Page 1

Service Manual

Fuller Heavy Duty Transmissions

TRSM0446

January 2010

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Warnings and Precautions

!

Warnings and Precautions

WARNING

Before starting a vehicle always be seated in the driver’s seat, place the transmission in neutral, set the parking brakes and

disengage the clutch.

Before working on a vehicle place the transmission in neutral, set the parking brakes and block the wheels.

Before towing the vehicle place the transmission in neutral, and lift the rear wheels off the ground, remove the axle shafts,

or disconnect the driveline to avoid damage to the transmission during towing.

The description and specifications contained in this service publication are current at the time of printing.

Eaton Corporation reserves the right to discontinue or modify its models and/or procedures and to change specifications at any

time without notice.

Any reference to brand name in this publication is made as an example of the types of tools and materials recommended for use

and should not be considered an endorsement. Equivalents may be used.

This symbol is used throughout this manual to call attention to procedures where carelessness or failure to follow

specific instructions may result in personal injury and/or component damage.

Departure from the instructions, choice of tools, materials and recommended parts mentioned in this publication may jeopardize

the personal safety of the service technican or vehicle operator.

Warning: Failure to follow indicated procedures creates a high risk of personal injury to the service technician.

Caution: Failure to follow indicated procedures may cause component damage or malfunction.

Note: Additional service information not covered in the service procedures.

Tip: Helpful removal and installation procedures to aid in the service of this unit.

Always use genuine Eaton replacement parts.

Page 4

Warnings and Precautions

Service Procedure

Page 5

Table of Contents

General Information

In-Vehicle Service Procedures

Transmission Overhaul

Procedures-Bench Service

Warnings and Precautions .......................................... 0

Transmission Overview ............................................... 0

Purpose and Scope of Manual .................................... 1

Serial Tag Information and Model Nomenclature ........ 5

Lubrication Specifications ........................................... 7

Tool Specifications ...................................................... 9

Transmission Torque Specifications ......................... 13

Preventative Maintenance Check Points .................... 15

Power Flow Diagrams ...............................................18

9 & 13 Speed Shift Patterns ...................................... 32

Air System Overview ................................................. 34

General Troubleshooting Chart ................................. 48

Air System Troubleshooting ...................................... 51

Timing Procedures .................................................... 66

How to Remove Oil Filter Adapter ............................. 68

How to Assemble Oil Filter Adapter ........................... 69

How to Disassemble Roadranger Valve A-5010 ........ 70

How to Assemble Roadranger Valve A-5010 ............. 72

How to Disassemble Roadranger Valve A-4900 ........ 74

How to Assemble Roadranger Valve A-4900 ............. 76

How to Install the Air Lines and Hoses ...................... 78

How to Remove Compression Type Fittings .............. 80

How to Remove the Air Lines and Hoses .................. 81

How to Install Compression Type Fittings ................. 83

How to Remove Push-To-Connect Type Fittings ....... 84

How to Install Push-To-Connect Type Fittings .......... 85

..................... How to Remove Rubber 1/4" Air Hoses 86

How to Remove the Air Filter/Regulator .................... 87

How to Install the Air Filter/Regulator ....................... 88

......................... How to Remove a Roadranger Valve 89

.............................How to Install a Roadranger Valve 90

.........................How to Install Rubber 1/4" Air Hoses 91

................................... How to Remove a Slave Valve 92

.......................................How to Install a Slave Valve 93

How to Remove the Gear Shift Lever/Remote Shift Control

94

How to Install the Gear Shift Lever/Remote Shift Control

95

. How to Adjust the Remote Shift Control (LRC Type) 96

........................Neutral Switch Operation and Testing 98

........................... How to Remove the Neutral Switch 99

............................How to Install the Neutral Switch 100

....................Reverse Switch Operation and Testing 101

....................... How to Remove the Reverse Switch 102

...........................How to Install the Reverse Switch 103

How to Remove the Shift Bar Housing ....................104

How to Install the Shift Bar Housing ........................105

How to Remove the Oil Seal - Mechanical Speedometer

107

How to Install the Oil Seal - Mechanical Speedometer ...

109

How to Remove the Oil Seal - Magnetic Speedometer ...

110

How to Install the Oil Seal - Magnetic Speedometer 113

How to Remove the Output Yoke/Companion Flange and

Nut ...................................................................115

How to Install the Output Yoke/Companion Flange and Nut

117

How to Remove the Auxiliary Section in Chassis .....119

How to Install the Auxiliary Section in Chassis ........121

How to Disassemble the Range Cylinder Assembly .124

How to Assemble the Range Cylinder Assembly ......126

How to Disassemble the Gear Shift Lever ................129

How to Assemble the Gear Shift Lever ....................131

....................How to Remove the Shift Bar Housing 133

....................... How to Install the Shift Bar Housing 135

How to Disassemble the Shift Bar Housing Assembly ...

137

How to Reassemble the Shift Bar Housing Assembly 140

How to Remove the Input Shaft Assembly (without main

case disassembly) ............................................144

How to Install the Input Shaft Assembly (without main

case disassembly) ............................................146

How to Remove the Auxiliary Section with Tapered Bear-

ings ..................................................................148

How to Remove the Auxiliary Countershaft Assemblies

(w/Tapered Bearings) .......................................150

How to Remove the Countershaft Assemblies (w/Ball

Bearings) A Series ............................................153

How to Remove the Splitter Cylinder Assembly .......155

How to Remove the Splitter Gear .............................157

How to Disassemble the Range Cylinder Assembly .158

.... How to Disassemble the Output Shaft Assembly 160

....How to Disassemble the Synchronizer Assembly 163

........ How to Assemble the Synchronizer Assembly 164

How to Assemble the Output Shaft Assembly ..........166

How to Install the Splitter Gear ................................169

How to Assemble the Range Cylinder Assembly ......170

How to Install Splitter Cylinder Assembly ................173

How to Install the Countershaft Assemblies (w/Tapered

Bearings) ..........................................................175

How to Install the Countershaft Assemblies (w/Ball Bear-

ings) A Series ...................................................178

How to Remove the Clutch Housing ........................181

How to Remove the Auxiliary Drive Gear Assembly .183

Page 6

How to Disassemble the Upper Reverse Idler Gear Assem-

bly .................................................................... 185

How to Remove the Upper and Lower Countershaft Bear-

ings .................................................................. 187

How to Remove the Mainshaft Assembly ................ 189

.........How to Remove the Countershaft Assemblies 190

How to Disassemble the Countershaft Assemblies . 192

How to Remove the Input Shaft and Main Drive Gear 194

How to Prepare the Main Case for Assembly .......... 197

......... How to Disassemble the Mainshaft Assembly 198

How to Assemble the Mainshaft Assembly with Selective

(Adjustable) Thickness

Tolerance Washers .......................................... 200

How to Assemble the Mainshaft Assembly with Non-Se-

lective (Non-Adjustable) Tolerance Washers .... 206

How to Assemble the Countershaft Assemblies ...... 209

How to Assemble the Lower Reverse Idler Gear Assembly

211

.................. How to Install Countershaft Assemblies 214

How to Install the Lower Countershaft Bearings ..... 215

How to Install .the Input Shaft and Main Drive Gear 217

....................How to Install the Mainshaft Assembly 219

How to Install the ...... Upper Countershaft Bearings 221

How to Assemble the Upper Reverse Idler Gear Assembly

224

How to Install the Auxiliary Drive Gear Assembly .... 227

How to Install the Clutch Housing ...........................229

How to Disassemble the Integral Oil Pump without Auxil-

iary Oil Tube .....................................................230

How to Assemble the Integral Oil Pump without Auxiliary

Oil Tube ........................................................... 233

.....................How to Remove the Integral Oil Pump 236

How to Install the Integral Oil Pump ....................... 238

How to Disassemble the Integral Oil Pump with Auxiliary

Oil Tube ........................................................... 240

How to Assemble the Integral Oil Pump with Auxiliary Oil

Tube ................................................................. 244

How to Install the Auxiliary Section with Tapered Bearings

248

Shim Procedure without a Shim Tool for Tapered Bear-

ings .................................................................. 250

Table of Contents

Page 7

Table of Contents

Page 8

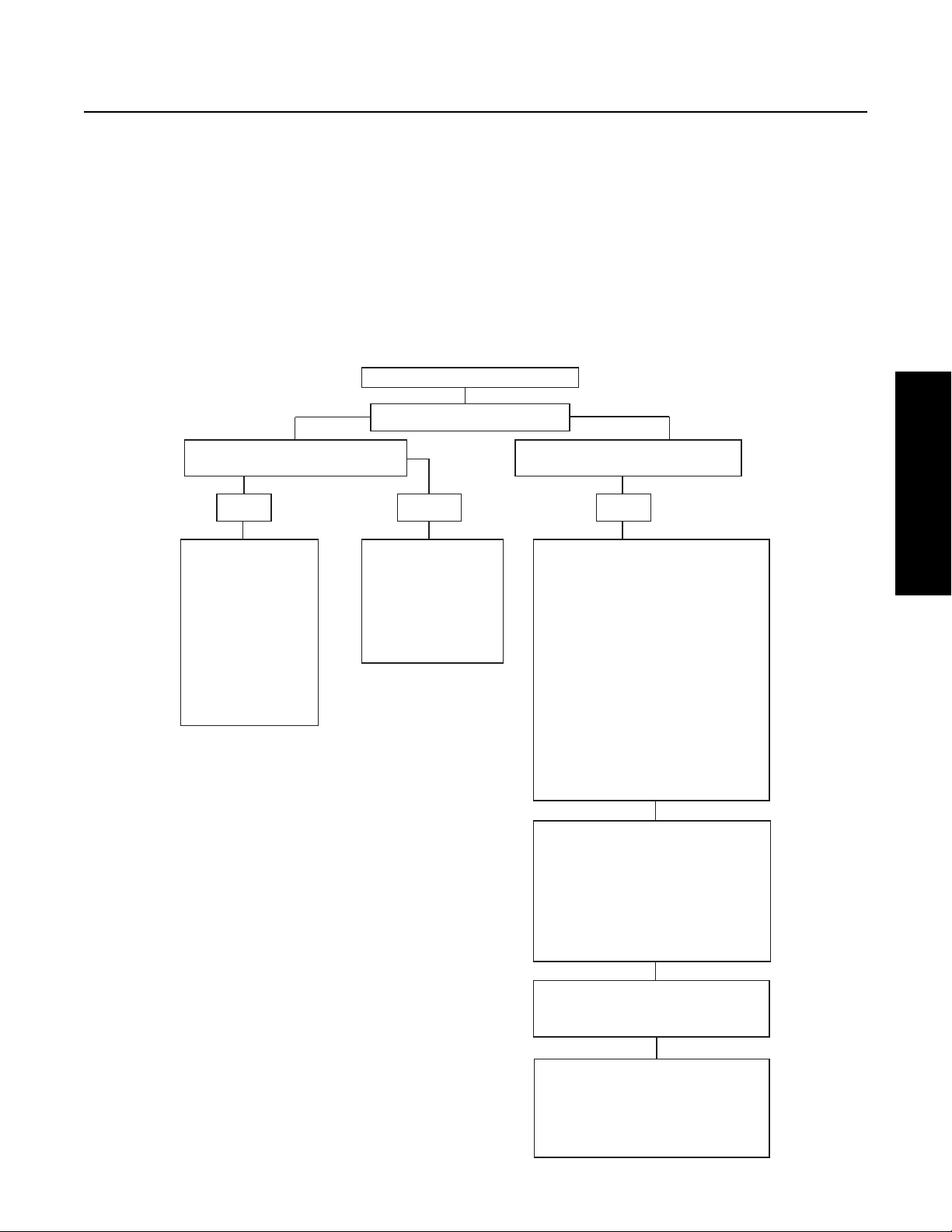

Transmission Overview

Shift Bar Housing:

