YAMAHA EF2800i SERVICE MANUAL

SERVICE MANUAL

EF2800i

7VU-28197-E0

310124

FOREWORD

This manual was written by the Yamaha Motor Company primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to put an entire mechanic’s education into one manual, so it is assumed that persons using this book to perform maintenance and repairs on Yamaha generators have a basic understanding of the mechanical precepts and procedures inherent to generator repair technology. Without such knowledge, attempted repairs or service to this model may render it unfit for use and/or unsafe.

Yamaha Motor Company Ltd. is continually striving to further improve all models manufactured by Yamaha. Modifications and significant changes in specifications or procedures will be forwarded to all Authorized Yamaha dealers and will, where applicable, appear in future editions of this manual.

HOW TO USE THIS MANUAL

PARTICULARLY IMPORTANT INFORMATION

This material is distinguished by the following notation.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

WARNING

WARNING

Failure to follow WARNING instructions could result in severe injury or death to the machine operator, a bystander, or a person inspecting or repairing the machine.

CAUTION:

CAUTION:

A CAUTION indicates special precautions that must be taken to avoid damage to the machine.

NOTE:

A NOTE provides key information to make procedures easier or clearer.

EF2800i

SERVICE MANUAL

©2001 by Yamaha Motor Co., Ltd. 1st Edition, April 2001

All rights reserved. Any reprinting or unauthorized use without the written permission of Yamaha Motor Co., Ltd. is expressly prohibited.

Printed in Japan

MANUAL FORMAT

The procedures in this manual are organized in a sequential, step-by-step format. The information has been compiled to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assembly, and inspection operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the course of action required will follow the symbol, e.g.,

•Bearings

Pitting/damage → Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before each disassembly section for ease in identifying the correct disassembly and assembly procedures.

1 |

|

2 |

|

|

GEN |

|

INSP |

|

|

INFO |

|

ADJ |

|

|

3 |

|

4 |

|

|

ENG |

|

ELEC – |

+ |

|

5 |

|

|

|

|

SPEC |

|

|

|

|

6 |

|

7 |

|

|

8 |

|

9 |

|

|

|

|

|

T |

|

|

|

|

. |

|

|

|

|

R |

|

|

|

|

. |

|

0 |

|

A |

|

|

B |

|

|

|

|

C |

D |

E |

|

|

E |

|

G |

M |

|

F |

G |

H |

|

|

B |

|

LS |

M |

|

I |

J |

K |

|

|

LT |

|

4 |

New |

|

|

|

|

|

|

ILLUSTRATED SYMBOLS (Refer to the illustration)

Illustrated symbols 1 through 5 are designed as thumb tabs to indicate the chapter’s number and content.

1 General information

2 Periodic inspections and adjustments

3Engine

4Electrical

5Specifications

Illustrated symbols 6 through B are used to identify the specific tools and test equipment.

6 Filling fluid

7Lubricant

8Special tool

9Tightening

0 Wear limit, clearance A Engine speed

B Ω, V, A

Illustrated symbols C through K in the exploded diagram indicate the grades of lubricant and the locations of the lubrication points.

C Apply engine oil D Apply gear oil

E Apply molybdenum disulfide oil F Apply wheel bearing grease

GApply lightweight lithium-soap base grease

HApply molybdenum disulfide grease

IApply a locking agent (LOCTITE®)

JApply Yamaha bond

KUse a new one

INDEX

GENERAL INFORMATION |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

||

INFOGEN |

1 |

||||

|

|||||

|

|

|

|

|

|

PERIODIC INSPECTIONS |

|

|

|

|

|

AND ADJUSTMENTS |

INSPADJ |

2 |

|||

ENGINE |

3 |

ENG |

|

– |

+ |

ELECTRICAL |

4 |

ELEC |

SPECIFICATIONS

SPEC 5

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION ................... |

1-1 |

SERIAL NUMBER ............................... |

1-1 |

STARTING SERIAL NUMBER ............ |

1-1 |

IMPORTANT INFORMATION .................. |

1-2 |

PREPARATION FOR REMOVAL AND |

|

DISASSEMBLY ................................... |

1-2 |

CAUTION ON SERVICE ..................... |

1-2 |

NOTES ON SERVICE ......................... |

1-2 |

ALL REPLACEMENT PARTS ............. |

1-3 |

GASKETS, OIL SEALS, |

|

AND O-RINGS .................................... |

1-3 |

BEARINGS AND OIL SEALS .............. |

1-3 |

SPECIAL TOOLS AND TESTERS ........... |

1-4 |

CHAPTER 2. |

|

PERIODIC INSPECTIONS |

|

AND ADJUSTMENTS |

|

INTRODUCTION ...................................... |

2-1 |

PERIODIC MAINTENANCE/LUBRICATION |

|

INTERVALS .............................................. |

2-1 |

ENGINE .................................................... |

2-2 |

ENGINE OIL LEAKAGE |

|

CHECKING ......................................... |

2-2 |

OIL LEVEL CHECKING ...................... |

2-2 |

OIL REPLACEMENT ........................... |

2-3 |

FUEL LEAKAGE ................................. |

2-4 |

FUEL COCK STRAINER |

|

INSPECTION ...................................... |

2-4 |

FUEL TANK FILTER ........................... |

2-5 |

AIR FILTER ELEMENT ....................... |

2-6 |

MUFFLER ........................................... |

2-7 |

VALVE CLEARANCE |

|

ADJUSTMENT .................................... |

2-8 |

COMPRESSION PRESSURE ........... |

2-10 |

RATED ENGINE SPEED .................. |

2-11 |

BREATHER HOSE ............................ |

2-11 |

ELECTRICAL ......................................... |

2-12 |

SPARK PLUG ................................... |

2-12 |

ENGINE SWITCH ............................. |

2-13 |

ECONOMY SWITCH ......................... |

2-13 |

PILOT LIGHT ..................................... |

2-13 |

RECEPTACLE ................................... |

2-14 |

CHAPTER 3.

