Epson AcuLaser C2600, AcuLaser 2600 Service Manual

SERVICE MANUAL

A4 Full Color Laser Printer

EPSON AcuLaser C2600/2600

SEPG04005

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof. EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: |

Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their |

|

respective owners. EPSON disclaims any and all rights in those marks. |

Copyright © 2005 SEIKO EPSON CORPORATION.

I&I CS/Quality Management & PL Department

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER |

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing |

|

procedures preceded by DANGER Headings. |

WARNING |

Signals a precaution which, if ignored, could result in damage to equipment. |

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1.ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2.NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3.WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1.REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2.MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3.ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4.IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5.REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration |

Symbols Used in this Manual |

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of Epsonapproved lubricants and adhesives required for servicing the product.

APPENDIX Provides the following additional information for reference:

•Connector pin assignments

•Electric circuit boards components layout

•Electrical circuit boards schematics

•Exploded diagram & Parts List

Various symbols are used throughout this manual either to provide additional information on a specific topic or to warn of possible danger present during a procedure or an action. Be aware of all symbols when they are used, and always read NOTE, CAUTION, or WARNING messages.

ADJUSTMENT |

Indicates an operating or maintenance procedure, practice or condition |

REQUIRED |

that is necessary to keep the product’s quality. |

|

|

CAUTION |

Indicates an operating or maintenance procedure, practice, or condition |

that, if not strictly observed, could result in damage to, or destruction of, |

|

|

equipment. |

CHECK |

May indicate an operating or maintenance procedure, practice or |

POINT |

condition that is necessary to accomplish a task efficiently. It may also |

|

provide additional information that is related to a specific subject, or |

|

comment on the results achieved through a previous action. |

WARNING |

Indicates an operating or maintenance procedure, practice or condition |

that, if not strictly observed, could result in injury or loss of life. |

|

|

Provides helpful tips and cautions on reassembly procedures, especially |

|

when incorrect reassembling may affect the print quality. |

General Precautions

To prevent possible accidents during maintenance work, strictly observe the servicing warnings and cautions described in this manual.

Power Supply

WARNING Before starting any service procedure, turn the printer power off and unplug the power cord from the wall outlet.

When the power supply cable must be connected, be aware of the potential for electrical shock and do all tasks by following the procedures in this manual.

Do not touch any live parts unless instructed to do so.

Make sure to ground the printer properly. Otherwise a short circuit may cause an electric fire or shock.

Handle the power cable with care observing the precautions listed below.

•Do not plug too many leads into a single socket.

•Do not damage or tamper with the power cable.

•Avoid putting heavy objects on the cable, plucking it, and bending it forcedly. To do so may damage the cable and cause an electric fire and shock.

•Do not insert or remove the power cable with wet hands to prevent electric shock.

•Never replace the fuse on the Power Supply Board (high pressure/low pressure) under any circumstances.

Mechanical Components

WARNING |

|

When servicing any driving assembly (e.g., gears), turn the power off and unplug the power cord to prevent injuries. |

|

|

|

|

Do not touch the driving part (e.g., gears) while the assembly (printer) is operating. |

|

|

|

|

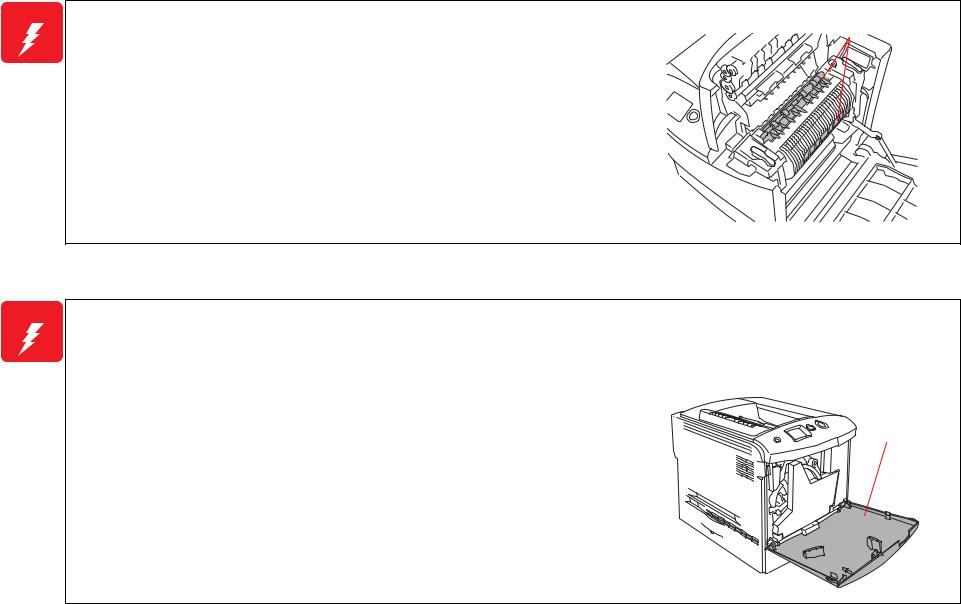

High Temperature Assembly

WARNING When working with hot parts (Fuser Unit etc.), turn the power off and unplug the power cord to prevent burns or injuries. After unplugging the power cable, wait until the part or unit

cools down before starting maintenance work.

Make sure to wait the hot section to cool enough especially when accessing near the section immediately after printing.

HIGH TEMPERATURE

00000101

Laser Beam

WARNING Understand hazardous nature of the laser beam, use extreme caution to avoid injury of yourself and anyone around you. Letting a laser beam get directly into your eyes could result in loss of vision.

Since the laser beam has a narrower frequency band and more coherent phases than any other light (sunlight, electric light), the beam has excellent monochromaticity and convergence, thus it reaches long distances. Because of these characteristics, the laser beam converges into one point, causing high density and high temperature, which is harmful to the human body.

Never turn the interlock switch on forcibly while servicing to prevent the laser beam from |

|

emitting accidentally. The interlock switch is designed to be turned off when the cover D is |

|

opened. |

Cover D |

When performing maintenance work, be sure to turn the power off and unplug the power cord.

If you need to work on the printer with power applied, strictly follow the instructions in this manual.

Never disassemble the Laser Scanner Unit under any conditions.

Be sure to take off a wristwatch, ring or any other metal materials especially when working on the printer with the power applied.

00000201

Handling Parts

WARNING Be careful not to throw out your back when handling heavy parts while taking care not to drop those parts.

Always wear gloves to perform maintenance work since the printer has many sharp edges.

Do not work with wet or oily hands, or may cause you to drop parts or affect the function of the printer.

Use only specified genuine parts for maintenance.

Do not repair or replace the ICs and other electrical components on the power circuit board (including fuse) under any circumstances.

Handling Consumables

WARNING To avoid dust explosion or ignition, never bring any consumables close to flame or throw them into fire.

Take extra care not to inhale the developing powder (such as toner), and get it into your mouth and eyes. Use extreme caution to avoid injury of yourself and anyone around you.

Before starting your work, spread a sheet of paper over the working place to prevent interior of the product and the place becoming tainted.

If the developer or oil adheres to your skin or clothes, wipe it off thoroughly with dry rags before rinsing with water.

Do not disassemble the toner cartridges.

To prevent ignition, explosion, burn, injury, etc., do not use a general vacuum cleaner for cleaning dropped toner. (To do so may cause the toner to catch fire by sparks in the vacuum cleaner.)

00000301

Irregular Use of the Printer

WARNING Cautions when performing work with covers or parts removed

•As a general rule, do not power the printer while covers or parts are removed.

•If you need to remove covers or parts from the printer with power applied, take care of your fingers and clothes so as not to get entangled by moving parts such as the driving belt, gears, and fans.

