Canon CXDI-55G, CXDI- 55C User manual

Printed by Canon

Jun. 2009 Rev. 01

Confidential

CXDI-55G/55C

Service Manual

Canon Inc. Japan

Copyright(C) Canon Inc. Medical Technical Service Dept. All rights reserved.

Manual Control No. |

: BY8-2289-0E2 |

Name of Product |

: CXDI-55G/55C |

Distribution Control No. |

|

Issued on |

|

Service Manual Introduction

This service manual belongs to a series of after-service guides Canon Inc. publishes as part of its comprehensive product quality guarantee program.

This service manual consists of nine chapters; “General”, “Installation Manual”, “Functions”, “Repair Guide”, “Parts Catalog”, “Troubleshooting”, “Service Manual Report”, “Tools” and “Appendix”. It describes an overview of the product, its functions, product configuration, installation procedures, dimensions, specifications, and notes.

If the product undergoes a large modification, a revised edition of the service manual will be sent to you. In other cases, a service manual report will be sent to you to update the manual.

Note 1:

This service manual is published by Canon Inc. in accordance with Article 6 (Furnishing the Referring Materials) of the Service Assignment Contract it has concluded with your company.

Note 2:

This service manual is the property of Canon Inc. and the company may seek to have it returned, depending on the circumstances. You are expected to keep it until then.

Note 3:

You inquiries, suggestions, etc. about the contents of this service manual should be addressed to:

Medical Equipment Technical Service Dept.

Canon Inc. Headquarters

30-2, Shimomaruko 3-chome, Ohta-ku, Tokyo 146-8501, Japan

Caution Regarding Service

This product was precisely assembled under strict manufacturing process control. There are several hazardous locations inside of this product. Careless work while the cover is removed can result in the pinching of fingers or electrical shock. Please perform the work with the following important points in mind:

1.Setup, Repair, and Maintenance

In order to ensure safety, the best performance, setup, repair, and maintenance work can only be performed by technicians who have received service training specified by Canon Inc. If there are order required certificates or restrictions specified by the law or ordinances, those regulations of the country must be observed.

2.Removing the external cover

When removing the cover during maintenance, repair, etc., perform the work after switching the power off. Never touch the device with wet hands, as there is a risk of electric shock.

3.Fuse

When replacing the fuse, first resolve the reason for its failure and then replace the fuse with the specified type. Never use a fuse other than the specified type.

4.Connecting the grounding wire

The provided ground wire must be connected to the ground terminal indoors. Make sure that the device is properly grounded.

5.Alternation prohibition

Never modify the medical device in any way.

6.Waste control

The service provider is responsible for the disposal of used service parts, packing material, etc. resulting from the setup, repair, or maintenance of the medical device. However, the customer is responsible for the disposal of the medical device. Disposal activities must follow the regulations (especially controlled industrial waste) of the country where the device is used.

VORSICHT

Befolgen Sie die unten angegebenen Sicherheitsanweisungen.

Mißachtung kann zu erletzungenoder Unfällen führen.

1.Zerlegung, Zusammenbau, Einstellung und Wartung

Zerlegung, Zusammenbau, Einstellung und Wartung dürfen nur von einem Wartungstechniker durchgeführt werden, der an einem von Canon vorgeschriebenen Wartungslehrgang teilgenommen hat.

2.Entfernen von Abdeckungen

Schalten Sie unbedingt die Stromversorgung des Instruments aus, bevor Sie die Abdeckungen zwecks Wartung und Reparatur entfernen.

Vermeiden Sie auch eine Berührung des Instruments mit nassen Händen.

Anderenfalls können Sie einen elektrischen Schlag erleiden, der zum Tod oder schwerer Verletzung führen kann.

3.Sicherung

Wenn die Sicherung ausgewechselt werden muß, schalten Sie unbedingt die Stromversorgung des Instruments aus, und beheben Sie die Ursache für das Durchbrennen der Sicherung.

Ersetzen Sie die Sicherung nur durch den vorgeschriebenen Typ. Anderenfalls kann es zu einem Brand oder elektrischen Schlag kommen.

4.Erdleiter

Erden Sie das Instrument unbedingt an einer Schukosteckdose.

Anderenfalls kann es zu einem Brand oder elektrischen Schlag durch Leckstrom kommen.

5.Umbau

Jeder Umbau des Produktes ist strengstens untersagt, da dies zu einem Brand oder elektrischen Schlag führen kann.

Caution Regarding the Setup

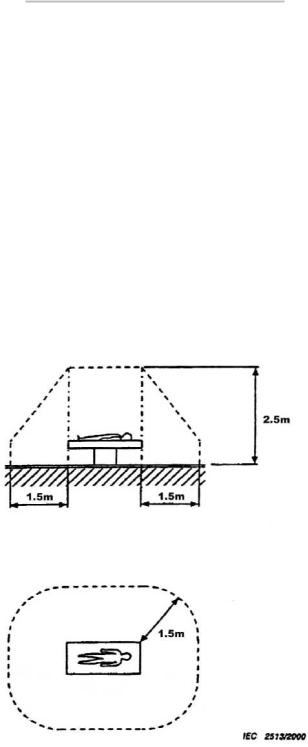

According to “IEC60601-1-1:2000”, devices installed in the patient environment are restricted to “electric medical devices conforming to IEC60601-1”.

The Control PC and operation unit are classified under the data processing device standard (IEC60950), therefore these items should not be installed in the patient environment.

The patient environment described below is an example cited from “IEC60601-1-1:2000” – the measurements are only guidelines. However, the “IEC60601-1-1:2000” example must be treated as the standard.

Therefore, the Control PC and operation unit must be installed in a location further than the measurements below (outside of the patient environment).

