Eaton Transmission RTLO-18918B-AS Service Manual

Service Manual

Fuller Automated Transmissions

TRSM0050

October 2007

RTAO-11710B-AC

RTAO-11710C-AC

RTAO-12710B-AC

RTAO-12710C-AC

RTAO-13710B-AC

RTAO-13710C-AC

RTAO-14710B-AC

RTAO-14710B-AS

RTAO-14710C-AC

RTAO-14710C-AS

RTAO-15710B-AC

RTAO-15710C-AC

RTAO-16710B-AC

RTAO-16710B-AS

RTAO-16710C-AC

RTAO-16710C-AS

RTLO-14918B-AS

RTLO-16918B-AS

RTLO-18918B-AS

RTLO-20918B-AS

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Introduction

Warnings and Cautions

WARNING: Follow the specified procedures in the indicated order to avoid personal injury

CAUTION: Follow the specified procedures in the indicated order to avoid equipment malfunction or damage.

Note: Additional relevant information not covered in the service procedure.

WARNING: Before starting a vehicle:

• Sit in the driver's seat

• Place shift lever in neutral

• Set the parking brake

WARNING: Before working on a vehicle or leaving the cab with engine running:

• Place shift lever in neutral

• Set the parking brake

• Block the wheels

WARNING: When parking the vehicle or leaving the cab:

• Place shift lever in neutral

• Set the parking brake

CAUTION: Do not release the parking brake or attempt to select a gear until the air pressure is at the correct level.

CAUTION: To avoid damage to the transmission during towing:

• Place shift lever in neutral

• Lift the drive wheels off of the ground or disconnect the driveline

CAUTION: Do not operate vehicle if alternator lamp is lit or if gauges indicate low voltage.

Every effort has been made to ensure the accuracy of all information in this manual. However, Eaton Truck Component Operations makes no expressed

or implied warranty or representation based on the enclosed information. Any errors or omissions may be reported to Marketing Services, Eaton Truck Component Operations, P.O. Box 4013, Kalamazoo, MI 49003.

Copyright Eaton Corporation, 2001. All rights reserved.

1

Introduction

Purpose .......................................................................1

Identification Tag ........................................................ 2

Model Designations .................................................... 3

Lubrication Information .............................................. 4

Maintenance/Lubricant Change Intervals ....................5

Preventive Maintenance Overview ............................... 7

Repair Warnings .......................................................10

Service Procedures

Reverse Ball Switch - Overview ................................. 12

How to Remove the Reverse Ball Switch ................... 13

How to Install the Reverse Ball Switch ...................... 15

Rail Select Sensor - Overview ................................... 18

How to Remove the Rail Select Sensor ..................... 19

How to Install the Rail Select Sensor ........................ 21

Gear Select Sensor - Overview .................................. 24

How to Remove the Gear Select Sensor .................... 25

How to Install the Gear Select Sensor ....................... 27

Input/Main Shaft Speed Sensors - Overview ............. 30

How to Remove the Input/Main Shaft

Speed Sensors .................................................. 31

How to Install the Input/Main Shaft

Speed Sensor ..................................................... 33

Output Shaft Speed Sensor - Overview ..................... 36

How to Remove the Output Shaft Speed Sensor ....... 37

How to Install the Output Shaft Speed Sensor .......... 39

Range Valve - Overview ............................................ 42

How to Remove the Range Valve ..............................43

How to Install the Range Valve ..................................45

Splitter Valve - Overview ........................................... 48

How to Remove the Splitter Valve .............................49

How to Install the Splitter Valve ................................ 51

Air Filter/Regulator - Overview ..................................54

How to Remove the Air Filter/Regulator .................... 55

How to Install the Air Filter/Regulator ....................... 57

Inertia Brake Solenoid - Overview ............................. 60

How to Remove the Inertia Brake Solenoid ............... 61

How to Install the Inertia Brake Solenoid .................. 63

Inertia Brake - Overview ............................................ 66

How to Remove the Inertia Brake .............................. 67

How to Install the Inertia Brake ................................. 69

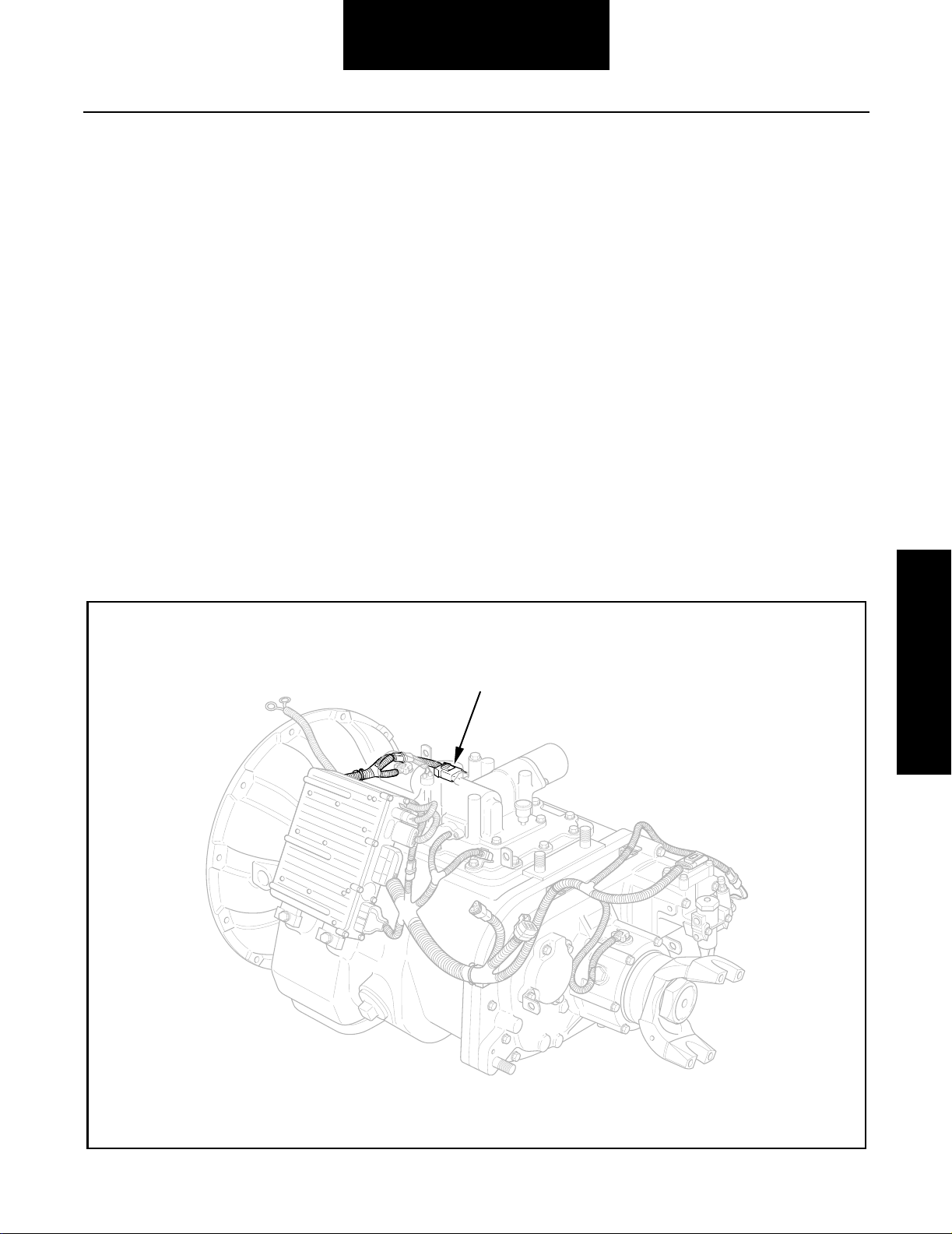

Power Module - Overview ......................................... 72

How to Remove the Power Module ........................... 73

How to Install the Power Module .............................. 75

Electric Shifter - Overview ......................................... 78

How to Remove the Electric Shifter ........................... 79

How to Install the Electric Shifter .............................. 81

Table of Contents

Transmission ECU - Overview ...................................84

How to Remove the Transmission ECU .....................85

How to Install the Transmission ECU .........................87

Transmission Harness - Overview .............................90

How to Remove the Transmission Harness ...............91

How to Install the Transmission Harness ..................93

Shift Lever - Overview ...............................................96

How to Remove the Shift Lever .................................97

How to Install the Shift Lever .....................................99

Power Relay - Overview ...........................................102

How to Remove the Power Relay .............................103

How to Install the Power Relay ................................105

System Manager - Overview ....................................108

How to Remove the System Manager ......................109

How to Install the System Manager .........................111

Tower Harness - Overview .......................................114

How to Remove the Tower Harness .........................115

How to Install the Tower Harness ............................117

Gear Display - Overview ...........................................120

How to Remove the Gear Display ............................121

How to Install the Gear Display ................................123

Table of Contents

Introduction

Purpose

This manual is designed to provide detailed information necessary to service and repair the Automation of Eaton® Fuller® transmissions listed on the front.

