Eaton Transmission 4106, 5206 Service Manual

Service Manual

Fuller Mid Range Transmissions

TRSM4106

October 2007

For parts or service call us Pro Gear & Transmission, Inc.

1(877) 776-4600

(407)872-1901 parts@eprogear.com

906 W. Gore St. Orlando, FL 32805

Eaton 6-Speed Synchromesh Transmission

Truck Components Operations Europe

PO Box 11 Worsley

Manchester M28 5GJ

England

Service Manual

(4106 / 5206)

Section 1 |

General |

1/1 |

Letter and Model Designation |

1/2 |

Technical Data |

1/3 |

Lubrication |

1/4 |

Recommended Lubricants |

1/5 |

Torque Tightening Recommendations |

1/7 |

Disassembly Precautions and Inspection of Expendable Parts |

1/9 |

Reassembly Precautions |

1/10 |

Gear End Floats |

1/11 |

Special Tools |

1/14 |

Locally Made Tools |

Section 2 |

General Discription |

2/1 |

Features |

2/2 |

Gear Change Pattern |

2/2 |

Power Flow Diagrams |

Section 3 |

Shifting Controls |

3/2 |

Remote Control - Exploded View |

3/3 |

Remote Control Disassembly |

3/4 |

Remote Control Reassembly |

3/7 |

Direct Control - Exploded View |

3/8 |

Direct Control Disassembly |

3/9 |

Direct Control Reassembly |

Section 4 |

Transmission Overhaul |

4/2 |

Transmission Case - Exploded View |

4/3 |

Transmission Case Disassembly |

4/9 |

Layshaft Disassembly |

4/10 |

Layshaft Reassembly |

4/11 |

Synchroniser Flange Removal / Fitment |

4/12 |

Maninshaft Disassembly (New Type) |

4/13 |

Maninshaft Reassembly (New Type) |

4/17 |

Mainshaft Assembly - Exploded View (NewType) |

4/31 |

Mainshaft Disassembly (Old Type) |

4/32 |

Mainshaft Assembly - Exploded View (Old Type) |

4/35 |

Mainshaft Reassembly (Old Type) |

4/41 |

Selector Shaft Disassembly |

4/42 |

Selector Shaft Reassembly |

4/44 |

Transmission Case Reassembly |

5/01

Section 2 |

General |

5/01

General

Model Designation

Example: FSO-4106A

FS |

Standard prefix |

OOverdrive

4 Nominal torque in 00 lbs ft

1Series 1

06 Number of forward gears A Standard ratio set

B, C Alternative ratio sets

Transmission Identification

All transmissions are fitted with an identification plate on the left hand side of the front case showing

1.Transmission serial number.

2.Transmission model.

3.Manufacturing data code.

4.Transmission specification number.

The transmission specification number is unique to each customer and gives precise details of the transmission design level. This number must be quoted when ordering replacement parts.

There are currently two design levels of the 4106 transmission. Each level is identified by the specification number.

Y0400

Y04100

The middle digit denotes the design level.

1/1 |

5/01 |

General

Technical Data

|

Models |

|

FS-4106A, FS-4106B, FS-5206A, FS(O)-5206B |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Nominal Input Torque |

