READ AND SAVE THESE INSTRUCTIONS

Installer: leave this guide with homeowner.

Register your product online at www.broan.com/register.

LP80 & LP110

Lo Profile

Ventilation Fan

INSTALLATION GUIDE

Easy installation

© 2018 Broan

Table of Contents

Warnings and Cautions 2

Typical Installation 2

Installation 3-6

Operation 7

Cleaning and Maintenance 7

Troubleshooting 7

Service Parts 8

Warranty 8

Page 2

LP80 & LP110

n

Installation Guide

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the address

or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service

disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction codes and

standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment

to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE), and the local code

authorities.

5. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Acceptable for use over a tub or shower (in the ceiling only)

when connected to a GFCI (Ground Fault Circuit Interrupter) protected branch circuit.

8. This unit must be grounded.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. When installed in a wall or sloped ceiling, the duct connector

must point up.

3. To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc. off power

unit.

4. Please read specification label on product for further

information and requirements.

NOT FOR USE IN A COOKING AREA

Do not install above or inside this area

45° 45°

Cooking

Equipment

Floor

Typical Installation

• Attaches to 2" x 4" or greater

wall studs or ceiling joists.

Joists I-Joists Trusses

INSULATION*

(Place around and

over Fan Housing.)

FAN

HOUSING

POWER

CABLE*

Seal gaps

around

Housing.

ROUND

DUCT*

*Purchase

separately.

The ducting from this fan to the outside of the building has a strong effect on the

air flow, noise and energy use of the fan. Use the shortest, straighest duct routing

possible for best performance, and avoid installing the fan with smaller ducts than

recommended. Insulation around the ducts can reduce energy loss and inhibit mold

growth. Fans installed with existing ducts may not achieve their rated airflow.

4-inch round rigid metal duct is recommended for best performance.

Seal duct

joints with

tape.

CEILING INSTALLATION SHOWN

ELBOWS*

OR

ROUND

ROOF CAP*

(with built-in

damper)

Keep duct

runs short.

WALL CAP*

(with built-in

damper)

Page 3

Installation

LP80 & LP110

n

Installation Guide

Tools needed

• Power screwdriver with a Phillips bit

• Phillips screwdriver

• Wire insulation stripper

• Wire cutter

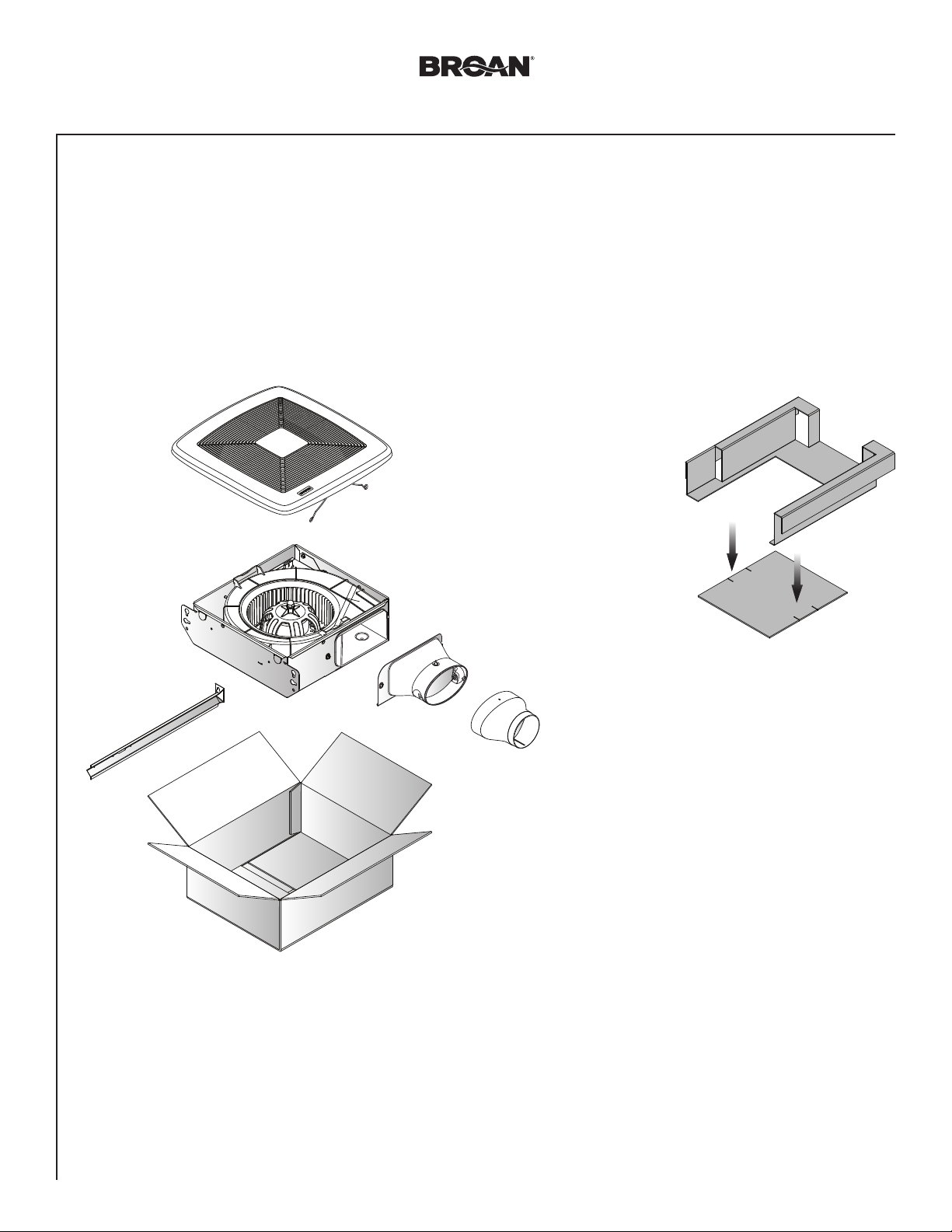

Remove from Packaging

1

Materials needed

• 4" round metal ducting recommended for best performance.

