Fanuc B-65280EN Information Manual

ADDITIONAL INFORMATION

S

CUS

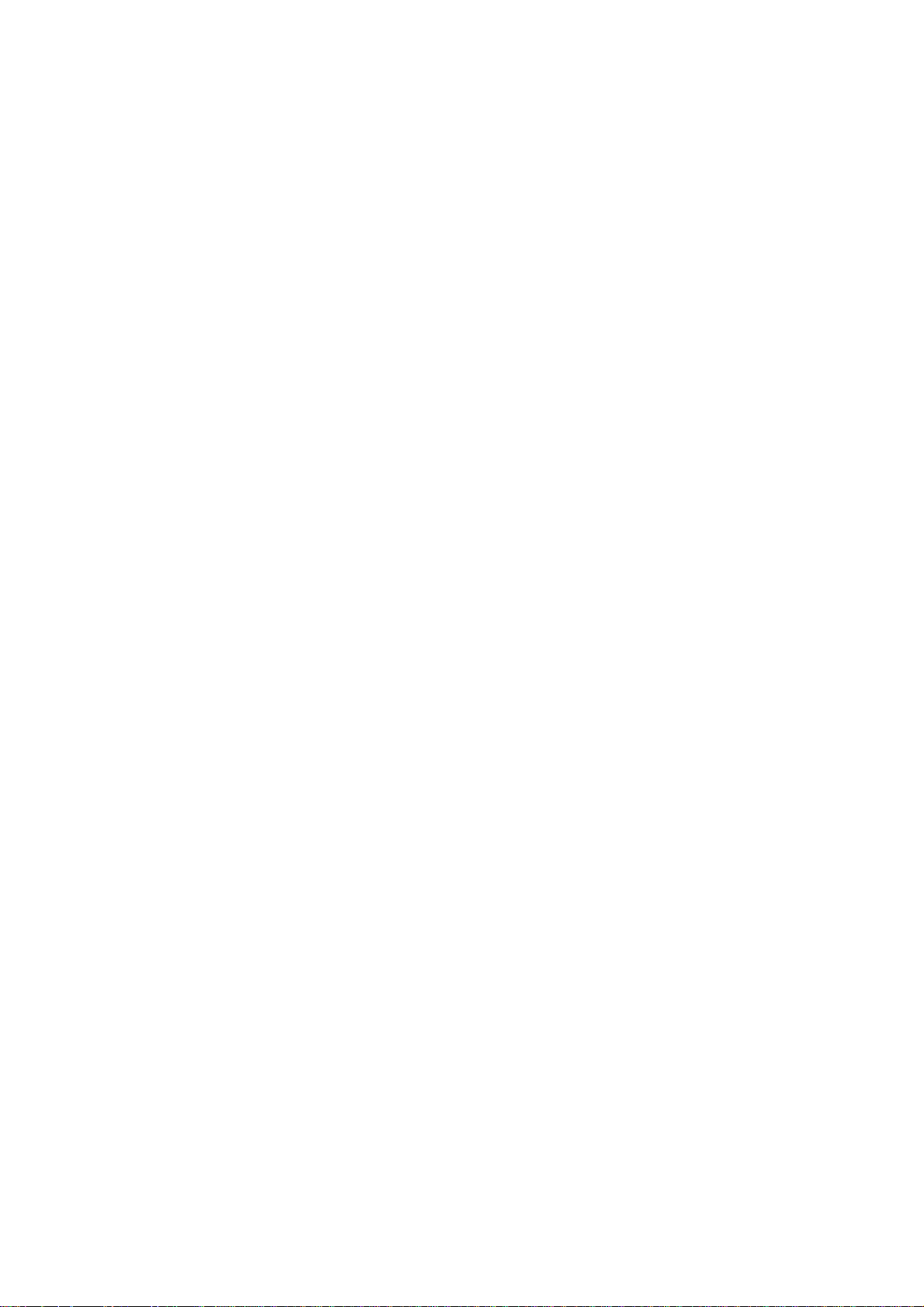

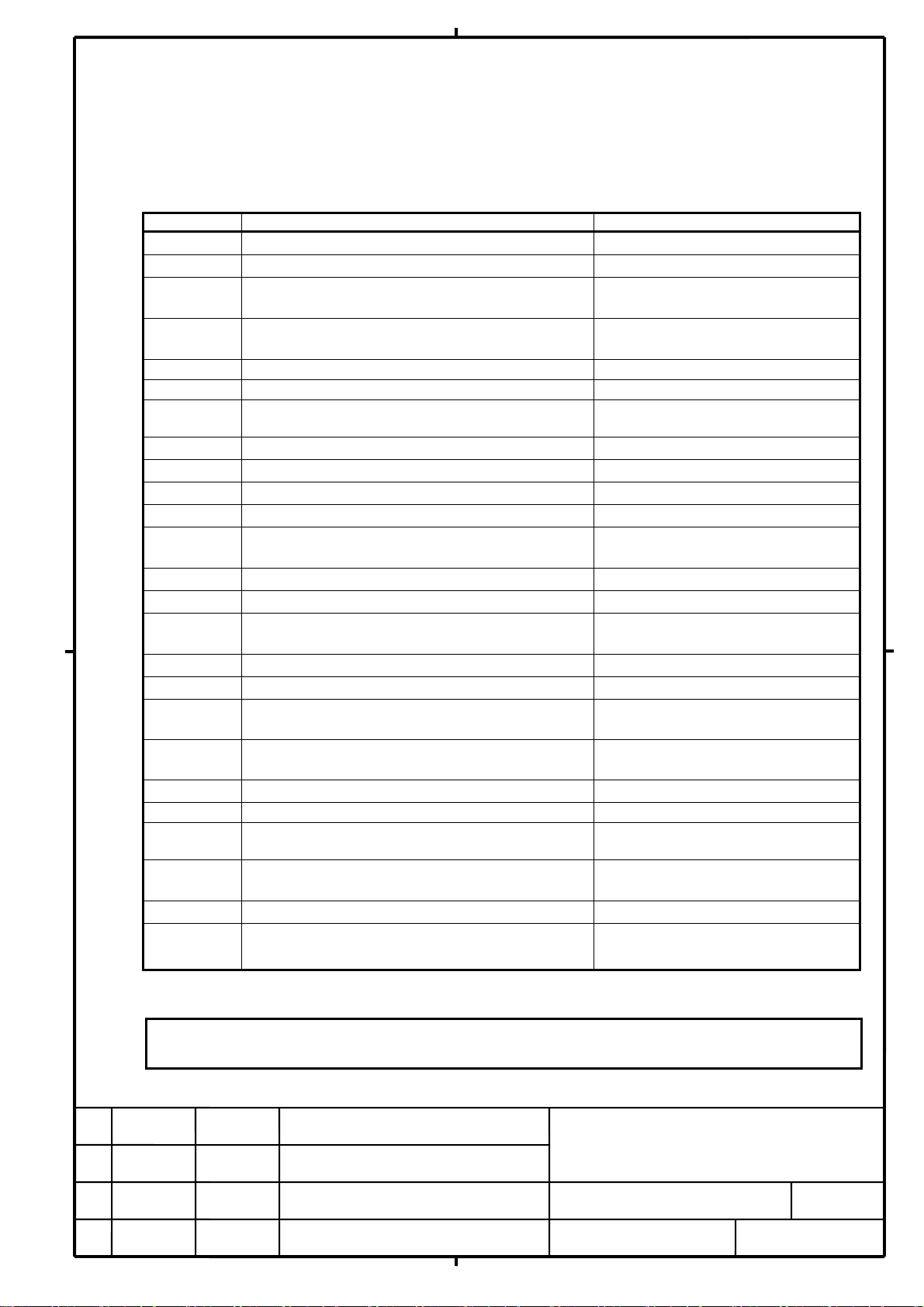

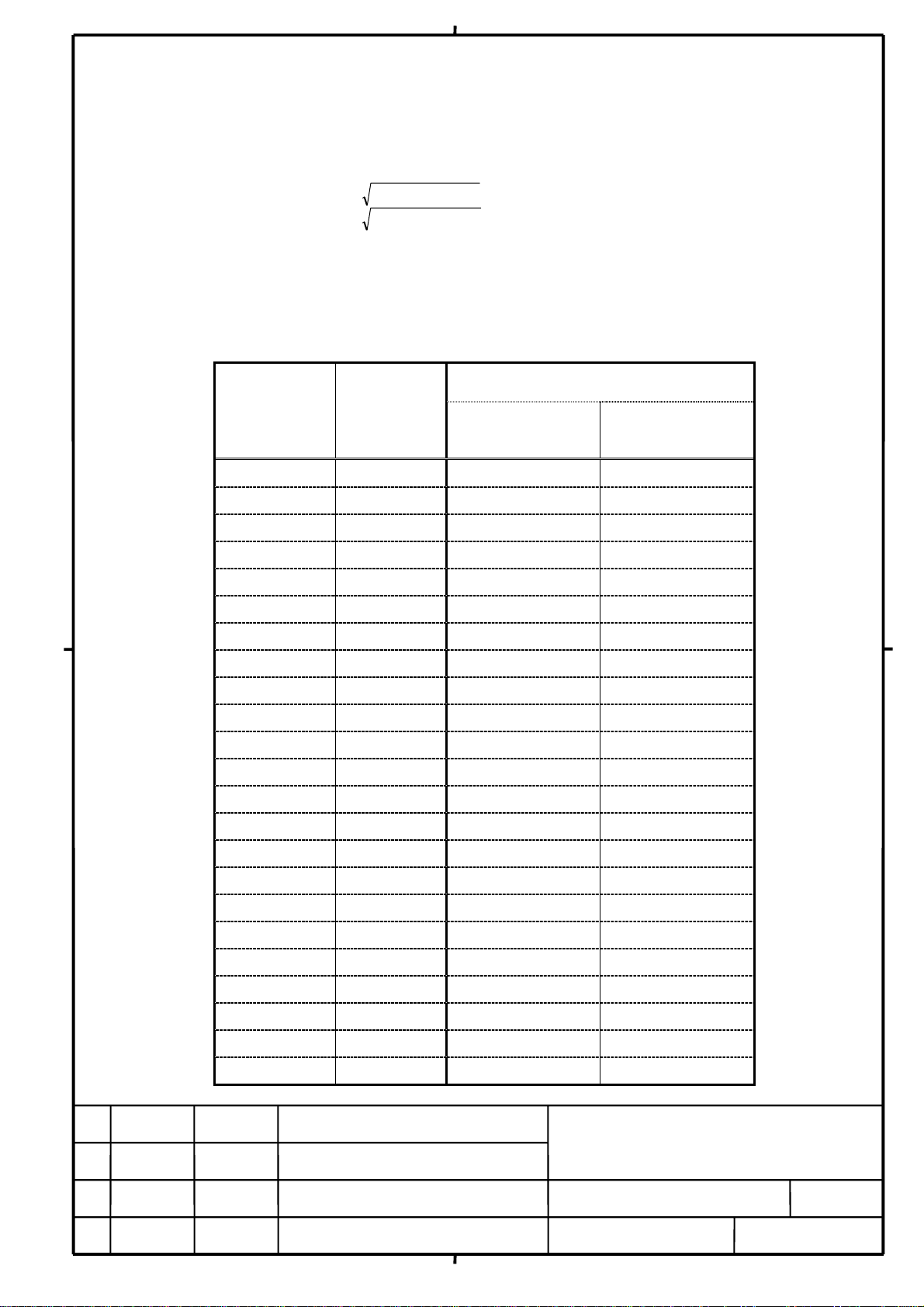

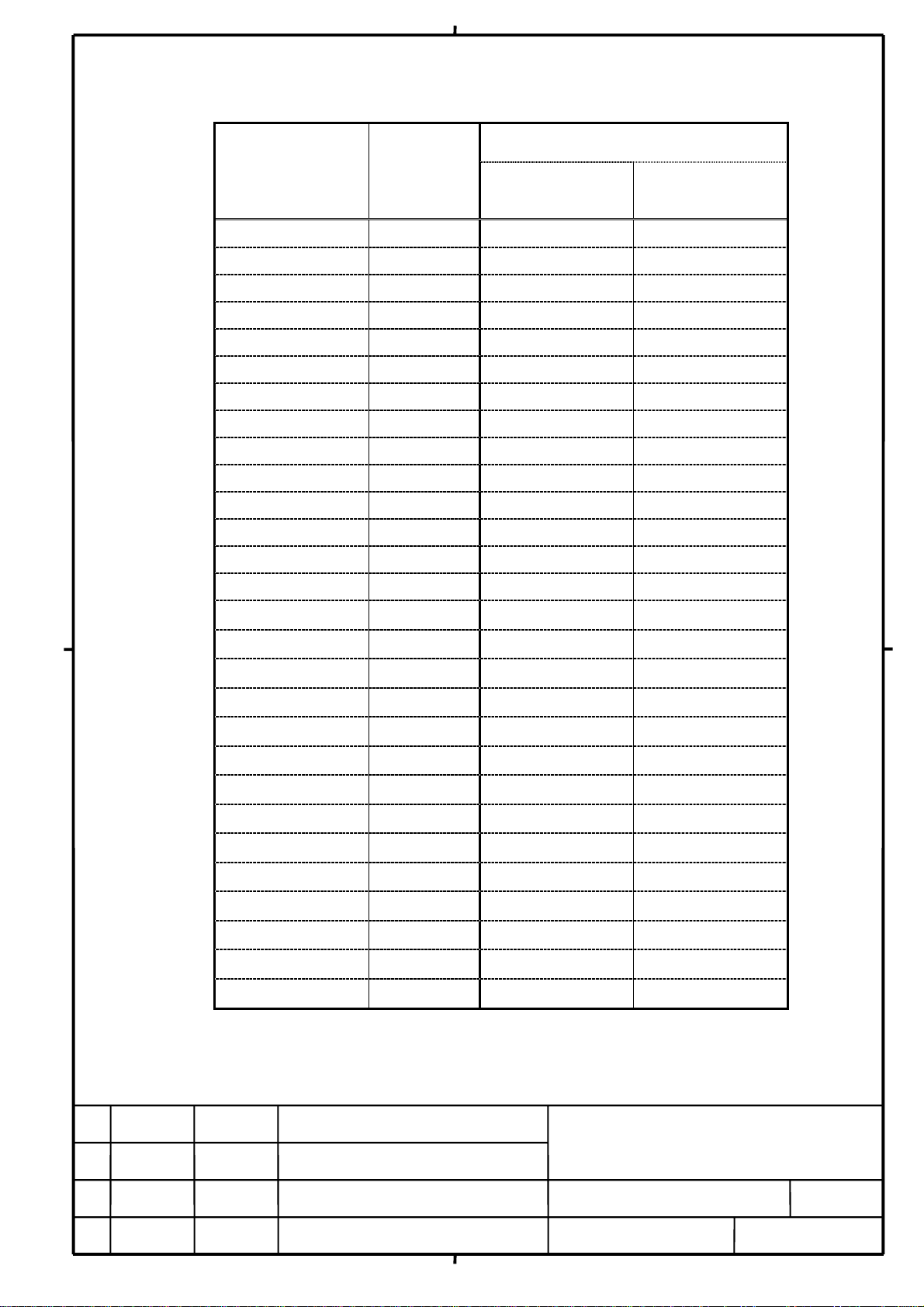

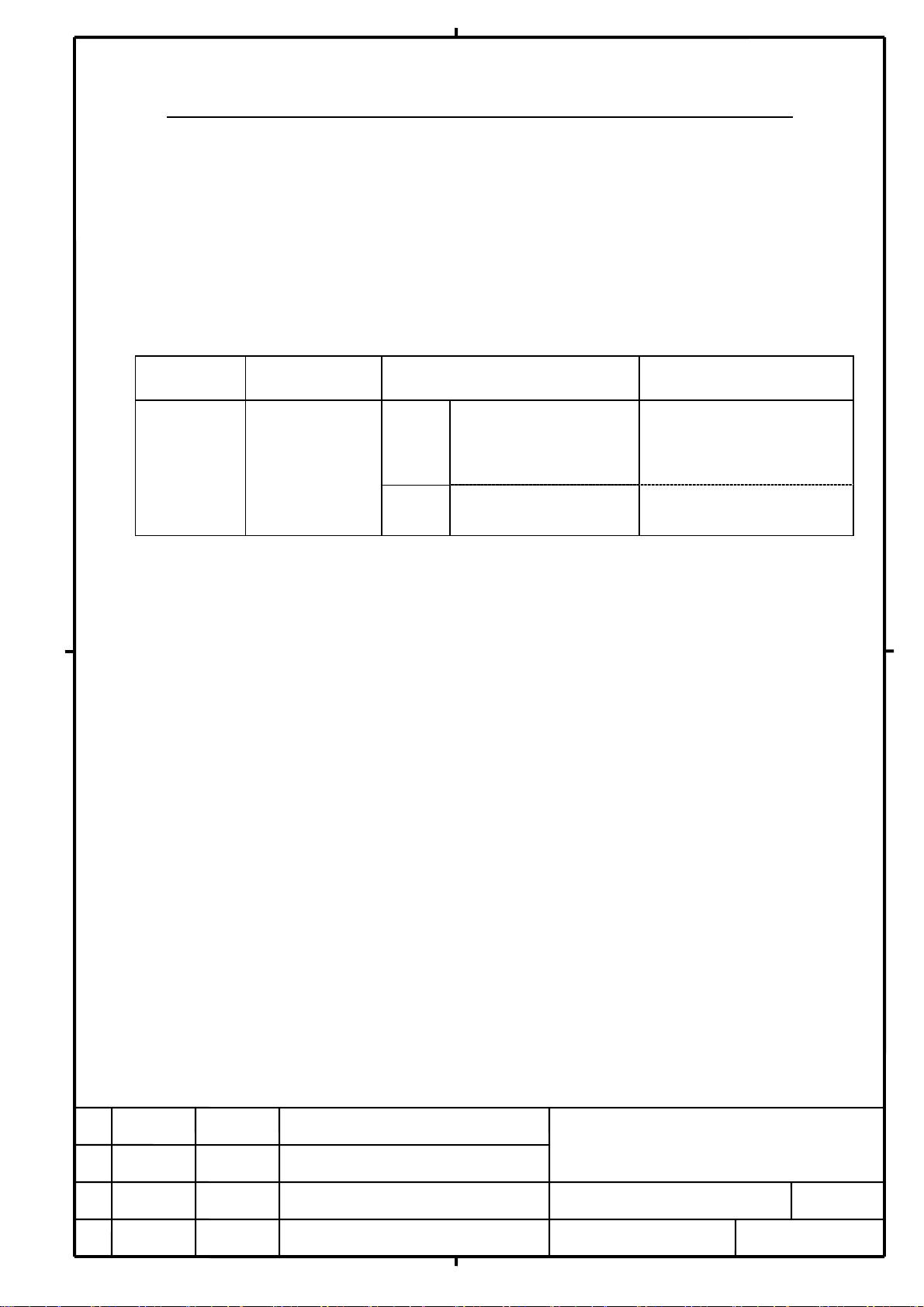

1. Type of applied documents

Name

Spec. No./Ver.

