Page 1

Troubleshooting Guide

Fuller Transmissions

TRTS0920

July 2011

Page 2

Warnings and Precautions

!

Warnings and Precautions

WARNING

Before starting a vehicle always be seated in the driver’s seat, place the transmission in neutral, set the parking brakes and

disengage the clutch.

Before working on a vehicle place the transmission in neutral, set the parking brakes and block the wheels.

Before towing the vehicle place the transmission in neutral, and lift the rear wheels off the ground, remove the axle shafts,

or disconnect the driveline to avoid damage to the transmission during towing.

The description and specifications contained in this service publication are current at the time of printing.

Eaton Corporation reserves the right to discontinue or modify its models and/or procedures and to change specifications at any

time without notice.

Any reference to brand name in this publication is made as an example of the types of tools and materials recommended for use

and should not be considered an endorsement. Equivalents may be used.

This symbol is used throughout this manual to call attention to procedures where carelessness or failure to follow

specific instructions may result in personal injury and/or component damage.

Departure from the instructions, choice of tools, materials and recommended parts mentioned in this publication may jeopardize

the personal safety of the service technican or vehicle operator.

Warning: Failure to follow indicated procedures creates a high risk of personal injury to the service technician.

Caution: Failure to follow indicated procedures may cause component damage or malfunction.

Note: Additional service information not covered in the service procedures.

Tip: Helpful removal and installation procedures to aid in the service of this unit.

Always use genuine Eaton replacement parts.

Page 3

Table of Contents

General Information

How to use this Troubleshooting/Operation Guide ...... 1

Transmission Identification ......................................... 2

Component Identification ............................................ 4

Lubricants and Sealants .............................................. 6

Suggested Test Fixtures .............................................. 7

Air System Troubleshooting

8, 9, 10, 11, 13, 15, and 18-Speed Troubleshooting ... 8

RTLO 10-Speed Troubleshooting .............................. 23

Combination Cylinder Troubleshooting ..................... 33

FR-1X210 Troubleshooting ....................................... 51

Operation

Air Line Color Chart ...................................................64

Slave Valve Preselection System ............................... 65

7,8,9 and 10-Speed Range Air Systems .................... 66

7L,8,9 and 10-Speed (2-Speed auxiliary) .................. 67

RT & RTO-610,6610, 6609, and 8609 Models .......... 69

Deep Reduction Air System

(with Dash Mounted Valve) ................................ 71

RT, RTO, & RTX xx607LL,

xx608LL, and xx615 models .............................. 72

Deep Reduction Air System

(with A-6915 Roadranger Valve) ........................ 75

RT, RTO, & RTX xx607LL,

xx608LL, and xx615 Models .............................. 76

9 and 13-Speed Air Systems

(Top 2 & Convertible) and 18-Speed (Top-2) .... 79

RT, RTO, & RTOO xx613 and xx813 Models ............. 83

RTLO-xx613 Models ................................................. 86

RTLO-xx713 Models ................................................. 89

RTLO-xx913 Models ................................................. 92

RT0-15618 and RTLO-xx618 Models ........................ 95

RTLO-xx718 Models ................................................. 99

RTLO-xx918 Models ............................................... 103

Combination Cylinder Air System ............................ 107

7LL/DLL/MLL, 8LL, 9MLL, and 15-Speed Models .. 108

Unique Air Systems ................................................. 111

RT &RTO 613 and 6613 Models ............................. 112

RT & RTO 613 and 6613 Models

With A-6913 Roadranger Valve ....................... 115

RT & RTO 613 and 6613 Models ............................ 116

7608LL with A-6915 Roadranger Valve ................... 119

7608LL Models ....................................................... 120

RTLO-xx610 Speed Air System ............................... 123

RTLO-xxX610 Models ..............................................125

RTL-xx710 Speed Models ........................................129

RTL-xx710 Models ..................................................130

AT-1202 Auxillairy Transmission

(with 2 Position Shift Valve) .............................134

AT-1202 Auxiliary Housing (3 Position Valve) .........135

System Components

A-4740 Air Filter/Regulator Assembly ......................137

A-5161/A-5454 Air Filter/Regulator Assembly .........138

A-3546 Range Valve ................................................139

A-5010/A-6909 Roadranger Valve ...........................140

14651 Reduction Valve (Dash-Mounted) .................141

A-5015/A-6915 Roadranger Valve ...........................142

Two Position Selector Valve ....................................143

A-4900/A-6913 Roadranger Valve ...........................144

A-5013/A-6913 Roadranger Valve ...........................145

Three Position Selector Valve ..................................147

A-5510/A-6910 Roadranger Valve ...........................148

Range Actuator Valve (Old Design) ..........................150

Range Actuator Valve (Latest Design) .....................151

19470 Poppet-Type Slave Valve ..............................152

A-4688 Slave Valve ..................................................153

A-5000 Slave Valve ..................................................154

Range Cylinder ........................................................155

Range Cylinder for 610, 6610, 6609 and 8609 ........156

Dash-Mounted Deep Reduction Cylinder .................157

Deep Reduction Cylinder with Roadranger Valve .....158

RTLO-xx610 Model Range Cylinder Assembly ........160

RTL-xx710 Model Range Cylinder Assembly ...........162

Intermediate Shift Cylinder Assembly

613 and 6613, 3-Position Selector Valve ..........164

Intermediate Shift Cylinder Assembly

613 and 6613, A-5015 Roadranger Valve .........166

Combination Cylinder Assembly ..............................168

Splitter Cylinder Assembly .......................................171

RTLO-xx610 Model Splitter Cylinder Assembly

(Old Design) ....................................................173

RTLO-xx610 Model Splitter Cylinder Assembly

(Latest Design) .................................................175

RTL-xx710 Model Splitter Cylinder Assembly ..........177

RTLO-xx613 Model Splitter Cylinder Assembly .......179

RTLO-xx713 Model Splitter Cylinder Assembly .......181

RTLO-xx913 Model Splitter Cylinder Assembly .......183

RTO-15618 and RTLO-xx618 Model

Splitter Cylinder Assembly ...............................185

RTLO-xx718 Model Splitter Cylinder Assembly .......187

RTLO-xx918 Model Splitter Cylinder Assembly .......189

Page 4

Table of Contents

Engineering Reference Drawings

Basic Air System Drawings -

6610,8609, and 6609 ....................................... 191

Basic Air System Drawings -

07L, 08, 08L, 09, and 10-Speed Models .......... 192

Basic Air System Drawings -

07LL, 08LL, and 15 Speed Models .................. 193

Basic Air System Drawings - 707LL, 7/908LL, 7/909LL,

and 7/915 Speed Models ................................. 194

Basic Air System Drawings - 11613, 14613, and 15613

Speed Models .................................................. 195

Basic Air System Drawings - 6613, and 7608LL Speed

Models ............................................................. 196

Basic Air System Drawings -

18 Speed Models Left-Hand Drive ...................197

Basic Air System Drawings -

18 Speed Right-Hand Drive .............................198

Page 5

General Information

How to use this Troubleshooting/Operation Guide

The purpose of this manual is to assist in the diagnosis and repair of your air system. Use this manual in conjunction with other

service literature produced by Eaton®, including Service Bulletins, Illustrated Parts Lists, Service Manuals, and OEM service material.

This guide provides four functions

• Troubleshooting Guide: Designed to isolate and resolve air system problems.

• System Operation and Schematics: Designed to explain a complete air system's operation.

• System Components: Designed to explain each component's function and operation.

• Engineering Reference Drawings: Detailed drawings with optional parts and part numbers.