Shift Bar Housing:

Levers/Housings

Levers/Housings

& Isolators

& Isolators

Introduction

Air System:

Roadranger® Valve

Auxiliary Section:

Range Cylinder

Shift Bar Housing:

Shift Bar Housing:

Shiftbar Housing Assembly

Shiftbar Housing Assembly

Front Section:

Clutch Housing / Case Assembly

Front Section:

Input Shaft / Drive Gear

106004-8-94 15 spd trans

Front Section:

Reverse Idler

Front Section:

Countershafts

Auxiliary Section:

Auxiliary Countershaft

Auxiliary Section:

Auxiliary Housing

Air System:

Slave Valve

Air System:

Air Filter/Regulator

Auxiliary Section:

Auxiliary Drive Gear

Front Section:

Mainshaft

Auxiliary Section:

Reduction Cylinder

Page 9

Introduction

Page 10

Introduction

Purpose and Scope of Manual

This manual is designed to provide information necessary to service and repair the Fuller® transmissions listed on the front.

How to use this Manual

The service procedures have been divided into two sections: In-Vehicle Service Procedures and Transmission Overhaul Procedures—Bench Service. In-Vehicle Service Procedures contain procedures that can be performed while the transmission is still

installed in the vehicle. Transmission Overhaul Procedures contain procedures that are performed after the transmission has been

removed from the vehicle.

The procedure sections are laid out with a general heading at the top outside edge of each page followed by more specific headings

and the procedures. To find the information you need in these sections, first go to the section that contains the procedure you

need. Then look at the heading at the top and outside edge of each page until you find the one that contains the procedure you need.

Transmission Overhaul Procedures follow the general steps for complete disassembly and then assembly of the transmission.

Note: In some instances the transmission appearance may be different from the illustrations, but the procedure is the same.

Disassemble Precautions

It is assumed in the detailed assembly instructions that the lubricant has been drained from the transmission, the necessary linkage and vehicle air lines disconnected and the transmission has been removed from vehicle chassis. Removal of the gear shift

lever housing assembly (or remote control assembly) is included in the detailed instructions (How to Remove the Gear Shift Lever). This assembly MUST be detached from the shift bar housing before the transmission can be removed.

General Information

Follow closely each procedure in the detailed instructions, make use of the text, illustrations, and photographs provided.

Assemblies

• When disassembling the various assemblies, such as the mainshaft, countershafts, and shift bar housing, lay all parts

on a clean bench in the same sequence as removed. This procedure will simplify assembly and reduce the possibility of

losing parts.

Bearings

• Carefully wash and lubricate all usable bearings as removed and protectively wrap until ready for use. Remove bearings

planned to be reused with pullers designed for this purpose.

Cleanliness

• Provide a clean place to work. It is important that no dirt or foreign material enters the unit during repairs. Dirt is an

abrasive and can damage bearings. It is always a good practice to clean the outside of the unit before starting the planned

disassembly.

Input Shaft

• The input shaft can be removed from the transmission without removing the countershafts, mainshaft, or main drive

gear. Special procedures are required and provided in this manual.

1

Page 11

Introduction

Snap Rings

• Remove snap rings with pliers designed for this purpose. Snap rings removed in this manner can be reused, if they are

not sprung or loose.

When Using Tools to Move Parts

• Always apply force to shafts, housings, etc., with restraint. Movement of some parts is restricted. Never apply force to

driven parts after they stop solidly. The use of soft hammers, soft bars, and mauls for all disassembly work is recom-

mended.

Inspection Precautions

Before assembling the transmission, check each part carefully for abnormal or excessive wear and damage to determine reuse or

replacement. When replacement is necessary, use only genuine Fuller

extended life from your unit.

Since the cost of a new part is generally a small fraction of the total cost of downtime and labor, avoid reusing a questionable part

which could lead to additional repairs and expense soon after assembly. To aid in determining the reuse or replacement of any

transmission part, consideration should also be given to the unit's history, mileage, application, etc.

Recommended inspection procedures are provided in the following checklist.

Bearings

• Wash all bearings in clean solvent. Check balls, rollers, and raceways for pitting, discoloration, and spalled areas. Re-

place bearings that are pitted, discolored, spalled, or damaged during disassembly.

• Lubricate bearings that are not pitted, discolored, or spalled and check for axial and radial clearances.

• Replace bearings with excessive clearances.

• Check bearing fit. Bearing inner races should be tight to shaft; outer races slightly tight to slightly loose in case bore. If

the bearing spins freely in the bore the case should be replaced.

Bearing Covers

• Check covers for wear from thrust of adjacent bearing. Replace covers damaged from thrust of bearing outer race.

• Check cover bores for wear. Replace those worn or oversized.

Clutch Release Parts

®

Transmission parts to assure continued performance and

• Check clutch release parts. Replace yokes worn at cam surfaces and bearing carrier worn at contact pads.

• Check pedal shafts. Replace those worn at bushing surfaces.

Gears

• Check gear teeth for frosting and pitting. Frosting of gear teeth faces presents no threat of transmission failure. Often

in continued operation of the unit, frosted gears "heal" and do not progress to the pitting stage. In most cases, gears

with light to moderate pitted teeth have considerable gear life remaining and can be reused, but gears in the advanced

stage of pitting should be replaced.

• Check for gears with clutching teeth abnormally worn, tapered, or reduced in length from clashing during shifting. Re-

place gears found in any of these conditions.

• Check axial clearance of gears.

2

Page 12

Introduction

Gear Shift Lever Housing Assembly

• Check spring tension on shift lever. Replace tension spring if lever moves too freely.

• If housing is disassembled, check gear shift lever bottom end and shift finger assembly for wear. Replace both gears if

excessively worn.

Gray Iron Parts

• Check all gray iron parts for cracks and breaks. Replace parts found to be damaged.

Oil Return Threads and Seals

• Check oil return threads on the input shaft. If return action of threads has been destroyed, replace the input shaft.

• Check oil seal in rear bearing cover. If sealing action of lip has been destroyed, replace seal.

O-Rings

• Check all o-rings for cracks or distortion. Replace if worn.

Reverse Idler Gear Assemblies

• Check for excessive wear from action of roller bearings.

Shift Bar Housing Assembly

• Check for wear on shift yokes and block at pads and lever slot. Replace excessively worn parts.

• Check yokes for correct alignment. Replace sprung yokes.

• Check lockscrew in yoke and blocks. Tighten and rewire those found loose.

General Information

• If housing has been disassembled, check neutral notches of shift bars for wear from interlock balls.

Sliding Clutches

• Check all shift yokes and yoke slots in sliding clutches for extreme wear or discoloration from heat.

• Check engaging teeth of sliding clutches for partial engagement pattern.

Splines

• Check splines on all shafts for abnormal wear. If sliding clutch gears, companion flange, or clutch hub has wear marks

in the spline sides, replace the specific shaft effected.

Synchronizer Assembly

• Check synchronizer for burrs, uneven and excessive wear at contact surface, and metal particles.

• Check blocker pins for excessive wear or looseness.

• Check synchronizer contact surfaces on the synchronizer cups for wear.

Washers

• Check surfaces of all washers. Washers scored or reduced in thickness should be replaced.

3

Page 13

Introduction

Assembly Precautions

Make sure that case interiors and housings are clean. It is important that dirt and other foreign materials are kept out of the transmission during assembly. Dirt is an abrasive and can damage polished surfaces of bearings and washers. Use certain precautions, as listed below, during assembly.

Axial Clearances

• Maintain original axial clearances of 0.006-0.015 in. for mainshaft gears.

Bearings

• Use a flange-end bearing driver for bearing installation. These special drivers apply equal force to both bearing races,

preventing damage to balls/rollers and races while maintaining correct bearing alignment with bore and shaft. Avoid us-

ing a tubular or sleeve-type driver, whenever possible, as force is applied to only one of the bearing races.

Capscrews

• To prevent oil leakage and loosening, use Fuller

Gaskets

• Use new gaskets throughout the transmission as it is being rebuilt. Make sure all gaskets are installed. An omission of

any gasket can result in oil leakage or misalignment of bearing covers.

®

sealant #71205 on all capscrews.

Initial Lubrication

• Coat all limit washers and shaft splines with Lubricant during assembly to prevent scoring and galling of such parts.

O-Rings

• Lubricate all o-rings with silicon lubricant.

Universal Joint Companion Flange or Yoke

• Pull the companion flange or yoke tightly into place with the output shaft nut, using 450-500 lb-ft (610.12-677.91 N•m)

of torque. Make sure the speedometer drive gear or a replacement spacer of the same width has been installed. Failure

to pull the companion flange or yoke tightly into place can result in damage to the mainshaft rear bearing.

IMPORTANT

See the appropriate Illustrated Parts Lists (specified by model series) to ensure that proper parts are used during assembly of the

transmission.

4

Page 14

Model Designations and Specifications

Serial Tag Information and Model Nomenclature

Transmission model designation and other transmission identification information are stamped on the transmission tag. To identify the transmission model designation and serial number, locate the tag on the transmission and then locate the numbers as

shown.

When calling for service assistance or parts, have the model and serial numbers handy.

