Page 1

INSTRUCTION MANUAL

IM191

Motor Driven: Long-Coupled Models 4E and 6E

Long-Coupled and Close-Coupled Models 2P, 3P, 4P

Marlow Series Prime Line

Self-Priming Centrifugal Pumps

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

®

Page 2

Table of Contents

Section Page

Recommended Precautions ...................................................................................................................................................3

Operating Instructions ...........................................................................................................................................................4

Coupling Alignment ............................................................................................................................................................... 4

Piping .................................................................................................................................................................................... 5

Wiring and Grounding ..........................................................................................................................................................6

Rotation ................................................................................................................................................................................. 6

Impeller Running Clearance ..................................................................................................................................................6

Operation ...............................................................................................................................................................................6

Disassembly ...........................................................................................................................................................................7

Reassembly ............................................................................................................................................................................7

Maintenance ..........................................................................................................................................................................8

Troubleshooting ...................................................................................................................................................................10

Repair Parts ..........................................................................................................................................................................11

Limited Warranty .................................................................................................................................................................. 16

Owner’s Information

Pump Model Number:

Pump Serial Number:

Dealer:

Dealer Telephone Number:

Date of Purchase:

Date of Installation:

2

Page 3

Congratulations

DANGER

WARNING

CAUTION

You are now the owner of a Goulds Water Technology

pump. This pump was carefully inspected and subjected

to final tests before releasing for shipment. In order to

have maximum performance, please follow the simple

instructions in this manual.

Recommended Precautions

1. If there is a possibility of air being entrapped in the

pump casing, install an automatic venting device to

bleed off the air.

2. All electric motors require a magnetic starter with

current over-load protection.

3. Drain casing completely when servicing pump

handling volatile or harmful liquids. SEE CAUTION.

4. Avoid system pressures that may exceed one and

a half times the operating point selected from the

pump performance curve.

5. Should the fluid temperature rise more than 50ºF

above ambient, expansion joints must be installed on

both the suction and discharge ports to relieve any

stress on the pump casing.

6. All electrical wiring of the pump installation must

be done by a licensed electrician who will observe all

national and local electrical codes.

7. No modifications, additions or deletions should be

made to the pump, without prior approval of the

factory.

8. After servicing the pump, always install the coupling

guards and other safety devices as originally found

prior to disassembly.

9. In systems where shock wave pressures may be

generated, protective devices such as check valves/

gate valves etc., must be installed on discharge line

to prevent shock pressures from entering the pump

casing.

10. In systems containing discharge check valves, gate

valves, etc., pump will not prime against a closed

valve. Check the discharge valves making sure they

are open before attempting to prime pump.

11. Overheated pumps are dangerous. Burns or

explosion could occur due to steam pressure.

Operation pumps with suction and discharge closed

is one cause of severe overheating. If over-heating of

pump casing occurs: 1. Stop pump immediately.

2. Allow pump to cool. 3. Slowly and cautiously

vent pump.

12. Do not use in a combustible atmosphere.

13. Make daily checks of the tightness of suction and

discharge pipe, drain, filter plug and pump gaskets.

Operation should not proceed until all of the above

items have been checked and are tight.

14. This pump is designed primarily for water use.

Before pumping other liquids, READ CAREFULLY

THE FOLLOWING WARNING.

WARNING

THE PERFORMANCE OF GOULDS

WATER TECHNOLOGY PUMPS

IS BASED UPON CLEAR, COLD,

FRESH WATER WITH SUCTION

CONDITIONS AS SHOWN ON

THE PERFORMANCE CURVE.

IF USED TO PUMP OTHER

LIQUIDS, PUMP PERFORMANCE

Hazardous fluids

can cause fire,

burns or death.

MAY DIFFER FROM RATED

PERFORMANCE BASED ON THE

DIFFERENT SPECIFIC GRAVITY,

TEMPERATURE, VISCOSITY, ETC.

OF THE LIQUID BEING PUMPED.

A STANDARD PUMP MAY NOT

BE SAFE FOR PUMPING ALL

TYPES OF LIQUIDS, SUCH AS

TOXIC, VOLATILE OR CHEMICAL

LIQUIDS, OR LIQUIDS UNDER

EXTREME TEMPERATURES OR

PRESSURES.

Please consult Goulds Water Technology catalogs as well as local

codes and general references to determine the appropriate pumps

for your particular application. Since it is impossible for us to

anticipate every application of an Goulds Water Technology pump,

if you plan to use the pump for a non-water application, consult

Goulds Water Technology beforehand to determine whether such

application may be proper or safe under the circumstances. Failure

to do so may result in property damage or personal injury.

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

THE MANUAL AND ON THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump or

in the manual, look for one of the following signal words and be alert to the potential for personal injury or property damage.

Warns of hazards that WILL cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause serious

personal injury, death or major property

damage.

Warns of hazards that CAN cause personal

injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT.

THOROUGHLY REVIEW ALL INSTRUCTIONS AND

WARNINGS PRIOR TO PERFORMING ANY WORK

ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

3

Page 4

Hazardous machinery

can cause personal

injury or death.

WARNING

Operating Instructions

WARNING

Hazardous voltage

can shock, burn or

cause death.

Extreme heat can

cause personal injury

or property damage.

WARNING

(1/2 to 3/4")

Allowance

for leveling

Wood

frame

Grout

NOTICE: INSPECT UNIT FOR DAMAGE AND

REPORT ALL DAMAGE TO CARRIER

IMMEDIATELY.

LOCATION

By placing your Goulds Water Technology pump on a

firm, level foundation, you reduce harmful vibrations and

unnecessary noise. Your Goulds Water Technology pump is

self-priming, must be mounted horizontally and may be located

above the source of liquid supply. Best pump operation is

obtained by locating the pump as close as possible to the liquid

being handled. Keep in mind a pump can push liquid more

effectively than it can pull or draw liquid. The actual priming

ability of a pump depends upon many factors such as the size

and layout of the piping, the type of liquid and its temperature,

the specific pump selected and its speed of operation.

Additional priming information is given in the Goulds Water

Technology Sales Catalog. Provide the necessary space around

the pump for future inspection and servicing of the unit.

Protect the pump and piping from freezing temperatures.

CONNECTIONS

Connections at the easily accessible suction and discharge

ports can be made either with hose or pipe. The use of

strongly reinforced suction hose will prevent collapsing

of the hose during operation. New hose washers should

be used at the couplings to prevent trouble-causing leaks.

All hose or pipe should be independently supported to

eliminate excessive strain on the pump.

ROTATION

Your pump is specifically designed to rotate in a clockwise

direction when viewed from the coupling end of the pump

shaft. Three phase motors can rotate in either direction.

Interchanging any two leads of a three phase will reverse

the rotation. Check your rotation. (Also refer to cast

rotation arrow on pump casing.)

SPLASHING OR IMMERSING

OPEN DRIP PROOF MOTORS

IN FLUID CAN CAUSE FIRE,

SHOCK, BURNS OR DEATH.

FRAME-MOUNTED UNITS

• A at substantial foundation surface MUST be provided to

avoid distortion and/or strain when tightening the foundation

bolts. A rubber mounting is acceptable to reduce noise or

excessive vibration.

• Tighten motor hold-down bolts BEFORE connecting piping

to pump.

Finished grouting

(1/4")

Grout hole Base

Leveling wedges or shims—left in place

Top of foundation—

clean and wet down

Sleeve

Washer

Lug

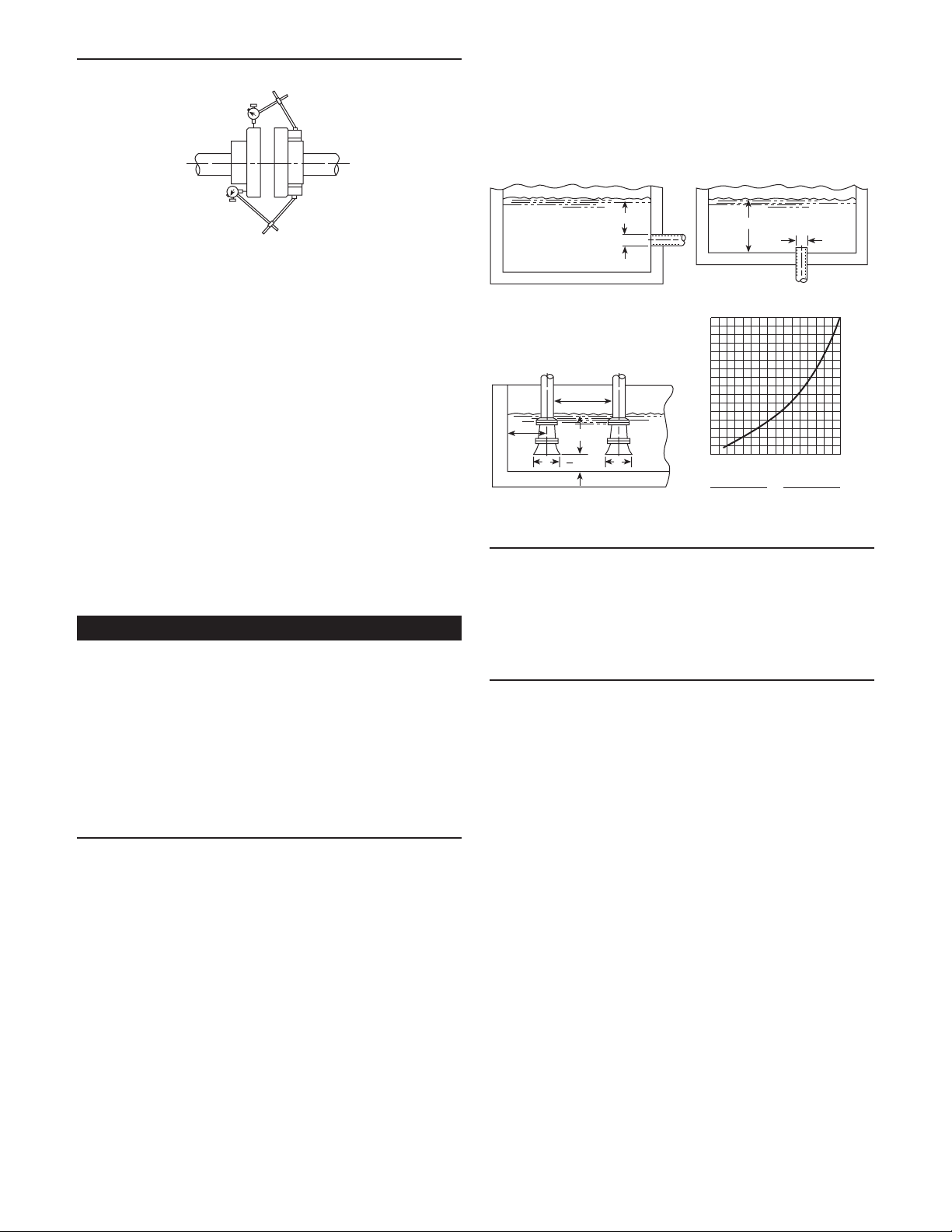

Figure 1

• It is recommended that the baseplate be grouted to a

foundation with solid footing. Refer to Figure 1.

• Place unit in position on wedges located at four points, two

below approximate center of driver and two below

approximate center of pump. Adjust wedges to level unit.

Level or plumb suction and discharge connections.

• Make sure bedplate is not distorted and nal coupling

alignment can be made within the limits of movement of

motor and by shimming, if necessary.

• Tighten foundation bolts nger tight and build dam around

foundation. Pour grout under bedplate making sure the areas

under the pump and motor feet are filled solid. Allow grout

to harden 48 hours before fully tightening foundation bolts.

