Page 1

Troubleshooting Guide

Fuller Heavy-Duty Transmissions

TRTS0011 EN-US

October 2007

RTLO-11118A-MT

RTLO-9118A-MT

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Page 4

Introduction

WARNING................................................................................................................2

Complaint Isolation, Verification & Remedy Procedure.............................................3

How to Use this Troubleshooting Guide...................................................................4

Complaint Diagnosis

Fault Code Diagnosis..............................................................................................6

Symptom Driven Diagnosis.....................................................................................7

Pre-Test

Transmission Electrical Test....................................................................................8

Performance Evaluation

Performance Evaluation Test.................................................................................10

Testing Procedures

Power Relay Coil Test..............................................................................................12

System Voltage Test................................................................................................13

Inertia Brake Solenoid Coil Test...............................................................................15

Inertia Brake Test....................................................................................................17

Inertia Brake Switch Test.........................................................................................18

Inertia Brake Air Supply Test...................................................................................19

Transmission Converter Open Lamp Test................................................................20

Engine Speed Sensor Test......................................................................................21

Bypass/Lockup Solenoid Coil Test..........................................................................23

Interrupt Clutch Solenoid Coil Test..........................................................................25

Hydraulic System Test............................................................................................27

Input Shaft Speed Sensor Test...............................................................................29

Output Shaft Speed Sensor Test.............................................................................31

Table of Contents

Appendix I

System Overview....................................................................................................33

Electrical Schematic................................................................................................34

Wiring Diagram (fold-out page)

1

Page 5

Introduction

• Before starting a vehicle always be seated in the driver’s seat,

move the shift lever to neutral, and set the parking brakes.

• If engine cranks in any other gear than neutral, service your vehicle neutral safety start circuit and start enable relay circuit immediately.

• Before working on a vehicle or leaving the cab with engine running, place the transmission in neutral, set the parking brakes,

AND block the wheels.

• Do not release the parking brake or attempt to select a gear until

the air pressure is at the correct level.

• For safety reasons, always engage the service brakes when moving the shift lever from neutral to one of the other gear positions.

• When parking the vehicle or leaving the cab, always place the shift

lever in neutral and set the parking brakes.

• TOWING: To avoid damage to the transmission during towing,

place the transmission in neutral and lift the drive wheels off the

ground or disconnect the driveline.

Every effort has been made to ensure the accuracy of all information in this manual. However, Eaton

Transmission Division makes no expressed or implied warranty or representation based on the

enclosed information. Any errors or omissions may be reported to Training and Publications, Eaton