How to Use This Manual

The service procedures in this manual are for transmission automation components only. To locate the information you need,

simply locate the procedure in the table of contents, turn to the page specified, and follow the procedure.

To service the mechanical portion of the transmission system, refer to the model specific transmission service manual.

1

Introduction

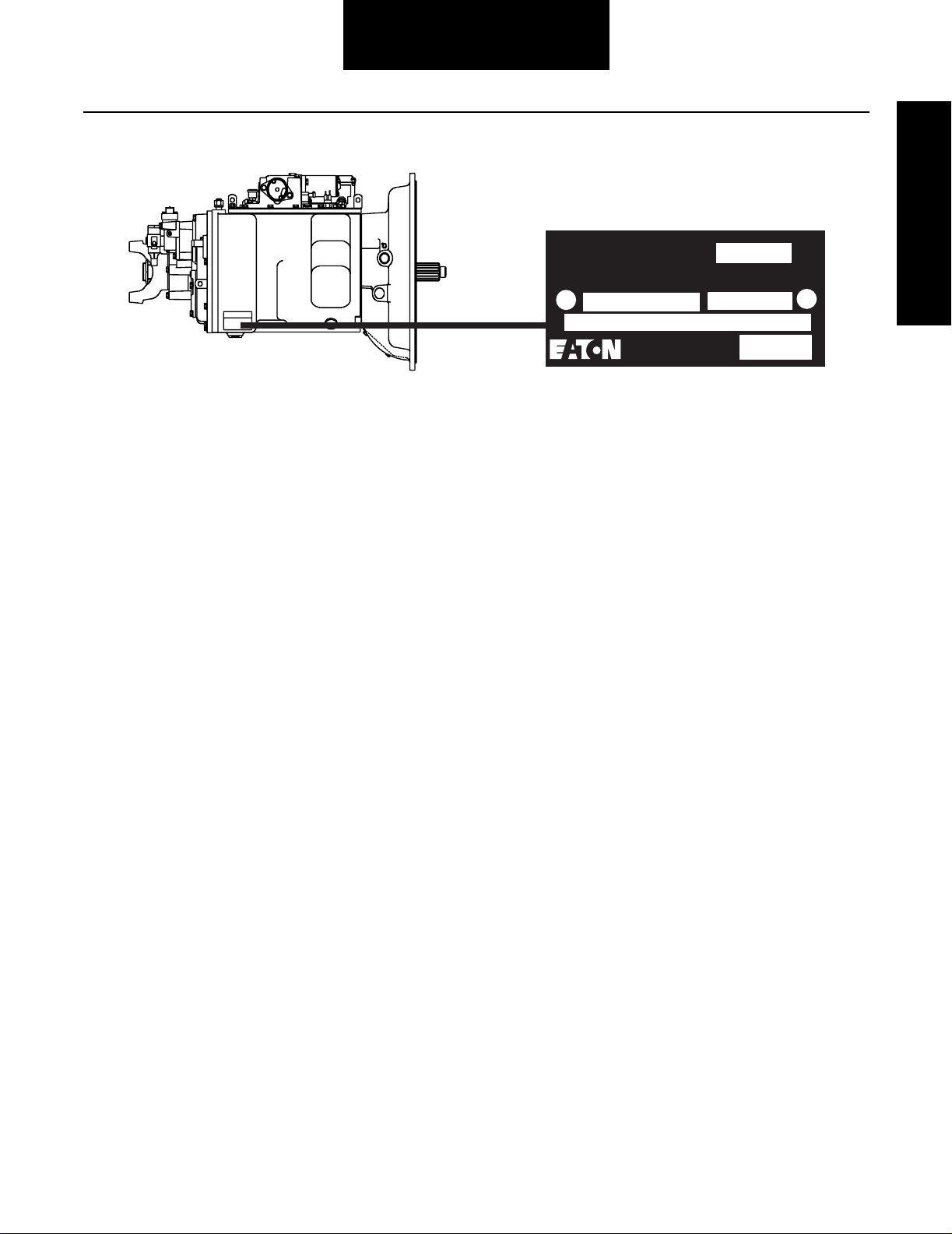

Identification Tag

PTO Code

Eaton Fuller

Transmissions

Model

Eaton Corporation

Transmission Div

Kalamazoo, MI 49003

All Eaton® Fuller® Transmissions are identified by the model and serial number. This information is stamped on the transmission identification tag and affixed to the case.

DO NOT REMOVE OR DESTROY THE TRANSMISSION IDENTIFICATION TAG.

Have reference numbers handy when ordering replacement parts or requesting service repairs.

