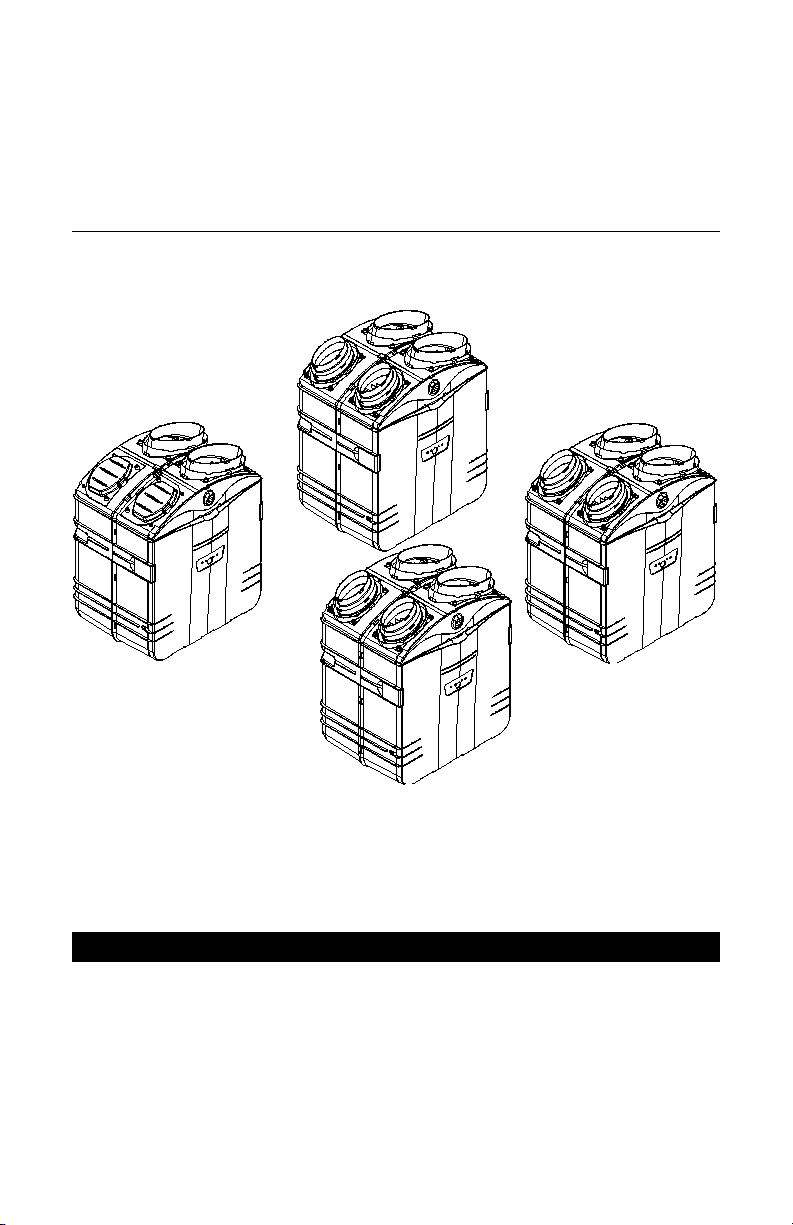

Broan HEPA 4000, HEPA 1000, HEPA 3000, HEPA 2000 User Manual

INSTALLATION INSTRUCTIONS

AND USER MANUAL

MODELS

HEPA 2000*

HF 2.0*

HEPA 1000*

HF 1.0*

VB0061

*Patents pending

NOTE: HEPA 4000 model available in United States only.

RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THIS MANUAL WITH THE HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION

ON PAGES 28 and 32 to 36.

HEPA 4000*

HEPA 3000*

HF 3.0*

04313 rev C

ABOUT THIS MANUAL

!

First, we want to congratulate you on your purchase of this excellent unit which will

allow you and your family to enjoy clean and health

years to come!

