Broan Erv200hc, Erv100hc, Hrv100h, Hrv200h, Gsfh1k Installation Guide

...

Installer Manual

VENTILATION SYSTEMS

VB0038

Canadian Model Numbers

1001 ERV

1001 HRV

U.S. Model Numbers

HRV100H

HRV200H

2001 ERV

2001 HRV

ERV100HC

ERV200HC

03119-03/09/09

Table of Contents

1.0 SERVICE..............................................................................................4

1.1 3-D Drawing ................................................................................4

1.2 Parts Ordering Chart....................................................................5

1.3 Technical Suppor t ........................................................................5

2.0 SIZING ................................................................................................6

3.0 UNIT TYPE & DEFROST SETTING VS GEOGRAPHICAL LOCATION ..7

4.0 TECHNICAL DATA ................................................................................8

4.1 Air Distribution (Normal Operation)..............................................8

4.2 Air Distribution (Defrost Mode) ....................................................8

4.3 Performance Charts................................................................9-12

4.4 Dimensions ................................................................................13

4.5 Controls and Furnace Link Option ............................................13

4.6 Specifications ............................................................................13

5.0 TYPICAL INSTALLATIONS ..................................................................14

5.1 Fully Ducted System..................................................................14

5.2 Exhaust Ducted System

5.3 Simplified

(Volume Ventilation)

(Source Point Ventilation)

..................................................14

..................14

6.0 INSTALLATION....................................................................................15

6.1 Adsjusting the Damper Rod (for ERVs installed in warm regions)..........15

6.2 Locating and Mounting the Unit ................................................15

6.3 Planning of the Ductwork ..........................................................16

6.4 Calculating the Duct Size ..........................................................16

6.4.1 Example Calculation........................................................16

6.4.2 Example of a Design for a Fully Ducted System ............17

6.5 Installing the Ductwork and Registers ......................................17

6.5.1 Fully Ducted System........................................................17

6.5.2 Exhaust Ducted System (Source Point Ventilation) ........18

6.5.3 Simplified Installation (Volume Ventilation)......................19

6.6 Connecting Duct to the Unit ......................................................20

6.7 Installing the Exterior Hoods......................................................21

6.8 Connecting the Drain ................................................................21

7.0 CONTROL DEVICES..........................................................................22

7.1 Main Controls ............................................................................22

7.2 Optional Control ........................................................................23

7.3 Other Features ..........................................................................23

7.4 Main and Optional Controls Available for your Unit ..................23

7.5 Special Cold Weather TBI Mode for ERVs ................................23

2

Table of Contents (cont’d)

!

8.0 INSTALLATION OF THE CONTROLS ..................................................24

8.1 Dimensions and Specifications ................................................24

8.2 Installation of the Main Control ..........................................24-25

8.3 Electrical Connection to Optional Controls ..............................26

8.4 Electrical Connection to the Furnace ......................................26

9.0 WIRING DIAGRAMS ....................................................................27-28

10.0 AIR F

LOW B

ALANCING................................................................29-30

11.0 OVERALL VERIFICATION ..................................................................31

11.1 Main Controls ..........................................................................31

11.2 Optional Control ......................................................................32

12.0 MAINTENANCE / INSTRUCTIONS FOR USER....................................33

13.0 TROUBLESHOOTING ....................................................................34-35

14.0 REFERENCES ....................................................................................36

About this Manual

This manual uses the following symbols to emphasize particular information:

WARNING

Identifies an instruction which, if not followed, might cause serious personal injuries including

possibility of death.

