Page 1

Model 750-HW-MT-120

5-1/2"

M

odel

7

5

0

-

HW

-MT

-

12

0

P

r

ob

e

T

y

pe

H

i

gh

W

a

t

er

Con

t

r

o

l

Uni

t

Probe Type High Water

Manual Reset Control Unit

Applications:

Conductance type control for steam boilers

when a manual reset high water alarm or

cut-off is required.

INSTRUCTION MANUAL

MM-273E

Model 750-HW-MT-120

Control Unit

!

WARNING

• Before using product, read and understand instructions.

N

O

I

T

U

CA

G

IN

N

R

WA

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation,

and maintenance of plumbing and electrical equipment and/or systems in accordance with all

applicable codes and ordinances.

• Boiler manufacturer schematics should always be followed. In the event that the boiler

manufacturer’s schematic does not exist, or is not available from the boiler manufacturer,

refer to the schematics provided in this document.

• To prevent serious burns, allow the control and surrounding equipment to cool to 80˚F (27˚C)

and allow pressure to release to 0 psi (0 bar) before servicing.

• To prevent an electrical fire or equipment damage, electrical wiring insulation must have a

rating of 167˚F (75˚C) if the liquid's temperature exceeds 180˚F (82˚C).

• This control can be installed in series with all other limit and operating controls installed

on the boiler. After installation, check for proper operation of all the limit and operating

controls, before leaving the site.

• When using mixed voltages, do not jumper from terminal 1 to terminal 3.

• To prevent electrocution, when the electrical power is connected to the control, do not touch

the terminals, or electrical wires.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

•

California Proposition 65 warning! This product contains chemicals known to the

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

Failure to fo

llow this warning could cause property damage, personal injury or death.

CAUTION:

A more frequent replacement interval may be necessary based on the condition of

•

the unit at time of inspection. McDonnell & Miller's warranty is one (1) year from date

of installation or two (2) years from the date of manufacture.

