GE Fanuc Automation

Computer Numerical Control Products

Laser C1000 / C2000 / C4000―Model E

for CE Mark

Maintenance Manual

GFZ-70315EN/01 May 2001

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2001 GE Fanuc Automation North America, Inc.

All Rights Reserved.

B-70315EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

1111 OVERVIEW

OVERVIEW................................

OVERVIEWOVERVIEW

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................

................................................................

......... 1111

..................

1.1

1.2

1.3

1.4

2222 SAFETY

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

ORGANIZATION OF THE MANUAL ............................................................................................. 2

APPLICABLE MODELS................................................................................................................... 3

RELATED MANUALS...................................................................................................................... 4

TO USE THE LASER OSCILLATOR SAFETY .............................................................................. 5

SAFETY ................................

SAFETYSAFETY

................................................................

................................................................

LASER BEAM ................................................................................................................................... 7

HIGH VOLTAGE............................................................................................................................. 12

SAFETY ENCLOSURE (AT YOUR WORK STATION) ............................................................... 16

FIRE ................................................................................................................................................. 17

TOXIC FUME.................................................................................................................................. 18

HIGH TEMPERATURE.................................................................................................................. 19

WARNING LABELS ....................................................................................................................... 23

HIGH-PRESSURE GAS.................................................................................................................. 34

KEY CONTROL............................................................................................................................... 35

SHUTTER LOCK ............................................................................................................................ 36

EMERGENCY STOP BUTTON ..................................................................................................... 37

................................................................

................................................................

................................................................

................................................................

..............................................

................................................................

.............. 6666

............................

2.12

3333 INTERNAL STRUCTURE

3.1

3.2

4444 INSTALLATION

4.1

4.2

WARNING LIGHT (OPTIONAL)................................................................................................... 38

INTERNAL STRUCTURE................................

INTERNAL STRUCTUREINTERNAL STRUCTURE

GENERAL ....................................................................................................................................... 40

COMPONENT DETAILS................................................................................................................ 44

INSTALLATION ................................

INSTALLATIONINSTALLATION

INSTALLATION PROCEDURE .................................................................................................... 53

PREPARATION PRIOR TO SHIPMENT ...................................................................................... 62

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...............................................................

................................................................

................................................

................................................................

............................... 52

..............................................................

................ 39

................................

4.2.1 Packing for Transportation ..................................................................................................... 63

4.2.2 Removing Cooling Water......................................................................................................... 64

4.3

4.4

DETAILS OF CHECKING .............................................................................................................66

OSCILLATOR CONNECTIONS .................................................................................................... 73

4.4.1 Cooling Water .......................................................................................................................... 73

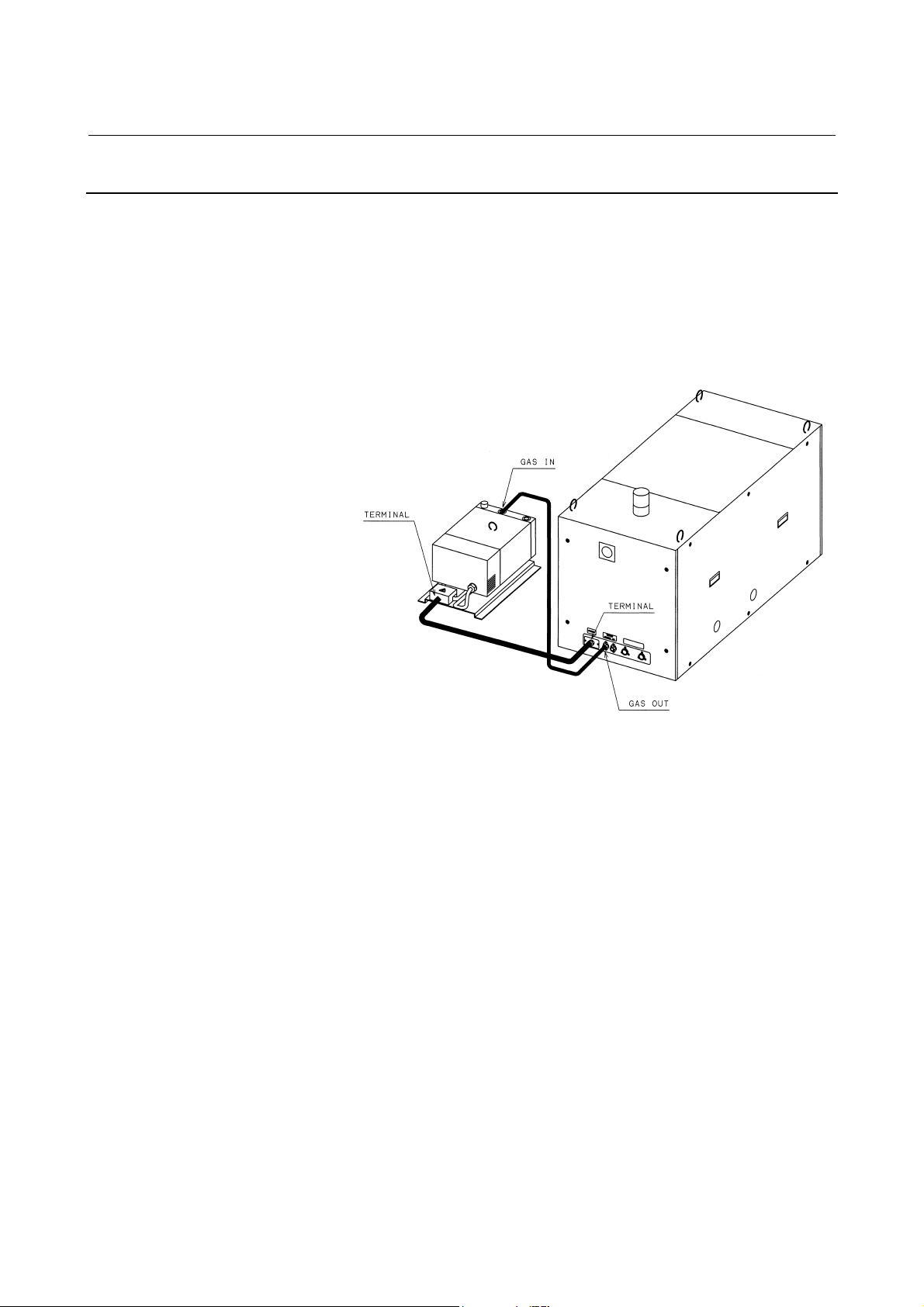

4.4.2 Laser Gas.................................................................................................................................. 77

4.4.3 Electrical Connection............................................................................................................... 78

4.4.4 Inter-unit Connections ............................................................................................................ 85

39

3939

52

5252

c - 1

TABLE OF CONTENTS B-70315EN/01

5555 MAINTENANCE

MAINTENANCE ................................

MAINTENANCEMAINTENANCE

................................................................

................................................................

................................................................

................................................................

..............................................................

................................................................

.............................. 86

............................................................

86

8686

5.1

5.2

5.3

DAILY INSPECTION ..................................................................................................................... 87

PERIODIC MAINTENANCE ......................................................................................................... 88

DETAILS OF MAINTENANCE ..................................................................................................... 89

5.3.1 Turbo Blower Oil...................................................................................................................... 91

5.3.2 Exhaust Pump Oil ................................................................................................................... 93

5.3.3 Exhaust Pump Filter ............................................................................................................... 94

5.4

6666 TROUBLESHOOTING

6.1

6.2

6.3

6.4

MAINTENANCE PARTS................................................................................................................ 95

TROUBLESHOOTING ................................

TROUBLESHOOTINGTROUBLESHOOTING

TROUBLESHOOTING PROCEDURE ........................................................................................ 100

ERROR MESSAGES AND COUNTERMEASURES .................................................................. 101

RESPONDING TO ALARM MESSAGES ON THE SCREEN ................................................... 102

MAJOR FAULTS........................................................................................................................... 128

................................................................

................................................................

................................................................

................................................................

.....................................................

................................................................

..................... 99

..........................................

6.4.1 Laser Power Supply Alarm Display ..................................................................................... 128

6.4.2 Power Supply Cannot Be Switched Off Using CRT/MDI Switch ....................................... 129

6.4.3 Power Supply Cannot Be Switched On Using CRT/MDI Switch........................................ 129

6.4.4 Laser Output Just After Switch On Is Low ......................................................................... 129

99

9999

6.4.5 Display of Fluctuating Laser Output On CRT..................................................................... 129

6.4.6 Electromagnetic Contactor of Exhaust Pump Trips Thermally ......................................... 130

6.4.7 Main Breaker Trips ............................................................................................................... 130

6.4.8 Excessive Laser Gas Consumption ....................................................................................... 131

6.4.9 Inverter Alarm Display ......................................................................................................... 131

6.5

OBSERVING VOLTAGE OF POWER LINE .............................................................................. 135

6.5.1 Measurement of Voltage........................................................................................................ 135

6.5.2 Phase Relation ....................................................................................................................... 135

6.5.3 Measurement of Voltage of DC Power Supply Unit ............................................................ 135

6.5.4 Checking the IF PCB Signals................................................................................................ 137

6.5.5 Checking the Jumper Pins .................................................................................................... 137

6.6

INDICATION OF STATE BY MEANS OF SELF DIAGNOSTIC FUNCTION ........................ 138

6.6.1 Data Items Displayed on the Diagnosis Screen................................................................... 138

6.6.2 Laser Oscillator Status Display ............................................................................................ 139

7777 OSCILLATOR CONNECTIONS

OSCILLATOR CONNECTIONS ................................

OSCILLATOR CONNECTIONSOSCILLATOR CONNECTIONS

7.1

ELECTRICAL CONNECTIONS .................................................................................................. 148

................................................................

................................................................

................................................................

................................................................

....................................

................................................................

.... 147

147

........

147147

7.2

7.3

COOLING WATER PIPING ......................................................................................................... 151

GAS PIPING.................................................................................................................................. 154

c - 2

B-70315EN/01 TABLE OF CONTENTS

8888 UNIT CONFIGURATION

UNIT CONFIGURATION ................................

UNIT CONFIGURATIONUNIT CONFIGURATION

................................................................

................................................................

................................................................

................................................................

..............................................

................................................................

.............. 158

............................

158

158158

8.1

8.2

8.3

8.4

9999 SETTING AND ADJUSTMENT

9.1

INPUT UNIT ................................................................................................................................. 159

INTERMEDIATE PCB B.............................................................................................................. 164

GAS CONTROLLER (C1000-E).................................................................................................... 165

PRESSURE CONTROL UNIT ..................................................................................................... 168

SETTING AND ADJUSTMENT ................................

SETTING AND ADJUSTMENTSETTING AND ADJUSTMENT

LASER POWER SUPPLY UNIT .................................................................................................. 171

................................................................

................................................................

................................................................

................................................................

....................................

................................................................

9.1.1 Preparatory Settings and Checks ......................................................................................... 171

9.1.2 Base Discharge Adjustment .................................................................................................. 172

9.1.3 Maximum Output Adjustment.............................................................................................. 173

9.1.4 Check ...................................................................................................................................... 173

9.1.5 RFI and DCV Value Recording and Adjustment ................................................................. 174

9.1.6 Alarm Processing after Modification of Intra-tube Pressure at Oscillation Time and

Bias Command Setting.......................................................................................................... 174

9.1.7 Checking of Electric Shutter Operation ............................................................................... 175

9.1.8 Alarm Level of Laser PSU..................................................................................................... 176

9.2

TURBO PCB .................................................................................................................................. 177

.... 170

170

........

170170

9.3

INVERTER .................................................................................................................................... 179

9.3.1 Adjusting the Inverter (A90L-0001-0500/8LF : Model Name SJH300).............................. 179

9.3.2 Adjusting the Inverter (A90L-0001-0464/CE, Model Name : JH300) ................................ 189

9.4

GAS CONTROLLER ..................................................................................................................... 195

9.4.1 Setting the Gas Supply Pressure Sensor ............................................................................. 195

9.4.2 Setting the Atmospheric Pressure Sensor............................................................................ 195

9.4.3 Adjusting the Exhaust Unit (Adjusting the Laser Gas Consumption) .............................. 197

9.5

SETTING THE GAS SUPPLY PRESSURE SENSOR AND ATMOSPHERIC PRESSURE

SENSOR......................................................................................................................................... 199

9.5.1 Names of Components ........................................................................................................... 199

9.5.2 Setting Procedure .................................................................................................................. 201

9.6

PRESSURE CONTROL UNIT ..................................................................................................... 204

9.6.1 Setting the Gas Supply Pressure Sensor ............................................................................. 204

9.6.2 Setting the Atmospheric Pressure Sensor............................................................................ 205

9.7

9.8

ADJUSTING THE EXHAUST CONTROL UNIT

(ADJUSTING THE LASER GAS CONSUMPTION) .................................................................. 206

SETTING THE POWER INPUT COMPENSATION COEFFICIENT ...................................... 207

9.9

WATER FLOW SENSOR.............................................................................................................. 208

9.9.1 Adjusting the Water Flow Sensor (C1000-E) ....................................................................... 208

c - 3

TABLE OF CONTENTS B-70315EN/01

9.9.2 Adjusting the Flow Sensor (C2000-E, C4000-E).................................................................. 210

9.10

10

10 REPLACEMENT PROCEDURES

1010

10.1

DISCHARGE AGING.................................................................................................................... 211

REPLACEMENT PROCEDURES ................................

REPLACEMENT PROCEDURESREPLACEMENT PROCEDURES

INPUT UNIT ................................................................................................................................. 217

................................................................

................................................................

..............................................................

................................................................

.............................. 216

............................................................

