Page 1

INSTRUCTION MANUAL

IM157

Model MPVN

COVERS PUMP SIZES: 40.2, 40.3, 65.1, 65.2, 100.1, 100.2, 125.1, 125.2

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Page 2

TABLE OF CONTENTS

SUBJECTS PAGE

1. General ......................................................................3

1.1 Foreword ..................................................................3

1.2 Guarantee ................................................................3

1.3 Safety Regulations ....................................................3

1.4 Safety instructions ....................................................3

Dangers of not following safety instructions .............3

Safety instructions for the operator ...........................3

Speed, Pressure, Temperature ...................................4

Permitted forces on flanges .......................................4

NPSH .......................................................................4

Sealing, flushing, cooling ..........................................4

Minimum flows ........................................................4

Protection against running dry ..................................4

Back flow ..................................................................4

2. DESCRIPTION .........................................................4

2.1 Model ......................................................................4

Installation position ..................................................4

2.2 Shaft Sealing .............................................................4

2.3 Bearings and Lubrication .........................................4

Lubrication of roller bearings ...................................5

Bearing types (roller bearings)...................................5

Interval of re-lubrication/grease quantity ..................5

3. TRANSPORT, HANDLING, STORAGE ...................5

3.1 Transport, handling ..................................................5

3.2 Storage .....................................................................5

Preservation ..............................................................5

4. INSTALLATION, OPERATION ...............................5

4.1 Assembly and connection of pump ...........................5

4.2 Installation and Alignment of Coupling ...................5

Capscrew Torques .....................................................6

Equipment Alignment ...............................................6

4.3 Connecting the Pipes to the Pump ............................6

Suction and Discharge Pipe .......................................6

Auxiliary Pipes ..........................................................6

4.4 Electrical Connection ...............................................6

4.5 Starting Up ...............................................................7

Hints for use as a boiler feed pump ...........................7

Starting up for the first time ......................................7

Putting into operation again (after longer standstill;

1 month) ..................................................................7

4.6 Operation and Monitoring .......................................7

Permitted number of starts ........................................7

4.7 Shutting Down .........................................................7

4.8 Dismantling ..............................................................8

5. MAINTENANCE, SERVICING ................................8

Mechanical seals .......................................................8

Lubrication of bearing ..............................................8

Coupling ..................................................................8

Cleaning the pump ...................................................8

6. LONGER PERIODS OF NON-OPERATION ............8

6.1 Drained pumps .........................................................8

6.2 Filled pumps .............................................................8

7. FAULTS – CAUSES AND SOLUTIONS ....................9

8. REPAIRS ..................................................................10

9. SPARE PARTS, SPARE PUMPS ................................10

9.1 Spare Parts .............................................................10

Ordering spare parts ...............................................10

9.2 Stand-by pumps .....................................................10

10. PLANT MANAGER LIST .....................................11

11. LOG BOOK ...........................................................11

2

Page 3

1. GENERAL

1.1 Foreword

The staff employed on installation, operation,

inspection and maintenance must be able

to prove that they know about the relevant

accident prevention regulations and that they

are suitably qualified for this work. If staff do not have

the relevant knowledge, they should be provided with

suitable instruction.

The operating safety of the pumps or units (i.e. pump

plus motor) supplied is only guaranteed if these are used

in accordance with the provisions in “Installation and

Operation”.

The operator is responsible for following the instructions

and complying with the safety requirements given in

these Operating Instructions.

Smooth operation of the pump or pump unit can only be

achieved if installation and maintenance are carried out

carefully in accordance with the rules generally applied in

the fields of engineering and electrical engineering.

If not all the information can be found in these Operating

Instructions, please contact us.

The manufacturer takes no responsibility for the pump or

pump unit if the Operating Instructions are not followed.

These Operating Instructions should be kept in a safe

place for future use.

If this pump or pump unit is handed on to any third

party, it is essential that these Operating Instructions and

the operating conditions and working limits given in the

Confirmation of Order are also passed on in full.

These Operating Instructions do not take into account

all design details and variants nor all the possible chance

occurrences and events which might happen during

installation, operation and maintenance.

Alterations or changes to the machine are only permitted

by agreement with the manufacturer. Original spare parts

and accessories authorized by the manufacturer should be

used for greater safety. We bear no responsibility for the

consequences of using other parts.

We retain all copyright in these Operating Instructions;

they are intended only for personal use by the owner of

the pump or the pump unit. The Operating Instructions

contain technical instructions and drawings which may

not, as a whole or in part, be reproduced, distributed or

used in any unauthorized way for competitive purposes

or passed on to others.

1.2 Guarantee

The guarantee is given in accordance with our

Conditions of Delivery and/or the confirmation of order.

Repair work during the guarantee period may only be

carried out by our authorized distributor. Otherwise the

guarantee ceases to apply.

The guarantee shall not cover natural wear and tear and

all parts subject to wear, such as impellers, shaft sealings,

shafts, shaft sleeves, bearings, wear rings etc., or damage

caused by transport or improper handling.

In order for the guarantee to apply, it is essential that

the pump or pump unit is used in accordance with

the operating conditions given on the type plate,

confirmation of order and in the Data Sheet. This applies

particularly for the endurance of the materials and

smooth running of the pump and shaft sealing.

If one or more aspects of the actual operating conditions

are different, we should be asked to confirm in writing

that the pump is suitable.

1.3 Safety Regulations

These Operating Instructions contain important

instructions which must be followed when the pump

is assembled and commissioned and during operating

and maintenance. For this reason, these Operating

Instructions must be read by the skilled staff responsible

and/or by the operator of the plant before it is installed

and commissioned, and they must be left permanently

ready to hand at the place where the pump or pump unit

is in use. The operator must ensure that the contents

of the Operating Instructions are fully understood by

the staff. The operator must confirm this by signing the

“Plant Manager List” (see Point 10). These Operating

Instructions do not refer to the General Regulations on

Accident Prevention or local safety and/or operating

regulations. The operator is responsible for complying

with these (if necessary by calling in additional

installation staff).

The safety instructions contained in these Operating

Instructions have the following special safety markings.

Warning against personal accidents which

could occur if the safety instructions given in

this part of the Operating Instructions are not

followed.

WARNING

Hazardous

voltage

ATTENTION: WARNING AGAINST POSSIBLE

DAMAGE TO PROPERTY OR THE

ENVIRONMENT.

It is absolutely essential that safety information affixed

directly to the pump ot pump unit is followed and

maintained so that it is always easily legible.

1.4 Safety Instructions

Dangers of not following safety instructions

Failure to follow the safety instructions can result in the

following, for example:

• People being at risk because of electrical, mechanical

and chemical factors.

• Important functions of the pump or pump unit failing.

• Dangers to the environment.

Safety instruction for the operator

• Depending on the operating conditions, wear and

tear, corrosion or age will limit the working life of

the pump/pump unit, and its specified characteristics.

The operator must ensure that regular inspection

and maintenance are carried out so that all parts

are replaced in good time which would otherwise

endanger the safe operation of the system. If abnormal

operation or any damage are observed, the pump must

cease operation immediately.

• If the breakdown or failure of any system or unit could

lead to people being hurt or property being damaged,

such system or unit must be provided with alarm

devices and/or spare modules, and they should be

tested regularly to ensure that they function properly.

Warning against dangerous electrical

voltage.

3

Page 4

• If there is any risk of injury from hot or cold machine

parts, these parts must be protected against contact by

the user, or suitable warning signs must be affixed.

• Contact protection on moving parts (e.g. Coupling

guards) must not be removed from systems that are in

operation.

• If dangerous media (e.g. explosive, toxic, hot) leak out

(e.g. from shaft seals), these must be directed away so

that there is no danger to people or the environment.

The provisions of the law must be observed.

• Measures should be taken to exclude any danger from

electricity (e.g. by complying with the local regulations

on electrical equipment). If work is carried out on

live electrical components, they should be unplugged

from the mains or the main switch turned off and fuse

unscrewed. A motor protection switch is to be provided.

• Basically, all work on the pump or pump unit should

only be carried out when the pump is stationary and

not under pressure. All parts must be allowed to return

to ambient temperature. Make sure that no one can

start the motor during such work. It is essential that

the procedure for stopping the system described in the

Operating Instructions is observed. Pumps or pump

systems that carry media that are dangerous to health

must be decontaminated before being taken apart. See

Safety Data Sheets for the various liquids handled. After

the work has been completed, all safety and protective

devices must be replaced or restarted.

Speed, Pressure, Temperature

Suitable safety measures must be taken at the plant to

ensure that the speed, pressure and temperature of the

pump and the shaft sealing do not exceed the limit values

given in the Data Sheet. The given suction pressures must

also be sufficiently high. In addition, the pump must be

protected against pressure surges such as can be caused by

switching off the plant quickly (e.g. by non-return valve on

the pressure side, flywheel, air vessel).

Permitted Forces on Flanges

Basically, the suction and pressure lines should be such that

the forces on the pump are kept to a minimum. If this is

not feasible, contact your distributor for limits.

NPSH

When entering the impeller, the liquid being handled must

have a minimum pressure NPSH to prevent cavitation or

breaking off of flow. This requirement is met if the unit

NPSH value (NPSHA) is well above the pump NPSH value

(NPSHR) under all operating conditions.

Attention must be paid to the NPSH value in particular

when liquids close to boiling point are being handled. If

the value falls below the pump NPSHR value, this can lead

to damage resulting from cavitation or serious damage

from overheating.

The NPSHR for each pump type is given in the sheets of

characteristic curves. We can supply leaflets for calculation

of NPSH values on request.

Sealing, Flushing, Cooling

Suitable facilities for the regulation and monitoring of

sealing, flushing or cooling are to be provided. When

handling dangerous liquids or if temperatures are high,

care should be taken to ensure that the pump ceases

operating if the sealing, flushing or cooling system fails.

Sealing, flushing and cooling systems must always be

operational before the pump is started up. They should

not be taken out of operation until the pump has stopped,

provided that he nature of the operation allows this at all.

Minimum Flows

If the pump is started against a closed pressure line

valve, it should be noted that the power taken up by the

pump is transmitted to the liquid handled in the form

of heat. This can cause the liquid to heat up excessively

within a relatively short time, which will then cause

damage to the pump’s internal fittings. After the pump

has reached operating speed, the discharge valve should

therefore be opened as quickly as possible. If operating

conditions mean that Q = 0 is unavoidable, or if hot

water is circulating, a free flow non-return valve, or, on

smaller systems, a by-pass pipe, should be provided. Your

distributor can help in determining the minimum flow or

designing the by-pass line.

Protection against Running Dry

The pumps must not run dry under any circumstances,

since overheating can damage pump components (e.g.

mechanical seals).