Use of other ducting is acceptable but may impact performance.

• Roof cap or wall cap (built-in damper recommended)

• Tape to seal duct connections

• Drywall screws, sheet metal screws or wire

• Electrical wiring and supplies per local code requirements

Punch out Mask

from packaging.

See Step 5.

4-in. to 3-in.

Reducer

(LP80 only)

Page 4

2

Installation

Install in Wall or Ceiling

2

UP

1

LP80 & LP110

(3 places)

n

Installation Guide

Wire

Install Ducting

3

Wall

2

2

Screw

through housing

on opposite side

1

- OR -

Ceiling

3

Tighten Screw into

housing to secure

4

mounting

1

Insert tab into slot

in housing.

2

4" Ducting

Tape

É

- OR -

3" Ducting

É

Tape

4" to 3"

Reducer

(LP80

É

only)

Tape

Page 5

Installation

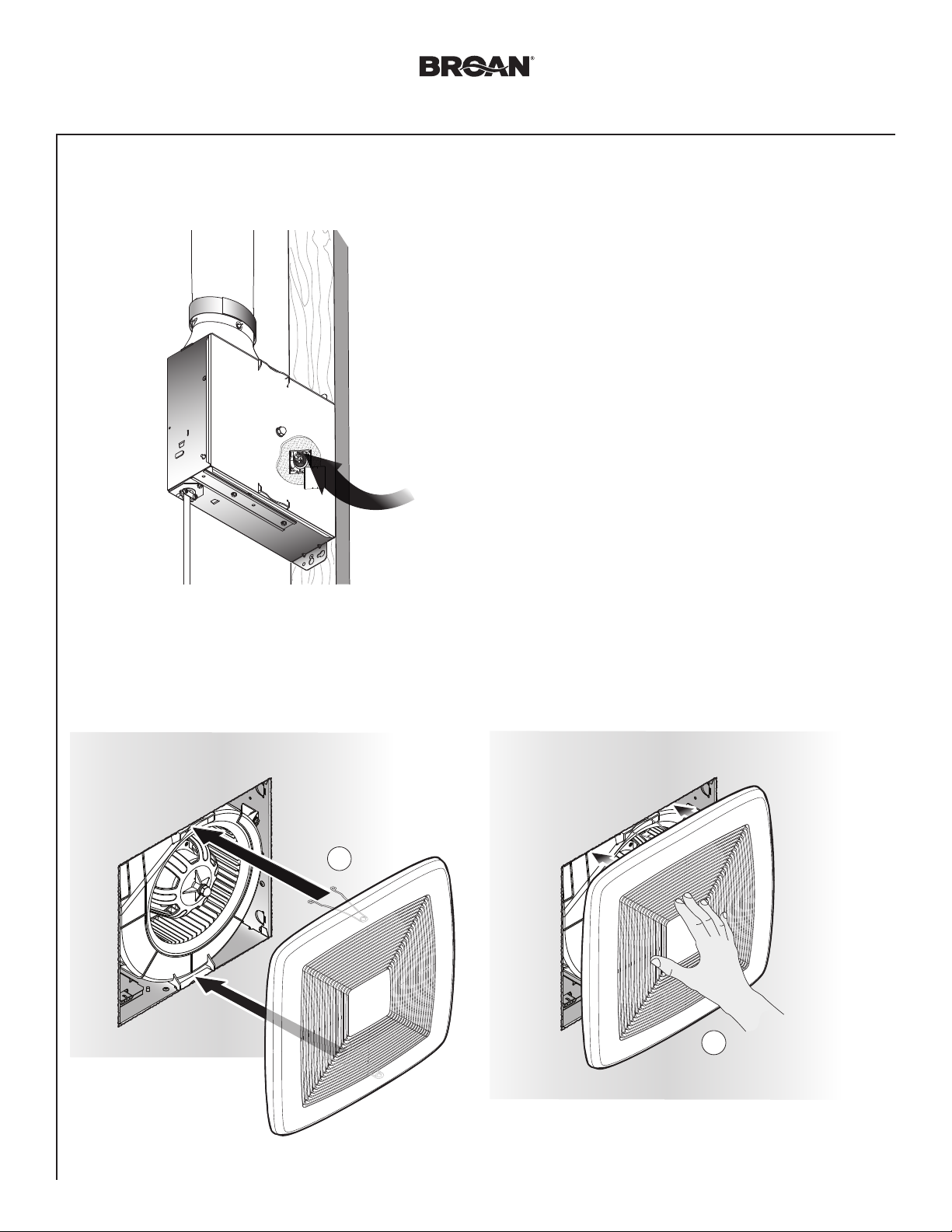

Connect Wires

4

• Run 120VAC electrical wiring to the installation location.

• Use proper UL-approved connectors to secure wiring to the Knockout Plate.

• Connect wires as shown in wiring diagram.

1

3

Connect

wires

Attach cable

clamp to Knockout

2

Plate. Knockout

Plate may be

oriented as

desired.