Made

In

Serial

Introduction

2

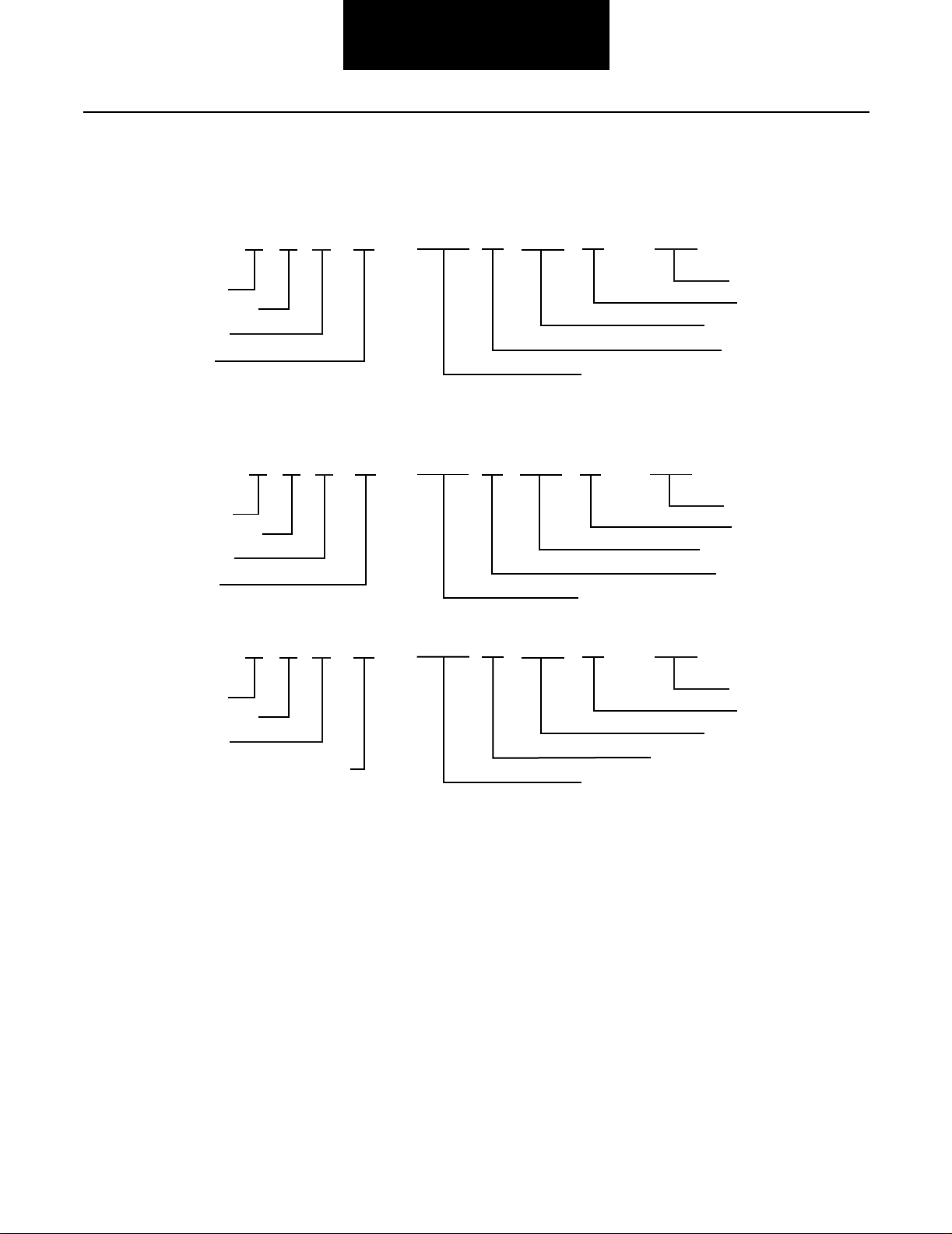

Model Designations

AutoSelect Nomenclature

RTA O -14710B-AC

Introduction

Roadranger

Twin Countershaft

Automated

Overdrive

AutoShift Nomenclature

RTA O -14710B-AS

Roadranger

Twin Countershaft

Automated

Overdrive

RTL O -20918B-AS

Roadranger

Twin Countershaft

Low-Inertia

O = Overdrive w/Direct Shift Pattern

AutoSelect

Gear Ratio

Forward Speeds

Design Level

This (x) 100 = Nominal Torque Capacity

AutoShift

Gear Ratio

Forward Speeds

Design Level

This (x) 100 = Nominal Torque Capacity

AutoSelect

Ratio Set

Forward Speeds

9 = Improved Seal System

This (x) 100 = Nominal Torque Capacity

3

Introduction

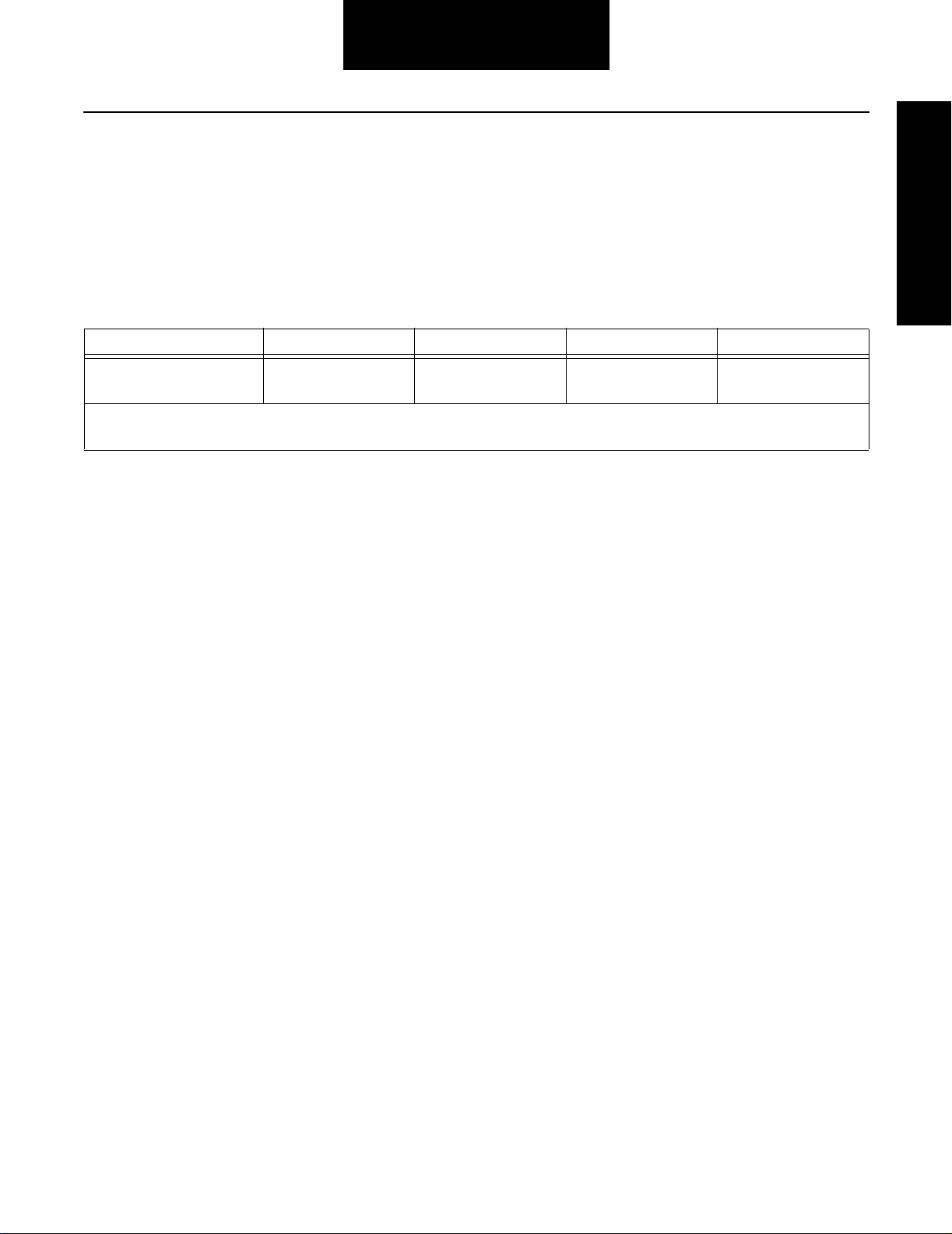

Lubrication Information

Recommended Lubricants

Where transmissions are concerned, lubrication is possibly the most important part of keeping a vehicle operating.

Lubricants which meet the Eaton (PS-164) specification are required in AutoSelect/AutoShift transmissions. Lubricants must be

approved by Eaton Corporation to qualify for the 5/750,000 warranty. For a list of Eaton® Roadranger® approved lubricants,

order item number TCMT-0021.

Type Grade (SAE) Ambient Temperature Drain Interval Note

Eaton® Roadranger®

CD-50 E500 (PS-164)

*The first lube change may be extended to 500,000 miles (800,000 km) when a new transmission has been factory filled with

a lube that is Eaton approved for 500,000 miles (800,000 km) (E-500, PS-164).

50 All 250,000*

(400,000)/1000 Hrs

Approved for

Oil Coolers

Introduction

4

Introduction

Maintenance/Lubricant Change Intervals

Transmission inspections and lubricant changes depend on the type of lubricant used and whether the vehicle is used On- or OffHighway.

On-Highway Lubricant - Vehicles operated on paved roads, interstate highways, and turnpikes are designated as onhighway vehicles. Lubricant change and inspection intervals are the most generous for on-highway vehicles using synthetic

lubricants.

Off-Highway Lubricant - When operating vehicles with AutoSelect/AutoShift transmissions in off-highway applications such as

coal trucks or mining vehicles, it is more important to use time rather than mileage to keep the transmission within its proper

preventive maintenance schedule. Off-highway applications are divided into two categories, severe and normal. 'Severe off-highway' is the designation used when there is excessive dust and dirt. 'Normal off-highway' is for applications where dust and dirt

are minimal.

PM Interval - The PM interval in off-highway vehicles with AutoSelect or AutoShift transmissions is every 40 hours.

Lubricant Change Interval - The lubricant must be changed in AutoSelect/AutoShift transmissions in off-highway vehicles every

500 hours in severe applications, and every 1000 hours for vehicles in normal applications.

Type Grade (SAE) Ambient Temperature Drain Interval Note

Eaton® Roadranger®

CD-50 E500 cm

(PS-164)

*The first lube change may be extended to 500,000 miles (800,000 km) when a new transmission has been factory filled with

a lube that is Eaton approved for 500,000 miles (800,000 km) (E-500, PS-164).