Altering the printer is banned under any circumstances.

|

|

Revision Status |

|

|

|

Revision |

Date of Issue |

Description |

A |

APR. 28, 2005 |

First release |

|

|

|

|

|

|

EPSON AcuLaser C2600/2600 |

Revision A |

Contents

Chapter 1 Product Description

1.1 |

Overview ............................................................................................................. |

13 |

|

1.1.1 Engine Features .......................................................................................... |

13 |

|

1.1.2 Controller Features ..................................................................................... |

13 |

|

1.1.3 Software Features ....................................................................................... |

13 |

1.2 |

Basic Specifications............................................................................................ |

14 |

|

1.2.1 Process Specifications & System................................................................ |

14 |

|

1.2.2 Printer Basic Specifications........................................................................ |

14 |

1.3 |

Paper Specifications ............................................................................................ |

22 |

|

1.3.1 Paper Type .................................................................................................. |

22 |

|

1.3.2 Paper That May Cause Printing Defects, Paper Jams or Printer Malfunction. |

|

|

22 |

|

|

1.3.3 Paper Feed Types........................................................................................ |

23 |

|

1.3.4 Printing Area............................................................................................... |

23 |

1.4 |

Reliability and Serviceability .............................................................................. |

24 |

|

1.4.1 Reliability ................................................................................................... |

24 |

|

1.4.2 Durability.................................................................................................... |

25 |

|

1.4.3 Serviceability .............................................................................................. |

25 |

1.5 |

Service Conditions............................................................................................... |

26 |

|

1.5.1 Space Requirements.................................................................................... |

26 |

1.6 |

Conditions for Storage and Transport ................................................................. |

27 |

1.7 |

Electrical Characteristics ..................................................................................... |

28 |

1.8 |

Compatible Specification .................................................................................... |

29 |

1.9 |

Consumables/Periodic Replacement Unit ........................................................... |

30 |

|

1.9.1 Specifications.............................................................................................. |

30 |

|

1.9.2 Conditions for Storage and Transport......................................................... |

31 |

1.10 Maintenance ...................................................................................................... |

32 |

|

1.11 External Appearance and Unit Names .............................................................. |

33 |

|

|

1.11.1 Unit Names ............................................................................................... |

33 |

1.12 Engine Restrictions............................................................................................ |

34 |

|

|

1.12.1 Factors Limiting Printing Speed............................................................... |

34 |

|

1.12.2 Toner Duty Limiting Value ...................................................................... |

34 |

1.13 |

Notes When Replacing Consumables and Installing Optional Products .......... |

35 |

1.13.1 Consumables............................................................................................. |

35 |

|

1.13.2 Options...................................................................................................... |

35 |

|

1.14 |

Notes on Fuser Pressure .................................................................................... |

35 |

1.15 |

Life Details ........................................................................................................ |

36 |

1.16 |

Controller Specifications................................................................................... |

40 |

1.16.1 Controller Basic Specifications ................................................................ |

40 |

|

1.16.2 Controller Configuration .......................................................................... |

40 |

|

1.16.3 External Interface Specifications.............................................................. |

41 |

|

1.17 |

Control Panel..................................................................................................... |

43 |

1.17.1 External Appearance and Names.............................................................. |

43 |

|

1.17.2 Panel Settings List .................................................................................... |

45 |

|

1.17.3 Explanation of Menu and Settings............................................................ |

56 |

|

1.17.4 Special Operations.................................................................................... |

58 |

|

1.18 |

Printer Status ..................................................................................................... |

59 |

1.18.1 List of Printer Messages ........................................................................... |

59 |

|

1.18.2 Status Messages and Troubleshooting...................................................... |

61 |

|

1.18.3 Warning Messages and Troubleshooting ................................................. |

61 |

|

1.18.4 Error Messages and Troubleshooting ....................................................... |

62 |

|

1.18.5 Help Messages.......................................................................................... |

65 |

|

1.18.6 Service Call Error Messages..................................................................... |

71 |

|

1.19 Expanding the RAM.......................................................................................... |

73 |

|

1.20 |

Handling Precautions ........................................................................................ |

73 |

1.20.1 Precautions When Turning Off the Power ............................................... |

73 |

|

1.20.2 Precautions for High Temperature Parts .................................................. |

73 |

|

1.21 |

Status Sheet ....................................................................................................... |

74 |

1.22 |

Engine Status Sheet........................................................................................... |

77 |

1.23 |

Paper Handling Algorithm ................................................................................ |

78 |

1.24 |

Toner Check Sheet ............................................................................................ |

79 |

1.24.1 For Color Mode ........................................................................................ |

79 |

|

1.24.2 For 4xB/W Mode...................................................................................... |

79 |

|

1.25 |

Form Overlay List ............................................................................................. |

80 |

9

EPSON AcuLaser C2600/2600 |

Revision A |

1.26 Switching between Color Mode and Monochrome Mode ................................ |

81 |

1.26.1 Switching of Operation Mode .................................................................. |

81 |

1.26.2 Switching of Printer Driver ...................................................................... |

84 |

Chapter 2 Operating Principle

2.1 Print Process ........................................................................................................ |

86 |

2.1.1 Print Process Overview............................................................................... |

86 |

2.1.2 Print Process Diagram ................................................................................ |

87 |

2.1.3 Technical Explanation of Print Process...................................................... |

88 |

2.2 Paper Feed Mechanism...................................................................................... |

104 |

2.2.1 Main Unit Paper Feed Mechanism ........................................................... |

105 |

2.2.2 Duplex Printing......................................................................................... |

110 |

2.2.3 Paper Feed from Opt. Feeder Unit............................................................ |

111 |

2.3 Drive ................................................................................................................. |

112 |

2.3.1 Main Drive Motor..................................................................................... |

113 |

2.3.2 Photoconductor Drive Motor.................................................................... |

115 |

2.3.3 Rotary Drive Motor .................................................................................. |

115 |

2.3.4 Development Drive Motor........................................................................ |

116 |

2.3.5 Duplex Motor............................................................................................ |

117 |

2.3.6 Opt. Feeder Motor .................................................................................... |

118 |

2.4 Electrical............................................................................................................ |

119 |

2.4.1 Electronic Circuit Board / R/W Module................................................... |

119 |

2.4.2 Motor ........................................................................................................ |

120 |

2.4.3 Solenoids and Clutches............................................................................. |

121 |

2.4.4 Sensors and Switches................................................................................ |

122 |

2.4.5 Interlock Switch........................................................................................ |

123 |

2.4.6 Fan ............................................................................................................ |

124 |

2.5 Control............................................................................................................... |

125 |

2.5.1 Hardware for Control................................................................................ |

125 |

2.5.2 Image-Stabilizing Control ........................................................................ |

126 |

2.5.3 Operation Sequence .................................................................................. |

131 |

2.5.4 Operating Mode ........................................................................................ |

133 |

2.5.5 Control of Consumables and Components Needing Periodic Replacement ... |

|

134 |

|

2.6 Electrical Circuit Operation Principle ............................................................... |

136 |

2.6.1 Electric Circuit.......................................................................................... |

136 |

2.6.2 Engine Control Circuit.............................................................................. |

138 |

2.6.3 Controller.................................................................................................. |

140 |

Chapter 3 Troubleshooting |

|

|

3.1 |

Overview ........................................................................................................... |

142 |

|

3.1.1 Procedure Outline for Troubleshooting.................................................... |

142 |

|

3.1.2 Preliminary Check .................................................................................... |

142 |

|

3.1.3 Precautions in Performing Troubleshooting Work................................... |

143 |

|

3.1.4 Procedure for Troubleshooting................................................................. |

143 |

3.2 |

Troubleshooting for Paper Jam ......................................................................... |

144 |

3.3 |

Troubleshooting According to the Error Message ............................................ |

145 |

|

3.3.1 List of Error Message ............................................................................... |

145 |

|

3.3.2 List of Service Request............................................................................. |

145 |

|

3.3.3 Troubleshooting for Error Message.......................................................... |

147 |

|

3.3.4 Troubleshooting for Service Request Error.............................................. |

157 |

3.4 |

Printing-quality troubleshooting (PQT) ............................................................ |