|

|

|

|

|

|

|

||

FS-4106A |

|

|

|

640 Nm |

|

|

|

|

|

FS-4106B |

|

|

|

650 Nm |

|

|

|

|

|

FS-5206A |

|

|

|

700 Nm |

|

|

|

|

|

FS(O)-5206B |

|

|

|

700 Nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Weight 1) |

|

|

|

115 kg |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Length 2) |

|

|

|

520 mm |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Oil capacity |

|

|

|

|

|

|

|

|

|

|

Vertical |

|

|

|

7,5 lit |

|

|

|

|

|

Horizontal |

|

|

6,5 lit |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Clutch Housing |

|

|

|

SAE Standard |

|

|

|

||

|

|

|

|

|

|||||

Power Take-off Openings |

|

|

Left side (vertical installation), bottom right |

|

|||||

|

|

|

|

|

(horizontal installation): 2 SAE 6 bolt facings |

|

|||

|

|

|

|

|

plus extended layshaft for Eaton PTO |

|

|

||

|

|

|

|

|

|

|

|

||

PTO Drive Gears 3) |

|

|

|

|

Rotation to Engine |

|

|

||

driven from the reverse idler gear at: |

|

|

engine speed x |

|

|

||||

FS-4106A, FS-5206A |

|

|

|

0,226 |

Same |

|

|

||

FS-4106B, FS-5206B |

|

|

|

0,271 |

|

|

|

||

FS-4106B, FS(O)-5206B |

|

|

|

0,336 |

|

|

|

||

driven from layshaft front gear at: |

|

|

engine speed x |

|

|

||||

FS-4106A, FS-5206A |

|

|

|

0,434 |

Opposite |

|

|||

FS-4106B, FS-5206B |

|

|

|

0,519 |

|

|

|

||

FS-4106B, FS(O)-5206B |

|

|

|

0,644 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Gear |

FS-4106A |

% |

FS-4106B |

% |

FS(O)-4106B |

% |

|

|

|

|

FS-5206A |

Step |

FS-5206B |

Step |

FS(O)-5206B |

Step |

|

|

|

|

|

|

|

|

|

|

|

|

6 |

1.00 |

|

1.00 |

|

|

1.00 |

|

|

|

|

|

__ |

38 |

__ |

|

26 |

__ |

26 |

|

5 |

1.38 |

|

1.29 |

|

|

1.37 |

|

|

|

|

|

__ |

45 |

__ |

|

43 |

__ |

37 |

|

4 |

2.00 |

|

1.86 |

|

|

2.12 |

|

|

|

|

|

__ |

55 |

__ |

|

50 |

__ |

55 |

|

3 |

3.10 |

|

2.80 |

|

|

3.56 |

|

|

|

|

|

__ |

69 |

__ |

|

57 |

__ |

69 |

|

2 |

5.25 |

|

4.38 |

|

|

6.08 |

|

|

|

|

|

__ |

72 |

__ |

|

72 |

__ |

72 |

|

1 |

9.03 |

|

7.54 |

|

|

9.03 |

|

|

|

|

|

__ |

|

__ |

|

|

__ |

|

|

|

Reverse |

8.07 |

|

6.74 |

|

|

5.43 |

|

|

1)including output coupling, low remote control; less clutch housing

2)front face of transmission case to rear face of output flange

3)recommended backlash is from 0.15 to 0.25mm.

1/2 |

5/01 |

General

Lubrication

Proper Oil Level

Before checking the oil level or refilling, vehicle should be on level ground.

Make sure that the oil is level with the filler opening.

Draining Oil

Drain transmission while oil is warn. To drain oil remove the drain plug at the bottom if case. Clean the drain plug before re-installing.

Refilling

Clean area round filler plug.

Fill transmission to the level of the filler opening.

The exact amount of oil depends on the transmission inclination. In every instance, fill to the

level of the filler opening. Do not overfill this causes oil to be forced out of the case past the mainshaft and input shaft seals.

Adding Oil

It is recommended that different types and brands of oil are not intermixed because of possible incompatibility.

Operating Temprature

It is important that the transmission operating temperature does not exceed 120¡C (250¡F) for an extended period of time. Operating temperatures above 120¡C (250¡F) cause breakdown of the oil and shorten transmission life.

The following conditions in any combination can cause operating temperatures of over 120¡C (250¡F):

1.Operating consistently at road speeds under 32 km/h (20m.p.h.)

2.High engine RPM

3.High ambient temperature

4.Restricted air flow around transmission

5.Exhaust system too close to transmission

6.High horsepower, over-drive operation

7.High power PTO operation for extensive periods while stationary

High operating temperatures may require more frequent oil change.

Towing

When towing the vehicle, the propeller shaft between the axle and transmission must be disconnected.

1/3 |

5/01 |

General

Recommended Lubricants

Only use recommended lubricants to ensure smooth running.

Models |

Grade |

Temprature Range |

|

|

|

Mild EP Gear Oil |

SAE 80 W |

-26¡C to 21¡C |

to Specification |

SAE 90 W |

-12¡C to 37¡C |

MIL-L-2105 or |

SAE 80 W/90 |

-26¡C to 38¡C |

API-GL-4 |

|

|

|

|

|

Heavy Duty Engine Oil |

|

|

to Specification |

|

above -12¡C |

MIL-L-2104C or |

SAE 50 |

above -12¡C |

MIL-L-46152 or |

SAE 40 |

below -12¡C |

API-CD |

SAE 30 |

|

|

|

|

DO NOT use oil additives, friction modifiers or synthetic lubricants.

Service Intervals

Lubrication Change and Inspection

Highway Use

First 5000 to 8000 km (3000 to |

Change transmission oil on new units |

5000 miles) |

|

|

|

Every 16000 km (10000 miles)* |

Inspect oil level. Check for leaks |

|

|

Every 80000 km (50000 miles)+ |

Change transmission oil |

|

|

Off Highway |

|

|

|

First 30 hours |

Change transmission oil on new units |

|

|

Every 40 hours * |

Inspect oil level. Check for leaks |

|

|

Every 500 hours |

Change transmission oil when severe dirt condi- |

|

tions exist |

|

|

Every 1000 hours + |

Change transmission oil (normal offhighway use) |

|

|

Remove and clean oil strainer at each oil change.

Transmissions fitted with an oil cooler may additionally be fitted with a filter in the cooler line, Renew the filter at every oil change.

* Or 2 months, whichever occurs first. + Or 12 months, whichever occurs first.