LP80 & LP110

n

Installation Guide

4

ON/OFF

SWITCH

BLK

120 VAC

LINE IN

(purchase separately)

WHT

GRD

BLACK

WHITE

ON/OFF

SWITCH

BLK BLK

WHT

GRD

GROUND (green or bare)

SWITCH BOX

UNITSWITCH BOX

KNOCKOUT

PLATE

M

RECEPTACLE

WHT

120 VAC LINE IN

Page 6

Installation

Insert Mask and Finish Wall or Ceiling

5

Use this mask to prevent constru ction dust, drywa ll spray,

or paint from damaging insid e of product.

REMOVE MASK BEFORE INSTALLI NG GRILLE.

Utiliser ce couvercle pour e mpêcher la poussière d e construction,

le plâtre ou la peinture d’endomm ager l’intérieur du produit .

ENLEVER LE COUVERCLE AVANT D’I NSTALLER LA GRILLE.

Utilice esta cubiert a para

prevenir daños al interior

del producto debidos

a polvo de construcción ,

rociado en el panel de

yeso o pintura.

RETIRE LA CUBIERTA ANTE S

DE INSTALAR LA REJILL A.

Mask protects unit

during construction.

79350207A

Remove before

installing Grille.

LP80 & LP110

n

Installation Guide

Install Grille

6

Squeeze

grille springs

and insert

into slots

in housing.

1

2

Page 7

LP80 & LP110

n

Installation Guide

Operation

To Operate Fan

Use an ON/OFF switch or speed control to operate this

ventilator.

WARNING Before servicing or cleaning unit,

switch power off at service panel and lock the service

disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting

means cannot be locked, securely fasten a prominent

warning device, such as a tag, to the service panel.

Cleaning and Maintenance

To Clean

For quiet and efficient operation, long life and attractive

appearance, remove Grille and vacuum interior of unit with

a dusting brush attachment.

The Motor is permanently lubricated and never needs

oiling. If the motor bearings are making excessive or

unusual noises, replace the Motor.

Troubleshooting

Symptom: The fan does not run.

• Check for an open fuse or circuit breaker in the building’s

service panel.

• Check that the plug-in connection for the Motor is seated

firmly in place.

• Check that the Blower Wheel spins freely.

Symptom: The fan runs erratically.

• Check that the Blower Wheel is firmly attached to the

Motor shaft and both spin freely.

Symptom: The fan seems noisy.

• Check that the back draft damper in the fan’s Duct

Connector pivots freely. Screws used to attach the

ducting to the Duct Connector may be preventing the

damper from opening.

• Check that the back draft damper in the wall or roof cap

pivots freely. These dampers are sometimes mistakenly

painted shut or obstructed by bird and insect debris.

Page 8

LP80 & LP110

n

Installation Guide

Service Parts

6

1

8

5

7

Key No. Part No. Description

1 77001277 Duct Connector Assembly

2 79140014 Grille Spring (2 included)

3 77001280 Grille Assembly (includes 2 grille springs)

4 77001297 Capacitor (LP80)

1100050 Capacitor (LP110)

5 77001298 Wire Panel Assembly

6 79110158 4” to 3” Reducer (LP80 only)

7 77001299 Hanger Bar

8 77001300 Knockout Plate

9 97020043 Blower Assembly (LP80)

1100048 Blower Assembly (LP110)

4

9

2

3

Warranty

BROAN ONE YEAR LIMITED WARRANTY

Broan warrants to the original consumer purchaser of its

products that such products will be free from defects in materials

or workmanship for a period of one year from the date of original

purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

During this one-year period, Broan will, at its option, repair or

replace, without charge, any product or part which is found to be

defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT

LAMP STARTERS, TUBES, HALOGEN AND INCANDESCENT

BULBS, FUSES, FILTERS, DUCTS, ROOF CAPS, WALL

CAPS AND OTHER ACCESSORIES FOR DUCTING. This

warranty does not cover (a) normal maintenance and service

or (b) any products or parts which have been subject to misuse,

negligence, accident, improper maintenance or repair (other

than by Broan), faulty installation or installation contrary to

recommended installation instructions.

The duration of any implied warranty is limited to the one-year

period as specified for the express warranty. Some states do not

allow limitation on how long an implied warranty lasts, so the

above limitation may not apply to you.

BROAN’S OBLIGATION TO REPAIR OR REPLACE, AT

BROAN’S OPTION, SHALL BE THE PURCHASER’S SOLE

AND EXCLUSIVE REMEDY UNDER THIS WARRANTY.

BROAN SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING

OUT OF OR IN CONNECTION WITH PRODUCT USE OR

PERFORMANCE. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights, which vary from state to state. This warranty

supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan at the

address or telephone number below, (b) give the model number

and part identification and (c) describe the nature of any defect

in the product or part. At the time of requesting warranty service,

you must present evidence of the original purchase date.

Broan

926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

Order replacement parts by Part No., not by Key No.

99045483B

LIRE CES DIRECTIVES ET LES CONSERVER

Installateur : veuillez laisser ce guide au propriétaire.

Enregistrez votre produit en ligne à : www.broan.com/register.

LP80 et LP110

Ventilateur à

profil surbaissé

GUIDE D’INSTALLATION

Installation facile

© 2018 Broan

Table des matières

Avertissements et mises en garde 10

Installation type 10

Installation 11-14

Fonctionnement 15

Nettoyage et entretien 15

Dépannage 15

Pièces de rechange 16

Garantie 16

Page 10

LP80 et LP110

n

Guide d’installation

AVERTISSEMENT

OBSERVEZ LES DIRECTIVES CI-DESSOUS AFIN DE RÉDUIRE

LES RISQUES D’INCENDIE, DE CHOC ÉLECTRIQUE OU DE

BLESSURES CORPORELLES :

1. N’utilisez cet appareil que de la manière prévue par le fabricant.

Si vous avez des questions, communiquez avec le fabricant à

l’adresse ou au numéro de téléphone indiqués dans la garantie.

