Eaton Transmission RTO-9109B-AT Service Manual

Troubleshooting Guide

Fuller Heavy Duty Transmissions

TRTS0020 EN-US

October 2007

RT-11109A-AT RT-11109A-ATR RT-11109A-ATS RT-12109A-AT RT-14109A-ATS RTO-11109A-AT RTO-11109A-ATS RTO-11109B-AT RTO-11109B-ATE RTO-11109B-ATR RTO-11109B-ATS RTO-12109A-AT RTO-12109B-AT RTO-13109A-ATE

RTO-13109B-AT RTO-13109B-ATE RTO-14109A-ATE RTO-14109A-ATS RTO-14109B-AT RTO-14109B-ATE RTO-14109B-ATS RTO-16109A-AT RTO-16109A-ATE RTO-16109B-AT RTO-16109B-ATE RTO-9109A-AT RTO-9109B-AT

For parts or service call us Pro Gear & Transmission, Inc.

1(877) 776-4600

(407)872-1901 parts@eprogear.com

906 W. Gore St. Orlando, FL 32805

General Warnings:

Before starting a vehicle:

• Sit in the driver’s seat

•Place shift lever in neutral

•Set the parking brake

Before working on a vehicle or leaving the cab with engine running:

•Place shift lever in neutral

•Set the parking brake

•Block the wheels

Do not release the parking brake or attempt to select a gear until the air pressure is at the correct level.

When parking the vehicle or leaving the cab:

• Place shift lever in neutral

• Set the parking brake

To avoid damage to the transmission during towing:

• Place shift lever in neutral

•Lift the drive wheels off of the ground or disconnect the driveline

Do not operate vehicle if alternator lamp is lit or if gauges indicate low voltage.

Suggested Tools:

Pressure Gauges:

•0-300 PSI Hydraulic gauge

•0-100 PSI Hydraulic gauge

•0-100 PSI Air gauge

OTC Tool & Equipment Division,

SPX Corporation

Eaton Part No. |

Description |

5505027 |

Volt /Ohm Meter (Standard |

|

commercially available VOM) |

For ordering in U.S. and Canada call 1-800-533-0492. (In

Minnesota call 507-455-7010.)

MPSI Micro Processor Systems, Inc.

MPSI Part No. |

Description |

104004 |

Pro-link Main (MPSI hand-held diagnostic |

|

tool) |

205040 |

Heavy Duty Multi-Protocol Cartridge (MPC) |

805001 |

MPC Eaton Systems Software |

For MPSI phone orders call 1-800-639-6774.

Related Publications

Installation Guide - Eaton TRIG-0020

Driver Instructions - Eaton TRDR-0020

Service Manual - Eaton TRSM-0020

Illustrated Parts List - Eaton TRIP-0023 (11109)

Eaton TRIP-0025 (13109)

Eaton TRIP-0022 (14109)

Eaton TRIP-0026 (16109)

For more information call 1-800-826-HELP (826-4357).

Every effort has been made to ensure the accuracy of all information in this manual. However, Eaton Transmission Division makes no expressed or implied warranty or representation based on the enclosed information. Any errors or omissions may be reported to Training and Publications, Eaton Transmission Division, P.O. Box 4013, Kalamazoo, MI 49003.

Table of Contents

Section 1: Introduction

Diagnostics Procedure ............................................... |

1-2 |

Fault Codes Retrieval/Clearing ..................................... |

1-3 |

Driving Techniques ..................................................... |

1-4 |

Fault Code Isolation Procedure Index .......................... |

1-8 |

Symptom Driven Diagnostics ................................... |

1-10 |

Section 2: Fault Isolation Procedures |

|

Pretests |

|

Electrical Pretest ......................................................... |

2-1 |

Pneumatic Pretest ...................................................... |

2-3 |

Power-Up Sequence Test ........................................... |

2-4 |

Component and System Codes |

|

Component Code 11, ECU .......................................... |

2-6 |

Component Code 14, Shift Lever Fault ........................ |

2-8 |

Component Code 15, Shift Lever Data Link ............... |

2-10 |

Component Code 21, Interrupt Solenoid Coil ............. |

2-16 |

Component Code 22, Lockup/Bypass |

|

Solenoid Coil ............................................................ |

2-18 |

Component Code 23, Engine Speed Sensor .............. |

2-20 |

Component Code 24, Hydraulic System Fault ............ |

2-24 |

Component Code 31, Engine Brake Relay Coil ........... |

2-28 |

Component Code 32, Defuel Solenoid Coil ................ |

2-32 |

Component Code 33, System Voltage ....................... |

2-36 |

Component Code 34, Throttle Position Sensor .......... |

2-38 |

System Code 35, Engine Control Failure |

|

(Mechanically-Governed Engines) ............................. |

2-42 |

System Code 35, Engine Control Failure |

|

(Electronically-Governed Engines) ............................ |

2-44 |

System Code 41, Range Failed to Engage .................. |

2-48 |

Component Code 43, Range Solenoid Coil ................ |

2-50 |

Component Code 44, Disc/Inertia Brake |

|

Solenoid Coil ............................................................ |

2-52 |

Component Code 45, Power Synchronizer |

|

Band/Engine Boost Solenoid Coil .............................. |

2-54 |

Component Code 51, Center Rail Sensor ................... |

2-56 |

Component Code 52, Neutral Sensor ........................ |

2-60 |

Component Code 53, Gear Engaged Sensor .............. |

2-64 |

Component Code 54, HI Range Sensor ..................... |

2-68 |

Component Code 55, LO Range Sensor .................... |

2-72 |

Component Code 56, Input Speed Sensor ................. |

2-76 |

Component Code 57, Output Speed Sensor .............. |

2-80 |

Component Code 61, Autoshifter Solenoid 1 |

|

Coil .......................................................................... |

2-84 |

Component Code 62, Autoshifter Solenoid 2 |

|

Coil .......................................................................... |

2-86 |

Component Code 63, Autoshifter Solenoid 3 |

|

Coil .......................................................................... |

2-88 |

Component Code 64, Autoshifter Solenoid 4 |

|

Coil .......................................................................... |

2-90 |

System Code 71, Stuck Engaged .............................. |

2-92 |

System Code 72, Failed to Select a Rail ..................... |

2-96 |

System Code 73, Failed to Engage Gear .................. |

2-100 |

System Code 74, Failed to Synchronize ................... |

2-104 |

System Code 81, Invalid Shift Lever at Start |

|

(Cable Only) ........................................................... |

2-108 |

Component Code 82, Multiple Non-Adjacent Senors |

|

(Cable Only) ........................................................... |

2-110 |

System Code 83, Shift Lever Missing |

|

(Cable Only) ........................................................... |

2-112 |

Component Code 83, Shift Lever Missing |

|

(Electronic Only) ..................................................... |

2-114 |

1-1

Table of Contents

Section 3: Symptom Isolation Procedures

Symptom Pretests

Transmission Basic Inputs Pretest .............................. |

3-1 |

Engine Interface Pretest .............................................. |

3-5 |

Symptom Tests |

|

Shift Complaint Test ................................................... |

3-7 |

High Operating Temperature Test ............................. |

3-14 |

Hand-Held Diagnostic Tool Failed to Operate Test ..... |

3-17 |

Shift Lever in Gear Signal Test .................................. |

3-20 |

Neutral Output Test .................................................. |

3-22 |

Splitshaft PTO Switch Test ........................................ |

3-24 |

Quick to Neutral Test ................................................ |

3-26 |

Shift Lever Auxiliary Output 2 Test ............................ |

3-27 |

Shift Lever Auto Neutral Input Test ........................... |

3-29 |

Shift Lever Back Light Test ....................................... |

3-30 |

Reverse Relay Indicator Test ..................................... |

3-31 |

Start Enable Relay Test ............................................. |

3-34 |

Start Enable Relay Latch Test .................................... |

3-40 |

Shift Lever Voltage Test (Driver Lever) ...................... |

3-42 |

Shift Lever Voltage Test (Work Lever) ....................... |

3-44 |

Appendix

Torque Converter Hydraulic Diagram .......................... |

A-1 |

Pneumatic Diagram AT, ATR and ATS ......................... |

A-2 |

Pneumatic Diagram ATE ............................................. |

A-3 |

Pneumatic Diagram |

|

Mechanical ATE with Throttle Boost ............................ |

A-4 |

Cable Shift Lever Wiring Diagram ............................... |

A-6 |

Single Station Electronic Shift Lever Wiring Diagram ... |

A-8 |

Dual Station Electronic Shift Lever Wiring Diagram ... |

A-10 |

Cable Shift Lever Adjustment Procedure ................... |

A-12 |

Linear Throttle Position Adjustment Procedure ......... |

A-14 |

Electro-Pneumatic Defuel Control |

|

Adjustment Procedure .............................................. |

A-15 |

Dual Station Start Enable .......................................... |

A-16 |

1-2

1-1

Introduction

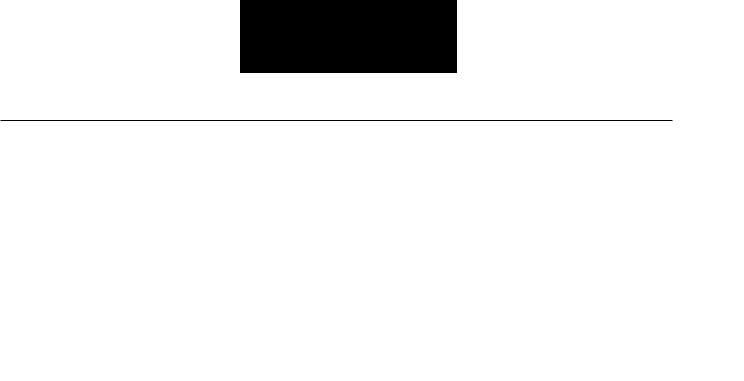

Diagnostics Procedure

Follow the flowchart below for all CEEMAT transmission failures. Perform tests and procedures as directed by the flowchart.

