Page 1

INSTRUCTION MANUAL

IM138

HMC

Close-Coupled Centrifugal Pump

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

Table of Contents

Table of Contents

SUBJECT PAGE

Important Information ................................................................................................................................................3

Installation ..................................................................................................................................................................3

Operation ....................................................................................................................................................................3

Maintenance................................................................................................................................................................3

Red Jacket Water Products Limited Warranty ..............................................................................................................4

2

Page 3

IMPORTANT

IMPORTANT

A. Inspect unit for shipping damage. Report damage to car-

rier immediately.

B. Electrical supply must be a separate branch circuit with

fuses or circuit breakers, wire sizes, per national and local

electrical codes.

C. ALWAYS disconnect electrical power when handling

pump or controls. Install all-leg disconnect switch near

pump.

D. Motors must be wired for proper voltage. (CHECK

NAMEPLATE). Wire size must limit voltage drop to 10%

of nameplate voltage at motor terminals, or motor life

and pump performance will be lowered.

E. Single-Phase: Thermal protection for single-phase units is

sometimes built-in (CHECK NAMEPLATE). If no builtin protection is provided, use a contactor with proper

overload. Fusing is permissible is properly fused.

F. Three-Phase: Provide three-leg protection with a proper

size magnetic starter.

lowed. Motor branch circuit must be protected by a suitable

manual or magnetic starter. Proper fusing and time delay for

starting must be selected to codes. Low voltage protection is

recommended.

Single phase motors are dual voltage, 115/230 V, 60 Hz,

A.C. All pumps are tested at the factory. At installation,

correct rotation (3-phase), phase, frequency and voltage

of power supply must be checked. Power lines must be of

proper size to carry the amperage.

Single Phase 3 HP motors are dual voltage 115/230 V,

60 Hz, A.C. Single phase 5 HP motors are 230 V, 60 Hz,

A.C. All other motors are three phase dual voltage

230/460 V, 60 Hz, A.C. The high voltages are

recommended wherever available.

Three phase rotation must be checked at installation.

Close, then break contacts quickly, observing rotation of

exposed portion of rotating parts. Rotation must agree with

arrow on pump casing. Standard rotation is counter-clockwise viewed from suction end. Motor wiring can be changed

in the field by following wiring diagram inside terminal box

cover or on motor nameplate.

G. Maximum liquid temperatures: HSC & 3673 plastic

fitted, 180°F (82°C) maximum. 3642-3656-3673, AI, BF,

AB, 212° F (100°C) with optional high-temperature seal.

H. Regular inspection and maintenance will increase service

life. Base schedule on operating time.

INSTALLATION

INSTALLATION

Location – Locate the pump as near the liquid source as

practical (below the level of liquid storage if automatic

operation is contemplated). Protect unit from cold weather

or water damage due to flooding. Low static lift and short,

direct suction and discharge pipes are desirable. At suction

lift higher than 15 ft. consult the pump performance curve

for NPSHR (Net Positive Suction Head - Required). Suction

pipe must be at least equal in size to suction connection of

pump, and slope upward to the pump to avoid air pockets.

If pipe larger than pump suction is used, an eccentric pipe

reducer must be used at the pump. Gate valve in suction is

necessary only on positive suction head installation and must

not be used to throttle the pump.

Allow adequate room for servicing and ventilation.

Foundation – Bolt unit to foundation for easy dismantling.

Foundation surface must be flat so there is no distortion and/

or strain developed when tightening bolts. The pumps are

quiet and smooth running, but rubber mounting is desirable

on foundations susceptible to sound effect.

Alignment – No filed alignment is necessary as pumps are

close-coupled.

Wiring – National Electric Code and local codes must be fol-

OPERATION

OPERATION

Fill suction pipe and casing with liquid to be pumped to

insure mechanical seal will not run dry. Four plugs are

provided in the casing. In any position one will be on top for

priming and/or venting and another at bottom for draining.

With pump primed and motor properly wired, the unit may

be started. Be sure pump is not started against a closed valve

in the discharge line.

Maximum temperature (212° F) limitation is imposed by the

mechanical seal material. Optional high temperature seals

are available.

MAINTENANCE

MAINTENANCE

1. Lubrication

Pumps should require no maintenance.

Motors use double-shielded ball bearings, prelubricated

for the life of the bearings. No further lubrication is

required.

2. Replacing Mechanical Seal

A) Dismantling:

1. Turn off power.

2. Drain system.

3. Remove bolts holding motor adapter to

foundation.

4. Remove casing bolts.

5. Remove motor and rotating element from

casing, leaving casing and piping undisturbed.