2. Summary of Change

Group Name / Outline

Basic Function

Optional

Function

Unit

Maintenance

Parts

Notice

Correction

Another

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

FANUC AC SPINDLE MOTOR αi series,

FANUC AC SPINDLE MOTOR βi series,

FANUC BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

B-65280EN/07

New, Add

Correct, Del

Revision of spindle software 9D5A/A,9D53/O, 9D70/O,9D80/K Add 2008.06

Applicable

Date

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

B-65280EN/07-01

HEET

T.

1/6

S

CUS

Revision of αi series Spindle software (9D5A/A, 9D53/O 9D70/O, 9D80/K)

1. General

αi series Spindle software was revised as follows.

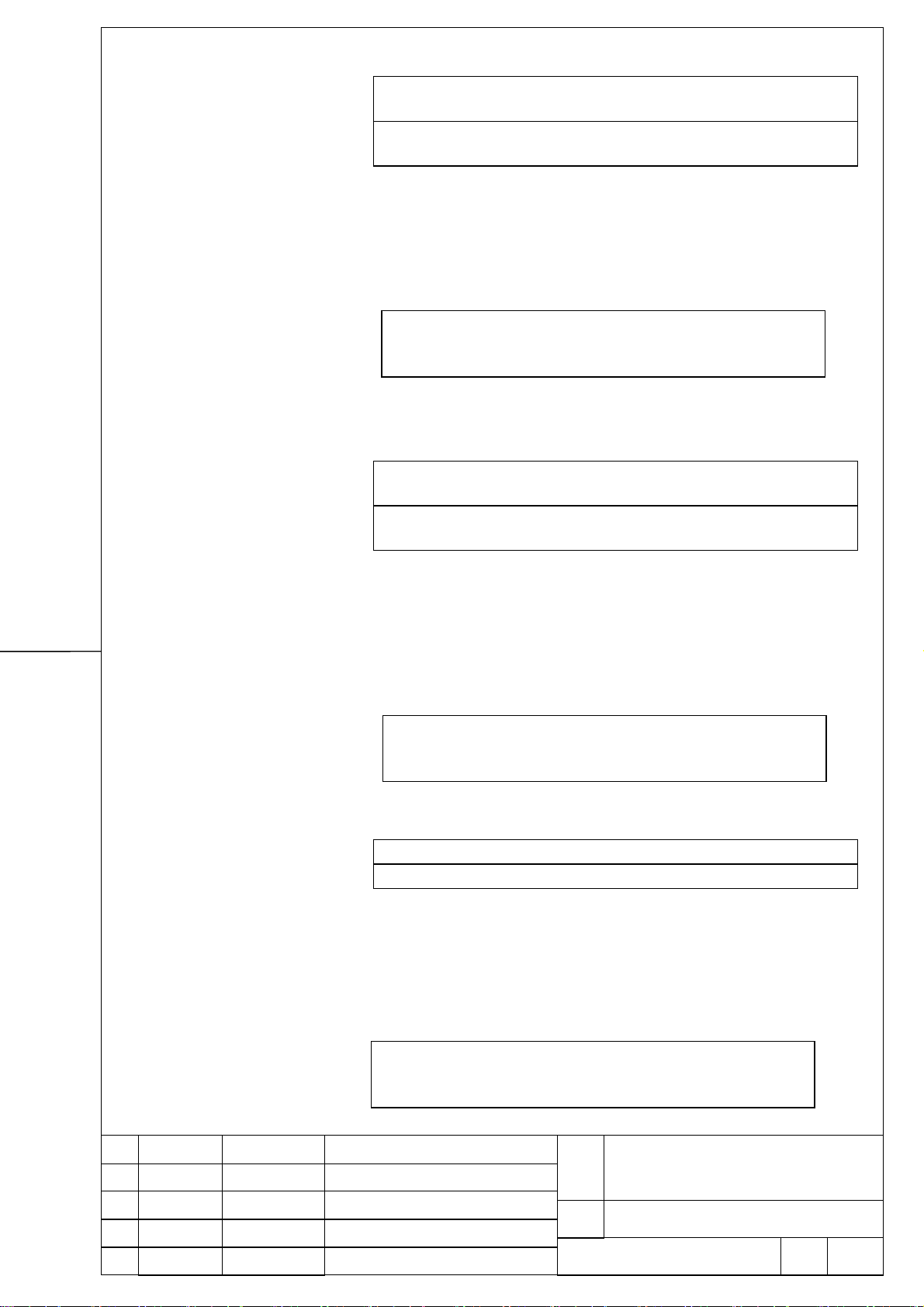

2. Software series, edition and applied spindle amplifier

Software

drawing No.

A06B-6111-H550

A06B-6111-H553

Software

edition

9D5A

edition A(01)

9D53

edition O(15)

Spindle amplifier

specification

A06B-6111-Hxxx#H550

A06B-6112-Hxxx#H550

A06B-6121-Hxxx#H550

A06B-6122-Hxxx#H550

A06B-6134-Hxxx#A

A06B-6134-Hxxx#D

A06B-6111-Hxxx#H553

A06B-6112-Hxxx#H553

A06B-6121-Hxxx#H553

A06B-6122-Hxxx#H553

Notes

16i/18i/21i,

0

i-B/C, 15i, PMi-D

For induction spindle motor

i-B/C, For βiSVSP

0

(Induction spindle motor)

16i/18i/21i,

0

i-B/C, 15i, PMi-D

For synchronous spindle motor

A06B-6111-Hxxx#H570

A06B-6111-H570

A06B-6141-H580

Note: 9D5A series is a succeeding series to 9D50 series. 9D50/Y is revised to 9D5A/A.

9D70

edition O(15)

9D80

edition K(11)

A06B-6112-Hxxx#H570

A06B-6121-Hxxx#H570

A06B-6122-Hxxx#H570

A06B-6141-Hxxx#H580

A06B-6142-Hxxx#H580

A06B-6151-Hxxx#H580

A06B-6152-Hxxx#H580

A06B-6164-Hxxx#H580

For induction/ synchronous spindle motor

0

For induction/ synchronous spindle motor

(Induction spindle motor)

30i/31i/32i

30i/31i/32i

16i/18i/21i

,

,

i-B/C, 0i-D ,15i , PMi-D

0

i-D, For βiSVSP

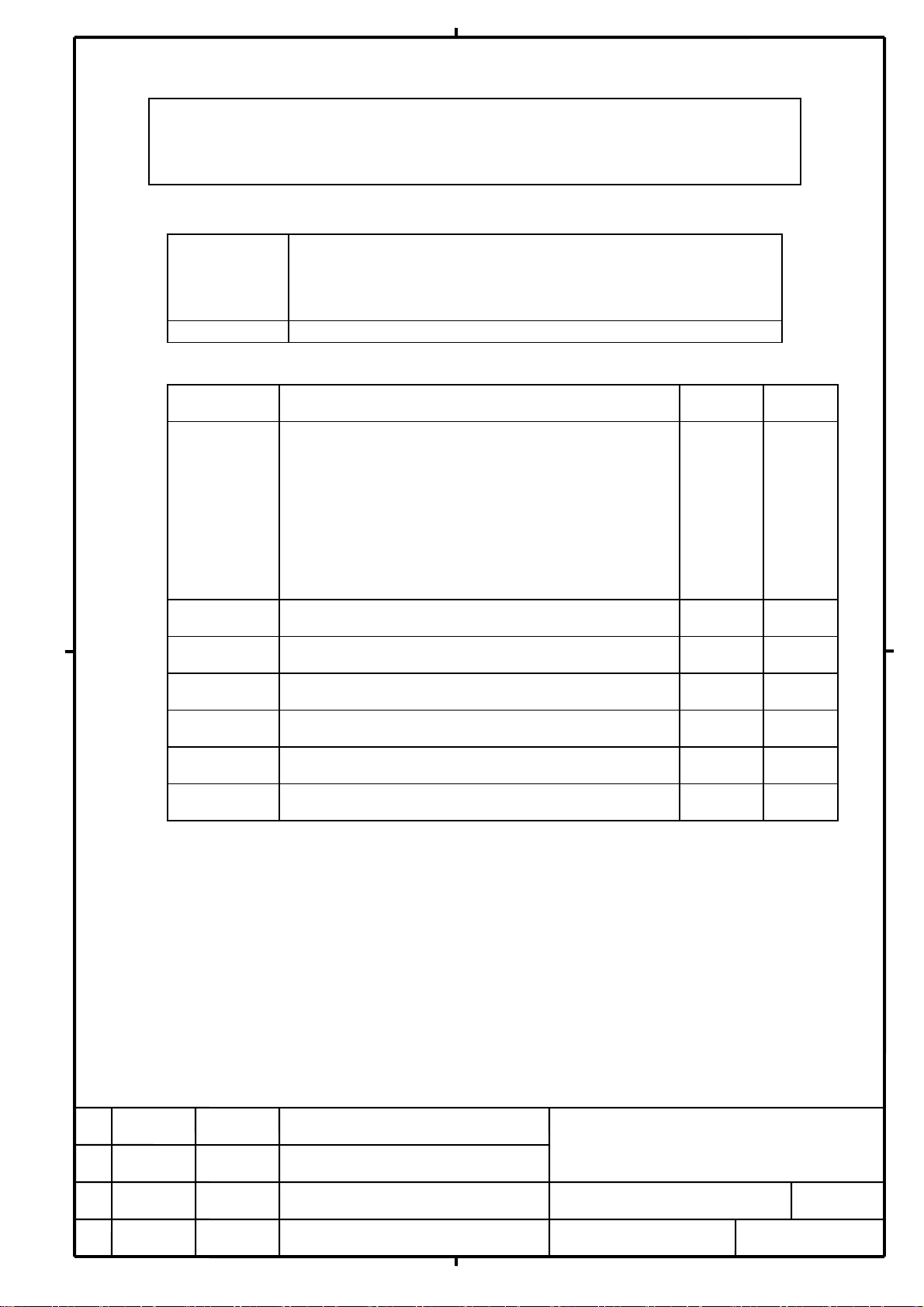

3. Contents of modification

Contents of modification 9D5A/A 9D53/O 9D70/O 9D80/K

(1) Magnetic Flux Boost Function is added.

Please refer to technical report (B-65280EN/07-02)

(2) The common parameters for rigid tap mode and

spindle synchronous control mode is improved to be

set for each operation mode.

Please refer to technical report (B-65280EN/07-03)

(3) The setting of motor voltage control characteristic is

improved to be set for each operation mode.

(Please refer to item 4.)

(4) Optimum Orientation Function is improved.

(Please refer to item 5.)

○

- - ○ ○

- - ○ ○

○

- ○ ○

○ ○ ○

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

B-65280EN/07-01

HEET

T.