1/4 |

5/01 |

General

Torque Tightening Recommedations

Screws and Nuts

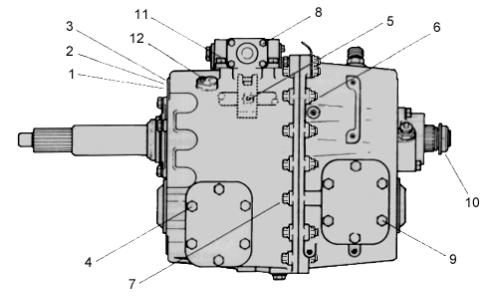

1.Clutch Housing

12 Studs M12 Thread 59 Nm (43 lbs ft) minimum. Installed with Loctite 242.

2.Clutch Housing

12 Nuts M12 Thread 69 to 78 Nm (51 to 58 lbs ft). With Plain Washers and Spring Lockwashers.

3.Clutch Housing

12 Capscrews M12 Thread 69 to 78 Nm (51 to 58 lbs ft). With Plain Washers and Spring ockwashers.

4.Front P.T.O. Cover

6 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft).

5.Selector Block Tapered Lockscrew

1 Lockscrew M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Patchlock or Thread coated with Loctite 270.

6.Main Casing Halves

|

15 Capscrews with Plain Nuts |

M10 Thread |

51 to 58 Nm (38 to 43 lbs ft). With Plain Washers |

|

|

under Capscrews and Nuts. |

|

|

|

|

15 Flange headed screws and Nuts M10 Thread 45 to 55 Nm. |

|||

7. |

Main Casing Halves |

|

|

|

|

3 Capscrews M10 Thread |

51 to 58 Nm (38 to 43 lbs ft). Plain Washers. |

||

|

3 Flange headed screws |

M10 Thread 30 to 40 Nm. |

||

8. |

Remote Control Housing End Cover |

|

||

|

4 Capscrews M8 Thread |

20 to 24 Nm (15 to 18 lbs ft). Spring Lockwashers. |

||

9. |

P.T.O./Reverse Idler Gear Cover |

|

||

|

6 Capscrews M10 Thread - 35 to 39 Nm (25 to 29 lbs ft). |

|||

10. |

Output Shaft |

|

|

|

|

Locknut M33 Thread 490 to 588 Nm (362 to 434 lbs ft). With Nylon Locking Insert. |

|||

11. |

Remote Control Housing |

|

|

|

|

4/6/8 Capscrews M10 Thread |

35 to 39 Nm (25 to 29 lbs ft). Plain Washers and Spring Lockwashers. |

||

12. |

Overdrive Selector fork Pivots |

|

||

|

2 Capscrews M8 Thread (with lockwashers) |

20 to 24 Nm (15 to 18 lbs ft). |

||

1/5 |

5/01 |

General

Torque Tightening Recommedations (continued)

Screws and Nuts

1.Remote Control Shaft Lever

1 Capscrew and Nut M10 Thread 35 to 39 Nm (25 to 29 lbs ft). With Spring Lockwasher.

2.Selector shaft Detent Cover

2 Capscrews M8 Thread 20 to 24 Nm (15 to 18 lbs ft). Spring Lockwashers.

3.Oil Filler Plug

M24 Thread 32 to 37 Nm (24 to 27 lbs ft).

4.Layshaft Front Bearing Cover

4 Capscrews M12 Thread 69 to 78 Nm (51 to 58 lbs ft). Spring Lockwashers.

5.Input Shaft Front Bearing Cover

5 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Spring Lockwashers.

6.Remote Control Housing Detent Cover

2 Capscrews M8 Thread 20 to 24 Nm (15 to 18 lbs ft). Lockwashers.

7.Oil Drain Plug (Magnetic)

M24 Thread 32 to 37 Nm (24 to 27 lbs ft).

8.Speedo Pinion Adaptor

M22 Thread 20 to 27 Nm (15 to 20 lbs ft). Copper Washer.

9.Speedometer Housing

4 Capscrews M10 Thread 35 to 39 Nm (25 to 29 lbs ft). Plain Washers and Spring Lockwashers.

10.Layshaft Rear Bearing Cover (Rear P.T.O.)

4 Capscrews M12 Thread 69 to 78 Nm (51 to 58 lbs ft). Spring Lockwashers.

11. Reverse Lamp Switch

M16 Thread 16 to 22 Nm (12 to 17 lbs ft).

1/6 |

5/01 |

General

Disassembly Precautions Inspection of Expendable

It is assumed in the detailed disassembly instructions that the lubricant has been drained and the necessary linkage and air lines (if fitted) have been removed from the chassis.

Removal of the gear shift remote control housing assembly is included in the detailed instructions; however, this assembly may also be removed from the transmission before removing unit from vehicle.

Follow each procedure closely in each section, making use of both the text and the pictures.

1.Bearings Carefully wash and relubricate all bearings as removed and protectively wrap until ready for use. Remove bearings with pullers designed for this purpose.

2.Assemblies When disassembling the various assemblies, such as the mainshaft, layshaft and remote control housing, lay all parts on a clean bench in the same sequence as removed. This procedure will simplify reassembly and reduce the possibility of losing parts. When pulling off synchroniser hubs follow the procedures detailed in Disassembly using a suitable puller of adequate capacity. Failure to adhere to the recommended procedures may cause irreparable damage.

