Page 1

Service Manual

Eaton Gen III Automated

Transmissions

TRSM0930 EN-US

May 2013

UltraShift®

AutoShift®

UltraShift® PLUS Linehaul Active Shifting (LAS)

UltraShift® PLUS Linehaul Small Step Efficiency (LSE)

UltraShift® PLUS Multipurpose Extreme Performance (MXP)

UltraShift® PLUS Multipurpose High Performance (MHP)

UltraShift® PLUS Vocational Active Shifting (VAS)

UltraShift® PLUS Vocational Construction Series (VCS)

UltraShift® PLUS Vocational High Performance (VHP)

UltraShift® PLUS Vocational Multipurpose Series (VMS)

UltraShift® PLUS Vocational Extreme Performance (VXP)

UltraShift® PLUS Passenger Vehicle (PV)

Page 2

TRTS0930 General Information |

Model:

F-5405B-DM3

F-6405B-DM3

F-14E316B-LSE

F-15E316B-LSE

F-17E316B-LSE

FM-15E316B-LSE

FM-14D310B-LST

FM-15D310B-LST

FO-16D313E-LEP

FO-5406B-DM3

FO-6406A-AW3

FO-6406B-AW3

FO-8406A-AW3

FOM-16D313E-LEP

RTLO-14918A-AS3

RTLO-16913L-DM3

RTLO-16918A-AS3

RTO-10910B-DM3

RTO-12910B-AS3

RTO-12910B-DM3

RTO-14910B-AS3

RTO-14910B-DM3

RTO-14910C-AS3

RTO-16910B-AS3

RTO-16910B-DM3

RTO-16910C-AS3

RTO-18910B-AS3

FO-10E310C-VAS

FO-12E310C-VAS

FO-14E310C-VAS

FO-16E310C-VAS

FOM-14E310C-VAS

F-5505B-DM3

F-6505B-DM3

RTLO-18918A-AS3

RTLO-20918A-AS3

RTLO-22918A-AS3

RTLOM-16913L-DM3

RTO-10910B-AS3

RTOM-16910B-DM3

FO-14E310C-LAS

FO-16E310C-LAS

FO-18E310C-LAS

FOM-14E310C-LAS

FOM-15E310C-LAS

FOM-16E310C-LAS

FM-14E310B-LAS

FM-15E310B-LAS

EO-11E406B-PV

FOM-15E310C-VAS

FOM-16E310C-VAS

FO-10E308LL-VCS

FO -11E308LL-VC S

FO-12E308LL-VCS

FO-14E308LL-VCS

FO-16E308LL-VCS

FO-17E308LL-VCS

FO-16E313A-VHP

FO-18E313A-VHP

FO-20E313A-VHP

FO -10E309A LL-VMS

FO -11E309AL L-VMS

FO -12E309ALL-VMS

FO -14E30 9ALL-VM S

FO -16E309ALL-VMS

FO -17E309ALL-VMS

FO-14E313B-MHP

FO-16E313B-MHP

FO-18E313B-MHP

FO-20E313B-MHP

FO-14E318B-MXP

FO-16E318B-MXP

FO-18E318B-MXP

FO-20E318B-MXP

FO-22E318B-MXP

FO-14E318B-VXP

FO-16E318B-VXP

FO-18E318B-VXP

FO-20E318B-VXP

FO-22E318B-VXP

FO-22E318B-VXP

EO-11E406B-PVER

EO-11E406B-PVHR

EO-11E406B-PV

2013.05.30

© 2013 Eaton. All rights reserved

1

Page 3

TRSM0930 Table of Contents |

Table of Contents

General Information

Warnings & Cautions. . . . . . . . . . . . . . . . . . . . . . . . . . .1

How to use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . 2

Transmission Overview . . . . . . . . . . . . . . . . . . . . . . . . . 3

Serial Tag Information and Model Nomenclature. . . . .15

Clutch Greasing Guidelines . . . . . . . . . . . . . . . . . . . . .19

Grease Interval Count Reset. . . . . . . . . . . . . . . . . 19

ServiceRanger Procedure . . . . . . . . . . . . . . . . . . 20

Operator Triggered Procedure . . . . . . . . . . . . . . . 22

Service Procedure

Thread-In ECA Speed Sensor. . . . . . . . . . . . . . . . . . . .23

Electronic Clutch Actuator (ECA) . . . . . . . . . . . . . . . . . 27

Low Capacity Inertia Brake . . . . . . . . . . . . . . . . . . . . . 31

Release Yoke and Cross-shaft(s). . . . . . . . . . . . . . . . .35

Cobra Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Shift Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Medium-Duty Transmission Harness. . . . . . . . . . . . . .49

Heavy-Duty Transmission Harness . . . . . . . . . . . . . . .53

Medium-Duty Transmission Electronic Control Unit (TE-

CU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Heavy-Duty Transmission Electronic Control Unit (TECU)

61

Electric Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Medium-Duty Inertia Brake . . . . . . . . . . . . . . . . . . . . . 69

Air Filter Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Heavy-Duty Inertia Brake . . . . . . . . . . . . . . . . . . . . . . . 79

Combination Valves (Range and Deep Reduction). . . . 83

Range Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Splitter Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Directional Output Shaft Speed Sensor . . . . . . . . . . . .95

Park Actuator Assembly. . . . . . . . . . . . . . . . . . . . . . . .99

Park Pawl Position Sensor. . . . . . . . . . . . . . . . . . . . .103

Medium-Duty Output Shaft Speed Sensor. . . . . . . . .107

Heavy-Duty Output Shaft Speed Sensor . . . . . . . . . . 111

Main Shaft Speed Sensor . . . . . . . . . . . . . . . . . . . . . 115

Medium-Duty Input Shaft Speed Sensor . . . . . . . . . .119

Heavy-Duty Input Shaft Speed Sensor. . . . . . . . . . . . 123

Rail Select Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Gear Select Sensor . . . . . . . . . . . . . . . . . . . . . . . . . .131

Lubricant Filter (AW3 Models Only). . . . . . . . . . . . . .135

Appendix

Operation and Basic Troubleshooting . . . . . . . . . . . . 139

Inspection Procedures. . . . . . . . . . . . . . . . . . . . . . . . 140

Lubrication Specifications . . . . . . . . . . . . . . . . . . . . . 141

UltraShift DM3 and AutoShift AS3 . . . . . . . . . . . 141

Buy From a Reputable Dealer. . . . . . . . . . . . . . . 141

Transmission Operating Angles . . . . . . . . . . . . . 141

Operating Temperatures with Oil Coolers . . . . . . 141

UltraShift™ ASW Models . . . . . . . . . . . . . . . . . . 141

Buy From a Reputable Dealer. . . . . . . . . . . . . . . 142

Synthetic Dextron III ATF . . . . . . . . . . . . . . . . . . 142

CD-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Maintenance and Lubricant Change Intervals . . 142

Checking Wet Clutch Lubricant . . . . . . . . . . . . . 142

Proper Wet Clutch Lubricant Level. . . . . . . . . . . 142

Checking Gearbox Lubricant . . . . . . . . . . . . . . . 142

Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Proper Gearbox Lubricant Level. . . . . . . . . . . . . 142

Drain the Transmission Gearbox and Wet Clutch

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Change Wet Clutch Filters . . . . . . . . . . . . . . . . . 143

Fill the Transmission . . . . . . . . . . . . . . . . . . . . . 143

Clutch Calibration. . . . . . . . . . . . . . . . . . . . . . . . 143

Maintenance and Lubricant Change Intervals . . . . . . 144

Checking Wet Clutch Lubricant . . . . . . . . . . . . . 144

Proper Wet Clutch Lubricant Level. . . . . . . . . . . 144

Checking Gearbox Lubricant . . . . . . . . . . . . . . . 144

Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Proper Gearbox Lubricant Level. . . . . . . . . . . . . 144

Drain the Transmission Gearbox and Wet Clutch

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Change Wet Clutch Filters . . . . . . . . . . . . . . . . . 145

Fill the Transmission . . . . . . . . . . . . . . . . . . . . . 145

Clutch Calibration. . . . . . . . . . . . . . . . . . . . . . . . 145

Tool Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .146

General Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . 147

Torque Overview . . . . . . . . . . . . . . . . . . . . . . . . 149

Grade Sensor Calibration. . . . . . . . . . . . . . . . . . . . . . 152

ServiceRanger Procedure . . . . . . . . . . . . . . . . . 152

Operator-Triggered Procedure . . . . . . . . . . . . . . 154

2013.05.30

© 2013 Eaton. All rights reserved

i

Page 4

Warnings & Cautions | General Information TRSM0930

!

!

!

!

!

!

!

!

Warnings & Cautions

Warning: Follow the specified procedures in the indicated

order to avoid personal injury.

Note: Additional relevant information not covered in the

service procedure.

Warning: Before starting a vehicle:

• Ensure adequate fuel level.

• Sit in the driver's seat.

• Place shift lever in neutral.

• Set the parking brake.

Warning: Before working on a vehicle or leaving the cab

with engine running:

• Ensure ignition is off while hands are within the

clutch housing area.

• Place shift lever in neutral.

• Set the parking brake.

• Block the wheels.

Warning: When parking the vehicle or leaving the cab:

• Place shift lever in neutral.

• Set the parking brake.

Caution: Follow the specified procedures in the indicated

order to avoid equipment malfunction or damage.

Caution: Do not release the parking brake or attempt to

select a gear until the air pressure is at the correct

level.

Caution: To avoid damage to the transmission during tow-

ing:

• Place shift lever in neutral.

• Lift the drive wheels off of the ground or disconnect the driveline.

Caution: Do not operate the vehicle if alternator lamp is lit

or if gauges indicate low voltage.

1

© 2013 Eaton. All rights reserved

2013.05.30

Page 5

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 6

TRSM0930 General Information | How to use this Manual

How to use this Manual

This publication is divided into three sections General Information, Service Repair Procedures and the Appendix.

General Information

This section contains the basic chapters like “Transmission

Overview,” “How to Use This Manual” and “Serial Tag and

Model Nomenclature.”

Service Repair Procedures

A “Components Identification” diagram is included at the

beginning of each procedure for disassembly, assembly,

removal and installation. Below the “Components Identifi

cation” diagram is a numerical listing for each part with the

part name.

Appendix

This section contains information like: “Operation,” “Lubrication Specifications,” “Inspection” (in base box manuals),

“Powerflow” (in base box manuals), “Air System Opera

tion” and “Troubleshooting” (in base box manuals), “Basic

Troubleshooting” (in base box manuals), “Tool Specifica

tions,” “Torque Specifications,” and the “Torque Overview.”

-

-

-

The service procedures in this manual are for transmission

automation components only. To find the information you

need, simply locate the procedure in the “Table of Con

tents,” turn to the page specified and follow the procedure.

If you are unsure of a components’ name, you can refer

ence the “Transmission Overview” pages.

To service the mechanical portion of the transmission system, refer to the specific transmission service manual.