184 |

|

3.4.1 Print Quality Trouble List......................................................................... |

184 |

|

3.4.2 Printing-quality troubleshooting............................................................... |

186 |

3.5 |

Test Print ........................................................................................................... |

208 |

Chapter 4 Disassembly and Assembly |

|

|

4.1 |

Overview ........................................................................................................... |

211 |

|

4.1.1 Precautions................................................................................................ |

212 |

|

4.1.2 Prohibited Disassembly ............................................................................ |

214 |

|

4.1.3 Tools ......................................................................................................... |

215 |

|

4.1.4 Inspection After Assembling.................................................................... |

215 |

4.2 |

Procedures for Disassembly and Assembly ...................................................... |

216 |

4.3 |

Disassembly and Reassembly ........................................................................... |

217 |

4.4 |

Disassembling Flowchart .................................................................................. |

219 |

4.5 |

Disassembling/Assembling the Main Unit........................................................ |

234 |

|

4.5.1 Consumables............................................................................................. |

234 |

|

4.5.2 Housing..................................................................................................... |

240 |

|

4.5.3 Paper Transport......................................................................................... |

253 |

|

4.5.4 Xerographic .............................................................................................. |

263 |

|

4.5.5 Exposure ................................................................................................... |

268 |

|

4.5.6 Deve.......................................................................................................... |

271 |

|

4.5.7 Transfer..................................................................................................... |

276 |

|

4.5.8 Fusing ....................................................................................................... |

293 |

|

4.5.9 Drive ......................................................................................................... |

294 |

|

4.5.10 Electrical................................................................................................. |

307 |

10

EPSON AcuLaser C2600/2600 |

Revision A |

|

4.5.11 MP Tray .................................................................................................. |

323 |

|

4.5.12 Paper Cassette......................................................................................... |

339 |

4.6 |

Disassembling/Assembling the Options............................................................ |

342 |

|

4.6.1 Opt. Feeder ............................................................................................... |

342 |

|

4.6.2 Duplex Unit .............................................................................................. |

355 |

Chapter 5 Adjustment |

|

|

5.1 |

Overview ........................................................................................................... |

365 |

|

5.1.1 Precautions................................................................................................ |

365 |

|

5.1.2 Reference Chapter .................................................................................... |

365 |

|

5.1.3 Adjustment Execution Timing.................................................................. |

366 |

5.2 |

Adjustment Program (LPssp) ............................................................................ |

367 |

|

5.2.1 Overview................................................................................................... |

367 |

|

5.2.2 Setup before Adjustment .......................................................................... |

367 |

|

5.2.3 Writing the model name ........................................................................... |

370 |

|

5.2.4 Writing USB ID........................................................................................ |

371 |

|

5.2.5 Counter Reset............................................................................................ |

372 |

|

5.2.6 Timing Adjustment................................................................................... |

373 |

|

5.2.7 Registration Adjustment (Top)................................................................. |

374 |

|

5.2.8 Registration Adjustment (Side) ................................................................ |

375 |

|

5.2.9 2nd Transfer Bias Adjustment .................................................................. |

376 |

|

5.2.10 Vpp Setting ............................................................................................. |

377 |

5.3 |

Firmware Update ............................................................................................... |

378 |

|

5.3.1 Main Controller Firmware Update ........................................................... |

379 |

|

5.3.2 Engine Controller Firmware Update ........................................................ |

381 |

Chapter 6 Maintenance |

|

|

6.1 |

Overview ........................................................................................................... |

385 |

6.2 |

Cleaning............................................................................................................. |

387 |

6.3 |

Maintenance Menu ............................................................................................ |

389 |

|

6.3.1 Entry into Maintenance Mode .................................................................. |

389 |

|

6.3.2 Maintenance Menu Items ......................................................................... |

390 |

6.4 |

Sheet for Servicing ............................................................................................ |

391 |

|

6.4.1 Engine Status Sheet .................................................................................. |

391 |

|

6.4.2 Print Log Report ....................................................................................... |

394 |

6.5 |

Consumables and Components That Need Periodic Replacement.................... |

396 |

|

6.5.1 Consumables............................................................................................. |

396 |

|

6.5.2 Regular Replacement Parts....................................................................... |

397 |

6.6 |

Gluing/Lubrication ............................................................................................ |

398 |

|

6.6.1 Gluing ....................................................................................................... |

398 |

|

6.6.2 Lubrication................................................................................................ |

398 |

Chapter 7 APPENDIX |

|

|

7.1 Connector Summary.......................................................................................... |

411 |

|

|

7.1.1 Connectors and Plug and Jack Layout...................................................... |

411 |

7.2 |

Wiring Connection Diagrams............................................................................ |

418 |

7.3 |

Parts List............................................................................................................ |

433 |

7.4 |

Exploded Diagrams ........................................................................................... |

437 |

7.5 |

Circuit Diagrams ............................................................................................... |

449 |

11

C H A P T E R

1

PRODUCT DESCRIPTION

EPSON AcuLaser C2600/2600 |

Revision A |

1.1 Overview

This printer is a non-impact color page printer that takes advantage of a laser and electrophotographic technologies.

It provides 600 dpi of resolution and 7.5 ppm (A4, color printing) or 30 ppm (A4, monochrome printing) of print speed.

1.1.1 Engine Features

High speed 4-cycle A4 engine

Table 1-1. Print Speed (When Printing A4)

|

Color printing |

Monochrome printing |

Simplex printing |

7.5 ppm |

30 ppm |

|

|

|

Duplex printing |

7.5 ppm |

20 ppm |

|

|

|

Two models: color and monochrome

The monochrome model has one black toner cartridge bundled as standard. Adding three black toner cartridges (option) allows the printer to print up to 20,000 copies. Furthermore, the monochrome model can be upgraded to color model.

The color model can be operated as monochrome model by replacing the color toners with black ones or removing them.

Compact and light weight, suitable for desktop placement

Dimension |

435 mm (W) x 516 mm (D) x 425 mm (H) |

|

|

Weight |

35 kg |

|

|

Paper supply (Maximum of 1150 sheets, 3-bin paper feed is possible)

Paper cassette

Standard |

MP Tray |

150 sheets |

|

|

|

||

Lower paper cassette |

500 sheets |

||

|

|||

Option |

Paper cassette unit |

500 sheets |

|

|

|

|

|

|

Maximum |

1150 sheets |

|

|

|

|

Paper eject capacity is 250 sheets, face-down only.

1.1.2 Controller Features

High speed intelligent controller

CPU: |

VR5532A (350 MHz) |

RAM

Standard RAM: 64 MB

Expanded RAM: 512 MB (When two 256 MB DIMMs are installed.)

Support for optional large capacity, 40 GB HDD.

Color technology

nPGI, which allows low price, high quality printing

Wide LCD panel with backlight

The new wide LCD panel supporting a maximum of 22 digits and 5 lines (132 x 65 dots) provides improved operation and visibility.

Improved serviceability with the addition of the Help function (with description and graphics).

Interface

USB interface (Rev. 2.0 HS, Supports bi-directional (D4))

Network interface (10Base-T/100Base-TX)

Parallel interface (IEEE1284)

Type-B interface

1.1.3 Software Features

Adobe PostScript 3 (17 fonts), PCL6 (monochrome) as standard ESC/Page Color, PCL5e, FX, LQ, and IBM emulations are also provided

Printer status and printer environment monitor with use of bi-directional EJL and MIB

Version upgrade function for engine program ROM

Support for DCC command (DIAG command only)

Support for firmware overwrite using RCC (full or partial overwrite)

Support for manual duplex

Product Description |

Overview |

13 |

EPSON AcuLaser C2600/2600 |

Revision A |

1.2 |

Basic Specifications |

|

1.2.1 |

Process Specifications & System |

|

Printing method: |

Semiconductor laser beam scan and |

|

|

|

electrophotography with dry single component system. |

Exposure light source: |

Semiconductor laser |

|

Photoconductor: |

Organic photoconductor |

|

Charging: |

Wire electrode scorotron |

|

Development: |

1-component non-contact development system |

|

Toner: |

1-component non-magnetic toner |

|

Primary transfer: |

Intermediate transfer belt method |

|

Fixing: |

Roller heat fixing system |

|

1.2.2 Printer Basic Specifications

RESOLUTION

600 x 600 dpi

WARMING UP TIME

120 V: 80 seconds or less (at 23 °C, 55 % RH, rated voltage)

230 V: 80 seconds or less (at 23 °C, 55 % RH, rated voltage)

OPERATION MODE

This engine supports the following operation modes.