Back Flow

In systems where pumps are operating in closed circuits

under pressure (gas cushions, steam pressure), the pressure

of the gas cushion must not be reduced via the pump,

since the back flow speed may be much higher than the

operating speed, which would destroy the unit.

2. DESCRIPTION

2.1 Model

Design MPVN

Design Features:

• Vertical conguration with separate thrust bearing,

grease lubrication with grease nipples.

• Motors according NEMA-Standard MG 1-4.07.

• Flexible coupling between pump and motor.

• Medium lubricated sleeve bearing in suction casing.

• Maintenance friendly design. Shaft sealing maintainable

without pump disassembly.

Installation Position

Shaft vertical.

Other installation positions only by agreement.

2.2 Shaft Sealing

Basic design with mechanical seal. Seal code SA with

unbalanced seal; seal code SB with balanced seal.

ATTENTION: YOU WILL FIND MORE

INFORMATION ABOUT

MECHANICAL SEALS, AND THE

RISKS OF ACCIDENTS THAT THESE

MAY INVOLVE, UNDER POINT 4.6

“OPERATION AND MONITORING”

AND IN POINT 5 “MAINTENANCE

AND REPAIRS’.

2.3 Bearings and Lubrication

Drive Side: re-lubricatable roller bearings (thrust

bearing).

Pump Side: medium-lubricated sleeve bearing in the

suction casing.

4

Page 5

Lubrication of Roller Bearings

Standard: grease lubrication with grease nipples.

Grease lubricants to be of Lithium Base Grade 2.

The bearings are already filled with grease and are thus

ready for use.

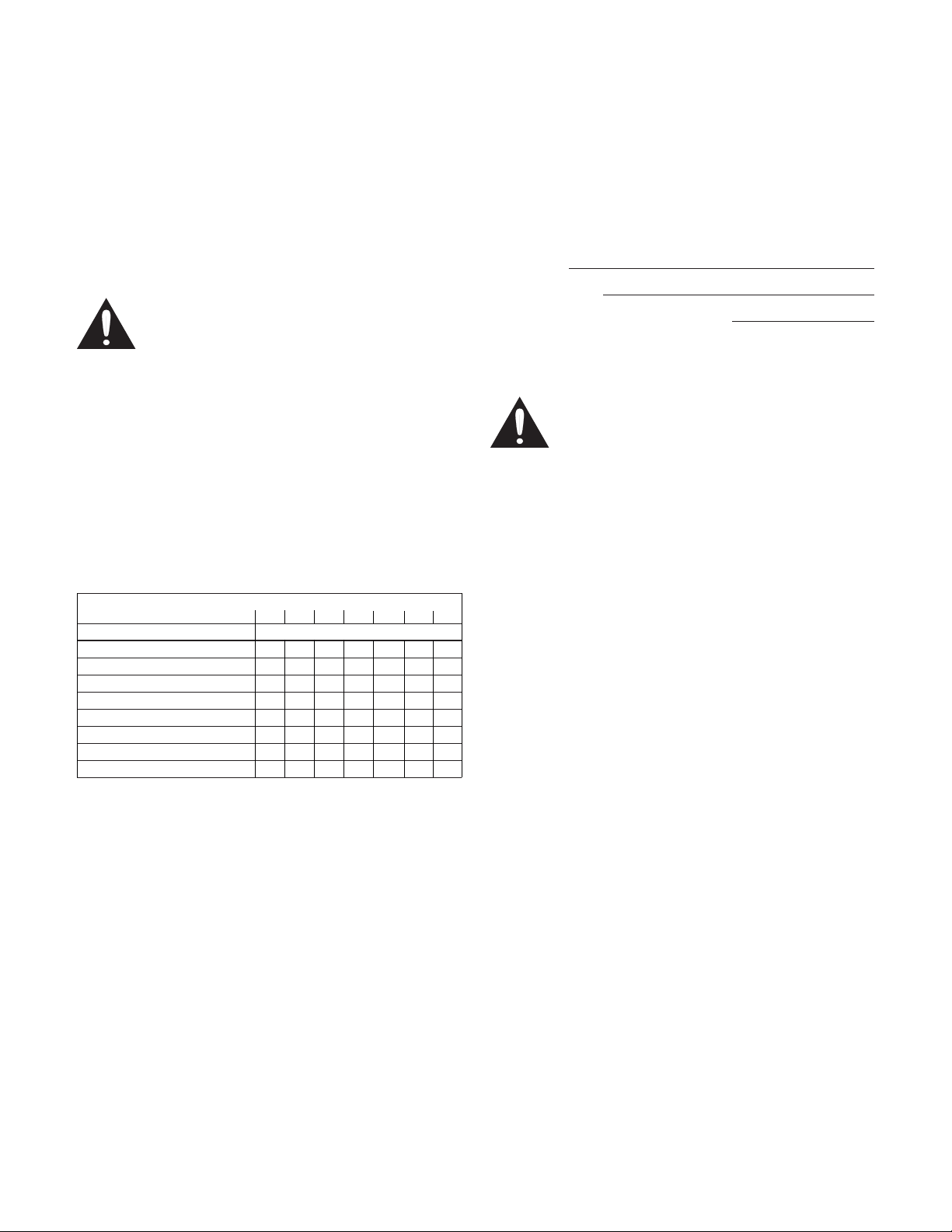

Bearing Types (roller bearings)

Bearing

MPVN 40.2 / MPVN 40.3 B306-C3

MPVN 65.2 / MPVN 65.2 B307-C3

MPVN 100.1 / MPVN 100.2 2 x 7308 (X-arrangement)

MPVN 125.1 / MPVN 125.2 2 x 7310 (X-arrangement)

Pump Size

Grease Lubricated

Interval of re-lubrication / grease quantity

Grease Interval of re-lubrication in operating hrs

Pump Size Qty.

[oz.]

MPVN 40.2 / MPVN 40.3 0.41 3800 4300 5500 6000 6500

MPVN 65.1 / MPVN 65.2 0.53 3500 4000 5000 5500 6000

MPVN 100.1 / MPVN 100.2 0.78 3300 3800 4500 5000 5500

MPVN 125.1 / MPVN 125.2 1.12 2500 3300 4300 4800 5000

3550 2950 2200 1750 1450

3. TRANSPORT, HANDLING, STORAGE

3.1 Transport, Handling

• Check the pump/pump unit immediately

upon delivery/receipt of shipment for

damage or missing parts.

• The pump/pump unit must be transported

carefully and by competent personnel.

Avoid serious impacts.

• Keep the pump/pump unit in the same

position in which it was supplied from the

factory. Take note of the instructions on the

packaging.

• The intake and discharge side of the pump

must be closed with plugs during transport

and storage.

ATTENTION: DISPOSE OF ALL

PACKING MATERIALS IN

ACCORDANCE WITH LOCAL

REGULATIONS.

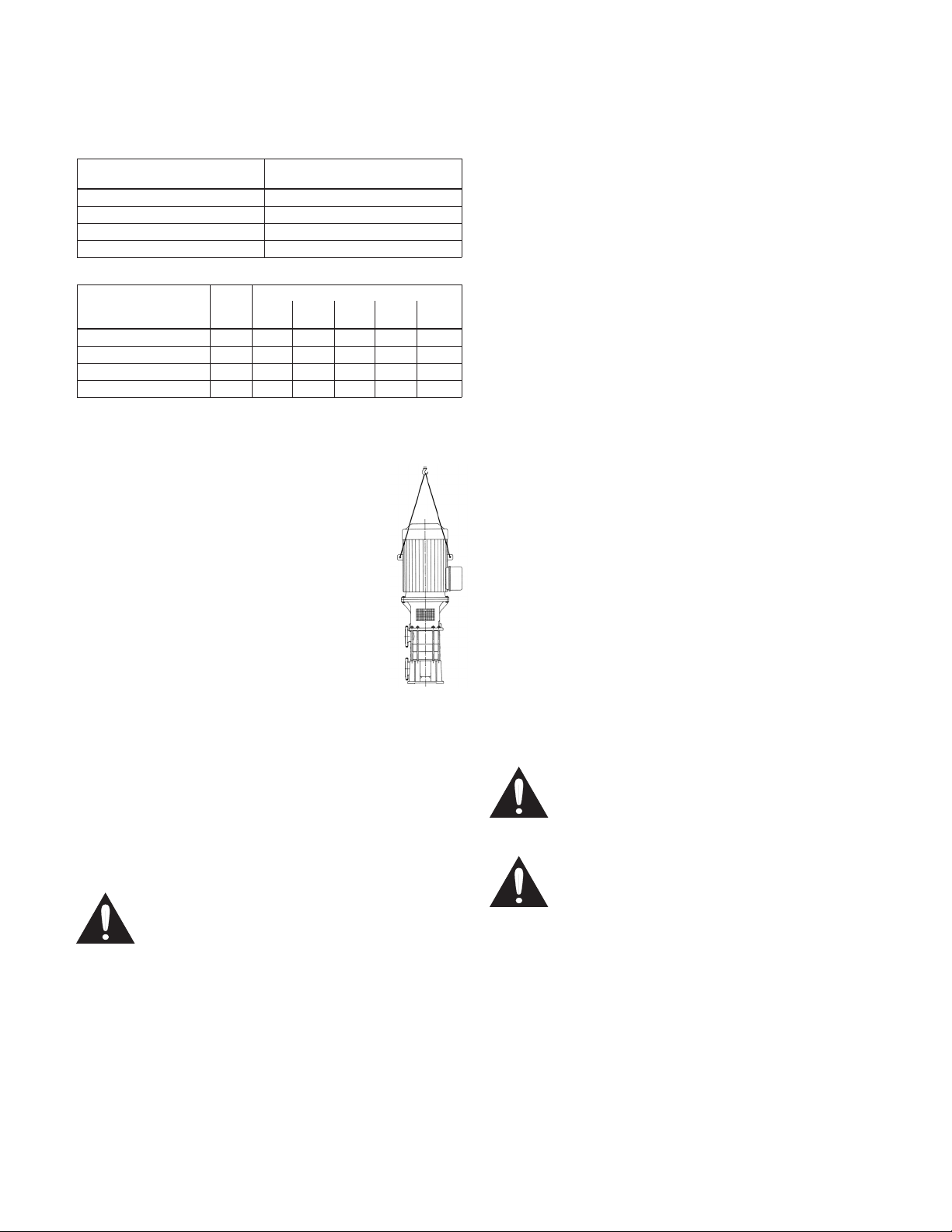

• Lifting devices (e.g. fork-lift truck, crane, crane device,

pulleys, sling ropes, etc.) must be sufficiently strong.

• The pump/pump unit may only be lifted by solid

points such as the casing, flanges or frame. The

illustration above shows the correct method of carrying

by crane.

Do not stand underneath suspended loads; take

note of the general regulations on prevention of

accidents.