ENGINE

CONTROL PANEL ................................... |

3-1 |

CONTROL BOX COVER |

|

AND FUEL TANK ..................................... |

3-3 |

MUFFLER AND AIR CLEANER ............... |

3-4 |

BREATHER HOSE INSTALLATION ...3-5 |

|

MUFFLER ASSEMBLY ....................... |

3-5 |

CONTROL UNIT AND AC-CDI UNIT ....... |

3-6 |

ENGINE ..................................................... |

3-7 |

CYLINDER HEAD COVER AND CYLINDER |

|

HEAD ........................................................ |

3-8 |

PUSH ROD INSPECTION ................. |

3-10 |

CYLINDER HEAD INSPECTION ....... |

3-10 |

CYLINDER HEAD ASSEMBLY ......... |

3-11 |

BREATHER HOSE ASSEMBLY ........ |

3-11 |

VALVE .................................................... |

3-12 |

VALVE AND VALVE SPRING |

|

REMOVAL ......................................... |

3-13 |

VALVE AND VALVE SPRING |

|

INSPECTION ..................................... |

3-13 |

ROCKER ARM INSPECTION ........... |

3-14 |

VALVE SEAT INSPECTION .............. |

3-15 |

VALVE LAPPING ............................... |

3-16 |

VALVE AND VALVE SPRING |

|

ASSEMBLY ....................................... |

3-17 |

RECOIL STARTER ................................. |

3-18 |

RECOIL STARTER |

|

DISASSEMBLY ................................. |

3-20 |

RECOIL STARTER INSPECTION ..... |

3-20 |

RECOIL STARTER ASSEMBLY ....... |

3-21 |

GENERATOR ......................................... |

3-23 |

MAGNETO ROTOR AND STATOR COIL |

|

ASSEMBLY REMOVAL ..................... |

3-25 |

MAGNETO ROTOR AND STATOR COIL |

|

ASSEMBLY INSTALLATION ............. |

3-26 |

CRANKCASE COVER |

|

AND CAMSHAFT ................................... |

3-28 |

CAMSHAFT INSPECTION ................ |

3-29 |

VALVE LIFTER INSPECTION .......... |

3-30 |

CAMSHAFT ASSEMBLY .................. |

3-30 |

CRANKCASE COVER |

|

INSPECTION .................................... |

3-30 |

CRANKCASE COVER |

|

INSTALLATION ................................. |

3-30 |

PISTON, CONNECTING ROD, CRANK- |

|

SHAFT AND CRANKCASE ................... |

3-31 |

CRANKCASE (CYLINDER) |

|

INSPECTION .................................... |

3-32 |

PISTON AND PISTON |

|

PIN INSPECTION ............................. |

3-32 |

PISTON RING INSPECTION ............ |

3-34 |

CRANKSHAFT INSPECTION ........... |

3-34 |

CONNECTING ROD OIL |

|

CLEARANCE INSPECTION ............. |

3-35 |

PISTON RING |

|

AND PISTON ASSEMBLY ................ |

3-36 |

CRANKSHAFT ASSEMBLY .............. |

3-37 |

CARBURETOR ...................................... |

3-38 |

FLOAT HEIGHT INSPECTION ......... |

3-40 |

CHOKE CABLE INSTALLATION ...... |

3-41 |

THROTTLE CONTROL MOTOR ...... |

3-41 |

TROUBLESHOOTING ........................... |

3-42 |

ENGINE ............................................. |

3-42 |

THROTTLE CONTROL SYSTEM ..... |

3-48 |

CHAPTER 4. |

|

ELECTRICAL |

|

ELECTRICAL COMPONENTS ................ |

4-1 |

CIRCUIT DIAGRAM ................................. |

4-2 |

SWITCHES ............................................... |

4-3 |

CHECKING SWITCH CONTINUITY ... 4-3 |

|

IGNITION SYSTEM .................................. |

4-4 |

TROUBLESHOOTING CHART ........... |

4-4 |

GENERATOR SYSTEM ........................... |

4-9 |

TROUBLESHOOTING CHART ........... |

4-9 |

CHAPTER 5.

SPECIFICATIONS

GENERAL SPECIFICATIONS .................. |

5-1 |

MAINTENANCE SPECIFICATIONS ......... |

5-3 |

ENGINE ............................................... |

5-3 |

GENERATOR AND ELECTRICAL ...... |

5-6 |

TIGHTENING TORQUE ............................ |

5-7 |

GENERAL TORQUE |

|

SPECIFICATIONS .................................... |

5-8 |

DEFINITION OF UNITS ............................ |

5-8 |

WIRE ROUTING DIAGRAM ..................... |

5-9 |

CONTROL BOX PANEL AND BEHIND |

|

CONTROL BOX ................................... |

5-9 |

ENGINE AND GENERATOR ............. |

5-10 |

GEN

MACHINE IDENTIFICATION INFO

GENERAL INFORMATION

MACHINE IDENTIFICATION

SERIAL NUMBER

The serial number is printed on a label 1 which is affixed to the generator as shown.