• Tighten pump and motor hold-down bolts before aligning

shaft or connecting the piping to pump.

• Allow grout to harden for 48 hours before tightening 4

foundation bolts.

CLOSE-COUPLED UNITS

• Units must be installed horizontally.

• The motor feet MUST be bolted to a substantial surface that

is capable of complete and rigid support for the pump and

motor.

OPERATION AT OR NEAR

ZERO FLOW CAN CAUSE EXTREME HEAT, PERSONAL INJURY OR PROPERTY DAMAGE.

NOTICE: NO NOT RUN PUMP DRY OR SEAL

DAMAGE WILL RESULT.

• After stabilizing the system at normal operating conditions,

check the piping. If necessary, adjust the pipe supports.

• On frame-mounted units, coupling alignment may have

changed due to the temperature differential between pump

and motor. Recheck alignment following procedures and

hazard warnings in “COUPLING ALIGNMENT” section

of this manual.

4

Coupling Alignment

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SEVERE PERSONAL INJURY.

Page 5

FRAME-MOUNTED UNITS ONLY

• Alignment MUST be checked prior to running. See Figure 2.

Parallel

• Use a foot valve or check valve ONLY if necessary for

priming or to hold prime during intermittent duty.

• The suction strainer or suction bell MUST be at least

3 times the suction pipe diameter area.

• Insure that the size and minimum submergence over suction inlet is sufficient to prevent air from entering pump

through a suction vortex. See Figures 3 through 6.

Angular

Figure 2

• Tighten all hold-down bolts before checking alignment.

• If realignment is necessary, always move the motor. Shim

as required.

• Parallel misalignment, shafts with axis parallel but not

concentric. Place dial indicator on one hub and rotate this

hub 360° while taking readings on the outside diameter of

the other hub. Parallel alignment is achieved when reading is

0.010" (0.254 mm) TIR, or less.

• Angular misalignment, shaft with axis concentric but not

parallel. Place dial indicator on one hub and rotate this hub

360° while taking readings on the face of the other hub.

Angular alignment is achieved when reading is 0.020"

(0.508 mm) TIR, or less.

• Final alignment is achieved when parallel and angular requirements are satisfied with motor hold-down bolts tight.

NOTICE: ALWAYS RECHECK BOTH ALIGNMENTS

AFTER MAKING ANY MECHANICAL

ADJUSTMENTS.

Piping

• Piping should be no smaller than pump’s discharge and

suction connections and kept as short as possible, avoiding

unnecessary fittings to minimize friction losses.

• All piping MUST be independently supported and MUST

NOT place any piping loads on the pump

NOTICE: DO NOT FORCE PIPING INTO PLACE

AT PUMP SUCTION AND DISCHARGE

CONNECTIONS.

• All pipe joints MUST be airtight.

PIPING – SUCTION

• For suction lifts over 10 ft. (3 m) and liquid temperatures

over 120° F (49° C), consult pump performance curve for

net positive suction head required (NPSHR).

• If a pipe size larger than pump suction is required, an eccentric pipe reducer, with the straight side up, MUST be

installed at the pump suction.

• If pump is installed below the liquid source, install a gate

valve in the suction for pump inspection and maintenance.

NOTICE: DO NOT USE THE GATE VALVE TO

THROTTLE PUMP. THIS MAY CAUSE LOSS

OF PRIME, EXCESSIVE TEMPERATURES

AND DAMAGE TO PUMP, VOIDING

WARRANTY.

• If the pump is installed above the liquid source, the following

MUST be provided:

• To avoid air pockets, no part of the piping should be above

the pump suction connection.

• Slope the piping upward from liquid source.

H min.

D

Figure 3 Figure 4

3.0D

min.

1.5D

min.

H min.

D min.

D D

2

H min.

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Min. Submergence in feet

1

123456789101112 13141516

V = Velocity in feet per second

= GPM x 0.321

Area

GPM x 0.4085

D

V

2

D

Figure 5 Figure 6

PIPING – DISCHARGE

• Install a check valve suitable to handle the ow, liquids and

to prevent backflow. After the check valve, install an appropriately sized gate valve to be used to regulate the pump

capacity, pump inspection and for maintenance.

• When required, pipe increaser should be installed between

the check valve and the pump discharge.

AIR RELEASE LINE (4E & 6E)

It is essential to allow the air to escape from the discharge

line to atmosphere during the initial priming and re-priming

cycle. In systems with high discharge heads, it may be advisable

to install an air release line between the pump casing and

discharge check valve to aid their venting. The size of the

air release line is selected such that it does not significantly

affect the discharge capacity. You may install an air release line

through the filler plug hole if necessary. However, the preferred

location is in the discharge line – between the pump and the

discharge check valve – as close to the discharge check valve

as possible. We recommend the following line sizes for the

following pumps:

4" pump – ¾" line

6" pump – 1" line

NOTES:

1. This line size may be increased or decreased depending on

application.

2. Direct the air release line back into the sump (not into

the pump suction line). Leave the end of the line open to

atmosphere. Do not submerge into the liquid being

pumped.

3. The air release line may clog, particularly if a shut-off

valve is installed in the line and is closed during operation.

If this condition occurs, either use a larger line or leave the

shut-off valve open during pumping operation. To aid in

maintaining air release lines, fit them with crosses

instead of elbows.

5

Page 6

Hazardous machinery

can cause personal

injury or death.

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous

voltage

Wiring and Grounding

Extreme heat can

cause personal injury

or property damage.

WARNING

Install, ground and wire according

to local and National Electrical Code

Requirements.

Install an all leg electrical power

disconnect switch near the pump.

Disconnect and lockout electrical

power before installing or servicing

the pump.

Electrical supply MUST match

pump’s nameplate specications. Incorrect voltage can cause fire, damage

motor and void the warranty.

Motors without built-in protection MUST be provided

with contactors and thermal overloads for single phase

motors, or starters with heaters for three phase motors.

See motor nameplate.

• Use only copper wire to motor and ground. The ground wire

MUST be at least as large as the wire to the motor. Wires

should be color coded for ease of maintenance.

• Follow motor manufacturer’s wiring diagram on the motor

nameplate or terminal cover carefully.

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN CAUSE

SHOCK, BURNS OR DEATH.

NOTE: Tightening the jack-screws will increase the front

clearance and tightening the capscrews will decrease the

front clearance.

Tighten one set of screws and loosen the other to go in

the direction required. Tighten locknut (111).

NOTE: Maximum allowable bearing carrier (110) pull

back movement is 1⁄8", (i.e. from the condition when

impeller is “just” touching the diffuser you can push back

the bearing carrier assembly by 1⁄8".

Operation

DO NOT OPERATE FRAME MOUNTED

OR SAE UNITS WITHOUT SAFETY

GUARDS IN PLACE OR SEVERE

PERSONAL INJURY MAY RESULT.

SPLASHING OR IMMERSING OPEN

DRIP PROOF MOTORS IN FLUID

CAN CAUSE FIRE, SHOCK, BURNS OR

DEATH.

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS

THE WARRANTY.

• Correct rotation is right-hand, CLOCKWISE when viewed

• To reverse three phase motor rotation, interchange any two

(Applicable for models with open impellers)

The impeller running clearance, the distance between the

impeller vanes and diffuser is adjusted at the factory prior

to shipment to .020"-.030". To adjust this clearance in the

field, shut down the pump, disconnect power supply to

the pump and use the following instructions.

1. Unscrew three jack-screws (112), jam-nuts (111) and

bearing carrier capscrews (45).

2. Adjust the jack-screws and capscrews until the

impeller just touches the diffuser (46) (slight rub).

Tighten the jam nuts.

3. Measure the gap between bearing housing surface

(coupling END) and bearing carrier flange.

4. Adjust jack-screws, jam-nuts and capscrews to

pull out the rotating assembly, until the gap between

bearing housing surface and bearing carrier flange

measures .020"-.030" more than previously

measured gap.

Rotation

from the motor end. For frame mounted units, switch power

on and off quickly to observe rotation. On close coupled

units, remove motor end plug or cover to observe rotation.

power supply leads.

Impeller Running Clearance (6E1 Only)

OPERATION AT OR NEAR ZERO

FLOW CAN CAUSE EXTREME HEAT,

PERSONAL INJURY OR PROPERTY

DAMAGE.

NOTICE: NO NOT RUN PUMP DRY OR SEAL

DAMAGE WILL RESULT.

STARTING

Follow the motor manufacturer’s instructions carefully.

Before starting fill the pump casing with liquid through

the priming plug provided. Your pump has been designed

to prime itself in a few minutes. High suction lifts require

additional time and reduce the performance of the pump.

Should you have difficulty, refer to the “Troubleshooting

Guide” table.

Goulds Water Technology self-priming pumps prime

and reprime themselves providing the casing is filled

with liquid. Should you lose this liquid from the casing

accidentally or by draining purposely, it will be necessary

to refill it with liquid before starting.

2P through 4P – Check grease in the bearing housing

cavity. Units are shipped with grease but should be

checked before starting. (Refer to Lubrication section for

more details.)

4E and 6E – Units are shipped without oil in the bearing

housing cavity. Fill this cavity with the proper amount

and proper grade of oil. (Refer to Lubrication section for

more details.)

6

Page 7

Check drive coupling alignment. (Refer to Coupling

Alignment section for instructions.)

Check motor wiring.

WARNING

1. All electrical work must be done

by a licensed electrician.

2. Before working on pump and/or

motor be certain the electrical power

is off at the main junction box.

Hazardous voltage

can shock, burn or

cause death.

3. Disconnect the fuse or circuit breaker

and have the main switch tagged

“DO NOT ENERGIZE THIS

SWITCH, PERSONNEL WORKING

ON EQUIPMENT.”

4. Some motors are equipped with built-in thermal

overloads to shut off the motors in the event the

temperature becomes excessive (as a result of

mechanical or electrical problems, such as low

voltage, poor ventilation, overloaded lines, etc.).

These motors will restart automatically as the motor

cools down. For safety sake, DO NOT work on any

motor without shutting off the electricity.

5. Never operate an electric motor driven pump

without properly grounding the motor frame. Serious

injury or death by electrocution could result.

6. Drain pump casing completely before taking pump

apart. It is advisable to flush the inside of the casing

with water before taking pump apart.

WARNING

7. Never start pump before putting

back all necessary guards such as

coupling guard.

Hazardous Machinery

• After stabilizing the system at normal operating conditions,

check the piping. If necessary, adjust the pipe supports.

• On frame-mounted units, coupling alignment may have

changed due to the temperature differential between pump

and motor. Recheck alignment following procedures and

hazard warnings in “COUPLING ALIGNMENT” section of

this manual.

SEASONAL SERVICE

• To REMOVE pump from service, remove drain plug and

drain all unprotected piping.

• To RETURN pump to service, replace drain plug using

Teflon™ tape or equivalent on male threads.

• Reconnect suction line if removed, examine union and repair

if necessary.

• Refer to OPERATION section of manual.

Disassembly

• Follow ALL warnings and instructions in the “MAINTE-

NANCE” section of this manual.

• Close-coupled units: Remove motor hold-down bolts.

• Frame-mounted units: Remove coupling guard, spacer, cou-

pling and frame hold-down bolts.

LIQUID END

1. Remove casing bolts (47).

2. Remove back pull-out assembly from casing (1).

Discard gasket (8).

3. Remove diffuser and o-ring.

NOTICE: DO NOT INSERT SCREWDRIVER BETWEEN

IMPELLER VANES TO PREVENT ROTATION.

4. On close-coupled units, remove motor end plug or cover

to expose screwdriver slot or flats on end of motor shaft.