-

-

2013.05.30

© 2013 Eaton. All rights reserved

2

Page 7

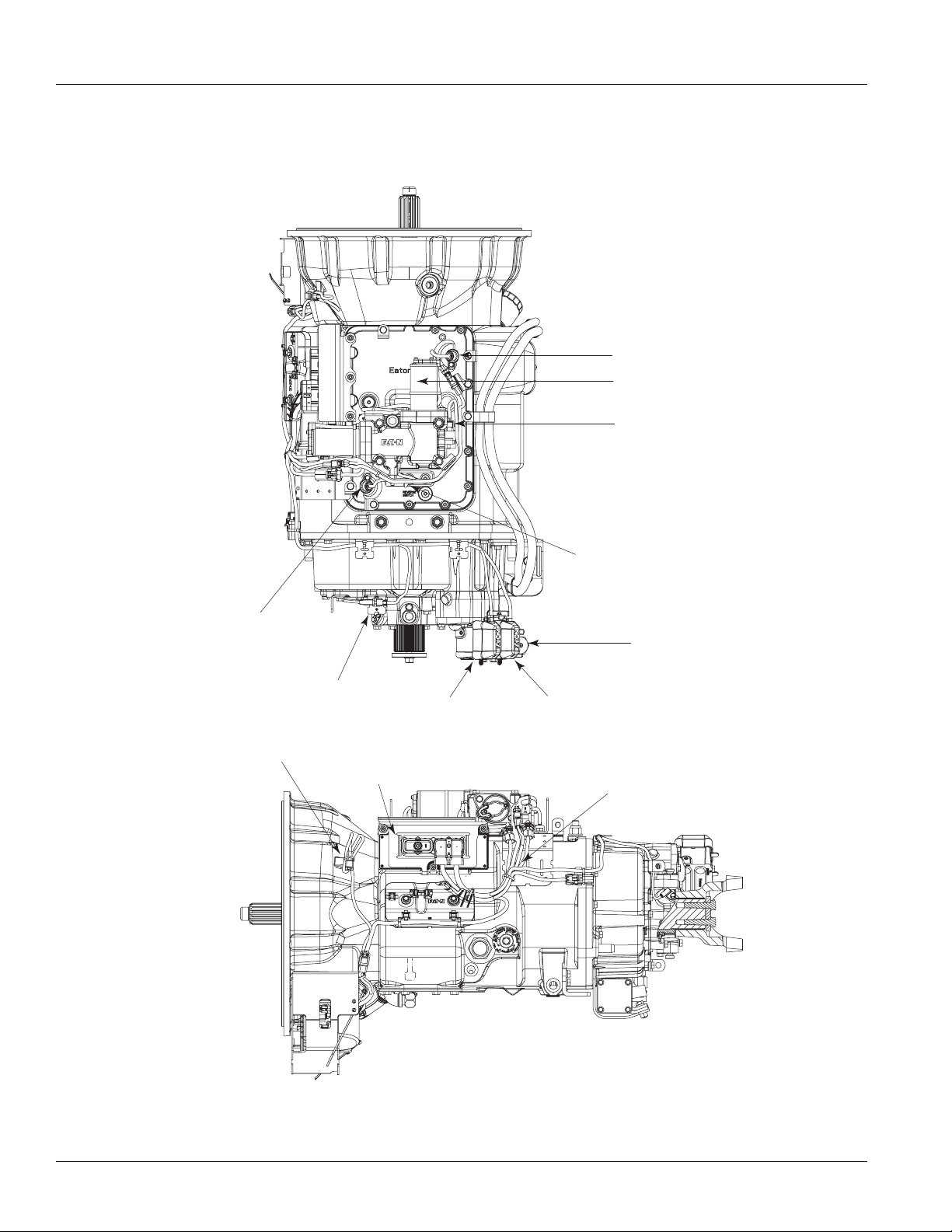

Transmission Overview | General Information TRSM0930

Transmission Overview

Heavy-Duty 8LL / VCS & 9ALL / VMS

Input Shaft Speed Sensor

Electric Shifter

Gear Selector Sensor

Mainshaft

Speed Sensor

Output Shaft

Speed Sensor

Flywheel Speed Sensor

(Shipping Location)

Transmission

ECU

Range

(Combination Valve)

Rail Selector Sensor

Air Filter

Regulator

Deep Reduction

Transmission

Harness

3

© 2013 Eaton. All rights reserved

2013.05.30

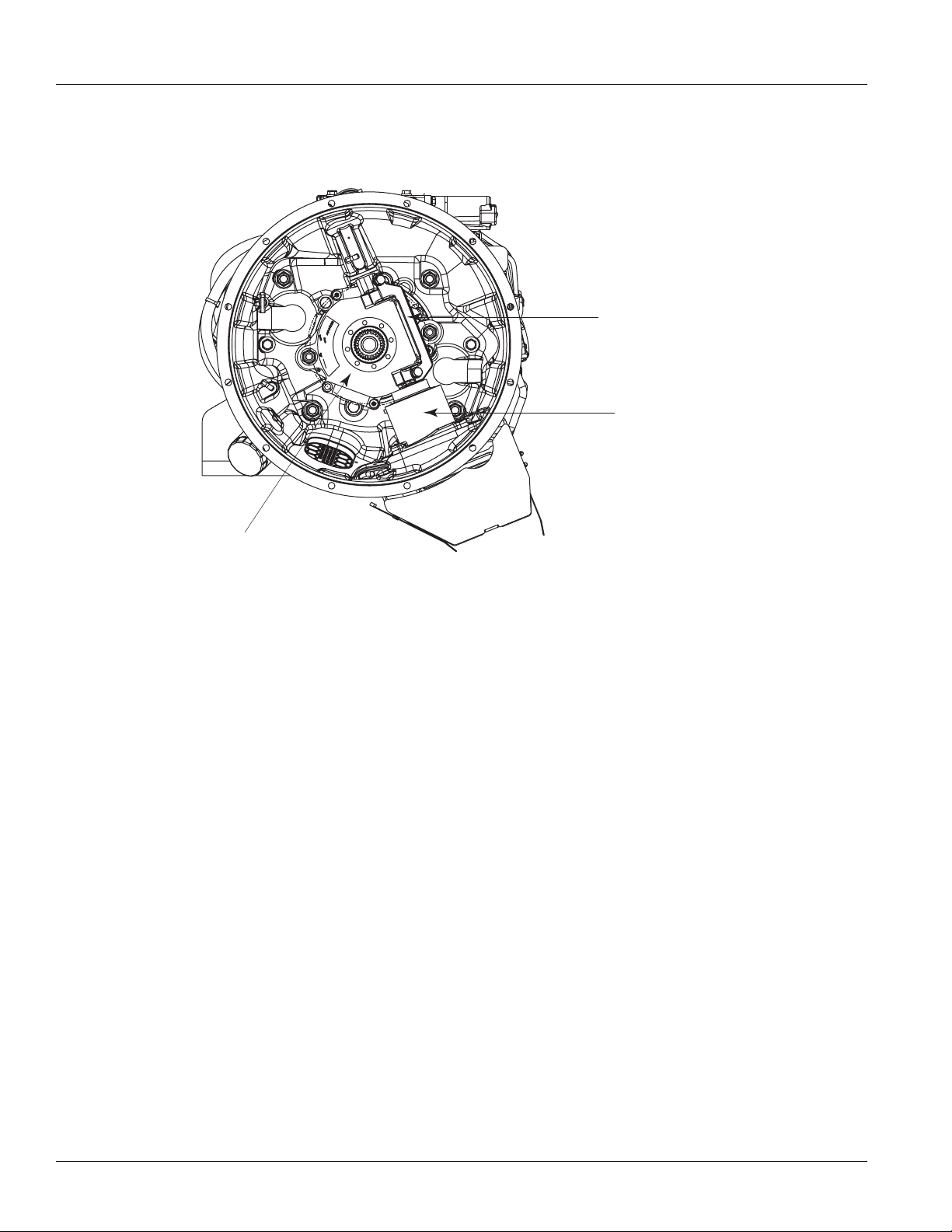

Page 8

TRSM0930 General Information | Transmission Overview

Heavy-Duty 8LL / VCS & 9ALL / VMS

Release Yoke and

Cross-shaft Assembly

Electronic Clutch

Actuator (ECA)

Low Capacity

Inertia Brake (LCIB)

2013.05.30

© 2013 Eaton. All rights reserved

4

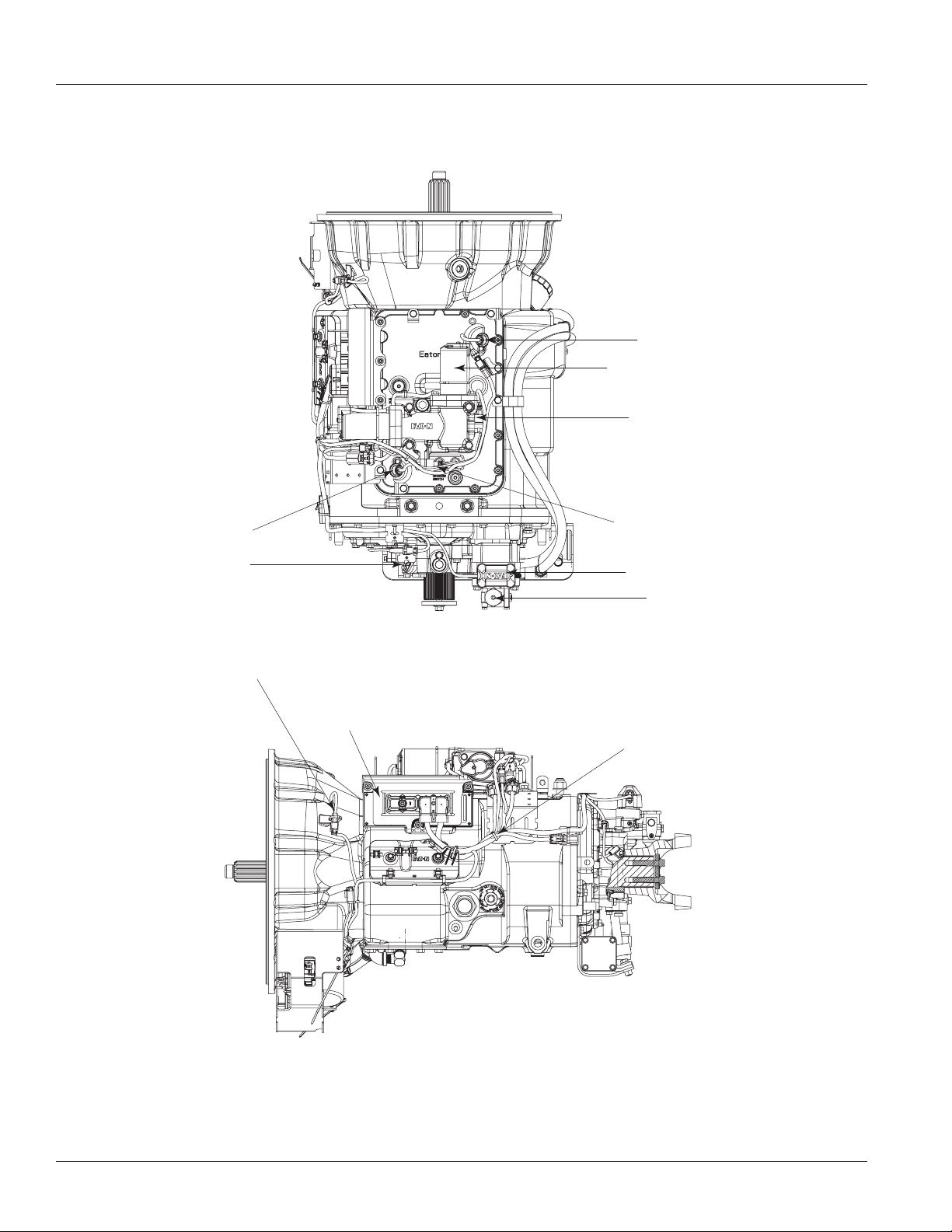

Page 9

Transmission Overview | General Information TRSM0930

Heavy-Duty 10-Speed LAS/VAS

Input Shaft Speed Sensor

Electric Shifter

Gear Select Sensor

Main Shaft

Speed Sensor

Output Shaft

Speed Sensor

Flywheel Speed Sensor

(Shipping Location)