*Areas where the patient moves (not only during imaging but when entering and leaving the room, etc.) are also considered as part of the patient environment, therefore the installation location should be determined upon consultation with the user regarding areas outside of the patient environment.

Example of patient environment

Note: These measurements are only guidelines.

Printed by Canon

Jun. 2009 Rev. 01

CXDI-55G/55C

1. General

Canon Inc. Japan

Copyright(C) Canon Inc. Medical Technical Service Dept. All rights reserved.

|

|

|

CONTENTS |

General ............................................................................................................................. |

1 |

||

1. |

CXDI-1 System Block Diagram .................................................................................. |

2 |

|

2. |

System Diagram ........................................................................................................... |

3 |

|

|

2.1 |

Standalone System .................................................................................................. |

3 |

|

2.2 |

Total System ........................................................................................................ |

3 |

3. |

CXDI Image Processing............................................................................................... |

4 |

|

|

3.1 |

Process Flow ........................................................................................................... |

4 |

|

3.2 |

Image Types ............................................................................................................ |

4 |

4. |

Specifications ............................................................................................................... |

5 |

|

1. General

General

CXDI-55G / CXDI-55C

CXDI-55G/55C represents a thin and lightweight advanced cassette model with a large imaging size that enhances users conveniences in portable digital radiography. It adopts the detachable connector, which is compatible with the CXDI-60G/60C, allowing the use of two sizes portable flat panel detector.

The vertical scanning drive (Drv-IC), the data read out and the AD conversion (Amp-IC) are located in one side of LANMIT. Image data was read out from one direction.

The appearance of the CXDI-50G is almost the same as that of the CXDI-50C, but their fluorescence substances are different.

CXDI System Software |

Ver.7.2 and later |

|

|

55G Imaging Unit Serial Number |

100001 and later |

|

|

55C Imaging Unit Serial Number |

100001 and later |

|

|

Notes on usage

From the view of risk management, guarantee is not made for the waterproofing for blood and chemicals, hygienic safety in operating room, usage with a defibrillation device in ICU, outdoor usage or application to animals. If the sensor unit needs to be used under such condition, the system integrator should be responsible for the operation and understanding of the tolerance of the product specification.

1

1 CXDI System Block Diagram

Power Box

|

CA1 |

|

|

|

|

|||||

|

|

|

|

|

||||||

AC100/120V/230V |

|

|

|

AC Power IN |

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

OUT PUT 1 |

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Control/Signal/ |

|

||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Power |

|

||

|

|

|

|

X-Ray |

OUT PUT 2 |

|

||||

|

|

|

|

|

I/F |

Control/Signal |

|

|||

|

|

|

|

|

|

CA3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X-Ray Generator

Symbol |

Description |

Remarks |

CA1 |

AC Cable |

3m |

CA2 |

Sensor Cable |

6.3m |

CA3 |

X-Ray I/F Cable |

20m |

CA4 |

LAN Cable (Category 5) |

|

CA5 |

LAN Cable (Category 5) |

|

CA6 |

Serial Cable (Touch Panel) |

|

CA7 |

VGA Cable |

|

CA8 |

AC Cable |

3m |

1. General

Remote Switch

Imaging Unit

(CXDI―55G/55C)

Control/Signal

/Power

CA2

SERIA1(COM1)

|

|

|

|

|

Control PC |

|

|||

CA4 |

VGA |

|

|

|

|||||

|

|||||||||

|

|||||||||

SERIAL(COM2) |

|

|

|

||||||

|

|

|

|

|

LAN2 |

|

|

|

|

|

|

|

|

|

MOUSE |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

CA5 |

|

|

|

|||

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

LAN1 |

KEY BOARD |

|

||

|

|

|

|

|

|

||||

Printer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Image diagnosis |

|

|

|

AC Power IN |

|

|

||

|

|

|

|

|

||||

W/S |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CA8 |

|||

|

|

|

|

|

|

|||

Image file device |

|

|

|

AC100V~240V±10% 50/60Hz 2.2A |

||||

|

|

|

|

|||||

CA6 |

|

|

|

RS232C |

Operation |

CA7 |

|

|

|

Unit |

|

|

|

|

VGA |

||

|

|

|

|||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mouse

Key Board

Network

Ethernet

(100/10bese-T)