General Information

1

Page 6

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 7

General Information

Transmission Identification

2-Speed Auxiliary/3-Speed and 2x2 Auxiliary

Roadranger

Valve

Slave

Valve

Air Hoses

Air Lines

Air Lines

Range Cylinder

Air Filter/

Regulator

2-Speed

Auxiliary

RoadrangerRoadranger

Valve

Range Cylinder

Air Filter/

Slave

Valve

Regulator

3-Speed

&

2X2 Auxiliary

Air Hoses

Deep Reduction or

Splitter Cylinder

2

Page 8

Combination Cylinder / RTLO-10 Speeds

Roadranger

Valve

General Information

Combination

Slave

Valve

Air Hoses

Air Lines

Roadranger

Valve

Combination

Cylinder

Cylinder

Air Filter/

Regulator

General Information

Air Lines

Range

Actuator

Valve

RTLO-10 Speeds

Range Cylinder

Air Filter/

Regulator

O

N

L

Y

C

C

N

Air Hose

Splitter Cylinder

3

Page 9

General Information

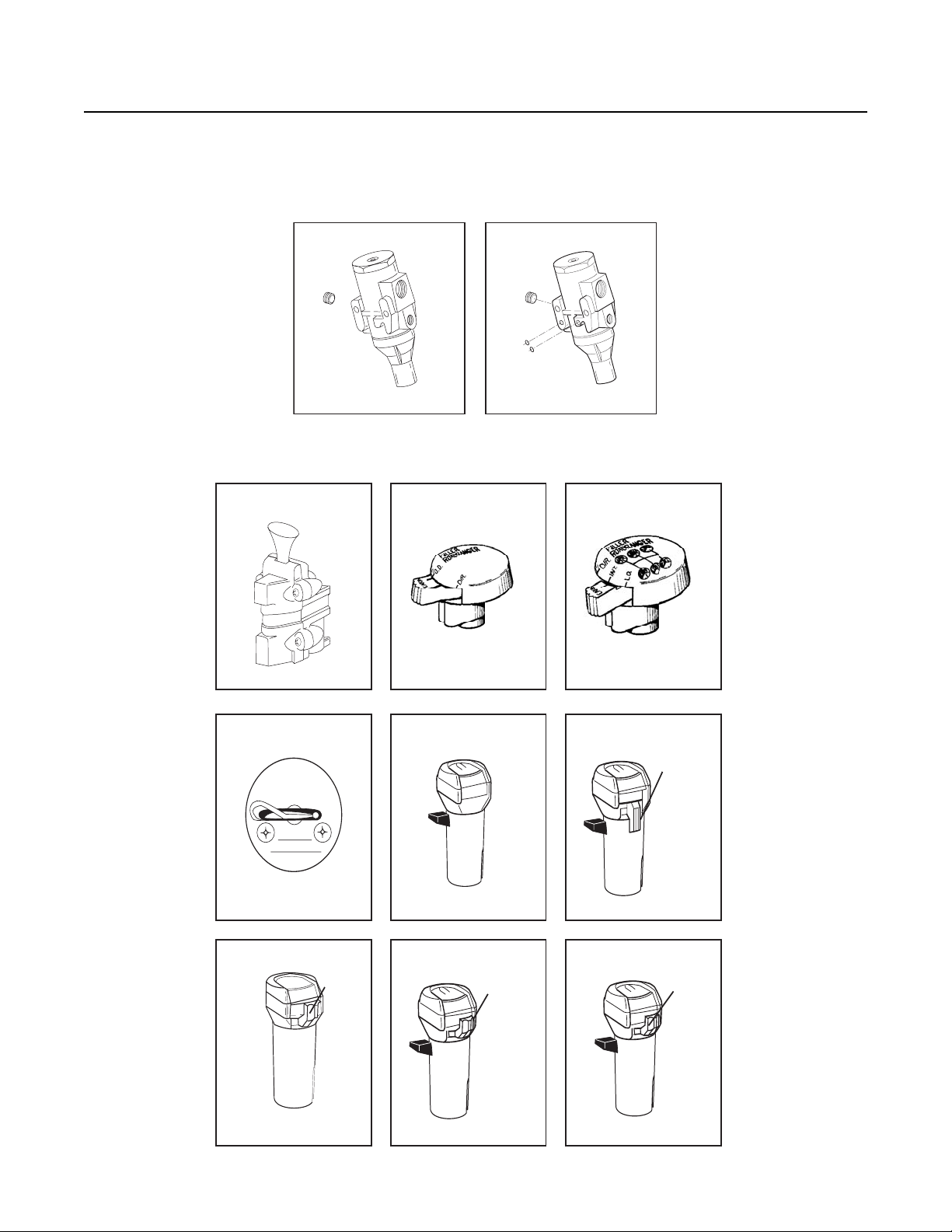

Component Identification

Air Filter/ Regulators

Control Valves - Old Production

A-3546

DOWN-LOW

H

IG

-H

UP

Deep Reduction Valve

14651

D

U

E

C

R

T

P

I

SHIFT ONLY

WHEN IN LOW

RANGE

DO NOT

PRE-SELECT

O

N

IN

OUT

E

E

D

Two Position Selector

A-5010

8, 9, and 10 Speeds 8LL, 15, 6613 Speeds

Three Position Selector

A-5015

Blue

A-5510

Gray

A-4900

Red

RT/RTLO 13 Speeds

A-5013

Gray

RTLO-18 SpeedsRTLO-10 Speeds

4

Page 10

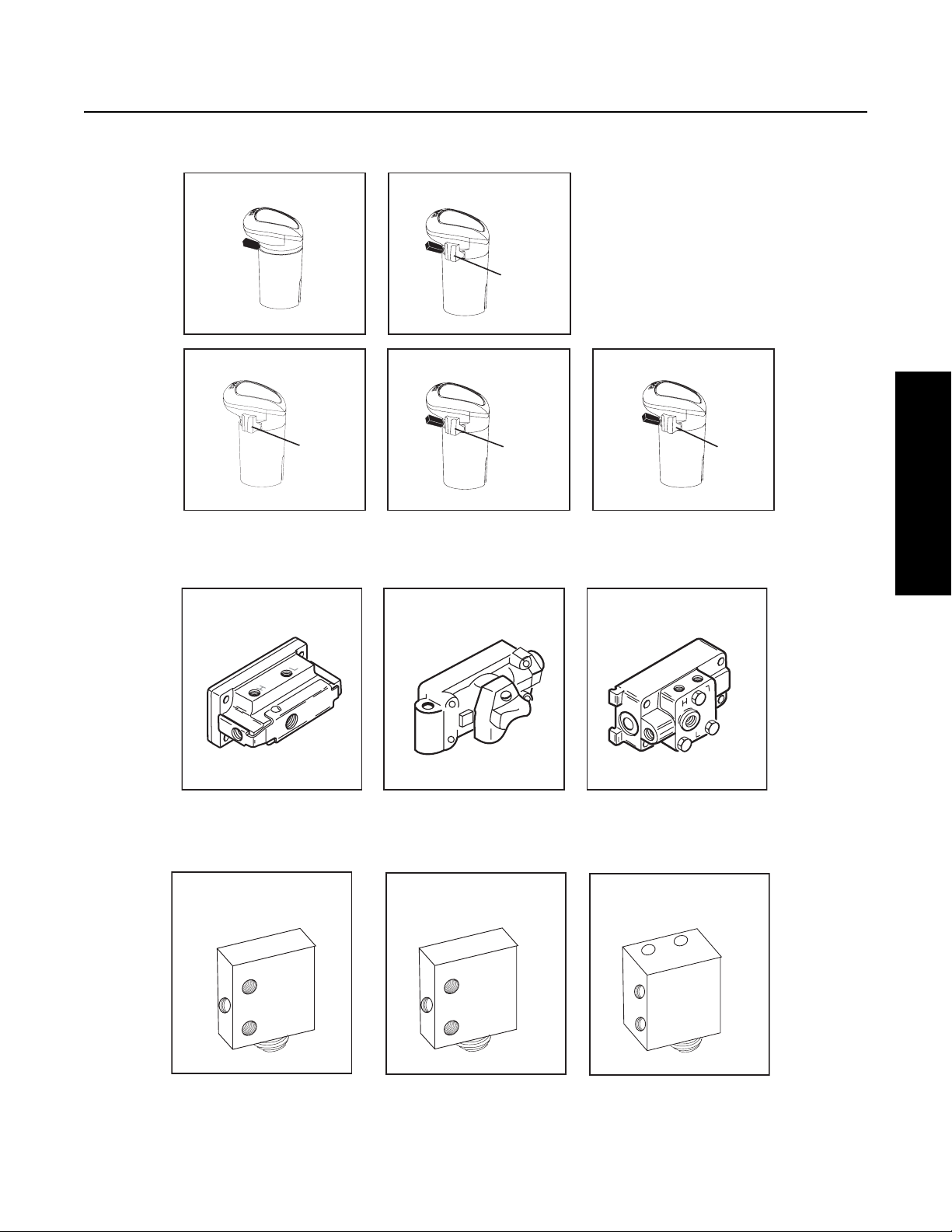

Control Valves - Current Production

General Information

Slave Valves

A-6909

8, 9, and 10 Speeds 8LL, 15, 6613 Speeds

A-6910

A-6915

A-6913

A-4688 - Old19470 - Obsolete A-5000 - Current

Blue

A-6918

General Information

Red

RT/RTLO 13 Speeds RTLO-18 SpeedsRTLO-10 Speeds

GrayGray

Range Valves

23545

CYL

NO

23545 - old design

S

NC

P

EXH

4303110 - latest design

S

P

S

EXH

5

Page 11

General Information

Lubricants and Sealants

The use of improper sealants and lubricants during air system assembly can cause improper component operation and severe

transmission damage.