Rail Select Sensor

Range Valve Solenoid

Air Filter Regulator

Transmission ECU

Transmission Harness

5

© 2013 Eaton. All rights reserved

2013.05.30

Page 10

TRSM0930 General Information | Transmission Overview

Heavy-Duty 10-Speed LAS/VAS

Release Yoke and

Cross-shaft Assembly

Electronic Clutch

Actuator (ECA)

Low Capacity

Inertia Brake (LCIB)

2013.05.30

© 2013 Eaton. All rights reserved

6

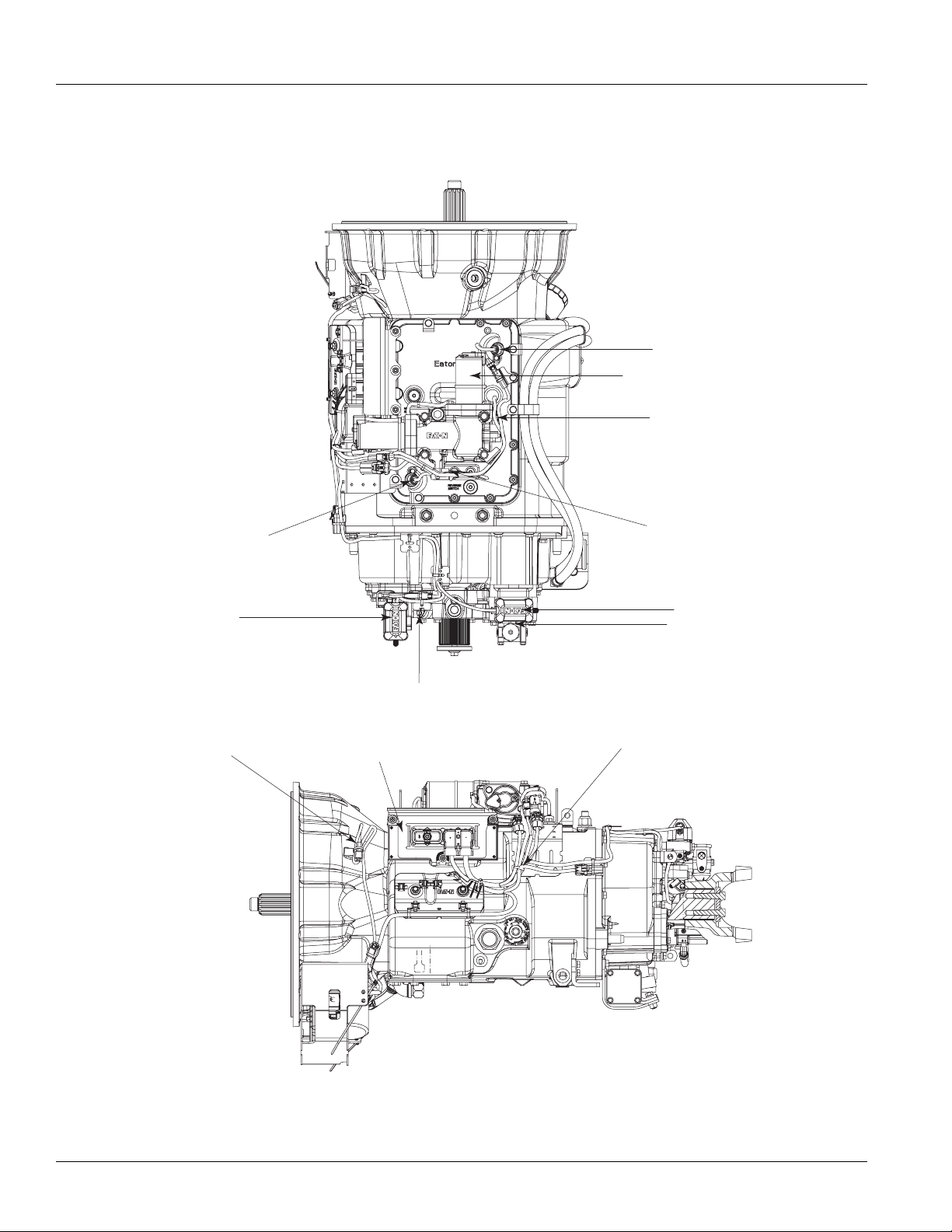

Page 11

Transmission Overview | General Information TRSM0930

Heavy-Duty 13-Speed MHP/VHP, 16-Speed LSE

& 18-Speed VXP/MXP

Input Shaft Speed Sensor

Electric Shifter

Gear Select Sensor

Mainshaft

Speed Sensor

Splitter Valve

Solenoid

Flywheel S

(Shipping Location)

peed Sensor

Rail Select Sensor

Range Valve Solenoid

Air Filter Regulator

Output Shaft

Speed Sensor

Transmission Harness

Transmission ECU

7

© 2013 Eaton. All rights reserved

2013.05.30

Page 12

TRSM0930 General Information | Transmission Overview

Heavy-Duty 13-Speed MHP/VHP, 16-Speed LSE

& 18-Speed VXP/MXP

Release Yoke and

Cross-shaft Assembly

Electronic Clutch

Actuator (ECA)

Low Capacity

Inertia Brake (LCIB)

2013.05.30

© 2013 Eaton. All rights reserved

8

Page 13

Transmission Overview | General Information TRSM0930

Heavy-Duty 13-Speed DM3 & 18-Speed AS3

Input Shaft

Speed Sensor

Electric Shifter

Gear Select Sensor

Main Shaft

Speed Sensor

Splitter Valve Solenoid

Transmission ECU

Rail Select Sensor

Range Valve Solenoid

Air Filter Requlator

Output Shaft Speed Sensor

Transmission Harness

Inertia Brake

(13-Speed DM3 Only)

9

© 2013 Eaton. All rights reserved

2013.05.30

Page 14

TRSM0930 General Information | Transmission Overview

Air Filter Regulator

Range Valve Solenoid

Rail Select Sensor

Gear Select Sensor

Electric Shifter

Input Shaft

Speed Sensor

Output Shaft

Speed Sensor

Main Shaft

Speed Sensor

Transmission ECU

Inertia Brake

(10-Speed DM3 Only)

Transmission Harness

Heavy-Duty 10-Speed AS3 & DM3

2013.05.30

© 2013 Eaton. All rights reserved

10

Page 15

Transmission Overview | General Information TRSM0930

Output Shaft

Speed Sensor

Rail Select Sensor

Gear Select Sensor

Electric Shifter

Transmission ECU

Inertia Brake

Input Shaft

Speed Sensor Location

Transmission Harness

Medium-Duty 6 & 5-Speed DM3

11

© 2013 Eaton. All rights reserved

2013.05.30

Page 16

TRSM0930 General Information | Transmission Overview

Electric Shifter

Gear Select Sensor

Rail Select Sensor

Output Shaft

Speed Sensor

Transmission ECU

Inertia Brake

Input Shaft

Speed Sensor Location

Wetclutch Solenoid

Connector

Oil Pan and Filters

Transmission Harness

Medium-Duty 6-Speed AW3

2013.05.30

© 2013 Eaton. All rights reserved

12

Page 17

Transmission Overview | General Information TRSM0930

Medium-Duty 6-Speed PV

Electric Shifter

Transmission ECU

Gear Select

Sensor

Rail Select

Sensor

Output Shaft

Speed Sensor

Transmission

Harness

Inertia

Brake

Input Shaft

Speed Sensor

13

© 2013 Eaton. All rights reserved

2013.05.30

Page 18

TRSM0930 General Information | Transmission Overview

ECA

Electronic Clutch

Actuator (ECA)

Release Yoke

& Cross-Shaft

Assembly

Medium-Duty 6-Speed PV

2013.05.30

© 2013 Eaton. All rights reserved

14

Page 19

Serial Tag Information and Model Nomenclature | General Information TRSM0930

Model

Serial

Eaton

Transmissions

R

Made In

RTLO-16913L-DM3

Eaton Corporation

Transmission Div.

Kalamazoo, MI. 49003

Fuller

R

Serial Tag Information and Model Nomenclature

Transmission model designation and other transmission

identification information are stamped on the serial tag. To

identify the transmission model and serial number, locate

the tag on the transmission and then locate the numbers as

shown. The figure below shows the tag location for these

transmissions.

When calling for service assistance or parts, have the

model and serial numbers handy.

Do not remove or destroy the transmission identification

tag!

Serial Number

The serial number is the sequential identification number of

the transmission. Before calling for service assistance,

write the number down as it may be needed.

Bill of Material or Customer Number

This number may be located below the model and serial

numbers. It is a reference number used by Eaton®.

Model Number

The model number gives basic information about the transmission and is explained below. Use this number when calling for service assistance or replacement parts.

15

© 2013 Eaton. All rights reserved

2013.05.30

Page 20

TRSM0930 General Information | Serial Tag Information and Model Nomenclature

R

Roadranger

Twi n Countershaft

Overdrive

TO-

Torque x 100

Design Level

Generation 3 Electronics

Gear Ratio

Forward Speeds

1X 109 X-

DM3

10-Speed

Automatic

w/DM Autoclutch

Roadranger

Twi n Countershaft

Overdrive

Torque x 100

Design Level

R T O -1X 9 10 X-AS3

Generation 3 Electronics

AutoShift

Gear Ratio

Forward Speeds

F

Fuller

Overdrive

- 3

Torque x 100

Design Level

Generation 3 Electronics

Gear Ratio

Forward Speeds

X406X-DM

Automatic

w/DM Autoclutch

X

Roadranger

Twi n Countershaft

Low-Inertia

Overdrive

R T L O M-1X9 13 X-DM3

Gen 3 Electronics

Automatic w/DM Autoclutch

Gear Ratio

Forward Speeds

Design Level

Torque x 100

1750 lb.ft. Torque in

Top Two Gears Only

3

Fuller

Overdrive

Torque x 100

Design Level

Automatic with WetClutch

Gear Ratio

Forward Speeds

FX X 064-

X-

A W

Generation 3 Electronics

10-Speed

6-Speed

6-Speed

13-Speed

F

Fuller

Overdrive

- 3

Torque x 100

Design Level

Generation 3 Electronics

Gear Ratio

Forward Speeds

X405X-DM

Automatic

w/DM Autoclutch

X

5-Speed

Roadranger

Twi n Countershaft

Low-Inertia

Overdrive

R T L O-1X9 18 X-AS 3

Gen 3 Electronics

AutoShift

Gear Ratio

Forward Speeds

Design Level

Torque x 100

18-Speed

Transmission Tag

2013.05.30

© 2013 Eaton. All rights reserved

16

Page 21

Serial Tag Information and Model Nomenclature | General Information TRSM0930

6-Speed

10-Speed

10-Speed

Brand - Eaton

Overdrive

Nominal Torque Lb. Ft.