2.

Avant de procéder à l’entretien ou au nettoyage de l’appareil, coupez

l’alimentation du panneau électrique et verrouillez l’interrupteur

principal afin d’empêcher que le courant ne soit accidentellement

rétabli. S’il est impossible de verrouiller l’interrupteur principal,

fixez solidement un message d’avertissement, par exemple une

étiquette, sur le panneau électrique.

3. La pose de l’appareil et les travaux d’électricité doivent être

effectués par des personnes qualifiées conformément à la

réglementation en vigueur, notamment les normes de la

construction ayant trait à la protection contre les incendies.

4. Pour éviter les refoulements, l’apport d’air doit être suffisant pour

brûler les gaz produits par les appareils à combustion et les

évacuer dans le conduit de fumée (cheminée). Respectez les

directives du fabricant de l’appareil de chauffage et les normes

de sécurité, notamment celles publiées par la National Fire

Protection Association (NFPA), l’American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE) et les

codes des autorités locales.

5. Veillez à ne pas endommager le câblage électrique ou d’autres

équipements non apparents lors de la découpe ou du perçage

du mur ou du plafond.

6. Les ventilateurs canalisés doivent toujours rejeter l’air à

l’extérieur.

7. Cet appareil peut être installé au-dessus d’une baignoire ou

d’une douche (uniquement dans le plafond) s’il est branché sur

un circuit de dérivation protégé par un disjoncteur de fuite à la

terre.

8. Cet appareil doit être relié à une mise à la terre.

ISOLANT* (Peut être

placé sur le boîtier de

ventilateur et autour.)

Installation type

BOÎTIER DE

VENTILATEUR

ATTENTION

1. Pour ventilation générale uniquement. N’utilisez pas

cet appareil pour évacuer des matières ou des vapeurs

dangereuses ou explosives.

2. Lorsque installé dans un mur ou un plafond en pente, le

raccord du conduit doit être tourné vers le haut.

3. Pour éviter d’endommager les roulements de moteur,

de déséquilibrer les pales ou de les rendre bruyantes,

débarrassez l’appareil de la poussière de plâtre, de

construction, etc.

4. Veuillez lire l’étiquette de spécifications du produit pour obtenir

plus de renseignements, notamment sur les exigences.

NE PAS INSTALLER DANS UNE ZONE DE CUISSON

Ne pas installer au-dessus ou à l’intérieur

de cette zone

45° 45°

Appareil

de cuisson

Plancher

CAPUCHON

DE TOIT*

(avec clapet

intégré)

• Se fixe aux montants de 2 po x 4 po

ou plus des murs ou aux solives du

plafond.

Solives Solives en I Fermes

Les conduits allant de ce ventilateur jusqu’à l’extérieur de l’habitation ont une grande influence sur le débit d’air, le bruit

du ventilateur et sa consommation d’énergie. Pour obtenir le meilleur rendement, utilisez les conduits les plus courts et

les plus droits que possible et évitez d’utiliser des conduits plus petits que ceux recommandés. L’isolation des conduits

peut contribuer à réduire les pertes d’énergie et éviter la prolifération de moisissures. Les ventilateurs installés sur

d’anciens conduits pourraient ne pas produire leur débit d’air nominal.

Pour un rendement optimal, il est recommandé d’utiliser des conduits métalliques ronds de 10 cm (4 po) de diamètre.

CÂBLE

D’ALIMENTATION*

Scellez l’écart

autour du boîtier.

CONDUIT ROND*

*Vendu

séparément.

OR

Scellez les

joints avec

du ruban

à conduit.

INSTALLATION DANS UN PLAFOND

COUDES

RONDS*

Utilisez des

conduits les

plus courts

possible.

CAPUCHON

MURAL* (avec

clapet intégré)

Pa g e 11

Installation

LP80 et LP110

n

Guide d’installation

Outils requis

• Tournevis électrique à pointe cruciforme

• Tournevis cruciforme

• Pince à dénuder les fils

• Pince coupante

Sortir de l’emballage

1

Matériel requis

• Conduit rond de 10,2 cm (4 po) recommandé pour un meilleur

rendement. D’autres types de conduits sont acceptables mais

peuvent affecter le rendement.

• Capuchon de toit ou mural (clapet intégré recommandé)

• Ruban pour sceller les raccords du conduit

• Vis à cloisons sèches, vis à tôle ou suspendre

• Fils électriques et fournitures conformes au code local

Détacher le masque

de l’emballage.

Voir étape 5.

Réducteur de

10,2 cm à 7,6 cm

(4 po à 3 po)

(LP80 seulement)

Page 12

2

Installation

Installer dans le mur ou le plafond

2

HAUT

1

LP80 et LP110

(en 3 points)

n

Guide d’installation

Suspendre

Installer le conduit

3

1

Mur

2

2

2

Vis à travers le

boîtier du côté

opposé

1

Conduit

de 10,2 cm

(4 po)

- OU -

4

Plafond

Réducteur de

10,2 cm à 7,6 cm

(4 po à 3 po)

(LP80 seulement)

3

Serrer la vis dans le

boîtier pour assurer

le montage

Conduit

de 7,6 cm

(3 po)

É

Ruban

Insérer la languette

dans la fente du boîtier.

Ruban

É

- OU -

É

Ruban

Page 13

Installation

Connecter les fils

4

• Acheminer un fil électrique de 120 VCA jusqu’au site d’installation.

• Utiliser les connecteurs homologués UL pour fixer le fil à l’ouverture préamorcée fournie.

• Connecter les fils, tel qu’illustré dans le schéma de câblage.