10.1.1 Replacing the Stabilized Power Supply................................................................................ 217

10.1.2 Replacing the Input Unit Control PCB ................................................................................ 217

10.1.3 Replacing the IF PCB on the Oscillator Side ....................................................................... 218

10.2

10.3

10.4

10.5

10.6

10.7

10.8

REPLACING THE LASER POWER SUPPLY ............................................................................ 219

REPLACING THE MATCHING BOX ......................................................................................... 224

REPLACING THE TURBO BLOWER......................................................................................... 225

REPLACING THE TURBO PCB.................................................................................................. 227

REPLACING INTERMEDIATE PCB B ...................................................................................... 228

REPLACING THE EXHAUST PUMP ......................................................................................... 229

REPLACING THE PRESSURE CONTROL UNIT ..................................................................... 231

10.8.1 Gas Controller (C1000-E)...................................................................................................... 231

10.8.2 Pressure Control Unit (C2000-E, C4000-E) ......................................................................... 232

10.9

REPLACING THE EXHAUST CONTROL UNIT (C2000-E, C4000-E)..................................... 233

216

216216

10.10

10.11

REPLACING A DISCHARGE TUBE....................................................................................... 234

REPLACING A FAN UNIT ...................................................................................................... 236

10.11.1 Replacing a Fan Unit......................................................................................................... 236

10.11.2 Replacing a Fan-assisted Radiator ................................................................................... 237

10.11.3 Attaching and Detaching a Cable To and From the Terminal Block ............................. 238

10.12

10.13

REPLACING THE POWER SENSOR UNIT........................................................................... 239

REPLACING THE SHUTTER SECTION ............................................................................... 240

10.13.1 Replacing the Shutter Unit ............................................................................................... 241

10.13.2 Replacing the Shutter Mirror............................................................................................ 241

10.13.3 Replacing the Shutter Switch (Thermal and Photoelectric Switches) ........................... 241

10.14

10.15

10.16

10.17

10.18

10.19

REPLACING THE BEAM ABSORBER................................................................................... 242

REPLACING THE INVERTER................................................................................................ 243

REPLACING THE WATER DISTRIBUTION UNIT .............................................................. 244

REPLACING THE CONDENSATION SENSOR .................................................................... 248

REPLACING THE GUIDE LASER.......................................................................................... 249

REPLACING THE TRIGGER ELECTRODE .......................................................................... 250

11

11 LASER OPTICAL SYSTEM

1111

LASER OPTICAL SYSTEM................................

LASER OPTICAL SYSTEMLASER OPTICAL SYSTEM

11.1

CLEANING AND REPLACING THE OPTICAL PARTS ........................................................... 253

................................................................

................................................................

................................................................

................................................................

........................................

................................................................

11.1.1 Cleaning and Replacing the Output Mirror......................................................................... 254

c - 4

........ 252

252

................

252252

B-70315EN/01 TABLE OF CONTENTS

11.1.2 Cleaning and Replacing the Rear Mirror............................................................................. 257

11.1.3 Cleaning and Replacing the Folding Mirrors....................................................................... 260

11.1.4 Cleaning and Replacing the Zero-shift Mirror and Circular Polarization Mirror............. 263

11.2

ALIGNMENT OF THE RESONATOR......................................................................................... 265

11.2.1 Method of Obtaining a Maximum Power by Adjusting All Mirrors ................................... 269

11.2.2 Alignment Procedure during Installation after Transportation......................................... 271

11.2.3 Alignment Procedure at Mirror Cleaning Time................................................................... 272

11.2.4 Obtaining a Maximum Power ............................................................................................... 273

11.3

11.4

APPENDIX

APPENDIX

APPENDIXAPPENDIX

AAAA EXTERNAL VIEW OF LASER OSCILLATOR

BBBB SPECIFICATIONS

CCCC ERROR CODE LIST

DDDD PARAMTER LIST

D.1

ALIGNMENT OF THE GUIDE LASER ...................................................................................... 275

ALIGNMENT OF THE BEAM FOLDING UNIT........................................................................ 277

EXTERNAL VIEW OF LASER OSCILLATOR................................

EXTERNAL VIEW OF LASER OSCILLATOREXTERNAL VIEW OF LASER OSCILLATOR

SPECIFICATIONS ................................

SPECIFICATIONSSPECIFICATIONS

ERROR CODE LIST ................................

ERROR CODE LISTERROR CODE LIST

PARAMTER LIST ................................

PARAMTER LISTPARAMTER LIST

PARAMETERS FOR ENABLING/DISABLING VARIOUS FUNCTIONS ...............................288

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................................

................................................................

................................................................

................................................................

...........................................................

................................................................

..............................................

................................................................

.......................................................

................................................................

........................... 287

......................................................

.............. 281

............................

......................... 284

..................................................

....................... 285

..............................................

281

281281

284

284284

285

285285

287

287287

D.2

D.3

D.4

D.5

D.6

D.7

D.8

D.9

D.10

D.11

D.12

D.13

D.14

D.15

D.16

D.17

D.18

PARAMETERS FOR POWER SUPPLY SELECTION ............................................................... 295

PARAMETERS FOR CONTOURING CONDITIONS ................................................................ 296

PARAMETERS FOR EDGE MACHINING CONDITIONS ....................................................... 297

PARAMETERS FOR PIERCING CONDITIONS........................................................................ 299

PARAMETERS FOR POWER CONTROL................................................................................... 301

PARAMETERS FOR ASSIST GAS PRESSURE AND TIME SETTING................................... 304

PARAMETERS FOR LASER MAINTENANCE TIMING INDICATION FUNCTIONS.......... 307

PARAMETERS FOR THE OSCILLATOR................................................................................... 309

PARAMETERS FOR DISCHARGE ............................................................................................. 312

PARAMETERS FOR GAS CONTROL (1) ................................................................................... 313

PARAMETERS FOR HIGHLY REFLECTIVE MATERIAL ALARMS ..................................... 316

PARAMETERS FOR LASER POWER/VOLTAGE DROP.......................................................... 317

PARAMETERS FOR POWER TABLE SETTING ...................................................................... 318

AUTOMATIC AGING FUNCTION ............................................................................................. 320

POWER CONTROL (2) ................................................................................................................. 323

LASER GAS MIXER FUNCTION................................................................................................ 324

PARAMETERS FOR GAS PRESSURE CONTROL (2) .............................................................. 326

c - 5

TABLE OF CONTENTS B-70315EN/01

EEEE CONTROL SEQUENCES IN LASER OSCILLATOR

CONTROL SEQUENCES IN LASER OSCILLATOR ................................

CONTROL SEQUENCES IN LASER OSCILLATORCONTROL SEQUENCES IN LASER OSCILLATOR

................................................................

................................................................

...................................

................................................................

... 327

327

......

327327

E.1

E.2

E.3

E.4

FFFF REFIXING AND REPLACING GAS TUBE

GGGG REFIXING AND REPLACING WATER TUBE

HHHH GLOSSARY

OUTLINE OF LASER OSCILLATION SEQUENCES ............................................................... 328

INTRA-TUBE GAS PRESSURE CONTROL SEQUENCES ...................................................... 330

TUBE VOLTAGE CONTROL SEQUENCES .............................................................................. 332

OSCILLATION SEQUENCES FLOW CHART ........................................................................... 334

REFIXING AND REPLACING GAS TUBE................................

REFIXING AND REPLACING GAS TUBEREFIXING AND REPLACING GAS TUBE

REFIXING AND REPLACING WATER TUBE................................

REFIXING AND REPLACING WATER TUBEREFIXING AND REPLACING WATER TUBE

GLOSSARY ................................

GLOSSARYGLOSSARY

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...................................................

................................................................

.............................................

................................................................

.....................................

................................................................

................... 340

......................................

............. 342

..........................

..... 344

..........

340

340340

342

342342

344

344344

c - 6

B-70315EN/01 1.OVERVIEW

1 OVERVIEW

This manual describes the maintenance of the FANUC LASER

C1000/C2000/C4000-MODEL E, as well as the structure,

configuration, and operation of the laser oscillator. This manual is

aimed at those personnel responsible for laser oscillator maintenance.

- 1 -

1.OVERVIEW B-70315EN/01

1.1 ORGANIZATION OF THE MANUAL

This manual is organized as described below.

1. Overview

This chapter describes the organization of this manual,

applicable models, related manuals, and notes on reading this

manual.

2. Safety

This chapter describes the handling of lasers, and provides

warnings, cautions and notes on high voltages, high temperatures,

and toxicity. All users must read this chapter carefully to

ensure safety.

3. Internal Structure

This chapter describes the structure and operation of the laser

oscillator.

4. Installation

This chapter describes the installation and checking of the laser

oscillator.

5. Maintenance

This chapter provides information on when and how the

consumable parts of the laser oscillator must be replaced.

6. Troubleshooting

This chapter describes the actions to be applied in the event of a

fault occurring in the laser oscillator.

7. Oscillator Connections

This chapter describes the internal connections of the electrical

system, cooling system, and gas system.

8. Unit Configuration

This chapter describes the internal units of the laser oscillator.

9. Setting and Adjustment

This chapter describes how to set and adjust the controls of the

laser oscillator.

10. Replacement Procedures

This chapter describes how to replace the individual units and

parts of the laser oscillator.

11. Laser Optical System

This chapter describes how to clean, replace, and align the

optical components of the laser oscillator.

Appendix

1. Appearance of the Laser Oscillator

2. FANUC LASER C series Specifications

3. Error Code List

4. Parameters

5. Control Sequences in Laser Oscillator

6. Refixing and Replacing Gas Tube

7. Refixing and Replacing Water Tube

8. Glossary

- 2 -

B-70315EN/01 1.OVERVIEW

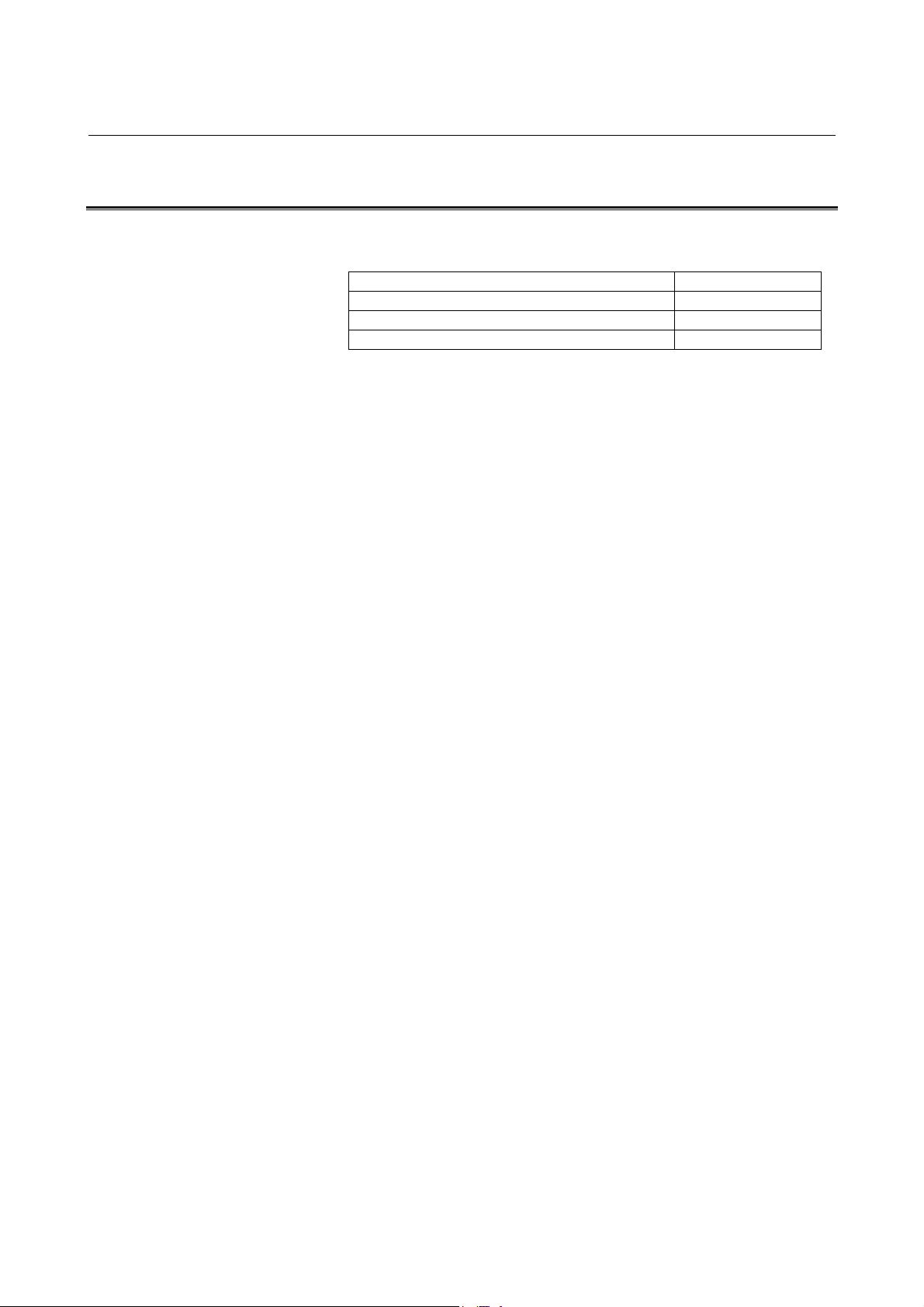

1.2 APPLICABLE MODELS

This manual covers the following models :