NOTE:

The first three characters of this number are

for model identification, the remaining digits

SVU1010H

are the unit production number.

SVU1020H

STARTING SERIAL NUMBER

7VU-300101~

NOTE:

Designs and specifications are subject to change without notice.

1-1

GEN

IMPORTANT INFORMATION INFO

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY CAUTION ON SERVICE

Fire prevention

When servicing the engine, always keep the engine and yourself

SVU1030H

away from fire.

NOTES ON SERVICE

1.Correct tools

Be sure to use the correct special tool for the job to guard against damage.

SVU1040H

2. Oil, grease and seals

Be sure to use genuine Yamaha oils, grease and sealers, or the equivalents.

SVU1050H

3.Expendable parts

Always replace the gaskets, O-rings, cotter pins and circlips with new parts when servicing engine.

SVU1060H

4.Tightening torque

Be sure to follow torque specifications. When tightening bolts, nuts or screws, start with the largest-diameter fastener and work from an inner position to an outer position in a crisscross pattern.

SVU1070H

5. Notes on disassembly and assembly

a.Parts should be cleaned in solvent and blown dry with compressed air after disassembly.

SVU1080H

SVU1090H

b.Contact surfaces of moving parts should be oiled when reassembled.

c.Make sure that the parts, move smoothly after each section of the machine is assembled.

SVU1100H

1-2

1 |

|

|

|

|

|

|

|

|

|

|

IMPORTANT INFORMATION |

|

GEN |

|

|

|

|

|

|

INFO |

|

|

||

|

|

|

|

|

|

|

|

|

|

ALL REPLACEMENT PARTS |

|||||

|

|

We recommend the use of genuine Yamaha parts for all replace- |

|||||

|

|

ments. Use oil and/or grease, recommended by Yamaha, for |

|||||

|

|

assembly and adjustment. |

|||||

|

|

GASKETS, OIL SEALS, AND O-RINGS |

|||||

|

|

1. All gaskets, seals, and O-rings should be replaced when an |

|||||

|

|

engine is overhauled. All gaskets surfaces, oil seal lips, and O- |

|||||

|

|

rings must be cleaned. |

|||||

|

|

2. Properly oil all mating parts and bearings during reassembly. |

|||||

|

|

Apply grease to the oil seal lips. |

|||||

|

|

BEARINGS AND OIL SEALS |

|||||

|

|

||||||

|

|

Install the bearing(s) 1 and oil seal(s) 2 with their manufacture’s |

|||||

|

|

marks or numbers facing outward. (In other words, the stamped let- |

|||||

|

|

ters must be on the side exposed to view.) When installing oil |

|||||

|

|

seal(s), apply a light coating of light-weight lithium base grease to |

|||||

SVU1110H |

|

the seal lip(s). Oil the bearings liberally when installing. |

|||||

|

|

||||||

|

|

||||||

|

|

CAUTION: |

|

||||

|

|

||||||

|

|

Do not use compressed air to spin the bearings dry. This |

|||||

|

|

causes damage to the bearing surfaces. |

|||||

SVU1120H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-3

GEN

SPECIAL TOOLS AND TESTERS INFO

SPECIAL TOOLS AND TESTERS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques.

1.Piston ring compressor P/N. 90890-05158

This tool is used to compress the piston rings when installing the piston.

SVU1130H

2.Valve spring compressor P/N. 90890-01253

This tool is used to remove the valve springs.

SVU1140H

3.Thickness gauge P/N. 90890-03079

This gauge is used to adjust valve clearance, piston clearance and piston ring end gap.

SVU1150H

4.Cylinder gauge Commercially obtainable

This instrument is used for checking cylinder bore size and condition.

SVU1160H

5.Engine tachometer P/N. 90890-03113

This instrument is used for reading engine r/min.

SVU1170H

6.Compression gauge 1 P/N. 90890-03081 Adapter 2

P/N. 90890-04082

This gauge is used for checking engine compression.

SVU1180H

7.Dial gauge

P/N. 90890-03097

This instrument is used for checking crankshaft side clearance.

SVU1190H

1-4

GEN

SPECIAL TOOLS AND TESTERS INFO

8.Piston pin puller P/N. 90890-01304

This tool is used to remove the piston pin.

SVU1200H

9.Sheave holder P/N. 90890-01701

This tool is necessary for holding the flywheel.

SVU1210H

10.Rotor puller

P/N. 90890-01362

This tool is necessary for removing the flywheel.

SVU1220H

11.Pocket tester P/N. 90890-03112

This instrument is necessary for checking the electrical system.

SVU1230H

12.Ignition checker P/N. 90890-06754

This instrument is necessary for checking the ignition system components.

SVU1240H

1-5

INTRODUCTION/PERIODIC MAINTENANCE/ INSP

LUBRICATION INTERVALS ADJ

PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer service life. The need for costly overhaul work will be greatly reduced. This information applies to machines already in service as well as new machines that are being prepared for sale. All service technicians should be familiar with this entire chapter.