The pump/pump unit must be secured against tipping

over and slipping until it has been fixed in its final

location.

3.2 Storage

Pump or pump units that are stored for a long time

before use must be protected against moisture,

vibrations and dirt (e.g. by wrapping in oil paper or

plastic sheeting). Pumps must basically be stored in a

place where they are protected from the weather, e.g.

under cover. During this time, all suction and discharge

branches and all other intakes and outlets must be closed

with dummy flanges or plugs.

Preservation

On storing the pump longer than 3 months (depends on

order): Special preservation has been used for shipment

prep. The product used for that must be removed from

the unit before the first normal operation.

4. INSTALLATION, OPERATION

4.1 Assembly and Connection of Pump

MPVN type pumps must be bolted to a xed subframe

(e.g. concrete foundation, steel plate, steel beam, etc.).

The subframe must withstand all loads that arise during

operation. The size of the subframe and the location and

size of the recesses for the foundation anchors are given

in the dimension drawing, which is binding.

ATTENTION: SUFFICIENT SPACE MUST BE

PROVIDED FOR MAINTENANCE

AND REPAIR WORK, ESPECIALLY

FOR REPLACING THE DRIVE

MOTOR OR THE COMPLETE

PUMP UNIT. THE MOTOR FAN

MUST BE ABLE TO TAKE IN

ENOUGH COOL AIR, AND THE

INTAKE GRILLE MUST THEREFORE

BE AT LEAST 10 CM AWAY FROM

ANY WALL, ETC.

To prevent vibrations being transmitted to adjoining

components, the foundation should be laid on a suitable

insulating base (panels providing insulation against

structure-borne sound or vibration panels).

ATTENTION: THE SIZE OF THESE INSULATING

PANELS WILL VARY, DEPENDING

ON CIRCUMSTANCES, AND

SHOULD THEREFORE BE

DETERMINED BY AN

EXPERIENCED SPECIALIST.

Concrete foundations must be completely set and the

surfaces must be smooth before the pump unit is mounted.

Put pump unit onto the foundation and, if necessary, level

vertically with the help of thin sheet-metal panels (with spirit

level). Tighten foundation anchor evenly and firmly.

The alignment must be carried out with the utmost

care and attention, so that the unit will operate

without failure. If you do not pay attention to this

hint you will lose your warranty!

4.2 Installation and Alignment of Coupling

Make sure that nobody can start the motor

when work is being carried out on the

coupling. In accordance with the Accident

Prevention Regulations, the pump unit may

only be operated when the coupling guard is mounted.

• Before starting installation, carefully clean shaft ends

and coupling components.

• Pull coupling hub onto motor shaft end. The coupling

may be heated beforehand in an oil bath to approx.

100°C. The motor hub will need to be mounted flush

to the motor shaft.

• The motor coupling hub will have an interference t

and the pump coupling hub will have a clearance fit.

The clearance allows the pump hub to be adjusted on

the pump shaft. Keep pump hub loose for adjusting the

elastomer element.

• Place half of the coupling elastomer element around

the hubs and secure with self-locking capscrews.

5

Page 6

• The elastomer element will space the pump hub. Now

secure the pump hub to the shaft.

• Mount other half of the elastomer element. Tighten all

capscrews to recommended torques.

• Mount coupling guard.

Capscrew Torques

Recommended Capscrew Torques Coupling Torque – Dry

Size In. lbs. Ft. lbs.

2

3

4 204 17

5

10

20

30 360 30

40

Capscrews can be further used

50

60

70 900 75

80

100 3240 270

120

140 7080 590

IMPORTANT

Capscrews have self-locking

patches which should not

be reused more than twice.

with applications of a thread-

locking adhesive.

Do Not Lubricate Capscrew

Threads.

Equipment Alignment

(coupling alignment is directly related to equipment and coupling life.)

Although Omega couplings can withstand gross

misalignment, care should be taken for best possible

alignment to assure optimum performance. The

caliper/straightedge alignment procedure is described

below. If greater alignment accuracy is desired, a dial

indicator method is recommended. There are occasions

when equipment manufacturers require more specific

alignment tolerances, in which case, the manufacturer’s

recommendations should be followed.

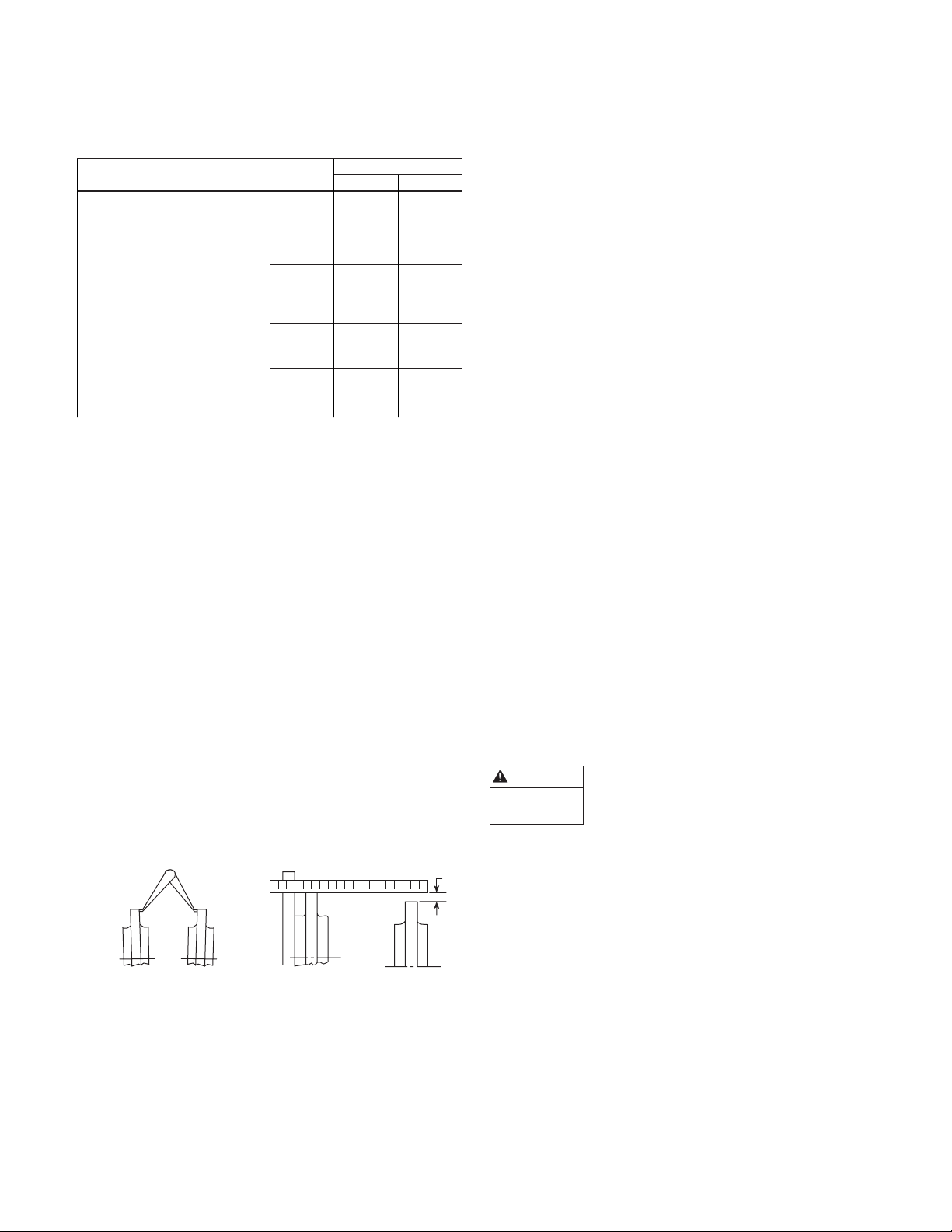

• To correct for angular misalignment, use calipers to

check the gap between hubs. Adjust or shim equipment

until the gap is the same at all points around the hubs.

• To correct parallel offset, place a straightedge across

the hub flanges in two places at 90° to each other.

Adjust or shim equipment until the straightedge lays

flat on both sides.

• Tighten down connected equipment and recheck

alignment.

• Install elastomer element, tightening all capscrews to

the values shown in table.

• If practical, recheck and tighten capscrews after several

hours of operation.

PARALLEL OFFSET

ADJUST FOR ANGULAR MISALIGNMENT ADJUST FOR PARALLEL OFFSET

4.3 Connecting the Pipes to the Pump

Suction and Discharge Pipe

• The pipes must be of a size and design that liquid can

flow freely into the pump and that the pump functions

without problems. Particular attention is to be paid to

ensuring that suction pipes are airtight and that the

NPSH values are observed. Lay the suction pipe in the

horizontal section towards the pump so that it is slightly

inclined upwards so that no air pockets occur. In most

cases, it is recommended that a non-return valve is

installed in the discharge pipe shortly after the pump.

• When laying the pipes, make sure that the pump is

accessible for maintenance and installation.

• Please note 1.4: “Permitted Forces on Flanges”.

• Before connecting up to pump: remove protective

coverings from suction and discharge branches.

• To protect the shaft sealing (especially mechanical seals)

against foreign bodies, it is recommended that a sieve,

800 micron, is installed in the suction/intake pipe

when the motor is being started up.

• Before starting up, the pipe system, ttings and

equipment must be cleaned to remove weld spatter,

scale etc. Any pollutants are to be completely removed

from pump units that are directly or indirectly

connected to drinking water systems before being

installed and taken into use.

• If the pipe system is tested with the pump installed, do

not exceed the maximum permitted casing pressure of

the pump and/or shaft sealing (see Data Sheet).

• When emptying the pipe after the pressure test, make

sure that the pump is treated properly (danger of rust

and problems when starting up).

• In the case of pumps with stufng boxes, replace

packing after pressure test (packing may be overcompressed and thus no longer suitable for use).

Auxiliary Pipes

Any sealing, flushing or cooling pipe connections that are

necessary must be installed. Please consult the Data Sheet

to see which pipes, pressures and quantities are necessary.

The relevant detail drawing of the shaft sealing contains

a diagrammatic proposal for the pipework and fittings.

This proposal does not take into account the safety

requirements for each specific pump unit.

ATTENTION: POINT 1.4, “SEALING, COOLING”

MUST BE OBSERVED AS REGARDS

REGULATION AND MONITORING.

It is recommended that a pipeline is installed to take off

any leakage from the shaft seal. For connection, see the

Dimension Sheet.

4.4 Electrical Connection

WARNING

Hazardous

voltage

Electrical connection work may

only be carried out by an authorized

professional. The rules and regulations

valid for electrical technology, especially

those concerned with safety measures,

must be observed. The regulations of the

power supply companies operating in

that area must also be observed.

