Aprilia Ditech 50 AC 2002 Owner's manual

aprilia

QUICK WORKSHOP

HANDBOOK

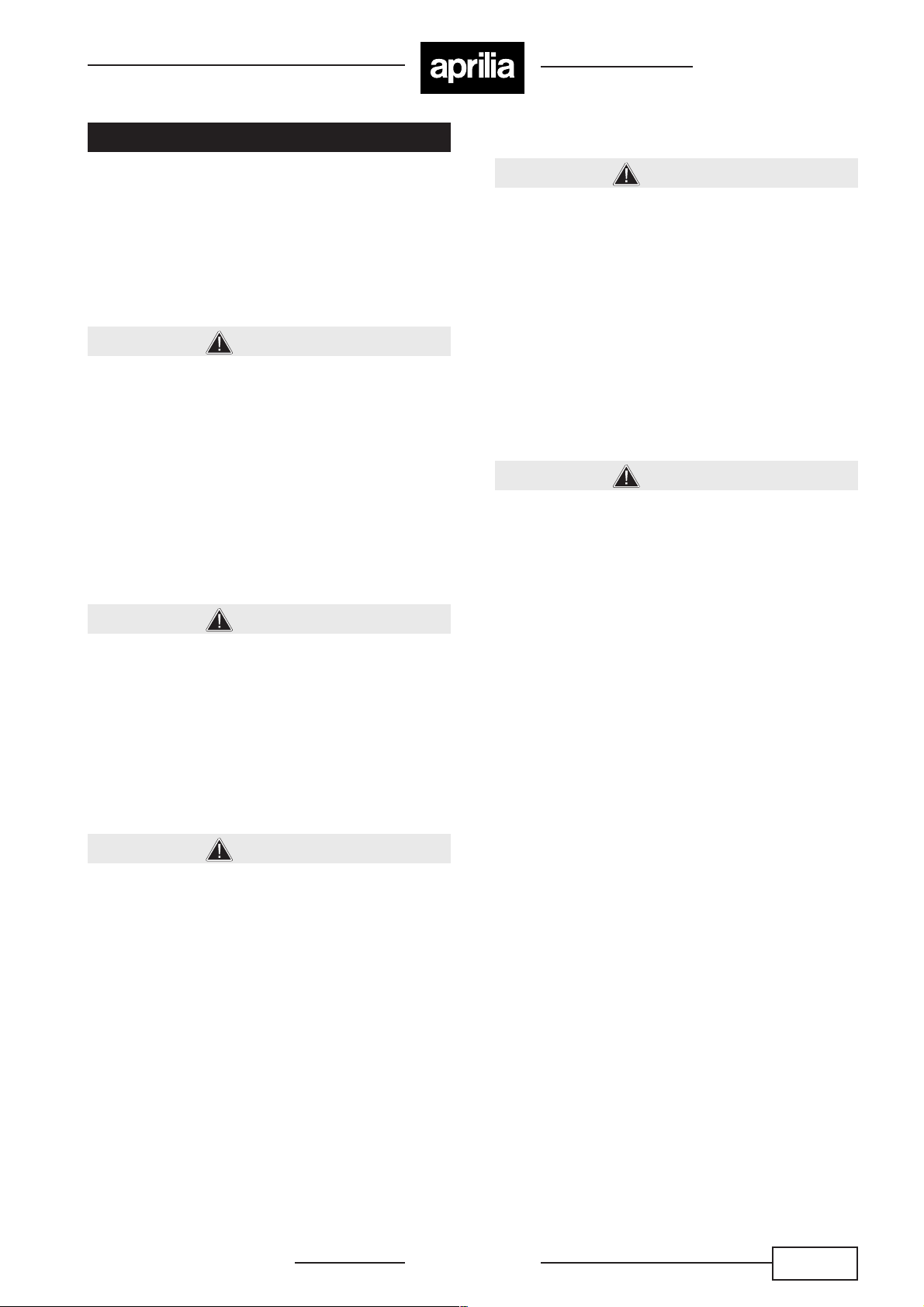

Electronic air injection

Aprilia Ditech Engine

1095 2

General safety

norms

Technical data

Oil chart

Special engine tools

Injection troubleshooting

Disassembly/Reassembly

sequence

1

2

3

44

5

6

Air-injection 50 cc

INTRODUCTIONCONTENTS

- This manual contains all the essential information for

carrying out routine vehicle procedures.

