Yaesu G-800SA, G-1000SA INSTRUCTION MANUAL

G-800SA

G-1000SA

Antenna Rotator & Controller

User Manual

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

YAESU EUROPE B.V.

P.O. Box 75525, 1118 ZN Schiphol, The Netherlands

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

IMPORTANT !

The installation of a rotatable antenna on a tower system is a dangerous and potentially life-threatening task, if due care

is not taken.

A tower must never be installed in a position where it could fall across power distribution cables in the event of a

catastrophic tower failure during a windstorm or earthquake.

The control cable attached to this rotator could, in the event of a nearby or direct lightning strike, carry lethal voltages

down the cable and into your home. Yaesu strongly recommends the installation of suitable lightning arrestors on all

control cables and coaxial lead-in cables from your antenna installation. See your dealer for details of available lightning-protection devices.

If an electrical storm should be reported in your area, quickly unplug the control cable from the rear of the rotator’s

controller box, and disconnect the AC cable from the wall outlet. Disconnect the coaxial cable(s) from the antenna(s) as

well. Do this only if the lightning is not in your immediate area, as you could be killed instantly if lightning should

strike while you are holding a cable.

If you have any doubts about your ability to install this rotator safely, enlist the services of a professional antenna

installation company.

G-800SA

G-1000SA

Heavy-Duty Antenna Rotator & Controller

The Yaesu G-800SA and G-1000SA are designed to

rotate large tower-mounted amateur and professional antenna arrays under remote control from the station operating position. The clamshell rotator design utilizes 98

7/16-inch dual-stacked circumferential ball bearings to

distribute load over the full diameter of the housing. This

design minimizes stress and wear, and practically eliminates the possibility of destructive water entry: there is

no shaft hole in the top of the housing.

Instead of the usual AC motor drive used in older rotator

designs, the G-800SA and G-1000SA use a DC motor,

obviating the need for a large starting capacitor with its

potential for failure exposed to outside temperature variations. The factory-lubricated rotator unit is housed in

melamine resin-coated die-cast aluminum, intended to

provide maintenance-free operation under all climatic

conditions. A mast alignment gauge on the rotator housing simplifies accurate mechanical alignment during installation.

The handsome desktop controller matches the design of

modern transceivers, providing 360° radial indication of

actual antenna bearing azimuth.

The operator may select the stopper heading (the bearing through which the rotator cannot be turned) most

convenient for his location and operation, allowing full

rotation through north, south or both, if desired. In any

case, 90° overlapping rotation allows rotation through

the selected stopper heading (450° total rotation).

The rotator is intended for mounting inside a support

tower (not supplied), at least 1 meter from the top, with

an optional (Yaesu model GS-065 or GS-680U) thrust

bearing above.

The G-800SA and G-1000SA includes one mast clamp

and related hardware, plus plug connectors for both the

rotator and controller. A six conductor cable of the necessary length must be supplied by the owner.

Please read this manual through carefully before installing the rotator, to acquaint yourself with the procedures

that will be required, and to ensure that you have all necessary items for your installation.