5. While restraining shaft with an appropriate tool (close coupled units) or with a strap wrench (frame-mounted

units) remove impeller bolt/nut (4). Impeller bolt/nut may

need to be heated with torch to remove. Discard.

NOTICE: EXERCISE CAUTION WHEN HANDLING

HOT IMPELLER BOLT/NUT.

6. Remove impeller washer (5).

7. Insert two pry bars, 180° apart, between impeller and

seal housing (10). CAREFULLY pry off impeller.

8. Remove impeller key (37).

9. Remove seal housing bolts (33) and seal housing (10)

pulling with it the mechanical seal assembly. Discard seal

assembly.

10. Inspect shaft sleeve (24). If badly scored, remove by

heating with torch. Discard.

11. Push out the mechanical seal stationary seat from the

seal housing. Discard.

NOTE: Check impeller and diffuser for any broken vanes or

wear. Replace it if necessary. Also check diffuser o-ring (7).

Replace if damaged.

DISASSEMBLY OF BEARING FRAME (P-SERIES)

1. Remove deflector (63) from shaft.

2. Remove bearing cover (80).

3. Remove shaft assembly from frame.

4. Remove lip seals (69, 81) from bearing frame (70) and

bearing cover (80) if worn. Discard.

5. Remove retaining ring (71).

6. Use bearing puller or arbor press to remove ball

bearings (74, 78).

DISASSEMBLY OF BEARING FRAME (4E AND 6E)

1. Drain bearing housing oil cavity by removing drain plug

(28) for oil lubrication bearing housing.

2. Remove capscrews (33) to disassemble bearing housing

(31) from bracket (67).

NOTE: Check gasket (8) if worn, replace it.

3. Remove the shaft assembly with bearings and bearing

carrier (110) out of the bearing housing (31).

4. Check both lip seals (42), replace if necessary.

5. Remove the snap ring (108) from the shaft (38).

6. Check the bearings. If they feel rough when turning by

hand, replace the bearings.

Reassembly

• All parts should be cleaned before assembly.

NOTICE: O-RING SHOULD BE REPLACED AFTER ANY

DISASSEMBLY OF UNIT.

7

Page 8

Hazardous fluids can

cause personal injury

or property damage.

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

Hazardous pressure can

cause personal injury,

property damage or death.

CAUTION

BEARING FRAME

1. Replace lip seals if removed.

2. Replace ball bearings if loose, rough or noisy when rotated.

3. Check shaft (38) for runout. Maximum permissible is

0.002" (0.05 mm) TIR.

4. Refer to the “MAINTENANCE” section of this manual

for bearing frame lubricating instructions.

5. Refer to the “MAINTENANCE” section of this manual

for bearing replacement of the E-Series bearing frame.

LIQUID END

1. Inspect shaft removing any debris or burrs.

2. Treat shaft with LOCQUIC® Primer “T”, or equivalent,

following manufacturer’s instructions carefully.

3. When replacing shaft sleeve, spray new shaft sleeve’s bore

with LOCQUIC® Primer “T”, or equivalent. Let parts dry

and then apply LOCTITE® #271 on the same surfaces.

Slide new sleeve, I.D. chamfer end first, over shaft with a

twisting motion, wipe off excess. Let cure according to

instructions.

NOTICE: MECHANICAL SEAL MUST BE REPLACED

WHENEVER SEAL HAS BEEN REMOVED.

FOLLOW SEAL MANUFACTURER’S

INSTRUCTIONS CAREFULLY. FOR PACKED

BOX PUMPS SEE “PACKED BOX

INSTRUCTIONS”.

4. The stationary seal seat may be dipped in water to ease

installation. Place stationary seal seat squarely into seal

housing bore. Cover the polished face of the seat with

a thin piece of cardboard or paper towel. Press seat firmly

into bore using a round piece of plastic or wood that

disperses the force over the entire seal face. NOTE: If

mechanical seal is supplied with a spring retainer, remove

and discard the retainer.

5. Place adapter, concave face pointing up, over motor/frame

shaft and lower it onto the mounting face.

6. Install seal housing on adapter. Exercise care in that the

motor shaft does not dislodge or damage seal seat.

7. Fully and squarely install the rotary assembly of seal

against the stationary seat.

NOTICE: REPLACE IMPELLER BOLT/NUT AND

WASHER WHENEVER IMPELLER IS REMOVED.

8. Install impeller key in shaft keyway. Mount impeller on

shaft and push until it bottoms. Hold in place.

9. Install new impeller washer.

Reverse disassembly procedure to reassemble the pump.

NOTE: Make sure all gaskets, o-ring, rubber check valve and

seal assembly are in good condition before reassembly.

HYDROTEST

NOTE: If hydrostatic test is required in the field, it must

be performed with check valve removed or with partially

open check valve.

The hydrotest pressure is generally 1½ times the working

pressure.

To set up the pump for hydrostatic test follow these

instructions:

Before hydrotesting the pump all air must be removed

from the suction priming chamber. This is done by:

(a) Removing ¼" pipe plug from top of the suction

inlet (50).

(b) Install a ¼" pet cock valve (not supplied by Goulds

Water Technology) in place of pipe plug.

(c) With pet cock open fill casing (1) with fluid being

pumped through filler plug (129) provided on top of

casing. Do not close pet cock until all air is out of

casing (as shown by a solid stream of liquid coming

out of pet cock).

(d) Close pet cock, reinstall filler plug. Unit is now ready

for hydrotest.

Maintenance

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE SHOCK,

BURNS OR DEATH.

FAILURE TO RELIEVE SYSTEM

PRESSURE AND DRAIN SYSTEM

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

IF PIPING HAZARDOUS OR TOXIC

FLUIDS, SYSTEM MUST BE FLUSHED

PRIOR TO PERFORMING SERVICE.

CLOSE-COUPLED UNITS

• Bearings are located in and are part of the motor. For lubrication information, refer to motor manufacturer’s instructions.

FRAME-MOUNTED UNITS

P-Series

• S Frame has greased for life bearings. No regreasing is

possible or necessary.

• ML frame should be regreased every 2,000 hours or at a

three month interval, whichever occurs first. Use a #2

sodium or lithium based grease. Fill until grease comes

out of relief fittings, or lip seals, then wipe off excess.

E-Series

• Set and maintain oil level as shown below.

1

/4"

MAX.

MIN.

SIGHT WINDOW

• Follow motor and coupling manufacturer’s lubrication

instructions.

• Recheck coupling alignment.

Approximately

52 fluids ounces.

8

Page 9

SHAFT AND BEARING REPLACEMENT (E-Series)

If shaft or bearing replacement is necessary, follow these

instructions. (Shut down the pump and disconnect power

supply to the pump before working on pump.)

1. Install the front (impeller end) bearing (36) on

the shaft (38).

2. Slide the carrier retaining ring (106) onto the

shaft (38) over the coupling end.

3. Install the rear (coupling end) bearing (117) on

the shaft (38).

4. Install the retaining ring (108) onto the shaft (38).

Add shims (107) between the retaining ring (108)

and the rear bearing (117) if required to lock the

rear bearing (117) on to the shaft axially.

5. Install O-ring (109) into the O.D. groove of the

bearing carrier (110).

6. Slide the bearing carrier (110) with o-ring over the

rear bearing such the rear bearing slides into the

bearing carrier (110). Install the retaining ring (106)

in place inside bearing carrier.

7. Insert shaft assembly with bearings and carrier into

the housing (31).

SEAL INSTALLATION INSTRUCTION

Seal is precision made. Handle carefully. Do not scratch

seal face.

1. Remove old seal. Clean shaft and all seal cavity

surfaces thoroughly.

2. Coat carbon washer, inside surface of rubber boot,

and rubber o-ring with a clean oil film.

3. Push stationary assembly into cavity, seating it

firmly and squarely with finger pressure only. DO

NOT use screwdriver or any tool which might

damage the stationary assembly.

4. Slide bellows assembly on shaft as far as possible,

pushing against rubber tail section only. Ease

bellows assembly into place. DO NOT DRIVE

WITH A HAMMER.

5. Install bellows spring with one end on flange of metal

seal flange. Some seal assemblies use a tapered spring.

On these, the smaller diameter fits on metal seal

flange.

6. Complete assembly of other pump parts.

A short “run-in” period may be necessary to provide a

tight seal joint.

CAUTION: Never run a seal dry for any length of time.

NOTE: Please make note that all “P” Series pumps are

equipped with shaft sleeve.

SHAFT SLEEVE INSTALLATION (2P, 3P, 4P ONLY)

Follow these instructions when applying loctite between

the shaft sleeve and shaft surface.

(a) Surface to be coated with loctite must be free of dirt

and grease. Wash with degreasing solvent if necessary.

(b) Spray these surfaces with loctite primer type “T”.

DO NOT OVERSPRAY. The thinnest film of primer

is best. Avoid skin contact or repeated breathing of

primer vapor. Allow three to four minutes for primer

to dry.

(c) Apply a coat (.005" or less thick) of loctite 271 (red)

to both shaft and inside of shaft sleeve.

(d) Slide shaft sleeve over the shaft all the way against

shaft shoulder. Make sure the chamfer on the I.D.

of the shaft sleeve is towards the shaft shoulder not

towards the impeller. Allow 5-10 minutes to cure if

primer type “T” is used, or 10-15 minutes if primer is

not used to attain full strength of loctite.

NOTE:

1. An evenly applied coat of loctite on both surfaces

will prevent leakage under shaft sleeve.

2. To remove shaft sleeve heat sleeve surface to

300º-350ºF with heat gun and tap gently on sleeve

to remove.

CHECK VALVE REPLACEMENT

To remove suction check valve follow these steps:

(a) Disconnect suction piping from suction inlet (50).

(b) Remove complete assembly, which includes suction

inlet (50) and check valve assembly.

(c) Remove shoulder bolts (54) to remove check valve

keeper plate (53) and rubber check valve (51).

If any of the parts of the check valve assembly are

damaged i.e. suction inlet (50), check valve (51), shoulder

bolt (54) and keeper plate (53), replace. Make sure the

sealing surface on suction inlet (angled surface) is not

damaged.

NOTE: Latest design check valve uses shoulder bolt (54)

instead of stud, space tube, locking nut, and washer.

Follow above procedure in reverse to reassemble the

pump.

NOTE: Make sure all gaskets, o-ring, rubber check

valve and seal assembly are in good condition before

reassemby. Replace as is necessary.

WINTER STORAGE

1. Wash off exterior of pump.

2. Flush suction line, discharge line, pump casing,

impeller and diffuser of all solids by pumping clear

liquid for a short time.

3. Drain pump casing, suction line and discharge line.

4. If complete draining is impossible add small amount

of anti-freeze into the pump casing. Rotate shaft for

mixing.

5. If the bearings are oil lubricated drain the old oil

from bearing housing and refill housing cavity with

proper grade of oil. (Refer to Maintenance section).

6. Seal off suction and discharge ports of pump casing.

7. Store the units in dry clean area if possible.

8. Motor windings should be protected from excessive

moisture. Follow motor manufacturer’s instructions.

9. Spray interior of pump casing with commercially

available anti-rust and anti-corrosion petroleum

aerosol.

10. Once a month rotate the pump shaft during storage

if possible.

9

Page 10

WARNING

Hazardous voltage

can shock, burn or

cause death.

Troubleshooting

DISCONNECT AND LOCKOUT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE.

FAILURE TO DO SO CAN CAUSE A

SHOCK, BURN OR DEATH.

NOTE: Before implementing any remedial action recommended in the following Troubleshooting guide, refer to

“Recommended Precautions” and “Warning” sections of this manual. The following are some common causes of

problems that may arise.