Model Abbreviation

FANUC LASER C1000-MODEL E C1000-E

FANUC LASER C2000-MODEL E C2000-E

FANUC LASER C4000-MODEL E C4000-E

- 3 -

1.OVERVIEW B-70315EN/01

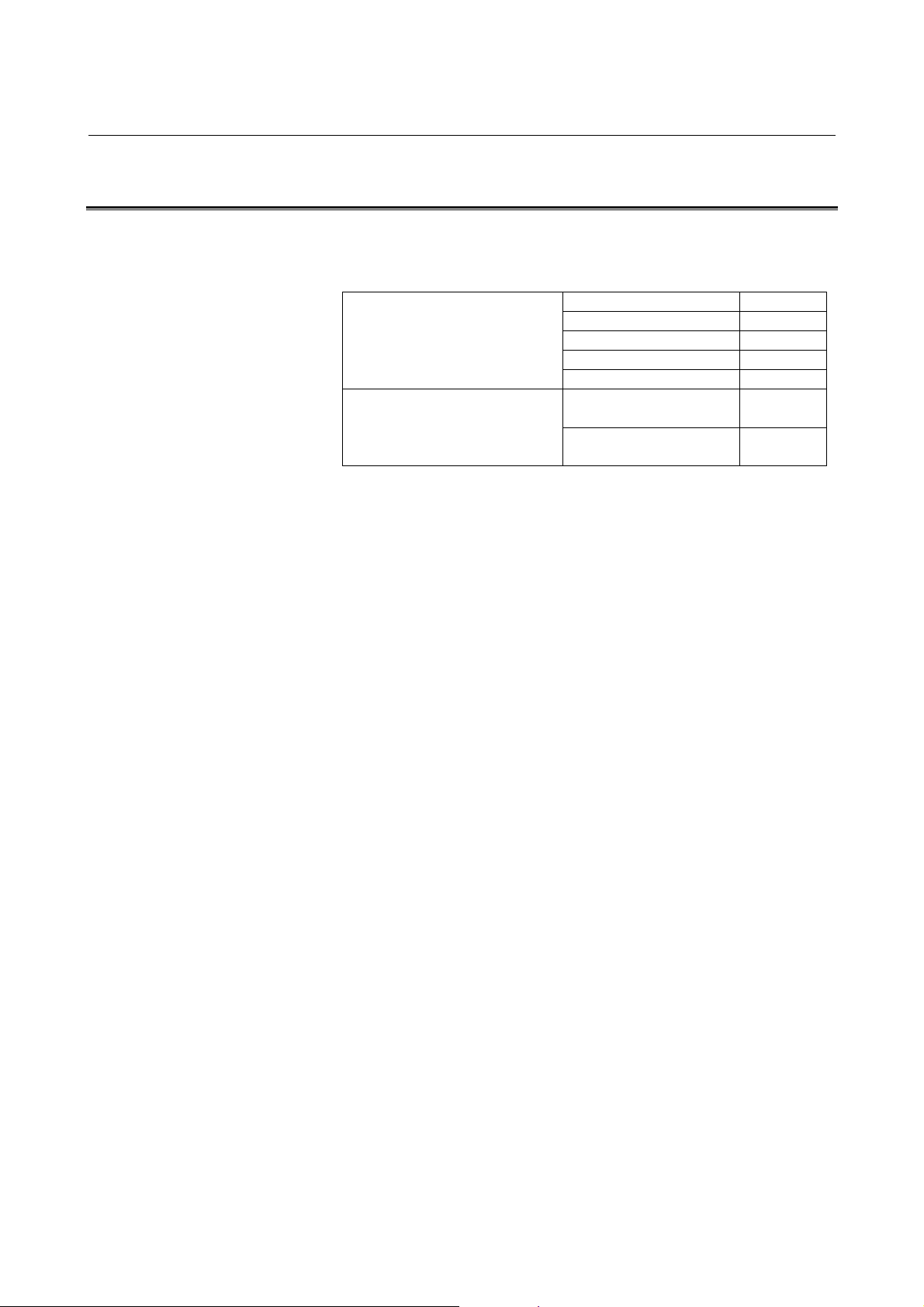

1.3 RELATED MANUALS

The following manuals are available for the FANUC LASER C1000/

C2000/C4000-MODEL E :

DESCRIPTIONS B-63192EN

CONNECTION MANUAL B-63193EN

FANUC Series 16i-LA

OPERATOR’S MANUAL B-63194EN

MAINTENANCE MANUAL B-63195EN

PARAMETER MANUAL B-63200EN

FANUC LASER

C1000/C2000/C4000-MODEL E

OPERATOR’S MANUAL B-70314EN

MAINTENANCE MANUAL

(This manual)

B-70315EN

- 4 -

B-70315EN/01 1.OVERVIEW

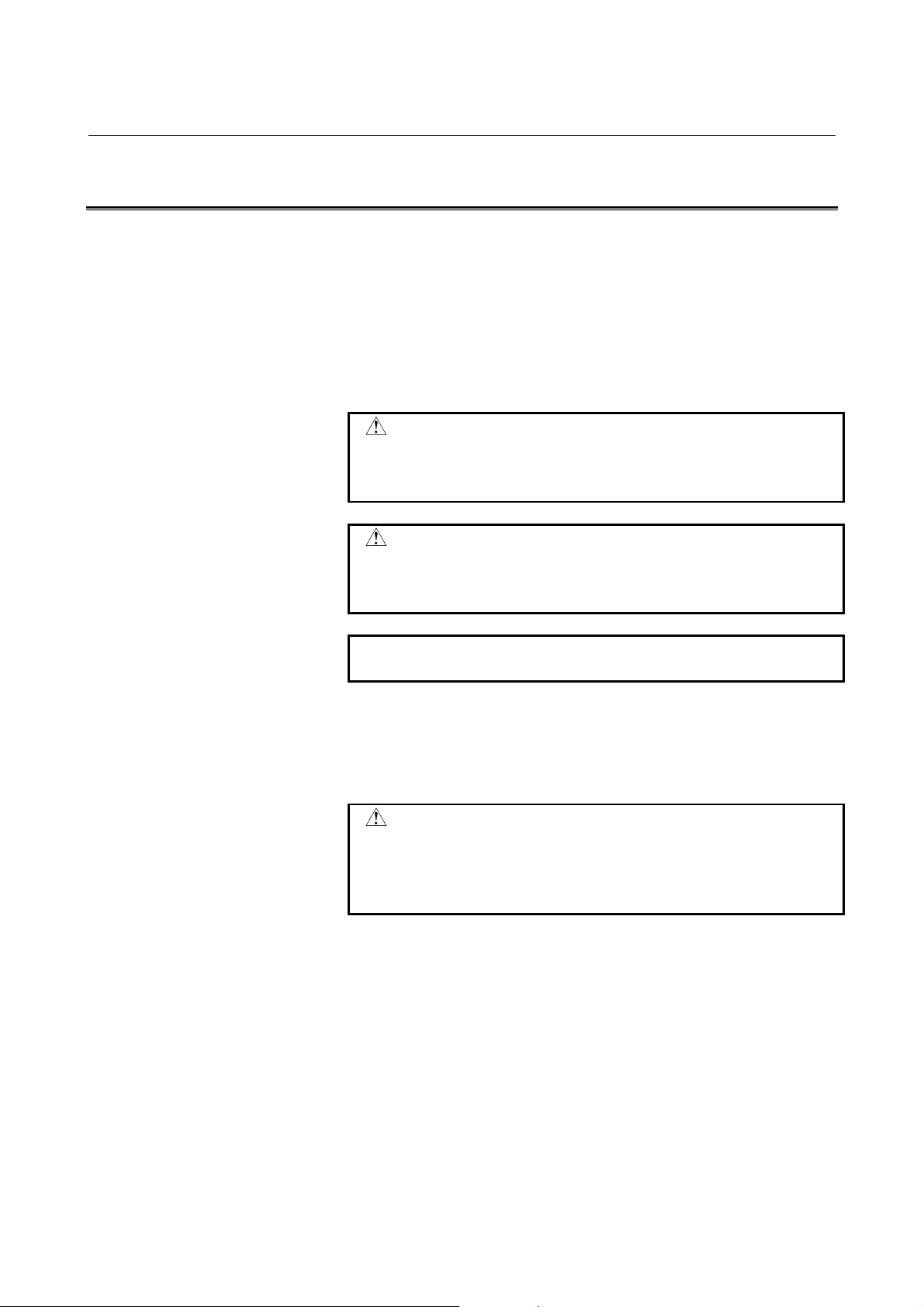

1.4 TO USE THE LASER OSCILLATOR SAFETY

In this manual, the words Warning and Caution, corresponding to

different levels of safety requirements, are provided to ensure the

user's safety and protect against damage to the laser oscillator.

Moreover, sections entitled Note are used to provide supplementary

information.

Before attempting to use the laser oscillator, read Section 2.1 to 2.11,

and also the descriptions in the Warnings, Cautions, and Notes that

appear in the text.

WARNING

Precautions to be applied in those situations where

there is a danger of the operator being killed or

seriously injured.

CAUTION

Precautions to be applied in those situations where

there is a danger of the operator being slightly

injured or the oscillator being damaged.

NOTE

Supplementary information other than precautions.

Before starting any maintenance work, take time to become familiar

with the functions of the individual units constituting the laser

oscillator, the relationships between the units, and the locations where

the units are installed.

WARNING

Never attempt handling, adjustment, or replacement

work using a method or procedure other than those

described and specified in this manual. Otherwise,

dangerous laser light may be emitted.

The function of the laser machining system depends not only on the

laser oscillator but also on other system components such as the

machine, power magnetics cabinet, servo system, CNC, and operator's

panel. This manual covers the laser oscillator only. For information

about equipment other than the laser oscillator, refer to the

appropriate manuals provided by the machine tool builder.

Take time to become familiar with the contents of this manual.

Store this manual in a safe place.

- 5 -

2.SAFETY B-70315EN/01

2 SAFETY

C1000-E, C2000-E, and C4000-E produce the rated output laser

power of 1000W, 2000W, and 4000W. The CO

wavelength of 10.6 µm, far infrared, and is invisible to human eyes.

The adequate care must be taken when CO

therefore. When removing the panel, always turn the power source off

and confirm no power is applied to the laser machine.

This oscillator fulfills the requirements of the relevant product safety

standard of EN60825-1:1994.

laser beam is the

2

laser is operated,

2

- 6 -

B-70315EN/01 2.SAFETY

2.1 LASER BEAM

1) Potential hazards

Laser oscillator emits CO

power and invisible.

• Being directly exposed to the CO

burn you.

• The CO

beam could bource off your workpiece and burn

2

your eyes or skin.

LASER oscillator have a guide laser. The guide laser beam

is visible (red color) and low power. It is used to ensure that

the CO

beam is correctly positioned on your workpiece.

2

• The diode laser beam is not considered harmful to your skin.

But if you stared head on into the guide laser beam, it could

harm your eyes.

2) Safety recommendations

Never expose the eyes and skin to the laser beam. Be careful of

the laser beam when performing the inspection and maintenance.

Do not turn on the power supply to the oscillator when the panel

open and do not drive. It is bleached to radiation of the laser

beam and high voltage.

Do the countermeasure (For instance, installs safety glasses and

the protection gloves) to danger in case of stopped no finish and

nor opening the panel while it energizes the oscillator.

Install beam safety cover after mirror cleaning or replacement.

And if not beam safety cover installation, do not operation and

alignment.

Confirm when it does alignment, the protection pipe (Safety

cover) is installed. If it dose not install the protection pipe, it will

put the finger in the laser beam and there is possibility to do the

burn.

When entering the area exposed to the scattered beam, wear the

safety glasses. Mount the stand made of acrylic resin or any

material which can absorb the CO

personnel from the scattered beam.

Avoid exposure of any part of your body to the CO

When testing the beam output, any personnel other than the

maintenance personnel should be out of the working

environment.

In designing a material processing machine utilizing laser

oscillator, be sure that the CO

workpiece only through the enclosed beam delivery system. This

prevents the exposure to laser beam by the operator switch could

otherwise take place. It is absolutely necessary to include the

instructions given here in the manuals of the laser materialprocessing machine as a whole, which are to be read.

laser beam(10.6 µm), which is high

2

beam could severely

2

laser beam to protect the

2

laser beam.

