Page 1

Variable Speed

Pump Control

Installation Programming & Operation

Models covered:

All AV2 Model

AQUAVAR

II

Controllers

software revision 120

AQUAVAR

®

AV II

IM131R01

U

®

L

Page 2

Page 3

2

AQUAVAR

II Controller Model

_________________ Transducer Model_______________________

AQUAVAR

II Serial Number

_________________ Transducer Rating_______________________

Date purchased _________________

Purchased from _________________

Pump Model _________________ Software Version _______________________

Pump Code Number _________________

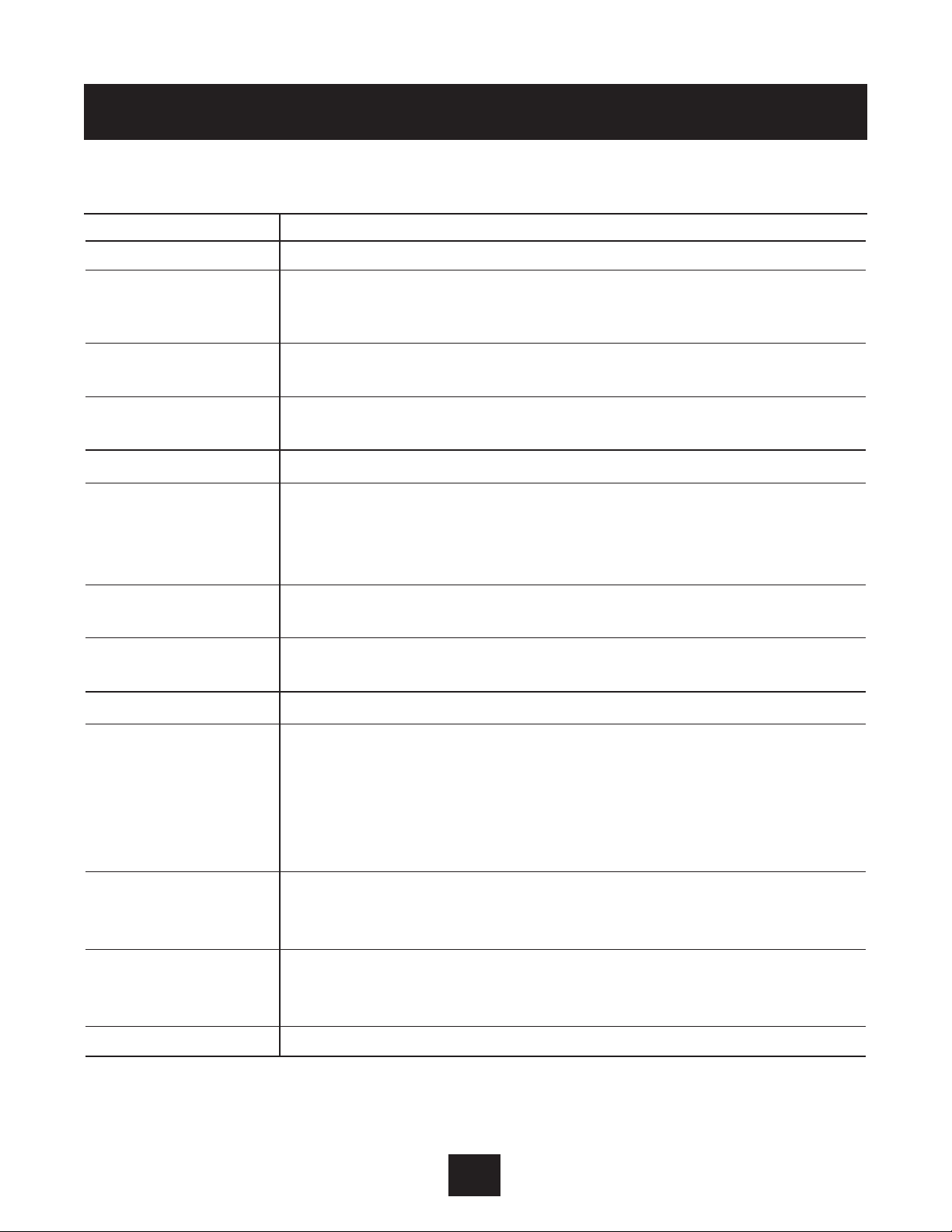

Program Record

Please use the following to record the final values programmed into the AQUAVAR controller after installation.

Required Value____________________ (select) Level 2____________________________ (%)

Autostart________________________ (on/off) Intensity 1 _________________________ (%)

Password ________________________ (value) Intensity 2 _________________________ (%)

Window ___________________________ (%) Pressure Increase ___________________ (PSI)

Ramp Hysteresis _____________________ (%) Pressure Decrease___________________ (PSI)

Ramp 1 _______________________ (seconds) Enable Sequence Control______________ (Hz)

Ramp 2 _______________________ (seconds) Switch Interval ___________________ (hours)

Ramp 3 _______________________ (seconds) Optional Value_________________________

Ramp 4 _______________________ (seconds) Synchron Limit _____________________ (Hz)

Max. Frequency _____________________ (Hz) Sychron Window____________________ (Hz)

Min. Frequency______________________ (Hz) Pump Address _________________ (# or off)

Config. F Min. __________ (F –>0/F –>F min.) ADC Reference ___________________ (select)

Stop - Delay F Min._______________ (seconds) Freq. Lifting ________________________ (Hz)

Sensor Adjust _______________ (out of range) Lift Intensity________________________ (%)

Sensor Curve _____________ (linear/quadratic) Analog out______________________ (select)

Sensor Range - 20mA=362.6 __________ (PSI) Pressure Unit ____________________ (select)

Mode ___________________________ (select) Test Run After __________________ (in hours)

(actuator/controller/multicontroller/synch.) Test Frequency______________________ (Hz)

Regulation Mode_________________ (normal) Conveyor Limit _____________________ (PSI)

Start Value_________________________ (PSI) Delay Time ____________________ (seconds)

Config. Second Value _________________ (off) Error Reset______________________ (on/off)

Relay Config.__________________ (run motor) Display Contrast_____________________ (%)

Offset Input____________________________ Lock Function____________________ (on/off)

Level 1 ____________________________ (%)

AQUAVAR

II

Controller Owner’s Information Record

Page 4

3

Index

System Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Materials Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1. Mounting the AQUAVARII Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Pump Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4. Run Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1. The Main Menu - Setting One Pump Constant Pressure . . . . . . . . . . . . . . . . 31

2. Single Pump - Pump Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

• To Set Run-Out Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

• To Set Low/No Flow Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3. Single Pump - System Curve Compensation . . . . . . . . . . . . . . . . . . . . . . . . 38

• Entering Compensation Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

• Circulator Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4. Single Pump Constant Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5. Single Pump - Level Control Applications . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6. Single Pump - Submersible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7. Setting a Second Required Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8. Variable Second Required Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9. Multiple Pump Constant Pressure and System Curve Compensation . . . . . . . 53

• Synchronous Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10. Multiple Pump - Pump Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

• To Set Low/No Flow Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operator Custom Features and Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

• Jog Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

•Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

• Ramp Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

• Ramp Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

• Ramp 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• Maximum Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

• Minimum Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

• Config. F Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

• Stop-Delay F Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

• Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

• Sensor Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

• Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

• Start Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• Config. Required Value 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• Relay Config. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• Submenu Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• Regulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• Submenu Sequence Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• Actual Value Increase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Index

!

▼

▼

Page 5

Index (continued)

Operator Custom Features and Displays (continued)

• Actual Value Decrease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• Enable Sequence Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• Switch Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• Source Required Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• Submenu Synchronous Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• Synchronous Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

•Synchronous Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

•Pump Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

• Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

•Pump - Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

• ADC Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

•Frequency Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

• Lift Intensity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

• Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

• Analog Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

•Pressure Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

•Test Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

• Submenu Test Run Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

• Submenu Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

• Clear Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Operating Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

•Total Run Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Set Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Lock Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Heating On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

• Save ?? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Repair of Faults and Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

•Lack of Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

• Conveyor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

• Error 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

•Pressure Sensor Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

• Inverter Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

• External Device Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

• Active Fault / Warning and Fault History Mode . . . . . . . . . . . . . . . . . . . . . . 70

• Aquavar II Electrical Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Programming Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Help Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Appendix A - Pressure Transducer Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

•Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Appendix B - AQUAVAR Controller Technical Data and Terminals . . . . . . . . . . . . . . . . .87

Appendix C - Interference Suppression Measures . . . . . . . . . . . . . . . . . . . . . . . . . .89

