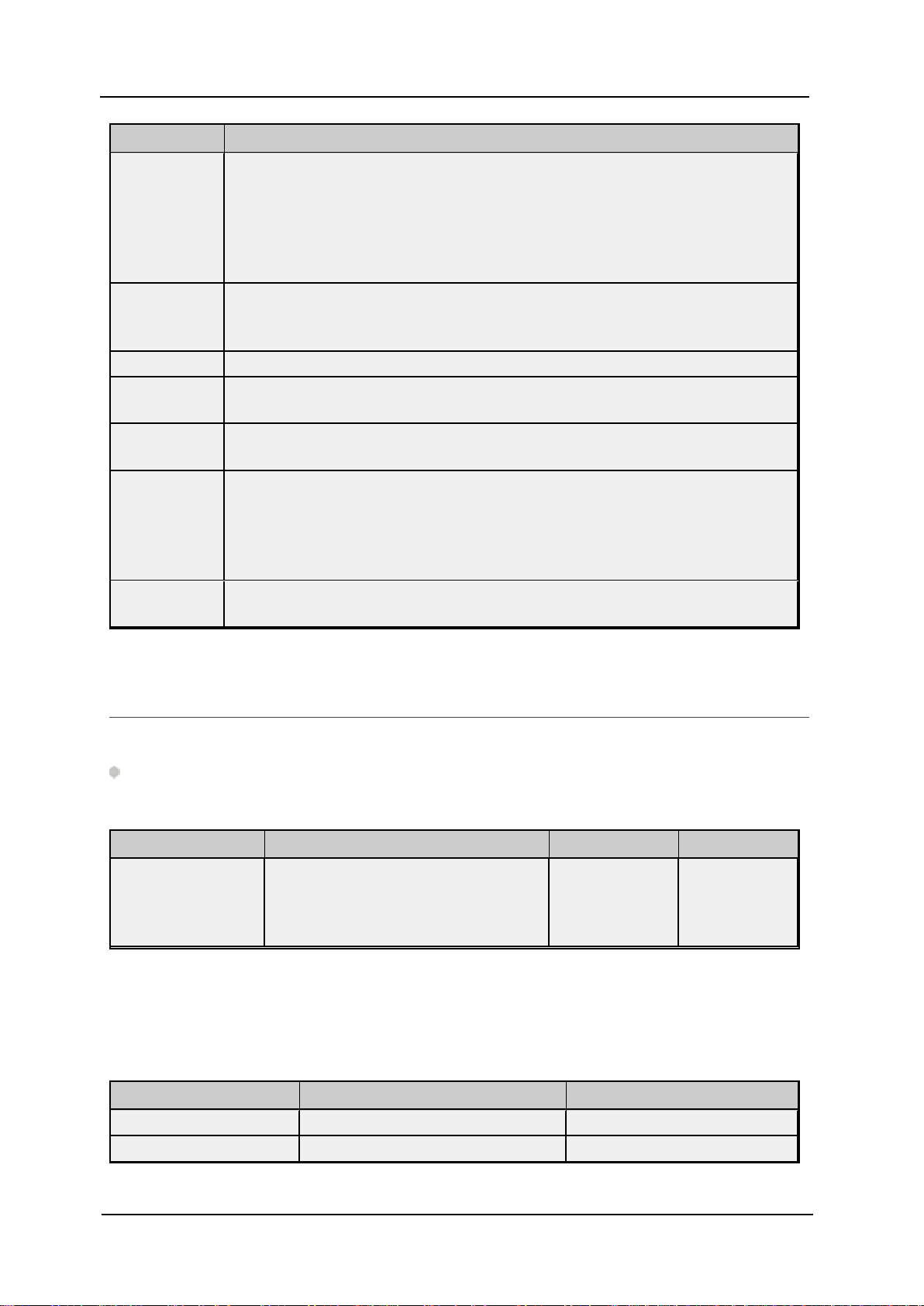

have the following locations and meanings:

20

REQ

Rxxxx.7 (or Exxxx.7)

After the ladder program constructs a message, it must set this bit to 1. This signals the communications

board to issue a notification that a new message is ready to be read.

COM

Rxxxx+1.6 (or Exxxx+1.6)

The communications board sets this bit to 1 when message transmission begins. The communications board

sets this bit back to 0 immediately before it sets RESto 1, and places the response code in RES_CODE.

RES

Rxxxx+1.7 (or Exxxx+1.7)

The communications board sets this bit to 1 immediately after message transmission completes. When the

ladder program detects that this bit is set to 1, it can read the response code from RES_CODE.The ladder

then acts depending on the value of RES_CODE.Once this is done, the ladder must set REQback to 0. This

causes the communications board to clear RES_CODE and set the bit back to 0. Then the communications

board is ready to perform the next unsolicited transaction.

RES_CODE

Rxxxx+1.0 to Rxxxx+1.5 (or Exxxx+1.0 to Exxxx+1.5)

The result of the unsolicited transaction is placed here. It can be a code passed down from the driver,or a

code set by the communications board if there was a communications failure.The possible values are displayed in the table below.

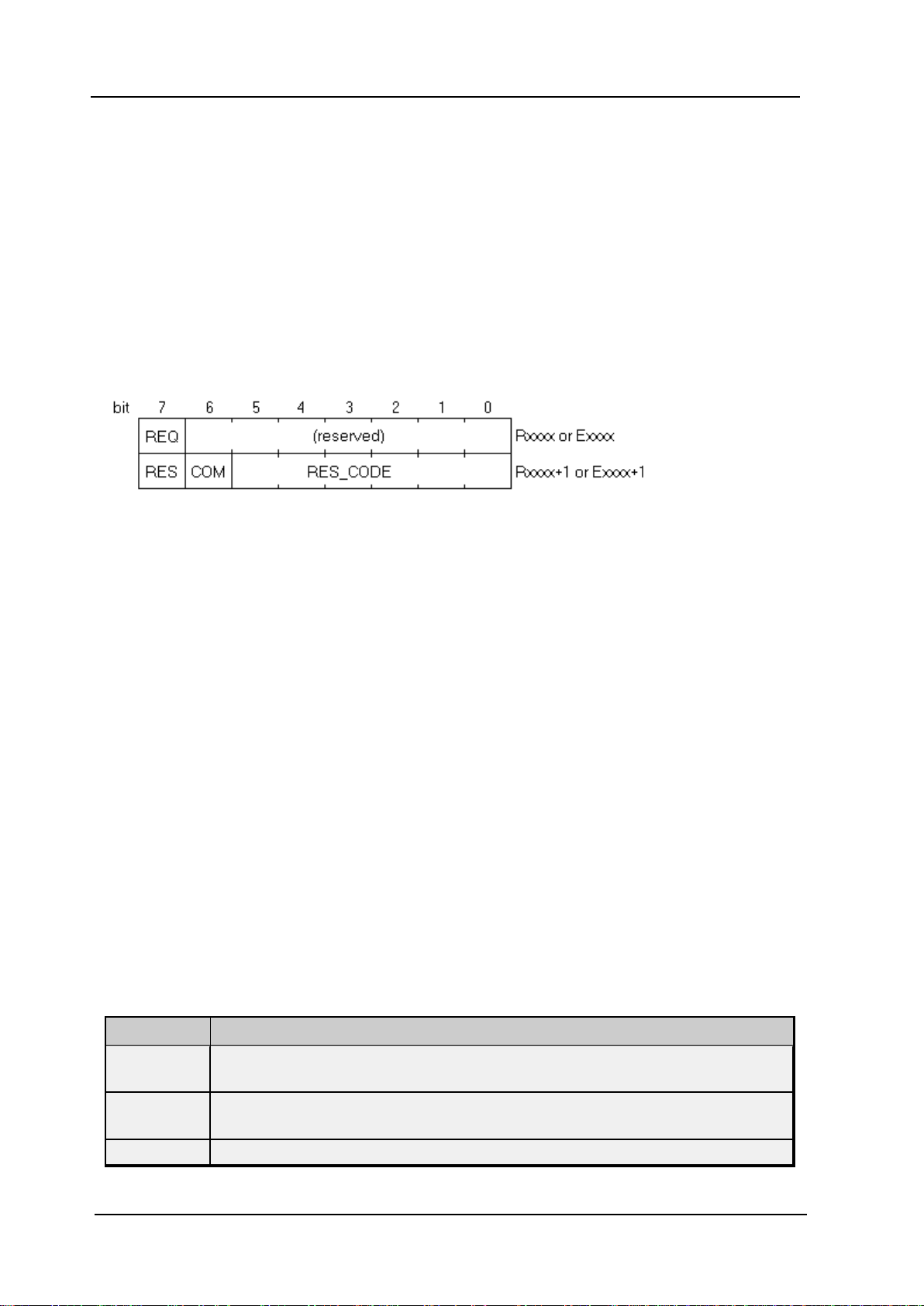

RES_CODE Meaning

0x00

0x01

0x02 The unsolicited message server is not running.

