Page 1

Ordering number : EN4696B

13097HA(OT)/83095HA (OT) No. 4696-1/11

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

Monolithic Digital IC

LB1823M

SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquarters

TOKYO OFFICE Tokyo Bldg., 1-10, 1 Chome, Ueno, Taito-ku, TOKYO, 110 JAPAN

Power Brushless Motor Predriver IC

for OA Applications

Overview

The LB1823M is a predriver IC developed for driving

power brushless motors in office automation applications.

A motor driver circuit with the desired output power

(current and voltage) can be constructed by attaching

either a driver array or discrete components at the output.

The LB1823M output supports direct PWM drive and thus

allows the implementation of low-loss drive circuits.

Additionally, the LB1823M includes several associated

circuits, such as a speed control circuit, and FG amplifier,

and an integrating amplifier, on chip.

Features

• Direct PWM drive output

• Crystal oscillator circuit

• Speed discriminator plus PLL speed control system

• Lock detector output

• Forward/reverse switching circuit

• Braking circuit (short braking technique)

• Start/stop switching circuit

• Over current limiter circuit (OCL)

• Thermal shutdown circuit (TSD)

• Built-in FG amplifier, integrating amplifier

• Shunt regulator output (7.0 V)

Package Dimensions

unit: mm

3073A-MFP30SD

∏SANYO: MFP30SD

[LB1823M]