6. Insert a screwdriver in impeller waterway

passage. Remove impeller nut with a socket

wrench (5⁄8” across flats).

7. Remove impeller from shaft as follows:

3

Page 4

a) Franklin motors:

Remove motor shaft end cap. Insert a

screwdriver in slot of motor shaft. While

holding shaft from rotation, unscrew impeller

from shaft by turning counter-clockwise

when facing it. To loosen three phase and

metal impellers, use a torch to apply heat

to exposed shaft thread and impeller hub, as

locking compound was used to secure

impeller in place.

b) A.O. Smith motors:

Remove motor end cover. Insert 7⁄16” open end

wrench under switch mechanism onto flats

on motor shaft. While holding shaft from

rotating, unscrew impeller from shaft.

Heat may be required as indicated in 7a.

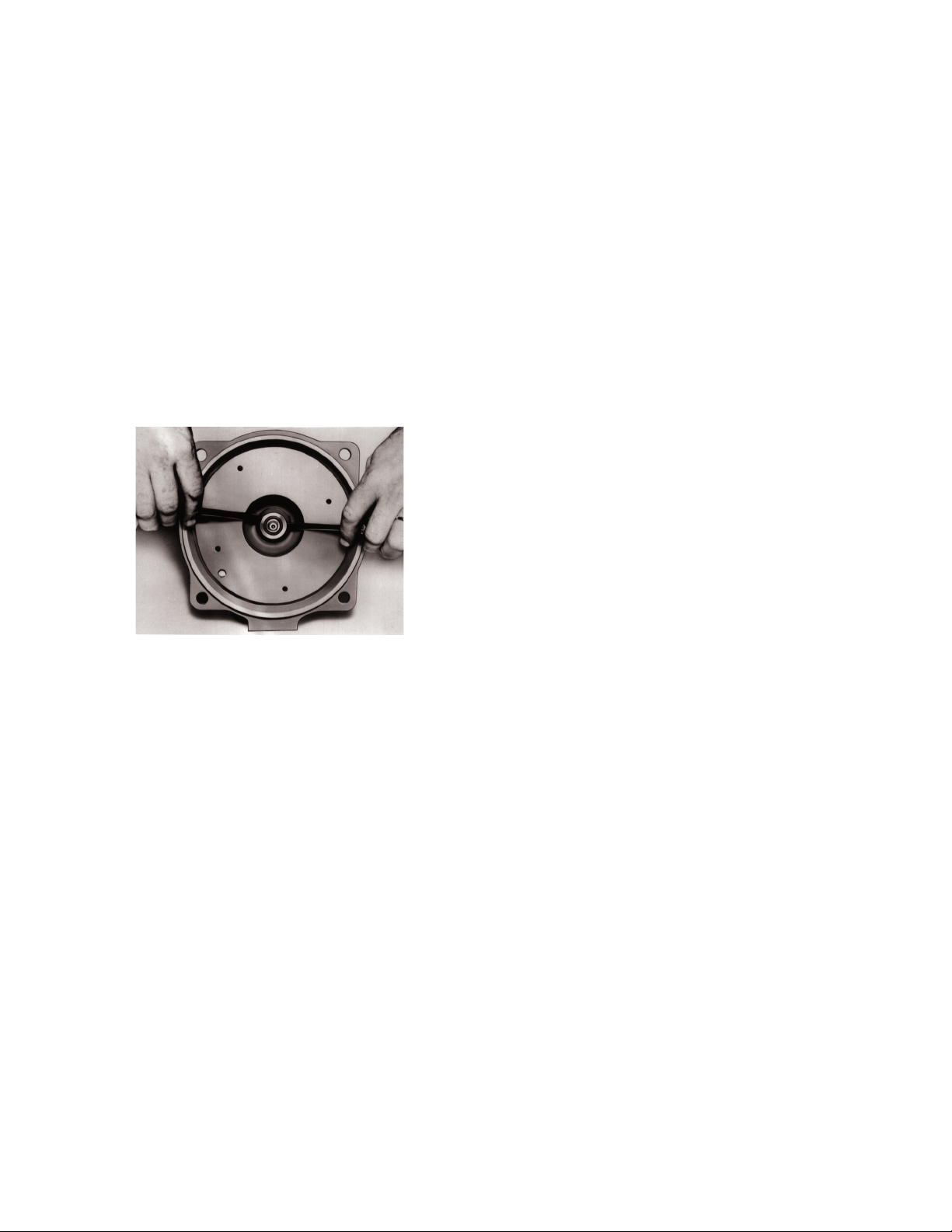

8. Pry off rotating member of mechanical seal

from shaft by using two (2) screwdrivers

(Fig. 1).