Before starting work, check that the information on the

motor rating plate is the same as the local mains network.

The power supply cable of the coupled drive motor must

be connected up in accordance with the wiring diagram

produced by the motor manufacturer. A protective motor

switch is to be provided.

ATTENTION: THE DIRECTION OF ROTATION

SHOULD ONLY BE CHECKED

WHEN THE PUMP IS FULL. DRY

RUNNING WILL CAUSE DAMAGE

TO THE PUMP.

6

Page 7

4.5 Starting Up

The plant may only be started up by people who

are familiar with the local safety regulations and

with these Operating Instructions (especially

with the safety regulations and safety instruction

given here).

In order to be able to observe and monitor the shaft sealing,

no protective covering is provided in this area. If the pump

is running, particular care should therefore be taken (watch

out for long hair, loose pieces of clothing etc.).

Hints for the Use as Boiler Feed Pump

Limits for cast iron when used in boiler feed or condensate

applications: pH-value 9,0 (optimum 9,3), short term:

pH-value 8,5.

The above stated values must be guaranteed at the suction

side of the pump in any case.

The water treatment must be in accordance with the

specifications for water treatment of boiler feed water in

steam plants up to 64 bar.

Air traps in the system must be avoided in any case.

Starting up for the First Time

• With MPV type pumps, no further lubrication is needed

before initial start-up.

• Pump and suction pipe must be completely exhausted

from air and filled with handling liquid before each

start up of the pump unit. When filling the pump open

screwed plug “PM2”. Close it when water is flowing out.

• Open slide valve in suction/intake pipe.

• Turn pump unit once again by hand and check that it

moves smoothly and evenly.

• Check that coupling guard is installed and that all safety

devices are operational.

• Switch on any sealing, ushing or cooling devices that are

provided. See Data Sheet for hydraulic requirements.

• Set discharge side slide valve to approx. 25% of rated

flow quantity. With pumps with a discharge branch rated

width less than 200 GPM, the slide valve can remain

closed when starting up (see also Point 1.4 “Minimum

Quantities”.

• Check direction of rotation by switching on and off

briefly. It must be the same as the directional arrow on

the bearing frame.

• Start drive device.

• As soon as it reaches normal operating speed, open

discharge valve immediately and adjust the required

operating point (see Data Sheet).

• Mechanical seals don’t need to be maintained and are

almost free of leakage.

Putting into Operation Again

(after longer standstill; 1 month)

Each time you put the pump into operation again you

have to do the same things you do when starting the pump

for the first time. The control of the rotation direction

of the unit can be dropped. You are only allowed to put

the pump into operation again automatically when the

pump remained filled with liquid during standstill and the

required test drives have been made, see point 4.7.

4.6 Operation and Monitoring

Be particularly careful not to touch hot machine

parts and when working in the unprotected

shaft seal area. Remember that automatically

controlled systems may switch themselves on

suddenly at any time. Suitable warning signs should be

affixed.

ATTENTION: REGULAR MONITORING AND

MAINTENANCE WILL EXTEND THE

LIFE OF YOUR PUMP OR PUMP

SYSTEM.

• You must observe the area of application given on the

Data Sheet.

• Do not exceed the output given on the motor rating

plate.

• Avoid dry running, running against closed discharge

valves or operation while the liquid handled is in the

vapor phase.

• Avoid sudden changes in temperature (temperature

shocks).

• The pump and motor should run evenly and without

vibrations; check at least once a week.

• Check the regulating and monitoring facilities of any

sealing, flushing or cooling systems once a week to

ensure that they function properly. Outgoing cooling

water should be body temperature.

• Pumps which are exposed to corrosive chemicals or to

wear through abrasion must be inspected periodically for

corrosion or wear and tear. The first inspection should

be carried out after six months. All further inspection

intervals should be determined on the basis of the state

of the pump.

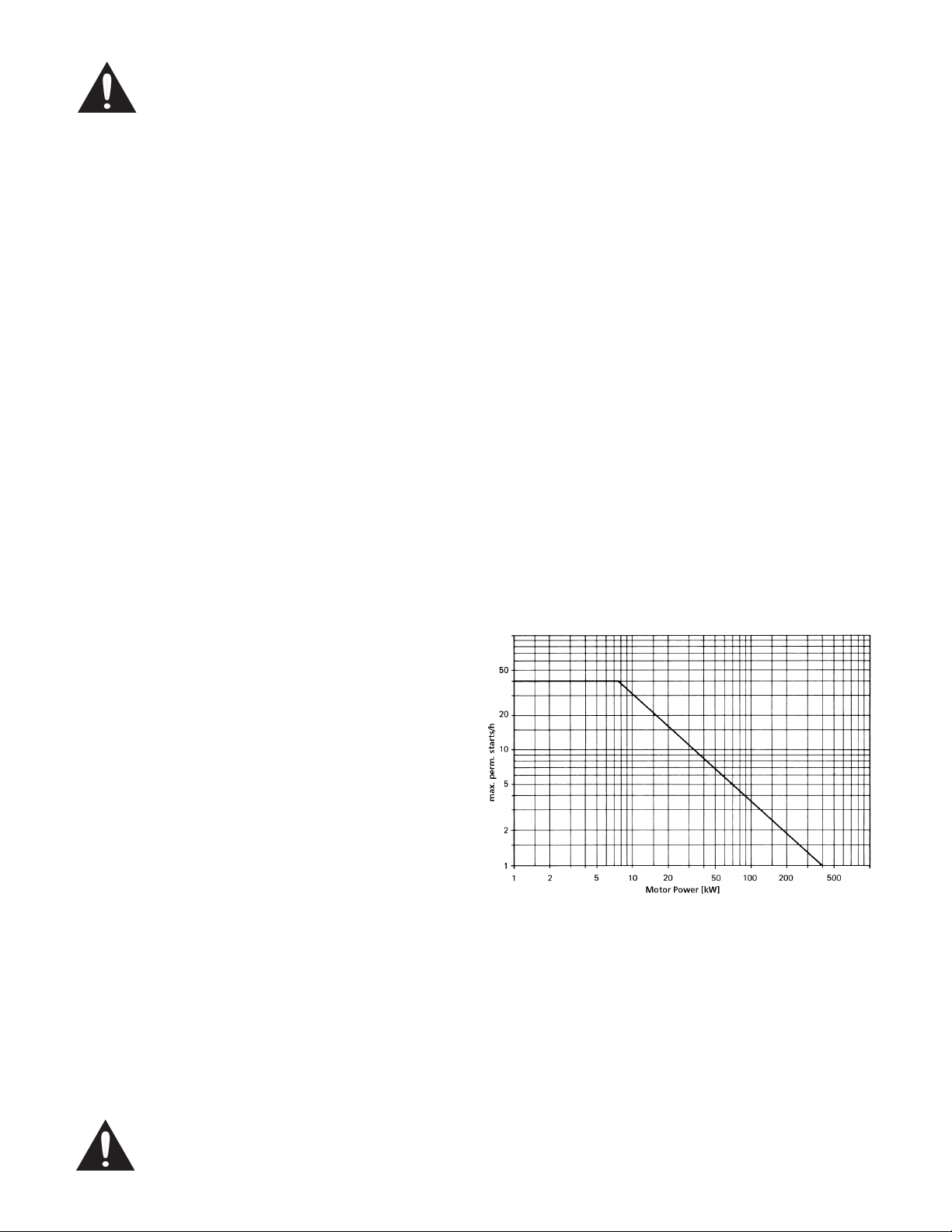

Permitted Number of Starts

Do not exceed the pump’s permitted number of starts

– see diagram. With electric motors, the permitted number

of starts is given in the motor operating instructions. If two

different figures are given, the lower figure is valid.

4.7 Shutting Down

• Close slide valve in discharge pipe. This is not necessary

if there is a spring-loaded non-return valve.

• Switch off motor (make sure it runs down quietly.

• Close slide valve on suction side.

• Close auxiliary systems. Do not shut down cooling

system until pump has cooled down.

• If there is any risk of freezing, empty pump, cooling

system and pipes completely.

• If the pump also remains under operating conditions

(pressure and temperature) when stationary: leave all

sealing, flushing and cooling systems switched on.

• If the pump remains under operating conditions when

stationary, test drives have to be made in regular intervals

with a duration of at least 5 minutes. The intervals

7

Page 8

between the test drives depend on the unit, but they

should be made at least once a week.

4.8 Dismantling

The operator’s or manufacturer’s fitters

should be informed as to the nature of the

liquid handled. In the case of pumps handling

dangerous liquids, the liquid handled should be

disposed of by environmentally acceptable means before

the pump is dismantled.

• Before starting to disassemble the pump unit make sure

that it cannot be switched on again.

• The pump casing must be depressurized and empty.

• All valves in the suction, intake and discharge pipes

must be closed.

• All components must have cooled down to ambient

temperature.

• To avoid corrosion it is recommended to ush the

pump and fill it with a water-repellant preservative,

e.g. KLÜBERTOP K01.601 or equal.

• To spread the preservative turn the pump several times

with the hand. Then drain the pump and lock the

nozzles.

5. MAINTENANCE, SERVICING

Work should only be carried out on the pump

or pump unit when it is not in operation. You

must observe Point 1.4 “Safety Instructions”.

ATTENTION: MAINTENANCE AND SERVICING

WORK MUST ONLY BE CARRIED

OUT BY TRAINED, EXPERIENCED

STAFF WHO ARE FAMILIAR WITH

THE CONTENTS OF THESE

OPERATING INSTRUCTIONS, OR BY

THE DISTRIBUTOR’S OWN SERVICE

STAFF. THE WORK CARRIED OUT

MUST BE DULY ENTERED IN THE

“LOG BOOK” (SEE POINT 11) AND

CONFIRMED BY BEING SIGNED.

Mechanical Seals

Before opening the pump, it is essential that

you note Point 1.4 “Safety Instructions”, Point

4.8 “Dismantling” and Point 8 “Repairs”.

Mechanical seals do not need to be maintained and

are completely free of leakage. Pumps with mechanical

seals must only be operated when completely filled and

without air locks (or air pockets). The seal casing where

the mechanical seal is located must always be filled with

the sealing liquid. If the liquid being handled drips out at

the mechanical seal, it is damaged and must be replaced.

When installing the mechanical seal, make sure that

the seal cavity is absolutely clean, particular care has to

be paid to the surface of the seal rings. To facilitate the

slip-on of the rotating components of the seal onto the

shaft, lubricate all moving components and sliding areas

by means of water, soapy water or soft soap. Use mineral

oils only in case all elastomers are oil resistant. Do not

lubricate the surface of the seal rings. Do not force

elastomeric elements over sharp edges, if necessary use

assembling aiding sleeves.

Lubrication of Bearing

• Intervals of re-lubrication/grease quantities (see point

2.3 “bearing and lubrication”).