Page 2

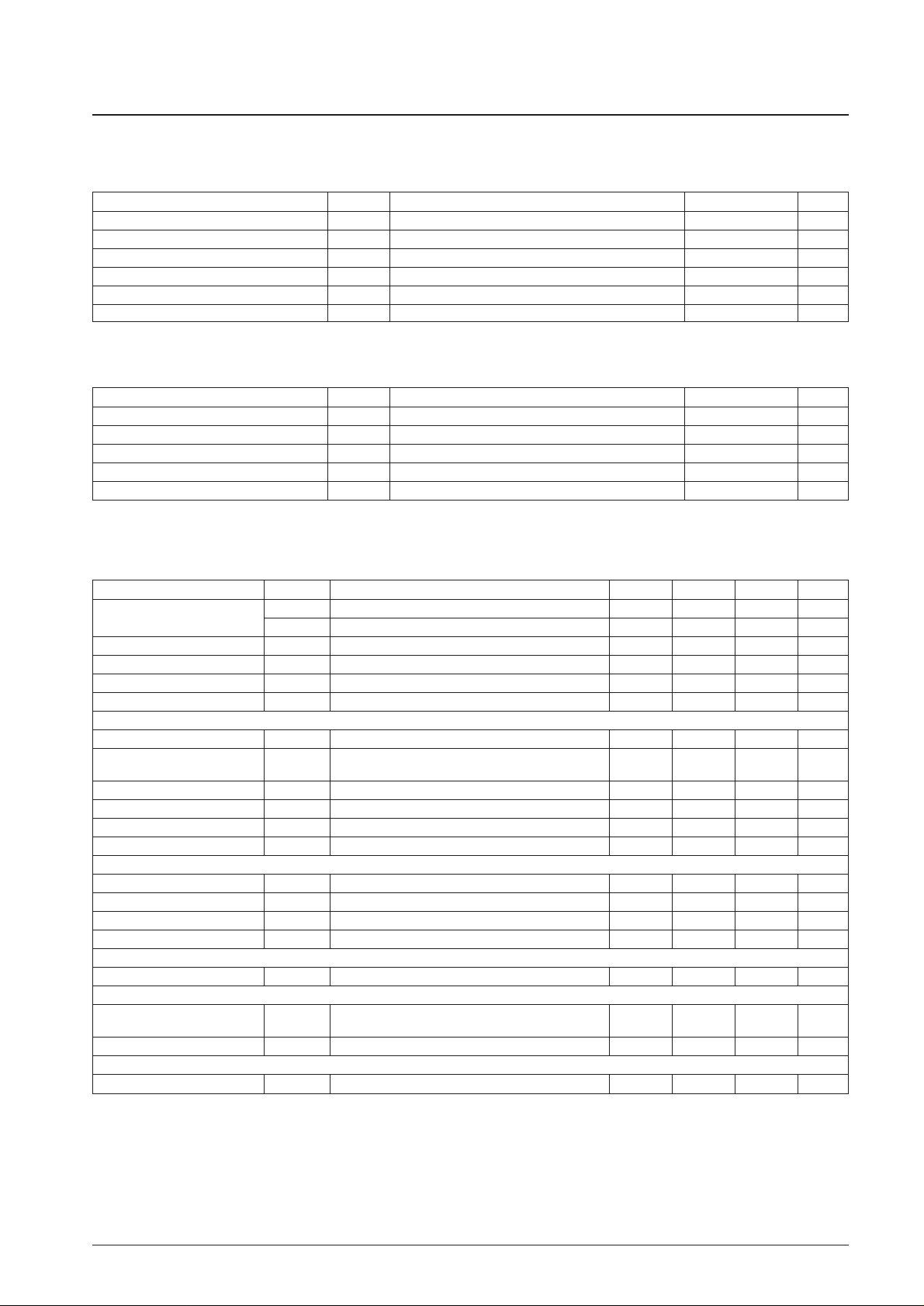

Specifications

Absolute Maximum Ratings at Ta = 25°C

Allowable Operating Ranges at Ta = 25°C

Electrical Characteristics at Ta = 25°C, VCC= 6.3 V

No. 4696-2/11

LB1823M

Parameter Symbol Conditions Ratings Unit

Maximum supply voltage V

CC

max 9 V

Maximum input current I

REG

V

REG

pin 10 mA

Output current I

O

UL, VL and WL outputs 30 mA

Allowable power dissipation Pd max 0.9 W

Operating temperature Topr –20 to +80 °C

Storage temperature Tstg –55 to +150 °C

Parameter Symbol Conditions Ratings Unit

Input current range I

REG

V

REG

pin (7 V) 1 to 5 mA

FG Schmitt output applied voltage V

FGS

0 to 8 V

FG Schmitt output current I

FGS

0 to 5 mA

Lock detector output current I

LD

0 to 20 mA

Supply voltage V

CC

4.5 to 7 V

Parameter Symbol Conditions min typ max Unit

Current drain

I

CC

1 33 50 mA

I

CC

2 When stopped 15 25 mA

Output saturation voltage V

O

sat UL, VL and WL outputs: IO= 20 mA 0.2 0.7 V

Output current I

O

UH, VH and WH outputs: V

OUT

= 1.4 V 8 12 16 mA

Output leakage current I

O

leak UL, VL and WL outputs 100 µA

Output off voltage V

O

off UH, VH and WH outputs 0.5 V

[Hall Amplifier]

Input bias current I

HB

–4 –1 µA

Common-mode input

V

ICM

1.5 4.4 V

voltage range

Hall input sensitivity ∆V

IN

60 mVp-p

Hysteresis ∆V

IN

17 32 60 mV

Input voltage low to high V

SLH

16 mV

Input voltage high to low V

SHL

–16 mV

[Oscillator]

Output high level voltage V

OH (CR)

3.1 3.4 3.7 V

Output low level voltage V

OL (CR)

1.2 1.5 1.8 V

Oscillator frequency f

(CR)

R = 56 kΩ, C = 1500 pF 20 kHz

Amplitude V

(CR)

2.0 Vp-p

[Current Limiter Operation]

Limiter V

RF

0.4 0.5 0.6 V

[Thermal Shutdown Operation]

Thermal shutdown operating

TSD Design target 150 180 °C

temperature

Hysteresis ∆TSD Design target 30 °C

[V

REG

Pin]

V

REG

pin voltage V

REG

6.6 7.0 7.3 V

Continued on next page.