B/W mode: |

Supports Toner cartridge K x 1 |

4xB/W mode: |

Supports Toner cartridge K x 4 |

Color mode: |

Supports Toner cartridges Y x 1, M x 1, C x 1, and K x 1. |

|

|

PRINT MODE |

|

Color mode: |

Color mode using Y, M, C, K toner (color mode only) |

Monochrome mode: Normal black and white mode, enabling printing at the highest speed of the main unit.

PRINTING SPEED MODE

Std. mode (plain paper 1): Makes prints at the maximum speed of the engine.

Std. mode (plain paper 2): This mode is to make prints on papers with less

fixability (such as bond papers) at the maximum speed of the engine. As the fuser unit takes a substantial amount of time to increase its temperature for fixing toner onto the papers firmly, the first print time becomes slow. When it comes to a continuous printing, however, the printing can be performed at the maximum speed of the engine.

Low speed mode 1: |

Slows down the speed of printing on papers with |

|

thickness of 90 g/m2 (24 lb) or more to sustain the |

|

fixability. |

Low speed mode 2: |

Slows down the speed of printing on envelopes for the |

|

better fixability or on transparents for the stable |

|

permeability. |

Product Description |

Basic Specifications |

14 |

EPSON AcuLaser C2600/2600 |

Revision A |

FIRST PRINT TIME

The following table shows the time from receiving a start command to when trailing edge of the paper leaves the paper eject roller. Note that the time given in the tables does not apply when the printer is in the conditions described in “1.12 Engine Restrictions” (p.34).

Monochrome mode*1

Table 1-2. Monochrome Mode (Unit: Seconds or Less)

Paper |

|

Simplex printing |

|

Duplex printing |

|||

Std. mode |

Std. mode |

Low speed |

Low speed |

Std. mode |

Std. mode |

||

size |

|||||||

|

(Plain paper 1) |

(Plain paper 2*2) |

mode 1 |

mode 2 |

(Plain paper 1) |

(Plain paper 2*2) |

|

A4 |

9.3 |

19.3 |

17.9 |

26.6 |

13.3 |

23.3 |

|

|

|

|

|

|

|

|

|

A5 |

8.9 |

18.9 |

17.1 |

25.0 |

12.9 |

22.9 |

|

B5 |

9.1 |

19.1 |

17.6 |

25.9 |

13.1 |

23.1 |

|

|

|

|

|

|

|

|

|

LT |

9.2 |

19.2 |

17.8 |

26.3 |

13.2 |

23.2 |

|

EXE |

9.2 |

19.2 |

17.7 |

26.1 |

13.2 |

23.2 |

|

|

|

|

|

|

|

|

|

Color mode*1

Table 1-3. Color Mode (Unit: Seconds or Less)

Paper |

Simplex printing |

|

Duplex printing |

||||

|

|||||||

Std. mode |

|

|

Std. mode |

Std. mode |

|||

size |

|

Std. mode |

Low speed |

Low speed |

|||

|

|

(Plain paper 1) |

(Plain paper 2*2) |

mode 1 |

mode 2 |

(Plain paper 1) |

(Plain paper 2*2) |

A4 |

|

15.3 |

25.3 |

23.9 |

32.6 |

23.3 |

33.3 |

|

|

|

|

|

|

|

|

A5 |

|

14.9 |

24.9 |

23.1 |

31.0 |

22.9 |

32.9 |

B5 |

|

15.1 |

25.1 |

23.6 |

31.9 |

23.1 |

33.1 |

|

|

|

|

|

|

|

|

LT |

|

15.2 |

25.2 |

23.8 |

32.3 |

23.2 |

33.2 |

EXE |

|

15.2 |

25.2 |

23.7 |

32.1 |

23.2 |

33.2 |

|

|

|

|

|

|

|

|

Note |

*1: The above speed are the same for any paper feeder including the option cassette. |

|

|||||

*2: The mode to be used for papers that are hardly fixed.

As the temperature for the fixation is set higher than that of the other modes, it takes relatively long period of time until the temp. reaches the required level.

CONTINUOUS PRINTING SPEED

This excludes operations that fall under the restrictions on printing speed explained in “1.12 Engine Restrictions” (p.34).

Monochrome mode

Table 1-4. Monochrome Mode (Unit: PPM)

|

|

|

Simplex printing |

|

Duplex printing |

|

|

|

|

||

Paper size |

|

Std. mode |

Low speed mode 1 Low speed mode 2 |

Std. mode |

|

|

|

(Plain paper 1, 2) |

(Plain paper 1, 2) |

||

|

|

|

|

|

|

A4, B5, LT |

|

30 |

4.2 |

2.6 |

20 |

|

|

|

|

|

|

A5, EXE |

|

30 |

4.2 |

2.6 |

20 |

Envelope C6, |

|

|

|

|

|

MON, DL, C5, |

|

– |

– |

2.6 |

– |

Com-#10 |

|

|

|

|

|

|

|

|

|

|

|

User defined size |

|

30 |

4.2 |

2.6 |

– |

Color mode |

|

|

|

|

|

|

|

Table 1-5. Color Mode (Unit: PPM) |

|

||

|

|

|

|

|

|

|

|

|

Simplex printing |

|

Duplex printing |

Paper size |

|

Std. mode |

Low speed mode 1 Low speed mode 2 |

Std. mode |

|

|

|

(Plain paper 1, 2) |

(Plain paper 1, 2) |

||

|

|

|

|

|

|

A4, B5, LT |

|

7.5 |

2.9 |

2.1 |

7.5 |

|

|

|

|

|

|

A5, EXE |

|

7.5 |

2.9 |

2.1 |

7.5 |

Envelope C6, |

|

|

|

|

|

MON, DL, C5, |

|

– |

– |

2.1 |

– |

Com-#10 |

|

|

|

|

|

|

|

|

|

|

|

User defined size |

|

7.5 |

2.9 |

2.1 |

– |

|

|

|

|

|

|

PAPER FEED REFERENCE

Center-line reference for each paper size and for both MP tray and 500-sheet cassette (optional).