G-800SA/G-1000SA User Manual Page 1

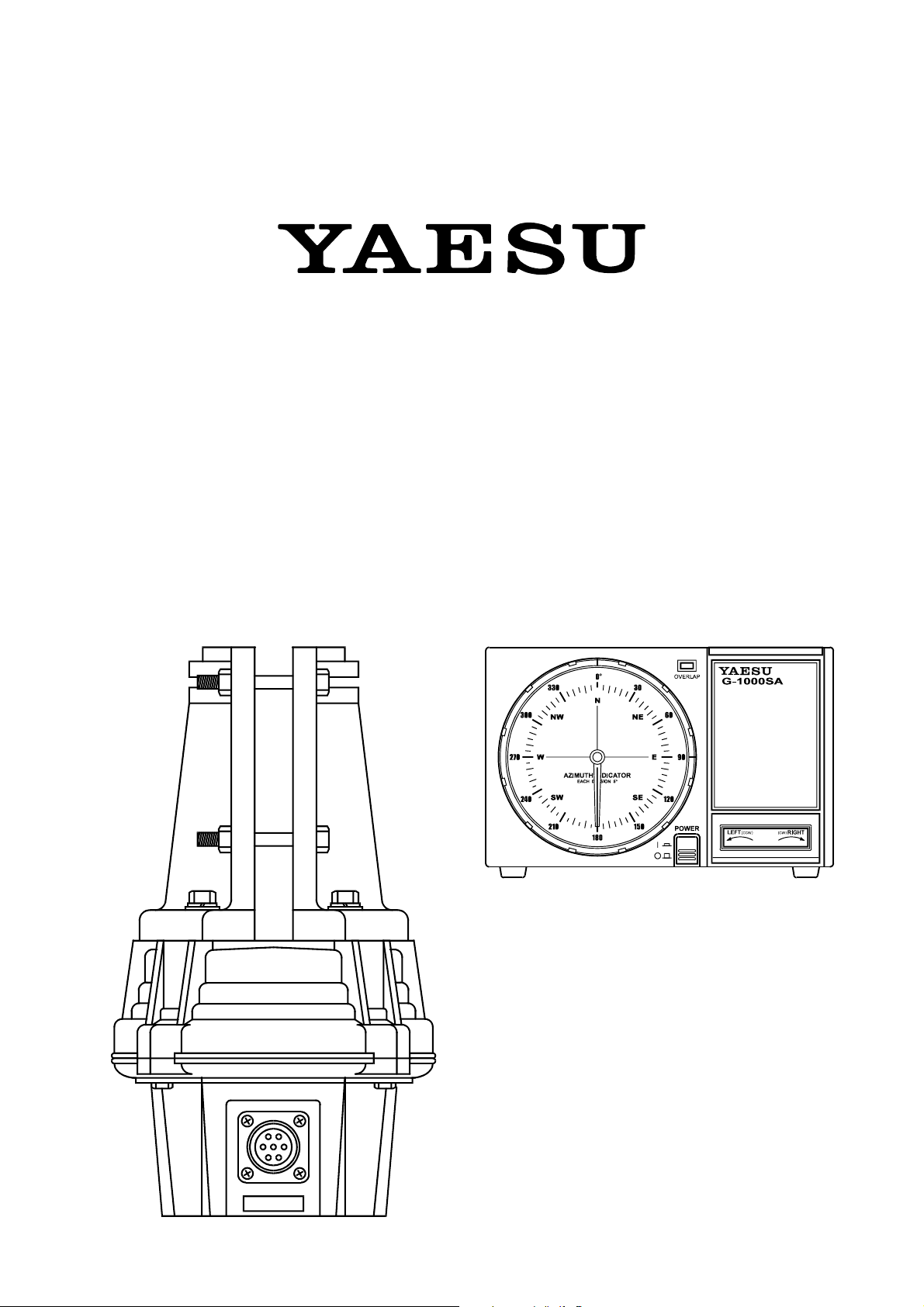

Controller Switches & Controls

FRONT PANEL REAR PANEL

POWER Switch

Press this switch to turn the controller on to rotate

the antenna. Turn it off when the rotator is not in

use.

LEFT/RIGHT Seesaw Switch

Press the LEFT side of this switch to rotate the antenna counter-clockwise (CCW). Press the RIGHT

side to rotate the antenna clockwise (CW).

OVERLAP Indicator

This red LED glows when the antenna is rotated

beyond about 180° (to 270°) from its original installation direction (180°). Check this indicator before rotating the antenna clockwise, and turn the

antenna counter-clockwise to the desired position if

the indicator is on.