Figure 1

with LOCQUIC®, Primer “T” - Loctite® product

Item No. 74756. (Purchase at Automotive

Parts or Hardware). Let parts dry and then

apply Loctite® #271 on same parts.

6. Hold shaft from rotating as described in

paragraph 7 of Dismantling. Thread impeller

on shaft until it is tight against shaft

shoulder.

7. Apply locking compound and replace

impeller nut. Hold impeller from rotating as

indicated in paragraph 6 of dismantling.

8. Remove burrs caused by screwdriver on

periphery of impeller in waterway passages.

9. Replace motor and rotating element in

casing. Be sure to install new gasket.

10. Tighten casing bolts alternately and evenly.

11. Replace hold-down bolts.

12. Check for free rotation after assembly is

complete.

13. Replace hold-down bolts.

14. Close all drain openings. Use pipe joint

compound on male threads.

15. Reprime before starting. Do not start unit

until pump is completely filled with water.

9. Remove bolts holding adapter to motor.

10. Place adapter on a flat surface. Push out

stationary parts of mechanical seal (seat and

rubber mounting cup).

B) Reassembly:

1. Clean gasket and flange faxes, male and

female locks, seal seat counterbore and shaft,

and in particular the shaft shoulder fitting

against impeller.

2. Lube counterbore of adapter and rubber

bushing of stationary seal with water or light

oil. Press stationary seat in counterbore

squarely and evenly. Caution: Do not mar the

lapped face of seat.

3. Remount adapter on motor. Make sure motor

shaft does not dislocate stationary seat of

the seal.

4. Apply a thin coat of light oil or water to

motor shaft and the rubber seal member of

seal. Slide rotating member of mechanical

seal on motor shaft. Be sure rotating seal face

stays in holding collar during installation.

Take extra care not to damage the seal

lapped faces.

5. Spray both shaft and metal impeller threads

4

Page 5

This warranty applies to all water systems pumps manufactured by Red Jacket Water Products.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The war-

ranty period shall exist for a period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever

period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Red Jacket Water Products distributor from whom the pump was

purchased and furnish complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Red Jacket Water

Products Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Red Jacket Water Products

and the dealer in purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing

pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corpora-

tion, limited liability company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

RED JACKET WATER PRODUCTS LIMITED WARRANTY

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products is a trademark of Xylem Inc. or one of its subsidiaries.

© 2012 Xylem Inc. IM138 Revision Number 1 July 2012

5

Page 6

MANUAL DE INSTRUCCIÓN

IM138

HMC

Bomba centrífuga de acoplamiento cerrado

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

6

Page 7

Índice

Índice

TEMA PÁGINA

Información importante ..............................................................................................................................................8

Instalación ................................................................................................................................................................... 8

Operación ...................................................................................................................................................................8

Mantenimiento ............................................................................................................................................................9

Garantía limitada de Red Jacket Water Products ........................................................................................................ 10

7

Page 8

IMPORTANTE

IMPORTANTE

A. Inspeccione la unidad para determinar si resultó dañada

durante el envío. Notifique cualquier daño a la compañía

de transporte de inmediato.

B. El suministro eléctrico debe ser un circuito derivado sepa-

rado con fusibles o cortacircuitos y tamaños de alambre

de acuerdo con los códigos eléctricos nacionales y locales.

C. SIEMPRE desconecte el suministro eléctrico cuando

maneje la bomba o los controles. Instale un desconectador de todos los circuitos, cerca de la bomba.

d. Los motores deben cablearse para la tensión apropiada.

(CONSULTE LA PLACA DEL FABRICANTE). El tamaño del alambre debe limitar la caída de tensión al 10% de

la tensión de la placa del fabricante en los terminales del

motor; de lo contrario se reducirá la vida útil del motor y

disminuirá el rendimiento de la bomba.

E. Monofásica: A veces la protección térmica para unidades

monofásicas está incorporada (CONSULTE LA PLACA

DEL FABRICANTE). Si no se proporciona protección

incorporada, utilice un contactador con una sobrecarga

apropiada. Se permite instalar fusibles siempre que sean

los adecuados.

F. Trifásica: Proporcione protección de tres circuitos deriva-

dos con arrancador magnético del tamaño adecuado.

G. Temperaturas máximas del líquido: HSC y 3673 ajusta-

dos con plástico, 180º F (82º) máximo. 3642-36563673, AI, BF, AB, 212º F (100º C) con sello de alta

temperatura opcional.

