Page 1

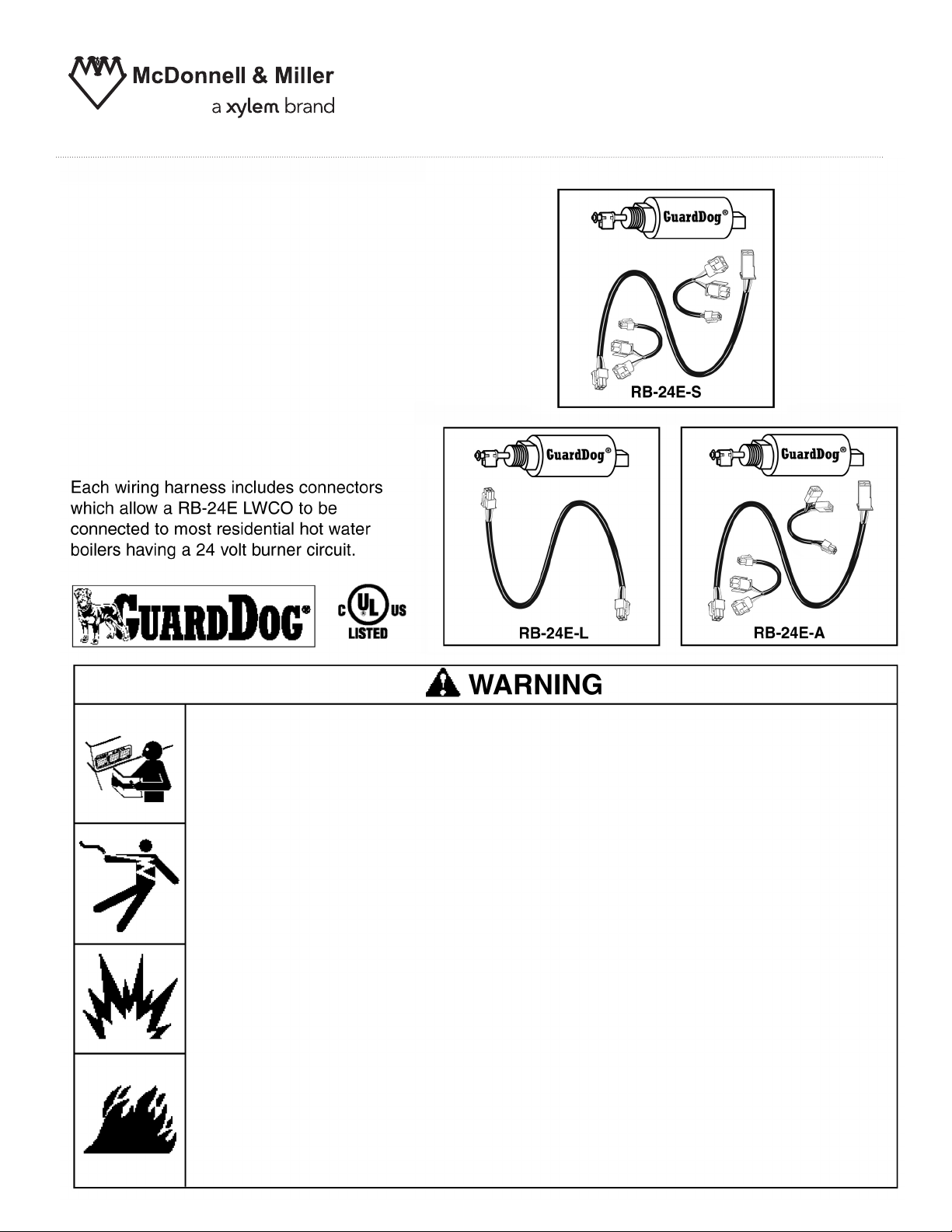

Model RB-24E-S

Model RB-24E-A

Model RB-24E-L

Conductance Type

Low Water Cut-Off

with Universal Wiring Harness

For Residential

24 VAC Hot Water Boilers

INSTRUCTION MANUAL

MM-277G

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam,hot water and electrical equipment and/or

systems in accordance with all applicable codes and ordinances.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls

installed on the boiler. After installation, check for proper operation of all of the operating

controls, before leaving the site.

• We recommend that secondary (redundant) Low Water Cut-Off controls be installed on all

steam boilers with heat input greater than 400,000 BTU/hour.At least two controls should

be connected in series with the burner

should the boiler experience a

low water cut-offs should be

calibration and performance.

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to follow this warning could cause property damage, personal inj ury or death.