Index

4?5

Page 6

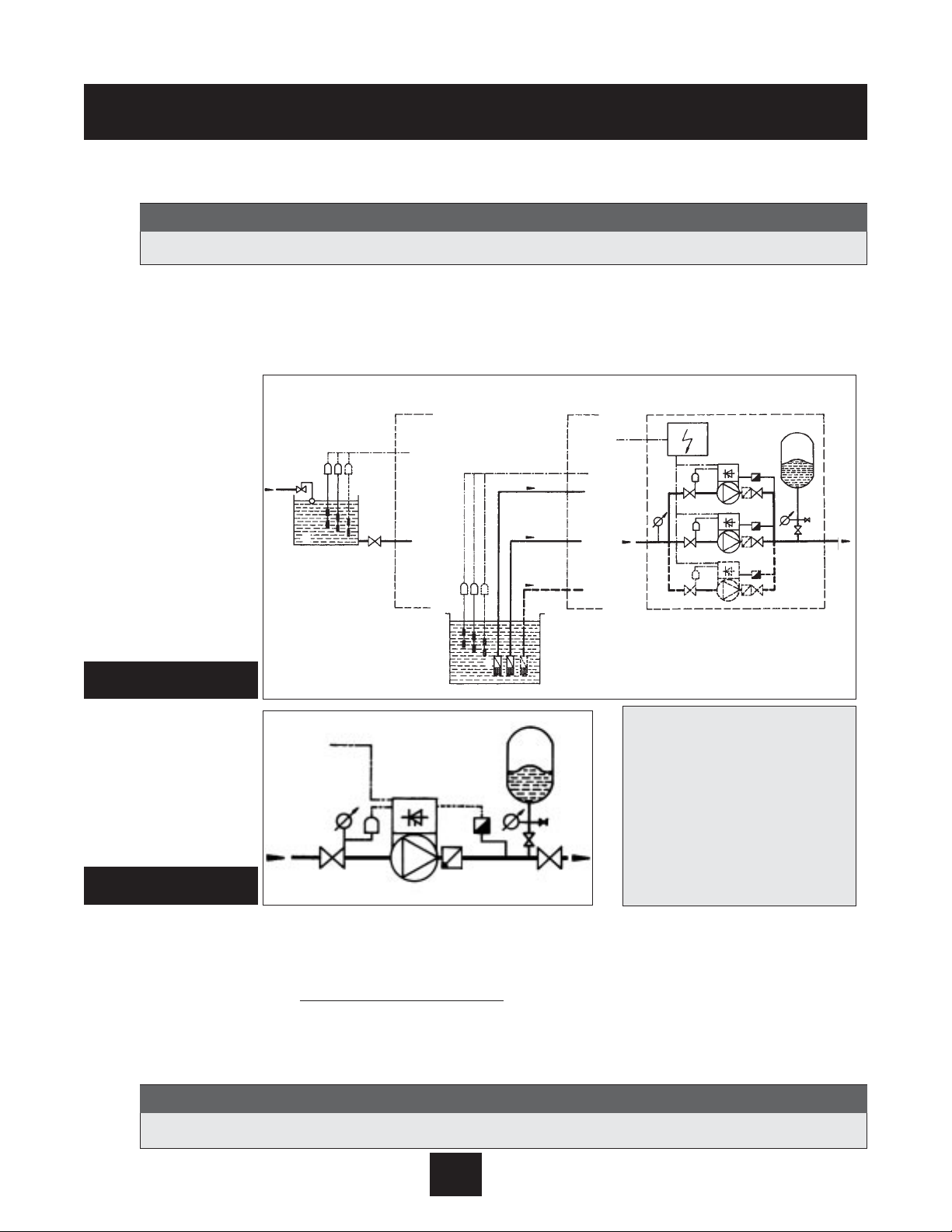

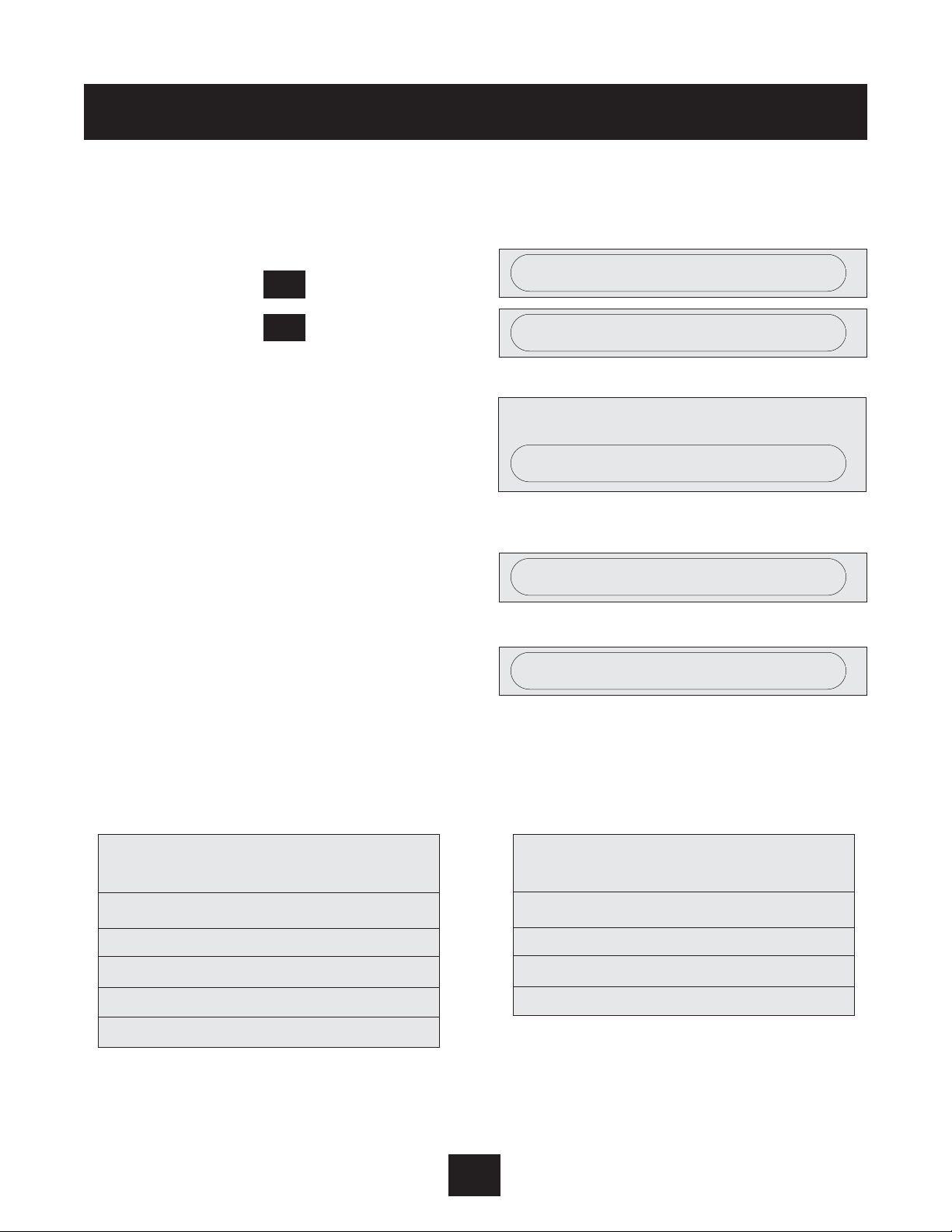

System Design -

Typical Constant Pressure Systems

The following diagrams show typical single pump and multi-pump systems using the AQUAVAR con-

troller. Connection can be made directly to a water supply or water can be drawn from a supply tank or

well. In the case of supply tanks and wells, level switches, (item 10) can be used to shut down the

pumps when water is low. In the direct connection, a pressure switch on the suction side (item 8) can

be used.

A diaphragm pressure tank is used on the discharge side of the pump or pumps to maintain pressure in the line when there is no demand. This will keep the pumps from continuing to run. With the

AQUAVAR controller, it is not necessary to have a large tank for supply purposes. In selecting a tank,

make sure it can withstand maximum system pressure

. The tank should have a capacity of at least

10% of the maximum system flow rate in gpm. Pre-charge the tank to the following:

System Design

1 Pump with AQUAVAR controller

2 Diaphragm tank

3 Distribution panel

4 Gate valves

5 Check valves

6 Foot valves

8 Incoming pressure switch

9 Pressure gauges

10 Level switches

11 Supply tank

14 Pressure transmitter

(Included with AQUAVAR) *

Closed loop circulator systems may not require a pressure tank.

Note

Systems MUST be designed by qualified technicians only.

Note

PSI Set Pressure 15 30 45 60 75 90 105 120 135 150

PSI Tank Pre-charge 12 21 37 52 64 77 95 110 125 138

Diagram 2

Single Pump Layout

Diagram 1

Multiple Pump Layout

Indirect connection

via tank

Suction out or a well

Direct connection

10

11

10

6

9

8

4

3

8

4

8

4

1

1

1

14

5

4

14

5

4

14

5

4

2

9

9

4

8

1

5

4

9

14

2

*Check with tank pressure limitations before precharge.

Page 7

Important: Read all safety information prior to

installation of the AQUAVAR controller.

1. This manual is intended to assist in the installation, operation, and repair of the AQUAVAR controller

and must be kept with the AQUAVAR controller.

2. To avoid serious or fatal personnel injury or major property damage, read and follow all safety

instructions in this manual.

This is a SAFETY ALERT SYMBOL. When you see this symbol on the pump or

in the manual, look for one of the following signal words and be alert to the

potential for personal injury or property damage.

Warns of hazards that WILL cause serious personal injury, death, or

major property damage.

Warns of hazards that CAN cause serious personal injury, death, or

major property damage.

Warns of hazards that CAN cause personal injury or property damage.

Indicates special instructions which are very important and must be

followed.

Note

6

Safety Instructions

NOTICE

All operating instructions must be read, understood, and followed by the operating

personnel. Goulds Pumps accepts no liability for damages or operating disorders

which are the result of non-compliance with the operating instructions.

When in

doubt, call for assistance.

Note

DANGER

WARNING

CAUTION

Page 8

7

Safety Instructions

3. Installation and maintenance MUST be performed by properly trained and qualified personnel.

4. Review all instructions and warnings prior to performing any work on the AQUAVAR controller.

5. Any safety decals MUST be left on the AQUAVAR controller unit and pump.

6. In addition to instructions contained in this manual, you must meet any local safety, electrical, or

plumbing codes and requirements. Installation, maintenance, or repair work must only be

carried out by trained, skilled, and qualified personnel, using proper protective gear and

tools.

7. The AQUAVAR controller drive head must be disconnected from the main power

supply before attempting any operation in the electrical or mechanical part of the

system.

Safety Instructions

When in operation, the motor can be stopped, but power remains at the drive head. The

motor and pump could start unexpectedly and produce serious injury. When the AQUAVAR

controller drive head is connected to the main power supply, the inverter power supply

and master control unit are also connected to the power supply.

Inspect AQUAVAR controller for any damage after unpacking from shipping crates.

Report any damage immediately to the carrier or distributor/dealer immediately.

Note

Note

FAILURE TO DISCONNECT ELECTRICAL POWER BEFORE ATTEMPTING ANY

MAINTENANCE CAN C AUSE SHOCK, BURNS, OR DEATH.

WARNING!

WARNING

Hazardous voltage

can shock, burn or

cause death.

Page 9

8

8. The AQUAVAR controller has electronic safety devices which will stop the motor in the event of

electrical or thermal faults. This does not remove power to the AQUAVAR controller.

9. The system must be properly grounded before being put into operation. Use a common

ground for the entire system.

10. High voltage tests of the AQUAVAR controller may damage the electronic components.

Before carrying out such a test, bridge the incoming and outgoing terminals L1 - L2 - L3 - U - V W. Isolate the motor from the AQUAVAR controller drive to avoid incorrect capacitor metering inside

the AQUAVAR controller.

Safety Instructions

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL POWER AND WAIT

FIVE MINUTES FOR C APACITOR DISCHARGE BEFORE SERVICING AQUAVAR

CONTROLLER CAN C AUSE SHOCK, BURNS, OR DEATH.

WARNING!

TOUCHING THESE COMPONENTS SERIOUSLY ENDANGERS LIFE! Voltages of up to

800 volts are possible (higher if there is a fault).

Before removing the AQUAVAR controller drive top cover, the system must be discon-

nected from the main power supply. After switching off the power supply, you must

wait at least 5 minutes before starting work on or inside the AQUAVAR controller drive

head. This allows the capacitors in the circuit to be discharged by the discharge

resistors.

Note

Care must be taken when connecting external control wires and jumpers to avoid short circuit to neighboring components.

Note

Repair of electrical faults can lead to the automatic restart of the motor and pump.

You must remove all main line power to the AQUAVAR controller before attempting to

correct a fault.

Note

WARNING

Hazardous voltage

can shock, burn or

cause death.

Page 10

Step 1- Identif y Materials

The following materials are provided with the AQUAVAR II controller. Please familiarize yourself with each prior to

installation.

Part Quantity

1. AQUAVAR Controller 1

2. Pressure Transducer Assembly 1

a. Pressure transducer - 25 bar

1

/4

” NPT

b. Transducer adapter - (

available as

1

/4

” NPT female threads &

3

/8

B male thread per

separate part only)

See price book.

UNI ISO/228/1 (British Standard pipe threads)

c. 30 ft. transducer cord (standard)

for AV II.

THE AQUAVAR CONTROLLER AND PUMP MUST BE TOTALLY DISCONNECTED FROM ALL

POWER SUPPLY SOURCES BEFORE BEGINNING INSTALLATION OR REPAIR.

WARNING

FAILURE TO DISCONNECT ELECTRICAL POWER BEFORE ATTEMPTING ANY MAINTENANCE CAN C AUSE SHOCK, BURNS, OR DEATH.

WARNING!

WARNING

Hazardous voltage

can shock, burn or

cause death.

3.45

1.07

3

⁄4” HEX

1

⁄4” NPT

2c 2a

2b

(If needed.)

9

Installation Procedures

YOU MUST USE THE CABLE THAT IS PROVIDED WITH THE TRANSDUCER. DO NOT USE

DIFFERENT CABLES OR OLDER STYLE C ABLES.