Symptoms Probable Cause Recommended Action

Will not prime No liquid in pump casing (1). Fill pump casing with liquid being

pumped.

Loose suction inlet (50). Tighten bolts.

Worn suction inlet gasket (49). Replace with new gaskets.

Loose drain plug (2). Tighten plug, use pipe dope or

Teflon tape.

Worn pump shaft seal assembly (17). Install new seal.

Leaky suction line. Fix leaky suction. Check all

gasketed surface.

Worn diffuser gasket (7). Replace diffuser gasket.

Suddenly stops pumping. Clogged suction line or suction Clean suction line and strainer

strainer (if used).

Stops pumping until motor is Collapsing suction hose lining. Replace suction line and strainer.

stopped and restarted.

Slowly stops pumping. Clogged impeller (6) or (91), Clean out debris from impeller eye

diffuser (46), check valve (51) or area, suction check valve, or from

suction line. diffuser vanes.

Excessive leakage around shaft. Work pump shaft seal (17). Replace seal assembly.

Will not hold prime. Dislodged or worn check valve (51). Clean or replace check valve. Clean

sealing surface.

Small leak in suction line. Check suction hose or piping for

leak.

Worn seal or packing. Replace seal or packing.

Poor performance Impeller (6) or (91), seal Install new impeller, seal or diffuser.

assembly (17) or diffuser (46).

Motor not up to speed: (a) larger lead wires required

(a) low voltage (b) worn bearings (b) replace bearings.

Noisy operation Worn motor bearings. Replace.

Low discharge head. Throttle discharge.

Impeller clogged. Remove and clean impeller.

Worn coupling or misalignment. Replace or realign coupling.

Units operating at extreme left or Adjust for best performance point

right end of performance curve of operation.

(capacity too high or too low).

Bearings running dry. Check oil level or grease –

add if required.

10

Page 11

Repair Parts

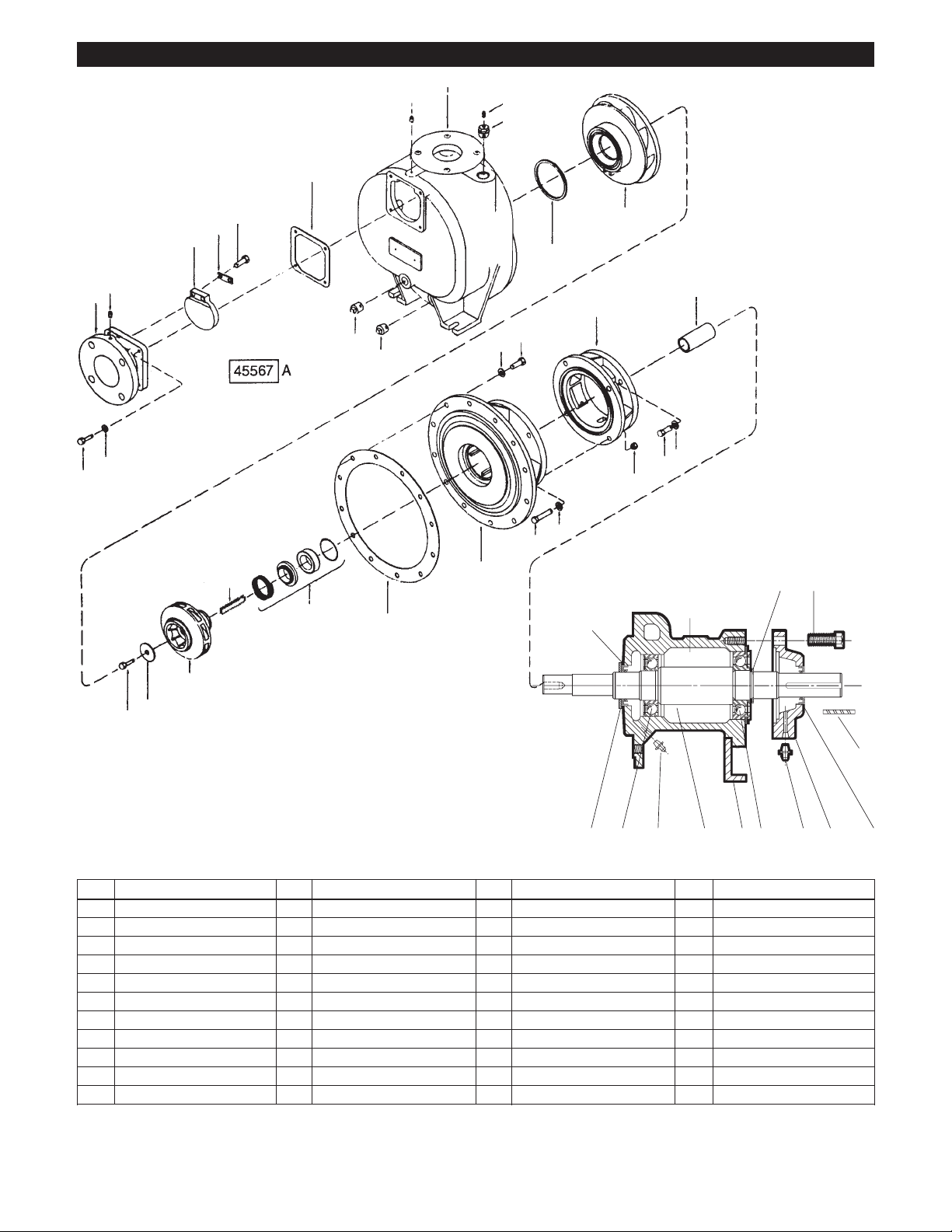

PRIME LINE FRAME MOUNT REPAIR PARTS – 2P, 3P, 4P

49

27

27

129

54

53

51

27

50

2

2

58

57

37

17

8

48

10

7

47

32

33

46

24

67

66

65

64

71 72

69

70

6

5

4

63 74 75 77 78 79 8076 81

Key Description Key Description Key Description Key Description

1 Casing 32 Lockwasher 57 Capscrew 129 Bushing

2 Pipe Plug 33 Capscrew 58 Lockwasher 74 Ball Bearing

4 Bolt, Impeller *37 Key, Impeller 64 Hexnut 75 Grease Fitting (ML)

5 Washer, Impeller 46 Diffuser 65 Capscrew 76 Shaft

•6 Impeller 47 Capscrew 66 Lockwasher 77 Foot

*7 O-Ring 48 Lockwasher 67 Adapter, Motor 78 Ball Bearing

*8 Gasket, Diecut *49 Gasket, Diecut 68 Stud 79 Grease Fitting (ML)

10 Seal Housing 50 Inlet, Suction 69 Lip Seal 80 Bearing Cover

•17 Seal,SingleMech •51 Valve,Check 70 BearingFrame 81 LipSeal

*24 Sleeve, Shaft 53 Keeper 71 Retaining Ring 82 Key

27 Pipe Plug 54 Shoulder Bolt 72 Hex Head Cap Screw

* Recommended Spare parts

• RecommendedDistributorStock,ExportSparesandCriticalService.

82

11

Page 12

Repair Parts (Continued)

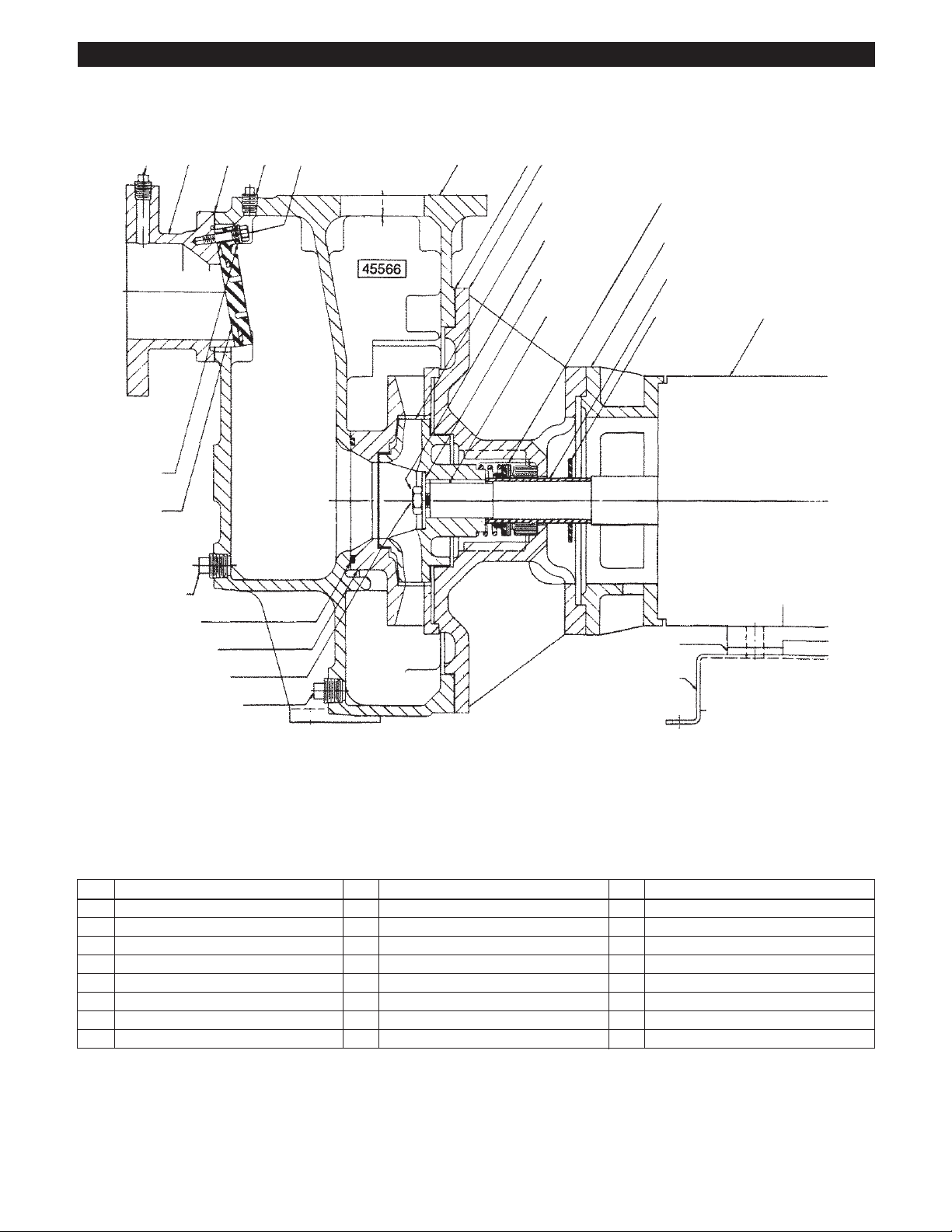

PRIME LINE CLOSE-COUPLED CROSS SECTION – 2P, 3P, 4P

50 49 27 54 1 8 10

27

6

4

5

37

53

51

2

7

46

17

67

24

63 69

72

68

2

Key Description Key Description Key Description

1 Casing •17 Seal,SingleMech 53 Keeper

2 Pipe Plug *24 Sleeve, Shaft 54 Shoulder Bolt

4 Bolt, Impeller 27 Pipe Plug 63 Slinger

5 Washer, Impeller *37 Key, Impeller 67 Adapter, Motor

•6 Impeller,Closed 46 Diffuser 68 Stud

*7 O-Ring *49 Gasket, Diecut 69 Motor (Specify)

*8 Gasket, Diecut 50 Inlet, Suction 72 Riser

10 SealHousing •51 Valve,Check 73 Base,Motor

* Recommended Spare parts

• RecommendedDistributorStock,ExportSparesandCriticalService.