Success. The communications board did not detect any failures in communication, and

the driver reported that it processed the received data successfully.

The transmission control properties are invalid or the unsolicited messaging session

was not started.

www. ptc.com

Page 21

21

RES_CODE Meaning

0x03 The CNCfailed to transmit message.

0x04 The CNCfailed to receive response.

0x05 The transmission retry count was exceeded.

0x06 The CNCfailed to construct the message data.

0x07 The CNCreceived an invalid packet.

0x08 The CNCaccepted termination of unsolicited messaging session.

0x10 The driver experienced a Focas 1 Library error while reading message.

0x11

0x21

0x22

0x23 The CNCfailed in writing the received message to the PC.

0x24 The timeout period and retry count have expired.

0x25 Illegal data was included in the received message.

The driver found the message data to be invalid or experienced other problems while

processing message data.

The PCapplication to receive the message does not exist, though the message was

received by the PC.Either the OPCserver or this driver is not running.

The PCapplication to receive the message was not recognized by the unsolicited message server,though the message was received by the PC.The unsolicited message

server may need be restarted, or there may have been a problem when the driver was

starting the unsolicited messaging session.

Fanuc FocasEthernet Driver

The Fanuc Focas Ethernet Driver stores unsolicited data in a memory cache. The OPCserver makes this

data visible to client applications via tags, whose addresses must be the same as the controller's data

source. For example, if an unsolicited data area is configured to include the byte at D1000, then a tag with an

address of D1000 must be used to view the data. These tags show the last values sent to the driver, which

may not necessarily be the current values in the controller.Topoll current values directly from the controller, users would need additional tags belonging to a non-server device. Fanuc Focus Server device tags

display a value of zero until the driver receives its first unsolicited data update from the controller.

Notes:

1. In addition to data ready notifications, the Unsolicited Message Server also apprises the driver of

other important events. These include CNCpower up,CNCpower down, Unsolicited Message Server

shutdown, and communications error notifications.The driver responds to each of these events in

such a way that communication with the hardware is maintained,if possible.

2. The device's _System._Error Tag is set if the driver fails to start an unsolicited messaging session,or

restarts the session after detecting a communications problem. Tags that belong to a Fanuc Focus

Server device in an error state will continue to display the last value received from the device or the

initial value of zero.

www. ptc.com

Page 22

Fanuc Focas Ethernet Driver

Optimizing Communications

The Fanuc Focas Ethernet Driver has been designed to provide the best performance with the least amount

of impact on the system's overall performance.While the driver is fast, there are a couple of guidelines that

can be used to control and optimize the application and gain maximum performance.