T

R

Roadranger

Twin Countershaft

Low-Inertia

C= Convertible

F= Forward Opening Shift Housing

C

or

F

1 6 6 0 9

This (x) 100 = Nominal Torque Capacity

E

Service Procedure

Ratio Set

Forward Speeds

6= Multi-Mesh Gearing

7= Helical Auxiliary Gearing and

Multi-Mesh Front Section Gearing

9= Improved Seal System

L

Do not remove or destroy the transmission identification tag.

The model number gives basic information about the transmission. Use this number when calling for service assistance or replacement parts.

Serial Number

The serial number is the sequential identification number of the transmission. Before calling for service assistance, write the number down. It may be needed.

Bill of Material or Customer Number

This number may be located below the model and serial numbers. It is a reference number used by Eaton®.

5

Page 15

Model Designations and Specifications

Model Options

Torque Rating

The torque rating of the transmission specified in the model number is the input torque capacity inLb•ft. Various torque ratings

are available. For more information, call your Eaton Fuller regional sales and service office at 1-800-826-HELP (4357).

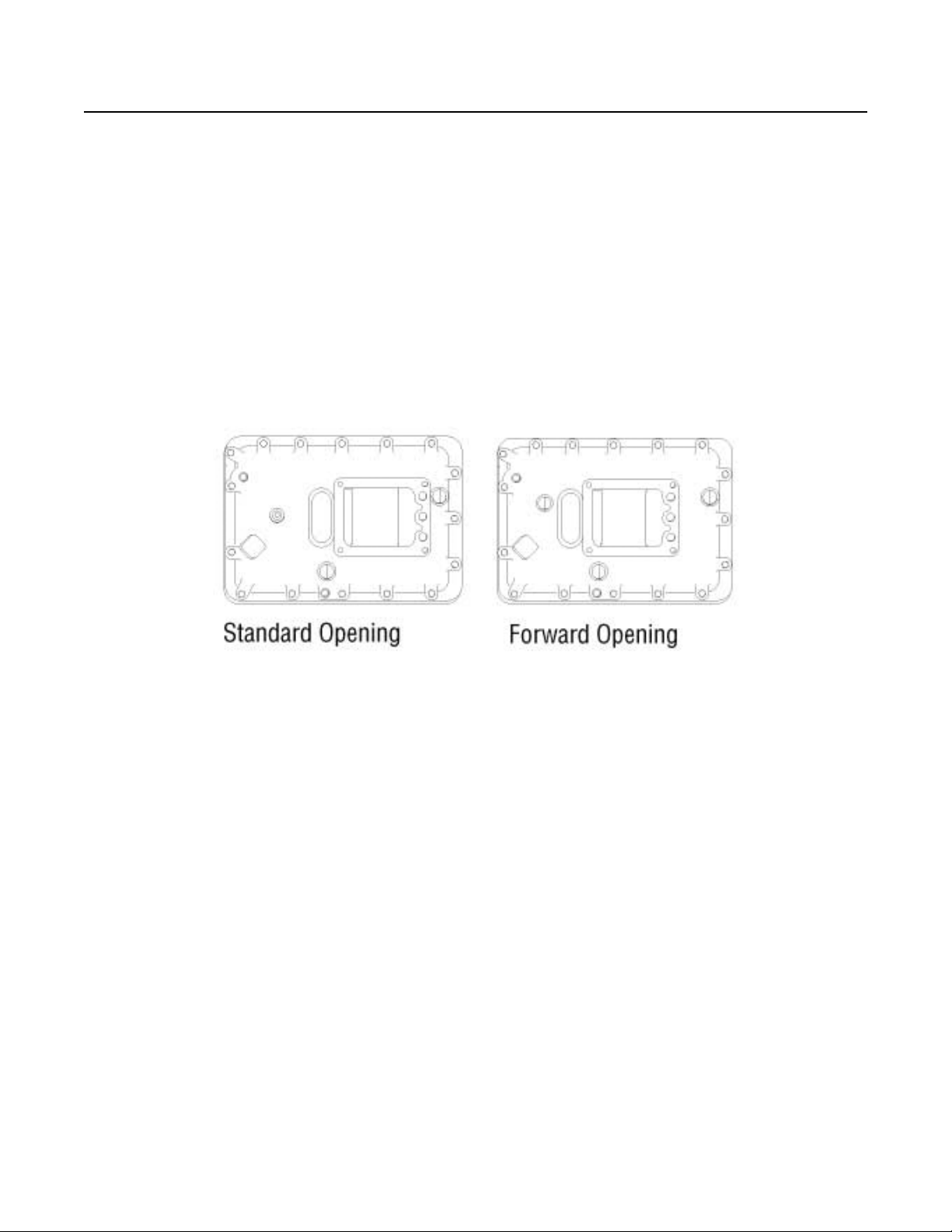

Shift Bar Housings

Two types of shift bar housings are available for this transmission. Both are described and shown below.

Standard

The standard shift bar housing has a gear shift lever opening that is located toward the rear of the transmission.

Forward

The forward shift bar housing has a gear shift lever opening located three inches closer to the transmission front than the standard

opening. This forward design allows greater flexibility in mounting the transmission and is indicated by an "F" in the model number

.

Power Take Off (PTO) Usage

PTOs can be mounted in the following way:

6 or 8 Bolt: The 6 or 8 bolt openings are standard with the transmission. The PTO is mounted to the opening and driven

from the PTO gear on the front countershaft.

Thru-Shaft: The thru-shaft PTO mounts on the rear of the transmission. It requires a special auxiliary housing and main

case countershaft with internal splines.

Lubrication Pumps

Internal: An internal lubrication pump is located in the lower front of the transmission and is driven off the upper coun-

tershaft. Transmissions rated

PTO Driven: A PTO driven pump is externally mounted on the 6 or 8 bolt PTO openings and driven off the PTO gear.

6

Page 16

Lubrication

Lubrication Specifications

IMPORTANT

Transmission filters should be changed during regular lube intervals. Inspection of the transmission filter should be conducted during preventive maintenance checks for damage or corrosion. Replace as necessary.

Note: For a list of Eaton

Note: The use of lubricants not meeting these requirements will affect warranty coverage.

Note: Additives and friction modifiers must not be introduced. Never mix engine oils and gear oils in the same transmission.

®

Approved Synthetic Lubricants, see TCMT0021 or call 1-800-826-HELP (4357).

Buy from a reputable dealer

For a complete list of approved and reputable dealers, write to: Eaton Corporation, Worldwide Marketing Services, P.O. Box 4013,

Kalamazoo, MI 49003,

Transmission Operating Angles

If the transmission operating angle is more than 12 degrees, improper lubrication will occur. The operating angle is the transmission mounting angle in the chassis plus the percent of upgrade (expressed in degrees). For operating angles over 12 degrees, the

transmission must be equipped with an oil pump or cooler kit to insure proper lubrication.

Operating Temperatures with Oil Coolers

The transmission must not be operated consistently at temperatures above 250°F. Operation at temperatures above 250°F [121°C]

causes loaded gear tooth temperatures to exceed 350°F [177°C] which will ultimately destroy the heat treatment of the gears. If

the elevated temperature is associated with an unusual operating condition that will reoccur, a cooler should be added, or the capacity of the existing cooling system increased.

The following conditions in any combination can cause operating temperatures of over 250° F [121°C]:

General Information

• Operating consistently at slow speed.

• High ambient temperatures.

• Restricted air flow around transmission.

• Use of engine retarder.

• High horsepower operation.

Note: Transmission coolers must be used to reduce the operating temperatures when the above conditions are encountered.

7

Page 17

Lubrication

Oil Cooler Chart

Table 4

TRANSMISSION OIL COOLERS ARE:

Recommended

• With engines of 350 H.P. and above.

Required

• With engines 399 H.P. and above and GCW’s over 90,000 lbs.

• With engines 399 H.P. and above and 1400 lb-ft (1898.15 N•m) or greater torque.

• With engines 1500 lb-ft (2033.73 N•m) and above

18-speed AutoShift transmissions require use of an Eaton® supplied oil-to-water cooler or approved equivalent.

• With engines 450 H.P. and above.

8

Page 18

Recommended Tools

Tool Specifications

Some repair procedures pictured in this manual show the use of specialized tools. Their actual use is recommended as they make

transmission repair easier, faster, and prevent costly damage to critical parts.

For the most part, ordinary mechanic's tools such as socket wrenches, screwdrivers, etc., and other standard shop items such as

a press, mauls and soft bars are the only tools needed to successfully disassemble and reassemble any Fuller

The following tables list and describe the typical tools required to properly service this model transmission above and beyond the

necessary basic wrenches, sockets, screwdrivers, and prybars.

®

transmission.

General Tools

The following tools are available from several tool manufacturers such as Snap-On, Mac, Craftsman, OTC, and many others.

Table 5 General Tools

TOOL PURPOSE

0-100 lb-ft 1/2" drive Torque Wrench General torquing of fasteners (Typically 15-80 lb-ft [20.34-108.47

N•m])

0-600 lb-ft 3/4" or 1" drive Torque Wrench Torquing of output nut to 500 lb-ft (677.91 N•m)

0-50 lb-in 3/8" drive Torque Wrench General torquing of fasteners

0-30 lb-in 1/4" drive Torque Wrench Torquing of capscrews to 7 lb-in (0.79 N•m) during auxiliary coun-

tershaft bearing endplay setting procedure

General Information

70 MM or 2 2/4" Socket - Standard Depth To remove the output yoke nut

Large Brass Drift Used to protect shafts and bearings during removal

Large Dead Blow Hammer or Maul To provide force for shaft and bearing removal

Snap Ring Pliers - Large Standard External To remove the snap rings at the auxiliary drive gear, input shaft

bearing, and countershaft bearings

Feeler Gauges To set mainshaft washer endplay and auxiliary tapered bearing

endplay

Rolling Head (Crow's Foot) Prybar To remove the auxiliary drive gear bearing

(2) Air Pressure Gauges 0-100 PSI (0-1034 kPa) To troubleshoot and verify correct operation of air system

Universal Bushing Driver To remove and install clutch housing bushings. Bushing OD =

1.125 in., ID = 1.000 in.

9

Page 19

Recommended Tools

The following special tools are designed for this Fuller® transmission. The addresses and phone numbers of the tool suppliers are

listed after the table. This list is provided as a convenience to our customers. These tools are manufactured by independent companies with no relationship to Eaton. Eaton does not warrant the fit or function of the listed tools. To obtain the tools, contact the

tool supplier directly.