8

• If the pump is left non-operational for any length of

time, the grease in the bearings should be changed

after 2 years.

Coupling

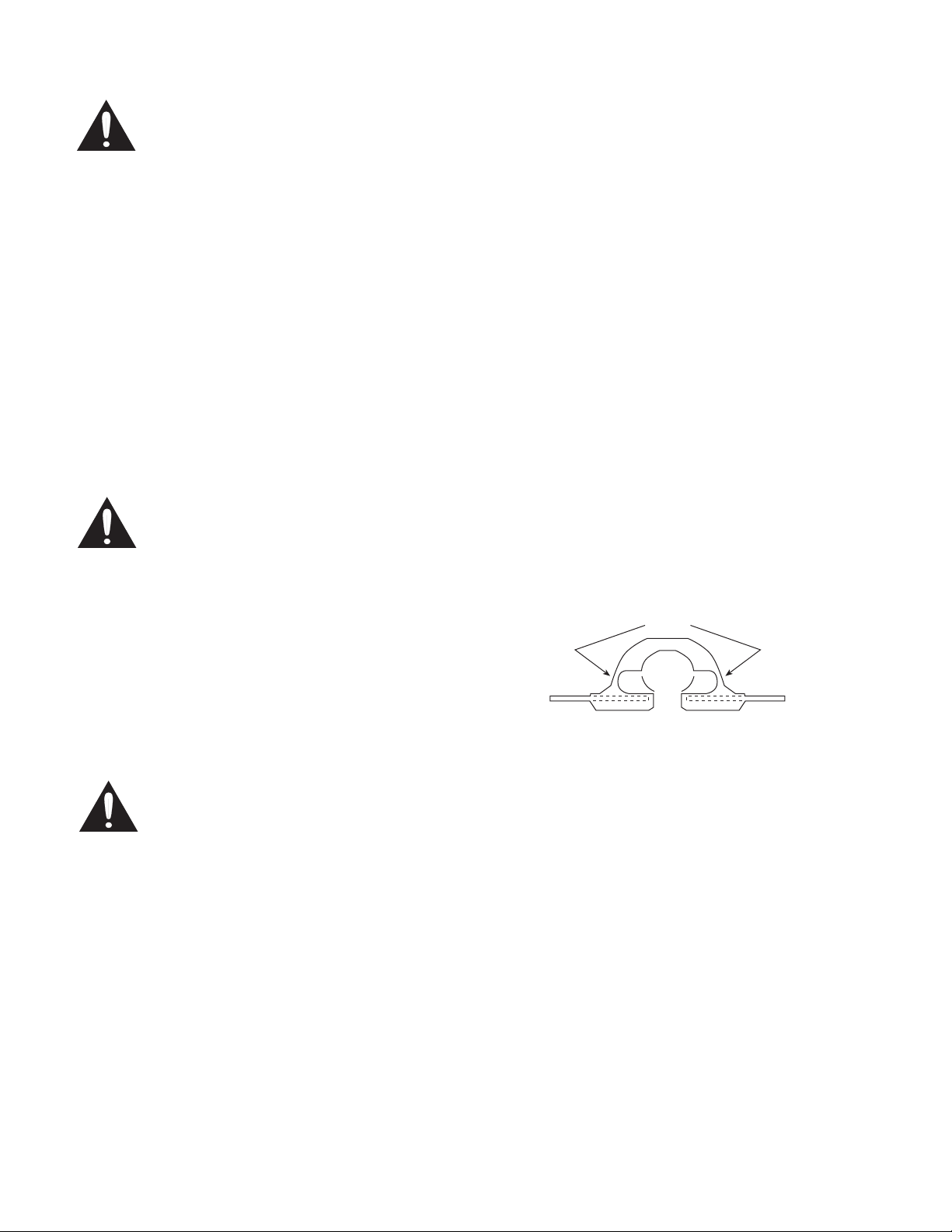

When inspecting the element, look for fatigue cracks

(over ½") originating near the stress relief grooves

(approximately ¼" – ½" above the metal shoe),

discoloration (a darker faded orange color signals

possible material degradation) or surface cracking if used

in adverse conditions such as cooling towers or severe

environments (pH < 4 or pH > 10).

In critical applications, the probability of unexpected

downtime can be greatly diminished by scheduling

flexible element replacement at regular intervals. The

frequency of replacement will depend upon the severity

of the application and environmental conditions. A

properly sized element which is stored and operated

under normal conditions (i.e. under 85% humidity and

85°F) should obtain a minimum of 6 to 8 years of service

life after the date of manufacture. A production date

sticker is applied to all elements for ease of inspection

(I.E. 3Q93 indicates Third Quarter 1993 production).

After the coupling has been in operation for some time,

a “torsional set” may develop in the flex element (up to

1

⁄4" on a size E40, even more on larger sizes). This does

not affect the performance of the coupling, as it is simply

the material creeping under the applied stress. A very

large torsional set may suggest a sizing problem and will

warrant a close review of the application and coupling

selection parameters. For ease of assembly/disassembly,

elements should be re-installed in the same “position of

rotation” in which they were removed.

INSPECT

HERE

Cleaning the Pump

Dirt on the outside of the pump has an adverse effect

on transmission of heat. The pump should therefore be

cleaned with water at regular intervals (depending on the

degree of dirt).

ATTENTION: THE PUMP SHOULD NOT BE

CLEANED WITH PRESSURIZED

WATER – WATER WILL GET INTO

THE BEARINGS AND INTO THE

MOTOR.

6. LONGER PERIODS OF NON-OPERATION

6.1 Drained Pumps

• Turn by hand at least 1 x week (do not switch on because

of dry running).

• If necessary, unblock by tapping gently on the coupling in

axial direction.

• Change the grease in the bearings after 2 years.

• Replace bearings after 5 years.

6.2 Filled Pumps

• Switch stand-by pumps on and immediately off again

once a week.

• If the stand-by pump is at operating pressure and

temperature:

• Change the grease in the bearings after 2 years.

• Replace bearings after 5 years.

Page 9

7. FAULTS – CAUSES AND SOLUTIONS

The following notes on causes of faults and how to

repair them are intended as an aid to recognizing the

problem. The distributor’s Customer Service Department

is available to help repair faults that the operator cannot

or does not want to repair. If the operator repairs or

changes the pump, the design data on the Data Sheet and

Points 1.2 – 1.4 of these Operating Instructions should be

particularly taken into account. If necessary, the written

agreement of the distributor must be obtained.

FAULTS

DISCHARGE TOO LOW

Code no. 1, 4, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15

DISCHARGE STOPS AFTER A TIME

Code no. 8, 10, 11, 12, 30

HEAD TOO LOW

Code no. 2, 4, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 30, 34

HEAD TOO HIGH

Code no. 3, 5, 34

DRIVE MECHANISM OVERLOADED

Code no. 2, 3, 5, 15, 25, 27

PUMP NOT RUNNING QUIETLY

Code no. 7, 10, 14, 22, 23, 24, 25, 29, 30, 33

TEMPERATURE IN THE PUMP TOO HIGH

Code no. 7, 10, 30

TEMPERATURE IN THE SHAFT SEALING TOO

HIGH

Code no. 18, 19, 21

TEMPERATURE AT THE BEARING TOO HIGH

Code no. 2, 14, 23, 24, 25, 26, 29, 31, 32

PUMP LEAKING

Code no. 25, 28

LEAKAGE RATE AT SHAFT SEALING TOO HIGH

Code no. 19, 21, 22, 25

MEANING OF CODE NUMBER FOR CAUSE AND

METHOD OF REPAIR

1. Back-pressure too high

• open discharge valve further

• reduce resistance in discharge pipe (e.g. clean lter if

necessary)

• Use larger impeller (note available motor power)

2. Back-pressure too low, discharge too low

• throttle discharge valve

3. Speed too high

• reduce speed

• compare speed of motor with specied pump speed

(rating plate)

• when adjusting speed (frequency transformer) check

reference value setting

4. Speed too low

• increase speed (check available motor power)

•compare speed of motor with specied pump speed

(rating plate)

• when adjusting speed (frequency transformer) check

reference value settings

5. Impeller diameter too large

• use smaller impeller

6. Impeller diameter too small

• use larger impeller (check available motor power)

7. Pump and/or pipes not completely filled with liquid

• ll

• vent

8. Pump or suction/intake pipe blocked

• clean

9. Air pocket in pipeline

• vent

• improve course of pipe

10. NPSH of system too small

• increase liquid level

• increase admission pressure

• reduce resistance in the intake/suction pipe (change

course and rated width, open shutoff valves, clean

filters)

11. Air being sucked in

• increase liquid level

• check suction pipe is vacuum-tight

• provide straightening vanes in suction pipe ttings with

water seal

12. Air being sucked in through shaft sealing

• clean sealing pipe

• increase sealing pressure

• replace shaft sealing

13. Direction of rotation is wrong

• swap over two phases of power supply (to be done by

a specialist electrician)

14. Inner components suffering from wear

• replace worn parts

15. Density and/or viscosity of liquid handled is too high

• seek assistance

16. Shaft sealing worn

• check sealing, ushing and cooling pipes (pressure)

• avoid dry running

17. Lines and roughness on shaft or shaft sleeve

• replace parts

18. Deposits on mechanical seal

• clean

• replace mechanical seal if necessary

• if necessary provide additional rinsing or quench

19. Impeller out of balance

• remove blocks/deposits

• replace if broken or unevenly worn

• check shafts to ensure that they are running true

20. Coupling not aligned

• align pump unit better

21. Coupling distance too small

• change

22. Forces in pipeline too high (pump unit under strain)

• change (support pipes, use copensators, etc.)

• is foundation plate/frame properly cast in place?

23. Too much, too little or the wrong type of lubricant

• change

24. Electricity supply not right

• check voltage of all phases (2-phase running)

• check cable connections

• check fuses

25. Sealing insufficient

• tighten screws

• replace sealing

26. Bearing damaged

• replace

• check lubricant and bearing cavity for pollutants (clean

grease cavity if needed)

27. Discharge too small

• increase min. amount carried (open slide valves, bypass)

28. Discharge too high

• reduce amount carried (throttle slide valve)

9

Page 10

29. Relief fittings insufficient

• clean balance in impeller

• replace worn parts (impeller, split rings)

• adjust in line with the system pressure/intake

pressure given on ordering

30. System-related vibrations (resonance)

• seek assistance

31. Flow indicator wrong

• check owmeter

• get rid of blockages

• put owmeter in suitable place (no ow distortion

or burbling)

8. REPAIRS

Repairs to the pump or pump system may only

be carried out by authorized skilled personnel

or by the distributor’s specialist staff.