- The information and diagrams in the manual are upto-date at the time of publication.

- This publication is intended for use by Aprilia dealers

and their trained mechanics. A large number of

procedures do not require explanation and therefore

have been omitted. It has not been possible to give

detailed mechanical data for every procedure. All personnel consulting this manual must therefore possess

the basis skills of a mechanic and be thoroughly familiar

with the most common motor cycle repair procedures.

Without these skills and the necessary familiarity any

repair or routine maintenance operation may be

ineffective or even dangerous.

Given the fact that it is not possible to provide detailed

descriptions of all procedures, special care must be

taken for whatever repair or maintenance work is done,

in order to prevent damage to the vehicle and injury to

persons.

In order to provide the best level of customer

satisfaction, Aprilia s.p.a. constantly improves its

products and relevant documentation. All important

technical changes and alterations to procedures are

notified to all Aprilia dealers, branches and points of

sale throughout the world. All changes will be included

in later editions of this manual.

If you have any doubts or queries about the procedures

described in this manual, please contact the Aprilia

Training and Documentation Department, who will be

pleased to give you all the information and explanations

you require, and to bring you up-to-date with any

changes.

For further information see:

- SPARE PARTS CATALOGUE no. 5601

Produced by

Training and Documentation Department

aprilia s.p.a.

Via G. Galilei, 15 - 30033 Noale (VE) - Italy

Tel. +39 - 041 55829111

Fax + 39 - 041 441054

www.aprilia.com

Produced and printed by

Studio Gallo Design srl

Via Mogno,34/1

35012 Camposampiero (PD)

tel. 049 - 9303475

fax. 049 - 9317954

Italy

www.stgallo.it

e-mail: design@stgallo.it

Release 00 / 2002 - 09

Without alteration to the basic features of its models

as described and illustrated in this manual, Aprilia

s.p.a. may carry out modifications to any of the models

without notice.

Unauthorized electronic retrieval or reproduction of any

part of this manual is unlawful in all countries. Products

or services manufactured or provided by third parties

are quoted merely as examples and do not constitute

a recommendation; Aprilia s.p.a. is not liable for the

performance or use of such products and services.

First edition. September 2002.

01 / 01Chapter.1

Air-injection 50 cc

GENERAL SAFETY NORMS

CARBON MONOXIDE

If the engine must be switched on to carry out certain

operations make sure the room is well ventilated or

open to the outside. Never switch on the engine in a

closed room, unless there is a smoke and fume removal

system installed

and the operating.

DANGER

Exhaust fumes contain carbon monoxide, a

poisonous gas which make cause loss of

consciousness and can be lethal.

Switch on the engine only in an open space or in a

closed room if fitted with a fully operating smoke and

fume removal system.

FUEL

Make sure the room is well ventilated. Extinguish all

cigarettes, keep fuel containers away from flames and

possible sources of sparks.

DANGER

Fuel is highly flammable and may explode.

Take special care to check the air and fuel injection

plant hoses; the operating pressure should not

exceed about 750 KPa (7.5 bar).

Any fuel hoses which are cut or cracked should be

replaced.

KEEP OUT OF THE REACH OF CHILDREN

HIGH TEMPERATURE COMPONENTS

DANGER

The engine and parts of the exhaust system reach

very high temperatures and remain hot for a certain

period after switching off the engine. Handle these

components only after putting on protective gloves

or waiting for the engine and parts to fully cool

down.

WASTE TRANSMISSION OIL

DANGER

Use latex gloves for maintenance operations

involving contact with oil. If left in contact with the

skin for long periods, used engine oil can cause

skin cancer. Although this is unlikely, unless

handled every day, wash your hands with soap and

water after handling used engine oil.

KEEP OUT OF THE REACH OF CHILDREN

GENERAL PRECAUTIONS AND INFORMATION

For repair and disassembly and reassembly operations

follow the instructions.

DANGER

Do not carry out any operation in the presence of

naked flames.

Before starting any maintenance or inspection

operation, switch off the engine and remove the

ignition key. Wait for the engine and exhaust

system to cool down. Place the motor cycle, if

possible, in a raised position on a level, even

surface. Take special care of heated parts (engine

and the exhaust) in order to avoid burns.

The vehicle is made with parts which cannot be

swallowed. Do not bite, chew, suck or otherwise

attempt to carry out operations using the teeth or

mouth.