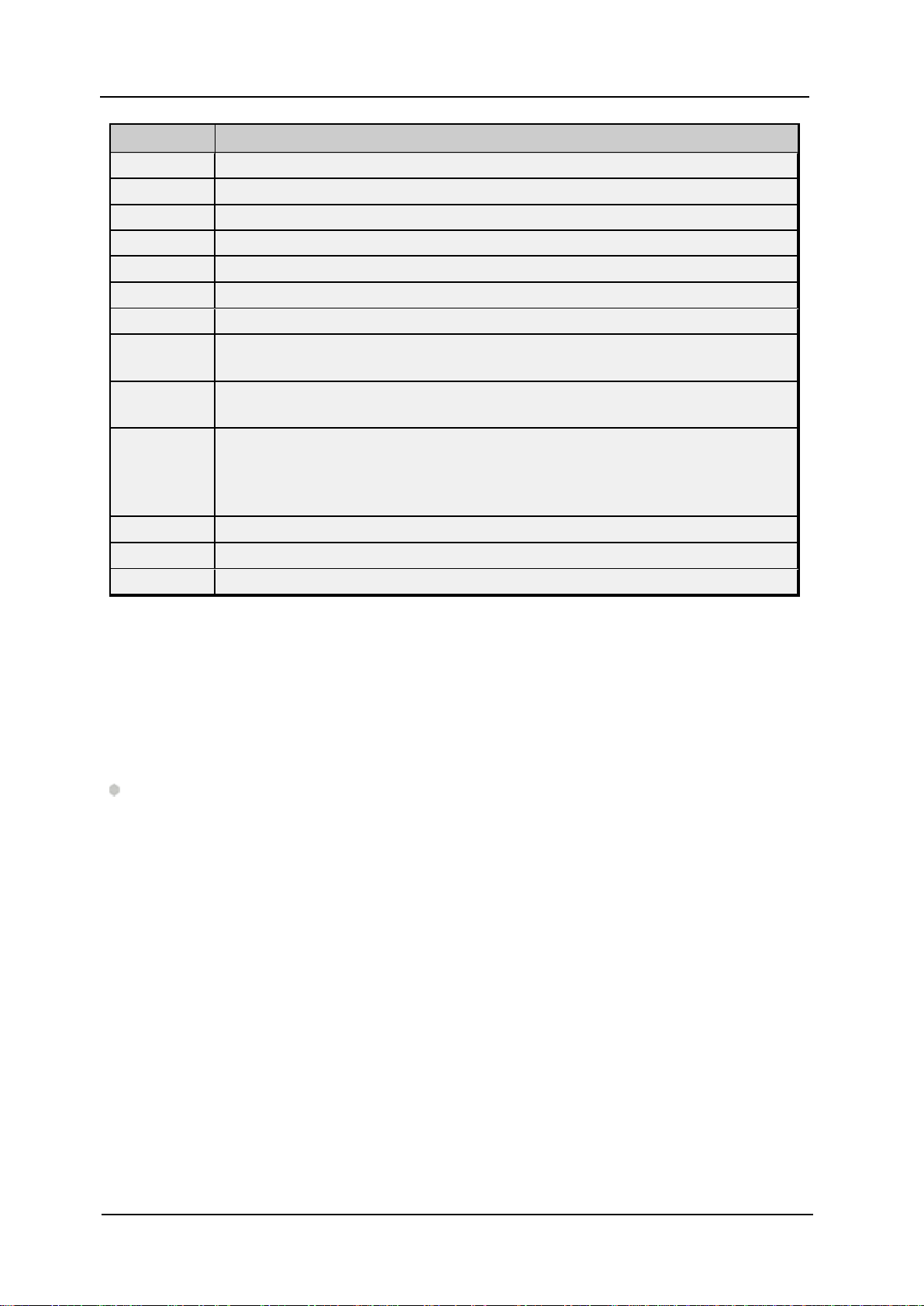

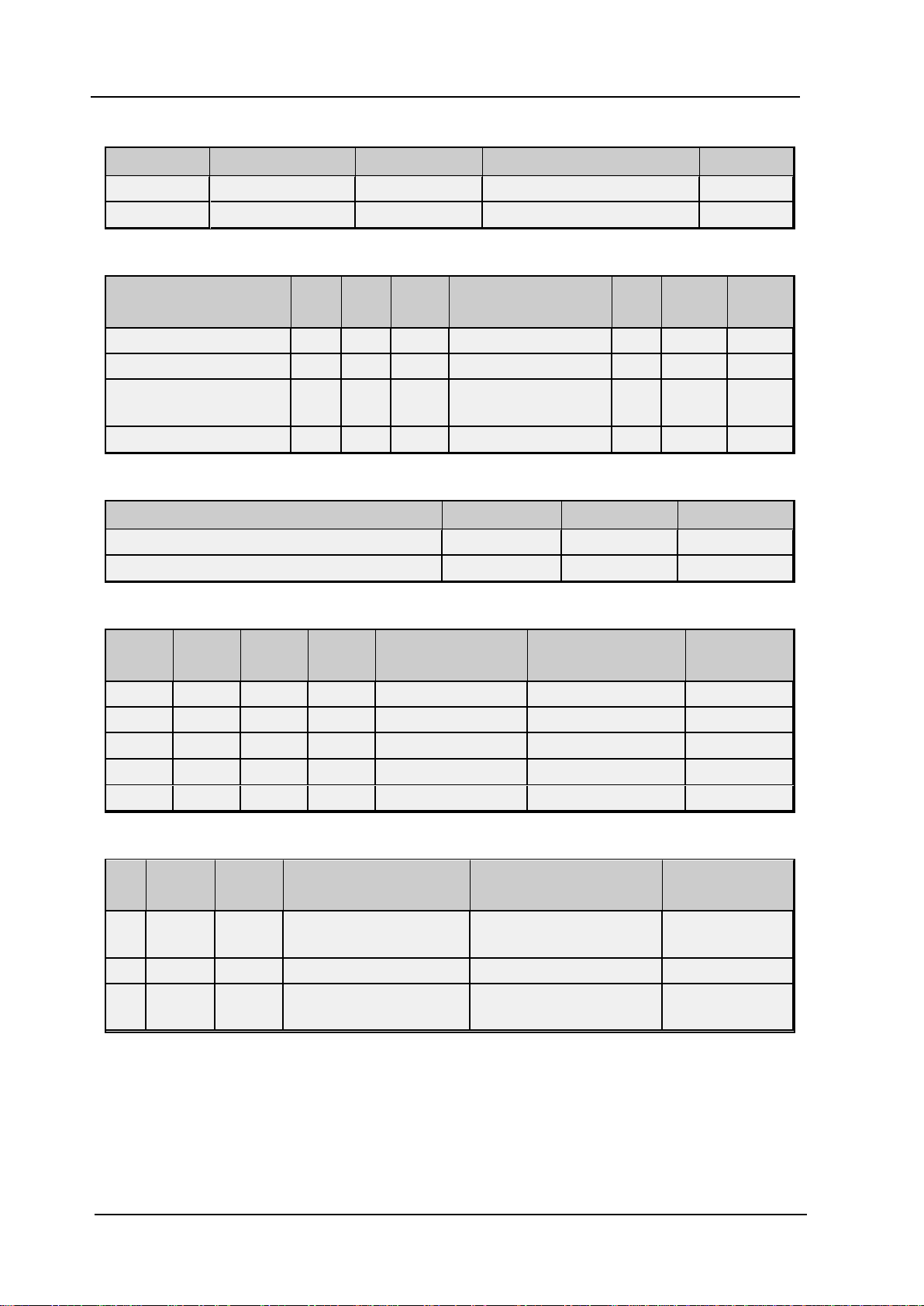

This server refers to communications protocols like Fanuc Focas Ethernet as a channel.Each channel

defined in the application represents a separate path of execution in the server. Once a channel has been

defined, a series of devices must then be defined under that channel.Each of these devices represents a

single Fanuc Focas controller from which data is collected. While this approach to defining the application

provides a high level of performance, it won't take full advantage of the Fanuc Focas Ethernet Driver or the

network. An example of how the application may appear when configured using a single channel is shown

below.

Each device appears under a single channel. In this configuration, the driver must

move from one device to the next as quickly as possible to gather information at an

effective rate. As more devices are added or more information is requested from a

single device, the overall update rate begins to suffer.

22

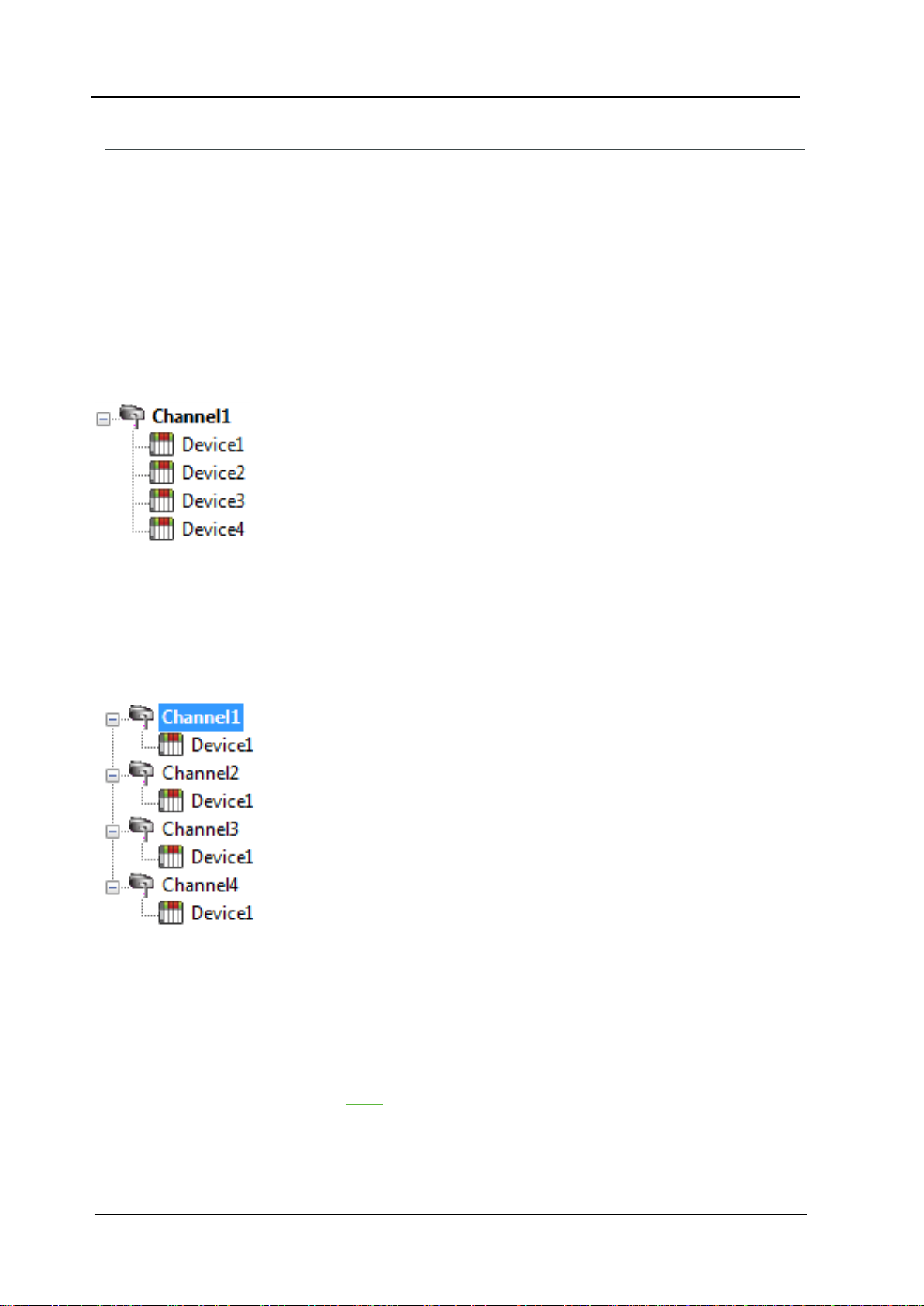

If the Fanuc Focas Ethernet Driver could only define one single channel, then the example shown above

would be the only option available; however, the driver can define up to 256 channels. Using multiple channels distributes the data collection workload by simultaneously issuing multiple requests to the network. An

example of how the same application may appear when configured using multiple channels to improve performance is shown below.