Nominal Torque Lb. Ft.

X 100 + 50

Configuration

Design Level

Mechicanical & Electronic

Brand - Fuller

Overdrive

Nominal Torque Lb. Ft.

X 100 + 50

Starting Device

(Clutch Type)

Design Level

Mechicanical & Electronic

Brand - Fuller

Overdrive

Multi-Torque

X 100 + 50

Starting Device

(Clutch Type)

Design Level

Mechicanical & Electronic

E

O

F

F

O

1XE406 B

-

O

M

1XE308 LL-

-

1XE310 C-

PV

Passenger

Vehicle

Ratio Set

Number of Speeds

VCS

Construction

Series

UltraShift

Vocational

Ratio Set

Number of Speeds

LAS

Active

Shifting

UltraShift

Line Haul

Ratio Set

Number of Speeds

10-Speed

11-Speed

13-Speed

Brand - Fuller

Overdrive

Multi-Torque

Nominal Torque Lb. Ft.

Nominal Torque Lb. Ft.

X 100 + 50

Starting Device

(Clutch Type)

Design Level

Mechicanical & Electronic

Brand - Fuller

Overdrive

X 100 + 50

Starting Device

(Clutch Type)

Design Level

Mechicanical & Electronic

Brand - Fuller

Overdrive

Nominal Torque Lb. Ft.

X 100 + 50

Starting Device

(Clutch Type)

Design Level

Mechicanical & Electronic

F

O

F

O

F

1XE310 C-

M

1XE309ALL-

-

O

1XE313A-

-

VAS

Active

Shifting

UltraShift

Vocational

Ratio Set

Number of Speeds

VMS

Mixer

Series

UltraShift

Vocational

Ratio Set

Number of Speeds

MHP

High Performance

UltraShift

Multipurpose

Ratio Set

Number of Speeds

17

© 2013 Eaton. All rights reserved

2013.05.30

Page 22

TRSM0930 General Information | Serial Tag Information and Model Nomenclature

F

Brand - Fuller

Overdrive

M

-

X 100 + 50

Nominal Torque Lb. Ft.

Starting Device

(Clutch Type)

UltraShift

Linehaul

Ratio Set

Number of Speeds

1XE316B-

LSE

Small Step

Efficiency

Design Level

Mechicanical & Electronic

16-Speed

F

Brand - Fuller

Overdrive

O

-

X 100 + 50

Nominal Torque Lb. Ft.

Starting Device

(Clutch Type)

UltraShift

Multipurpose

Ratio Set

Number of Speeds

1XE318 B-

MXP

Xtreme Performance

Design Level

Mechicanical & Electronic

18-Speed

F

Brand - Fuller

Overdrive

O

-

X 100 + 50

Nominal Torque Lb. Ft.

Starting Device

(Clutch Type)

UltraShift

Multipurpose

Ratio Set

Number of Speeds

1XE318 B-

MXP

Xtreme Performance

Design Level

Mechicanical & Electronic

F

Brand - Fuller

Overdrive

O

-

X 100 + 50

Nominal Torque Lb. Ft.

Starting Device

(Clutch Type)

UltraShift

Vocational

Ratio Set

Number of Speeds

1XE313A-

VHP

High Performance

Design Level

Mechicanical & Electronic

13-Speed

18-Speed

2013.05.30

© 2013 Eaton. All rights reserved

18

Page 23

Clutch Greasing Guidelines | General Information TRSM0930

!

Clutch Greasing Guidelines

Caution: It is highly important to follow proper clutch lube

intervals as specified in Lubrication Manual

TCMT0021. Failure to do so may result in clutch

failure and unnecessary repairs.

The heavy-duty ECA clutch housing has 2 grease fittings on

the lower right side. The upper port is marked “CS” for the

upper cross-shaft assembly, while the lower port is marked

“RB” for the release bearing.

For more detailed cross-shaft greasing information refer to

the Release Yoke and Cross-shaft Installation section of this

manual. Refer to Clutch Service Manual CLSM0200, for

release bearing greasing information.

ServiceRanger Procedure

Grease Interval Count Reset

The Heavy-Duty UltraShift PLUS has an optional prognostic

feature that notifies the operator when the Clutch Release

Bearing needs greasing. This feature can be enabled or dis

abled via ServiceRanger.

At the appropriate grease interval and shortly after each

engine start, “GI” will momentarily appear in the gear dis

play, along with an audible tone. This will continue to occur

at each engine start until clutch service has been com

pleted.

Note: “GI” stands for grease interval and may be misread

as “G1”on gear display.

The operator can choose to follow this automated lube

schedule or the published lube guidelines in the Lubrication

Manual TCMT0021. When enabled, it is highly important to

reset the grease interval count every time the Release Bear

ing is greased.

The grease interval count can be reset via ServiceRanger or

Operator-Triggered Special Function.