3.Snap rings Remove snap rings with pliers designed for this purpose. New selective fit snap rings must be fitted as specified in Reassembly .

4.Cleanliness Provide a clean place to work.

It is important that no dirt or foreign material enters the unit during repairs. The outside of the unit should be carefully cleaned before starting the disassembly. Dirt is abrasive and can damage bearings.

5. When Pressing Apply force to shafts, housings etc. with restraint. Movement of some parts is restricted. Do not apply force after the part being driven stops solidly. Use soft hammers for all disassembly work.

Do not use pry bars or chisels to separate casing halves and housings or irreparable damage may be caused.

Before reassembling the transmission, the individual parts should be carefully checked to eliminate those damaged. They should be renewed. This inspection procedure should be carefully followed to ensure the maximum wear life from the rebuilt unit.

The cost of a new part is generally a small fraction of the total cost of downtime and labour, should the use of a questionable part make additional repairs necessary before the next regularly scheduled overhaul. Recommended inspection procedures are set forth in the following check list.

A. Bearings

1. Wash all bearings in clean solvent. Check rollers and races for pits and spalled areas. Renew damaged bearings.

2. Lubricate undamaged bearings and check for axial and radial clearances. Renew bearings with excessive clearances.

3. Check fits of bearings in housing bores. If outer races turn too freely in the bores, the housing should be renewed. Check housing bores for signs of wear prior to taking this action. Only replace housing if wear is seen as a result of bearing spin.

B. Gears

1.Check gear teeth for pitting of the tooth faces. Gears with pitted teeth should be renewed. Check the reverse gear dog engagement teeth for freedom from damage.

2.Check the internal bearing surfaces for wear of the effects of overheating.

3.Check axial clearances of gears. Where excessive clearance is found, check gear and hub for excessive wear.

Maintain the specified axial clearance on mainshaft forward gears.

C. Bearing Sleeve Mainshaft

1. Sleeves with groove formation, pits or which have either been overheated or worn out must be renewed.

1/7 |

5/01 |

General

Inspection of Expendable Parts

D. Synchroniser Assemblies

1.Check to ensure all splines are free from excessive wear.

2.Check that the engagement dog teeth on the sliding sleeves, synchroniser rings are free from chipping and burring.

3.Check that the synchroniser ring cones are not excessively worn or showing the effects of overheating. Check the clearance between the synchroniser ring and the synchroniser flange is between 1.9 mm maximum and 0.5 mm minimum.

4.Renew the springs, plungers and rollers.

4. Check condition and fit of selector key and interlock key in shift shaft. Worn or damaged keys must be renewed.

J.Gear Shift Remove Control

1.Check spring tension on cross shaft. Renew tension springs if shaft moves too freely.

2.If housing is dismantled, check cross shaft and inner lever and the bearing bushes for wear. Renew worn parts.

3.Check all seals and locating journals. Renew worn parts.

E. Splines

1. Check splines on all shafts for wear. If synchroniser hubs, output drive flange or clutch hub have worn into the sides of the splines, the shafts in this condition must be renewed.

K. Bearing Covers

1.Check covers for wear from thrust. Renew covers worn or grooved from thrust of bearing outer race.

2.Check bores of covers for wear. Renew those worn oversize.

F. Thrust Washers |

L. Oil Return Threads and Seals |

1. Check surfaces of all thrust washers. Washers scored or reduced in thickness should be renewed.

G. Reverse Idler Gear

1. Check bearings and shaft for wear from action of roller bearings.

H. Clutch Release Parts

1. Check clutch release parts, yokes and bearing carrier. Check pedal shafts. Renew worn shafts and bearings.

I.Gear Selector Shaft Assembly

1.Check forks and keys for wear at contact points. Renew worn parts.

2.Check forks for excessive and uneven wear, renew worn forks.

3.Check lockscrew in selector block. A lockscrew with worn taper must be renewed.

1.Check oil seal in front bearing cover for damage and wear, renew if necessary.

2.Check oil seal in speedometer housing for damage or wear, renew if necessary. Renew grit shield if worn or loose on flange.

3.Check oil seal journals for wear and renew if worn or grooved.

M. O-Rings

1. Renew all O-rings.

1/8 |

5/01 |

General

Reassembly Precautions

Make sure that interiors of all housings are clean. It is important that dirt be kept out of transmission during reassembly. Dirt is abrasive and can damage polished surfaces of bearings and washers. Use certain precautions, as listed below, during reassembly.

1.Gaskets Use new gaskets where detailed only (neutral detent cover and remote control housing covers). All other locations ensure mating faces are clean and undamaged and apply a continuous bead of Loctite

518Flange Sealant to one face only. Do not apply excessive sealant or allow it to penetrate into the bearings.

2.Capscrews Use thread sealant (Loctite 641) on all capscrews. The corresponding torque ratings are to be found in Torque Recommendations for Screws and Nuts .

3. O Rings Lubricate all O rings lightly with silicone lubricant.

4.Initial Lubrication Lubricate bearings with gearbox oil during reassembly.