Note

Page 11

10

Installation Procedures

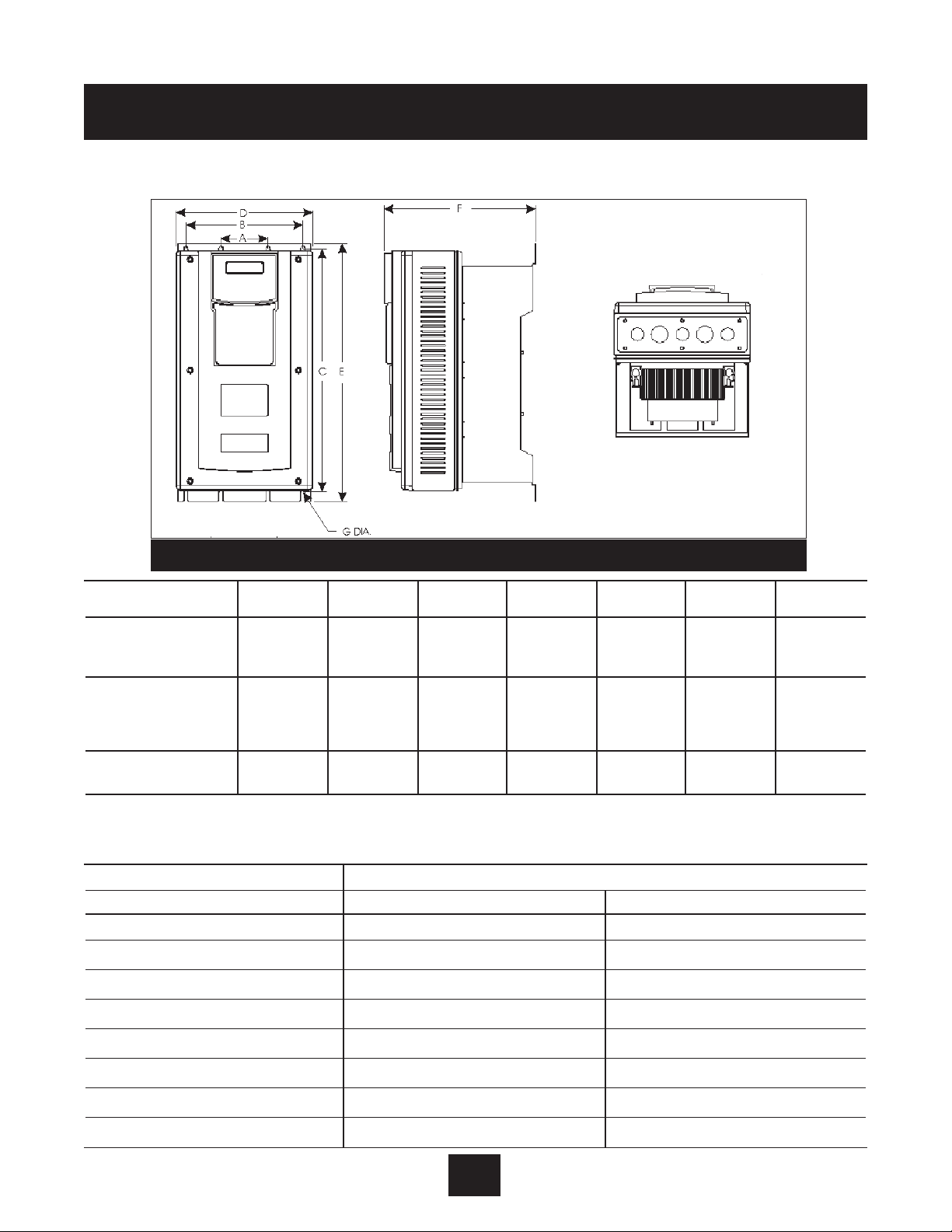

Step 2 - Mounting the AQUAVAR

II

controller:

AQUAVAR Controller

The AQUAVAR controller may be installed as a wall or panel mounted unit. The AQUAVAR controller may

be mounted up to 60 feet away from the pump motor*. In addition, alternative motor enclosures

may be selected such as ODP, explosion proof or wash down motors in addition to the TEFC enclosure required for on the pump mounting.

Typical applications for the AQUAVAR Wall Mount controller include:

1. Hazardous environment applications including high heat, humidity or combustibility.

2. Installation to an existing pumping system with non-standard motors.

3. Installations where the operator desires all controls to be grouped together.

Mounting of the AQUAVARII Controller

1. An alternative mounting style is used in the AQUAVAR

II

controller configuration.

In this style, the AQUAVAR

II

controller is supplied with a fan and mounting bracket already

installed and can be mounted to a wall or panel.

2. The mounting bolts for all units should be 1⁄4". The length of bolt and the strength of the

mounting surface must be adequate to support the weight of the AQUAVAR

II

controller.

3. The AQUAVAR

II

controller may be positioned up to 60 feet from the pump motor. The pump

motor must be three phase. Unlike the standard AQUAVAR controller, the motor may be

ODP, TEFC or explosion proof.*

4. Mount the AQUAVAR controller to the panel, wall or frame using bolts at the points indicated

on the following drawings. Be sure the unit is level and secured to the mounting surface

before continuing.

5. Ensure plenty of airflow for the AQUAVAR controller, when mounting.

*NOTE: If the AQUAVAR

II

controller is more than 60 feet wire length to motor, then the use of a

load reactor (impedance coil) is required.

Page 12

Installation Procedures

Step 2 - Mounting the AQUAVAR controller:

(continued)

Power Rating Weight

HP Pounds Kilograms

1 24.0 10.9

2 24.0 10.9

3 24.0 10.9

5 24.0 10.9

71⁄

2

24.0 10.9

10 24.0 10.9

15 28.0 12.7

20 28.0 12.7

HP Rating

ABCDE FG

in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm)

1 – 10 (230 – 3)

3.20 7.88 16.50 9.32 17.44 12.08 0.28

1 – 5 (230 – 1)

(81.28) (200.15) (419.10) (236.70) (442.98) (306.71) (7.11)

1 – 20 (575)

15 – 20 (230 – 3)

7

1

⁄2 – 10 (230 – 1) 3.20 7.88 19.25 11.44 20.19 13.51 0.28

25 – 40 (460) (81.28) (200.15) (488.95) (290.53) (512.83) (343.20) (7.11)

25 – 40 (575)

25 – 75 (460) 3.20 7.88 28.00 12.68 31.37 14.00 0.42

25 – 75 (575) (81.28) (200.15) (711.20) (322.07) (796.80) (355.60) (10.67)

Note that the E-dimension in the 50-75 HP is maximum overall height to the conduit box rather than the bottom of the foot.

Diagram 3

WEIGHTS OF MODELS - Table 1: NEMA 12

11

Page 13

12

Electrical Connections

Installation Procedures

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL POWER AND WAIT

FIVE MINUTES FOR C APACITOR DISCHARGE BEFORE SERVICING AQUAVAR

CONTROLLER CAN C AUSE SHOCK, BURNS, OR DEATH.

WARNING!

WARNING!

Installation and maintenance must only be performed by properly trained and

qualified personnel equipped with the proper tools.

Note

INSTALL AN ALL LEG DISCONNECT SWITCH NEAR THE MOTOR.

INSTALL, GROUND, AND WIRE ACCORDING TO LOCAL AND

NATIONAL ELECTRICAL CODE REQUIREMENTS.

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE

INSTALLING OR SERVICING.

MOTORS WITH AUTOMATIC THERMAL PROTECTION MAY OPEN THEIR

ELECTRICAL CIRCUIT WHEN A THERMAL OVERLOAD EXISTS. THIS CAN

CAUSE THE MOTOR TO START UNEXPECTEDLY AND WITHOUT WARNING.

ELECTRICAL SUPPLY MUST

MATCH PUMP’S AND AQUAVAR CONTROLLER NAME

PLATE SPECIFICATIONS. INCORRECT VOLTAGE OR WIRING CAN CAUSE FIRE

DAMAGE, AND VOIDS WARRANTY.

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous voltage

can shock, burn or

cause death.

Power Rating Weight

HP Pounds Kilograms

25 52.0 23.6

30 52.0 23.6

40 60.0 27.2

50 107.0 48.6

60 107.0 48.6

75 107.0 48.6

Page 14

Electrical Connections continued

Step 3 - Preliminary Inspection

Before storing or installing the AQUAVAR controller, thoroughly inspect the device for possible

shipping damage. Upon receipt:

1. Remove the controller from its package and inspect exterior for shipping damage. If damage is

apparent, notify the shipping agent and your sales representative.

2. Remove the cover and inspect the controller for any apparent damage or foreign objects.

Ensure that all mounting hardware and terminal connection hardware is properly seated,

securely fastened and undamaged.

3. Read the technical data label affixed to the controller and ensure that the correct horsepower

and input voltage for the application had been purchased.

4. If you will store the controller af ter receipt, place it in its original packaging and store in a

clean, dry place free from direct sunlight or corrosive fumes, where the ambient temperature

is not less than -20ºC (-4ºF) or greater than +65ºC (+149ºF).

Step 4 - Installation Precautions

Improper installation of the AQUAVAR controller will greatly reduce its life. Be sure to observe the

following precautions when selection a mounting location. Failure to obser ve these

precautions will void the warranty!

1. Do not install the controller in a place subjected to high temperature, high humidity, excessive

vibration, corrosive gases or liquids or airborne dust or metallic particles. See Technical Data

Appendix B for temperature, humidity and maximum vibration limits or contact factor

y.

2. Do not mount the controller near heat-radiating elements or in direct sunlight.

3. Mount the controller vertically and do not restrict the air flow to the heat sink fins.

4. The controller generates heat. Allow sufficient space around the unit for heat dissipation.

13

Installation Procedures

CAUTION!

EQUIPMENT DAMAGE HAZARD - DO NOT OPERATE OR INSTALL ANY CONTROLLER THAT APPEARS DAMAGED. FAILURE TO OBSERVE THIS INSTRUCTION CAN RESULT IN INJURY OR EQUIPMENT DAMAGE.

Page 15

14

Electrical Connections continued

Step 5 - Considerations for Mounting AQUAVAR Controllers

in Host Enclosures

The AQUAVAR controller is available from stock in a variety of enclosures that meet the requirements

of almost any application. Yet, special applications (such as use in washdown environments or in

integrated systems) may make it desirable to mount AQUAVAR controllers in a host enclosure.

When the AQUAVAR controllers are mounted in a host enclosure, the watts dissipated by the drives

must be dissipated by the host enclosure. If this is not accomplished, the control circuitry of the

AQUAVAR controller will be damaged.

Two techniques are available for mounting AQUAVAR controllers in a host enclosure:

• The controllers may be entirely enclosed in the host enclosure or

• The controllers may be mounted with their cooling fins outside of the host enclosure.

The following sections discuss these two mounting techniques in greater detail.

Models Entirely Enclosed in the Host Enclosure

When an AQUAVAR controller is entirely enclosed in a host enclosure, the host enclosure must be

properly sized to dissipate the heat generated by the controller and any other power-dissipated

by the various models of the AQUAVAR controller at various switching frequencies. Use this

information to adequately size the host enclosure.

Models with Fins External to the Host Enclosure

By mounting an AQUAVAR controller so that its heatsink fins are outside of the host enclosure, you

may select a smaller host enclosure than that required when the controller is mounted entirely

inside the host enclosure. For most applications with this type of mounting, typically you will not

need such additional cooling devices as fans, heat exchangers or air conditioners.

The amount by which the load on the host enclosure is reduced is the amount of watts dissipated

by the heatsinks of the controllers. Table 3 shows the watts dissipated by each AQUAVAR model

after deducting the amount of watts dissipated by the heatsinks of the model. Use the values

shown in the table to adequately size the host enclosure.

Installation Procedures

Page 16

Installation Procedures

15

AQUAVAR

Switching Frequency

Max. Switching

Model

Watts Dissipated Watts Dissipated Watts Dissipated

Frequency for

AV2V-

at 4 kHz at 7 kHz at 10 kHz

Rated Current (kHz)

2S010D 37 44 51 10

2S020D 59 71 81 10

2S030D 77 92 106 10

2S050D 162 212 220 10

2S075D 195 251 271 10

2S100D 267 312 354 10

20010D 37 44 51 10

20020D 59 71 81 10

20030D 77 92 106 10

20050D 112 135 156 10

20075D 162 212 220 10

20100D 195 251 (1) — 6

20150D (2) (2) (2) (2)

20200D (2) (2) (2) (2)

40010D 33 43 53 10

40020D 52 69 84 10

40030D 68 90 110 10

40050D 99 131 161 10

40075D 112 144 174 10

40100D 139 180 217 10

40150D 170 210 255 (1) 9

40200D 200 245 — 7

40250D 280 383 — 7

40300D 335 371 (1) — 5

40400D 398 (1) — — 2.5

40500D 600 670 (1) — 5

40600D 710 (1) — — 4

40750D 720 (1) — — 2

50010D 40 52 64 10

50020D 62 83 101 10

50030D 82 108 132 10

50050D 85 115 155 10

50075D 91 131 172 10

50100D 112 160 — 8

50150D 164 — 282 (1) 9

50200D 218 277 (1) — 6

50250D 286 364 (1) — 6

50300D 343 388 (1) — 5

50400D 417 — — 4

50500D 700 — — 4

50600D 720 (1) — — 3

50750D 745 (1) — — 2

(1) Dissipation at rated current and

maximum switching frequency.