-

-

-

-

19

© 2013 Eaton. All rights reserved

2013.05.30

Page 24

TRSM0930 General Information | Clutch Greasing Guidelines

Operator Triggered Procedure

2013.05.30

© 2013 Eaton. All rights reserved

20

Page 25

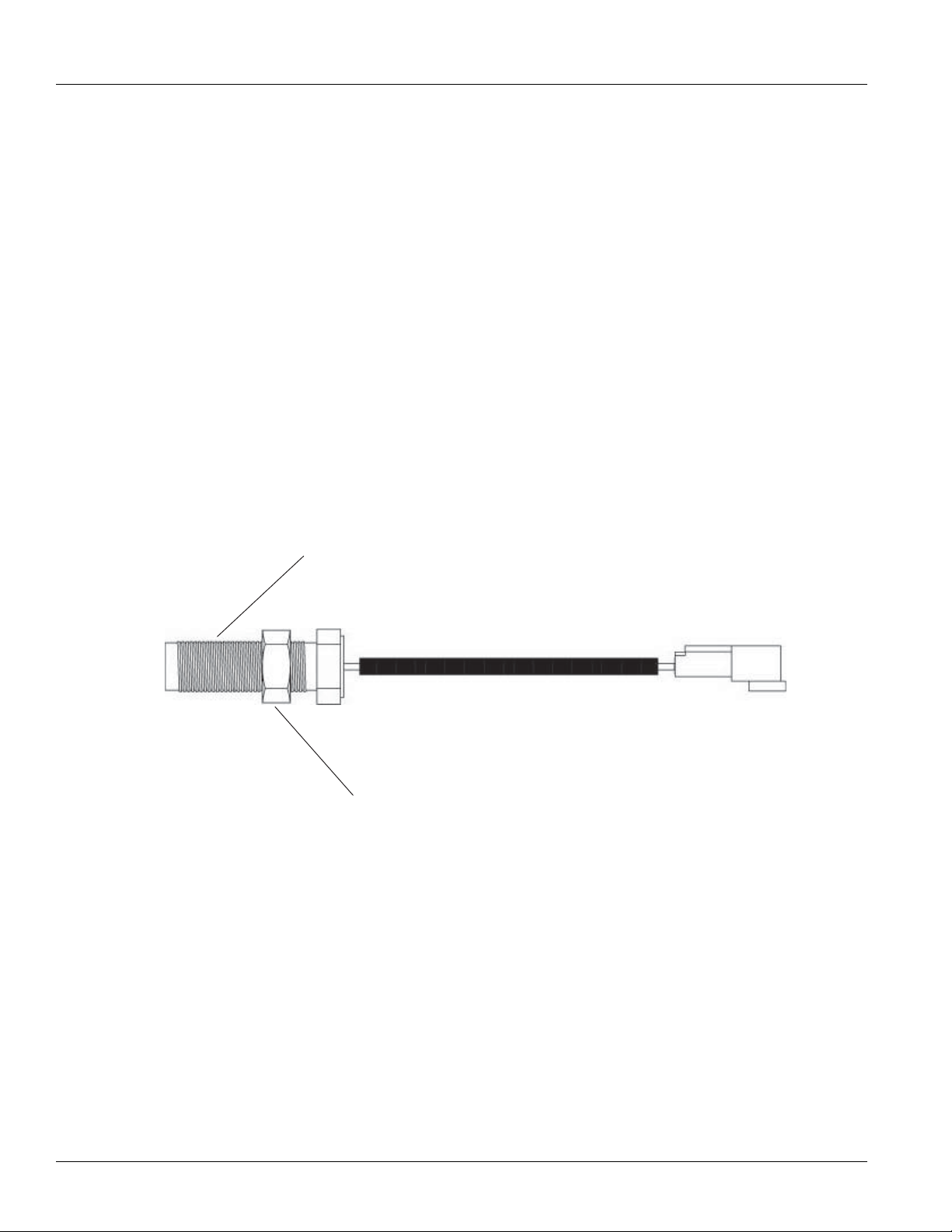

Thread-In ECA Speed Sensor | Service Procedure TRSM0930

1

2

Thread-In ECA Speed Sensor

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

23

1. Sensor

2. Jam Nut

© 2013 Eaton. All rights reserved

2013.05.30

Page 26

TRSM0930 Service Procedure | Thread-In ECA Speed Sensor

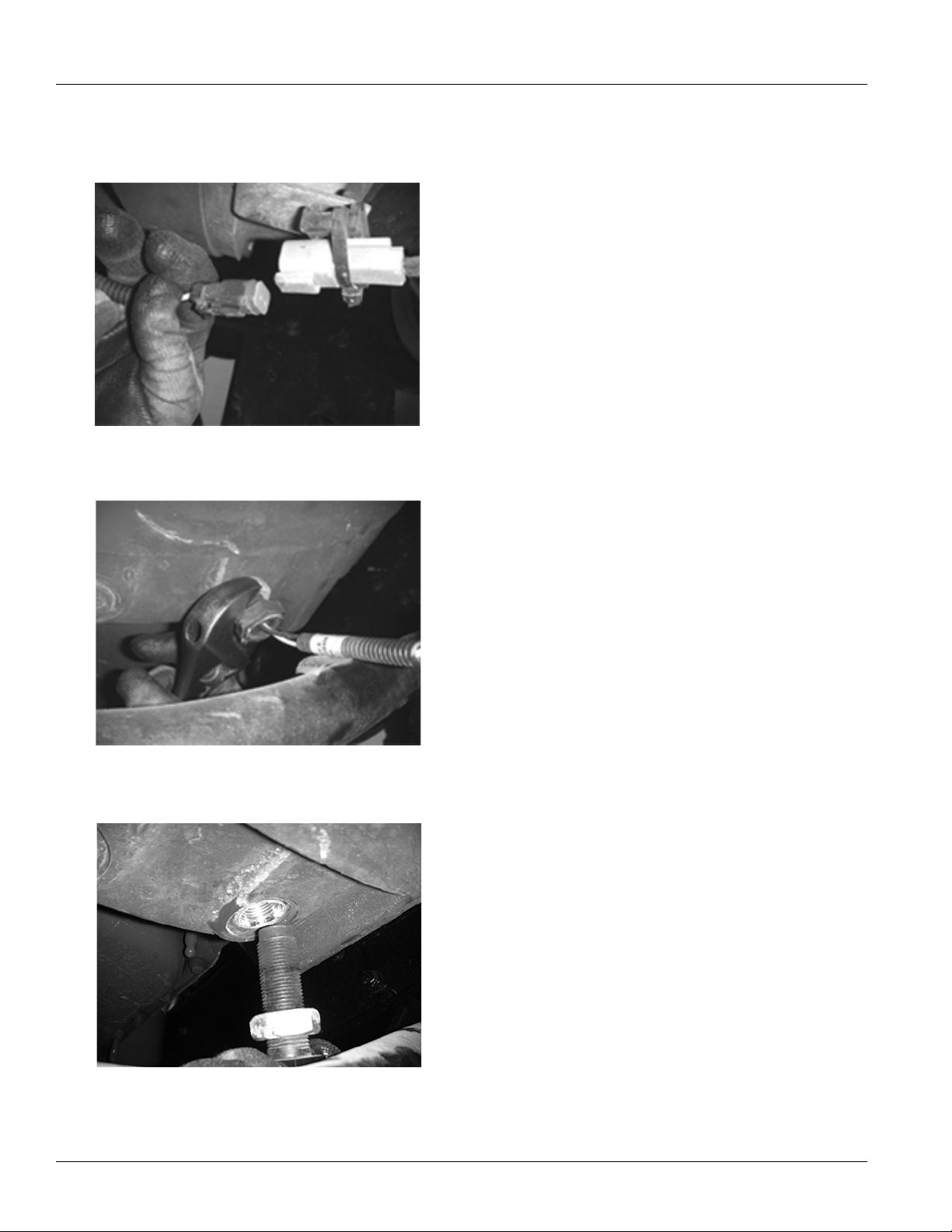

Procedure - Removal

1. Disconnect ECA Speed Sensor Connector.

2. Loosen jam nut on ECA.

3. Rotate sensor counterclockwise to remove it.

2013.05.30

© 2013 Eaton. All rights reserved

24

Page 27

Thread-In ECA Speed Sensor | Service Procedure TRSM0930

Procedure - Installation

1. Thread Speed Sensor into the Engine Bell Housing until

it touches the flywheel.

2. After the sensor touches the flywheel, rotate it counter-

clockwise 1/2 to 1 full turn.

3. Hold the sensor in place and tighten the 3/4”-16 jam

nut to 15 lb-ft. (20.3 Nm).

4. Apply included material to low-voltage 4-way harness

connector terminals.

Note: Apply just enough material to cover the end of

the terminal.

Note: Use only Eaton lubricant part number 5564527.

(Nye Lubricants NYOGEL 760G. For MSDS safety

or other information see www.nyelubri

-

cants.com).

5. Connect Engine Speed Sensor Connector to the mating

connector on the transmission and fasten harness, if

needed.

25

© 2013 Eaton. All rights reserved

2013.05.30

Page 28

TRSM0930 Service Procedure | Thread-In ECA Speed Sensor

2013.05.30

© 2013 Eaton. All rights reserved

26

Page 29

Electronic Clutch Actuator (ECA) | Service Procedure TRSM0930

Electronic Clutch Actuator (ECA)

Special Instructions

If vehicle is equipped with an 8-bolt PTO, removal may be

required prior to removing the ECA. Follow PTO manufac

turer’s guidelines for removal.

Component Identification

Special Tools

-

Basic hand tools

1. Bracket Cap Screw

2. ECA Cap Screw

3. ECA

4. 8-Way Connector

5. 3-Way Connector

6. ECA Shield (Optional)

27

© 2013 Eaton. All rights reserved

2013.05.30

Page 30

TRSM0930 Service Procedure | Electronic Clutch Actuator (ECA)

!

Procedure - Removal

Warning: Ensure the Hand Hole Cover is closed when

removing the ECA.

1. Disconnect the negative battery cable.

2. Disconnect the 8-way and 3-way connectors from the

ECA.

Note: Some models do not use a shield.

3. Remove the 4 cap screws from the ECA shield and

remove shield.

Note: Medium-duty models are mounted with 3 cap

screws and 1 lock nut.

4. Remove the 4 cap screws from the ECA mounting

flange.

5. Remove the ECA.

Note: The ECA has an alignment pin that requires the

unit to be rotated to exit the clutch housing bore.

Note: If ECA will not slide from the clutch housing after

all the fasteners are removed, use the available

pusher holes found on both sides of the ECA

casting. Place the included jackscrews into the

holes. Turn each jackscrew until it touches. Next,

turn the upper jackscrew 1 turn; then rotate to

the lower jackscrew and rotate it 1 turn. Continue

until the ECA is fully displaced from the bore.

2013.05.30

© 2013 Eaton. All rights reserved

28

Page 31

Electronic Clutch Actuator (ECA) | Service Procedure TRSM0930

Procedure - Installation

1. Install the ECA into the clutch housing bore. Align it

with the lower cross-shaft.

Note: The ECA will have to be rotated to align with the

slot in the Clutch Housing.

Note: Ensure you rotate the Release Yoke as close to

the Case Dowel in the Clutch Housing prior to

mating with the cross-shaft. This allows the

Release Yoke to clear the Release Bearing during

installation.

2. Install the 4 cap screws from the ECA Mounting Flange.

Tighten them to 35-45 lb-ft. (47-61 Nm).

3. If applicable, install the 4 cap screws for the ECA

shield. Tighten them to 35-45 lb-ft. (47-61 Nm).

4. Apply NyoGel to terminals and reconnect the 8-way

and 3-way connectors to the ECA.

Note: Apply just enough material to cover the end of

the terminal.

Note: Use only Eaton lubricant part number 5564527

(Nye Lubricants NYOGEL 760G. For MSDS safety

or other information see www.nyelubri

-

cants.com.)

Note: Medium-duty models are mounted with 3 cap

screws and 1 lock nut. Tighten to 35-45 lb-ft. (47-61

Nm).

Note: The cap screws for the ECA are longer than the

ECA Bracket cap screws.

Note: Ensure the ECA does not bind on the cross-shaft

by snugging all cap screws before tightening to

the specified torque.

5. Reconnect the negative 12-volt battery cable.

6. If previously removed, install the 8-bolt PTO after ECA

installation. Follow the PTO manufacturer’s guidelines

for installation instructions.

29

© 2013 Eaton. All rights reserved

2013.05.30

Page 32

TRSM0930 Service Procedure | Electronic Clutch Actuator (ECA)

2013.05.30

© 2013 Eaton. All rights reserved

30

Page 33

Low Capacity Inertia Brake | Service Procedure TRSM0930

1

2

Low Capacity Inertia Brake

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

1. Mounting Nut

2. Low Capacity Inertia Brake (LCIB)

31

© 2013 Eaton. All rights reserved

2013.05.30

Page 34

TRSM0930 Service Procedure | Low Capacity Inertia Brake

Procedure - Removal

Note: The Transmission and ECA must be removed prior to

removing the LCIB.

1. Remove the 2 mounting nuts with a breaker bar and

socket.

2. Remove the LCIB by hand by sliding off of the splined

Input Shaft.

2013.05.30

© 2013 Eaton. All rights reserved

32

Page 35

Low Capacity Inertia Brake | Service Procedure TRSM0930

Procedure - Installation

1. Slide the LCIB onto the splined Input Shaft while cen-

tering the holes onto the retaining studs.

2. Install the 2 retaining nuts and torque nuts to 140-150

lb-ft. (190-203 Nm).

Note: The LCIB can only be installed one way. The label

is toward the right side of the vehicle and facing

the flywheel.

33

© 2013 Eaton. All rights reserved

2013.05.30

Page 36

TRSM0930 Service Procedure | Low Capacity Inertia Brake

2013.05.30

© 2013 Eaton. All rights reserved

34

Page 37

Release Yoke and Cross-shaft(s) | Service Procedure TRSM0930

Release Yoke and Cross-shaft(s)

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

1

2

3

4

5

1. Plug

2. O-ring

3. Upper Cross-shaft

4. Bushing

5. Seal

6. Lock Washer

7. Mounting Screw

8. Release Yoke

9. Lower Cross-shaft

6

7

8

9

35

© 2013 Eaton. All rights reserved

2013.05.30

Page 38

TRSM0930 Service Procedure | Release Yoke and Cross-shaft(s)

Procedure - Removal

Note: The Transmission and ECA must be removed prior to

removing the Release Yoke and Cross-shaft(s).

1. Remove the upper and lower Cross-Shaft Mounting

cap screws and lock washers from the Release Yoke.

2. Remove the lower Cross-Shaft and Release Yoke.

3. Remove the upper Cross-Shaft.

4. If necessary, remove the Cross-Shaft Plug with o-ring.

2013.05.30

5. If necessary, remove the upper Cross-Shaft Seal

© 2013 Eaton. All rights reserved

assembly.

36

Page 39

Release Yoke and Cross-shaft(s) | Service Procedure TRSM0930

6. If necessary, remove the 2 upper Cross-Shaft bush-

ings.

37

© 2013 Eaton. All rights reserved

2013.05.30

Page 40

TRSM0930 Service Procedure | Release Yoke and Cross-shaft(s)

Procedure - Installation

1. If previously removed, install the 2 upper Cross-shaft

bushings.

Note: Make sure to apply grease to the bushings.

2. If previously removed, install the upper Cross-shaft

grease seal.

3. If previously removed, install the o-ring onto the

Cross-shaft plug and then install the Cross-shaft plug

into the transmission housing and torque to 34-48

lb-ft. (46-65 Nm).

4. Install the upper Cross-shaft into the bore.

2013.05.30

© 2013 Eaton. All rights reserved

38

Page 41

Release Yoke and Cross-shaft(s) | Service Procedure TRSM0930

5. Slide yoke onto upper Cross-shaft assembly and install

1 cap screw and lock washer by hand.

6. Install lower Cross-shaft assembly and install 1 cap

screw and lock washer by hand.

8. Grease upper Cross-shaft assembly until grease

purges from the bleed hole in the upper Cross-shaft

boss.

7. Tighten the 2 Yoke cap screws to 35-45 lb-ft. (47-61

Nm).

39

© 2013 Eaton. All rights reserved

2013.05.30

Page 42

TRSM0930 Service Procedure | Release Yoke and Cross-shaft(s)

2013.05.30

© 2013 Eaton. All rights reserved

40

Page 43

Cobra Lever | Service Procedure TRSM0930

1

2

3

4

Cobra Lever

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

1. Tower

2. Screw

3. 8-Way Cobra Lever Harness Connector

41

© 2013 Eaton. All rights reserved

2013.05.30

Page 44

TRSM0930 Service Procedure | Cobra Lever

Procedure - Removal

1. Using a Phillips screwdriver, remove the 4 screws from

the Cobra Lever housing.

2. Disconnect the 8-way Cobra Lever Harness connector

and remove the Cobra Lever from the housing.