5.Axial Clearances Maintain the end float of mainshaft gears as detailed in the chart on the following page.

6.Bearings Use of flange-end bearing drivers is recommended for the installation of bearings. These drivers apply equal force to both races of the bearing, preventing damage to balls and races and maintaining correct bearing alignment with shaft and bore. A tubular type driver, if used, will apply force only to the inner race. Heating the bearing inner tracks will aid installation.

7. |

Output Shaft Drive Flange Tighten the nut to |

the correct torque. |

|

8. |

Synchroniser Hubs All synchroniser hubs are |

an interference fit on the mainshaft splines and must be heated to approximately 85¡C (180¡F) before installation.

9.Layshaft The layshaft gears are a shrink and press fit on the layshaft body. The gears must be heated to 150¡C (300¡F) before assembly.

10.Prior to fitting a flange (or yoke) ensure that the seal track is not grooved, scored or pitted. If in doubt, it must be replaced.

11.All synchroniser flanges are now loctited to the gears. It is recommended that this is carried out before reassembly commences to allow sufficient time for the Loctite to cure.

1/9 |

5/01 |

General

Gear End Floats All dimensions in mm

Gear |

5th (o,d. 6th) |

4th |

3rd |

2nd |

1st |

Reverse |

|

|

|

|

|

|

|

Low Limit |

0,31 |

0,35 |

0,35 |

0,35 |

0,40 |

Sliding |

High Limit |

0,53 |

0,48 |

0,48 |

0,48 |

0,57 |

Gear |

Tolerance |

0,22 |

0,13 |

0,13 |

0,13 |

0,17 |

|

|

|

|

|

|

|

|

1/10 |

5/01 |

General

Special Tools

Some illustrations show the use of specialised tools. These tools are recommended for disassembly and reassembly of the transmission. They make repair easier, faster and prevent damage.

The following tools are available from SPX UK (Ltd) Tel : +44 (0)1327 704461

LC 105A Bearing remover. |

E 109 Driver. |

|

E 105-4 Countershaft bearing remover.

E 109-5 Selector control seal and bush installer. Use with E 109.

E 108 Driver. |

E 109-6 Countershaft bearing cup installer adaptor. |

|

Use with E 109. |

E 108-5 Replacer adaptor for auxiliary countershaft E 109-7 Input shaft seal installer adaptor. bearing and input bearing.

Use with E 108.

E 108-6 Mainshaft rear seal replacer adaptor.

E 109-8 Selector shaft bush installer adaptor. Use with E 109.

1/11 |

5/01 |

General

Special Tools (continued)

E 109-9 Selector shaft plug installer adaptor. Use with E 109.

E 109-10 Driver extension.

Use with E 109.

E 109-11 Countershaft bearing cone installer. Use with E 109.

E 116-2 Adaptor gear assembly lifting fixture. Use with E 116A.

LC 113A Flange holding wrench.

MS 284 Slide hammer.

E 114 Rear mainshaft bearing pilot. |

E 117 Reverse idler shaft retaining pin installer. |

E 115 Flange holding adaptor plate |

MS 284-1 Extractor set - bearing/bush. |

E 116A Gear assembly lifting fixture.

1/12 |

5/01 |

General

Special Tools (continued)

The following general purpose pullers are available from Sykes-Pickavant Ltd., or through their Dealers.

Three Legged Puller - Series 1500 with Hydraulic |

Puller Kit - Series 1500 with Hydraulic Ram |

Ram |

|

Locally Made Tools

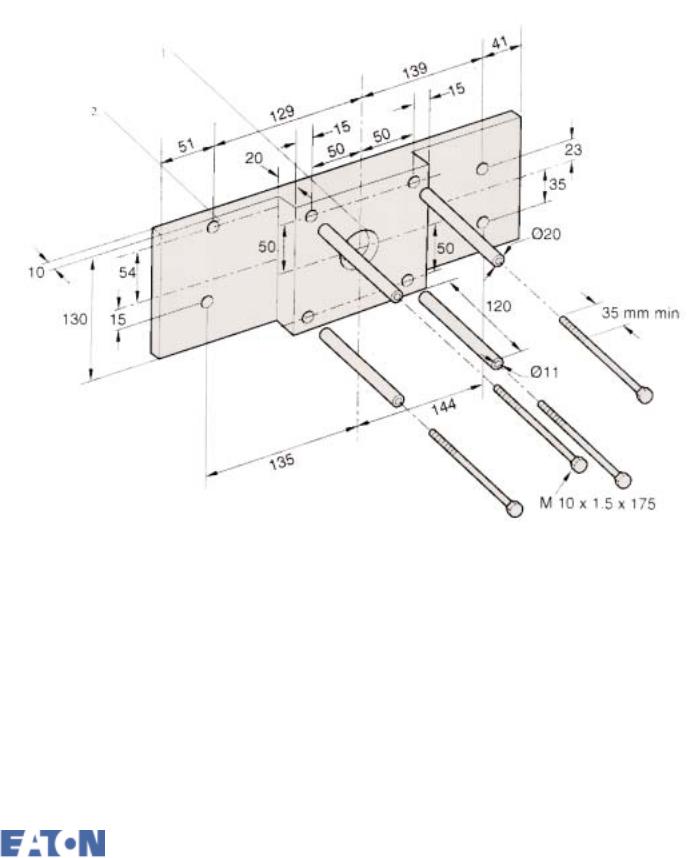

The following illustration shows a suitable cradle which can be used to stand the transmission ’on end’ during ’Disassembly’ and ’Reassembly’. The thickness of the block has been calculated to lift the mainshaft the required distance during removal and installation of the layshaft. If the height of the cradle is increasing, the thickness of the block should be increased by the same amount.