The following are the recommended sealants and lubricants to be used when assembling air system components:

Name: Eaton® Fuller® Silicone Lubricant

Part #: 71203 (8 oz. container)—Fleet size

Part #: 71206 (4 cc container)—Single application

Where Used: All O-rings and mating surfaces

Name: Eaton® Fuller® Sealant

Part #: 71205 (2 cc container)—Single application

Part #: 71206 (4 cc container)—Single application

Where Used: Air fittings and threads

6

Page 12

General Information

Suggested Test Fixtures

Note: For the Automated transmission models, refer to their Troubleshooting Guides for air system diagnostics.

Test Fixture for Range Cylinder

5/32" Air Line

0-100 PSI Gauge

84006 - 5/32" Push-To-Connect

to 1/8" NPTF

General Information

12881 - 1/8" Tee

Test fixture for 1/8" Air lines

0-100 PSI Gauge

85002 - Elbow Assembly

Test Fixture For 5/32" Air Line

0-100 PSI Gauge

12769 - 1/8" Nipple

5/32" Air Line

84006 - 5/32" Push-To-Connect

to 1/8" NPTF

84502 - Elbow

12881 - 1/8" Tee

1/8" Air Line

5/32" Air Line

83501 - Grip Nut

83001 - Compression Sleeve

85003 - Elbow

84006 - 5/32" Push-To-Connect

to 1/8" NPTF

85003 - Elbow

12881 - 1/8" Tee

5/32" Air Line

7

Page 13

Air System Troubleshooting

8, 9, 10, 11, 13, 15, and 18-Speed Troubleshooting

Symptom

• Air Leak at Shift Knob

• Air Leak at Slave Valve

• Air Leak from Transmission Breather or Transmission Case is Pressurized

• Air Leak at Splitter Cylinder Cover Exhaust Port

• No or Slow Range Shift into Low

• No or Slow Range Shift into High

• Range Shifts with Shift Lever in Gear

WARNING: Use care when removing air lines or checking for air flow from disconnected lines. High pressure air may

exhaust suddenly. Wear safety glasses. Exhaust all air pressure from system before removing air filter/regulator or combination cylinder cover.

Note: During all testing, the vehicle air pressure must be greater than 90 PSI (620 kPa). If during testing the pressure falls below

90 PSI (620 kPa), make sure the transmission is in neutral, start the engine, and let the pressure build to governor cutoff.

After the pressure reaches the governor cutoff, continue testing. The pressure is critical if the vehicle is equipped with a

Pressure Protection Valve that would shut off the air supply to certain air circuits if the system pressure dropped below a

preset level.

IMPORTANT: Use the following air system troubleshooting procedures for part replacement only if the symptom can be duplicated. If the problem is intermittent, parts that are not defective could be replaced.

Instructions

1. Start at “Procedures” for Step A.

2. Based on the “Result” of the procedure, go to the corresponding “What To Do Next”.

8

Page 14

Air System Troubleshooting

Procedure 1: Symptom - Air Leak at Shift Knob

Normal Operation:

• A burst of air will be exhausted from the shift knob when moving the range selector from low to high. This is the air being

exhausted from the “P” air line.

• A burst of air will be exhausted from the shift knob when moving the splitter button rearward (shifting to low split). This

is the air being exhausted from the “SP” air line.

Possible Causes:

• Incorrectly attached air lines

• Internal leak in slave valve

• Internal leak at insert valve

• Internal leak at shift knob

Table 10 Air Leak at Shift Knob

Procedure Result What to do next

Step A Remove lower skirt on shift knob.

Check for leaking fitting at the shift

knob.

Step B Check air lines to make sure all lines

are connected to the proper ports on

the shift knob.

A.) Reversal of “S” and “P” lines will

result in a constant leak from the exhaust when high range is selected.

B.) Reversal of the H/L and “SP”

lines will result in a constant leak

when the splitter button is rearward.

Step C Move the range selector lever down

to low range. Check for constant air

flow from the exhaust “E” port.

Leak found. Repair leaking fitting or air line.

No leak found. Go to Step B.

Air lines are not connected to the

proper ports.

Air lines are connected to the proper

ports.

Constant air flow from the “E” port. Replace knob.

Connect lines properly.

Go to Step C.

Air System Troubleshooting

Step D Move the range selector up to high

range. Disconnect the small air line

connected to the “P” port of the shift

knob. Check for air flow from the

port and air line.

No air flow from “E” port. Go to Step D.

Constant air is leaking from the “P”

port or the “E” port.

Air is coming out of the disconnected air line.

Air is not leaking from either port or

disconnected air line.

Repair or replace the shift knob.

1. Verify that the air line is connected

to the slave valve “p” port.

2. If properly connected, replace the

slave valve.

Go to Step E.

9

Page 15

Air System Troubleshooting

Table 10 Air Leak at Shift Knob

Procedure Result What to do next

Step E Reattach the air line to the “P” port.

Move the range selector down to low

range and move the splitter button

rearward. Disconnect line from the

“SP” port. Check for air flowing from

the SP port on the shift knob.

Air is flowing from the SP line. 1. Check to make sure the “SP” line

is connected to the splitter cylinder

cover.

2. If the line is properly attached,

check that the insert valve (old style)

is properly installed (stem facing inward) and that the insert valve bore

is not defective.

3. Replace the insert valve.

Air is not flowing from the line. Repair or replace the shift knob.

10

Page 16

Air System Troubleshooting

Procedure 2: Symptom - Air Leak at Slave Valve

Normal Operation:

A momentary exhaust of air at the slave valve occurs during a range shift. The air from the low side of the range cylinder is

exhausted as air pressure is applied to the high range side. Likewise, air from the high range side of the piston is exhausted as air

pressure is applied to the low range side. The exhaust port is located at the slave valve to transmission mounting interface.

Possible Causes:

• Internal leak in range cylinder.

• Internal leak in slave valve.

Table 11 Air Leak at Slave Valve

Procedure Result What to do next

Step A Confirm that air is leaking from the ex-

haust port on the slave valve and not a

fitting or air line.

Step B Move range selector down to select low

range.

Remove the 1/4" I.D. rubber air line at

the high range supply port on the range

cylinder.

Feel for air flow from the open port on

the range cylinder.

Notice if the air leak at the slave valve

only occurs when the transmission is in

high range.

Repeat the above test but remove the

low range air hose and check with high

range selected.

Air is leaking from fitting or air line. Repair or replace fitting or air line.

Air is definitely leaking from slave

valve exhaust port.

Air is flowing from high range supply port on range cylinder.

No air flow from high range port. Repair or replace slave valve.

Go to Step B.

Remove range cylinder cover and

repair leaking range piston or piston seal. After repair, check for

proper range operation.

Air System Troubleshooting

11

Page 17

Air System Troubleshooting

Procedure 3: Symptom - Air Leak from Transmission Breather or Transmission Case is

Pressurized

Normal Operation:

There should be no measurable air flow from the transmission breather.

Possible Causes:

• Leak at range yoke bar O-ring

• Leak at splitter yoke bar O-ring

Table 12 Air Leak from Transmission Breather or Transmission Case is Pressurized

Procedure Result What to do next

Step A Listen for the air leak with the trans-

mission shifted to both low and

high range.

Leak is only in low range. Remove range cylinder and inspect for

damaged range yoke bar, yoke bar Oring, or range cylinder. Repair as necessary.

Leak is in both low and

high range.

Remove splitter cylinder. Inspect for

damaged splitter yoke bar, O-ring, or cylinder. Repair as necessary.

12

Page 18

Air System Troubleshooting

Procedure 4: Symptom - Air Leak at Splitter Cylinder Cover Exhaust Port

Normal Operation:

A burst of air will exhaust from this port when shifting into low split (the splitter button is moved rearward while in low range).

Possible Causes:

• Damaged/defective insert valve

• Leak past insert valve external O-rings

• Leak past splitter cylinder piston

Table 13 Air Leak at Splitter Cylinder Cover Exhaust Port

Procedure Result What to do next

Step A (old

style)

Remove insert valve. Check for contamination, damaged seals, or sticky movement. Check the insert

valve bore in the splitter cylinder cover for contamination or damage which would result in leakage past

the insert valve O-rings.

Contamination or damage

found.

Repair or replace as necessary.

Air System Troubleshooting

Step B Remove the splitter cylinder cover and piston.

Check the piston bore for contamination or damage.

Check the piston seals for damage.

NOTE: Early production transmissions used a paper

gasket to seal the splitter cover to cylinder, if necessary, replace this configuration with the spool valve

design which uses an O-ring.

No contamination or damage

found.

Contamination or damage

found.

Go to Step B.

Repair or replace as necessary.

13

Page 19

Air System Troubleshooting

Procedure 5: Symptom - No or Slow Range Shift into Low

Normal Operation:

When the range selector on the shift knob is moved down to select low range, air pressure will flow through the shift knob to the

"P" port on the slave valve. The slave valve will direct air pressure through the low range 1/4" rubber hose to the range cylinder to

shift the range. There will be a brief burst of air at the slave valve as the high range side of the range piston exhausts. Likewise,

when high range is selected, the air pressure in the "P" will be exhausted at the shift knob. This will cause the slave valve to direct

air to the rear side of the range cylinder piston. The air pressure on the low range side will be exhausted at the slave valve.