Because of the large amount of models covered by this publication, the illustrations

are typical ones. Some details of your unit may be slightly different than the ones

shown.

Please take note that this manual uses the following symbols to emphasize

particular information:

WARNING

Identifies an instruction which, if not followed, might cause serious

personal injuries including possibility of death.

CAUTION

Denotes an instruction which, if not followed, may severely damage the unit

and/or its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

We welcome any suggestions you may have concerning this manual and/or the

unit, and we would appreciate hearing your comments on ways to better serve you.

Please contact us by phone at one of the following numbers:

y air throughout your home for

Exclusiv

Broan-NuTone Canada Inc. Venmar Ventilation inc.

1 866 737-7770 1 800 567-3855

ely for all HF Models: Exclusively for all HEPA Models:

- 2 -!- 3 -

ABOUT THESE UNITS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSON(S) OBSERVE THE FOLLOWING:

1. This unit is intented for residential installation only.

2. Use this unit only in the manner intended by the manufacturer. If you have

questions, contact the manufacturer at the address or telephone number listed

in the warranty.

3. Before replacing filters, servicing or cleaning unit, disconnect power cord from

electrical outlet.

4. Installation must be done in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

5. This unit is not designed to provide combustion and/or dilution air for fuel-burning

appliances.

6. When cutting or drilling into wall or ceiling, do not damage electrical wiring and

other hidden utilities.

7. Do not use this unit with any solid-state speed control device other than

optional wall controls C12, CM, C34 and CMR (sold separately).

8. This unit must be grounded. The power supply cord has a 3-prong grounding

plug for your personal safety. It must be plugged into a mating 3-prong grounding

receptacle, grounded in accordance with the national electrical code and local

codes and ordinances. Do not remove the ground prong. Do not use an

extension cord.

9. Do not install in a cooking area or connect directly to any appliances.

10. Do not use to exhaust hazardous or explosive materials and vapors.

CAUTION

1. To avoid prematurate clogged filters, turn OFF the unit during construction or

renovation.

2. Please read specification label on product for further information and requirements.

3. For HEPA 2000, HF 2.0, HEPA 3000, HF 3.0 and HEPA 4000 units only: Be

sure to duct air outside – Do not intake / exhaust air into spaces within walls

or ceiling or into attics, crawl spaces, or garage.

4. Itended for residential installation only in accordance with the requirements of

NFPA 90B.

5. Do not run any air ducts directly above or closer than 2 ft (0.61 m) to any furnace

or its supply plenum, boiler, or other heat producing appliance. For HEPA 2000,

HF 2.0, HEPA 3000, HF 3.0 and HEPA 4000 units only, if a duct has to be

connected to the furnace return plenum, it must be connected not closer than

9’10” (3 m) from this plenum connection to the furnace. For HEPA 1000 and

HF 1.0 units only, the distance must be not closer than 2’ (0.61 m).

6. The ductwork is intended to be installed in compliance with all local and

national codes that are applicable.

TABLE OF CONTENTS

1.0 BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1 Inspect the Content of the Boxes . . . . . . . . . . .. . 6

2.0 TYPICAL INSTALLATIONS . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 HEPA 1000 and HF 1.0 Unit Installations . . . . . . 7

2.1.1 Stand Alone . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1.2 Central Draw Point . . . . . . . . . . . . . . . . . . . . .8

2.1.3 Return-to-Return Installation . . . . . . . . . . . . . . . .9

2.2 Installations for HEPA 4000 Only . . . . . . . . . . . .10

2.2.1 Geographical Location . . . . . . . . . . . . . . . . .10

2.2.2 HEPA 4000 Attic Installation . . . . . . . . . . . . . .11

2.3 HEPA 2000, HF 2.0, HEPA 3000, HF 3.0

and HEPA 4000 Unit Installations . . . . . . . . . . . .12

2.3.1 Stand Alone . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3.2 Central Draw Point . . . . . . . . . . . . . . . . . . . .13