All dimensions in mm. |

Mounting Plates - 2 off. |

1/13 |

5/01 |

General

Special Tools (continued)

Locally made tools

1.1 off hole 1.5 inches diameter 16 threads per inch Whitworth form to suit Sykes Picavant hydraulic ram No 150 000.

2.8 holes 11 mm diameter.

Tool for 4 point ball bearing removal.

1/14 |

5/01 |

General

Special Tools for United States

|

|

Eaton 4106/5206 |

SPX # |

NEW UK # |

Description |

|

|

|

J-45895 |

LC 105A |

Bearing Remover |

J-45896 |

E 105-4 |

Countershaft bearing remover |

J-45902 |

E 108 |

Driver |

|

|

Replacer adaptor for auxiliary countershaft bearing and input |

J-45897 |

E 108-5 |

bearing |

J 39588 |

E 108-6 |

Mainshaft real seal replacer adaptor |

J-8092 |

E 109 |

Driver |

J 39592-1&2 |

E 109-5 |

Selector control seal and bush installer. Use with E109 |

J-39587 |

E 109-6 |

Countershaft bearing cup installer adaptor. Use with E109 |

J-39589 |

E 109-7 |

Input shaft seal installer adaptor |

J-39585-2 |

E 109-8 |

Selector shaft bush installer adaptor. Use with E109 |

J-39585-1 |

E 109-9 |

Selector shaft plug installer adaptor. Use with E109 |

J-21465-13 |

E 109-10 |

Driver extension |

J-39586 |

E 109-11 |

Countershaft bearing cone installer. Use with E109 |

J-39590 |

E 114 |

Rear mainshaft bearing pilot |

J-45899 |

E 115 |

Flange holding adaptor plate |

J-39584 |

E 116A |

Gear assembly lifting fixture |

J-39584 |

E 116-2 |

Adaptor gear assembly lifting fixture. Use with E116A |

J-45898 |

LC 113A |

Flange holding wrench |

MS284 |

MS 284 |

Slide hammer |

J-39591 |

E 117 |

Reverse idler shaft retaining pin installer |

J-45901 |

MS 284-1 |

Extractor set - bearing/bush |

1/15 |

5/01 |

Section 2 |

General |

|

Description |

5/01

General Description

Features

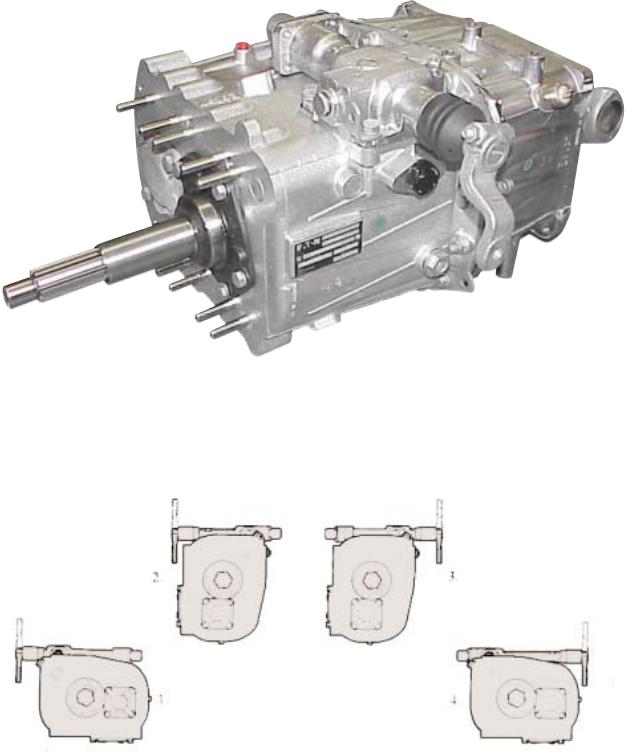

The Eaton six-speed transmissions have six forward speeds and are part of a family of synchromesh transmissions. They have a simple shift pattern using a unique single rail selector mechanism.