2/6

S

CUS

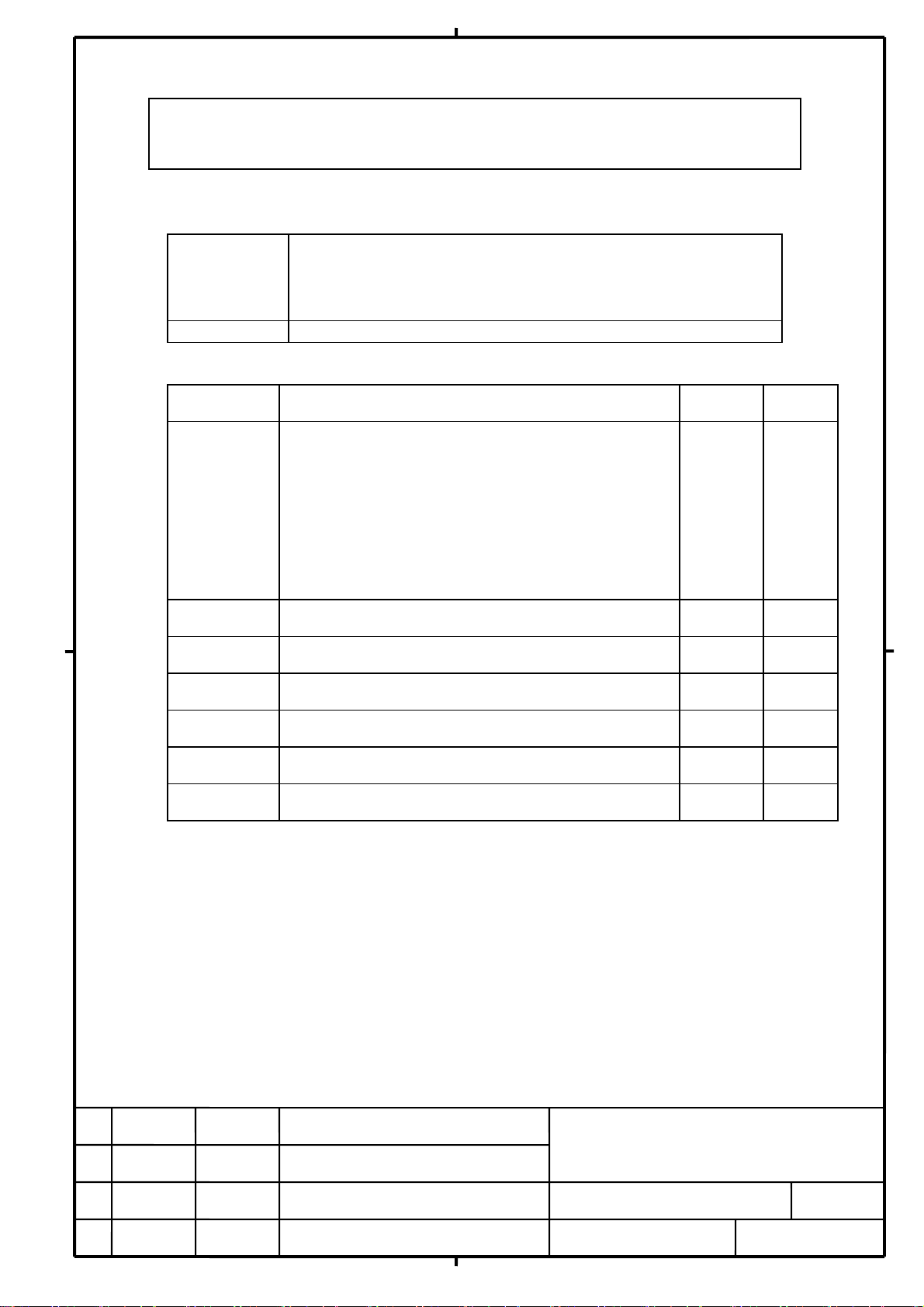

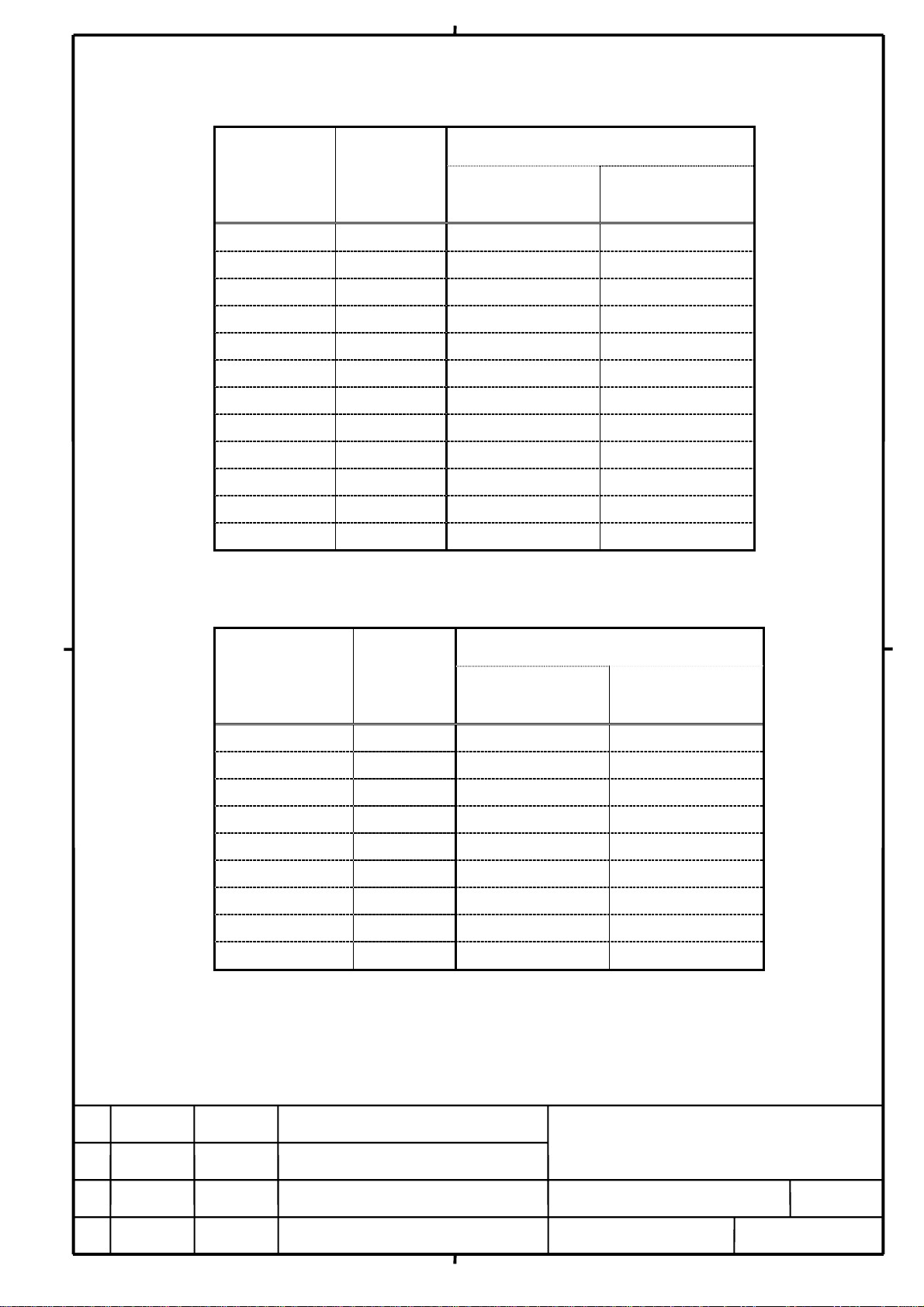

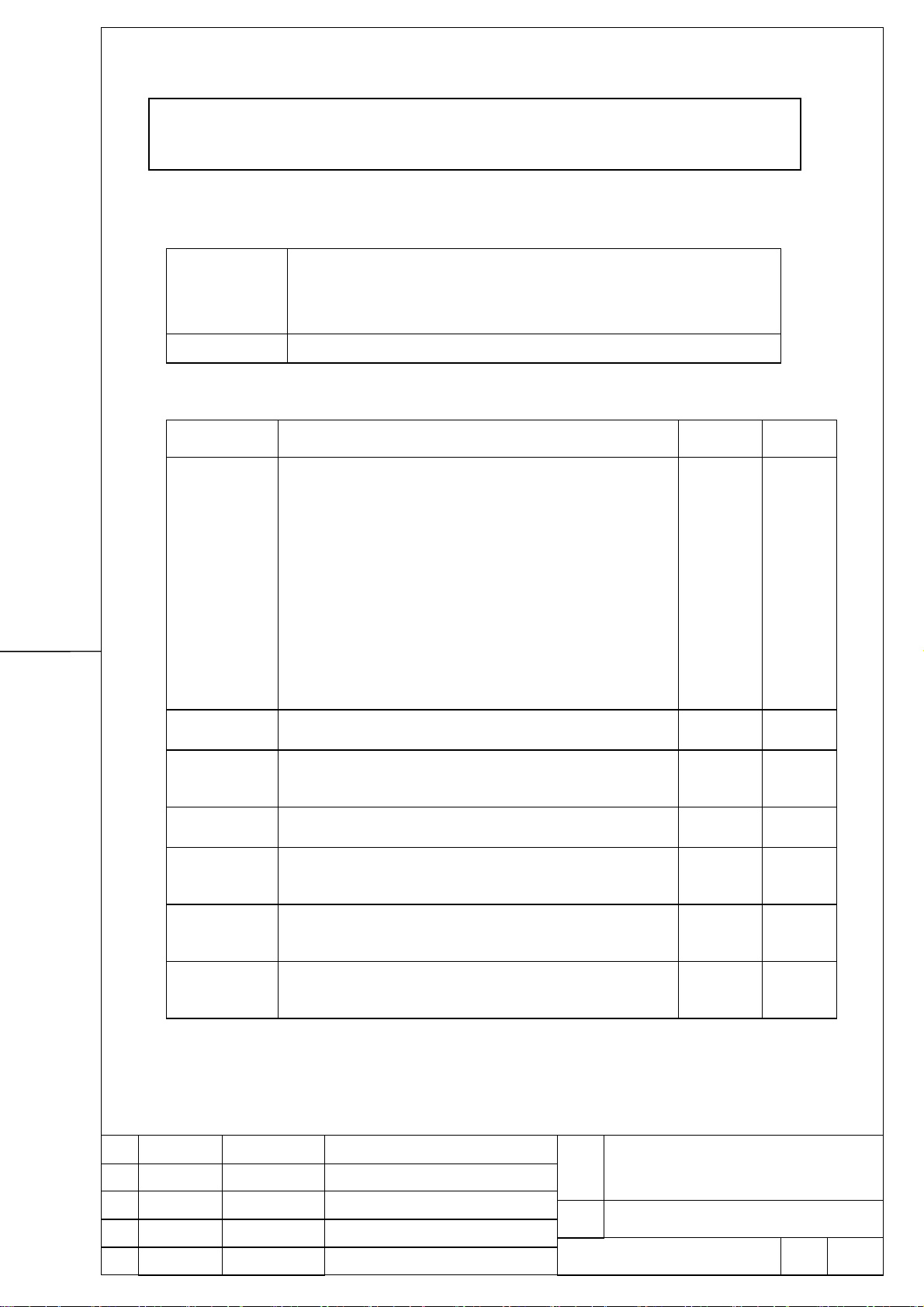

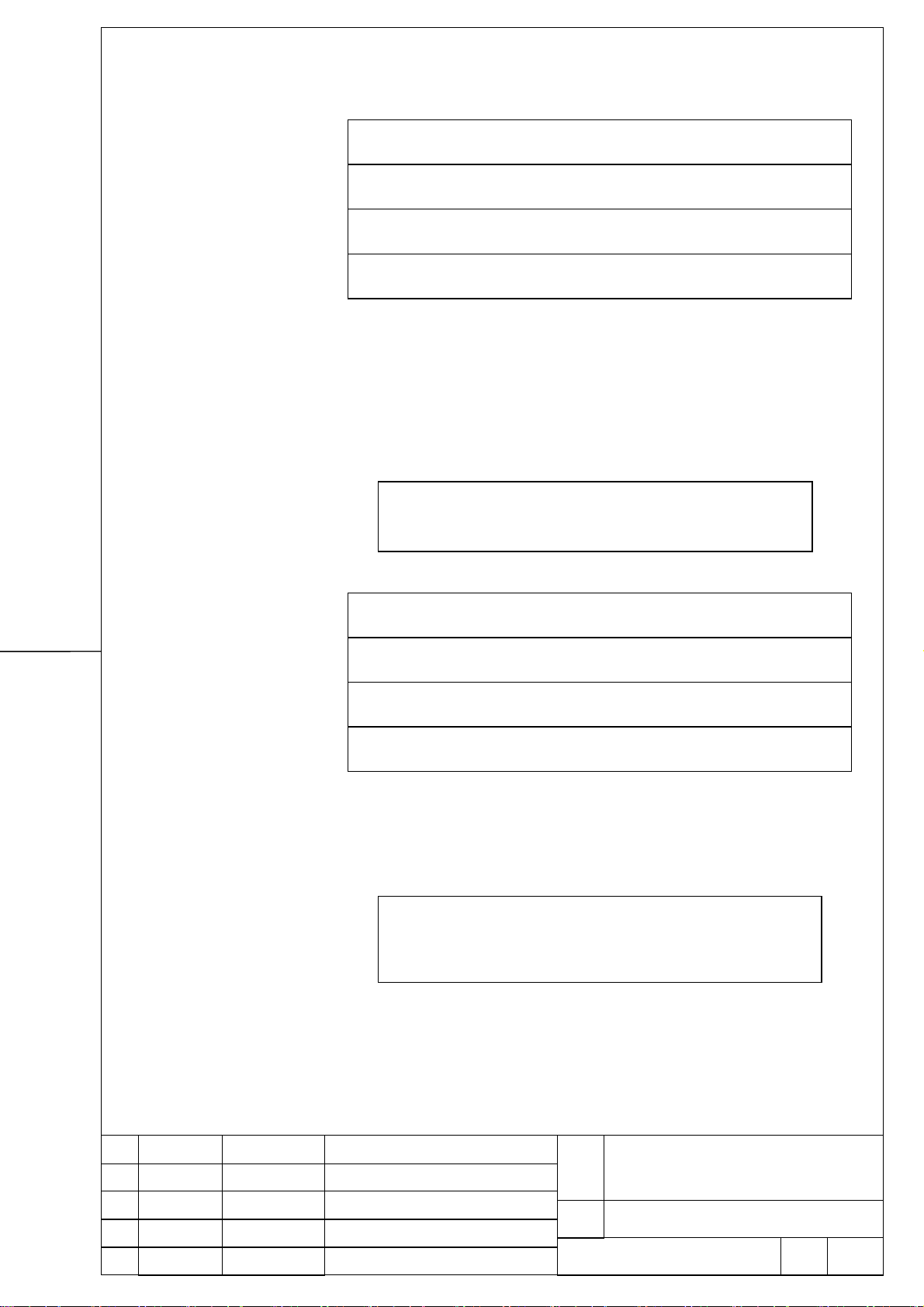

4. The setting of motor voltage control characteristic

(1) Over view

If spindle motor runs over the base speed in Cs contouring mode, rigid tapping mode or spindle

synchronous control mode, the setting of motor voltage control characteristic (No.4016#4) is set

to 1 and the motor voltage setting is reduced. The parameter (No.4016#4) is valid for all three

operation modes.

So the setting of motor voltage control characteristic is improved to be set each operation

mode.

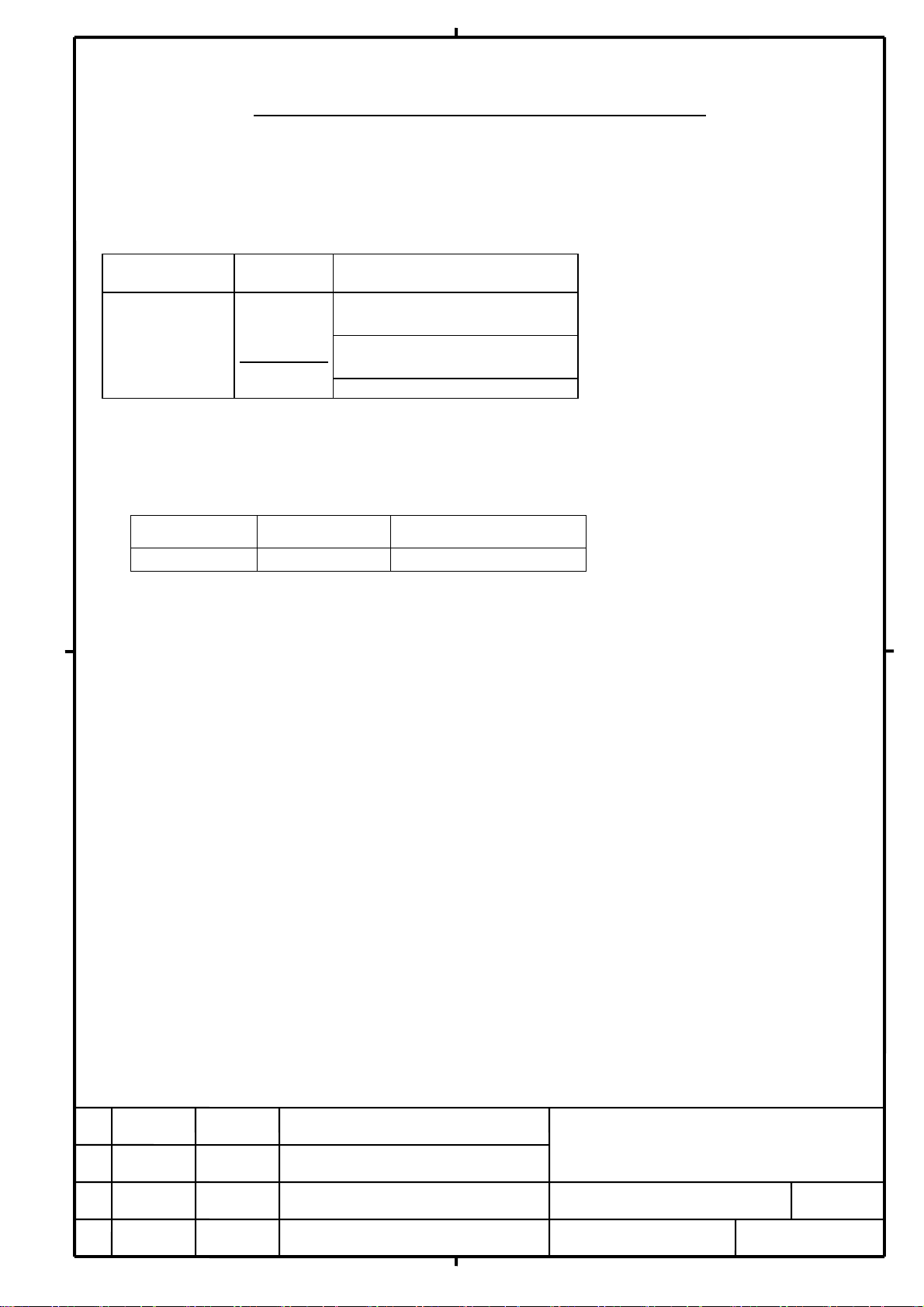

(2) Parameter

- - 4540

15i 16i,0i-B,C 30i,0i-D

EXPTCS (#0) The setting of motor voltage control characteristic for Cs contouring mode

EXPTRG (#1) The setting of motor voltage control characteristic for rigid tapping mode

EXPTSY (#3) The setting of motor voltage control characteristic for spindle synchronous

NOTE

*1 If parameter of motor voltage is set for each mode(rigid tapping mode or spindle synchronous control

mode), the motor voltage parameters are No.4558(high-speed characteristic) and No.4559(low-speed

characteristic) for spindle synchronous control mode.

*2 In case of FS30i Series, the parameter No.4540 is applicable with the following CNC software series and

editions.

FS30i/300i/300is-A G002 / G012 / G022 series : 24.0 editions or later

G00B / G01B / G02B series : 44.0 editions or later

G003 / G013 / G023 / G033 series : 07.0 editions or later

G00C / G01C / G02C / G03C series : 27.0 editions or later

FS31i/310i/310is-A5 G121 / G131 series : 24.0 editions or later

G12B / G13B series : 44.0 editions or later

G123 / G133 series : 07.0 editions or later

G12C / G13C series : 27.0 editions or later

FS31i/310i/310is-A G101 / G111 series : 24.0 editions or later

G103 / G113 series : 07.0 editions or later

FS32i/320i/320is-A G201 series : 24.0 editions or later,

G203 series : 07.0 editions or later

#7 #6 #5 #4 #3 #2 #1 #0

Set this bit to 1 when the motor voltage for Cs contouring control (No.4086)

is set to less than 100.

This parameter is valid when No.4016#4=0.