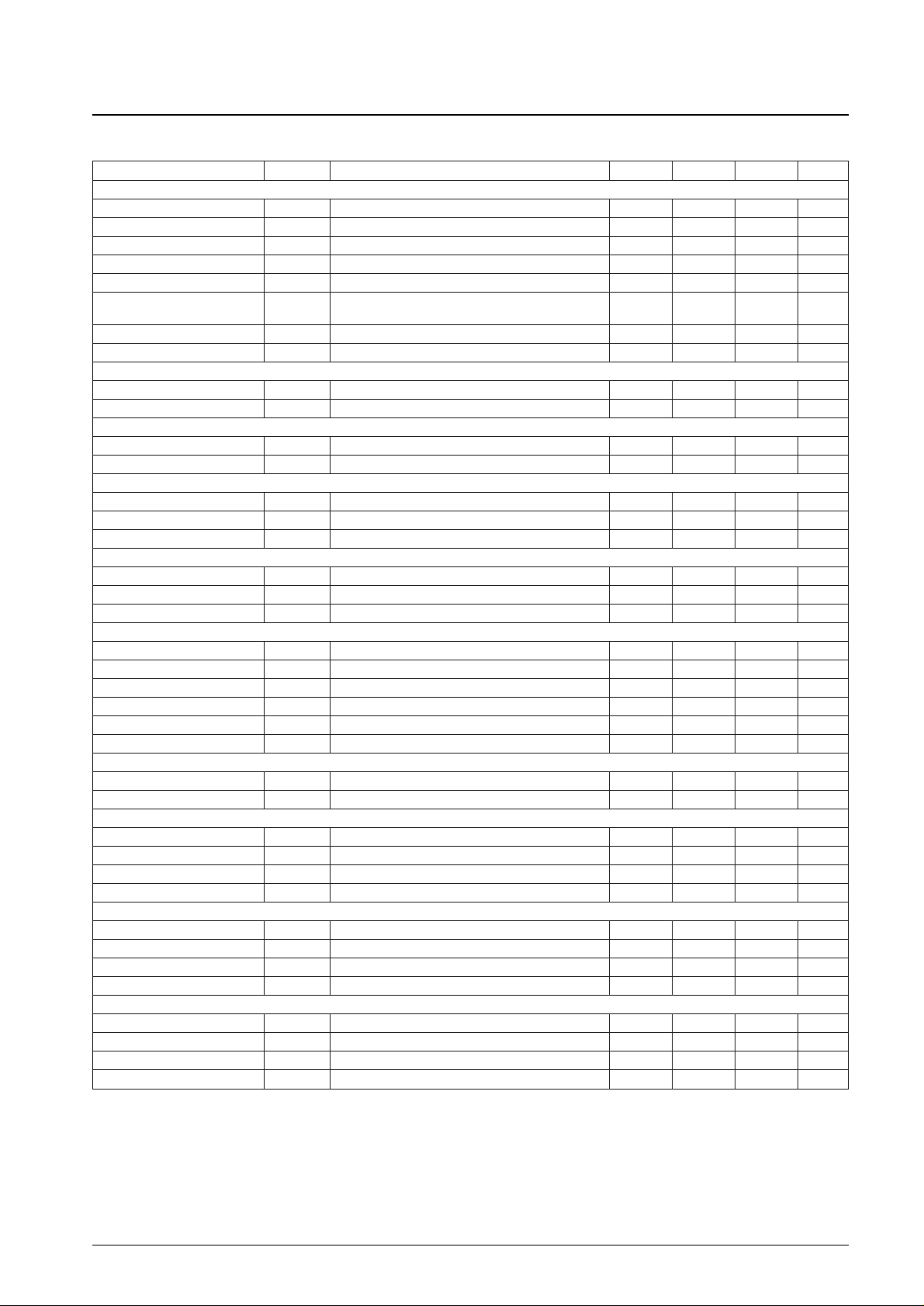

Page 3

Continued from preceding page.

No. 4696-3/11

LB1823M

Parameter Symbol Conditions min typ max Unit

[FG Amplifier]

Input offset voltage V

IO (FG)

–10 +10 mV

Input bias current I

B (FG)

–1 +1 µA

Output high level voltage V

OH (FG)

4.8 5.3 V

Output low level voltage V

OL (FG)

1 1.5 V

FG input sensitivity Gain: 100

× 3 mV

Schmitt amplitude for the

100 180 250 mV

next stage

Operating frequency range 2 kHz

Open-loop gain f

(FG)

= 2 kHz 45 51 dB

[FGS Output]

Output saturation voltage V

O (FGS)IO (FGS)

= 2 mA 0.1 0.5 V

Output leakage current I

L (FGS)VO

= V

CC

10 µA

[Speed Discriminator]

Output high level voltage V

OH (D)

5.3 5.6 V

Output low level voltage V

OL (D)

0.4 1.1 V

[PLL Output]

Output high level voltage V

OH (P)

4.05 4.35 4.65 V

Output low level voltage V

OL (P)

1.85 2.15 2.45 V

Number of counts 512

[Lock Detector]

Output low level voltage V

OL (LD)ILD

= 10 mA 0.1 0.5 V

Output leakage current I

L (LD)

VO= V

CC

10 µA

Lock range ±6.25 %

[Integrator]