Unless otherwise specified, to reassemble parts,

reverse the order for disassembly operations.

Some operations may involve disassembling parts

previously disassembled for other operations to

be carried out. Consult the various pages of the

manual where each operation is described in order

to avoid unnecessary work. Never use fuel as a

solvent for cleaning the vehicle.

If welding operations are to be carried out,

disconnect the negative pole (-) of the battery and

take special care with all electrical components

used for the injection system.

If more than one person is working on the vehicle

make sure both are in a safe position whatever the

work being done.

Release 00 / 2002 - 09

Chapter.1

01 / 02

Air-injection 50 cc

BEFORE DISASSEMBLY

- Remove dirt, mud, dust and foreign bodies from the

vehicle before disassembling the components.

- Use all the tools specifically designed for the vehicle.

DISASSEMBLY

- Before separating pipes or wires etc. (joints and

junctions) mark each part with a unique marking.

Each piece should be clearly marked for reassembly

purposes.

-Clean and wash the disassembled components with

close to non-inflammable detergent.

-Keep paired parts together, because normal wear and

tear create a natural pairing. In some cases, where

one part is replaced the other must also be replaced.

Keep away from sources of heat.

REASSEMBLY

DANGER

Never re-use a snap ring. If removed, replace it with

a new ring. If a new ring is fitted, do not stretch

more than necessary when fitting it to the shaft.

Afterwards, check that the ring is properly fitted to

the housing.

- Lightly smear the edges of oil seals with lithium based

grease.

- Refit the oil seals and bearings with the trademark or

manufacturer’s serial number facing outwards (so it

is visible).

- Grease the bearings fully before fitting.

- Check that all components have been reassembled

properly.

After a maintenance or repair operation, carry out

preliminary checks and commission the vehicle on

private property or in a low traffic area.

Do not clean bearings with compressed air.

IMPORTANT Bearings must rotate freely, without

sticking or noise. Replace if necessary.

- Use only ORIGINAL Aprilia SPARE PARTS.

- Stick to the oil chart and recommended wearing parts.

- Wherever possible, lubricate parts before

reassembling them.

- When tightening screws and nuts begin with the

largest diameters, or inner nuts and screws, and

tighten diagonally. Tighten each before finally

tightening to the specified torque.

- Always replace gaskets, gasket rings, snap rings, Orings and split pins with new ones.

- Clean all joint surfaces, oil seal edges and gaskets

before reassembling.

Release 00 / 2002 - 09

01 / 03Chapter.1

ENGINE

Air-injection 50 cc

TECHNICAL DATA

Type

Engine type

Number of valves

Number of cylinders

Piston displacement

Bore/Stroke

Corrected compression ratio

Idle rpm

Starter system

Clutch

Gearbox

Lubrication system

Cooling system

TRANSMISSION

Variator

Primary

Gears

Secondary

CAPACITY

air/injection

air-injection with direct petrol injection

-

mono-cylindrical horizontal

49.38 cm

41.0 mm / 37.4 mm

rc = 10.7 ± 0.1

1650 ± 50 r/min

electric

centrifuge

automatic stepless variator

Electric oil pump

forced air

automatic stepless

V- belt

minimum for stepless change: 2.9

maximum for stepless change: 0.75

with gears

3

Transmission oil

THROTTLE BODY

Type

Diffuser

FUEL SUPPLY

Fuel injector

Air injector

IGNITION UNIT

Type of ignition

Ign advance

SPARK PLUG

Standard

Electrode-spark plug distance

ELECTRICAL INSTALLATION

Battery

Fuse

Generator (magneto)

130 cm

Ø18 mm

SIEMENS DEKA

SYNERJECT

Inductive

Variable: 20° at 3000 rpm 17° at 7500 rpm.