1

3

Connecter

les fils

Fixer la pince du

câble à l’ouverture

2

préamorcée. La

plaque peut être

orientée dans le

sens voulu.

LP80 et LP110

n

Guide d’installation

4

INTERRUPTEUR

NOIR

ENTRÉE

120 VCA

INTERRUPTEUR

(vendu séparément)

BLANC

TERRE

NOIR

BLANC

NOIR NOIR

BLANC

TERRE

FIL DE TERRE (vert ou fil nu)

BOÎTE

D'INTERRUPTEUR

M

APPAREILBOÎTE D'INTERRUPTEUR

OUVERTURE

PRÉAMORCÉE

BLANC

PRISE

ALIMENTATION 120 VCA

Page 14

Installation

Insérer le masque et finir le mur ou le plafond

5

Use this mask to prevent constru ction dust, drywa ll spray,

or paint from damaging insid e of product.

REMOVE MASK BEFORE INSTALLI NG GRILLE.

Utiliser ce couvercle pour e mpêcher la poussière d e construction,

le plâtre ou la peinture d’endomm ager l’intérieur du produit .

ENLEVER LE COUVERCLE AVANT D’I NSTALLER LA GRILLE.

Utilice esta cubiert a para

prevenir daños al interior

del producto debidos

a polvo de construcción ,

rociado en el panel de

yeso o pintura.

RETIRE LA CUBIERTA ANTE S

DE INSTALAR LA REJILL A.

Ce masque protège

79350207A

l’appareil durant la

construction. Le retirer

avant d’installer la grille.

LP80 et LP110

n

Guide d’installation

Installer la grille

6

Pincer les ressorts

de la grille et les

insérer dans les

fentes du boîtier.

1

2

Page 15

LP80 et LP110

n

Guide d’installation

Fonctionnement

Pour actionner le ventilateur

Utilisez un interrupteur marche/arrêt ou une commande de

vitesse pour actionner le ventilateur.

AVERTISSEMENT

à l’entretien ou au nettoyage de l’appareil, coupez

l’alimentation du panneau électrique et verrouillez

l’interrupteur principal afin d’empêcher que le courant

ne soit accidentellement rétabli. S’il est impossible de

verrouiller l’interrupteur principal, fixez solidement un

message d’avertissement, par exemple une étiquette,

sur le panneau électrique.

Avant de procéder

Nettoyage et entretien

Pour nettoyer

Pour un fonctionnement silencieux et efficace, ainsi qu’une

durabilité et une apparence supérieures, enlevez la grille

et nettoyez l’intérieur de l’appareil avec un aspirateur muni

d’une brosse à épousseter.

Le moteur est lubrifié en permanence et n’a pas

besoin d’être huilé. Si les roulements du moteur sont

anormalement bruyants, remplacez le moteur.

Dépannage

Symptôme : Le ventilateur ne démarre pas.

• Vérifiez que le disjoncteur ou le fusible ne sont pas

coupés dans le panneau électrique de l’édifice.

• Vérifiez que la fiche du moteur est bien branchée et

fermement appuyée.

• Vérifiez que la roue à ailettes tourne librement.

Symptôme : Le ventilateur tourne de manière inégale.

• Vérifiez que la roue à ailettes est solidement fixée à

l’arbre du moteur et que les deux tournent librement.

Symptôme : Le ventilateur semble bruyant.

• Vérifiez que le clapet à l’arrière du raccord de conduit

pivote librement. Les vis utilisées pour fixer le conduit

au raccord peuvent empêcher le clapet de s’ouvrir

correctement.

• Vérifiez que le clapet antirefoulement du capuchon mural

ou de toit pivote librement. Ces clapets sont parfois peints

par erreur, ce qui les empêche de s’ouvrir, ou obstrués par

des débris d’oiseaux ou d’insectes.

Page 16

LP80 et LP110

n

Guide d’installation

Pièces de rechange

6

1

8

5

7

N° de repère N° de pièce Description

1 77001277 Ensemble de raccord de conduit

2 79140014 Ressort de grille (2 inclus)

3 77001280 Ensemble de grille (comprend

4 77001297 Condensateur (LP80)

1100050 Condensateur (LP110)

5 77001298 Ensemble de panneau de câblage

6 79110158 Réducteur de 10,2 cm à 7,6 cm

7 77001299 Tige de suspension

8 77001300 Plaque à ouverture préamorcée

9 97020043 Ensemble de ventilateur (LP80)

1100048 Ensemble de ventilateur (LP110)

Veuillez commander les pièces par N° de pièce et non par N° de

repère.

4

9

2

3

2 ressorts)

(4 po à 3 po) (LP80 seulement)

Garantie

GARANTIE LIMITÉE D’UN AN BROAN

Broan garantit à l’acheteur original que les produits vendus

en vertu de la présente sont libres de tout vice de matériau ou

de fabrication pour une période d’un an à compter de la date

d’achat originale. CETTE GARANTIE NE COMPORTE AUCUNE

AUTRE GARANTIE, EXPRESSE OU TACITE, Y COMPRIS,

MAIS SANS S’Y LIMITER, LES GARANTIES TACITES DE

VALEUR MARCHANDE OU D’ADAPTATION À UN USAGE

PARTICULIER.

Durant cette période d’un an, Broan réparera ou remplacera

gratuitement, à sa discrétion, tout produit ou toute pièce jugés

défectueux dans des conditions normales d’utilisation.