Input bias current I

B (INT)

–0.4 +0.4 µA

Output high level voltage V

OH (INT)

5.0 5.6 V

Output low level voltage V

OL (INT)

0.8 1.2 V

Open-loop gain 60 dB

Gain bandwidth product 1.6 MHz

Reference voltage –5% V

CC

/2 5% V

[Crystal Oscillator]

Crystal oscillator frequency f

OSC

Crystal oscillator 1 10 MHz

External input frequency f

CLK

External signal input 1 10.2 MHz

[S/S Pin]

Input high level voltage V

IH (S/S)

4.0 3.05 V

Input low level voltage V

IL (S/S)

2.60 1.5 V

Hysteresis ∆V

IN

0.45 V

Pull-up resistor R

U (S/S)

63 kΩ

[F/R Pin]

Input high level voltage V

IH (F/R)

4.0 3.05 V

Input low level voltage V

IL (F/R)

2.60 1.5 V

Hysteresis ∆V

IN

0.45 V

Pull-down resistor R

D (F/R)

30 50 70 kΩ

[BR Pin]

Input high level voltage V

IH (BR)

4.0 3.05 V

Input low level voltage V

IL (BR)

2.60 1.5 V

Hysteresis ∆V

IN

0.45 V

Pull-down resistor R

D (BR)