CAUTION:

•

A more frequent replacement interval may be necessary based on the condition of

the unit at time of inspection. McDonnell & Miller s warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

low-water condition. Moreover, at each annual outage, the

dismantled, inspected, cleaned, and checked for proper

!

control circuit to provide safety redundancy protection

&

'

Page 2

OPERATION

The Model RB-24E Low Water Cut-Off is specifically designed to provide burner cut-off if there is

an unsafe water

or

ken

tion

Water/glycol

may be used.

leaking radiator or pipe, or a cracked sec-

in

the boiler.

loss, which can result from a bro-

mixtures up to 50% concentration

SPECIFICATIONS

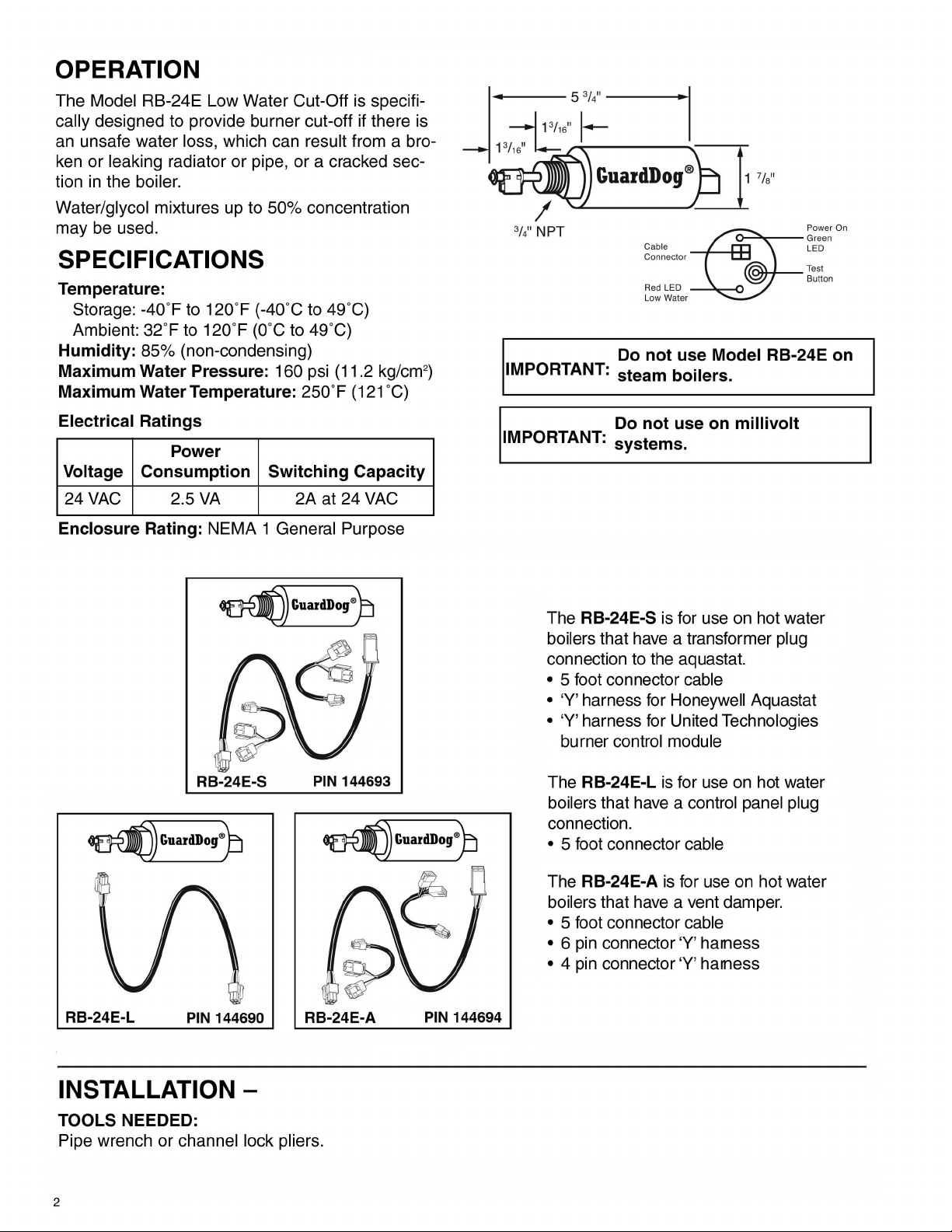

Temperature:

Storage: -40'F to 120'F (-40'C to 49'

Ambient: 32'F to 120'F (O'C to 49'C)

Humidity:

Maximum Water Pressure:

Maximum Water Temperature:

85% (non-condensing)

160 psi (11.2 kg/cm2)

250' F

C)

(121 'C)

3//

NPT

IMPORTANT: steam boilers.