CETTE GARANTIE NE S’APPLIQUE PAS AUX TUBES

FLUORESCENTS ET AUX DÉMARREURS, NI AUX AMPOULES

HALOGÈNES OU INCANDESCENTES, FUSIBLES, FILTRES,

CONDUITS, CAPUCHONS DE TOIT, CAPUCHONS MURAUX

ET AUTRES ACCESSOIRES POUR CONDUITS. Cette garantie

ne couvre pas (a) les frais d’entretien ou de service normaux ni

(b) tout produit ou toute pièce soumis à un abus, une négligence,

un accident, un entretien ou une réparation inadéquats (autres

que ceux effectués par Broan), une mauvaise installation ou

une installation contraire aux instructions recommandées.

La durée de toute garantie tacite est limitée à la période d’un

an stipulée pour la garantie expresse. Certains territoires ou

provinces interdisant de limiter la durée d’une garantie tacite,

la limitation ci-dessus peut ne pas s’appliquer à votre situation.

L’OBLIGATION POUR BROAN DE RÉPARER OU DE

REMPLACER LE PRODUIT, À SA DISCRÉTION, CONSTITUE

LE SEUL RECOURS DE L’ACHETEUR EN VERTU DE LA

PRÉSENTE GARANTIE. BROAN NE PEUT ÊTRE TENUE

RESPONSABLE DES DOMMAGES INDIRECTS OU

CONSÉCUTIFS NI DES DOMMAGES-INTÉRÊTS PARTICULIERS

DÉCOULANT DE L’UTILISATION OU DU RENDEMENT DU

PRODUIT. Certains territoires ou provinces ne permettant pas la

limitation ou l’exclusion des dommages indirects ou consécutifs,

la limitation ci-dessus peut ne pas s’appliquer à votre situation.

La présente garantie vous confère des droits spécifiques

reconnus par la loi. D’autres droits pourraient également vous

être accordés selon la législation locale en vigueur. La présente

garantie remplace toutes les autres garanties précédentes.

Pour vous prévaloir de cette garantie, vous devez (a) aviser

Broan à l’adresse ou au numéro de téléphone indiqués cidessous, (b) donner le numéro de modèle du produit et le

numéro d’identification de la pièce et (c) décrire la nature de la

défectuosité du produit ou de la pièce. Lors de votre demande

de garantie, vous devez présenter une preuve de la date d’achat

originale.

Broan

926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

99045483B

LEA Y CONSERVE ESTAS INSTRUCCIONES

Aviso al instalador: deje esta guía con el dueño de la casa.

Registre su producto en línea en www.broan.com/register.

LP80 y LP110

Ventilador de

bajo perfil

GUÍA DE INSTALACIÓN

Instalación sencilla

© 2018 Broan

Índice

Advertencias y precauciones 18

Instalación típica 18

Instalación 19-22

Funcionamiento 23

Limpieza y mantenimiento 23

Resolución de problemas 23

Piezas de servicio 24

Garantía 24

Página 18

LP80 y LP110

n

Guía de instalación

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIOS, DESCARGAS

ELÉCTRICAS O LESIONES PERSONALES, SIGA LAS

SIGUIENTES PRECAUCIONES:

1. Use la unidad sólo de la manera indicada por el fabricante. Si

tiene preguntas, comuníquese con el fabricante a la dirección o

al número telefónico que se incluye en la garantía.

2. Antes de dar servicio a la unidad o de limpiarla, interrumpa el

suministro eléctrico en el panel de servicio y bloquee los medios

de desconexión del servicio para evitar que la electricidad se

reanude accidentalmente. Cuando no sea posible bloquear los

medios de desconexión del servicio, fije firmemente una señal

de advertencia (como una etiqueta) en un lugar visible del panel

de servicio.

3. Una o más personas calificadas deben realizar el trabajo de

instalación y el cableado eléctrico, de acuerdo con todos los

códigos y normas correspondientes, incluidos los códigos y

las normas de construcción específicos de protección contra

incendios.

4. Es necesario suficiente aire para que se lleve a cabo una

combustión y una extracción adecuadas de los gases a través

del tubo de humos (chimenea) del equipo quemador de

combustible, con el fin de evitar el contratiro. Siga las directrices

y las normas de seguridad del fabricante del equipo de

calefacción, como las publicadas por la Asociación Nacional de

Protección contra Incendios (National Fire Protection Association,

NFPA), la Sociedad Americana de Ingenieros de Calefacción,

Refrigeración y Aire Acondicionado (American Society for

Heating, Refrigeration and Air Conditioning Engineers, ASHRAE)

y las autoridades normativas locales.

5. Al cortar o perforar a través de la pared o del techo, tenga cuidado

de no dañar el cableado eléctrico ni otros servicios ocultos.

6. Los ventiladores en conductos siempre deben ventearse hacia el

exterior.

7. Esta unidad puede instalarse sobre una tina o ducha (en el cielo

raso solamente) siempre que se conecte a un GFCI (interruptor

accionado por pérdida de conexión a tierra) en un circuito de

derivación protegido.

8. Esta unidad debe estar conectada a tierra.

AISLAMIENTO* (Coloque

alrededor y sobre la

cubierta del ventilador).

CUBIERTA DEL

VENTILADOR

PRECAUCIÓN

1. Sólo para usarse como medio de ventilación general. No debe

usarse para la extracción de materiales o vapores peligrosos o

explosivos.

2. Cuando se instale en una pared o un cielo raso con

pendiente, el conector del conducto debe apuntar hacia arriba.

3. Para evitar daños a los cojinetes del motor y rotores ruidosos

o desbalanceados, mantenga la unidad de potencia protegida

contra rociados de yeso, polvos de construcción, etc.

4. Lea la etiqueta de especificaciones del producto para ver

información y requisitos adicionales.