Set this bit to 1 when the motor voltage for rigid tapping control (No.4085:

high-speed characteristic, No.4137: low-speed characteristic) is set to less

than 100.

This parameter is valid when No.4016#4=0.

control mode

Set this bit to 1 when the motor voltage for spindle synchronous control

(No.4085: high-speed characteristic, No.4137: low-speed characteristic *1) is

set to less than 100.

This parameter is valid when No.4016#4=0.

EXPTSY EXPTRG EXPTCS

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

B-65280EN/07-01

HEET

T.

3/6

S

CUS

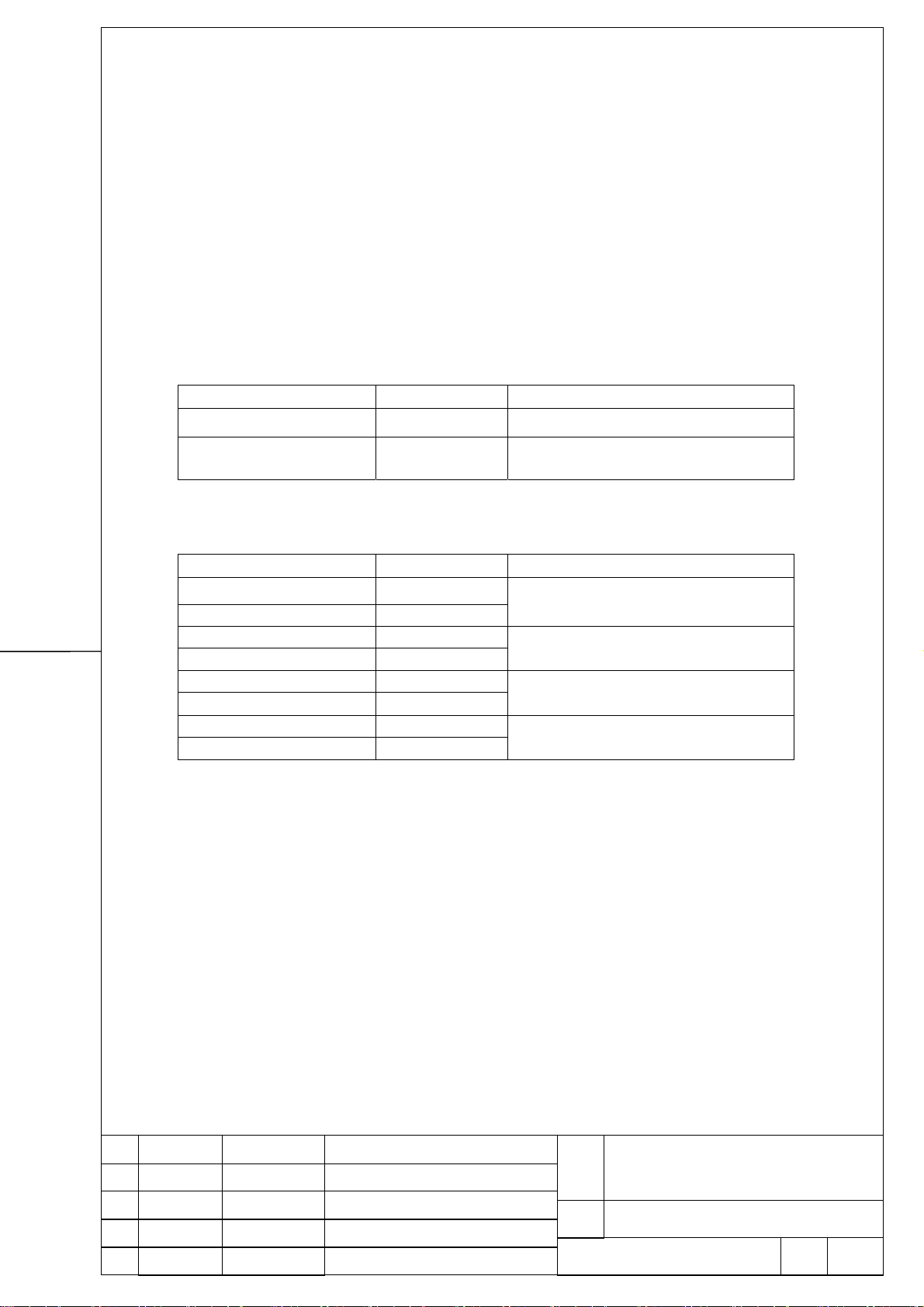

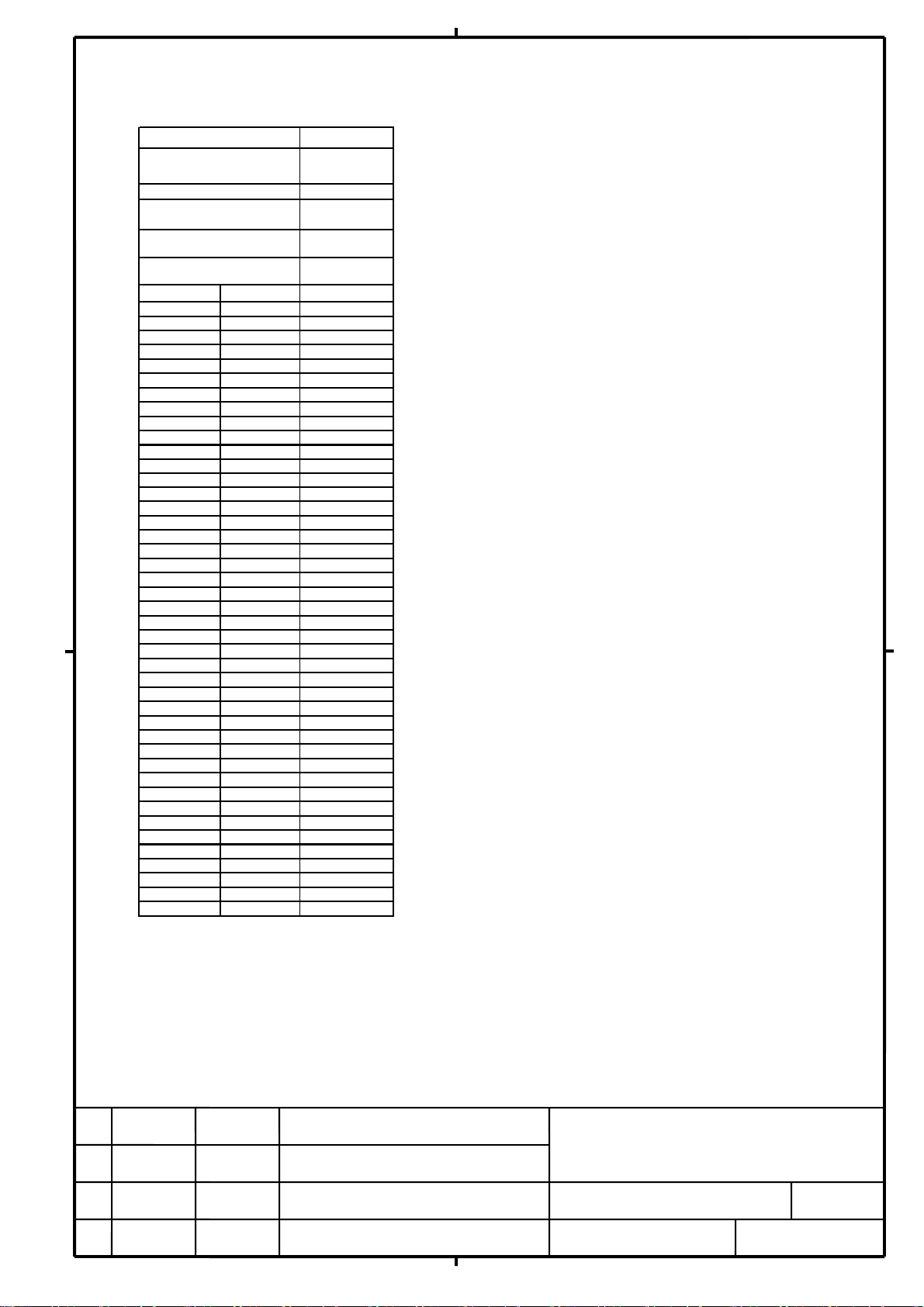

The improvement of Optimum Orientation Function

(1) Over view

Three spindle parameters (No4019#6, No.4590, No.4591) are added for Optimum Orientation.

For details of Optimum Orientation Function, refer to spindle parameter manual.

No. Description Initial setting

4003#0 Selecting a spindle orientation type 0

4003#3,#2 Spindle rotation direction at orientation Select a rotation direction.

4006#1 Unit of gear ratio setting

4017#7

4018#6,3

4018#4,5

4019#6

4031 Spindle orientation stop position Specify a stop position.

4038 Spindle orientation speed upper limit 0

4042 to 4043 Velocity proportional gain on orientation 10

4050 to 4051 Velocity integral gain on orientation 10

4056 to 4059 Gear ratio

4060 to 4063 Position gain on orientation 3000

4064 Percentage limit to an acceleration during deceleration 100

4075 Orientation completion signal detection level

4077 Orientation stop position shift value Specify a stop position.

4084 Motor voltage on orientation 100

4171,4173

4172,4174

4320 to 4323 Acceleration during motor deceleration

4324

4326,4327

4328 Command multiplier for orientation

4370 Filter time constant for spindle accerelation detection 0

4590,4591

*1

Short-cut function when spindle orientation from

stopped state is specified

Type of position coder method orientation 0, 1

Setting of velocity feedforward 1, 1

Setting of the compensation of spindle acceleration

command

Denominator of the motor sensor-to-spindle arbitrary

gear ratio

Numerator of the motor sensor-to-spindle arbitrary gear

ratio

One-rotation signal detection speed 0

Limit ratio for spindle acceleration command /

Time constant for overshoot compensation

Spindle orientation speed limit ratio 1/

Spindle orientation speed limit ratio 2

Specify an appropriate value depending

on the system configuration.

Specify an appropriate value according

to the use of the machine.

1

Specify an appropriate value depending

on the system configuration.

Specify an appropriate value according

to the use of the machine.

Specify an appropriate value depending

on the system configuration.

Specify an appropriate value depending

on the system configuration.

Tune according to actual measurements.

0

Specify an appropriate value according

to the use of the machine.

0

01

1

08.06.25

Date Ed.

*: Newly added.

NOTE

*1 In case of FS30i Series and FS 0i-D, spindle parameters (No.4590, No.4591) are available.

TITLE

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

Ts ut sum i

DRAW. No.

B-65280EN/07-01

Design.

HEET

T.