Page 2

SPECIFICATIONS

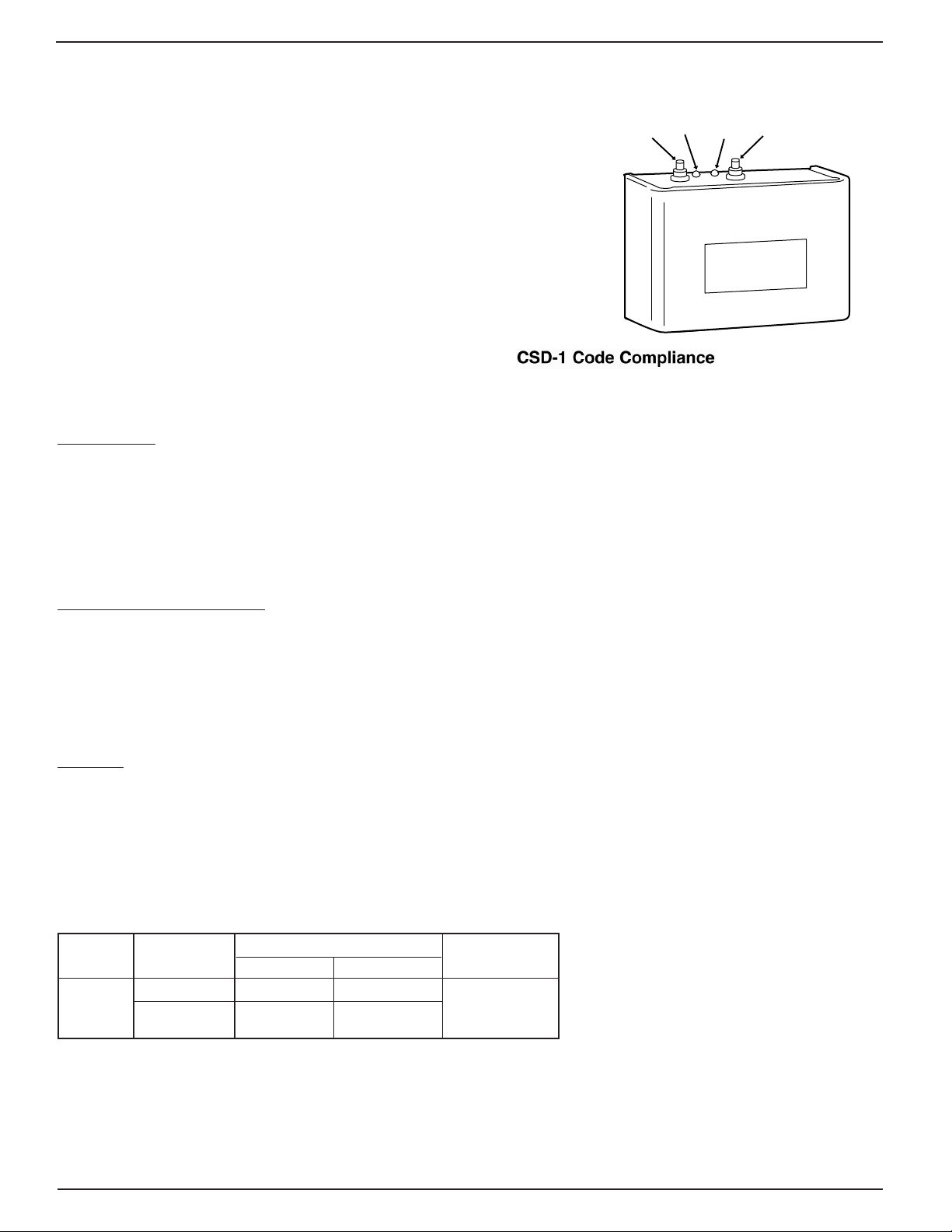

The Model 750-HW-MT-120 control provides continuous protection

against a high water condition in steam boilers. It can be used to

interrupt the burner circuit to turn off the burner, interrupt the

feedwater pump circuit to turn off the pump, or both. The control

can also be used to provide an alarm (light, horn or both) when a

high water condition occurs. The manual reset function will require

that the unit be reset after water has dropped below the level of

the probe.

Manual Reset

If a high water condition occurs (water is on the probe),

the Burner will turn Off. The Manual Reset button must

be pressed to make the control back to function after the

water level drops below the probe.

Control Unit

Temperature Ratings:

Storage: -40˚F to 135˚F (-40˚C to 57˚C)

Ambient: 32˚F to 120˚F (0˚C to 49˚C)

On Manual Reset Units, if the control is in high water

condition (water reaches the probe) and there is an

interruption of electric power, the Burner will remain off

even if power is restored. The Reset button must be

depressed to make the control back to function after

the water level drops below the probe.

T

est

Green

Power On

R

ed

High

Water

75

Model

Type

robe

P

5-1/2"

ontr

C

Reset Button

-

T

HW-M

0-

Water

igh

H

l Unit

o

120

Humidity: 85% (non-condensing)

Electrical Enclosure Rating: NEMA 1 General Purpose

RS-1-BR1 Remote Sensor

Maximum Steam Pressure: 250 psi (17.6 kg/cm2)

Maximum Water Pressure: 250 psi (17.6 kg/cm

2

)

Maximum Water Temperature: 406˚F (208˚C)

Electrical Enclosure Rating: NEMA 4X Watertight,

Corrosion Resistant

Connection Size: 1” NPT

RS-1-LP

Maximum Steam Pressure: 15 psi (1.0 kg/cm2)

2

Maximum Water Pressure: 160 psi (11.2 kg/cm

)

Maximum Water Temperature: 250˚F (121˚C)

Electrical Enclosure Rating: NEMA 1 General Purpose

Connection Size: 3/4” NPT

Electrical Specifications

Motor Switch Rating (Amperes)

Model Voltage Full Load Locked Rotor Pilot Duty

120 VAC

120 VAC 7.2 43.2

240 VAC 3.6 21.6

125 VA at

120 or 240 VAC

50 or 60 Hz

Control Voltage: 120 VAC

Hz: 50/60

Control Power Consumption: 3 VA (max.)