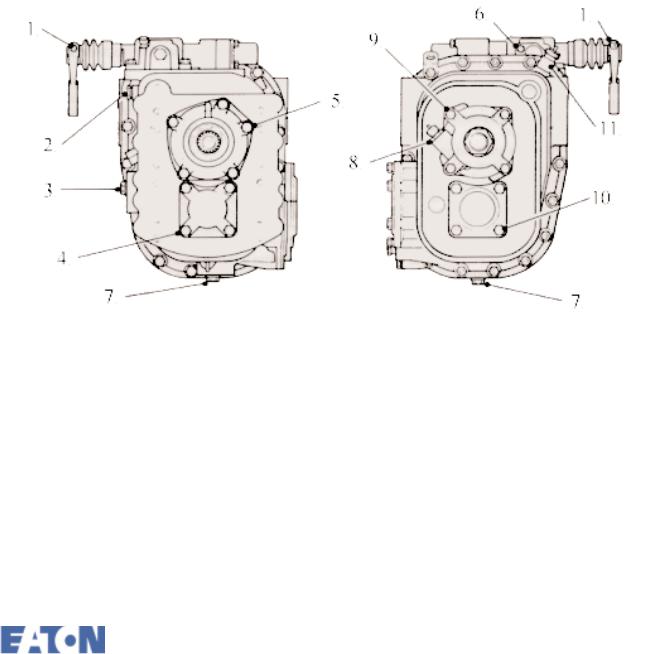

The transmissions may be mounted vertically or horizontally and in both positions the gear change remote control may be to the right or the left.

1. |

Left-Hand Horizontal |

3. |

Right-Hand Vertical |

2. |

Left-Hand Vertical |

4. |

Right-Hand Horizontal |

The synchroniser assemblies are of the baulk ring type with the gear ring cones manufactured separately from the gears. This allows the synchroniser rings and flanges to be renewed without the need to renew the gears themselves. Reverse gear is engaged by sliding the reverse gear on the mainshaft into mesh with a dog clutch ring splined to the mainshaft.

2/1 |

5/01 |

General Description

Gear Change Pattern

Simple shift pattern with the mechanism biased in neutral between 3rd and 4th gears.