Table 6 Special Tools

REFERENCE

NUMBER

T1 Output Yoke Puller May be required to remove a

T2 Auxiliary Section

T3 Auxiliary Counter-

T4 Shift Lever Spring

T5 Slide Hammer To remove the output seal

TOOL PURPOSE G & W TOOL NO. GREAT LAKES

rusted output yoke.

To support, or hang, the aux-

Hanger

shaft Support and

Shim Tool

Installation Tool

(Tension Spring

Driver)

iliary section in the horizontal position.

To hold the auxiliary countershafts in position while installing the auxiliary section

in the horizontal position.

Also to simplify the checking

and setting of the auxiliary

countershaft bearing endplay.

To install the shift tower tension spring.

and reverse idler shafts. Requires 1/2"-13 threads. (Optional, idler shaft can be

driven out from front.)

OTC

TOOL NO.

SP-450 7075

G-40 T-125 5061

G-250 T-311 5062

G-116 T-170

G-70 T-150 1155 Slide

TOOL NO.

Hammer / 8007

1/2" -13 Adapter

T6 Bearing Puller To remove front section

countershaft bearings.

T7 Bearing Driver To install front section coun-

tershaft bearings (3.97" OD,

1.78" ID).

T8 Bearing Driver To install the front counter-

shaft rear bearings (3.5" OD,

1.6" ID).

T9 Countershaft Sup-

port Tools (2)

T10 Input Bearing Driver To install input bearing on

T11 Bearing Puller To remove the auxiliary

10

To support and locate the

front section countershafts

during bearing removal and

installation.

input shaft.

countershaft tapered bearings.

G-10 or G-15 T-1 and T-2

for 9-Series

G200 Kit T-101 Kit

G200 Kit T-101 Kit

G-50 / G-51 / G-58 T-145S 7109

G-35 T-120 5066 (2" shaft)

4332/4232 1123 / 927

7070A Kit

Page 20

Recommended Tools

Table 6 Special Tools (Continued)

REFERENCE

NUMBER

T12 Bearing Driver To install the auxiliary coun-

T13 Output Seal Remov-

T14 Auxiliary Section

T15 Mainshaft Hook To assist in lifting of main-

T16 Input Bearing Puller To remove input bearing. G-38 T-3 7070A Kit

T17 Bearing Race Puller To remove the auxiliary

T18 Bearing Race In-

TOOL PURPOSE G & W TOOL NO. GREAT LAKES

TOOL NO.

G-200 Kit T-105 Kit

tershaft tapered bearings.

To remove the output seal in

al Tool

Removal Adapter

Plate

staller

chassis. Can use slide hammer.

To attach transmission jack

to auxiliary section for auxiliary section removal in chassis.

shaft from front section.

countershaft tapered bearing

outer races.

To install the auxiliary countershaft tapered bearing outer races.

G-115 49611 (Used

G-225 T-165

OTC

TOOL NO.

Use 27315

hook with 1155

slide hammer

with OTC transmission jack P/

N 5019.)

7136 puller attached to 1155

slide hammer

27524/27530

discs used with

27488 handle

and 10020

screw.

General Information

* Tool ID numbers are referenced in the service procedures.

Special Tools

Table 7 Shop Equipment

20 Ton capacity press To press countershaft gears from countershaft.

Specialty Tool Manufacturers

Below are the addresses and phone numbers of the companies that make tools specifically for Eaton®Fuller® transmissions:

G and W Tool Company

1105 E. Louisville, Broken Arrow, OK 74012-5724, Phone: 800-247-5882, or 918-258-6881

Great Lakes Tool

8530 M-89, Richland, MI 49083, Phone: 800-877-9618, or 269-629-9628

O.T.C. 655 Eisenhower Dr., Owatonna, MN 55060-117, Phone: 800-533-6127, or 507-455-7000

The specialized tools can be obtained from a tool supplier or made from tool prints as required by the individual user. Detailed

®

Fuller

Transmission Tool Prints are available upon request by writing to:

Eaton Corporation, Truck Components Operations Technical Service, P.O. Box 4013, Kalamazoo, Michigan 49003

11

Page 21

Recommended Tools

Eaton Aftermarket Parts

The following tools are available through Eaton Aftermarket Parts. To obtain any of the tools listed, contact your local Eaton parts

distributor.

Table 8

TOOL PURPOSE EATON® PART NUMBER

5/32” Air Line Release Tool To remove 5/32” air lines from push-to-

connect fittings.

Air Line Cutting Tool To cut plastic air lines smoothly and

squarely.

Output Seal Driver To install output seal. For 7 series: Eaton P/N 5564501 driver.

Output Seal Slinger Driver To install output seal slinger. For 7 series: Eaton P/N 71223.

P/N 4301157 included in kit K-2394

P/N 4301158 included in kit K-2394.

For 9 series: Use Eaton® P/N 5564509

adapter with 5564501 driver. Both parts

included in complete Eaton® seal kit P/

N TCMT0912.

For 9 series: Eaton P/N 4303829.

12

Page 22

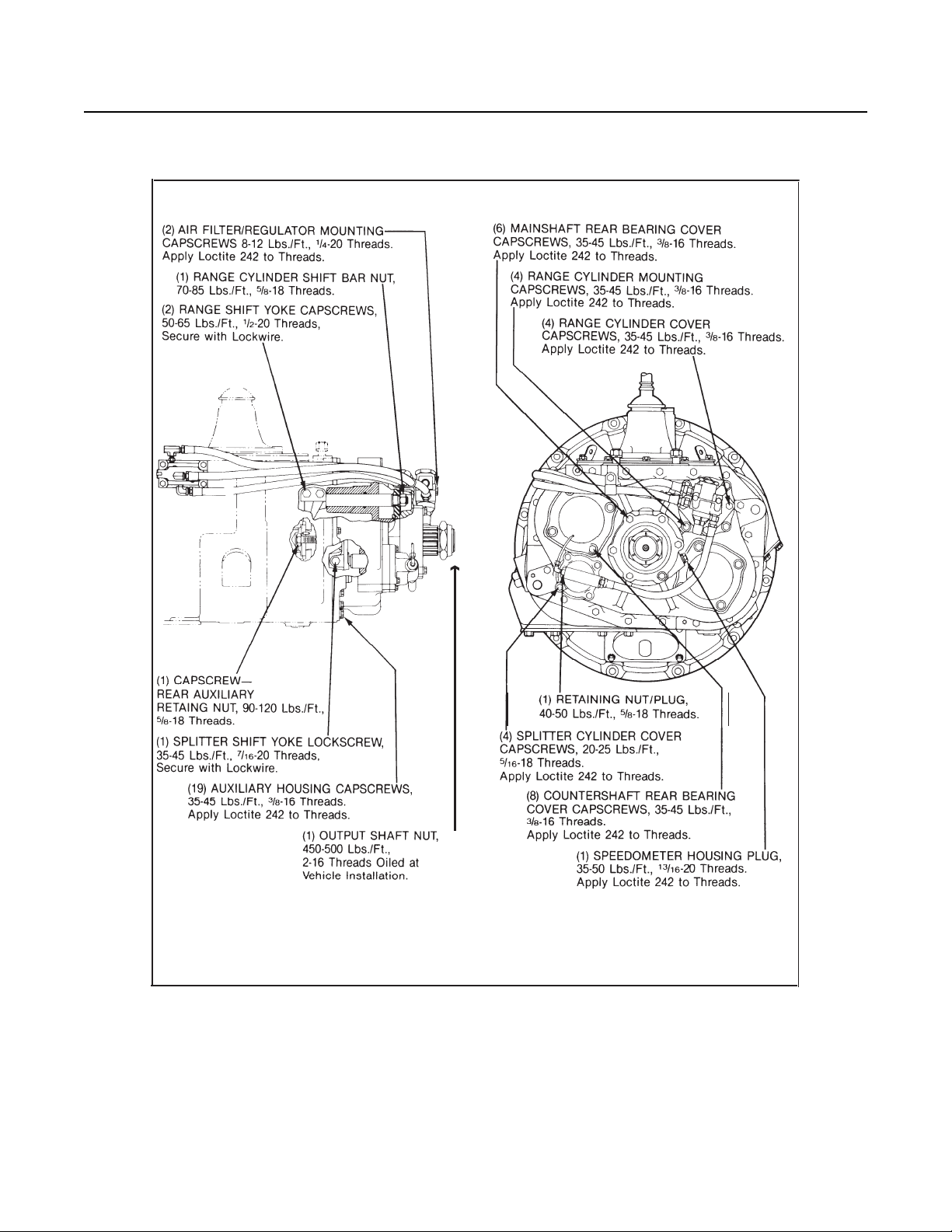

Torque Specifications

Transmission Torque Specifications

Correct torque application is extremely important to assure long transmission life and dependable performance. Over-tightening

or under-tightening can result in a loose installation and in many instances, eventually cause damage to transmission gears,

shafts, and/or bearings. Use a torque wrench whenever possible to attain recommended Lbs•ft. ratings. Do not torque capscrews

dry.

FRONT SECTION: ALL MODELS

Service Procedure

Cut 7190 K-11/87

13

Page 23

Torque Specifications

Auxiliary Sections

AUXILIARY SECTIONS

14

Cut 7191 Q-11/87

Page 24

Preventive Maintenance

Preventative Maintenance Check Points

Everyday there are countless vehicles operating over the highways with transmissions in such a neglected mechanical condition,

they can be referred to as failures looking for a place to break down. They lack a proper and organized preventive maintenance

program.

Preventive maintenance is a general term which applies to all procedures necessary to have maximum life and satisfactory service

at the lowest possible cost, short of removing and repairing the unit.

A number of conditions contrary to good preventive maintenance can generally be pointed to when inspecting a failed transmission. Taking a few minutes every so many hours or miles to do a few simple checks could help avoid eventual breakdown or

reduce the repair cost. If the transmission is not cared for, it will breakdown.

Service Procedure

Note: Transmission appearance may differ, however the procedure is the same.

15

Page 25

Preventive Maintenance

1. Air System and Connections

• Check for leaks, worn air lines, loose connections and capscrews.

2. Clutch Housing Mounting

• Check all capscrews of clutch housing flange for looseness.

3. Clutch Release Bearing (Not Shown)

• Remove hand hole cover and check radial and axial clearance in release bearing.

• Check relative position of thrust surface of release bearing with thrust sleeve on push-type clutches.

4. Clutch Pedal Shaft and Bores

• Pry upward on shafts to check wear.