CAUTION

Denotes an instruction which, if not followed, may severely damage the unit and/or

its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

3

1.0 Service

1.1 3-D DRAWING

23

24

25

26

23

DAMPER ASSEMBLY (REAR VIEW)

3

22

21

20

10

18

19

16

15

12

11

13

17

14

9

6

1

2

3

4

5

7

8

VL0016

4

1.0 Service (cont’d)

1.2 PARTS ORDERING CHART

No Description

1 Double collar port #2 00866 00866 00866 00866 00866 00866 00866 00866

2 Wing nut #10-32 00874 00874 00874 00874 00874 00874 00874 00874

3 Balancing double collar port 02256 02256 02256 02256 02256 02256 02256 02256

4 Inlet ring 12913 12913 12913 12913 12913 12913 12913 12913

5 Top wheel 14307 03093 14308 03093 14307 03093 14308 03093

6 Electronic board V99 13507 13507 13507 13507 13508 13507 13508 13507

7 Motor assembly 13504 13555 13556 13506 13504 13555 13505 13506

8 Bottom wheel 02015 02015 03093 03093 02015 02015 03093 03093

9 Square balancing damper 12645 12645 12645 12645 12645 12645 12645 12645

10 Door latches (latch) 00886 00886 00886 00886 00886 00886 00886 00886

11 Drain connector 02418 02418 02418 02418 02418 02418 02418 02418

12 Drain gasket 0,625”D 02419 02419 02419 02419 02419 02419 02419 02419

13 Washer 5/8” ID x 1”OD 03117 03117 03117 03117 03117 03117 03117 03117

14 Nut 5/8-18 02420 02420 02420 02420 02420 02420 02420 02420

15 Recovery core 03132 03136 03133 03137 03134 03136 03135 03137

16 Door assembly 12644 12644 12644 12644 12648 12648 12648 12648

17 Door latches (keeper) 00887 00887 00887 00887 00887 00887 00887 00887

18 Hinge assembly 00672 00672 00672 00672 00672 00672 00672 00672

19 Filter 03096 03096 03097 03097 03096 03096 03097 03097

20 Switch E69 10A 01825 01825 01825 01825 01825 01825 01825 01825

21 Damper assembly #2 12643 12643 12649 12649 12643 12643 12649 12649

22 Plastic balancing damper 02253 02253 02253 02253 02253 02253 02253 02253

23 Damper rod 12620 12620 12620 12620 12620 12620 12620 12620

24 Double collar port #5 02021 02021 02021 02021 02021 02021 02021 02021

25 Damper #1 12459 12459 12459 12459 12459 12459 12459 12459

26 Damper actuator assembly 03124 03124 03124 03124 03124 03124 03124 03124

1001 1001 2001 2001 HRV ERV HRV ERV

HRV ERV HRV ERV 100H 100HC 200H 200HC

Please take note that parts not listed are not available;those parts require assembly knowledge that only

manufacturer can guarantee.

TO ORDER PARTS: Contact your local distributor

1.3 Technical Support (for assistance)

For assistance, call on week days, 8:30 AM to 5:00 PM (Eastern Standard Time).

Technical Support Department

Canada: tel: 1-888-908-2633 (for distributors only)

U.S.A.: tel: 1-800-637-1453

NOTE: Do not call these numbers for ordering parts.