2

1. General

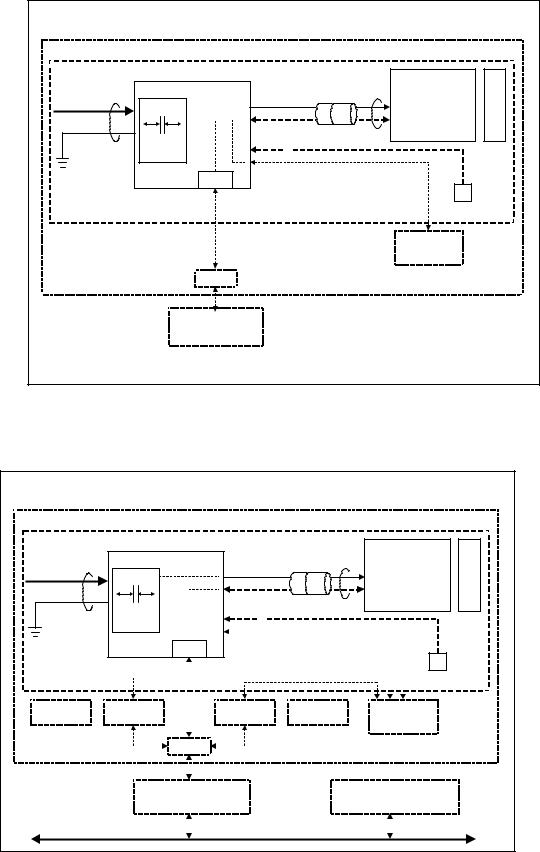

2 System Diagram

2.1 Standalone System

Standalone System Block Diagram |

|

|

|

|||

Patient Circumstances or Medical Room |

|

|

|

|

||

CXDI- |

|

|

|

|

|

|

55G/55C |

Power Box |

|

|

|

Grid |

|

|

SELV* |

|

|

|||

AC or DC IN |

|

Imaging Unit |

||||

Power Supply |

Control/Signal |

Unit |

||||

|

|

|

||||

|

|

|

|

|||

|

1st / 2nd |

Control |

Connector |

|

|

|

|

|

|

|

|||

|

AC250V |

|

|

|

||

|

Insulation with |

Control/Signal |

|

|

|

|

|

reinforcement |

|

|

|

||

|

|

|

|

|

||

Protective |

|

AC250V |

|

|

|

|

Grounding |

|

Basic Insulation |

|

|

|

|

|

Control/Signal |

|

|

|

||

|

|

|

|

|

||

|

|

Ethernet |

(2) |

Remote Switch |

|

|

|

|

|

|

|||

|

|

|

X-ray Generator |

|

||

|

|

(1) |

(601Compatible) |

|

||

|

|

General HUB |

|

|

|

|

|

|

|

|

* SELV = Safety Extra-Low Voltage |

||

|

|

FC-E21 A |

|

|

|

|

|

|

or |

|

|

|

|

|

Recommended general PC |

|

|

|

||

2.2 Total System

It can be connect to (1) and (2) of the system where the existing products have already been connected. Extend the ethernet port by general switching HUB or ethernet card. The maximum number of connections is limited to four by the control software specification.

Total System Block Diagram (Example) |

|

|

|

|

||

Patient Circumstances or Medical Room |

|

|

|

|

||

CXDI- |

|

|

|

|

|

|

55G/55C |

Power Box |

|

|

|

|

|

|

|

SELV* |

|

|

Grid |

|

AC or DC IN |

|

|

|

Imaging Unit |

||

Power Supply |

|

Control/Signal |

|

Unit |

||

|

|

|

|

|||

|

|

|

|

|

|

|

|

1st/2nd |

|

Control |

Connector |

|

|

|

|

|

|

|

||

|

AC250V |

|

|

|

|

|

|

Insulation |

|

Control/Signal |

|

|

|

|

with reinforcement |

|

|

|

|

|

|

|

|

|

|

|

|

Protective |

|

AC250V |

|

|

|

|

Grounding |

|

Basic Insulation |

|

|

|

|

|

Control/Signal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ethernet |

|

|

Remote Switch |

|

|

|

|

|

|

||

CXDI-40E |

Power Box |

Power Box |

CXDI-50 |

X-ray generator |

|

|

Imaging Unit |

Imaging Unit |

|

||||

|

|

|

(601 Compatible) |

|

||

|

|

|

|

|

|

|

|

Control/Signal |

General HUB |

Control/Signal |

|

|

|

|

Ethernet |

|

Ethernet |

|

|

|

|

|

|

|

|

*SELV = Safety Extra-Low Voltagej |

|

|

|

FC-E21 A |

|

|

Image Examination WS |

|

|

|

or |

|

|

Image File Equipment |

|

|

Recommended general PC |

|

|

Printer etc. |

|

|

|

|

|

Ethernet |

|

|

|

|

|

|

3 |

|

|

|

1.General

3.CXDI Image Processing

3.1 Proccess Flow

|

Born image |

Offset correction |

|||

|

|

|

|

Correction |

Gain correction |

|

|

|

|

||

|

|

|

|

processing |

|

|

|

|

|

|

|

|

Raw image |

|

Defect correction |

||

|

|

|

|

|

|

|

|

|

|

|

dtstore |

|

Original image |

|

|

||

|

|

|

|

|

Characteristic extraction |

|

|

|

QA processing |

||

|

|

|

|

||

|

|

|

|

|

• Sharpening |

|

QA image |

|

|||

|

|

• DEP |

|||

|

|

|

|

|

|

|

|

|

DICOM output |

• Gradation processing |

|

|

|

|

|

|

• MTF enhancement |

|

Diag. image |

|

|||

|

|

(Frequency enhancement) |

|||

|

|

|

|

|

|

|

|

|

|

|

• Grid stripe reduction |

|

|

|

|

|

• High density clipping |

|

Processed image |

|

|||

|

|

request |

|||

|

|

|

|

|

|

3.2Image Types

(1)BORN IMAGE

The image obtained with LANMIT before any correction is made.

Outside distribution of these images is prohibited, including dtstore images.

(2)RAW IMAGE

Born image after offset processing, gain correction.

This is the image with LANMIT specific characteristics corrected.

(3)ORIGINAL IMAGE

Raw image after preprocessing.

(4)QA IMAGE

Original image after gradation processing, sharpening, and other processing. The CXDI performs image processing up to this point.

(5)DIAG. IMAGE

QA image after further image processing necessary for diagnosis. Image processed by the user for diagnostic purposes.

(6)PROCESSED IMAGE

Diagnosis image after post-processing.

Image modified by the user or the default processed image.

4

1. General

4. Specifications

The CXDI-55G/55C (Imaging Unit/Power Box) is the Digital Cassette that has the mobility and can be used on the optional angles.