4/6

S

CUS

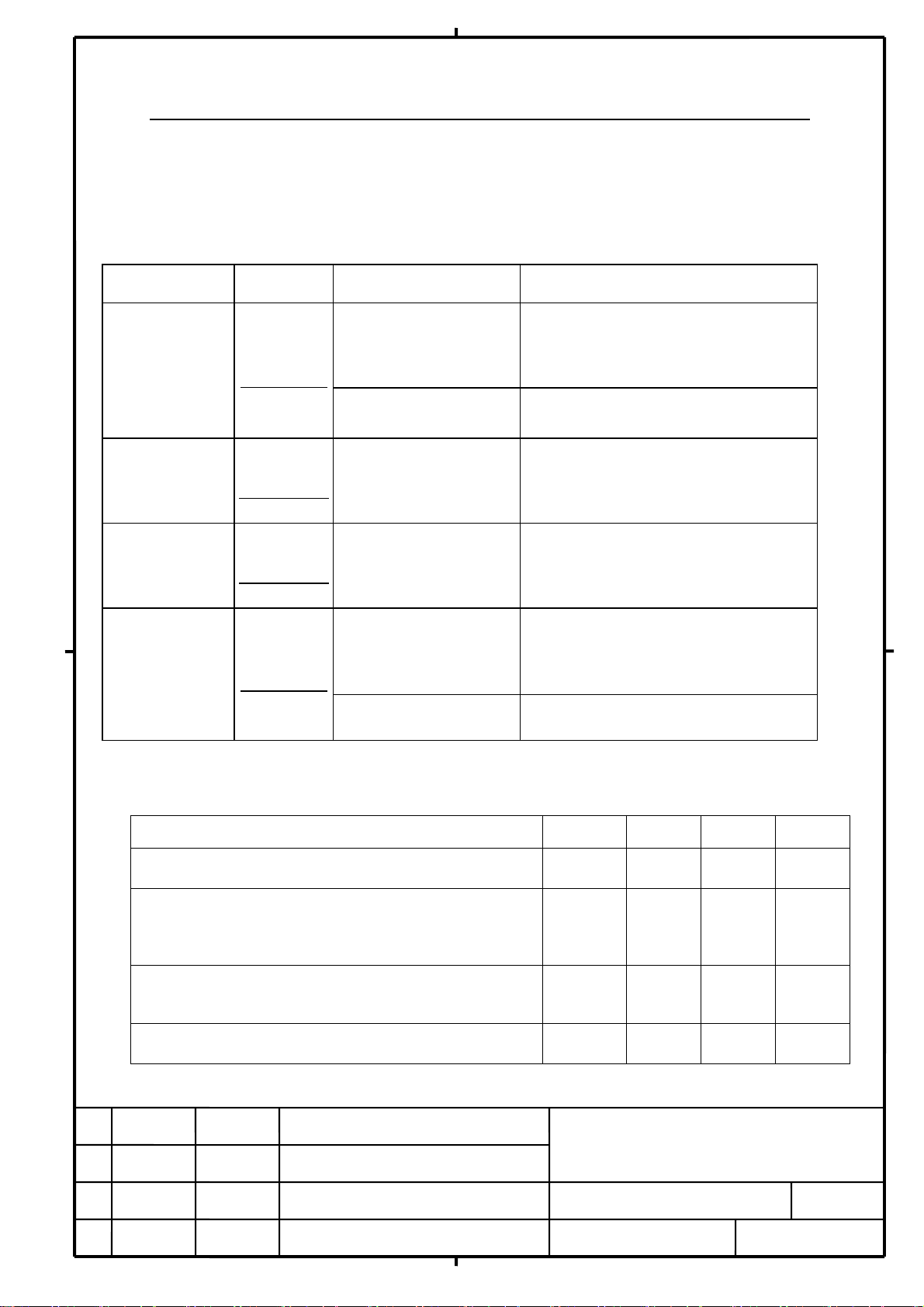

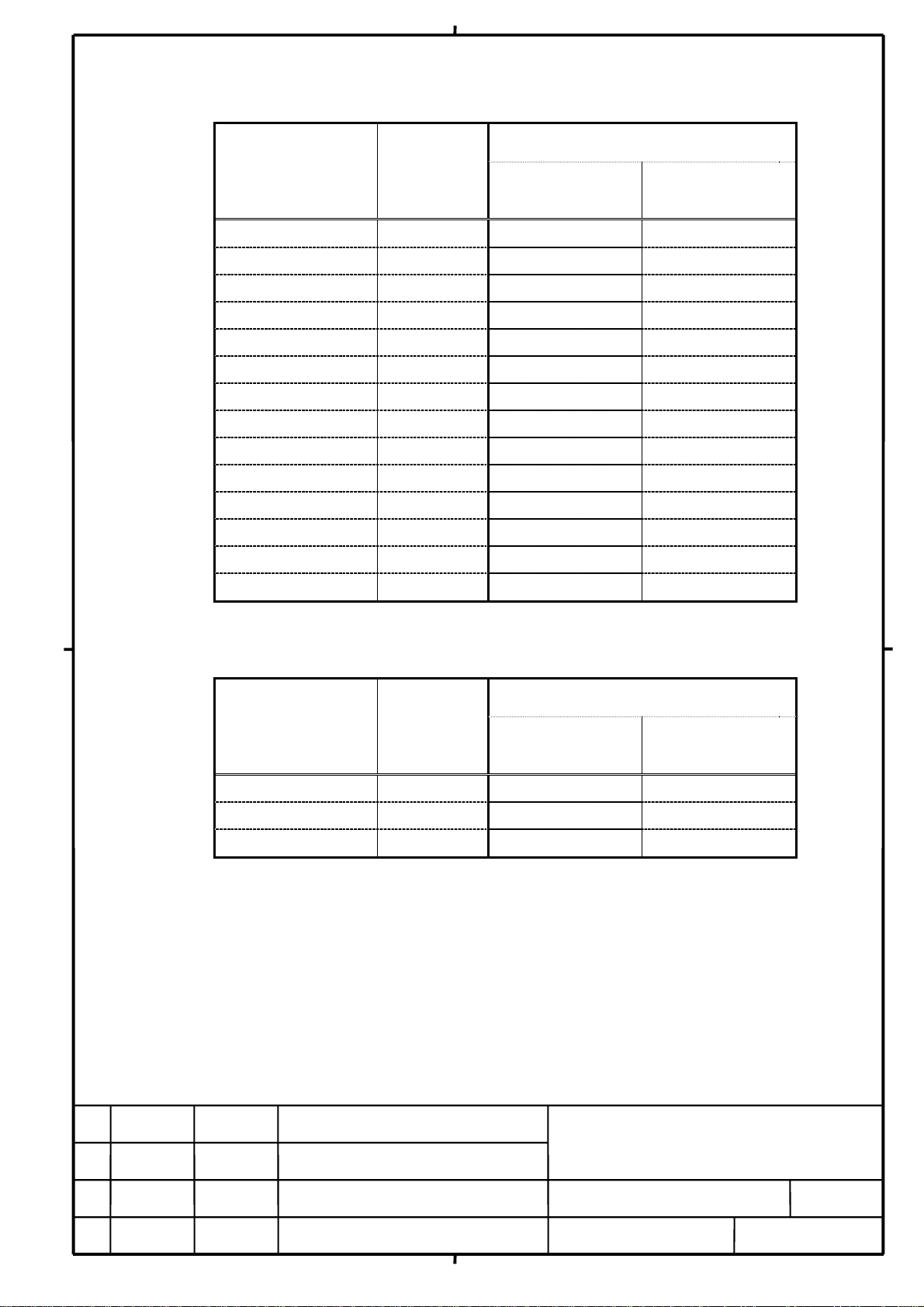

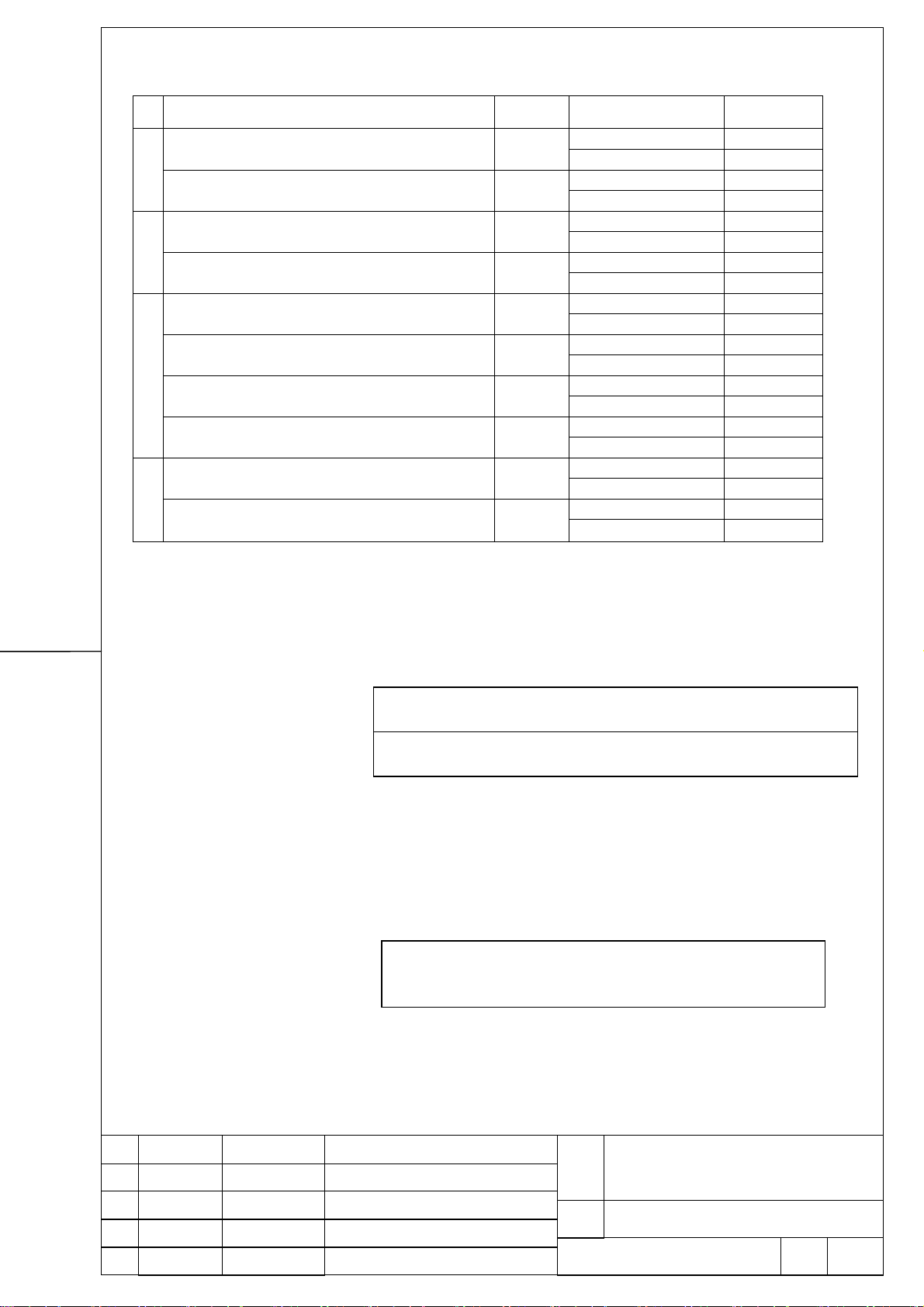

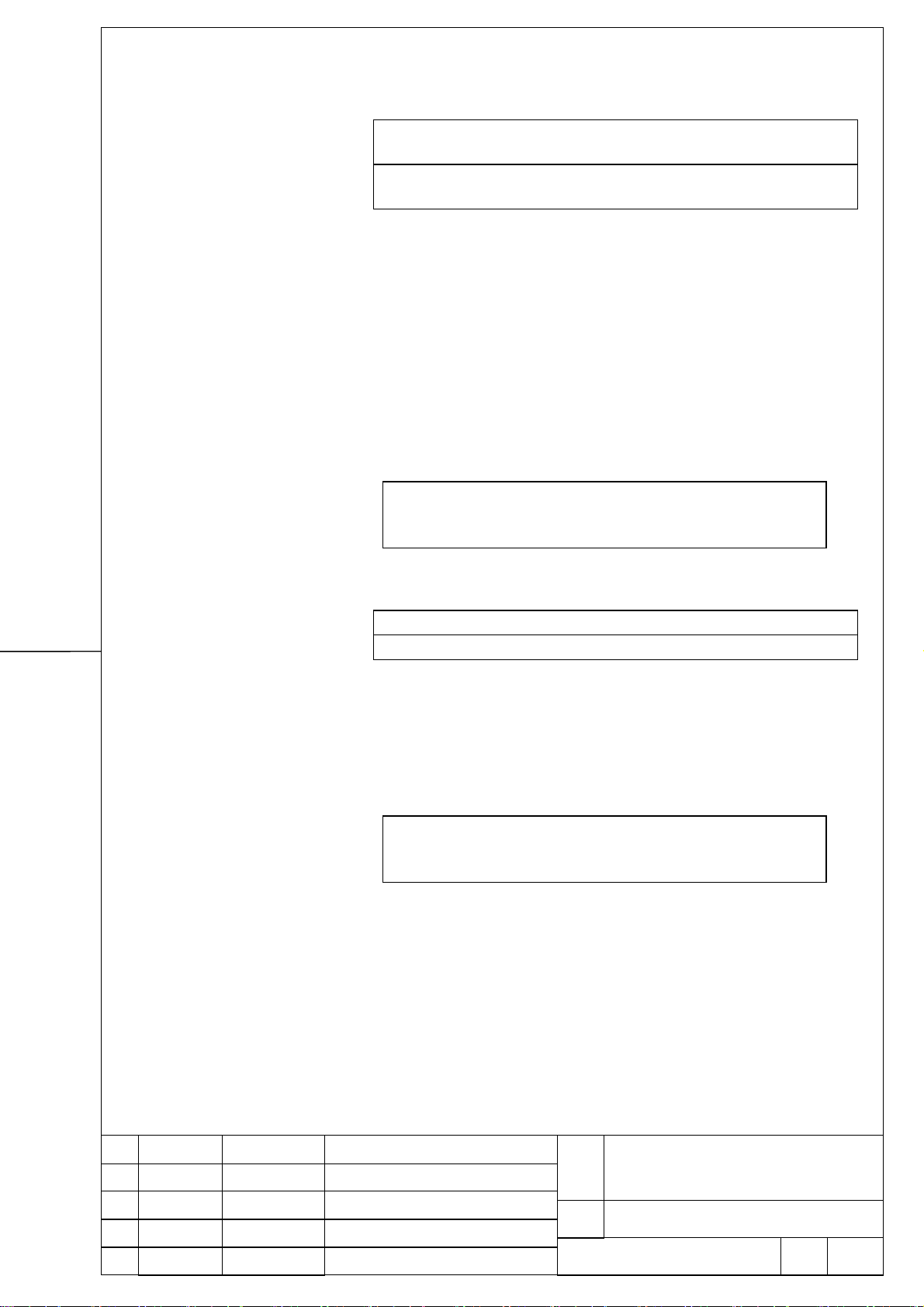

(2) Parameter

3019 4019 4019

- - -

- - -

15i 16i,0i-B/C 30i,0i-D

#7 #6 #5 #4 #3 #2 #1 #0

ORACMP Whether to enable the compensation of the spindle acceralation for

15i 16i,0i-B/C 30i,0i-D

4590[L]

-

4590[H]

4591[L]

-

4591[H]

Optimum orientation: spindle orientation speed limit ratio1(HIGH) (CTH1A=0)

Optimum orientation: spindle orientation speed limit ratio2(HIGH) (CTH1A=0)

Optimum orientation: spindle orientation speed limit ratio1(LOW) (CTH1A=1)

Optimum orientation: spindle orientation speed limit ratio2(LOW) (CTH1A=1)

Unit of data : 1%

Valid data range: 0 to 100

Standard setting value: 0

<REFERENCE> There is a possibility to shorten the orietation time by adjusting this

ORACMP

Optimum Orientation.

0: Enabled

1: Disabled

This parameter is for the compensation of the spindle acceleration

command when the orientation starts below the upper limit of orientation

speed.

Usually, set this bit to “1”.

This data is used to set an orientation speed according to upper limit of

orientation speed(No.4038). Set to “0” because it is not usually necessary to

adjust this parameter.

parameter when the orientation starts near upper limit of orientation

speed(No.4038).

Lower limit of orientation speed(ORSPDL) is calculated according to the

following equation with spindle orientation limit ratio 1(ORSCF1).

ORSCF1100

ORSPDL ×

−

=

100

ORSPDU

Orientation speed (ORSPD) is calculated according to the following

equation.

Spindle speed when the orientation command is on; ORSINI

Upper limit of orientation speed(No.4038): ORSPDU

Lower limit of orientation speed: ORSPDL

Orientation speed limit ratio2 ORSCF2

ORSPD ××=

ORSCF2

100

ORSINI

+

−

ORSCF2100

100

ORSPDL

(ORSPD is clamped by ORSPDU and ORSPDL)

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

B-65280EN/07-01

HEET

T.

5/6

S

CUS

NOTE

In case of FS30i Series, the parameter No.4590,4591 are applicable with the following CNC software

series and editions.

FS30i/300i/300is-A G002 / G012 / G022 series : 24.0 editions or later

G00B / G01B / G02B series : 44.0 editions or later

G003 / G013 / G023 / G033 series : 07.0 editions or later

G00C / G01C / G02C / G03C series : 27.0 editions or later

FS31i/310i/310is-A5 G121 / G131 series : 24.0 editions or later

G12B / G13B series : 44.0 editions or later

G123 / G133 series : 07.0 editions or later

G12C / G13C series : 27.0 editions or later

FS31i/310i/310is-A G101 / G111 series : 24.0 editions or later

G103 / G113 series : 07.0 editions or later

FS32i/320i/320is-A G201 series : 24.0 editions or later,

G203 series : 07.0 editions or later

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Revision of αi series Spindle software

(9D5A/A, 9D53/O, 9D70/O, 9D80/K)

B-65280EN/07-01

HEET

T.

6/6

S

CUS

Magnetic Flux Boost Function for Spindle Motor Description

1.Type of applied documents

FANUC AC SPINDLE MOTOR αi series,

Name

FANUC AC SPINDLE MOTOR βi series,

FANUC BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

Spec. No./Ver.

2.Summary of Change

Group Name / Outline

Basic Function

Optional

Function

Unit

Maintenance

Parts

Notice

Correction

Another Magnetic Flux Boost Function Add 2008.06

B–65280EN/07

New,Add

Correct,Del

Applicable

Date

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

1/12

S

CUS

Spindle amplifier αi series

Magnetic Flux Boost Function Description

1. General .............................................................................................................................................. 3

1.1. Overview ..................................................................................................................................... 3

1.2. Applicable software ..................................................................................................................... 3

1.3. Remarks ..................................................................................................................................... 3

2. Explanation of operation .................................................................................................................... 4

3. Examples of application ..................................................................................................................... 5

4. Parameters ........................................................................................................................................ 6

5. Adjustment procedure of parameters ................................................................................................. 7

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

2/12

S

CUS

1. General

1.1. Overview

This specification describes Magnetic Flux Boost Function which shortens the time required to

change rigid tapping mode or Cs contouring mode and is able to start the position control quickly.

1.2. Applicable software

Spindle software

Series Edition Applicable CNC

9D80 K(11) edition or later

FS30i, FS16i, FS0i-B/C, FS0i-D, FS15i

1.3. Remarks

1.This function is not available for synchronous spindle motors.

2.This function is not available for torque tandem control function(when tandem mode signal is on),

and twin drive control function.

3.This function is not available for differential speed rigid tapping (slave spindle) .

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

3/12

S

CUS

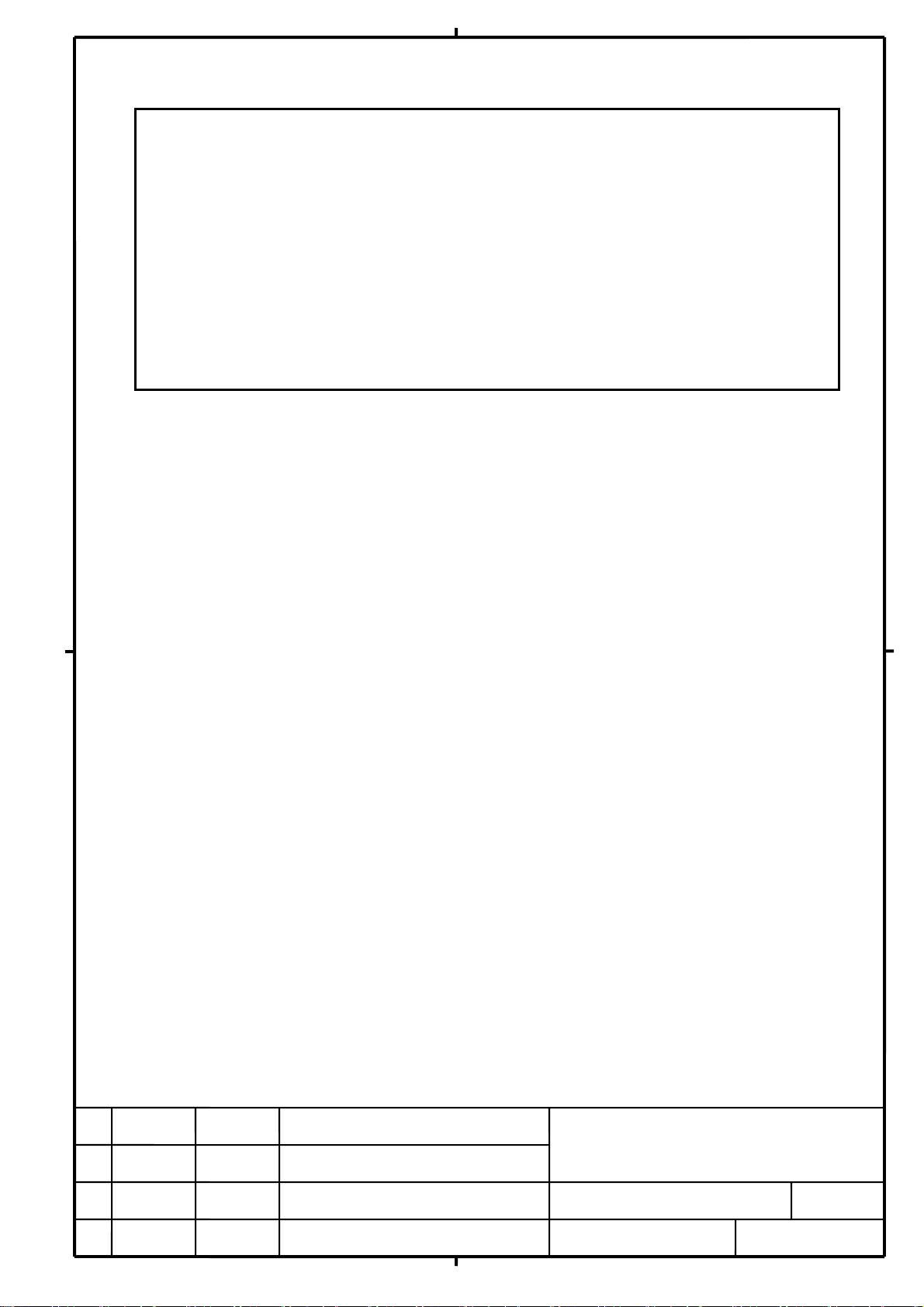

2. Explanation of operation

In induction spindle motors, the excitation current is flowed to generate magnetic flux to generate

torque. But the excitation current is not always rated value. If low load, the excitation current is

controlled to under rated value to reduce the motor heatgeneration.

