Page 1

Replacement Snap Switch Assembly

!

SWA-42S

For Series 42S Low Water Cut-Off/

Pump Controllers (All Models)

INSTRUCTION MANUAL

MM-244B

Replacement Switch Assembly

WARNING

TION

AU

C

G

NIN

R

A

W

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, installation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

• To prevent electrical shock, turn off all sources of electrical power before servicing unit.

• This low water cut-off must be installed in series with all other limit and operating controls

installed on the boiler. After servicing unit, check for proper operation of all of the limit and

operating controls before leaving the site.

• To prevent a fire, do not use this low water cut-off to switch currents over 7.4A, 1/3 Hp at

120 VAC or 3.7A, 1/3 Hp at 240 VAC, unless a starter or relay is used in conjunction with it.

Failure to follow this warning could cause property damage, personal injury or death.

Page 2

Verify that you have the Correct Replacement Switch Assembly Model

IMPORTANT:

• Installation of an incorrect switch-assembly could cause damage to the boiler and/or boiler system.

• Modification of the switch assembly before or after installation could cause damage to the boiler

and/or boiler system.

• Series 42S Replacement Snap Switch Assemblies are not interchangeable with Series 42 Mercury Switch

Replacement Assemblies.

• Series 42S Replacement Snap Switch Assemblies are not interchangeable with Series 150S Snap Switch Replacement

Assemblies, nor with Series 150 Mercury Switch Replacement Assemblies.

For Model Repl. Switch

Model No. Description

42S

42S-A SWA-42S Snap-action

42S-N switch assembly

42S-HD

Model SWA-42S

P/N 310488

2

Page 3

BURNER

ON

BURNER

OFF

NORMAL BOILER

WATER LINE

BURNER

CUT-OFF LEVEL

AT CAST LINE

7/8

" (22mm)

PUMP

OFF

BURNER

OFF

NORMAL BOILER

WATER LINE

BURNER

CUT-OFF LEVEL

AT CAST LINE

1 3/8

" (35mm)

PUMP

OFF

PUMP

ON

NORMAL BOILER

WATER LINE

3/4

" (19mm)

OPERATION

Maximum Pressure: 50 psi (3.5 kg/cm2)

Electrical Ratings

Pump Circuit Rating (Amperes)

Voltage Full Load Locked Rotor Pilot Duty

120 VAC 7.4 44.4

240 VAC 3.7 22.2

345 VA at

120 or 240 VAC

Settings and Differential Pressures

Values are ±1/8” (3.2mm).

Series 42S

Approximate

Distance Above

Cast Line Differential

Pressure

50 psi

(3.5 kg/

cm2)

Setting In. (mm) In. (mm)

Pump Off 1

Pump On

Burner On

3

/8 (35)

5

/8 (16)

7

/8 (22)

3

/4 (19)

7

/8 (22)

Burner Off 0 (0)