Trained Customer Service engineers are available to

assist with installation and repair work on request. When

removing the pump, you must comply with Point 1.4

“Safety Instructions”, Point 3.1 “Transport, Handling”

and Point 4.8 “Dismantling”.

9. SPARE PARTS, SPARE PUMPS

9.1 Spare Parts

Spare parts should be selected to last for two-years

continuous operation. If no other guidelines are

applicable, we recommend that you stock the number of

parts listed below.

ATTENTION: TO ENSURE OPTIMUM

AVAILABILITY, WE RECOMMEND

THAT SUITABLE QUANTITIES OF

SPARE PARTS ARE HELD IN STOCK,

ESPECIALLY IF THESE ARE MADE

FROM SPECIAL MATERIALS AND IN

THE CASE OF MECHANICAL SEALS,

BECAUSE OF THE LONGER

DELIVERY TIMES.

Ordering Spare Parts

When ordering spare parts, please supply the following

information:

Pump Type:

Pump Order No.

Part Designation in sectional drawing

All the information is given in the Data Sheet and the

relevant sectional drawing.

9.2 Stand-By Pumps

It is essential that a sufficient number of standby pumps are kept ready for use in plants where

failure of a pump could endanger human life or

cause damage to property or high costs. Regular

checks should be carried out to ensure that such pumps are

always ready for use (see Point 6.2).

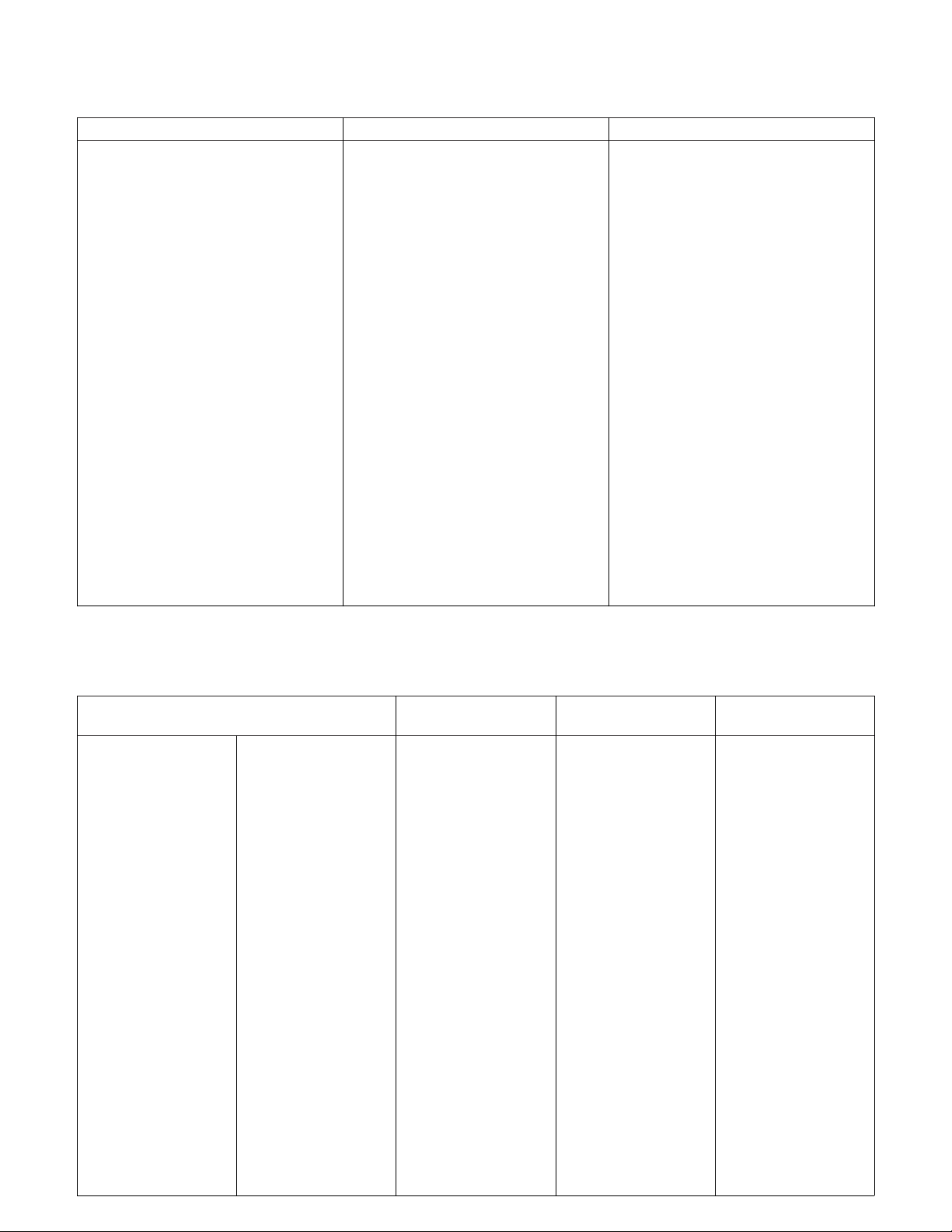

Number of Pumps (including stand-by pumps)

2 3 4 5 6/7 8/9 10+

Spare Part Number of Spare Parts

Impeller i i i 2i 2i 3i 30%

Diffuser i/2 i/2 i/2 i i 3i/2 15%

Shaft with key and shaft screws/nuts 1 1 2 2 2 3 30%

Bearing (roller bearing) 1 1 2 2 2 3 30%

Shaft sleeve 2 2 2 3 3 4 50%

Joints for Pump Casing – sets 4 6 8 8 9 12 150%

Other joints†– sets 4 6 8 8 9 10 100%

Mechanical seal 2 3 4 5 6 7 90%

i = no. of stages

10

Page 11

10. PLANT MANAGER LIST

Each plant manager should sign below to confirm that he has received, read and understood these Operating

Instructions. He undertakes to follow the instructions conscientiously. If these instructions are not followed, the

manufacturer’s guarantee and liability shall cease to apply.

Name: Date: Signature:

11. LOG BOOK

Each plant operator shall duly enter all maintenance and service work that has been carried out, and shall see that the

person responsible confirms such work by signing below.

Plant Operator Person Responsible

Maintenance Work Date

Signature Confirmed By

11

Page 12

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty

period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is

shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased

and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology

Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology

and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation,

limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

© 2012 Xylem, Inc. IM157 Revision Number 2 July 2012

Page 13

MANUAL DE LA INSTRUCCIÓN

IM157

Modelo MPVN

PARA BOMBAS DE LOS SIGUIENTES TAMAÑOS: 40.2, 40.3, 65.1, 65.2, 100.1, 100.2, 125.1, 125.2

MANUAL DE INSTALACIÓN, OPERACIÓN Y MANTENIMIENTO

Page 14

ÍNDICE

TEMAS PÁGINA

1. Consideraciones generales ........................................15

1.1 Introducción...........................................................15

1.2 Garantía .................................................................15

1.3 Reglamentaciones de seguridad ..............................15

1.4 Instrucciones de seguridad......................................15

Riesgos en los que se incurre de no seguir estas in-

strucciones ..............................................................15

Instrucciones de seguridad para el operador ...........16

Velocidad, presión y temperatura ............................16

Fuerzas permitidas en las bridas ..............................16

NPSH (carga de succión positiva neta) ....................16

Sellado, limpieza por descarga de agua y

enfriamiento .......................................................16

Caudales mínimos ...................................................16

Protección contra la operación en seco ...................16

Flujo de retorno ......................................................16

2. DESCRIPCIÓN .......................................................17

2.1 Modelo ..................................................................17

Posición de instalación ............................................17

2.2 Sellado del eje .........................................................17

2.3 Cojinetes y su lubricación .......................................17

Lubricación de los cojinetes de rulemán .......................17

Tipos de cojinetes (rulemanes) ................................17

Intervalo de lubricación / cantidad de grasa ............17

3. TRANSPORTE, MANIPULEO Y ALMACE-

NAMIENTO ..........................................................17

3.1 Transporte y manipuleo ..........................................17

3.2 Almacenamiento.....................................................17

Conservación ..........................................................17

4. INSTALACIÓN Y OPERACIÓN .............................17

4.1 Montaje y conexión de la bomba ...........................17

4.2 Instalación y alineación del acoplamiento ..............18

Par de torsión de los tornillos .................................18

Alineación del equipo .............................................18

4.3 Conexión de las tuberías ........................................18

Tuberías de succión y descarga ................................18

Tuberías auxiliares ..................................................19

4.4 Conexiones eléctricas .............................................19

4.5 Arranque ................................................................19

Consejos para el uso como bomba de alimentación

de caldera ...............................................................19

Arranque inicial ......................................................19

Arranque luego de un período de detención pro-

longado (1 mes) ......................................................20

4.6 Operación y monitoreo ..........................................20

Número de arranques permitidos ............................20

4.7 Detención ...............................................................20

4.8 Desmontaje ............................................................20

5. MANTENIMIENTO Y SERVICIO .........................20

Sellos mecánicos .....................................................21

Lubricación de los cojinetes ....................................21

Acoplamiento .........................................................21

Limpieza de la bomba ............................................21

6. PERÍODOS PROLONGADOS DE INACTIVIDAD 21

6.1 Bombas drenadas ...................................................21

6.2 Bombas llenas ........................................................21

7. FALLAS - CAUSAS Y SOLUCIONES ......................21

8. REPARACIONES .....................................................23

9. PIEZAS Y BOMBAS DE REPUESTO ......................23

9.1 Piezas de repuesto ..................................................23

Cómo efectuar pedidos de piezas de repuesto .........23

9.2 Bombas de reserva ..................................................23

10. LISTA DE GERENTES DE PLANTA .....................23

11. REGISTRO DE SERVICIO Y

MANTENIMIENTO .............................................24

14

Page 15

1. CONSIDERACIONES GENERALES

1.1 Introducción

Este producto cumple con los requisitos de seguridad de las

directivas para máquinas 89/392/EEC, 91/368/EEC y 93/44

EEC de la CE y la Ordenanza sobre Seguridad para Máquinas (MSO) de Austria del 27 de abril de 1994.

El personal a cargo de la instalación, operación,

inspección y mantenimiento debe ser capaz de

demostrar que conoce las regulaciones relevantes

para la prevención de accidentes y que está satisfactoriamente calificado para realizar dichas tareas. Si el

personal no cuenta con el conocimiento suficiente, deberá

recibir instrucción adecuada.

La seguridad de la operación de las bombas o unidades de

bombeo provistas (entendiéndose por unidad de bombeo el

conjunto de bomba y motor) está garantizada únicamente si

se utilizan de acuerdo con las provisiones de la Planilla de

datos técnicos adjunta y del punto 4, “Instalación y operación”.

El operador tiene la responsabilidad de seguir las instrucciones y cumplir con todos los requisitos de seguridad

presentados en estas Instrucciones de operación.