2

laser beam goes from laser to the

2

- 7 -

2.SAFETY B-70315EN/01

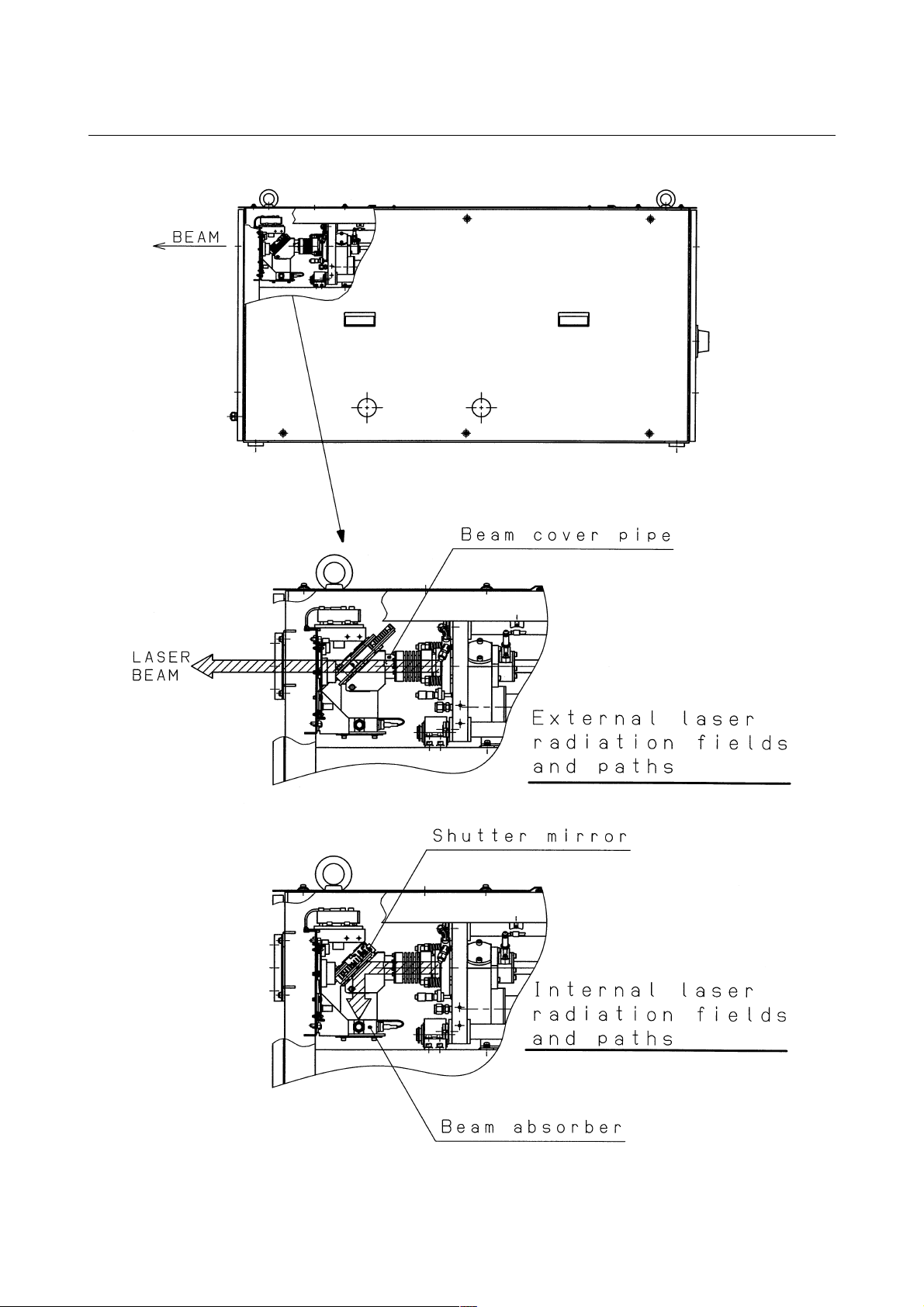

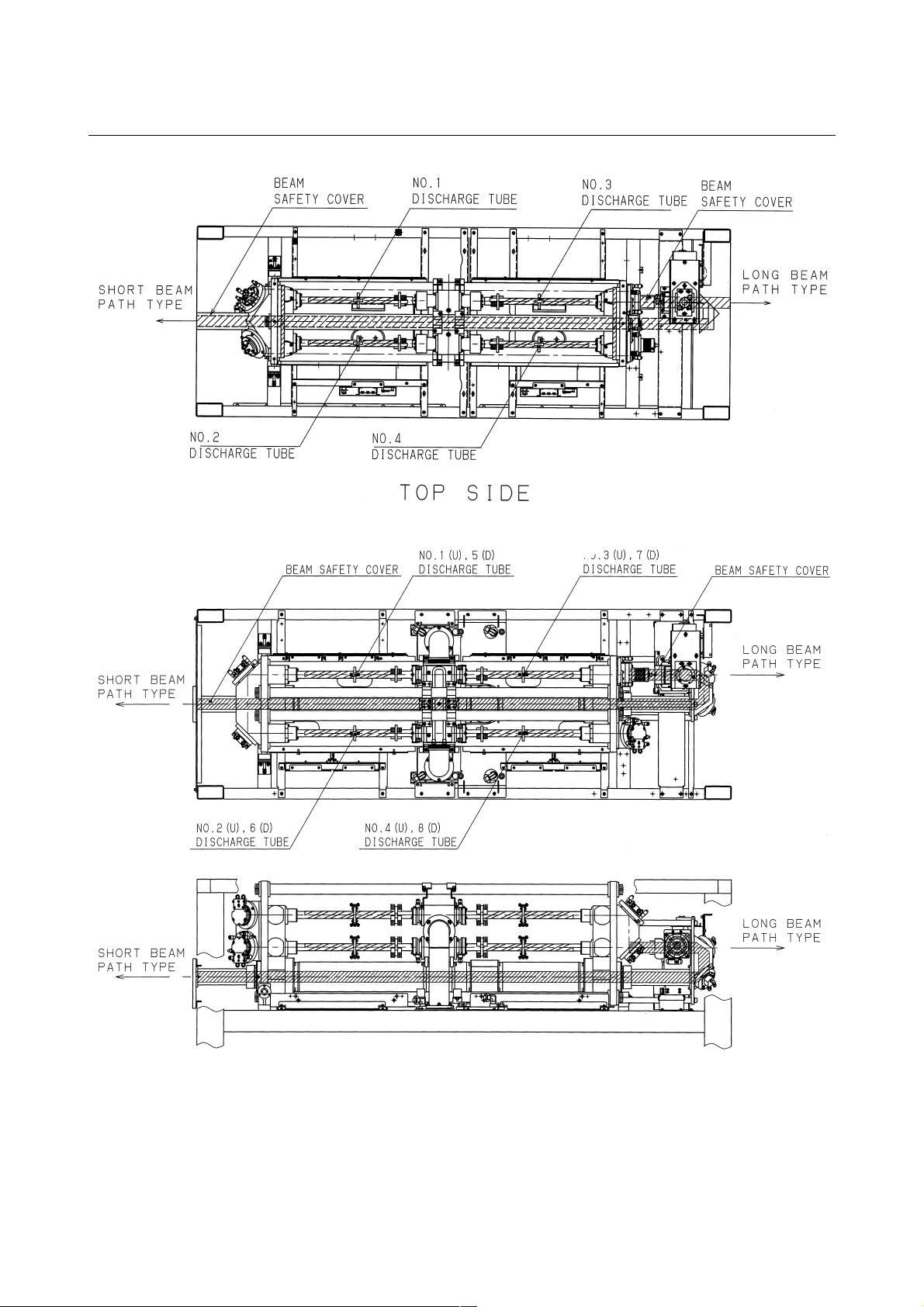

3) Position of laser beam emission

Fig.2.1(a) is the position of panel that laser beam exposure is

occurred without panel in C1000-E, when your maintenance.

Fig.2.1(b) is the position of panel that laser beam exposure is

occurred without panel in C2000-E, when your maintenance.

Fig.2.1(c) is the position of panel that laser beam exposure is

occurred without panel in C4000-E, when your maintenance.

Fig.2.1(d) is the position of laser beam delivery in C1000-E.

Fig.2.1(e) is the position of laser beam delivery in C2000-E.

Fig.2.1(f) is the position of laser beam delivery in C4000-E.

- 8 -

B-70315EN/01 2.SAFETY

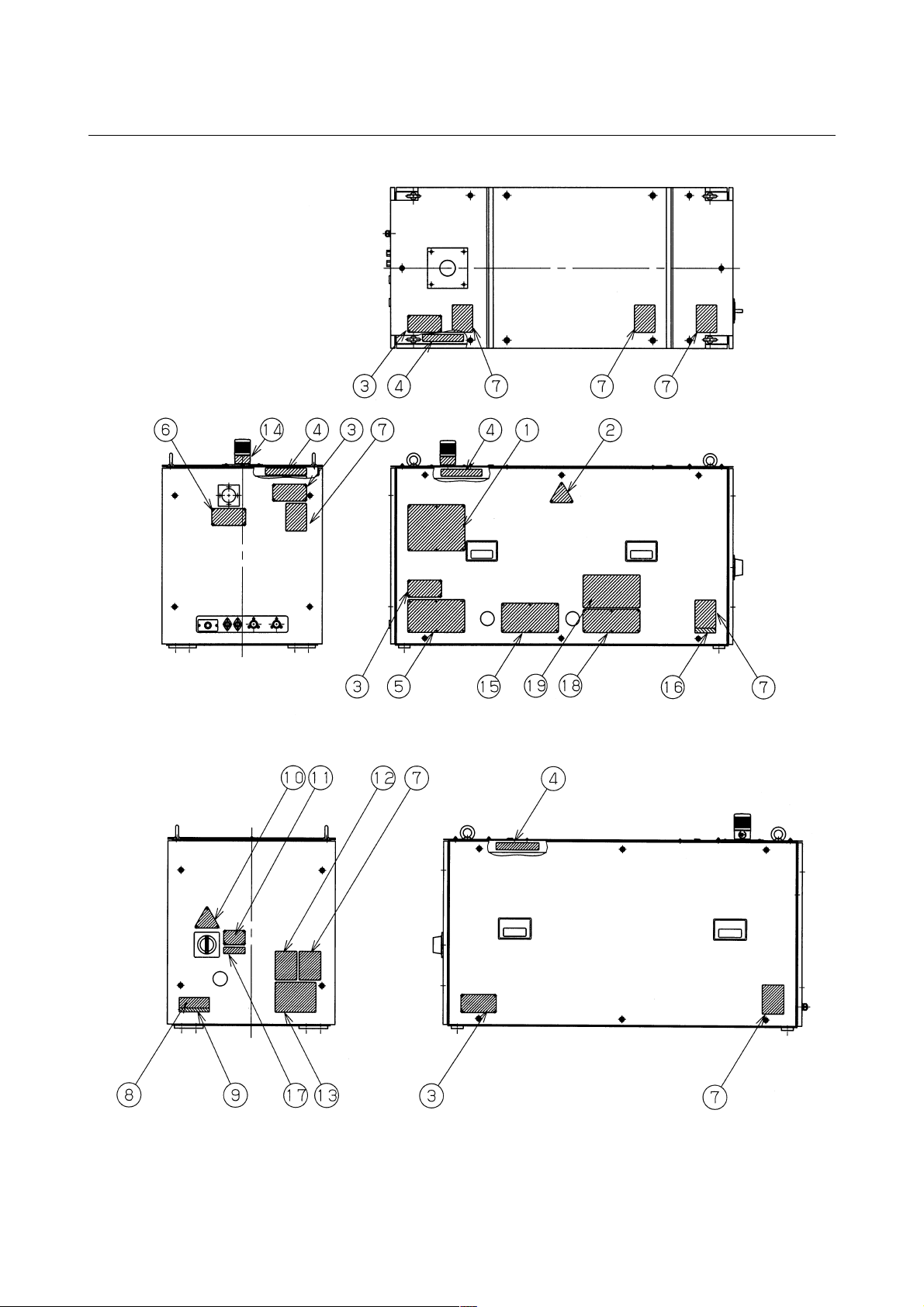

Fig.2.1(a) Laser beam exposure position without panel as operating (C1000-E)

Fig.2.1(b) Laser beam exposure position without panel as operating (C2000-E)

Fig.2.1(c) Laser beam exposure position without panel as operating (C4000-E)

- 9 -

2.SAFETY B-70315EN/01

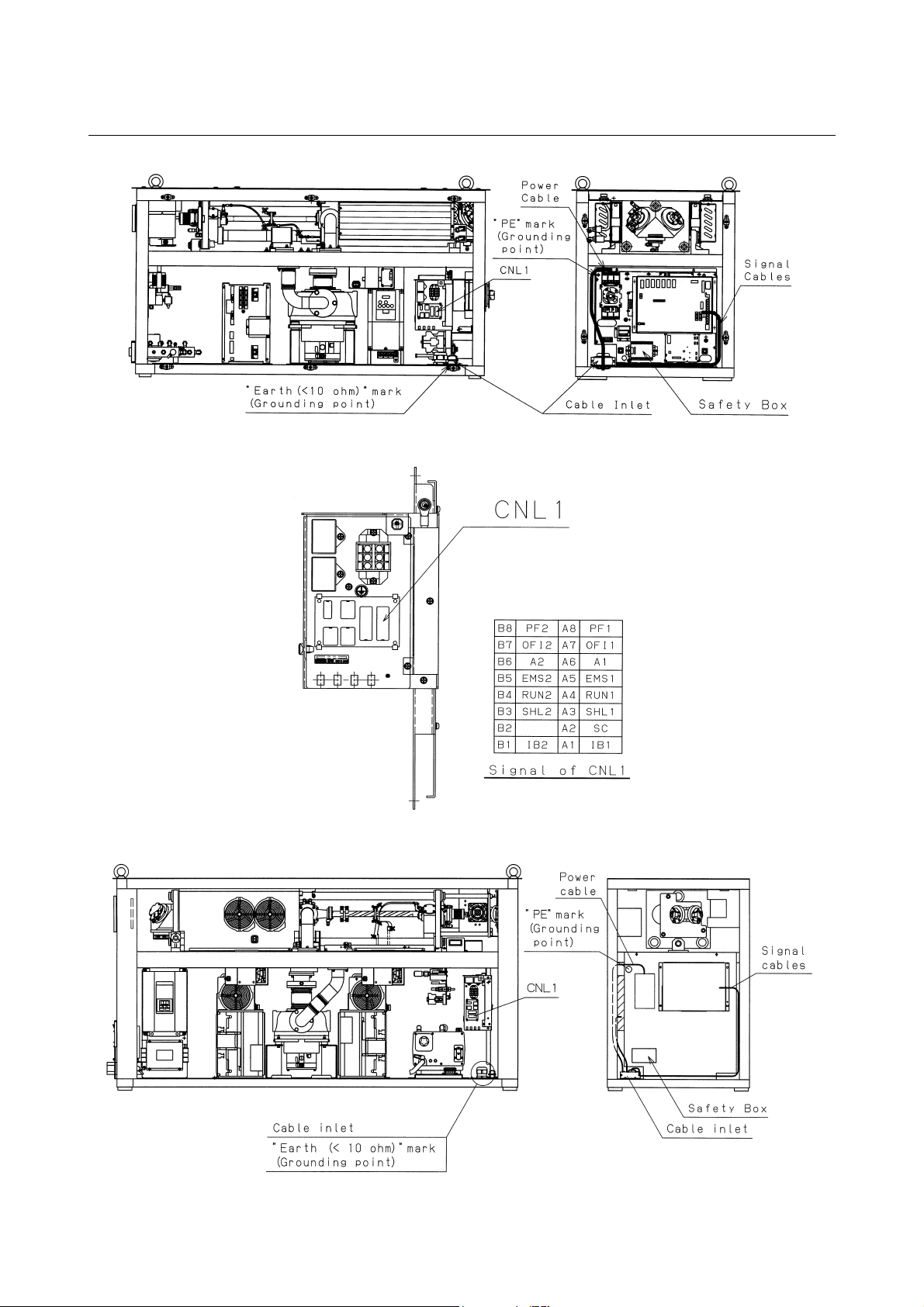

Fig.2.1(d) The position of laser beam delivery (C1000-E)

- 10 -

B-70315EN/01 2.SAFETY

Fig.2.1(e) The position of laser beam delivery (C2000-E)

Fig.2.1(f) The position of laser beam delivery (C4000-E)

- 11 -

2.SAFETY B-70315EN/01

2.2 HIGH VOLTAGE

1) Potential hazards

There is RF voltage of 3 to 4kVo-p in the cabinet of the laser

oscillator.