Probe Sensitivity: 20,000 ohm

2

Page 3

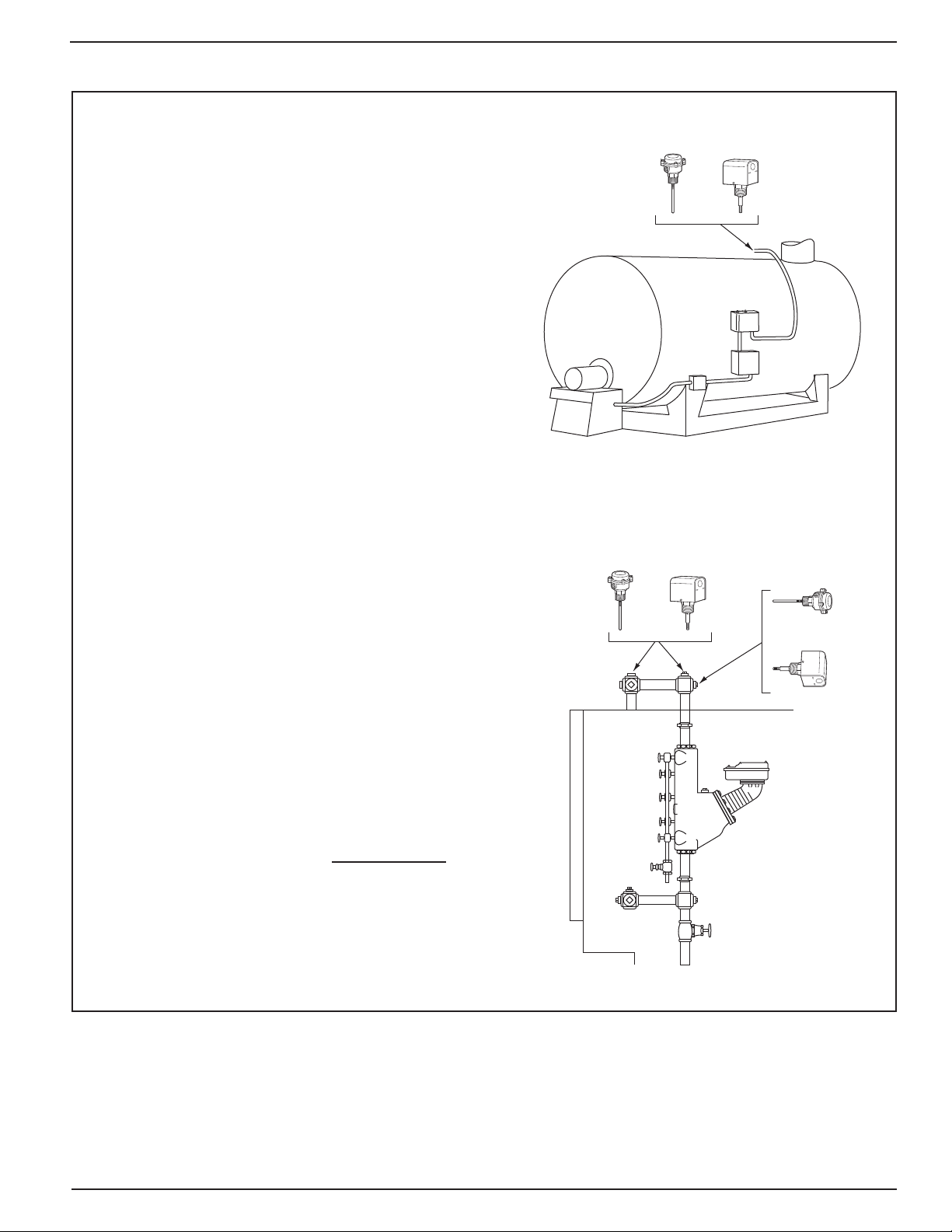

STEP 1 - Where to Install the Remote Sensors

o

r

or

or

Upright or Vertical

Position

Sideways or Horziontal

Position

Determine where to install the remote sensor (sold separately) based on the following requirements:

Option A

a. The Remote Sensor can be installed directly in a 1"

or larger tapping in the top of the boiler.

b. The probe of the RS-1-BR-1 Remote Sensor will

need to be cut to appropriate length based upon the

level where high water cutoff/alarm is desired.

c. The probe of the RS-1-LP Remote Sensor is

approximately 2" long therefore high water

cutoff/alarm will occur at that level.

d. There must be a minimum 1/4" (6.4mm) clearance

between the probe and any grounding surface inside

the boiler or pipe.

Option B

a. The Remote Sensor can be installed directly into the

1" fittings of the boiler’s equalizing piping.

b. If installed in the upright or vertical position:

• The probe of the RS-1-BR-1 Remote Sensor will

need to be cut to appropriate length based upon

the level where high water cutoff/alarm is desired.