50 All 250,000*

(400,000)/1000 Hrs

Approved for

Oil Coolers

5

Introduction

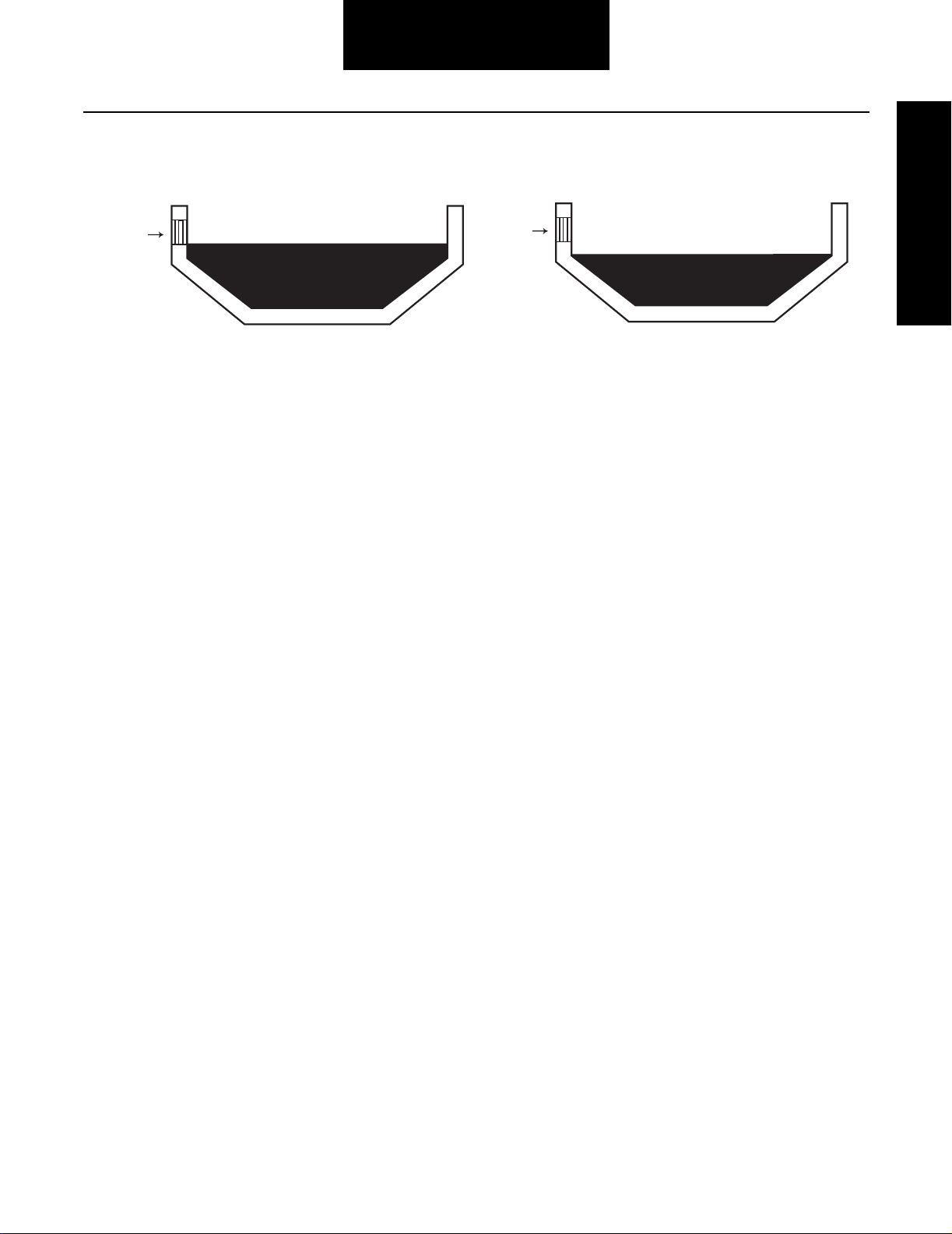

Oil Level

Hole

When checking the transmission lubricant there are two important points to know: where to check the lubricant and what the

proper lubricant level is. Always be cautious when checking the transmission lubricant as it may be hot.

• Checking Location - Check the lubricant at the lubricant fill plug located on the left side of the main transmission case.

• Proper Lubricant Level - The lubricant is at the proper level when it is even with the bottom of the fill hole. When you

remove the plug to check the lubricant level, lubricant should actually seep out. Do not use your finger to feel for the

lubricant. Even if you can touch the lubricant, it may not be at the proper level. In a transmission one inch of lubricant

level equals about one gallon of lubricant.

Proper Oil Level

Hole

Improper Oil Level

Recommended Lubricant

Eaton requires the use of Eaton approved lubes meeting the E-500 performance requirements (PS-164) for these transmissions.

A current list of approved lubes is available from Eaton Roadranger Field Marketing, call 1-800-826-4357. Failure to use a

required lube may affect AutoSelect/AutoShift performance and warranty coverage.

Introduction

Buy from a reputable dealer

For a complete list of approved and reputable dealers, write to:

Eaton Corporation

Truck Components Operations

Global Marketing Services

P.O. Box 4013

Kalamazoo, MI 49003

http://truck.eaton.com/na/service_products/lubricant_requirements/

6

Introduction

Preventive Maintenance Overview

To keep a vehicle running properly, it is important to perform preventive maintenance on the vehicle components. This insures

the vehicle and its subassemblies will operate properly throughout their useful life. To cover preventive maintenance completely,

you must review the following subjects in detail.

• Inspecting the Transmission

• Changing the Fluid

• Vehicle System Effects

Transmission Inspections

When performing preventive maintenance (PM) inspections, several items must be checked. It is important to perform every

step to ensure the transmission meets its life expectancy. Proper PM consists of the following steps:

• Check the transmission oil level

• Inspect under the vehicle for loose/missing bolts

• Check the transmission for air leaks

• Check the transmission for lubricant leaks

Loose or Missing Bolts

While you are under the vehicle checking the lubricant, make a quick check for loose or missing bolts. Check all bolts on the back

box, PTO covers, shift bar housing, clutch housing and transmission controller. Replace any missing or broken bolt with the

proper bolt as called out in the illustrated parts listing. Follow the procedure defined in the manual transmission service manual

when tightening any bolts.

Air Leaks

While you are under the vehicle, check for air leaks as well. The two steps when checking for an air leak are inspection and repair.

• Audible Inspection for Leaks - To find air leaks, make sure the vehicle air system has at least 90 PSI air pressure. Then,

listen for leaks, making sure a vehicle leak is not mistaken for a transmission air leak.

• Refer to Troubleshooting Procedures for Repair - Once you find an air leak, use the troubleshooting guide to isolate

the air leak to the faulty component.

Lubricant Leaks

Oil leak repair is very important. An lubricant leak could cause a catastrophic transmission failure. Check for leaks first at the gasket surfaces, the rear seal, and the transmission cooler.

Visual Check for Leaks at Gaskets

A visual check at each gasket to ensure that no leak is present. Typically a moist spot is acceptable; however drips or larger wet

areas are not. Check for leaks at the rear housing, PTO, shift bar housing, shift tower, and clutch housing gasket surfaces. It is

also Important to ensure that the leak is indeed coming from the transmission. Make sure the lubricant is not being blown back

from the engine or another vehicle component.

7

Introduction

Check for Leaks Around the Input Shaft

Check for leaks around the input shaft. Leaks in this area could be caused by a faulty gasket, the input shaft, or pressurization of

the main transmission case by the air system. If you find a leak at the input shaft, make sure the air system is not leaking into the

case before looking for leaking gaskets.

Rear Seal

The rear seal is very important in maintaining lubricant in the transmission. If the seal is improperly installed or has failed, the

transmission may experience a catastrophic failure. Check the rear seal by performing the following steps:

• Visual Check For Leak - Visually inspect the rear seal for a leak. If a rear seal leak is suspected, proper isolation is nec-

essary.

• Verify the Leak Path - Other leaks may give the impression the rear seal is leaking. One possible cause is the vehicle

speed sensor. Any lubricant leak above and in front of the rear seal could cause lubricant to collect around the seal.

Wipe the seal with a clean rag, operate the vehicle, and recheck to verify the leak path. More information can be found in

the rear seal maintenance guide (TRSM-0912).

Transmission Cooler Leaks

If the vehicle is equipped with a transmission lubricant cooler, make sure there are no leaks at the lubricant cooler, hoses, and fitting of the cooler circuit. Repair any cooler leaks as necessary.

Introduction

Transmission Fluid Change

When it is time to change the transmission lubricant, there are only a few steps to follow: draining and filling the transmission,

draining and filling the cooler (if equipped), and changing the oil filter (if equipped). Remember to be careful when changing the

transmission lubricant, as it may be hot.

• Transmission Drain - Draining the transmission consists of removing the drain plug located on the bottom of the trans-

mission case. Put a drain pan in place under the drain plug before removing it. Once the oil has finished draining, install

the drain plug and torque to 45-55 Lb f ·ft. No sealant is required on the drain plug.

• Cooler Drain - If the vehicle is equipped with a transmission cooler, you must drain the cooler as well. To drain the

cooler, remove both cooler lines at the transmission and pressurize one line with 30 PSI of air pressure. This will force

the oil out of the cooler. Once the cooler has drained, reconnect the coolant lines to the transmission, making sure the

lines are not crossed.

• Transmission Fill - Remove the transmission fill plug and fill the transmission with the desired approved oil. The trans-

mission is full once oil starts flowing out of the fill hole. Replace the fill plug and torque to 60-70 Lb f ·ft.

• Cooler Fill - If the transmission is equipped with a cooler, the best way to fill the cooler is to place the transmission in

neutral, start the vehicle, then release the clutch pedal so the input shaft of the transmission can rotate. This allows the

pump to fill the cooler. Once the vehicle has run for about one minute, shut it off and recheck the transmission oil level.

• Filter Change - If the transmission is equipped with a spin-on oil filter, remove and replace the filter as you would any

spin-on filter. It is also necessary to remove the filter when draining the oil from the cooler. As you unscrew the filter,

catch the oil that seeps out between the filter opening and the "spin-on" casting.

