Broan PM500SS Installation Manual

POWER

MODULE

REGISTER YOUR PRODUCT ONLINE AT www.broan.com/register

READ AND SAVE THESE INSTRUCTIONS

PM500 SERIES

!

INTENDED FOR DOMESTIC COOKING ONLY

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY

TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you

have questions, contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel

and lock service panel to prevent power from being switched on

accidentally. When the service disconnecting means cannot be

locked, securely fasten a prominent warning device, such as a tag,

to the service panel.

3. Installation work and electrical wiring must be done by a qualified

person(s) in accordance with all applicable codes and standards,

including fire-rated construction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s

guidelines and safety standards such as those published by the National Fire Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any separate solid-state speed control device.

8. To reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on

low or medium settings.

B. Always turn hood ON when cooking at high heat or when flambeing

food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef

Flambe’).

C. Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filter.

D. Use proper pan size. Always use cookware appropriate for the size

of the surface element.

!

!

CAUTION

1. For indoor use only.

2. To reduce risk of fire and to properly exhaust air, be sure to duct air

outside. Do not vent exhaust air into spaces within walls or ceilings

or into attics, crawl spaces, or garages.

3. Take care when using cleaning agents or detergents.

4. Avoid using food products that produce flames under the Range Hood.

5. For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

6. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust, etc. off power unit.

7. Your hood motor has a thermal overload which will automatically shut

off the motor if it becomes overheated. The motor will restart when it

cools down. If the motor continues to shut off and restart, have the

hood serviced.

8. For best capture of cooking impurities, the bottom of the hood should

be a minimum of 22" and a maximum of 30" above the cooking

surface.

9. Two installers are recommended.

10. Use with approved cord-connection kit only.

11. Please read specification label on product for further information and

requirements.

!

CAUTION

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal

tray, then turn off the burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately, EVACUATE AND CALL

THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent

steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already

know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

Wear safety gloves before every installation

and/or maintenance operation

INSTALL THE DUCTWORK

NOTE: To reduce the risk of fire, use only metal ductwork.

1. Decide where the ductwork will run between the hood and the

outside (Refer to Figure 1).

2. A straight, short duct run will allow the hood to perform most

efficiently.

3. Long duct runs, elbows, and transitions will reduce the performance

of the hood. Use as few of them as possible. Larger ducting may

be required for best performance with longer duct runs.

4. Install a roof or wall cap. Connect round metal ductwork to cap

and work back towards hood location. Use duct tape to seal the

joints between ductwork sections.