La operación regular y pareja de la bomba o la unidad de

bombeo sólo puede lograrse si la instalación y el manten-

imiento se realizan cuidadosamente y de acuerdo con las

reglas de ingeniería e ingeniería eléctrica de aplicación general. Si no encuentra toda la información en estas Instrucciones de operación, sírvase comunicarse con nosotros.

El fabricante no asume ninguna responsabilidad por la

bomba o la unidad de bombeo si no se siguen las Instruc-

ciones de operación.

Estas instrucciones deberán guardarse en un lugar seguro

para referencia en el futuro.

Si la bomba o la unidad de bombeo se entrega a un tercero,

es esencial que se entreguen también estas Instrucciones

de operación completas junto con todas las condiciones

operativas y los límites de funcionamiento mencionados en

la conrmación del pedido.

Estas instrucciones de operación no toman en consider-

ación todos los detalles y variantes de diseño ni los sucesos

o hechos fortuitos que pudieran ocurrir durante la insta-

lación, operación o mantenimiento.

Las alteraciones o modificaciones a la máquina se permitirán únicamente con el acuerdo expreso del fabricante.

Para mayor seguridad, se recomienda el uso de partes de

repuesto y accesorios originales autorizados por el fabricante. El fabricante no se responsabiliza por las consecuencias

derivadas del uso de otras partes o accesorios.

El fabricante conserva todos los derechos de autor de este

manual. Las instrucciones aquí incluidas están destinadas

únicamente al uso personal del propietario de la bomba o

la unidad de bombeo. Las instrucciones de operación contienen instrucciones técnicas y diagramas que no pueden ser

total ni parcialmente reproducidos, distribuidos o usados

en forma no autorizada con fines competitivos ni traspasados a terceros.

1.2 Garantía

La garantía se otorga de acuerdo con nuestras condiciones

de entrega y la conrmación del pedido. Las tareas de reparación durante el período de garantía pueden ser efectuadas

sólo por el distribuidor autorizado. De otra manera, la

garantía quedará sin efecto.

La garantía no cubre el desgaste natural ocasionado por el

uso ni ninguna de las partes sujetas a desgaste, tales como

impulsores, sellos del eje, mangas del eje, cojinetes, anillos de desgaste, etc. Tampoco cubre daños causados por el

transporte o el manipuleo inapropiado.

A fin de que la garantía tenga validez, es esencial que la

bomba o la unidad de bombeo sea utilizada de acuerdo con

las condiciones de operación indicadas en la placa identicatoria, en la conrmación del pedido o en la Planilla

de datos técnicos. Estas consideraciones son de particular

importancia para la duración de los materiales y el funcionamiento uniforme y sin problemas de la bomba y los sellos

del eje.

Si uno o más de los aspectos considerados difieren en las

condiciones reales de operación, se deberá solicitar al fabricante que confirme por escrito que la bomba es apropiada

para tales condiciones.

1.3 Reglamentaciones de seguridad

Estas instrucciones de operación contienen información e

instrucciones importantes que deben seguirse durante el

montaje y puesta en funcionamiento de la bomba, así como

también durante la operación y el mantenimiento Por este

motivo, estas instrucciones deben ser leídas por el personal

calificado responsable o el operador de la planta antes de

instalar y poner en funcionamiento la bomba, y se las debe

conservar en el lugar donde funciona la bomba o la unidad

de bombeo de modo que sean fácilmente accesibles en todo

momento. El operador debe cerciorarse de que el personal

comprende claramente las instrucciones de operación

contenidas en este manual.Tal hecho deberá ser confirmado

firmando la lista de gerentes de planta (ver el punto 10).

Estas instrucciones de operación no se reeren a las reglamentaciones generales para la prevención de accidentes ni

a las reglamentaciones locales de seguridad u operación.

Es responsabilidad del operador cumplir y hacer cumplir

estas instrucciones y, si fuera necesario, convocar a personal

adicional para la instalación.

Las instrucciones de seguridad contenidas en este manual

de operación se identican con los siguientes símbolos.

Advertencia sobre accidentes personales que

podrían ocurrir de no seguirse las instrucciones

presentadas en esta parte del Manual de instrucciones de operación.

ADVERTENCIA

Tensión

peligrosa

Advertencia sobre voltaje peligroso.

ATENCIÓN: ADVERTENCIA SOBRE POSIBLES

DAÑOS MATERIALES O AL MEDIO

AMBIENTE.

Es absolutamente imperativo observar la información de

seguridad que se encuentra adherida a la bomba o unidad

de bombeo y mantener dicha información legible en todo

momento.

1.4 Instrucciones de seguridad

Riesgos en los que se incurre de no seguir estas instrucciones

Si no se observan las instrucciones de seguridad se pueden

generar, entre otros, los siguientes riesgos:

• Peligro para el personal derivado de factores eléctricos,

mecánicos o químicos.

• Fallas en funciones importantes de la bomba o de la

unidad de bombeo.

• Daños ambientales.

15

Page 16

Instrucciones de seguridad para el operador

• Dependiendo de las condiciones de operación, el des-

gaste, la corrosión y la edad limitarán la vida útil de la

bomba o la unidad de bombeo, así como sus características específicas. El operador deberá asegurar que se

lleven a cabo todas las inspecciones y el mantenimiento

regular de manera que todas las piezas sean reemplazadas

a tiempo, ya que de otra manera podría verse afectada

la operación segura y conable del sistema. Si se observa

un funcionamiento anormal o cualquier tipo de daño, se

debe detener la bomba inmediatamente.

• Si la falla o rotura de algún sistema o unidad pudiera

poner en peligro la integridad física del personal o la

propiedad, se deberá equipar a dicho sistema o unidad

con dispositivos de alarma o módulos de repuesto, y los

mismos se deben probar regularmente para asegurar su

funcionamiento correcto.

• Si existe algún riesgo de lesión por contacto con partes

calientes o frías de la máquina, dichas partes deberán

contar con protección contra el contacto por parte del

usuario o con avisos de advertencia apropiados adheridos

a la máquina.

• La protección de contacto en las partes movibles (por

ejemplo, los protectores del acoplamiento) no debe qui-

tarse de los sistemas que están en operación.

• Si hay fugas de elementos peligrosos (explosivos, tóxicos,

calientes) en, por ejemplo, los sellos del eje, se las debe

dirigir hacia donde no representen un peligro para el

personal ni el medio ambiente. Se deben observar todas

las disposiciones legales.

• Se deben tomar medidas para excluir cualquier riesgo de-

rivado de la electricidad (por ejemplo, se deben observar

todas las reglamentaciones locales sobre equipos eléctricos). Si se realizan tareas en componentes eléctricos con

corriente, los mismos deberán desconectarse del suministro eléctrico o se deberá apagar el interruptor principal

y retirar el fusible. Se debe suministrar un interruptor de

protección para el motor.

• Básicamente, todo trabajo que se realice en la bomba o la

unidad de bombeo debe llevarse a cabo cuando la unidad

está estacionaria y no bajo presión. Se debe permitir que

todas las partes retornen a la temperatura ambiente.

Asegúrese de que nadie puede arrancar el motor cuando

se realizan dichas tareas. Es esencial que se observe

el procedimiento para detener el sistema tal como se

describe en las Instrucciones de operación. Las bombas o

sistemas de bombeo que impulsan elementos peligrosos

para la salud deben ser descontaminadas antes de desarmarlas. Consulte las Planillas de datos de seguridad para

los distintos líquidos. Una vez que se ha completado el

trabajo, todos los dispositivos de protección y seguridad

deben volver a colocarse en su lugar o volver a ponerse

en marcha, según corresponda.

Velocidad, presión y temperatura

Se deben tomar medidas apropiadas en la planta para

asegurar que la velocidad, la presión y la temperatura de la

bomba y del sellado del eje no superen los límites especificados en la Planilla de datos técnicos. Las presiones de

succión dadas (presiones del sistema) también deben ser

suficientemente altas. Además, se debe proteger la bomba

contra picos de presión como los que se pueden generar al

detener la planta rápidamente (por ejemplo, con una vál-

vula de retención en el lado de presión, volante, recipiente

de aire).

Fuerzas permitidas en las bridas

Básicamente, las líneas de succión y presión deben ser tales

que las fuerzas sobre la bomba se reduzcan a un mínimo.

Si esto no es posible, comuníquese con su distribuidor para

obtener los límites permitidos.

NPSH (Carga de succión positiva neta)

El líquido bombeado debe tener una carga de succión

positiva neta de presión mínima al entrar al impulsor para

evitar la cavitación o la interrupción del ujo. Este requi-

sito se cumple si el valor NPSH de la unidad (NPSHA) está

bien por encima del valor NPSH de la bomba (NPSHR)

bajo todas las condiciones de operación.

Se debe prestar particular atención al valor de NPSH cu-

ando se bombean líquidos próximos al punto de ebullición.

Si el valor cae por debajo del valor NPSH de la bomba, se

pueden producir daños causados por cavitación o graves

daños por sobrecalentamiento.

El valor de NPSHR para cada tipo de bomba se encuentra

en las hojas de curvas características. Por pedido, podemos

proporcionar folletos para el cálculo de los valores de

NPSH.

Sellado, limpieza por descarga de agua y enfriamiento

Se debe proveer instalaciones adecuadas para la regulación

y el monitoreo de las tareas de sellado, limpieza por descarga de agua y enfriamiento. Cuando se bombean líquidos

peligrosos o a alta temperatura, debe tenerse cuidado en

asegurar que la bomba deje de funcionar si los sistemas

de sellado, limpieza por descarga de agua o enfriamiento

fallan.

Estos tres sistemas siembre deben estar operativos antes de

arrancar la bomba. No se deben poner fuera de operación

hasta que la bomba se haya detenido, y esto siempre y

cuando la naturaleza de la operación así lo permita.

Caudales mínimos

Si la bomba se hace arrancar contra una válvula cerrada

en la línea de presión, debe hacerse notar que la potencia

tomada por la bomba es transmitida al líquido bombeado

en forma de calor. Esto puede hacer que el líquido se

sobrecaliente excesivamente en un período de tiempo relativamente corto, lo que dañará los accesorios internos de la

bomba. Una vez que la bomba ha alcanzado la velocidad de

operación, se debe abrir la válvula de descarga tan pronto

como sea posible. Si las condiciones de operación hacen

que Q = 0 sea inevitable o si lo que circula es agua caliente,

se debe proveer una válvula de retención de insuación

directa o, en sistemas pequeños, una tubería de desvío. Su

distribuidor puede ayudarlo a calcular el caudal mínimo o

diseñar la tubería de desvío.