2.3.3 Return-to-Return Installation . . . . . . . . . . . . . . .14

3.0 DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.1 HEPA 1000 and HF 1.0 Units . . . . . . . . . . . . . .15

3.2 HEPA 2000, HF 2.0, HEPA 3000, HF 3.0

and HEPA 4000 units . . . . . . . . . . . . . . . . . . . .15

3.3 Mounting and Servicing Considerations . . . . . . . .16

4.0 INSTALL THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.1 Locating and Mounting the Unit . . . . . . . . . . . . .17

4.2 Mount the Ports on the Unit . . . . . . . . . . . . . . . .17

4.3 How to Hang the Unit . . . . . . . . . . . . . . . . . . .18

4.4 Planning of the Ductwork . . . . . . . . . . . . . . . . .19

4.5 Installing Ductwork and Registers . . . . . . . . . . . .20

4.5.1 Stand Alone System . . . . . . . . . . . . . . . . . . .20

4.5.2 Central Draw Point . . . . . . . . . . . . . . . . . . . .21

4.5.3 Return-to-Return . . . . . . . . . . . . . . . . . . . . . .22

- 4 -

TABLE DES MATIÈRES

4.6 Installation des conduit flexibles isolés . . . . . . . . .23

4.6.1 Raccordement à la transition Tandem® . . . . . .23

4.6.2 Raccordement aux bouches ovales de 5”à 6” . .24

4.7 Installation de la bouche extérieure double . . . . . .25

4.7.1 Assemblage de la bouche extérieure double . . .25

4.7.2 Localisation de la bouche extérieure double . . .25

4.7.3 Raccordement de la transition Tandem®

à la bouche extérieure double . . . . . . . . . . . . .25

4.8 Raccordement du boyau de drainage . . . . . . . . .27

5.0 CONTRÔLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.1 Interrupteur principal . . . . . . . . . . . . . . . . . . . .28

5.2 Contrôle muraux optionnels . . . . . . . . . . . . . . . .28

5.3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . .28

5.4 Installation des contrôles muraux optionnels . . . . .29

5.5 Fonctionnement du contrôle C12 / CM . . . . . . . .32

5.5.1 Description du contrôle C12 / CM . . . . . . . . .32

5.5.2 Utilisation du contrôle C12 / CM . . . . . . . . . .32

5.6 Fonctionnement du contrôle C34 / CMR . . . . . . .33

5.6.1 Description du contrôle C34/ CMR . . . . . . . .33

5.6.2 Utilisation du contrôle C34 / CMR . . . . . . . . .33

6.0 ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.1 Entretien semestriel . . . . . . . . . . . . . . . . . . . . . .34

6.2 Entretien annuel . . . . . . . . . . . . . . . . . . . . . . .36

6.3 Réinitialisation générale . . . . . . . . . . . . . . . . . . .36

7.0 PIÈCES DE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.0 D

ÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

- 5 -

1. BEFORE STARTING

!

1

.1 INSPECT THE CONTENTS OF THE BOXES

WARNING

To avoid risk of suffocation, discard the plastic bag wrapping the unit.

• Inspect the exterior of the unit for shipping damage. Ensure that there is

no damage to the door, door latches, main switch, etc.

CAUTION

Remove the cardboard strip inside the unit (if applicable).

• Inspect the interior of the unit for damage. Ensure that blower assembly, heat

recovery core (HEPA 3000 et HF 3.0), energy recovery core (HEPA 4000),

insulation, dampers (HEPA 2000, HF 2.0, HEPA 3000, HF 3.0 and HEPA 4000),

prefilter, HEPA filter, etc. are all intact.

2. TYPICAL INSTALLATIONS

Installations may vary according to the model number and the position in which

the unit is installed. Use the following illustrations as guidelines to help you decide

on how your unit will be installed.