Each device can be defined under its own channel. In this configuration, a single

path of execution is dedicated to the task of gathering data from each device. If the

application has fewer devices, it can be optimized exactly how it is shown here.

There is performance improvement even if the application has more devices.

While fewer devices may be ideal,the application still benefits from additional channels.Although spreading the device load across all channels causes the server to

move from device to device again, it can now do so with far less devices to process

on a single channel.

Request Size can also affect the Fanuc Focas Ethernet Driver performance.The request size refers to the

number of bytes that may be requested from a device at one time and is available on every defined device.

To refine the driver's performance, configure the request size to one of the following settings:8,16, 32, 64,

128,256, or 512 bytes. Depending on the model of the device being used, the setting chosen for request size

can dramatically affect the application. The default value of 256 bytes is recommended. If the application

consists of large requests for consecutively ordered data, try increasing the request size setting for the

device. For more information, refer to Setup.

www. ptc.com

Page 23

23

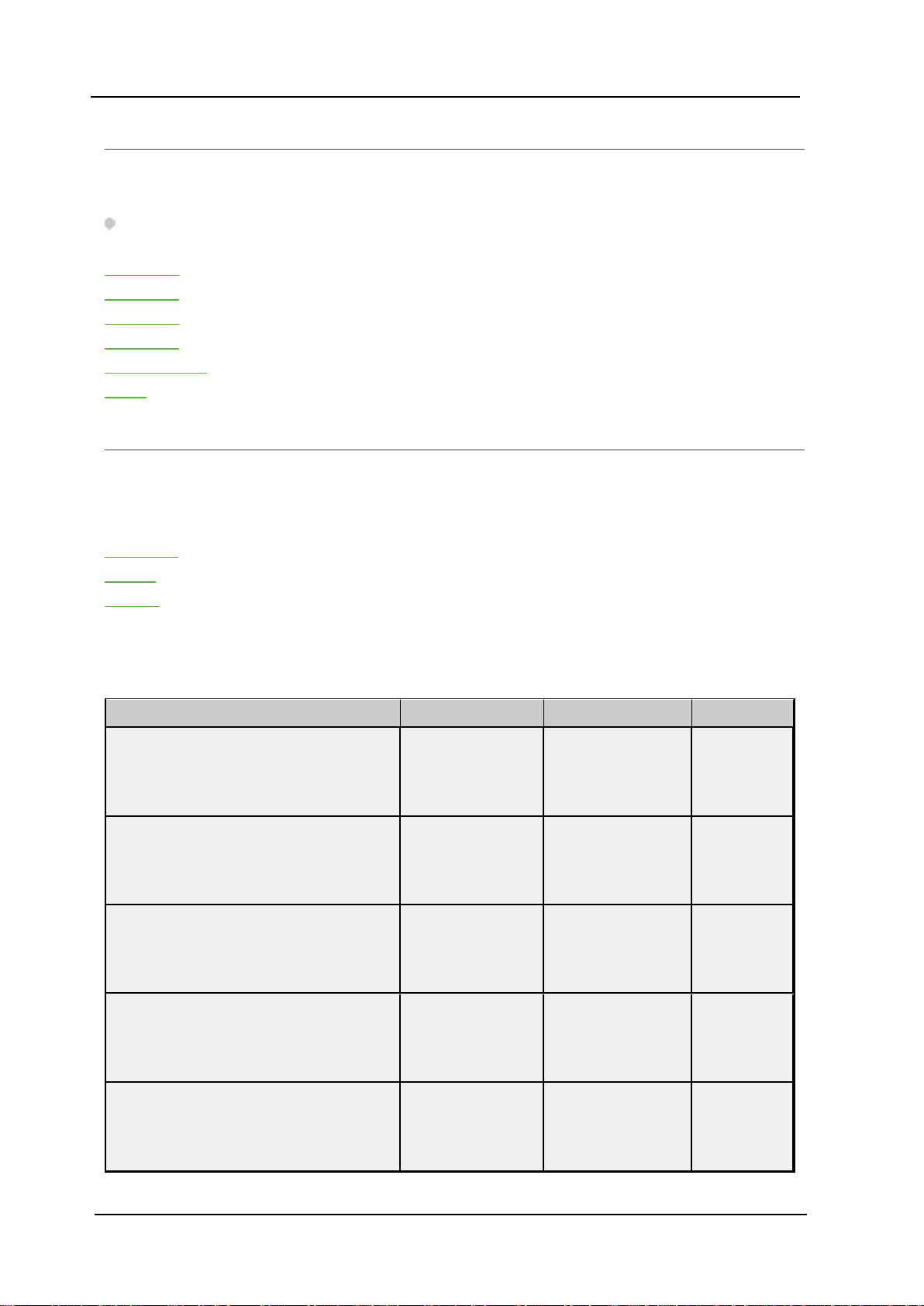

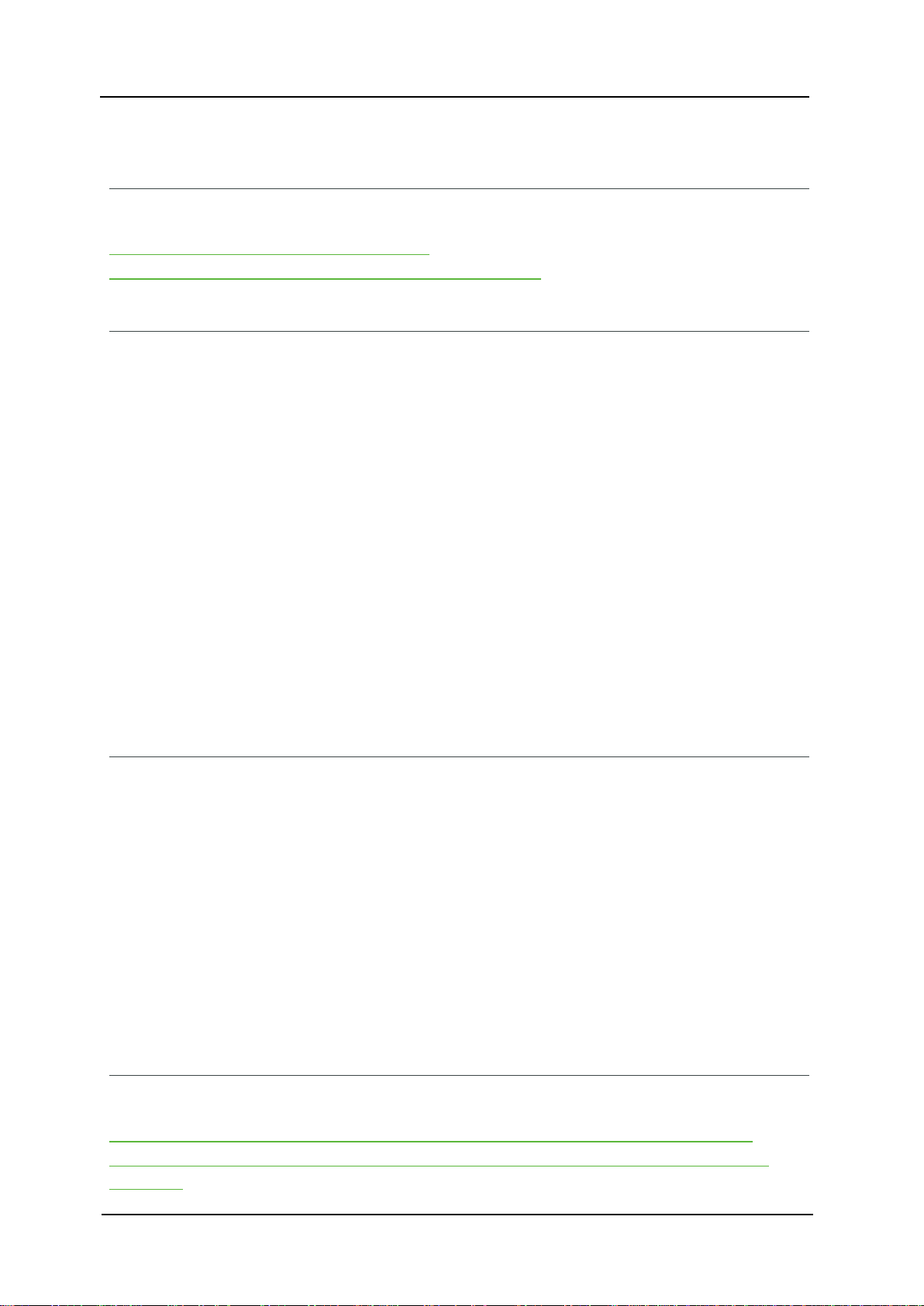