2013.05.30

© 2013 Eaton. All rights reserved

42

Page 45

Cobra Lever | Service Procedure TRSM0930

Procedure - Installation

1. Connect the 8-way Cobra Lever Harness connector and

place the Cobra Lever into the tower.

2. Using a Phillips screwdriver install the 4 screws into

the Cobra Lever housing.

43

© 2013 Eaton. All rights reserved

2013.05.30

Page 46

TRSM0930 Service Procedure | Cobra Lever

2013.05.30

© 2013 Eaton. All rights reserved

44

Page 47

Shift Control | Service Procedure TRSM0930

Shift Control

Special Instructions

The exact location varies depending on vehicle manufacturer.

Component Identification

Special Tools

Basic hand tools

5

4

1. Nut

2. Washer

3. Push Button Shift Control 30-Way Connector

4. Backing Plate

5. Push Button Shift Control

3

2

1

45

© 2013 Eaton. All rights reserved

2013.05.30

Page 48

TRSM0930 Service Procedure | Shift Control

Procedure - Removal

1. Using a 1/4” socket, loosen the retaining bolt and dis-

connect the 30-way connector from the back of the

Shift Control.

2. Using a 11/32” wrench, remove the 2 nuts and lock

washers from the back of the Shift Control and remove

the Shift Control.

Note: Shift Control location and use varies with each

truck.

2013.05.30

© 2013 Eaton. All rights reserved

46

Page 49

Shift Control | Service Procedure TRSM0930

Procedure - Installation

1. Install the Shift Control in the mounting location. Then,

using a 11/32” wrench, install the 2 lock washers and

nuts and tighten to 14-16 lb-in. (18–21 Nm).

2. Using a 1/4” wrench, reconnect the 30-way connector

to the back of the Shift Control and tighten to 10 +/- 3

lb-in. [13.5 +/- 4 Nm]

47

© 2013 Eaton. All rights reserved

2013.05.30

Page 50

TRSM0930 Service Procedure | Shift Control

2013.05.30

© 2013 Eaton. All rights reserved

48

Page 51

Medium-Duty Transmission Harness | Service Procedure TRSM0930

Medium-Duty Transmission Harness

Special Instructions

None

Component Identification

Medium-Duty

7

Special Tools

Basic hand tools

2

3

9

4

8

1

5

1. Transmission ECU 38-way Connector

2. Gear Sensor Connector

3. Rail Sensor Connector

4. Future position of 4-way Transmission Diagnostic Connector

5. Input Shaft Speed Sensor Connector

6. Inertia Brake Connector

7. Wet Clutch Solenoid Connector (AW3 only)

8. Output Shaft Speed Sensor Connector

9. Electric Shifter Connector

6

49

© 2013 Eaton. All rights reserved

2013.05.30

Page 52

TRSM0930 Service Procedure | Medium-Duty Transmission Harness

!

!

Procedure - Removal

Caution: The battery negative must be disconnected prior

to unhooking the Transmission ECU (TECU)

38-way Connectors.

Caution: Do not allow contamination into the TECU or con-

nectors.

1. Using a 5/32” hex wrench, disconnect the Transmis-

sion Harness 38-way Connector.

2. Disconnect the following harness connectors:

• Inertia Brake Coil (if equipped)

• Input Shaft Speed Sensor

• Gear Select Sensor and Rail Select Sensor

• Wet clutch solenoid (AW3 only)

• Output Shaft Speed Sensor (location may vary)

• 4-way Transmission Diagnostic connector

• Electric Shifter

2013.05.30

© 2013 Eaton. All rights reserved

50

Page 53

Medium-Duty Transmission Harness | Service Procedure TRSM0930

!

!

!

!

!

!

Procedure - Installation

Caution: Do not allow contamination into the TECU Connec-

tors.

Caution: Do not over tighten tie-downs.

Caution: Leave a service loop in the Transmission Harness.

Caution: Do not put sharp bends in the Transmission Har-

ness.

Caution: The battery negative must be disconnected while

installing the TECU connectors.

1. Reconnect the following harness connectors:

• Gear Select and Rail Select Sensor

• Input Shaft Speed Sensor

• Inertia Brake Coil

• Output Shaft Speed Sensor

• 4-way Transmission Diagnostic connector

• Electric Shifter

• Wet clutch solenoid (AW3 only)

2. Using a 5/32” hex wrench, reconnect the Transmission

Harness 38-way Connector and tighten to 22–28 lb-in.

(29–37 Nm).

Caution: Do not exceed the torque on the Transmission

Harness or Vehicle Harness Connector or bolt

failure will occur.

51

© 2013 Eaton. All rights reserved

2013.05.30

Page 54

TRSM0930 Service Procedure | Medium-Duty Transmission Harness

2013.05.30

© 2013 Eaton. All rights reserved

52

Page 55

Heavy-Duty Transmission Harness | Service Procedure TRSM0930

1

2

3

4

5

7

8

10

11

6

9

Heavy-Duty Transmission Harness

Special Instructions

None

Special Tools

Basic hand tools

Component Identification

Heavy-Duty LAS/VAS Models

5

9

12

7

10

3

2

11

1

8

11

4

6

1. Transmission ECU 38-way Connector

2. Gear Sensor Connector

3. Rail Sensor Connector

4. 4-way Transmission Diagnostic Connector

5. Input Shaft Speed Sensor Connector

6. Inertia Brake Connector (DM3 models)

7. Range Solenoid Connector

8. Output Shaft Speed Sensor Connector

9. Splitter Solenoid Connector (13-,18-speeds only)

10. Mainshaft Speed Sensor Connector

11. Electric Shifter Connector

1. ECU 38-way Connector

2. Gear Sensor Connector

3. Rail Sensor Connector

4. 4-way Diagnostic Connector

5. Input Shaft Speed Sensor Connector

6. ECA 8-way Connector

7. Range Solenoid Connector

8. Output Shaft Speed Sensor Connector

9. Engine Speed Sensor Connector

10. Mainshaft Speed Sensor

11. Electric Shifter Connector

12. Terminating Resistor Connector

53

© 2013 Eaton. All rights reserved

2013.05.30

Page 56

TRSM0930 Service Procedure | Heavy-Duty Transmission Harness

6

13

12

1

11

4

8

3

10

11

2

5

7

9

VMS and VCS Models LSE, MHP/VHP and MXP/VXP Models

7

1. ECU 38-way Connector

2. Gear Sensor Connector

3. Rail Sensor Connector

4. 4-way Diagnostic Connector

5. Input Shaft Speed Sensor Connector

6. ECA 8-way Connector

7. Range Solenoid Connector

8. Output Shaft Speed Sensor Connector

9. Reduction Solenoid Connector

10. Mainshaft Speed Sensor

11. Electric Shifter Connector

12. Engine Speed Sensor Connector

13. Terminating Resistor Connector

10

5

2

3

8

11

12

1

11

9

4

6

13

1. ECU 38-way Connector

2. Gear Sensor Connector

3. Rail Sensor Connector

4. 4-Way Diagnostic Connector

5. Input Shaft Speed Sensor Connector

6. ECA 8-way Connector

7. Range Solenoid Connector

8. Output Shaft Speed Sensor Connector

9. Splitter Solenoid Connector

10. Mainshaft Speed Sensor

11. Electric Shifter Connector

12. Engine Speed Sensor Connector

13. Terminating Resistor Connector

2013.05.30

© 2013 Eaton. All rights reserved

54

Page 57

Heavy-Duty Transmission Harness | Service Procedure TRSM0930

!

!

Procedure - Removal

Caution: The battery negative must be disconnected prior

to unhooking the TECU 38-way connectors.

Caution: Do not allow contamination into the TECU or con-

nectors.

1. Disconnect the following connectors:

• Using a 5/32” hex wrench, unscrew and disconnect

the Transmission Harness 38-way Connector and

Vehicle Interface 38-way Connector.

2. Disconnect the following harness connectors:

• Inertia Brake Coil (if equipped)

• Input Shaft Speed Sensor

• Main Shaft Speed Sensor

• Gear Select Sensor and Rail Select Sensor

• Output Shaft Speed Sensor

• Range and Splitter Valve Solenoids

• 4-way Transmission Diagnostic connector

• Electric Shifter

55

© 2013 Eaton. All rights reserved

2013.05.30

Page 58

TRSM0930 Service Procedure | Heavy-Duty Transmission Harness

!

!

!

!

!

!

Procedure - Installation

Caution: Do not allow contamination into the TECU connec-

tors.

Caution: Do not over tighten tie-raps.

Caution: You need to leave a service loop in the Transmis-

sion Harness.

Caution: Do not put sharp bends in the Transmission Har-

ness.

Caution: The battery negative must be disconnected, while

installing the TECU connectors.

1. Reconnect the following harness connectors:

• Gear Select and Rail Select Sensor

• Main Shaft Speed Sensor

• Input Shaft Speed Sensor

• Inertia Brake Coil (if equipped)

• Output Shaft Speed Sensor

• 4-way Transmission Diagnostic Connector

• Electric Shifter

• Range and Splitter Valve Solenoids

2. Using a 5/32” hex wrench, reconnect the Transmission

Harness 38-way Connector and tighten to 25 +/- 3

lb-in. (2.82 +/- 0.33 Nm).

Caution: Do not exceed the torque on the Transmission

Harness or Vehicle Harness Connector or bolt

failure will occur.

2013.05.30

© 2013 Eaton. All rights reserved

56

Page 59

Medium-Duty Transmission Electronic Control Unit (TECU) | Service Procedure TRSM0930

1

2

3

Medium-Duty Transmission Electronic Control Unit (TECU)

Special Instructions

None

Component Identification

Medium-Duty

Special Tools

Basic hand tools

1. Cap Screw

2. Transmission ECU (TECU)

3. 38-way Connectors

4. Cap Screw (Located inside 38-way connectors)

57

© 2013 Eaton. All rights reserved

2013.05.30

Page 60

TRSM0930 Service Procedure | Medium-Duty Transmission Electronic Control Unit (TECU)

!

!

Procedure - Removal

Caution: The battery negative must be disconnected prior

to unhooking the Transmission ECU (TECU)

38-way connectors.

Caution: Do not allow contamination into the TECU or con-

nectors.

1. Connect ServiceRanger to vehicle and record current

configuration settings before removing the TECU from

the transmission. (Refer to “ServiceRanger User

Guide” TCMT-0071 for more information.)

2. Disconnect the following connectors:

• Using a 5/32” hex wrench, unscrew and disconnect

the Transmission Harness 38-way Connector and

Vehicle Interface 38-way Connector.

4. Remove the Transmission Controller assembly from

the locating studs.

3. Using a 7/16” socket, remove the 3 mounting bolts.

2013.05.30

© 2013 Eaton. All rights reserved

58

Page 61

Medium-Duty Transmission Electronic Control Unit (TECU) | Service Procedure TRSM0930

!

!!!

Procedure - Installation

Caution: Battery negative must remain disconnected until

the TECU 38-way connectors are installed.

Caution: Do not allow contamination into the TECU or con-

nectors.

1. Position the Transmission Controller on the locating

studs.

2. Using a 7/16” socket, install the 3 Transmission Con-

troller mounting bolts and tighten to 7-9 lb-ft.