ROOF CAP

ROUND

DUCT

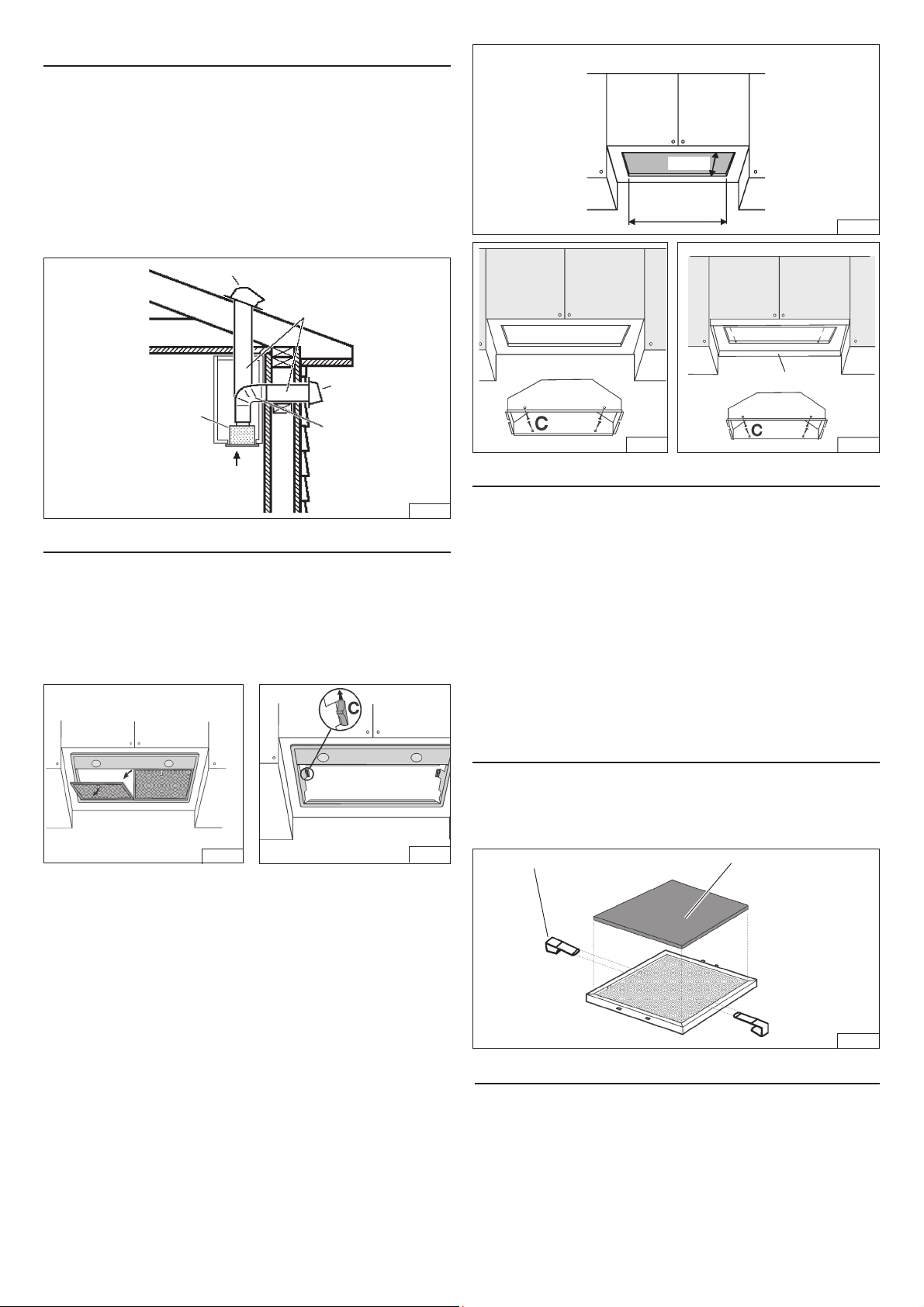

CUT A HOLE IN THE BOTTOM OF THE CABINET

10-1/4”

19-1/2”

FIG. 4

WALL

CAP

POWER

MODULE

22” TO 30” ABOVE

COOKING SURFACE

6”

ROUND

ELBOW

FIG. 1

INSTALL THE HOOD

NOTE: the hood has to be installed, inside the cabinet.

The internal height of cabinet has to be minimum 16”.

The hood should be mounted centered over the cook top burners.

1. Remove the grease filters, push in on the metal latch tab. Tilt

the filters downward and remove (Fig. 2).

2. Take the filters support away moving the 2 lateral locks C (Fig. 3).

METAL LINER

FIG. 5 FIG.5A

CONNECT DUCTWORK

Ducted Configuration

1. Take the damper and assemble it onto the hood’s discharge

opening, pressing slightly.

2. Use 6" round metal duct to connect the discharge collar on the

hood to the ductwork above.

3. Use duct tape to make all joints secure and air tight.

Non-Ducted Recirculation Configuration

1. Connect a 6” round metal duct to the discharge opening so

that the air is sent outside the cabinet and sent back into the

room.

2. Use duct tape to make all joints secure and air tight.

NON-DUCTED RECIRCULATION FILTERS

INSTALLATION

Install the Non-ducted recirculation filters over the grease filters and

secure them with the metal clips supplied with the Non-ducted

recirculation Filters (Fig. 6).

FIG. 2

FIG. 3

3. Cut a hole in the bottom of the cabinet, using the dimensions shown

(Fig. 4).

4. NOTE: For installations where the Power Pack is less than 30”

above cook top, it is recommended that the Power Pack be

mounted into a metal liner or non-combustible material. This will

allow easier cleaning and provide protection to the cabinetry

(Fig.5A).

5. Insert the hood in the cabinet (Fig. 5) or metal liner (Fig. 5A) and

secure with the (4) “C” mounting sheet metal screws.