NGK R CPR8-E

0.55 - 0.65 mm

12 V - 4 Ah

12 V - 140 W

3

BING

7.5 A

Release 00 / 2002 - 09

02 / 01Chapter.2

Air-injection 50 cc

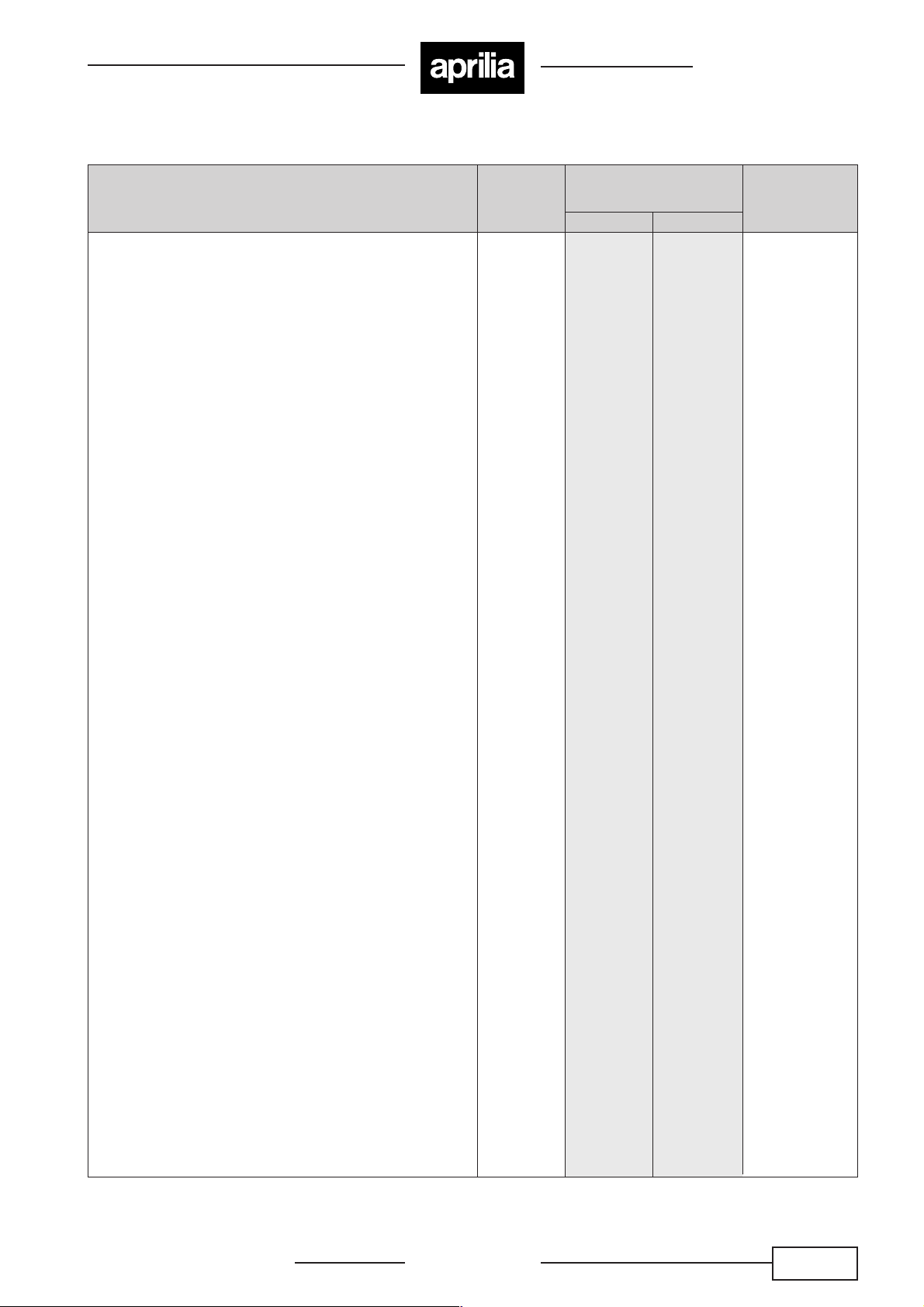

TIGHTENING TORQUE 50 cc AIR INJECTION ENGINE

Application

Pick-up locking

Stator locking

Transmission steel plate locking

Throttle body (with roller) hose clamp locking

Suction manifold (built-in, hexagonal) locking

Screws and pin securing intake manifold

Transmission cover

Variator cover

Bendix support locking

Starter motor

L/r carter locking

Wheel bearing retaining plate locking

Oil load plug (flanged)

Oil unload (Ch. 8)

Variator sliding pulley cover locking

Head locking (nut)

Clutch locking (nut)

Flywheel locking (nut)

Exhaust stud

Cylinder stud

Spark plug (thread)

Compressor screw locking

Fuel rail screw locking (flanged TE)

Variator fixed pulley locking (nut)