Transmission Division, P.O. Box 4013, Kalamazoo, MI 49003

2

Page 6

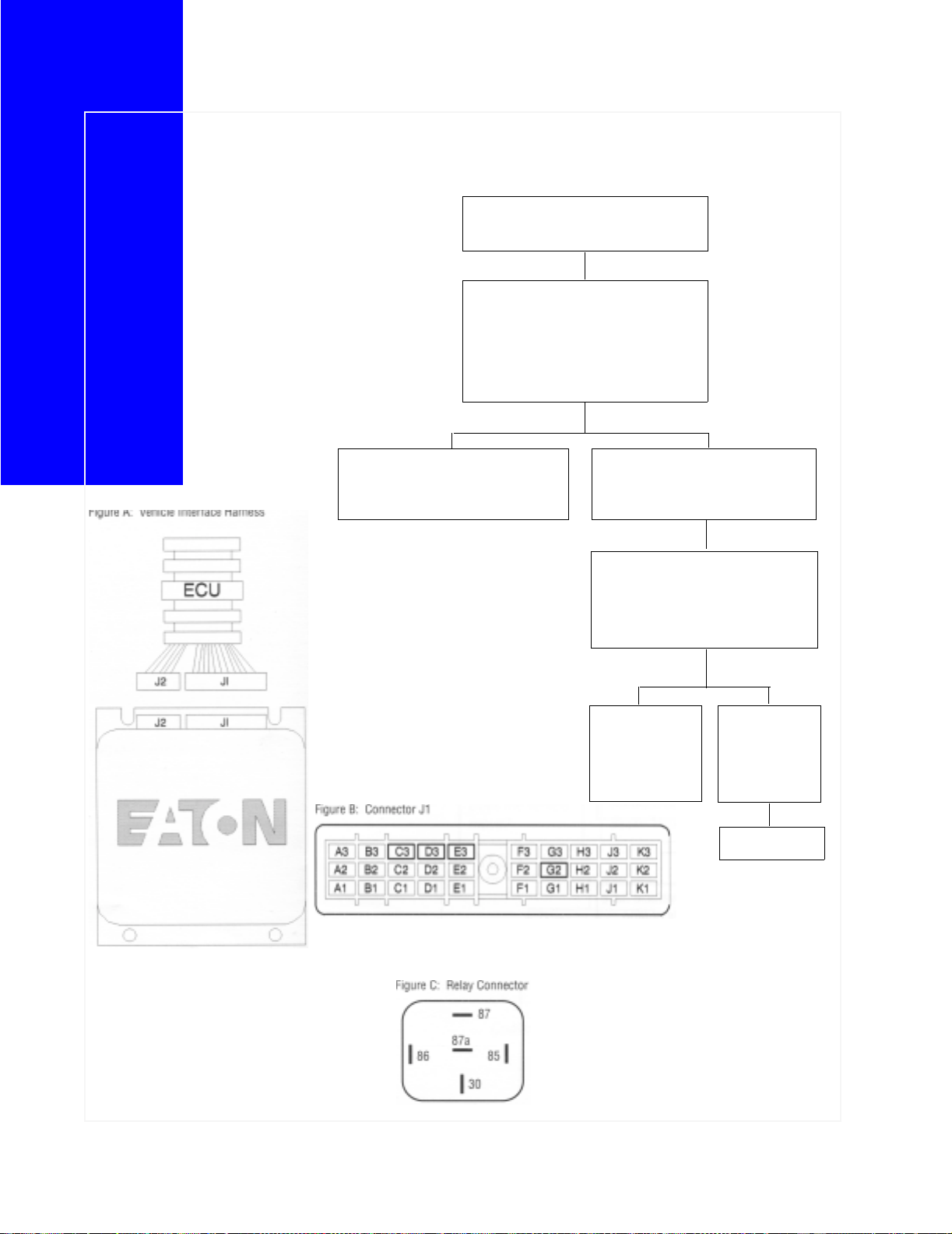

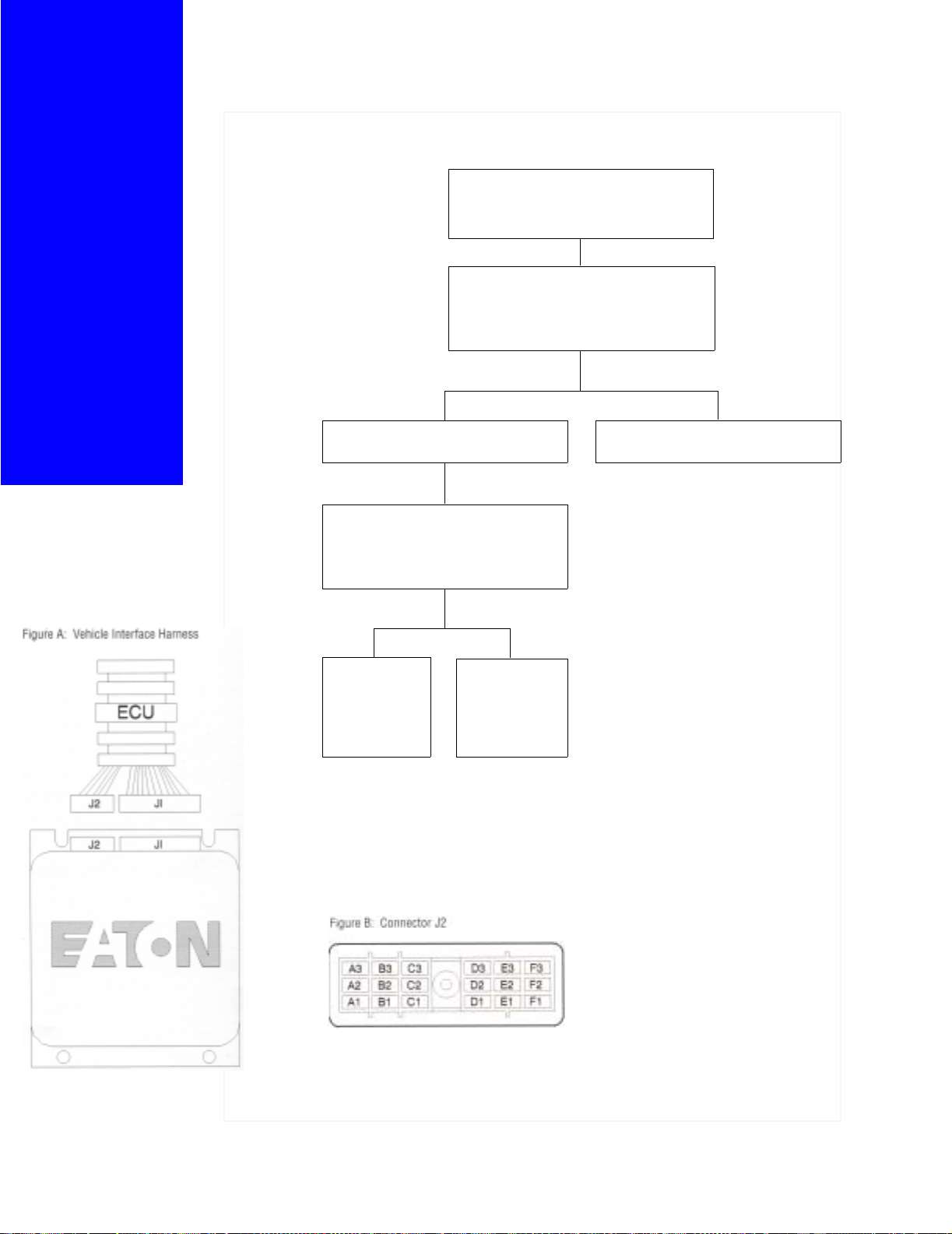

Complaint Isolation, Verification & Remedy Procedure

Complaint

Identify System Error via Fault Codes

Using: Service Transmission Light

Service Transmission LIght

Able to Identify Fault Codes Observe and Record

Symptoms

Introduction

Utilize Trouble Shooting Guide

Fault Code Diagnosis

Isolate System or Component Failure

Follow Trouble Shooting Guide Test Sequences

PASS

Follow Trouble Shooting Guide

Remedy Sequence Instructions

Next Step in Trouble Shooting Guide

as Required for Further Diagnosis or Repair

Utilize Trouble Shooting guide

Symptom Driven Diagnosis

FAIL

Proceed to

Re-Test

3

Page 7

Introduction

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

How To Use this Troubleshooting Guide

The purpose of this manual is to assist in the diagnosis and verification of your

electronically managed heavy-duty transmission system. It should be used in

conjunction with Eaton Driver Instructions, Illustrated Parts List, Installation

Guide, and Service Manual -- as well as OEM service related material.

This guide provides three functions:

1. Service Transmission Light Diagnostics: designed to lead the service techni-

cian to the source of a problem through flashing error codes.

2. Performance Evaluation: designed to lead the service technician to the source

of a problem through a performance evaluation.

3. Test and remedy Sequences: detailed component testing designed to isolate

and resolve system failures.

Service Transmission Light Diagnostics

The Service Transmission indicator light, which is also the torque converter

open lamp, assists the mechanic in problem diagnosis via flashing signals equal

to Fault Code numbers as listed in the Fault Codes Diagnosis section of this

manual.

If a driver reports a degraded mode of operation, advise that the capabilities of

the truck should be assessed and then taken to a service site. The transmission

temperature should be monitored during the trip to the service site.

Examples of potential problem conditions under which a vehicle with a Converter Enhanced Mechanical Transmission can be driven include:

• Transmission fails to lock torque converter, but vehicle can still proceed although

speed and/or power is limited.

• Transmission is not able to select all ratios and limits the gears available.

1. Using the Service Transmission Light for Diagnostics: To activate the retrieval

of fault codes via the Service Transmission light perform the following steps:

• Active Codes: Place the Shift Lever in Neutral. Set the parking brakes. Begin

with the key in the off position. Turn the key off and back on two (2) times within

5 seconds (OFF/ON/OFF/ON). It is OK if the engine stops, or continues running,

however do not re-energize the starter when retrieving Fault Codes as you may

cause codes to clear.

• If there are no active fault codes, then retrieve the intermittent codes.

• Intermittent codes: Follow instructions for Active Codes, but turn key OFF and

ON four (4) times.

• To clear fault codes: Follow instructions for Active Codes, but turn key OFF and

ON six (6) times. Fault codes should be cleared each time the transmission is

serviced.

4

Page 8

1a. After activating the retrieval of codes, to read transmission errors via the Service Transmission

light, observe the sequence of flashes exhibited by the light. The Service Transmission light will

flash in coded sequences equal to Fault Codes identified in this manual. A long pause (5 seconds) follows each code before it is repeated, or the next codes sequence is given.

Examples:

• Flash / Pause / Flash = Fault Code 11 System Controller

• Flash - Flash / Pause / Flash - Flash - Flash = Fault Code 23 Engine Speed Sensor

• Flash / Pause / Flash - Long Pause - Flash - Flash / Pause / Flash - Flash - Flash = Fault Codes 11

& 23.

1b. To identify fault codes and applicable tests signalled by the Service Transmission light refer to

the Fault code Diagnosis section of this manual.

Symptom Diagnosis

1. Refer to the Performance Evaluation test in this manual.

2. Locate and perform appropriate Test Sequence as indicated by the Performance Evaluation Test.

Before Beginning Diagnostic Procedures

It is possible to “clear” or “reset” the Converter Enhanced Mechanical Electronic Control Unit

(ECU) for some transmission errors. If the transmission is not functioning properly try these

steps before beginning diagnostic procedures:

1. Stop the vehicle.

2. Place the shift lever in neutral.

3. Set the parking brakes.

4. Turn off the engine/ignition and wait for one minute.

5. Restart the engine.

6. Resume operation.

Introduction

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Test Sequence and Remedy Sequence

1. Locate the correct Test Sequence.

2. Always perform pre-test procedures found at the top of each Test Sequence page before begin-

ning test procedure.

3. Follow test steps in sequence.

4. Go to Remedy Sequence when required.

5. Perform appropriate removal, replacement or adjustment procedures.

5

Page 9

Fault

Code

Diagnosis

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Fault

Code

Test Procedure Page

13 Power Relay Coil Test 12

15 Inertial Brake Solenoid Coil Test 15

22 Bypass/Lockup Solenoid Coil Test 23

23 Engine Speed Sensor Test 21

33 System Voltage Test 13

56 Input Shaft Speed Sensor Test 29

57 Output Shaft Speed Sensor Test 31

6

Page 10

Symptom

If no fault codes exist perform the Performance Evaluation Test. Locate and perform appropriate

test sequence as indicated by the evaluation.

Driven

Diagnosis

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

7

Page 11

Transmission

Electrical

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Test

Measure voltage across vehicle battery

terminals [voltage = 12.6 volts].

Is voltage correct?