5

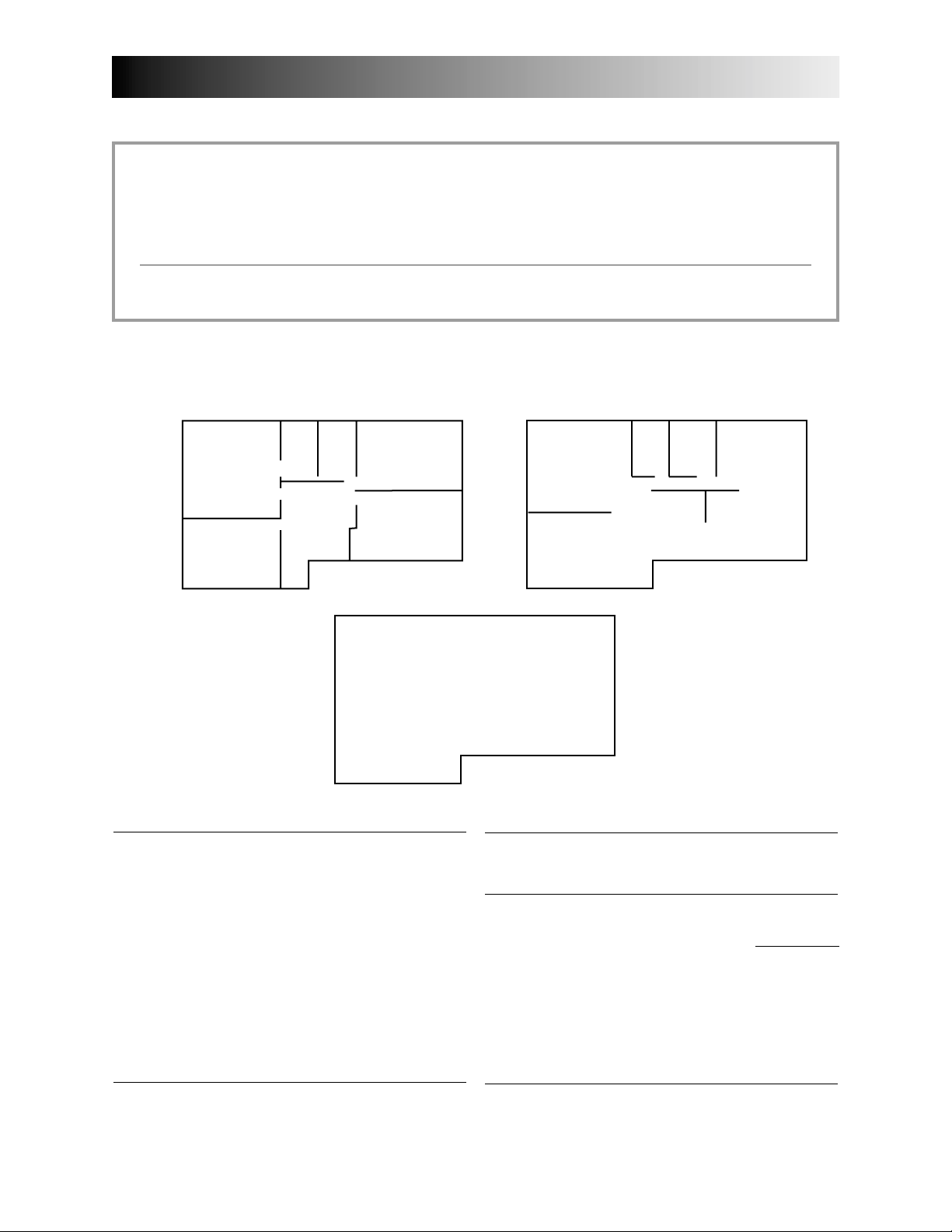

2.0 Sizing

These are the two most common methods used to evaluate the ventilation needs of a house:

CSA F326 and Canadian Building Code:

• High speed: 10 cfm per room

20 cfm for the master bedroom and the basement

• Low speed: 40-60% of high speed

ASHRAE Standard 62-2001:

• 0.35 air change per hour

Refer to ventilation code of your area to determine which method to use.

Example:

Second floor

Master

Bedroom

Bedroom #1

Bathroom

#1

Bathroom

#2

Bedroom

#2

Bedroom

#3

1320 ft

2

Basement

Basement

VH0021A

CSA F326

Kitchen (10 cfm)

Dining room (10

Living room (10

Family room (10

Master bedroom (20

Bedroom #1 (10

Bedroom #2 (10

Bedroom #3 (10

Bathroom #1 (10

Bathroom #2 (10

Bathroom #3 (10

Laundry room (10

Basement (20 cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

cfm)

Main floor

Laundry

room

Bathroom

Living room

Family room

2

1320 ft

#3

ASHRAE Standard 62-2001

Volume of basement 10560 ft

Volume of main floor 10560 ft

Volume of second floor 10560 ft

Total volume 31680 ft

Kitchen

Dining room

2

1320 ft

11090 ft3/h

÷ 60 (min/h)

x .35/h

3

3

3

3

Total 150

(high speed)

cfm

Total 185 cfm

(high speed)