Product Description |

Basic Specifications |

15 |

EPSON AcuLaser C2600/2600 |

Revision A |

PAPER FEED

Table 1-6. Paper Feed

|

Paper feed |

Sheet capacity |

Paper type/Paper size |

Acceptable paper |

|

|

Height capacity |

basis weight* |

|||

|

|

|

|||

|

|

150 sheets |

Standard paper: |

82 g/m2 |

|

|

|

EPSON high quality plain paper |

|||

|

|

|

|

||

|

|

|

|

|

|

|

|

16.5 mm |

Plain paper/recycled paper: |

64 to 90 g/m2 |

|

|

|

A4, A5, B5, LT, GLT, HLT, EXE |

|||

|

|

|

|

||

|

|

60 sheets |

Transparency: A4, LT |

– |

|

|

|

|

|

|

|

|

|

50 sheets |

Labels: A4, LT |

– |

|

|

MP tray |

EPSON coated papers: A4 |

|||

|

|

|

|||

Standard |

75 sheets |

Thick Paper: |

91 to 163 g/m2 |

||

|

|||||

|

A4, A5, B5, LT, GLT, HLT, EXE |

||||

|

|

||||

|

|

|

|

||

|

|

|

|

|

|

|

|

15 sheets |

Envelopes: |

– |

|

|

|

C5, C6, Com-#10, DL, Monarch, |

|||

|

|

|

ISO-B5 |

|

|

|

|

16.5 mm |

User defined size: |

64 to 163 g/m2 |

|

|

|

Width 98 to 216/ Length 148 to 297 |

|||

|

|

|

|

||

|

|

|

|

|

|

|

Lower paper |

500 sheets |

Standard paper: |

82 g/m2 |

|

|

EPSON high quality plain paper |

||||

|

cassette (C1) |

|

|

||

|

55 mm |

Plain paper: A4, LT |

64 to 90 g/m2 |

||

|

|

||||

|

Paper |

500 sheets |

Standard paper: |

82 g/m2 |

|

Option |

cassette unit |

|

EPSON high quality plain paper |

|

|

|

(C2) |

55 mm |

Plain paper: A4, LT |

64 to 90 g/m2 |

|

|

Duplex |

– |

A4, LT, B5, A5, EXE |

64 to 90 g/m2 |

|

Note |

*: Refer to |

“1.3 Paper Specifications” (p.22). |

|

||

OPTIONAL PAPER SOURCE COMBINATION

Installing an optional paper cassette unit enables the printer to load the maximum number of papers as shown in the table below.

Table 1-7. Optional Paper Source Combination

|

Combination |

|

(1) |

(2) |

|

|

|

||||

|

|

|

|

|

|

Standard |

MP tray |

150 sheets* |

{ |

{ |

|

|

|

|

|

||

Lower paper cassette (C1) |

500 sheets* |

{ |

{ |

||

|

|||||

Option |

Paper cassette unit (C2) |

500 sheets* |

– |

{ |

|

|

|

|

|

|

|

|

Total number of sheets |

|

650 sheets |

1150 sheets |

|

|

|

|

|

|

Note *: Standard paper: EPSON high quality plain paper (82 g/m2)

Product Description |

Basic Specifications |

16 |

EPSON AcuLaser C2600/2600 |

Revision A |

SUPPORTED PAPER SIZE, TYPE AND ORIENTATION

Supported paper

Table 1-8. List of Supported Paper Size, Type and Orientation

|

|

Paper |

Paper size Dimensions in mm (inches) |

MP tray |

Standard lower |

Optional paper |

Paper orientation |

Duplex printing |

||

|

|

Vertical (length) |

Horizontal (width) |

paper cassette |

cassette unit |

|||||

|

|

|

|

|

|

|

||||

|

A4 |

|

|

297.00 |

210.00 |

{ |

{ |

{ |

SEF |

{ |

|

|

|

|

|

|

|

|

|

|

|

|

A5 |

|

|

210.00 |

148.00 |

{ |

– |

– |

SEF |

{ |

Standard |

JIS-B5 |

|

|

257.00 |

182.00 |

{ |

– |

– |

SEF |

{ |

|

|

|

|

|

|

|

|

|

|

|

LT |

|

|

279.40 (11.00") |

215.90 (8.50") |

{ |

{ |

{ |

SEF |

{ |

|

|

|

|

||||||||

|

HLT |

|

|

215.90 (8.50") |

139.70 (5.50") |

{ |

– |

– |

SEF |

– |

|

|

|

|

|

|

|

|

|

|

|

|

GLT |

|

|

266.70 (10.50") |

203.20 (8.00") |

{ |

– |

– |

SEF |

– |

|

EXE |

|

|

266.70 (10.50") |

184.15 (7.25") |

{ |

– |

– |

SEF |

{ |

|

|

|

|

|

|

|

|

|

|

|

|

User defined paper size |

148.00 to 297.00 |

98.00 to 216.00 |

{ |

– |

– |

Free |

– |

||

|

Transparency |

A4: 297.00 |

A4: 210.00 |

{ |

– |

– |

SEF |

– |

||

|

|

|

|

|

|

|

|

|||

|

LT: 279.40 |

LT: 215.90 |

{ |

– |

– |

SEF |

– |

|||

|

|

|

|

|||||||

|

Labels |

|

|

A4: 297.00 |

A4: 210.00 |

{ |

– |

– |

SEF |

– |

|

|

|

|

|

|

|

|

|

|

|

paper |

|

|

LT: 279.40 |

LT: 215.90 |

{ |

– |

– |

SEF |

– |

|

|

|

|

||||||||

|

|

MONARCH |

190.50 (7 1/2) |

98.43 (3 7/8) |

{ |

– |

– |

SEF |

– |

|

Special |

Envelopes |

|

|

|

|

|

|

|

|

|

|

Com-#10 |

241.30 (9 1/2) |

104.78 (4 1/8) |

{ |

– |

– |

SEF |

– |

||

|

|

|

||||||||

|

|

|

DL |

220.00 |

110.00 |

{ |

– |

– |

SEF |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C5 |

229.00 |

162.00 |

{ |

– |

– |

SEF |

– |

|

|

|

C6 |

162.00 |

114.00 |

{ |

– |

– |

SEF |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ISO-B5 |

250.00 |

176.00 |

{ |

– |

– |

SEF |

– |

Note |

1: SEF (Short Edge Feed): Set paper to be loaded from its short side. |

|

|

|

|

|

||||

2:The supported sizes differ depending on the destination.

3:For the orientation of envelopes, refer to “Envelope orientation” (p.18).

4:Curls must be straightened.

Product Description |

Basic Specifications |

17 |

EPSON AcuLaser C2600/2600 |

Revision A |

Paper orientation

Paper Feed |

|

MP Tray |

|

Cassette (C1/C2) |

||

|

|

|

|

|

|

|

Paper Orientation/ |

|

Place Print Side Down. |

|

|

Place Print Side Up. |

|

Feeding Direction |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Envelope orientation

Feeding Direction |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

01000201 |

|

|

01000101 |

||||

|

|

|

|

|

|

Envelope Types |

MONARCH, DL, |

C5 |

|||

Com- #10, C6 |

|||||

|

|

||||

|

|

|

|

|

|

NOTE 1: Place papers in the MP tray with the printable side face down.

2:When the flap is closed, printing on the reverse (flap side) is not available.

(The flap may adhere to the transfer belt and open, which may result in paper wrinkles and paper jams.)

3:Only envelopes without tape or glue can be used.

4:Change the fuser unit lever when printing envelopes.

(For details, refer to “1.14 Notes on Fuser Pressure” (p.35).)

5:Only envelopes with trapezoid shaped flaps can be fed with the flap opened.

Envelopes with triangular shaped flaps should not be used. (It may cause a slip off or stack defect.)

PAPER EJECT

Only for face-down (FD) 250 sheets

NOTE: Standard paper: EPSON high quality plain paper (82 g/m2)