YES

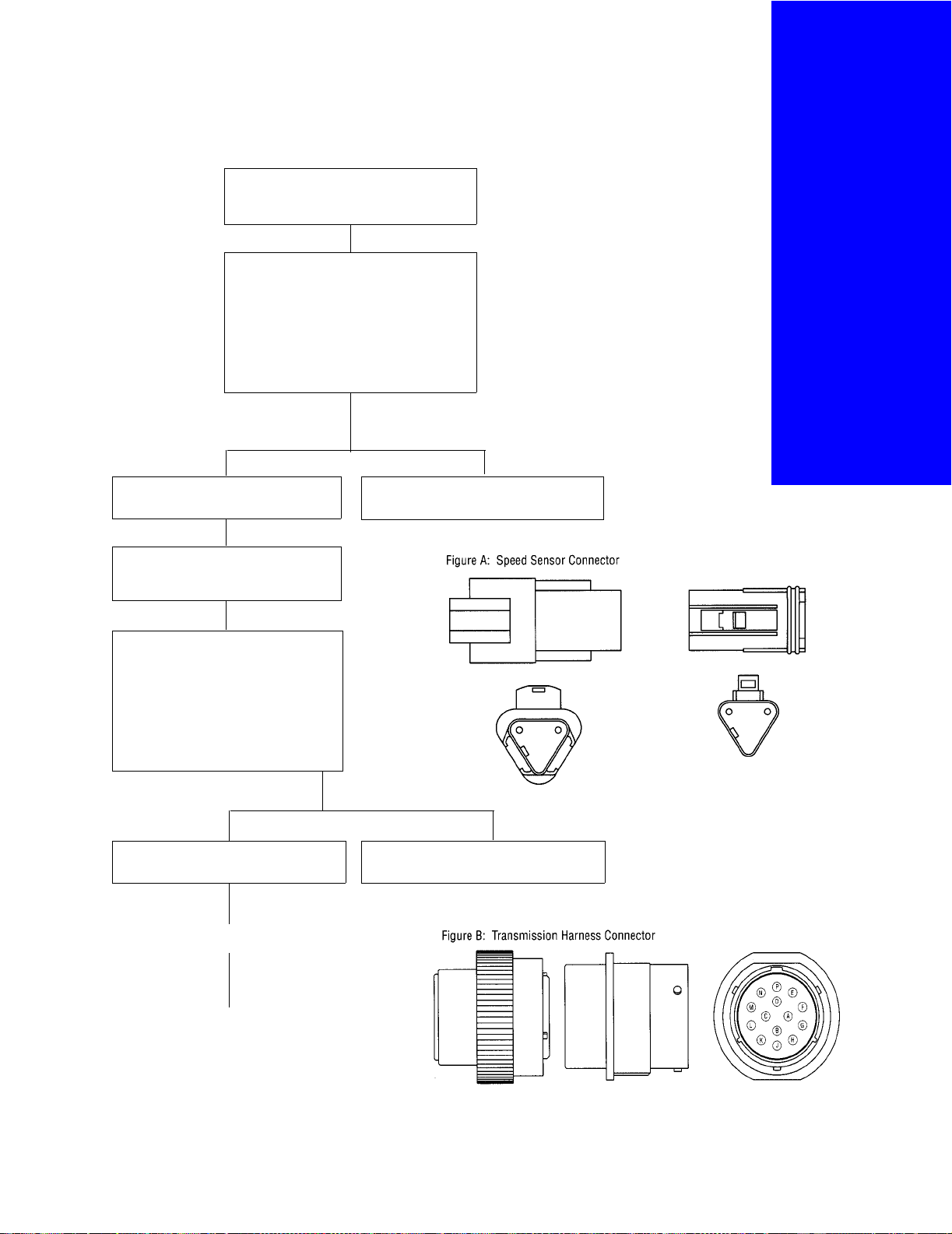

Refer to Figure A below. Disconnect

vehicle interface harness connector J1

from ECU.

Refer to Figure B below. Measure resistance between pins A3, B3, C3, and battery negative terminal [resistance = 0.0-

0.4 ohms].

Is resistance correct?

YES NO

Refer to Figure B on

page 9.

Measure voltage

between harness

connector pins A3

and G2 [voltage =

battery voltage].

Is voltage correct?

A problem exists

with transmission electrical

grounds.

Contact OEM for

service information.

NO

Repair low voltage problem. Contact OEM

for service information.

YES

Refer to Figure B

below. Measure

voltage between

harness connector

pins A3 and G1

[voltage = 0 volts.]

Is voltage correct?

YES NO

CONTINUE

NO

A problem exists

in vehicle interface harness or

batter supply circuit breaker. Contact service

information.

A problem exists

in vehicle interface

harness or ignition

voltage supply circuit breaker. Contact OEM for

service information.

8

Page 12

Continuation

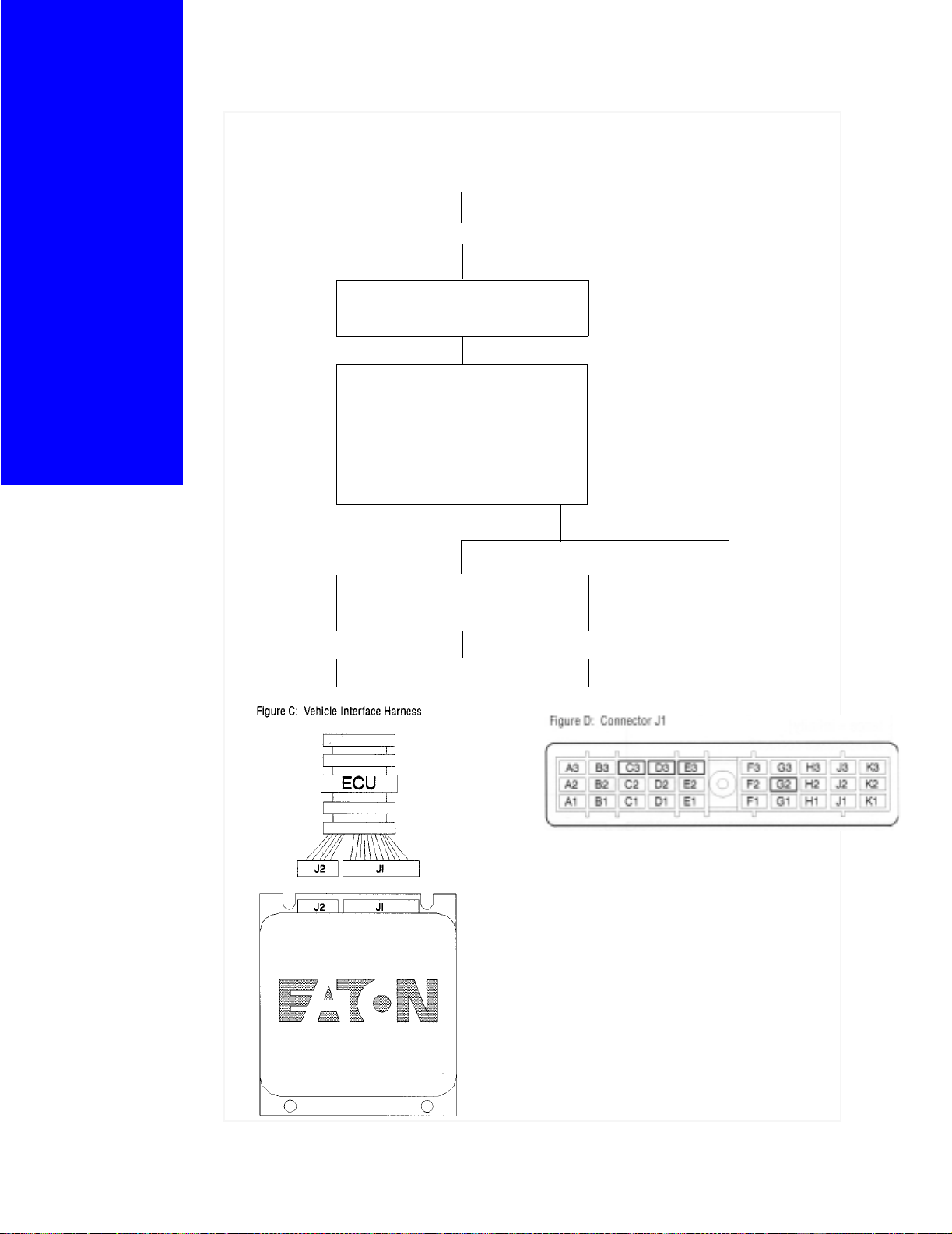

Turn the ignition key “ON”.

Refer to Figure B on page 12.

Measure the voltage between

the harness connector pins A3

and G1 [voltage = battery voltage]. Is voltage correct?

YES NO

Turn ignition key “OFF”. A problem exists in vehicle interface har-

ness or ignition voltage supply circuit

breaker. Contact OEM for service information.

Transmission

Electrical

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure B below. Place

jumper wire across vehicle

interface harness connector

pins F1 and A3.

Refer to Figure B below. Measure voltage between harness

connector pins B3 and E1 [voltage = battery voltage]. Is volt-

age correct?

YES

Refer to Figure A on page 8.

Disconnect vehicle interface

harness J2 connector from

ECU.

Refer to Figure C on page 12. Measure

voltage between J1 connector pin B3

and J2 connector pin A3 [voltage = battery voltage]. Is voltage correct?

YES

NO

A problem exists in transmission power relay or vehicle

interface harness. contact

OEM for service information.

NO

Test complete

Repair/replace vehicle interface harness according to OEM service

information.

9

Page 13

Performance

Evaluation

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Test

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Turn ignition key “ON”.

Does converter open lamp turn “ON”?

YES

Perform fault code retrieval as outlined

in the introduction section of this manual. Are fault codes present?

YES

Perform

diagnostics for

fault codes as

outlined in the

fault code diagnostic section of

this manual.

NO

Start the vehicle

and allow the air

system to reach

governor cut off

[90-120 psi].

NO

Perform Transmission Electrical Test,

then torque Converter Open Lamp Test.

Continue

Allow the transmission temperature to

reach operating temperature [180-

°F].

220

Fully depress the clutch pedal and place

the shift lever in gear. Does the trans-

mission engage gears without harsh

grinding?

YES

Does the vehicle

move?

NO

Perform Inertia

Break Test.

YES NO

Perform the Interrupt Clutch Solenoid Test and the

Hydraulic System

Test.

10

Page 14

t

Continuation

Performance

Evaluation Tes

Drive the vehicle and increase engine

rpm to 1600 rpm. Does the torque con-

verter open lamp turn “OFF”?

YES

Perform range

shift. Does range

shift complete

properly?

YES

Perform splitter

shift. Does the

splitter shift complete properly?

YES

NO

Perform Hydraulic System Test.

NO

Perform range system evaluation

according to Eaton

Fuller Air System

Troubleshooting

and Operation

Guide.