(Fig. 5 - wood bottom installation; recommended thickness 1/2”3/4”).

(For alternate mounting, use machine screws with washers and

nuts. This alternate mounting method needs to be done prior to

installation of metal liner).

6. Replace the filters support.

7. In the Non-Ducted Recirculation Configuration, install the Nonducted recirculation Filters before replacing the grease filters (see

section “Non-ducted recirculation filters installation”).

8. Replace the grease filters.

9. Install the switch push button covers supplied in the hardware

package.

METAL CLIPS

NON-DUCTED

RECIRCULATION FILTER

(purchased seperately)

FIG. 6

WIRING

Note: This range hood must be properly grounded.

The unit should be installed by a qualified electrician in accor-

dance with all applicable national and local electrical codes.

1. Remove the wiring box cover. Remove a knockout from the wiring

box.

2. Secure the conduit to the wiring box through a conduit connector.

3. Make electrical connections. Connect white to white, black to black

and green to green.

4. Replace wiring box cover and screws. Make sure that wires are

not pinched between cover and box.

WIRING BOX

FIG. 7

OPERATION

Controls

The light switch turns the halogen lights on and off.

The blower off switch turns the blower off.

The blower low speed switch turn the blower speed to low.

The blower medium speed switch turn the blower speed to

medium.

The blower high speed switch turn the blower speed to to high.

The pilot lamp lights up whenever the blower is on.

BLOWER

LOW SPEED

BLOWER

OFF

LIGHT

FIG. 8

PILOT

LAMP

BLOWER

HIGH

SPEED

BLOWER

MEDIUM

SPEED

MAINTENANCE

ALWAYS SWITCH OFF THE ELECTRICITY SUPPLY BEFORE

CARRYING OUT ANY OPERATIONS ON THE APPLIANCE.

Grease Filters

The grease filters should be cleaned frequently. Use a warm

detergent solution. Grease filters is dishwasher safe.

To remove the grease filters: push in on the metal latch tab. Tilt the

filters downward and remove (Fig. 2).

Non-Ducted Recirculation Filters

The Non-Ducted Recirculation filters (purchase seperately) should

be changed every 6 months.

To remove the Non-Ducted Recirculation filters:

1. To remove the grease filters: push in on the metal latch tab. Tilt

the filters downward and remove (Fig. 2).

2. Remove the metal wires (Fig. 6) and replace the Non-ducted

recirculation Filters.

Cleaning

Occasional care will help preserve its fine appearance.

• Clean with warm water and mild detergent only.

• Follow all cleaning by rinsing with clear water.

• Wipe dry with clean, soft cloth.

Halogen bulbs

This range hood requires two 20-Watt halogen bulbs.

To change bulbs:

1. Remove filters.

2. Remove frame.

3. Remove the lamp cover by prying from the proper slots (Fig. 9). DO NOT ROTATE. CAUTION: BULB MAY BE HOT!

4. Replace with light bulbs of the same type (Type T3, 12Volt, 20

Watt Max, G-4 Base).

SERVICE PARTS

KEY NO. PART NO. DESCRIPTION

1 B003102348 Frame

4 B03293065 Side Fastener

6 B02011013 Spring

9 B08087039 Grease Filter

14 B02300233 Condenser

19 B03295104 Transformer Protection

26 B02300891 Halogen Lamp Bulb

45 BW0000021 Blower

48 B02310260 Motor

49 B03295071 Blower Wheel

53 B03204177 Rubber Washer

86 B08088378 Damper

115 BE3334250 Wiring Box

116 BE3334252 Wiring Box Cover

134 B03293066 Grid Stop

165 B03295008 Box Condenser

208 B02300861 Transformer

223 B03200376 Blower Switch

228 B08086303 Controls Board

229 B03201014 Pilot Lamp

230 B03294831 Control Box Cover

234 B03294830 Control Box

274 B03295035 Fuse Box

472 BE3348670 Controls Bracket

474 B02300798 Halogen Lamp

477 B03295105 Transformer Protection Cover

998 B080810886 Hardware Package

AQI B06108858 Switch box Assembly

(Included Key No. 234, 228,

14, 230)

- B08999053 Non-Ducted Filter Kit

(purchased separately)

FIG. 9

Loading...

Loading...