There is 200 VAC power in the relay panel, be careful not to

touch the high voltage.

2) Safety recommendations

When it checks the oscillator and exchange the unit, intercept a

main breaker of the oscillator and the power supply. Lock the

breaker to prevent misconnection and display the sign while

working.

Install safety cover after unit replacement or cable connection.

Unless safety cover is installed, never perform operation.

Follow standard industrial safety practices for working with high

voltage.

EXAMPLES

• Do not work on the laser oscillator if you are tired or have

taken medicine.

• Do not wear anything metal, like a ring, bracelet, watch,

belt buckle, earrings, or keys.

• They might contact high voltage.

• Never stand on a wet surface.

• Do not touch electrical components in the cabinets with

both hands at once. Keep one hand in a pocket.

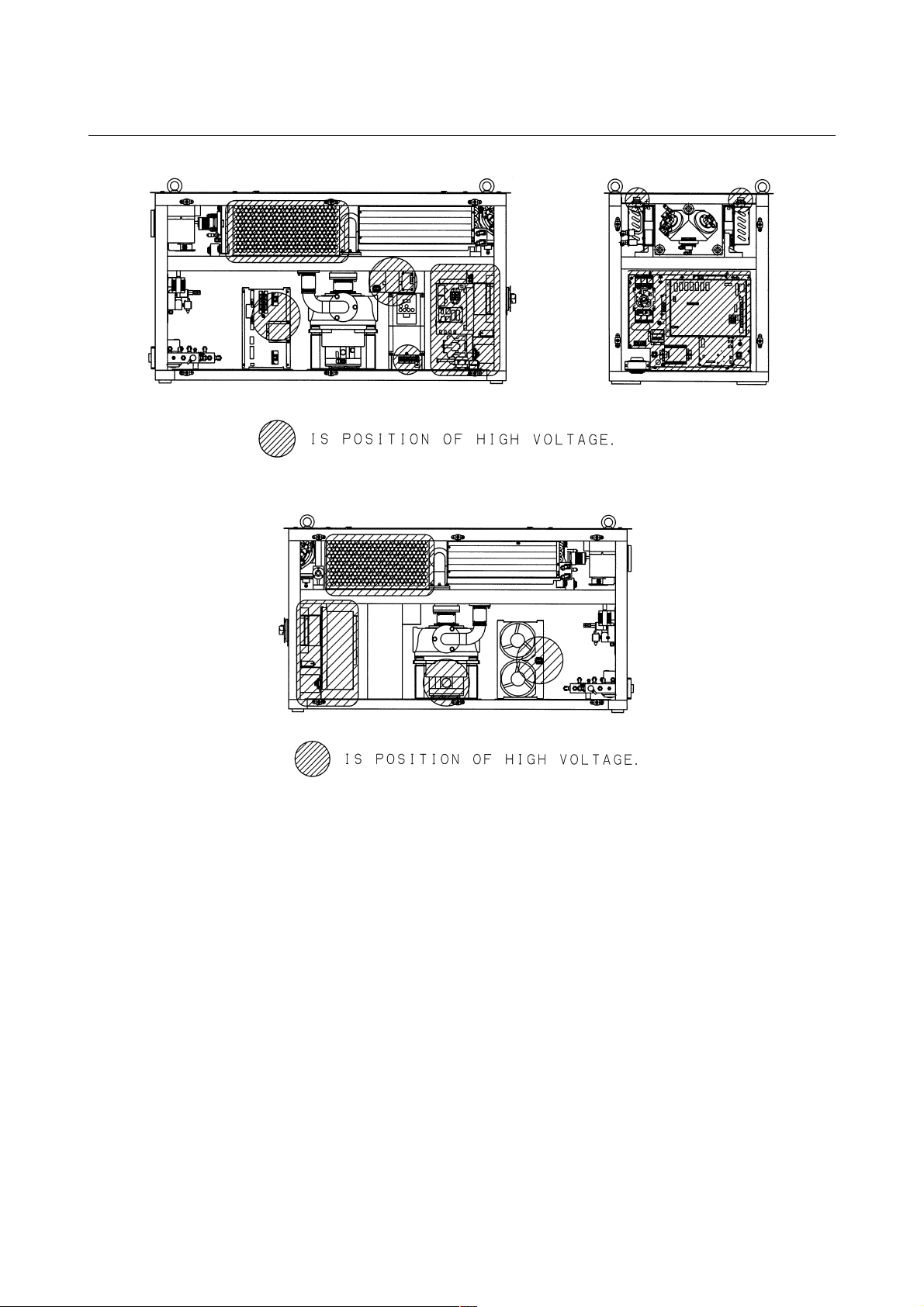

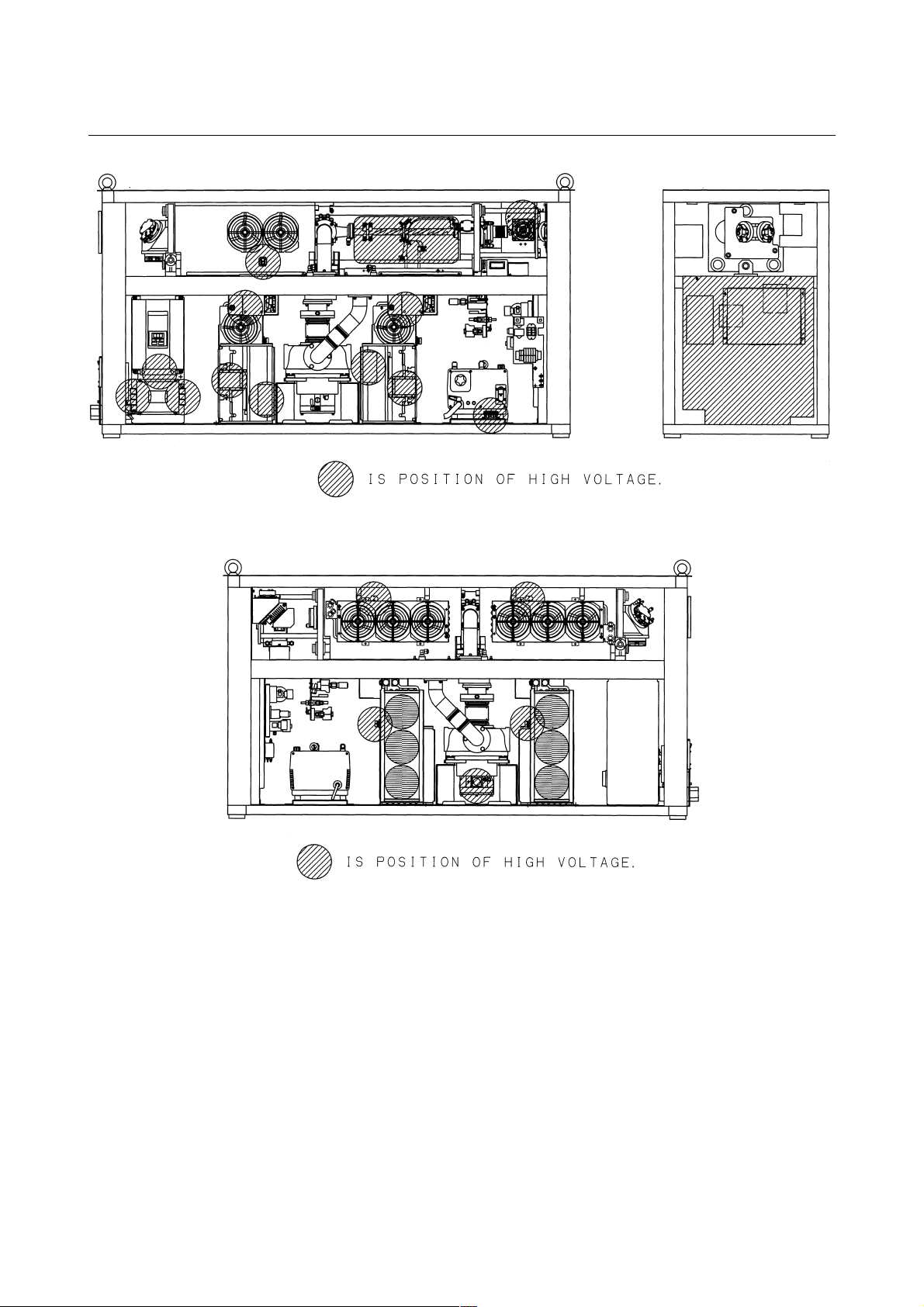

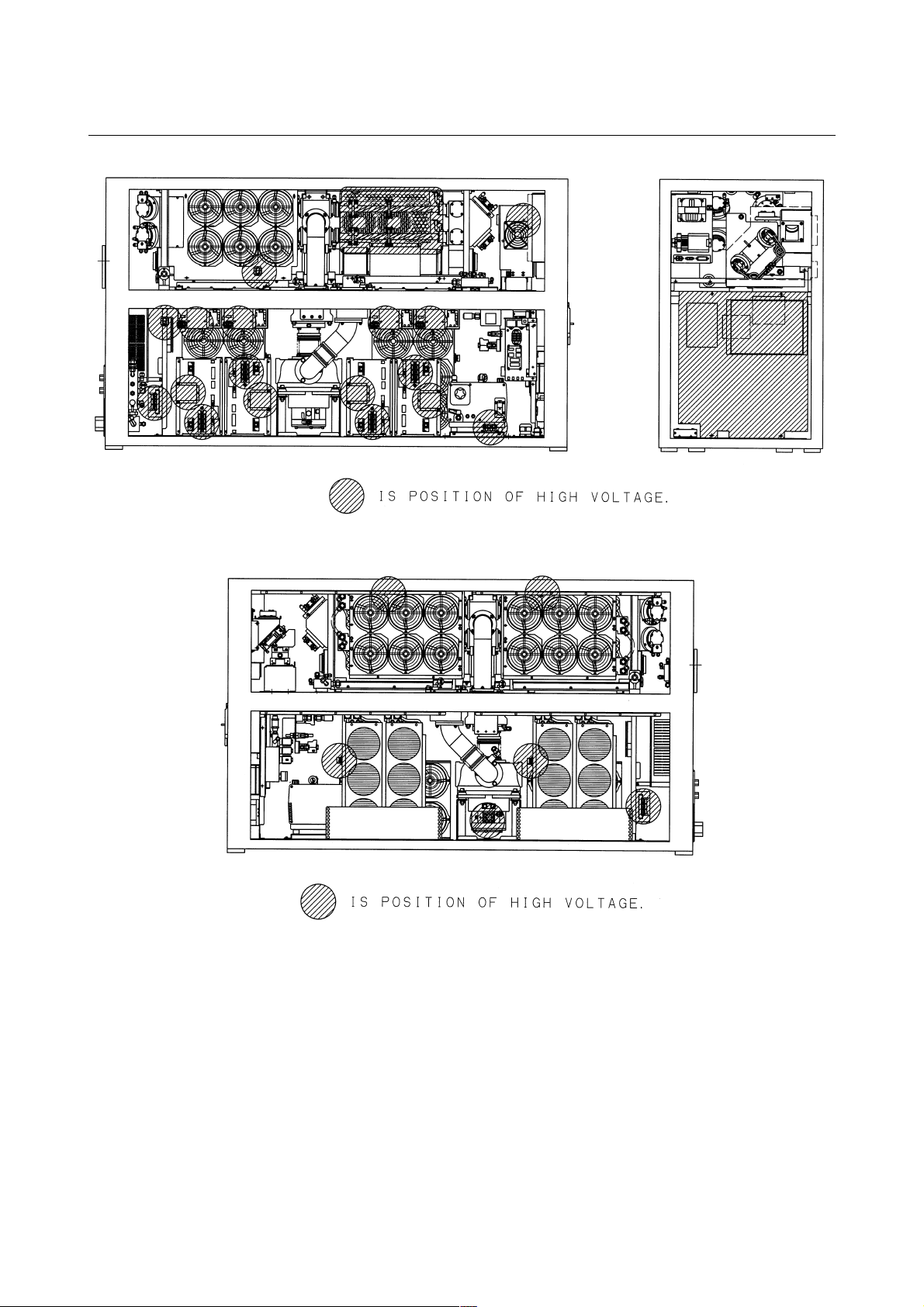

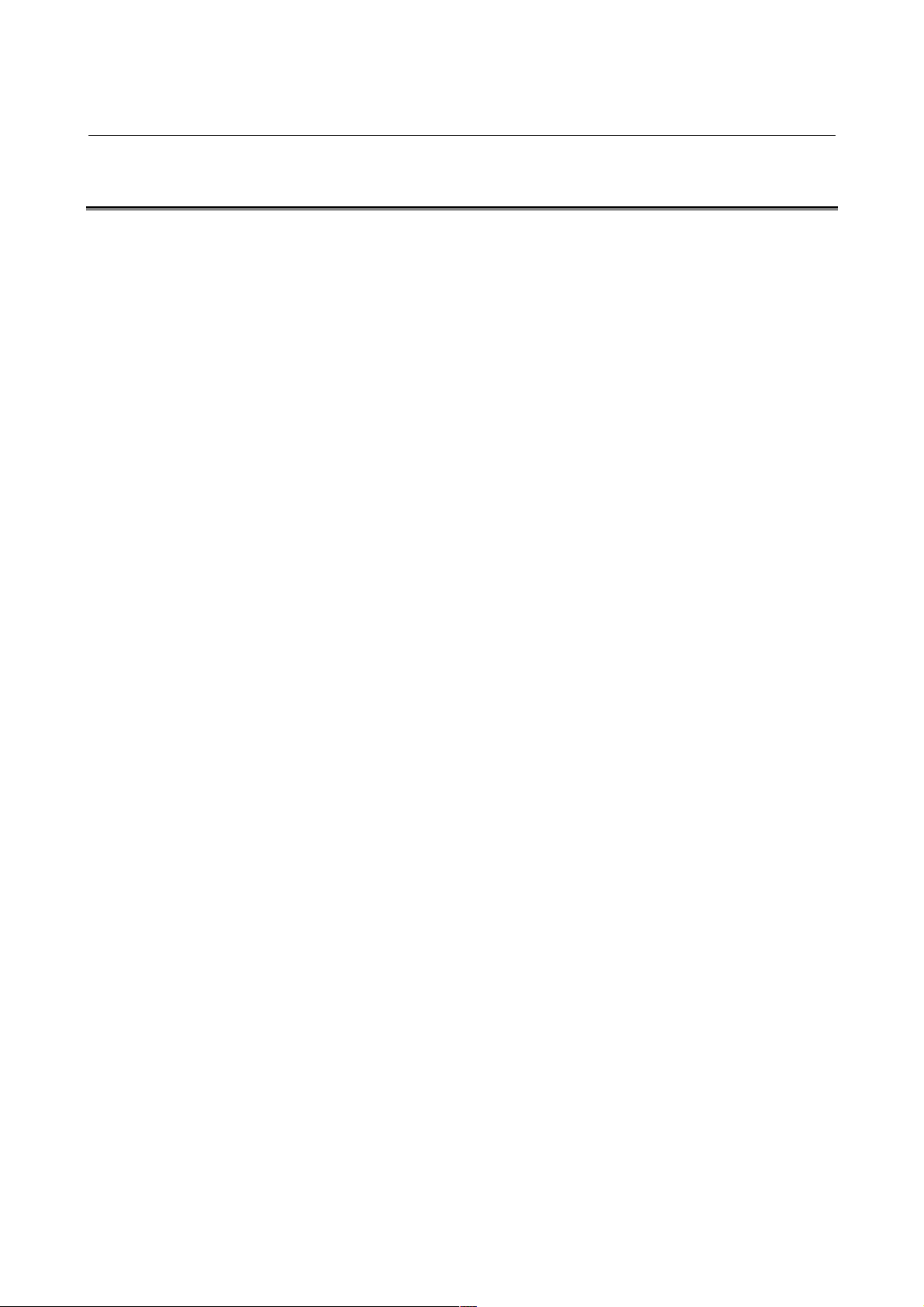

3) Position of high voltage

Fig.2.2(a) is the position of high voltage in C1000-E (Front,

maintenance side).

Fig.2.2(b)is the position of high voltage in C1000-E (Back side).

Fig.2.2(c) is the position of high voltage in C2000-E (Front,

maintenance side).

Fig.2.2(d)is the position of high voltage in C2000-E (Back side).

Fig.2.2(e) is the position of high voltage in C4000-E (Front,

maintenance side).

Fig.2.2(f) is the position of high voltage in C4000-E (Back side).

- 12 -

B-70315EN/01 2.SAFETY

Fig.2.2(a) Position of high voltage in C1000-E (Front, maintenance side)

Fig.2.2(b) Position of high voltage in C1000-E (Back side)

- 13 -

2.SAFETY B-70315EN/01

Fig.2.2(c) Position of high voltage in C2000-E (Front, maintenance side)

Fig.2.2(d) Position of high voltage in C2000-E (Back side)

- 14 -

B-70315EN/01 2.SAFETY

Fig.2.2(e) Position of high voltage in C4000-E (Front, maintenance side)

Fig.2.2(f) Position of high voltage in C4000-E (Back side)

- 15 -

2.SAFETY B-70315EN/01

2.3 SAFETY ENCLOSURE (AT YOUR WORK STATION)

1) Potential hazards

CO

beam is delivery from oscillator. Direct or scattered beam is

2

exposed.

2) Safety recommendations

Mount the safety enclosure made of acrylic resin which can

absorb the laser beam around the working environment.

Mount the interlock switch on the safety enclosure door which

extinguishes the laser beam output when the door is open. Never

perform operation without safety cover of laser machine.

- 16 -

B-70315EN/01 2.SAFETY

2.4 FIRE

1) Potential hazards

When you work with the laser oscillator or machine, hot

fragments or slag can scatter from your workpiece. The CO

beam or a reflection of it could ignite flammable material.

2) Safety recommendations

The direct or scattered laser beam can ignite flammable materials

such as paper, cloth, and wood. Provide a beam absorber behind

the workpiece and around it during maintenance. The absorber

can be anodized aluminum, graphite or brick.Put a shield

between yourself and the workpiece when the CO

Even diffuse reflections can harm eyes and skin and may ignite

flammable material.

beam is on.

2

2

- 17 -

2.SAFETY B-70315EN/01

2.5 TOXIC FUME

1) Potential hazards

Some materials such as certain plastics can emit toxic fume

when they burn under the laser beam.

2) Safety recommendations

Install the exhaust system to remove toxic fume from the work

environment.

Consult the manufacturer of the material you are processing to

learn if it creates any fumes when heated or burned.

- 18 -

B-70315EN/01 2.SAFETY

2.6 HIGH TEMPERATURE

1) Potential hazards

When you touch a part of high temperature, your skin burn.

2) Safety recommendations

The pipes of the gas circular system are very a high temperature.

Do not touch pipes, heat exchanger and turbo blower because it

does not do the burn. It is hot immediately after having stopped

driving. After getting cold enough in case of removing, dismount

it.