H. La inspección y el mantenimiento regulares prolongarán

la vida de servicio. Base la programación en el tiempo de

operación.

de manera que no se produzca deformación o esfuerzo al

apretar los pernos. Las bombas son de funcionamiento silencioso y suave, pero se recomienda instalar una montura de

caucho sobre los cimientos susceptibles a los efectos sonoros.

Alineamiento – El alineamiento fino no es necesario ya que

las bombas son de acoplamiento cerrado.

Conexiones – Deben ser de acuerdo con el Código Eléctrico

de EE.UU. y los códigos locales. El circuito derivado del

motor debe protegerse con un arrancador manual o magnético adecuado. Se deben seleccionar los fusibles y retardo

de tiempo apropiados para el arranque, de acuerdo con los

códigos. Se recomienda protección contra la baja tensión.

Los motores monofásicos son de doble tensión - 115/230

voltios, 60 Hz, de C.A. Todas las bombas se someten a

prueba en la fábrica. Durante la instalación, se debe comprobar la rotación correcta (unidades trifásicas), fase, frecuencia

y tensión de la fuente de alimentación. Las líneas de energía

deben ser del tamaño apropiado para conducir la corriente.

Los motores monofásicos de 3 HP son de doble tensión 115/230 voltios, 60 Hz, de C.A. Los motores monofásicos

de 5 HP son de 230 V, 60 Hz, C.A. Todos los demás motores son trifásicos, de doble tensión - 230/460 voltios, 60

Hz, de C.A. Se recomiendan las tensiones altas cuando estén

disponibles. La rotación trifásica debe ser verificada en el

momento de la instalación. Cierre y luego abra los contactos

rápidamente, observando la rotación de la sección expuesta

de las partes giratorias. La rotación debe concordar con la

flecha en la carcasa de la bomba. La rotación estándar es en

sentido contrahorario cuando se observa desde el extremo

de succión. Las conexiones del motor pueden cambiarse en

el campo siguiendo el diagrama de conexiones dentro de la

tapa de la caja de terminales o en la placa del fabricante del

motor.

INSTALACIÓN

INSTALACIÓN

Ubicación – Sitúe la bomba lo más cerca de la fuente de

líquido que sea práctico (por debajo del nivel de almacenaje

de líquido si se considera la operación automática). Proteja

la unidad contra los daños causados por el tiempo frío y el

agua debido a inundación. Se desea una elevación estática

baja y tuberías de succión y de descarga cortas y directas.

Para una elevación de succión de más de 15 pies, consulte

la curva de rendimiento de la bomba con respecto a la carga

de succión positiva neta requerida (NPSHR). La tubería de

succión debe ser al menos del mismo tamaño que la conexión de succión de la bomba, e inclinarse hacia arriba a la

bomba para evitar las bolsas de aire. Si se utiliza una tubería

más grande que la succión de la bomba, debe instalarse un

reductor de tubo excéntrico en la bomba. Se requiere una

válvula de compuerta en la succión sólo en una instalación

de carga de succión positiva y no debe usarse para estrangular la bomba.

Deje un espacio adecuado para el mantenimiento y la ventilación.

Cimiento – Emperne la unidad al cimiento para facilitar el

desmantelamiento. La superficie del cimiento debe ser plana,

OPERACIÓN

OPERACIÓN

Llene la tubería de succión y la carcasa con el líquido que

se va a bombear para asegurar que el sello mecánico no

funcione en seco. Se proporcionan cuatro tapones en la carcasa. En cualquier posición, un tapón estará en el extremo

superior para cebar y/o ventear, y otro en el extremo inferior

para drenar. Con la bomba cebada y el motor conectado

correctamente, puede arrancarse la unidad. Asegúrese de

que la bomba no sea puesta en marcha contra una válvula

cerrada en la tubería de descarga. La limitación de temperatura máxima (212º F) es impuesta por el material del sello

mecánico. Se ofrecen sellos de alta temperatura opcionales.

8

Page 9

MANTENIMIENTO

MANTENIMIENTO

1. Lubricación

Las bombas no requieren mantenimiento.

Los motores utilizan rodamientos de doble blindaje,

prelubricados para toda la vida útil de los mismos. No se

requiere lubricación adicional.

2. Reemplazo del sello mecánico

A) Desmantelamiento:

1. Apague el suministro eléctrico.

2. Drene el sistema.

3. Quite los pernos que sujetan el adaptador para

el motor al cimiento.

4. Quite los pernos de la carcasa.

5. Retire el motor y el elemento giratorio de

la carcasa, dejando la carcasa y tubería inalteradas.