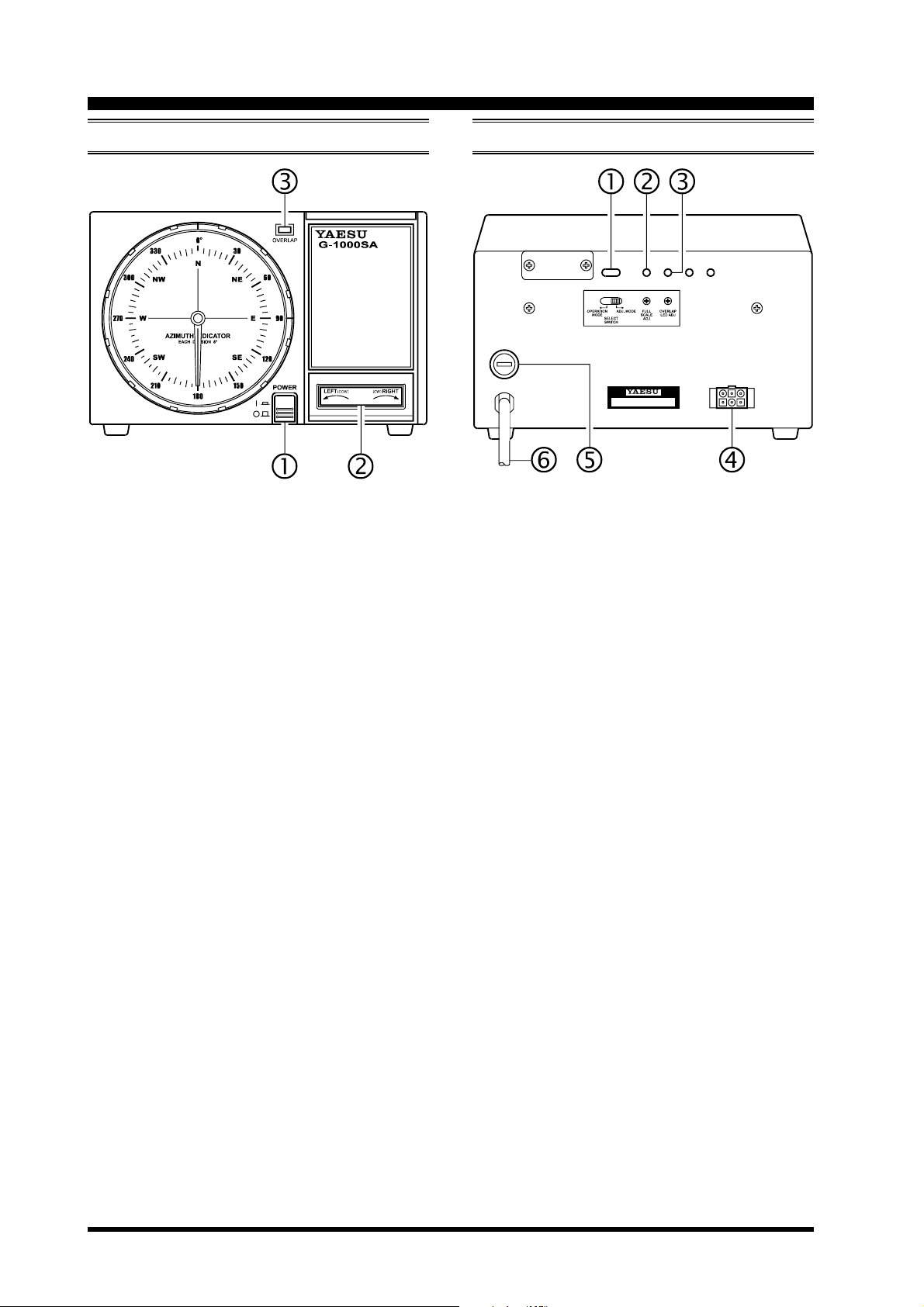

SELECT SWITCH

Set this switch to the “ADJ. MODE” position while

calibrating the internal adjustments of the controller. During normal operation, however, set this switch

to the “OPERATION MODE” position.