• If excessive movement is found, remove clutch release mechanism and check bushings on bores and wear on

shafts. See OEM literature.

5. Lubricant

• Change at specified service intervals.

• Use only the types and grades as recommended. See “Recommended Lubrication Chart” (see Table 2).

6. Filler and Drain Plugs

• Remove filler plugs and check level of lubricant at specified intervals. Tighten fill and drain plugs securely.

7. Capscrews and Gaskets

• For applicable models, check all capscrews, especially those on PTO covers and rear bearing covers for looseness

which would cause oil leakage.

• Check PTO opening and rear bearing covers for oil leakage due to faulty gasket.

8. Gear Shift Lever

• Check for looseness and free play in housing. If lever is loose in housing, proceed with Check No. 9.

9. Gear Shift Lever Housing Assembly

• If present, remove air lines at air valve or slave valve. Remove the gear shift lever housing assembly from the transmission.

• Check the tension spring and washer for set and wear.

• Check the gear shift lever spade pin and slot for wear.

• Check bottom end of gear shift lever for wear and check slot of yokes and blocks in shift bar housing for wear at

contact points with shift lever.

Checks With Drive Line Dropped

10. Universal Joint Companion Flange or Yoke Nut

• Check for tightness. Tighten to recommended torque.

11. Output Shaft (Not Shown)

• Pry upward against output shaft to check radial clearance in mainshaft rear bearing.

16

Page 26

Preventive Maintenance

Checks With Universal Joint Companion Flange or Yoke Removed

Note: If necessary, use solvent and shop rag to clean sealing surface of companion flange or yoke. Do not use crocus cloth, emery

paper, or other abrasive materials that will mar surface finish.

12. Splines on Output Shaft (Not Shown)

• Check for wear from movement and chucking action of the universal joint companion flange or yoke.

13. Mainshaft Rear Bearing Cover (Not Shown)

• Check oil seal for wear.

Oil Leak Inspection Process

Inspect for Oil Leak

Determine if it is a Weep or a Leak

Weep: Stained, damp, no drips, light oil film,

dirt adhered to the contaminated area.

Gasket Rear Seal Leak

1. Clean suspected oil weep

area with a clean dry cloth

or mild soluble degreaser.

2. Ensure lube is to proper

level.

3. Notify the customer that it

is only a weep and it is not

considered to be detrimental

to the life of the transmission.

4. Repair is complete.

1. Do not repair: Rear seal is

designed to allow min

seepage (refer to Roadranger

TCSM-0912 Seal Maintance

Guide).

2. Ensure lube is to proper

level.

imal

Leak: Extremely wet or dripping of oil in the

contaminated area.

Step 1

Step 2

Step 3

1. Determine the origin of the leak path.

2. If origin of leak is obvious skip to Step 3.

3. If the origin of the oil leak is not obvious then

use either of the two following steps to determine

the oil leak:

Note: Do not use a high pressure spray washer to

clean the ar

force contamination into the area of concern and

temporarily disrupt the leak path.

i. Clean area with a clean dry cloth or mild

soluble degreaser and fill the transmission to

the proper lube level.

OR

ii. Clean the area as noted above and insert tracer

dye into the tr

transmission to proper lube level.

Operate vehicle to normal transmission operating

temperature and inspect the area for oil leak(s)

visually or if tracer dye was introduced use an UVL

(Ultraviolet Light) to detect the tracer dye’s point

of origin.

Note: When i

make sure the assumed leak area is not being

contaminated by a source either forward or above

the identified area such as the engine, shift tower,

shift bar housing, top mounted oil cooler, etc...

Once the origin of the leak is identified, repair the

oil leak using proper repair proced

designated model service manual.

ea. Use of a high pressure spray may

ansmission lube and fill

nspecting for the origin of the leak(s)

ures from the

Service Procedure

Step 4

After the repair is completed, verify the leak is

repaired and operate the vehicle to normal

transmission operating temperature.

Inspect repaired area to ensure oil leak has been

eliminated. If the leak(s) still occurs, repeat steps

or contact the Roadranger Call Cen

1-800-826-4357.

ter at

17

Page 27

Power Flow

Power Flow Diagrams

An understanding of the engine's power flow through a transmission in each particular gear will assist the technician in troubleshooting and servicing a transmission.

The Eaton®Fuller®Roadranger transmission can be thought of as two separate "transmissions" combined into one unit. The first

"transmission" or front section contains six gear sets which are shifted with the gear shift lever. The second "transmission" called

the auxiliary section, contains three gear sets and is shifted with air pressure.

Note: This transmission is referred to as a constant mesh type transmission. When in operation, all gears are turning even though

only some of them are transferring power.