(1)Imaging Unit

This unit consists of the internal sensor, PWB-Di Board, PCB-REF Board, and its outer cover. The sensor unit converts the X-ray image to the electrical signal (O/E Conversion) and after performs the A/D conversion, transfer its signal through the Power Box with Ethernet cable to the Control PC.

|

Item |

|

55G |

|

55C |

Remarks |

|

|

|

|

|

||

Object |

|

General Shooting Cassette |

|

Å |

(Mobile/Desktop PC) |

|

Effective filming range |

353 x 430mm |

|

Å |

|

||

Number of Pixels |

2220 x 2706 |

|

Å |

|

||

Effective Number of Pixels |

2208 x 2688 |

|

Å |

|

||

Pixel pitch |

|

160µm x 160µm |

|

Å |

|

|

Fluorescent substance |

GOS Fluorescent screen |

|

CsI |

one panel |

||

Output gradations |

12bit (4,096 gradations) |

|

Å |

|

||

A/D 14bit |

|

|

||||

|

|

|

|

|

||

Transfer method |

Ethernet: Imaging Unit to |

|

|

|

||

Control PC |

|

Å |

|

|||

|

|

(Through the Power Box) |

|

|

|

|

Imaging cycle |

15 sec. (standard) |

|

Å |

|

||

Image display time |

3 sec. (thumbnail) |

|

Å |

|

||

|

|

8 sec. (full size image) |

|

|

||

|

|

|

|

|

||

Dimension |

|

480 (W) x 481 (D) x 15 (H) |

|

Å |

|

|

|

|

|

mm |

|

|

|

|

|

|

|

|

|

|

Imaging Unit coloring |

Cool white |

|

Å |

|

||

Imaging Unit mass |

3.4 Kg |

|

Å |

Except the cable |

||

3.7 Kg |

|

Å |

With 1.5m cable |

|||

|

|

|

||||

Space between surface where |

|

|

|

|

|

|

patient gets in contact (CFRP) |

|

4.5mm |

|

Å |

|

|

and sensor surface (glass) |

|

|

|

|

|

|

Heat |

Remote SW OFF |

36kcal/h |

|

Å |

|

|

emission |

Max load mode |

115kcal/h |

|

Å |

1 image per 15 Sec. |

|

Power |

Remote SW OFF |

11W |

|

|

Å |

|

Consumpt |

Max load mode |

32W |

|

|

Å |

1 image per 15 Sec. |

-ion |

|

|

||||

|

|

|

|

|

|

|

Power Control |

None |

|

|

Å |

Power Box: Operation with Remote switch |

|

(ON/OFF) |

|

|

|

manually |

||

|

|

|

|

|

||

|

|

The Imaging unit is put on |

the plain surface with |

|

||

Mechanical strength |

the Sensor side (Detector) is up. |

|

Self-restriction |

|||

Load uniformly: 150Kg |

|

|||||

|

|

|

|

|||

|

|

|

Load partly: 100Kg/φ40mm |

|

||

|

|

• |

FC-E21A for CXDI |

|

|

|

|

|

• |

ControlStation |

|

|

|

Control PC |

|

Standard desktop |

|

Å |

|

|

|

|

computer with the |

|

|

||

|

|

|

|

|

|

|

|

|

|

same performance |

|

|

|

|

|

|

as the FC-E21A |

|

|

|

Grid attach/remove detector |

Yes |

|

|

Å |

|

|

Sensor cable S150-55 |

Detachable connector |

|

Å |

1.5m |

||

cable on the sensor side |

|

|||||

|

|

|

|

|

||

Sensor cable S630 |

Detachable connector |

|

|

6.3m |

||

cable on the power box |

|

Å |

||||

|

|

side |

|

|

|

|

|

|

• |

4 possible connections |

|

|

|

|

|

|

to the Control PC1 |

|

|

|

|

|

• |

(via HUB) |

|

|

|

|

|

Maximum of three |

|

|

HUB shall be procured by each sales |

|

Count of connected sensor |

|

same type sensor can |

|

Å |

||

|

be connected to a |

|

company. |

|||

|

|

|

|

|

||

|

|

• |

control PC |

|

|

|

|

|

Each Imaging unit |

|

|

|

|

|

|

|

works in pair with a |

|

|

|

|

|

|

Power Box |

|

|

|

5

1. General

Item |

|

55G |

|

55C |

|

Remarks |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Scattered radiation backward |