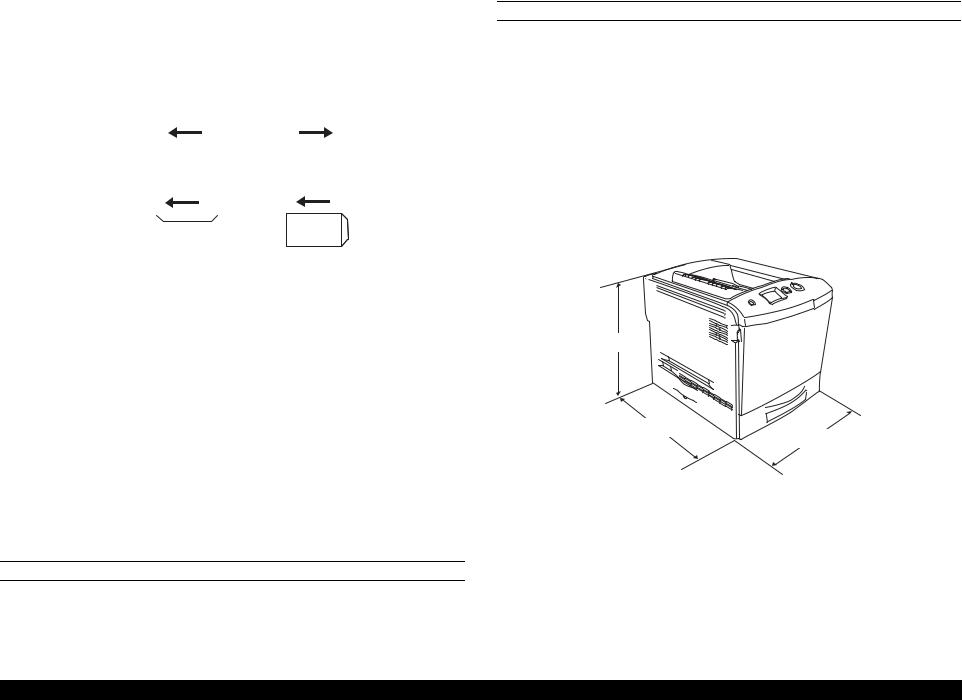

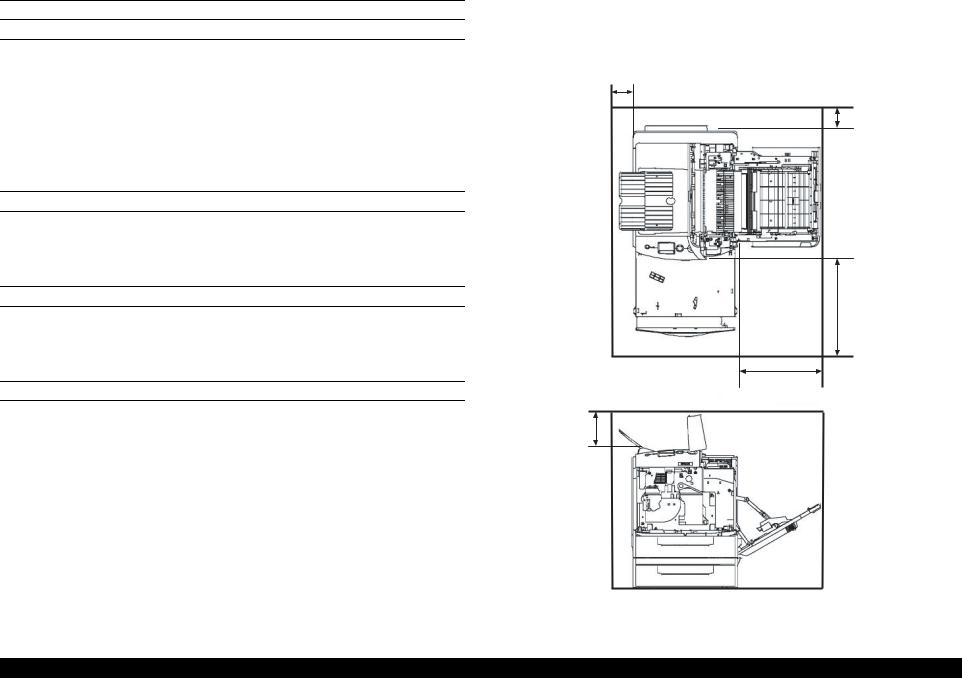

DIMENSIONS AND WEIGHT

Stand alone outline dimensions and weight

Table 1-9. Stand Alone Outline Dimensions and Weight

|

Width (mm) |

Depth (mm) |

Height (mm) |

Weight (kg) |

|

||||

|

|

|

|

|

Main unit |

431 |

518 |

425 |

37*1 / 33*2 |

500-sheet cassette unit (option) |

408 |

482 |

140 |

5 |

Duplex unit (option) |

132 |

282 |

220 |

0.9 |

|

|

|

|

|

Note : Manufacturing tolerance is ± 5 mm in dimensions and ± 0.5 kg in weight. Note *1: Includes consumables.

*2: Initial condition (exc. Toner Cartridges)

425 mm

518 mm

431 mm

01000301

Figure 1-1. Dimensions (Main Unit)

Product Description |

Basic Specifications |

18 |

EPSON AcuLaser C2600/2600 |

Revision A |

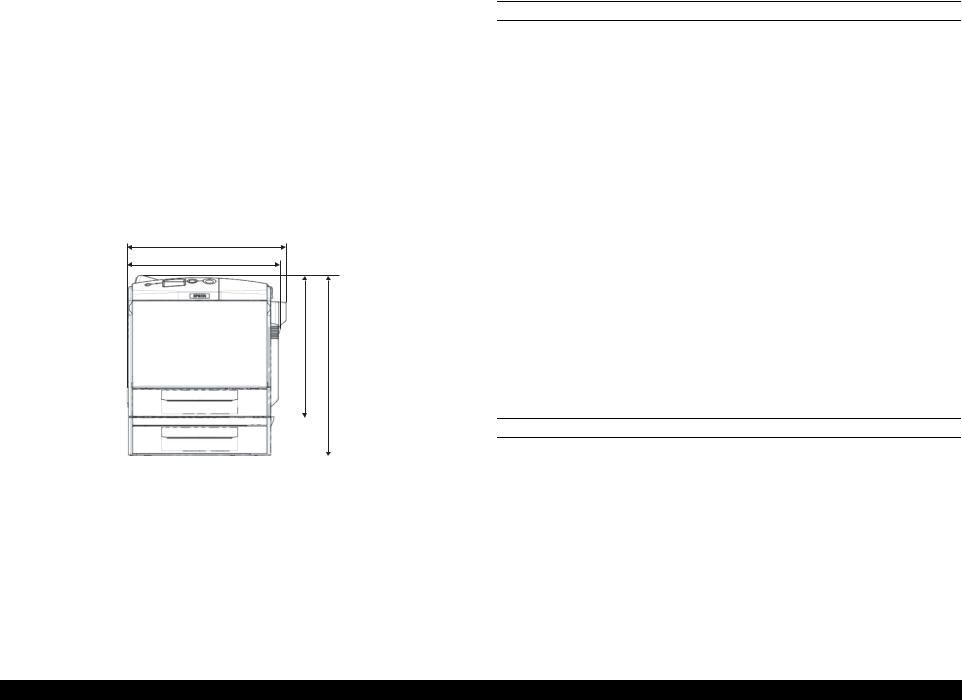

Outline dimensions and weight with options installed

Table 1-10. Outline Dimensions and Weight With Options Installed

|

|

Width (mm) |

Depth (mm) Height (mm) |

Weight (kg) |

||

|

|

|||||

|

|

|

|

|

|

|

Main unit + Optional paper cassette |

431 |

518 |

538 |

42* |

||

unit |

|

|||||

|

|

|

|

|

||

|

|

|

|

|

||

Main unit + Duplex unit |

447 |

518 |

425 |

38* |

||

Main unit + Optional paper cassette |

447 |

518 |

538 |

43* |

||

unit + Duplex unit |

||||||

|

|

|

|

|||

|

|

|

|

|

|

|

Note : |

Manufacturing tolerance is ± 5 mm in dimensions and ± 0.5 kg in weight. |

|||||

Note *: |

Includes consumables. |

|

|

|

|

|

447 mm |

431 mm |

425 mm |

mm |

|

538 |

|

|

|

|

01000401

Figure 1-2. Dimensions (Including Options)

CONSUMABLES AND PERIODIC REPLACEMENT UNIT

Table 1-11. List of Consumables and Periodic Replacement Unit

Classification |

Replacement unit |

|

|

|

|

|

Toner cartridge (Black, Cyan, Yellow, Magenta) |

|

|

|

|

|

Photoconductor unit |

|

Consumables |

Fuser unit |

|

|

|

|

|

Waste toner collector |

|

|

Filter |

|

|

|

|

|

Transfer belt unit (TRANSFER, Assy; ASP) |

|

|

Cleaning tape (MOUNTING PLATE, ANTI-STATIC; ASP) |

|

|

|

|

|

Cleaner clutch (CLUTCH, CLEANER) |

|

Periodic replacement units |

2nd transfer clutch (CLUTCH, 2ND TRANSFER) |

|

|

|

|

|

Paper eject roller (COVER Assy., FU; ASP) |

|

|

Post-fixing roller (COVER Assy., FU; ASP) |

|

|

|

|

|

Pickup roller (ROLLER ASSY, PICK UP) |

|

|

|

NOTE: For detailed specifications, refer to “1.9 Consumables/Periodic Replacement Unit” (p.30).