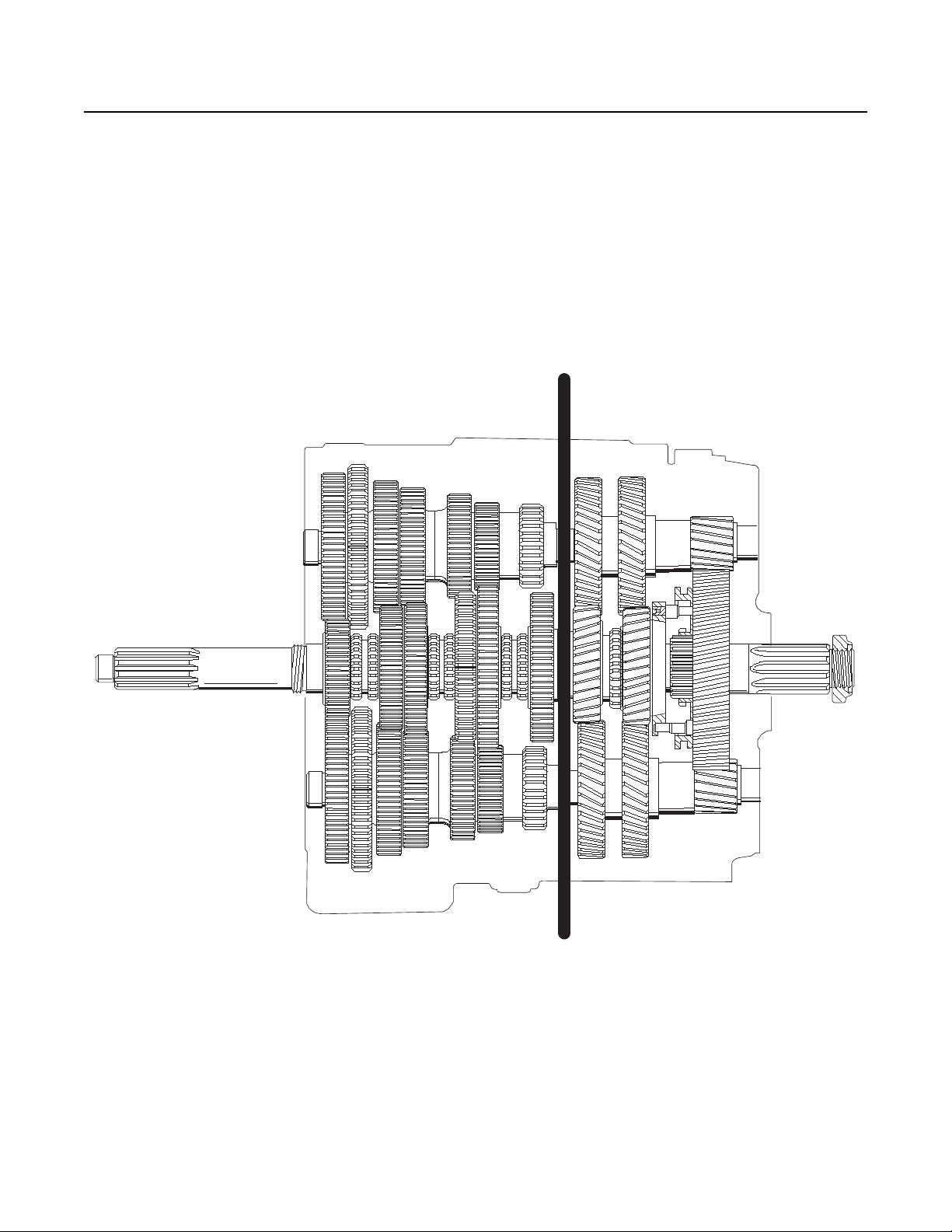

12

Cross Sectional View

1. Front Section

2. Front Section

18

Page 28

Power Flow

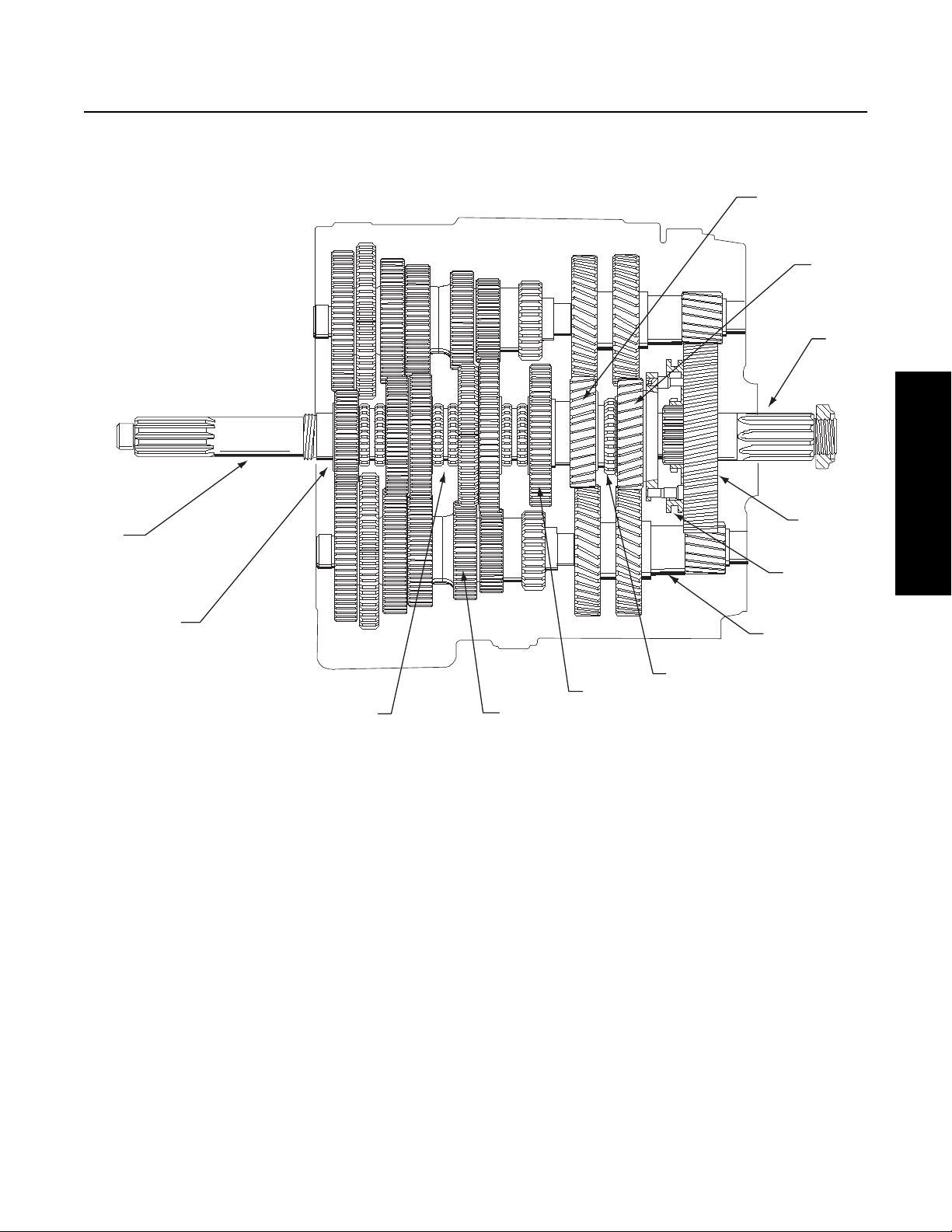

The transmission components in the figure below shows the transmission with the main components called out. Note that the

transmission is in the neutral position because the sliding clutches are all in their center positions and not engaged in any gears.

12

11

10

Service Procedure

1

2

34

Transmission Components

1. Input Shaft

2. Main Drive Gear

3. Sliding Clutch

4. Countershaft

5. Mainshaft Gear

6. Auxiliary Splitter Clutch (slides on front section mainshaft)

9

8

7

6

5

7. Auxiliary Countershaft

8. Range Sliding Clutch

9. Auxiliary Mainshaft Reduction Gear

10. Output Shaft (Auxiliary Mainshaft)

11. Splitter Gear

12. Auxiliary Drive Gear

19

Page 29

Power Flow

Front Section Power Flow

Note: The heavy lines in the figure below outline the power flow description. For help in understanding the transmission compo-

nents, refer to the figure “Transmission Components” on the previous page.

1. Power (torque) from the vehicle's engine is transferred to the transmission's input shaft.

2. The input shaft rotates the main drive gear through internal splines in the hub of the gear.

3. The main drive gear meshes with both countershaft driven gears and the torque is split between both countershafts.

4. Because the countershaft gears are in constant mesh with the mainshaft gears, all the front section gearing rotates. However, only the engaged or selected mainshaft gear will have torque. External clutching teeth on the sliding clutch will

engage internal clutching teeth on the selected mainshaft gear. Torque will now be provided from both opposing countershaft gears, into the engaged mainshaft gear, and through the sliding clutch to the front section mainshaft.

5. The rear of the front section mainshaft is splined into the auxiliary splitter clutch and torque is now delivered to the auxiliary splitter clutch.

Front Section Power Flow

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch rearward

20

R

LO

RTO

153

Neutral

264

3

1

RTX

7

8

R

Neutral

LO

8

154

7

263

2

Page 30

Power Flow

Front Section Power Flow - Direct Gear

In direct gear, the front sliding clutch is moved forward and engages into the back of the main drive gear. Torque will flow from

the input shaft to the main drive gear, main drive gear to sliding clutch, sliding clutch straight into the front section mainshaft

which delivers the torque to the auxiliary splitter clutch. See figure below.

Note: All countershaft and mainshaft gears will rotate, but the gears will not be loaded.

Service Procedure

Front Section Power Flow - Direct Gear

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch rearward

R

LO

RTO

153

Neutral

264

3

1

7

8

R

LO

RT

1

7

5

3

1

6

8

4

2

2

21

Page 31

Power Flow

Front Section Power Flow - Reverse Gear

Torque will flow from the countershafts to the reverse idler gears. Torque will then flow from the reverse idler gears to the mainshaft reverse gear. Torque will now travel through the mainshaft reverse gear, the sliding clutch in the reverse position and then

to the mainshaft and auxiliary splitter clutch. See figures below.

Note: The idler gears cause the reversal of rotation.

Reverse LO - 9/13 speed

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch rearward

3

1

2

1

3

2

Reverse HI - 9/13 speed

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch forward

22

Page 32

Power Flow

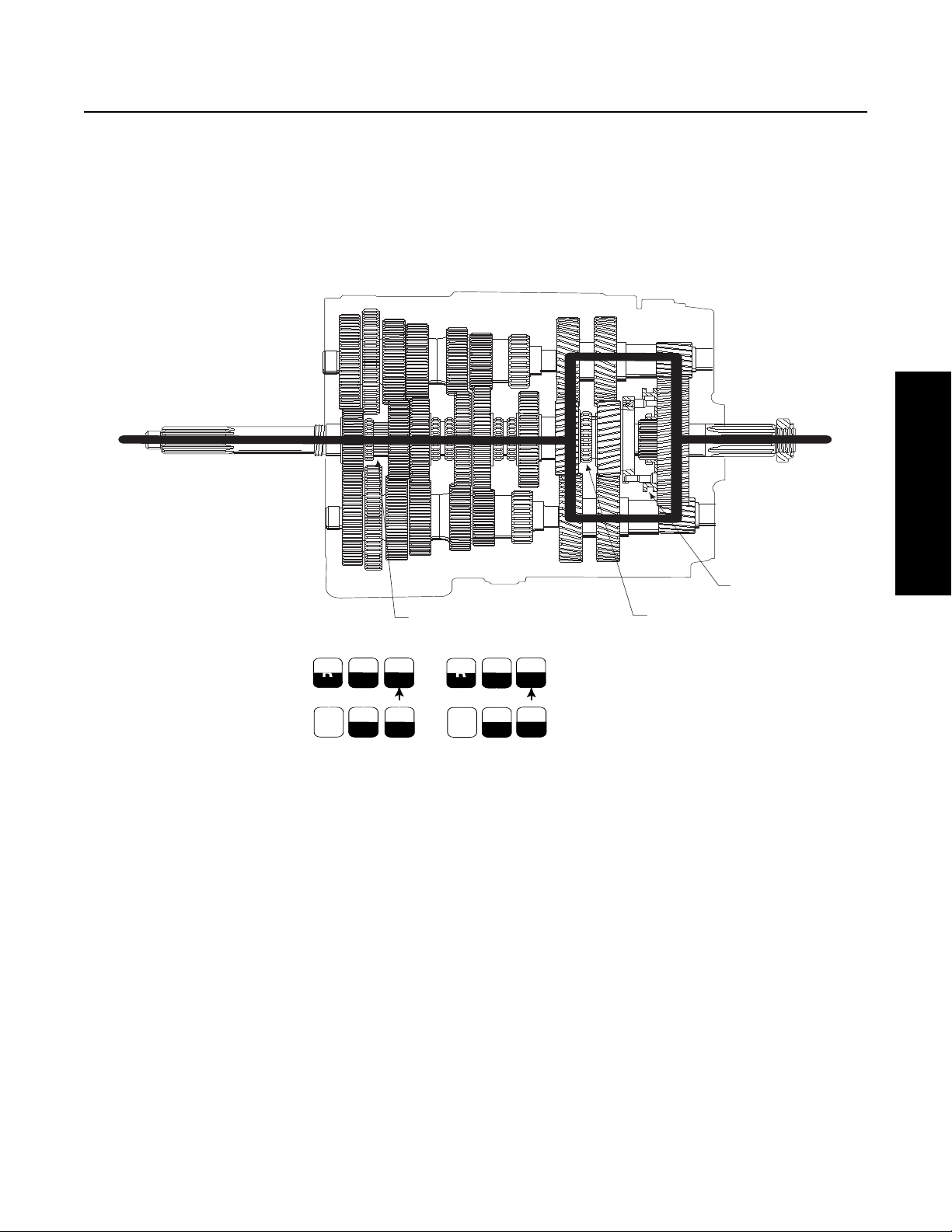

Auxiliary Section Power Flow - Low Range

If the auxiliary section is in low range, the range sliding clutch is rearward and engaged into the auxiliary mainshaft reduction gear.

Torque flows from the auxiliary countershafts, into the auxiliary mainshaft reduction gear, through the range sliding clutch and

then into the output shaft (auxiliary mainshaft).

RTO

R

153

Neutral

LO

264

LO - 9/13 Speed

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch rearward

3

1

RTX

7

8

8

R

154

Neutral

7

LO

263

2

Service Procedure

23

Page 33

Power Flow

Auxiliary Section Power Flow - High Range

If the auxiliary section is in high range, the range sliding clutch is forward and engaged into the back of the auxiliary drive gear.

Torque flows through the auxiliary section in high range depending on the splitter state selected (L or H). If splitter (L) is selected,

torque flows from the auxiliary splitter clutch to the auxiliary drive gear. From the auxiliary drive gear, torque flows to both countershafts and then to the splitter gear. Torque then flows into the range sliding clutch and output shaft.

If splitter (H) is selected, torque flows directly through the auxiliary section. Torque flows from the auxiliary splitter clutch to the

auxiliary reduction gear to the range sliding clutch to the output shaft. The auxiliary gearing still turns, but the gear teeth will not

be loaded.