Cable LED

Connector

=e;;=

R

ed

LED

Low Water

Do not use Model RB-24E on

On

~

~:ee

~

Test

Button

Electrical Ratings

Power

Voltage Consumption Switching Capacity

24VAC

Enclosure Rating:

2.5

VA

NEMA 1 General Purpose

RB-24E-S

2A at 24 VAC

PIN 144693

Do not use on

IMPORTANT:

The

boilers that have a transformer plug

connection to the aquastat.

• 5 foot connector cable

•

'V' harness for Honeywell Aquastat

• 'V' harness for United Technologies

burner control module

The

boilers that have a control panel plug

connection.

• 5 foot connector cable

systems.

RB-24E-S

RB-24E-L

is

for use on hot water

is

for use on hot water

millivolt

RB-24E-L

PIN 144690

INSTALLATION -

TOOLS NEEDED:

Pipe wrench or channel lock pliers.

2

RB-24E-A

PIN 144694

is

RB-24E-A

The

boilers that have a vent damper.

• 5 foot connector cable

•

6 pin connector 'V' hamess

• 4 pin connector 'V' hamess

for use on hot water

Page 3

STEP 1 - Electrical Wiring Options

A

'"'

.

~

",

~

To

prevent electrical shock,

•

This

low

the

water

boiler.

leaving

to

follow

After

•

on

before

Failure

cut-off

installation,

the

site.

this

warning

must

turn

be

could

off

the

installed

check

for

cause

electrical

a

WARNING

power

in

series

proper

property

with

operation

damage,

before making electrical

all

other

limit

and

of

all

of

personal

the

injury

operating

limit

connections.

controls

and

operating

or

death.