3) Position of high temperature

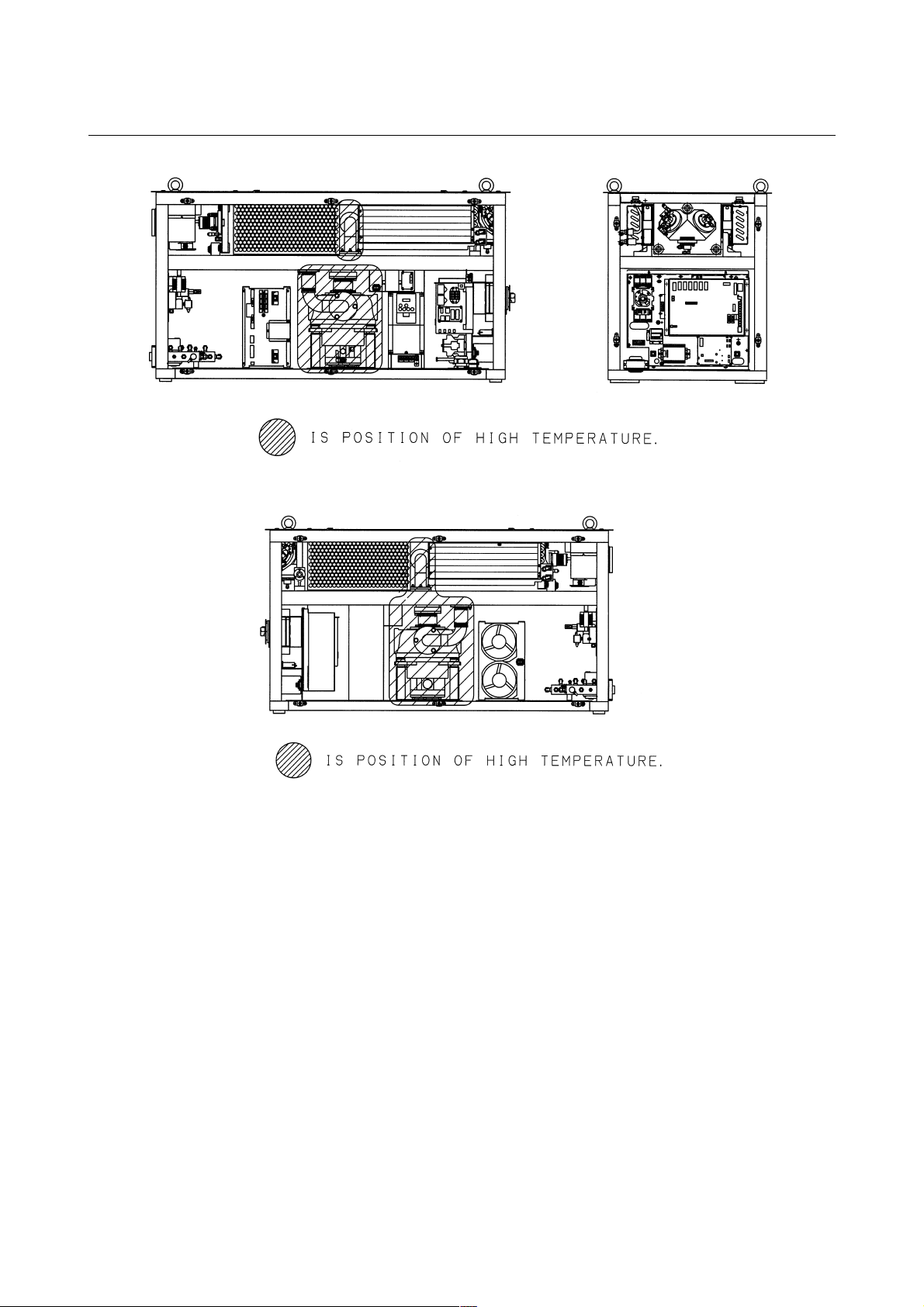

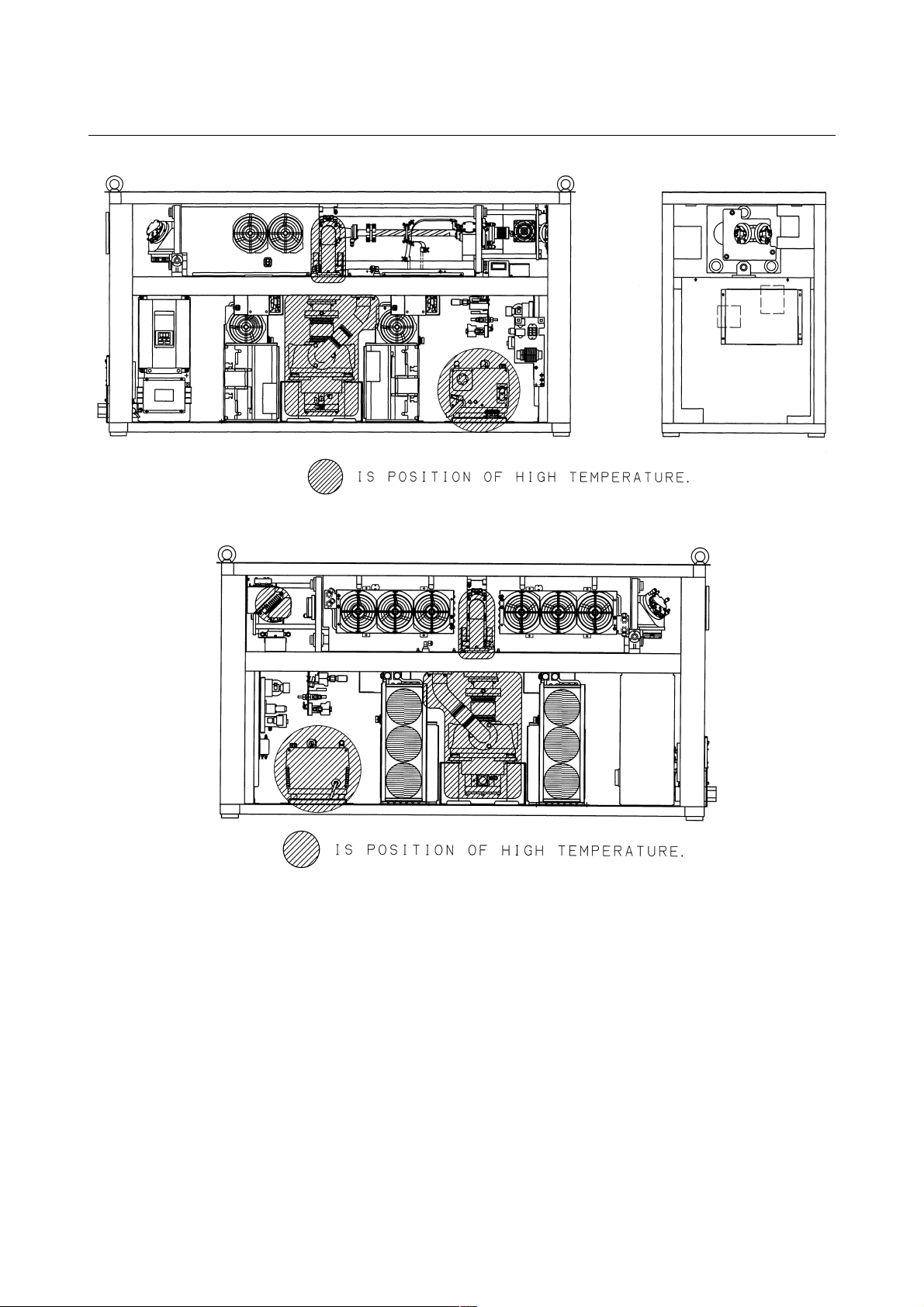

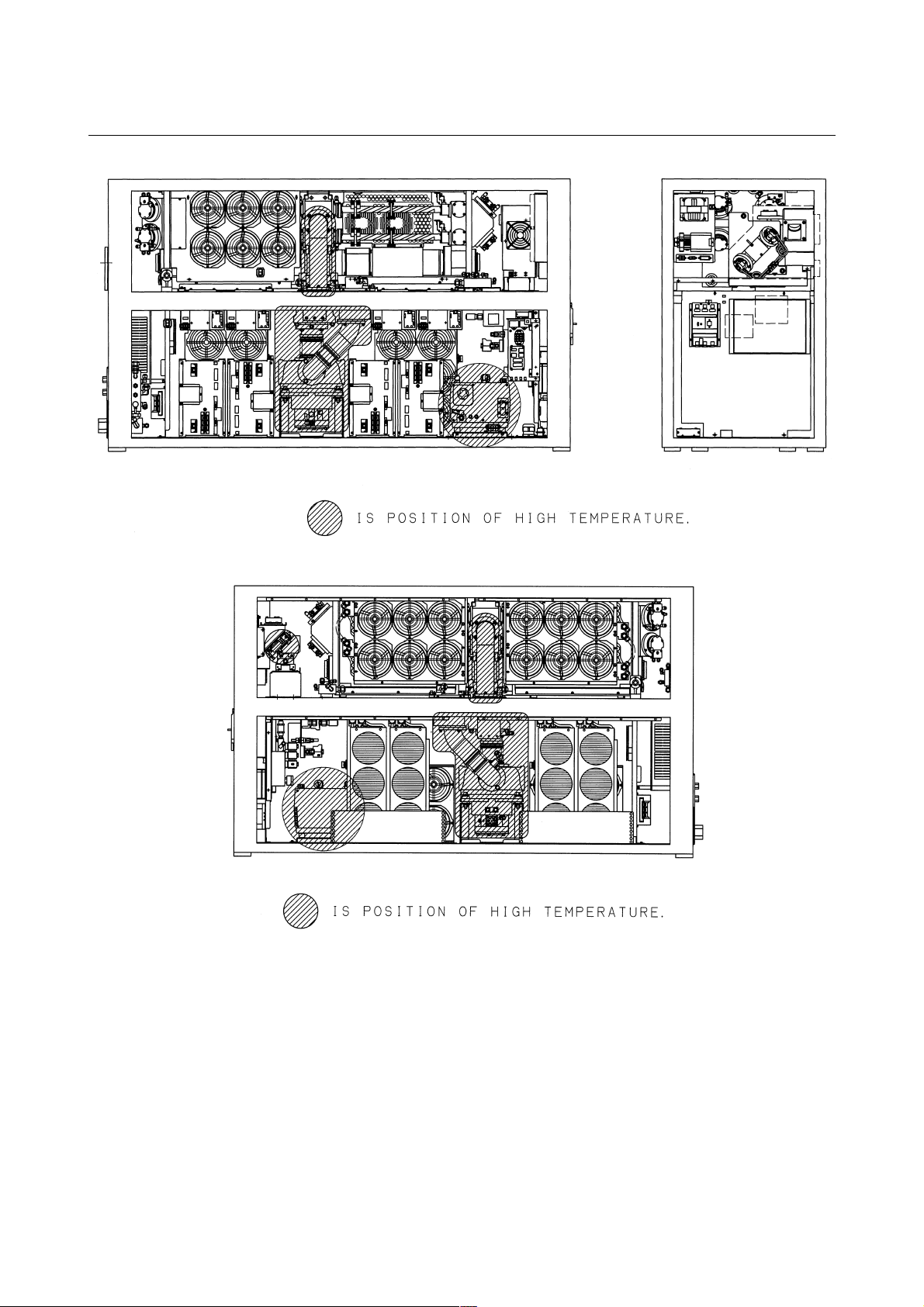

Fig.2.6(a) is the position of high temperature in C1000-E (Front,

maintenance side).

Fig.2.6(b) is the position of high temperature in C1000-E (Back

side).

Fig.2.6(c) is the position of high temperature in C2000-E (Front,

maintenance side).

Fig.2.6(d) is the position of high temperature in C2000-E (Back

side).

Fig.2.6(e) is the position of high temperature in C4000-E (Front,

maintenance side).

Fig.2.6(f) is the position of high temperature in C4000-E (Back

side).

- 19 -

2.SAFETY B-70315EN/01

Fig.2.6(a) Position of high temperature in C1000-E (Front, maintenance side).

Fig.2.6(b) Position of high temperature in C1000-E (Back side).

- 20 -

B-70315EN/01 2.SAFETY

Fig.2.6(c) Position of high temperature in C2000-E (Front, maintenance side).

Fig.2.6(d) Position of high temperature in C2000-E (Back side).

- 21 -

2.SAFETY B-70315EN/01

Fig.2.6(e) Position of high temperature in C4000-E (Front, maintenance side).

Fig.2.6(f) Position of high temperature in C4000-E (Back side).

- 22 -

B-70315EN/01 2.SAFETY

2.7 WARNING LABELS

Fig.2.7(a)-(f) show the location of the warning labels indicating the

high voltage and laser beam path.

Fig.2.7(a) is the location of the warning sticker (C1000-E:Front side).

Fig.2.7(b) is the location of the warning sticker (C1000-E:Back side).

Fig.2.7(c) is the location of the warning sticker (C2000-E:Front side).

Fig.2.7(d) is the location of the warning sticker (C2000-E:Back side).

Fig.2.7(e) is the location of the warning sticker (C4000-E:Front side).

Fig.2.7(f) is the location of the warning sticker (C4000-E:Back side).

- 23 -

2.SAFETY B-70315EN/01

Fig.2.7(a) Location of the warning sticker (C1000-E:Front side).

Fig.2.7(b) Location of the warning sticker (C2000-E:Back side).

- 24 -

B-70315EN/01 2.SAFETY

Fig.2.7(c) Location of the warning sticker (C2000-E:Front side).

Fig.2.7(d) Location of the warning sticker (C2000-E:Back side).

- 25 -

2.SAFETY B-70315EN/01

Fig.2.7(e) Location of the warning sticker (C4000-E:Front side).

Fig.2.7(f) Location of the warning sticker (C4000-E:Back side).

- 26 -

B-70315EN/01 2.SAFETY

Detail of warning sticker

(1) Warning logotype (C1000-E)

(1) Warning logotype (C2000-E, C4000-E)

- 27 -

2.SAFETY B-70315EN/01

(2) Warning logotype

(3) Label for defeasible non-interlocked protective housing

(4) Label for defeasible non-interlocked protective housing

(5) Caution label for lifting

- 28 -

B-70315EN/01 2.SAFETY

(6) Aperture label

(7) Label of non-interlocked protective panel

(8) Identification label

- 29 -

2.SAFETY B-70315EN/01

(9) Address label

(10) High voltage warning label

(11) Supply voltage label

(12) Label of over-current protective

- 30 -

B-70315EN/01 2.SAFETY

(13) Label of motor and transformer (C1000-E)

(13) Label of motor and transformer (C2000-E)

(13) Label of motor and transformer (C4000-E)

- 31 -

2.SAFETY B-70315EN/01

(14) Label of warning light

(15) Maintenance label

(16) Certification label

(17) Short-circuit interrupting capacity of main breaker (C1000-E)

(17) Short-circuit interrupting capacity of main breaker (C2000-E,

C4000-E)

- 32 -

B-70315EN/01 2.SAFETY

(18) Label for regurating the atmospheric gases in the oscillator

housing

(19) Label for cooling water and laser gas

- 33 -

2.SAFETY B-70315EN/01

2.8 HIGH-PRESSURE GAS

Do not allow any dangerous or high-pressure gas to get into the

oscillator housing. The oscillator cabinet has a hermetic structure

(dustproof and dripproof), it cannot be ventilated easily.

Flammable gases such as oxygen can cause a fire or explosion.

Toxic gases can harm operators during maintenance. Organic gases

can degrade machining performance. High-pressure gases can damage

a panel or the cabinet, resulting in injury from flying matters.

If such a gas accidentally gets into the oscillator housing, remove a

panel for ventilation. The installation room must be also well

ventilated.

To purge the oscillator housing, use purified, low-pressure air or

nitrogen.

- 34 -

B-70315EN/01 2.SAFETY

2.9 KEY CONTROL

All the laser products have to comply with the various kinds of laser

safety regulations, which include the use of key control. For instance,

FDA PART 1040 PERFORMANCE STANDARDS FOR LIGHTEMITTING PRODUCTS, Sec 1040. 10 (f), (4) states: "Each laser

system classified as a Class IIIb or IV laser product shall incorporate a

key-actuated master control. The key shall be removable and the laser

shall not be operable when the key is removed" and EN60825-1:1994,

4.5 Key control state "Any laser system belonging to one of the

following classes shall incorporate a key operation master control:

Class 4 and Class 3B, except for Class 3B with not more than five

times the AEL of Class 2 in the wavelength range from 400 nm to 700

nm. The key shall be removable and the laser radiation shall not be

accessible when the key is removed."

Because the laser package products offered by FANUC cannot

produce the laser beam as they are in the state of shipment, the system

integrator who incorporates FANUC products into the system, which

generates the laser beam, is obliged to incorporate the master key as

defined by the relevant regulation.

- 35 -

2.SAFETY B-70315EN/01

2.10 SHUTTER LOCK

The shutter lock is prepared because it dose not put out the laser beam

by mistake. If you do not put out the beam, lock the shutter.

Use the mechanical switch at shutter lock switch, not electrical

component (Relay)or switching circuit (Transistor, FET).

Use the one with the compulsion dissociation mechanism for the