8

Introduction

Vehicle System Effects

Some vehicle systems can affect transmission operation and possibly cause a failure. The major system that can affect AutoSelect or AutoShift is the air system.

Air System

If the air system is not given recommended preventive maintenance, it can cause transmission system problems. Although the

transmission has an air filter regulator it cannot protect the transmission from contaminants indefinitely. This is why it is important to follow OEM recommendations for air system PM. It is important to regularly drain the air tanks and insure that oil is not

being pumped by the air compressor into the vehicle air system. If moisture enters the transmission system, it may cause corrosion. Also, in cold climates it may freeze, preventing the shift mechanisms from operating. If allowed into the system, oil could fill

the air system components causing them to lose valuable air volume, slowing or preventing movement.

9

Introduction

Repair Warnings

When disassembling various assemblies, lay all parts on a clean bench in the same sequence as removed to simplify assembly

and reduce the possibility of losing parts.

Provide a clean work area. Make sure no dirt or foreign material enter the unit during repair and assembly.

Disconnect the vehicle's battery before removing or installing electronic parts.

Since the cost of a new part is generally a small fraction of the total cost of downtime and labor, avoid reusing a questionable part

that could lead to additional repairs and expense.

Use of other than recommended tools, parts, and instructions listed in this manual may place the safety of the service technician

or vehicle driver in jeopardy.

The location of some components may vary with each O.E.M.

The removal and installation procedure described for each component may vary for your vehicle.

Always use genuine Eaton replacement parts. For a complete list of approved and reputable dealers, write to:

Eaton Corporation

Truck Components Operations

Global Marketing Services

P.O. Box 4013

Kalamazoo, MI 49003

http://truck.eaton.com/na/service_products/lubricant_requirements/

Introduction

10

Introduction

11

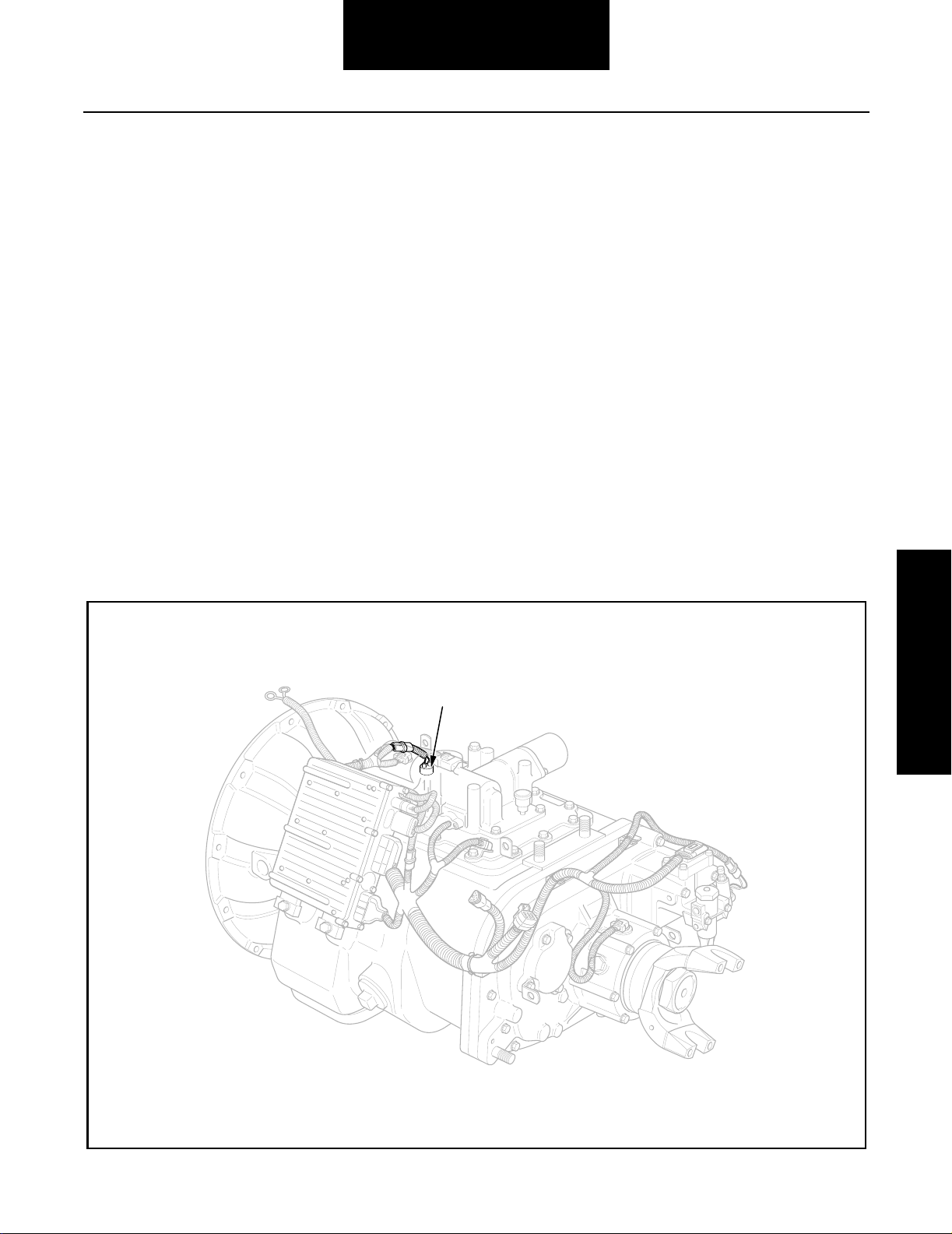

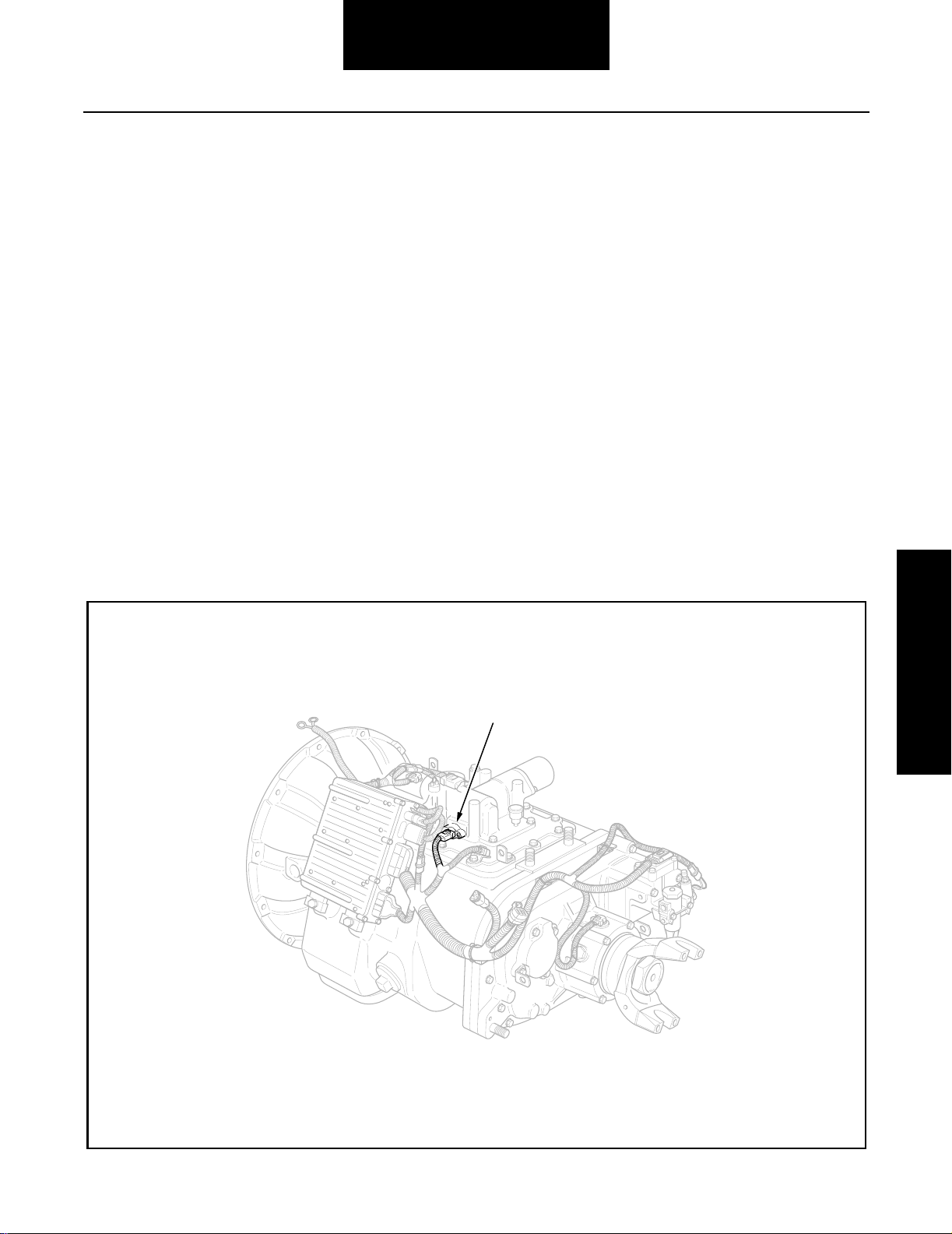

Reverse Ball Switch - Overview

Service Procedure

Special Instructions

None.