Cylinder head temperature probe

Screw

M5 x 12

M5 x 25

M6 x 12

M6 x 20

M6 x 25

M6 x 25

M6 x 30

M6 x 25

M6 x 55

M6 x 75

M6 x 100

M6 x 16

M8 x 12

M6 x 12

M4 x 8

M6 h=9

M10x1.5

M10x1.25

M10x1.0

M5 x 20

M5 x 25

M12x1.25

6 - 9

TIGHTENING

TORQUE

Nm

4 - 6

4 - 6

8 - 12

end stop

8 - 12

9 - 11

8 - 12

8 - 12

8 - 12

8 - 12

8 - 12

6 - 10

10 - 14

5 - 6

2

11 - 13

45 - 55

35 - 45

4 - 5

4 - 5

13 - 15

4 - 5

6 - 7

35 - 45

6 - 9

Kgm

0.4 - 0.6

0.4 - 0.6

0.8 - 1.2

end stop

0.8 - 1.2

0.9 - 1.1

0.8 - 1.2

0.8 - 1.2

0.8 - 1.2

0.8 - 1.2

0.8 - 1.2

0.6 - 1.0

1.0 - 1.4

0.5 - 0.6

0.2

1.1 - 1.3

4.5 - 5.5

3.5 - 4.5

0.4 - 0.5

0.4 - 0.5

1.3 - 1.5

0.4 - 0.5

0.6 - 0.7

3.5 - 4.5

0.6 - 0.9

Sealant

not

not

Loctite 270

not

not

not

not

not

not

not

not

Loctite 243

not

not

not

not

not

not

Loctite 270

not

/

not

not

not

Release 00 / 2002 - 09

02/ 02Chapter.2

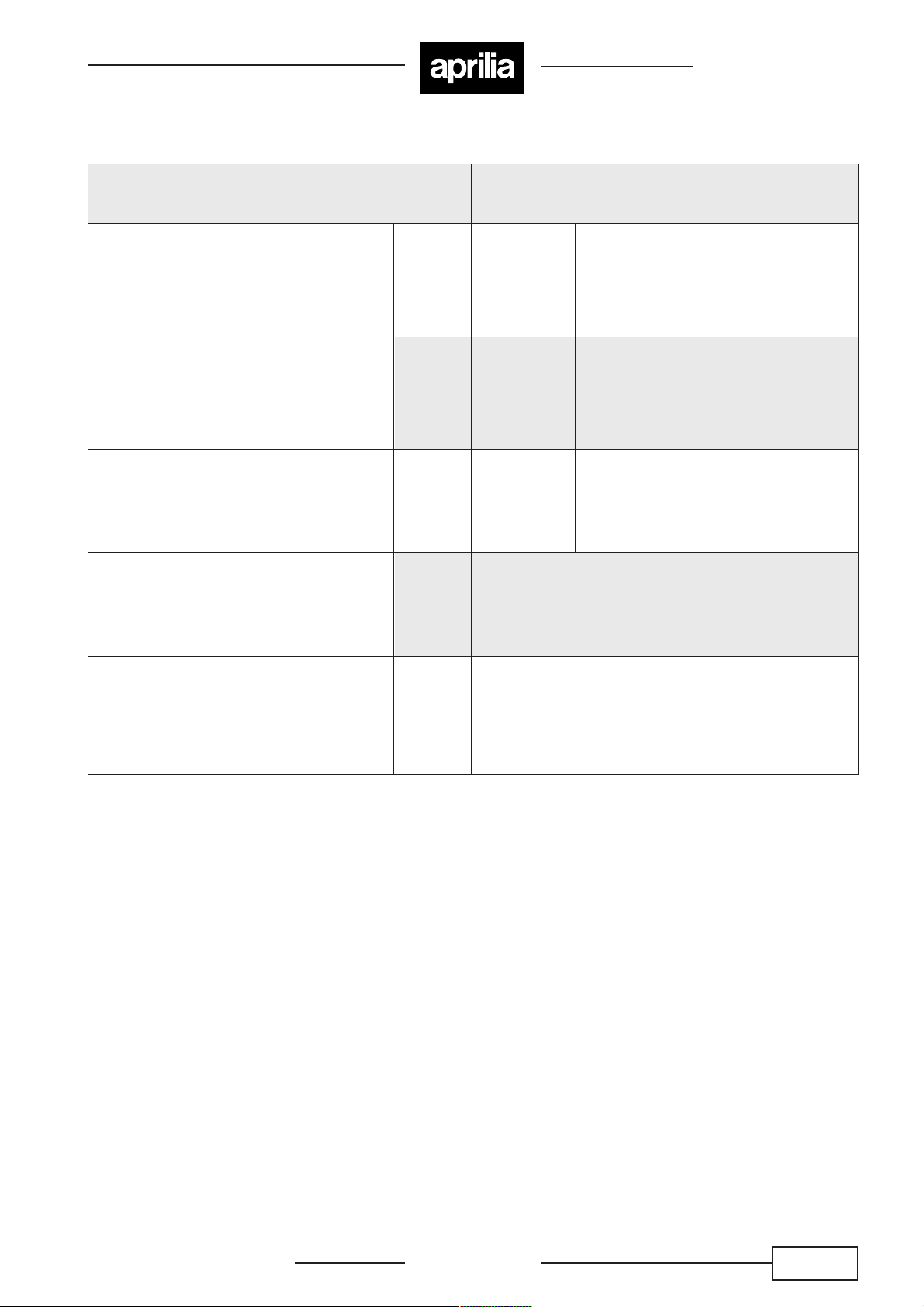

TECHNICAL DATA

CYLINDER + PISTON + RINGS

Air-injection 50 cc

Item:

Piston to cylinder

clearance

Piston diam.

Cylinder bore

Air-

injection

Air-

injection

Air-

injection

Standard: mm (in)

0.028-0.040

(0.0011-0.0016)

Selection A 40.966-40.972

(*) (1.6128-1.6131)

Selection B 40.972-40.978

(*) (1.6131-1.6133)