NO

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Does engine flare

after clutch pedal

release?

YES

Perform Hydraulic

System Test.

Perform Hydraulic

System Test

Perform splitter

system evaluation

according to Eaton

Fuller Air System

Troubleshooting

and Operation

Guide.

NO

Does vehicle have

trouble pul ling

light loads?

YES NO

Test complete

11

Page 15

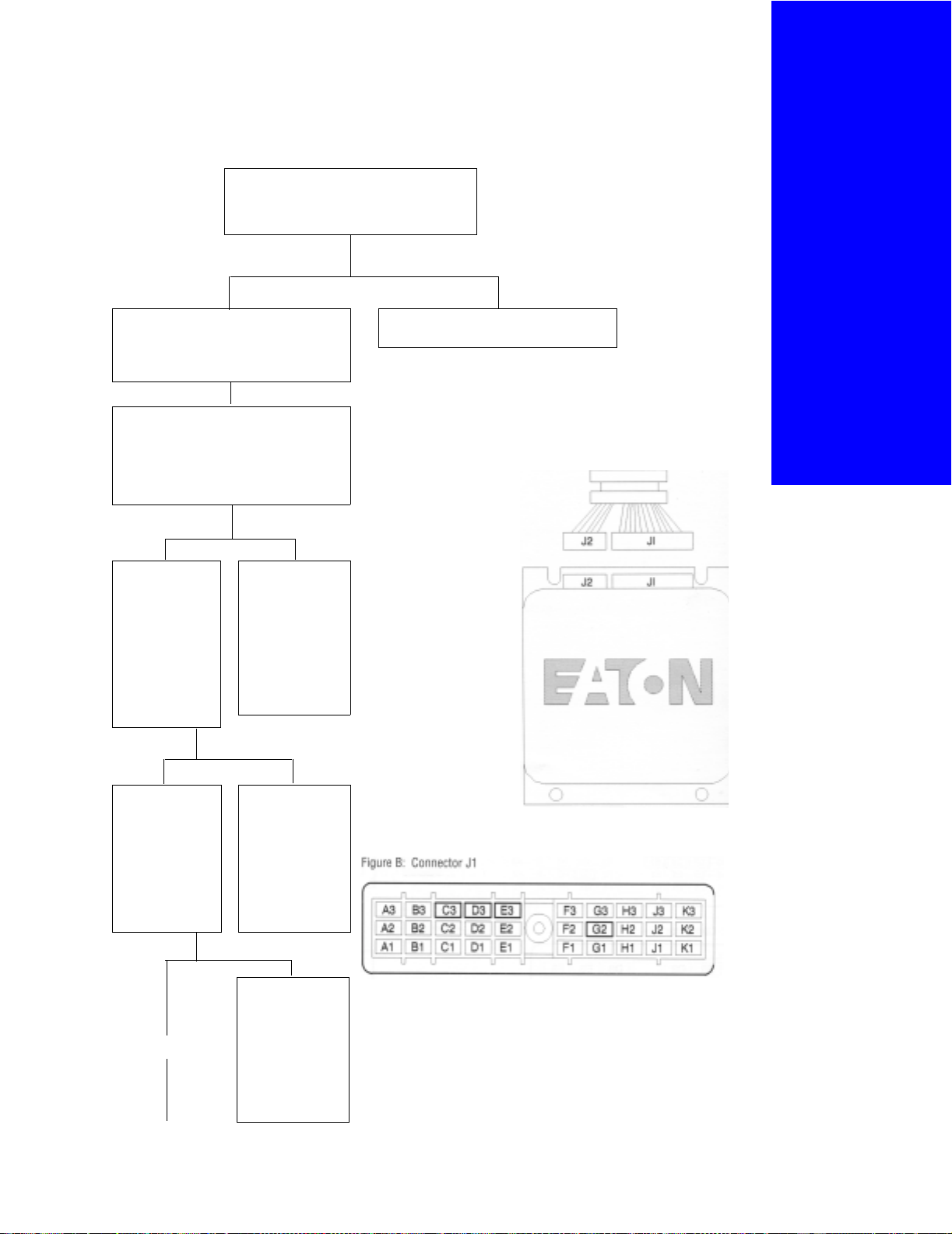

Power

Relay

Coil

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect

vehicle interface harness J1 connector

from the transmission ECU.

Refer to Figure B below. Measure resistance between J1 connector pins F1 and

G2 [resistance = 40-90 ohms]. Measure voltage between G2 and vehicle

ground, F1 and vehicle electrical ground

[should = battery voltage].

YES

Replace transmission ECU. Locate power relay assembly and

NO

disconnect vehicle interface harness

from relay assembly.

Refer to Figure C below. Measure

resistance between pins 85 and 86 of

each power relay [resistance = 40-90

ohms]. Is resistance correct?

YES

Replace vehicle

interface harness

according to OEM

service information.

NO

Replace power

relay assembly

according to

OEM service

information.

Test complete

12

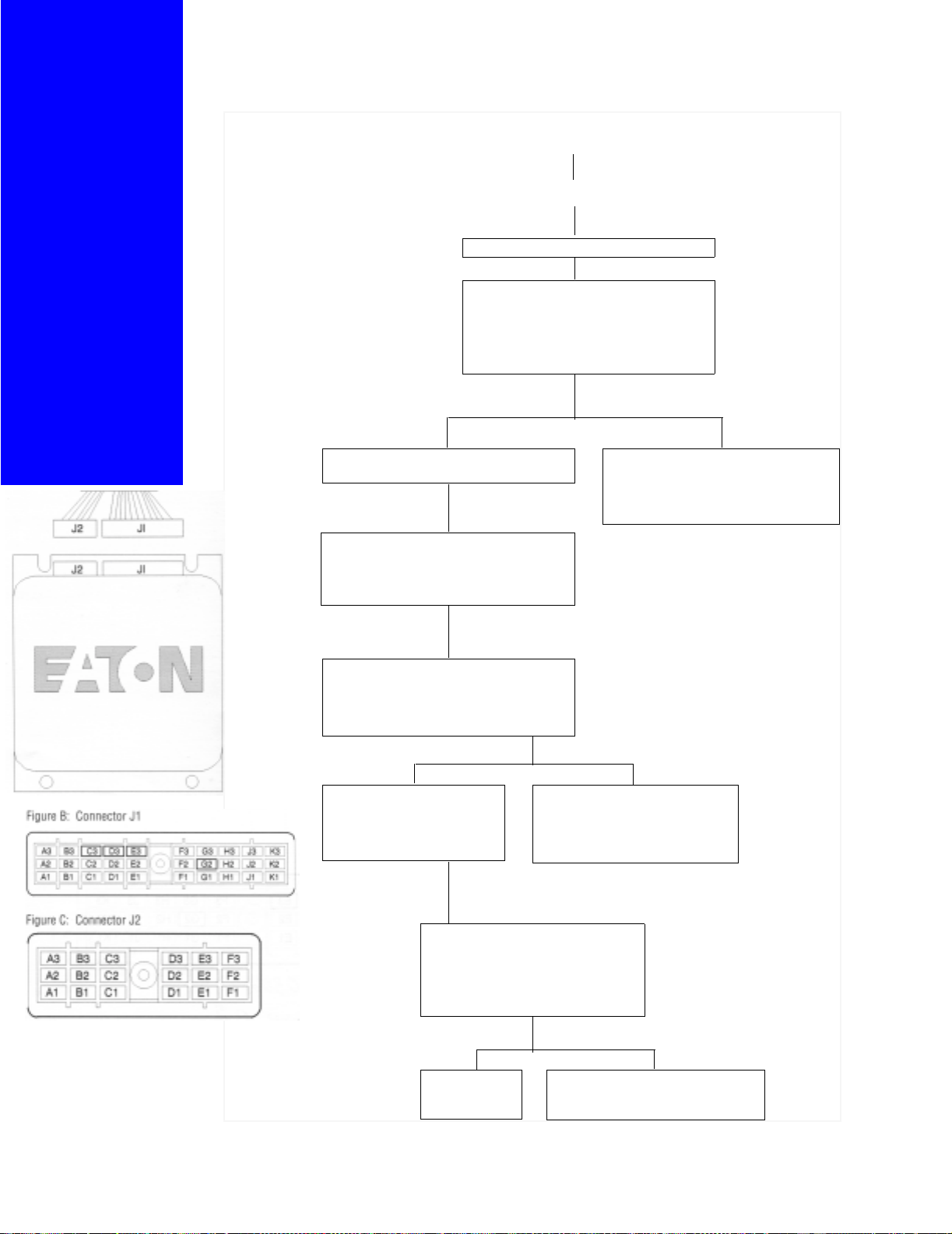

Page 16

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

System

Voltage

Measure voltage across vehicle battery

terminals [voltage = 12.6 volts].

Is voltage correct?