installed

controls,

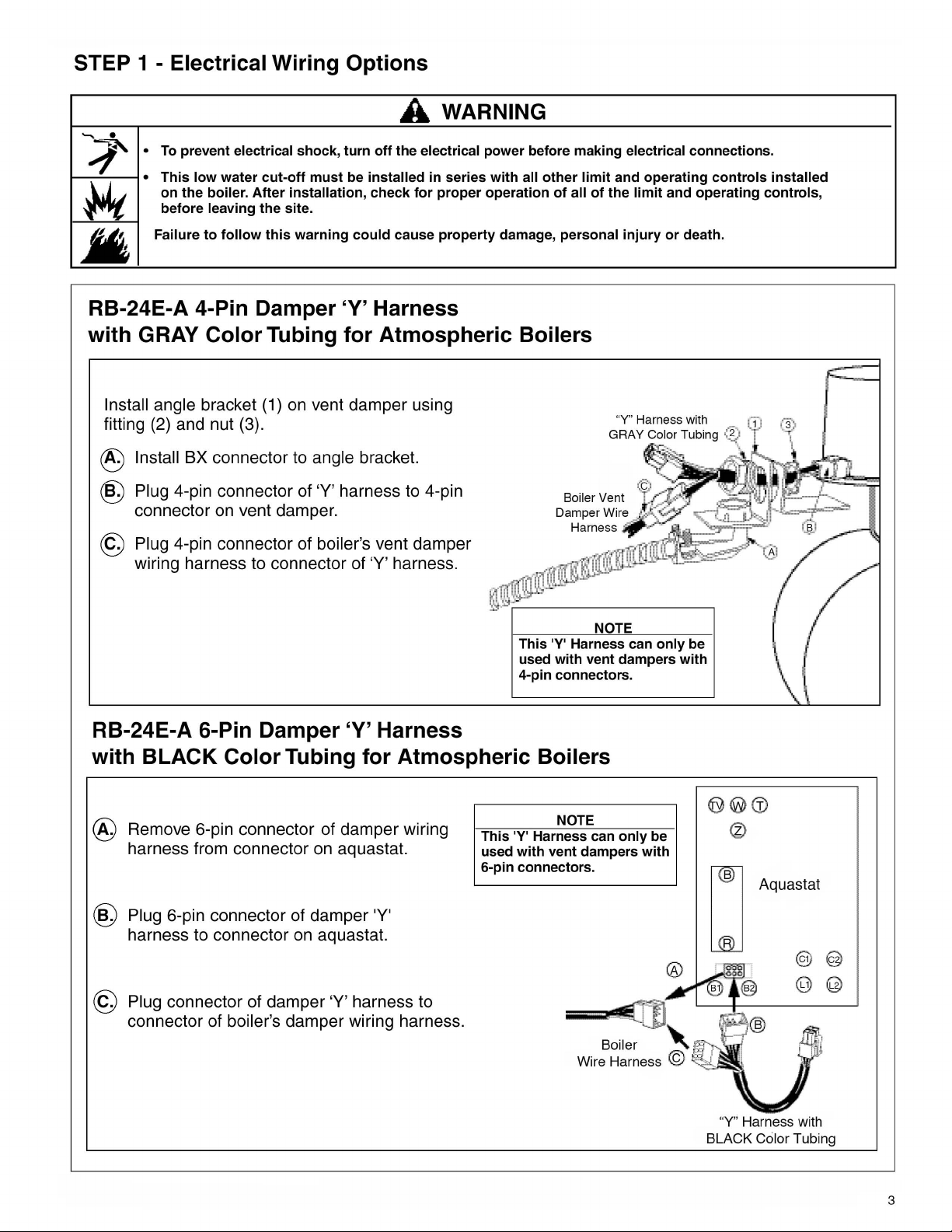

RB-24E-A 4-Pin Damper

with GRAY

Install angle bracket (1)

Color Tubing for Atmospheric Boilers

on

vent damper using

Harness

'Y'

fitting (2) and nut (3).

®

Install BX connector to angle bracket.

®

Plug 4-pin connector of 'Y' harness to 4-pin

connector

@

Plug 4-pin connector of boiler's vent damper

on

vent damper.

Boiler Vent

Damper Wire

Harness ·

wiring harness to connector of 'Y' harness.

NOTE

This

'Y' Harness can

with

vent

RB-24E-A 6-Pin Damper

Harness

'Y'

used

4-pin connectors.

with BLACK Color Tubing for Atmospheric Boilers

"Y" Harness with -

GRAY Color Tubing

..

~

only

dampers

~

with

be

.

~~I

~

..

If

Remove 6-pin connector of damper wiring

®

harness from connector

®

Plug 6-pin connector of damper 'Y'

harness to connector

©

Plug connector of damper 'Y' harness to

connector of

boiler's damper wiring harness.

on

on

aquastat.

aquastat.

NOTE

'Y'

This

used

6-pin connectors.

Harness can

with

vent

dampers

only

be

with

Aquastat

"Y" Harness

BLACK

Ceilor

with

Tubing

3

Page 4

STEP 1 - Electrical Wiring Options (continued)

RB-24E-S Transformer ‘Y’ Harness

with BLUE Color Tubing

A. Remove connector of boiler wiring

harness from boiler control transformer

connector.

B. Plug connector of boiler wiring harness to

connector of ‘Y’ harness with BLUE color

tubing.

C. Plug connector of ‘Y’ harness with BLUE

color tubing to boiler control transformer

connector.

Burner will not operate and

RB-24E red LED will blink if

wrong ‘Y’ harness is used.

NOTE

RB-24E-S Transformer ‘Y’ Harness

with GREEN Color Tubing

A. Remove connector of boiler wiring

harness from Aquastat transformer

connector.

B. Plug connector of boiler wiring

harness to connector of ‘Y’ harness with

GREEN color tubing.

C. Plug connector of ‘Y’ harness with GREEN

color tubing to Aquastat transformer

connector.

NOTE

Burner will not operate and

RB-24E red LED will blink if

wrong “Y” harness is used.

Page 5

RB-24E-L Connector

with Gray

a. Remove jumper plug from plug-in connector

on

control panel.

b. Plug connector of wiring harness into plug-in Connector

on

control panel.

Color Tubing for Control Panel Connection

o

locilinvar Knight

Control

Pane

So

l

o

il@r

5

Page 6

STEP 2 - Installing the Low Water Cut-Off

Determine where

If tappings are provided

1.

control must

minimum safe water

boiler manufacturer. If

safe water level

to

install the probe control based

on

the boiler, the probe

be

installed

in

a tapping above the probe control can

level, as specified

no

specified minimum Typical Installation Diagrams below.

is

designated, contact the

by

boiler manufacturer.

For all Application:

1. Make sure probe is installed above minimum

safe water line as determined by the boiler

TYPICAL INSTALLATIONS

manufacturer.

On

the

Boiler

2. Make sure that ends and side of the probe

(RECOMMENDED)

are at least 1/4 (6.4mm) from all internal

metal surfaces.