POWER SUPPLY

Power supply operating voltage/frequency

AC 110 V to 120 V ± 10 %, 50 Hz / 60 Hz ± 3 Hz

AC 220 V to 240 V ± 10 %, 50 Hz / 60 Hz ± 3 Hz

Power supply for the controller

DC 5.0 V ± 5 %, 2A

DC 3.3 V ± 5 %, 5A

Product Description |

Basic Specifications |

19 |

EPSON AcuLaser C2600/2600 |

Revision A |

POWER CONSUMPTION

The maximum rated current is measured with all engine options and controller options installed.

Table 1-12. List of Power Consumption

|

|

|

120V |

230V |

|

Maximum rated current |

10 A or less |

6 A or less |

|||

|

|

|

|

|

|

consumption |

Maximum |

880 W |

900 W |

||

Continuous printing average |

Color |

335 W |

332 W |

||

|

|||||

|

|

|

|

||

|

Monochrome |

567 W |

583 W |

||

|

|

||||

Power |

Average during standby with the heater on |

96 W |

99 W |

||

|

|

|

|

||

Sleep mode* |

10 W or less |

12 W or less |

|||

|

|||||

|

Power supply off |

0 W |

0 W |

||

|

|

|

|

|

|

Note *: Refer to “Table 1-13. Operating State” (p.20).

CONSUMPTION CURRENT

500-sheet cassette unit (option)

5 V / 0.3 A or less

24 V / 0.35 A or less

Duplex unit (option)

5 V / 0.1 A or less

24 V / 1.0 A or less

OPERATING STATE

This printer operates in the following 3 operating states.

|

|

|

Table 1-13. Operating State |

|

|

|

|

|

|

|

Operational mode |

|

|

Explanation |

|

Operating state |

Performs a print job in various printing mode upon receiving a command |

||

|

from the controller. |

|||

|

|

|||

|

|

|

|

|

|

|

Standby state. Switches to this mode automatically after completing a |

||

|

Standby state |

print job (exits out of the operating state) without receiving any |

||

|

|

commands. |

||

|

|

Switches to this mode on receiving a command from the controller. |

||

|

Sleep state |

Supporting BAM and International Energy Star Program (power |

||

|

|

consumption 21W or less within 30 minutes after the printing operation) |

||

|

|

|

|

|

|

|

|

|

|

|

PRODUCT LIFETIME |

|

|

|

|

|

|

Table 1-14. Product Lifetime |

|

|

|

|

|

|

|

|

|

|

Product lifetime |

|

Main unit |

|

|

300,000 pages (color*1) or 600,000 pages (monochrome)*2 or |

|

|

|

5 years; whichever comes first. |

|

|

|

|

|

|

|

|

|

|

|

|

Optional paper cassette unit |

|

400,000 pages*3 |

|

|

Duplex unit |

|

|

600,000 pages*4 |

Note *1: 1,200,000 pages for single color images

*2: 480,000 pages when the ratio of color and monochrome is 1:1 (1,200,000 images) *3: 2/3 of the main unit max pages (Monochrome 600,000 pages)

*4: When all of the main unit max pages (Monochrome 600,000 pages) are made by duplexing.

Product Description |

Basic Specifications |

20 |

EPSON AcuLaser C2600/2600 |

Revision A |

NOISE

Sound pressure

Table 1-15. Sound Pressure

|

|

Operating state |

Standby state |

Sleep state |

|

|

|

||||

|

|

|

|

|

|

Main unit |

Color mode |

56 dB (A) |

40 dB (A) |

Background noise |

|

Monochrome mode |

56 dB (A) |

40 dB (A) |

|||

|

|

||||

Note : Reference values |

|

|

|

||

Sound power |

|

|

|

||

|

|

Table 1-16. Sound Power |

|

||

|

|

|

|

|

|

|

|

Operating state |

Standby state |

Sleep state |

|

|

|

|

|

|

|

Main unit |

Color mode |

68 dB (A)* |

52 dB (A) |

|

|

|

|

|

|

||

Monochrome mode |

66 dB (A)* |

52 dB (A) |

Background noise |

||

With all optional installations |

Exceeds the main |

|

|||

|

|

||||

unit values by less |

52 dB (A) |

|

|||

(reference value) |

|

||||

than 1 db |

|

|

|||

|

|

|

|

||

|

|

|

|

|

|

Note *: The method of measuring and calculation conforms to ISO-7779 and ISO-9296. (Employing standard values for RAL-UZ85 (BAM standard))

Note : (A) indicates that the value has been adjusted with consideration of human sensitivity to frequencies (correction by A characteristic).

EXHAUST GAS

|

Table 1-17. Exhaust Gas |

|

|

|

Value |

Ozone Concentration |

0.02 mg/m3 or less (the measuring method conforms to BAM) |

Styrene Concentration |

0.07 mg/m3 or less (the measuring method conforms to BAM) |

Fine Particles Concentration |

0.075 mg/m3 or less (the measuring method conforms to BAM) |

TVOC |

0.40 mg/m3 or less |

Product Description |

Basic Specifications |

21 |

EPSON AcuLaser C2600/2600 |

Revision A |

1.3 Paper Specifications

1.3.1 Paper Type

Standard paper

RX-80 paper (Monochrome), 4024 paper (20 lb) (Monochrome), EPSON high quality plain paper (A4)

Plain paper

64 g/m2 to 90 g/m2 (17 lb to 24 lb)

(General purpose copy papers and recycled papers.)

Recommended recycled paper: Recommended Recycling Copy classic

Special paper

EPSON transparency sheets (A4, LT)

Labels

Thick papers (91 g/m2 to 163 g/m2)

Envelopes (75 g/m2 to 105 g/m2)

EPSON coated papers (A4) (Guarantees only the paper feedability)

CHECK |

|

lb: |

Ream weight = Total weigh of 500 sheets of 17" x 22" |

POINT |

|

|

sized paper |

|

|

g/m2: 1 g/m2 = 0.2659763 lb |

|

|

Before purchasing a large amount of paper, test the paper if it |

||

|

|

can be printed normally. |

|

|

|

|

|

1.3.2Paper That May Cause Printing Defects, Paper Jams or Printer Malfunction

Transfer paper (carbon paper, non-carbon paper), thermal paper, impact paper, acid paper

Paper that is too thin or too thick

Paper that is wet or damp

Paper with special coatings or color printer paper with processed surfaces

Glossy (too slick) paper, or paper with too rough surface

Paper that the roughness is significantly different by side

Paper with punch holes or perforations

Creased, curled or torn paper

Irregularly shaped paper or paper with non-perpendicular corners

Labels that peel off easily

Paper with glue, staples or paper clips attached to it

Special paper for ink jet applications (super-fine, glossy, glossy film, etc.)

Paper previously used in a thermal or ink jet printer

Transparencies for other color laser printers or color photocopiers

Paper that has been already printed with other color/monochrome laser printers or photocopiers

Sheets of paper stuck together

Postcards for ink jet printers, unofficial postcards, and adhesive postcards

Iron print coated paper (for both ink jet and laser printers)

Paper that is deteriorated or discolored, due to temperatures lower than 235 ºC.