YES NO

Refer to Figure A below. Disconnect

vehicle interface harness connector J1

from ECU.

Refer to Figure B below. Measure

resistance between pins A3, B3, C3,

and battery negative terminal [resistance = 0.0-0.4 ohms].

Is resistance correct?

YES NO

Refer to Figure B

below. Measure

voltage between

harness connector pins A3 and

G2 [voltage =

battery voltage].

Is voltage correct?

YES NO

A problem exists

with transmission electrical

grounds.

Contact OEM for

service information.

Repair low voltage problem. Contact

OEM for service information.

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure B

below. Measure

voltage between

harness connector pins A3 and

G1 [voltage = 0

volts]. Is voltage

correct?

YES NO

Continue

A problem exists

in vehicle interface harness or

battery supply circuit breaker. Contact OEM for

service information.

A problem exists

in vehicle interface harness or

ignition voltage

supply circuit

breaker. Contact

OEM for service

information.

13

Page 17

System

Voltage

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Continuation

Turn the ignition key “ON”.

Refer to Figure B below. Measure the

voltage between the harness connector

pins A3 and G1 [voltage = battery voltage. Is voltage correct?

YES

Turn ignition key “OFF”. A problem exists in vehicle interface

Refer to Figure B below. Place jumper

wire across vehicle interface harness

connector pins F1 and A3.

NO

harness or ignition voltage supply circuit breaker. Contact OEM for service

information.

Refer to Figure B below. Measure voltage between harness connector pins B3

and E1 [voltage = batter voltage]. Is volt-

age correct?

YES NO

Refer to Figure A at left.

Disconnect vehicle interface

harness J2 connector from

ECU.

Refer to Figure C at left. Measure

voltage between J1 connector pin B3

and J2 connector pin A3 [voltage =

battery voltage]. Is voltage correct?

YES

Test Complete Repair/replace vehicle interface

A problem exists in transmission

power relay or vehicle interface

harness. Contact OEM for service information.

NO

harness according to OEM service

information

14

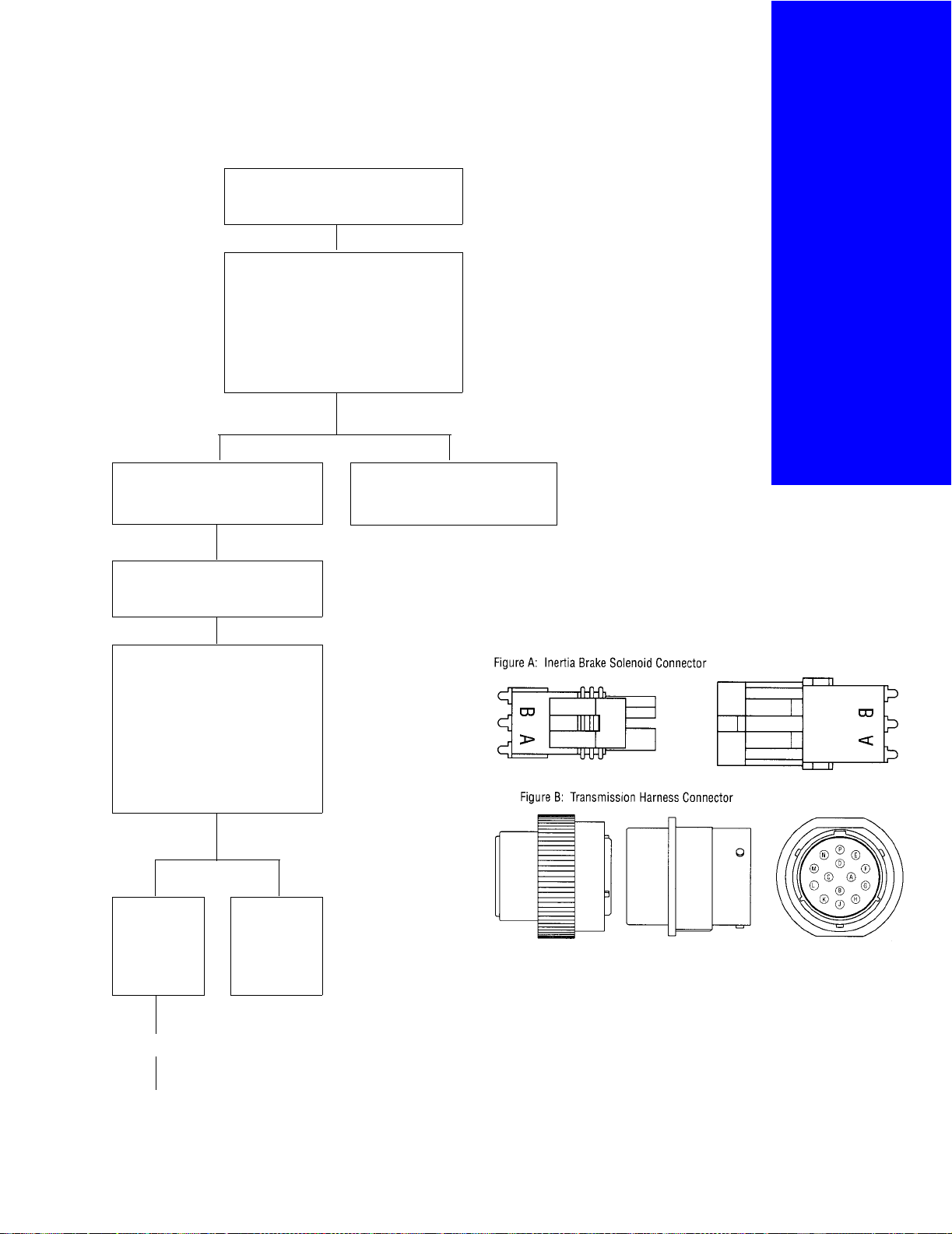

Page 18

t

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect

inertia brake solenoid from the transmission electrical harness.

Measure resistance between inertia

brake solenoid connector pins [resistance = 11-18 ohms]. Measure resistance between inertia brake solenoid

and vehicle electrical ground [resistance = infinity]. Is resistance correct?

YES

Connect inertia brake solenoid to

transmission harness.

NO

Replace inertia brake solenoid.

I n e r t i a B r ak e

Solenoid

Coil Tes

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Disconnect transmission harness

from vehicle interface harness.

Refer to Figure B below. Measure

resistance between transmission

harness pins G and H [resistance

= 11-18 ohms]. Measure resistance between transmission harness pin H and vehicle electrical

ground [resistance = infinity]. Is

resistance correct?

YES

Connect transmission harness to vehicle

interface harness.

NO

Replace transmission harness.