NO USAR EL PRODUCTO EN UN ÁREA DE COCINA

No instale el equipo sobre o dentro de esta área.

45° 45°

Equipo

de cocina

Piso

TAPA DE

TECHO* (con

regulador de

tiro integrado)

Instalación típica

• Se fija a vigas 2 x 4 pulg. o a

montantes de pared o viguetas de

cielo raso de mayor tamaño.

Viguetas Viguetas “I” Vigas

Los conductos desde este ventilador hacia el exterior del edificio tienen un gran efecto sobre el flujo de aire, el ruido y el uso de energía

del ventilador. Utilice el tramo de conductos más corto y recto posible para obtener un desempeño óptimo y evite instalar el ventilador

con conductos menores que los recomendados. El aislamiento alrededor de los conductos puede reducir la pérdida de energía e inhibir

el desarrollo de moho. Los ventiladores instalados en conductos existentes podrían no obtener el flujo de aire nominal.

Para un mejor desempeño, se recomienda utilizar conductos metálicos redondos y rígidos de 4 pulg. (10 cm).

CABLE

ELÉCTRICO*

Selle las

separaciones

alrededor de la

cubierta.

CONDUCTO

REDONDO*

*Se compra

por separado.

Selle con

cinta las

uniones

de los

conductos.

SE MUESTRA LA INSTALACIÓN EN EL CIELO RASO

OR

OR

CODOS

REDONDOS*

Mantenga

cortos los

tramos de

conductos.

TAPA DE

PARED* (con

regulador de

tiro integrado)

Página 19

Instalación

LP80 y LP110

n

Guía de instalación

Herramientas necesarias

• Destornillador eléctrico con punta Phillips

• Destornillador Phillips

• Desforrador de aislamiento de cables

• Cortador de cables

Retire del empaque

1

Materiales necesarios

• Se recomienda el conducto metálico redondo de 4 pulg. (10.2 cm)

para obtener el mejor desempeño. Es aceptable usar otros conductos,

pero se puede afectar el desempeño.

• Tapa de techo o tapa de pared (se recomienda el regulador integrado)

• Cinta para sellar las conexiones de los conductos

• Tornillos para placa de yeso, para chapa metálica o cable

• Cableado eléctrico y suministros de acuerdo con los requisitos del

código local

Perfore la cubierta

del empaque.

Vea el paso 5.

Reductor de

4 a 3 pulg.

(10.2 a 7.6 cm)

(LP80 solamente)

Página 20

2

Instalación

Instale en la pared o el cielo raso

2

ARRIBA

1

LP80 y LP110

n

Guía de instalación

Cable

(3 lugares)

Pared

Instale los conductos

3

1

2

2

2

Tornillo a través de

la cubierta al lado

opuesto

1

Conducto

de 4 pulg.

(10.2 cm)

- O BIEN -

4

Cielo raso

Reductor de

4 a 3 pulg.

(10.2 a 7.6 cm)

(LP80

solamente)

É

- O

3

Apriete el tornillo

en la caja para

asegurar el

montaje

Conducto

de 3 pulg.

(7.6 cm)

É

Cinta

É

Inserte la pestaña en

la ranura de la cubierta.

Cinta

BIEN -

Cinta

Página 21

Instalación

Conecte los cables

4

• Coloque el cable eléctrico de 120 VCA hasta el lugar de la instalación.

• Use conectores adecuados y aprobados por UL para asegurar el cableado a la placa de agujero ciego.

• Conecte los cables tal como se ilustra en el diagrama de cableado.

1

3

Conecte

los cables

Fije la abrazadera del

2

cable a la placa de

agujero ciego. La placa de

agujero ciego se puede

orientar como se desee.

LP80 y LP110

n

Guía de instalación

4

INTERRUPTOR

DE ENCENDIDO/

APAGADO

NEGRO

LÍNEA DE

ENTRADA

DE 120 VCA

INTERRUPTOR DE

ENCENDIDO/APAGADO

(se compra por separado)

BLANCO

TIERRA

NEGRO

BLANCO

NEGRO NEGRO

BLANCO

TIERRA

TIERRA (verde o desnudo)

CAJA DEL

INTERRUPTOR

M

UNIDADCAJA DEL INTERRUPTOR

PLACA DE

AGUJERO CIEGO

BLANCO

RECEPTÁCULO

LÍNEA DE ENTRADA DE 120 VCA

Página 22

LP80 y LP110

n

Instalación

Inserte la cubierta protectora y dé acabado a la pared o al cielo raso

5

Use this mask to prevent constru ction dust, drywa ll spray,

or paint from damaging insid e of product.

REMOVE MASK BEFORE INSTALLI NG GRILLE.

Utiliser ce couvercle pour e mpêcher la poussière d e construction,

le plâtre ou la peinture d’endomm ager l’intérieur du produit .

ENLEVER LE COUVERCLE AVANT D’I NSTALLER LA GRILLE.

Utilice esta cubiert a para

prevenir daños al interior

del producto debidos

a polvo de construcción ,

rociado en el panel de

yeso o pintura.

RETIRE LA CUBIERTA ANTE S

DE INSTALAR LA REJILL A.

La cubierta protectora

protege la unidad durante

79350207A

la construcción. Quítela

antes de instalar la rejilla.

Guía de instalación

Instale la rejilla

6

Comprima los

resortes de la

rejilla e inserte

en las ranuras

de la cubierta.

1

2

Página 23

LP80 y LP110

n

Guía de instalación

Funcionamiento

Para accionar el ventilador

Para accionar este ventilador, utilice el interruptor de

encendido/apagado o el control de velocidad.