• The probe of the RS-1-LP Remote Sensor is

approximately 2" long therefore high water

cutoff/alarm will occur at that level.

c. If installed in the sideways or horizontal position:

• The probe of the RS-1-BR-1 Remote Sensor

cannot exceed 4" in length.

NOTE: The Remote Sensors SHOULD NOT be

installed in equalizing piping that is smaller than

1" NPT.

d. There must be a minimum 1/4" (6.4mm) clearance

between the probe and any grounding surface

inside the boiler or pipe.

3

Page 4

STEP 2 - Installing the Remote Sensor

For the Model RS-1-BR-1 sensors, only:

a. Cut the probe (purchased separately) to desired length.

Screw, clockwise, the threaded stainless steel probe

extension (A) into the remote sensor (B). Carefully tighten

the locking nut to approximately 1 ft•lb (1.7 N•m). Do not

cut the clear plastic protective tube.

For All Remote Sensors

b. Apply a small amount of pipe dope to the first

threads (L) of the remote sensor.

B

A

IMPORTANT: Do not use PTFE tape or thread

sealant.

c. Insert the remote sensor (B) into the boiler

tapping (M) as determined in Step 1.

d. Using a wrench (N), tighten the brass hex

adapter (P) on the remote sensor (B) to

approximately 63 ft•lb (85 N•m). DO NOT

TIGHTEN BY TURNING THE SENSOR

HOUSING.

B

B

1/4" MIN. (6.4 mm)

P

OR

L

L

M

1/4" MIN. (6.4 mm)

N

4

Page 5

STEP 3 - Installing the Control Box

a. Using the flatblade screwdriver or nut driver (C),

loosen the two (2) screws (D) and remove

cover (E).

IMPORTANT: To protect control from damage

caused by liquid or debris, mount as shown with

buttons on top.

D

x2)

(

M

od

e

l 7

5

0

-

HW-

MT

-1

2

0

Pr

o

be

T

yp

Co

ntr

e

Hig

h

Wa

te

r

o

l Un

it

E

C

b. Using the four (4) 3/16" (4.8mm) mounting

holes (F), attach the control (G) to the boiler

jacket, entry plate, or other suitable location.

NOTE: Mounting hardware is not included.

STEP 4 - Electrical Wiring

IMPORTANT

!

Boiler manufacturer schematics should always be

followed. In the event that the boiler manufacturer’s

schematic does not exist, or is not available from

the boiler manufacturer, refer to the schematics

provided in this document.

• Mount Control Box in a suitable location near

the boiler’s main electrical panel.

NOTE

Boiler sight glass must be visible from location of

Control Box and must be within 25 feet of Control

Body.

GND

F

(x4)

WARNING

!

To prevent an electrical fire or equipment damage,

electrical wiring must have a rating of 167˚F (75˚C) if the

liquid's temperature exceeds 180˚F (82˚C).

Failure to follow this warning could cause property

damage, personal injury or death.

PROBE

RS1-BR-1

SENSOR

G

a. Remove the sensor housing cover (Q).

1. For Model RS-1-BR-1, using a flathead

screwdriver (R), remove the four (4) screws

and separate the housing cover (Q) from the

sensor (B).

2. For Model RS-1-LP, using a flathead screw-

driver or nut driver (R), loosen the two (2)

screws and separate the housing cover (Q)

from the sensor (B).

R

Q

B

Model RS-1-BR-1

OR

Q

B

R

Model RS-1-LP

5

Page 6

• Install electrical conduit between Probe

Housing and Control Box.

NOTE

Wire must be 18 AWG stranded with glass braided

silicone jacket (UL 3071) suitable for high

temperature (200˚C) service.

NOTE

Refer to and follow local codes and standards

when selecting conduit and electrical fittings.

Wires from Probe Housing and Control Box must

be in their own conduit. If they are run in conduit

with other wires, there may be interference that

an affect the performance of the control.

c

b. For all wire connections to the terminal block (M).

1. Strip about 1/3" (8.5 mm) of insulation from

the wire.

2. Loosen the terminal screw (N), DO NOT

REMOVE, and move the wire clamping plate

(P) back until the plate touches the back side

of the screw head.

3. Insert the stripped end of the wire under the

wire clamping plate (P) and securely tighten

the terminal screw (N).

RS1-BR-1

SENSOR

N

P

M

Wiring Diagram Legends

1. Bold lines indicate action to be taken in Step shown.

2. Dotted black lines indicate internal wiring.

Remote Sensor Wiring:

• Connect wire from probe end to Terminal

• Connect wire from remote sensor green ground

screw to

Terminal connection "GND" on PCB.