73

12

Page 13

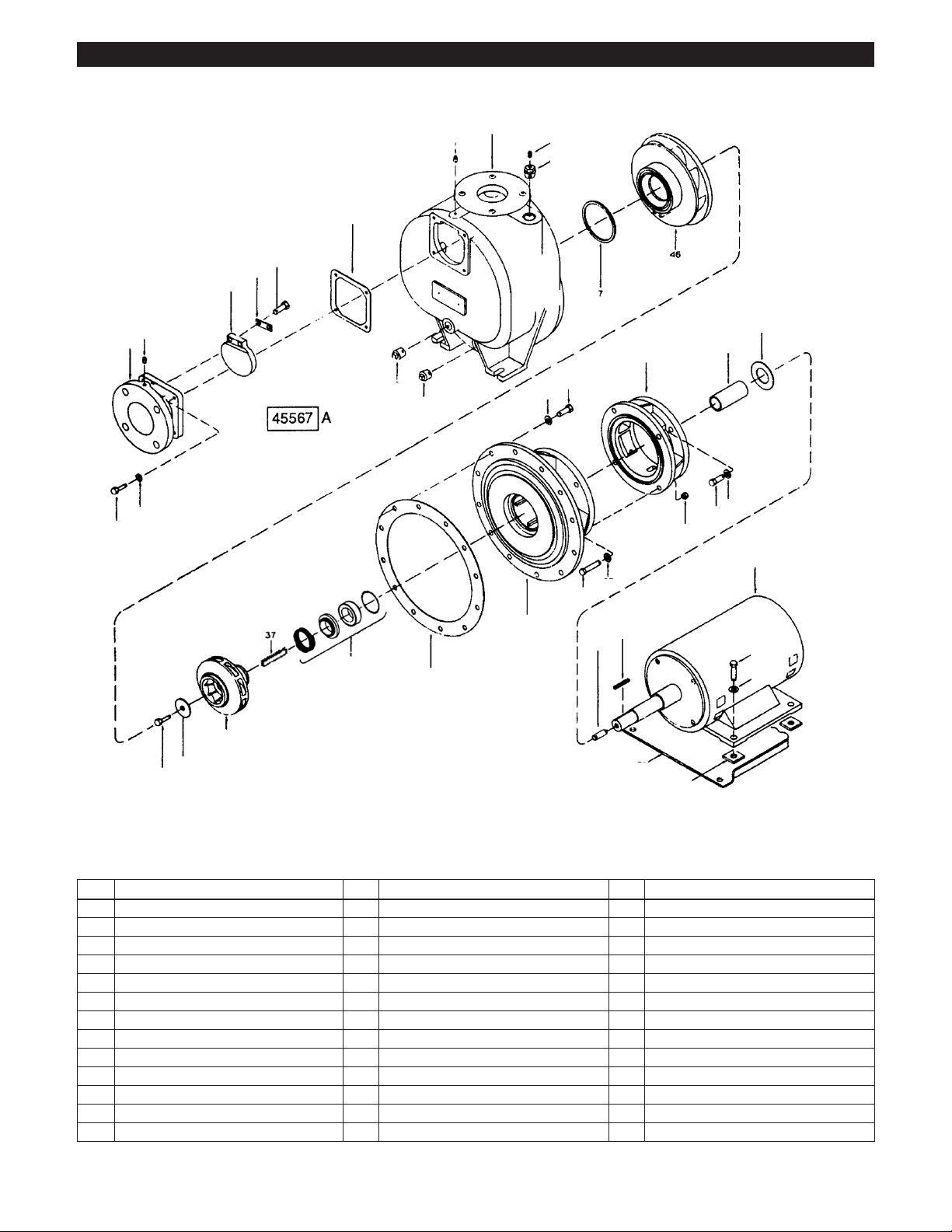

Repair Parts (Continued)

PRIME LINE CLOSE COUPLED REPAIR PARTS – 2P, 3P, 4P

49

1

27

27

129

54

53

51

27

50

2

2

58

57

17

8

7

47

48

10

46

63

67

32

33

37

66

24

66

65

64

69

70

71

6

5

4

Key Description Key Description Key Description

1 Casing *37 Key, Impeller 58 Lockwasher

2 Pipe Plug 46 Diffuser 63 Slinger

4 Bolt, Impeller 47 Capscrew 64 Hexnut

5 Washer, Impeller 48 Lockwasher 65 Capscrew

•6 Impeller *49 Gasket,Diecut 66 Lockwasher

*7 O-Ring 50 Inlet, Suction 67 Adapter, Motor

*8 Gasket,Diecut •51 Valve,Check 68 Stud

10 Seal Housing 52 Spacer 69 Motor (Specify)

•17 Seal,SingleMech 53 Keeper 70 Capscrew

*24 Sleeve, Shaft 54 Stud 71 Lockwasher

27 Pipe Plug 55 Flatwasher 72 Riser

32 Lockwasher 56 Locknut 73 Base, Motor

33 Capscrew 57 Capscrew 129 Bushing

* Recommended Spare parts

• RecommendedDistributorStock,ExportSparesandCriticalService.

73

72

13

Page 14

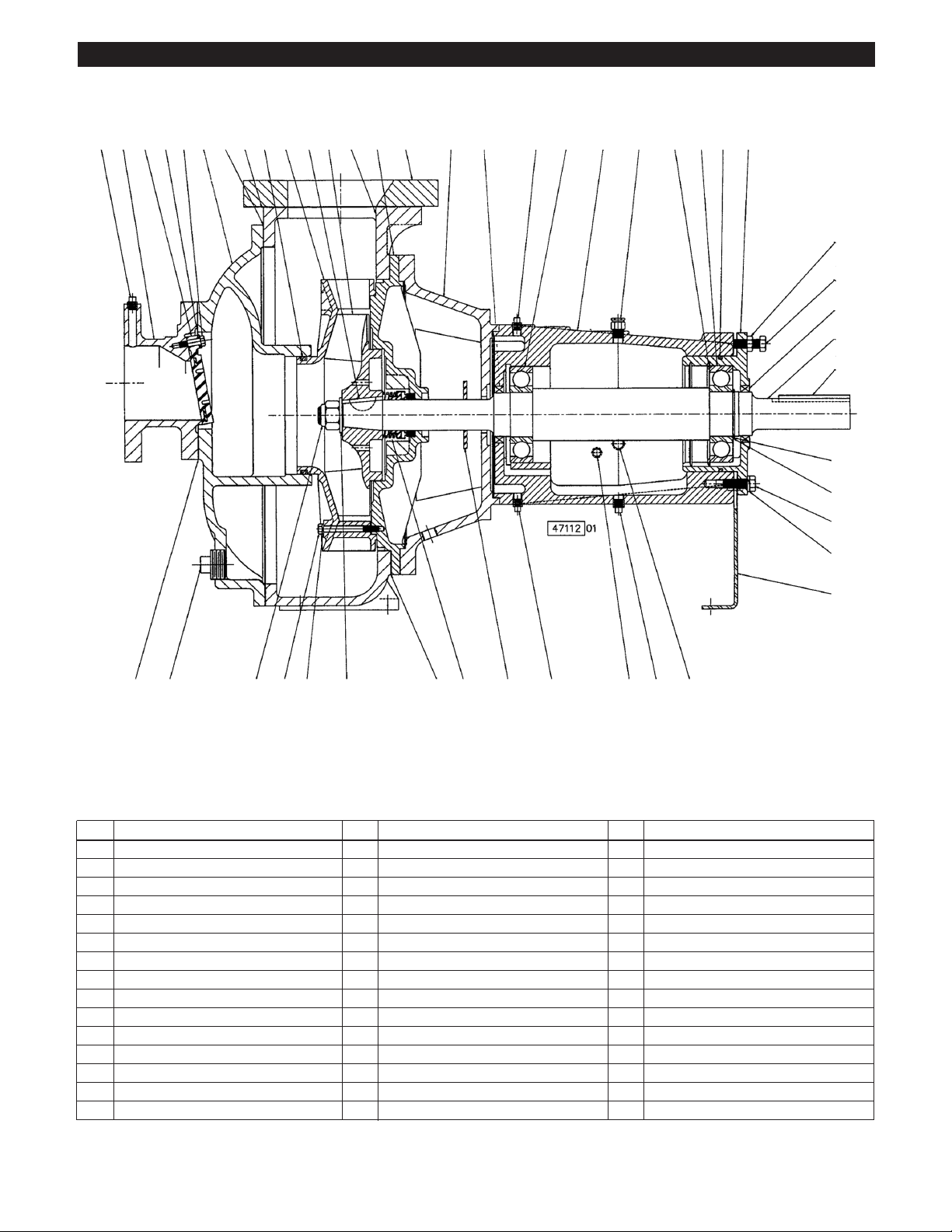

Repair Parts (Continued)