It takes a certain time determined by the motor circuit constants for magnetic flux to rise up from

weakened value to rated value. So spindle parameter No.4099 (Delay time for stable motor

excitation) is prepared to wait for changing from the velocity control mode to rigid tapping mode or

Cs contouring mode which requires the high response of torque.

The Magnetic Flux Boost Function shortens the waiting time by commanding the over rated

excitation current when changing to rigid tapping mode or Cs contouring mode, and is able to start

the position control quickly.

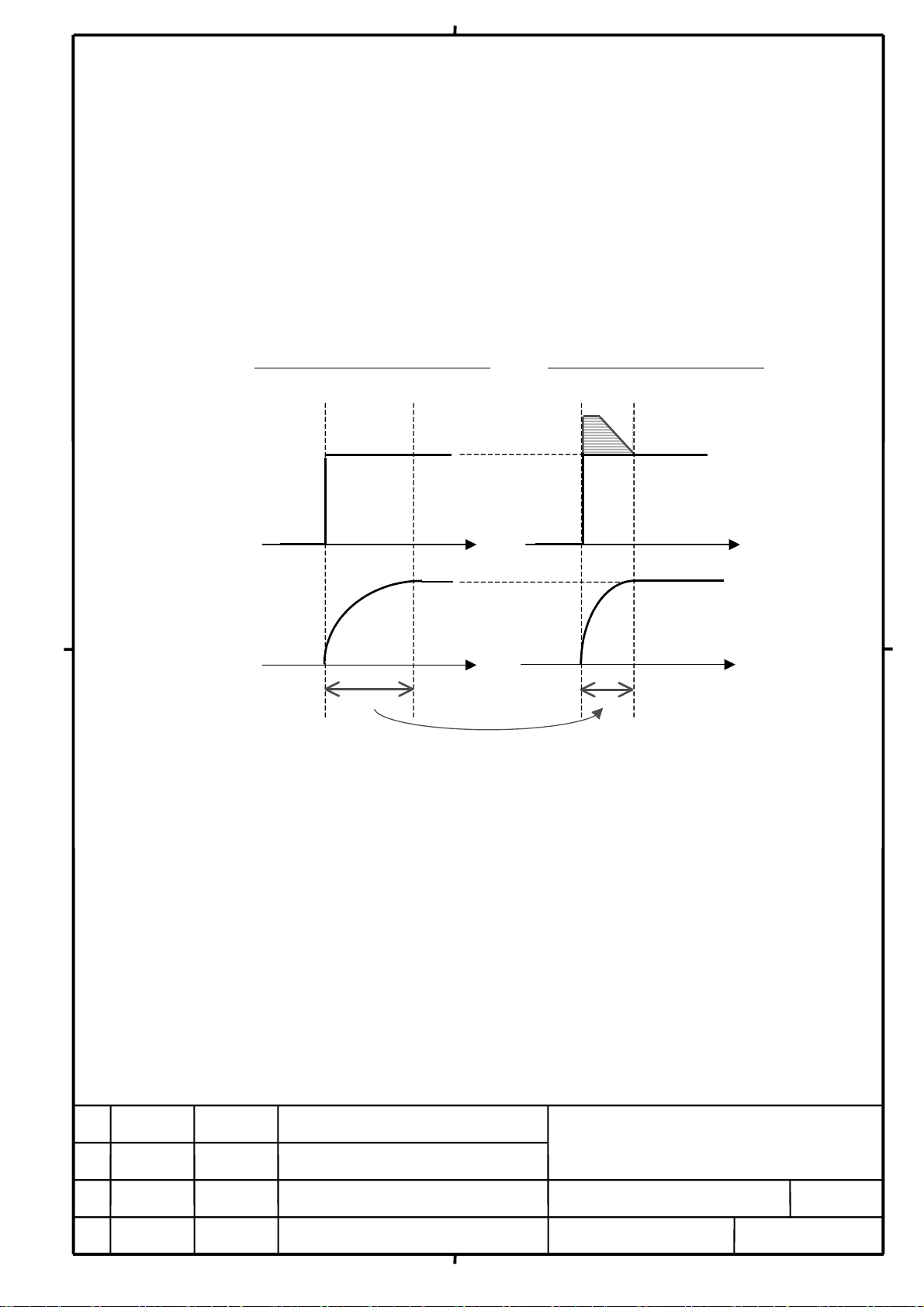

With Magnetic Flux Boost FunctionWithout Magnetic Flux Boost Function

Excitaiton current

command

Magnetic flux

Example) With αiI8

flux from about 300ms to about 100ms (33%).

(The effect depends on the spindle motor model.)

time

Shortening the rising time of magnetic flux

L/15000, the Magnetic Flux Boost Function shortens the rising time of magnetic

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

4/12

S

CUS

1ON

g

(

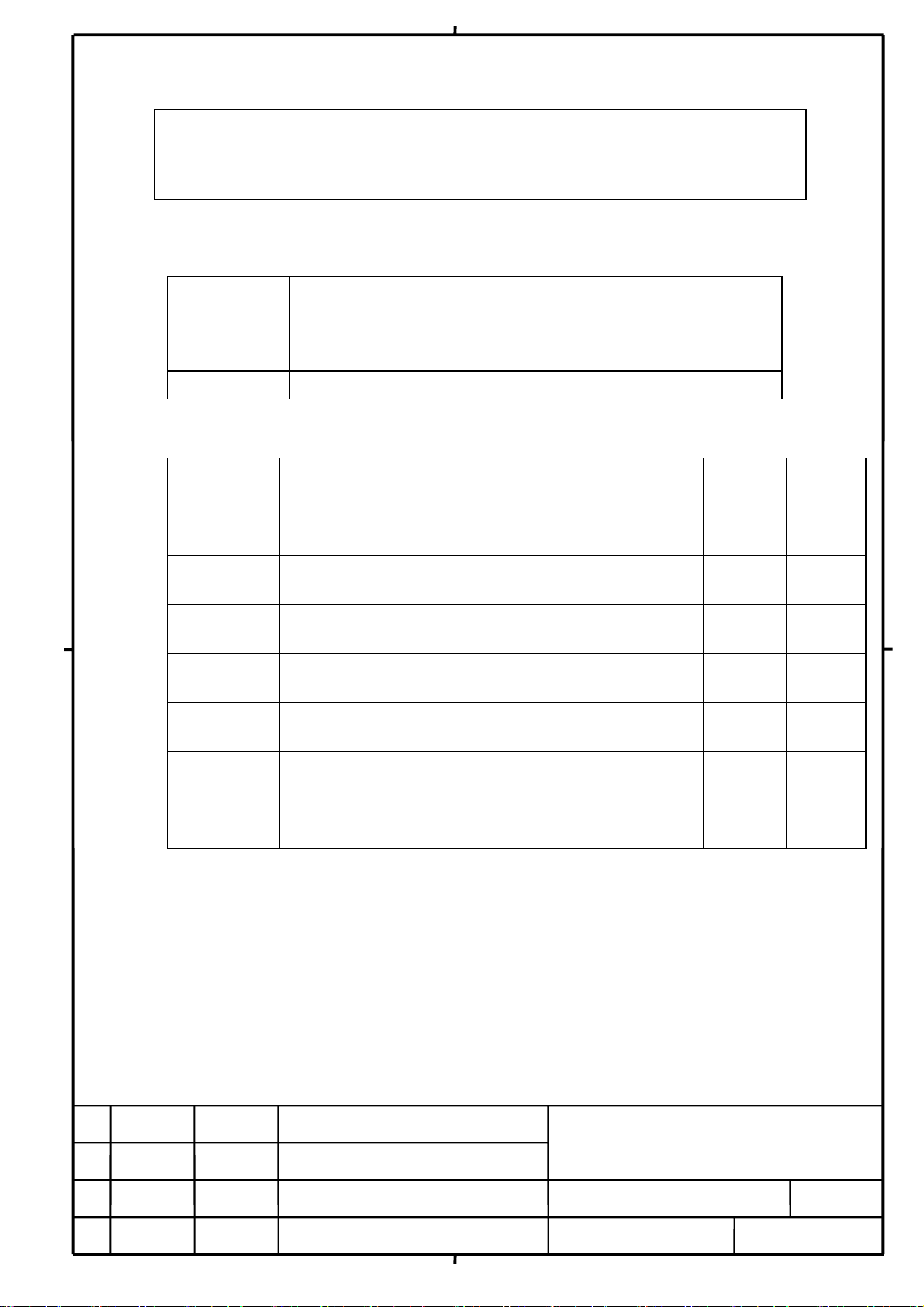

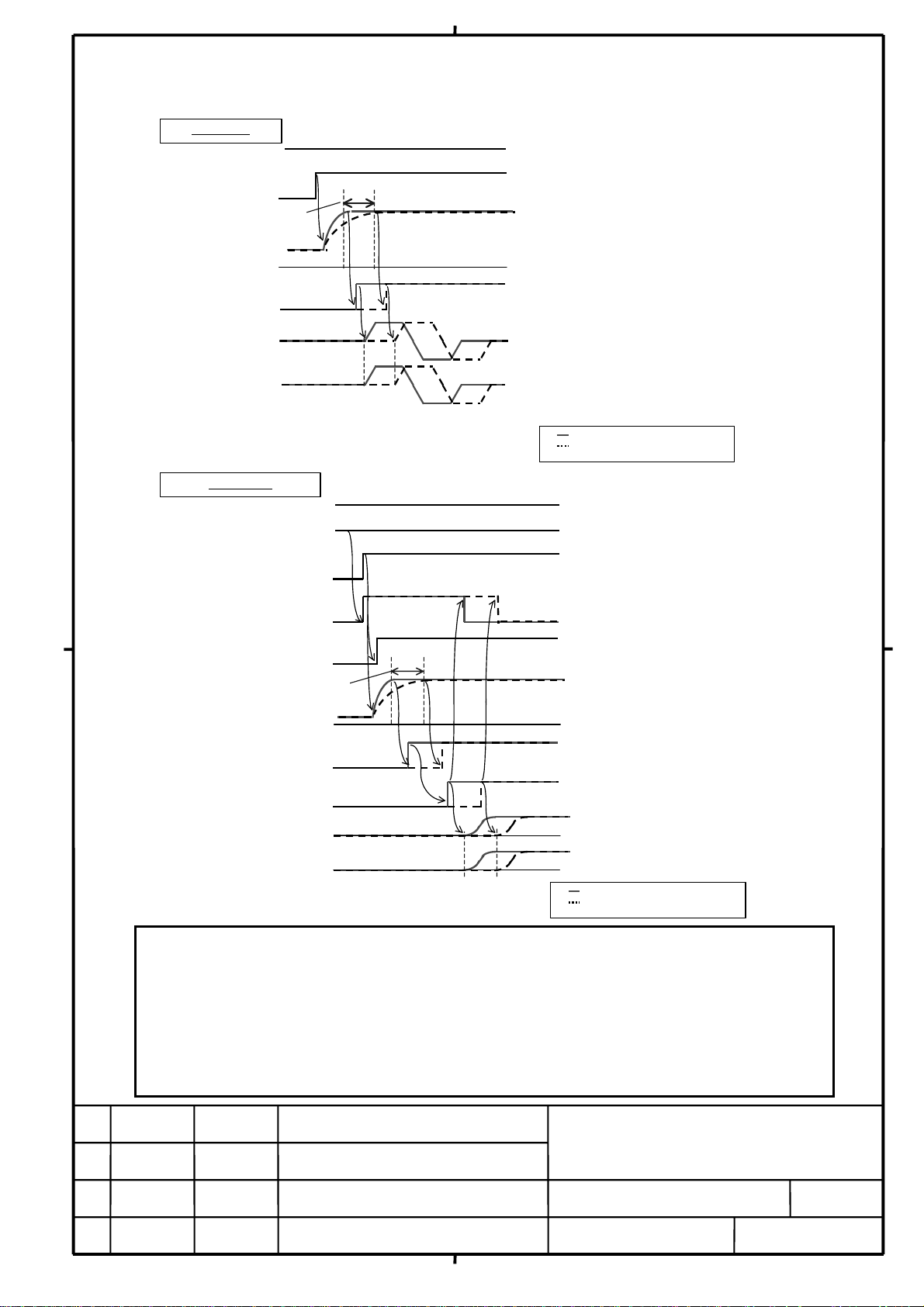

3. Examples of application

Rigid tapping

Shortening the rising time

of ma

netic flux

Cs contouring

Shortening the rising time

of magnetic flux

1

Forward/reverse rotation command (SFR/SRV)

Rigid tapping mode

Magnetic flux

Position loop

Move command

Spindle speed

With Magnetic Fl ux Boost Function

Without Magnetic Flux Boost Function

1

1

1

Cs axis coordinate setup request signal

0

1

Spindle contour control change complet ion signal

ON

1

Reference position establishment signal

Forward/reverse rotation command

Cs axis origin setup status signal

Spindle contour control change signal

(SFR/SRV)

(CSPEN)

(CON)

(CSFI)

(FSCSL)

Magnetic Flux

Position loop

ZRFx)

Move command

Cs axis speed

With Magnetic Fl ux Boost Funct ion

Without Magnetic Fl ux Boost Function

Note

*1 The Magnetic Flux Boost Function is enabled if spindle speed is zero(SSTA=1) and

velocity command is zero when changing to rigid tap mode or Cs contouring mode.

*2 The Magnetic Flux Boost Function is not enabled if reference positon return is

commanded immediately after changing to Cs contouring mode. So, this function is

effective with using Cs axis coordinate setup function.

(As for Cs axis coordinate setup function, refer to the Connection manual(Function) of

relevant CNC)

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

5/12

S

CUS

4. Parameters

16i,0i-B/C 30i,0i-D

Main 3353 4353 4353

Sub 3374 4374 4374

Main 3124 4124 4124

Main 3155 4155 4155

Sub 3332 4332 4332

Sub 3333 4333 4333

3099 4099 4099

15i

FBSTCS Whether to enable Magenetic Flux Boost Function

16i,0i-B/C 30i,0i-D

15i

16i,0

15i

i-B/C 30i,0i-D

Unit of data: 1ms

Valid data range: 0 to 32767

Standard settingvalue: 0

0: Disable Magenetic Flux Boost Function

1: Enable Magenetic Flux Boost Function

NOTE

・ In case of the sub spindle in spindle switching control, this function is

This parameter specifies the setting on Magnetic Flux Boost Function.

Please refer to “5. Adjustment procedure of parameters” about setting of this paremeter

Dlay time for stable motor exitation

This parameter sets a period of time required until motor excitation becomes stable in

rigid tapping or Cs contouring mode.

注

#7 #6 #5 #4 #3 #2 #1 #0

FBTCSC

FBTCSC

available for rigid tap mode

Magnetic flux boost completion level (high speed characteristics)/

Magnetic flux boost constant (high speed characteristics)

Magnetic flux boost completion level (low speed characteristics)/

Magnetic flux boost constant (low speed characteristics)

Magnetic flux boost completion level (high speed characteristics)/

Magnetic flux boost constant (high speed characteristics)

Magnetic flux boost completion level (low speed characteristics)/

Magnetic flux boost constant (low speed characteristics)

In general, set a value from about 300 to 400 (300 to 400ms), even

when the Magnetic Flux Boost Function is used.

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

6/12

S

CUS

5. Adjustment procedure of parameters

1.If the motor model is not included in the below list, calculate parameter of No.4124(without speed

range switching or for high-speed characteristic) and No.4155(for low-speed characteristic) value

according to the following equation.