(9.5-12.2 Nm).

3. Reconnect the following connectors:

Caution: Do not exceed the torque on the Transmission

Harness or Vehicle Harness Connector or bolt

failure will occur.

• Using a 5/32” wrench, reconnect the Transmission

Harness 38-way Connector and tighten to 25 +/- 3

lb-in. (2.82 +/- 0.33 Nm).

• Using a 5/32” wrench, reconnect the Vehicle Inter-

face 38-way Connector and tighten to 25 +/- 3 lb-in.

(2.82 +/- 0.33 Nm).

• Reconnect the negative battery cable.

4. To operate properly, the system must be calibrated as

follows:

Important: The Electric Shifter must be calibrated

before the vehicle is placed in operation.

• Turn ignition switch on. Allow the transmission to

power up.

• Turn ignition off and wait 2 minutes.

Note: UltraShift AW3- Perform clutch calibration:

“Clutch Calibration” on page 143.

5. Connect ServiceRanger to vehicle and compare

recorded configuration settings (step 1 in removal pro

cess) to the replacement TECU. Update and save all

configurations that are different. (Refer to “Ser

viceRanger User Guide” TCMT-0071 for more information.)

-

-

59

© 2013 Eaton. All rights reserved

2013.05.30

Page 62

TRSM0930 Service Procedure | Medium-Duty Transmission Electronic Control Unit (TECU)

2013.05.30

© 2013 Eaton. All rights reserved

60

Page 63

Heavy-Duty Transmission Electronic Control Unit (TECU) | Service Procedure TRSM0930

1

23

4

Heavy-Duty Transmission Electronic Control Unit (TECU)

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

1. Nut

2. Bracket

3. Transmission ECU (TECU)

4. 38-Way Connectors

5. Cap Screw (Located inside 38-way connectors)

61

© 2013 Eaton. All rights reserved

2013.05.30

Page 64

TRSM0930 Service Procedure | Heavy-Duty Transmission Electronic Control Unit (TECU)

!

!

Procedure - Removal

Caution: The battery negative must be disconnected prior

to unhooking the Transmission ECU (TECU)

38-way connectors.

Caution: Do not allow contamination into the TECU or con-

nectors.

1. Connect ServiceRanger to vehicle and record current

configuration settings before removing the TECU from

the transmission. (Refer to “ServiceRanger User

Guide” TCMT-0071 for more information.)

2. Disconnect the following connectors:

• Using a 5/32” hex wrench, unscrew and disconnect

the Transmission Harness 38-way Connector and

Vehicle Interface 38-way Connector.

4. Remove the Transmission Controller Retaining

Bracket.

5. Remove the Transmission Controller assembly from

the locating studs.

3. Using a 7/16” socket, remove the 3 mounting nuts.

2013.05.30

© 2013 Eaton. All rights reserved

62

Page 65

Heavy-Duty Transmission Electronic Control Unit (TECU) | Service Procedure TRSM0930

!

!

!

Procedure - Installation

Caution: Battery negative must remain disconnected until

the TECU 38-Way connectors are installed.

Caution: Do not allow contamination into the TECU or con-

nectors.

1. Position the Transmission Controller on the locating

studs.

2. Place the Transmission Controller retaining bracket

over the TECU.

3. Using a 7/16” socket, install the 3 Transmission Con-

troller mounting nuts and tighten to 7-9 lb-ft. (9.5-12.2

Nm).

4. Reconnect the following connectors:

Caution: Do not exceed the torque on the Transmission

Harness or Vehicle Harness Connector or bolt

failure will occur.

• Using a 5/32” wrench, reconnect the Transmission

Harness 38-way Connector and tighten to 25 +/- 3

lb-in. (2.82 +/- 0.33 Nm).

• Using a 5/32” wrench, reconnect the Vehicle Inter-

face 38-way Connector and tighten to 25 +/- 3 lb-in.

(2.82 +/- 0.33 Nm).

• Reconnect the negative battery cable.

63

© 2013 Eaton. All rights reserved

2013.05.30

Page 66

TRSM0930 Service Procedure | Heavy-Duty Transmission Electronic Control Unit (TECU)

!

5. Connect ServiceRanger to vehicle and compare

recorded configuration settings (step 1 in removal pro

cess) to the replacement TECU. Update and save all

configurations that are different. (Refer to “Ser

viceRanger User Guide” TCMT0071 for more information.)

6. To operate properly, the system must be calibrated as

follows:

Important: The Electric Shifter must be calibrated

before the vehicle is placed in operation.

a. Turn ignition switch on. Allow transmission to

power up.

b. Turn ignition off. Wait 2 minutes.

2013.05.30

© 2013 Eaton. All rights reserved

64

Page 67

Electric Shifter | Service Procedure TRSM0930

1

2

3

Electric Shifter

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

1. Cap Screw

2. Electric Shifter

3. Gasket

65

© 2013 Eaton. All rights reserved

2013.05.30

Page 68

TRSM0930 Service Procedure | Electric Shifter

!

Procedure - Removal

1. Remove nylon cable ties from motor wires. Disconnect

Transmission Harness from the Rail Select Sensor and

the Gear Select Sensor.

2. Disconnect the Rail Select and Gear Select Motors

from the Transmission ECU (TECU).

3. Using a 9/16” socket, remove the 4 mounting cap

screws.

4. Remove X-Y Shifter and gasket.

Warning: Possible Pinch Point - Ensure battery is dis-

connected before removing X-Y Shifter.

2013.05.30

© 2013 Eaton. All rights reserved

66

Page 69

Electric Shifter | Service Procedure TRSM0930

Procedure - Installation

1. Ensure Shift Blocks are in the neutral position, then

move Shift Finger to the center (neutral) location.

Note: If the Shift Finger is not properly aligned, the X-Y

Shifter will not fit properly at its mounting location.

2. Clean and remove old gasket material from Shift Bar

Housing. Then, install new gasket on the Shift Bar

Housing.

Note: Apply Eaton sealant part number 71205 or equiv-

alent to the mounting cap screws before installing.

3. The dowel pin on the X-Y Shifter must be aligned with

hole in the Shift Bar Housing (used only on 10-, 13and 18-Speed models).

4. Position X-Y Shifter on the Shift Bar Housing. Using a

9/16” socket, install mounting cap screws and tighten

in a cross pattern as follows:

• 5- and 6-Speed (aluminum housing)- Tighten to

20-25 lb-ft. (27-34 Nm).

• 10- 13- and 18-Speed (cast iron housing) - Tighten

to 34-45 lb-ft. (45-60 Nm).

67

© 2013 Eaton. All rights reserved

2013.05.30

Page 70

TRSM0930 Service Procedure | Electric Shifter

!

5. Reconnect the Rail Select Sensor and Gear Select Sen-

sor.

6. Reconnect the Transmission Harness to the Rail Select

and Gear Select motors. Using nylon ties, secure

motor wires to the transmission in their previous posi

tion.

7. To operate properly, the system must be calibrated as

follows:

Important: X-Y Shifter must be calibrated before the

vehicle is placed into operation.

• Turn ignition switch on. Allow the transmission to

power up.

• Turn ignition switch off. Wait 2 minutes.

-

2013.05.30

© 2013 Eaton. All rights reserved

68

Page 71

Medium-Duty Inertia Brake | Service Procedure TRSM0930

Medium-Duty Inertia Brake

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

5

4

3

2

1. Cap Screw

2. Inertia Brake

3. Gasket

4. Spacer (Used on all Medium-Duty ratios except the “N”)

5. Gasket (Used on all Medium-Duty ratios except the “N”)

1

69

© 2013 Eaton. All rights reserved

2013.05.30

Page 72

TRSM0930 Service Procedure | Medium-Duty Inertia Brake

!

Procedure - Removal

1. Drain the lubrication from transmission and disconnect

the Transmission Harness from the Input Shaft Speed

Sensor and Inertia Brake Coil.

2. Using a 3/8” wrench, remove Input Shaft Speed Sen-

sor.

3. Using a 7/8” wrench, remove the lubricant supply line

from the transmission.

4. Using a 9/16” wrench, remove the 6 mounting bolts

from the Inertia Brake.

Caution: The Inertia Brake is heavy. Be prepared to

handle the weight of the Inertia Brake when

mounting bolts are removed.

2013.05.30

© 2013 Eaton. All rights reserved

70

Page 73

Medium-Duty Inertia Brake | Service Procedure TRSM0930

5. Remove the Inertia Brake, gaskets and spacer (depend-

ing on model) from the transmission.

Note: The Inertia Brake will contain some lubricant.

Note: The spacer and extra gasket are used on all

transmission ratios except the N.

71

© 2013 Eaton. All rights reserved

2013.05.30

Page 74

TRSM0930 Service Procedure | Medium-Duty Inertia Brake

!

Procedure - Installation

Warning: The Inertia Brake is heavy. Be prepared to handle

weight of the Inertia Brake until mounting bolts

are installed.

1. Install Inertia Brake, gaskets and spacer (depending on

model) being careful to align the Inertia Brake gear

with the drive gear.

Note: The spacer and extra gasket are used on all

transmission ratios except N.

3. Using a 7/8” wrench, reconnect Inertia Brake lubricant

supply line to the transmission and tighten to 20-22

lb-ft. (27-29 Nm).

4. Using a 3/8” wrench, install Input Shaft Speed Sensor

and tighten to 8-12 lb-ft. (11-16 Nm).

2. Using a 9/16” socket, install the 6 mounting bolts.

Tighten mounting bolts to 35-45 lb-ft. (47-60 Nm)

using a cross pattern.

2013.05.30

© 2013 Eaton. All rights reserved

72

Page 75

Medium-Duty Inertia Brake | Service Procedure TRSM0930

5. Reconnect the Transmission Harness to Input Shaft

Speed Sensor and Inertia Brake Coil.

Note: Fill transmission with lubricant See “Lubrication

Specifications” on page 141.

73

© 2013 Eaton. All rights reserved

2013.05.30

Page 76

TRSM0930 Service Procedure | Medium-Duty Inertia Brake

2013.05.30

© 2013 Eaton. All rights reserved

74

Page 77

Air Filter Regulator | Service Procedure TRSM0930

2

1

Air Filter Regulator

Special Instructions

The Air Filter Regulator has 2 o-rings located between the

Air Filter/Regulator and the Range or Combination Cylinder

Cover.

Component Identification

Special Tools

Basic hand tools

1. Air Filter Regulator

2. Cap Screw

75

© 2013 Eaton. All rights reserved

2013.05.30

Page 78

TRSM0930 Service Procedure | Air Filter Regulator

Procedure - Removal

1. Relieve system air pressure by draining all air tanks on

the vehicle. Then, remove the vehicle air supply line

from the Air Filter Regulator.

2. Using a 7/16” socket, remove the 2 mounting cap

screws.

3. Remove the Air Filter Regulator assembly.

Note: Be careful not to let the o-rings drop out of the

Range or Combination Cylinder Cover when removing

the Air Filter Regulator.

2013.05.30

© 2013 Eaton. All rights reserved

76

Page 79

Air Filter Regulator | Service Procedure TRSM0930

!

Procedure - Installation

Important: Lubricate o-rings with Eaton Fuller silicone

71214 or Equivalent.