Selection C 40.978-40.984

(*) (1.6133-1.6135)

Measure 18 mm (0.7) from

the outer edge

Selection A 41.000-41.006

(1.6141-1.6144)

Selection B 41.006-41.012

(1.6144-1.6146)

Selection C 41.012-41.018

(1.6146-1.6149)

Limit: mm

(in)

0.100

(0.0039)

40.912

(1.6107)

40.918

(1.6109)

40.924

(1.6112)

41.050

(1.6161)

41.056

(1.6164)

41.066

(1.6168)

Measure 15 mm (0.59) from

the outer edge

Cylinder distortion

Cylinder head distortion

0.005

(0.0002)

0.02

(0.0008)

0.03

(0.0012)

0.05

(0.0020)

(*) N.B. During disassembly selections A,B, C may not be visible. In this case, refer to limit

values.

Release 00 / 2002 - 09

02 / 03Chapter.2

CYLINDER + PISTON + RINGS

Air-injection 50 cc

Item:

Port at the end of the unassembled

segment

Port at the end of the segment fitted

into the cylinder

Segment/slot clearance

Piston pin housing bore on piston

Air-

injection

Air-

injection

Air-

injection

Air-

injection

1°-2°

1°-2°

1°-2°

Standard:

mm (in)

T Approx.

T

12.002 - 12.010

(0.4725 - 0.4728)

0.25 - 0.40

(0.0098 - 0.0157)

0.036 - 0.076

(0.0014 - 0.0030)

4.5

(0.18)

Limit:

mm (in)

3.6

(0.14)

0.70

(0.027)

-

-

12.030

(0.4736)

Piston pin outer diameter

Air-

injection

11.996 - 12.000

(0.4723 - 0.4724)

11.980

(0.4717)