R

TO

R

153

N

eutra

l

LO

264

5th - 9/13 speed Split Low

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch forward

1

R

7

8

T

7

5

R

3

1

6

8

LO

4

2

2

3

RTO

R

153

Neutral

LO

264

1

RTX

7

8

8

R

154

Neutral

7

LO

263

3

2

5th - 9/13 speed Split High

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch forward

24

Page 34

9-Speed

Power Flow

RTO

R

153

Neutral

LO

264

LO Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch rearward

RTO

R

153

Neutral

LO

264

2nd Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch rearward

3

1

RTX

7

8

8

R

154

Neutral

7

LO

263

2

RTO

R

153

Neutral

LO

264

1

RTX

7

8

8

R

154

Neutral

7

LO

263

3

2

Service Procedure

1st Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch rearward

3

1

RT

7

8

7

5

R

3

1

6

8

LO

4

2

2

R

LO

RTO

Neutral

153

264

1

7

8

1

RT

7

5

R

3

1

6

8

LO

4

2

3

2

3rd Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch rearward

25

Page 35

Power Flow

R

TO

R

153

N

eutra

l

LO

264

4th Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch rearward

RTO

7

R

153

Neutral

8

LO

264

6th - Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch forward

3

1

7

8

1

R

T

7

5

R

3

1

6

8

LO

4

2

2

R

TO

R

153

N

eutra

l

LO

264

1

R

7

8

T

7

5

R

3

1

6

8

LO

4

2

2

3

5th - Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch forward

3

1

RT

7

5

R

3

1

6

8

LO

4

2

2

1

RTO

R

153

Neutral

LO

264

RT

7

7

8

5

R

3

1

6

8

LO

4

2

3

2

7th - Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch forward

26

Page 36

8th Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch forward

Power Flow

9 Speed - Non Top 2 Models

3

1

2

Service Procedure

9 Speed Top 2 Models

8th - Low Split Gear

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch forward

3

1

2

1

3

2

8th - High Split Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch forward

27

Page 37

Power Flow

13 Speed — Power Flow by Gear

RTO

R

153

Neutral

LO

264

LO Gear

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch rearward

RTO

R

153

Neutral

LO

264

2nd Gear

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch rearward

3

1

RTX

7

8

8

R

154

Neutral

7

LO

263

2

RTO

R

153

Neutral

LO

264

1

RTX

7

8

8

R

154

Neutral

7

LO

263

3

2

1st Gear

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch rearward

3

1

RT

7

8

7

5

R

3

1

6

8

LO

4

2

2

R

LO

RTO

Neutral

153

264

1

7

8

1

RT

7

5

R

3

1

6

8

LO

4

2

3

2

3rd Gear

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch rearward

28

Page 38

R

TO

R

153

N

eutra

l

LO

264

4th Gear

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch rearward

Power Flow

3

1

7

8

1

R

T

7

5

R

3

1

6

8

LO

4

2

2

3

1

2

5th - Low Split Gear

1. Sliding Clutch rearward

Service Procedure

2. Sliding Clutch forward

3. Sliding Clutch forward

RTO

R

153

Neutral

LO

264

5th - High Split Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch forward

3

1

RTX

7

8

8

R

154

Neutral

7

LO

263

2

3

1

2

6th - Low Split Gear

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch forward

29

Page 39

Power Flow

RTO

R

Neutral

LO

6th - High Split Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch forward

153

264

3

1

7

8

RT

7

5

R

3

1

6

8

LO

4

2

2

3

1

2

7th - Low Split Gear

1. Sliding Clutch forward

2. Sliding Clutch forward

3. Sliding Clutch forward

RTO

7

R

153

Neutral

8

LO

264

7th - High Split Gear

1. Sliding Clutch forward

2. Sliding Clutch rearward

3. Sliding Clutch forward

3

1

RT

7

5

R

3

1

6

8

LO

4

2

2

1

RTO

R

153

Neutral

LO

264

RT

7

8

7

5

R

3

1

6

8

LO

4

2

3

2

8th - Low Split Gear

1. Sliding Clutch rearward

2. Sliding Clutch forward

3. Sliding Clutch forward

30

Page 40

RTO

R

153

LO

264

8th - High Split Gear

1. Sliding Clutch rearward

2. Sliding Clutch rearward

3. Sliding Clutch forward

Power Flow

3

1

7

8

RT

7

5

R

3

1

6

8

LO

4

2

2

Service Procedure

31

Page 41

Transmission Shift Patterns

9 & 13 Speed Shift Patterns

9-Speed Transmissions (Shift Lever Patterns and Shifting Controls)

32

Page 42

Transmission Shift Patterns

13-Speed Overdrive Models (Shift Lever Patterns and Shifting Controls)

RTO (Overdrive) Models

With Splitter Control Button in "DIR."/REARWARD

position . . .

Shift LO-1-2-3-4 in LOW

RANGE.

Range shift . . .

And shift 5.6-7-8 in HIGH

RANGE (Direct).

Service Procedure

WHILE IN HIGH RANGE

ONLY . . .

Ratios can be split by

moving Splitter Control

Button to the "O.D."/

FORWARD position to

gain OVERDRIVE 5-6-7-8.

Roadranger Valve

(A-4900)

SPLITTER CONTROL BUTTON

33

Page 43

Air System

Air System Overview

Pressurized air from the vehicle's air system is used to shift the transmission low/high range and low/high split. The low/high

range and low/high split gearing and shift mechanisms are located in the auxiliary section of the transmission. The vehicle operator

controls these shifts with two separate switches on the shift knob (master control valve). The following components are part of

the air shift systems.

34

Page 44

Air System

Range System Operation

The range shift air system consists of the air filter/ regulator, slave valve, a range control valve or master control valve, range cylinder, fittings and connecting air lines.

Constant air from the air filter/regulator is supplied to the "S" or supply port of slave valve and passed through to the inlet or "S"

port of control valve.

While in LO range, the control valve is open and air is returned to slave valve at the "P" or end port. This signals the valve to supply

air in line between the LO range or "L" port of slave valve and the LO range port of range cylinder housing. Air received at this port

moves the range piston to the rear and causes the auxiliary LO range gear to become engaged.

While in HI range, the control valve is closed and no air is returned to the slave valve. This signals the slave valve to supply air in

line between the HI range or "H" port of valve and the HI range port of range cylinder cover. Air received at this port moves the

range piston forward to engage the auxiliary drive gear with sliding clutch and bypass the LO range gear set.

Range shifts can be made only when the gearshift lever is in, or passing through, neutral. Thus, the range desired can be preselected while the shift lever is in a gear position. As the lever is moved through neutral, the actuating plunger in the shift bar housing

releases the slave valve, allowing it to move to the selected range position.

Service Procedure

35

Page 45

Air System

Splitter System Operation

In addition to the various components of the range shift air system, the splitter shift air system utilizes a splitter cylinder and the

Roadranger valve A-4900.

Constant air from the air filter/regulator assembly is supplied to the splitter cylinder at the port on right side of cylinder cover. The

insert valve installed in the cover provides the proper air flow needed to move the splitter piston in the cylinder (rearward to engage

rear auxiliary drive gear for operation in direct; forward to engage the front auxiliary drive gear for operation in overdrive).

While in HI or LO range, air needed to make the splitter selection and complete the shift is supplied to the Roadranger valve from

the tee fitting at the HI range or "H" port of the slave valve. When the overdrive selection is made, the air passes through the

Roadranger valve and is supplied to the left port of cylinder cover.

With splitter control button in the "DIRECT"/REARWARD position, the "SP" port of the Roadranger valve is closed and no air is

supplied to the left port of the splitter cylinder cover.

Button REARWARD

("SP" Port Closed)

While in HI range, the button can be moved forward to operate in overdrive. The "SP" port of valve is opened when overdrive is

selected, supplying air to the left port of the splitter cylinder cover.

Button FORWARD

("SP" Port Opened)

36

Page 46

Air System

Insert Valve (Equipped with Roadranger Valve A-4900)

The insert valve is a self-contained 1- 3/16" valve assembly located in the splitter cylinder cover. It cannot be disassembled except

for the three O-rings on the outer diameter. The O-rings provide a stationary seal and do not move in the cylinder.

When installing the insert valve in the bottom edge of the cover, apply Fuller #71206 silicone lubricant or its equivalent to the Orings and cylinder walls. Install the valve in the bore with the flat surface to the outside. When installing the special valve retaining

nut, apply Fuller #71204 adhesive/sealant or its equivalent to the threads and tighten. See torque specifications.

Travel of the small insert valve piston is only 3/16". As shown in the illustrations below, when no air is applied to the top side of

valve piston, constant air supplied from the regulator passes to the front side of cylinder piston, moving the yoke bar backward

to engage the rear auxiliary drive gear (LO Range DIRECT and HI Range DIRECT). The piston moves up to cut off air to the back

side of the cylinder piston. This air is exhausted out the cylinder cover as the piston moves rearward.

When air is applied to top side of valve piston, through the signal line, the piston moves down passing air through the bottom of

the insert valve to the front and backside of the cylinder piston, moving the yoke bar forward engaging the front auxiliary drive

gear (HI Range overdrive).

LOW RANGE AND HIGH RANGE DIRECT

OVERDRIVE

AIR APPLIED THROUGH SIGNAL LINE

PUSHES INSERT VALVE PISTON DOWN

Service Procedure

37

Page 47

Air System

Shift Knob 13-Speed

The shift knob contains two switches.

• The range selector lever on the front of the knob is moved down to select low range. When the range selector lever is

moved up, high range is selected.

• The splitter button or the button on the side of the shift knob is moved rearward to select LO split and forward for HI split

of each lever position. When in LO range a mechanical interlock prevents moving the splitter button to HI.

Component Nomenclature and Auxiliary Countershaft Sectional View

1. Medallion

2. Spring

3. Retainer

4. Housing

5. Spring

6. Washer

7. O-Ring

8. Range Selector

9. Pin

10. Cover

38

11. Screw

12. O-Ring

13. Spring

14. 5/32” Ball

15. Spring

16. Ball

17. Seal

18. Detent

19. Splitter Button

20. Old Style Shift Knob

Page 48

Air System

Shift Knob 9-Speed

This shift knob contains one switch.

• The range selector lever on the front of the knob is moved down to select low range. When the range selector lever is

moved up, high range is selected.

1

7

2

2

2

6

Old Design

6

8

2

9

Service Procedure

3

8

5

4

5

Component Nomenclature and Auxiliary Countershaft Sectional View

1. Medallion

2. Spring

3. Lever

4. Cover

5. Screw

6. Ball 5/32"

7. Retainer

8. O-Ring

5

5

39

Page 49

Air System

Air Filter/Regulator

The filter/regulator assembly filters the vehicle supply air and regulates the pressure to 58 - 63 PSI. Two holes in the front face of

the filter/regulator assembly supply air to the range cylinder cover. The filter element can be removed by turning out the end cap.

Component Nomenclature and Auxiliary Countershaft Sectional View

1. End Cap

2. O-Rings

3. Filter Element

40

4. Housing

5. Capscrews

6. Air Regulator

Page 50

Air System

Slave Valve

The slave valve controls the supply of air to the low and high range sides of the range shift cylinder. A small air line from the shift

knob (master control valve) provides a signal pressure to the slave valve.