Electrical Connections continued

Table 2: Required Dissipation for Models Entirely Inside an Enclosure

Page 17

Installation Procedures

16

AQUAVAR

Model

Watts Dissipated

AV2V2S010D 19

AV2V2S020D 20

AV2V2S030D 27

AV2V20010D 19

AV2V20020D 20

AV2V20030D 27

AV2V20050D 29

AV2V20070D 36

AV2V20100D 34

AV2V20150D 68

AV2V20200D 73

AV2V40010D 20

AV2V40020D 21

AV2V40030D 27

AV2V40050D 30

AV2V40070D 36

AV2V40100D 40

AV2V40150D 46

AV2V40200D 50

AV2V40250D 75

AV2V40300D 76

AV2V40400D 80

AV2V40500D 134

AV2V40600D 145

AV2V40750D 150

AV2V50010D 20

AV2V50020D 21

AV2V50030D 27

AV2V50050D 30

AV2V50070D 33

AV2V50100D 39

AV2V50150D 43

AV2V50200D 44

AV2V50250D 73

AV2V50300D 78

AV2V50400D 82

AV2V50500D 135

AV2V50600D 143

AV2V50750D 152

Electrical Connections continued

Table 3: Required Dissipation When Fins are External to the Enclosure

Page 18

Installation Procedures

17

Electrical Connections continued

Step 6 - Maintenance

Minimum Torque Values to Secure Cover

If you remove the cover of an IP55 AQUAVAR controller, it is imperative that the cover be

closed and re-secured with sufficient tightness to maintain environmental integrity. The table

below specifies the torque values for the bolts that secure the covers on the various models.

Step 7 - General Wiring Information

Wiring Practices

When making power and control connections, observe these precautions:

• Follow all Federal, State, NEC codes and local codes.

• Never connect input AC power to the motor output terminals T1/U, T2/V or T3/W – or

damage to the controller will result.

• Power wiring to the motor must have the maximum possible separation from all other power

wiring. Do not run in the same conduit, this separation reduces the possibility of coupling

electrical noise between circuits.

• Cross conduits at right angles whenever power and control wiring cross.

• Good wiring practice also requires separation of control circuit wiring from all power wiring.

Since power delivered from the controller contains high frequencies which may cause

interference with other equipment, do not run control wires in the same conduit or raceway

with power or motor wiring.

Considerations for Power Wiring

Power wiring refers to the line and load connections made to terminals L1/R, L2/S, L3/T and

T1/U, T2/V, T3/W respectively. Select power wiring as follows:

• Use only UL recognized wire. (Shielded or armored wire is recommended for power and motor

wiring.)

• Wire voltage rating must be a minimum of 300 V for 230 Vac systems and 600 V (Class 1 wire)

for 460 Vac and 575 Vac systems.

AV2 Enclosure Type

Torque Value

English Metric

1-20 HP, 230 Vac input 12 in-lbs 1.35 Nm

IP55 1-20 HP, 460 and 575 Vac input 18 in-lbs 2.03 Nm

25-75 HP, 460 and 575 Vac input 12 in-lbs 1.35 Nm

Page 19

Electrical Connections continued

• Use circuit breakers on the incoming power lines.

• Grounding must be in accordance with NEC and CEC. If multiple AQUAVAR controllers are

installed near each other, each must be connected to ground. Take care to not form a ground

loop. Maintain a common ground.

• Wire must be made of copper and rated 60 / 75ºC (unless otherwise specified in the table

below). Refer to Tables 4, 5 and 6 for recommended wire gauges and temperature ratings.

Considerations for Control Wiring

Control wiring refers to the wires connected to the control terminal strip. Select control wiring

as follows:

• Shielded wire is recommended to prevent electrical noise interference from causing improper

operation or nuisance tripping.

• Use only UL™ recognized wire.

• Wire voltage rating must be at least 300 V for 230 Vac systems.

Installation Procedures

18

Model

Wire Size 208 Vac Wire Size 230 Vac

Number

AWG mm

2

AWG mm

2

AV2V2S010D 14 2.5 14 2.5

AV2V2S020D 12 4.0 12 4.0

AV2V2S030D 10 6.0 10 6.0

AV2V2S050D 8 10.0 8 10.0

AV2V2S075D 6 16.0 6 16.0

AV2V2S100D 4 25.0 4 25.0

AV2V20010D 14 2.5 14 2.5

AV2V20020D 14 2.5 14 2.5

AV2V20030D 12 4.0 14 2.5

AV2V20050D 10 6.0 10 6.0

AV2V20070D 8 10.0 8 10.0

AV2V20100D 8

1

10.0

1

8 10.0

AV2V20150D 6

1

16.0

1

6

1

16.0

1

AV2V20200D 6

1

16.0

1

6

1

16.0

1

(1) Use wire rated 90ºC in an environment where the ambient temperature is greater than 40ºC (122ºF).

Table 4: Recommended Wire Gauges (230 Vac Models)

Page 20

Model Number

Wire Size

AWG mm

2

AV2V50010D 14 2.5

AV2V50020D 14 2.5

AV2V50030D 14 2.5

AV2V50050D 14 2.5

AV2V50075D 14 2.5

AV2V50100D 12 4.0

AV2V50150D 10 6.0

AV2V50200D 8 10.0

AV2V50250D 8 10.0

AV2V50300D 8 10.0

AV2V50400D 6

1

16.0

1

AV2V50500D 4

1

25.0

1

AV2V50600D 4

1

25.0

1

AV2V50750D 2

1

35.0

1

(1) Use wire rated 90ºC in an environment where the ambient temperature is greater than 40ºC (122ºF).

Installation Procedures

19

Electrical Connections continued

Table 5: Recommended Wire Gauges (460 Vac Models)

Model Number

Wire Size

AWG mm

2

AV2V40010D 14 2.5

AV2V40020D 14 2.5

AV2V40030D 14 2.5

AV2V40050D 14 2.5

AV2V40075D 12 4.0

AV2V40100D 12 4.0

AV2V40150D 10 6.0

AV2V40200D 10

1

6.0

1

AV2V40250D 8

1

10.0

1

AV2V40300D 6

1

16.0

1

AV2V40400D 6

1

16.0

1

AV2V40500D 3

1

35.0

AV2V40600D 2

1

35.0

1

AV2V40750D 1

1

50.0

1

(1) Use wire rated 90ºC in an environment where the ambient temperature is greater than 40ºC (122ºF).

Table 6: Recommended Wire Gauges (575 Vac Models)

Page 21

Installation Procedures

Electrical Connections continued

Step 8 - Input Line Requirements

Line Voltage

See the Power and Current Ratings table for the allowable fluctuation of AC line voltage for your

particular model. A supply voltage above or below the limits given in the table will cause the

drive to trip with either an overvoltage or under voltage fault.

When supplying line voltages other than the factory default values (either 230 Vac, 460 Vac or

575 Vac depending on the model), set the Supply Voltage parameter to the appropriate value.

Exercise caution when applying the AQUAVAR controller on low-line conditions.

For example, and AQUAVAR controller will operate properly on a 208 Vac line – but the maximum

output voltage will be limited to 208 Vac. Now if a motor rated for 230 Vac line voltage is

controlled by this drive, higher motor currents and increased heating will result.

Therefore, ensure that the voltage rating of the motor matches the applied line voltage. If other

than 60 Hz output is desired, proper V/Hz can be programmed into the AVII by setting the

Nom Mtr Voltage and Nom Mtr Freq parameters.

Use of Isolation Transformers and Line Reactors

The AQUAVAR controller is is per fectly suitable in most cases for direct connection to a power source

as specified in this manual and the technical nameplate affixed to the unit. There are however a

few cases where a properly sized isolation transformer or line reactor should be employed to

minimize the risk of drive malfunctionor damage or nuisance tripping:

• As noted in

Table 7

, transformer sizing, when line capacity is greater than 10 times the KVA

rating of the drive. Consult the factory for assistance in sizing the reactor.

• When power factor correction capacitors are employed on the drive’s power source.

• When the power source is known to be subject to transient power interruptions or

significant voltage spikes.

• When the power source supplying the drive also supplies large devices such as DC drives

that contain controller rectifiers.

Table 7: Transformer Sizing for the AQUAVAR Controller

Controller HP 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75

Transformer kVA 2 4 5 9 13 18 23 28 36 42 56 70 90 112

20

Page 22

Electrical Connections continued

Phase Imbalance

Phase voltage imbalance of the input AC source can cause unbalanced currents and excessive

heat in the drive’s input rectifier diodes and DC bus capacitors. Phase imbalance can also damage

motors running directly across the line.

Step 9 - Terminals Found on the Power Board

Description of the Terminals

Diagram 4 shows the power terminals for the AQUAVAR controller. Table 8 describes the terminals.

Table 8: Description of Power Terminals

Terminal Description

TB1 Terminal Group

GND Earth ground.

L1/R These terminals are the line connections for three-phase models. (Single-phase

L2/S models will only have the L1/R terminal, with the other two terminals being

L3/T replaced by a terminal labeled N.)

T1/U

T2/V These terminals are for motor connections.

T3W

Installation Procedures

21

CAUTION!

EQUIPMENT DAMAGE HAZARD - NEVER USE POWER-FACTOR CORRECTION

CAPACITORS ON MOTOR TERMINALS T1/U, T2/V OR T3/W. DOING SO WILL

DAMAGE THE SEMICONDUCTORS. FAILURE TO OBSERVE THIS INSTRUCTION CAN RESULT IN INJURY OR EQUIPMENT DAMAGE.

Diagram 4: AQUAVAR Controller Power Terminals

GND

L1/R

L2/S

L3/TB–B+DB

T1/U

T2/V

T3/W

GND

Page 23

Electrical Connections continued

Typical Power Connections

Diagram 5 shows the terminal connections for line power and motor output. See Step 8 for input

line requirements.

Note that when testing for a ground fault, do not short any motor lead (T1/U, T2/V or T3/W) back

to an input phase (L1/R, L2/S or L3/T).

As shown in Diagram 5, it is necessary to provide fuses and a disconnect switch for the input AC

line in accordance with all applicable electrical codes. The drive is able to withstand a 110% over

load for 60 s. For maximum protection of the drive, use the fuses listed in Tables 9, 10 and 11

found below and on the next page. The recommended supplier is Bussman.

Table 9: Recommended Fuses (230 Vac Models)

Fuse Size 208 Vac Fuse Size 230 Vac

Model Number

JJS/JJN

1

JJS/JJN

1

AV2V2S010D 15 10

AV2V2S020D 20 20

AV2V2S030D 30 30

AV2V2S050D 45 45

AV2V2S075D 60 60

AV2V2S100D 80 80

AV2V20010D 10 6

AV2V20020D 15 10

AV2V20030D 20 15

AV2V20050D 30 25

AV2V20075D 40 35

AV2V20100D 50 40

AV2V20150D 70 60

AV2V20200D 70 60

(1) For sizes up to and including 30 A, KTK fuses may be substituted.