Possible Causes:

• Incorrect air line hook up

• Insufficient air supply to transmission

• Damaged or defective air filter / regulator assembly

• Damaged or defective shift knob master valve

• Damaged or defective slave valve

• Damaged or defective range cylinder

• Damaged or defective range yoke or yoke bar

• Damaged or defective range synchronizer

• Damaged or defective gearing in auxiliary section of transmission

Table 14 No or Slow Range Shift into Low

Procedure Result What to do next

Step A Place the shift lever in neutral.

Check for constant air leakage at the shift

knob, slave valve, and transmission case

breather when both low and high range

have been selected.

Step B Place shift lever in neutral.

Move range selector up to high range

position. At the rear of the transmission,

disconnect the 1/4" rubber air line from

the low range supply port on the range

cylinder. Check for air flow from the low

range port.

Step C Check for air flow from the disconnected

air line.

Constant air leak is detected. Go to the other corresponding symp-

No constant leak is detected. Go to Step B.

Air flows from the low range

port.

No air flow from low range

port.

Air flows from disconnected

air line.

tom first. See beginning of Air System

Troubleshooting section.

Remove range cylinder cover and repair leaking range piston or piston seal.

Go to step C.

Go to step F.

14

No air flow from disconnected line.

Go to step D.

Page 20

Table 14 No or Slow Range Shift into Low

Procedure Result What to do next

Air System Troubleshooting

Step D Install a 100 PSI air gauge in the discon-

nected air line end. With the shift lever in

neutral, move the range selector down to

select low range. Observe the gauge.

Step E Confirm that shift lever is still in neutral.

Have an assistant move the range selector up and down between low and high

range. Does the pressure measured at

the gauge respond rapidly when going

from high to low?

The gauge read 0 PSI. Go to step F.

The gauge reads pressure but

is lower than 58 PSI or higher

than 63 PSI.

The gauge reads between 58 63 PSI.

Pressure rapidly changes between 58-63 PSI and 0 at the

gauge.

Pressure does not change

rapidly at gauge.

Replace the filter/regulator and check

for proper range operation.

Go to step E.

Air system appears to be operating

satisfactory. Go to step R.

1. Check for a plugged or dirty filter in

the filter/regulator assembly.

2. Check for a pinched or obstructed

1/4" rubber air line between the filter/

regulator and slave valve.

3. Check for a pinched or obstructed

1/4" rubber air line between the slave

valve and the test gauge.

Air System Troubleshooting

Step F Place shift lever in neutral.

At the shift knob, move the range selection lever up to select high range.

At the slave valve, remove the air line

from the "P" port. (should be a black

line). Check for air flow from the disconnected line.

Step G Check for air flow from the "P" port on

the slave valve.

4. If all are satisfactory, go to step F.

Air flows from the disconnected line.

No air flow from the disconnected line.

Air flows from this port. Replace the slave valve.

No air flow from this port. Go to step H.

1. Confirm that the air lines are connected to the correct ports at the shift

knob.

2. If the lines are correct, replace the

shift knob.

Go to step G.

15

Page 21

Air System Troubleshooting

Table 14 No or Slow Range Shift into Low

Procedure Result What to do next

Step H Place the shift lever in neutral. Install a

100 PSI pressure gauge in line with the

"P" line. Move the range selector back

and forth from low to high range. The

gauge should show rapid pressure

change.

Step I If possible, leave air lines attached to

slave valve. Unbolt the slave valve from

transmission side. Check for free movement of the plunger pin protruding from

the case under the slave valve. The pin

should extract when the transmission is

shifted into gear and retract when shifted

into neutral.

NOTE: If desired, the slave valve can be

actuated and tested while unbolted from

the transmission case. The air lines, of

course, must remain attached.

The gauge responds slowly. 1. Check for a restricted line between

the shift knob and slave valve.

2. If the lines are correct, replace the

shift knob.

3. Check for a plugged or dirty filter in

the filter / regulator assembly.

4. Check for a pinched or obstructed

1/4" rubber air line between the filter/

regulator and slave valve.

5. Check for a pinched or obstructed air

line between the slave valve and the "S"

port on the shift knob.

6. If all are good, replace the shift knob.

The gauge rapidly moves between 58-63 PSI and 0 PSI.

Actuating plunger pin does

not move freely.

Go to step I.

1. Remove actuating plunger pin and

check for damage.

16

Actuating plunger pin moves

freely.

2. Check for missing or broken spring.

Repair or replace slave valve and check

for proper range operation.

Page 22

Table 14 No or Slow Range Shift into Low

Procedure Result What to do next

Step R If air system has been tested and found

to operate satisfactory, the auxiliary section must be removed to inspect for mechanical problem.

Remove auxiliary section and inspect

for:

•Binding of range yoke bar or piston

•Damaged or defective range yoke

•Damaged or defective range synchronizer

•Cracked countershaft weld resulting in

gear turning on shaft

•Damaged or defective range sliding

clutch

•Auxiliary section gearing out of time

Air System Troubleshooting

Air System Troubleshooting

17

Page 23

Air System Troubleshooting

Procedure 6: Symptom - No or Slow Range Shift into High

Normal Operation:

When the range selector on the shift knob is moved down to select low range, air pressure will flow through the shift knob to the

'P" port on the slave valve. The slave valve will direct air pressure through the low range 1/4" rubber supply hose to the range

cylinder to shift the range. There will be a brief burst of air at the slave valve as the high range side of the range piston exhausts.

Likewise, when high range is selected, the air pressure in the "P" will be exhausted at the shift knob. This will cause the slave valve

to direct air to the rear side of the range cylinder piston. The air pressure on the low range side will be exhausted at the slave valve.

Possible Causes:

• Incorrect air line hook up

• Insufficient air supply to transmission

• Plugged filter

• Incorrect regulator pressure

• Damaged or defective shift knob master valve

• Damaged or defective slave valve

• Damaged or defective range cylinder

• Damaged or defective range yoke or yoke bar

• Damaged or defective range synchronizer

• Damaged or defective gearing in auxiliary section of transmission

Table 15 No or Slow Range Shift into High

Procedure Result What to do next

Step A Place the shift lever in neutral.

Check for constant air leakage at the shift

knob, slave valve, and transmission case

breather when both low and high range

have been selected.

Step B Place shift lever in neutral.

Move range selector down to low range

position.

At the transmission rear, disconnect the

1/4" rubber air line from the range cylinder high range supply port.

Check for air flow from the cylinder high

range port.

Constant air leak is detected. Go to the other corresponding symp-

No constant leak is detected. Go to Step B.

Air flows from the high range

port.

No air flow from high range

port.

tom first. See beginning of Air System

Troubleshooting section.

Remove range cylinder cover and repair leaking range piston or piston seal.

After repair, check for proper range operation.

Go to step C.

Step C Check for air flow from the disconnected

air line.

18

Air flows from disconnected

air line.

No air flow from disconnected line.

Go to step F.

Go to step D.

Page 24

Table 15 No or Slow Range Shift into High

Procedure Result What to do next

Air System Troubleshooting

Step D Install a 100 PSI air gauge in the discon-

nected air line end. With the shift lever in

neutral, move the range selector up to

select high range. Observe the gauge.

Step E Confirm that shift lever is still in neutral.

Have an assistant move the range selector up and down between low and high

range. Does the pressure measured at

the gauge respond rapidly when going

from high to low.

The gauge reads 0 PSI. Go to step F.

The gauge reads pressure but

is lower than 58 PSI or higher

than 63 PSI.

The gauge reads between 58 63 PSI.

Pressure rapidly changes between 58-63 PSI and 0 at the

gauge.

Pressure does not change

rapidly at gauge.

Replace the filter/regulator and check

for proper range operation.

Go to step E.

Air system appears to be operating

satisfactory. Go to step R.

1. Check for a plugged or dirty filter in

the filter/regulator assembly.

2. Check for a pinched or obstructed 1/

4" rubber air line between the filter/regulator and slave valve.

3. Check for a pinched or obstructed 1/

4" rubber air line between the slave

valve and the test gauge.

Air System Troubleshooting

Step F Place shift lever in neutral.

At the shift knob, move the range selection lever up to select high range.

At the slave valve, remove the air line

from the "P" port. (should be black line).

Check for air flow from the disconnected

line.

Step G Check for air coming out of the slave

valve "P" port.

4. If all are satisfactory, go to step F.

Air flows from the disconnected line.

No air flow from the disconnected line.

Air flows from this port. Replace the slave valve.