30 50 70 kΩ

Page 4

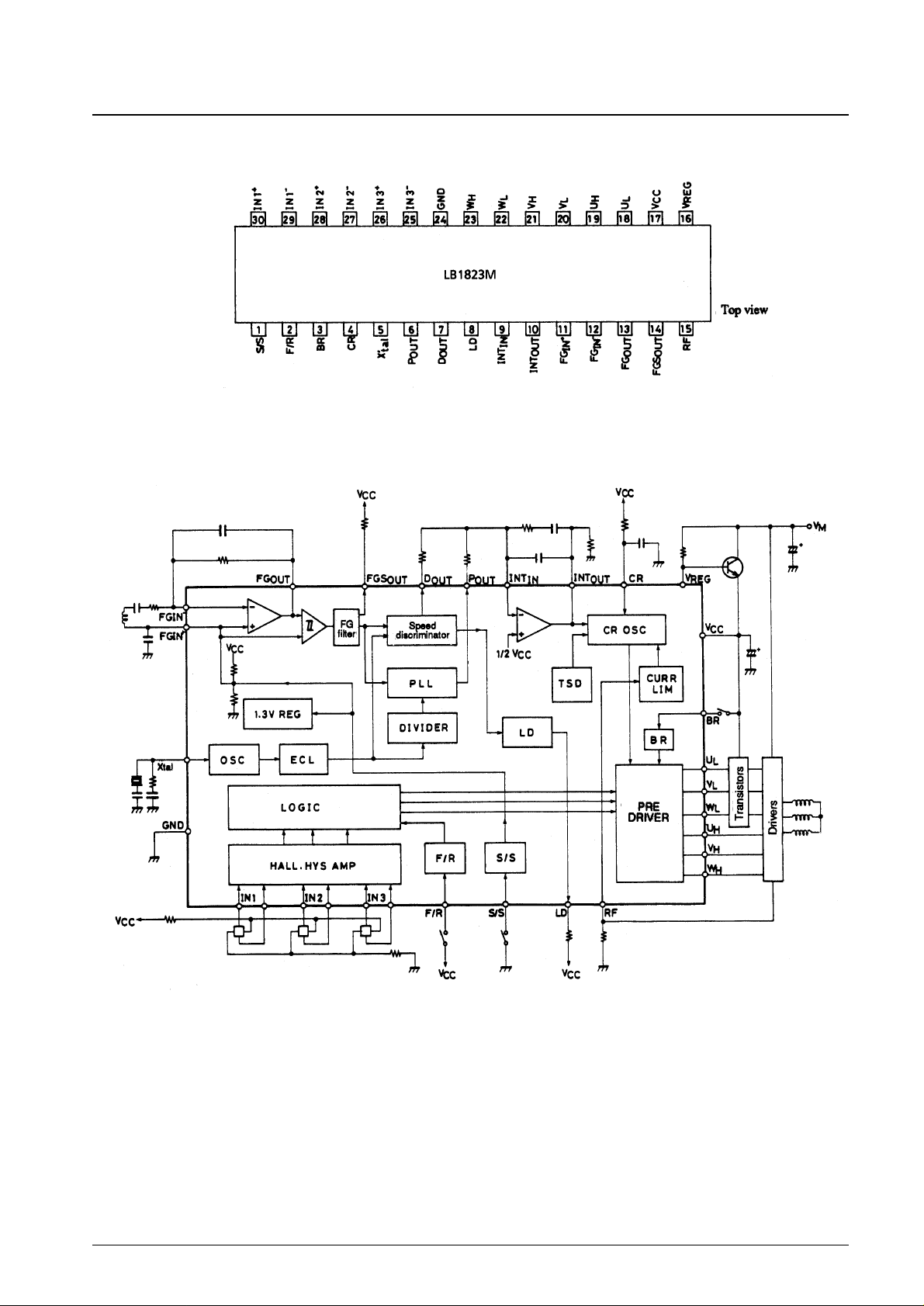

Pin Assignment

Block Diagram

No. 4696-4/11

LB1823M

Page 5

Sample Application Circuit

Truth Table

Note: High (H) for a given input (IN) specifies the state where IN+> IN–.

The formula below gives the relationship between the crystal oscillator frequency (f

OSC

) and the FG frequency (fFG).

fFG(servo) = f

OSC

/(ECL16 divisor × number of counts)

= f

OSC

/8192

No. 4696-5/11

LB1823M

Item

F/R = L F/R = H Output

IN1 IN2 IN3 IN1 IN2 IN3 Source Sink

1 H L H L H L VH UL

2 H L L L H H WH UL

3 H H L L L H WH VL

4 L H L H L H UH VL

5 L H H H L L UH WL

6 L L H H H L VH WL

Unit (capacitance: F)

Page 6

No. 4696-6/11

LB1823M

External Crystal Oscillator Circuit External Constants (reference value, VCC= 6.3 V)

External Constants (reference value, VCC= 5 V)

Note: However, an oscillator element with crystal fundamental frequency fOimpedance to 3f

O

impedance ratio = 1:5 or greater must be used.

Xtal (MHz) C1(pF) C2(pF) R(Ω)

3 to 4 39 120 390

4 to 5 39 120 560

5 to 7 39 82 820

7 to 10 39 68 2200

Xtal (MHz) C1(pF) C2(pF) R(Ω)

3 to 4 39 180 330

4 to 5 39 150 390

5 to 7 39 100 560

7 to 10 39 68 1200

Pin Functions

Pin No. Symbol Function

30, 29 IN1

+

, IN1

–

Hall input pin

28, 27 IN2

+

, IN2

–

Hall input pin

26, 25 IN3

+

, IN3

–

Hall input pin

19 UH Output pin, constant current source output

21 VH Output pin, constant current source output

23 WH Output pin, constant current source output

18 UL Output pin, open collector sink output

20 VL Output pin, open collector sink output

22 WL Output pin, open collector sink output

17 V

CC

Power supply

16 V

REG

7 V shunt regulator output

24 GND Ground

4 CR PWM oscillator frequency setting

9 INT

IN

Integrator input

10 INT

OUT

Integrator output (speed control pin)

7 D

OUT

Speed discriminator output. High on overspeed.

6 P

OUT

PLL output

8 LD

Lock detector

Low when the motor speed is in the lock range (±6.25%)

11 FG

IN+

FG pulse input (1/2 of the VCCvoltage)

12 FG

IN–

FG pulse input

13 FG

OUT

FG amplifier output

14 FGS

OUT

FG amplifier output (following the Schmitt circuit)

5 X’tal Crystal oscillator. Connect a crystal oscillator element to this pin.

15 RF Output current detection

1 S/S

Start/stop control pin

Low for start, high or open for stop

2 F/R

Forward/reverse control

Low or open for forward, high for reverse

3 BR

Brake, short brake

Low or open for start, high for brake. The S/S pin must be set to the stop state when releasing the brake.