|

|

|

|

|

|

|

|

|

|

|

block sheet |

Mo sheet (0.3 mm thick) |

Å |

|

|

|

|

|

|

|||

Environment-conscious |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

unleaded type |

|

|

|

|

|

|

|

|

|

|

|

Photo timer |

Cannot be built in |

|

Å |

|

|

|

|

|

|

||

Imaging restriction |

When |

the |

internal |

|

|

|

|

|

|

|

|

(Imaging Prohibition) |

temperature of Imaging Unit |

|

|

|

|

|

|

|

|||

|

is above 49 degree Celsius, |

|

|

|

|

|

|

|

|||

|

its state is changed to sleep |

|

|

|

|

|

|

|

|||

|

mode. |

And |

the |

Imaging |

Å |

|

|

|

|

|

|

|

prohibition will be continued |

|

|

|

|

|

|

|

|||

|

when |

the |

internal |

|

|

|

|

|

|

|

|

|

temperature |

is below 48 |

|

|

|

|

|

|

|

||

|

degree Celsius. |

|

|

|

|

|

|

|

|

||

User interface |

On in blue: Imaging unit |

|

INDICATION |

BUSY |

SENSOR |

|

POWER |

||||

|

power is on. |

|

|

|

Color |

Orange*5 |

Green |

|

|

Blue |

|

|

Blinking in blue: Imaging |

|

Imaging unit |

Off |

Off |

|

|

Off |

|||

|

|

is off |

|

|

|||||||

|

unit power is off. |

|

|

|

|

|

|

|

|||

|

|

|

Imaging unit |

-- |

Off |

|

|

On |

|||

|

On in orange: Imaging unit is |

|

|

|

|||||||

|

|

is on |

|

|

|||||||

|

busy. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Preparing |

-- |

Blinking |

*1 |

|

On |

|

|

Blinking in green: Preparing |

|

imaging |

|

|

||||||

|

imaging/error status. |

|

|

Imaging |

|

|

|

|

|

||

|

On in |

green: |

Imaging |

|

preparation |

-- |

On |

|

|

On |

|

|

preparation is complete. |

|

complete |

|

|

|

|

|

|||

|

|

|

|

|

|

Error status |

-- |

Blinking *2 |

|

On |

|

|

|

|

|

|

|

Communi- |

On *3 |

-- |

|

|

On |

|

|

|

|

|

Å |

cating |

|

|

|

|

|

|

|

|

|

|

Initialization |

|

Blinking *3 |

|

|

||

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

(when |

-- |

|

On |

||

|

|

|

|

|

|

startup) |

|

|

|

|

|

|

|

|

|

|

|

Network not |

|

Blinking *4 |

|

|

|

|

|

|

|

|

|

set (when |

-- |

|

On |

||

|

|

|

|

|

|

startup) |

|

|

|

|

|

|

|

|

|

|

|

*1: Turns on |

and off for 0.5 seconds each |

||||

|

|

|

|

|

|

*2: Turns on and off twice for 0.5 seconds, then |

|||||

|

|

|

|

|

|

turns off for 0.5 seconds |

|

|

|

||

|

|

|

|

|

|

*3: Turns on and off randomly |

|

|

|

||

|

|

|

|

|

|

*4: Fades in for 1 second and fades out for 1 |

|||||

|

|

|

|

|

|

second |

|

|

|

|

|

|

|

|

|

|

|

*5: Turns on in green for China products. |

|

||||

6

1. General

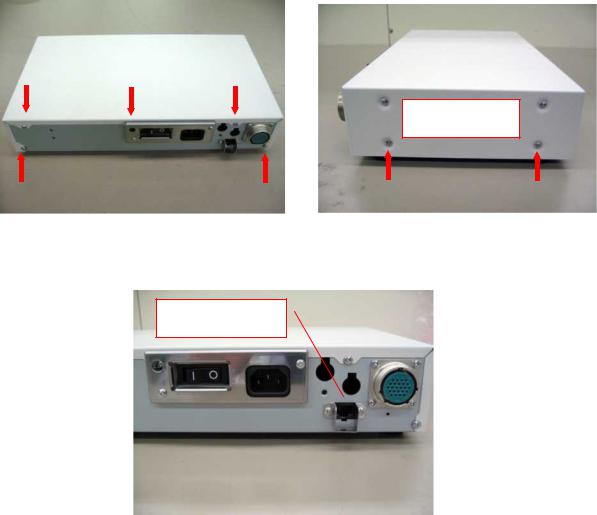

(2)Power Box

This unit consists of PWB-60XRAY Board, 60 Sensor Power Supply unit and outer covers.

The function; the signal transition between Imaging unit and Control PC, the interface to the X-ray generator equipment and power supply to the Imaging unit has been implemented.

Item |

Content |

Remarks |

|

|

|

|

|

Communication |

IEEEE 802.3u (100BASE-TX)*6 |

|

|

interface standard for |

Connector type: RJ45 |

||

control PC |

|

|

|

Communication method |

Asynchronous serial communication |

Data length: 10bit |

|

with PWB-60XRAY |

method |

Data rate: 15.625 kHz |

|

|

|

Reference |

|

Power supply |

AC 100-240V 50/60Hz 1.2A-0.7A |

60 Sensor Power Supply |

|

Rated Voltage: |

|||

|

|

||

|

|

AC 100-240V (AC 85-264V) |

|

Mass |

3.7 Kg |

|

|

|

|

Except bottom rubber parts |

|

Dimension |

358(W) x 200(D) x 65(H)* mm |

(With bottom rubber parts: |

|

|

|

75mm) |

|

(3) Environment rated parameters |

|

||

|

|

|

|

Item |

Content |

Remarks |

|

|

|

|

|

Operating temperature |

+5 to +35°C |

Must be without dewing |

|

Operating humidity |

30 to 75% RH |

||

|

|||

Keeping or |

Temperature: -30 to +50°C |

|

|

Humidity: 10 to 60% RH |

|

||

Transporting |

|

||

Atmospheric pressure: 700 to 1060 hPa |

|

||

|

|

||

7

Printed by Canon

Jun. 2009 Rev. 01

CXDI-55G/55C

2. Installation

Manual

Canon Inc. Japan

Copyright(C) Canon Inc. Medical Technical Service Dept. All rights reserved.

|

|

|

Contents |

|

1 |

Caution During the Installation.................................................................................................... |

1 |

||

2 |

Restrictions on Installation .......................................................................................................... |

1 |

||

3 |

Caution on Installation................................................................................................................. |

2 |

||

4 |

Product Configuration.................................................................................................................. |

3 |

||

|

4.1 |

Product Configuration List .................................................................................................. |

3 |

|

|

4.2 |

Configuration....................................................................................................................... |

4 |

|

|

4.3 |

Sensor Cable (Optional) ...................................................................................................... |

5 |

|

5 |

Packing Diagram ......................................................................................................................... |

6 |

||

|

5.1 |

X-ray Digital Radiography System (CXDI-55G/55C) ........................................................ |

6 |

|

|

5.2 |

Grid Frame (Optional) ......................................................................................................... |

8 |

|

6 |

Installation Procedures................................................................................................................. |

9 |

||

|

6.1 |

Lists of Tools Needed for Installation ................................................................................. |

9 |

|

|

6.2 |

System Installation Procedures.......................................................................................... |

10 |

|

7 |

Installation |

................................................................................................................................. |

12 |

|

|

7.1 |

Connection to Each Unit.................................................................................................... |

12 |

|

|

|

7.1.1 |

Connection Diagram................................................................................................ |