Data Types Description

Data Type Description

Boolean Single bit

Unsigned 8-bit value

Byte

bit 0 is the low bit

bit 7 is the high bit

Unsigned 16-bit value

Fanuc FocasEthernet Driver

Word

Short

DWord

Long

Float 32-bit floating point value

String Null terminated ASCII string

bit 0 is the low bit

bit 15 is the high bit

Signed 16-bit value

bit 0 is the low bit

bit 14 is the high bit

bit 15 is the sign bit

Unsigned 32-bit value

bit 0 is the low bit

bit 31 is the high bit

Signed 32-bit value

bit 0 is the low bit

bit 30 is the high bit

bit 31 is the sign bit

www. ptc.com

Page 24

Fanuc Focas Ethernet Driver

Address Descriptions

Address specifications may vary depending on the model in use. Select a link from the following list to obtain

specific address information for the model of interest.

Note: If the model of interest is listed as supported but is not selectable, use the Open model.

Series 15i

Series 16i

Series 18i

Series 21i

Power Mate i

Open

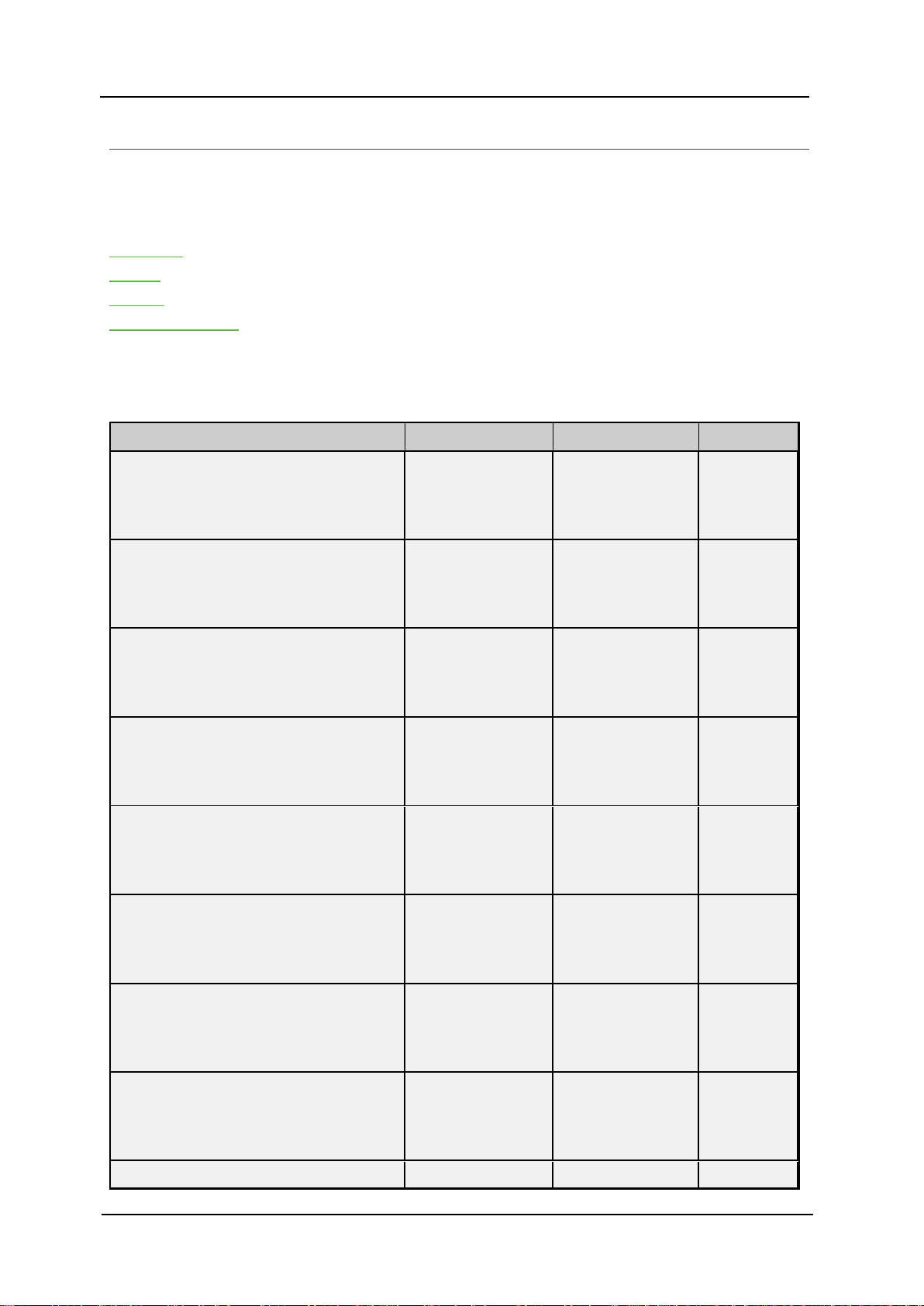

Series 15i

The following addresses are supported for this model. Not all address ranges may be valid for the particular

device being used. For more information,refer to the specific device's documentation. To jump to a specific

section, select a link from the list below.

24

CNC Data

Arrays

Strings

PMCData

The default data types for dynamically defined DDE tags are shown in bold.