6. Introduzca un destornillador en el pasaje de agua

del impulsor. Quite la tuerca del impulsor con una

llave de cubo (5⁄8 pulg. en las secciones planas).

7. Retire el impulsor del eje de la siguiente manera:

a) Motores Franklin:

Retire la tapa del extremo del eje del motor.

Introduzca un destornillador en la ranura del

eje del motor. Sujetando el eje para que no gire,

destornille el impulsor del eje girando en sentido

contrahorario cuando esté de frente al mismo.

Para aflojar los impulsores metálicos y trifásicos,

utilice un soplete para aplicar calor a la rosca del

eje expuesto y al cubo del impulsor, ya que se

empleó compuesto fijador para sujetar el impulsor en posición.

b) Motores A.O. Smith:

Retire la tapa del extremo del motor. Introduzca

una llave de boca de 7⁄16 pulg. debajo del mecanismo del interruptor en las secciones planas

sobre el eje del motor. Sujetando el eje para que

no gire, destornille el impulsor del eje. Podría ser

necesario aplicar calor, tal como se indicó en 7a.

8. Retire la sección giratoria del sello mecánico del

eje con dos (2) destornilladores (Fig. 1).

Figura 1

9. Quite los pernos que sujetan el adaptador al motor.

10. Coloque el adaptador sobre una superficie plana.

Empuje hacia afuera las partes estacionarias del sello

mecánico (asiento y tazón de montaje de caucho).

B) Reensamble:

1. Limpie las caras de la empaquetadura y brida,

los cierres macho y hembra, el

ensanchamiento del asiento del sello y el eje, y

en particular el reborde del eje que calza

contra el impulsor.

2. Lubrique el ensanchamiento del adaptador y

el buje de caucho del sello estacionario con

agua y aceite liviano. Oprima el asiento

estacionario en el ensanchamiento en forma

encuadrada y pareja. Precaución: No estropee

la cara pulida del asiento.

3. Monte nuevamente el adaptador sobre

el motor. Asegúrese de que el eje del motor no

desplace el asiento estacionario del sello.

4. Aplique una capa delgada de aceite liviano o

agua al eje del motor y el componente de

caucho del sello. Deslice el componente

rotatorio del sello mecánico sobre el eje del

motor. Asegúrese de que la cara del sello

rotatorio se mantenga en el interior, sujetando

el collar durante la instalación. Tenga cuidado

de no dañar las caras pulidas del sello.

5. Rocíe las roscas del eje y del impulsor metálico

con LOCQUIC®, Primer “T”—Loctite®, Nº de

producto 74756. (Puede adquirirse en una

tienda de partes automotrices o en una

ferretería). Deje las partes secar y luego

aplique Loctite® #271 sobre las mismas partes.

6. Sujete el eje para que no gire, tal como se

describió en el párrafo 7 de la sección de

Desmantelamiento. Atornille el impulsor en

el eje hasta que quede ajustado contra el

reborde del eje.

7. Aplique compuesto fijador y reemplace la

tuerca del impulsor. Sujete el impulsor para

que no gire, tal como se describió en el párrafo

6 de la sección de Desmantelamiento.

8. Quite las rebabas en la periferia del impulsor,

en los pasajes de agua con un destornillador.

9. Reinstale el motor y el elemento rotatorio en

la carcasa. Asegúrese de instalar una

empaquetadura nueva.

10. Apriete los pernos de la carcasa en forma

alterna y pareja.

11. Reinstale los pernos de sujeción.

12. Verifique que el conjunto gire libremente

después de finalizar el ensamble.

13. Reinstale los pernos de sujeción.

14. Cierre todos los orificios de drenaje. Utilice

compuesto para juntas de tubería sobre las

roscas macho.

15. Recebe antes de arrancar. No arranque la

bomba hasta que esté completamente llena

con agua.

9

Page 10

GARANTÍA LIMITADA DE RED JACKET WATER PRODUCTS

Esta garantía es aplicable a todas las bombas para sistemas de agua fabricadas por Red Jacket Water Products.

Toda parte o partes que resultaren defectuosas dentro del período de garantía serán reemplazadas durante dicho período de garantía sin cargo para el

comerciante. Tal período de garantía se extiende por doce (12) meses a partir de la fecha de instalación, o dieciocho (18) meses a partir de la fecha de

fabricación, la que se cumpla primero.

El comerciante que considere que existe lugar a un reclamo de garantía deberá ponerse en contacto con el distribuidor autorizado de Red Jacket Water

Products del cual adquiriera la bomba y brindar información detallada con respecto al reclamo. El distribuidor está autorizado a liquidar todos los

reclamos por garantía a través del Departamento de Servicios a Clientes de Red Jacket Water Products.