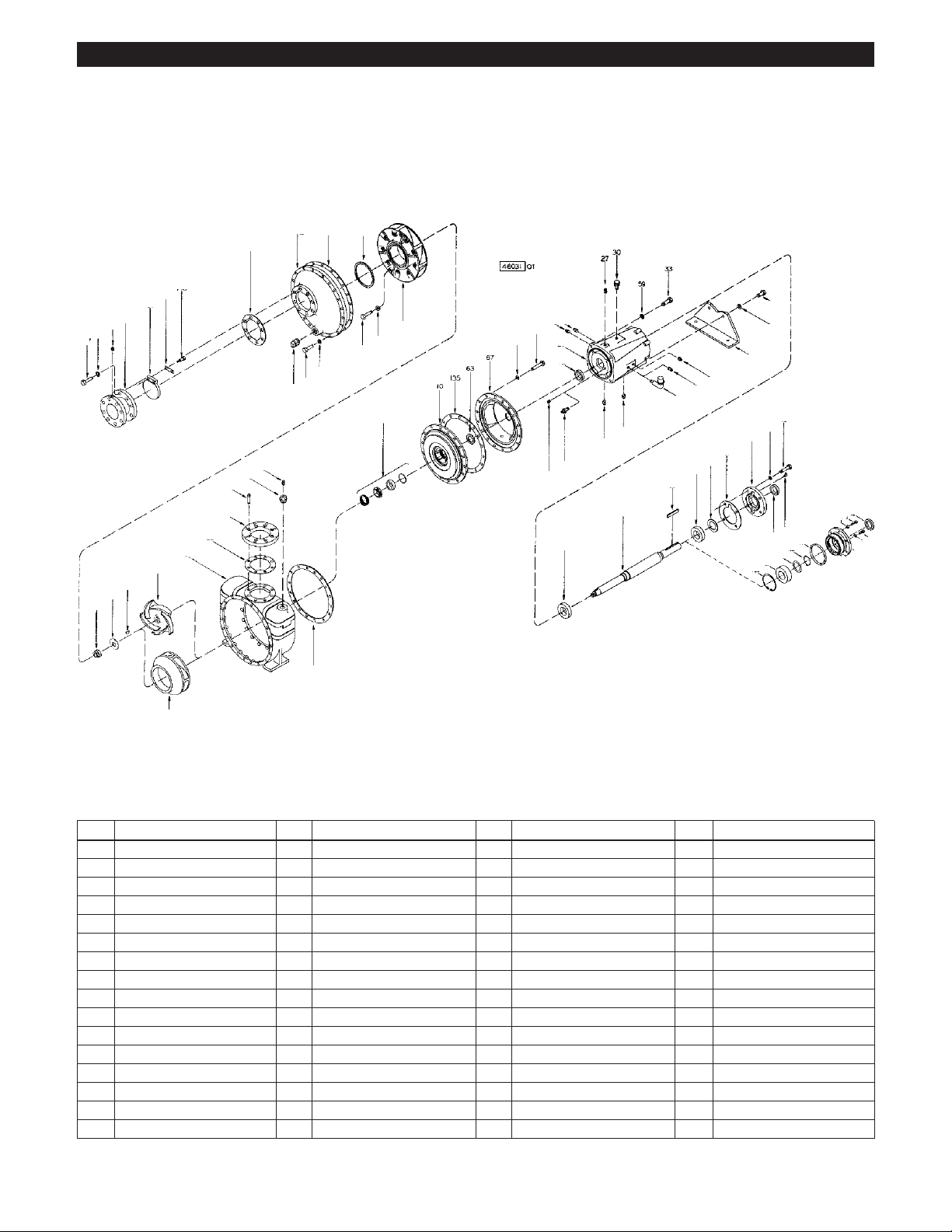

PRIME LINE CROSS SECTION – 4E, 6E

50 51 53 118 93132

27

7 46 37 91 10196 67 42 27 36 3031130 117 109 110106

111

112

42

38

39

108

107

2 4 133 134 8549 63 27 29, 27 28 2817

Key Description Key Description Key Description

1 Casing 37 Key, Impeller 96 Gasket, Diecut

2 Pipe Plug 38 Shaft 106 Ring, Retaining

4 Locknut, Impeller 39 Key, Coupling 107 Shim, Bearing

5 Washer, Curved, Impeller 42 Lip Seal 108 Ring, Retaining

7 O-Ring 44 Lockwasher 109 O-Ring, Molded

8 Gasket, Diecut 45 Capscrew 110 Carrier, Bearing

10 Seal Housing 46 Diffuser 111 Hexnut, Jam

17 Seal, Single Mechanical 49 Gasket, Diecut 112 Jackscrew

27 Pipe Plug 50 Inlet, Suction 117 Bearing, Rear

28 PipePlug 51 Valve,Check 118 Screw,Shouldered

29 Oiler, Optional 53 Keeper 130 Adaptor, Plate

30 Vent,Filter 63 Slinger 132 Cover,Casing

31 Housing, Bearing 67 Bracket 133 Capscrew

35 Foot, Mounting 92 Impeller, Open 134 Lockwasher

36 Bearing, Front 93 Gasket, Diecut

* Recommended Spare parts

• RecommendedDistributorStock,ExportSparesandCriticalService.

45

44

35

14

Page 15

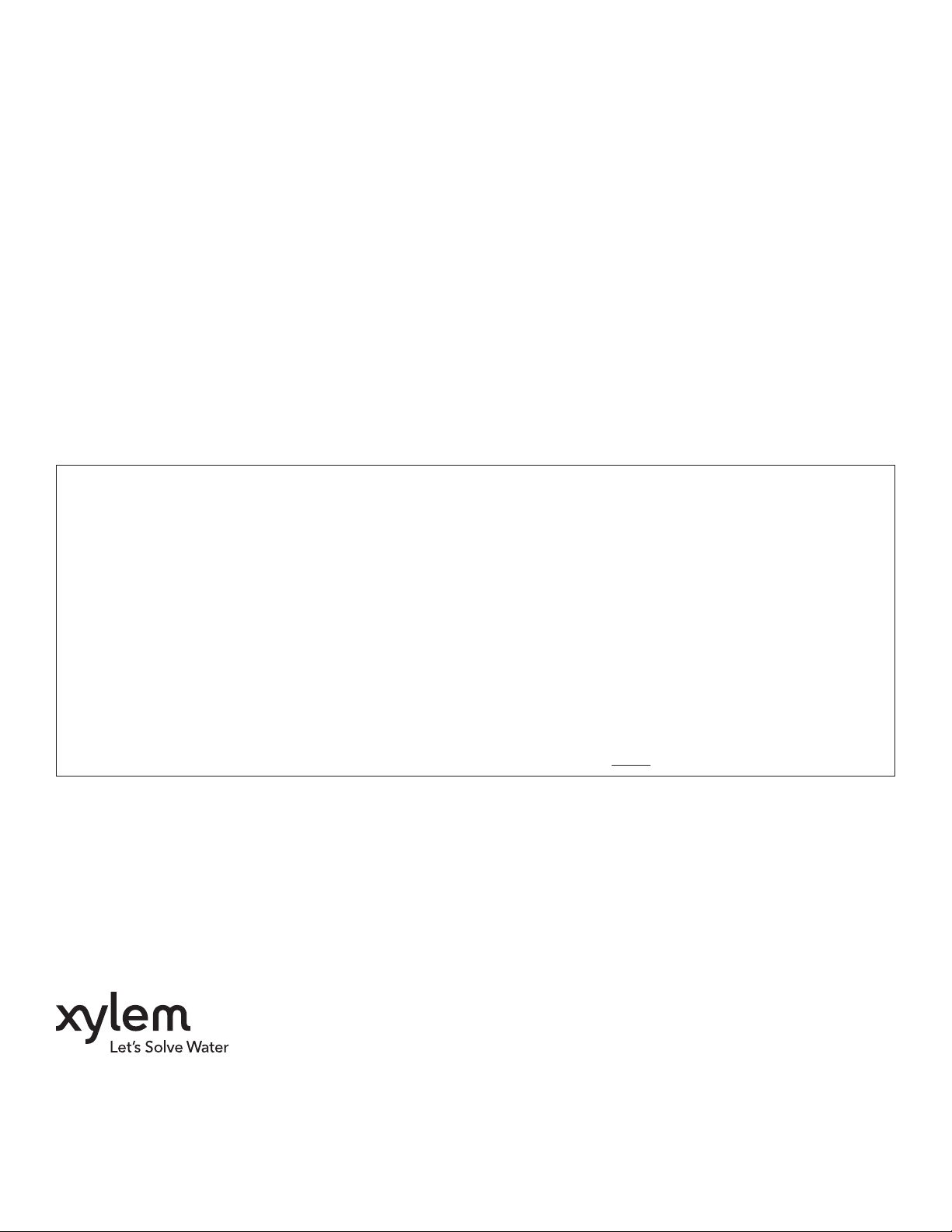

Repair Parts (Continued)

PRIME LINE REPAIR PARTS – 4E, 6E

132

7

93

49

118

53

51

50

27

58

57

59

92

2

133

46

134

27 28

47

44

31

42

28

27

29

17

28

27

27

129

131

130

96

1

61

26

39

38

36

41

40

36

91

37

5

4

34

59

35

45

44

43

112

42

111

106

117

62

109

42

108

107

44

110

45

8

6

Key Description Key Description Key Description Key Description

1 Casing 34 Capscrew 51 Valve,Check 109 O-Ring

2 Pipe Plug 35 Foot, Mounting 53 Keeper 110 Carrier, Bearing

4 Locknut, Impeller 36 Bearing, Front 57 Capscrew 111 Hex Nut, Jam

5 Washer, Curved, Impeller 37 Key Impeller 58 Lockwasher 112 Capscrew

6 Impeller, Closed 38 Shaft 59 Lockwasher 117 Bearing, Rear

7 O-Ring 39 Key, Coupling 61 Fitting, Hydraulic 118 Screw, Shoulder

8 Gasket, Diecut 40 Shim, Bearing 62 Fitting, Hydraulic 129 Bushing

10 Seal Housing 41 Gasket, Diecut 63 Slinger 130 Adapter, Plate

17 Seal, Single Mech. 42 Lip Seal 67 Bracket 131 Capscrew, Socket

26 Pipe Plug 43 Cap, Bearing 91 Impeller, Open 132 Cover, Casing

27 Pipe Plug 44 Lockwasher 92 Capscrew 133 Capscrew

28 Pipe Plug 45 Capscrew 93 Gasket, Diecut 134 Lockwasher

29 Oiler (Optional) 46 Diffuser 96 Gasket, Diecut 135 Shim, Lantern

30 Vent,Filter 47 Capscrew 106 Ring,Retaining

31 Housing, Bearing 49 Gasket, Diecut 107 Shim, Bearing

33 Capscrew 50 Inlet, Suction 108 Ring, Retaining

15

Page 16

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish complete

details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem Inc. IM191 Revision Number 3 July 2012

Page 17

MANUAL DE INSTRUCCIÓN

IM191

Motorizadas: Modelos 4E y 6E de acoplamiento largo

Modelos 2P, 3P, 4P de acoplamiento largo y acoplamiento próximo

®

Serie Marlow Prime Line

Bombas centrífugas de autocebadura

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

Page 18

Índice

Sección Página

Precauciones recomendadas ................................................................................................................................................19

Instrucciones de operación ...................................................................................................................................................20

Alineación de acoplamiento ................................................................................................................................................. 20

Tuberías ................................................................................................................................................................................21

Cableado y conexión a tierra ................................................................................................................................................22

Rotación ................................................................................................................................................................................22

Huelgo de funcionamiento del impulsor ............................................................................................................................. 22

Funcionamiento ...................................................................................................................................................................22

Desensamble ........................................................................................................................................................................23

Reensamble .........................................................................................................................................................................24

Mantenimiento ....................................................................................................................................................................25

Investigación y solución de fallas ......................................................................................................................................... 27

Refacciones ........................................................................................................................................................................... 28

Garantía limitada .................................................................................................................................................................. 34

Información del propietario

Modelo de bomba

Número de serie

Distribuidor

Teléfono del dist.

Fecha de compra

Fecha de instalación

18

Page 19

DANGER

WARNING

CAUTION

Felicidades

Usted es ahora propietario de una bomba Goulds Water Technology. Esta bomba se inspeccionó y se sometió cuidadosamente

a pruebas finales antes de autorizar su traslado. Para obtener su

máximo desempeño, por favor siga las sencillas instrucciones de

este manual.

Precauciones recomendadas

1. Si existe la posibilidad de que haya aire atrapado en

la caja de la bomba, instale un dispositivo de

ventilación automático para purgar el aire.

2. Todos los motores eléctricos requieren de un

activador magnético con protección de sobrecarga de

corriente.

3. Drene la caja por completo para el mantenimiento de

bombas que manejen líquidos volátiles o dañinos.

VER PRECAUCIONES.

4. Evite cualquier presión del sistema que exceda una

y media veces el punto de operación seleccionado de

la curva de desempeño de la bomba.

5. En caso de que la temperatura del fluido se eleve

más de 50°F por encima de la temperatura

ambiente, se deben instalar las juntas de expansión

tanto en el puerto de succión como en el de descarga

para liberar cualquier tensión de la caja de la bomba.

6. Un electricista autorizado deberá realizar todo el

cableado eléctrico de la instalación de la bomba de

conformidad con todos los códigos nacionales y

locales de electricidad.

7. No deberán hacerse modificaciones, añadiduras ni

omisiones a la bomba sin el consentimiento previo de

la fábrica.

8. Una vez que haya terminado el mantenimiento de

la bomba, instale siempre las guardas de acoplamien to y demás dispositivos de seguridad tal como se

encontraban antes del desensamble.

9. En los sistemas en los que pueda generarse presión

de ondas de choque, se deberán instalar en la línea

de descarga los dispositivos de protección como las

válvulas de retención/válvulas de compuertas, etc.,

para evitar que las presiones de choque entren en la

caja de la bomba.

10. En los sistemas que contienen válvulas de retención

de descarga, válvulas de compuertas, etc., la bomba

no se cebará si la válvula está cerrada. Verifique las

válvulas de descarga asegurándose de que están

abiertas antes de intentar cebar la bomba.