Motor Horsepower

Voltage Hp

120 VAC

1/3

240 VAC 1/3

3

Page 4

LOW WATER

CUT-OFF

TERMINALS

BURNER

SWITCH

PUMP

SWITCH

PUMP CIRCUIT

TERMINALS

OFF

ON

A

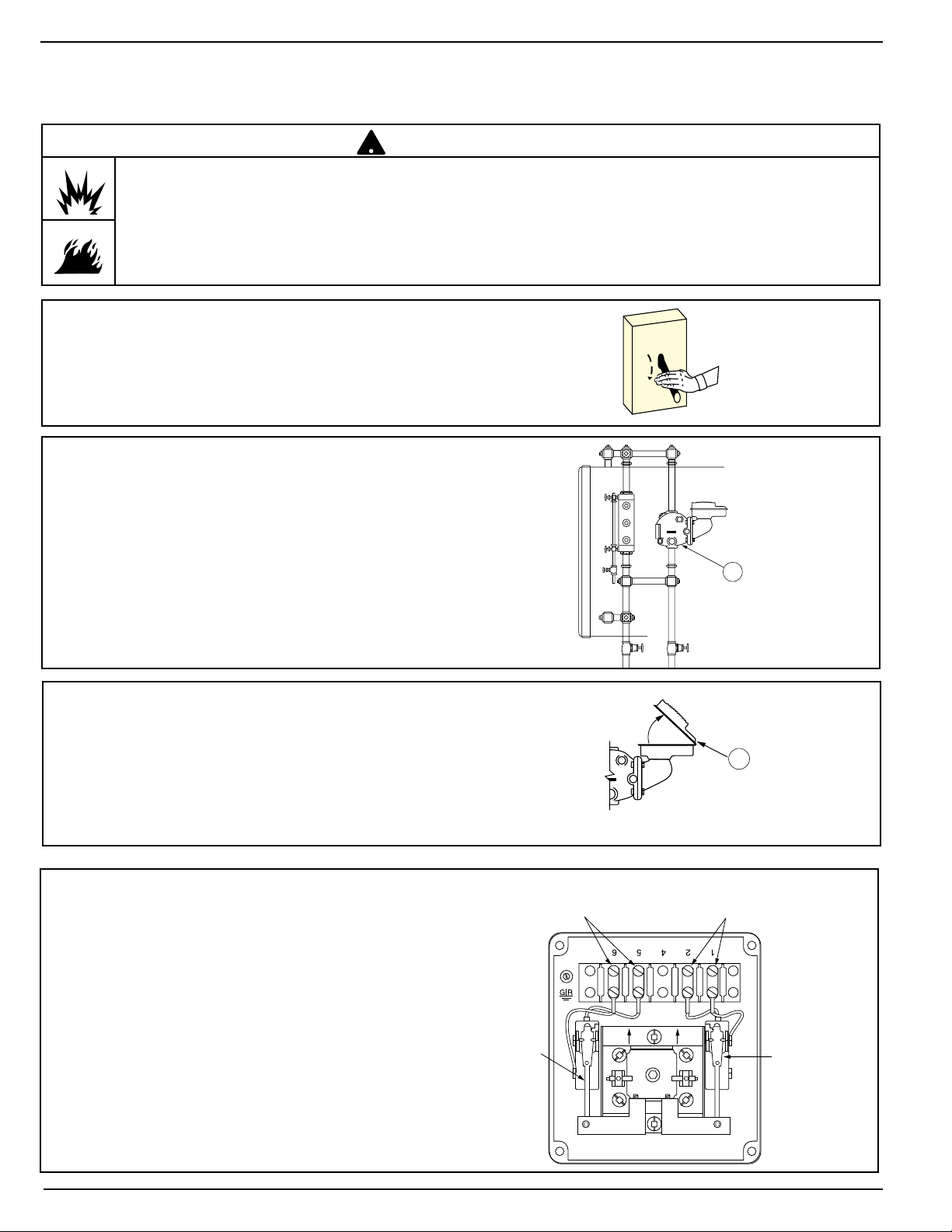

INSTALLATION –

!

SECTION 1 - Switch Bracket Replacement

WARNING

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• This low water cut-off must be installed in series with all other limit and operating controls installed on the

boiler. After installation, check for proper operation of all of the limit and operating controls, before leaving

the site.

Failure to follow this warning could cause electrical shock, an explosion and/or a fire, which could result in

property damage, personal injury or death.

1. Turn the boiler off.

2. Allow the boiler to cool to 80˚F (27˚C) and

release the boiler pressure to 0 psi (0 bar).

Drain water in the boiler to a level which is

below the float chamber (A).

3. Remove the cover (B).

4. Mark and remove the pump switch

and burner/alarm switch wires from

terminal block.

B

4

Page 5

B

A

C

C

Terminal Connection Reference Chart

Product Switch 1 2 4 5 6

2 Wire Blue Orange

42S Pump

2 Wire White Red

Burner

5a. Locate the actuator assembly (A) and the

two fillister head screws (B) which secure

it to the bearing of the control.

b. Clean the inspection lacquer out of the

screw slots in the two fillister head

screws.

c. Remove the two screws holding the actu-

ator assembly in place using a flat head

screwdriver. Remove actuator assembly

and place aside for reinstallation.

Terminal Connection

6. Remove the two Torx®screws (C) holding

the switch bracket assembly in place using

®

a flat head screwdriver or a Torx

T30

wrench.