La presente garantía excluye:

(a) La mano de obra, el transporte y los costos relacionados en los que incurra el comerciante;

(b) los costos de reinstalación del equipo reparado;

(c) los costos de reinstalación del equipo reemplazado;

(d) daños emergentes de cualquier naturaleza; y

(e) el reembolso de cualquier pérdida causada por la interrupción del servicio.

A los fines de esta garantía, los términos “Distribuidor”, “Comerciante” y “Cliente” se definen como sigue:

(1) “Distribuidor” es aquel individuo, sociedad, corporación, asociación u otra entidad jurídica que opera entre Red Jacket Water Products y el comer-

ciante para la compra, consignación o contratos de venta de las bombas en cuestión.

(2) “Comerciante” es todo individuo, sociedad, corporación asociación u otra entidad jurídica que realiza negocios de venta o alquiler-venta (leasing)

de bombas a los clientes.

(3) “Cliente” es toda entidad que compra o adquiere bajo la modalidad de leasing las bombas en cuestión de un comerciante. El término “cliente”

puede significar un individuo, sociedad, corporación, sociedad de responsabilidad limitada, asociación o cualquier otra entidad jurídica con actividades en cualquier tipo de negocios.

LA PRESENTE GARANTÍA SE EXTIENDE AL COMERCIANTE ÚNICAMENTE.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Teléfono: (866) 325-4210

Fax: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products son una marca registrada de Xylem Inc. o una de sus filiales.

© 2012 Xylem Inc. IM138 Revisión Número 1 Julio 2012

Page 11

MANUEL D'UTILISATION

IM138

HMC

Pompe centrifuge montée sur moteur

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

Page 12

Table des matières

Table des matières

SUJET PAGE

Informations importantes .......................................................................................................................................... 13

Installation ................................................................................................................................................................13

Utilisation ..................................................................................................................................................................13

Entretien ...................................................................................................................................................................14

Garantie limitée de Red Jacket Water Products .......................................................................................................... 16

12

Page 13

INFORMATIONS IMPORTANTES

INFORMATIONS IMPORTANTES

A. Inspecter l’appareil pour s’assurer qu’il n’a pas

été endommagé pendant le transport. Signaler

immédiatement tout dommage au transporteur.

B. L’alimentation électrique doit être assurée par un circuit

de dérivation distinct dont les fusibles ou les disjoncteurs,

le calibre des fils, etc. sont conformes aux prescriptions

du code provincial ou national de l’électricité.

C. On doit TOUJOURS couper le courant lorsque l’on

effectue quelque travail que ce soit sur la pompe ou les

commandes. Poser un sectionneur tout conducteur près

de la pompe.

D. Le câblage d’alimentation du moteur doit convenir

à la tension de fonctionnement (VOIR LA PLAQUE

SIGNALÉTIQUE DU MOTEUR). Les fils doivent

avoir un calibre limitant la chute de tension maximale,

aux bornes du moteur, à 10 % de la valeur de tension

indiquée sur la plaque signalétique, sinon la durée de vie

du moteur et les performances de la pompe diminueront.

E. Moteurs monophasés — ces moteurs sont parfois munis

d’une protection thermique intégrée (VOIR LA PLAQUE

SIGNALÉTIQUE). Dans le cas contraire, utiliser un

contacteur à protection appropriée contre les surcharges.

Les dispositifs fusibles sont admissibles s’ils offrent une

protection adéquate.

F. Moteurs triphasés — employer une protection trois

conducteurs appropriée et un démarreur magnétique

convenant à la charge électrique.

G. Température maximale du liquide — HSC et 3673

avec composants en plastique : 82 °C (180 °F) — 36423656-3673, AI, BF, AB : 100 °C (212 °F), avec garniture

mécanique optionnelle pour hautes températures.

H. Un programme d’inspection et d’entretien réguliers basé

sur le temps de fonctionnement augmentera la durée de

vie de l’appareil.

INSTALLATION

INSTALLATION

Emplacement — Placer la pompe aussi près de la source

de liquide que possible (au-dessous du niveau du liquide

si l’on veut que la pompe fonctionne automatiquement).