PERIODIC MAINTENANCE/LUBRICATION INTERVALS

|

|

Pre-Opera- |

Initial |

|

Every |

|

Item |

Remarks |

tion check |

1 month or |

3 months |

6 months |

12 months |

|

|

(daily) |

20 Hr |

or 50 Hr |

or 100 Hr |

or 300 Hr |

|

|

|

|

|

|

|

Spark plug |

Check condition, adjust gap and clean. |

|

|

● |

|

|

Replace if necessary. |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Valve clearance |

Check and adjust when engine is cold. |

|

|

|

|

● |

|

|

|

|

|

|

|

Crankcase breather |

Check breather hose for cracks or damage. |

|

|

|

|

● |

system |

Replace if necessary. |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

Idle speed |

Check and adjust engine idle speed. |

|

|

|

|

● |

|

|

|

|

|

|

|

|

Check for leakage. |

● |

|

|

|

|

|

Retighten or replace gasket if necessary. |

|

|

|

|

|

Exhaust system |

|

|

|

|

|

|

|

|

|

|

|

|

|

Check muffler screen and spark arrester. |

|

|

|

|

● |

|

|

|

|

|

|

||

|

Clean/replace if necessary. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine oil |

Check oil level. |

● |

|

|

|

|

|

|

|

|

|

|

|

Replace. |

|

● |

|

● |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

Air filter |

Clean. Replace if necessary. |

|

|

● |

|

|

|

|

|

|

|

|

|

Fuel filter |

Clean fuel cock and fuel tank filter. |

|

|

|

● |

|

Replace if necessary. |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fuel line |

Check fuel hose for cracks or damage. |

● |

|

|

|

|

Replace if necessary. |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Choke knob |

Check choke operation. |

● |

|

|

|

|

|

|

|

|

|

|

|

Cooling system |

Check for fan damage. |

|

|

|

|

● |

|

|

|

|

|

|

|

Starting system |

Check recoil starter operation. |

● |

|

|

|

|

|

|

|

|

|

|

|

Decarbonization |

More frequently if necessary. |

|

|

|

|

● |

|

|

|

|

|

|

|

Generation |

Check the pilot light comes on. |

● |

|

|

|

|

|

|

|

|

|

|

|

Fittings/fasteners |

Check all fittings and fasteners. |

|

|

|

● |

|

Correct if necessary. |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

2-1

ENGINE OIL LEAKAGE CHECKING/ OIL LEVEL CHECKING

INSP ADJ

SVU2010H |

ECON. |

SW |

OVER

AC LOAD

ENGINE

ENGINE OIL LEAKAGE CHECKING

1.Check the areas outside of the engine for

oil leakage.

Oil leakage → Replace the gasket, oil seal, or O-ring.

OIL LEVEL CHECKING

1.Check:

•Oil level with oil warning light 1

Check whether the oil warning light

flashes by operating the recoil starter. Oil warning light flashes → Add oil. Oil warning light does not flash → OK

SVU2020H

2. Remove:

• Oil filler cap 1 3. Check:

• Check that the engine oil is at the specified level a.

Oil level checking steps:

• Place the engine on a level surface.

SVU2030H • Warm up the engine for several minutes.

• Stop the engine.

• Check that the engine oil is at the specified level a. Add oil if necessary.

4. Install:

• Oil filler cap

2-2

INSP

OIL REPLACEMENT ADJ

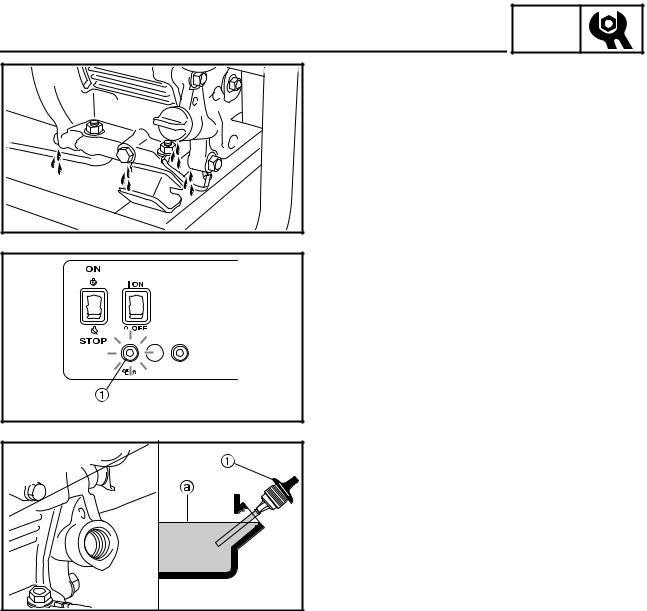

SVU2040H |

OIL REPLACEMENT

1.Warm up the engine for several minutes.

2.Stop the engine.

3.Place a receptacle under the engine.

4.Remove:

• Oil drain bolt 1

5.Tilt the engine to drain the oil completely.

6.Tighten:

• Oil drain bolt 1

T .

R .

Oil drain bolt:

17 Nm (1.7 m · kg, 12 ft · lb)

SVU2050H |

7.Remove:

• Oil filler cap 1

8.Fill:

Recommended oil: È SAE #30 or 10W-30 É SAE #20 or 10W-30

Ê SAE 10W or 10W-30

Engine oil quantity:

0.6 L (0.53 Imp qt, 0.63 US qt)

NOTE:

Recommended engine oil classification:

API Service “SE” or “SF”, if not available, “SD”.