Required Tools

• Torque Wrench with 25 lb.ft. capacity.

Essential Steps

Install a new fiber washer.

Service Procedure

Reverse Ball Switch

12

Service Procedure

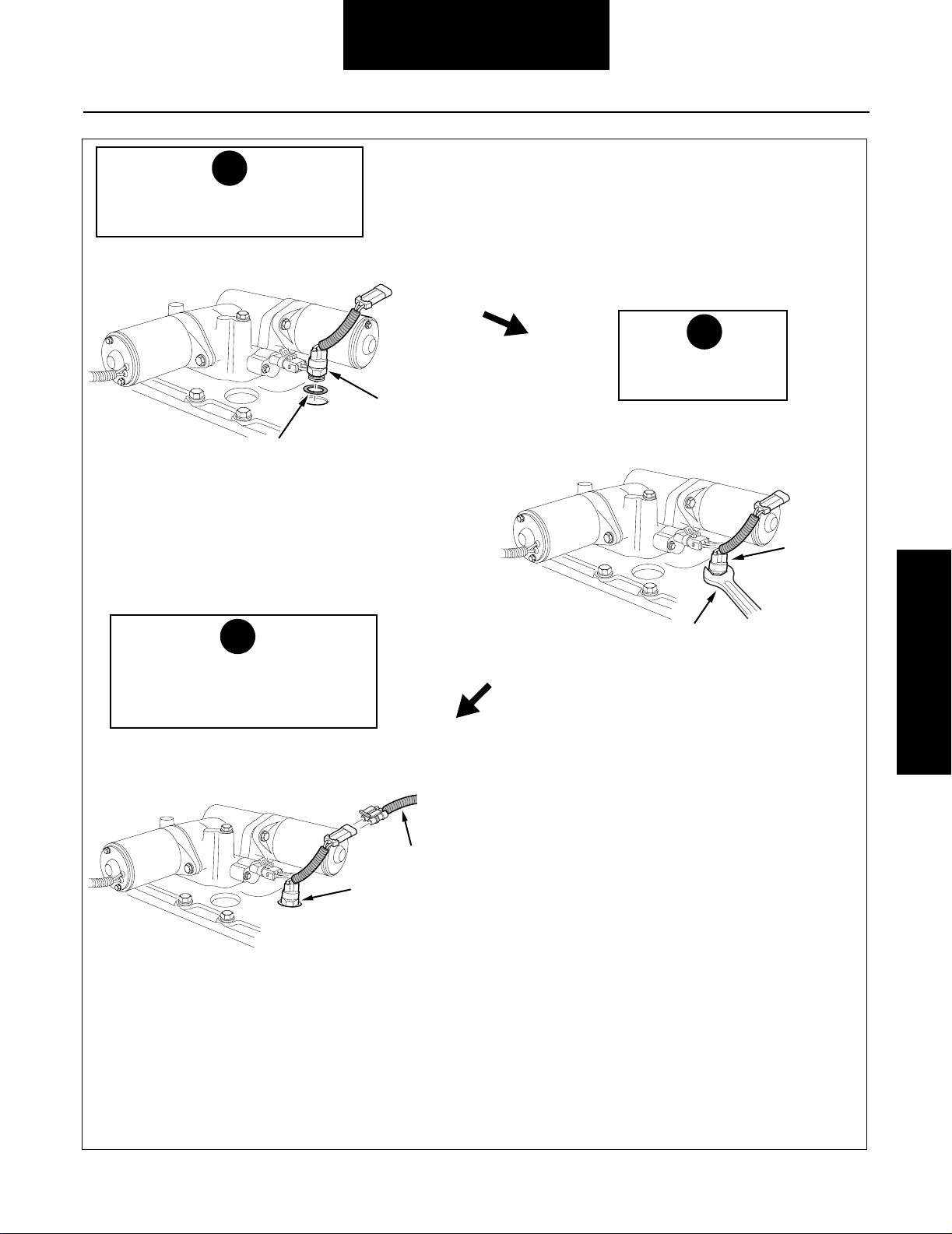

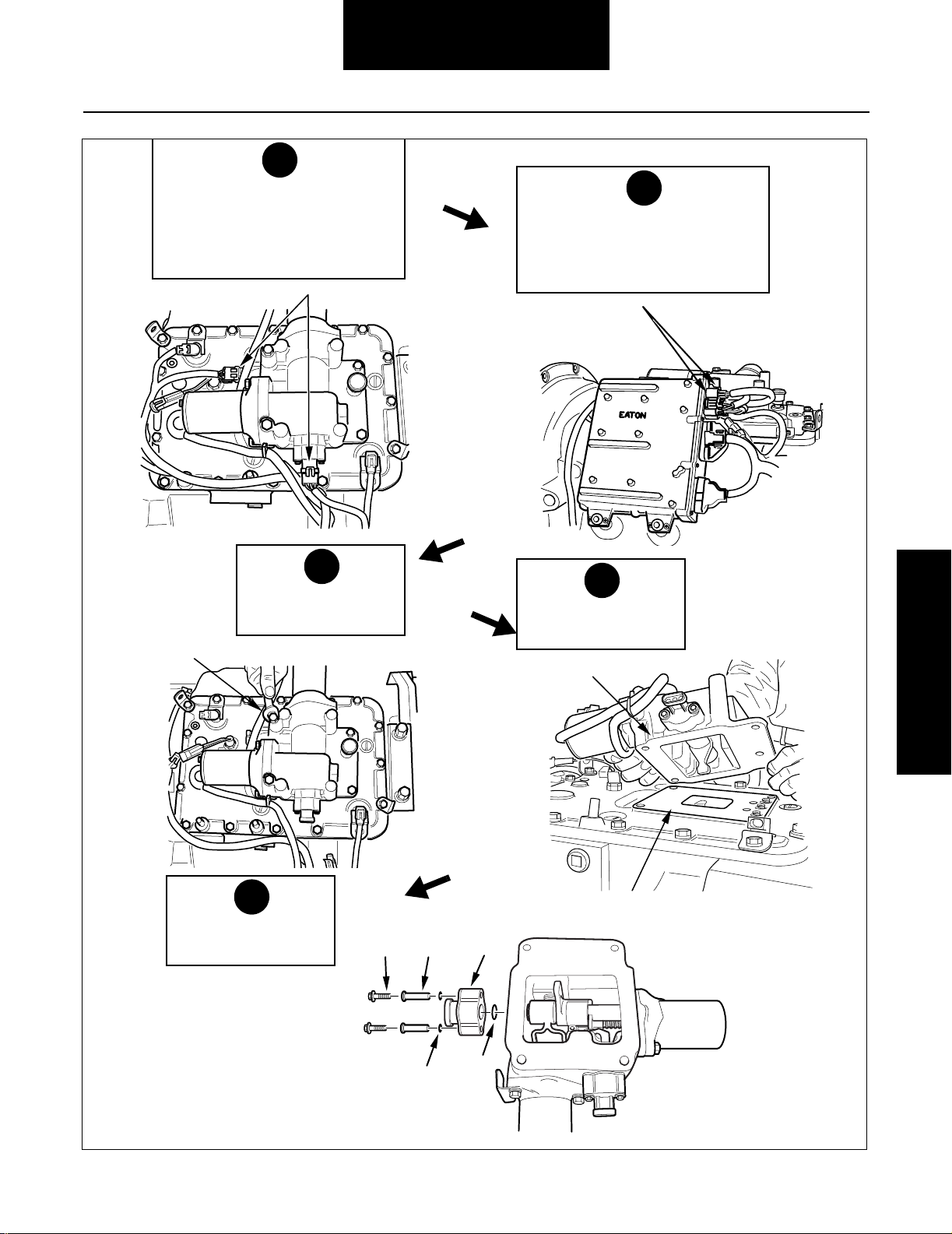

How to Remove the Reverse Ball Switch

Procedure-

1. Disconnect the Transmission Harness from the Reverse

Ball Switch.