No air flow from this port. Go to step H.

1. Confirm that the air lines are connected to the correct ports at the shift

knob.

2. If the lines are correct, replace the

shift knob.

Go to step G.

19

Page 25

Air System Troubleshooting

Table 15 No or Slow Range Shift into High

Procedure Result What to do next

Step H Place the shift lever in neutral. Install a

100 PSI pressure gauge in line with the

"P" line. Move the range selector back

and forth from low to high range. The

gauge should show rapid pressure

change.

Step I If possible, leave air lines attached to

slave valve.

Unbolt the slave valve from transmission

side.

Check for free movement of the plunger

pin protruding from the case under the

slave valve. The pin should extract when

the transmission is shifted into gear and

retract when shifted into neutral.

If desired, the slave valve can be actuated and tested while unbolted from the

transmission case. The air lines, of

course, must remain attached.

The gauge responds slowly. 1. Check for a restricted line between

the shift knob and slave valve.

2. Check for a restricted exhaust port

on the shift knob.

3. Check for a plugged or dirty filter in

the filter/regulator assembly.

4. Check for a pinched or obstructed

1/4" rubber air line between the filter/

regulator and slave valve.

5. Check for a pinched or obstructed air

line between the slave valve and the "S"

port on the shift knob.

6. If all are good, replace the shift knob.

The gauge rapidly moves between 58-63 PSI and 0 PSI.

Actuating plunger pin does

not move freely.

Go to step I.

1. Remove actuating plunger pin and

check for damage.

20

Actuating plunger pin moves

freely.

2. Check for missing or broken spring.

Repair or replace slave valve and check

for proper range operation.

Page 26

Table 15 No or Slow Range Shift into High

Procedure Result What to do next

Step R If air system has been tested and found

to operate satisfactory, the auxiliary section must be removed to inspect for mechanical problem.

Remove auxiliary section and inspect

for:

•Binding of range yoke bar or piston

•Damaged or defective range yoke

•Damaged or defective range synchronizer

•Cracked countershaft weld resulting in

gear turning on shaft

•Damaged or defective range sliding

clutch

•Auxiliary section gearing out of time

Air System Troubleshooting

Air System Troubleshooting

21

Page 27

Air System Troubleshooting

Procedure 8: Symptom - Range Shifts with Shift Lever in Gear

Normal Operation:

Range shifts should only occur when the shift lever is in neutral. The range selector can be moved up or down while the shift lever

is in a gear position, but the shift will not occur until the shift lever is moved to neutral.

Possible Causes:

• Worn or missing actuating pin or air valve shaft

• Worn shift rail

Procedure:

If the range has been confirmed to shift with the shift lever in gear, unbolt the slave valve from the side of the transmission. Confirm that the actuating pin is present and that it is the proper part number for the corresponding slave valve. If correct, remove the

shift bar housing assembly and check for a worn or damaged air valve shaft or worn shift rails. Replace necessary parts.

22

Page 28

Air System Troubleshooting

RTLO 10-Speed Troubleshooting

Confirm Correct Components and Plumbing

• A-5454 Air Filter/Regulator on the range cylinder cover.

• 1/4 inch air hose from the air filter/regulator to the splitter cylinder cover (iron port).

• A red air line from the air filter/regulator to the tee in the range actuator valve "S" port on the shift bar housing.

• A red air line from the tee to the A-5510/A-6910 Roadranger valve "S" port.

• A black air line from the range actuator valve "P" port to the range cylinder.

• A blue air line from the Roadranger A-5510/A-6910 valve "SP" port to the splitter cylinder cover (brass port.)

WARNING: Prior to removing the air module, exhaust the air from it. Failure to exhaust the air module may result in

personal injury or damage to parts from the sudden release of air.

WARNING: Use care when removing the test port pipe plugs. If air pressure is present on the plug, it can become a

projectile during removal. When removing the “L” plug or “H” plug, pressure can be shut off by selecting the opposite

range mode. If removing the “F” plug, exhaust the air to the module inlet.

Air System Troubleshooting

Blue Air Line

Red Air Line

Red Air Line

Black Air Line

O

N

L

Y

C

C

N

A-5454

Air Filter/

Regulator

Air Hose

23

Page 29

Air System Troubleshooting

Air Filter/ Regulator Test

Figure 1

Figure 2

Table 1 Air Filter/Regulator Test

Step Procedure Result What to do next

A Place the transmission shift lever

in neutral.

B Start the engine and wait for the

air system pressure to reach governor cut off (90 to 125 PSI.)

C Turn the engine off.

If at any time during testing the

truck's air pressure falls below 90

PSI; restart the engine, wait for air

pressure to reach governor pressure, turn the engine off, and continue testing.

D Make sure the splitter control but-

ton is rearward.

E Remove the two (2) screws on the

Roadranger valve cover and pull

the cover down.

F Disconnect the blue air line from

the "SP" port.

G Install the correct test fixture for

your air line size in the "SP" line.

24

Page 30

Air System Troubleshooting

Table 1 Air Filter/Regulator Test

Step Procedure Result What to do next

H Move the splitter control button

forward to overdrive. The air pressure gauge should read between

58 and 63 PSI.

R Remove the test fixture. Assemble

the Roadranger valve.

Air pressure is outside the 58 to

63 PSI range and the truck's air

system pressure is 90 to 125 PSI.

Air pressure slowly comes up to

between 58 and 63 PSI.

Replace the A-5454 Filter/Regulator.

Inspect the red air line from the filter/regulator

to the range actuator valve and the red air line

from the range actuator valve to the A-5510/A6910 Roadranger valve for restrictions

Air System Troubleshooting

25

Page 31

Air System Troubleshooting

Range System Test

If water or oil is found in an insert valve, remove both insert valves, the filter/regulator, the range cylinder cover, and the range

piston. Clean everything and replace the range piston O-rings and range cylinder cover gasket. Apply silicone grease to the external range piston O-ring and the insert valve O-rings. Assemble and test.

Note: If you replace or repair any parts, return to Step A after completion

Figure 3

Figure 4

Table 2 Range System Test

Step Procedure Result What to do next

A Move the transmission shift lever in

neutral away from the driver to the top

gear rail position.

B Remove the black air line from the

range cylinder cover.

C Check for air flow out of the black air

line.

There is no air flow from the black air

line.

There is air flow. Check the range actuator valve retain-

Go to step D.

ing bolts. Tighten any loose bolts and

check again for air flow. If air flow continues, remove the range actuator

valve retaining bracket bolts. Push the

button all the way into the valve. If air

flow continues, replace the range actuator valve. If air flow stops when the

range actuator valve is manually operated, remove the actuating pin (lift it

out with a magnet). Check the pin for

wear. It should be 1.029 to 1.032 inches long. If it is not, replace the pin. If

the pin length is correct, refer to the

service manual for shift bar housing

inspection.

26

Page 32

Air System Troubleshooting

Table 2 Range System Test

Step Procedure Result What to do next

D Check for air flow from the range cyl-

inder port.

E Install the correct test fixture, for your

air line size, in the range cylinder port.

There is no air flow from the port. Go to step E.

There is air flow. Remove the insert valve retaining plug

from the range cylinder cover bottom.

The insert valve will be blown out of

the cover. Clean the insert valve, using

compressed air and apply silicone

grease to the external O-rings. Assemble and check for air flow from the

port. If air flow persists, replace the

insert valve.

Air System Troubleshooting

F Move the transmission shift lever to-

ward the driver (center rail.) The air

pressure should rapidly be between 58

and 63 PSI.

Air pressure rapidly comes up to between 58 and 63 PSI.

Air pressure does not rapidly come up

to between 58 and 63 PSI.

Remove the test fixture and connect

the black air line to the range cylinder.

If air pressure does rapidly come up to

between 58 and 63 PSI, remove the

actuating pin (lift it out with a magnet).

The pin should be between 1.029 and

1.032 inches long. If it is not, replace

it. If the pin length is correct, refer to

the service manual for shift bar housing inspection.

Inspect the black air line from the

range actuator valve "CYL" port for restrictions.If there are no restrictions,

remove the range actuator valve retaining bolt. Push the button all the

way into the valve and release it. If air

pressure does not rapidly come up to

between 58 and 63 PSI, replace the

range actuator valve.

27

Page 33

Air System Troubleshooting

Table 2 Range System Test

Step Procedure Result What to do next

G Listen for a range shift while moving

the transmission shift lever from neutral to the top gear rail and back toward

the driver into the center rail. If there is

no range shift, move the transmission

shift lever back and forth again and

check for a momentary exhaust from

the insert valve retaining plug in the

range cylinder cover bottom.

I Move the transmission shift lever in

neutral toward the driver to the center

rail. Check both insert valve retaining

plugs for continuous air flow from the

exhaust port.