All the units should be hung to the joist, and installed either vertically or

horizontally. NOTE: For more details, see Point 5.3 in Section 5 INSTALL THE

UNIT.

In every case, bathroom fans and a range hood should be used to exhaust stale

air. Also, for homes with more than one level, we recommend one exhaust

register at the highest level.

There are 3 installation methods: Stand Alone, Central Draw Point and Return-toReturn Installation.

NOTE: An electrical outlet has to be available within 3 feet from the unit.

- 6 -

2. TYPICAL INSTALLATIONS (CONT’D)

2.1 HEPA 1000 AND HF 1.0 UNIT INSTALLATIONS

2.1.1 STAND ALONE (Primarily for homes with radiant hot water or electric

baseboard heating.)

Stale air is drawn to the unit by the register located at the highest level of the

house. Filtered air is supplied by the register located at the lowest level.

See figure below.

- 7 -

2. TYPICAL INSTALLATIONS (CONT’D)

2.1 HEPA 1000 AND HF 1.0 UNIT INSTALLATIONS (CONT’D)

2.1.2 CENTRAL DRAW POINT (CONNECTION TO FORCED AIR SYSTEM)

Stale air is drawn to the unit by the register located at the highest level of the

house. Filtered air is supplied to the retur

For this type of installation, it is not essential that the forced air system blower

runs when the unit is in operation, but we recommend it.

See figure below.

NOTE: Home with multiple forced air systems should have 1 unit on each system.

n (plenum) of the forced air unit.

VH0038

CAUTION

Do not connect the unit (HEPA 1000 or HF 1.0) on any forced air system supply

duct. Connect it only to the air return duct. Do not install duct or duct

connector directly above the forced air unit or not less than 2’ (0.61 m) of the

plenum connection to the forced air unit, as measured along the length of

the duct.

- 8 -

2. TYPICAL INSTALLATIONS (CONT’D)

2.1 HEPA 1000 AND HF 1.0 UNIT INSTALLATIONS (CONT’D)

2.1.3 RETURN-RETURN INSTALLATION (CONNECTION TO A FORCED AIR SYSTEM)

Filtered air and stale air flow through the forced air system ducts which simplifies

the installation. Filtered air is supplied to the return (plenum) of the forced air unit.

To avoid cross-contamination and achieve highest efficiencies, the f

blower must always be ON (or the unit efficiency will be affected).

See figure below.

NOTE: Home with multiple forced air systems should have 1 unit on each system.

orced air system

CAUTION

Do not connect the unit (HEPA 1000 or HF 1.0) on any forced air system supply

duct. Connect it only to the air return duct. Do not install duct or duct

connector directly above the forced air unit or not less than 2’ (0.61 m) of the

plenum connection to the forced air unit, as measured along the length of

the duct.