(( ))

(( ))

2

2

1009.01100/4111.No,255MIN243204124.No

××++=

1009.01100/4147.No,255MIN243204155.No

××++= (No.4155=0 without speed range switching control)

2.If there is some vibration of spindle during boosting magnetic flux, decreased the value of

No.4124 (No.4155) by 10 and more 10 if necessary (The minimum value of the parameter setting

is 24420)

■Parameter list of No.4124 (No.4155)

a.Spindle motor α

iI series(200V)

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

Motor model

Applicable

amplifier

αiI 0.5/10000 αiSP2.2 24570 0

αiI 1/10000 αiSP2.2 24448 0

αiI 1.5/10000 αiSP5.5 24535 0

αiI 2/10000 αiSP5.5 24501 0

αiI 3/10000 αiSP5.5 24521 0

αiI 6/10000 αiSP11 24570 0

αiI 8/8000 αiSP11 24497 0

αiI 12/7000 αiSP15 24499 0

αiI 15/7000 αiSP22 24556 0

αiI 18/7000 αiSP22 24575 0

αiI 22/7000 αiSP26 24564 0

αiI 30/6000 αiSP45 24575 0

αiI 40/6000 αiSP45 24575 0

αiI 50/4500 αiSP55 24575 0

αiI 1.5/15000 αiSP15 24505 0

αiI 2/15000 αiSP22 24501 0

αiI 3/12000 αiSP11 24513 0

αiI 6/12000 αiSP11 24464 24570

αiI 8/10000 αiSP11 24493 24497

αiI 12/10000 αiSP15 24499 24499

αiI 15/10000 αiSP22 24515 24556

αiI 18/10000 αiSP22 24570 24575

αiI 22/10000 αiSP26 24477 24531

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

7/12

S

CUS

b.Spindle motor αiIP series(200V)

Motor model

αiIP 12/6000 αiSP11

αiIP 12/8000 αiSP11

αiIP 15/6000 αiSP15

αiIP 15/8000 αiSP15

αiIP 18/6000 αiSP15

αiIP 18/8000 αiSP15

αiIP 22/6000

αiIP 22/8000 αiSP22 24575 24575

αiIP 30/6000 αiSP22 24575 24575

αiIP 40/6000 αiSP26 24575 24575

αiIP 50/6000 αiSP26 24575 24575

Applicable

amplifier

iSP22

α

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

24575 24575

24575 24575

24575 24575

24575 24575

24541 24575

24541 24575

24575 24575

c.Spindle motor α

αiIP 60/4500 αiSP30 24575 24575

iIT series(200V)

Magnetic Flux Boost completion level

Motor model

Applicable

amplifier

αiIT 1.5/15000 αiSP15

αiIT 2/15000 αiSP22

αiIT 3/12000 αiSP11

αiIT 6/12000 αiSP15

αiIT 8/12000 αiSP15

αiIT 8/15000 αiSP26

αiIT 15/10000 αiSP22

αiIT 15/12000 αiSP30

αiIT 22/10000 αiSP26

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

24505 0

24501 0

24513 0

24509 24575

24447 24491

24450 24514

24515 24556

24566 24575

24477 24531

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

8/12

S

CUS

d.Spindle motor α

e.Spindle motor α

iI series(400V)

Motor model

αiI 0.5/10000HV αiSP5.5HV

αiI 1/10000HV αiSP5.5HV

αiI 1.5/10000HV αiSP5.5HV

αiI 2/10000HV αiSP5.5HV

αiI 3/10000HV αiSP5.5HV

αiI 6/10000HV αiSP11HV

αiI 8/8000HV αiSP11HV

αiI 12/7000HV αiSP15HV

αiI 15/7000HV αiSP30HV

αiI 22/7000HV αiSP30HV

αiI 30/6000HV αiSP45HV

αiI 40/6000HV αiSP45HV

αiI 60/4500HV αiSP75HV

αiI 100/4000HV αiSP75HV

Applicable

amplifier

iIP series(400V)

Motor model

αiIP 15/6000HV αiSP15HV

αiIP 40/6000HV αiSP30HV

αiIP 50/6000HV αiSP30HV

Applicable

amplifier

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

24558 0

24449 0

24537 0

24575 0

24551 0

24575 0

24544 0

24562 0

24575 0

24539 0

24575 0

24564 0

24575 0

24533 24553

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

24575 24575

24575 24575

24541 24575

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

9/12

S

CUS

f.Spindle motor α

iIT series(400V)

Motor model

αiIT 1.5/15000HV αiSP15HV

αiIT 3/12000HV αiSP11HV

αiIT 6/12000HV αiSP15HV

αiIT 8/12000HV αiSP15HV

αiIT 8/15000HV

αiIT15/10000HV

αiIT15/12000HV

αiIT22/10000HV

Applicable

amplifier

iSP15HV

α

iSP30HV

α

iSP30HV

α

α

iSP30HV

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

24548 0

24513 0

24513 24575

24447 24510

24494 24575

24544 24575

24575 24575

24489 24575

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

10/12

S

CUS

g.Built-in spindle motor B

Motor model

BiI 50S/30000 αiSP2.2

BiI 50M/25000 αiSP2.2

BiI 50L/25000 αiSP5.5

BiI 80S/20000 αiSP5.5

BiI 80M/15000 αiSP2.2

BiI 80L/8000

BiI 100S/12500

BiI 112SS/20000

BiI 112S/15000 αiSP22

BiI 112M/15000 αiSP11

BiI 112L/15000 αiSP30

BiI 112LL/15000

BiI 132M/14000

BiI 132L/14000

iI series(standard type)

Applicable

amplifier

iSP5.5

α

iSP5.5

α

iSP11

α

iSP30

α

iSP30

α

α

iSP30

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

24575 0

24551 0

24575 0

24506 24569

24448 0

24535 0

24551 0

24575 24575

24487 24575

24568 0

24575 24575

24575 24575

24575 24575

24575 24575

No.4155

(low-speed

characteristic)

BiI 160S/13000 αiSP22

BiI 160M/13000 αiSP30

BiI 160L/13000 αiSP22

α

BiI 160LL/13000

BiI 170S/6000

BiI 170M/6000

BiI 180M/6000

BiI 180L/6000

BiI 180LL/8000 αiSP30

BiI 200S/6000

BiI 200M/6000 αiSP30

BiI 200L/6000 αiSP45

BiI 250S/6000 αiSP45

BiI 250M/3000

iSP30

α

iSP22

α

iSP26

α

iSP30

α

iSP30

α

iSP37

α

iSP55

24575 24575

24575 24575

24575 24575

24575 24575

24533 24575

24575 24575

24575 24575

24575 24575

24575 24575

24575 24575

24575 24575

24575 24575

24514 24575

24575 24575

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

Date Ed.

T.Tsutsumi Newly

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

11/12

S

CUS

h.Built-in spindle motor B

Motor model

BiI 40S/70000 αiSP2.2

BiI 40M/70000 αiSP11

BiI 60SS/50000 αiSP11

BiI 60S/50000 αiSP22

BiI 80S/40000 αiSP45

BiI 100S/20000 αiSP22

BiI 100S/30000 αiSP30

BiI 100L/30000 αiSP30

BiI 112S/20000

BiI 112M/20000

BiI 112L/20000

BiI 112L/25000

BiI 160M/20000

BiI 160L/20000

iI series(high speed type)

Applicable

amplifier

iSP30

α

iSP30

α

iSP30

α

iSP75HV

α

iSP30

α

α

iSP30

Magnetic Flux Boost completion level

/ Magnetic flux boost constant

No.4124

(high-speed

characteristic)

No.4155

(low-speed

characteristic)

24467 0

24575 0

24575 0

24575 24575

24575 0

24575 24575

24569 24575

24575 24575

24575 24575

24499 24575

24522 24575

24575 24575

24575 24575

24575 24575

BiI 160LL/20000

BiI 200S/10000

iSP75HV

α

iSP75HV

24575 24575

24575 24575

α

TITLE

Magnetic Flux Boost

Function Description

08.06.24 01

T.Tsutsumi Newly

Date Ed.

Design.

DRAW. No.

B-65280EN/07-02

HEET

T.

12/12

TITLE

DRAW

Improvement of spindle parameter specification

for rigid tapping and spindle synchronous control

1. Type of applied documents

Name

Spec. No./Ver. B-65280EN/07

2. Summary of Change

Group Name / Outline

FANUC AC SPINDLE MOTOR αi series,

FANUC AC SPINDLE MOTOR βi series,

FANUC BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

New, Add

Correct, Del

Applicable

Date

Basic Function

Optional

Function

Unit

Maintenance

Parts

Notice

Correction

EDIT

Another Improvement of parameter specification for rigid

tapping and spindle synchronous control

G.Li 08.06.24 01

DESCRIPTION DESIGNDATE

No.

.

Add 2008.06

Improvement of parameter specification for

rigid tapping and spindle synchronous

control

B-65280EN/07-03

FANUC LTD

Page

1/6

TITLE

DRAW

Improvement of spindle parameter specification

for rigid tapping and spindle synchronous control

(1) General

Concerning spindle parameters for rigid tapping and spindle synchronous control, common parameters

have been used for velocity loop gain, position gain and motor voltage. So the specifications are improved

to set separately.

This manual describes new parameters for the separate setting. And if the new

parameter is set to 0, the common parameter is available as before.

(2) Series and edition of software

Spindle software series and edition

Series Edition Usable CNC

9D70 O(15)or later FANUC Series 30i /31i /32i

9D80 K(11)or later

CNC software series and edition

In case of 30i Series, applicable software is as follows.

Series Edition Usable CNC

G002/G012/G022/G032 X(24) or later

G003/G013/G023/G033 G(07) or later

G121/G131 X(24) or later

G123/G133 G(07) or later

G101/G111 X(24) or later

G103/G113 G(07) or later

G201 X(24) or later

G203 G(07) or later

FANUC Series

FANUC Series 0i–D

FANUC Series 30

FANUC Series 31i /310i /310is –A5

FANUC Series 31i /310i /310is –A

FANUC Series 32

30i /31i /32i ,

i /300i /300is –A

i /320i /320is –A

EDIT

G.Li 08.06.24 01

DESCRIPTION DESIGNDATE

Improvement of parameter specification for

rigid tapping and spindle synchronous

control

.

No.