2. Using a 7/8" wrench, Loosen the Reverse Ball Switch.

3. Remove the Reverse Ball Switch and Fiber Washer from

the Shift Bar Housing.

13

1

Disconnect

Transmission Harness

from Reverse Ball Switch

Service Procedure

2

3

Remove Reverse Ball

Switch and Fiber Washer

Transmission Harness

Reverse Ball Switch

Loosen Reverse

Ball Switch

Reverse Ball Switch

Service Procedure

7/8" Wrench

Fiber Washer

Reverse Ball Switch Removal

Reverse Ball Switch

14

Service Procedure

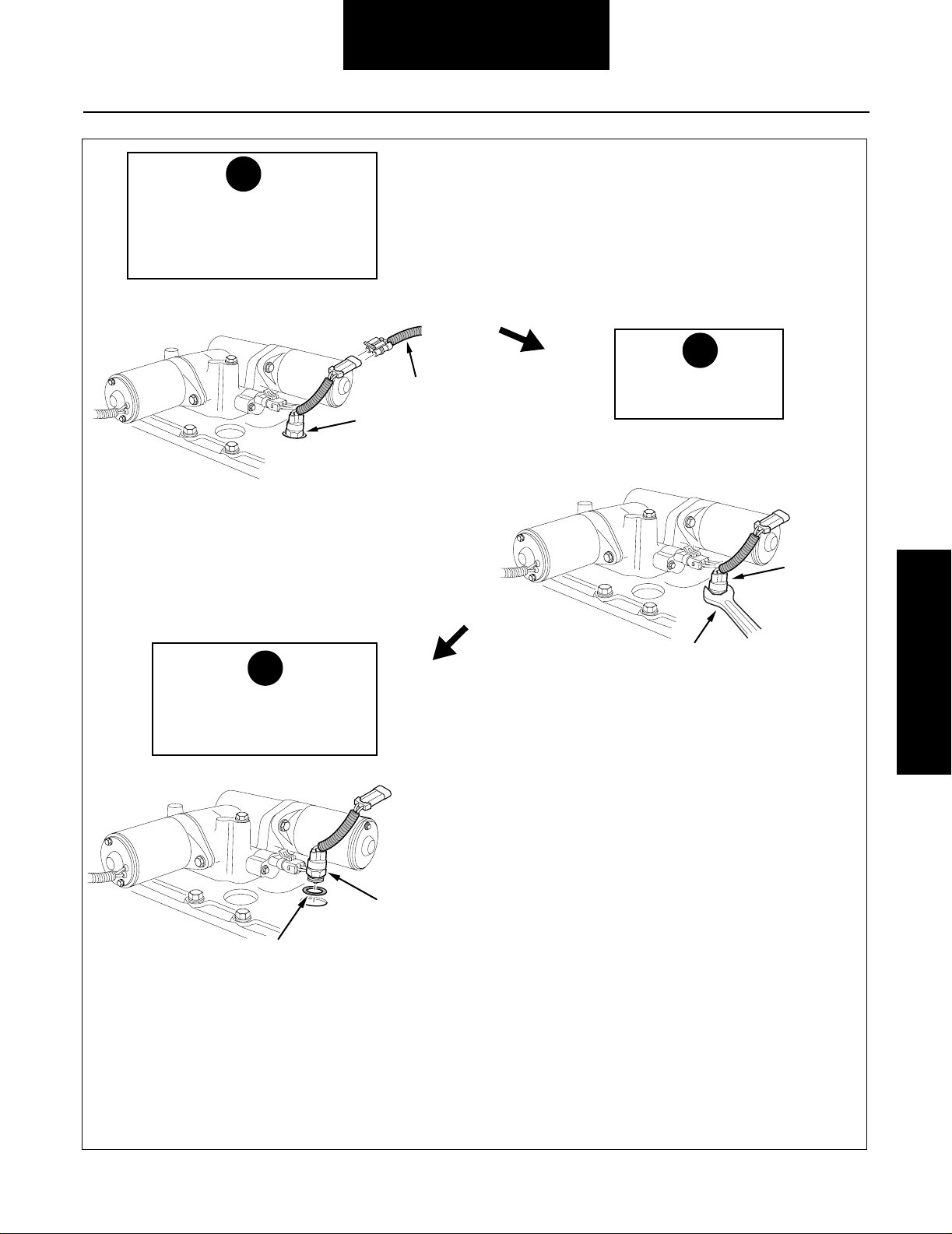

How to Install the Reverse Ball Switch

Procedure-

1. Install a new fiber washer (included in the Reverse Ball

Switch service kit) on the Reverse Ball Switch.

2. Using a 7/8" wrench, install and tighten the Reverse Ball

Switch to 20-25 lbs. ft. (27.1-33.9 N•m).

3. Connect the Transmission Harness to the Reverse Ball

Switch.

Final Check

Verify Harness is locked.

15

1

Install reverse ball

Switch and Fiber Washer

Fiber Washer

Service Procedure

2

Tighten Reverse

Ball Switch

Reverse Ball Switch

3

Connect

Transmission Harness to

Reverse Ball Switch

Reverse Ball Switch

Service Procedure

7/8" Wrench

Transmission Harness

Reverse Ball Switch

Reverse Ball Switch Installation

16

Service Procedure

Solo Heavy Duty Clutch - Install, Con’t

17

Rail Select Sensor - Overview

Service Procedure

Special Instructions

Install the sensor with the connector on top.

While removing or installing the capscrews, hold the sensor

in place. Don't allow it to snap out of position.

Required Tools

• Basic Hand Tools

Essential Steps

The shifter module must be calibrated before the vehicle is

placed into operation.

Service Procedure

Rail Select Sensor

18

Service Procedure

How to Remove the Rail Select Sensor

Procedure-

1. Disconnect the Transmission Harness from the Rail

Select Sensor.

2. Using a 5/16" wrench, remove the two (2) sensor capscrews.

3. Carefully allow the sensor to rotate (not snap) to a

relaxed position. Then remove the sensor, steel sleeves

and O-rings from the housing.

4. Insert your finger into the sensor bore and push the arm

slightly.