Installation Procedures

22

Diagram 5: Connections for Power Wiring

Disconnect

Switch

Fuses

AC Power

Three-Phase

Motor

AV2V Drive

GND

L1/R

L2/S

L3/T

T1/U

T2/V

T3/W

GND

Page 24

Installation Procedures

23

Electrical Connections continued

Table 10: Recommended Fuses (460 Vac Models)

Fuse Size 380 Vac Fuse Size 460 Vac

Model Number

JJS/JJN

1

JJS/JJN

1

AV2V40010D 6 6

AV2V40020D 6 6

AV2V40030D 10 10

AV2V40050D 15 15

AV2V40075D 20 20

AV2V40100D 20 20

AV2V40150D 40 35

AV2V40200D 50 40

AV2V40250D 60 50

AV2V40300D 70 60

AV2V40400D 80 60

AV2V40500D 90 90

AV2V40600D 110 110

AV2V40750D 150 150

(1) For sizes up to and including 30 A, KTK fuses may be substituted.

Table 11: Recommended Fuses (575 Vac Models)

Fuse Size 575 Vac

Model Number

JJS/JJN

1

AV2V50010D 6

AV2V50020D 6

AV2V50030D 10

AV2V50050D 10

AV2V50075D 15

AV2V50100D 20

AV2V50150D 30

AV2V50200D 35

AV2V50250D 50

AV2V50300D 50

AV2V50400D 70

AV2V50500D 70

AV2V50600D 80

AV2V50750D 100

(1) For sizes up to and including 30 A, KTK fuses may be substituted.

Page 25

Electrical Connections continued

1. The wires routed from the

terminal block U, V, W, and

ground screw, should now be

connected to the motor leads

using the motor nameplate and

Diagram 6 for reference. Always

refer to motor wiring nameplate.

2. Pressure Transducer

Installation and Wiring

It is recommended that the

transducer be mounted in the

discharge piping

. The location should be in a non-turbulent, straight piece of pipe. See layout

on page 5. Locate the adapter for the pressure transducer, if needed.

Installation Procedures

24

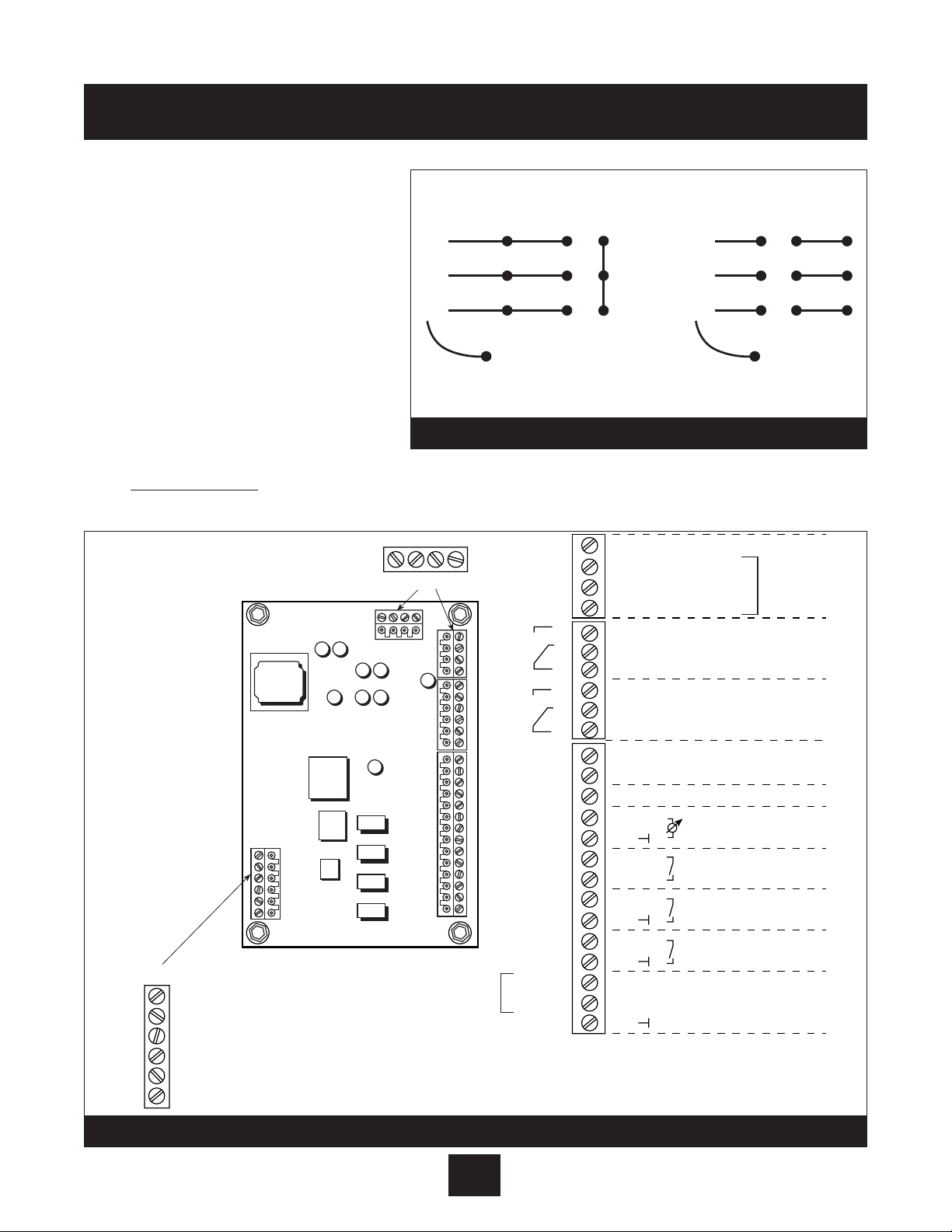

Diagram 6

Diagram 7

220 Volt 460 Volt

4

3

RS485

AQUAVAR

WU V

GROUND = PE

2

1

X6

4

3

2

X5

1

6

5

4

3

2

1

X2

14

13

12

11

10

9

8

7

6

5

4

3

2

1

X1

Transducer

connection

123

BROWN – 3

WHITE – 2

X9

- 24 VDC

+ 24 VDC

+ 24 VDC

FAULT RELAY

6 – CONNECTED TO DRIVE

5 – CONNECTED TO DRIVE JUMPER

4 – CONNECTED TO DRIVE JUMPER

3 – CONNECTED TO DRIVE

2 – ANALOG OUT (PRESSURE)

1 – RETURN SIGNAL

789

6

AQUAVAR

WU V

123

789

54

GROUND = PE

4

+ 5VDC

3

GND

2

SIO +

1

X5

X2

SIO -

6

NO

5

CC

4

NC

3

NO

2

CC

1

NC

14

Digital Input

13

Voltage Signal Input (0-10Vor 2-10V)

12

Current Signal Input (4-20 mA)

11

10

9

8

7

6

5

4

3

15 V

2

IN

1

X1

* NOTE: Jumpers are installed from the factory.

Must remove to wire motor thermal, low water

switch or external ON/OFF if used.

RS-485

connected to drive

“Run Signal”

fault signal

Analog signal output (0-10V)

connected to drive

Motor thermo or PTC *

low Water or jumper *

external on or jumper *

U

b (max 100 mA)

(4-20 mA)

actual value signal

shielding

Multipump

456

Page 26

Installation Procedures

25

Electrical Connections continued

3. Place the square gasket over the end of the transducer, plug the cable connector on,

and tighten the screw.

• The transducer is supplied with

1

⁄4

” NPT threads for direct mounting in the discharge piping.

4. Now select one of the remaining ports in the AQUAVAR controller to route the transducer cable.

Route the transducer cable through the strain relief, cut to length and connect to locations X1

#2 and #3 as shown in Diagram 7. (Note: Control board is mounted to the inside front cover

of the drive enclosure.) The brown wire is connected to X1 #3 and the white wire to X1 #2.

Tighten strain relief.

5. Terminals Found on the AV II Drive Control Board (Internal Drive)

Description of the Control Terminals: Figure 8 shows the control terminals found on the I/O

board of the AV IIdrive. (The actual control board cannot be accessed by the user.) These

terminals are prewired by the factory with color coded wires below.

Note that due to labeling constraints, the labels for some terminals start on the left (either on

the side or top of the terminal block), are interrupted by the terminal screw, and then finish on

the right (either on the side or top of the terminal block). For example, terminal A11 is labeled

with A on the left side of the block and 11 to the right of the terminal screw on top of the

block. Similarly, terminal NC2 is labeled with N to the left of the terminal screw on top of the

block and then C2 on the

right side of the block.

As is shown in the figure,

the terminals are divided

into four terminal blocks,

each of which pulls apart

for ease of field wiring:

• TB1 - analog input,

analog output and

digital output terminals.

• TB2 - output relay 1 (R1).

• TB3 - output relay 2 (R2).

• TB4 - digital input

terminals.

Table 12 starting on the

next page describes the

control terminals.

Cable connector will fit on one way only! Do not force on or damage may occur.

Note

Diagram 8

Enhanced

Keypad

Port

On side of

terminal block

Yellow Wire

White Wire

Black Wire

CM

CM

CM

CM

CM

DQ

DQ

DQ

10

9

8

7

6

5

4

3

2

1

24

24

24

C2

C2

O2

On side of

terminal block

Black Wire

Jumper

Blue Wire

Orange Wire

Red Wire

TB1

A0

A0

CM

A1

A1

CM

A

11

12

A

+

10

21

A

CM

CM

CM

D

PQ

3

DIP Switches

2

1

C1

R

N

C1

N

C1

TB2

TB4

CM

EN

D

D

D

D

D

D

D

D

D

D

+

+

+

R

N

N

TB3

CM

EN

Page 27

26

Installation Procedures

Electrical Connections continued

Table 12: Description of AV II Drive Control Terminals (Internal Drive)

Terminal Description

TB2 Terminal Block

Common terminal for the first auxiliary relay. The function of the relay is

RC1 set by parameter R1 Configure. The default setting is for the relay to

activate when a fault is detected (Drv Flted).

NC1 Normally-closed contact for the first auxiliary relay. It will open when the

relay is activated.

NO1 Normally-open contact for the first auxiliar y relay. It will close when the

relay is activated.

TB3 Terminal Block (Drive Run Contacts)

Common terminal for the second auxiliary relay. The function of the relay

RC2

is set by parameter ROUT R2 Config. The default setting is for the relay

to activate when the drive is running.

The contact ratings are 115 VAC at 1 A or 230 VAC at 0.5 A .

NC2

Normally-closed contact for the second auxiliary relay. It will open when

the relay is activated.

NO2

Normally-open contact for the second auxiliary relay. It will close when

the relay is activated.

TB4 Terminal Block

Enable terminal. A jumper is placed between this terminal and the +2

terminal at the factory. You may replace this with a contact if desired. The

EN

circuit from EN to +24 must be closed for the drive to operate.

Note that unlike all other terminals, this terminal cannot be configured

for “pull-down logic.” That is, a high input to this terminal is always

regarded as true – and must be present if the drive is to operate.

Digital inputs. The function of a digital input is configured by the

D3 to D10 parameter with the same name as the digital input in the DI Configure

parameter group.

Digital input. In 3-wire control, this must be a Stop input. In 2-wire

D2 control, it may be configured to another function with parameter

D2 Configure.

D1 Digital input. This must be a Start or Run input.

Page 28

6. For multi-pump systems:Use a three core shielded cable to connect terminals 1, 2, and 3

on X5 between the AQUAVAR controller units. These are the RS-485 inter face connections.

(See Diagram 11 and 13). Note: either RS485 port can be used.

• Connect pump one to pump two, two to three, and three to four (maximum is 4 pumps).

7. External pressure switch or float switch- (if used) to check incoming pressure and low/no

suction. Connect to terminal block X1 at the 6 and 7 location. Refer to Diagram 11.

When using a suction pressure switch, set the cut off at the maximum NPSH required by the pump.

8. External on/off

If used to turn the AQUAVAR controller on or off from an external panel or controller, connect to

terminal block X1 at the 4 and 5 location (refer to Diagram 7, page 24).

9. Analog output of pressure

A meter can be connected to X9 pins 2 and 1 for remote display of actual system pressure.

The meter must be 0-10 VDC volt with no more than 2 mA.