FANUC LTD

B-65280EN/07-03

Page

2/6

TITLE

DRAW

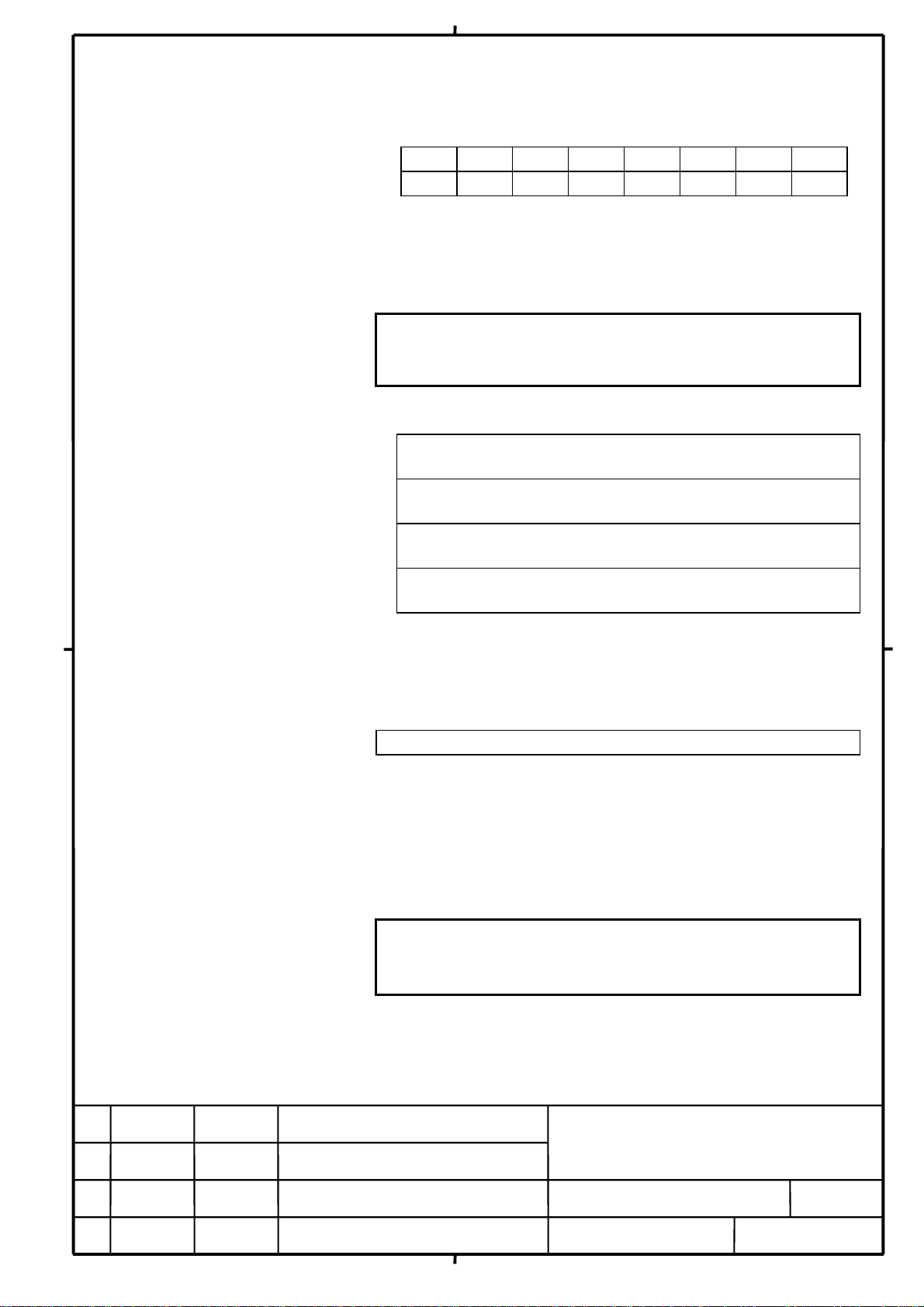

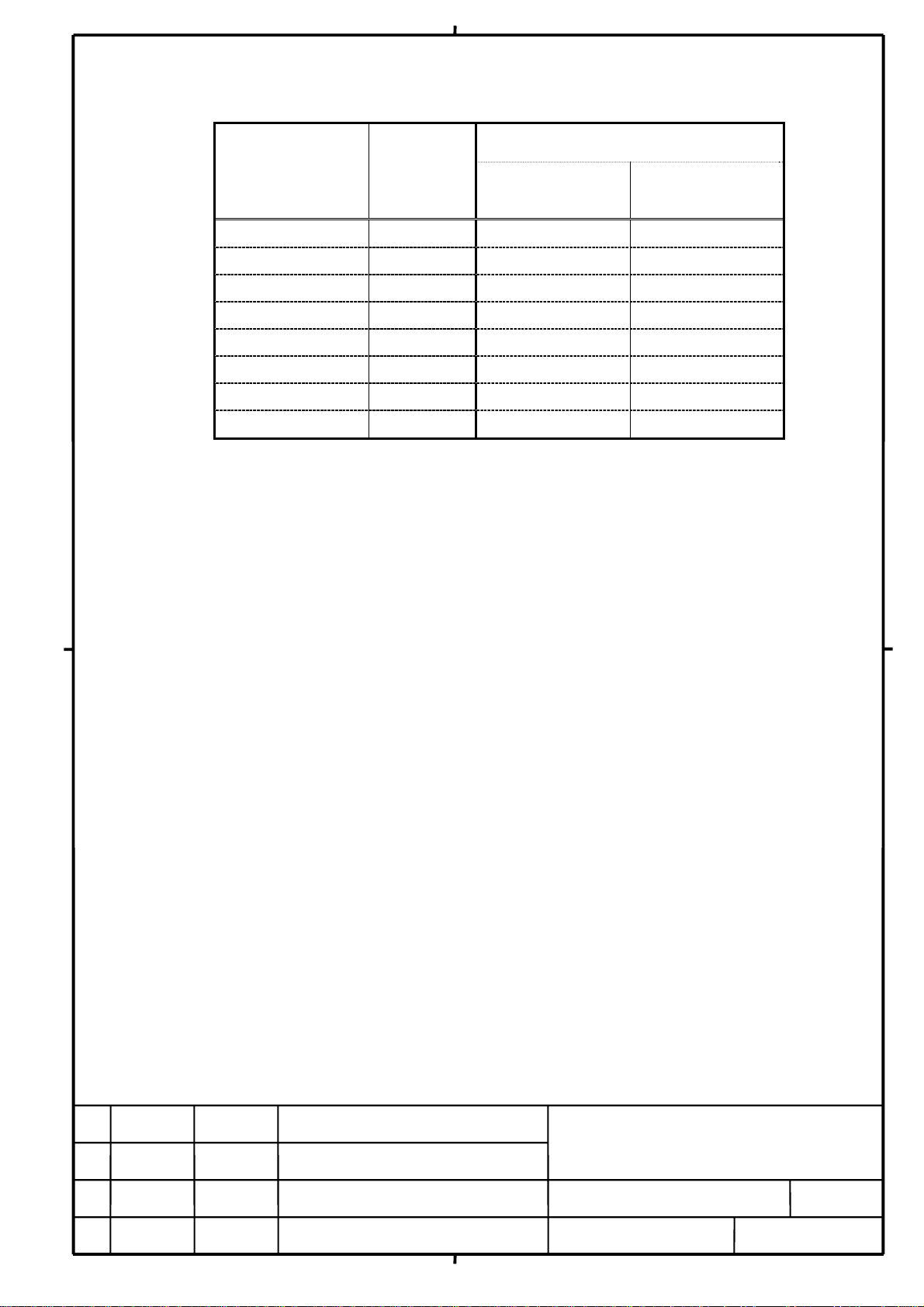

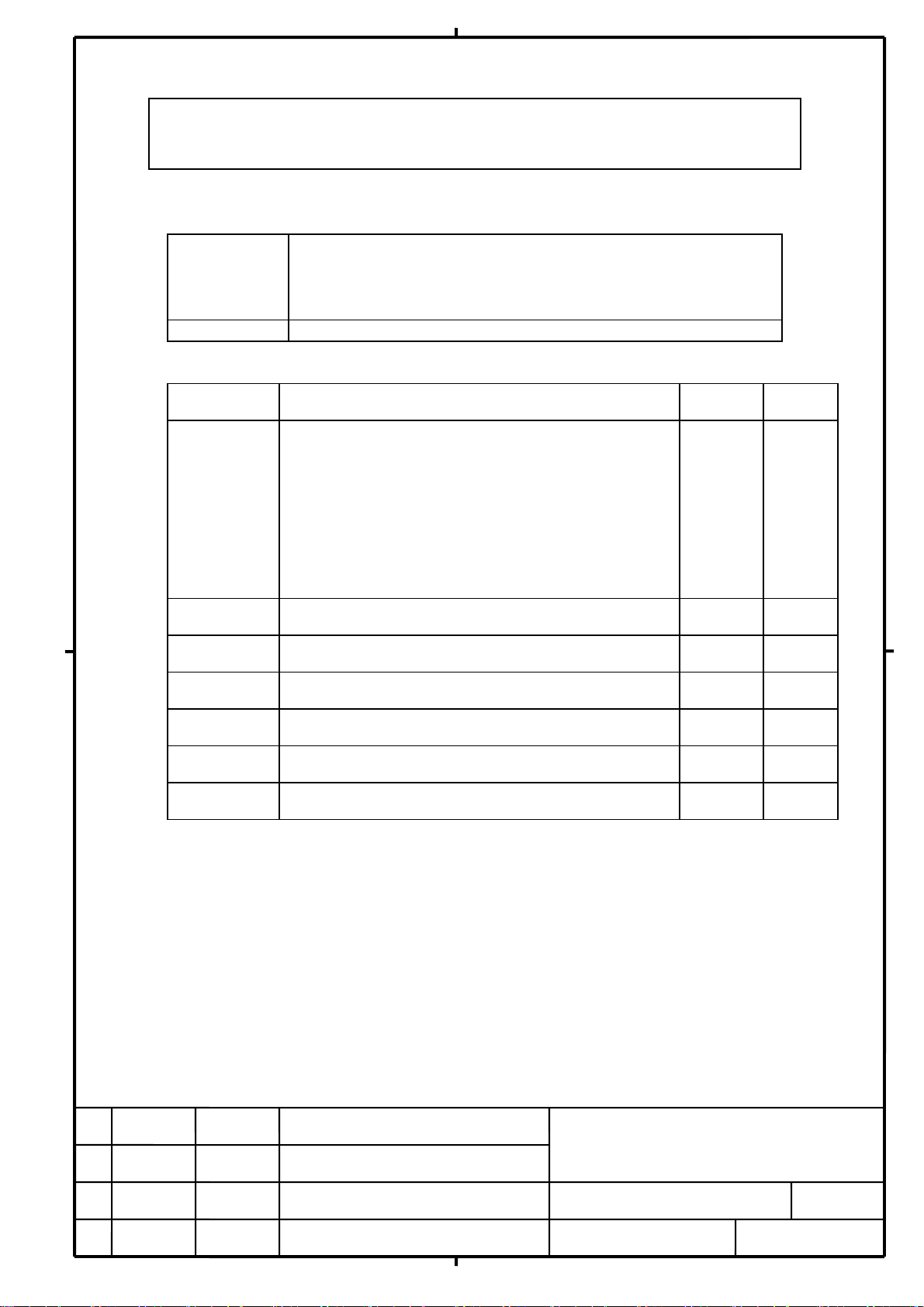

(3) List of parameters

Velocity loop proportional gain(HIGH) CTH1A=0

1

Velocity loop proportional gain(LOW) CTH1A=1

Velocity loop integral gain (HIGH) CTH1A=0

2

Velocity loop integral gain (LOW)

Position gain(HIGH) CTH1A=0,CTH2A=0 No.4065

Position gain(MEDIUM HIGH)

CTH1A=0,CTH2A=1

3

Position gain(MEDIUM LOW)

CTH1A=1,CTH2A=0

Position gain(LOW) CTH1A=1,CTH2A=1 No.4068

Motor voltage (High-speed characteristics)

4

Motor voltage (Low-speed characteristics)

(4) Details of parameters

(4-1)

Velocity loop proportional gain parameters

4044

4045

Unit of data:

Valid data range: 0 to 32767

Standard setting value: 10

These parameters set a velocity loop proportional gain for rigid apping

30i,0i -D

CTH1A=1

Rigid

tapping

No.4044

No.4045

No.4052

No.4053

No.4066

No.4067

No.4085

No.4137

Spindle synchronous

control

No.4044 No.4550=0

No.4550 No.4550≠0

No.4045 No.4551=0

No.4551 No.4551≠0

No.4052 No.4552=0

No.4552 No.4552≠0

No.4053 No.4553=0

No.4553 No.4553≠0

No.4065 No.4554=0

No.4554 No.4554≠0

No.4066 No.4555=0

No.4555 No.4555≠0

No.4067 No.4556=0

No.4556 No.4556≠0

No.4068 No.4557=0

No.4557 No.4557≠0

No.4085 No.4558=0

No.4558 No.4558≠0

No.4137 No.4559=0

No.4559 No.4559≠0

Condition

Velocity loop proportional gain for rigid tapping /spindle synchronous control

(HIGH) CTH1A=0

Velocity loop proportional gain for rigid tapping/spindle synchronous control

(LOW) CTH1A=1

(servo mode) or spindle synchronous control. When the input signal

CTH1A=0,(HIGH) is selected. When the input signal CTH1A=1,

(LOW) is selected.

NOTE

If No.4550/No.4551≠0, No.4550/ No.4551 is valid for spindle

synchronous control.

EDIT

G.Li 08.06.24 01

DESCRIPTION DESIGNDATE

Improvement of parameter specification for

rigid tapping and spindle synchronous

control

.

No.

FANUC LTD

B-65280EN/07-03

Page

3/6

TITLE

DRAW

4550

4551

30i,0i -D

Unit of data:

Valid data range: 0 to 32767

Standard setting value: 0

These parameters set a velocity loop proportional gain for spindle

(4-2)Velocity loop integral gain parameters

4052

4053

30i,0i -D

Unit of data:

Valid data range: 0 to 32767

Standard setting value: 10

Velocity loop proportional gain for spindle synchronous control (HIGH)

CTH1A=0

Velocity loop proportional gain for spindle synchronous control (LOW)

CTH1A=1

synchronous control . When the input signal CTH1A=0,(HIGH) is

selected. When the input signal CTH1A=1,(LOW) is selected.

NOTE

If No.4550/No.4551=0, No.4044/ No.4045 is valid for both

spindle synchronous control and rigid tapping.

Velocity loop integral gain for rigid tapping/spindle synchronous control

(HIGH) CTH1A=0

Velocity loop integral gain for rigid tapping/spindle synchronous control

(LOW) CTH1A=1

These parameters set a velocity loop integral gain for rigid tapping

(servo mode ) or spindle synchronous control. When the input signal

CTH1A=0,(HIGH) is selected. When the input signal CTH1A=1,

(LOW) is selected.

NOTE

If No.4552/No.4553≠0, No.4552/ No.4553 is valid for spindle

synchronous control.

4552

4553

30i,0i -D

Velocity loop integral gain for spindle synchronous control (HIGH) CTH1A=0

Velocity loop integral gain for spindle synchronous control (LOW) CTH1A=1

Unit of data:

Valid data range: 0 to 32767

Standard setting value: 0

These parameters set a velocity loop integral gain for spindle

synchronous control. When the input signal CTH1A=0,(HIGH) is

selected. When the input signal CTH1A=1, (LOW) is selected.

NOTE

If No.4552/No.4553=0, No.4052/ No.4053 is valid for both

spindle synchronous control and rigid tapping.

DESCRIPTION DESIGNDATE

Improvement of parameter specification for

rigid tapping and spindle synchronous

control

.

No.

B-65280EN/07-03

FANUC LTD

Page

4/6

EDIT

G.Li 08.06.24 01

TITLE

DRAW

S

S

/

(4-3) Position gain parameters

4065

4066

4067

4068

30i,0i -D

Unit of data: 0.01sec

Valid data range: 0 to 32767

Standard setting value: 1000

4554

4555

4556

4557

30i,0i -D

Unit of data: 0.01sec

Valid data range: 0 to 32767

Standard setting value: 0

pindle position gain for rigid tapping/spindle synchronous control

(HIGH) CTH1A=0, CTH2A=0

Spindle position gain for rigid tapping/spindle synchronous control

(MEDIUM HIGH) CTH1A=0, CTH2A=1

Spindle position gain for rigid tapping/spindle synchronous control

(MEDIUM LOW) CTH1A=1, CTH2A=0

Spindle position gain for rigid tapping/spindle synchronous control

(LOW) CTH1A=1, CTH2A=1

-1

These parameters set a position gain for rigid tapping (servo mode) or

spindle synchronous control.A parameter is selected according to the

input siganals CTH1A and CTH2A.

NOTE

If No.4554/No.4555/No.4556/No.4557≠0, No.4554/No.4555

No.4556 /No.4557 is valid for spindle synchronous control.

pindle position gain for spindle synchronous control

(HIGH) CTH1A=0, CTH2A=0

Spindle position gain for spindle synchronous control

(MEDIUM HIGH) CTH1A=0, CTH2A=1

Spindle position gain for spindle synchronous control

(MEDIUM LOW) CTH1A=1, CTH2A=0

Spindle position gain for spindle synchronous control

(LOW) CTH1A=1, CTH2A=1

-1

These parameters set a position gain for spindle synchronous control.

A parameter is selected according to the input siganals CTH1A and CTH2A.

NOTE

If No.4554/No.4555/No.4556/No.4557=0, No.4065/No.4066

No.4067 /No.4068 is valid for both spindle synchronous control

and rigid tapping.

EDIT

G.Li 08.06.24 01

DESCRIPTION DESIGNDATE

Improvement of parameter specification for

rigid tapping and spindle synchronous

control

.

No.

FANUC LTD

B-65280EN/07-03

Page

5/6

TITLE

DRAW

(4-4) Motor voltage parameters

4085

4137

Unit of data: 1%

Valid data range: 0 to 100

Standard setting value: Depends on the model

30i,0i -D

Motor voltage for rigid tapping/spindle synchronous control

(High-speed characteristics)

Motor voltage for rigid tapping/spindle synchronous control

(Low-speed characteristics)

These parameters set a motor voltage for rigid tapping (servo mode)

or spindle synchronous control.

When performing rigid tapping,set 100 usually. When setting a value

less than 100,set bit 1 of No.4540 to 1 as the setting of control

characteristics for rigid tapping .

When performing spindle synchronous control, usually set the same

value as for the setting of a motor voltage (No.4083/ No.4136) for the

velocity control mode.

NOTE

If No.4558/No.4559≠0, No.4558/No.4559 is valid for spindle

synchronous control.

4558 Motor voltage for spindle synchronous control (High-speed characteristics)

4559 Motor voltage for spindle synchronous control (Low-speed characteristics)

Valid data range: 0 to 100

Standard setting value: 0

30i,0i -D

Unit of data: 1%

These parameters set a motor voltage for spindle synchronous control.

Usually set the same, value as for the setting of a motor voltage

(No.4083/ No.4136) for the velocity control mode.

NOTE

If No.4558/No.4559=0, No.4085/No.4137 is valid for both

spindle synchronous control and rigid tapping.

EDIT

G.Li 08.06.24 01

DESCRIPTION DESIGNDATE

Improvement of parameter specification for

rigid tapping and spindle synchronous

control

.

No.

FANUC LTD

B-65280EN/07-03

Page

6/6

S

CUS

1. Type of applied documents

Name

Spec. No./Ver.

2. Summary of Change

Group Name / Outline

Basic Function

Optional

Function

Unit

Maintenance

Parts

Notice

Correction

Another

Change of spindle software series name

(9D50 series

→ 9D5A series)

FANUC AC SPINDLE MOTOR αi series,

FANUC AC SPINDLE MOTOR βi series,

FANUC BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

B-65280EN/07

New, Add

Correct, Del

9D5A series is the succeeding software to 9D50 series. Add 2008.06

Applicable

Date

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Change of spindle software series name

(9D50 series → 9D5A series)

B-65280EN/07-04

HEET

T.

1/2

S

CUS

Change of spindle software series name (9D50 series → 9D5A series)

1. General

The name of a spindle software series is changed.

9D5A series is the succeeding software to 9D50 series, and 9D50/Y(25) is revised to 9D5A/A(01).

…→ 9D50/X →(revise)→ 9D50/Y →(revise)→ 9D5A/A →…

2. Spindle software series, drawing No. and amplifier specification No.

Software

series

9D50 series

(Old)

↓

9D5A series

(New)

• Only the name of the spindle software is changed.

• The specification No. of the amplifier is not changed.

• 9D5A series is revised from 9D50 series, and has an upper compatibility with 9D50 series.

Software

drawing No.

A06B-6111-H550

Amplifier specification No. Notes

αiSP

β

iSVSP

A06B-6111-Hxxx#H550

A06B-6112-Hxxx#H550

A06B-6121-Hxxx#H550

A06B-6122-Hxxx#H550

A06B-6134-Hxxx#A

A06B-6134-Hxxx#D

For induction spindle motors

For induction spindle motors

16i/18i/21i,

0

i-B/C, 15i, PMi-D

0

i-B/C

01

1

08.06.25

Date Ed.

Ts ut sum i

Design.

TITLE

DRAW. No.

Change of spindle software series name

(9D50 series → 9D5A series)

B-65280EN/07-04

HEET

T.

2/2

S

CUS

1. Type of applied documents

Name

Spec. No./Ver.

2. Summary of Change

Group Name / Outline

Basic Function

Optional

Function

Unit

Maintenance

Parts

Notice

Correction

Another

Revision of spindle software (sensorless) (9D60/E)

FANUC AC SPINDLE MOTOR αi series,

FANUC AC SPINDLE MOTOR βi series,

FANUC BUILT-IN SPINDLE MOTOR Bi series

PARAMETER MANUAL

B-65280EN/07

New, Add

Correct, Del

Revision of spindle software 9D60/E Add 2008.08

Applicable

Date

01

1

08.08.06

Date Ed.

Morita

Design.

TITLE

Revision of spindle software (sensor less)

(9D60/E)

DRAW. No.

B-65280EN/07-05

HEET

T.

1/3

S

CUS

Revision of spindle software (sensorless) (9D60/E)

1. General

Spindle software for βiSVSP (sensorless spindle) and αiSP(TYPE C) was revised as follows.

2. Software series, edition and applied spindle amplifier

Software

drawing No.

Software

edition

Spindle amplifier specification

A06B-6165-Hxxx#H560

A06B-6116-H560

9D60

edition E(05)

A06B-6134-Hxxx#C

A06B-6116-Hxxx#H560

3. Contents of modification

(1) βiSVSP (A06B-6165-Hxxx#H560) for FS0i-D is supported.

(2) Model code of a βiΙ spindle motor (sensorless) is added. Refer to item4.

Model code Motor model Applicable amplifier

252

βiΙ 3/6000 βiSVSP*-7.5 (6165)

01

1

08.08.06

Date Ed.

Morita

Design.

TITLE

Revision of spindle software (sensor less)

(9D60/E)

DRAW. No.

B-65280EN/07-05

HEET

T.

2/3

S

CUS

(

)

1

1

,

,

4. Added model code

Motor model

Applicable amplifier

Model code

Applicable software series and

4040

4042~4045 100

4048

4050~4053 400

edition

Continuous rating

Short-time rating

FS0

i

4001

4002

4010

4011

4012

4013

4019

4020 6000

4041 50

4049 200

4080 75

4083 60

4084 60

4085 60

4100 1500

4101 90

4102 1800

4103 53

4104 400

4105 25

4106 100

4107 800

4108 200

4109 25

4110 928

4111 250

4112 200

4113 1000

4114 0

4115 100

4116 8500

4117 29530

4118 120

4119 10

4120 15

4124 0

4127 164

4129 0

4130 100

4131 12900

4134 110

3/6000

βiΙ

i

SVSP* -7.5

β

6165

252

9D60/E

3.7kW

2000/6000min

5.5kW

1500/6000min

00000001

00000000

00000000

00011000

00000000

00001100

00000000

-

-

TITLE

Revision of spindle software (sensor less)

(9D60/E)

08.08.06

01

1

Morita

Date Ed.

Design.

DRAW. No.

B-65280EN/07-05

HEET

T.

3/3

Loading...

Loading...