Product Description |

Paper Specifications |

22 |

EPSON AcuLaser C2600/2600 |

Revision A |

1.3.3 Paper Feed Types

Table 1-18. Paper Feed Types

|

|

|

|

|

Special paper |

|

||

|

Feeder |

Standard |

Plain |

|

|

Thick |

|

|

|

paper |

paper |

Transpar- |

Labels |

paper, |

Envelopes |

||

|

|

|||||||

|

|

|

|

ency |

Coated |

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

paper |

|

|

Standard |

MP tray |

{ |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Paper |

{ |

|

X |

X |

X |

X |

||

|

||||||||

|

cassette |

|||||||

|

|

|

|

|

|

|

||

Option |

Paper |

{ |

|

X |

X |

X |

X |

|

cassette unit |

||||||||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Duplex unit |

{ |

|

X |

X |

X |

X |

|

Note : |

|

|

|

|

|

|

||

{ : Paper feed and image quality is guaranteed.

: Paper feed and printing is possible. However, this is limited to types of paper for general applications. Image quality is not guaranteed.

X : Paper feed is impossible.

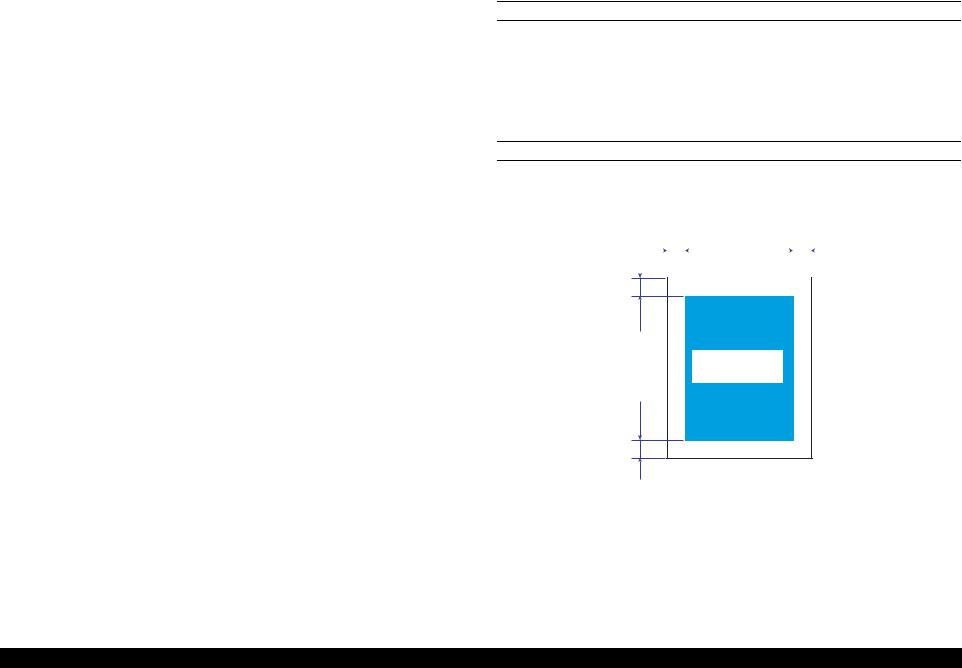

1.3.4 Printing Area

MAXIMUM PRINTABLE AREA

208 mm (width) x 289 mm (length)

NOTE: Although papers smaller than the maximum printable size can be printed without margins, continuous printing on such papers, especially if the left, right, top, and bottom margins beyond the paper exceed 4 mm, causes contamination inside the printer and paper jam.

GUARANTEED PRINTING AREA

The guaranteed printing area is shown below. The minimum left, right, top and bottom margins are 4 mm for any type of paper.

4 mm |

|

|

|

|

|

|

|

|

4 mm |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 mm

Guaranteed

Printing Area

4 mm

01000501

Figure 1-3. Guaranteed Printing Area

Product Description |

Paper Specifications |

23 |

EPSON AcuLaser C2600/2600 |

Revision A |

1.4 Reliability and Serviceability

1.4.1 Reliability

MPBF/MTBF

60,000 pages or more*1 / 3,000 hours or more*2

NOTE *1: Assuming the ratio of color and monochrome is 1:1

*2: Assuming an average power-on time is 300 hours per month.

PAPER FEED RELIABILITY

Jam rate

Table 1-19. Jam Rate

|

|

Paper Type |

|

||

Reliability issue |

Environment A*1 |

Environment B*2 |

|||

|

Simplex printing |

Duplex printing |

Simplex printing |

Duplex printing |

|

|

|

|

|

|

|

Standard paper |

1/4000 sheets or |

2/4000 sheets or |

3/4000 sheets or |

6/4000 sheets or |

|

less |

less |

less |

less |

||

|

|||||

|

|

|

|

|

|

Plain paper |

1/2000 sheets or |

2/2000 sheets or |

3/2000 sheets or |

6/2000 sheets or |

|

less |

less |

less |

less |

||

|

|||||

Special paper |

1/100 sheets or |

– |

3/100 sheets or |

– |

|

less |

less |

||||

|

|

|

|||

|

|

|

|

|

|

Paper feed error / multiple sheet feeding*3 / paper wrinkles / creased corner rate*4

Table 1-20. Paper Feed Error/Multiple Sheet Feeding/

Paper Wrinkles/Creased Corner Rate

|

|

|

|

Paper Type |

|

|

Reliability issue |

|

Environment A*1 |

Environment B*2 |

|||

|

|

Simplex printing |

Duplex printing |

Simplex printing |

Duplex printing |

|

|

|

|

|

|

|

|

Standard paper |

1/1000 sheets or |

2/1000 sheets or |

3/1000 sheets or |

6/1000 sheets or |

||

less |

|

less |

less |

less |

||

|

|

|

||||

|

|

|

|

|

|

|

Plain paper |

|

1/500 sheets or |

2/500 sheets or |

3/500 sheets or |

6/500 sheets or |

|

|

less |

|

less |

less |

less |

|

|

|

|

||||

Special paper |

|

1/25 sheets or less |

– |

3/25 sheets or less |

– |

|

|

|

|

|

|

||

Note *1: Conditions for environment A (15 to 28 °C / 35 to 70 % RH) |

|

|||||

|

Paper size: |

Standard-size |

|

|

||

|

Humidity control: no regulation |

|

|

|||

*2: Conditions for environment B (10 to 30 °C / 15 to 65, 85 % RH) |

|

|||||

|

Paper size: |

Standard-size |

|

|

||

Humidity control: uncontrolled packed papers

*3: The multiple sheet feeding rate does not include the performance at the boundary of the originally loaded papers and additionally replenished papers.

*4: Counts creases more than C1 mm.

Product Description |

Reliability and Serviceability |

24 |

EPSON AcuLaser C2600/2600 |

Revision A |

PRINTING START POSITION ACCURACY

Table 1-21. Printing Start Position Accuracy

|

A4/A3 |

|

|

Simplex printing |

Duplex printing |

||||||||||

Main scanning direction Reference point (c) |

|

|

± 2.0 mm |

± 3.0 mm |

|||||||||||

Sub-scanning direction Reference point (a) |

|

|

± 2.5 mm |

± 2.5 mm |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

c |

a |

|

b |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

f |

DirectionFeed |

|

|

|

|

|

|

|

|

|

|

Printable Area |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

d |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e |

|

01000601 |

|

||||||

|

|

|

|

|

|

|

|

|

|||||||

|

Figure 1-4. Printing Start Position Accuracy |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SKEW |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

Table 1-22. Skew |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A4 |

|

|

Simplex printing |

Duplex printing |

|

|||||||

|

Main scanning direction (| a-b |) |

|

|

1.47 mm |

2.21 mm |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Sub-scanning direction (| c-d |) |

|

|

2.05 mm |

3.07 mm |

|

|||||||||

|

Table 1-23. Length Standard of Measurement |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A4 |

|

|

Simplex printing |

|

|

Main scanning direction (e) |

208 mm |

|

|||||||||

|

Duplex printing |

|

|

Sub-scanning direction (f) |

289 mm |

|