Key on.

Failure detected |

|

|

• Perform Electrical Pretest |

||

during self-check? |

YES |

(Page 2-1) |

|||

|

|

|

• Perform Power-Up |

||

|

|

|

|

|

|

|

|

|

|

|

Sequence Test (Page 2-4) |

NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Retrieve active codes. (Page 1-3)

Active codes?

YES

NO

Retrieve inactive codes. (Page 1-3)

•Refer to the Fault Code Isolation Procedure Index (Page 1-8) to select a fault code isolation procedure

•Perform Electrical Pretest (Page 2-1)

Inactive codes?

YES

NO

Symptom?

YES

NO

•Record and clear codes (Page 1-3)

•Refer to the Fault Code Isolation Procedure Index (Page 1-8) to select a fault code isolation procedure

•Perform Electrical Pretest (Page 2-1)

•Perform Pneumatic Pretest (Page 2-3)

•Perform Electrical Pretest (Page 2-1)

•Perform Pneumatic Pretest (Page 2-3)

•Perform Transmission Basic Inputs Pretest (Page 3-1)

•Perform Engine Interface Pretest (Page 3-5)

•Refer to Symptom Driven Diagnostics Table (Page 1-10) to select a fault isolation procedure

Test complete.

1-2

Introduction

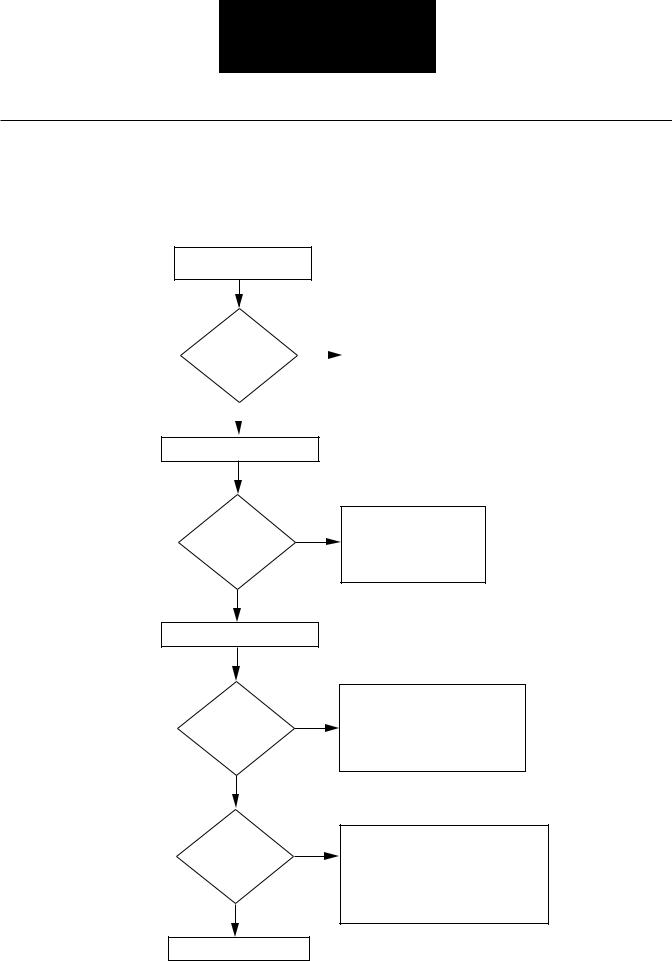

Fault Codes Retrieval/Clearing

Retrieving Fault Codes

Retrieve CEEMAT fault codes by enabling the CEEMAT system’s self-diagnostic mode.

Note: You can also use a diagnostic scan tool, such as the

MPSI Pro Link Main, to retrieve CEEMAT fault codes. Refer to the OEM’s documentation for more information.

1.Place the shift lever in neutral.

2.Set the parking brakes.

3.Turn the ignition key on but do not start the engine.

4.To Retrieve Active Codes: Start with the key in the on position. Turn the key off and on two times within five seconds ending with the key in the on position.

2 times off on

on

To Retrieve Inactive (Intermittent) Codes: Start with the key in the on position. Turn the key off and on four times within five seconds ending with the key in the on position.

4 times

off  on

on

After a brief pause, the service transmission indicator lamp begins flashing two-digit fault codes.

5.Observe the sequence of flashes on the indicator lamp and record the codes. A one to two second pause separates each stored code, and the sequence automatically repeats after all codes have been flashed.

Clearing Fault Codes

The following procedure clears all inactive (intermittent) fault codes from the ECU’s memory. (Active fault codes are automatically cleared when the fault has been corrected.)

1.Place the shift lever in neutral.

2.Set the parking brakes.

3.Turn the ignition key on but do not start the engine.

4.Start with the key in the on position. Turn the key off and on six times within five seconds ending with the key in the on position.

6 times

off on

on

2 Flashes |

1 Flash |

3 Flashes |

1 Flash |

Short |

(1–2 sec) |

|

Short |

pause |

|

|

pause |

(1/2 sec) |

|

|

(1/2 sec) |

Code 21 |

|

|

Code 31 |

DiagnosticsCodes Fault

ProcedureRetrieval/Clearing

1-3

Introduction

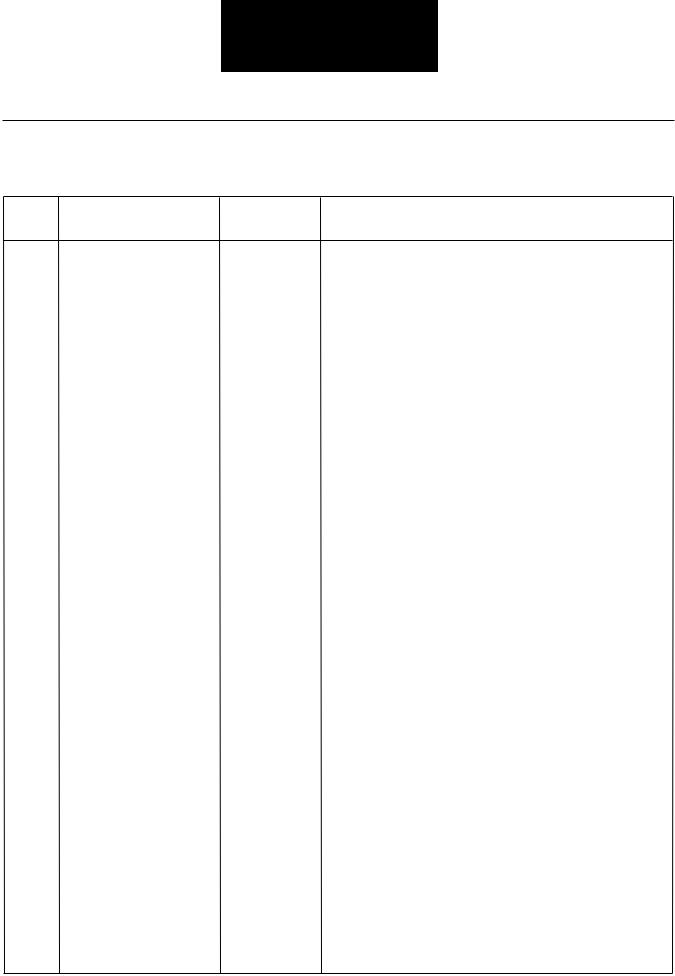

Driving Techniques

|

Fault |

Description |

Type of Code |

Driving Technique |

|

Codes |

|

|

|

11 |

ECU |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

14 |

Shift Lever Fault |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat, vibration and |