6

3.0

Unit Type and Defrost Setting vs Geographical Location

ST JOHN'S

GOOSE BAY

CHARLOTTETOWN

BATHURST

QUEBEC

HALIFAX

ST-JOHN

BOSTON

SYMPTOM SOLUTION

(condensation)

SEPT-ILES

LABRADOR CITY

GASPÉ

MATANE

YELLOWKNIFE

HAY RIVER

FORT SMITH

ZONE A

FORT MCMURRAY

GRANDE PRAIRIE

PRINCE ALBERT

SASKATOON

EDMONTON

JASPER

CHIBOUGAMAU

WINNIPEG

REGINA

CALGARY

PENTICTON

KAMLOOPS

CHICOUTIMI

VAL-DOR

TIMMINS

ZONE B

HELENA

LETHBRIDGE

MONTRÉAL

OTTAWA

NORTH BAY

TORONTO

SUDBURY

SAULT STE MARIE

ST. PAUL

BISMARCK

HARTFORD

DETROIT

MADISON

DES MOINES

ZONE C

SALT LAKE CITY

BOISE

WASHINGTON

HARRISBURG

COLUMBUS

INDIANAPOLIS

SPRINGFIELD

TOPEKA

DENVER

RENO

RALEIGH

COLUMBIA

NASHVILLE

OKLAHOMA CITY

SANTA FE

ATLANTA

ZONE D

PHOENIX

BATON ROUGE

AUSTIN

Excess moisture problem ERV

Important excess moisture problem HRV

Indoor air quality problem ERV

and / or

ZONE C SELECTION CHART

and / or

see ZONE C SELECTION CHART beside

WHITEHORSE

ANCHORAGE

JUNEAU

Prince Rupert

VICTORIA

OLYMPIA

SALEM

HRV MODELS: 1001 HRV, 2001 HRV, HRV 100H, HRV 200H.•ERV MODELS: 1001 ERV, 2001 ERV, ERV 100HC, ERV 200HC.

problems)

SACRAMENTO

VN0002

•

ZONE C (HRV or ERV according to your client’s particular

(HRVs only)

Set Extended Defrost according to section 8.2, point 10.

•

ZONE A

ZONE D ERVs recommended)

(HRVs only)

MODELS: 1001 HRV, 2001 HRV, HRV 100H, HRV 200H.

•

ZONE B

• ERV MODELS: 1001 ERV, 2001 ERV, ERV 100H, ERV 200H.

• ERVs: Set Defrost mode #1 according to section 6.1.

Extended Defrost setting not required (factory defrost

strategy pre-set).

MODELS: 1001 HRV, 2001 HRV, HRV 100H, HRV 200H

•

•

7

4.0 Technical Data

4.1 AIR DISTRIBUTION (NORMAL OPERATION)

Applicable to all model numbers.

STALE AIR

TO OUTSIDE

FRESH AIR

TO BUILDING

VF0013

4.2 A

IR DISTRIBUTION (DEFROST MODE)

Defrost Mode 1

Applicable to model numbers:

• 1001 HRV

• 2001 HRV

• HRV100H

• HRV200H

FRESH AIR

TO BUILDING

VF0020

FRESH AIR

FROM

OUTSIDE

STALE AIR

FROM

BUILDING

STALE AIR

FROM

BUILDING

Defrost Mode 2

Applicable to model numbers:

• 1001 ERV

• 2001 ERV

• ERV100HC

• ERV200HC

Model numbers ERV100HC

and ERV200HC should be

set to defrost mode 1 when

installed in warm regions

(Zone D, as defined in

Section 3.0). Refer to

Section 6.1 for setting

instructions.

For defrost cycles tables, refer to Section 9.0, Wiring Diagrams.