SVU2060H

9.Install:

• Oil filler cap

2-3

FUEL LEAKAGE/ FUEL COCK STRAINER INSPECTION

INSP ADJ

FUEL LEAKAGE

1.Check:

•Leakage

Check at fuel tank, fuel cock, fuel hose, and carburetor.

CAUTION:

CAUTION:

Replace hose every four years.

SVU2070H

FUEL COCK STRAINER INSPECTION

1.Turn the fuel cock to the “OFF” a position, detach the strainer cup, and then remove the debris from inside the cup.

2.Remove:

•Fuel cock cup 1

•Gasket 2

•Strainer 3

3.Inspect:

•Fuel cock cup Dirt/debris → Clean.

•Gasket 2

Damage → Replace.

•Strainer 3 Dirt/debris→ Clean.

NOTE:

Clean the cup with solvent, and then dry it thoroughly.

SVU2080H

4.Install:

•Strainer

•Gasket

•Fuel cock cup

T .

R .

Fuel cock cup:

1.3 Nm (0.13 m · kg, 0.94 ft · lb)

CAUTION:

CAUTION:

Securely install the strainer cup to prevent fuel leaks.

2-4

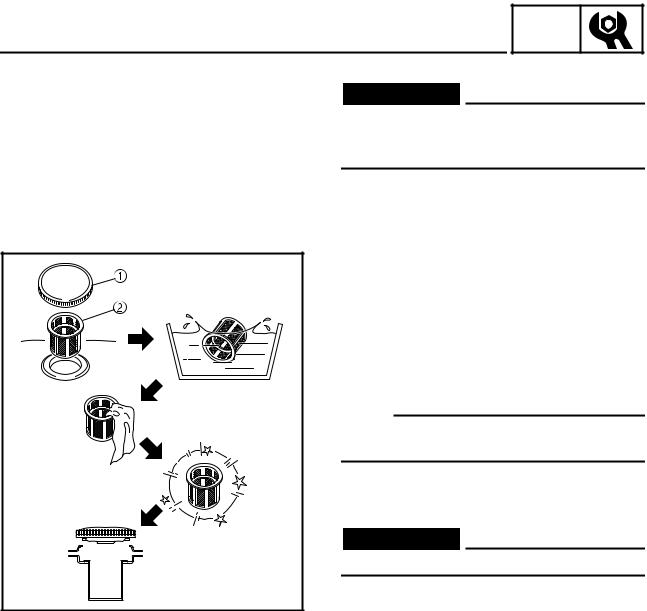

FUEL TANK FILTER

FUEL TANK FILTER

WARNING

WARNING

INSP ADJ

Do not smoke, and keep away from open flames, sparks, or any other source of fire when handling or in the vicinity of fuel.

SVU2090H |

1.Remove:

•Fuel tank cap 1

•Fuel tank filter 2

2.Inspect:

•Fuel tank filter Damage → Replace.

3.Clean:

•Fuel tank filter

NOTE:

Clean the fuel tank filter with solvent, and then dry it thoroughly.

4.Install:

•Fuel tank filter

•Fuel tank cap

WARNING

WARNING

Be sure the tank cap is tightened securely.

2-5

INSP

AIR FILTER ELEMENT ADJ

AIR FILTER ELEMENT

1.Remove:

•Screws 1

•Air filter case cover 2

SVU2100H

2.Remove:

• Air filter element 1

SVU2110H

3.Inspect:

•Element

Damage → Replace.

Clogging → Wash the element in a solvent, and then dry it thoroughly.

Oil the element and squeeze out the excess oil.

CAUTION:

CAUTION:

•Do not wring out the element: this could cause it to tear.

•Do not wash the element in gasoline or in acidic, alkalinic, or organic solvents.

SVU2120H

4.Install:

•Air filter element

•Air filter case cover

•Screws

CAUTION:

CAUTION:

The engine should never run without the element, otherwise excessive piston and/or cylinder wear may result.

2-6

INSP

MUFFLER ADJ

SVU2130H

SVU2140H

SVU2150H

MUFFLER

1.Remove:

•Muffler

Refer to “MUFFLER AND AIR CLEANER” in CHAPTER 3.

•Muffler band 1

•Muffler cap 2

•Washer 3

• Muffler screen 4

2.Decarbonize:

•Muffler

Tap on the muffler in the area shown in the illustration to loosen carbon buildup, and then shake it out of the end of the muffler.

CAUTION:

CAUTION:

Don’t use a wire to clean, otherwise the noise damping material may come out, and the damping effect may be reduced.

3.Decarbonize:

•Muffler screen

4.Install:

•Muffler screen

•Muffler cap

•Muffler band

•Muffler

Refer to “MUFFLER AND AIR

CLEANER” in CHAPTER 3.

2-7

INSP

VALVE CLEARANCE ADJUSTMENT ADJ

SVU2160H |

SVU2170H |

VALVE CLEARANCE ADJUSTMENT

1.Remove:

•Breather hose 1

•Spark plug cap 2

•Cylinder head cover 3

•Spark plug 4

2.Gently operate the starter rope to bring the piston to the top-dead-center of its compression stroke (when the screwdriver inserted into the spark plug hole reaches the highest position).

3.Measure:

•Valve clearance

Out of specification → Adjust.