12 |

|

|

7.1.2 Connecting to the Power Box .................................................................................. |

13 |

|

|

|

7.1.3 Using the Sensor Unit in the Multiple Rooms ......................................................... |

19 |

|

|

|

7.1.4 Interchanging a Sensor Unit .................................................................................... |

20 |

|

|

|

7.1.5 |

Sensor Cable (Optional)........................................................................................... |

22 |

|

|

7.1.6 Connection Diagram for Control PC Rear Panel ..................................................... |

23 |

|

|

|

7.1.7 Adjusting the Length of the X-ray I/F Cable ........................................................... |

24 |

|

|

7.2 |

Starting up and Shutting down the System........................................................................ |

25 |

|

|

|

7.2.1 Sequence for Starting up the System ....................................................................... |

25 |

|

|

|

7.2.2 Sequence for Turning the Power off ........................................................................ |

25 |

|

|

7.3 |

X-ray Controller Interface ................................................................................................. |

26 |

|

|

|

7.3.1 |

Interface Signal Description .................................................................................... |

26 |

|

|

7.3.2 Signal Names and Functions in the Connection with the X-ray Generator ............. |

28 |

|

|

|

7.3.3 Rating and Characteristics for Relay and Photo Coupler (on PWB-XRAY)........... |

30 |

|

|

7.4 |

Network Settings ............................................................................................................... |

32 |

|

|

7.5 |

Setting the Fixed ROI Areas.............................................................................................. |

35 |

|

|

7.6 |

Adjusting the Phototimer................................................................................................... |

38 |

|

|

7.7 |

Settings .............................................................................................................................. |

40 |

|

|

7.8 |

Adjusting the Alignment ................................................................................................... |

97 |

|

|

7.9 |

Image Quality .................................................................................................................. |

103 |

|

|

7.10 Post-installation Checks................................................................................................... |

105 |

||

8 |

Dimension................................................................................................................................ |

|

107 |

|

2. Installation

1 Caution during the installation

Please pay attention to the followings when installing the system.

(1)If the equipment is hoisted, lowered or transported, it must be supported at both sides by a minimum of two people so there is no danger of it falling.

(2)When installing the equipment, be sure the site meets the following criteria:

1)There must be no dripping water in the area.

2)The environment must be free of harmful elements such as humid or acidic air, air with a saline or sulfur content, where there is poor ventilation or where air pressure or temperature is unusual.

3)The equipment must not be placed at an angle or subjected to vibration or shock (this includes during transportation).

4)The equipment must not be kept where chemical products are stored or where gasses are generated.

5)The site’s power supply must be of the correct voltage and frequency for the equipment.

6)The site must be connected to a fully earthed cable with sufficient ground resistance to meet standard values.

(3)After installation, be sure to dispose of waste product packaging with care and with full respect for the environment.

2 Restrictions on Installation

(1)A clearance of at least 150mm must be left between a sensor unit and power box.

(2)It is forbidden to use the cables (sensor cable, X-ray interface cable, etc.) from the power box for moving parts. The only exception to this restriction is the sensor cable that is to be connected to the sensor unit.

- 1 -

2. Installation

3 Caution on Installation

(1)Do not install the sensor near electronic devices as noises and artifacts tend to appear on images in the electromagnetic field.

e.g. CRT monitor, X-ray generator, and any other medical electronic devices.

(2)Follow the following steps to detach the sensor cable while the system is running.

1)To detach the sensor cable

-Check the LED of the sensor unit and the display of the control PC to make sure the status of communication between the imaging unit and Control PC is idle. (*1)

-Turn off the main power switch of the power box or the remote switch. (*2)

-Make sure the LED on the imaging unit, switch on the power box and remote switch are turned off. Power supply to the Imaging unit must be disconnected.

-Detach the connector of the sensor cable.

*1: Do not detach the sensor cable during the data transmission between the sensor unit and control PC, it may cause equipment breakdown.

*2: Do not detach the sensor cable when the power is being supplied from the power box, it may cause equipment breakdown. If you disconnect the sensor by improper steps, the “Error” LED on the power box and remote switch will be turned on to alert you the sensor cable is detached improperly. To restore from the error, turn off the main switch of the power box or the remote switch. Then connect the sensor cable again by following the steps described in the next column.

2)To attach the sensor cable

-Make sure the LED on the imaging unit, switch on the power box and remote switch are turned off. Power supply to the Imaging unit must be disconnected.

-Connect the connector of the sensor cable.

-Turn on both the main switch of the power box and remote switch.

(3)Before proceeding with installation, ensure that the static accumulated in the bodies of the installation personnel is discharged. Similarly, before touching the PCBs (when removing them) or cable connectors, ensure that all static is discharged.

- 2 -

2. Installation

4 Product Configuration

4.1 Product Configuration List

1) CXDI-55G/55C

No. |

Item Name |

Qty |

Remarks |

1 |

CXDI-55G/55C Imaging Unit |

1 |

with 1.5 m sensor cable |

S150-55 (sensor side) |

|||

|

|

|

attached. |

2 |

Sensor cable P630 (on the power box side) |

1 |

6.3m |

3 |

Operation manual (for imaging unit) |

- |

|

4 |

Attached documents for medical |

- |

(JPN) |

5 |

Warranty registration |

- |

(JPN) |

6 |

Warranty card |

- |

(US) |

7 |

German Security leaflet/WEEE leaflet |

- |

(EU) |

2) CXDI SYSTEM II

No. |

Item Name |

Qty |

Remarks |

1 |

Power Box |

1 |

|

2 |

X-ray I/F cable |

1 |

20m |

3 |

Remote switch |

1 |

20m |

4 |

Power supply cable (with AC plug) |

1 |

3m (100/120/230V) |

5 |

Operation manual (for power box) |

- |

|

3) Sensor Cable (Optional)

No. |

Item Name |

Qty |

Remarks |

|

1 |

Sensor Cable P630-PM |

1 |

6.3m |

|

(Panel mount type) |

||||

|

|

|

||

2 |

Sensor Cable SP780-55 |

1 |

7.8 m |

|

(Straight type) |

||||

|

|

|

LAN cable for connecting Control PC / Power Box and Network switch (Switching HUB) for connecting the multiple Imaging Units shall be procured at each sales company.