6

5

4

3

2

7

8

Slave-Valve

1

19

18

9

10

Plunger Pin

Poppet-Type

11

Spring

Gasket

12

13

Sleeve

14

15

Slave Valve

Assembly

Service Procedure

16

Component Nomenclature

and Auxiliary Countershaft

Sectional View

1. Slave Valve Housing

2. “U” Seal

3. Washer

4. Spring

5. Plug

6. Snap Ring

7. O-Rings

8. Plate

9. Capscrew

10. Cap

11. Gasket

12. Seal

13. O-Ring

14. Piston

15. “U” Seal

16. Cap

17. O-Ring

18. Seal

19. Spring

41

Page 51

Air System

Slave Valve Preselection System

This interlock mechanism prevents the slave valve from shifting when the transmission is engaged into gear. The air valve shaft

is moved towards the slave valve by the shift rails when the transmission is shifted into gear. A spring pushes the air valve shaft

back when the front section is shifted into a neutral position.

Component Nomenclature and Auxiliary Countershaft Sectional View

1. Actuation Spring

2. Actuating Pin

3. Air Valve Shaft

Refer to the drawing for disassembly and reassembly of the piston-type slave valve assemblies. Should the poppet-type slave valve

assembly prove to be defective, replace the complete assembly, as it is non-serviceable. The actuating components used with

these valve assemblies are non-interchangeable. Failure to use the correct plunger pin, spring, and alignment sleeve during installation on the transmission will cause hard shifting in LO Range gears.

42

4. Shift Bar Housing

5. Slave Valve

6. Alignment Sleeve

Page 52

RTLC-1X909 (2-Speed Auxiliary)

Range-LO

A-4900 Roadranger

Valve

Air System

Slave Valve

Identification

Down

Rearward

r

Fule

l

Transmissions

®

H/L

PS SP

A-5000

Slave Valve

S

A-5000 Valve

Service Procedure

H/L

HI

P

LO

Air Filter/Regulator

Assembly

Air from

Vehicle

Source

Splitter Cylinder

Assembly

Constant Air

No Air

SP

Range Cylinder Assembly

Air to

LO

Housing

Port

No Air

HI

43

Page 53

Air System

RTLC-1X909

Range-HI

A-5000

Slave Valve

S

A-5010 Roadranger

Valve

Up

Slave Valve

Identification

A-5000 Valve

SP

HI

P

Air Filter/Regulator

Assembly

Air from

Vehicle

Source

Splitter Cylinder

Assembly

Constant Air

LO

Breather

Range Cylinder Assembly

No Air

LO

Air to

Cover Port

HI

44

Page 54

RTLO-1X913

LO-Range

A-4900 Roadranger

Valve

Air System

Slave Valve

Identification

Down

Rearward

Fule

l

Transmissions

®

r

H/L

PS SP

A-5000

Slave Valve

S

A-5000 Valve

Service Procedure

H/L

HI

P

LO

Air Filter/Regulator

Assembly

Air from

Vehicle

Source

Splitter Cylinder

Assembly

Constant Air

No Air

SP

Range Cylinder Assembly

Air to

LO

Housing

Port

No Air

HI

45

Page 55

Air System

RTLO-1X913

HI Range L

A-4900 Roadranger

Valve

Slave Valve

Identification

Rearward

Fule

l

Transmissions

®

r

Up

PS SP

H/L

A-5000

Slave Valve

A-5000 Valve

H/L

HI

S

P

LO

46

Air Filter/Regulator

Assembly

Air from

Vehicle

Source

Constant Air

Splitter Cylinder

Assembly

No Air

SP

Range Cylinder Assembly

No Air

LO

Air to Cover

Port

HI

Page 56

RTLO-1X913

HI Range H

HI Range H

A-4900 Roadranger

Valve

Air System

Slave Valve

Identification

Forward

Fule

Transmissions

Up

®

r

l

PS SP

H/L

A-5000

Slave Valve

H/L

HI

S

A-5000 Valve

Service Procedure

P

LO

Air Filter/Regulator

Assembly

Air from

Vehicle

Source

Splitter Cylinder

Assembly

Constant Air

SP

Range Cylinder Assembly

LO

Air to Cover

Port

No Air

HI

47

Page 57

General Troubleshooting

General Troubleshooting Chart

The chart on the following pages contains some of the most common problems that may occur with this transmission along with

the most common causes and solutions.

Complaint Cause Corrective Action

Noise - Growl / Rumble Torsional Vibration.

[Noise may be most pronounced when

transmission is in a “float” (low torque)

condition. May also be confined to a particular vehicle speed.]

Transmission bearing or gear failure.

[Noise may be most pronounced under

hard pull or coast (high torque).]

Noise - Growl / Rumble at Idle (Idle Gear

Rattle)

Noise - High Pitched Whine Gear Noise.

Excess engine torsional vibration at idle. Check for low engine RPM.

Isolate as to axle or transmission noise.

If transmission, isolate to specific gear

or gears.

Check driveline angles for proper u-joint

working angles.

Check driveline for out of balance or

damage.

Check u-joints for proper phasing.

Check clutch assembly for broken

damper springs.

Check for inadequate clutch disc damping.

Check transmission oil for excessive

metal particles.

Check for uneven engine cylinder performance.

Check for proper clutch damper operation.

Check for worn or defective shift lever

isolator.

Check for direct cab or bracket contact

with transmission (“grounding”).

Check for proper driveline u-joint working angles.

Check for damaged or worn gearing.

48

Page 58

General Troubleshooting

General Troubleshooting Chart (cont)

Complaint Cause What to do next

Hard Lever Shifting

(Shift lever is hard to gear into or out of

gear)

Shift Lever Jumpout

(Shift lever comes out of gear on rough

roads)

Master clutch dragging. Check master clutch for proper disen-

gagement.

Check master clutch for proper adjustment (both release bearing travel and

clutch brake height).

Shift linkage problem. (Remote shifter) Check shift linkage or cables for proper

adjustment, binding, lubrication, or

wear.

Shift bar housing problem. Check shift bar housing components for

binding, wear, or damage.

Transmission mainshaft problem. Check mainshaft for twist.

Check sliding clutches for binding, damage, or excessive wear.

Driver technique. Driver not familiar or skilled with proper

double-clutching technique.

Driver contacting the clutch brake during

shifts.

Loose or worn engine mounts. Check engine mounts for damage, wear,

or excessive looseness.

Shift lever problem. Check shift lever floor boot for binding

or stretching.

Check shift lever isolator for excessive

looseness or wear.

Check for excessive offset or overhang

on the shift lever.

Check for extra equipment or extra

weight added to shift lever or knob.

General Information

Worn or broke detent spring or mechanism.

Check for broken detent spring.

Check for excessive wear on the detent

key of detent plunger.

Replace detent spring with heavier

spring or add additional spring.

49

Page 59

General Troubleshooting

General Troubleshooting Chart (cont)

Complaint Cause Corrective Action

Shift Lever Slipout

(Transmission comes out of gear under

torque)

Transmission goes to neutral

(Shift lever doesn’t move)

No range shift or slow range shift

(Also see Air System Troubleshooting)

Internal transmission problem. Check for excessively worn or damaged

sliding clutches or shift yokes.

Low air pressure. Check air regulator pressure.

Internal transmission problem. Check for excessively worn or damaged

range sliding clutch or yoke.

Transmission air system problem. Preform air system troubleshooting pro-

cedure.

Check for proper air signal from master

valve.

Check air module test ports for proper

air delivery.

Range cylinder problem. Check for failed or damaged range pis-

ton, piston bar, or cylinder.

Check for failed or loose range piston

snap ring.

Range yoke assembly problem. Check for failed or damaged range yoke.

Check for failed or loose range yoke

snap rings.

Check for excessively long fastener

installed in rear support hole.

Check for binding between range yoke

bar and range alignment lock cover.

Range synchronizer problem. Check for failed or damaged range syn-

chronizer, sliding clutch, or mating gear.

Check for excessively worn range synchronizer friction material.

Grinding Noise on Range Shift Driver not preselecting range shift. Instruct driver to preselect range shifts.

Range synchronizer worn or defective. Check range synchronizer and mating

parts for excessive wear or damage.

50

Page 60

Air System

Air System Troubleshooting

WARNING

Use care when removing air lines or checking for air flow from disconnected lines. High pressure air may exhaust suddenly.

Wear safety glasses. Exhaust all air pressure from system before removing air filter/regulator or combination cylinder cover.

General Information

Note: During all testing, the vehicle air pressure must be greater than 90 PSI (620 kPa). If during testing the pressure falls below

90 PSI (620 kPa), make sure the transmission is in neutral, start the engine and let the pressure build to governor cutoff.

After the pressure reaches the governor cutoff, continue testing. The pressure is critical if the vehicle is equipped with a

vehicle air system Pressure Protection Valve that would shut off the air supply to certain air circuits if the system pressure

dropped below a preset level.

IMPORTANT

Use the following air system troubleshooting procedures for part replacement only if the symptom can be duplicated

problem is intermittent, parts that are not defective could be replaced.

Instructions

1. Start at “Procedures” for Step A.

2. Based on the “Result” of the procedure, go to the corresponding “What To Do Next”.

. If the

51

Page 61

Air System

Procedure 1: Symptom - Air Leak at Shift Knob

Normal Operation:

• A burst of air will be exhausted from the shift knob when moving the range selector from low to high. This is the air being

exhausted from the “P” air line.

• A burst of air will be exhausted from the shift knob when moving the splitter button rearward (shifting to low split). This

is the air being exhausted from the “SP” air line.

Possible Causes:

• Incorrectly attached air lines

• Internal leak in slave valve

• Internal leak at insert valve

• Internal leak at shift knob

Table 10 Air Leak at Shift Knob

PROCEDURE RESULT WHAT TO DO NEXT

Step A Remove lower skirt on shift knob.

Check for leaking fitting at the shift

knob.

Step B Check air lines to make sure all lines

are connected to the proper ports on

the shift knob.

A.) Reversal of “S” and “P” lines will

result in a constant leak from the exhaust when high range is selected.

B.) Reversal of the H/L and “SP”

lines will result in a constant leak

when the splitter button is rearward.

Step C Move the range selector lever down

to Low range. Check for constant air

flow from the exhaust “E” port.

Step D Move the range selector up to high

range. Disconnect the small air line

connected to the “P” port of the shift

knob. Check for air flow from the

port and air line.

Leak found. Repair leaking fitting or air line.

No leak found. Go to Step B.

Air lines are not connected to the

proper ports.

Air lines are connected to the proper

ports.