Continue

15

Page 19

Inertia

Brake

Solenoid

Coil Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Continuation

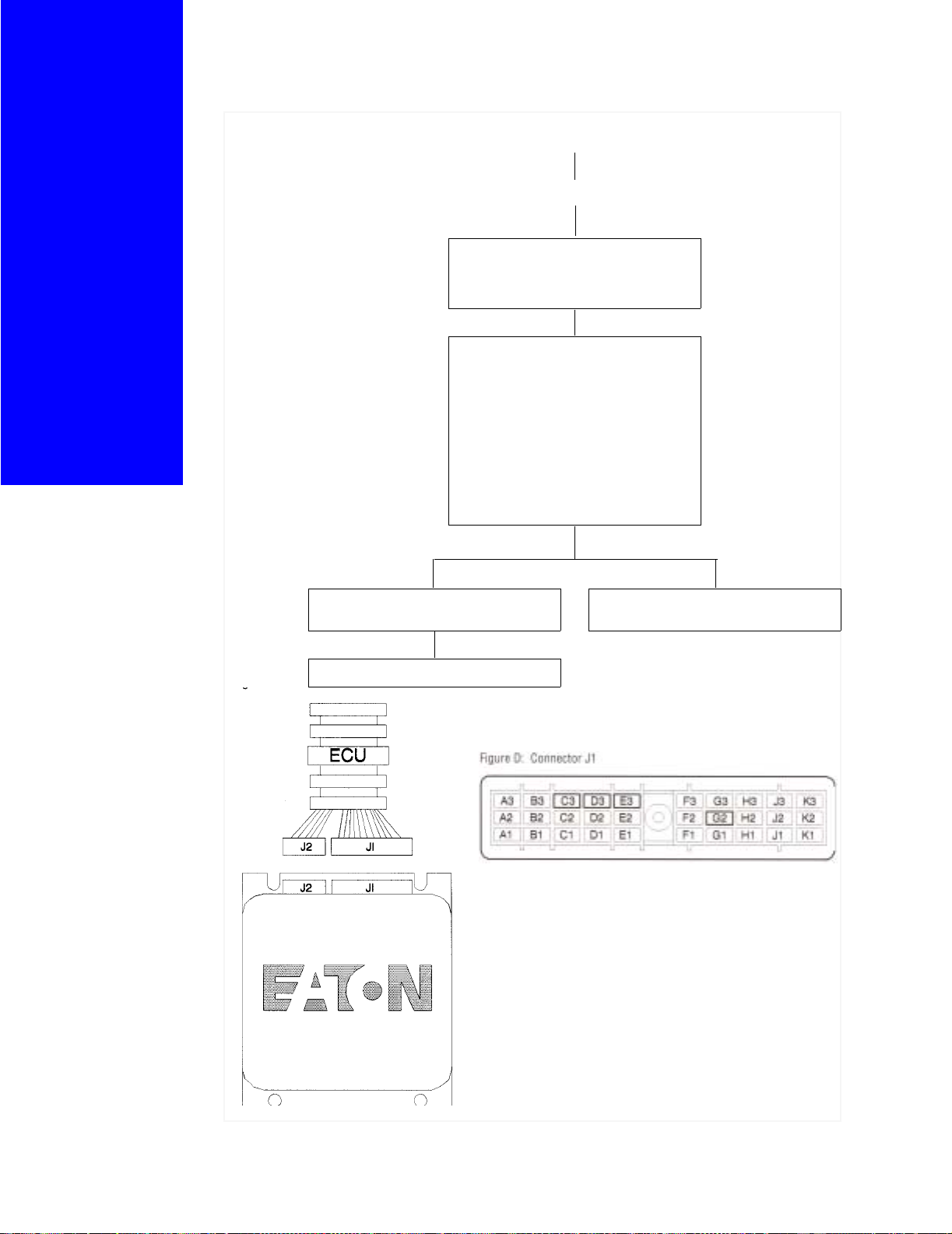

Refer to Figure C below. Disconnect

vehicle interface harness J1 connector

from transmission ECU.

YES

Refer to Figure D below. Measure resistance between vehicle interface harness

connector pins E1 and H1 [resistance =

11-18 ohms]. Measure resistance

between pin H1 and vehicle electrical

ground [resistance = infinity]. Is resis-

tance correct?

NO

YES NO

Replace transmission ECU. Replace vehicle interface harness

according to OEM service information.

Test complete

16

Page 20

t

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Install 0-100 psi

air gauge in inertia brake air line. Gauge

should be installed in “T” fashion.

Inertia

Brake Tes

Start vehicle and allow air pressure to

reach governor cut off [90-125 psi].

With the vehicle at idle fully depress clutch

pedal and monitor air pressure gauge.

Does the inertia brake air pressure cycle

on and off?

Replace inertia brake according to

service manual.

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

NOYES

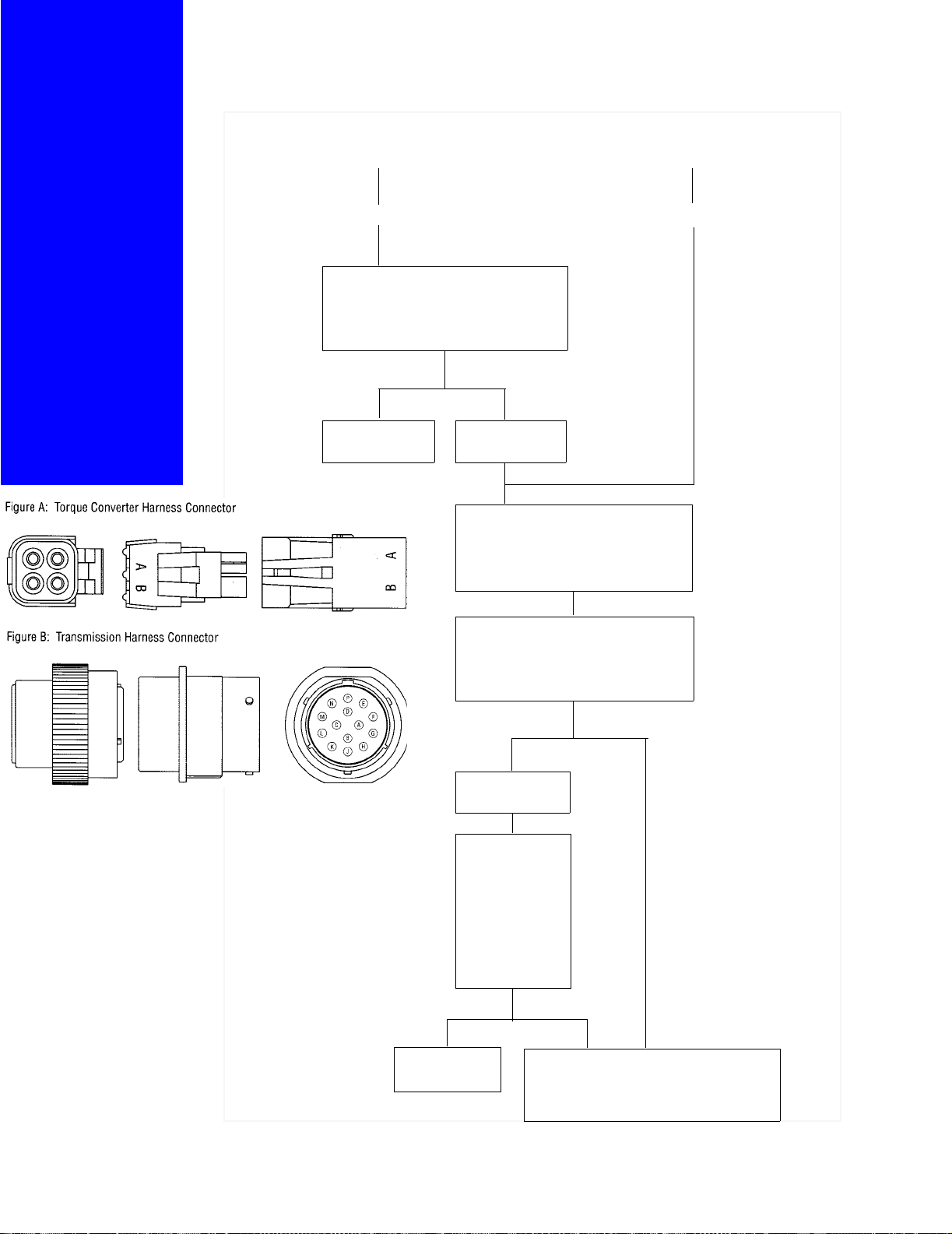

Refer to Figure B below. Disconnect vehicle interface harness connector J1 from

transmission ECU.

Refer to Figure C below. Place jumper wire

between pins G2 and E1.

Refer to Figure C below. Place jumper wire

between pins H1 and A3. Monitor pressure

gauge. Does the inertia brake air pressure

read 85-95 psi?

YES

Go to Inertia

Brake Switch

Test

NO

Remove air gauge

from inertia brake

air line.

Go to Inertia Brake

Air Supply Test

17

Page 21

Inertia

Brake

S w i t c h

Test

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect vehicle interface harness connector J2 from the

transmission ECU.

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure B below. Measure the resistance between pin F3 and vehicle electrical

ground [resistance = infinity]. Is resistance

correct?

YES NO

Fully depress the clutch pedal. Repair inertia brake switch according to

OEM service information.

Refer to Figure A below. Measure the

resistance between pin F3 and vehicle

electrical ground [resistance = 0-5

ohms]. Is resistance correct?

YES NO

Replce transmission ECU according to

transmission service manual.

Repair inertia

brake switch circuit according to

OEM service

information.

18

Page 22

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Install 0-100 psi

air gauge in inertia brake solenoid air

regulator port.

I n e r t i a

Brake

A i r

S u pp l y

Test

Start the vehicle and allow air system to

reach governor cut-off [90-120 psi].

Monitor air pressure gauge. Does air

pressure equal 73-83 psi?

YES NO

Replace inertia brake solenoid

according to transmission service

manual.

Replace air filter regulator according

to transmission service manual.

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

19

Page 23

Transmission

Converter

Open

Lamp

Test

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect vehicle

interface harness connector J1 from the

transmission ECU.

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure B below. Place jumper wire

between pins G2 and E1. Place jumper wire

between pins C2 and A3. Does Converter

open lamp turn “ON”?

YES NO

Replace transmission ECU according

to OEM service information.

Replace converter open lamp and

inspect the vehicle interface harness.

Does condition still exist?

YES

Perform Tr an smission Electrical Test.

NO

Test Complete

20

Page 24

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect engine

speed sensor from transmission electrical

harness.

Measure resistance between engine speed

sensor connector pins [resistance = 3k-4k

ohms]. Measure resistance between

engine speed sensor pin A and vehicle electrical ground [resistance = infinity]. Is

resistance correct?

Connect engine speed sensor to

transmission harness.

YES NO

Replace engine speed sensor.