- LAN cable (Over category 5)

Recommended length of the cable is 30m or less.

When Control PC and Power Box are connected directly, Cross type is used, but when they are connected via Network switch, Straight type is used. However, this is not applied when Network switch has AUTO-MDI/MDI-X function*.

- Network switch (Switching HUB)

Sales companies adopt Network switch (Switching HUB) after conducting the test and the operation check for Switching HUB that meets the general standard.

- 3 -

2. Installation

4.2 Configuration

No. |

|

|

1 |

|

No. |

2 |

|

Name |

CXDI-55G/55C Imaging Unit |

Name |

Sensor cable P630 |

||||

(Power box side) |

|||||||

|

|

|

|

|

|

||

Qty |

1 |

|

|

|

Qty |

1 |

|

Remarks |

With |

the |

sensor |

cable |

Remarks |

6.3m |

|

S150-55 (imaging unit side) |

|||||||

|

|

|

|||||

|

|

|

|

|

|

|

|

No. |

|

|

3 |

|

No. |

4 |

|

Name |

Power Box |

|

|

Name |

X-ray I/F cable |

||

Qty |

1 |

|

|

|

Qty |

1 |

|

Remarks |

I/F and Power supply |

Remarks |

Connection with X-ray |

||||

generator |

|||||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

No. |

|

|

5 |

|

No. |

6 |

|

Name |

Remote switch |

|

Name |

Power supply cable |

|||

Qty |

1 |

|

|

|

Qty |

1 |

|

Remarks |

Switch |

to |

turn on |

and off |

Remarks |

For Power Box |

|

Power Box |

|

|

(100/120/230V each type) |

||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

- 4 -

2.Installation

4.3Sensor Cable (Optional)

No. |

1 |

No. |

2 |

|

Name |

Sensor Cable P630-PM |

Name |

Sensor cable SP780-55 |

|

(Panel mount type) |

(Straight type) |

|||

|

|

|||

Qty |

1 |

Qty |

1 |

|

Remarks |

6.3m |

Remarks |

7.8m |

|

Detachable cable connector |

Non-detachable cable |

|||

|

|

|||

|

|

|

|

Sensor cable P630-PM (panel mount type)

This sensor can be used instead of a standard sensor cable P630 (power box side). Only the difference is the form of the connector. There is no difference in the function of the cable.

Sensor cable SP780-55 (straight type)

This is a single straight type sensor cable with no detachable connectors. This single cable can be used instead of the sensor cable S150-55 (sensor side) and sensor cable P630 (power box side). There is no difference in the function of the cable.

- 5 -

2. Installation

5 Packing Diagram

5.1 X-ray Digital Radiography System (CXDI-55G/55C)

(1) CXDI-55G/55C Imaging Unit Package

Sensor cable P630 (6.3m)