Protéger l’appareil contre le froid et les inondations. Une

hauteur géométrique d’aspiration réduite et une tuyauterie

d’aspiration et de refoulement directe et courte sont

souhaitables. Pour les hauteurs d’aspiration de plus de

15 pi, utiliser la hauteur nette d’aspiration requise (NPSHR)

indiquée sur la courbe de performances de la pompe. La

tuyauterie d’aspiration doit avoir un calibre au moins égal

à celui du raccord d’aspiration de la pompe, ainsi qu’une

inclinaison vers le haut depuis la source de liquide jusqu’à

la pompe pour prévenir les poches d’air. S’il faut un calibre

plus gros, on doit installer un raccord réducteur excentré

à la pompe. On doit poser un robinet-vanne sur le tuyau

d’aspiration seulement quand la hauteur totale de charge

à l’aspiration est positive, mais ne pas employer ce robinet

pour réduire la section de passage vers la pompe.

Surface portante — Assujettir la pompe à la surface portante

avec des boulons d’ancrage pour en faciliter le démontage.

La surface portante doit être plane pour prévenir toute

contrainte ou déformation due au serrage des boulons. La

pompe a un fonctionnement régulier et silencieux, mais

on recommande de la monter sur caoutchouc si la surface

portante résonne.

Alignement — Aucun alignement n’est requis étant donné

que la pompe est montée sur moteur.

Câblage — Il faut se conformer aux prescriptions du

code provincial ou national de l’électricité. Le circuit de

dérivation alimentant le moteur doit être protégé par un

démarreur manuel ou magnétique. Les dispositifs fusibles et

de démarrage temporisés doivent être conformes au code. Il

est recommandé d’utiliser une protection contre les basses

tensions.

Les moteurs monophasés sont bitension (115/230 V c.a.,

60 Hz). Chaque pompe est mise à l’essai en usine. S’il s’agit

d’une pompe à moteur triphasé, on doit en vérifier le sens

de rotation durant l’installation, ainsi que le nombre de

phases, la fréquence et la tension du courant d’alimentation.

Les lignes électriques doivent avoir le calibre approprié à

l’intensité de courant.

Les moteurs monophasés de 3 hp sont bitension

(115/230 V c.a., 60 Hz), et ceux de 5 hp fonctionnent en

230 V c.a., 60 Hz. Tous les autres sont triphasés et bitension

(230/460 V c.a., 60 Hz). La tension la plus haute est

recommandée dans la mesure du possible.

Pour vérifier le sens de rotation des pompes à moteur

triphasé, mettre et couper le courant immédiatement tout

en observant l’une des pièces tournantes. Le sens de rotation

approprié est antihoraire, vu du côté aspiration, comme

l’indique la flèche sur le corps de pompe. On peut modifier

le câblage selon le schéma de câblage figurant sur la plaque

signalétique du moteur ou à l’intérieur du couvercle de la

boîte à bornes.

UTILISATION

UTILISATION

Remplir la tuyauterie d’aspiration et le corps de pompe de

liquide à pomper pour s’assurer que la garniture mécanique

ne sera pas utilisée à sec. Quatre bouchons sont montés sur

le corps de pompe pour qu’il y en ait toujours un en haut

pour le remplissage et la mise à l’air libre et un autre en

bas pour la vidange, peu importe la position de montage

de la pompe. Une fois le moteur câblé correctement et la

tuyauterie et le corps de pompe remplis, on peut mettre la

pompe en service. S’assurer qu’il n’y a aucun robinet fermé

sur la tuyauterie de refoulement au moment du démarrage.

Les matériaux de la garniture mécanique standard limitent

la température maximale du liquide à 100 °C (212 °F), mais

des garnitures mécaniques pour hautes températures sont

offertes en option.

Prévoir assez d’espace autour de la pompe pour l’entretien et

l’aération.

13

Page 14

ENTRETIEN

ENTRETIEN

1. Lubrification

Les pompes ne devraient pas requérir d’entretien.

Les roulements à billes du moteur sont à double flasque

et à graissage permanent. Ils ne nécessitent donc aucune

lubrification.

2. Remplacement de la garniture mécanique

A. Démontage

1. Couper le courant.

2. Vidanger le système.

3. Déposer les boulons d’ancrage de l’adaptateur de

moteur à la surface portante.

4. Enlever les vis du corps de pompe

5. Séparer l’ensemble moteur-éléments de pompage

mobiles d’avec le corps de pompe, sans détacher

celui-ci ni la tuyauterie.

6. Insérer un tournevis dans un passage de roue pour

immobiliser celle-ci, puis déposer l’écrou de

blocage de roue avec une clé à douilles de 5⁄8 po.

7. Enlever la roue de l’arbre comme suit :

a) Moteurs Franklin

Ôter l’obturateur de bout d’arbre du moteur.

Insérer un tournevis dans la fente de l’arbre

et immobiliser celui-ci, puis dévisser (sens

antihoraire, face à la roue) la roue. S’il s’agit

d’une roue en métal ou de pompe à moteur

triphasé, chauffer les filets et le moyeu de roue au

chalumeau pour amollir l’enduit frein des filets et

dévisser la roue.

b) Moteurs A.O. Smith

Déposer le couvercle d’extrémité du moteur.