|

|

|

|

selecting different shift lever positions. |

|

|

|

|

|

15 |

Shift Lever Data Link |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

21 |

Interrupt Solenoid Coil |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

22 |

Lockup/Bypass Solenoid |

Component |

Key on. If the fault is present, the system should |

|

|

|

Coil |

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

23 |

Engine Speed Sensor |

Component |

Operate the vehicle above 4th gear until the fault occurs. |

|

|

|

|

|

Maintain a steady speed. If may be necessary to operate |

|

|

|

|

the vehicle for a prolonged period of time if the cause of |

|

|

|

|

the failure is related to heat or vibration. |

|

|

|

|

|

24 |

Hydraulic System Fault |

Component |

Complete several automatic shifts while driving the vehicle |

|

|

|

|

|

through terrain that loads the engine. |

|

|

|

|

|

31 |

Engine Brake Relay Coil |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

32 |

Defuel Solenoid Coil |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

1-4

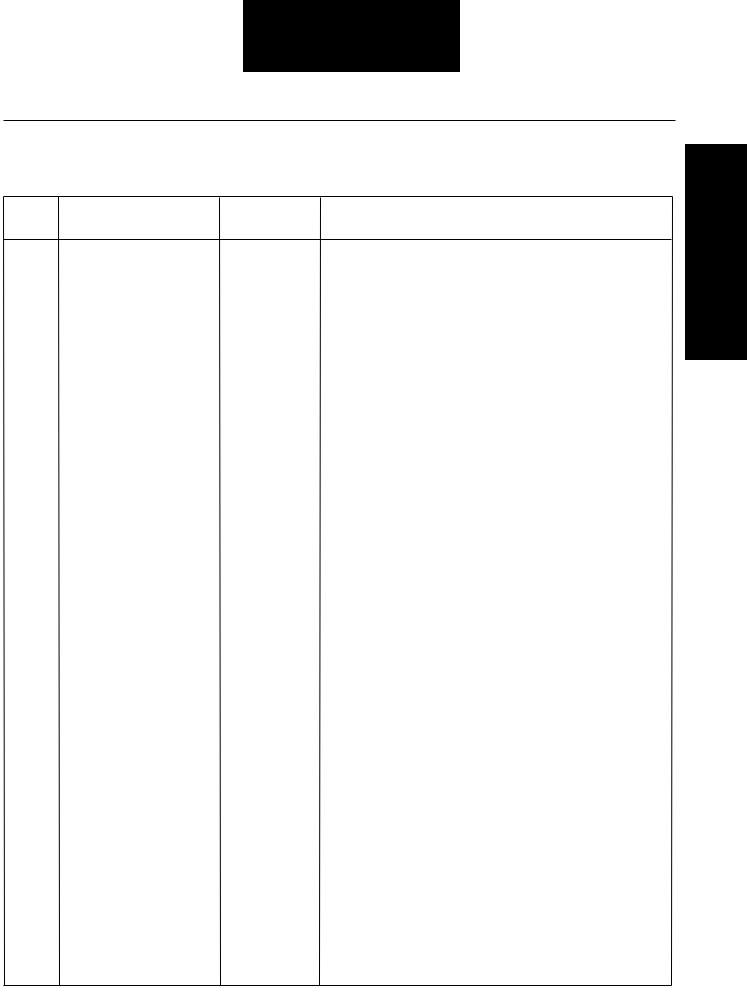

Introduction

Driving Techniques, continued

|

Fault |

Description |

Type of Code |

Driving Technique |

|

Codes |

|

|

|

33 |

System Voltage |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

34 |

Throttle Position Sensor |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat, vibration and |