1 |

|

2 |

|

|

|

|

|

|

3 |

|

4 |

|

|

|

|

|

|

5 |

|

6 |

|

|

|

|

|

|

R

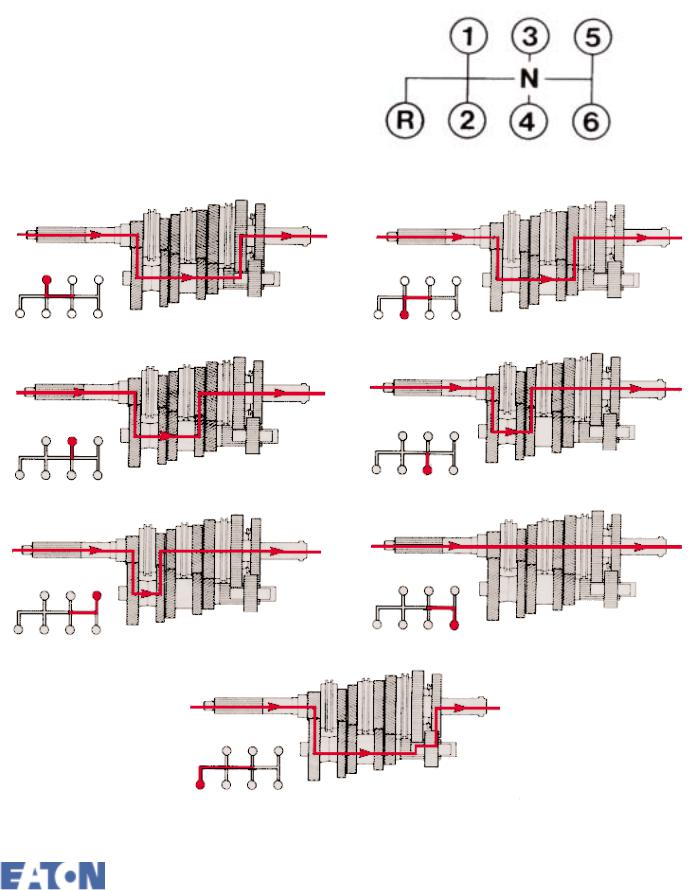

Power Flow in the Gears - Direct Drive Top Gear Version

2/2 |

5/01 |

Section 3 |

Shifting |

|

Controls |

|

6 Speed MK.4 |

3/1 |

5/01 |

Shifting Controls

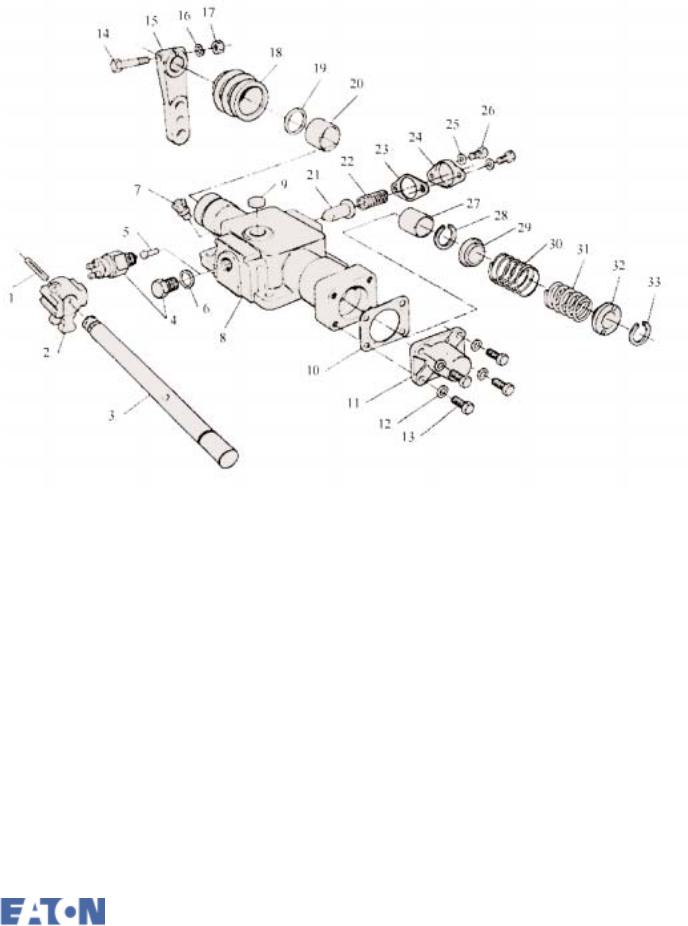

Remote Control - Exploded View

1. |

Grooved pin |

18. |

Boot |

|

2. |

Inner striking lever |

19. |

Oil Seal |

|

3. |

Cross shaft |

20. |

Bush |

|

4. |

Plug or Neutral switch |

21. |

Reverse plunger |

|

5. |

Pin |

22. |

Reverse detent spring |

|

6. |

Washer |

23. |

Detent cover gasket |

|

7. |

Breather |

24. |

Detent cover |

|

8. |

Housing |

25. |

Spring washer M8 |

|

9. |

Plug |

26. |

Screw M8 |

|

10. |

Gasket |

27. |

Bush |

|

11. End cover |

28. |

Circlip |

||

12. |

Spring washer M8 |

29. |

Spring retainer |

|

13. |

Screw M8 |

30. |

Spring |

|

14. |

Bolt M10 x 50 |

31. |

Spring (LH only) |

|

15. |

Outer lever |

32. |

Spring retainer |

|

16. |

Washer |

33. |

Circlip |

|

17. |

Nut M10 |

|

|

|

3/2 |

5/01 |

Remote Control Disassembly

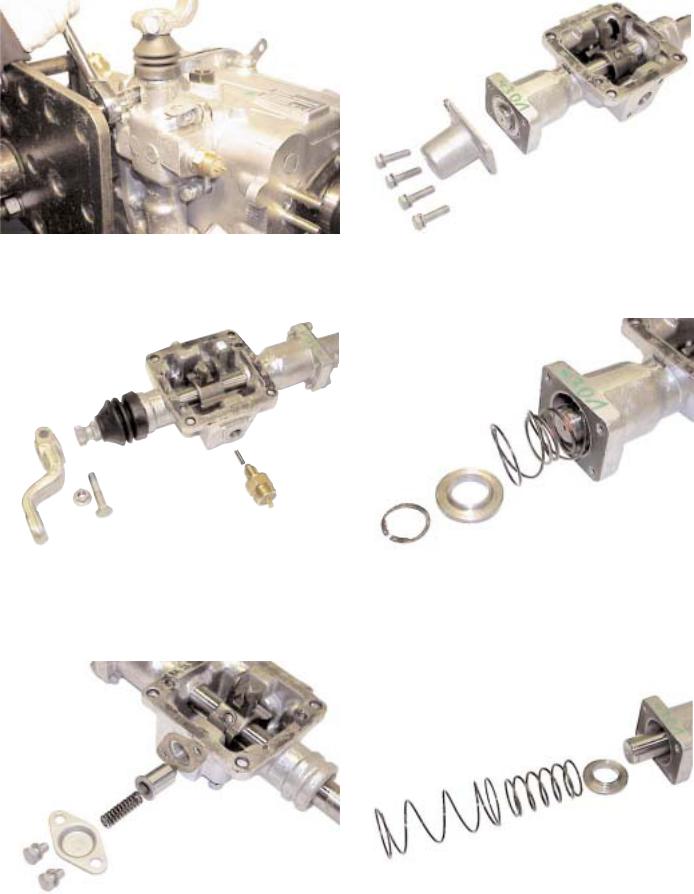

1. Ensure neutral is selected and remove the control assembly from the transmission.

2. Remove the outer shift lever and rubber boot. Remove the neutral switch and pin (if fitted). Note: The position of the lever is marked on the shaft. Check before removal.

3. Remove the reverse detent cover and pull out the spring and plunger.

4. Remove the four separate capscrews and lift off the end cover.

5. Remove the circlip from the shaft and remove the spring retainer.

6. Withdraw the booster spring, bias, spring inner retainer and circlip.

3/3 |

5/01 |

Loading...

Loading...