19

g

1

Disconnect

Transmission Harness

from Sensor

Service Procedure

2

Remove Mounting

Capscrews

Select Sensor

Remove Rail

Select Sensor

Sensor Connector

Service Procedure

3

Sleeve O-Rin

Sensor O-Ring

Rail Select Sensor Removal

Select

Sensor

Sleeve

Capscrew

20

Service Procedure

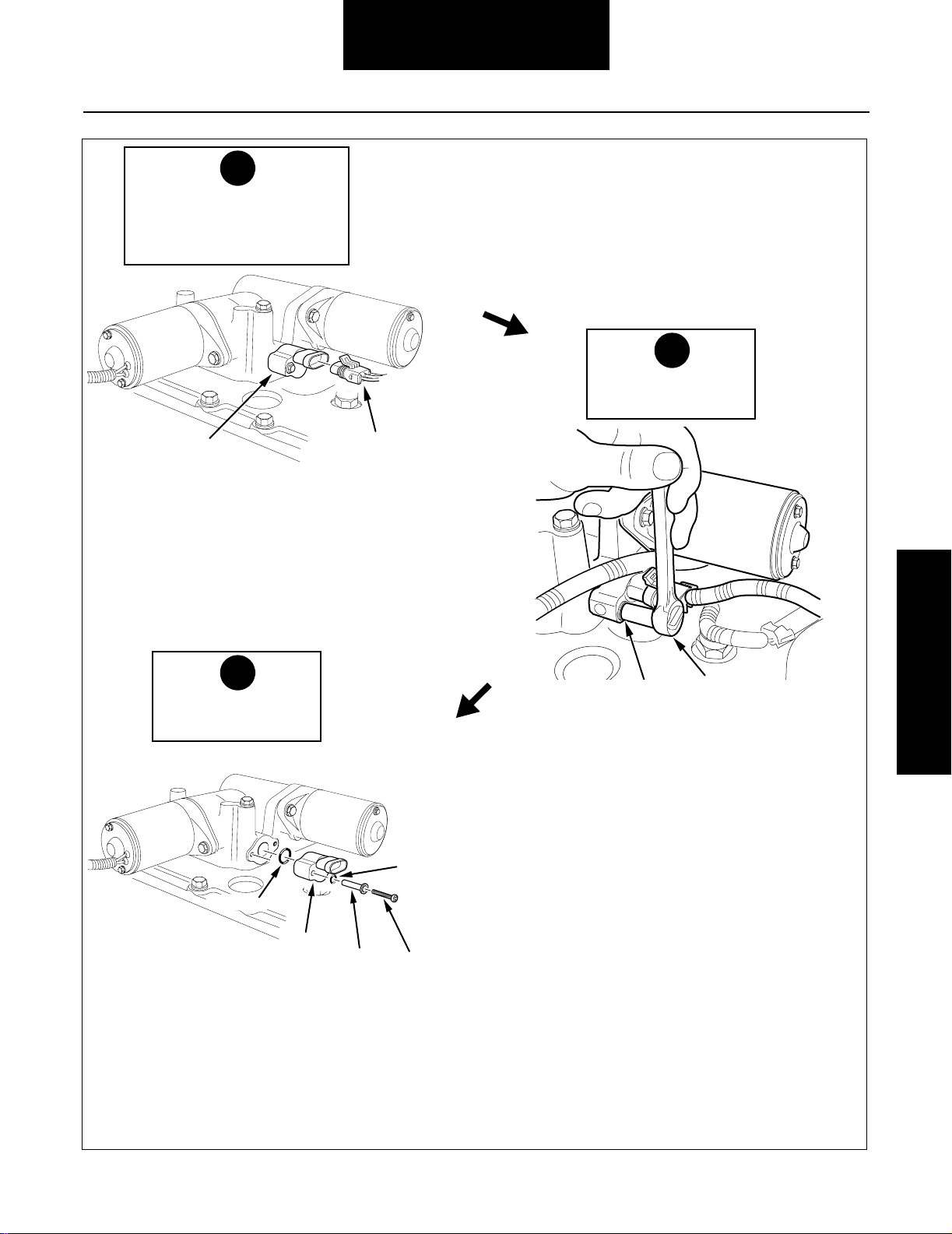

How to Install the Rail Select Sensor

Procedure-

1. Align the sensor's tab with the slot in the shifter housing.

Then position the Sensor O-ring and insert the Rail Sensor into its mounting location.

2. Insert the new sleeve O-rings, new steel sleeves and capscrews into the sensor mounting holes.

3. Using a 5/16" wrench, install and tighten the capscrews

to 21-27 lbs. in. (2.4-3.1 N•m).

4. Reconnect the Transmission Harness to the Rail Select

Sensor.

Final Check

Make sure that the capscrews are tightened to specification.

Make sure that the sensor connections are secure.

Calibration

To operate properly, the system must be calibrated as follows:

a. Turn the ignition switch to ON and allow the trans-

mission to power up.

b. Turn the ignition switch to OFF and wait two minutes.

IMPORTANT: The shifter module must be calibrated before

the vehicle is placed into operation.

21

g

1

Insert Rail

Select Sensor

Sensor O-Ring

Sensor

Select

Sleeve

Service Procedure

Sleeve O-Rin

Capscrew

2

Attach Mounting

Capscrews

3

Reconnect Transmission

Harness to Sensor

Select Sensor

2

Service Procedure

5/16" Wrench

Mounting Capscrew

Sensor Connector

Rail Select Sensor Installation

22

Service Procedure

Solo Heavy Duty Clutch - Install, Con’t

23

Gear Select Sensor - Overview

Service Procedure

Special Instructions

Install the sensor with the connector on top.

While removing the capscrews, hold the sensor in place.

Don't allow it to snap out of position.

Required Tools

• Basic Hand Tools.

Essential Steps

The shifter module must be calibrated before the vehicle is

placed into operation.

Service Procedure

Gear Select Sensor

24

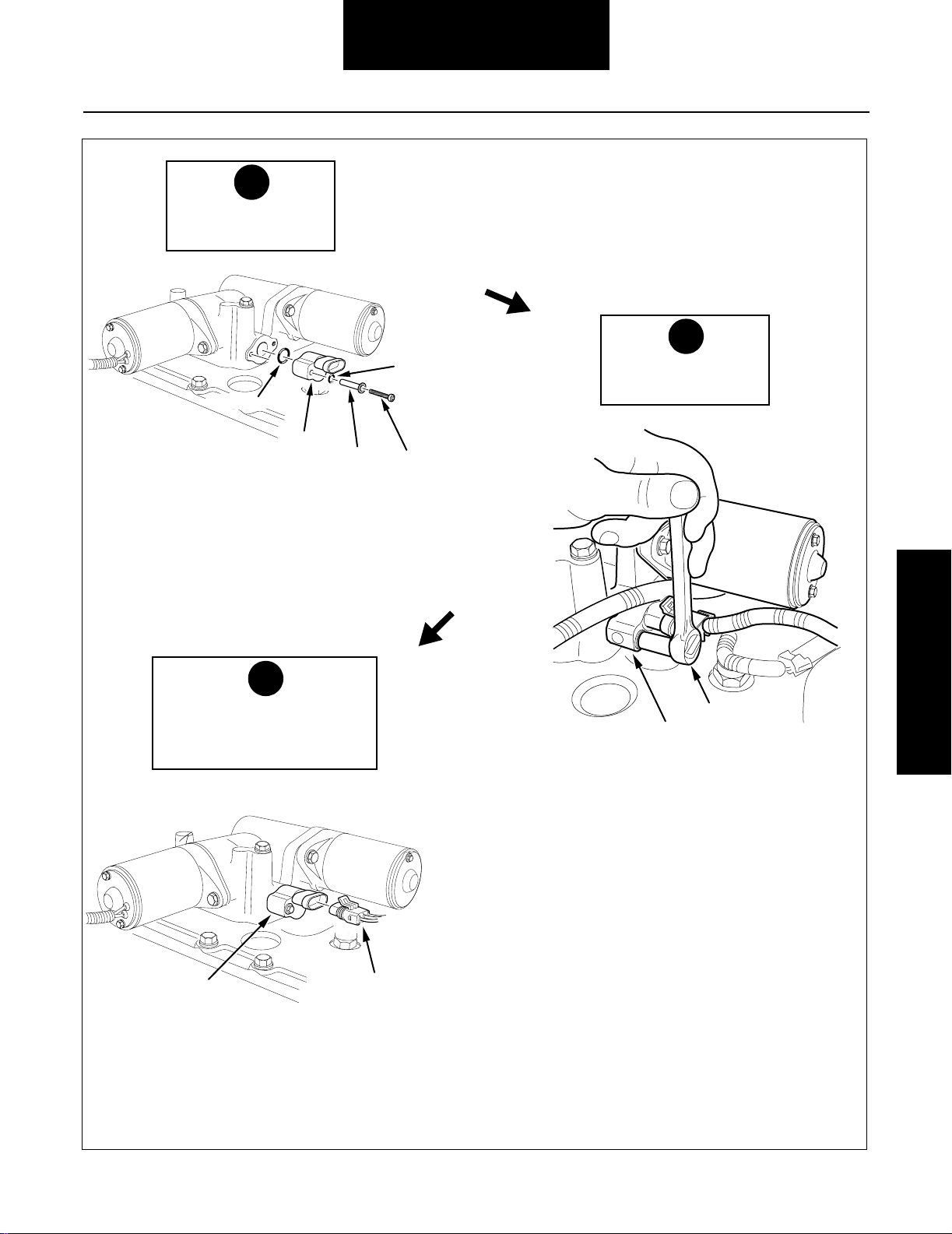

Service Procedure

How to Remove the Gear Select Sensor

Procedure-

1. Remove nylon cable ties from motor wires.

2. Disconnect the Transmission Harness from the Gear

Select Sensor and Rail Select Sensor.

3. Disconnect the Gear Select Motor and Rail Select Motor

from the Transmission ECU.

4. Using a 5/16" wrench, remove the four (4) Electric Shifter

capscrews.

5. Remove the Electric Shifter and gasket.

6. Turn the shifter over (upsidedown).

7. Using a 5/16" wrench, remove the two (2) Gear Select

Sensor capscrews.

8. Carefully allow the sensor to rotate (not snap) to a

relaxed position, then remove the sensor, steel sleeves

and O-ring from the housing.

9. Insert your finger into the sensor bore and push the arm

slightly.

25

Service Procedure

1

9/16" Wrench

Disconnect

Transmission Harness

from Rail and Gear

Select Sensor

Sensor Connectors

3

Remove Mounting

Capscrews

2

Disconnect Rail Motor

and Gear Motor from

Transmission ECU

Motor Connectors

4

Remove Electric

Shifter and Gasket

Electric Shifter

T

Service Procedure

5

Remove Gear

Select Sensor

Gear Select Sensor Removal

Capscrew

Sleeve

Sleeve

O-Ring

Gasket

Position

Sensor

Sensor

O-Ring

26

Loading...

Loading...