7. Take the new switch bracket assembly

out of the package and place the bagged

supplies to one side while discarding the

insert.

5

Page 6

C

C

8a. Install the new switch bracket assembly

B

A

LOW WATER

CUT-OFF

TERMINALS

PUMP

SWITCH

BURNER

SWITCH

PUMP

CIRCUIT

TERMINALS

into the junction box in the same orientation as the old switch bracket assembly

(i.e. with arrows on the bracket pointing

toward the terminal block).

b. Secure the new assembly with Torx

®

screws (C) and torque to 80 - 140 in. lb.

(92 - 161 cm. kg.).

9a. Reaffix the actuator assembly using the

two fillister head screws (B) and torque to

30 - 40 in. lb. (34.5 - 46 cm. kg.).

b. Apply a drop of the supplied adhesive to

the threads of each fillister head screw.

10. Reconnect the pump switch and burner/

alarm switch wires to terminal block as

noted when disconnected and torque to

13 - 17 in. lb. ( 15 - 19.5 cm. kg.) (Refer

to "Terminal Connection Chart" on page

5 if unsure of proper switch to terminal

block wire connections).

11. Reattach the cover (B).

B

Proceed with normal operational checks of controls as described in Section 2; “Checking Switch Settings and

Adjusting Switch Setpoints at Operating Pressure”; or Section 3; “Checking Switch Settings at "0" Pressure”.

The pump or burner switch operating points should be within +/- 1/4" of those specified for your control.

6

Page 7

SECTION 2 - Checking Switch Settings and Adjusting Switch Setpoints at

D

3"

(76.2mm)

2"

(50.8mm)

1"

(25.4mm)

Casting

Cut-Off

Line

1"

(25.4mm)

TOP

RULER

LEVEL

Operating Pressure

IMPORTANT: All switches have fixed differentials.

Adjustment of switches referred to in Section 2 and

3 are all based upon Pump Off and Burner Off setpoints. The Pump On and Burner On setpoints are

not adjustable.

1. Cut out the "Switching Level Ruler" (page 11)

along the indicated lines.

We strongly recommend that you check the control at both the operating pressure and at 0 pressure. All boilers start at 0 psi regardless of the oper-

ating pressure.

The operating points will spread out as the pressure

goes up and shrink as the pressure goes down.

3"

(76.2mm)

2"

(50.8mm)

1"

(25.4mm)

Casting

Cut-Off

Line

1"

(25.4mm)

2a. Hold the ruler against the side of the

gauge glass in a position so the “Cast

Line” mark is on the same level as the

Cast Line on the float chamber of the

control (D) (a carpenter's level should be

used to insure the cast line on the float

chamber is at the same level as the one

on the ruler).

b. Once the ruler is properly positioned,

tape it to the gauge glass.

3a. Bring boiler up to normal operating pressure

and turn the pump off.

b. Remove the cover (B).

(Not to Scale. Template

located on page 11).

B

7

Page 8

F

ADD ADHESIVE HERE

BURNER

SET SCREW

BURNER

SWITCH

E

PUMP OFF

PUMP ON

BURNER

CUT-OFF LEVEL

AT CAST LINE

4 - Setting the Operating Points of the Burner Switch

4a. Slowly bring the boiler water level down to

the point at which the burner cuts off. If the

burner does not shut off automatically by the

time the water level reaches 3/8" (9.5mm)

below the cast line on the unit body, shut the

burner off manually.

4b. If the cut-off point does not match the one

shown in chart for the control (page 3) as

measured on the "Switch Level Ruler," using

an awl, dig the inspection lacquer out of the

socket in the set screw (E) above the burner

switch in the actuator assembly.

c. Using an Allen wrench with a 5/64" hex, turn

the screw 1/4 turn:

- clockwise when viewed from top (if the

“Burner Off” point is too high)

- counterclockwise when viewed from top

(if the “Burner Off” point is too low )

4d. Turn the pump back on, allowing the boiler

to fill with water.

4f. Repeat steps a. through d. as necessary to

match the Burner Off point specification for

your model.