Engine

Speed

Sensor

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure B below. Disconnect

transmission harness from the vehicle interface harness.

Measure resistance between transmission harness pins N and P [resistance = 3k-4k ohms]. Measure

resistance between transmission

harness pin P and vehicle electrical

ground [resistance = infinity]. Is

resistance correct?

YES NO

Connect transmission harness to vehicle

interface harness.

Replace transmission harness.

Continue

21

Page 25

Engine

Speed

Sensor

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Test

Continuation

Refer to Figure C below. Disconnect

vehicle interface harness J1 connector

from transmission ECU.

Refer to Figure D below. Measure resistance between vehicle interface harness

connector pins J3 and K3 [resistance =

3k-4k ohms]. Measure resistance

between pin K3 and vehicle electrical

ground [resistance = infinity]. Is resis-

tance correct?

YES NO

Replace transmission ECU. Replace vehicle interface harness accord-

ing to OEM service information.

Test complete

22

Page 26

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

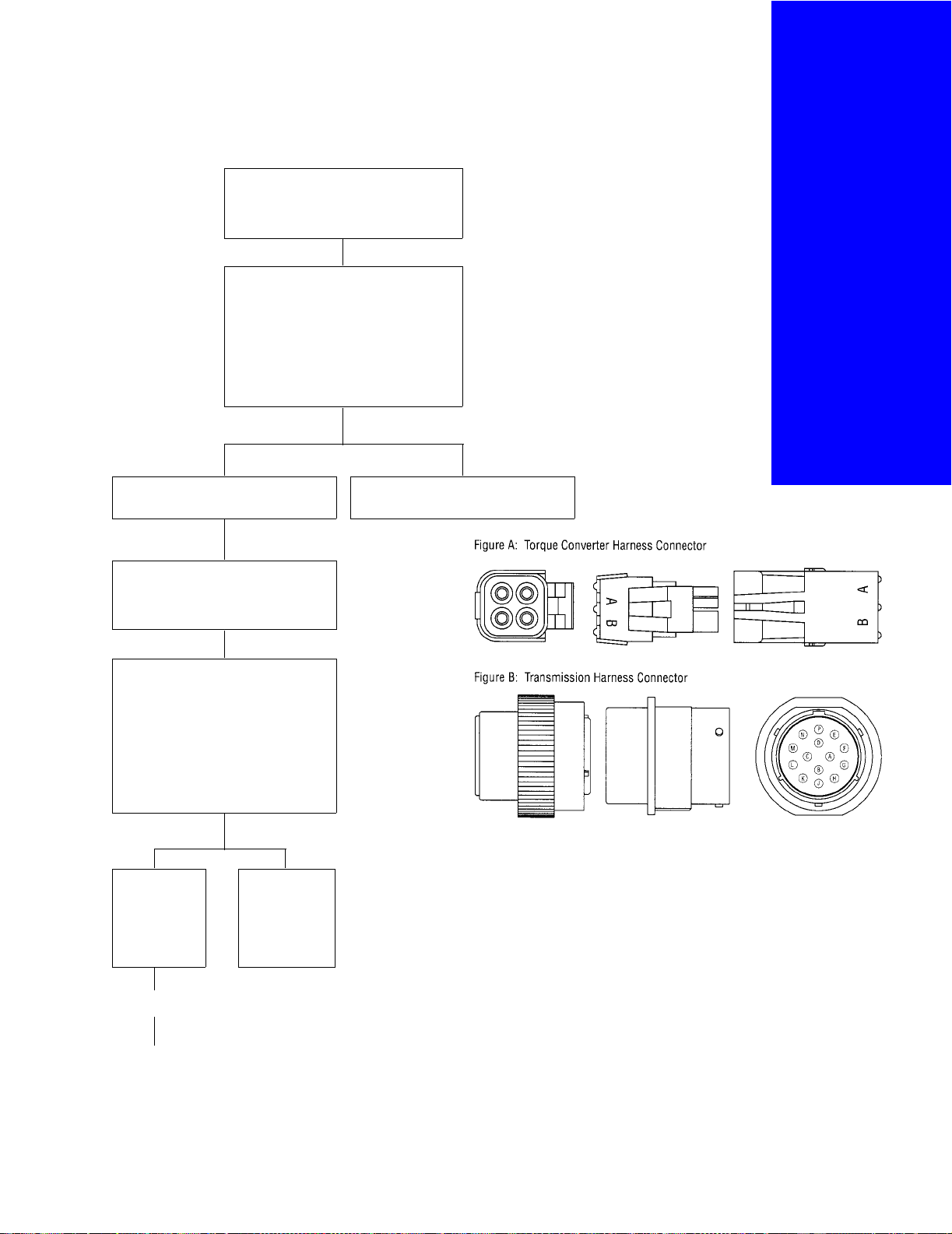

Refer to Figure A below. Disconnect

torque converter harness from transmission electrical harness.

Bypass/

Lockup

S o l e n o i d

Coil

Test

Measure resistance between torque

converter harness pins A and B [resistance = 2.5-4 ohms]. Measure resistance between torque converter

harness pin A and vehicle electrical

ground [resistance = infinity]. Is resis-

tance correct?

YES NO

Connect torque converter harness to

transmission harness.

Refer to Figure B below. Disconnect

transmission harness from the vehicle interface harness.

Measure resistance between transmission harness pins A and B [resistance = 2.5-4 ohms]. Measure

resistance between transmission

harness pin B and vehicle electrical

ground [resistance = infinity]. Is

resistance correct?

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Replace torque converter harness.

YES

Connect transmission harness to vehicle

interface harness.

Continue

NO

Replace transmission harness.

23

Page 27

Bypass/

Lockup

Solenoid

Coil

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Test

Continuation

Refer to Figure C below. Disconnect

vehicle interface harness J1 connector

from transmission ECU.

Refer to Figure D below. Measure resistance between vehicle interface harness

connector pins E1 and K2 [resistance =

2.5-4 ohms]. Measure resistance

between vehicle electrical ground pins E1

and C1 [resistance = 2.5-4 ohms]. Measure resistance between pin C1 and vehicle electrical ground [resistance infinity].

Is resistance correct?

YES

Replace transmission ECU. Replace vehicle interface harness

NO

according to OEM service information.

Test complete

24

Page 28

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Disconnect torque converter harness

from transmission harness.

Refer to Figure A below. Measure resistance between torque converter harness

pins C and D [resistance = 2.5-4 ohms].

Is resistance correct?

YES NO

Refer to Figure A below. Measure

resistance between torque converter

harness pin C and vehicle electrical

ground [resistance = infinity]. Is

resistance correct?

Replace torque converter harness.

Interrupt

Clutch

So len oid

Coil

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

YES

Turn ignition key

“ON”.

Refer to Figure A

at right. Measure

voltage between

transmission harness pins C and

D [voltage = battery voltage]. Is

voltage correct?

YESNO

Depress clutch

pedal.

NO

Replace torque

converter harness.

Continue Continue

25

Page 29

Interrupt

Clutch

Solenoid

Coil

Test

Continuation Continuation

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure A below. Measure voltage between transmission harness pins

C and D [voltage = 0 volts]. Is voltage

correct?

YES NO

Test Complete Release clutch

pedal.

Connect torque converter harness to

transmission harness. Disconnect

transmission harness from vehicle

interface harness.

Refer to Figure B below. Measure voltage between vehicle interface harness

pins C and D [voltage = battery voltage]. Is voltage correct?

YES NO

26

Depress clutch

pedal.

Refer to Figure B

at left. Measure

voltage between

vehicle interface

harness pins C

and D [voltage = 0

volts].

correct

YES NO

Replace transmission harness

Is voltage

?

A problem exists in the vehicle interface

harness, clutch switch or power

connect relay. Contact OEM for service

information.

Page 30

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Set Parking brake and place shift lever in

neutral position.