Page 7

External Component Functions

Notes on LB1823M Operation and External Components

1. Speed control circuit

The LB1823M uses a speed discriminator circuit and a PLL circuit in combination for speed control. The speed

discriminator generates an error output once every two FG periods using a charge pump technique. The PLL circuit

generates a phase error output once every FG period, also using a charge pump technique. By using a speed

discriminator circuit and a PLL circuit together, the LB1823M can suppress speed variations better than earlier

systems that only used a speed discriminator for speed control when used with motors faced with large load

variations. Since the following formula determines the FG servo frequency, the motor speed is set by the number of

FG pulses and the crystal oscillator frequency.

fFG(servo) = f

OSC

/8192

f

OSC

: Crystal oscillator frequency

2. Direct PWM drive

This IC adopts a direct PWM drive technique to minimize power loss in the outputs. The output transistors are

always saturated when on, and the motor drive power is adjusted by changing the duty with which the outputs are on.

Since the upper side transistors switch the outputs, Schottky, fast recovery, or similar diodes must be inserted

between OUT and ground (diodes D1, D2 and D3). (This is because through currents will flow in the upper side

transistors at the instant they turn on if these diodes do not have a short reverse recovery time.) Ordinary rectifying

diodes can be used between OUT and VCC. Transistors with no parasitic diodes must be used for the output lower

side transistors. If these transistors include parasitic diodes, through currents will flow due to their reverse recovery

time, even if Schottky diodes are used for D1, D2 and D3.

3. Current limiter circuit

The current limiter circuit operates (to limit the peak current) at a current determined by the formula I = 0.5/R

f

(where Rf= R10). The limiting operation suppresses the current by reducing the on-duty. No phase compensation

capacitor is required.

No. 4696-7/11

LB1823M

Part Function Description

C1 Power supply stabilization

Choose a value such that the voltage fluctuations due to the motor drive currents are

stabilized.

C2 IC power supply stabilization Attach as close as possible to pins 17 and 24.

R1, C3 PWM frequency setting Use a resistor of 30 kΩ or larger for R1.

C4, C5, R2 External crystal oscillator circuit See the figure on page 6.

C6, C7, R3, R4, R5 Servo constants

IC internal power supply If the capacitance of this capacitor is too small, it will become harder to reset the internal IC

C8 stabilization logic reliably and incorrect logic operation may occur. Attach as close as possible to pins 11

Reset pulse generation and 24.

C9, C10, R7, R8

FG amplifier gain and frequency

characteristics settings

R10 Limit current setting Output current I

OUT

= VRF/R10

R11, R12 Hall element bias current settings

R13, R14, R15 Sink current settings These resistors set the sink currents for the UL, VL and WL (open collector) outputs.

R16

Shunt regulator bias current Select a value such that a current of over 1 mA flows in the V

M

voltage range for which

settings guaranteed correct operation is desired.

R17, R18, R19 Pull-down resistors These resistors speed up the motor drive output transistor off times.

R20 Start time assurance Include R20 in applications in which the start up time is a problem.

D1, D2, D3 Regeneration current absorption Use Schottky diodes for D1, D2 and D3.

Page 8

4. Speed lock range

The speed lock range is ±6.25% of the rated speed, and the LD pin (which is an open collector output) will be low

when the motor speed is within the lock range. The LB1823M controls the motor speed to be within the lock range

by generating a speed error signal when the motor speed goes out of the lock range and adjusting the motor drive on

duty according to that signal.

5. PWM frequency

The PWM frequency is determined by R1 and C3, which are connected to the CR pin.

When R1 is connected to a 6.3 V power supply (the application circuit pin 17 voltage):

f

PWM

≈ 1/(0.6 · C · R)

R1 must not be any smaller than 30 kΩ. A PWM frequency of 15 kHz is desirable. If the PWM frequency is too low,

the motor will resonate at the PWM frequency during motor constraint. This can result in disturbing audible

frequency noise. Inversely, the output transistor switching loss can become significant if the PWM frequency is too

high.

6. Grounding

The signal system ground must be separated from the output system ground, and these grounds must be connected to

a single ground point at the connector. The output system ground should be kept as short as possible since it carries

large current.

Output system ground – – The Rf(R10) ground side. The D1, D2, and D3 ground side.

Signal system ground – – The IC pin 24 and the IC peripheral circuit ground.

7. External interface pins

• LD pin

Output type: open collector

Breakdown voltage:8 V

Manufacturing variation in the saturation voltage (reference value at ILD= 10 mA)

0.10 to 0.30 V

• FGS pin

Output type: open collector

Breakdown voltage: 8 V

Manufacturing variation in the saturation voltage (reference value at I

FGS

= 2 mA)

0.05 to 0.10 V

The FGS pin outputs the FG amplifier output converted to a pulse signal by a hysteresis comparator. Thus FGS is a

speed monitor output. No pull-up resistor is required when unused.