Address Type Range Data Type Access

A (Message demand)

C(Counter)

D (Data table)

F(Signal to CNC->PMC)

G (Signal to PMC->CNC)

A00000-A00124

A00000-A00123

A00000-A00121

Axxxxx.0-Axxxxx.7

C00000-C00199

C00000-C00198

C00000-C00196

Cxxxxx.0-Cxxxxx.7

D00000-D09999

D00000-D09998

D00000-D09996

Dxxxxx.0-Dxxxxx.7

F00000-F00511

F00000-F00510

F00000-F00508

Fxxxxx.0-Fxxxxx.7

G00000-G00511

G00000-G00510

G00000-G00508

Gxxxxx.0-Gxxxxx.7

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Read/Write

Read/Write

Read/Write

Read Only

Read/Write

www. ptc.com

Page 25

25

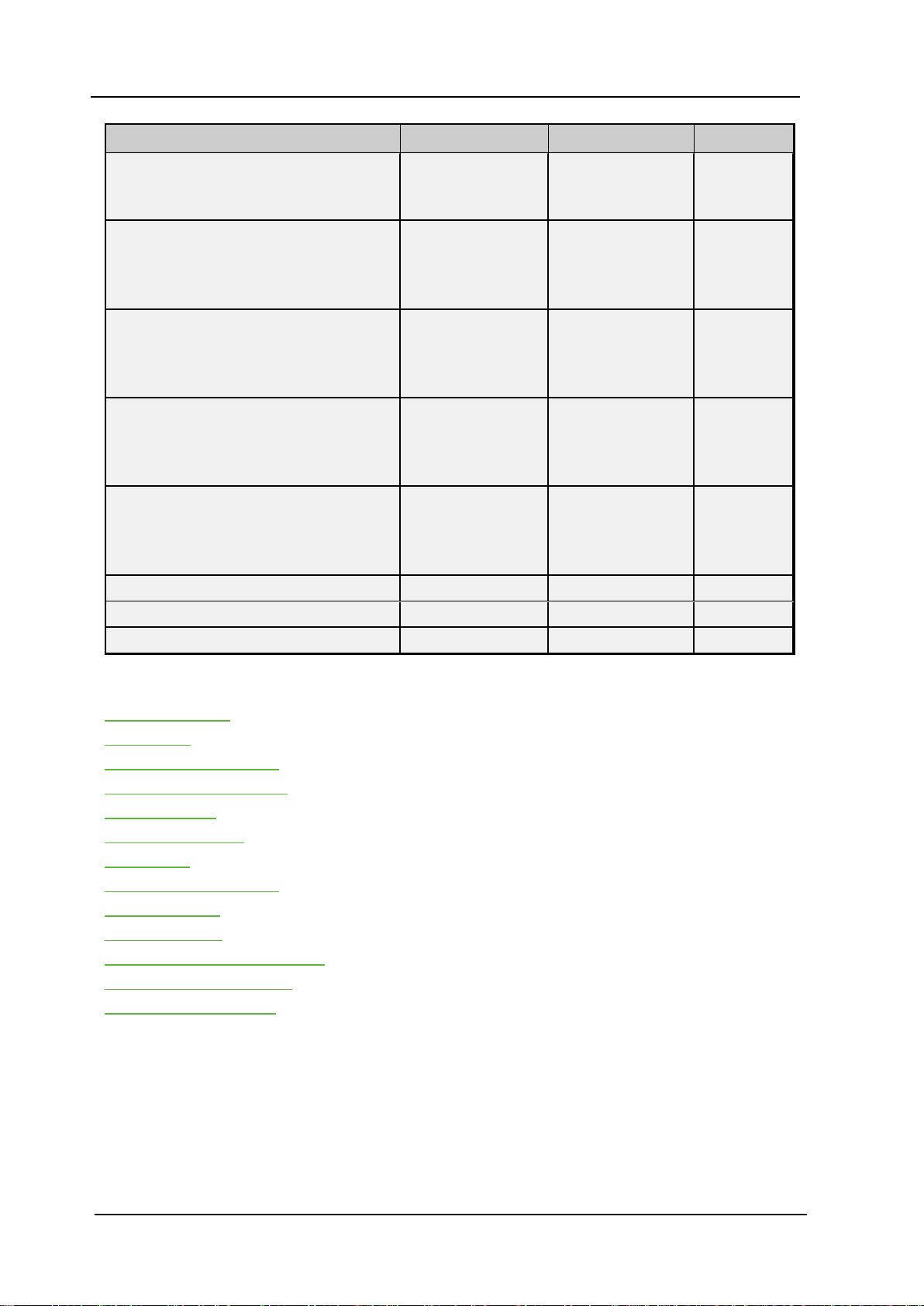

Fanuc FocasEthernet Driver

Address Type Range Data Type Access

K00000-K00909

K(Keep relay)

R(Internal relay)

T (Changeable timer)

X(Signal to machine->PMC)

Y(Signal to PMC->machine)

Custom Macro Value (common range) #0100-#0999 Float, Double Read/Write

Custom Macro Value (local range) #0001-#0033 Float, Double Read Only

Custom Macro Value (system range) #1000-#9999 Float, Double Read/Write

K00000-K00908

K00000-K00906

Kxxxxx.0-Kxxxxx.7

R00000-R09199

R00000-R09198

R00000-R09196

Rxxxxx.0-Rxxxxx.7

T00000-T00299

T00000-T00298

T00000-T00296

Txxxxx.0-Txxxxx.7

X00000-X00127

X00000-X00126

X00000-X00124

Xxxxxx.0-Xxxxxx.7

Y00000-Y00127

Y00000-Y00126

Y00000-Y00124

Yxxxxx.0-Yxxxxx.7

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Read/Write

Read/Write

Read/Write

Read Only

Read/Write

CNC Data

Status Info Tags

Tool Offset

Workpiece Zero Offset

Parameter Read Values

Alarms Values

Diagnostic Values

Path Value

Read Axis Data Values

Program Value

Program Name

Read Dynamic2 Data Values

Read Timer Data Values

Read Alarm Messages

Arrays

Arrays are supported for all PMC addresses,except for Custom Macros in the system range and where

Boolean or string data types are used.Tool Offset data cannot be addressed as an array. The syntax for

declaring an array is as follows:

Mxxxx[cols]with assumed row count of 1.

www. ptc.com

Page 26

Fanuc Focas Ethernet Driver

Mxxxxx[rows][cols] where M is the address type and xxxxx is the byte offset of the first element in the array.

Note:For all arrays, the total number of bytes being requested cannot exceed the specified request size.

Strings

All address types can be read and written to as ASCIIstrings. Each byte of memory contains one ASCIIcharacter.The length of strings can range from 1 to 120 and is entered in place of the bit number. An additional

character "M" is appended to the address to distinguish string addresses from bit addresses.

Example

To address a string of length 100 characters, starting at D00200, enter: D00200.100 M.

Note:Use caution when modifying Word,Short, DWord, Long, and Float types. Since all addresses start at

a byte offset within the device, it is possible for the memory associated with tags to overlap. For example,

word tags D00000 and D00001 overlap at byte 1. Writing to D00000 also modifies the value held in D00001.

It is recommended that these memory types be used such that each value to be read and written to by the

driver occupy a unique range of memory in the device. For example, map 3 Word values to bytes D00000D00001, D00002-D00003, and D00004-D00005.Tags to access these values would then have addresses

D00000, D00002,and D00004 respectively, and a data type of Word.

26

Series 16i

The following addresses are supported for this model. Not all address ranges may be valid for the particular

device being used. For more information,refer to the specific device's documentation. To jump to a specific

section, select a link from the list below.

CNC Data

Arrays

Strings

Unsolicited Data

PMCData

The default data types for dynamically defined DDE tags are shown in bold.