STALE AIR

TO OUTSIDE

FRESH AIR TO

BUILDING

VF0012

STALE AIR

FROM

BUILDING

8

4.0 Technical Data (cont’d)

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0041

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0042

4.3 PERFORMANCE CHARTS

MODEL NUMBER: 1001 ERV

Electrical requirements: 120 volts, 1.3 Amps

Exhaust Air Transfer Ratio: 0.06

VENTILATION PERFORMANCE

External Static Net Supply Gross AirFlow

Pressure Air Flow Supply Exhaust

Pa in. w.g. L/s cfm L/s cfm L/s cfm

25 0.1 81 173 87 184 93 197

50 0.2 78 165 83 175 86 182

75 0.3 72 152 76 162 80 169

100 0.4 67 142 71 151 77 163

125 0.5 55 117 59 124 67 143

150 0.6 46 98 49 104 56 118

175 0.7 36 77 39 82 41 87

200 0.8 30 63 32 67 24 51

Note: Unit operating at maximum speed.

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F L/s cfm Watts % %

HEATING

0 32 29 60 56 71 79 0.53

0 32 47 100 80 64 73 0.41

0 32 65 137 126 60 68 0.36

-15 5 31 65 64 56 81 0.41

COOLING

35 95 28 59 52 45

MODEL NUMBER: 2001 ERV

Electrical requirements: 120 volts, 1.9 Amps

Exhaust Air Transfer Ratio: 0.06

(250 Pascals = 1” of water)

External Static Pressure - Pascals

Supply

(l/s)

Exhaust

(l/s)

Gross Airflow - L/s (0.47 L/s = 1 cfm)

Total Recovery Efficiency

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. L/s cfm L/s cfm L/s cfm

25 0.1 109 231 116 245 128 271

50 0.2 107 228 114 241 123 260

75 0.3 101 214 107 227 118 249

100 0.4 95 201 101 213 110 233

125 0.5 86 182 91 193 103 217

150 0.6 79 167 83 177 92 195

175 0.7 62 132 66 140 81 172

200 0.8 40 85 43 90 55 116

Note: Unit operating at maximum speed.

ENERGY PERFORMANCE

HEATING

COOLING

Supply

(l/s)

Exhaust

(l/s)

(250 Pascals = 1” of water)

External Static Pressure - Pascals

Gross Airflow - L/s (0.47 L/s = 1 cfm)

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F L/s cfm Watts % %

0 32 52 110 93 69 76 0.45

0 32 74 157 130 64 71 0.38

0 32 96 203 193 60 68 0.30

-15 5 52 110 122 55 76 0.26

Total Recovery Efficiency

35 95 50 106 89 41

9

4.0 Technical Data (cont’d)

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0039

4.3 PERFORMANCE CHARTS (CONT’D)

MODEL NUMBER: 1001 HRV

Electrical requirements: 120 volts, 1.3 Amps

Exhaust Air Transfer Ratio: 0.05

VENTILATION PERFORMANCE

External Static Net Supply Gross AirFlow

Pressure Air Flow Supply Exhaust

Pa in. w.g. L/s cfm L/s cfm L/s cfm

25 0.1 84 177 88 186 90 190

50 0.2 80 169 84 178 86 182

75 0.3 77 163 81 171 81 171

100 0.4 69 146 72 153 76 161

125 0.5 61 130 65 137 66 139

150 0.6 46 98 49 103 52 110

175 0.7 38 81 40 85 31 67

Note: Unit operating at maximum speed.

(250 Pascals = 1” of water)

External Static Pressure - Pascals

Supply

(l/s)

Exhaust

(l/s)

ENERGY PERFORMANCE

Gross Airflow - L/s (0.47 L/s = 1 cfm)

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F L/s cfm Watts % %

HEATING

0 32 30 64 54 75 83 -0.03

0 32 46 97 78 67 74 0.01

0 32 65 138 124 64 72 -0.02

-25 -13 26 55 62 67 89 0.05

COOLING

35 95 Not tested

Total Recovery Efficiency

MODEL NUMBER: 2001 HRV

Electrical requirements: 120 volts, 1.9 Amps

Exhaust Air Transfer Ratio: 0.042

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. L/s cfm L/s cfm L/s cfm

50 0.2 120 253 124 264 126 268

75 0.3 118 250 123 262 119 251

100 0.4 111 235 116 245 114 241

125 0.5 102 216 106 224 107 226

150 0.6 87 185 91 193 96 204

175 0.7 75 160 78 167 81 172

200 0.8 57 120 59 124 57 121

Note: Unit operating at maximum speed.