NOTE:

Valve clearance must be measured when the engine is cool to the touch.

Intake valve (cold):

SVU2180H 0.1 mm (0.004 in)

Exhaust valve (cold): 0.1 mm (0.004 in)

Thickness gauge: 90890-03079

2-8

INSP

VALVE CLEARANCE ADJUSTMENT ADJ

4.Adjust:

• Valve clearance

Adjustment steps:

•Loosen the locknut 1.

•Turn the adjuster 2 in or out to obtain the proper clearance.

|

|

Adjuster |

Valve clearance |

|

SVU2190H |

|

|

||

Turn in |

Decrease |

|||

|

|

|||

|

|

|||

|

|

|

|

|

|

|

Turn out |

Increase |

|

|

|

|||

|

|

|

|

|

• Tighten the locknut 1.

T .

R .

Locknut:

10 Nm (1.0 m · kg, 7.2 ft · lb)

SVU2200H

5.Install:

•Cylinder head cover

•Breather hose

•Spark plug

•Spark plug cap

T .

R .

Cylinder head cover bolt:

10 Nm (1.0 m · kg, 7.2 ft · lb) Spark plug:

18 Nm (1.8 m · kg, 13 ft · lb)

2-9

INSP

COMPRESSION PRESSURE ADJ

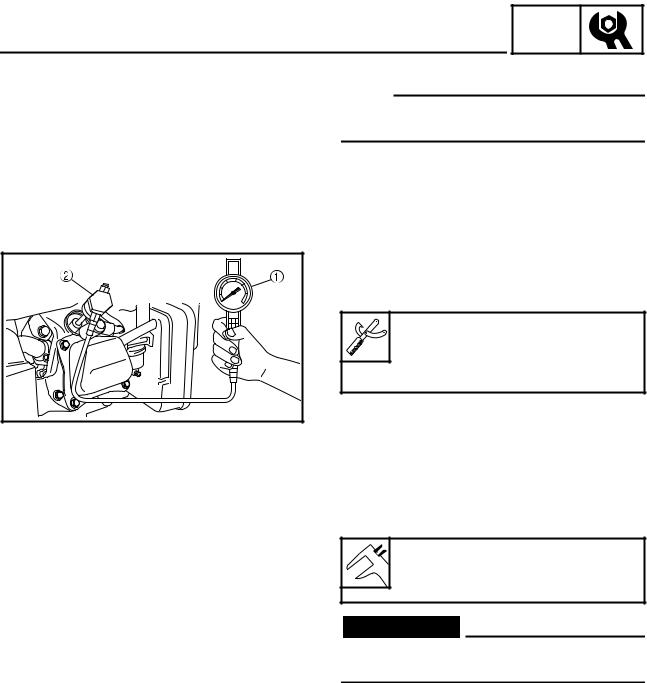

COMPRESSION PRESSURE

NOTE:

Measure the compression after checking and adjusting the valve clearance.

1.Warm up the engine for several minutes.

2.Remove:

• Spark plug

SVU2210H |

3.Connect:

•Compression gauge 1

•Adapter 2

Compression gauge: 90890-03081

Adapter: 90890-04082

4.Measure:

•Compression

To measure the compression, pull the recoil starter until the needle stops rising on the compression gauge.

Standard compression pressure: 400 ~ 600 kPa

(4 ~ 6 kg/cm2, 57 ~ 85 psi)

WARNING

WARNING

To prevent sparking when cranking the engine, ground the high-tension cord.

Testing steps (below minimum level):

•Squirt a few drops of oil into the cylinder.

•Measure the compression again.

Reading |

|

Diagnosis |

|

|

|

|

|

If higher than |

• |

Worn cylinder, piston, and |

|

without oil |

|

piston ring |

|

|

|

|

|

|

• |

Defective piston, ring(s), |

|

If the same as |

|

valve(s), and cylinder |

|

|

head gasket |

||

without oil |

|

||

• Improper valve timing and |

|||

|

|||

|

|

valve clearance |

|

|

|

|

|

2-10

COMPRESSION PRESSURE/ RATED ENGINE SPEED/BREATHER HOSE

INSP ADJ

SVU2220H |

SVU2230H

Testing steps (above maximum level):

•Check the cylinder head, valve surfaces, and piston crown for carbon deposits.

5.Install:

• Spark plug

|

Spark plug: |

. |

18 Nm (1.8 m · kg, 13 ft · lb) |

T |

|

R |

|

. |

|

RATED ENGINE SPEED

1.Connect:

• Engine tachometer 1

Engine tachometer: 90890-03113

2.Inspect:

•Rated engine speed Specified engine speed → OK

Out of specification → Refer to “TROUBLESHOOTING” in CHAPTER 3.

Inspection steps:

•Operate the engine (with no load).

•Turn economy switch 1 to “OFF” a.

•Measure the rated engine speed.

Rated engine speed: 3,550 r/min

SVU2240H |

BREATHER HOSE

1.Inspect:

•Breather hose 1 Cracks/damage → Replace. Poor connection → Correct.

2-11

SPARK PLUG

ELECTRICAL

SPARK PLUG

WARNING

WARNING

INSP ADJ

Inspect and adjust the areas around the cylinder head after the engine has cooled down completely.

CAUTION:

CAUTION:

Before removing the spark plug, use compressed air to clean the cylinder head cover to prevent dirt from falling into the engine.