There is no range shift and there is

momentary exhaust from both insert

valves.

There is no momentary exhaust. Remove the insert valve retaining plug

There is momentary exhaust. Move the transmission shift lever in

There is air flow. Remove the insert valve retaining plug.

Remove the range cylinder cover. If

the piston is stuck from rust and contamination, remove the piston, clean

the cylinder, replace the O-rings, and

assemble. Clean the insert valve, use

compressed air and apply silicone

grease to the external O-rings. Assemble and test.

from the range cylinder cover bottom.

The insert valve will be blown out of

the cover. Clean the insert valve, use

compressed air and apply silicone

grease to the external O-rings. Assemble and test. If there is still no momentary exhaust, replace the insert valve.

neutral back and forth again and check

for momentary exhaust from the insert

valve retaining plug on the range cylinder cover side. Continue to step I.

The insert valve will be blown out of

the cover. Clean the insert valve, use

compressed air and apply silicone

grease to the external O-rings. Assemble and check for air flow. If air

flow persists, replace the insert valve.

If air flow persists with a new insert

valve, remove the range cylinder cover

and inspect the range piston O-rings

for damage or contamination and the

range piston for cracks.

J Move the transmission shift lever in

neutral away from the driver to the top

gear rail. Check both insert valve retaining plugs for continuous air flow

from the exhaust port.

28

There is no air flow. Go to step J.

There is air flow. Remove the insert valve retaining plug.

The insert valve will be blown out of

the cover. Clean the insert valve, use

compressed air and apply silicone

grease to the external O-rings. Assemble and check for air flow. If air

flow persists, replace the insert valve.

There is no air flow. Go to step K.

Page 34

Air System Troubleshooting

Table 2 Range System Test

Step Procedure Result What to do next

K With the transmission shift lever in

neutral, toward the driver in the center

rail, remove the breather or breather

hole plug on the shift bar housing.

Check for air flow from the hole in the

shift bar housing. If there is airflow

move the transmission shift lever in

neutral, away from the driver, to the

top gear rail.

R If the insert valves were not removed

and cleaned during the test, remove

them now (remove the insert valve retaining plugs.) The insert valves will

be blown out the cover. Clean the insert valve, use compressed air and apply silicone grease to the external "O"

rings. Assemble and test. The range

portion of the test is now complete.

Air flow stopped. Refer to the service manual and re-

place the range piston shaft to range

cylinder O-ring.

Air System Troubleshooting

Air flow did not stop. Refer to the service manual and re-

place the splitter piston shaft to splitter

cylinder O-ring.

29

Page 35

Air System Troubleshooting

Splitter System Test

If you replace or repair any parts , return to Step A after completion

Ffigure 1

Figure 3

Figure 2

Table 3 Splitter System Test

Step Procedure Result What to do next

A Wipe off the area around the insert

valve exhaust port.

B Move the control button back and

forth several times to clear the exhaust port.

C Make sure the control button is rear-

ward. Loosen the control air line retaining nut at the splitter cylinder.

30

Page 36

Air System Troubleshooting

Table 3 Splitter System Test

Step Procedure Result What to do next

D Remove the loosened control air line

and check for air flow from the cylinder fitting.

E Install, between the control line and

the cylinder fitting, the correct test fixture for your air line size.

F Move the control button forward. Air pressure rapidly changes to be-

G Check the insert valve exhaust port for

leakage.

H Move the control button rearward and

listen for the shift.

There is no air flow. Go to step E.

There is air flow. Remove the insert valve and clean us-

tween 58 and 63 PSI and the truck's

air system is 90 to 125 PSI.

Air pressure does not change to between 58 and 63 PSI and the truck's

air system is 90 to 125 PSI.

No leakage is detected. Go to next step H.

Leakage is detected. Go to Step L.

There is a shift. Go to next step I.

ing compressed air. Then apply silicone grease to the o-rings and

recheck for airflow.

Air System Troubleshooting

Go to next step G.

Inspect the control air line for restrictions.

There is no shift or a delayed shift. Go to Step L.

I Check the exhaust port for leakage. No leakage is detected. Go to next step J.

Leakage is detected. Go to Step L.

J Move the control button forward and

listen for the shift.

K If there is air pressure at the control

line, move the control button rearward

and remove the test fixture. Connect

the control line to the cylinder.

L Remove the insert valve retaining

plug. The insert valve will be blown

out of the cover (note valve orientation.)

M Clean insert valve using compressed

air.

There is a shift. Go to next step K.

There is no shift or a delayed shift. Go to Step L.

There is no water and/or oil blown out. Go to next step M.

Water and/or oil is blown out. Remove the cylinder cover and clean

the cover and cylinder. Replace the

cylinder cover gasket with a new gasket. Install cover.

31

Page 37

Air System Troubleshooting

Table 3 Splitter System Test

Step Procedure Result What to do next

N Install the insert valve, as noted in

Step L, and replace the retaining plug.

O Check the insert valve exhaust port for

leakage.

P Move the control button forward and

listen for the shift.

Q Check the insert valve exhaust port for

leakage.

R Move the control button rearward and

listen for the shift

S Check the insert valve exhaust port for

leakage.

No leakage is detected. Go to next step P.

Leakage is detected. Replace the insert valve.

There is a shift. Go to next step Q.

There is no shift or a delayed shift. Replace the insert valve.

No leakage is detected. Go to next step R.

Leakage is detected. Replace the insert valve.

There is a shift. Go to next step S.

There is no shift or a delayed shift. Replace the insert valve.

No leakage is detected. Go to next step T.

Leakage is detected. Disassemble (see service manual)

and inspect splitter/reduction piston

O-ring and piston to shaft seal.

T Move the control button forward and

listen for the shift.

V The air system test procedure is now

complete and the air system has been

confirmed to be operating correctly. If

performance irregularities persist,

they are not caused by the air system.

There is a shift. Go to next step V.

There is no shift or a delayed shift. Disassemble (see service manual)

and inspect splitter/reduction piston

O-ring and piston to shaft seal.

32

Page 38

Air System Troubleshooting

Combination Cylinder Troubleshooting

The symptoms listed below are covered on the following pages. Before beginning any of those troubleshooting procedures, place

the transmission in neutral and move the range selection lever from low to high. Listen for any constant air leak from the shift

knob, air module base (exhaust), or transmission breather. If a constant leak is heard, go to that particular leak troubleshooting

procedure first.

If you do not see the symptom you need to correct, refer to the General Troubleshooting chart.

Symptom

• Air Leak from Air Module Base (Exhaust Leak)

• No or Slow Range Shift into High (Shift into low range is good)

• No or Slow Range Shift into Low (Shift into high range is good)

• Constant Air Leak from Shift Knob

• Range Shifts in Gear

• Air Leak from Transmission Breather or Transmission Case is Pressurized

Note: Use the air system troubleshooting procedures for part replacement only if the symptom can be duplicated. If the problem

is intermittent, parts that are not defective could be replaced.

Air System Troubleshooting

Note: During all testing, the vehicle air pressure must be greater than 90 PSI (620 kPa). If during testing the pressure falls below

90 PSI (620 kPa), make sure the transmission is in neutral, start the engine and let the pressure build to governor cutoff.

After the pressure reaches the governor cutoff, continue testing. The pressure is critical if the vehicle is equipped with a vehicle air system Pressure Protection Valve that would shut off the air supply to certain air circuits if the system pressure

dropped below a preset level.

Note: A 0-150 PSI (0-1034 kPa) air gauge with a 1/16” male pipe thread fitting attachment is required for some of the test proce-

dures.

WARNING: Prior to removing the air module, exhaust the air from it. Failure to exhaust the air module may result in

personal injury or damage to parts from the sudden release of air.

WARNING: Use care when removing the test port pipe plugs. If air pressure is present on the plug, it can become a

projectile during removal. When removing the “L” plug or “H” plug, pressure can be shut off by selecting the opposite

range mode. If removing the “F” plug, exhaust the air to the module inlet.

33

Page 39

Air System Troubleshooting

Procedure 1: Symptom - Air Leak at Shift Knob

Normal operation:

A burst of air will be exhausted from the shift knob when moving the range selector from low to high. This is the air being exhausted from the "P" air line.

A burst of air will be exhausted from the shift knob when moving the deep reduction button rearward (shifting out of deep reduction).This is the air being exhausted from the “SP” air line.

Possible causes:

• Incorrectly attached air lines

• Internal leak in slave valve

• Internal leak at insert valve

• Internal leak at shift knob

Table 1 Air Leak at Shift Knob

Procedure Result What to do next

Step A Remove lower skirt on shift knob. Check

for leaking fitting at the shift knob.

Step B Check air lines to make sure all lines are

connected to the proper ports on the shift

knob. Reversal of “S” and “P” lines will

result in a constant leak from the exhaust

when high range is selected. Reversal of

the H/L and “SP” lines will result in a constant leak when the deep reduction button is rearward.