switch used for the shutter lock circuit and the switch for welding

prevention.

To designer of laser processing machine

1 Use a mechanical switch for the switch used to lock

the shutter. Do not use an electric switch (For

instance, transistor circuit, etc.). Moreover, use the

one with the contact dissociation mechanism to

prevent welding for a mechanical switch.

2 Put it in the series of the contact of the emergency

stop button in the shutter lock circuit. When the

emergency stop switch is pushed, it is necessary to

intercept the power supply to the shutter.

- 36 -

B-70315EN/01 2.SAFETY

2.11 EMERGENCY STOP BUTTON

Press the emergency stop button when it is dangerous and breaks

down. The oscillator is stopped discharging, gas pressure control and

stand by purge state.

Use the one with the compulsion dissociation mechanism for the relay

used for the emergency stop circuit and the switch for welding

prevention.

- 37 -

2.SAFETY B-70315EN/01

2.12 WARNING LIGHT (OPTIONAL)

Laser oscillator is equipped with the warning light optionally. The

light is flashed during discharging and ready of laser beam emission.

Be careful of laser beam and high voltage.

To designer of laser processing machine

In EN60825-1, it needs the design with the fail safe

or redundant for warning equipment. The redundant

warning light is needed near the work-point of

processing machine. The warning light is prepared

for the oscillator. Select this as a warning light more

than the second for the fail safe.

- 38 -

B-70315EN/01 3.INTERNAL STRUCTURE

3 INTERNAL STRUCTURE

- 39 -

3.INTERNAL STRUCTURE B-70315EN/01

3.1 GENERAL

Figs.3.1(a) to (c) show the block diagram of the laser oscillator.

The FANUC LASER C1000/C2000/C4000-MODEL E consists of a

laser resonator, laser excitation power supply, forced gas circulating

system, pressure controller, exhaust controller, CNC interface, and a

protective housing.

Fig.3.1(a) Block diagram (C1000-E)

- 40 -

B-70315EN/01 3.INTERNAL STRUCTURE

Fig.3.1(b) Block diagram (C2000-E)

- 41 -

3.INTERNAL STRUCTURE B-70315EN/01

Fig.3.1(c) Block diagram (C4000-E)

(1) Laser resonator

The laser resonator consists of several discharge tubes,

connected in series using folding mirrors, with a rear mirror and

output mirror placed at the open ends of the discharge tubes, thus

sealing the tubes. The resonator is fitted with a gas pipe

connecting port through which laser gas is fed into the discharge

tubes.

A discharge from the electrodes of the discharge tube energizes

CO

molecules, which emit light. This light is amplified by

2

stimulated emission, repeated between the rear mirror and output

mirror, a laser beam being emitted from the output mirror.

(2) Laser excitation power supply

This is a 2 MHz high-frequency power supply, the output of

which is controlled by the CNC. This power supply is used to

create a discharge in the laser gas flowing through the discharge

tubes, thus energizing CO

molecules.

2

- 42 -

B-70315EN/01 3.INTERNAL STRUCTURE

(3) Forced gas circulating system

A gas circulating system is configured by connecting the

resonator and turbo blower with a circulating pipe. Laser gas is

forced through the discharge tubes at a speed of 200 m/s or

higher.

A water-cooled heat exchanger, used to cool the hightemperature gas from the discharge tubes, is provided at the inlet

side of the turbo blower. At the outlet side of the turbo blower,

another water-cooled heat exchanger dissipates the compression

heat.

(4) Pressure control unit

The laser gas pressure within the forced gas circulating system is

controlled by commands issued from the CNC, thus ensuring

stable laser output.

(5) Exhaust control unit

The laser gas flow is controlled by commands issued from the

CNC.

(6) CNC interface

Interface used to connect a FANUC Series 16i-L. CNC

commands that, control the operation of the laser oscillator, such

as start/stop and laser output, are input via this interface.

(7) Protective housing

An enclosure that houses the above components. The housing,

consisting of metal panels and doors, completely encloses the

laser oscillator, thus protecting the operator from exposure to

laser radiation and from high voltages. All panels are screwfixed and cannot be removed without an appropriate tool.

The doors are also designed to prevent an accident from

occurring as a result of careless operation. The doors can be

opened only when the main circuit breaker is open. A door

interlock function is also supported.

- 43 -

3.INTERNAL STRUCTURE B-70315EN/01

3.2 COMPONENT DETAILS

The following describes the details of each component of the laser

oscillator. Figs.3.2(a) to (f) show the internal structure.

Fig.4.2(a) Internal structure of C1000-E (Front, maintenance side)

Fig.4.2(b) Internal structure of C1000-E (Back side)

- 44 -

B-70315EN/01 3.INTERNAL STRUCTURE

Fig.4.2(c) Internal structure of C2000-E (Front, maintenance side)

Fig.4.2(d) Internal structure of C2000-E (Back side)

- 45 -

3.INTERNAL STRUCTURE B-70315EN/01

Fig.4.2(e) Internal structure of C4000-E (Front, maintenance side)

Fig.4.2(f) Internal structure of C4000-E (Back side)

- 46 -

B-70315EN/01 3.INTERNAL STRUCTURE

(1) Resonator

The resonator consists of an output coupler, rear mirror, folding

mirrors, discharge tubes, power sensor unit, etc. It converts

electrical energy first to laser gas, then to optical energy (10.6mm single-wavelength laser beam).

(2) Output coupler

A transmitting/reflecting mirror which outputs the laser beam

after it has been amplified. The output coupler consists of a ZnSe

(zinc selenide) substrate, coated with dielectric. ZnSe is tightly

toxic. Be particularly careful, therefore, when handling the

output coupler.