1.Remove:

•Spark plug cap

•Spark plug

2.Inspect:

•Electrode 1 Wear/damage → Replace.

•Insulator color 2

3.Measure:

•Spark plug gap a

Use a wire gauge or thickness gauge. Out of specification → Regap.

SVU2250H

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

If necessary, clean the spark plug with a spark plug cleaner.

Standard spark plug (with resistor):

BPR4ES (NGK)

Before installing the spark plug, clean the gasket surface and plug surface.

SVU2260H

2-12

SPARK PLUG/ENGINE SWITCH/ ECONOMY SWITCH/PILOT LIGHT

INSP ADJ

SVU2270H

SVU2280H

SVU2290H

ECON.

SW

OVER

AC LOAD

4.Tighten:

• Spark plug

|

Spark plug: |

. |

18 Nm (1.8 m · kg, 13 ft · lb) |

T |

|

R |

|

. |

|

NOTE:

To prevent thread damage, finger tighten a the spark plug before tightening it to the specified torque b.

ENGINE SWITCH

1.Check:

• Engine switch 1

Checking steps:

•Set the engine switch 1 to “ON” a.

•Start the engine.

•Check that the engine stops when the switch is set to “STOP” b.

ECONOMY SWITCH

1.Check:

• Economy switch 1

Checking steps:

•Set the economy switch 1 to “ON” a.

•Start the engine.

•Turn the switch of the electric device connected to the AC outlet “ON” and “OFF” to check whether the engine speed increases and decreases.

PILOT LIGHT

1.Check:

• Pilot light 1

Checking steps:

•Start the engine.

•Make sure that the pilot light 1 turns on.

SVU2300H

2-13

INSP

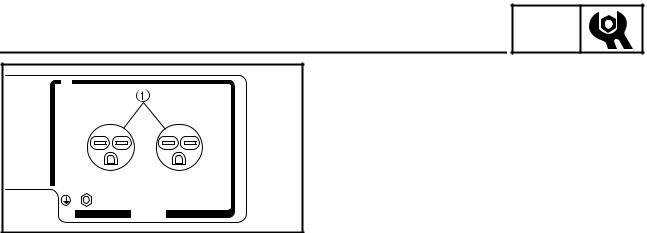

RECEPTACLE ADJ

TO RESET AC |

RESTART ENGINE |

AC~ |

SVU2310H |

RECEPTACLE

1.Check:

•AC receptacles (15 A) 1 Cracks/damage → Replace. Poor connection → Correct.