FULL SCALE ADJ Potentiometer

This control calibrates the maximum rotation angle

(range) of the azimuth indicating needle to match

the maximum angle of the rotator.

OVERLAP LED ADJ Potentiometer

This control calibrates the OVERLAP Indicator to

match the azimuth indicating needle.

Rotator Control Cable Jack

The supplied control cable from the rotator connects

to this 6-pin jack.

FUSE Holder

This holder requires a 2-A fuse for 117V AC. If the

fuse is blown, replace only with a fuse of the same

rating.

AC Cable

Connect this cable to the 117V AC wall outlet.

G-800SA/G-1000SA User ManualPage 2

Antenna Considerations

The types of antennas that can be attached to this product differ widely, depending on the installation method, local

terrain, and the maximum expected wind speeds at your location.

The following pages described typical antennas which are acceptable for installation with the G-800SA or G-1000SA.

The discussion below assumes maximum wind speeds of 30 meters per second, and it is recommended that you include

a safety margin of at least 40% to account for higher wind gusts or other factors which might potentially cause

damage to your installation.

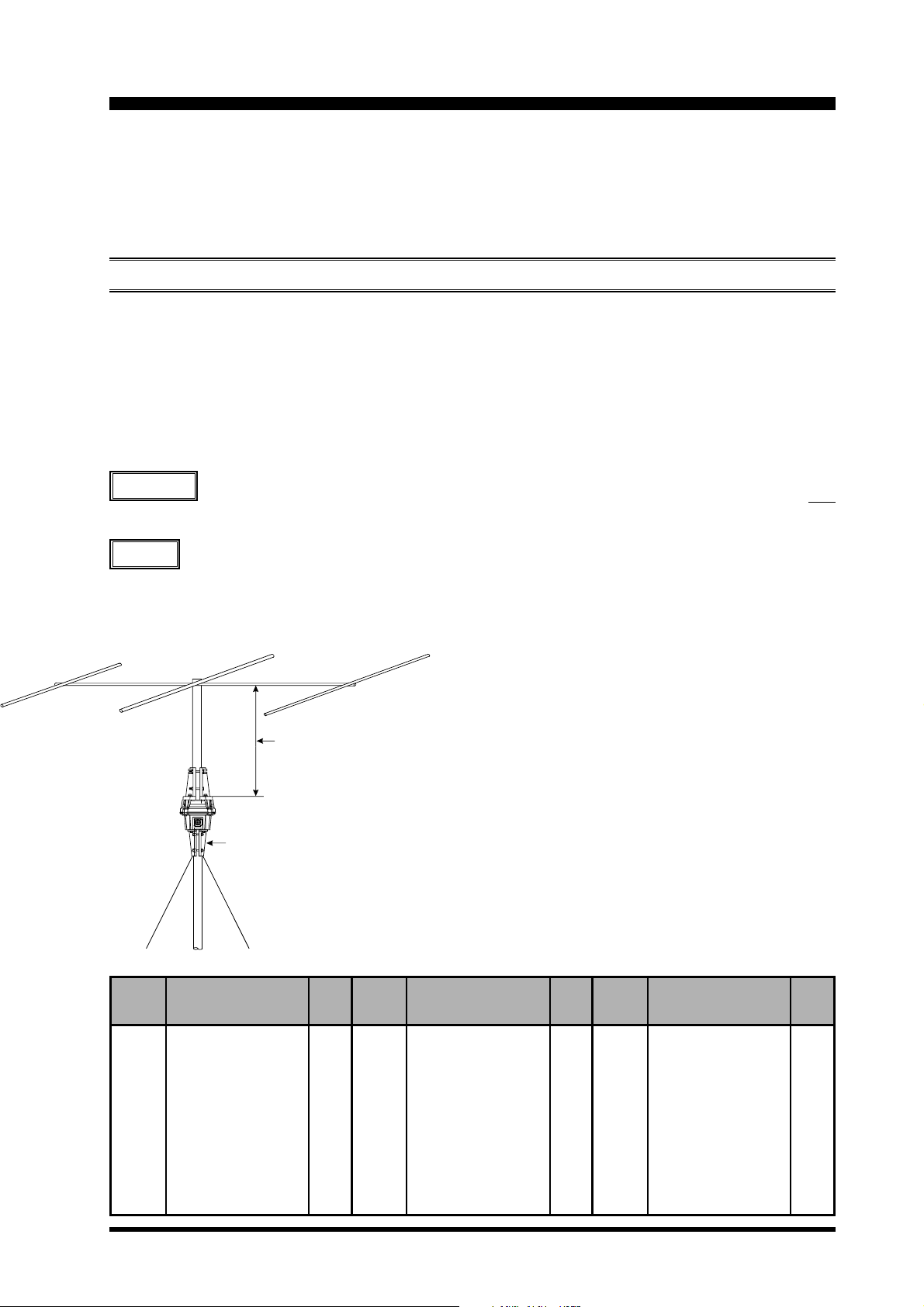

POLE-MOUNTED ANTENNAS

Mounting of the rotator on a pole or mast results in a significant de-rating of the size of the antenna which can be

mounted, due to the tremendous bending forces applied to the rotator’s clamps. For pole mounting, the product of

multiplying the [Antenna Wind Load Area (in m2)] by the [Height of the Antenna Mast (in m)] must be less than 0.45.

See below Table and Figure.

[

Antenna Wind Load Area

] x [

Height of Antenna Mast] = 0.45