Step C Move the range selector lever down to

Low range. Check for constant air flow

from the exhaust “E” port.

Step D Move the range selector up to high range.

Disconnect the small air line connected

to the “P” port of the shift knob. Check

for air flow from the port and air line.

Leak found. Repair leaking fitting or air

line.

No leak found. Go to step B.

Air lines are not connected to the proper

ports.

Air lines are connected to proper ports. Go to step C.

Constant air flow from “E” port. Replace knob.

No air flow from “E” port. Go to Step D.

Constant air is leaking from the “P” port

or the “E” port.

Air is coming out of the disconnected

air line.

Connect lines properly.

Repair or replace the shift

knob.

1. Verify that the air line is

connected to the slave valve

“p” port.

34

Air is not leaking from either port or disconnected air line.

2. If properly connected, replace the slave valve.

Go to Step E.

Page 40

Table 1 Air Leak at Shift Knob

Procedure Result What to do next

Air System Troubleshooting

Step E Reattach the air line to the “P” port. Move

the range selector down to low range and

move the deep reduction button rearward. Disconnect the air line from the

“SP” port. Check for air flowing from the

SP line.

Air is flowing from the SP line. 1. Check to make sure the

“SP” line is connected to the

deep reduction cylinder cover.

2. If the line is properly attached, check that the insert

valve is properly installed

(stem facing inward) and

that the insert valve bore is

not defective.

3. Replace the insert valve.

Air is not flowing from the line. Repair or replace the shift-

knob.

Air System Troubleshooting

35

Page 41

Air System Troubleshooting

Procedure 2: Symptom - Air Leak at Slave Valve

Normal operation:

A momentary exhaust of air at the slave valve occurs during a range shift. The air from the low side of the range cylinder is exhausted as air pressure is applied to the high range side. Likewise, air from the high range side of the piston is exhausted as air

pressure is applied to the low range side. The exhaust port is located at the slave valve to transmission mounting interface.

Possible Causes:

• Internal leak in range cylinder

• Internal leak in slave valve.

Table 2 Air Leak at Slave Valve

Procedure Result What to do next

Step A Confirm that air is leaking from the

exhaust port on the slave valve and

not a fitting or air line.

Step B Move range selector down to select

low range. Remove the 1/4” I.D.

rubber air line at the high range supply port on the range cylinder. Feel

for air flow from the open port on

the range cylinder. Note: If the air

leak at the slave valve only occurs

when the transmission is in high

range, repeat the above test, but remove the low range air hose and

check with high range selected.

Air is leaking from fitting or air line. Repair or replace fitting or air line.

Air is definitely leaking from slave

valve exhaust port.

Air is flowing from high range supply port on range cylinder.

No air flow from high range port. Repair or replace slave valve.

Go to Step B.

Remove range cylinder cover and repair leaking range piston or piston seal.

After repair, check for proper range operation.

36

Page 42

Air System Troubleshooting

Procedure 3: Symptom - Air Leak from Transmission Breather or Transmission Case is

Pressurized

Normal Operation:

There should be no measurable air flow from the transmission breather.

Possible causes:

• Leak at range yoke bar O-ring

• Leak at deep reduction yoke bar O-ring

Table 3 Air Leak from Transmission Breather or Transmission Case is Pressurized

Procedure Result What to do next

Step A Listen for the air leak with the trans-

mission shifted to both low and high

range.

Leak is only in low range. Remove range cylinder and inspect

for damaged range yoke bar, yoke bar

O-ring, or range cylinder. Repair as

necessary.

Leak is in both low and high range. Remove deep reduction cylinder. In-

spect for damaged deep reduction

yoke bar, O-ring, or cylinder. Repair

as necessary.

Air System Troubleshooting

37

Page 43

Air System Troubleshooting

Procedure 4: Symptom: Air Leak at Deep Reduction Cylinder Cover Exhaust Port

Normal operation:

A burst of air will exhaust from this port when shifting into deep reduction (the deep reduction button is moved forward while in

low range).

Possible causes:

• Damaged/defective insert valve

• Leak past insert valve external O-rings

• Leak past deep reduction cylinder piston

Table 4 Air Leak at Deep Reduction Cylinder Cover Exhaust Port

Procedure Result What to do next

Step A Remove insert valve. Check for con-

tamination, damaged seals, or sticky

movement. Check the insert valve

bore in the deep reduction cylinder

cover for contamination or damage

which would result in leakage past

the insert valve O-rings.

Step B Remove the deep reduction cylinder

cover and piston. Check the piston

bore for contamination or damage.

Check the piston seals for damage.

NOTE: Early production transmissions used a paper gasket to seal the

piston to the yoke bar, if necessary,

replace this configuration with the

current design which uses an Oring.

Contamination or damage found. Repair or replace as necessary.

No contamination or damage found. Go to step B.

Contamination or damage found. Repair or replace as necessary.

38

Page 44

Air System Troubleshooting

Procedure 5: Symptom - No or Slow Range Shift into Low

Normal Operation:

When the range selector on the shift knob is moved down to select low range, air pressure will flow through the shift knob to the

‘P port on the slave valve. The slave valve will direct air pressure through the low range 1/4” rubber hose to the range cylinder to

shift the range. There will be a brief burst of air at the slave valve as the high range side of the range piston exhausts. Likewise,

when high range is selected, the air pressure in the “P” will be exhausted at the shift knob. This will cause the slave valve to direct

air to the rear side of the range cylinder piston. The air pressure on the low range side will be exhausted at the slave valve.

Possible Causes:

• Incorrect air line hook up

• Insufficient air supply to transmission

• Damaged or defective air filter / regulator assembly

• Damaged or defective shift knob master valve

• Damaged or defective slave valve

• Damaged or defective range cylinder

• Damaged or defective range yoke or yoke bar

• Damaged or defective range synchronizer

• Damaged or defective gearing in auxiliary section of transmission

Table 5 No or Slow Range Shift into Low

Procedure Result What to do next

Step A Place the shift lever in neutral. Check

for constant air leakage at the shift

knob, slave valve, and transmission

case breather when both low and

high range have been selected.

Step B Place shift lever in neutral. Move

range selector up to high range position. At the rear of the transmission,

disconnect the 1/4” rubber air line

from the low range supply port on the

range cylinder. Check for air flow

from the low range port.

Constant air leak is detected. Go to the other corresponding symp-

No constant leak is detected. Go to step B.

Air flows from the low range port. Remove range cylinder cover and re-

Air System Troubleshooting

tom first. See beginning of Air System

Troubleshooting section.

pair leaking range piston or piston

seal.

Step C Check for air flow from the discon-

nected air line.

No air flow from low range port. Go to step C.

Air flows from disconnected air line. Go to step F.

No air flow from disconnected line. Go to step D.

39

Page 45

Air System Troubleshooting

Table 5 No or Slow Range Shift into Low

Procedure Result What to do next

Step D Install a 100 PSI air gauge in the dis-

connected air line end. With the shift

lever in neutral, move the range selector down to select low range and

observe the gauge.

Step E Confirm that shift lever is still in neu-

tral. Have an assistant move the

range selector up and down between

low and high range. Does the pressure measured at the gauge respond

rapidly when going from high to low.

The gauge read 0 PSI. Go to step F.

The gauge reads pressure but is lower than 58 PSI or higher than 63 PSI.

The gauge reads between 58 - 63

PSI.

Pressure rapidly changes between

58-63 PSI and 0 at the gauge.

Pressure does not change rapidly at

gauge.

Replace the filter/regulator and check

for proper range operation.

Go to step E.

Air system appears to be operating

satisfactory. Go to step R.

1. Check for a plugged or dirty filter in

the filter/regulator assembly.

2. Check for a pinched or obstructed

1/4” rubber air line between the filter/

regulator and slave valve.

Step F Place shift lever in neutral. At the

shift knob, move the range selection

lever up to select high range. At the

slave valve, remove the air line from

the “P” port (should be black line).

Check for air flow from the disconnected line.

Step G Check for air flow from the “P” por-

tion the slave valve.

3. Check for a pinched or obstructed

1/4” rubber air line between the slave

valve and the test gauge.

4. If all are satisfactory, go to step F.

Air flows from the disconnected line. 1. Confirm that the air lines are con-

nected to the correct ports at the shift

knob.

2. If the lines are correct, replace the

shift knob.

No air flow from the disconnected

line.

Air flows from this port. Replace the slave valve.

No air flow from this port. Continue to step H.

Go to step G.

40

Page 46

Table 5 No or Slow Range Shift into Low

Procedure Result What to do next

Air System Troubleshooting

Step H Place the shift lever in neutral. Install

a 100 PSI pressure gauge in line with

the “P” line. Move the range selector

back and forth from low to high

range. The gauge should show rapid

pressure change.