10. Second Sensor Input

The ground pin (X1-10) used for analog output can also be used to bridge a connection for

a second sensor. This can be digital (on/off) such as a switch which would be connected

between X1-10 and X1-14. Another choice is a sensor with a voltage signal of 0-10V or 2-10V

which would be connected to X

1-10 and X1-13. A final choice is a 4-20 mA current sensor

which would be connected to pins X

1-10 and X1-12.

27

Installation Procedures

Power supplies using G.F.I. breakers will cause nuisance tripping which will result in the

AQUAVAR

controller displaying an “undervoltage” fault.

Note

If an external switch is NOT used, install a jumper wire between X1 Locations 4 and 5.

Note

Diagram 9

4

3

2

X5

1

6

5

4

3

2

1

X2

14

13

12

11

10

9

8

7

6

5

4

3

2

1

X1

4

3

2

X5

1

6

5

4

3

2

1

X2

14

13

12

11

10

9

8

7

6

5

4

3

2

1

X1

4

3

2

X5

1

6

5

4

3

2

1

X2

14

13

12

11

10

9

8

7

6

5

4

3

2

1

X1

Page 29

Pump Priming

Refer to your pump operation manual for instructions on pump priming. You will need to unscrew

the pressure transducer and adapter if you used the pump fill plug for mounting. When priming is

complete, replace the pressure transducer and check for leaks!

Run Test

Instructions

1. Check all wiring.

All motors used with the AQUAVAR controller are

three phase. You will need to check the

direction of rotation of the motor shaft. If you

have followed all of the previous steps carefully,

you should now be ready to apply power to the

AQUAVAR controller unit.

2. Close discharge valve.

Make sure the discharge valve is closed.

Apply power to the AQUAVAR controller. The first

screen appears for 2 seconds and shows the

software version and manufacture date. The

next screen will appear automatically

*If auto start is preprogrammed “ON”, pump will start immediately.

3. Check Power Light

Check the AQUAVAR controller panel. The

“power on”

light should be illuminated and the

display should say

“No Autostart - disable inverter.”

If either of these conditions is not

present, turn off all power to the AQUAVAR controller and recheck all connections.

To change the display language on the AQUAVAR controller, press the “ ” key and the up arrow key at the

same time. A scrolling line will appear on the bottom of the screen and tell you which button to push for

the language you want. After selecting the language, press the up arrow to return to the main display.

Note

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL POWER AND WAIT

FIVE MINUTES FOR C APACITOR DISCHARGE BEFORE SERVICING AQUAVAR

CONTROLLER CAN C AUSE SHOCK, BURNS, OR DEATH.

WARNING!

WARNING

Hazardous voltage

can shock, burn or

cause death.

Installation Procedures

DO NOT APPLY POWER TO THE AQUAVAR CONTROLLER OR PUMP UNTIL ELECTRICAL CONNECTIONS HAVE BEEN REVIEWED BY A QUALIFIED ELECTRICIAN AND

MEET ALL APPLICABLE STATE AND LOCAL REQUIREMENTS.

WARNING

Screen

—

NO AUTOSTART - DISABLE INVERTER

ITT Industries

SW:120 Date: 10/30/00

28

*

Page 30

4. Check Display.

* If these conditions exist, proceed.

If NOT, check all wiring.

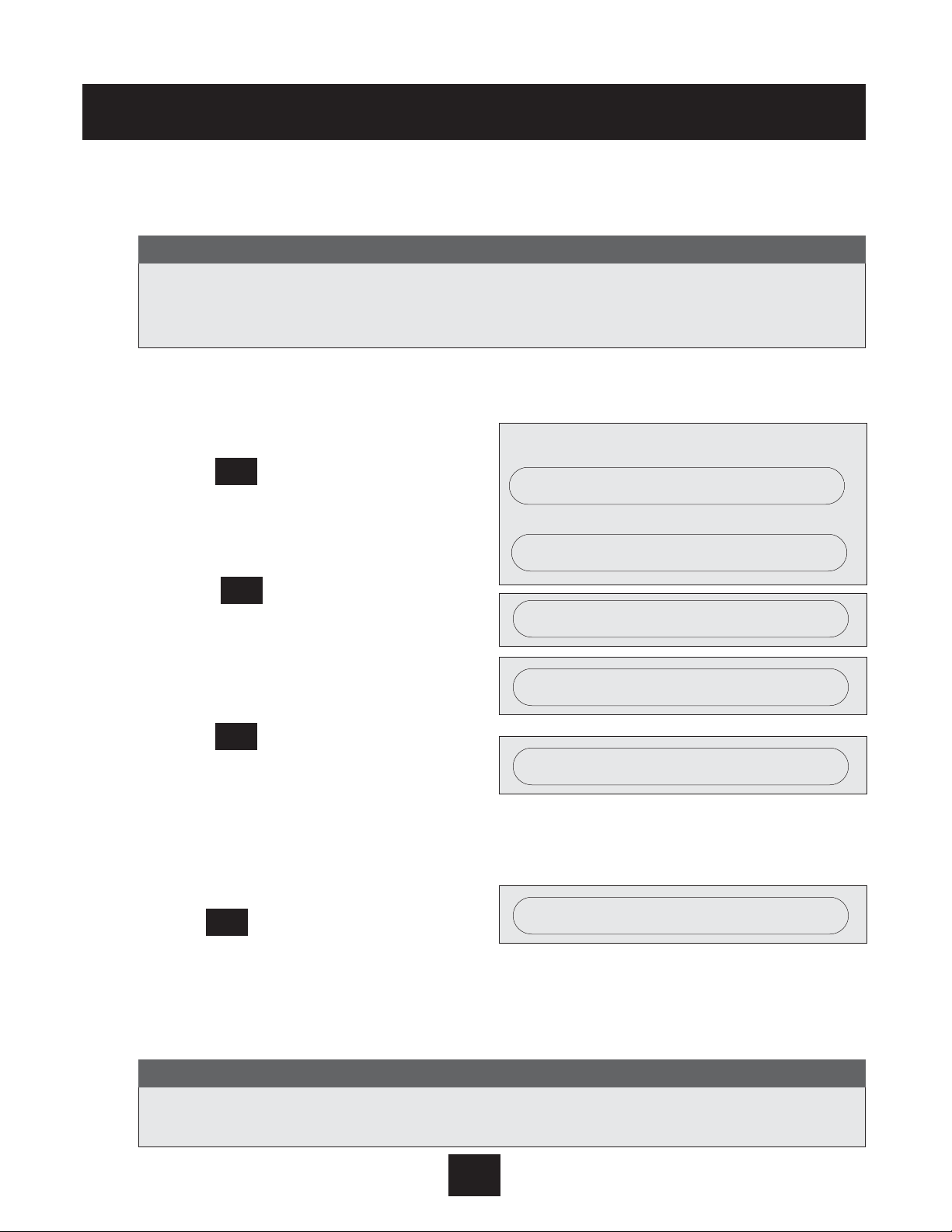

5. Drive Component Keypad (Internal Drive)

The AQUAVAR

II

units have an additional keypad inside the cabinet. You will need to use

this keypad one time for initial system set up. Once set, all other functions are programmed

with the main display on the front panel. Below are the instructions for initial programming of

the internal keypad.

This keypad provides access to a

comprehensive set of parameters that

allow the AV

II

drive to meet the needs

of almost any application. To make

customization as simple as possible, two

levels of programming are available.

Programming Mode

A. Programming mode is entered by

pressing the PROG key.

B. To program a parameter ’s value, per

form the following steps:

C. Press PROG to initiate programming.

D. The Operate display will change to the list of parameters. An arrowhead indicates which

one is selected.

E. If the desired parameter is indicated by the arrowhead, press ENTER to select the

parameter and display its current value. If the indicated parameter is not the one you

want to program, use the up or down arrow keys to move the arrowhead to the desired

parameter and then press ENTER to select the parameter and display its current value.

F. After the ENTER key is pressed, the value for the parameter will be displayed. For exam-

ple, parameter Motor voltage may range from 100V to 690 V and you may configure

any value

within

that range

as shown

on the

motor

nameplate.

Installation Procedures

29

Screen

NO AUTOSTART - DISABLED INV.

Diagram 11

Diagram 10

2 Line by 16 Character Display

RUN WARNING FAULT PROG POWER

FWD

REV

SHIFT ENTER

PROG

STOP

Sample display for

parameters assigned a value

MIN FREQUENCY

V0301 160.05 Hz

Name of Parameter

Sample display for

parameters assigned a function

STOP TYPE

P0403 CST to Stp

Data

Memory

Address

Value

Units

Can Parameter

Be Changed?

P

Unlocked — Yes.

V

Locked — No.

Memory

Address

10-Character

Description

of Assigned Function

Page 31

G. Use the up or down arrow keys to change the parameter’s value to the desired value.

H. Press ENTER to save the new value. (If you do not wish to save the new value, press

SHIFT.)

I. The new value is stored, or discarded, and then the list of parameters is shown.

J. You may now select another parameter or return to the Operate mode by pressing

the PROG key.

6. You need to set up the AQUAVAR controller for the type of pump motor you are using. Press the

PROG key to display the list of functions. Use the up or down arrow to scroll to the NOM MTR

CURRENT parameter.

7. Press the ENTER key and then the up and down arrows to change the value to match the SFA

(Service Factor Amps) shown on your pump motor data plate. Once complete, press ENTER

again. (Maximum S.F. amps is 10% above nominal controller output amps.)

See pages 86 and 87.

8. Scroll to the NOM MTR VOLTAGE parameter and press ENTER. Use the up and down arrows

to enter the voltage on the motor nameplate. For multi-voltage motors, select the voltage to

match your line voltage. Press ENTER to save the value.

9. Scroll to the NOM MTR FREQ parameter and press ENTER. Use the up and down arrows to

enter the maximum frequency for the motor design you are using. This would be either 50 Hz

or 60 Hz. Press ENTER to save the value.

10. Scroll to the NOM MTR RPM parameter and press ENTER. Use the up and down arrows to

enter the maximum RPM for the motor you are using. THis can be found on the motor

nameplates. Press ENTER to save the value.

11. Scroll to the SUPPLY VOLTAGE parameter. Press ENTER and use the up and down arrows to

put in the voltage available on the input line. Press ENTER to save the value.

12. Scroll to the Language parameter. Press the ENTER key and use the up and down arrows to

change the display language if needed. Press ENTER to save the value.

13. Press the PROG key again, close the panel door and go back to the main AQUAVAR display.

14. Press the down arrow key

The next display will be:

15. Press the up arrow

to turn on the AQUAVAR

II

controller.

16. Open the discharge valve slowly until the pump starts.

Observe the rotation of the pump shaft or motor fan.

17. Close the discharge valve.

18. Press the down arrow to turn off the AQUAVAR

II

controller.

Installation Procedures

(continued)

30

INVERTER STOP - ON -> START

RUN LIGHT ON

▼

▼

▼

Page 32

Installation Procedures continued

19. If the direction of rotation was correct, proceed to the Programming section beginning on

the following page.

20. If the direction was not correct, remove all power from the AQUAVARIIcontroller and wait

five minutes.

Open the motor conduit box and exchange any two of the three motor leads. Close the conduit box.

Repeat steps 15 through 18 to check the direction of the motor shaft rotation.

Programming

Programming of the AQUAVARIIcontroller is accomplished by using the three pressure sensitive buttons on the control panel along with the two line

LCD display.

The format of the program is a series of menus

which can be scrolled through by using the select

button. Each screen display is used to provide

information about the operation of the system or to

change one or more of the operating parameters.

Changes are made by pushing the up or down

arrows.

I. The Main Menu - Setting Single Pump Constant Pressure

Diagram 15 shows the display screens in a flow chart format. Refer to this flow chart for the next 6 steps.

There are ten display screens in the main menu which will allow you to set the required system pressure,

save it, and turn the system on. Several of these display screens were already used during the test run.