8

Page 9

PUMP

ON

PUMP

OFF

BURNER

CUT-OFF LEVEL

AT CAST LINE

H

ADD ADHESIVE HERE

G

PUMP SET SCREW

PUMP SWITCH

PUMP

OFF

PUMP

ON

NORMAL BOILER

WATER LINE

3/4

" (19mm)

5 - Setting the Operating Points of the Pump Switch

5a. Slowly drain the water in the boiler until the

pump turns on. Allow pump to fill the boiler

and observe the point on the ruler where the

water level shuts off.

5b. If the Pump Off point does not match the

one shown in chart for the control (page 3)

and as measured on the "Switching Level

Ruler", dig the inspection lacquer out of the

socket in the set screw (G) above the pump

switch in the actuator assembly using an

awl.

c. Using an Allen wrench with a 5/64" hex, turn

the screw 1/4 turn:

- clockwise (if the “Pump Off” point is too

high when viewed from top)

- counterclockwise (if the “Pump Off” point

is too low when viewed from top)

5d. Slowly drain the water in the boiler until the

pump turns on. Allow pump to fill the boiler

and observe the point on the ruler where

the water level shuts off.

5e. Repeat steps 5a. through d. as necessary

to match the specified Pump Off point specification.

f. Apply one drop of adhesive (furnished) to

the set screw threads (H) above the pump

switch in the actuator assembly.

9

Page 10

RULER

CAST

LINE

LEVEL

3"

(76.2mm)

2"

(50.8mm)

1"

(25.4mm)

Casting

Cut-Off

Line

1"

(25.4mm)

TOP

SECTION 3 - Checking Switch Settings at 0 Pressure

PUMP OFF

PUMP ON

BURNER

CUT-OFF LEVEL

AT CAST LINE

BURNER

ON

BURNER

OFF

NORMAL BOILER

WATER LINE

BURNER

CUT-OFF LEVEL

AT CAST LINE

7/8

" (22mm)

IMPORTANT: All switches have fixed differentials. Adjustment of switches referred to in Sections 2 and 3 are

all based upon Pump Off and Burner Off setpoints. The Pump On and Burner On setpoints are not adjustable.

1. Find the "Switching Level Ruler" on page 11,

and cut it out along the indicated lines.

2. Hold the ruler against the side of the gauge glass

in a position so the Cast Line mark is on the same

level as the cast line on the float chamber of the

control (a carpenter's level should be used to

insure the cast line on the float chamber is on the

same plane as the one on the marker).

3"

(76.2mm)

2"

(50.8mm)

1"

(25.4mm)

Casting

Cut-Off

Line

1"

(25.4mm)

(Not to Scale. Template

located on page 11).

3. Once the marker is properly positioned, tape it to

the gauge glass.

4a. Drain the water level in the boiler until the pump

turns on. Note the level at which the pump turns on

and then turns off. Verify that pump settings are

acceptable.

b. Turn the pump off.

5a. Drain the water level in the boiler until the burner turns

off. Observe the burner off point.

b. Turn the pump back on and observe the Burner On

point as the boiler fills with water. In the case of manual

reset models, try resetting the burner switch as close as

possible to the Burner On point as shown in chart for

the control and as measured on the switch level ruler.

Verify that burner settings are acceptable.

10

Page 11

B

6. Reattach the cover (B).

7. Turn the boiler on.

TOP

3"

(76.2mm)

2"

(50.8mm)

1"

(25.4mm)

Casting

Cut-Off

Line

ON

OFF

CUT HERE

1"

(25.4mm)

Switch Level Ruler

Cut to actual size and attach to piece of

cardboard.

11

Page 12

1) The tissue in plants that brings water upward from the roots;

2) a leading global water technology company.

We’re 12,500 people unified in a common purpose: creating innovative solutions

to meet our world’s water needs. Developing new technologies that will improve

the way water is used, conserved, and re-used in the future is central to our work.

We move, treat, analyze, and return water to the environment, and we help people

use water efficiently, in their homes, buildings, factories and farms. In more than

150 countries, we have strong, long-standing relationships with customers who

know us for our powerful combination of leading product brands and applications

expertise, backed by a legacy of innovation.

Xylem

For more information on how Xylem can help you, go to www.xyleminc.com

Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. MM-244B August 2012 Part No. 210527

Loading...

Loading...