Release 00 / 2002 - 09

02 / 04Chapter.2

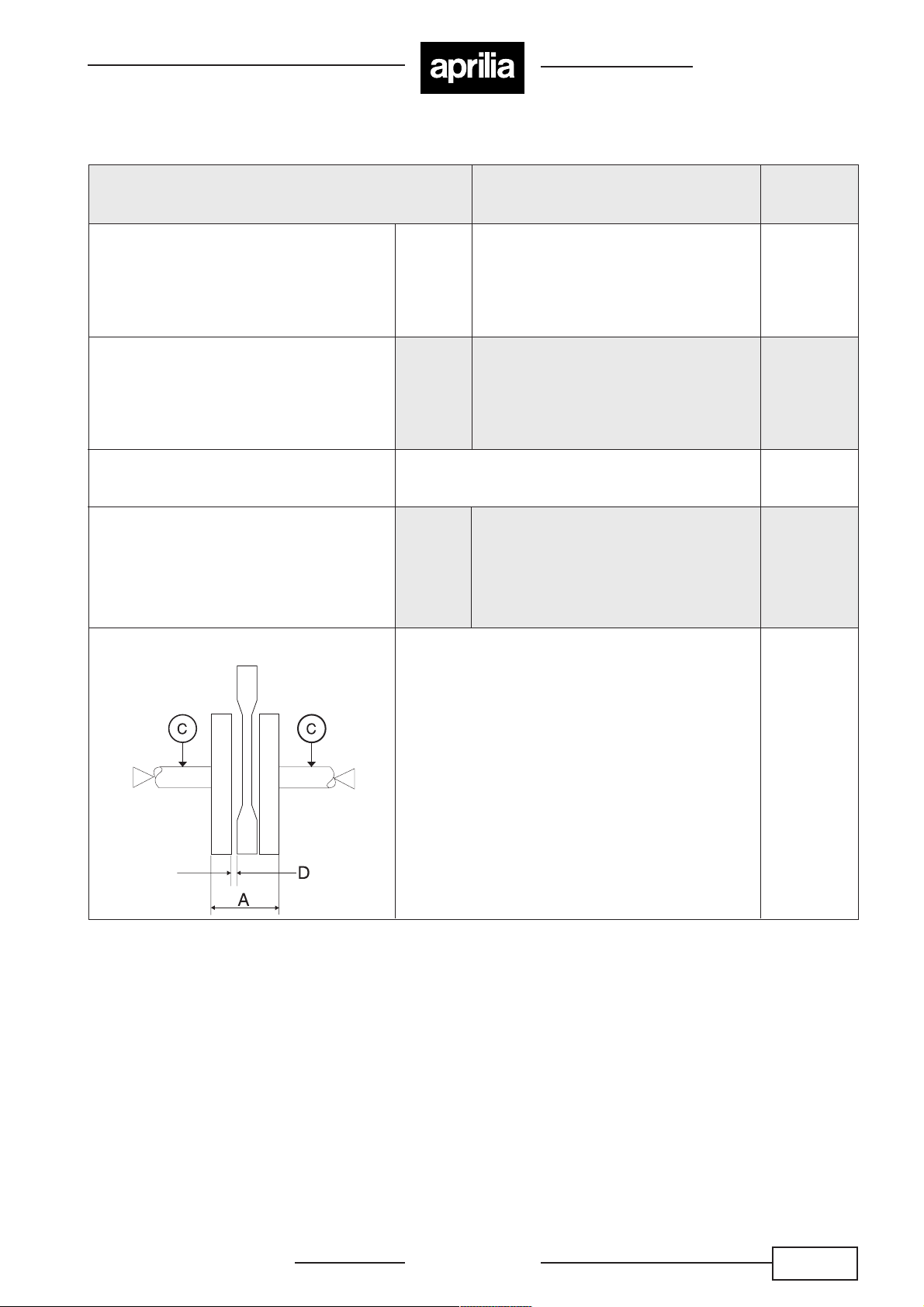

CONROD + CRANKSHAFT

Air-injection 50 cc

Item:

Connecting rod small end diameter

Width from crank arm to arm (A)

Misalignment limit (C)

Side clearance of connecting rod big

end (D)

Standard:

mm (in)

Air-

injection

Air-

injection

Measured between two opposite points

Air-

injection

(0.6300 - 0.6304) 36.0 ± 0.05

16.003 - 16.011

37.95 - 38.10

(1.494 - 1.5)

0.15 - 0.75

(0.0059 - 0.029)

Limite:

mm (in)

16.040

(0.6315)

-

-

0.03

(0.001)