|

|

|

|

varying levels of throttle demand. |

|

|

|

|

|

35 |

Engine Control Failure |

System |

Operate the vehicle and shift the transmission up and down |

|

|

|

(Mechanically-Governed |

|

through the gears. |

|

|

Engines) |

|

|

|

|

|

|

|

35 |

Engine Control Failure |

System |

Key on. If the fault is present, the system should |

|

|

|

(Electronically-Governed |

|

automatically detect the problem and set the code. |

|

|

Engines) |

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat, vibration and |

|

|

|

|

varying levels of throttle demand. |

|

|

|

|

|

41 |

Range Failed to Engage |

System |

Operate the vehicle and perform several range upshifts |

|

|

|

|

|

and downshifts. The failure is detected after 5 consecutive |

|

|

|

|

attempts to complete the same type of range shift. Several |

|

|

|

|

shifts (ten or more) may be necessary before the ECU |

|

|

|

|

confirms the failure. |

|

|

|

|

|

43 |

Range Solenoid Coil |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

44 |

Disc/Inertia Brake Coil |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

|

automatically detect the problem and set the code. |

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

45 |

Power Synchronizer |

Component |

Key on. If the fault is present, the system should |

|

|

|

Band/Engine Boost |

|

automatically detect the problem and set the code. |

|

|

Solenoid Coil |

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

51 |

Center Rail Sensor |

Component |

Complete several front box gear shifts, including |

|

|

|

|

|

selections from NEUTRAL and automatic shifts while |

|

|

|

|

in motion. |

Techniques Driving

1-5

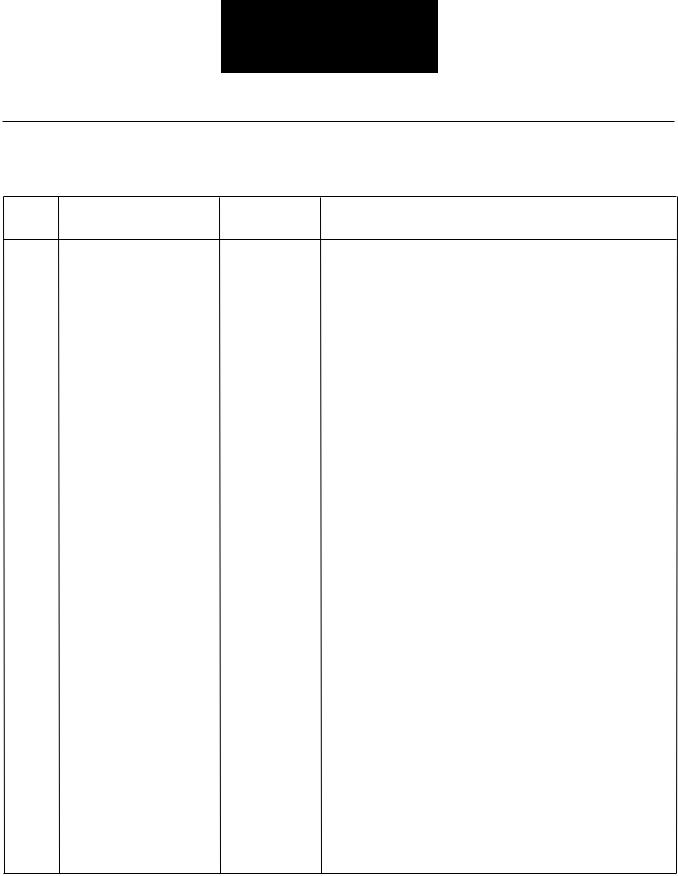

Introduction

Driving Techniques, continued

|

Fault |

Description |

Type of Code |

Driving Technique |

|

|

Codes |

|

|

|

|

52 |

Neutral Sensor |

Component |

Complete several front box gear shifts, including |

|

|

|

|

|

|

selections from NEUTRAL and automatic shifts while in |

|

|

|

|

|

motion. |

|

|

|

|

|

|

|

53 |

Gear Engaged Sensor |

Component |

Complete several front box gear shifts, including |

|

|

|

|

|

|

selections from NEUTRAL and automatic shifts while in |

|

|

|

|

|

motion. |

|

|

|

|

|

|

|

54 |

HI Range Sensor |

Component |

Complete several range shifts up and down across the |

|

|

|

|

|

|

entire range while the vehicle is in motion. |

|

|

|

|

|

|

|

55 |

LO Range Sensor |

Component |

Complete several range shifts up and down across the |

|

|

|

|

|

|

entire range while the vehicle is in motion. |

|

|

|

|

|

|

|

56 |

Input Speed Sensor |

Component |

Select a forward gear and drive at a steady speed for |

|

|

|

|

|

|

at least two minutes. |

|

|

|

|

|

|

|

57 |

Output Speed Sensor |

Component |

Select a forward gear and drive at a steady speed for |

|

|

|

|

|

|

at least two minutes. |

|

61 |

Autoshifter Solenoid 1 |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

Coil |

|

automatically detect the problem and set the code. |

|

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

|

|

62 |

Autoshifter Solenoid 2 |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

Coil |

|

automatically detect the problem and set the code. |

|

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

|

|

63 |

Autoshifter Solenoid 3 |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

Coil |

|

automatically detect the problem and set the code. |

|

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

|

|

|

64 |

Autoshifter Solenoid 4 |

Component |

Key on. If the fault is present, the system should |

|

|

|

|

Coil |

|

automatically detect the problem and set the code. |

|

|

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

1-6

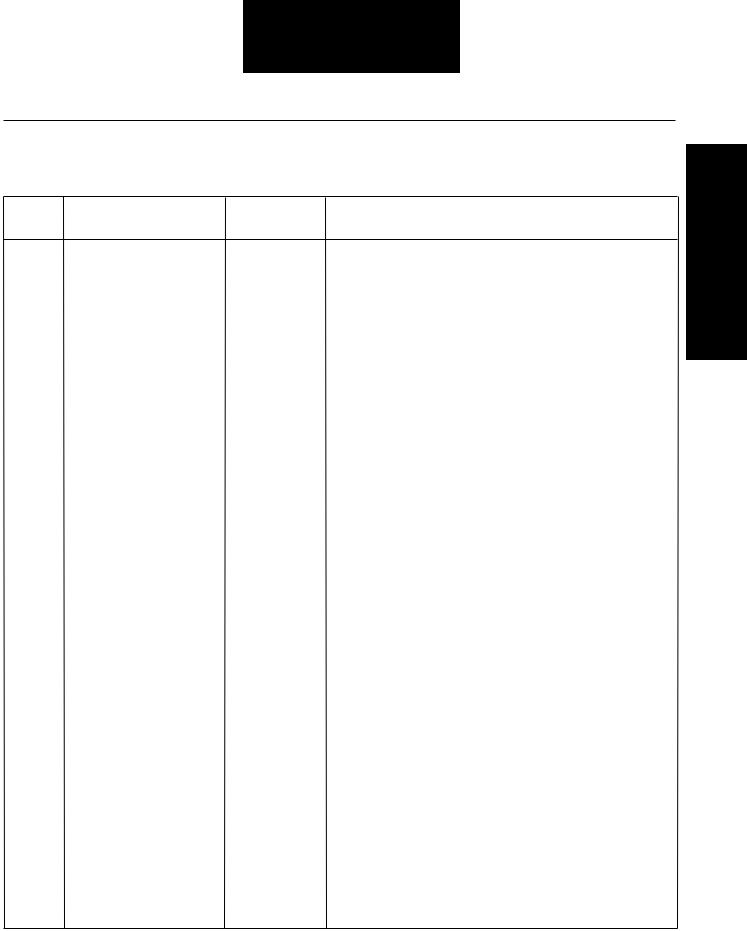

Introduction

Driving Techniques, continued

Fault |

Description |

Type of Code |

Driving Technique |

Codes |

|

|

|

71 |

Stuck Engaged |

System |

Engage LO gear and allow the vehicle to slowly move |

|

|

|

forward. While the vehicle is in motion, move the shift |

|

|

|

lever to Reverse LO and slowly bring the vehicle to a stop. |

|

|

|

The vehicle will shift into Reverse LO. Several shifts (ten |

|

|

|

or more) may be required before the ECU confirms |

|

|

|

the failure. |

72 |

Failed to Select a Rail |

System |

Complete several shifts while the vehicle is in motion, |

|

|

|

including selections from neutral. Also allow the |

|

|

|

transmission to complete several automatic shifts. |

|

|

|

|

73 |

Failed to Engage Gear |

System |

Complete several shifts while the vehicle is in motion, |

|

|

|

including selections from neutral. Also allow the trans- |

|

|

|

mission to complete several automatic shifts. |

|

|

|

|

74 |

Failed to Synchronize |

System |

Operate the vehicle at high speeds while shifting the |

|

|

|

transmission between 7th, 8th and 9th gears. Since the |

|

|

|

transmission makes several calculations before setting |

|

|

|

code 71, ten or more shifts may be required before the |

|

|

|

ECU confirms the failure. |

81 |

Invalid Shift Lever at |

System |

Key on. If the fault is present, the system should |

|

Start (Cable Only) |

|

automatically detect the problem and set the code. |

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

the fault code. Possible triggers include heat and vibration. |

|

|

|

|

82 |

Multiple Non-Ajacent |

Component |

Key on. If the fault is present, the system should |

|

Sensors (Cable Only) |

|

automatically detect the problem and set the code. |

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

the fault code. Possible triggers include heat, vibration and |

|

|

|

varying levels of shift lever positions. |

|

|

|

|

83 |

Shift Lever Missing |

System |

Key on. If the fault is present, the system should |

|

(Cable Only) |

|

automatically detect the problem and set the code. |

|

|

|

If the fault is not present at key on, operate the vehicle and |

|

|

|

attempt to duplicate the driving conditions that triggered |

|

|

|

the fault code. Possible triggers include heat, vibration or |

|

|

|

different lever positions. |

|

|

|

|

83 |

Shift Lever Missing |

Component |

Key on. If the fault is present, the system should |

|

(Electronic Only) |

|

automatically detect the problem and set the code. |

|

|

|

If the fault is not present at key on, operate the vehicle and |

attempt to duplicate the driving conditions that triggered the fault code. Possible triggers include heat, vibration or different lever positions.