314

' (2

Omm) NP

Tappi

ng

~

Model RB -24 E

Low Water

Gul-oH

T

. _

.,

I

"

m

~

----

~~-

Hot Water

Minimum

Safe

Waler Level

(as

determined

by

OOilill'

the

manufacturer)

Boil

er

on

the following requirements:

2.

If

no

tapping

is

provided

be

on

installed

the boiler, the

in

a header or

the riser pipe above the boiler. Refer to the

NOTE

Make

sure

RB-24E

than

4 ft.)

to

be

connected.

In a Pipe Tee

Above

the

Optional

Isolation

Val\l~

(MUSIOO

inslaUed

above too)

A

1/4"

E

(6mm)

burner

Boiler

-

is

located

control

--I-+-H--I

To

close

so

the

System

t

,

C0

enough

harness

Circulating

/

Pump

314'

/

P1peToo

......

Hot

(no

can

(2

Omm)

NPT

RB

I>Jl<xlel

Low

Wate

Cut-off

Mjnirn~lm

Wat€rLevei

(as

by the bolter

mamlfacturer)

WalQf

r

Safe

determined

BolIQf

more

-24E

STEP 3 - Installing the Low Water Cut-Off

a.

Sparingly, apply pipe sealant to the external threads

of the probe(A}.

IMPORTANT:

Do

not use PTFE tape. Only use pipe sealant.

1

(D)

1/4"

(6mm)

Page 7

STEP 4 - Testing

a.

Before filling the system, turn

boiler. The low water cut-off's green "Power On" LED

should

"heat:' confirm that the burner

water

should

NOTE:

and then shut off to verify proper operation.

be

illuminated. With the room thermostat set

in

the system. The low water cut-off's

be

illuminated.

The burner will come

on

the electric power to the

will

not

operate without

red

on

briefly

(1

second or less)

on

LED

Fill the system with water. When water

b.

probe, the

low water cut-off's

red

LED

should turn

is

just above the

c. Check and confirm that the boiler's thermostat, burner and

safety

before

Check the threaded connection of the low water cut-off for

d.

limits are operating properly after filling system and

leaving the site.

leakage. Tighten, if necessary.

Testing Control Using "Test

Pressing the "Test

a.

Press and hold "test button" while burner

b. The burner

c. Release the test button and the

provided that the boiler water

Button"

interrupts

should turn OFF and

Button"

the probe

red

red

light should turn off and the boiler should turn

in

contact with the probe.

circuit

is

running.

light turn

ON

INSTALLATION COMPLETE

off.

which

if burner

Cable

Connector

Red LED

Low Water

simulates water

is

wired correctly.

o-....."",.~--

__

~I-+-

off

the probe.

on

Power

Green

LED

Test

Button

On

Page 8

TROUBLESHOOTING:

If

control

1. Check to

2. Re-check all wiring to ensure proper connections as specified

wiring diagrams.

3. Check to ensure that tape has not been used

the boiler.

4. Check the quality of the boiler water to ensure adequate conductance.

fails

to

operate, perform the

be

sure that the water level

following

in

the boiler is at or above the level of the probe.

diagnostic

on

the threaded connection of the probe to

checks.

in

boiler manufacturers

Boiler

• Turn off boiler and check boiler wiring connections.

• Turn off boiler, drain boiler and remove control to check if the tip of the probe

Boiler

• Make sure water is above the level of the probe.

• Make sure probe is installed

• Check boiler wiring connections.

Boiler

• Problem is wrong transformer 'V' harness.

• Turn off boiler and install correct transformer 'V' harness .

Does Not Turn

a metal surface.

Does Not Turn

Does Not Turn

Off

(when water

is

ON

in

a location where

ON

and RB-24E Red LED

below probe)

an

blinking

air pocket cannot develop.

MAINTENANCE

SCHEDULE:

• Test the

• Remove and

• Replace the

low

water

inspect

low

water

cut-off

annually

or

more frequently.

the self-cleaning probe every 5 years.

cut-off

every 15 years.

is

touching

NOTE

Clean probe by wiping with non-abrasive cloth and rinsing with clean water.

use sharp instruments

Replace Probe if:

PTFE

•

• Probe is loose.

Failure

insulator is cracked or worn.

to

foII owthis caution could cause

xylem

Let's Solve

to

Water

remove any accumulations

A

CAUTION

prope

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-277G July 2013 Part No. 210589

of

rust or scale.

damage, personal injury

rty

DO

or

NOT

death.

Loading...

Loading...