Protección contra la operación en seco

Las bombas no deben funcionar en seco bajo ninguna circunstancia, puesto que el sobrecalentamiento puede dañar

los componentes (por ejemplo, los sellos mecánicos).

Flujo de retorno

En sistemas en los que las bombas operan en circuito cer-

rado bajo presión (colchones de gas, presión de vapor),

la presión del colchón de gas no se debe reducir con la

bomba, puesto que la velocidad del flujo de retorno puede

ser mucho mayor que la velocidad de operación, lo que

destruiría la unidad.

16

Page 17

2. DESCRIPCIÓN

Modelo

Diseño MPVN

Características de diseño:

• Conguración vertical con cojinetes de empuje separa-

dos, lubricación con grasa por medio de niples.

• Motores de acuerdo con Norma NEMA MG 1-4.07.

• Acoplamiento exible entre la bomba y el motor.

• Cojinete de deslizamiento de lubricación media en la

carcasa de succión.

• Diseñada para el fácil mantenimiento. El sellado del eje

puede recibir mantenimiento sin necesidad de desarmar

la bomba.

Posición de instalación

Con el eje vertical.

Cualquier otra posición de instalación debe contar con el

acuerdo previo del fabricante.

2.2 Sellado del eje

Diseño básico con sello mecánico. Sello código SA con sello

no balanceado; sello código SB con sello balanceado.

ATENCIÓN: ENCONTRARÁ MÁS INFORMACIÓN

SOBRE LOS SELLOS MECÁNICOS Y

LOS RIESGOS DE ACCIDENTE QUE

PUEDEN IMPLICAR EN EL PUNTO

4.6, “OPERACIÓN Y MONITOREO”,

Y EN EL PUNTO 5,

“MANTENIMIENTO Y

REPARACIONES”.

2.3 Cojinetes y su lubricación

Lado del motor: cojinetes de rulemán lubricables (cojinetes

de empuje)

Lado de la bomba: cojinete de deslizamiento de lubricación

media en la carcasa de succión.

Lubricación de los cojinetes de rulemán

Estándar: lubricación con grasa a través de niples. Las grasas lubricantes deben ser a base de litio, grado 2.

Los cojinetes de rulemán ya vienen engrasados y listos para

el uso.

Tipos de cojinetes (cojinetes de rulemán)

Tamaño de bomba

Tipo de cojinete

MPVN 40.2 / MPVN 40.3 B306C§

MPVN 65.2 / MPVN 65.2 B307C§

MPVN 100.1 / MPVN 100.2 2 x 7308 (arreglo X)

MPVN 125.1 / MPVN 125.2 2 x 7308 (arreglo X)

Intervalo de lubricación / calidad de grasa

Cantidad Intervalo de lubricación en horas de operación

Tamaño de la bomba de grasa

MPVN 40.2 / MPVN 40.3 12,1 3800 4300 5500 6000 6500

MPVN 65.1 / MPVN 65.2 15,5 3500 4000 5000 5500 6000

MPVN 100.1 / MPVN 100.2 23,0 3300 3800 4500 5000 5500

MPVN 125.1 / MPVN 125.2 33,0 2500 3300 4300 4800 5000

Lubricación con grasa

3550 2950 2200 1750 1450

3. TRANSPORTE, MANIPULEO Y

ALMACENAMIENTO

3.1 Transporte y manipuleo

• Inspeccione la bomba -o la unidad de bomba

y motor- inmediatamente al recibirla para

asegurarse de que no esté dañada y contenga

todas las partes.

• La bomba o la unidad de bombeo deben ser

transportadas cuidadosamente por personal

competente. Evite los impactos fuertes.

• Mantenga la bomba o unidad de bombeo en

la misma posición en que fue provista por la

fábrica. Tome nota de las instrucciones en el

embalaje.

• Los lados de admisión y descarga de la

bomba deben estar cerrados con tapones durante el transporte y almacenamiento.

ATENCIÓN: DESECHE EL MATERIAL DE

EMBALAJE DE ACUERDO CON LAS

REGLAMENTACIONES LOCALES.

• Los dispositivos de elevación que se utilicen (montacar-

gas de horquilla, grúa, poleas, eslingas, etc. ) deben ser

suficientemente fuertes.

• La bomba o la unidad de bombeo sólo deben levantarse

por sus puntos sólidos, como por ejemplo la carcasa,

las bridas o el armazón. La ilustración arriba muestra el

modo correcto de transportar la unidad por grúa.

No se pare bajo cargas suspendidas; tome nota

de las regulaciones generales para prevención de

accidentes.

La bomba o unidad de bombeo debe asegurarse para que

no se vuelque ni deslice hasta tanto sea colocada en su

ubicación final.

3.2 Almacenamiento

Las bombas o unidades de bombeo que se almacenan por

un período prolongado antes de usarlos deben protegerse

de la humedad, las vibraciones y el polvo (por ejemplo,

envolviéndolos en papel de aceite o en una cubierta de

plástico). Básicamente, las bombas deben almacenarse en

lugares donde estén protegidas contra la intemperie, es

decir, bajo cubierta. Durante este tiempo, se deben cer-

rar todas las ramas de succión y descarga y todas las otras

entradas y salidas con bridas falsas o tapones.

Conservación

Cuando la bomba se almacena por más de 3 meses (dependiendo del pedido): En la fábrica ya se ha efectuado un tra-

bajo especial de conservación. El producto utilizado debe

ser quitado con agua antes de hacer funcionar la bomba por

primera vez.

4. INSTALACIÓN Y OPERACIÓN

4.1 Montaje y conexión de la bomba

Las bombas del tipo MPV deben sujetarse con pernos a

un bastidor auxiliar jo (por ejemplo, una fundación de

concreto, una placa o una viga de acero, etc.) El bastidor

auxiliar debe soportar todas las cargas que se generen

durante el funcionamiento. El tamaño del bastidor auxiliar

y la ubicación y el tamaño de los recesos para el anclaje de

los cimientos se dan en el diagrama de dimensiones, el

cual es obligatorio.

17

Page 18

ATENCIÓN: SE DEBE PROVEER ESPACIO

SUFICIENTE PARA REALIZAR

TAREAS DE MANTENIMIENTO Y

REPARACIÓN, ESPECIALMENTE

PARA REEMPLAZAR EL MOTOR O

LA UNIDAD COMPLETA. EL

VENTILADOR DEL MOTOR DEBE

PODER TOMAR SUFICIENTE AIRE

FRESCO, POR LO TANTO LA

PARRILLA DE ENTRADA DEBE ESTAR

A POR LO MENOS 10 CM DE

CUALQUIER PARED, ETC.

Para evitar que las vibraciones se transmitan a los compo-

nentes vecinos, la cimentación debe colocarse sobre una

base aisladora apropiada (por ejemplo, paneles que aíslan

los sonidos generados por la estructura o paneles que absorben vibraciones).

ATENCIÓN: EL TAMAÑO DE ESTOS PANELES

AISLANTES VARIARÁ

DEPENDIENDO DE LAS

CIRCUNSTANCIAS, POR LO QUE

DEBE SER CALCULADO POR UN

ESPECIALISTA CON EXPERIENCIA.

Los cimientos de concreto deben estar completamente secos y su superficie debe ser lisa antes de montar la unidad.

Coloque la unidad sobre la base de montaje y, si fuera necesario, nivélela verticalmente con ayuda de paneles delgados

de metal (con nivel de burbuja de aire). Ajuste el anclaje de

montaje en forma pareja y segura.

La alineación debe realizarse con sumo cuidado

y atención de modo que la unidad pueda operar

sin fallas. Si no se sigue este consejo la garantía

quedará anulada.

4.2 Instalación y alineamiento del acoplamiento

Asegúrese de que nadie puede arrancar el motor mientras se trabaja en el acoplamiento. De

acuerdo con los Reglamentos para Prevención de

Accidentes, la unidad puede funcionar únicamente cuando el protector del acoplamiento está montado

en su lugar.

• Antes de comenzar la instalación, limpie cuidadosamente

los extremos del eje y los componentes del acoplamiento.

• Jale la cabeza de acoplamiento hacia el extremo del eje

del motor. Previamente, se puede calentar el acoplamiento hasta aproximadamente 100°C en un baño de aceite.

La cabeza del motor deberá montarse a ras con el eje del

motor.

• La cabeza de acoplamiento del motor tendrá un ajuste

con apriete y la cabeza de acoplamiento de la bomba

tendrá un ajuste con holgura. La holgura permite ajustar

la cabeza de la bomba al eje. Mantenga la cabeza de la

bomba oja para ajustar el elemento elastómero.

• Coloque la mitad del elemento elastómero del acopla-

miento alrededor de las cabezas y asegúrelo con tornillos

de casquete autobloqueantes.

• El elemento elastómero separará la cabeza de la bomba.

Ahora, asegure la cabeza de la bomba al eje.

• Monte la otra mitad del elemento elastómero. Ajuste

todos los tornillos al par de torsión recomendado.

• Monte el protector del acoplamiento.

18

Par de torsión para los tornillos de casquete

Par de torsión recomendado

2

3

4 204 17

5

10

20

30 360 30

queantes que no deben usarse

40

más de dos veces. Los tornillos

50

60

70 900 75

80

100 3240 270

120

140 7080 590

IMPORTANTE

Los tornillos de casquete

tienen conexiones autoblo-

pueden seguir utilizándose

aplicándoles un adhesivo

bloqueante en el roscado.

No lubrique el roscado de

los tornillos.

Tamaño del Par de torsión – Seco

acoplamiento

Pulg./Libra Pies/Libra

Alineación del equipo

(la alineación del acoplamiento está directamente relacionada con la vida

útil del equipo y el acoplamiento)

Si bien los acoplamientos Omega pueden soportar un gran

desalineamiento, se debe tener cuidado de lograr el mejor

alineamiento posible para asegurar el rendimiento óptimo.

A continuación se describe el procedimiento de alineación

de calibre/línea recta. Si se desea un alineamiento con

mayor exactitud, se recomienda utilizar el método de indicador de cuadrante. En algunos casos el fabricante de los

equipos requiere tolerancias de alineación más especícas.

En tales situaciones se deberán seguir las recomendaciones

del fabricante.

• Para corregir un defecto de alineación angular, utilice

calibres para medir la distancia entre las cabezas. Ajuste

los equipos o coloque cuñas hasta que la separación sea la

misma en todos los puntos alrededor de las cabezas.

• Para corregir una desviación paralela, coloque un canto

en línea recta transversalmente entre las bridas de la

cabeza en dos lugares a 90° entre ellos. Ajuste los equipos o coloque cuñas hasta que el canto en línea recta se

apoye en forma plana en ambos lados.

• Ajuste los equipos conectados y vuelva a vericar la

alineación.

• Instale el elemento elastómero ajustando todos los tornil-

los de casquete a los valores indicados en la tabla.