After power has been turned on, the

“Power on”

light should be illuminated and the display should

briefly show the software version and date, then show

“No Autostart - disable inverter.”

31

Programming

Diagram 12

▼

▼

Page 33

Instructions

1. Check Power Light

2.

Press the down arrow to advance the display to:

3. Press Select to advance the display to:

4. Enter the pressure you want the pump

to maintain (constant pressure) for your system.

Press the until the reading shows the

value you want. Use the down arrow to back up

if you have gone too far.

For example: if you need a constant pressure

of 50 PSI in your system at various demand

rates, you would enter 50 as the value by

using the .

5. Autostart setting

Press to advance the display to:

(This displays the autostart setting.)

Push to turn the autostart function on.

If the autostart function is on, the AQUAVARIIcontroller will automatically turn on and

resume activity when power is restored after a failure. If autostart is off, the AQUAVAR

II

controller must be manually turned on by the operator after a power failure. Be sure the dis

charge valve is closed to prevent pump start.

32

Programming

REQ. PRESS - XXX PSI

*

▼

▼

▼

50

AUTO START - OFF

AUTO START - ON

Screen

▼

▼

▼

REQUIRED VALUE - XXX PSI

NO AUTOSTART - DISABLE INVERTER

Screen

▼

*

If “Inverter Locked” is displayed, the external on/off switch is in the off position or contacts at X1:4 and 5 are not jumpered.

Note

INVERTER STOP - ON->START

REQUIRED VALVE - XXX PSI

Page 34

6. Press to advance the display to:

This display shows the last recorded error or

fault encountered by the AQUAVAR controller.

7. Press to advance the display to:

This in the error which occurred before the last

one.

8. Press to advance the display to:

The error before error 2.

9. Press to advance the display to:

The error before error 3.

10. Press to advance the display to:

The error before error 4.

11. Press to advance the display to:

This is the total amount of run time of the

motor. It can be reset using a method

described later.

12. Saving changes

Press to advance the display to:

13. Press and hold down BOTH

arrows

at the same time until the display changes to:

This will allow you to save the changes you

have made in the microprocessor memory.

14. Af ter about five seconds the display will

automatically return to:

Push . The AQUAVAR

II

controller will begin to automatically maintain system pressure at the

point you have selected and the display will show the pressure set point.

Programming

33

▼

▼

*

▼

SAVE ??? +

SAVE ??? SAVED

INVERTER STOP - ON->START

If the

AQUAVAR

II controller is not maintaining the rating you selected, check the sen-

sor adjustment procedures on page 60 or check rotation again.

Note

▼

▼

ERROR 5

*

*

TOTAL RUN TIME

0000:00

If you have advanced past a window and want to return to it, press and at

the same time to back up.

Note

*

ERROR 1

ERROR 2

*

*

ERROR 3

*

ERROR 4

▼

*

Page 35

AQUAVAR

II

Controller Program Flow Chart

Single Pump Constant Pressure

II. Single Pump - Pump Protection

The

AQUAVARIIcontroller has the ability to protect the pump by shutting it off in low/no suction or run out conditions.

To set run out protection:

For steps 1 through 8, refer to the flow chart on page 36.

Instructions

1. Password

The password protection prevents

untrained personnel from accidentally

changing the base settings.

• From the main menu, hold down the

key for 2-3 seconds until the display

changes to:

34

Programming

Diagram 13

FAILURE TO SAVE SETTINGS AFTER PROGRAMMING RESULTS IN LOSS OF

PROGRAM VALUES WHEN POWER IS REMOVED!

WARNING

Low/no suction protection can be managed by the installation of a suction line pressure switch,

or float switch for a tank. This switch is connected to the AQUAVARII controller as described

earlier in the Electrical Installation section. The cut off setting for this switch should be the

maximum NPSH required by the pump.

Note

PASSWORD 0000

Screen

*

SW Ver.

Date:

Press • long

ITT Ind.

50 PSI

REQUIRED

VALUE

50 PSI

Auto-START

ON

ERROR 1 ERROR 2 ERROR 3 ERROR 4 ERROR 5

TOTAL RUN

TIME

0000: 41

SAVE ??

– + v

Page 36

2. Press the key until you reach the number

66. You will now be able to access all of the

alternate menus for all AQUAVAR controller

optional controls.

3. Press to advance the display to the next

window:

The jog mode is very useful because it allows

you to check on the actual outgoing frequency

and system pressure. By pressing either or

the controller changes to manual, and you

can change the frequency to set any constant

speed. The Aquavar returns to normal automatic operation when you leave the jog mode

window.

4. Continue to briefly touch the key to

scroll past all of the windows and submenus

until you reach:

5. Hold the key down for 2-3 seconds

until the display changes to:

6. Set the minimum pressure the system is

allowed to maintain before shutting down. For

example, if the set point for the system is 50

PSI, and the operator will allow anything

above 41 PSI, then the conveyor limit would

be set at 40 PSI.

This function can also be turned

off by pressing until “disabled” is shown.

To set timed protection:

7. Delay Time

Enter the amount of

time that the pump is allowed to run at

maximum frequency after pressure begins

to drop below the conveyor limit. This should never occur if the system has been

properly sized and there are no leaks in the system. Note: This delay time is also

applied to low suction pressure switch, on terminal X1, 6 and 7.

35

Programming

SET CONVEYOR LIMIT

40 PSI

DELAY TIME

*

*

SUBMENU ERRORS

CONVEYOR LIMIT

Disabled

▼

▼

*

0066

JOG MODE

▼

▼

Page 37

Press the to enter the number of seconds.

The pump will run after pressure begins to drop

at pump run out or a suction switch activates.

8.

Error Reset Turning this control on will enable the AQUAVARII controller to retry its operation five

times when a fault condition occurs. Turning the control to “off” means that the AQUAVARII

controller will shut down the first time a fault occurs. Select the mode you want by pushing the up

or down arrow key.

• Press to advance the display to:

Press to set the time between attempted

restarts or to disable this function

9. Clear error. The error memor y can be deleted

by entering a password supplied by your

distributor.

Returning to normal operation:

10. Hold down the key for 2-3 seconds

until the display changes to:

11. Briefly touch the key to scroll until you

reach the display:

12. Press both at the same time until the display

changes to:

After a moment, the screen will automatically

return to the main menu start position.

36

Programming

SUBMENU ERRORS

Screen

*

*

▼

▼

SAVE ??? +

SAVE ??? SAVED

▼

▼

*

ERROR RESET

▼

▼

CLEAR ERRORS

0000

▼

“Fatal” errors will always shut down the system the first time.

Note

15 SEC

▼

Page 38

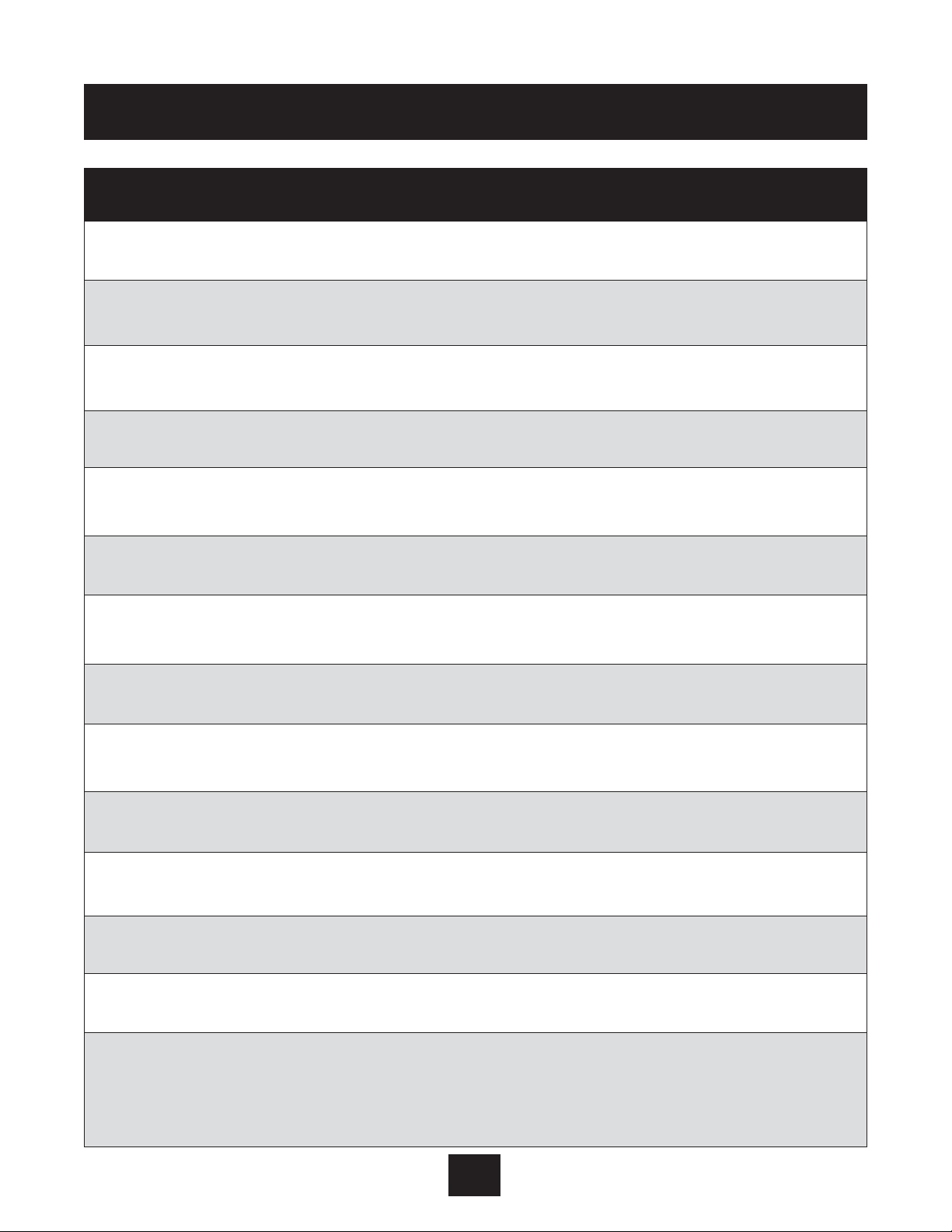

37

Programming - Single Pump Protection

Diagram 14

REQUIRED

VALUE

126.9 PSI

Auto-START

ON

ERROR 1 ERROR 2 ERROR 3 ERROR 4 ERROR 5

TOTAL RUN

TIME

0000: 41

SAVE ??

+

PASSWORD

0000

JOG-MODE

XX Hz

XX PSI

WINDOW

5%

RAMP

HYSTERISIS

80%

RAMP 1

4.0 Sec.

RAMP 2

4.0 Sec.

RAMP 3

70 Sec.

RAMP 4

70 Sec.

MAX.

FREQUENCY

60.0 Hz

MIN.

FREQUENCY

0.0 Hz

CONFIG.

FMIN

F -> 0

STOP–

DELAY FMIN

0 Sec.

SENSOR–

ADJUST

out of range

SENSOR–

CURVE

Linear

NORMALIZE

20 mA –

362.6 PSI

REGULATION

MODE

Normal

START

VALUE

DISABLED

CONFIG. REG.

Val. 2

OFF

RELAY

CONFIG.

Run

Motor

MODE

Controller

SUBMENU

Seq. Control

SUBMENU

RS485–

Interface

FREQU. –

LIFTING

37.0 Hz

LIFT

INTENSITY

0.0%

DIMENSION

UNIT

PSI

SUBMENU

TEST RUN

xxx

SUBMENU

ERRORS

ANALOGUE –

OUT

Actual Value

SUBMENU

Offset

TEST RUN

after 100 h.

OPERATING

HOURS 0000 h.

Control unit’s

operating time

DISP.–

CONTRAST

50%

SET

PASSWORD

xxxx

LOCK

FUNCTION

OFF

SUBMENU

DEFAULT

VALUES

SAVE ??