Address Type Range Data Type Access

A (Message demand)

C(Counter)

D (Data table)

E(Extended relay)

A00000-A00124

A00000-A00123

A00000-A00121

Axxxxx.0-Axxxxx.7

C00000-C00199

C00000-C00198

C00000-C00196

Cxxxxx.0-Cxxxxx.7

D00000-D09999

D00000-D09998

D00000-D09996

Dxxxxx.0-Dxxxxx.7

E00000-E07999

E00000-E07998

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

Read/Write

Read/Write

Read/Write

Read/Write

www. ptc.com

Page 27

27

Fanuc FocasEthernet Driver

Address Type Range Data Type Access

E00000-E07996

Exxxxx.0-Exxxxx.7

F00000-F02511

F(Signal to CNC->PMC)

G (Signal to PMC->CNC)

K(Keep relay)

M (Input signal from other devices)

N (Output signal from other devices)

R(Internal relay)

T (Changeable timer)

X(Signal to machine->PMC)

Y(Signal to PMC->machine)

Custom Macro Value (common range) #0100-#0999 Float,Double Read/Write

Custom Macro Value (local range) #0001-#0033 Float, Double Read Only

Custom Macro Value (system range) #1000-#9999 Float,Double Read/Write

F00000-F02510

F00000-F02508

Fxxxxx.0-Fxxxxx.7

G00000-G02511

G00000-G02510

G00000-G02508

Gxxxxx.0-Gxxxxx.7

K00000-K00909

K00000-K00908

K00000-K00906

Kxxxxx.0-Kxxxxx.7

M00000-M00511

M00000-M00510

M00000-M00508

Mxxxxx.0-Mxxxxx.7

N00000-N00511

N00000-N00510

N00000-N00508

Nxxxxx.0-Nxxxxx.7

R00000-R09119

R00000-R09118

R00000-R09116

Rxxxxx.0-Rxxxxx.7

T00000-T00299

T00000-T00298

T00000-T00296

Txxxxx.0-Txxxxx.7

X00000-X00127

X00000-X00126

X00000-X00124

Xxxxxx.0-Xxxxxx.7

Y00000-Y00127

Y00000-Y00126

Y00000-Y00124

Yxxxxx.0-Yxxxxx.7

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Read Only

Read/Write

Read/Write

Read Only

Read/Write

Read/Write

Read/Write

Read Only

Read/Write

CNC Data

Status Info Tags

Tool Offset

Workpiece Zero Offset

www. ptc.com

Page 28

Fanuc Focas Ethernet Driver

Parameter Read Values

Alarms Values

Diagnostic Values

Path Value

Read Axis Data Values

Program Value

Program Name

Read Dynamic2 Data Values

Read Timer Data Values

Read Alarm Messages

Arrays

Arrays are supported for all PMC addresses,except for Custom Macros in the system range and where

Boolean or string data types are used.Tool Offset data cannot be addressed as an array. The syntax for

declaring an array is as follows:

Mxxxxx[cols]with assumed row count of 1.

Mxxxxx[rows][cols] where M is the address type and xxxxx is the byte offset of the first element in the array.

28

Note:For all arrays, the total number of bytes being requested cannot exceed the specified request size.

Strings

All address types can be read and written to as ASCIIstrings. Each byte of memory contains one ASCIIcharacter.The length of strings can range from 1 to 120 and is entered in place of the bit number. An additional

character "M" is appended to the address to distinguish string addresses from bit addresses.

Example

To address a string of length 100 characters, starting at D00200, enter D00200.100 M.

Unsolicited Data

If tags belong to a Fanuc Focus Server device, then their address types and ranges are validated according

to the data areas configured for that device) For example, if the Fanuc Focus Server device is configured with

a single area with D01000 to D01100, then a tag with address D01000 would be valid, but tags with

addresses D01101 or C00001 would be invalid. All tags belonging to a Fanuc Focus Server device are Read

Only.

See Also: Unsolicited Data Areas

Note:Use caution when modifying Word,Short, DWord, Long, and Float types. Since all addresses start at

a byte offset within the device, it is possible for the memory associated with tags to overlap. For example,

word tags D00000 and D00001 overlap at byte 1. Writing to D00000 also modifies the value held in D00001.

It is recommended that these memory types be used such that each value to be read and written to by the

driver occupy a unique range of memory in the device. For example, map 3 Word values to bytes D00000D00001, D00002-D00003, and D00004-D00005.Tags to access these values would then have addresses

D00000, D00002,and D00004 respectively, and a data type of Word.

www. ptc.com

Page 29

29

Fanuc FocasEthernet Driver

Series 18i

The following addresses are supported for this model. Not all address ranges may be valid for the particular

device being used. For more information,refer to the specific device's documentation. To jump to a specific

section, select a link from the list below.

CNC Data

Arrays

Strings

Unsolicited Data

PMCData

The default data types for dynamically defined DDE tags are shown in bold.

Address Type Range Data Type Access

A (Message demand)

C(Counter)

D (Data table)

E(Extended relay)

F(Signal to CNC->PMC)

G (Signal to PMC->CNC)

K(Keep relay)

M (Input signal from other devices)

N (Output signal from other devices)

A00000-A00124

A00000-A00123

A00000-A00121

Axxxxx.0-Axxxxx.7

C00000-C00199

C00000-C00198

C00000-C00196

Cxxxxx.0-Cxxxxx.7

D00000-D09999

D00000-D09998

D00000-D09996

Dxxxxx.0-Dxxxxx.7

E00000-E07999

E00000-E07998

E00000-E07996

Exxxxx.0-Exxxxx.7

F00000-F02511

F00000-F02510

F00000-F02508

Fxxxxx.0-Fxxxxx.7

G00000-G02511

G00000-G02510

G00000-G02508

Gxxxxx.0-Gxxxxx.7

K00000-K00909

K00000-K00908

K00000-K00906

Kxxxxx.0-Kxxxxx.7

M00000-M00511

M00000-M00510

M00000-M00508

Mxxxxx.0-Mxxxxx.7

N00000-N00511 Byte, Char

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Read/Write

Read/Write

Read/Write

Read/Write

Read Only

Read/Write

Read/Write

Read Only

Read/Write

www. ptc.com

Page 30

Fanuc Focas Ethernet Driver

Address Type Range Data Type Access

30

N00000-N00510

N00000-N00508

Nxxxxx.0-Nxxxxx.7

R00000-R09119

R(Internal relay)

T (Changeable timer)

X(Signal to machine->PMC)

Y(Signal to PMC->machine)

Custom Macro Value (common range) #0100-#0999 Float,Double Read/Write

Custom Macro Value (local range) #0001-#0033 Float, Double Read Only

Custom Macro Value (system range) #1000-#9999 Float,Double Read/Write

R00000-R09118

R00000-R09116

Rxxxxx.0-Rxxxxx.7

T00000-T00299

T00000-T00298

T00000-T00296

Txxxxx.0-Txxxxx.7

X00000-X00127

X00000-X00126

X00000-X00124

Xxxxxx.0-Xxxxxx.7

Y00000-Y00127

Y00000-Y00126

Y00000-Y00124

Yxxxxx.0-Yxxxxx.7

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Read/Write

Read/Write

Read Only

Read/Write

CNC Data

Status Info Tags

Tool Offset

Workpiece Zero Offset

Parameter Read Values

Alarms Values

Diagnostic Values

Path Value

Read Axis Data Values

Program Value

Program Name

Read Dynamic2 Data Values

Read Timer Data Values

Read Alarm Messages

Arrays

Arrays are supported for all PMC addresses,except for Custom Macros in the system range and where

Boolean or string data types are used.Tool Offset data cannot be addressed as an array. The syntax for

declaring an array is as follows:

Mxxxxx[cols]with assumed row count of 1.

Mxxxxx[rows][cols] where M is the address type and xxxxx is the byte offset of the first element in the array.

www. ptc.com

Page 31

31

Note:For all arrays, the total number of bytes being requested cannot exceed the specified request size.

Fanuc FocasEthernet Driver

Strings

All address types can be read and written to as ASCIIstrings. Each byte of memory contains one ASCIIcharacter.The length of strings can range from 1 to 120 and is entered in place of the bit number. An additional

character "M" is appended to the address to distinguish string addresses from bit addresses.

Example

To address a string of length 100 characters, starting at D00200, enter D00200.100 M.

Unsolicited Data

If tags belong to a Fanuc Focas server device, then their address types and ranges are validated according

to the data areas configured for that device. For example, if the Fanuc Focas server device is configured with

a single area with D01000 to D01100, then a tag with address D01000 would be valid, but tags with

addresses D01101 or C00001 would be invalid. All tags belonging to a Fanuc Focas server device are Read

Only.

See Also: Unsolicited Data Areas

Note:Use caution when modifying Word,Short, DWord, Long, and Float types. Since all addresses start at

a byte offset within the device, it is possible for the memory associated with tags to overlap. For example,

word tags D00000 and D00001 overlap at byte 1. Writing to D00000 also modifies the value held in D00001.