Techniques Driving

1-7

Introduction

Fault Code Isolation Procedure Index

|

Fault |

Description |

Type of Code |

Page |

|

|

Codes |

|

|

Number |

|

11 |

ECU |

Component |

2-6 |

|

|

14 |

Shift Lever Fault |

Component |

2-8 |

|

|

|

|

|

|

|

|

15 |

Shift Lever Data Link |

Component |

2-10 |

|

|

|

|

|

|

|

|

21 |

Interrupt Solenoid Coil |

Component |

2-16 |

|

|

|

|

|

|

|

|

22 |

Lockup/Bypass Solenoid Coil |

Component |

2-18 |

|

|

|

|

|

|

|

|

23 |

Engine Speed Sensor |

Component |

2-20 |

|

|

|

|

|

|

|

|

24 |

Hydraulic System Fault |

Component |

2-24 |

|

|

|

|

|

|

|

|

31 |

Engine Brake Relay Coil |

Component |

2-28 |

|

|

|

|

|

|

|

|

32 |

Defuel Solenoid Coil |

Component |

2-32 |

|

|

|

|

|

|

|

|

33 |

System Voltage |

Component |

2-36 |

|

|

|

|

|

|

|

|

34 |

Throttle Position Sensor |

Component |

2-38 |

|

|

|

|

|

|

|

|

35 |

Engine Control Failure (Mechanically-Governed Engines) |

System |

2-42 |

|

|

|

|

|

|

|

|

35 |

Engine Control Failure (Electronically-Governed Engines) |

System |

2-44 |

|

|

|

|

|

|

|

|

41 |

Range Failed to Engage |

System |

2-48 |

|

|

|

|

|

|

|

|

43 |

Range Solenoid Coil |

Component |

2-50 |

|

|

|

|

|

|

|

|

44 |

Disc/Inertia Brake Solenoid Coil |

Component |

2-52 |

|

|

|

|

|

|

|

|

45 |

Power Synchronizer Band/Engine Boost Solenoid Coil |

Component |

2-54 |

|

|

|

|

|

|

|

|

51 |

Center Rail Sensor |

Component |

2-56 |

|

|

1-8

Introduction

Fault Code Isolation Procedure Index, continued

|

Fault |

Description |

Type of Code |

Page |

|

|

Codes |

|

|

Number |

|

52 |

Neutral Sensor |

Component |

2-60 |

|

|

53 |

Gear Engaged Sensor |

Component |

2-64 |

|

|

|

|

|

|

|

|

54 |

HI Range Sensor |

Component |

2-68 |

|

|

|

|

|

|

|

|

55 |

LO Range Sensor |

Component |

2-72 |

|

|

|

|

|

|

|

|

56 |

Input Speed Sensor |

Component |

2-76 |

|

|

|

|

|

|

|

|

57 |

Output Speed Sensor |

Component |

2-80 |

|

|

|

|

|

|

|

|

61 |

Autoshifter Solenoid 1 Coil |

Component |

2-84 |

|

|

|

|

|

|

|

|

62 |

Autoshifter Solenoid 2 Coil |

Component |

2-86 |

|

|

|

|

|

|

|

|

63 |

Autoshifter Solenoid 3 Coil |

Component |

2-88 |

|

|

|

|

|

|

|

|

64 |

Autoshifter Solenoid 4 Coil |

Component |

2-90 |

|

|

|

|

|

|

|

|

71 |

Stuck Engaged |

System |

2-92 |

|

|

|

|

|

|

|

|

72 |

Failed to Select a Rail |

System |

2-96 |

|

|

|

|

|

|

|

|

73 |

Failed to Engage Gear |

System |

2-100 |

|

|

|

|

|

|

|

|

74 |

Failed to Synchronize |

System |

2-104 |

|

|

|

|

|

|

|

|

81 |

Invalid Shift Lever at Start (Cable Only) |

System |

2-108 |

|

|

|

|

|

|

|

|

82 |

Multiple Non-Anjacent Sensors (Cable Only) |

Component |

2-110 |

|

|

|

|

|

|

|

|

83 |

Shift Lever Missing (Cable Only) |

System |

2-112 |

|

|

|

|

|

|

|

|

83 |

Shift Lever Missing (Electronic Only) |

Component |

2-114 |

|

|

Code Fault

Procedure Isolation

Index

1-9

Introduction

Symptom Driven Diagnostics

Symptom |

Isolation Procedure |

Page |

|

|

Number |

|

|

|

Shift complaint |

Shift Complaint Test |

3-7 |

|

|

|

High operating temperature |

High Operating Temperature Test |

3-14 |

|

|

|

Hand-held diagnostic tool failed to operate properly |

Hand-Held Diagnostic Tool Test |

3-17 |

Shift lever in gear signal not functioning properly |

Shift Lever In Gear Signal Test |

3-20 |

Neutral output not functioning properly |

Neutral Output Test |

3-22 |

|

|

|

Splitshaft PTO switch not functioning properly |

Splitshaft PTO Switch Test |

3-24 |

|

|

|

Quick to neutral not functioning properly |

Quick to Neutral Test |

3-26 |

|

|

|

Shift lever auxiliary output 2 not functioning properly |

Shift Lever Auxiliary Output 2 Test |

3-27 |

Shift lever auto neutral input not functioning properly |

Shift Lever Auto Neutral Input Test |

3-29 |

Shift lever back light not functioning properly |

Shift Lever Back Light Test |

3-30 |

|

|

|

Reverse relay indicator not functioning properly |

Reverse Relay Indicator Test |

3-31 |

|

|

|

Start enable relay not functioning properly |

Start Enable Relay Test |

3-34 |

|

|

|

Start enable relay latch not functioning properly |

Start Enable Relay Latch Test |

3-40 |

Shift lever voltage (Driver lever) not functioning properly |

Shift Lever Voltage Test (Driver Lever) |

3-42 |

Shift lever voltage (Work lever) not functioning properly |

Shift Lever Voltage Test (Work Lever) |

3-44 |

|

|

|

1-10

Fault Isolation Procedures

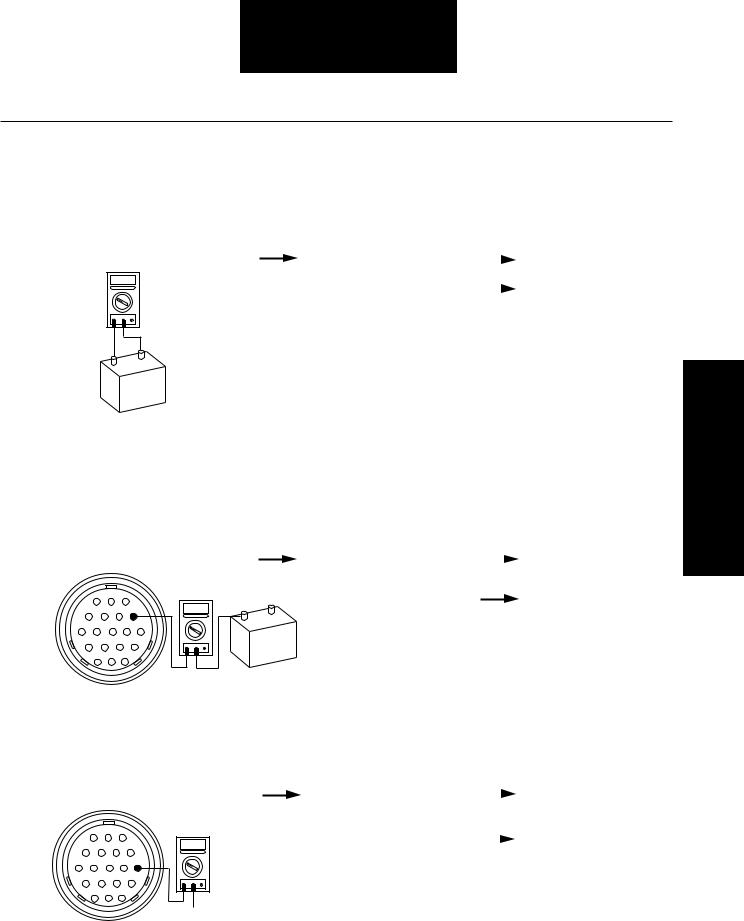

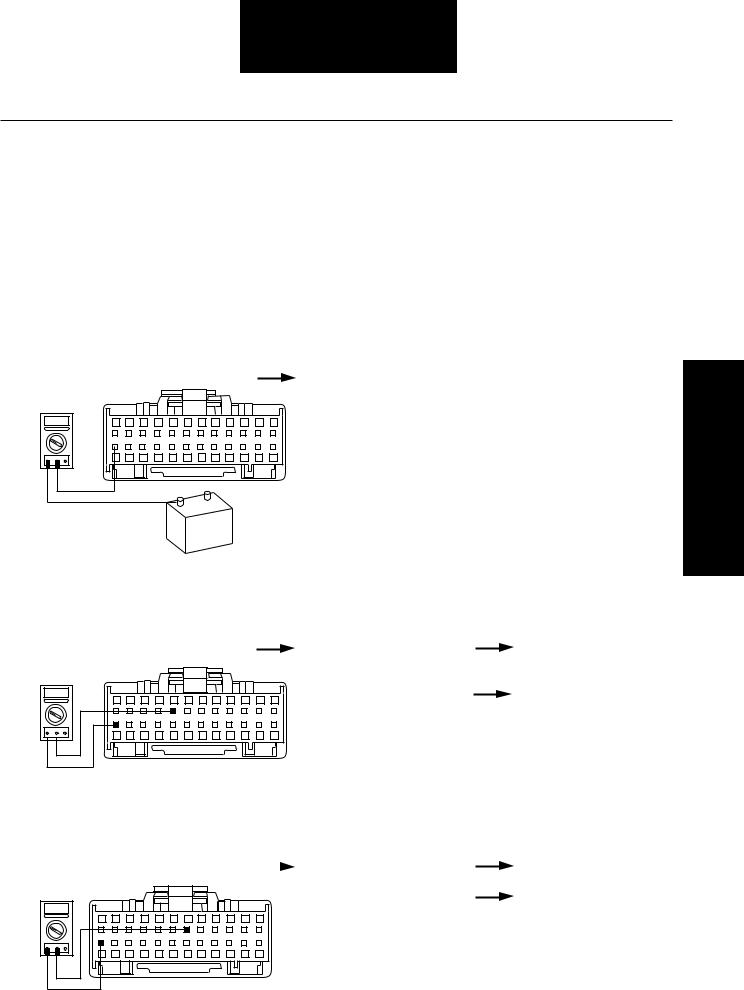

Electrical Pretest

|

Step A |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key off.

2.Measure battery voltage at the battery terminals.

VOLTS

V COM A

+ –

If voltage is 11 to 13 volts |

|

Go to Step B. |

|

||

If voltage is outside of range |

|

Repair or replace battery |

|

||

|

|

and/or charging system |

|

|

as required. Repeat |

|

|

this step. |

|

Step B |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key off.

2.Disconnect vehicle interface harness from CEEMAT.

3.Measure voltage between vehicle interface harness pin L and battery negative (–) terminal.

If voltage is within |

|

Go to Step C. |

|

||

1 volt of battery voltage |

|

|

B |

A |

M |

|

|

If voltage is outside of range |

Repair or replace vehicle |

C |

P |

N |

L |

VOLTS |

||

|

|

|

|

– |

+ |

interface harness, battery |

D R |

V |

U |

K |

|

||

E |

S |

T |

J |

|

|

circuit breaker or battery |

|

|

|

|

V COM A |

|

circuit as required. Repeat |

F |

G |

H |

|

|

|

|

|

|

|

|

|

|

this step. |

|

Step C |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key on.

2.Measure voltage between vehicle interface harness pin K and ground.

B A M

C P N L |

VOLTS |

|

D R V U K

E S T J

V COM A

F G H

Ground

If voltage is within |

|

|

Go to Step D. |

|

|

|

|||

1 volt of battery voltage |

|

|

|

|

If voltage is outside of range |

|

|

|

Repair or replace vehicle |

|

|

|

||

|

|

|

|

interface harness, ignition |

|

|

|

|

circuit breaker or ignition |

|

|

|

|

circuit as required. Repeat |

|

|

|

|

this step. |

Pretest Electrical

2-1

Fault Isolation Procedures

Electrical Pretest, continued

|

Step D |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key off.

2.Disconnect positive battery cable.

3.Measure resistance between vehicle interface harness pin:

•B and battery negative (–) terminal.

•C and battery

negative (–) terminal.

B A M

OHMS

C P N L

D R V U K

V |

COM A |

E S T |

J |

If resistance is 0 to .3 ohms |

|

Test complete. |

|

If resistance is outside of range  Repair or replace vehicle interface harness or ground connections as required. Repeat this step.