– + v

PUMP

ADDRESS

OFF

ADC

REFERENCE

Local

CONVEYOR–

LIMIT

disabled

DELAY

TIME

2 sec.

ERROR–

RESET

disabled

CLEAR

ERROR

0000

DEFAULT

EUROPE

– + v

DEFAULT

USA

– + v

TEST RUN

Man.

– + v

TEST –

FREQUENCY

30.0 Hz

ACTU. VALUE

INC.

5.0 PSI

ACTU. VALUE

DEC.

2.1 PSI

ENABLE

SEQ. CTL.

58.0 Hz

SWITCH

INTERVAL

12 hours

SUBMENU

Synch.

Control

BUSARBIT –

DIAG.

0

SOURCE

REQ. VALUE

ADR1

PUMP

SEQUENCE

Adrl disabled

LEVEL 1

2.0%

LEVEL 2

0.0%

INTENSITY 1

0.0%

INTENSITY 2

0.0%

SYNCHRON.

LIMIT

0.0 Hz

SYNCHRON–

WINDOW

2.5 Hz

OFFSET –

INPUT

OFF

SW Ver.

Date:

ITT Ind.

50 PSI

Press • long

Page 39

III. Single Pump - System Cur ve Compensation

The AQUAVAR controller can automatically compensate for system friction losses due to

increased flow. Tables are available in most

pump catalogs indicating the amount of friction loss that can be expected in various sizes

of pipe at different flow rates. Use these

tables to determine the friction loss for the

pipe size you are using at your maximum

flow rate.

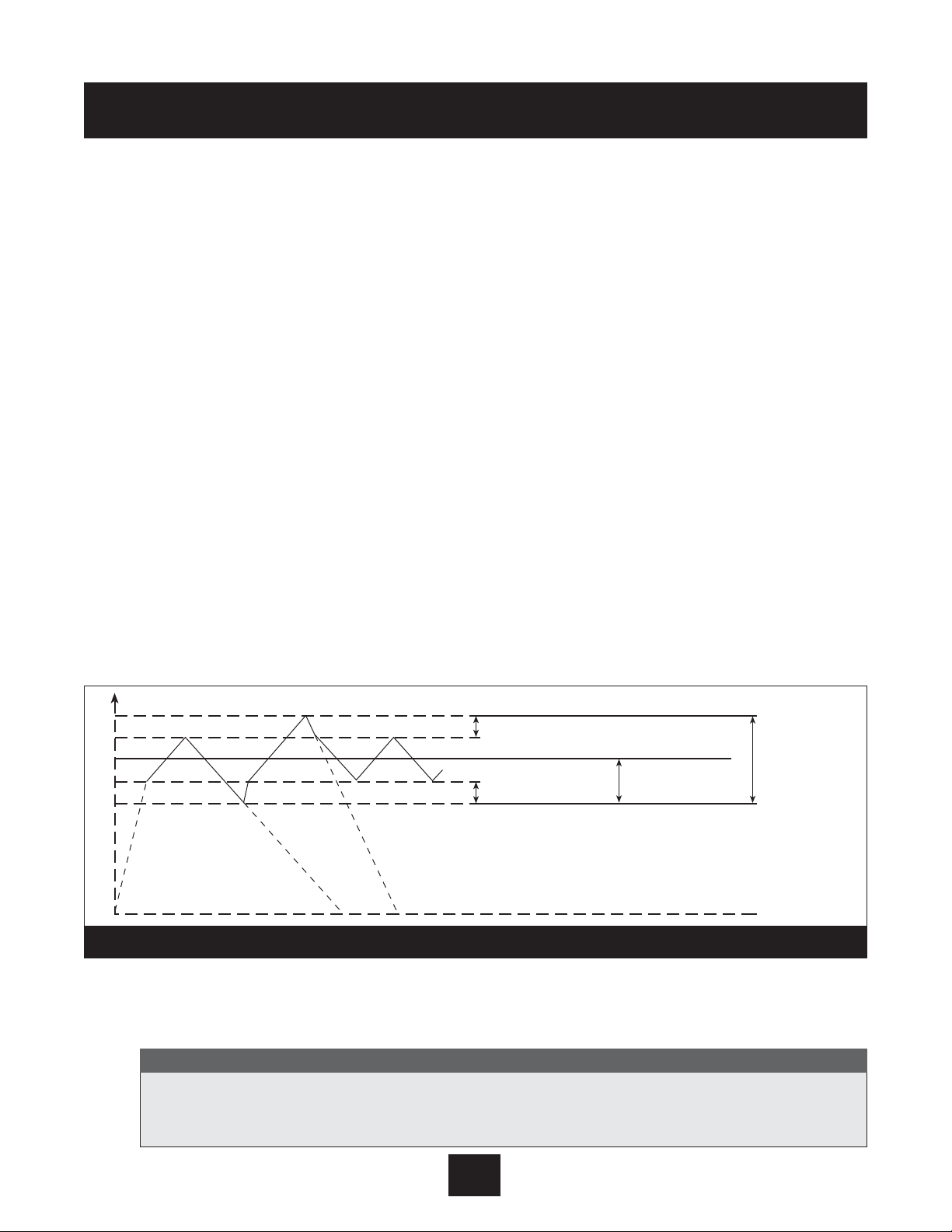

Diagram 15 shows a typical system curve.

The system pressure set point is shown at

shut off and the pressure increase is shown

for increasing flow.

Calculate the pressure increase required to

overcome friction loss at maximum flow as

a percent of the set point.

For example, if your required system pressure is 30 PSI, and it takes an additional 3

PSI for friction loss at maximum flow, the

percent increase is 10%.

38

Programming

Diagram 15

H

f = 100%

% f

% f

WINDOW

LIFT INTENSITY

10% OF

SET PRESSURE VALUE

SET PRESSURE

% f

0

0

4

3

2

1

0

Q

Page 40

Entering compensation values:

For steps 1 through 4, refer to the flow chart.

Instructions

1. From the main menu, hold down the key

for 2-3 seconds until the display changes to:

• Enter 66 by pressing the

2. Freq.- Lifting 30.0 hz

This indicates the speed (flow rate)

at which you want the pressure compensation to begin. On a

60 hz system, there is virtually no flow below 40 hz. Set this

frequency with the up arrow. On a 50 hz system, the normal

starting point would be 30 hz.

• Use the key to scroll through the

menu screens until you reach:

Change if required.

3. Use the key to move to the next screen:

• Use the to enter the percentage

pressure increase calculated on page 37.

Increase values are recommended from 0

to 20%. If your friction loss increase is above

20% of your set pressure, please contact the

AQUAVAR distributor or factory for application assistance. 0-99.9% actual.

4. Save the new settings.

• Use the key to scroll to the screen

• Press both the arrows until the display

indicates the save process is complete.

The screen will automatically return to the main menu.

39

Programming

PASSWORD 0000

0066

Screen

FREQ - LIFTING 40.0 HZ

LIFT - INTENS. 0.0%

LIFT - INTENS. 3.0%

SAVE ??? +

SAVE ??? SAVED

▼

*

*

*

*

▼

▼

▼

▼

▼

▼

Page 41

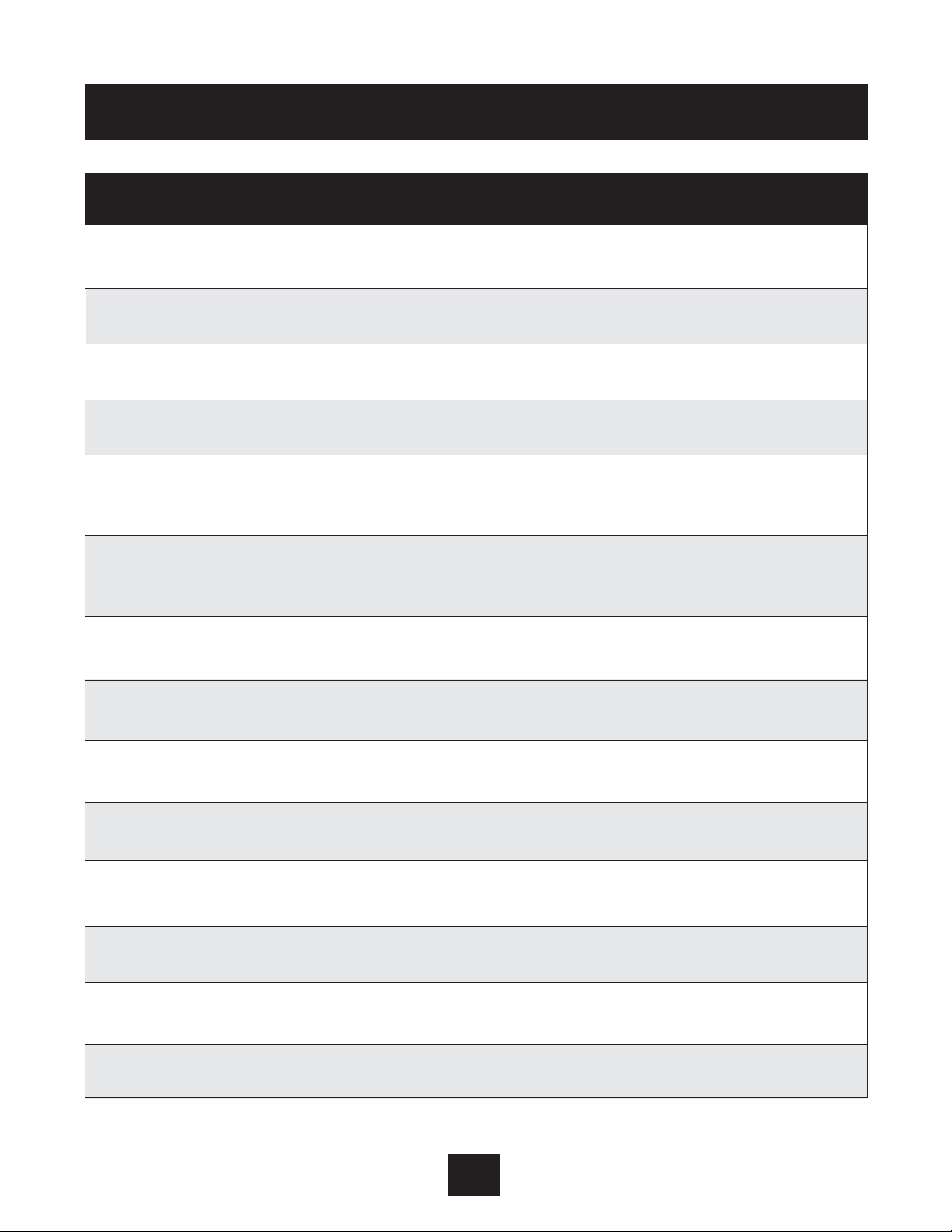

40

Programming - System Cur ve Compensation

Diagram 16

REQUIRED

VALUE

126.9 PSI

Auto-START

ON

ERROR 1 ERROR 2 ERROR 3 ERROR 4 ERROR 5

TOTAL RUN

TIME

0000: 41

SAVE ??

– + v

PASSWORD

0000

JOG-MODE

XX Hz

XX PSI

WINDOW

5%

RAMP

HYSTERISIS

80%

RAMP 1

4.0 Sec.

RAMP 2

4.0 Sec.

RAMP 3

70 Sec.

RAMP 4

70 Sec.

MAX.

FREQUENCY

60.0 Hz

MIN.

FREQUENCY

0.0 Hz

CONFIG.

FMIN

F -> 0

STOP–

DELAY FMIN

0 Sec.

SENSOR–

ADJUST

out of range

SENSOR–

CURVE

Linear

SENSOR

RANGE

20 mA –

362.6 Bar

REGULATION

MODE

Normal

START

VALUE

Disabled

CONFIG. REG.

Val. 2

OFF

RELAY

CONFIG.

Run

Motor

MODE

Multi-

Controller