• S/S pin

Input type: PNP transistor base with a 63 kΩ pull-up resistor to V

CC

Threshold level: About 2.6 V (high to low), about 3.05 V (low to high)

(typical) Hysteresis: about 0.45 V

In the stop state, power is cut from all but certain circuits (the input, crystal oscillator and divider circuits) and the

LB1823M does not operate.

• F/R pin

Input type: PNP transistor base with a 50 kΩ pull-down resistor to ground

Threshold level: About 2.6 V (high to low), about 3.05 V (low to high)

(typical) Hysteresis: about 0.45 V

The forward/reverse direction must be switched in the stop state.

• BR pin

Input type: PNP transistor base with a 50 kΩ pull-down resistor to ground

Threshold level: About 2.6 V (high to low), about 3.05 V (low to high)

(typical) Hysteresis: about 0.45 V

Braking must be released in the stop mode.

No. 4696-8/11

LB1823M

Page 9

8. FG amplifier

The FG amplifier gain is determined by R7 and R8, with the DC gain, G, being R8/R7. C9 and C10 determine the

FG amplifier frequency characteristics. (R7 and C9 form a high-pass filter and R8 and C10 form a low-pass filter.)

Since a Schmitt comparator is connected following the FG amplifier, the components R1, R2, C4 and C5 must be

chosen so that the amplitude is at least 250 mVp-p. (It is desirable that the FG output be set up to provide a level of

between 1 and 3 Vp-p during steady state motor rotation.)

9. Notes on external capacitors

• C8

C8 is required for stabilization of the FGIN+ pin constant voltage power supply and to generate the IC internal

logic reset pulse. The reset pulse is generated when the FGIN– pin reaches about 1.3 V from 0 V. If the reset does

not operate, the LD pin will go on briefly during IC start.

• C2

C2 is required for power supply stabilization. Since this IC adopts a PWM technique that switches large output

currents, it can generate noise extremely easily. Thus the power supply must be stabilized adequately so that this

noise does not cause the IC to operate incorrectly. C2 should be located as close as possible to pins 17 and 24.

10. Notes on external resistors

• R13, R14 and R15

These resistors set the external output (source side) transistor drive currents. The drive currents (ID) can be derived

from the following formula.

ID≥ I

OUT/hFE

min

ID= (VCC– 0.7 – VOsat)/R

I

OUT

: Maximum output current

h

FE

min: Output transistor minimum current amplification factor

VOsat: The LB1823M output saturation voltage

• R16

R16 sets the shunt regulator bias current. R16 must be selected so that a current of over 1 mA flows in the V

M

voltage range for which guaranteed correct operation is desired.

R16 ≤ (VMmin – V

REG

)/1 mA

• R17, R18 and R19

R17, R18 and R19 prevent leakage from the lower side output transistors and make the switching time faster.

• R20

R20 prevents leakage from the integrator. A value of around 24 kΩ is recommended. If this resistor is not used, the

INT OUT pin will go high in stop mode due to leakage currents. Startup is delayed by the integrator external time

constant at start time, since the motor is accelerated when the INTOUT pin is low.

11. External transistors

• Regulator transistor

Select a transistor with a current capacity of at least 70 mA and a breakdown voltage greater than the largest V

M

voltage. Heat generation will be a problem. Use a heat sink or other cooling technique if required.

Pd = (VMmax – V

REG

) × I

I: ICC+ Hall bias current + output current (source) + α

When the internal shunt regulator is not used, the power supply must be connected directly to the VCCpin

(4.5 to 7 V). The regulator transistor is not required in this case.

2SC2314 (TO126), 2SD330 (TO220)

2SC3985 (TO220ML) or similar transistor

• Output interface transistors

These transistors are used to assure that high voltages are not applied to the IC. (The total system cost is lower by

restricting the IC breakdown voltage.) Select transistors with a current capacity of at least 30 mA and a breakdown

voltage greater than the largest VMvoltage. (R13, R14 and R15 determine the currents.)

2SC4641 (NP), 2SC4640 (SPA)

2SC4520 (PCP), 2SC4211 (MCP) or similar transistors

No. 4696-9/11

LB1823M

Page 10

• Output transistors

The output transistors must be chosen according to the current and breakdown voltage settings determined by the

required motor power. Printed circuit board space considerations determine the choice of discrete or driver array

components.