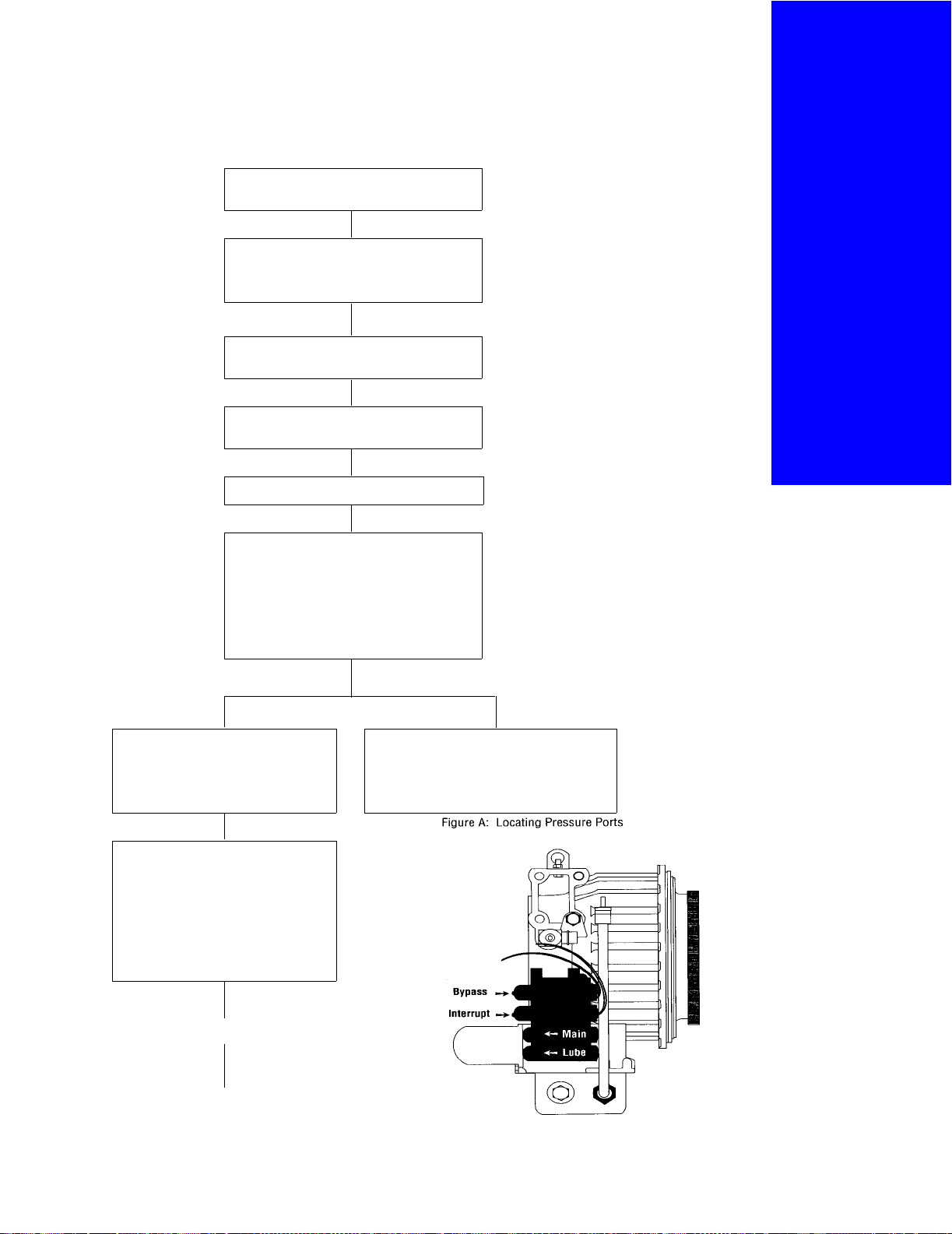

Refer to Figure A below. Connect 0-300

psi gauges to main interrupt and bypass/

lockup torque converter ports.

Refer to Figure A below. Connect 0-100

psi gauge to torque converter lube port.

Start vehicle and allow transmission temperature to reach 180-220

Depress clutch pedal.

°F.

H y d r a u l i c

S y s t e m

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Monitor pressure gauges.

Main pressure: 225-255 psi

Interrupt pressure: 0 psi

Bypass/lockup pressure: 0 psi

Lube pressure: 20-35 psi

Are the pressures correct?

YES NO

Release clutch pedal. Inspect/clean oil strainer in oil pan.

Replace hydraulic valve. If conflict still

exists, a failure has occurred in the

hydraulic system.

Monitor pressure gauges.

Main pressure: 225-255 psi

Interrupt pressure:

Bypass/lockup pressure: 0 psi

Lube pressure: 15-20 psi

Are the pressures correct?

±5 psi of main

Continue

27

Page 31

Hydraulic

System

Test

Continuation

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

YES NO

Increase engine rpm to 1600 rpm to

lock up the torque converter. Torque

converter open light turns “OFF”.

Note: Light should come back on at

1400 rpm.

Monitor pressure gauges.

Main pressure: 225-255 psi

Interrupt pressure:

Bypass/lockup pressure:

Lube pressure: 15-20 psi

Are the pressures correct?

Test complete Replace hydrau-

±5 psi of main

±5 psi of

main

lic valve. If conflict still exists, a

failure has

occurred in the

hydraulic system.

Replace hydraulic valve. If conflict

still exists, a failure has occurred in

the hydraulic system.

28

Page 32

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect

input shaft speed sensor from the transmission electrical harness.

Measure resistance between input shaft

speed sensor connector pins [resistance

= 3k-4k ohms]. Measure resistance

between input shaft speed sensor pin A

and vehicle electrical ground [resistance

= infinity].

Is resistance correct?

YES

NO

Input

Shaft

Speed

Sensor

Test

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Connect input shaft speed sensor to

transmission harness.

Refer to Figure B below. Disconnect

transmission harness from vehicle

interface harness.

Measure resistance between transmission harness pins J and K [resistance = 3k-4k ohms]. Measure

resistance between transmission harness pin K and vehicle electrical

ground [resistance = infinity].

Is resistance correct?

YES NO

Connect transmission harness to

transmission electrical harness.

Replace the input shaft speed sensor.

Replace the transmission harness.

Continue

29

Page 33

Input

Shaft

Sensor

Test

Continuation

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure C below. Disconnect

vehicle interface harness J1 connector

from transmission ECU.

Refer to Figure D below. Measure resistance between vehicle interface harness

connector pin G3 and H3 [resistance = 3k4k ohms]. Measure resistance between

pin H3 and vehicle electrical ground

[resistance = infinity].

Is resistance correct?

YES

Replace transmission ECU. Replace vehicle interface harness

Test Complete

NO

according to OEM service information.

30

Page 34

Before beginning test procedure:

1. Set parking brakes.

2. Perform Transmission Electrical Test.

3. Turn ignition key “OFF”.

Refer to Figure A below. Disconnect output shaft speed sensor from the transmission electrical harness.

Output

Shaft

Speed

Sensor

Test

Measure resistance between output shaft

speed sensor connector pins [resistance =

3k-4k ohms]. Measure resistance

between output shaft speed sensor pin A

and vehicle electrical ground [resistance =

infinity].

Is resistance correct?

YES

Connect output shaft speed sensor to

transmission harness.

Refer to Figure B below. Disconnect

transmission harness from vehicle

interface harness.

Measure resistance between transmission harness pins E and F [resistance =

3k-4k ohms]. Measure resistance

between transmission harness pin F

and vehicle electrical ground [resistance = infinity].

Is resistance correct?

NO

Replace the output shaft speed sensor.

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

YES

Connect transmission harness to

transmission electrical harness.

Continue

NO

Replace the transmission harness.

31

Page 35

Output

Shaft

Sensor

Test

Continuation

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Refer to Figure C below. Disconnect

vehicle interface harness J1 connector

from transmission ECU.

Refer to Figure D below. Measure resistance between vehicle interface harness

connector pins A1 and B1 [resistance =

3k-4k ohms]. Measure resistance

between pin B1 and vehicle electrical

ground [resistance = infinity]. Is resis-

tance correct?

YES NO

Replace transmission ECU. Replace vehicle interface harness

according to OEM service information.

Test complete

32

Page 36

System Overview

Appendix I

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

33

Page 37

Appendix I

For all questions

concerning

inspection,

removal,

replacement,

or adjustment

procedures,

refer to Eaton or

OEM Service and

Parts Literature.

Electrical Schematic

34

Page 38

Page 39

Copyright Eaton Corporation, 2012.

Eaton hereby grant their customers,

vendors, or distributors permission

to freely copy, reproduce and/or

distribute this document in printed

format. It may be copied only in

its entirety without any changes or

modifications. THIS INFORMATION

IS NOT INTENDED FOR SALE OR

RESALE, AND THIS NOTICE MUST

REMAIN ON ALL COPIES.

Note: Features and specifications

listed in this document are subject to

change without notice and represent

the maximum capabilities of the

software and products with all options

installed. Although every attempt has

been made to ensure the accuracy of

information contained within, Eaton

makes no representation about the

completeness, correctness or accuracy

and assumes no responsibility for

any errors or omissions. Features and

functionality may vary depending on

selected options.

For spec’ing or service assistance,

call 1-800-826-HELP (4357) or visit

www.eaton.com/roadranger.

In Mexico, call 001-800-826-4357.

Roadranger: Eaton and trusted partners

providing the best products and services in the

industry, ensuring more time on the road.

Eaton Corporation

Vehicle Group

P.O. Box 4013

Kalamazoo, MI 49003 USA

800-826-HELP (4357)

www.eaton.com/roadranger

Printed in USA

Page 40

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Loading...

Loading...