2-14

CONTROL PANEL ENG

ENGINE

CONTROL PANEL

1 |

|

|

2 |

2 |

3 |

|

|

3 |

SVU3010H |

|

Order |

Job name/Part name |

Q’ty |

Remarks |

|

|

|

|

|

Control panel assembly removal |

|

Remove the parts in the order listed |

|

|

|

below. |

1 |

Control panel assembly |

1 |

|

2 |

Wire harness |

1 |

Disconnect all couplers and lead wires. |

3 |

Ground terminal |

1 |

|

|

|

|

For installation, reverse the removal pro- |

|

|

|

cedure. |

|

|

|

|

3 |

3-1

|

CONTROL PANEL |

ENG |

1 |

|

|

|

|

2 |

2 |

3 |

|

|

|

|

3 |

|

SVU3010H |

|

|

Order |

Job name/Part name |

Q’ty |

Remarks |

|

|

|

|

|

Control panel disassembly |

|

Remove the parts in the order listed |

|

|

|

below. |

1 |

Control panel |

1 |

|

2 |

Engine switch |

1 |

|

3 |

Economy switch |

1 |

|

4 |

Oil warning light |

1 |

|

5 |

Pilot light |

1 |

|

6 |

Over load warning light |

1 |

|

7 |

AC receptacle (15 A) |

2 |

|

|

|

|

For assembly, reverse the disassembly |

|

|

|

procedure. |

|

|

|

|

3-2

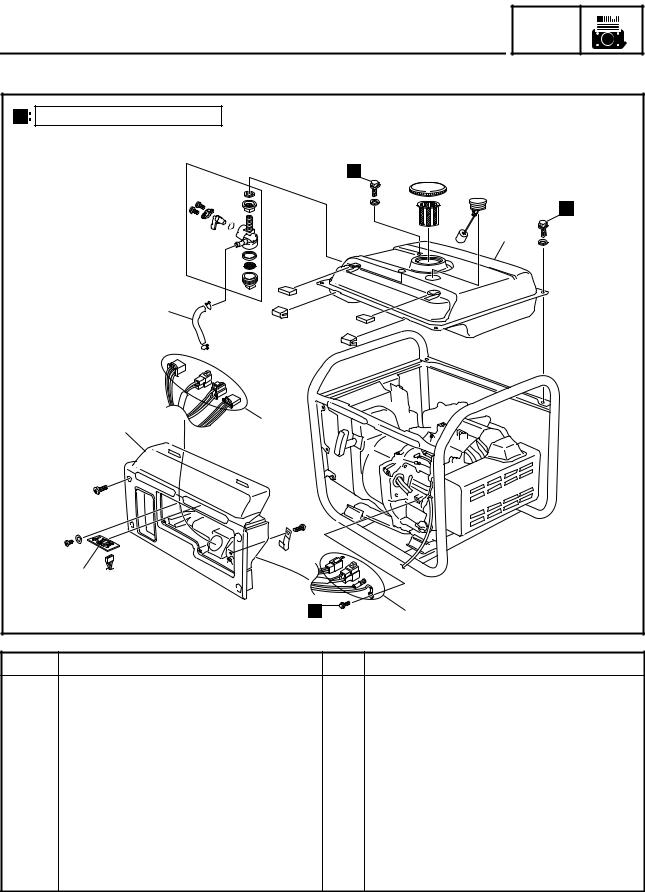

CONTROL BOX COVER AND FUEL TANK ENG

CONTROL BOX COVER AND FUEL TANK

7 Nm (0.7 m · kg, 5.1 ft · lb) |

|

|

|

|

|

|

5 |

|

4 |

|

|

|

1 |

3 |

|

|

|

|

|

|

2 |

|

|

|

|

|

3 |

|

|

|

SVU3020H |

Order |

Job name/Part name |

Q’ty |

Remarks |

|

Control box cover and fuel tank |

|

Remove the parts in the order listed |

|

removal |

|

below. |

|

Control panel assembly |

|

|

1 |

Control box cover |

1 |

|

2 |

Oil warning unit |

1 |

|

3 |

Wire harness |

1 |

Disconnect all couplers, lead wires and |

|

|

|

connections. |

4 |

Fuel hose |

1 |

Set the fuel cock “OFF” position. |

5 |

Fuel tank |

1 |

|

|

|

|

For installation, reverse the removal |

|

|

|

procedure. |

3-3

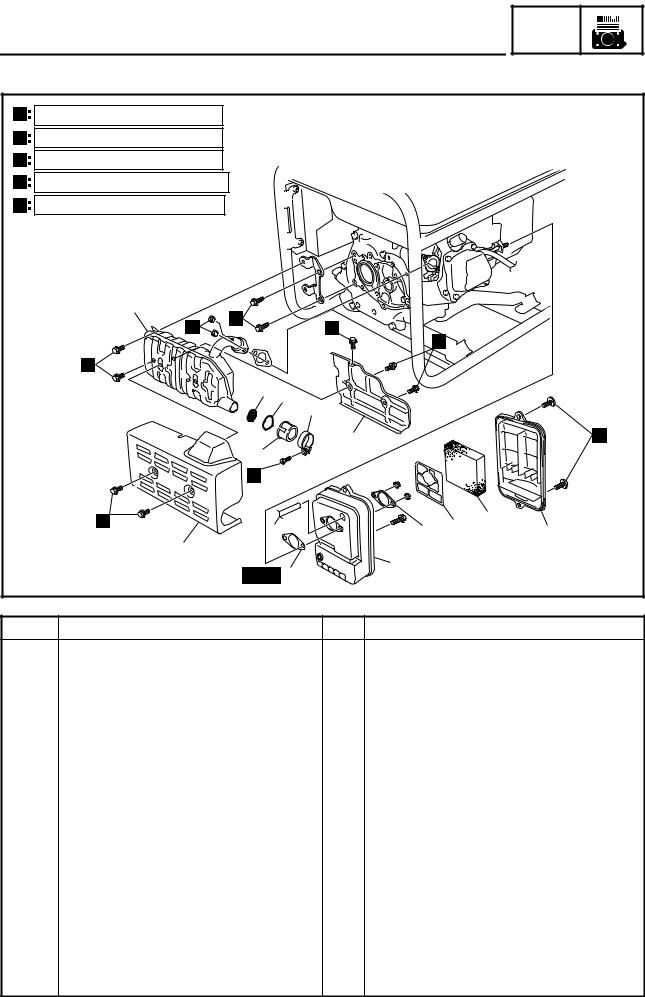

MUFFLER AND AIR CLEANER ENG

MUFFLER AND AIR CLEANER

2 Nm (0.2 m · kg, 1.4 ft · lb) |

|

|

|

|

4 Nm (0.4 m · kg, 2.9 ft · lb) |

|

|

|

|

7 Nm (0.7 m · kg, 5.1 ft · lb) |

|

|

|

|

10 Nm (1.0 m · kg, 7.2 ft · lb) |

|

|

|

|

16 Nm (1.6 m · kg, 11 ft · lb) |

|

|

|

|

|

2 |

|

|

|

|

7 |

6 |

|

|

|

|

4 |

|

|

|

5 |

3 |

|

|

|

|

|

|

|

|

13 |

|

10 |

9 |

|

11 |

8 |

||

|

1 |

12 |

|

|

|

|

|

|

|

|

New 14 |

|

SVU3030H |

|

|

|

|

|

|

Order |

Job name/Part name |

Q’ty |

|

Remarks |

|

Muffler and air cleaner removal |

Remove the parts in the order listed |

|

|

below. |

1 |

Muffler protector 1 |

1 |

2 |

Muffler |

1 |

3 |

Muffler protector 2 |

1 |

4 |

Muffler band |

1 |

5 |

Muffler cap |

1 |

6 |

Washer |

1 |

7 |

Muffler screen |

1 |

8 |

Air filter case cover |

1 |

9 |

Air filter element |

1 |

10 |

Metal gasket |

1 |

11 |

Plate |

1 |

12 |

Air filter case |

1 |

13 |

Breather hose |

1 |

14 |

Gasket |

1 |

|

|

For installation, reverse the removal |

|

|

procedure. |

3-4

Loading...

Loading...