-

Standard crank width

Release 00 / 2002 - 09

02 / 05Chapter.2

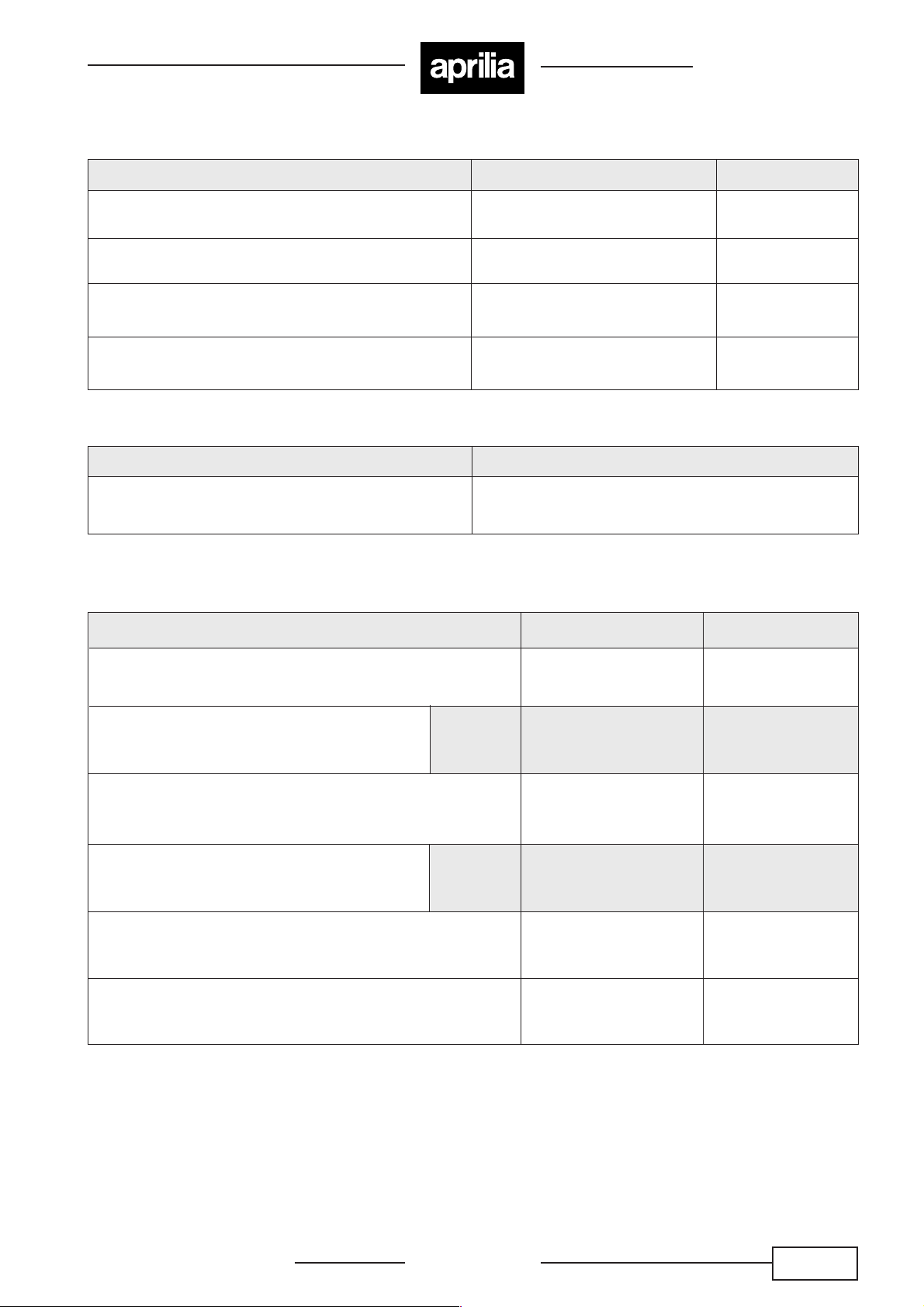

CLUTCH

Air-injection 50 cc

Item:

Clutch wheel inner diameter

Clutch shoe thickness

Clutch engagement

Clutch lock-up

OIL PUMP

Item:

Inner coil

TRANSMISSION

Standard: mm (in)

110.00 - 110.15

(4.331 - 4.337)

3.0

(0.12)

3200 ± 200 rpm

6700 ± 300 rpm

Specification:

Ri = 26.3 ± 2.6 Ω a 20° C

Limit:mm (in)

110.50

(4.350)

2.0

(0.08)

-

-

Item:

Reduction ratio

Final reduction ratio

Drive belt width

Driven face spring free

Guide roller for variator

Drum diameter

Air-

injection

Air-

injection

Standard: mm (in)

Variable 2.9 - 0.75

51/15 x 67 x 14

18.4 (0.724)

110 (4.33)

17 (0.669)

107 - 107.2

(4.213 - 4.220)

Limit: mm (in)

-

-

17.4 (0.685)

104.5 (4.114)

16.5 (0.650)

107.5

(4.232)

Release 00 / 2002 - 09

02 / 06Chapter.2

Loading...

Loading...