Repair or replace vehicle interface harness or ground connections as required. Repeat this step.

F G H

–

+

B A M

OHMS

C P N L

D R V U K

V |

COM A |

E S T |

J |

F G H

–

+

2-2

Fault Isolation Procedures

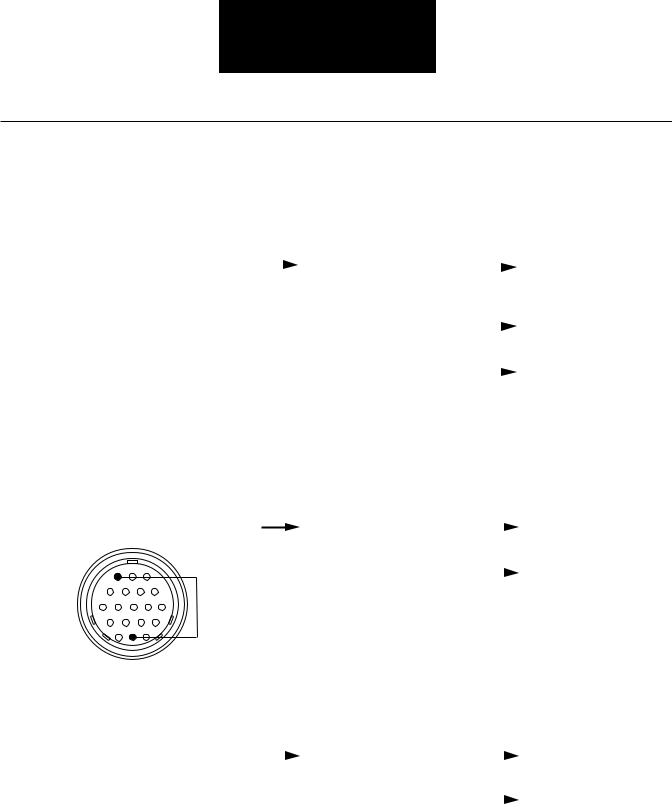

Pneumatic Pretest

Step A |

Procedure |

Condition |

Action |

|

|

1. |

Key off. |

|

|

|

2. |

Install a 0-150 PSI air gauge |

|

|

|

|

in the regulated test port of |

|

|

|

|

the CEEMAT air filter/regulator. |

|

|

|

3. |

Start engine. |

|

|

|

4. |

Allow air pressure to build to |

|

|

|

|

governor cutoff. |

|

|

|

5. |

Read vehicle main air pressure |

|

Go to Step B. |

|

|

gauge. |

If air pressure cuts off at |

|

|

|

|

90 to 120 PSI |

|

|

|

|

If air pressure is outside of |

Repair vehicle air system |

|

|

|

range |

as required. Repeat |

|

|

Regulated test port |

|

this step. |

|

|

|

|

|

Step B |

Procedure |

Condition |

Action |

|

|

1. |

Key off. |

|

|

|

2. |

Monitor air pressure on vehicle |

If vehicle maintains air pressure |

Go to Step C. |

|

|

main air pressure gauge. |

||

|

|

|

If vehicle loses air pressure |

Repair leak in vehicle |

|

|

|

|

air system. Repeat this step. |

Step C |

Procedure |

Condition |

Action |

|

|

1. Read air pressure gauge installed |

If air pressure is 75 to 85 PSI |

Test complete. |

|

|

|

in the air filter/regulator. |

||

|

|

|

If air pressure is outside of |

Go to Step D. |

|

|

|

range |

|

Step D |

Procedure |

Condition |

Action |

|

1.Key off.

2.Remove air supply line to the air filter/regulator and check air flow.

If air flows from the supply line |

|

Replace air filter/regulator. |

|

||

|

|

Go to Step C. |

If air does not flow from the |

|

Repair vehicle air supply |

|

||

supply line |

|

to air filter/regulator. |

|

|

Go to Step C. |

Pretest Pneumatic

2-3

Fault Isolation Procedures

Power-Up Sequence Test

|

Step A |

Procedure |

|

Condition |

|

Action |

|

|

|

|

|

|

|

|

|

1. Key on. |

|

|

|

|

|

|

2. Observe service transmission |

|

If service transmission lamp |

|

|

|

|

lamp. |

|

|

Test complete. |

|

|

|

|

|

|||

|

|

|

|

lights for one second and |

|

|

|

|

|

|

goes off |

|

|

|

|

|

|

If service transmission lamp |

|

Go to Step B. |

|

|

|

|

|

||

|

|

|

|

never comes on |

|

|

|

|

|

|

If service transmission lamp is |

|

Go to Step C. |

|

|

|

|

|

||

|

|

|

|

on steady |

|

|

|

|

|

|

|

|

|

|

Step B |

Procedure |

|

Condition |

|

Action |

|

|

|

|

|

|

|

1.Key off.

2.Disconnect vehicle interface harness from CEEMAT.

3.Place jumper wire across vehicle interface harness pins G and B.

B A M

C P N L

D R V U K

E S T J

If service transmission lamp |

|

Replace ECU. |

|

||

turns on |

|

Go to Step A. |

If service transmission lamp |

|

Repair or replace vehicle |

|

||

never comes on |

|

interface harness as |

|

|

required. Go to Step A. |

F G H

|

Step C |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key on.

2.Disconnect vehicle interface

connector at CEEMAT. |

|

If service transmission lamp |

|

Replace ECU. |

|

|

|||

|

|

turns off |

|

Go to Step A. |

|

|

If service transmission lamp |

|

Repair or replace vehicle |

|

|

|||

|

|

remains on |

|

interface harness as |

|

|

|

|

required. Go to Step A. |

2-4

Fault Isolation Procedures

Up-Power

Test Sequence

This Page left blank intentionally

2-5

Fault Isolation Procedures

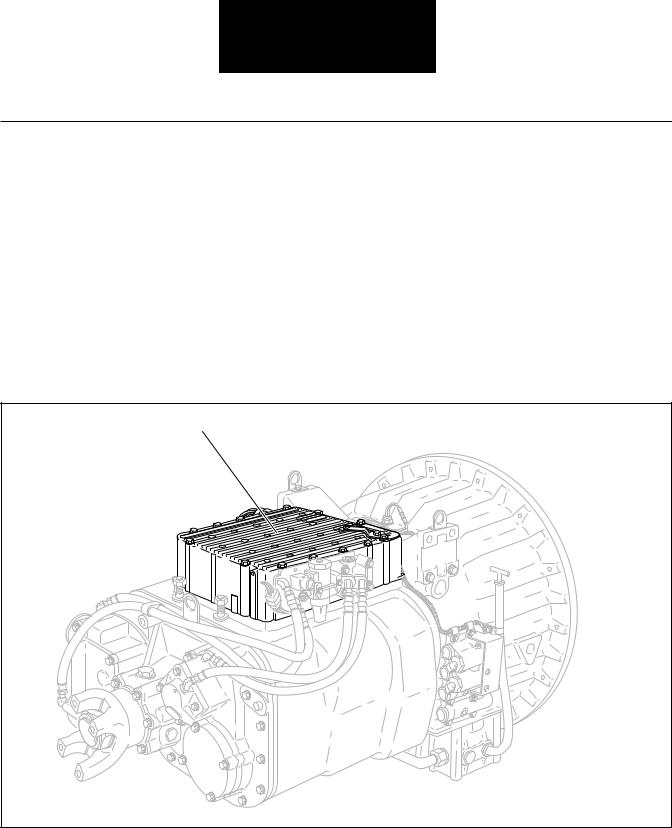

Component Code 11

ECU

Fault Description

This code indicates an electrical problem inside the electrical control unit which is part of the ECU.