It is recommended that these memory types be used such that each value to be read and written to by the

driver occupy a unique range of memory in the device. For example, map 3 Word values to bytes D00000D00001, D00002-D00003, and D00004-D00005.Tags to access these values would then have addresses

D00000, D00002,and D00004 respectively, and a data type of Word.

Series 21i

The following addresses are supported for this model. Not all address ranges may be valid for the particular

device being used. For more information,refer to the specific device's documentation. To jump to a specific

section, select a link from the list below.

CNC Data

Arrays

Strings

Unsolicited Data

PMCData

The default data types for dynamically defined DDE tags are shown in bold.

Address Type Range Data Type Access

A (Message demand)

C(Counter)

A00000-A00124

A00000-A00123

A00000-A00121

Axxxxx.0-Axxxxx.7

C00000-C00199

C00000-C00198

C00000-C00196

www. ptc.com

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Read/Write

Read/Write

Page 32

Fanuc Focas Ethernet Driver

Address Type Range Data Type Access

Cxxxxx.0-Cxxxxx.7 Boolean

D00000-D09999

D (Data table)

E(Extended relay)

F(Signal to CNC->PMC)

G (Signal to PMC->CNC)

K(Keep relay)

M (Input signal from other devices)

N (Output signal from other devices)

R(Internal relay)

T (Changeable timer)

X(Signal to machine->PMC)

Y(Signal to PMC->machine)

Custom Macro Value (common range) #0100-#0999 Float,Double Read/Write

D00000-D09998

D00000-D09996

Dxxxxx.0-Dxxxxx.7

E00000-E07999

E00000-E07998

E00000-E07996

Exxxxx.0-Exxxxx.7

F00000-F02511

F00000-F02510

F00000-F02508

Fxxxxx.0-Fxxxxx.7

G00000-G02511

G00000-G02510

G00000-G02508

Gxxxxx.0-Gxxxxx.7

K00000-K00909

K00000-K00908

K00000-K00906

Kxxxxx.0-Kxxxxx.7

M00000-M00511

M00000-M00510

M00000-M00508

Mxxxxx.0-Mxxxxx.7

N00000-N00511

N00000-N00510

N00000-N00508

Nxxxxx.0-Nxxxxx.7

R00000-R09119

R00000-R09118

R00000-R09116

Rxxxxx.0-Rxxxxx.7

T00000-T00299

T00000-T00298

T00000-T00296

Txxxxx.0-Txxxxx.7

X00000-X00127

X00000-X00126

X00000-X00124

Xxxxxx.0-Xxxxxx.7

Y00000-Y00127

Y00000-Y00126

Y00000-Y00124

Yxxxxx.0-Yxxxxx.7

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Read/Write

Read/Write

Read Only

Read/Write

Read/Write

Read Only

Read/Write

Read/Write

Read/Write

Read Only

Read/Write

32

www. ptc.com

Page 33

33

Fanuc FocasEthernet Driver

Address Type Range Data Type Access

Custom Macro Value (local range) #0001-#0033 Float, Double Read Only

Custom Macro Value (system range) #1000-#9999 Float,Double Read/Write

CNC Data

Status Info Tags

Tool Offset

Workpiece Zero Offset

Parameter Read Values

Alarms Values

Diagnostic Values

Path Value

Read Axis Data Values

Program Value

Program Name

Read Dynamic2 Data Values

Read Timer Data Values

Read Alarm Messages

Arrays

Arrays are supported for all PMC addresses,except for Custom Macros in the system range and where

Boolean or string data types are used.Tool Offset data cannot be addressed as an array. The syntax for

declaring an array is as follows:

Mxxxxx[cols]with assumed row count of 1.

Mxxxxx[rows][cols] where M is the address type and xxxxx is the byte offset of the first element in the array.

Note:For all arrays, the total number of bytes being requested cannot exceed the specified request size.

Strings

All address types can be read and written to as ASCIIstrings. Each byte of memory contains one ASCIIcharacter.The length of strings can range from 1 to 120 and is entered in place of the bit number. An additional

character "M" is appended to the address to distinguish string addresses from bit addresses.

Example

To address a string of length 100 characters, starting at D00200, enter D00200.100 M.

Unsolicited Data

If tags belong to a Fanuc Focas server device, then their address types and ranges are validated according

to the data areas configured for that device. For example, if the Fanuc Focas server device is configured with

a single area with D01000 to D01100, then a tag with address D01000 would be valid, but tags with

addresses D01101 or C00001 would be invalid. All tags belonging to a Fanuc Focas server device are Read

Only.

See Also: Unsolicited Data Areas

www. ptc.com

Page 34

Fanuc Focas Ethernet Driver

Note:Use caution when modifying Word,Short, DWord, Long, and Float types. Since all addresses start at

a byte offset within the device, it is possible for the memory associated with tags to overlap. For example,

word tags D00000 and D00001 overlap at byte 1. Writing to D00000 also modifies the value held in D00001.

It is recommended that these memory types be used such that each value to be read and written to by the

driver occupy a unique range of memory in the device. For example, map 3 Word values to bytes D00000D00001, D00002-D00003, and D00004-D00005.Tags to access these values would then have addresses

D00000, D00002,and D00004 respectively, and a data type of Word.

Power Mate i

The following addresses are supported for this model. Not all address ranges may be valid for the particular

device being used. For more information, refer to thespecific device's documentation. To jump to a specific sec-

tion, select a link from the list below.

CNC Data

Arrays

Strings

PMCData

The default data types for dynamically defined DDE tags are shown in bold.

34

Address Type Range Data Type Access

A (Message demand)

C(Counter)

D (Data table)

E(Extended relay)

F(Signal to CNC->PMC)

G (Signal to PMC->CNC)

K(Keep relay)

A00000-A00124

A00000-A00123

A00000-A00121

Axxxxx.0-Axxxxx.7

C00000-C00199

C00000-C00198

C00000-C00196

Cxxxxx.0-Cxxxxx.7

D00000-D09999

D00000-D09998

D00000-D09996

Dxxxxx.0-Dxxxxx.7

E00000-E07999

E00000-E07998

E00000-E07996

Exxxxx.0-Exxxxx.7

F00000-F02511

F00000-F02510

F00000-F02508

Fxxxxx.0-Fxxxxx.7

G00000-G02511

G00000-G02510

G00000-G02508

Gxxxxx.0-Gxxxxx.7

K00000-K00909

K00000-K00908

K00000-K00906

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Boolean

Byte,Char

Word, Short

DWord, Long, Float

Read/Write

Read/Write

Read/Write

Read/Write

Read Only

Read/Write

Read/Write

www. ptc.com

Page 35

35

Fanuc FocasEthernet Driver

Address Type Range Data Type Access

Kxxxxx.0-Kxxxxx.7 Boolean

M00000-M00511

M (Input signal from other devices)

N (Output signal from other devices)

R(Internal relay)

T (Changeable timer)

X(Signal to machine->PMC)

Y(Signal to PMC->machine)

Custom Macro Value (common range) #0100-#0999 Float,Double Read/Write

Custom Macro Value (local range) #0001-#0033 Float, Double Read Only

Custom Macro Value (system range) #1000-#9999 Float,Double Read/Write

M00000-M00510

M00000-M00508

Mxxxxx.0-Mxxxxx.7

N00000-N00511

N00000-N00510

N00000-N00508

Nxxxxx.0-Nxxxxx.7

R00000-R09119

R00000-R09118

R00000-R09116

Rxxxxx.0-Rxxxxx.7

T00000-T00299

T00000-T00298

T00000-T00296

Txxxxx.0-Txxxxx.7

X00000-X00127

X00000-X00126

X00000-X00124

Xxxxxx.0-Xxxxxx.7

Y00000-Y00127