- 9 -

2. TYPICAL INSTALLATIONS (CONT’D)

S

2.2 INSTALLATION FOR HEPA 4000 ONLY

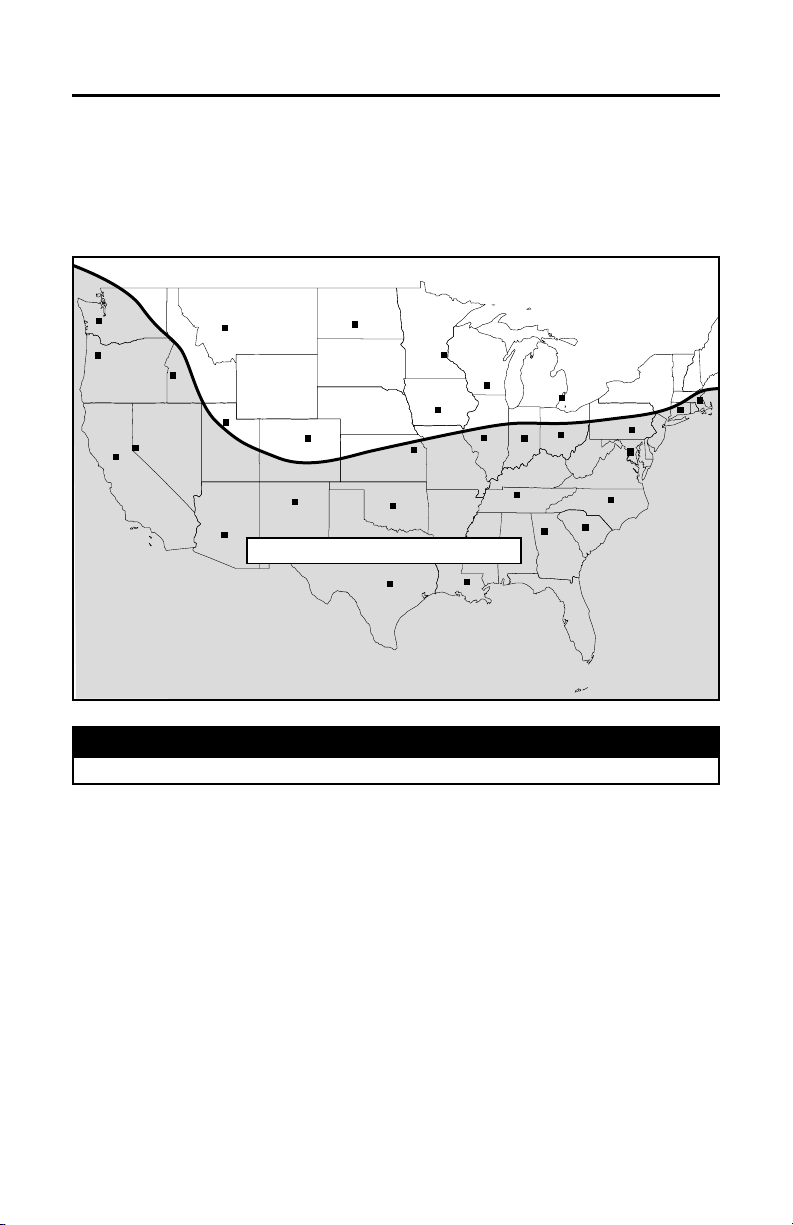

2.2.1 GEOGRAPHICAL LOCATION

The HEPA 4000 unit was created to meet specific requirements related to

geographic locations. Take a look on the map below. The shaded area shows

where the HEPA 4000 can be installed.

BOISE

HELENA

SALT LAKE CITY

PHOENIX

DENVER

SANTA FE

BISMARCK

TOPEK

A

OKLAHOMA CITY

ST. PAUL

MADISON

DES MOINES

SPRINGFIELD

DETROIT

INDIANAPOLIS

NASHVILLE

ATLANTA

HARRISBURG

COLUMBUS

BO

HARTFORD

WASHINGTON

RALEIGH

COLUMBIA

OLYMPIA

SALEM

RENO

SACRAMENTO

HEPA 4000 RESTRICTED AREA

AUSTIN

VN0005A

BATON ROUGE

CAUTION

Never install an HEPA 4000 unit out of the HEPA 4000 restricted area.

NOTE:The HEPA 4000 unit is designed to assist in the management of humidity

introduced into the home. In extreme humidity conditions, the use of additional

dehumidification may be desirable.Quickly remove all excess moisture and

keep areas clean.