Refer to the antenna manufacturer’s specification sheet for determining the weight and the surface area of the proposed

antenna.

Example

For a 14 MHz 3-element Yagi of Surface area of 0.7 m2 (see Table 1), the above specifications for pole

mounting will be met if the antenna is mounted on a mast not longer than 0.3 m (0.7 m2 x 0.3 m = 0.21

< 0.27 [0.45 x 40% safety margin].

Advice

We recommend that your antennas/mast should not exceed 60% of the maximum rating, to ensure a

safety margin.

Less than 0.3m

Optional Mast Clamp GC-038

Example of a 14 MHz Band, 3-Element Yagi Antenna

Wind Loading Areas for Common Antennas (Typical)

Band

(MHz)

7

7

7

7

14

14

14

21

21

21

21

21

Elements

2-element

1-element, w/loading coi ls

2-element, w/loading coi ls

3-element, w/loading coi ls

3-element

4-element

5-element

3-element

4-element

5-element

6-element

2-element, Swiss Quad

Area

(m

2.2

0.2

0.6

1.1

0.7

1.2

1.7

0.45

0.6

0.8

1.3

0.3

2

)

Band

(MHz)

28

28

28

28

7/14

7/14

14/21

14/21

21/28

21/28

14/21/28

14/21/28

Elements

3-element

4-element

5-element

2-element, Swiss Quad

3-element, trapped

4-element, trapped

3-element, trapped

4-element, trapped

3-element, trapped

4-element, trapped

3-element, trapped

4-element, trapped

Area

(m

0.3

0.42

0.6

0.3

0.5

0.8

0.4

0.5

0.3

0.4

0.4

0.5

2

)

Band

(MHz)

50

50

50

50

14 4

14 4

14 4

14 4

43 0

43 0

43 0

43 0

Elements

4-element

5-element

6-element

2-element, Swiss Quad

10 - ele me nt

10-elem en t, s tacked

10-element, x 4

10-element, x 4 x 2

12 - ele me nt

12-elem en t, s tacked

12-element, x 4

12-element, x 4 x 2

Area

(m

0.25

0.3

0.37

0.3

0.2

0.44

0.95

2.0

0.06

0.12

0.3

0.6

2

)

G-800SA/G-1000SA User Manual Page 3

Loading...

Loading...