Imaging Unit

Positioning sheet

Cardboard sheet

Place the sensor cable S150-55 on the packet corner of the paper tube

Paper tube

Center pad

Plastic bag

Corner pad

Common to right and left

Cardboard box for imaging unit

- 6 -

2. Installation

(2) CXDI System II Assembly Package

Accessories box

Power box

- 7 -

2. Installation

5.2 Grid Frame (Optional)

(1) Outer Packaging

Corner packing

Material label

Product division label

Outer package

Handle with care label

Origin label

Shipping environment label

(2) Inner Packaging

Protection sheet

Dummy sheet

Grid frame

Protection sheet

Plastic bag

Inner Package

- 8 -

2. Installation

6 Installation Procedures

6.1 Lists of Tools Needed for Installation

No. |

Tool Name |

Unit |

Remarks |

|

1. |

General Tools |

1 set |

JIS Screwdriver set |

|

2. |

Note PC |

1 |

PC/AT compatible |

|

(OS: Microsoft Windows XP Professional recommend) |

||||

|

|

|

||

3. |

LAN Card |

1 |

For Note PC (as required) |

|

4. |

Mouse |

1 |

PS/2 type |

|

5. |

Keyboard |

1 |

PS/2 type |

|

6. |

HUB |

1 |

Connection between Control PC and Note PC |

|

7. |

10/100BASE-TX cable |

2 |

Straight type (Control PC to Note PC) |

|

8. |

CXDI Software version |

- |

|

|

compatibility table |

|

|||

|

|

|

||

9. |

Mirror, oil-based |

1 |

For adjusting the alignment with the X-ray tube. |

|

marker and paper etc. |

||||

|

|

|

- 9 -

2.Installation

6.2System Installation Procedures

No. |

Step |

|

|

|

Conditions and Checkpoints |

Reference Section |

1 |

Unpacking and checking |

-There must be no missing parts, |

|

|||

|

the product’s constituent |

damage, dents, etc. |

|

|||

|

parts |

|

|

|

-There must no color changes in the |

|

|

|

|

|

|

shock sensor. |

|

2 |

Connect the Imaging Unit |

-Handle the instrument carefully, as it |

|

|||

|

and the Power Box |

|

may be damaged if something is hit |

|

||

|

|

|

|

|

against it, dropped or receives the strong |

|

|

|

|

|

|

jolt. |

|

|

|

|

|

|

-The cable must be routed in such a way |

|

|

|

|

|

|

that no unreasonable loads are brought to |

|

|

|

|

|

|

bear upon them. |

|

3 |

Connect |

the |

Power |

Box |

-The cable must be routed in such a way |

|

|

and the Control PC |

|

that no unreasonable loads are brought to |

|

||

|

|

|

|

|

bear upon them. |

|

4 |

Connect the Power Box |

-The manufacturer of the X-ray |

|

|||

|

and the X-ray generators |

generators must be asked to handle the |

|

|||

|

|

|

|

|

connections with the generators. |

|

5 |

Check date and time |

|

- Date and time must be changed |

“(1) Checking and |

||

|

|

|

|

|

according to the area where the |

Setting the Date and |

|

|

|

|

|

instrument is installed. |

Time” in section |

|

|

|

|

|

|

7.6. |

6 |

Check the software |

|

-The compatibility of the sensor unit and |

“(2) Checking the |

||

|

program’s version |

|

the Control PC must be checked on the |

Firmware Version” |

||

|

|

|

|

|

compatibility list, and the software |

in section 7.6. |

|

|

|

|

|

program must be installed or upgrade as |

|

|

|

|

|

|

required. |

|

7 |

Identifying the Imaging |

|

“(6) Identifying the |

|||

|

Unit (input the sensor |

|

|

Sensor Units” in |

||

|

serial numbers) |

|

|

section 7.6. |

||

8 |

Enter control PC serial |

|

“(7) Entering |

|||

|

number. |

|

|

|

|

Control PC Serial |

|

|

|

|

|

|

Number” in section |

|

|

|

|

|

|

7.6. |

(9) |

Adjusting the timing with |

-No required usually. |

|

|||

|

X-ray generator |

|

|

|

||

10 |

Calibration |

|

|

-No error must be displayed. |

Operation Manual |

|

11 |

Setting |

the |

Fixed |

ROI |

If necessary, set the ROI area. |

|

|

Areas |

|

|

|

|

|

12 |

Set exposure |

parameter |

-Set it in consultation with the technician. |

“(8) Table Setup |

||

|

table |

|

|

|

|

Setting” in section |

|

|

|

|

|

|

7.6. |

13 |

Set annotation |

|

|

-Set it in consultation with the technician. |

“(9) Performing the |

|

|

|

|

|

|

|

Annotation Setting” |

|

|

|

|

|

|

in section 7.6. |

14 |

Connect the network and |

|

“(10) Network |

|||

|

set the output destination |

|

Connections” in |

|||

|

|

|

|

|

|

section 7.6. |

15 |

Startup settings |

|

|

“(5) Set Up Startup |

||

|

|

|

|

|

|

Menu” in section |

|

|

|

|

|

|

7.6. |

- 10 -

2. Installation

No. |

Step |

Conditions and Checkpoints |

Reference Section |

16 |

Exposure testing |

-The data must be sent to the printer and |

Section 5.7 Image |

|

|

storage and the image quality must be |

Quality. |

|

|

checked. |

|

17 |

Check the linearity of the |

|

“(11) Linearity |

|

transferred image density. |

|

Check Image |

|

|

|

Density” in section |

|

|

|

7.6. |

18 |

Operation unit Gamma |

|

“(12) Operation |

|

correction |

|

Unit Gamma |

|

|

|

Correction” in |

|

|

|

section 7.6. |

19 |

Body parts settings |

-Set it in consultation with the technician. |

Operation Manual |

20 |

Check and set the system |

-Set it in consultation with the technician. |

Each section in |

|

settings. |

|

section 7.6. |

|

|

|

Settings. |

21 |

Total adjustments and |

-Conform according to the check sheet. |

Section 7.9 |

|

delete the unnecessary |

-Delete the unnecessary data. |

Post-installation |

|

data. |

|

check. |

22 |

Cleaning |

|

|

23 |

Explain the operation to |

|

Operation Manual |

|

the user |

|

|

24 |

Final parameter |

-Consult with the technician to narrow |

Operation Manual |

|

adjustment |

down the adjustments to the final values. |

|

25 |

Inserting the backup |

-It must be confirmed at re-start that |

“(15) Backing up |

|

floppy disk. |

backup files have been made. |

Setting Data to FD” |

|

|

-No necessary for the system installed in |

in section 7.6. |

|

|

vehicles. |

|

26 |

Back up valuable data |

-Copy the CCR folder to the removal |

“(14) Backing Up |

|

|

drive. |

when Installing” in |

|

|

|

section 7.6. |

- 11 -

2. Installation Manual

7 Installation

7.1 Connection to Each Unit

7.1.1 Connection Diagram

CXDI-55G/55C

J1 |

POWER SUPPLY |

|

J2

J3

J4

PWB-XRAY

POWER BOX

Control PC

Remote Switch

- 12 -

2.Installation

7.1.2Connecting to the Power Box

(1)Removing the cover

1)Remove the 5 screws from the back of the power box and the 2 screws on each side at the bottom of the power box to remove the top cover.

Different types of screw are used for backside and lateral side. Make sure to use the proper type of screw respectively on installation.

Also remove screws on the far side

2)Before connecting the X-ray I/F cable and remote cable, remove the LAN cable connector guard to avoid injury.

LAN cable connector guard

- 13 -

2. Installation

(2)Cable connections

1)Loosen the skin top spiral and lock nut of the remote cable and X-ray I/F cable. Do not remove the insulation lock from the X-ray I/F cable as it is put on the cable to prevent the cable from falling off.

*The X-ray I/F cable is 20m in length. If the cable is too long, you may need to make it shorter. Refer to “7.1.4. Adjusting the length of X-ray I/F cable” for details.

Remote Cable

Lock nut

Skin top spiral

Insulation lock

X-ray I/F Cable

2) Get the connector and lock nut of the remote cable through the hole in a power box.

Adjust the direction of the connector to the notch of a hole.

Get the lock nut through the hole.

- 14 -

Loading...

Loading...