(3) Rear mirror

A reflecting mirror consisting of a Ge (germanium) substrate,

coated with dielectric. Having a high reflectance of 99.5%, the

rear mirror is used to reflect the laser beam within the resonator

while transmitting 0.5% of the laser light so that the beam can be

monitored externally.

(4) Folding mirror

The folding mirror, consisting of a 45° block and a gold-coated

Si (silicon) substrate, is used to divert the laser beam through

90°. It also linearly polarizes the laser beam.

(5) Discharge tube

A pair of Ag (silver) electrodes are metallized on the surface of a

hollow quartz glass pipe. A high-frequency discharge between

these electrodes injects electrical energy into the laser gas.

Each electrode is coated with ceramic, preventing it from

degrading and thus improving system reliability.

(6) Trigger electrode

A predischarge placed outside the laser oscillation area can

facilitate the start of the main discharge. With it, the laser output

is completely zero when the beam is off.

(7) Power sensor

An optical sensor which detects the intensity of the laser beam,

transmitted through the rear mirror, thus enabling monitoring of

the laser output level.

(8) Gas circulating system

A gas circulating path including a turbo blower, heat exchangers,

and circulating pipes, which supplies and exhausts laser gas to

and from the discharge tubes at high speed.

- 47 -

3.INTERNAL STRUCTURE B-70315EN/01

(9) Turbo blower

During laser oscillation, the laser gas pressure is 100 to 700

(1330 to 9310 Pa) when DGN. The turbo blower circulates this

rough-vacuum gas at high speed (up to 200 m/s within the

discharge tubes) without contaminating the gas.

(10) Heat exchanger (inlet)

Heat exchanger used to cool the laser gas that has been heated by

discharge, before it is drawn into the turbo blower.

(11) Heat exchanger (outlet)

Heat exchanger used to cool the laser gas that has been heated by

compression in the turbo blower, before being forced into the

discharge tubes.

(12) Gas controller (C1000-E)

The gas controller always monitors the gas pressure in each

discharge tube and supplies the fresh laser gas to the circulating

system to keep the pressure constant. It also monitors the supply

status of the laser gas, purge check for the circulating system,

and other items and has a function of adjusting the amount of

flow of the gas to be exhausted.

(13) Pressure controller (C2000-E, C4000-E)

This unit constantly monitors the gas pressure in the discharge

tubes and supplies fresh laser gas to the gas circulating system,

thus maintaining a constant pressure in the discharge tubes.

This unit also monitors the laser gas supply state and the purging

state in the gas circulating system.

(14) Exhaust pump unit

This unit is used to vacuum-exhaust laser gas from the gas

circulating system such that its pressure falls to that used for

laser oscillation. Also, within this unit, a small amount of

circulating gas is constantly being exchanged, to prevent

degradation of the circulating gas. For the C1000-E, the exhaust

pump is installed separately.

(15) Exhaust controller (C2000-E, C4000-E)

The exhaust controller controls the flow rate of the laser gas

exhausted by the exhaust pump unit. It adjusts the gas flow rate

from that used for gas exchange to that used for pressure control.

In the event of a power failure, the exhaust controller

immediately returns the exhaust pump unit to atmospheric

pressure, thus protecting the pump.

(16) Hour meter

The hour meter indicates the total number of hours that the laser

oscillator has operated (how many hours the exhaust pump has

operated), to indicate whether maintenance or inspection is

necessary.

- 48 -

B-70315EN/01 3.INTERNAL STRUCTURE

(17) Shutter

The shutter consists of a gold-coated reflecting mirror, mounted

on the rotating arm of a rotary solenoid. The shutter can be

opened and closed instantaneously by issuing a CNC command.

For safety, the shutter is equipped with a temperature sensor

which allows the system to monitor the temperature of the

shutter.

(18) Beam absorber

While the laser oscillator is operating with the shutter closed, the

laser beam is guided into the beam absorber. The beam absorber

absorbs nearly 100% of laser beam and is water-cooled, allowing

it to safely absorb the beam for relatively long periods. For

safety, the beam absorber is equipped with a temperature sensor

which allows the system to monitor the temperature of the beam

absorber.

(19) Water distributor

This unit distributes cooling water, supplied from either a chiller

unit or a temperature-regulated external water supply, to each

unit in the laser oscillator. For safety, the water distribution unit

is equipped with a flow sensor which allows the system to

monitor the flow rate of the

(20) Laser power supply unit

This unit rectifies and smoothes the 3-phase 200/220-VAC input,

then supplies DC power to the RF inverter by controlling the

PWM DC-DC converter, as directed by commands received

from the CNC.

The RF inverter converts DC power to 3 to 4 kVP

frequency (2 MHz) power, then outputs it to the matching box.

(21) Matching box

The matching box contains a matching circuit, consisting of coils

and capacitors, which ensures that power is effectively input to

the discharge tubes. The matching box is connected to the laser

power supply unit via either a high-voltage cable or coaxial

cable.

(22) Beam folding unit (C2000-E, C4000-E)

This unit reverses the direction of the laser beam in the oscillator.

Two zero-shift mirrors are used to ensure that the polarization of

the light remains constant. The C4000-E (short optical path type)

employs a circular polarization mirror as upper one, such that a

circularly polarized beam is produced.

(23) Intermediate PCB B

This PCB transmits signals output by the shutter section, such as

those from the limit switch, absorber temperature sensor, power

sensor, and condensation sensor, to the interface PCB.

O-P

high-

- 49 -

3.INTERNAL STRUCTURE B-70315EN/01

(24) Input unit

The input unit consists of an interface PCB, stabilized power

supply, and power magnetics cabinet. It transfers signals

between the laser oscillator and CNC, and supply power to each

unit.

(25) Interface PCB

I/O LINK (serial interface). Because this is a serial interface,

optical fiber cable can be used to enable long-distance

transmission.

(26) Stabilized power supply

This unit converts the 200/220 VAC power source to DC power

for the interface PCB and other units.

(27) Input unit (Control PCB)

This PCB sends the contractor open/close signal to the power

magnetics cabinet, as directed by commands received from the

CNC. It also notifies the CNC of the open/close status of the

circuit breaker in the power magnetics cabinet.

(28) Condensation sensor unit

This unit is mounted on the output mirror holder. If the sensor

detects that the amount of dew has exceeded the maximum

allowable level, an alarm (abnormal water temperature) is issued

and laser output is stopped, thus preventing a fault from

occurring.

(29) Inverter

This inverter drives the turbo blower. It is responsible for

acceleration/deceleration control during start and stop of the

blower.

(30) Guide laser (laser diode unit)

A CO

laser beam is invisible to the naked eyes. The

2

semiconductor light source, therefore, is provided to enable

checking of the laser beam optical axis by superimposing a

visible semiconductor laser beam on the same optical axis.

The operation of this light source is linked to the mechanical

shutter. The semiconductor laser beam is output only while the

shutter is closed. Using this beam, the optical axis of the external

optical system can be adjusted roughly and a reference position

for the machining point determined.

(31) Turbo PCB

This PCB relays signals between the turbo blower and inverter,

interface PCB.

- 50 -

B-70315EN/01 3.INTERNAL STRUCTURE

(32) Safety box

This is consisted of relay and indicator for interlock circuit.

(Run ON, HV ON, Shutter open)

- 51 -

4.INSTALLATION B-70315EN/01

4 INSTALLATION

- 52 -

B-70315EN/01 4.INSTALLATION

4.1 INSTALLATION PROCEDURE

Use the following procedure to make adjustments and checks during

installation.

(1) Check the environment at the installation location.

• Environmental conditions

1) Ambient temperature : +5° C to +30°C

2) Temperature variation : 1.1°C/minute maximum

3) Humidity : 75% or below (relative humidity)

4) Vibration : Acceleration not to exceed 0.05G.

Vibration amplitude not to exceed 5mm.

5) Atmosphere : Dust must be minimized. There must

be no organic volatile components.

6) Laser gas : Composition

CO

He : 40±2.0%

N

H

C

Purity : 99.99% or more

:5±0.25%

2

:55±2.75%

2

O : 5 ppm or less

2

: 1 ppm or less

mHn

(2) Remove all clamps.

The clamps are used only in transit. In particular, loosen the

resonator clamp before it is stored. If the resonator is left for a

long time with the clamp tightened, the resonator is likely to be

deformed. The clamp locations are shown in Fig. 4.1 (a) to Fig.

4.1 (c).

- 53 -

4.INSTALLATION B-70315EN/01

Fig.4.1(a) Clamp layout (C1000-E)

- 54 -

B-70315EN/01 4.INSTALLATION

Fig.4.1(b) Clamp layout (C2000-E)

- 55 -

4.INSTALLATION B-70315EN/01

Fig.4.1(c) Clamp layout (C4000-E)

- 56 -

B-70315EN/01 4.INSTALLATION

(3) Check the units installed in the main unit cabinet.

• Check items

1) Check whether any printed circuit boards are loose or

removed.

2) Check whether any cables are damaged (such as

damaged sheathing).

3) Check whether any connectors are loose or detached.

4) Check that the discharge tubes are neither cracked nor

damaged.

5) Check that the turbo blowers, exhaust pump, and other

units are neither loose nor missing.

6) Check that the power supply units and matching boxes

are neither loose nor missing.

7) Check that the input unit is neither loose nor missing.

8) Check that the connection to the electrode (copper

plate) of each discharge tube is not loose.

9) Check that the water and gas pipes are not loose.

(4) Check all screw terminals in the units.

• Check items

1) Terminal block of the input unit

2) Power supply units and matching boxes

(5) Check the oil level in the turbo blowers and exhaust pump, and

check for oil contamination.

For details of how to supply and replace the oil, see Section 5.3.

(6) Connect the power and signal lines to the oscillator.

See Section 4.4.3 for details.

• Check items

1) Cable between the CNC and oscillator

To connect this cable, apply the procedure described

in the "FANUC Series 16i-L Connection Manual."

2) Oscillator power cable

3) Grounding cable (< 10Ω)

4) Inter-unit connection between the oscillator and

exhaust pump (C1000-E)

(7) Check all printed circuit board settings.

• Check items

1) Setting pins on the oscillator IF PCB

See Section 6.5.5 for an explanation of the setting pins

on the IF PCB.

(8) Laser gas and cooling water pipes.

See Section 4.4.1 and Section 4.4.2 for details.

• Check items

1) Laser gas pipe material

Recommended gas pipe

Nylon tube AS1, manufactured by Junko Co. Ltd.

Polyfrotube, manufactured by Imperial Co. Ltd.

- 57 -

4.INSTALLATION B-70315EN/01

2) Gas leakage from external piping

3) Laser gas composition and purity (See Section

4.4.1.2.)

4) Quality of cooling water (See Section 4.4.1.1.)

5) Flow of cooling water (IN, OUT)

6) Exhaust pump connection (See Subsec.4.4.4.)

(9) Check the input power supply voltage, frequency and phase

sequence.

• Check items

1) 200/220 VAC +10%, -15%, 50/60 Hz ±1 Hz, 3-phase.

Note, however, that the combination of 220 V and 50

Hz is not supported.

2) Input power supply rating

3) Direction of phase rotation

(10) Turn on the power, then check the operation of the fan motors in

the housing.

The fan motors installed in the housing of the oscillator start as

soon as the power to the CNC is turned on. Check the operation

of each fan motor. Note, however, that the fan motor installed in

the laser power supply does not start until the oscillator sequence

reaches the turbo blower ON operation.

(11) Check the parameters and setting data.

Check the parameters against the data sheets attached to the

oscillator. If a value other than those given on the data sheets is

set, correct the setting. Note, however, that parameter No. 15270

and parameter No. 15204 are set automatically, so that these

parameters need not be modified.

CAUTION

Each oscillator has unique parameters. Check the

setting data according to the attached data sheets.

Be particularly careful to store these data sheets

safely.

(12) Check that cooling water is supplied normally, and that there is

no water leakage inside the oscillator or at any external

connection points.

• Check items

1) Turn off the main circuit breaker of the oscillator and

power supply.

2) Check that the water inlet (IN) and outlet (OUT) of the

oscillator are connected correctly. If the connections

are reversed, the flow sensor installed at the outlet will

not function. When a valve is attached to the

distributor unit (C4000-E : see Fig. 4.2.2), check that

the valve is open.

3) Fully open the valves on the exhaust side so that the

flow of water is not impeded. By manually operating

- 58 -

B-70315EN/01 4.INSTALLATION

the chiller unit, pass cooling water through the system

at a flow rate of about 10liters/minute. Then, check

that there is no water leakage at the following

locations:

1. The water inlet (IN) and outlet (OUT) of the

oscillator

2. The water piping (including all tubes and joints)

in the oscillator

4) Provided no water leakage is observed in step 3) above,

allow cooling water to flow through the oscillator at

the specified flow rate. Set the output pressure of the

cooling water circulating unit to 0.5 MPa. Then, check

that there is no water leakage at the following

locations:

1. The water inlet (IN) and outlet (OUT) of the

oscillator

2. The water piping (including tubes and joints) in

the oscillator

5) Stop the chiller unit, then switch the operation mode

from manual (local) mode to automatic (remote)

mode.

6) Provided no water leakage is observed, start the

oscillator, then set the RUN key to ON. Check that the

cooling water circulating unit can be operated

according to commands issued from the CNC. At this

time, check whether the cooling water is flowing at the

specified flow rate through each pipe in the oscillator.

If the flow rate is less than the specified value, alarm

No. 4072 (low cooling water flow rate) is issued soon

after the chiller unit is started. If this alarm is issued,

proceed as indicated in the guidance corresponding to

this alarm.

7) Check that the temperature of the cooling water is set

to room temperature plus 1°C. (The temperature of the

cooling water may be set to about 27°C throughout the

year.) The highest temperature that may be set is 30°C.

(13) Conduct an oscillator vacuum leakage test.

1) Check the oscillator for any internal leakage.

The procedure for performing a leakage check is given in

Section 4.3 (3).

2) When first starting the oscillator, check that gas is output

from the gas outlet of the oscillator. Depending on the