Required Tools

• CEEMAT Troubleshooting Guide

Likely Failed Components

Possible Causes

This code can be caused by any of the following conditions:

•Improper configuration software

•Faulty ECU

ECU |

2-6

Fault Isolation Procedures

Code 11, ECU Test

Step A |

Procedure |

Condition |

|

Action |

||

|

|

|

|

|

|

|

|

1. |

Key on. |

|

|

|

|

|

2. |

Retrieve codes (see page 1-3). |

|

If code 11 is active |

|

Replace ECU. |

|

|

|

||||

|

|

|

|

If code 11 is inactive |

|

Test complete. |

|

|

|

|

|

||

11 Code

2-7

Fault Isolation Procedures

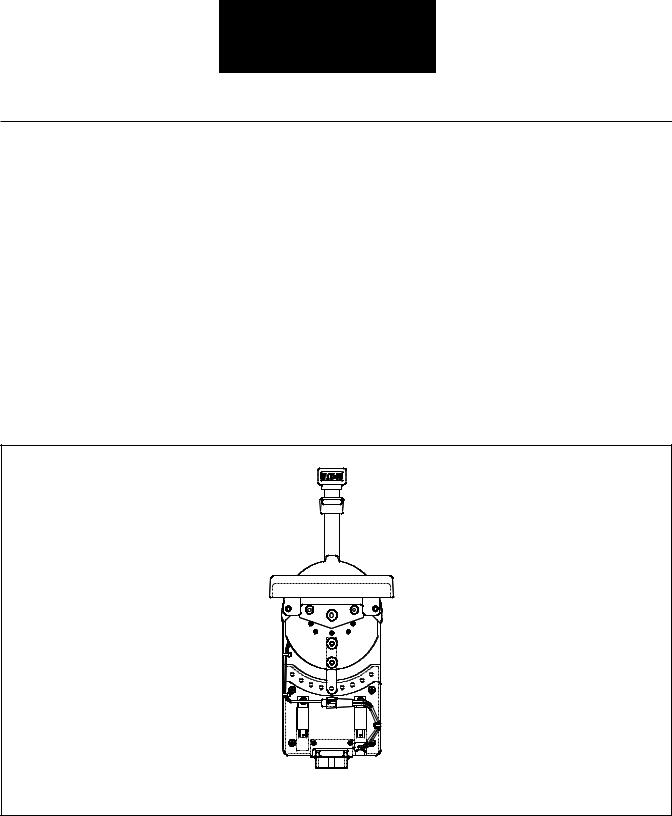

Component Code 14

Shift Lever Fault

Fault Description

This code indicates an electrical problem inside the electronic shift lever. The ECU detects this failure when it receives fault information from the electronic shift lever.

Required Tools

•Basic Hand Tools

•CEEMAT Troubleshooting Guide

Likely Failed Component

Possible Causes

This code is likely caused by a faulty shift lever.

Electronic shift lever (ESL)

2-8

Fault Isolation Procedures

Code 14, Shift Lever Fault Test

|

Step A |

Procedure |

Condition |

Action |

|

|

|

|

|

1. Key on.

2. Retrieve codes (see page 1-3). If code 14 is active

If code 14 is active  Replace electronic shift lever.

Replace electronic shift lever.

If code 14 is inactive |

|

Test complete. |

|

14 Code

2-9

Fault Isolation Procedures

Component Code 15

Shift Lever Data Link

Fault Description

This code indicates the CEEMAT ECU did not receive an updated shift lever status signal from the electronic shift lever via the J-1922 data link.

Required Tools

•Basic Hand Tools

•Digital Volt/Ohm Meter

•CEEMAT Troubleshooting Guide

Possible Causes

This code can be caused by any of the following conditions:

•Faulty J-1922 data link

•No electrical power to shift lever

•Faulty shift lever

•Faulty ECU

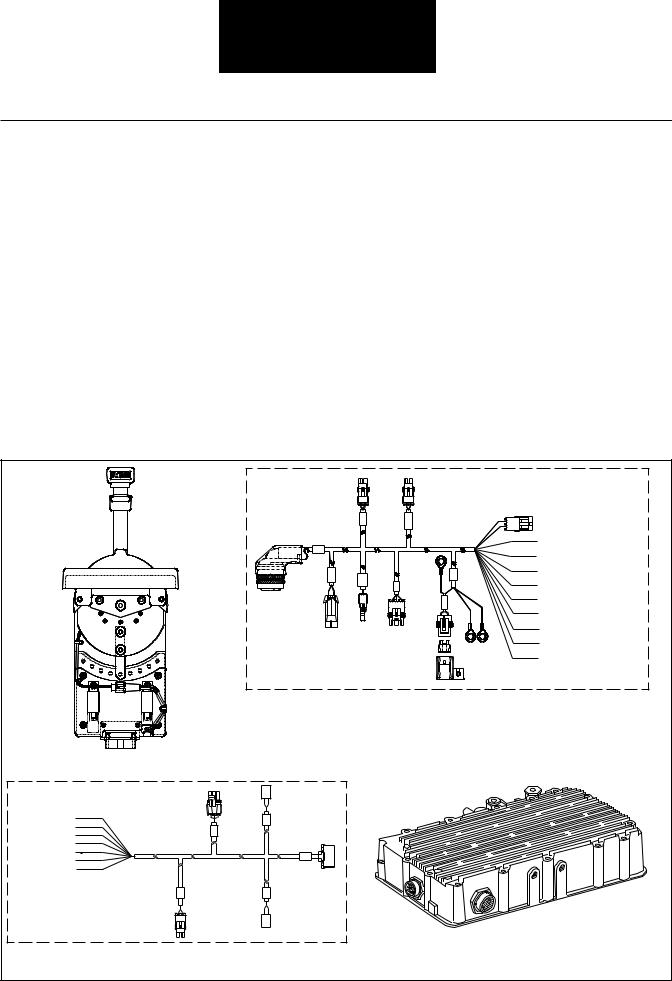

Likely Failure Locations

|

|

PTO |

|

Defuel |

B A |

|

ECU |

|

|

|

W4 ATA (+) |

|

|

|

|

W3 ATA(-) |

|

|

|

|

|

|

|

J1 |

ressP |

Neut Out |

|

GND |

W7 Eng Brake |

TPS |

W15 Aux 1 Input |

||||

|

|

|

|

Fuse |

W16 Service Light Ground |

|

|

|

|

|

W1B Service Light (+) |

|

|

|

|

|

W6 Service Brake |

|

|

|

|

|

W1C Service Brake (+) |

|

|

|

|

|

W1 Ignition Power |

|

|

Typical vehicle interface harness |

|||

|

|

|

|

(OEM supplied) |

|

Electronic shift lever (ESL) |

|

|

|

|

|

W1 VIGN |

|

|

|

|

|

W2 VBAT |

|

|

|

|

|

W13 GND |

|

|

|

|

|

W24 LAMP_GND |

|

|

|

|

|

W25 AUX_IN |

|

|

|

|

|

W27 AUX_OUT1 |

|

|

|

|

|

W28 AUX_OUT2 |

|

|

|

|

|

Typical shift lever harness |

|

|

|

|

ECU |

(OEM supplied) |

|

|

|

|

|

2-10 |

|

|

|

|

|

Fault Isolation Procedures

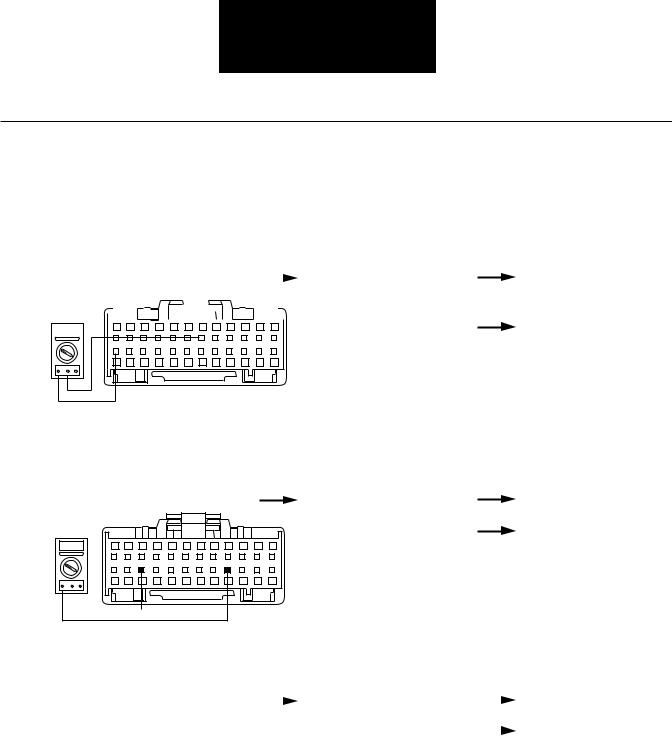

Code 15, Shift Lever Data Link Test

|

Step A |

Procedure |

Condition |

Action |

|

|

|

|

|

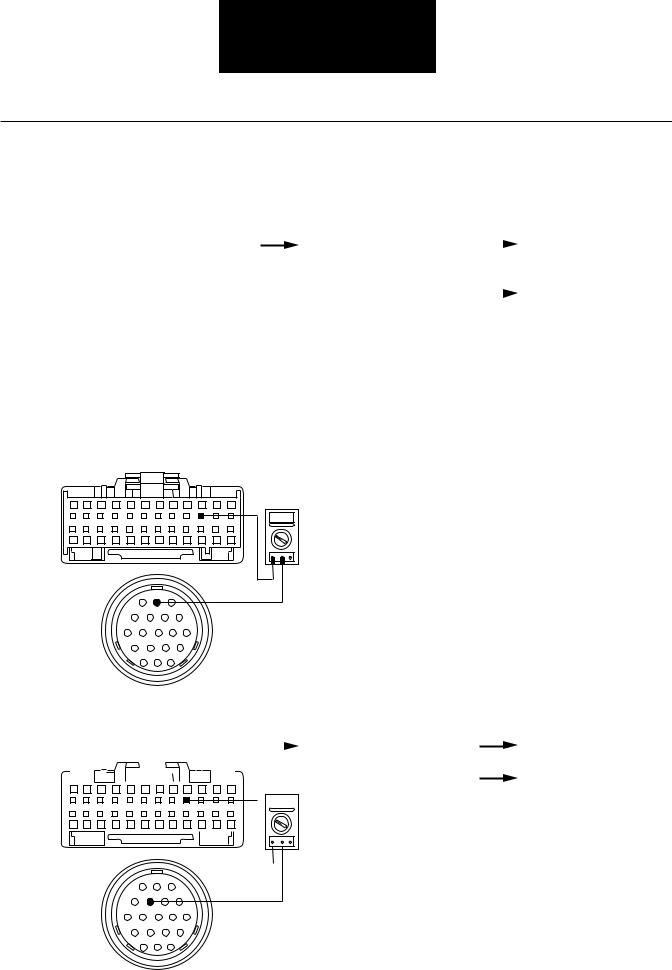

1.Select the lever to be tested (driver or work lever).