11. Las bombas sobrecalentadas son peligrosas. La

presión del vapor podría ocasionar quemaduras o

explosión. Una causa de sobrecalentamiento grave en

las bombas es la operación de las mismas con las

tuberías de succión y descarga cerradas. En caso que

la caja de la bomba se sobrecaliente: 1. Detenga la

bomba de inmediato. 2. Permita que se enfríe. 3.

Ventílela despacio y con cuidado.

12. No la utilice en atmósferas inflamables.

13. Verifique todos los días si están bien apretados la

tubería de succión y descarga, el drenaje, el tapón

del filtro y las juntas de la bomba. La operación no

debe proseguir hasta que se hayan verificado y estén

apretados todos estos elementos.

14. Esta bomba ha sido diseñada principalmente para

manejar agua. Antes de bombear otros líquidos, LEA

CON ATENCIÓN LAS SIGUIENTES

PRECAUCIONES.

DAD, TEMPERATURA, VISCOSIDAD, ETC. DEL

LÍQUIDO BOMBEADO. UNA BOMBA ESTÁNDAR

PUEDE NO SER SEGURA PARA BOMBEAR TODO

TIPO DE LÍQUIDOS, COMO TÓXICOS, VOLÁTILES

O QUÍMICOS, O LÍQUIDOS SOMETIDOS A TEMPERATURAS O PRESIONES EXTREMAS.

Por favor, consulte los catálogos Goulds Water Technology así como los códigos locales y referencias generales

para determinar cuáles son las bombas adecuadas para sus

necesidades particulares. Debido a que es imposible que

anticipemos cada aplicación de una bomba Goulds Water

Technology, si usted planea utilizar la bomba para una

aplicación distinta del agua, consulte antes con Goulds

Water Technology, para determinar si tal aplicación sería la

adecuada o segura en tales circunstancias. No hacerlo puede ocasionar daños en la propiedad o lesiones corporales.

INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA

EL DESEMPEÑO DE LAS BOMBAS

Goulds Water Technology SE BASA

EN AGUA LIMPIA, FRÍA Y DULCE

EN CONDICIONES DE SUCCIÓN,

COMO SE MUESTRA EN LA

CURVA DE DESEMPEÑO. SI SE

UTILIZA PARA BOMBEAR OTROS

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

LÍQUIDOS, QUIZÁ EL DESEMPEÑO

DE LA BOMBA DIFIERA DEL DESEMPEÑO CALIFICADO, A CAUSA

DE LA DIFERENCIA DE GRAVE-

CON EL FIN DE EVITAR LESIONES CORPORALES GRAVES O FATALES O DAÑOS IMPORTANTES EN LAS INSTALACIONES, LEA

Y SIGA LAS INSTRUCCIONES DE SEGURIDAD QUE SE ENCUENTRAN EN EL MANUAL Y EN LA BOMBA.

Este es un SÍMBOLO DE ALERTA DE

SEGURIDAD Cuando usted lo vea en

la bomba o en el manual, busque una de

las siguientes palabras de señalización

y esté alerta a la posibilidad de lesiones

corporales o daños en las instalaciones.

Advierte de peligros que CAUSARÁN

lesiones corporales graves, muerte o

daños importantes en la propiedad.

Advierte de peligros que PUEDEN

ocasionar lesiones corporales graves,

muerte o daños importantes en la

propiedad.

Advierte de peligros que PUEDEN

ocasionar lesiones corporales o daños en

las instalaciones.

NOTA: INDICA INSTRUCCIONES ESPECIALES

MUY IMPORTANTES Y QUE DEBEN

SEGUIRSE.

ESTE MANUAL ESTÁ DESTINADO A AYUDAR

EN LA INSTALACIÓN Y OPERACIÓN DE ESTA

UNIDAD. ANTES DE REALIZAR CUALQUIER

TRABAJO EN ESTA BOMBA, REVISE METICULOSAMENTE TODAS LAS INSTRUCCIONES Y

ADVERTENCIAS.

CONSERVE TODAS LAS ETIQUETAS DE

SEGURIDAD.

19

Page 20

NOTA: INSPECCIONE LA UNIDAD PARA

Las maquinarias

peligrosas pueden

causar lesiones

personales o la muerte.

ADVERTENCIA

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

Extreme heat can

cause personal injury

or property damage.

WARNING

DETERMINAR QUE NO ESTÉ DAÑADA; EN

CASO DE DESCUBRIR DAÑOS NOTIFIQUE

AL TRANSPORTISTA DE INMEDIATO.

UBICACIÓN

Para minimizar vibraciones dañinas y ruido innecesario, coloque su bomba Goulds Water Technology en una base nivelada. Su bomba Goulds Water Technology es de autocebadura

y puede colocarse por encima de la fuente de abastecimiento

de líquido. Se obtiene el mejor funcionamiento de la bomba

al colocarla lo más cerca posible del líquido en cuestión.

Tenga en cuenta que la bomba es más efectiva para empujar

un líquido que para jalarlo o succionarlo. La capacidad real

de cebado de una bomba depende de muchos factores como

el tamaño y la disposición de la tubería, el tipo de líquido y su

temperatura, la bomba específica seleccionada y su velocidad

de operación. El Catálogo de Ventas de Goulds Water Technology ofrece más información acerca del cebado. Considere

el espacio necesario alrededor de la bomba para permitir

inspecciones futuras y el mantenimiento de la unidad. Proteja

la bomba y la tubería de las temperaturas heladas.

CONEXIONES

Se pueden hacer las conexiones a los puertos de fácil acceso

de succión y descarga ya sea con mangueras o con tubos. El

uso de una manguera de succión fuertemente reforzada evitará que la manguera se colapse durante la operación. Deben

utilizarse abrazaderas nuevas en los acoplamientos de las

mangueras para evitar fugas problemáticas. Todos los tubos y

mangueras deben tener un soporte independiente para eliminar la tensión excesiva en la bomba.

ROTACIÓN

Su bomba ha sido diseñada específicamente para girar en el

sentido de las manecillas del reloj, vista desde el extremo del

acoplamiento del eje de la bomba. Los motores trifásicos

pueden girar en cualquier dirección. El intercambio de dos

cables de un trifásico, cualesquiera que sean, invertirá la

rotación. Verifique su rotación. (También consulte la flecha

NOTA: NO ACCIONE LA BOMBA EN SECO, DE LO

CONTRARIO HABRÁ DAÑOS EN EL SELLO.

• Una vez estabilizado el sistema en condiciones de operación

Instrucciones de operación

del eje de rotación fundida en la caja de la

bomba.)

SALPICAR O SUMERGIR LOS MOTORES ABIERTOS A PRUEBA DE

GOTERAS EN FLUIDOS PUEDE OCASIONAR INCENDIOS, DESCARGAS,

QUEMADURAS O LA MUERTE.

LA OPERACIÓN EN FLUJO MÍNIMO

O NULO PUEDE OCASIONAR SOBRECALENTAMIENTO, DAÑOS CORPORALES O DAÑOS EN LA PROPIEDAD.

normales, verifique la tubería. Ajuste los soportes de los

tubos si es necesario.

• En las unidades montadas en armazones, la alineación del

acoplamiento pudo haber cambiado debido al diferencial de

temperatura entre la bomba y el motor. Vuelva a verificar

los procedimientos de seguimiento de la alineación y las

advertencias de peligro que aparecen en la sección

“ALINEACIÓN DEL ACOPLAMIENTO” de este manual.

UNIDADES MONTADAS EN ARMAZONES

• Se DEBERÁ proporcionar una base segura y nivelada

para evitar la distorsión y/o tensión al apretar los pernos de cimentación. Se aceptan armazones de hule para

la reducción del ruido y la vibración excesivos.

• Apriete los pernos de cimentación del motor ANTES de

conectar la tubería a la bomba.

Enlechado terminado

(1∨2 a 3∨4")

Tole rancia

de nivelación

Bastidor

de madera

(

Cuñas o calzas de nivelación – dejadas en posición

Camisa

Arandela

BaseAgujero para lechada

Lengüeta

Lechada

Extremo superior del

cimiento – límpielo y mójelo

1

∨4")

Figura 1

• Se recomienda enlechar la base a una cimentación con una base

sólida. Consulte la Figura 1.

• Coloque cuñas en cuatro puntos diferentes, dos aproximadamente al centro del impulsor y dos al centro de la bomba. Ajuste

las cuñas para alinear la unidad. Nivele o emplome las conexiones de succión y descarga.

• Asegúrese de que la base no esté distorsionada y que pueda

efectuar la alineación final del acoplamiento dentro de los límites

del movimiento del motor o con un calibrador de separación, en

caso de ser necesario.

• Apriete los pernos de cimentación con los dedos y construya un

dique alrededor de la cimentación. Vierta la lechada debajo de

la base, asegurándose de que las áreas debajo de la bomba y de

los pies del motor estén completamente llenas de cemento. Deje

pasar 48 horas para que se solidifique por completo la lechada

de cemento, antes de apretar los pernos de cimentación.

• Apriete los pernos de cimentación de la bomba y del motor antes

de alinear el eje o conectar la tubería a la bomba.

• Deje pasar 48 horas para que se solidique por completo la lechada

de cemento, antes de apretar 4 pernos de cimentación.

UNIDADES DE ACOPLAMIENTO PRÓXIMO

• Se deberá instalar horizontalmente la unidad.

• Se DEBERÁN jar los pies del motor a una supercie

resistente y capaz de brindar apoyo firme y total a la bomba

y al motor.

Alineación de acoplamiento

NO DESCONECTAR NI BLOQUEAR

LA CORRIENTE ELÉCTRICA ANTES

DE INTENTAR CUALQUIER

MANTENIMIENTO, PUEDE

OCASIONAR LESIONES GRAVES.

20

Page 21

UNICAMENTE UNIDADES MONTADAS EN ARMAZONES

• Se DEBERÁ verificar la alineación antes de arrancar la

bomba. Vea la Figura 2.

Paralelo

Angular

Figura 2

• Apriete todos los pernos de cimentación antes de vericar la alineación.

• Si se requiere una realineación, retire el motor cada vez. Se deberá

espaciar lo necesario.

• Mala alineación paralela, ejes paralelos pero no concéntricos. Coloque

un indicador de cuadrante sobre una de las mitades del acoplamiento

y gírelo 360° mientras toma las medidas del diámetro exterior de la

otra mitad del acoplamiento. La alineación paralela será correcta cuando la lectura del indicador sea de 0.010" (0.254 mm) TIR o inferior.

• Mala alineación angular, ejes concéntricos pero no paralelos. Coloque un indicador de cuadrante sobre una de las mitades

del acoplamiento y gírelo 360° mientras toma las medidas de la cara

de la otra mitad del acoplamiento. La alineación angular será correcta cuando la lectura del indicador sea de 0.020" (0.508 mm) TIR

o inferior.

• Se obtiene la alineación nal cuando se cumplen los requerimientos

de alineación paralela y angular con los pernos de sujeción apretados.

NOTA: SIEMPRE VUELVA A VERIFICAR AMBAS

ALINEACIONES DESPUÉS DE CUALQUIER

AJUSTE MECÁNICO.

Tubería

• Las tuberías no deberán ser menores en diámetro a las

conexiones de descarga y de succión, y deben ser tan cortas

como sea posible y con el menor número de codos posible

para reducir la pérdida por fricción.

• Toda la tubería DEBERÁ tener un soporte independiente y

NO SE DEBERÁ colocar ninguna carga de la tubería sobre

la bomba.

NOTA: NO FUERCE LA COLOCACIÓN DE LOS

TUBOS EN LAS CONEXIONES DE SUCCIÓN Y

DESCARGA.