- 10 -

2. TYPICAL INSTALLATIONS (CONT’D)

2.2 INSTALLATION FOR HEPA 4000 ONLY (CONT’D)

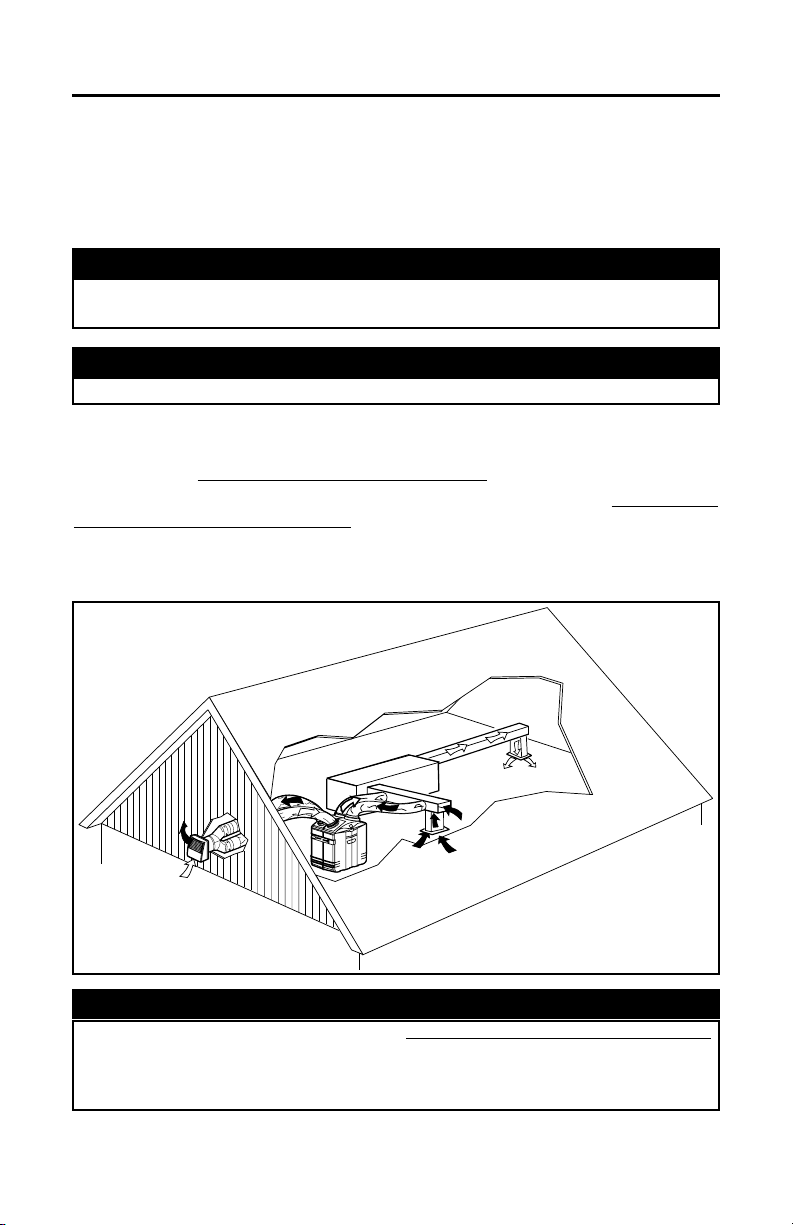

2.2.2 HEPA 4000 ATTIC INSTALLATION

All 3 types of installation can be used in the attic (Stand Alone, Central Draw Point

or Return-Return). The example shown below is a Return-Return installation

(connection to a forced air system).

CAUTION

Due to the potential temperature difference between the attic and the rest of

the house, all unit ducts must be insulated.

CAUTION

The attic temperature must always be above 0°C (32°F).

A portion of stale air is exhausted to the outside and the rest is drawn to the unit.

Outside fresh air is blended with interior air and then filtered. This filtered air is

supplied to the retur

To avoid the cross-contamination and achieve highest efficiencies, the forced air

system blower must always be ON (or the unit efficiency will be affected).

See figure below.

NOTE: Home with multiple forced air systems should have 1 unit on each system.

n (plenum) of the forced air unit.

VH0051

CAUTION

Do not connect the HEPA 4000 on any forced air system supply duct.

Connect it only to the air return duct. Do not install duct or duct connector

directly above the forced air unit or not less than 9’10’’ (3 m) of the plenum

connection to the forced air unit, as measured along the length of the duct.