The 2SC4070 (SPA) and 2SC4113 (SPA) lower side predriver transistors include an emitter-base resistor.

When no resistor is required, the same transistors as used in the output interface can be used.

Driver arrays:

SLA6022 and SLA6023 (Sanken)

12. Through currents due to the direct PWM technique

In the direct PWM technique through currents flow in the outputs due to the switching, e.g., when used in a discrete

structure (including predriver circuits) or in LB1822 applications. These trough currents are due to the delays and

parasitic capacitances in the output transistors. Although additional capacitors were previously used to deal with this

problem, the LB1823M includes circuit modifications to ameliorate through currents. However, even despite these

measures, through currents can still occur if the values of R17, R18 and R19 are made too large, since the switching

time of the lower side transistors will be increased. Although whiskers of under 10 ns can be seen in the Rfvoltage

waveform during switching, this will not be a problem. (These occur in the probe and do not correspond to current

flows.)

13. Oscillator element

Normally, a crystal resonator, a resistors, and two capacitors are connected to the LB1823M Xtal pin. A ceramic

oscillator could also be used in applications that do not require such precise speed control characteristics. To avoid

problems, consult with the manufacturer of the oscillator element when selecting the oscillator element and the

values of the external resistor and capacitors used. Use a circuit consisting of resistors and a pnp transistor as shown

in the figure to apply an external clock signal (CLK) to the Xtal pin.

f

CLK

= 1 to 10.2 MHz

Input signal levels

High level voltage: 4.0 V minimum

Low level voltage: 1.5 V maximum

Capacitors must be added to this circuit if overshoot

and/or undershoot appears in the input waveform. Be

sure to check for this condition in that case.

Reference values

No. 4696-10/11

LB1823M

Upper side transistors

Lower side transistors Current Breakdown voltage

(Darlington)

2SA1259 2SD1060 5 A 50 V

2SB881 2SD1061 7 A 50 V

2SB882 2SD1062 10 A 50 V

2SB883 2SD1065 15 A 50 V

VCC= 6.3 V typ (5.8 to 6.8 V) Ra = 1.5 kΩ Rb = 2.0 kΩ

V

CC

= 5.0 V typ (4.5 to 5.5 V) Ra = 2.0 kΩ Rb = 1.0 kΩ

Page 11

No. 4696-11/11

LB1823M

14. Servo constants

The servo constant calculation varies significantly with the motor used, and requires specialized know-how. Thus

this should be handled by the motor manufacturer. We can provide the IC characteristics data required for the servo

constants calculations as well as frequency characteristics simulation data for the filter constants set by the motor

manufacturer. If the resistor between D

OUT

and INT.IN(R4) is too small, the values of C6 and C7 will become large.

If R4 is too large, speed errors will be likely to occur due to the speed discriminator cutoff current and the integrator

input current. Therefore, we think that a value in the range 10 to 100 kΩ is appropriate. If the resistor between P

OUT

and INT.IN(R3) is too small, the influence of the PLL system will be too large and pull-in to lock synchronization

will be degraded. Therefore, this resistor should not be too small. (We recommend a value of about 1 MΩ when R4

is 75 kΩ.) First determine the constants for the speed discriminator system only (R4, R5, C6 and C7), and then

determine the value of R3 in the PLL system.

This catalog provides information as of January, 1997. Specifications and information herein are subject to

change without notice.

■ No products described or contained herein are intended for use in surgical implants, life-support systems, aerospace

equipment, nuclear power control systems, vehicles, disaster/crime-prevention equipment and the like, the failure of

which may directly or indirectly cause injury, death or property loss.

■ Anyone purchasing any products described or contained herein for an above-mentioned use shall:

➀ Accept full responsibility and indemnify and defend SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and

distributors and all their officers and employees, jointly and severally, against any and all claims and litigation and all

damages, cost and expenses associated with such use:

➁ Not impose any responsibility for any fault or negligence which may be cited in any such claim or litigation on

SANYO ELECTRIC CO., LTD., its affiliates, subsidiaries and distributors or any of their officers and employees

jointly or severally.

■ Information (including circuit diagrams and circuit parameters) herein is for example only; it is not guaranteed for

volume production. SANYO believes information herein is accurate and reliable, but no guarantees are made or implied

regarding its use or any infringements of intellectual property rights or other rights of third parties.

Loading...

Loading...