• Todas las juntas de la tubería DEBERÁN ser completamente

herméticas.

TUBERÍA DE SUCCIÓN

• Para elevaciones de succión de más de 10 pies (3 m), con

temperaturas líquidas de 120° F (49° C), consulte la curva

de desempeño de NPSH requerida (NPSHR).

• En caso de necesitar tubería más grande que la succión de

la bomba, se DEBERÁ instalar un reductor excéntrico en la

bomba de succión con el lado recto hacia arriba.

• Si se instala la bomba por debajo del nivel de la fuente del

líquido, instale una válvula de compuerta en la bomba de

succión para su inspección y mantenimiento.

NOTA: NO UTILICE LA VÁLVULA DE COMPUERTA

PARA CERRAR LA BOMBA, ESTO PUEDE

PROVOCAR PÉRDIDA DE CEBADURA,

TEMPERATURAS EXCESIVAS Y DAÑOS A LA

BOMBA, LO QUE ANULARÍA LA GARANTÍA

• Si se coloca la bomba por encima del nivel del líquido, se

DEBERÁ de proporcionar lo siguiente:

• Para evitar la formación de bolsas de aire, ninguna parte

de la tubería deberá estar más arriba de la conexión del

tubo de succión de la bomba.

• Coloque la tubería con una elevación gradual desde la

fuente del líquido.

• Utilice una válvula de pie o de retención ÚNICAMENTE si la necesita para cebar o para mantener el

cebado durante el servicio intermitente.

• El ltro de aspiración o la campana de succión

DEBERÁN cubrir al menos 3 veces el área del diámetro

de la tubería de succión.

• Asegúrese de que el tamaño y el sumergimiento mínimo

sobre la entrada de succión, sean suficientes para evitar

que entre aire de un vórtice de succión a la bomba. Vea

las figuras 3 a 6.

H min.

D

Figure 3 Figure 4

3.0D

min.

1.5D

min.

H min.

D min.

D D

2

H min.

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Min. Submergence in feet

1

123456789101112 13141516

V = Velocity in feet per second

= GPM x 0.321

Area

GPM x 0.4085

D

V

2

D

Figure 5 Figure 6

TUBERÍA DE DESCARGA

• Instale una válvula de retención adecuada para controlar el

flujo de líquido y para evitar el contraflujo. Después de la

válvula de retención, instale una válvula de compuerta para

regular la capacidad de la bomba y para la inspección y el

mantenimiento de la bomba.

• Cuando se requiera, instale un aumentador de tubería entre

la válvula de retención y la descarga de la bomba.

LÍNEA DE LIBERACIÓN DE AIRE (4E y 6E)

Es esencial permitir el escape del aire de la línea de descarga a

la atmósfera durante el cebado inicial y el ciclo de recebado.

En los sistemas con presiones hidrostáticas altas de descarga, se

recomienda instalar una línea de liberación de aire entre la caja

de la bomba y la válvula de retención de descarga para contribuir a su ventilación. Se selecciona el tamaño de la línea de

liberación de aire de manera que no afecte significativamente la

capacidad de descarga. Si es necesario, puede instalar una línea

de liberación de aire a través del orificio del tapón de llenado.

Sin embargo la ubicación preferente es en la línea de descarga

–entre la bomba y la válvula de retención de descarga- tan

cerca de la válvula de retención de descarga como sea posible.

Recomendamos el uso de los siguientes tamaños de líneas para

las bombas que se mencionan a continuación:

Bomba de 4" – línea ¾";

Bomba de 6" – línea 1"

21

Page 22

Las maquinarias

peligrosas pueden

causar lesiones

personales o la muerte.

ADVERTENCIA

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

ADVERTENCIA

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

ADVERTENCIA

Voltaje

peligroso

ADVERTENCIA

El calor extremo

puede causar lesiones

personales o daños

materiales.

NOTAS:

1. Este tamaño de línea puede aumentar o disminuir

dependiendo de su aplicación.

2. Dirija la línea de liberación de aire al pozo (no a la línea

de succión de la bomba). Deje el final de la línea abierto a

la atmósfera. No lo sumerja al líquido bombeado.

3. Es posible que la línea de liberación de aire se obstruya,

en especial si una válvula de apagado está instalada en

la línea y se cierra durante la operación. Si esto ocurre,

utilice una línea más grande, o bien, deje abierta la válvula

de apagado durante la operación de bombeo. Para con

tribuir al mantenimiento de las líneas de liberación de

aire, adáptelas con cruces y no con codos.

Cableado y conexión a tierra

Instale, conecte a tierra y cablee de

acuerdo con los requerimientos del

Código Eléctrico Nacional y Local.

Instale un interruptor de desconexión de todas las ramificaciones cerca

de la bomba.

Desconecte y asegure la energía

eléctrica antes de instalar o dar

servicio a la bomba.

El suministro eléctrico DEBERÁ coincidir con las

especificaciones de la placa de datos de la bomba. Un

voltaje incorrecto puede causar incendio, dañar el motor y anular la garantía.

Los motores que no tengan protección integrada

DEBERÁN incluir contactos descargas térmicas para

motores monofásicos, o arrancadores con calefacción para motores trifásicos. Vea la placa de datos del

motor.

• Utilice cable de cobre para el motor y la conexión a tierra.

El cable de tierra DEBERÁ ser al menos del tamaño del

cable del motor. El cableado se deberá realizar de acuerdo

con un código por colores, para facilitar su mantenimiento.

• Siga con atención el diagrama eléctrico del fabricante localizado en la placa de datos del motor o en la cubierta de la

terminal.

NO ASEGURAR UNA CONEXIÓN

A TIERRA PERMANENTE PARA LA

BOMBA, EL MOTOR Y LOS CONTROLES ANTES DE CONECTARLOS A

LA CORRIENTE ELÉCTRICA PUEDE

PROVOCAR CHOQUES ELÉCTRICOS, QUEMADURAS

O MUERTE.

Rotación

NOTA: LA ROTACIÓN INCORRECTA PUEDE DAÑAR

LA BOMBA Y ANULA LA GARANTÍA.

• La rotación correcta es hacia la derecha, EN EL SENTIDO

DE LAS MANECILLAS DEL RELOJ con vista desde el lado

del motor. Para las unidades de montaje de armazón, encienda y apague rápidamente para observar la rotación. Para

las unidades de acoplamiento próximo, retire el tapón del

extremo del motor o la cubierta para observar la rotación.

• El intercambio de dos cables de un trifásico, cualesquiera que

sean, invertirá la rotación.

Huelgo de funcionamiento del impulsor (únicamente 6E1)

(Aplicable para modelos con impulsores abiertos)

El huelgo de funcionamiento del impulsor, es decir la

distancia entre los álabes del impulsor y el difusor, se ajusta

en fábrica, antes del envío, a .020”- .030”. Para ajustar este

margen en campo, apague la bomba, desconecte el suministro

de corriente a la bomba y siga las instrucciones que aparecen

a continuación.

1. Destornille los tres tornillos de apriete y separación (112),

las contratuercas (111) y los tornillos ensamblados del

cojinete de apoyo (45).

2. Ajuste los tornillos de apriete y separación y los tornillos

ensamblados hasta que el impulsor apenas toque el

difusor (46) (roce ligero). Apriete las contratuercas.

3. Mida la brecha entre la superficie del alojamiento del

cojinete (EXTREMO del acoplamiento) y la pestaña del

cojinete de apoyo.

4. Ajuste los tornillos de apriete y separación, las contratuer cas y los tornillos ensamblados para jalar el ensamble

rotatorio, hasta que la brecha entre la superficie del

alojamiento del cojinete y la pestaña del cojinete de apoyo

mida .020"-.030" más que la brecha medida con

anterioridad.

NOTA: Al apretar los tornillos de apriete y separación

incrementará el margen delantero y al apretar los tornillos

ensamblados disminuirá el margen delantero.

Apriete un conjunto de tornillos y afloje el otro para ir en la

dirección deseada. Apriete la contratuerca (111).

NOTA: El máximo movimiento hacia atrás permitido para el

cojinete de apoyo (110) es de 1⁄8", (es decir, de la condición cuando el impulsor está “apenas” tocando el difusor, usted puede

empujar hacia atrás el ensamble del cojinete de apoyo 1⁄8").

Funcionamiento

NO OPERE LAS UNIDADES DE

MONTAJE DE ARMAZÓN O SAE SIN

GUARDAS DE SEGURIDAD YA QUE

PODRÁ RESULTAR EN LESIÓN

PERSONAL GRAVE.

SALPICAR O SUMERGIR LOS MOTORES

ABIERTOS A PRUEBA DE GOTERAS EN

FLUIDOS PUEDE OCASIONAR INCENDIOS, DESCARGAS, QUEMADURAS O

LA MUERTE.

LA OPERACIÓN EN FLUJO MÍNIMO O

NULO PUEDE OCASIONAR SOBRECALENTAMIENTO, DAÑOS CORPORALES

O DAÑOS EN LA PROPIEDAD.

22

NOTA: NO ACCIONE LA BOMBA EN SECO, DE LO

CONTRARIO HABRÁ DAÑOS EN EL SELLO.

Page 23

ARRANQUE

Siga las instrucciones del fabricante del motor con atención.

Antes de empezar, llene la caja de la bomba con líquido a

través de su tapón de cebado. Su bomba está diseñada para

autocebarse en pocos minutos. Las elevaciones de alta succión

requieren tiempo adicional y minimizan el desempeño de la

bomba. En caso de que surja alguna dificultad, consulte la

tabla en la “Guía de investigación y solución de fallas”.

Las bombas Goulds Water Technology de autocebado se ceban y receban solas siempre que su caja esté llena de líquido.

En caso de que este líquido se salga accidentalmente de la caja

o por drenado intencional, será necesario volverla a llenar

antes de empezar de nuevo.

De 2P a 4P – Verifique la grasa en la cavidad del alojamiento

del cojinete. Las unidades se envían con grasa pero antes de

arrancar verifíquelo. (Consulte la sección de Lubricación para

ver más detalles.)

4E y 6E – Las unidades se envían sin aceite en la cavidad de

alojamiento del cojinete. Llene esta cavidad con la cantidad

y el grado adecuados de aceite. (Consulte la sección de

Lubricación para ver más detalles.) Verifique la alineación del

acoplamiento del impulsor. (Consulte la sección de

Alineación de acoplamiento para obtener instrucciones.)

Verifique el cableado del motor.

ADVERTENCIA

1. Un electricista autorizado deberá realizar

todo el trabajo eléctrico.

2. Antes de trabajar en la bomba y/o el

motor, asegúrese de que la corriente

eléctrica esté apagada en la caja principal

de conexiones.

Un voltaje peligroso puede

producir golpes eléctricos,

quemaduras o la muerte.

3. Desconecte el fusible o el cortacircuitos

y en el interruptor principal ponga una

etiqueta con la leyenda “NO

ENERGICE ESTE INTERRUPTOR,

HAY PERSONAL TRABAJANDO EN

EL EQUIPO.”

4. Algunos motores están equipados con sobrecargas

térmicas incorporadas para apagar los motores en caso

de que la temperatura se vuelva excesiva (a consecuencia

de problemas mecánicos o eléctricos, como bajo voltaje,

ventilación deficiente, líneas sobrecargadas, etc.). Estos

motores se reiniciarán automáticamente una vez que el

motor se haya enfriado. Por su seguridad, NO trabaje en

ningún motor sin apagar la electricidad.

5. Nunca opere una bomba con motor eléctrico sin la base

adecuada del armazón del motor. Hacerlo puede dar

como resultado lesiones graves o muerte por

electrocución.