Control Wiring:

• Connect 120V hot wire to terminal 1

• Connect 120V neutral wire to terminal 2

• Connect jumper wire from Terminal 1 to

Terminal 3

• Connect wire from beginning of limit circuit

(thermostat, gas valve, limits, etc.) to terminal 5

• Connect wire from end of limit circuit to terminal 2

connection "PROBE" on PCB.

GND

WHITE

PROBE

1

HOT

2

NEUTRAL

3 4 5

ALARM

Note:

Contact positions shown

with water off probe

Limit Circuit

6

Page 7

c. Secure the sensor housing cover (Q).

1. For model RS-1-BR-1, using the flatblade screw-

driver (R), tighten the four (4) screws into the

housing (Q) to approximately 3 ft•lb (4 N•m).

2. For model RS-1-LP, using the flatblade screw-

driver or nut driver (R), tighten the two (2) screws

into the

housing (Q) to approximately 2 ft•lb (2.6 N•m).

d. Secure the control housing cover by using the

flatblade screwdriver or nut driver (R) to tighten the

two (2) screws (D) to approximately 2 ft•lb (2.6 N•m).

R

Q

R

Q

OR

Model RS-1-BR-1 Model RS-1-LP

D

(x2)

Mo

d

el

7

5

0

-H

W

-M

T

-

1

20

Pro

b

e

T

y

p

e

H

i

g

h

W

a

t

e

r

C

on

trol Uni

t

R

STEP 5 -Testing and Diagnostic Procedures

Start-Up

a. Before filling the system, turn on the electric power to the boiler.

1.

Upon initial power up, the Green and Red lights will flash simultaneously

4 times.

2. The Green light will turn "ON".

3. The Red light will turn "OFF" and the burner will turn “ON” as long

as there is water off the probe.

Test

Green

Power On

Manually Testing Control

b. Slowly fill the boiler with water.

1. When water touches the probe, the Green light will remain "ON".

2. The Red light will turn “ON” and the burner will turn “OFF”, when

water touches the probe.

Testing Control Using "Test Button"

c. Depressing test button with "water off probe”

(Must depress and hold test button to activate test cycle.)

1. When test cycle is activated the Red and Green lights will flash simultaneously

2. The Red light will turn "ON".

3. Burner will turn "OFF".

4. The Green light while the test button is depressed.

(Release test button. You must depress the manual reset button to unlock the high water cut-off.)

5. After depressing manual reset button, the Green and Red lights will flash simultaneously 4 times.

6. Then the Green light will turn "ON" and the Red light will turn "OFF".

7. The burner will turn "ON" if

stays "ON"

the water is off the probe.

twice.

Red

High

Water

el

d

Mo

be Type High

o

Pr

5-1/2"

50-HW-MT-1

7

ntrol U

o

C

Reset Button

0

2

r

e

t

a

W

it

n

7

Page 8

McDonnell & Miller

Troubleshooting

If control fails to operate as required, perform the following diagnostic checks:

1. Check to be sure that the water level in the boiler is below the probe.

2. Re-check all wiring to ensure proper connections as specified in boiler manufacturer’s wiring diagrams

or these instructions.

3. Check to ensure that PTFE tape has not been used on the threaded base of the remote sensor

the boiler.

4. Re-check the electrical ground connection for the remote sensor and control unit.

to

MAINTENANCE

SCHEDULE:

• Inspect probe annually or more frequently for scale build-up and clean or replace if necessary.

Make certain there is no scale or build-up on the probe or its white PTFE insulator. Be careful not to damage

the PTFE insulator.

CAUTION

!

Replace Probe if:

• PTFE insulator is cracked or worn.

• Probe is loose.

Failure to follow this caution could cause property damage, personal injury or death.

• Replace probe every 10 years. More frequent replacement of the probe is required if it is used in locales

where significant water treatment is required, or in applications with high make-up water requirements.

• Replace the control unit every 15 years.

NOTE

Clean probe by wiping with non-abrasive cloth and rinsing with clean water. DO NOT

use sharp instruments to remove any accumulations of rust or scale.

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.mcdonnellmiller.com

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2013 Xylem Inc. MM-273 2013

E

December

Part No.

210564

Loading...

Loading...