2.Key off.

3.Disconnect connector from electronic shift lever.

4.Disconnect positive battery cable

5.Measure resistance between electronic shift lever harness

pin B1 and battery negative (–) terminal.

OHMS

A |

|

|

|

|

|

|

|

|

|

|

A |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

B |

|

|

|

|

|

|

|

|

|

|

|

B |

If resistance is 0 to .3 ohms

If resistance is outside of range

Go to Step B.

Go to Step B.

Repair ground. Go to Step V.

Repair ground. Go to Step V.

V COM A

+ –

|

Step B |

Procedure |

Condition |

Action |

|

|

|

|

|

1. Measure voltage between electronic shift lever harness pins A5 and B1.

VOLTS |

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

A |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

B |

|

|

|

|

|

|

|

|

|

|

B |

V COM A |

|

|

|

|

|

|

|

|

|

|

|

If voltage is within 1 volt of battery voltage

If voltage is outside of range

Go to Step C.

Repair harness to shift lever connector. Go to Step V.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step C |

Procedure |

Condition |

Action |

||

|

|

|

|

|

|

|

1.Measure voltage between electronic shift lever harness

pins A7 and B1. |

|

If voltage is 0 |

|

If voltage is not 0

VOLTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

A |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

V COM A |

B |

|

|

|

|

|

|

|

|

|

|

B |

Go to Step D.

Repair short to power or incorrectly wired circuit (should be ignition power).Go to

Step V.

15 Code

2-11

Fault Isolation Procedures

Code 15, Shift Lever Data Link Test, continued

|

Step D |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key on.

2.Measure voltage between electronic shift lever harness

|

pins A7 and B1. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If voltage is within 1 volt |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

of battery voltage |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If voltage is outside of range |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VOLTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

||||||||

1 |

2 |

3 |

4 |

5 |

|

|

6 |

7 |

|

8 |

9 |

10 |

11 |

12 |

|

|

|

|

|

||||||||||||||||

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|||||||

Go to Step E.

Repair ignition power line. Go to Step V.

VCOM A

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step E |

Procedure |

Condition |

Action |

||

|

|

|

|

|

|

|

1.Measure resistance between electronic shift lever harness

pins B9 and B3. |

|

|

|

|

|

If resistance is 0 to .3 ohms |

|||||

|

|

|

|

|

|

|

|

|

|

|

If resistance is outside of |

OHMS |

|

|

|

|

|

|

|

|

|

|

range |

A |

|

|

|

|

|

|

|

|

|

|

A |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

B |

|

|

|

|

|

|

|

|

|

|

B |

Go to Step F.

Repair open circuit between pins B9 and B3. Go to Step V.

V COM A

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Step F |

Procedure |

|

Condition |

|

Action |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Check to see if there are |

|

One shift lever |

|

Go to Step H. |

|

|

|

|

|

two shift levers. |

|

|

|||

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

Two shift levers |

|

Go to Step G. |

|

|

|

|

|

|

|

|||

2-12

Fault Isolation Procedures

Code 15, Shift Lever Data Link Test, continued

|

Step G |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Disconnect connector from second electronic shift lever.

2.Measure resistance between electronic shift lever harness

pin B9 and ground.

OHMS

A |

|

|

|

|

|

|

|

|

|

|

A |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

B |

|

|

|

|

|

|

|

|

|

|

B |

VCOM A

GROUND

If resistance is more than 10K ohms or infinite

If resistance is less than 10K ohms

Go to Step H.

Both levers selected. Repair wiring harness to pin B9 to ensure infinite resistance on non-selected lever. Go to Step V.

|

Step H |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Key off.

2.Disconnect J-1922 data link from engine ECM.

3.Disconnect harness from electronic shift lever.

4.Connect hand-held diagnostic tool.

5.Key on.

6.Select Perform Tests.

7.Select Throttle Dip Test.

8.Measure voltage between electronic shift lever pins A9

and A10 (connect positive lead to A10).

|

|

|

|

|

|

|

|

|

|

|

VOLTS |

|

A |

|

|

|

|

|

|

|

|

|

|

A |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

B |

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

V |

COM A |

If voltage is +3.0 to +4.0 volts

If voltage is outside of range

Go to Step I.

Go to Step J.

15 Code

2-13

Fault Isolation Procedures

Code 15, Shift Lever Data Link Test, continued

|

Step I |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Activate Throttle Dip Test.

If voltage changes to |

|

Replace shift lever. |

|

||

–3.0 to –4.0 volts |

|

Go to Step V. |

If voltage does not change |

|

Go to Step J. |

|

||

to –3.0 to –4.0 volts |

|

|

|

Step J |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Disconnect vehicle interface harness from CEEMAT.

2.Measure resistance between vehicle interface harness pin A and shift lever harness pin A10.

A |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

A |

OHMS |

1 |

12 |

|

||||||||||

B |

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

V COM A |

B A M

C P N L

D R V U K

E S T J

F G H

3.Measure resistance between vehicle interface harness

|

|

|

|

pin P and shift lever harness |

|

|

|

|

|

|

|

If resistance is 0 to .3 ohms |

|||||||||||||||||||||||

|

|

|

|

pin A9. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If resistance is outside of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

|

|

|

|

|

|

range |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OHMS |

|

||||||||||

1 |

2 |

3 |

4 |

5 |

|

|

6 |

7 |

8 |

9 |

10 |

11 |

12 |

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V COM A |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Go to Step K.

Repair or replace J-1922 data link between electronic shift lever and CEEMAT. Go to Step V.

B A M

C P N L

D R V U K

E S T J

F G H

2-14

Fault Isolation Procedures

Code 15, Shift Lever Data Link Test, continued

|

Step K |

Procedure |

Condition |

Action |

|

|

|

|

|

1.Measure resistance between vehicle interface harness pins:

•A to ground

•P to ground

B |

A |

M |

|

OHMS |

|

|

|||

C |

P |

N |

L |

|

D R |

V |

U |

K |

V COM A |

E |

S |

T |

J |

|

F |

G |

H |

|

GROUND |

B |

A |

M |

|

OHMS |

|

|

|||

C |

P |

N |

L |

|

D R |

V |

U |

K |

V COM A |

E |

S |

T |

J |

|

F |

G |

H |

|

GROUND |

If resistance is more than |

|

Replace ECU. Go |

|

||

10K ohms or infinite |

|

to Step V. |

If resistance is less than |

|

Repair or replace vehicle |

|

||

10K ohms |

|

interface harness. Go |

|

|

to Step V. |

15 Code

|

Step V |

Procedure |

|

Condition |

|

Action |

|

|

|

|

|

|

|

|

|

|

|

|

|

1. |

Key off. |

|

|

|

|

|

|

|

2. |

Reconnect all connectors. |

|

|

|

|

|

|

|

3. |

Key on. |

|

|

|

|

|

|

|

4. |

Clear codes (see Clearing |

|

|

|

|

|

|

|

|

Fault Codes, page 1-3). |

|

|

|

|

|

|

|

5. |

Use Driving Technique |

|

|

|

|

|

|

|

|

to attempt to reset the code |

|

|

|

|

|

|

|

|

(page 1-4). |

|

|

|

|

|

|

|

6. |

Check for codes |

|

|

|

|

|

|

|

|

(see Retrieving Fault Codes, |

|

If no codes |

|

Test complete. |

|

|

|

|

page 1-3). |

|

|

|||

|

|

|

|

|

||||

|

|

|

|

|

If code 15 appears |

|

Return to Step A |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

to find error in testing. |

|

|

|

|

|

|

If code other than 15 appears |

|

Go to Fault Isolation |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Procedure Index (page 1-8). |

|

2-15

Loading...

Loading...