1. If removed, press the two o-rings into the recesses in

the Range or Combination Cylinder Cover.

Note: Apply Eaton Fuller sealant 71205 or equivalent to

the two (2) mounting cap screws.

2. Using a 7/16” socket, install the 2 mounting cap

screws and tighten to 8-12 lb-ft. (11-16 Nm).

3. Reinstall the vehicle air supply line to the Air Filter Reg-

ulator and close all air tank drains.

Note: Hold the Air Filter Regulator flush with the Range

Cylinder Cover until in place to prevent the

o-rings from dropping out.

77

© 2013 Eaton. All rights reserved

2013.05.30

Page 80

TRSM0930 Service Procedure | Air Filter Regulator

2013.05.30

© 2013 Eaton. All rights reserved

78

Page 81

Heavy-Duty Inertia Brake | Service Procedure TRSM0930

Heavy-Duty Inertia Brake

Special Instructions

None

Component Identification

Special Tools

Basic hand tools

3

2

1. Cap Screw

2. Inertia Brake

3. Gasket

79

1

© 2013 Eaton. All rights reserved

2013.05.30

Page 82

TRSM0930 Service Procedure | Heavy-Duty Inertia Brake

!

Procedure - Removal

1. Drain the lubricant from the transmission and discon-

nect the Transmission Harness from the Inertia Brake

Coil.

2. Using a 7/8” wrench, disconnect the Inertia Brake

lubricant supply line from the transmission.

3. Using a 9/16” socket, remove the 6 mounting bolts

from the Inertia Brake.

Caution: The Inertia Brake is heavy. Be prepared to

handle the weight of the Inertia Brake when

the mounting bolts are removed.

4. Remove the Inertia Brake and gasket from the trans-

mission.

2013.05.30

© 2013 Eaton. All rights reserved

80

Page 83

Heavy-Duty Inertia Brake | Service Procedure TRSM0930

!

Procedure - Installation

Warning: The Inertia Brake is heavy. Be prepared to handle

the weight of the Inertia Brake until the mounting

bolts are installed.

1. Clean and remove all old gasket material. Then, install

the Inertia Brake and new gasket, being careful to align

the Inertia Brake gear with the drive gear.

2. Using a 9/16” socket, install the 6 mounting bolts.

Tighten mounting bolts to 35-45 lb-ft. (47-60 Nm)

using a cross pattern.

3. Using a 7/8” wrench, reconnect the Inertia Brake lubri-

cant supply line to the transmission and tighten to

20-22 lb-ft. (27-29 Nm).

4. Reconnect the Transmission Harness to the Inertia

Brake Coil.

Note: Fill the transmission with lubricant. See “Lubrication Specifications” on page 141..

81

© 2013 Eaton. All rights reserved

2013.05.30

Page 84

TRSM0930 Service Procedure | Heavy-Duty Inertia Brake

2013.05.30

© 2013 Eaton. All rights reserved

82

Page 85

Combination Valves (Range and Deep Reduction) | Service Procedure TRSM0930

Combination Valves (Range and Deep Reduction)

Special Instructions

Torques given below are in lb-in.

Component Identification

Special Tools

Basic hand tools

1. Protective Cover (Optional)

2. Cap Screw

3. Valve

4. O-rings

83

© 2013 Eaton. All rights reserved

2013.05.30

Page 86

TRSM0930 Service Procedure | Combination Valves (Range and Deep Reduction)

!

Procedure - Removal

Note: Follow same procedure for the removal of Deep

Reduction or Range Valve.

1. If equipped, remove Protective Cover by pulling up on

the Release Tab.

2. Relieve system air pressure by draining air tanks on

the vehicle. When air pressure has been relieved, dis

connect the Transmission Harness from the Valve.

-

3. Using a 5/16” socket, remove the 4 mounting cap

screws from the valve.

4. Lift and remove the valve from the housing.

Caution: Do not use a hammer to loosen the valve in

the housing or it could be damaged.

Note: The harness should be removed from the Valve

tie-down prior to removing the cap screws.

2013.05.30

© 2013 Eaton. All rights reserved

84

Page 87

Combination Valves (Range and Deep Reduction) | Service Procedure TRSM0930

!

!

Procedure - Installation

Important: Lubricate o-rings with Eaton Fuller silicone

71214 or equivalent.

Important: The valve is keyed to fit its mounting location.

Take care to align the key in the valve with the

notch in the housing.

Note: Follow same procedure for installing the Deep Reduc-

tion Valve or Range Valve.

1. Install and push the valve down into the housing.

3. Reconnect the Transmission Harness to the valve and

close all air tanks drains.

Note: Install the Range Harness back into the tie-down

on the valve.

4. If equipped, install the Protective Cover. Push the cover

down by hand until it snaps into place.

2. Using a 5/16” socket, install the valve mounting cap

screws and tighten to 21-27 lb-in. (2.3-3.0 Nm) using a

cross pattern.

85

© 2013 Eaton. All rights reserved

2013.05.30

Page 88

TRSM0930 Service Procedure | Combination Valves (Range and Deep Reduction)

2013.05.30

© 2013 Eaton. All rights reserved

86

Page 89

Range Valve | Service Procedure TRSM0930

Range Valve

Special Instructions

The Range Valve may be difficult to remove from the Transmission Housing because of the o-rings.

Component Identification

Special Tools

Basic hand tools

1. Protective Cover (Optional)

2. Cap Screw

3. Valve

4. O-rings

87

© 2013 Eaton. All rights reserved

2013.05.30

Page 90

TRSM0930 Service Procedure | Range Valve

!

Procedure - Removal

1. If equipped, remove the Protective Cover by pulling up

on the Release Tab.

2. Relieve system air pressure by draining air tanks on

the vehicle. When air pressure has been relieved, dis

connect the Transmission Harness from the Range

Valve.

Note: The harness should be removed from the Range

Valve tie-down prior to removing the cap screws.

-

3. Using a 5/16” socket, remove the 4 mounting cap

screws from the Range Valve.

4. Lift and remove the Range Valve from the housing.

Caution: Do not use a hammer to loosen the Range

Valve in the housing or it could be damaged.

2013.05.30

© 2013 Eaton. All rights reserved

88

Page 91

Range Valve | Service Procedure TRSM0930

!

!

Procedure - Installation

Important: Lubricate o-rings with Eaton Fuller silicone

71214 or equivalent.

Important: The valve is keyed to fit its mounting location.

Take care to align the key with the notch in the

housing.

1. Install and push the Range Valve down into the hous-

ing.

3. Reconnect the Transmission Harness to the Range

Valve and close all air tanks drains.

Note: Install the Range Harness back into the tie-down

on the Range Valve.

4. If equipped, install the Protective Cover. Push the cover

down by hand until it snaps into place.

2. Using a 5/16” socket, install the 4 Range Valve mount-

ing cap screws and tighten to 21-27 lb-in. (2.3-3.0 Nm)

using a cross pattern.

89

© 2013 Eaton. All rights reserved

2013.05.30

Page 92

TRSM0930 Service Procedure | Range Valve

2013.05.30

© 2013 Eaton. All rights reserved

90

Page 93

Splitter Valve | Service Procedure TRSM0930

Splitter Valve

Special Instructions

The Splitter Valve may be difficult to remove from the housing because of the o-rings.

Component Identification

Special Tools

Basic hand tools

1. Protective Cover (Optional)

2. Cap Screw

3. Valve

4. O-rings

91

© 2013 Eaton. All rights reserved

2013.05.30

Page 94

TRSM0930 Service Procedure | Splitter Valve

!

Procedure - Removal

1. If equipped, remove Protective Cover by pulling up on

the Release Tab.

2. Relieve system air pressure by draining the air tanks

on the vehicle. When air pressure is relieved, discon

nect the Transmission Harness from the Splitter Valve

assembly.

Note: The harness should be removed from the Splitter

Valve tie-down, prior to removing the cap

screws.

-

3. Using a 5/16” wrench, remove the 4 mounting cap

screws from the Splitter Valve.

4. Lift and remove the Splitter Valve from the housing.

Caution: Do not use a hammer to loosen the Splitter

Valve in the housing or it could be damaged.

2013.05.30

© 2013 Eaton. All rights reserved

92

Page 95

Splitter Valve | Service Procedure TRSM0930

!

!

Procedure - Installation

Important: Lubricate o-rings with Eaton Fuller silicone

71214 or equivalent.

Important: The valve is keyed to fit its mounting location.

Take care to align the key with the notch in the

housing.

1. Install and push the Splitter Valve down into the hous-

ing.

3. Reconnect the Transmission Harness to the Splitter

Valve and close all air tank drains.

Note: Install the Splitter Harness back into the

tie-down on the Splitter Valve.

4. If equipped, install the Protective Cover. Push the cover

down by hand until it snaps into place.

2. Using a 5/16” wrench, install the 4 mounting cap

screws and tighten to 21-27 lb-in.(2.3-3.0 Nm) using a

cross pattern.

93

© 2013 Eaton. All rights reserved

2013.05.30

Page 96

TRSM0930 Service Procedure | Splitter Valve

2013.05.30

© 2013 Eaton. All rights reserved

94

Page 97

Directional Output Shaft Speed Sensor | Service Procedure TRSM0930

Directional Output Shaft Speed Sensor

Special Instructions

The Directional Output Shaft Speed Sensor is used on the

Fuller® UltraShift® PLUS model transmissions. The Out

put Shaft Speed Sensor location may vary depending on

OEM design specifications. The sensor will be located at 10

o’clock on the Output Shaft Housing in heavy-duty models

and 12 o’clock on the Output Shaft Housing in

medium-duty models.

Special Tools

Basic hand tools

-

95

© 2013 Eaton. All rights reserved

2013.05.30

Page 98

TRSM0930 Service Procedure | Directional Output Shaft Speed Sensor

1

2

Component Identification

1. Cap Screw

2. Sensor with Harness

2013.05.30

© 2013 Eaton. All rights reserved

96

Page 99

Directional Output Shaft Speed Sensor | Service Procedure TRSM0930

Procedure - Removal

1. Disconnect the Transmission Harness from the Output

Shaft Speed Sensor Pigtail Connector.

2. Remove the Sensor Retaining Bolt.

3. Remove the Speed Sensor from the Transmission Rear

Bearing Cover.

97

© 2013 Eaton. All rights reserved

2013.05.30

Page 100

TRSM0930 Service Procedure | Directional Output Shaft Speed Sensor

!

Procedure - Installation

Important: Lubricate Sensor with Eaton lubricant 5564527.

1. Using a smooth, twisting motion, fully insert the Out-

put Shaft Speed Sensor in the transmission housing

opening.

2. Install the Retaining Bolt and tighten to 8-10 lb-ft.

(11-13 Nm).

4. Reconnect the Transmission Harness to the Output

Shaft Speed Sensor and install the tie-down.

3. Apply included material to the Sensor Connector termi-

nals.

Note: Apply just enough material to cover the end of

the terminal.

Note: Use only Eaton lubricant 5564527. (Nye Lubri-

cants NYOGEL 760G - For MSDS safety or other

information see www.nyelubricants.com)

2013.05.30

© 2013 Eaton. All rights reserved

98

Loading...

Loading...