Step I If possible, leave air lines attached to

slave valve. Unbolt the slave valve

from transmission side. Check for

free movement of the plunger pin

protruding from the case under the

slave valve. The pin should extract

when the transmission is shifted into

gear and retract when shifted into

neutral.

The gauge responds slowly. 1. Check for a restricted line between

the shift knob and slave valve.

2. Check for a restricted exhaust port

on the shift knob.

3. Check for a plugged or dirty filter in

the filter / regulator assembly.

4. Check for a pinched or obstructed 1/

4” rubber air line between the filter/

regulator and slave valve.

5. Check for a pinched or obstructed

air line between the slave valve and the

“S” port on the shift knob.

6. If all are good, replace the shift

knob.

The gauge rapidly moves between

58-63 PSI and 0 PSI.

Actuating plunger pin does not move

freely.

Go to step I.

1. Remove actuating plunger pin and

check for damage.

Air System Troubleshooting

2. Check for missing or broken spring.

Actuating plunger pin moves freely. Repair or replace slave valve and

check for proper range operation.

41

Page 47

Air System Troubleshooting

Table 5 No or Slow Range Shift into Low

Procedure Result What to do next

Step R If air system has been tested and

found to operate satisfactory, the

auxiliary section must be removed to

inspect for mechanical problem. Remove auxiliary section and inspect

for:

•Binding of range yoke bar or piston

•Damaged or defective range yoke

•Damaged or defective range synchronizer

•Cracked c/s weld resulting in gear

turning on shaft

•Damaged or defective range sliding

clutch

•Auxiliary section gearing out of

time.

42

Page 48

Air System Troubleshooting

Procedure 6: Symptom - No or Slow Range Shift into High

Normal Operation:

When the range selector on the shift knob is moved down to select low range, air pressure will flow through the shift knob to the

‘P” port on the slave valve. The slave valve will direct air pressure through the low range 1/4” rubber supply hose to the range

cylinder to shift the range. There will be a brief burst of air at the slave valve as the high range side of the range piston exhausts.

Likewise, when high range is selected, the air pressure in the “P” will be exhausted at the shift knob. This will cause the slave valve

to direct air to the rear side of the range cylinder piston. The air pressure on the low range side will be exhausted at the slave valve.

Possible Causes:

• Incorrect air line hook up

• Insufficient air supply to transmission

• Plugged filter

• Incorrect regulator pressure

• Damaged or defective shift knob master valve

• Damaged or defective slave valve

• Damaged or defective range cylinder

• Damaged or defective range yoke or yoke bar

• Damaged or defective range synchronizer

• Damaged or defective gearing in auxiliary section of transmission

Table 6 No or Slow Range Shift into High

Procedure Result What to do next

Step A Place the shift lever in neutral. Check

for constant air leakage at the shift

knob, slave valve, and transmission

case breather when both low and high

range have been selected.

Step B Place shift lever in neutral. Move

range selector down to low range position. At the transmission rear, disconnect the 1/4” rubber air line from

the range cylinder high range supply

port. Check for air flow from the cylinder high range port.

Constant air leak is detected. Go to the above corresponding

No constant leak is detected. Go to step B.

Air flows from the high range port. Remove range cylinder cover and re-

Air System Troubleshooting

symptom first. See beginning of Air

System Troubleshooting section.

pair leaking range piston or piston

seal. After repair, check for proper

range operation.

Step C Check for air flow from the discon-

nected air line.

No air flow from high range port. Go to step C.

Air flows from disconnected air line. Go to step F.

No air flows from disconnected line. Go to step D.

43

Page 49

Air System Troubleshooting

Table 6 No or Slow Range Shift into High

Procedure Result What to do next

Step D Install a 100 PSI air gauge in the dis-

connected air line end. With the shift

lever in neutral, move the range selector up to select high range. Observe

the gauge.

Step E Confirm that a shift lever is still in

neutral. Have an assistant move the

range selector up and down between

low and high range. Does the pressure measured at the gauge respond

rapidly when going from low to high

to low.

The gauge reads 0 PSI. Go to step F.

The gauge reads pressure but is lower than 58 PSI or higher than 63 PSI.

The gauge reads between 58-63 PSI. Go to Step E.

Pressure rapidly changes between

58-63 PSI and O at the gauge.

Pressure does not respond rapidly at

gauge.

Replace the filter/regulator and check

for proper range operation.

Air system appears to be operating

satisfactory. Go to Step R.

1. Check for a plugged or dirty filter in

the filter/regulator assembly.

2. Check for a pinched or obstructed

1/4" rubber air line between the filter/

regulator and slave valve.

3. Check for a pinched or obstructed

1/4" rubber air line between the slave

valve and the test gauge.

Step F Place shift lever in neutral. At the shift

knob, move the range selector up to

select high range. At the slave valve,

remove the air line from the "P" port

(should be black line). Check for air

flow from the disconnected line.

Step G Check for air coming out of the slave

valve "P" port.

4. If all are satisfactory, Go to Step F.

Air flows from the disconnected line. 1. Confirm proper air line hook-up at

the shift knob.

2. If correct hook-up, replace the shift

knob.

No air flow from the disconnected

line.

Air flows from this port. Replace the slave valve.

No air flow from this port. Continue to Step H.

Go to Step G.

44

Page 50

Table 6 No or Slow Range Shift into High

Procedure Result What to do next

Air System Troubleshooting

Step H Place the shift lever in neutral. Install

a 100 PSI pressure gauge in line with

the "P" line end. Move the range selection lever back and forth from low to

high range. The gauge should show

rapid pressure change.

Step I If possible, leave air lines attached to

slave valve. Unbolt the slave valve

from the transmission side. Check for

free movement of the plunger pin protruding from the case under the slave

valve. The pin should extract when the

transmission is shifted into gear and

retract when shifted into neutral.

NOTE: If desired, the slave valve can

be actuated and tested while unbolted

from the transmission case. The air

lines, of course, must remain attached.

The gauge responds slowly. 1. Check for a restricted line between

the shift knob and slave valve.

2. Check for a restricted exhaust port

on the shift knob.

3. Check for a plugged or dirty filter in

the filter/regulator assembly.

4. Check for a pinched or obstructed

1/4" rubber air line between the filter/

regulator and slave valve.

5. Check for a pinched or obstructed

air line between the slave valve and

the "S" port on the shift knob.

6. If all are good, replace the shift

knob.

The gauge rapidly moves between

58-63 PSI and 0 PSI.

Actuating plunger pin does not move

freely.

Go to Step I.

1. Remove actuating plunger pin and

check for damage.

Air System Troubleshooting

2. Check for missing or broken

spring.

Actuating plunger pin moves freely. Repair or replace slave valve and

check for proper range operation.

45

Page 51

Air System Troubleshooting

Table 6 No or Slow Range Shift into High

Procedure Result What to do next

Step R If air system has been tested and

found to operate satisfactory, the

auxiliary section must be removed to

inspect for mechanical problem. Remove auxiliary section and inspect

for:

•Binding of range yoke bar or piston

•Damaged or defective range yoke

•Damaged or defective range synchronizer

•Cracked c/s weld resulting in gear

turning on shaft

•Damaged or defective range sliding

clutch

•Auxiliary section gearing out of time.

46

Page 52

Air System Troubleshooting

Procedure 7: Symptom - No or Slow Shift into Deep Reduction

Normal Operation:

When the deep reduction button is moved forward to select deep reduction, air pressure is supplied through the “SP” air line to

the insert valve signal port. This air pressure causes the insert valve to exhaust the air pressure on the rear of the deep reduction

piston and the piston moves rearward. A burst of air occurs at the deep reduction cylinder exhaust port as this air is exhausted

from the piston back side. A burst of air also occurs at the shift knob when the deep reduction button is moved rearward. This is

the signal air being exhausted out of the “SP” line.

Possible causes:

• Incorrect air line hook up, Plugged filter.

• Incorrect regulator pressure. Insufficient air supply to transmission.

• Damaged or defective shift knob master valve.

• Damaged or defective deep reduction insert valve.

• Damaged or defective deep reduction piston or cylinder.

• Damaged or defective deep reduction yoke bar or yoke.

• Damaged or defective deep reduction sliding clutch or gearing.

Note: Before completing the following troubleshooting procedure, move the deep reduction button both rearward and forward an

check for constant exhaust air at either the shift knob or deep reduction cylinder exhaust port. If a constant leak is noticed,

go to that troubleshooting procedure first. In addition, confirm that the low and high range shifts are occurring properly. If

not, go to the appropriate range shift troubleshooting procedure before completing the following procedure.

Table 7 No or Slow Shift into Deep Reduction

Procedure Result What to do next

Step A Move range selector down to select

low range. Move the deep reduction