- 11 -

2. TYPICAL INSTALLATIONS (CONT’D)

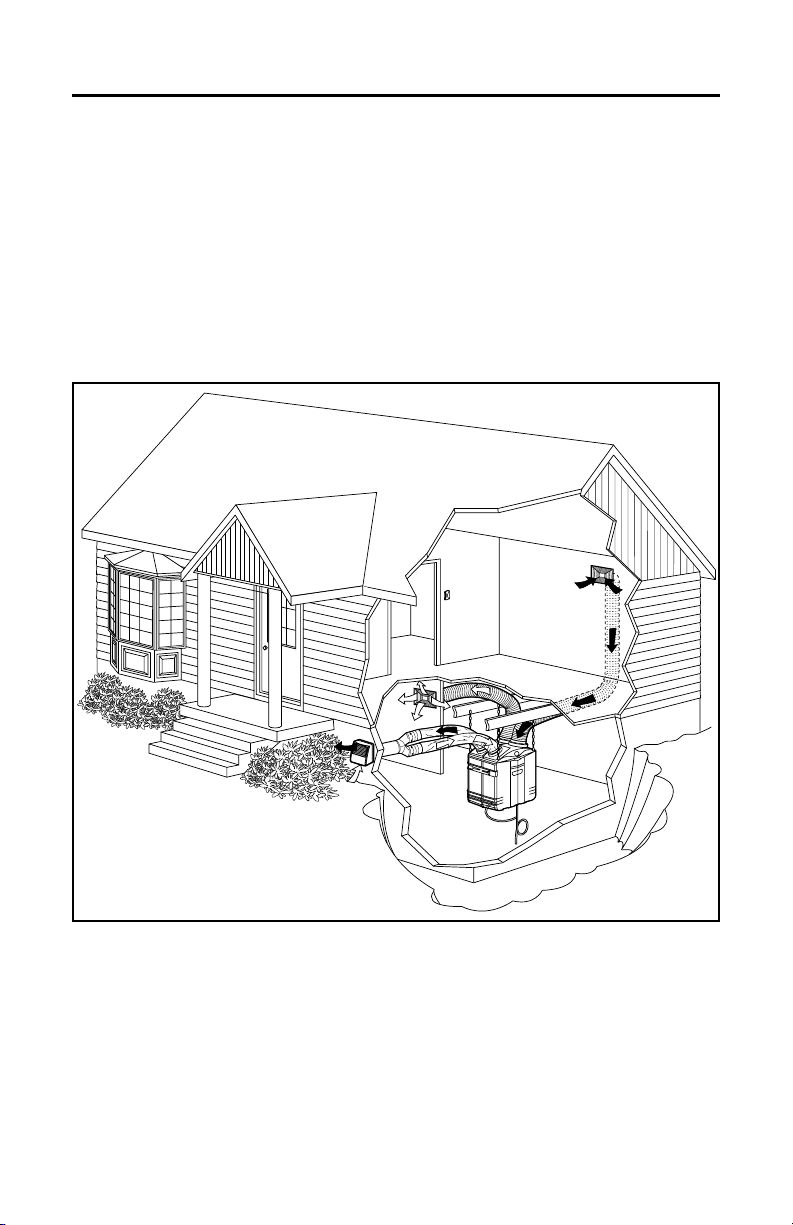

2.3 HEPA 2000, HF 2.0, HEPA 3000, HF 3.0 AND HEPA 4000

UNIT INSTALLATIONS

2.3.1 STAND ALONE (Primarily for homes with radiant hot water or electric

baseboard heating.)

A portion of stale air (coming from the register located at the highest level of the

house) is exhausted to the outside and the rest is drawn to the unit. Outside fresh

air is blended with interior air and then filtered. Fresh filtered air is supplied by the

register located in the lowest livable level. See figure below.

VH0039

- 12 -

Loading...

Loading...