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F L/s cfm Watts % %

HEATING

COOLING

0 32 51 109 92 70 77 -0.01

0 32 73 155 128 65 72 -0.02

0 32 102 215 191 62 70 -0.01

-25 -13 52 110 104 60 94 0.05

35 95 Not tested

External Static Pressure - Pascals

VG0040

225

200

175

150

125

100

75

(250 Pascals = 1” of water)

50

25

0

05025 100 12575

Gross Airflow - L/s (0.47 L/s = 1 cfm)

Total Recovery Efficiency

Supply

(l/s)

Exhaust

(l/s)

150

10

4.0 Technical Data (cont’d)

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0043

225

175

200

150

125

100

75

50

25

0

05025 100 12575

150

VG0044

4.3 PERFORMANCE CHARTS (CONT’D)

MODEL NUMBER: HRV100H

Electrical requirements: 120 volts, 1.3 Amps

Exhaust Air Transfer Ratio: 0.05

VENTILATION PERFORMANCE

External Static Net Supply Gross AirFlow

Pressure Air Flow Supply Exhaust

Pa in. w.g. L/s cfm L/s cfm L/s cfm

25 0.1 78 164 81 172 83 176

50 0.2 74 156 78 165 80 168

75 0.3 71 151 75 158 75 158

100 0.4 64 135 67 142 70 149

125 0.5 56 120 60 127 61 129

150 0.6 43 91 45 95 48 102

175 0.7 35 75 37 79 29 62

Note: Unit operating at maximum speed.

(250 Pascals = 1” of water)

External Static Pressure - Pascals

Supply

(l/s)

Exhaust

(l/s)

ENERGY PERFORMANCE

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F L/s cfm Watts % %

HEATING

0 32 30 64 54 72 80 -0.03

0 32 46 97 78 65 72 0.01

0 32 65 138 124 62 70 -0.02

-25 -13 26 55 62 65 87 0.05

COOLING

35 95 Not tested

MODEL NUMBER: HRV200H

Electrical requirements: 120 volts, 1.9 Amps

Exhaust Air Transfer Ratio: 0.04

VENTILATION PERFORMANCE

External Static Net Supply Gross Air Flow

Pressure Air Flow Supply Exhaust

Pa in. w.g. L/s cfm L/s cfm L/s cfm

50 0.2 107 226 111 236 113 240

75 0.3 106 224 110 234 107 225

100 0.4 99 210 104 219 102 216

125 0.5 91 193 95 200 96 202

150 0.6 78 166 81 173 86 183

175 0.7 67 143 70 149 72 154

200 0.8 51 107 53 111 51 108

Note: Unit operating at maximum speed.

(250 Pascals = 1” of water)

External Static Pressure - Pascals

Gross Airflow - L/s (0.47 L/s = 1 cfm)

Total Recovery Efficiency

Supply

(l/s)

Exhaust

(l/s)

ENERGY PERFORMANCE

HEATING

COOLING

Gross Airflow - L/s (0.47 L/s = 1 cfm)

Supply Net Average Sensible Recovery Apparent Sensible Latent Recovery

Temperature Airflow Power Efficiency Effectiveness Moisture Transfer

°C °F L/s cfm Watts % %

0 32 51 109 92 69 76 -0.01

0 32 73 155 128 65 72 -0.02

0 32 102 215 191 62 70 -0.01

-25 -13 52 110 104 60 94 0.05

Total Recovery Efficiency

35 95 Not tested

11

Loading...

Loading...