ADVERTENCIA Antes de realizar el

servicio o de limpiar la unidad, corte el suministro

eléctrico en el panel de servicio y bloquee el servicio

desconectando los medios que evitan que se conecte

la energía en forma accidental. Cuando no se puedan

bloquear los medios que desconectan el servicio,

coloque un dispositivo de alarma importante, como

por ejemplo una etiqueta, en el panel de servicio.

Limpieza y mantenimiento

Para limpiar

Para lograr un funcionamiento silencioso y eficiente, larga

vida y una apariencia atractiva, retire la rejilla y aspire

el interior de la unidad con el accesorio del cepillo para

sacudir polvo.

El motor está permanentemente lubricado y nunca

necesitará ponerle aceite. Si los cojinetes del motor hacen

ruidos excesivos o inusuales, reemplace el motor.

Resolución de problemas

Síntoma: el ventilador no funciona.

• Compruebe si hay un fusible o interruptor de circuitos

abierto en el panel de servicio del edificio.

• Compruebe que la conexión enchufable del motor esté

firmemente asentada en su lugar.

• Compruebe que la rueda del ventilador gira libremente.

Síntoma: el ventilador funciona erráticamente.

• Compruebe que la rueda del ventilador esté firmemente

acoplada al eje del motor y que ambas giren libremente.

Síntoma: el ventilador parece ruidoso.

• Compruebe que el regulador de contratiro en el conector

de conductos del ventilador pivotee libremente. Los

tornillos empleados para fijar el conducto al conector

podrían impedir que se abra el regulador.

• Compruebe que el regulador de contratiro en la pared

o tapa de techo pivotee libremente. A veces a estos

reguladores se les tapa con pintura por error, o están

obstruidos por desechos de aves e insectos.

Página 24

LP80 y LP110

n

Guía de instalación

Piezas de servicio

6

1

8

5

7

Clave N.º Pieza N.º Descripción

1 77001277 Conjunto del conector de conductos

2 79140014 Resorte de la rejilla (se incluyen 2)

3 77001280 Conjunto de la rejilla (incluye 2 resortes de la rejilla)

4 77001297 Capacitor (LP80)

1100050 Capacitor (LP110)

5 77001298 Conjunto del panel de cableado

6 79110158 Reductor de 4 a 3 pulg. (10.2 a 7.6 cm)

(LP80 solamente)

7 77001299 Barra de suspensión

8 77001300 Placa de agujero ciego

9 97020043 Conjunto del ventilador (LP80)

1100048 Conjunto del ventilador (LP110)

Pida las piezas por número de pieza, no por número de clave.

4

9

2

3

Garantía

GARANTÍA LIMITADA DE UN AÑO DE BROAN

Broan garantiza al consumidor comprador original de sus

productos que dichos productos estarán libres de defectos en

materiales o mano de obra durante un período de un año a partir de

la fecha de compra original. NO EXISTEN OTRAS GARANTÍAS,

EXPLÍCITAS O IMPLÍCITAS, INCLUYENDO, ENTRE OTRAS,

GARANTÍAS IMPLÍCITAS DE COMERCIALIZACIÓN O APTITUD

PARA UN PROPÓSITO PARTICULAR.

Durante este período de un año, Broan, a su criterio,

reparará o reemplazará sin cargo alguno cualquier pieza o

producto que se encuentre defectuoso bajo condiciones normales

de uso y servicio.

LA PRESENTE GARANTÍA NO CUBRE TUBOS O

ARRANCADORES DE LÁMPARAS FLUORESCENTES,

BOMBILLAS HALÓGENAS E INCANDESCENTES, FUSIBLES,

FILTROS, CONDUCTOS, TAPAS DE TECHO O DE PARED

Y DEMÁS ACCESORIOS DE CANALIZACIÓN. Esta garantía

no cubre (a) mantenimiento y servicio normales, ni (b) ningún

producto o piezas que se hayan sometido a uso inadecuado,

negligencia, accidente, mantenimiento o reparación inadecuada

(no hecha por Broan), instalación incorrecta o instalación en

contra de las instrucciones de instalación recomendadas.

La duración de cualquier garantía implícita se limita a un

período de un año, como se especifica en la garantía expresa.

Algunos estados no permiten limitaciones en cuanto al tiempo

de vencimiento de una garantía implícita, por lo que la limitación

antes mencionada podría no aplicarse a usted.

LA OBLIGACIÓN DE BROAN DE REPARAR O REEMPLAZAR,

A CRITERIO DE BROAN, SERÁ EL ÚNICO Y EXCLUSIVO

RECURSO DEL COMPRADOR BAJO ESTA GARANTÍA. BROAN

NO SERÁ RESPONSABLE POR DAÑOS INCIDENTALES,

RESULTANTES O ESPECIALES QUE SURJAN DEL USO

O DESEMPEÑO DEL PRODUCTO O EN RELACIÓN CON

ESTE. Algunos estados no permiten la exclusión o limitación de

daños incidentales o resultantes, por lo que la limitación antes

mencionada podría no aplicarse a usted.

Esta garantía le otorga derechos legales específicos, y usted

podría tener otros derechos que varían de un estado a otro.

Esta garantía sustituye todas las garantías anteriores.

Para tener derecho al servicio de la garantía, usted debe (a)

notificar a Broan NuTone a la dirección y número de teléfono

que aparecen abajo, (b) proporcionar el número de modelo

y la identificación de la pieza y (c) describir la naturaleza de

cualquier defecto en el producto o pieza. En el momento de

solicitar el servicio cubierto por la garantía, debe presentar un

comprobante de la fecha original de compra.

Broan

926 W. State Street, Hartford, Wisconsin 53027

www.broan.com 800-558-1711

99045483B

Loading...

Loading...