Bloquer l’arbre par ses méplats (sous le

mécanisme interrupteur) avec une clé ouverte de

7

⁄16 po, puis dévisser la roue. Au besoin, chauffer

les filets et le moyeu de roue (v. 7 a ci-dessus).

8. Extraire l’élément mobile de la garniture

mécanique (fig. 1) avec deux (2) tournevis utilisés

comme leviers.

Figure 1

9. Enlever les vis retenant l’adaptateur de moteur

au moteur.

10. Placer le côté pompe de l’adaptateur de moteur sur

une surface plane, puis, par l’autre côté, pousser

l’élément fixe (bague et coupelle de caoutchouc)

de la garniture mécanique hors de son logement

(siège).

B. Remontage

1. Nettoyer les surfaces de guidage, de contact,

d’épaulement et d’étanchéité des brides, des sièges

et de l’arbre.

2. Avec de l’eau ou une huile légère, lubrifier le

caoutchouc de l’élément fixe de la garniture

mécanique ainsi que les surfaces de son siège, puis

pousser l’élément fixe uniformément jusqu’au fond

du siège. Prendre garde de ne pas abîmer les

surfaces du siège et de l’élément fixe.

3. Reposer l’adaptateur sur le moteur en s’assurant

que l’arbre de moteur ne déloge pas l’élément fixe

de son siège.

4. Enduire d’un peu d’eau ou d’huile légère l’arbre de

moteur et le caoutchouc de l’élément mobile de la

garniture mécanique. Enfiler l’élément mobile sur

l’arbre. S’assurer que la surface d’étanchéité de la

garniture reste dans son collier de retenue pendant

la pose et veiller particulièrement à ne pas abîmer

les surfaces de la garniture.

5. Pulvériser de l’apprêt Primer T de LOCQUICMD

(produit LoctiteMD no 74756, vendu dans les

magasins de pièces d’automobile et les

quincailleries) sur les filets de l’arbre et de la roue

en métal et le laisser sécher. Enduire ensuite les

mêmes filets de LoctiteMD no 271.

6. Immobiliser l’arbre (v. 7 a et 7 b ci-dessus) et y

visser la roue à fond.

7. Appliquer de l’enduit frein sur les filets de

l’écrou de blocage de roue, puis poser celui-ci tout

en immobilisant la roue (v. paragr. 6 sous

Démontage).

8. Enlever toute barbe produite par le tournevis du

côté extérieur du passage de roue utilisé.

9. Joindre l’ensemble moteur-éléments de pompage

mobiles au corps de pompe. Voir à utiliser un joint

d’étanchéité neuf.

10. Poser et serrer les vis du corps de pompe

uniformément et tour à tour.

11. Reposer les boulons d’ancrage.

12. Une fois le remontage terminé, vérifier si la roue

tourne librement.

13. Après en avoir enduit les filets de pâte à joints,

poser un bouchon sur tout orifice non obturé du

corps de pompe, sauf l’orifice d’amorçage.

14. Amorcer la pompe avant de la mettre en service.

Ne pas la mettre en marche tant qu’elle n’est pas

pleine d’eau.

14

Page 15

NOTES/NOTAS

NOTES/NOTAS

15

Page 16

GARANTIE LIMITÉE DE RED JACKET WATER PRODUCTS

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Red Jacket Water Products.

Toute pièce se révélant défectueuse sera remplacée sans frais pour le détaillant durant la période de garantie suivante expirant la première : douze (12)

mois à compter de la date d’installation ou dix-huit (18) mois à partir de la date de fabrication.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Red Jacket Water Products agréé

chez lequel la pompe a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du

service à la clientèle de Red Jacket Water Products.

La garantie ne couvre pas :

a) les frais de main-d’œuvre ni de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) « Distributeur » signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant

d’intermédiaire entre Red Jacket Water Products et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) « Détaillant » veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités

commerciales sont la vente ou la location de pompes à des clients.

3) « Client » signifie une entité qui achète ou loue les pompes en question chez un détaillant. Le « client » peut être une personne, une société de personnes, une société de capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (866) 325-4210

Télécopie: (888) 322-5877

www.xyleminc.com/brands/redjacketwaterproducts

Red Jacket Water Products est une marque déposée de Xylem Inc. ou d'une de ses filiales.

© 2012, Xylem Inc. IM138 Révision numéro 1 Juillet 2012

Loading...

Loading...